Method for deep dephosphorization by using embedded lanthanum oxide composite resin

A technology of composite resin and lanthanum oxide, which is applied in chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of lack of nano-small size effect of functional adsorption materials, low working adsorption capacity, and single force, etc., to achieve improvement Dispersed state on the inner surface, solving the effect of large fluid resistance and strengthening the adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

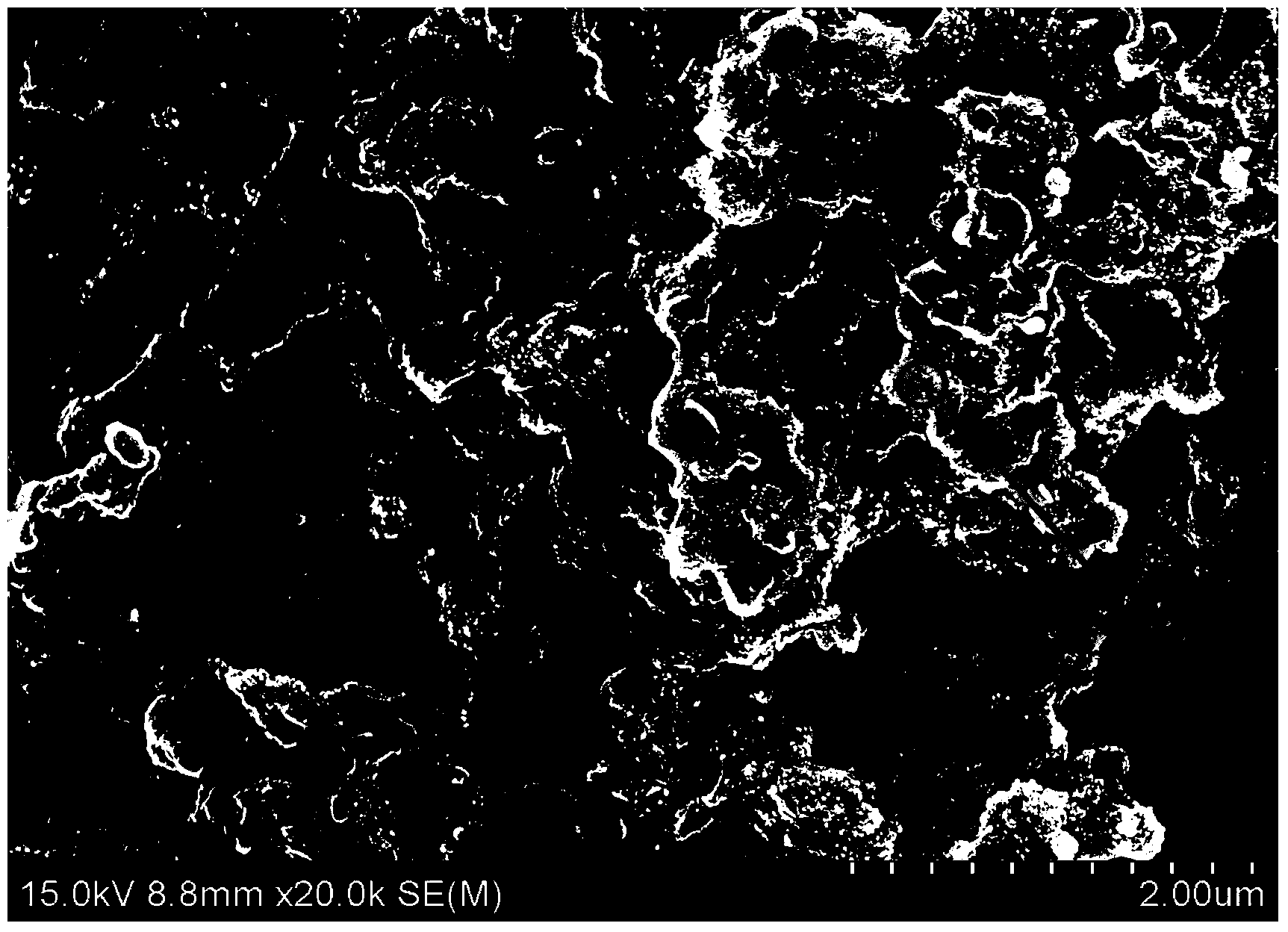

[0020] Take 25g of D201 type anion exchange resin (manufactured by Hangzhou Zhengguang Industrial Co., Ltd.) as a carrier material, place it in 2.5L aqueous solution containing 5% lanthanum nitrate, control the reaction temperature at 40°C, fully stir the reaction for 10h, and gradually diffuse La to the inner surface of the anion exchange resin pores. Then filter the resin and put it in 1500mL of 5% sodium hydroxide solution for in-situ precipitation reaction at room temperature, control the precipitation reaction time for 10h, after the reaction is completed, filter and heat treatment at 40°C for 5h, so as to obtain Formula nano-lanthanum oxide composite resin, such as figure 1 As shown, its loading is 6.5%.

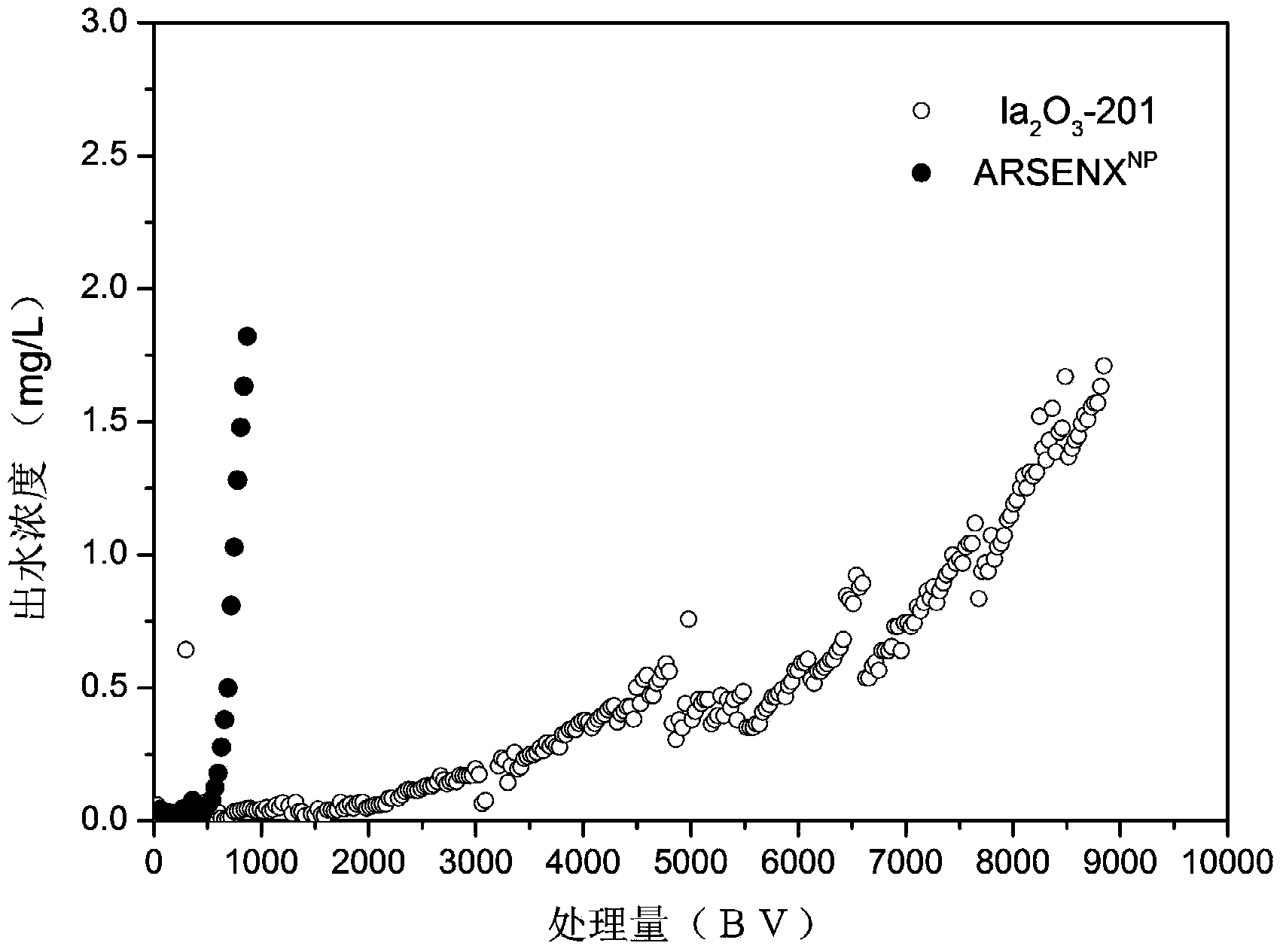

[0021] Put 3mL of the above composite resin in a glass adsorption column (ф12×220mm) 4 2- =200mg / L, Cl - =100mg / L, NO 3 - =160mg / L, pH=5) flow through the adsorption column equipped with composite resin from top to bottom, the temperature is controlled at 15°C, t...

Embodiment 2

[0023] Take 50g of 201x7 type anion exchange resin (manufactured by Tianjin Bohong Resin Technology Co., Ltd.) as a carrier material, place it in 1000mL aqueous solution containing 10% lanthanum nitrate, control the reaction temperature at 60°C, fully stir the reaction for 12h, so that La gradually diffuses to the inner surface of the anion exchange resin pores. Then filter the resin and place it in 2000mL of 10% sodium hydroxide solution for in-situ precipitation reaction at room temperature. The precipitation reaction time is controlled to be 12h. Type nano-lanthanum oxide composite resin, its loading capacity is 22.31%.

[0024] Put 5mL of the above-mentioned composite resin in a glass adsorption column (ф20×420mm) and phosphate-containing surface water (P=10mg / L and 4 2- =180mg / L, Cl - =200mg / L, NO 3 - =220mg / L, pH=10) flow through the adsorption column equipped with composite resin from top to bottom, the temperature is controlled at 50°C, the flow rate is 50BV / h, an...

Embodiment 3

[0026]Take 20g of D202 (produced by Hebei Guoao Resin Factory) as a carrier material, place it in 2L aqueous solution containing 35% lanthanum nitrate, control the reaction temperature at 55°C, stir and react for 11h, so that La gradually diffuses into the anion exchange resin channel surface. Then filter the resin and place it in 2000mL of 15% sodium hydroxide solution for in-situ precipitation reaction at room temperature, control the precipitation reaction time for 12h, after the reaction is completed, filter and heat-treat at 55°C for 5h to obtain intercalation Formula nano-lanthanum oxide composite resin, such as figure 1 As shown, its loading is 18.5%.

[0027] Put 4mL of the above composite material in a glass adsorption column (ф12×220mm) 4 2- =200mg / L, Cl - =200mg / L, NO 3 - =260mg / L, pH=6) flow through the adsorption column equipped with composite resin from top to bottom, the temperature is controlled at 20°C, the flow rate is 10BV / h, and the concentration of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com