Patents

Literature

151 results about "Phosphate treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate treatment involves adding the phosphate removing chemicals to the pool, typically through the skimmer while the pool pump is running. This rapidly disperses the chemical throughout the pool, allowing it to have the maximum effect. The chemical precipitates the phosphates out of the water,...

Ordinary temp. parkerizing liquid

InactiveCN1401820AFast phosphatingFast combinationMetallic material coating processesSoftened waterManganese

An ordinary-temp phosphating liquid for the phosphate treatment of surface of iron and steel contains phosphoric acid (2-4 wt.%), zinc oxide (0.4-0.6 wt.%), zinc nitrate (0.5-1.5 wt.%), nickel nitrate (3-5 wt.%), manganese nitrate (2-4 wt.%), sodium borofluorate (0.2-1 wt.%), sodium chlorate (2-3 wt.%), citric acid (0.5-2 wt.%), and softened water (the rest). Its advantages are high stability, long film-forming time, and high film strength and resistance to corrosion.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

Iron-based soft magnetic composite and preparation method thereof

ActiveCN104425093AHigh compressibilityIncrease green densityInorganic material magnetismCompressibilityMelting point

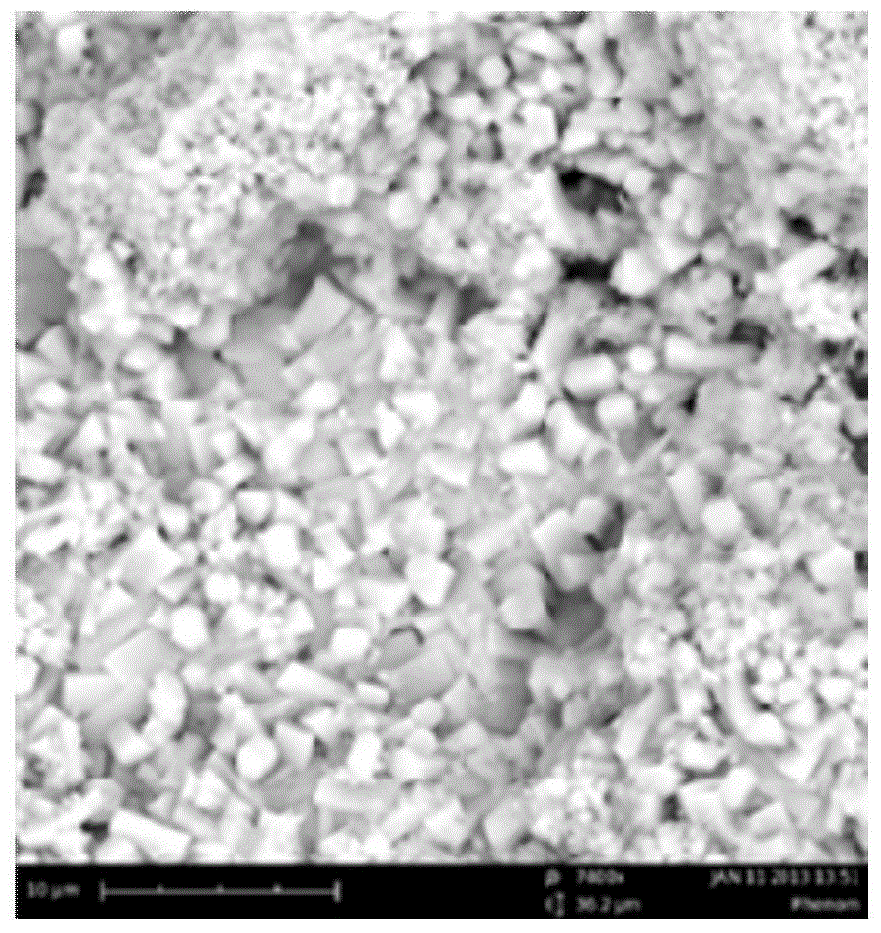

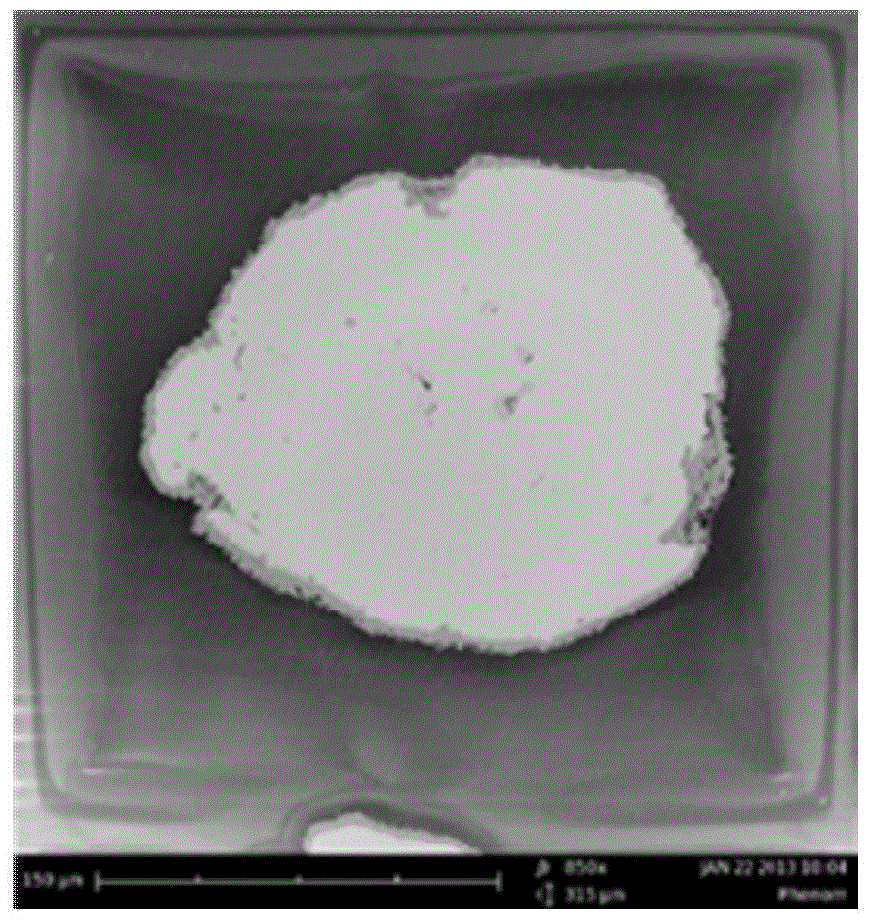

The invention discloses an iron-based soft magnetic composite. The iron-based soft magnetic composite comprises atomized iron-based powder, ultra-fine high melting point inorganics and lubricant, wherein phosphate and an organic silicone resin insulating layer cover the surface of the atomized iron-based powder. A preparation method of the iron-based soft magnetic composite comprises the following steps that the atomized iron-based powder and the ultra-fine high melting point inorganics are fully mixed to obtain a mixture, high-temperature heating treatment is conducted on the mixture in a non-oxidizing atmosphere, heat preservation is conducted on the mixture for above 30min, the mixture is cooled to enable the temperature of the mixture to be the room temperature, surface phosphating treatment and organic silicon resin covering are conducted on obtained iron powder isolated through the inorganics, and then pressing annealing is carried out. Due to the fact that the iron powder is isolated through the ultra-fine high melting point inorganics, annealing can be conducted on the iron powder at a high temperature of about 1000 DEG C, sintering cannot happen, and the iron powder has high compressibility; an insulating layer covers the surface of the iron powder after phosphating treatment is conducted on the iron powder, phosphide has a lubricating effect on the iron powder, internal friction is reduced in the pressing process, and the compaction density of the powder is improved; due to the fact that organic silicon resin is added, distribution of the insulating layer on the surface of the iron powder is improved, and the soft magnetic property is optimized after forming sintering is conducted on the powder.

Owner:NBTM NEW MATERIALS GRP

Neodymium-iron-boron magnet of aluminum or aluminum alloy composite coating and preparation method thereof

ActiveCN102031522AImprove processing efficiencyLow costVacuum evaporation coatingSputtering coatingHigh humidityAlloy composite

The invention discloses a neodymium-iron-boron magnet of an aluminum or aluminum alloy composite coating and a preparation method thereof. An aluminum or aluminum alloy film is deposited on the neodymium-iron-boron magnet by adopting multi-arc ion plating technology, and then phosphate treatment is performed. The coating is uniform and dense, and is well combined with a matrix. The neodymium-iron-boron magnet applied with the aluminum composite coating with thickness of 10 to 20 microns tolerates high pressure and high humidity (100 to 130 DEG C, 2 to 2.6atm, and 95 to 100 percent RH) for over 200 hours, and tolerates NaCl salt fog corrosion (3.5 to 5 weight percent of NaCl and 25 to 35 DEG C) for over 500 hours. The coating process has high efficiency and low cost; and the prepared composite coating has good corrosion resistance and adhesion performance, and has no influence on the magnetism of the neodymium-iron-boron matrix (mainly small-size magnet).

Owner:北京钐元新材料股份有限公司

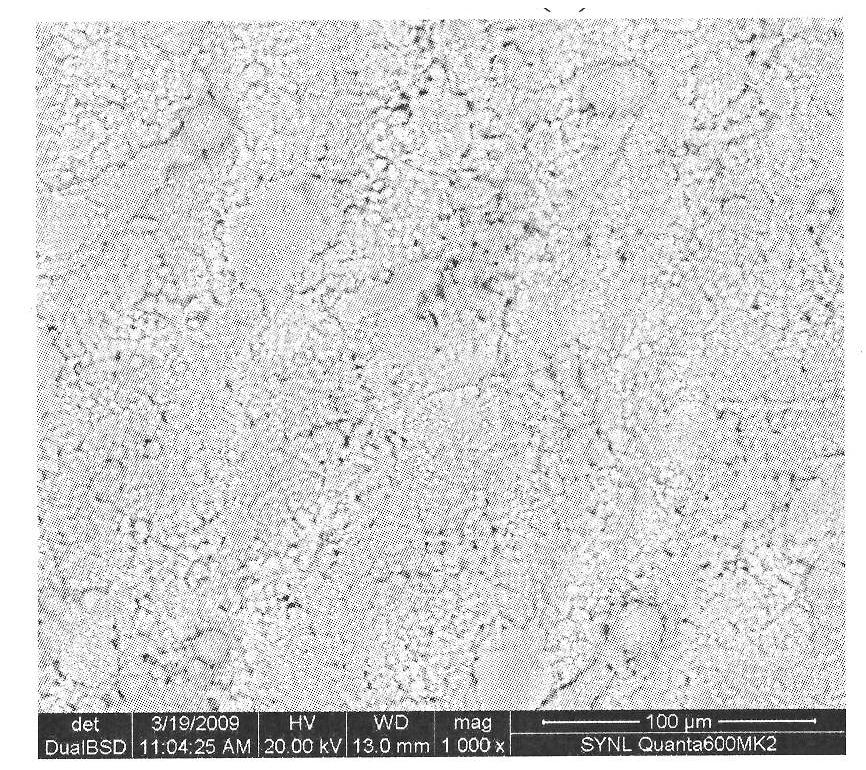

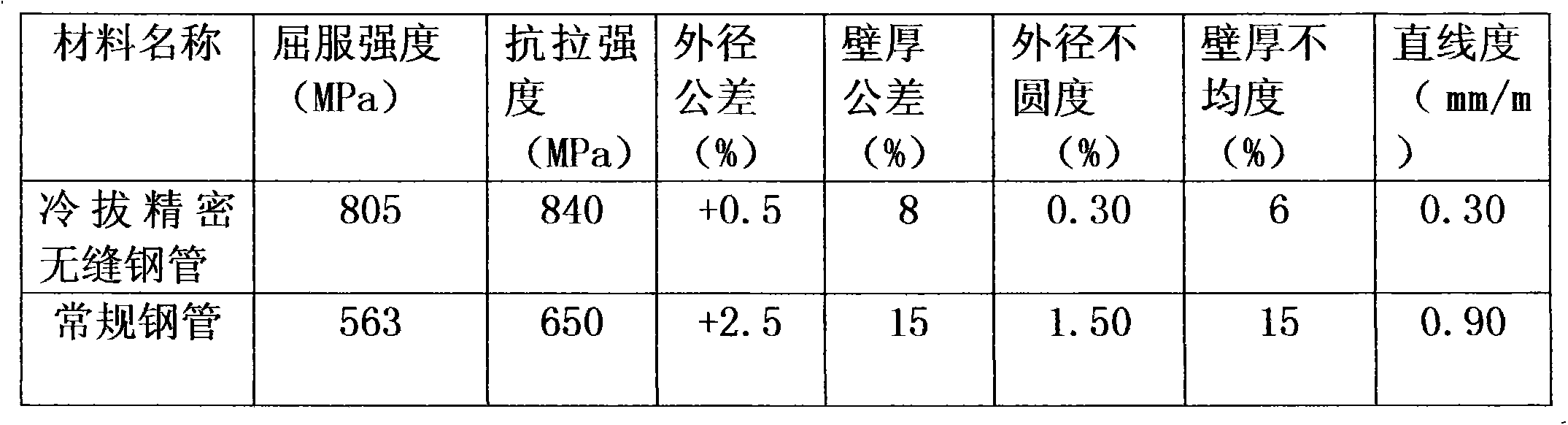

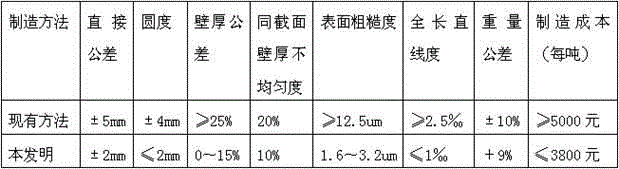

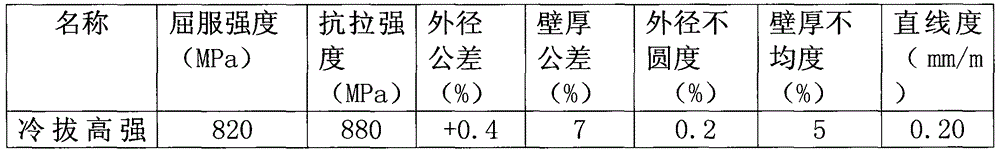

Production method of cold-drawn precision seamless steel pipes

InactiveCN104338777AImprove performanceImprove low temperature impact toughnessAcid washingLubrication

The invention relates to a production method of cold-drawn precision seamless steel pipes. The production method comprises the steps of: heating: pipe blanks are heated in an annular furnace; perforation: the heat pipe blanks are perforated by a perforation machine; annealing: the pipe blanks are annealed; cold rolling: the annealed pipe blanks are leaded into a pipe rolling machine for cold rolling to obtain rolled pipes; stress relieving: the rolled pipes are leaded into a heating furnace for heating to obtain annealed pipe blanks; acid washing treatment: the acid washing is performed for the annealed pipe blanks to remove scales on the surfaces; phosphating treatment: zinc phosphate chemical generation films are formed on the surfaces of the pipe blanks; saponification treatment: such lubrication films as metallic soaps are formed on the films; cold drawing: the cold drawing is performed for the pipe blanks to be cold drawn to obtain cold-drawn pipes; normalization air-cooling treatment; first straightening treatment; induction furnace quenching treatment; box furnace tempering treatment; honing; thermal straightening treatment; and obtaining of the cold-drawn precision seamless steel pipes. The production method obtains the cold-drawn precision seamless steel pipes with high yield strength, high tensile strength, precise sizes and smooth surfaces.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

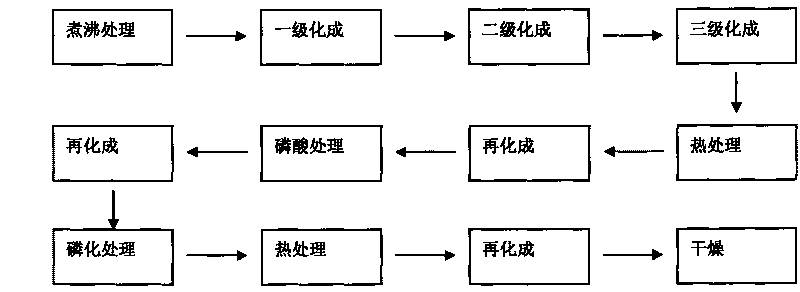

Formation technique of medium/high-voltage anode aluminum foil for enhancing aluminum electrolytic capacitance

ActiveCN103243369AIncrease capacityShort boost timeSurface reaction electrolytic coatingCapacitanceElectrolysis

The invention relates to the technical field of medium / high-voltage formation of anode foils, particularly a six-stage formation technique for enhancing capacity of an anode foil for an aluminum electrolytic capacitor and lowering the boosting time Tr and Tr60 by medium / high voltage. The technique is characterized by comprising the following steps: treating an aluminum foil subjected to electrolytic corrosion treatment in 50-100 DEG C pure water, and forming with phytic acid and citrate solution in the primary, secondary and tertiary stages; forming in phytic acid, boric acid and citrate solution in the quaternary, quinary and senary stages; and depolarizing by heat treatment and phosphate treatment. The boosting time Tr is at least lowered by 23%, the boosting time Tr60 is at least lowered by 66%, and the specific capacity effect of the aluminum foil is enhanced by 10-20%.

Owner:YIDU DONGYANGGUANG FORMED FOIL

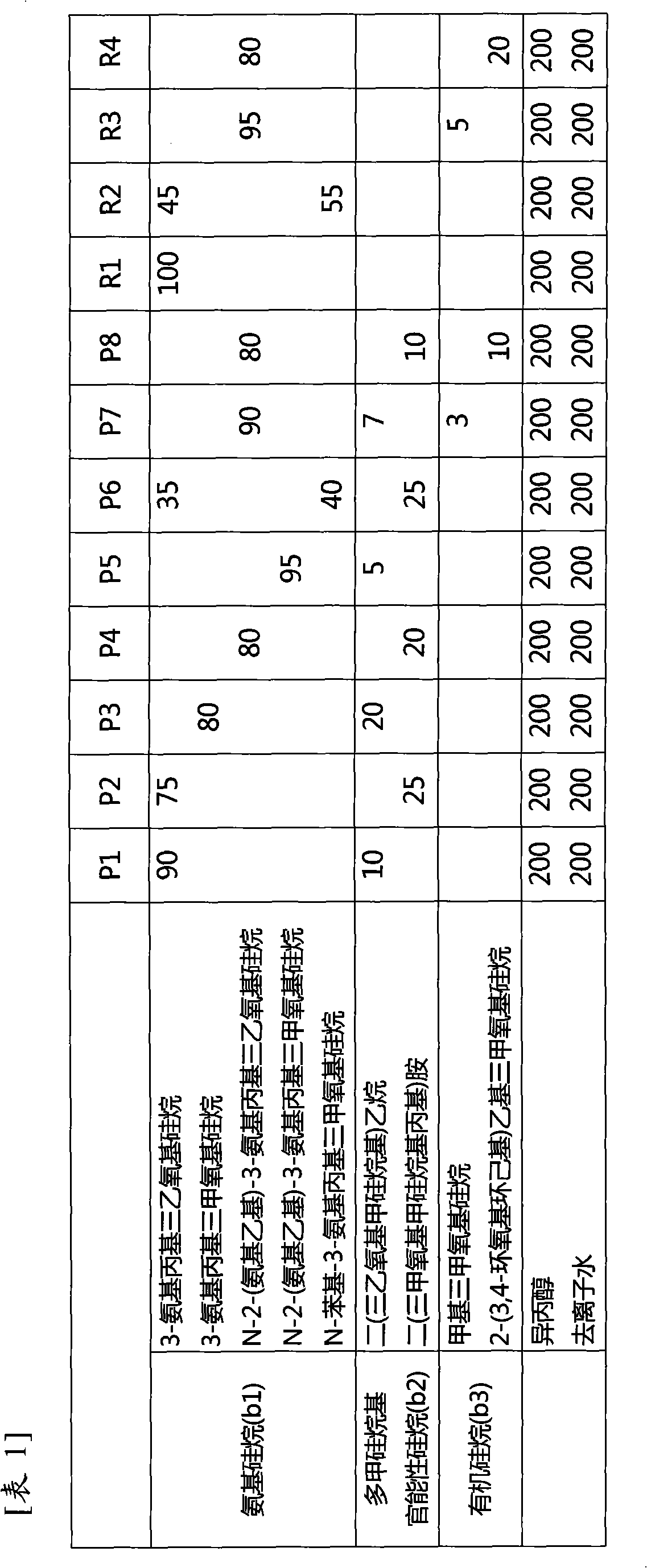

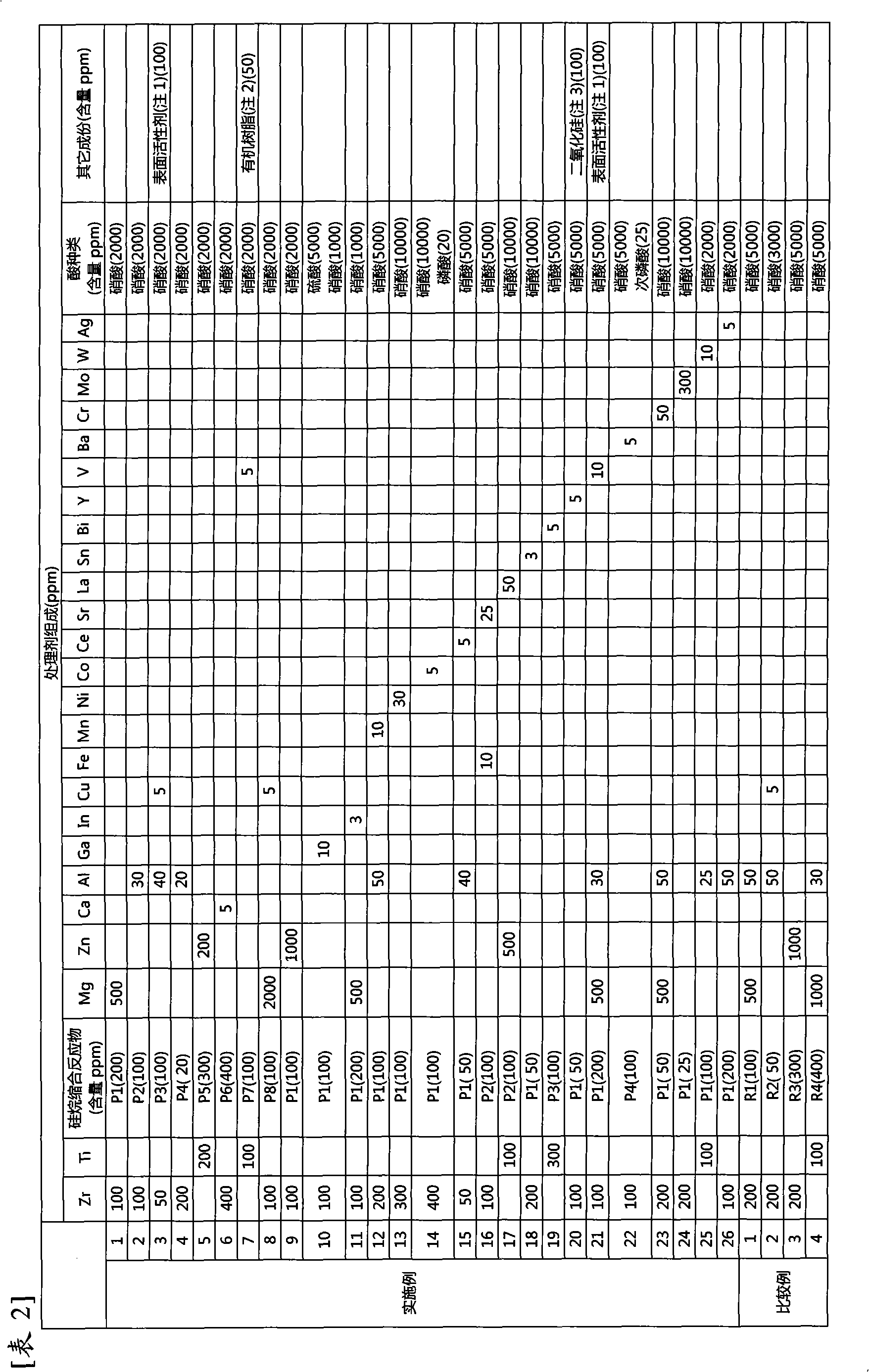

Composition for metal surface treatment, metal surface treatment method and coating method of metal material

The present invention relates to a composition for metal surface treatment, a metal surface treatment method and a coating method of metal material. An aim of the invention is to provide the composition for metal surface treatment, the metal surface treatment method and the coating method of metal material, wherein composition can obtain corrosion resistance equivalent with chromate treatment or phosphate treatment and can form a coating film with excellent adhesiveness of the coating film formed through a coating step after treatment. The composition for metal surface treatment comprises the following components: (A) titanium compound and / or zirconium compound, and (B) condensation reactant of (b1) amino silane and (b2) polysilyl functional silane.

Owner:KANSAI PAINT CO LTD

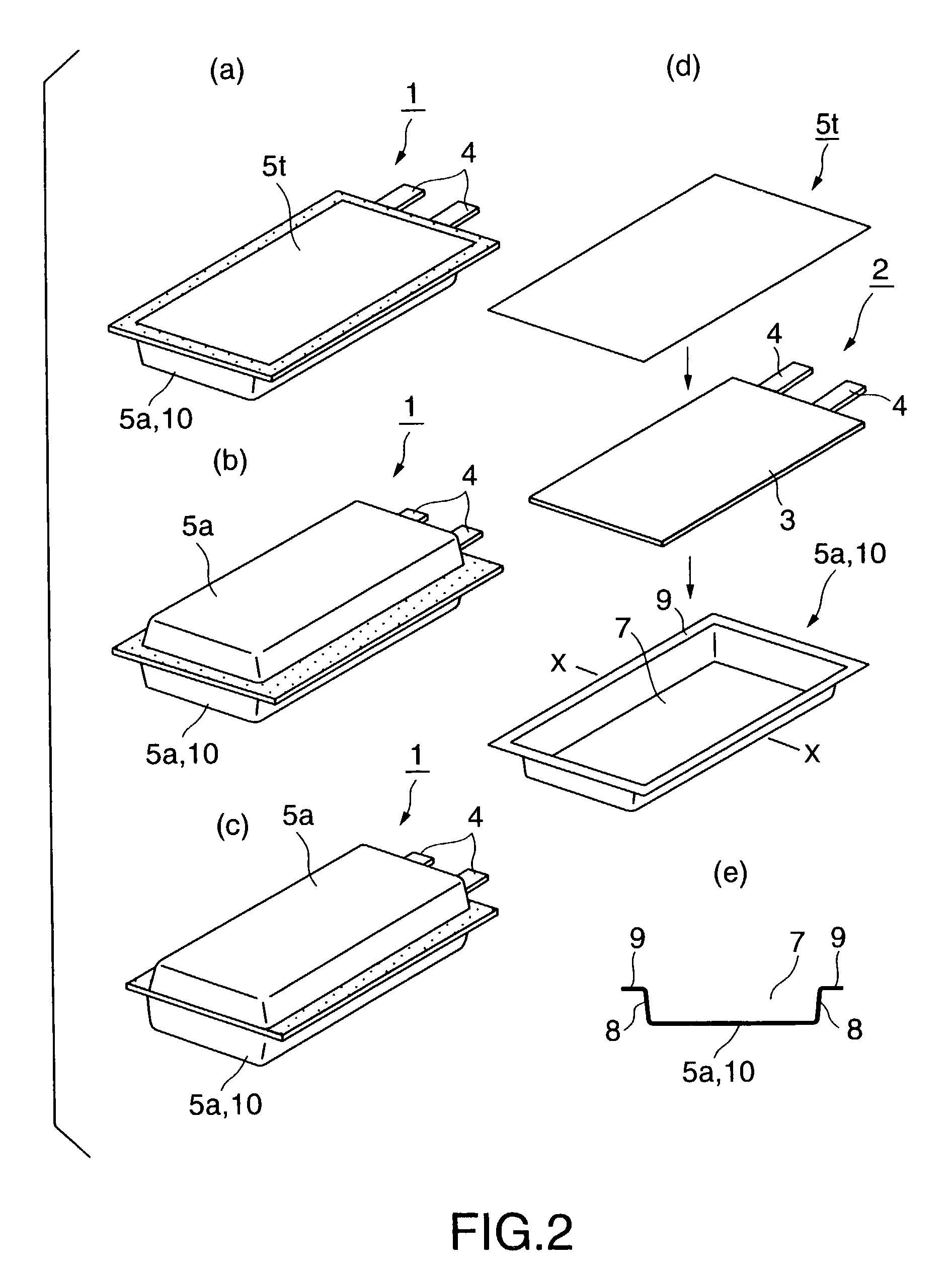

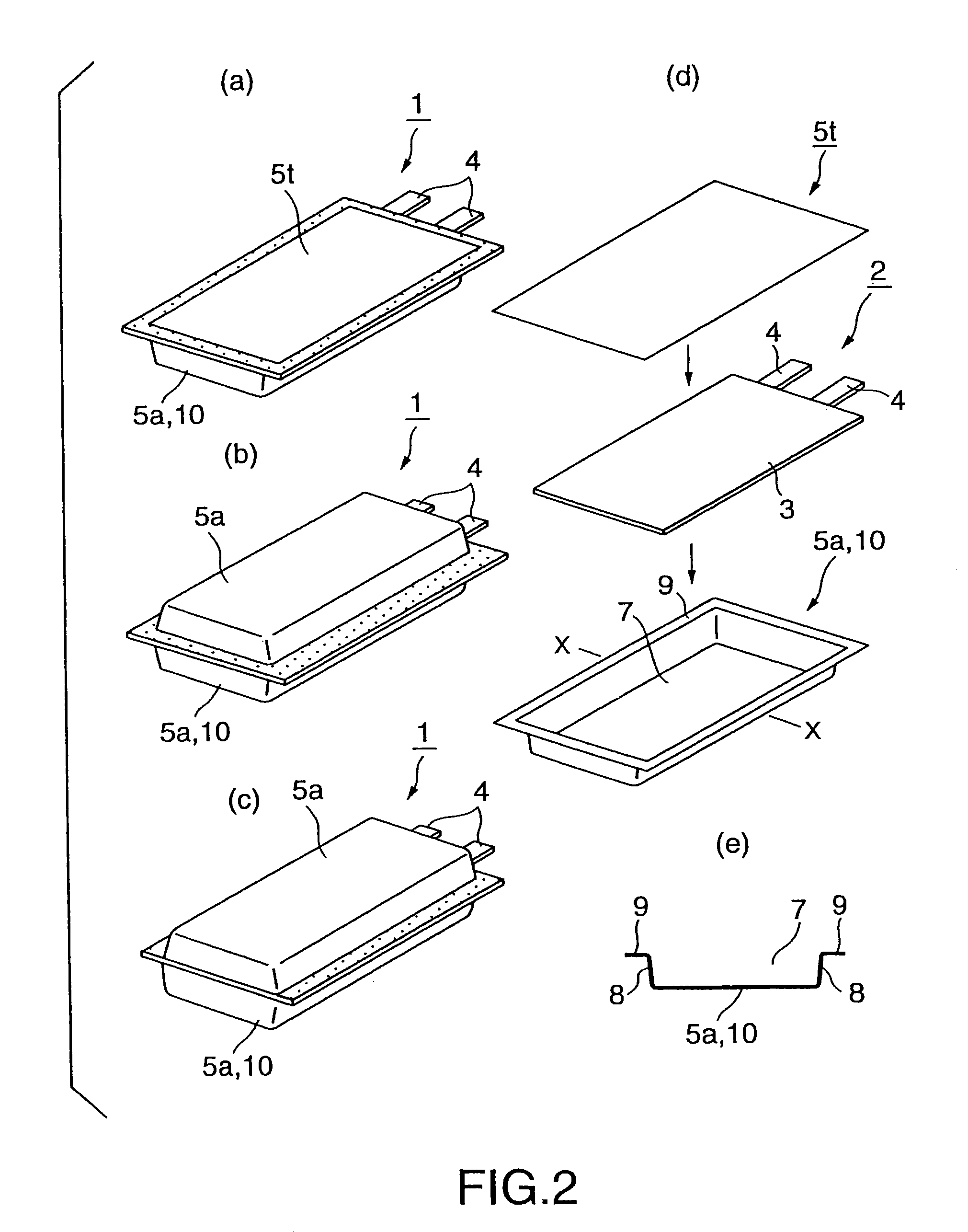

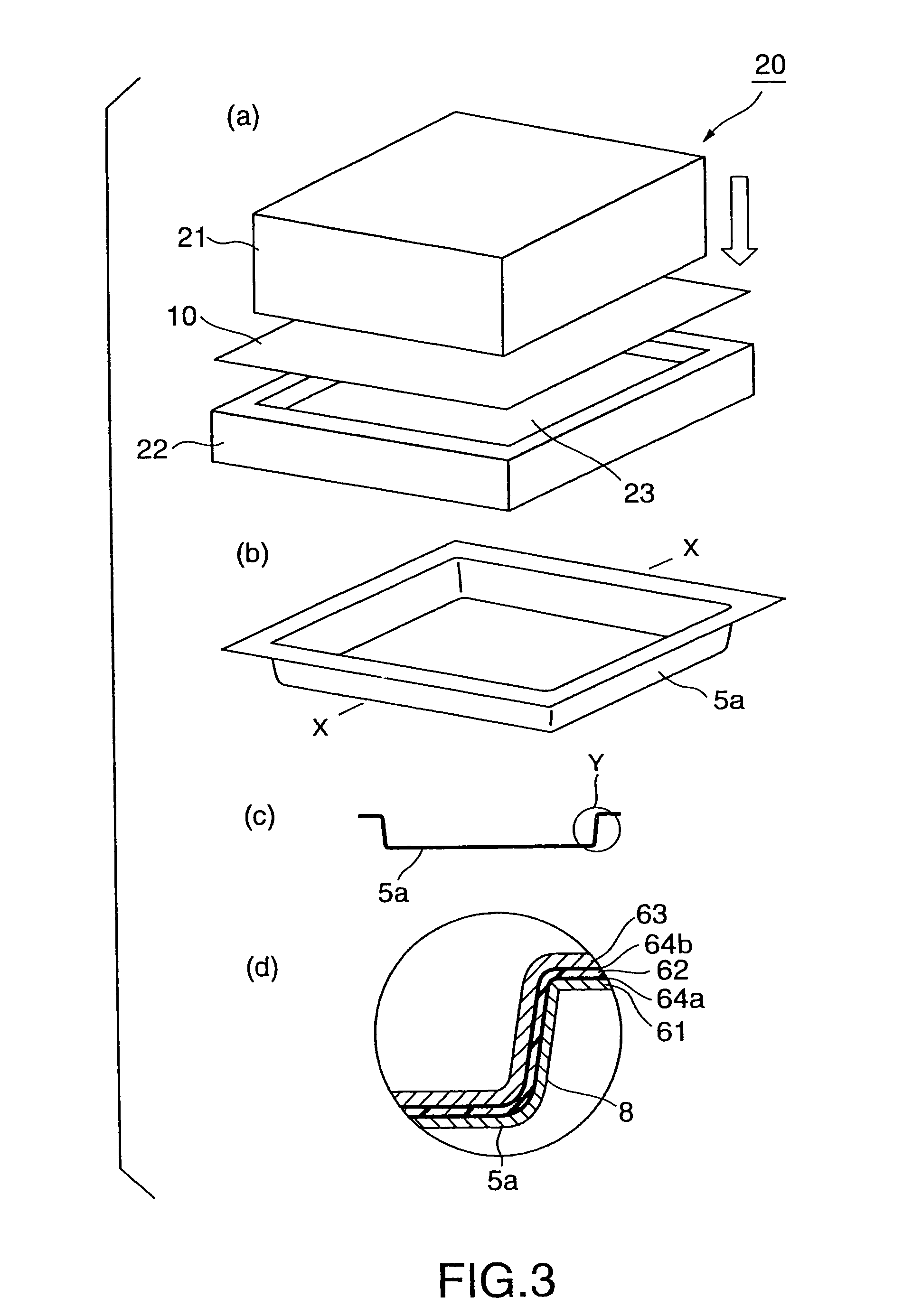

Packaging material for polymer cell and method for producing the same

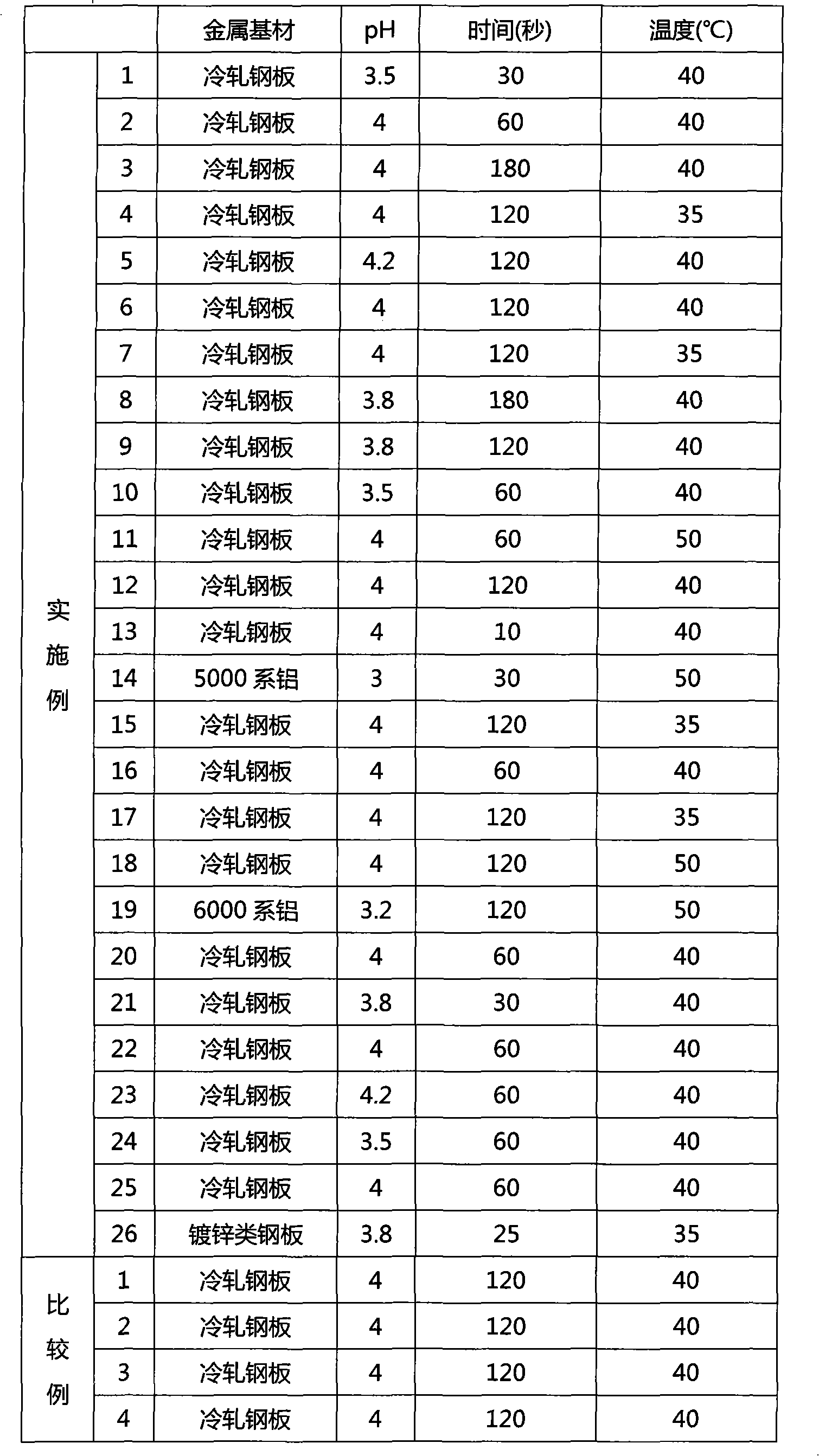

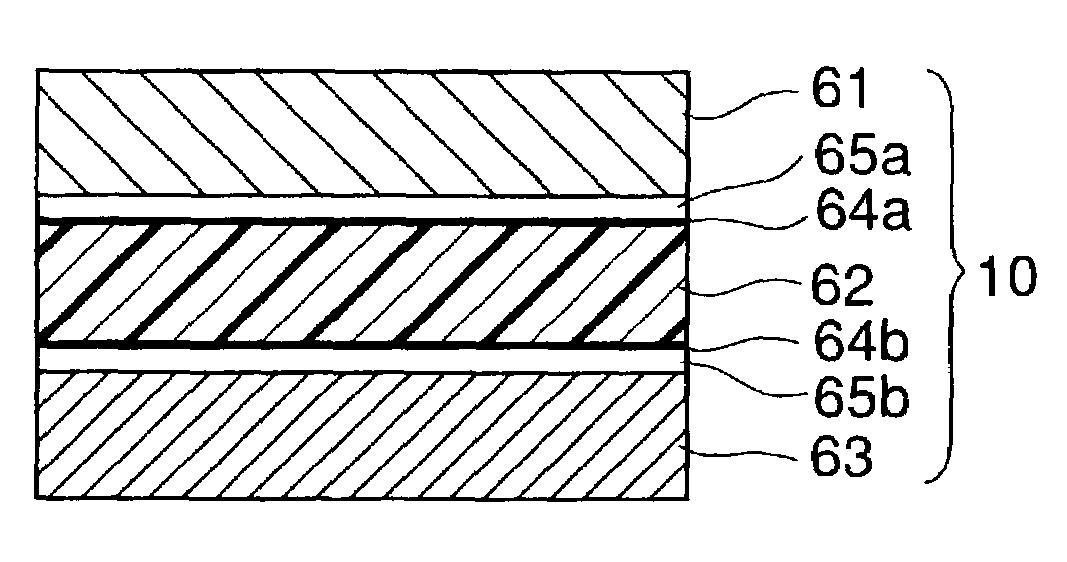

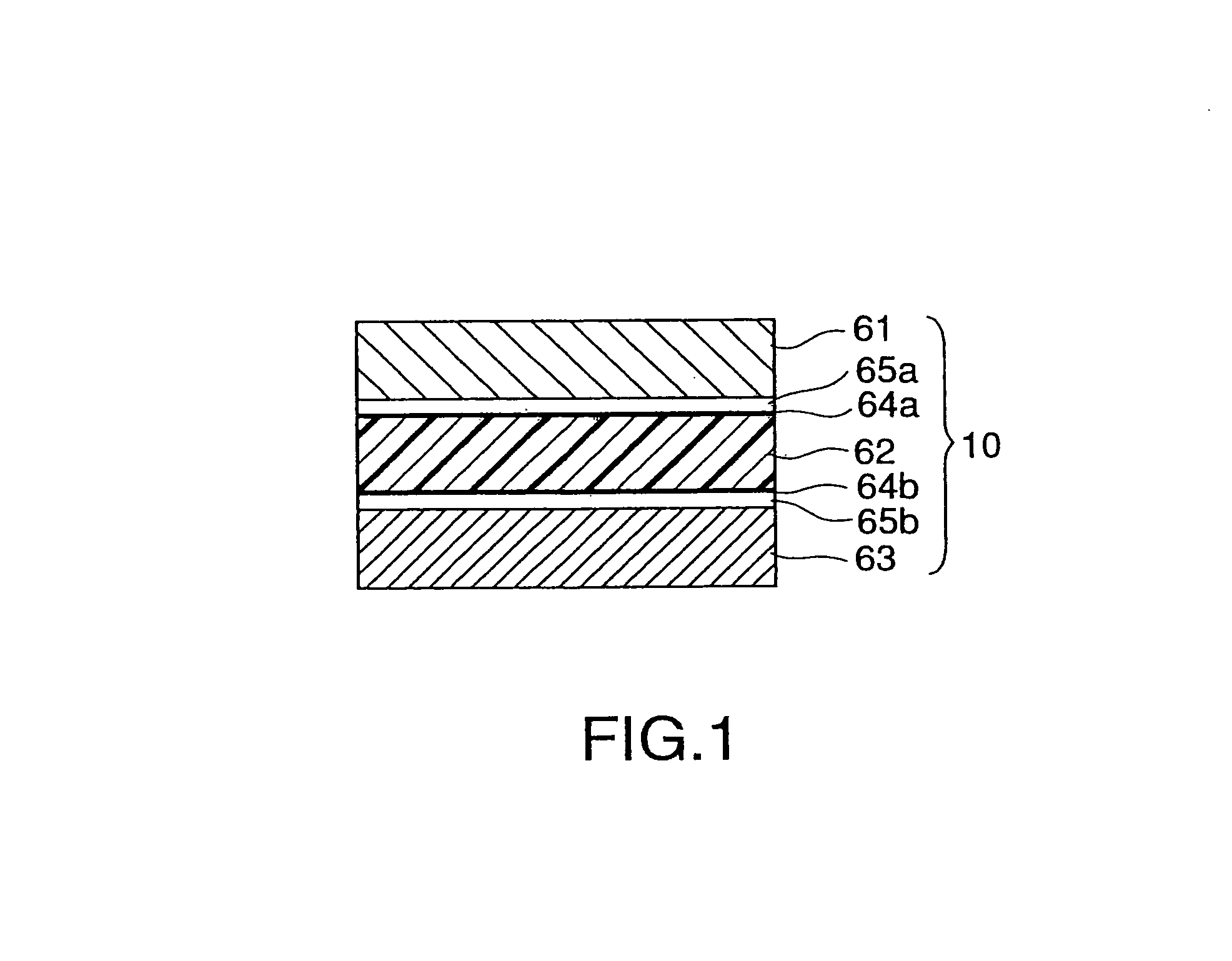

InactiveUS7048822B2Improve the protective effectNon-aqueous electrolyte accumulatorsFinal product manufactureMetallurgyChemical conversion

A polymer battery module packaging sheet includes, as essential components, a base layer (61), an aluminum layer (62), chemical conversion coatings (64a, 64b) coating the opposite surfaces of the aluminum layer (62), and an innermost layer (63). The chemical conversion coatings (64a, 64b) are formed by processing the opposite surfaces of the aluminum layer (62) by a phosphate treatment method. The base layer (61) and the innermost layer (63) are bonded to the chemical conversion coatings (64a, 64b) of the aluminum layer (62) with adhesive layers (65a, 65b), respectively.

Owner:DAI NIPPON PRINTING CO LTD

Production method and die of cold-drawing transmission shaft

The invention discloses a method for producing a transmission shaft by adopting a cold-drawing process, comprising the following steps of: A. detection, classification and grading of blanks, classifying the blanks into the following 5 section categories based on hardness: the Brinell Hardness (HB) less than or equal to 170, the HB between 170 and 200, the HB between 200 and 230, the HB between 230 and 250 and the HB larger than 250; B. pre-treatment before the drawing, the pre-treatmetnt comprises acid cleaning treatment, neutralizing treatment, phosphating treatment and soaping treatment of molybdenum disulfide; C. drawing treatment: pointing, drawing, strengthening and detecting the blanks, then packing and putting in the storage. The invention also provides a die for producing the transmission shaft by adopting the cold-drawing and the die comprises an A type wiredrawing hard alloy die and a C type drawing hard alloy die. The invention improves a lead-in conicity and a lead-out conicity of the die as well as the size of a die cavity diameter fixing strip and increases the lead-in cone and extends the diameter fixing strip of the die, thereby reducing the contact area between the blanks and the die when being lead in and increasing the stability of the blanks in the die cavity when being drawn.

Owner:HENGYANG KANGYI METAL PRODS +1

Method for manufacturing anodic foil of aluminum electrolytic capacitor

InactiveCN101707141AHydration resistance boost time reducedImprove bending strengthElectrolytic capacitorsPhosphatisationAfter treatmentPhosphoric acid

The invention discloses a method for manufacturing an anodic foil of an aluminum electrolytic capacitor, which comprises the following steps of boiling treatment, three polarization, heat treatment, formation, phosphate treatment, formation, heat treatment, and reformation. Different from the prior art, the phosphate treatment is carried out before the second heat treatment, and an after-treatment is removed. The phosphate treatment is dipping treatment performed under the conditions of the concentration of a phosphate treating agent of between 1 and 5 v / v%, and the temperature of between 20 and 80 DEG C for 1 to 10 minutes. The method can ensure that after three months of storage, the anodic foil of the aluminum electrolytic capacitor has short boosting time, short hydration resistance boosting time, stable pressure resistance and good bending performance.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

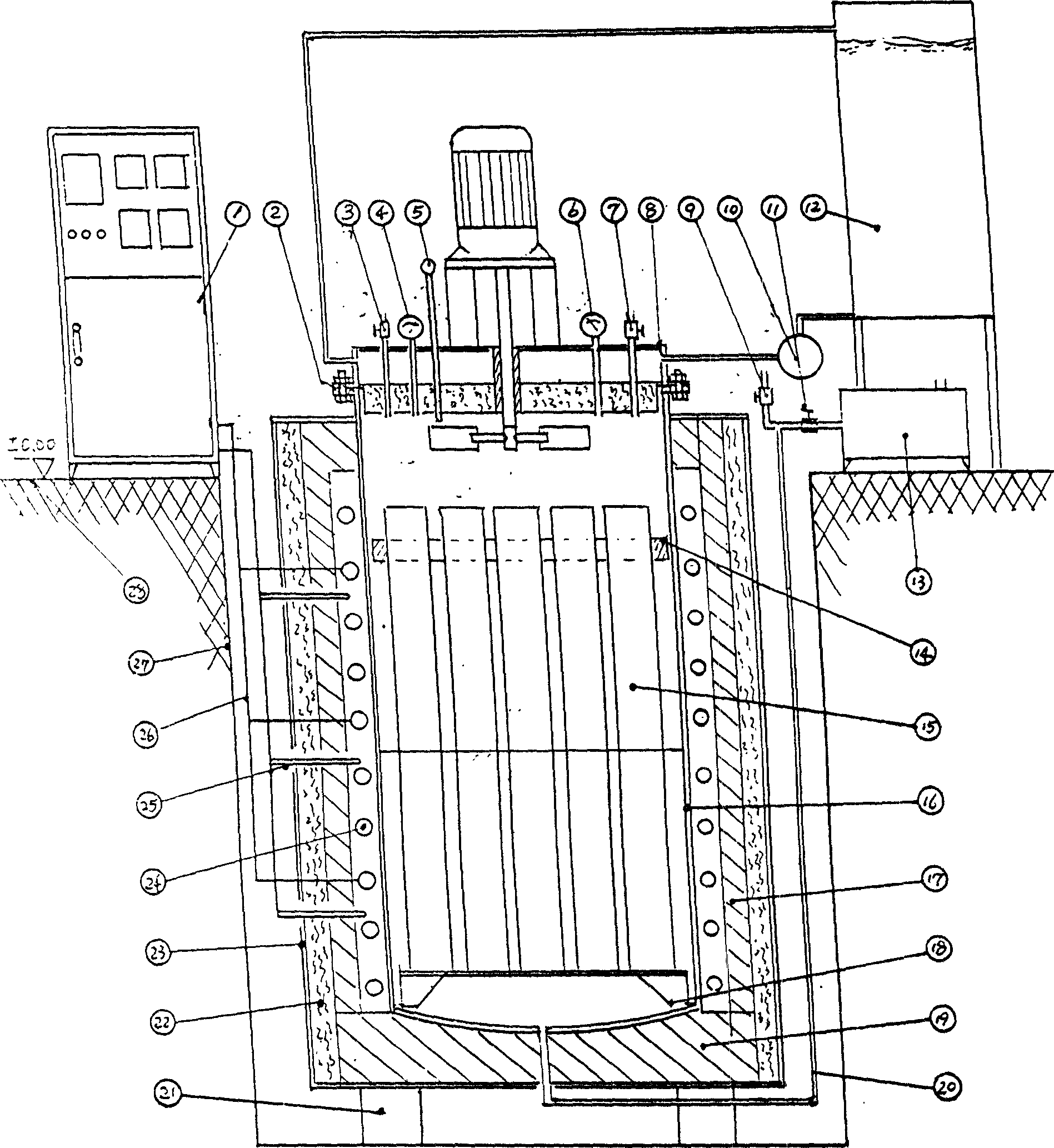

Graphite sleeves of rollers at furnace bottom and their dipping process and special apparatus thereof

InactiveCN1583668AHigh bulk densityLow resistivityFurnace typesHeat treatment furnacesChemical treatmentGraphite carbon

A graphite carbon sleeve of the roller at furnace bearth is prepared from calcined coke powder, adhesive, and additional coke through proportional mixing, kneading, die pressing, calcining, high-pressure dipping in metallic phosphate solution, graphitizing machining for shaping, chemical treating and high-temp treating. Its dipping method and dedicated apparatus are also disclosed.

Owner:BASAN SPECIAL FIRE RETARDANT MATERIAL FACTORY SHANDONG

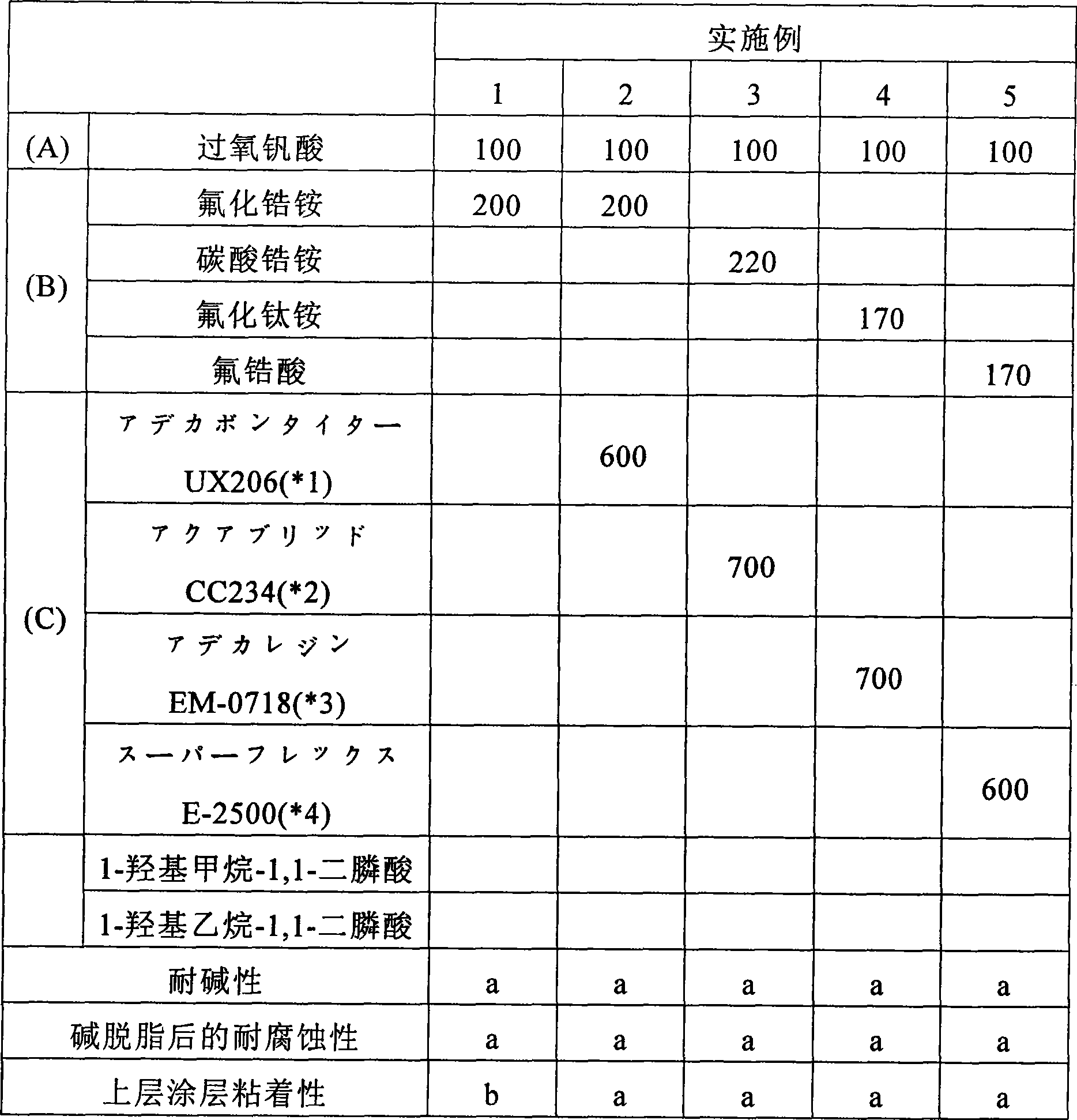

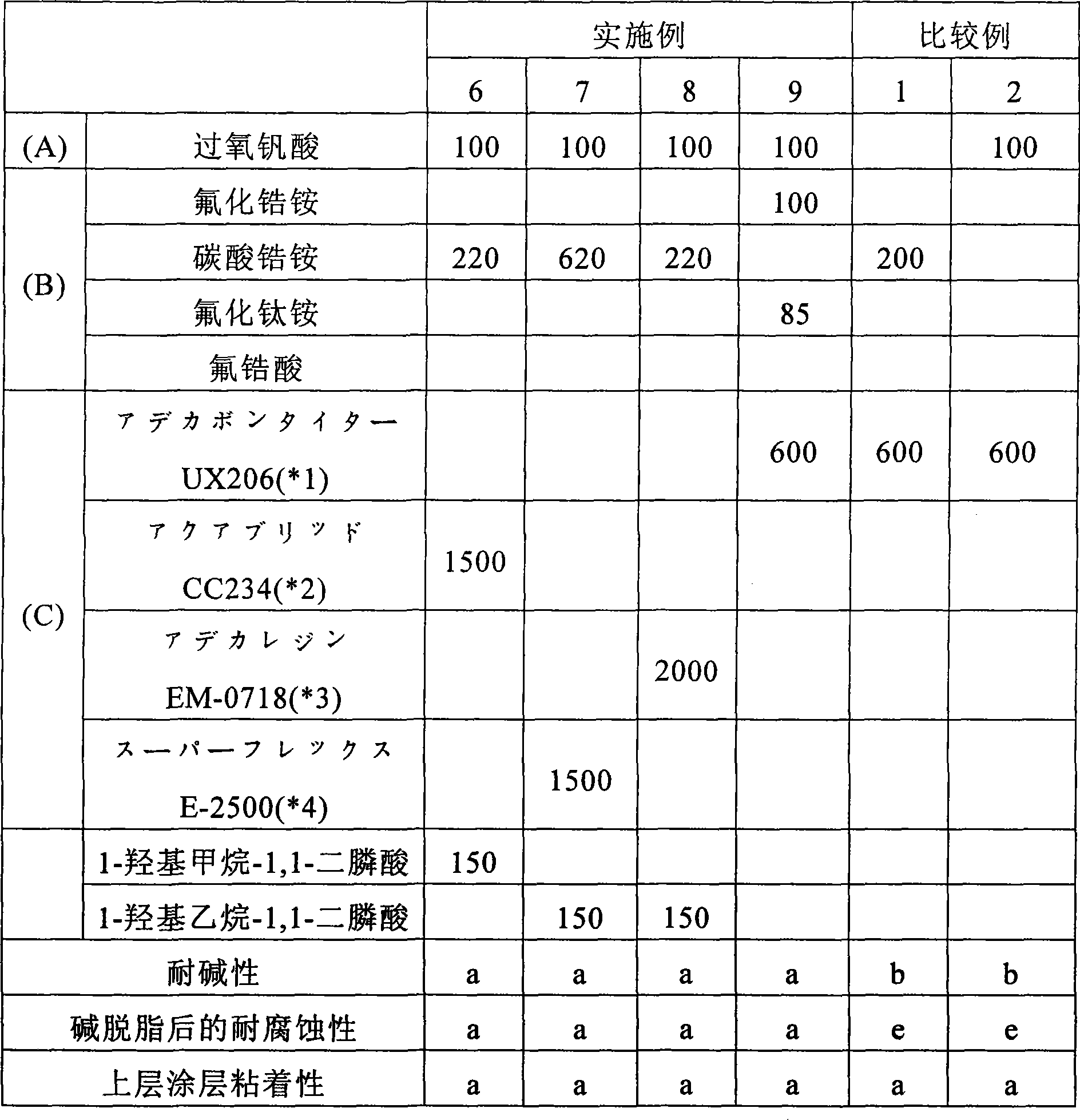

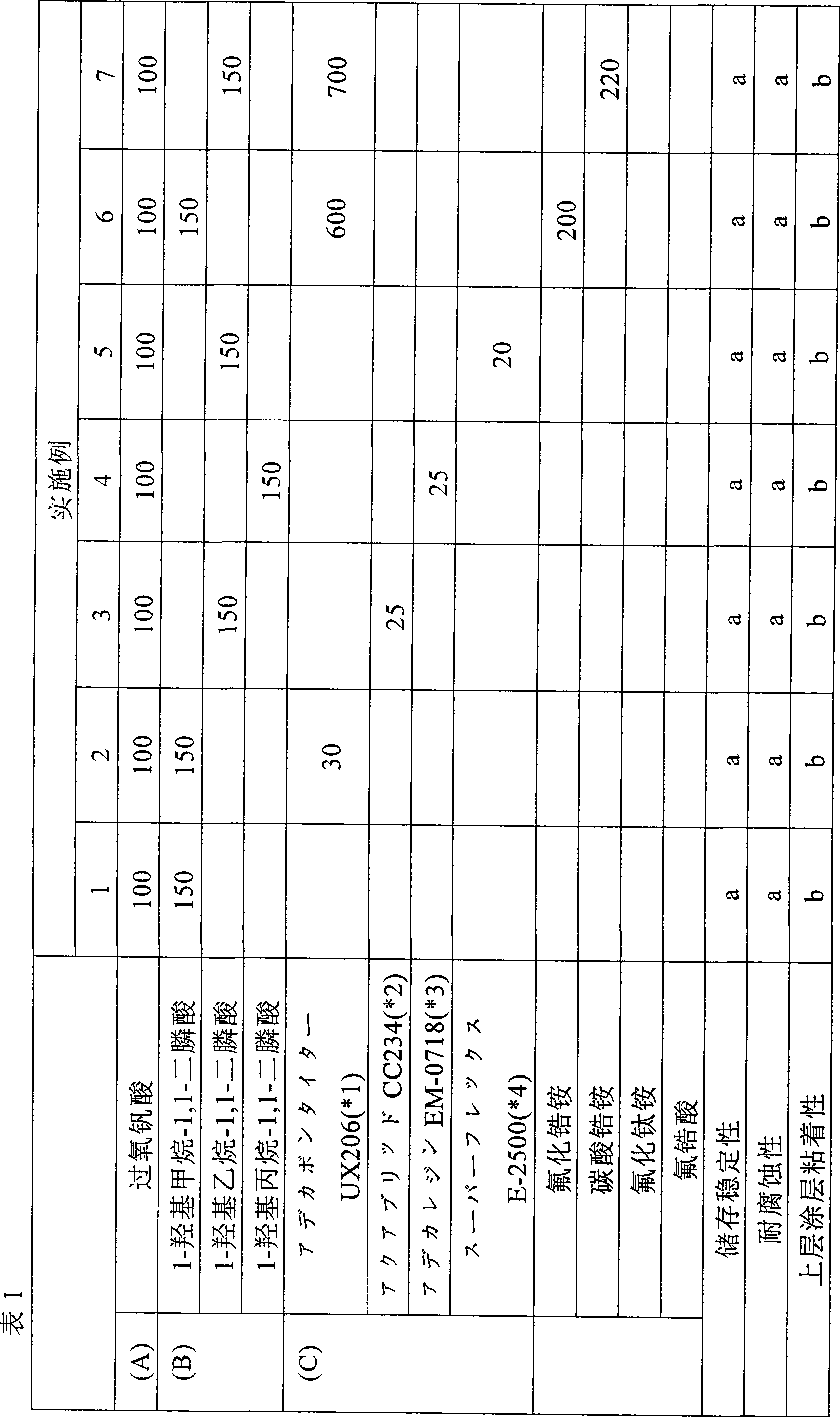

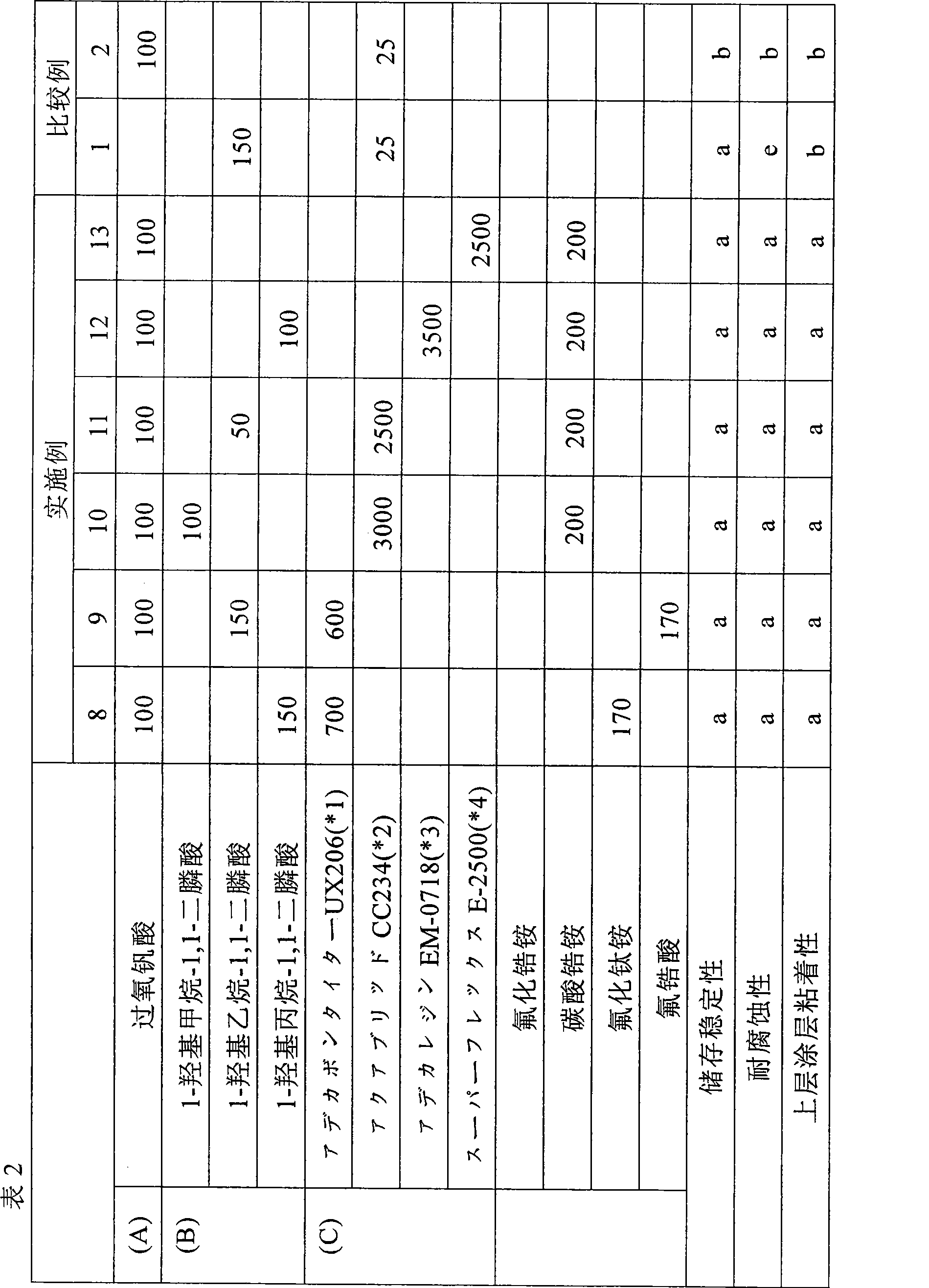

Metal surface treating composition and surface treating metal material with metal surface treating film obtained therefrom

The aim of the invention is to provide a non-pollution metal surface treatment composition which can obtain the film that has comparative anti-rusting capability with the previous chromate treatment agent and phosphate treatment agent and has excellent alkaline resistance, excellent processability, excellent corrosion resistance, excellent coating property, etc. The invention also provides a surface treatment metal material of metal surface treatment film obtained by the composition. The surface treatment composition provided by the invention is characterized by comprising the following components: (A) peroxide vanadic acid; (B) titanium compound and / or zirconium compound, and (C) water-soluble or water-dispersive organic resin which is included according to requirement.

Owner:KANSAI PAINT CO LTD

Manufacturing method for formed foil of electrolytic capacitor of energy-saving lamp

ActiveCN102610396ASimple process conditionsImprove performanceElectrolytic capacitorsChemical reactionProcess engineering

The invention discloses a manufacturing method for a formed foil of an electrolytic capacitor of an energy-saving lamp. According to the manufacturing method, four-stage forming is carried out, and corresponding steps are adjusted, which comprises a one-time feed treatment step, a two-time phosphate treatment step, a three-time high-temperature treatment step all well as an additional step; and an oxidant is added in each stage of formation groove to improve process conditions of the formed foil in the production process, and further the chemical reaction temperature and the current density are reduced and the formation time is shortened. According to the manufacturing method disclosed by the invention, the time of each stage of formation time is shortened, electric energy consumed by producing the formed foil is saved by 10 percent and heat energy consumed by the formed foil is saved by 7 percent. The manufacturing method is high in production vehicle speed, high in efficiency and favorable in storage performance of products.

Owner:新疆荣泽铝箔制造有限公司

Composite treatment method for improving tenderness of conditioned and cooked pork in storage period

The invention discloses a composite treatment method for improving tenderness of conditioned and cooked pork in a storage period, belonging to the field of food processing. The method comprises the following steps: by taking square rib of the pig as the raw material, carrying out evenly knocking or rolling, enzyme tenderization, composite parkerizing, half curing treatment, composite phosphate marinating treatment and the like by a composite treatment method, so as to keep the quality and structure characteristics of good tenderness of the conditioned and cooked pork during the storage period, and meanwhile, the smell and the taste of the cooked pork are not affected. By adopting the composite treatment method disclosed by the invention, not only can the fresh and tender degree of the cooked pork be improved, but also the shear force value for representing the tenderness is reduced to 2000-1200g from about 2500g in the past, the tender and juicy characteristics are achieved, good tenderness also can be kept after the pork is frozen, thawed and cooked, the tenderness is improved by 30-50% in comparison with the tenderness of the pork which is not subjected to composite treatment, and the poor phenomenon that the conditioned and cooked pork in the storage period becomes hard can be effectively controlled.

Owner:JIANGNAN UNIV +1

Method for adsorbing phosphate in sewage by using eggshells

InactiveCN102190343AAchieve reuseRich sourcesWater/sewage treatment by sorptionSocial benefitsEggshell

The invention belongs to the field of phosphate-containing sewage treatment, and discloses a method for adsorbing phosphate in sewage by using eggshells. The method comprises the following steps that: first, cleaned and shell-membranes-removed eggshells are dried at a temperature of 102 to 105 DEG C, and are grinded; the grinded eggshells are screened with a sieve of 300 meshes, such that eggshell power with a gain size of less than 300 meshes is obtained; 0.2 to 5g of eggshell powder is added to 50 to 1000mL of sewage with a phosphate concentration of 0.2 to 20mg / L and a pH value of 7 to 10; the resulting mixture is stirred for 8 to 12 hours under a temperature of 10 to 40 DEG C, and with a rotary speed of 50 to 200 rpm, such that the adsorption process is finished. According to the method, the phosphate adsorption is realized with the phosphate absorbability of eggshells. Compared with current common phosphate treatment methods, the method provided by the present invention has characteristics of no secondary pollution, abundant raw material source, low operation cost, and stable phosphate removing effect. The method accords with an environmental protective idea of: restricting waste with waste, and brings in good social benefit and environmental benefit.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Seamless steel pipe for long pipe trailer and manufacturing method for seamless steel pipe

InactiveCN102720943ATo satisfy the market's needsIncrease storage capacityElongated constructional elementsAbrasion apparatusPipeMechanical engineering

The invention discloses a seamless steel pipe for a long pipe trailer and a manufacturing method for the seamless steel pipe. The outer diameter of the seamless steel pipe is 630 to 720mm, the wall thickness is 18 to 30mm, and the length is 10,000 to 12,500mm. The manufacturing method comprises the following steps of: 1) rechecking a pipe blank, and turning a chuck; 2) performing shot blasting treatment on the pipe blank by using an outer shot blasting machine and an inner shot blasting machine respectively; 3) performing surface quality inspection, and polishing; 4) washing the pipe blank, and performing phosphate treatment; 5) saponifying the pipe blank for a first time; 6) performing cold drawing on the pipe blank for a first time; 7) polishing the inner and outer surfaces of a cold drawing pipe, and saponifying the cold drawing pipe for a second time; 8) performing cold drawing on the cold drawing pipe for a second time; and 9) performing dimensional inspection, alignment, defect polishing, surface quality inspection and non-destructive inspection on the cold drawing pipe respectively to form a finished seamless steel pipe, and cropping the top. The seamless steel pipe and the manufacturing method have the characteristics that the seamless steel pipe and the manufacturing method are economical, environment-friendly, low in metal consumption, high in quality and yield of finished products, efficient in processing, easy to operate, and the like, and completely meet the market requirement of seamless steel pipes for long pipe trailers.

Owner:DEYANG YUXIN MACHINERY MFG

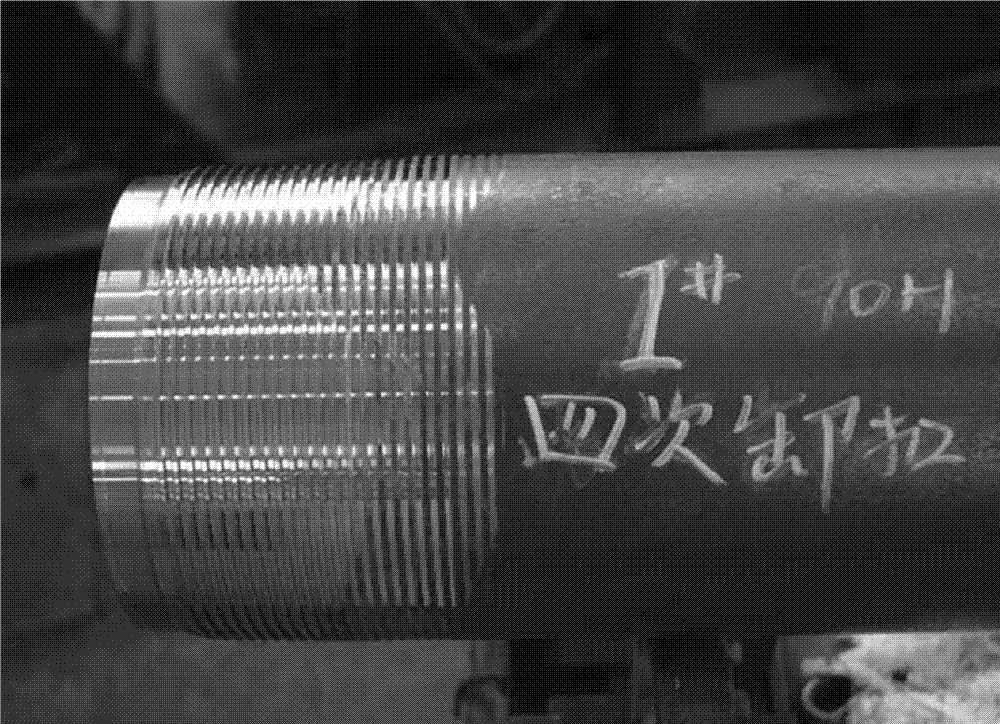

Oil casing pipe joint anti-thread-gluing coating and preparation method thereof

An anti-galling coating for a threaded joint of an oil casing. The mass percentages of the components of the coating are: organic binder 30-60 wt%, solid lubricant 30-60 wt%, anticorrosive agent 6-15 wt%, leveling agent 0.01-0.1 wt%, wetting agent 0.01-0.1 wt% and mixed solvent in addition. The organic binder is polyamide-imide liquid resin with a solid content of 38-42 wt%. The solid lubricant is any one of molybdenum disulphide and tungsten disulfide, or a combination of molybdenum disulfide or tungsten disulfide and polytetrafluoroethylene. Preferably the solid lubricant and the anticorrosive agent are surface modified with silane coupling agent. The anti-galling coating is obtained by spraying the coating on the surface of an oil casing joint processed with phosphate, and the environmental pollution caused by heavy metal powder in thread compounds is avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

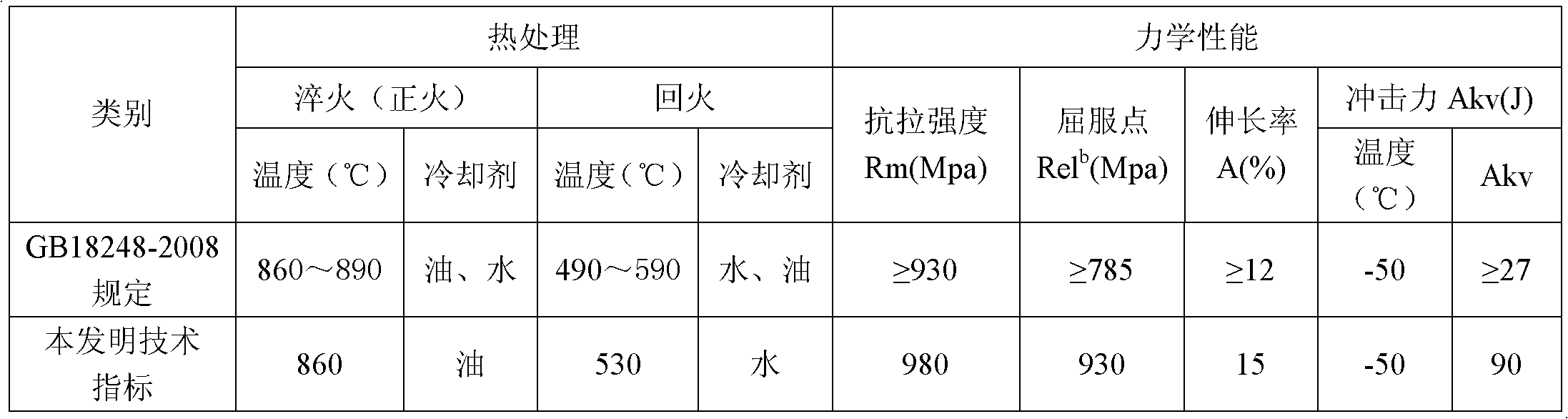

Manufacturing method of cold-drawing seamless steel tube for oxygen supplying bottles

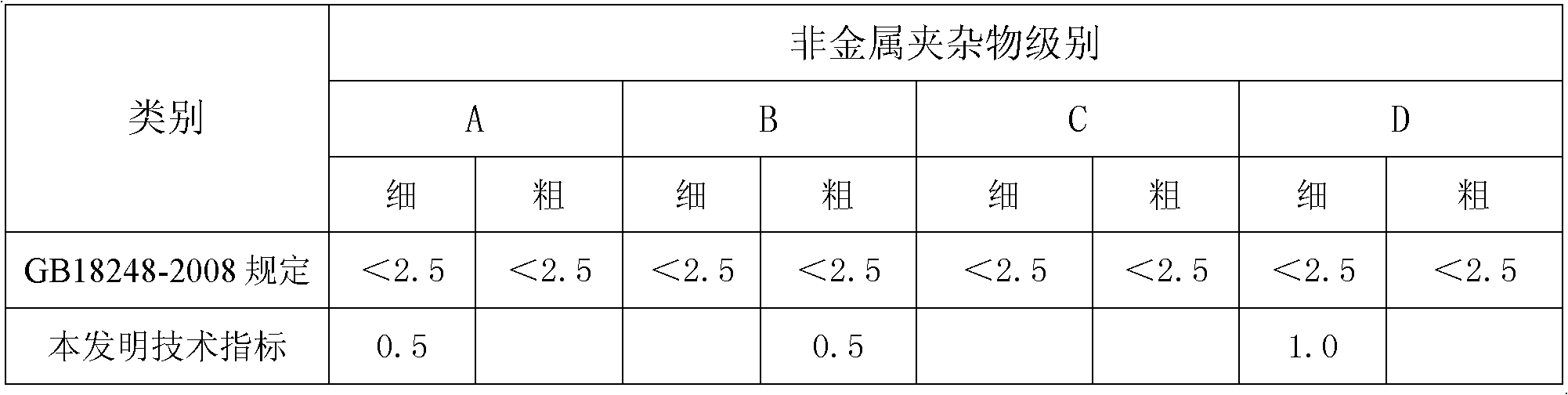

The invention relates to a manufacturing method of a cold-drawing seamless steel tube for oxygen supplying bottles, comprising the following steps: (1) inspection; (2) acid washing; (3) phosphate treatment; (4) soap treatment; (5) cold drawing; (6) straightening; (7) inspections on the quality, the wall thickness, the outer diameter and the flexibility of the inner surface and the outer surface of the seamless steel tube; (8) ultrasonic flaw detection; (9) denseness test; and (10) saw cutting. The oxygen supplying bottles manufactured by the method has the advantages of simple structure, small size, large capacity and long oxygen supplying time; in particular for the cold-drawing seamless steel tube for the oxygen supplying bottles, which adopts the material of 30CrMo and the specification of phi 178*4.8 mm is used as a representative variety, the product quality fully meets the technical requirements and is in the leading level in the same domestic industry and comprehensively meets the standard of the Seamless Steel Tubes for Air Bottles GB18248-2008 and some stricter quality requirements of users.

Owner:天津润德中天钢管有限公司

Method for forming high self-heal high corrosion resistance phosphide composite film layer on zinc coat surface

InactiveCN101168839ANon-toxic and environmentally friendly poresImprove bindingMetallic material coating processesComposite filmMolybdate

The invention proposes a method for forming a high corrosion resistant phosphatizing compound film with self-healing performance on the surface of galvanized coating. A galvanized workpiece is phosphatized and hermetically treated with molyadate solution. The phosphate treatment is operated after the iron and steel workpiece is galvanized, an impregnation method is adopted, the workpiece is put in phosphating solution to be phosphatized for 30-600 seconds, and then the workpiece is taken out, the phosphate treatment temperature is 30-50 DEG C; a phosphating solution group comprises a membrane agent component, namely, ZnO, and the content of the ZnO is 0.8-1.5 g / L; the molyadate hermetical treatment includes the steps thatthe phosphatized workpiece is directly immerged in molyadate confinig liquid for 20-60 seconds and then is taken out, the molyadate hermetical treatment temperature is 50-70 DEG C, and the workpiece is put in the air to hypergolically dry. The corrosion resistant performance of the phosphatizing compound film acquired by the invention is superior to the chromate passivating film, and the phosphatizing compound film has the self-healing performance. The invention is adopted to be capable of replacing toxic hexavalent chrome normal passivation which is widely adopted at present, and the phosphatizing compound film is beneficial to the environmental protection, thereby having good promotion and application value and social efficiency.

Owner:SOUTH CHINA UNIV OF TECH

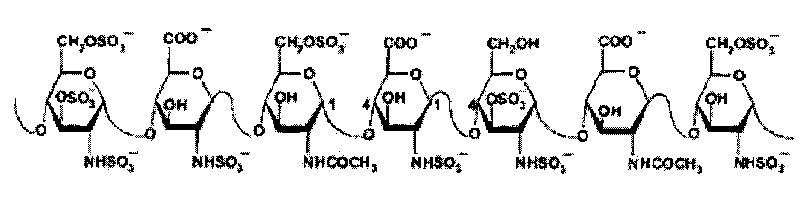

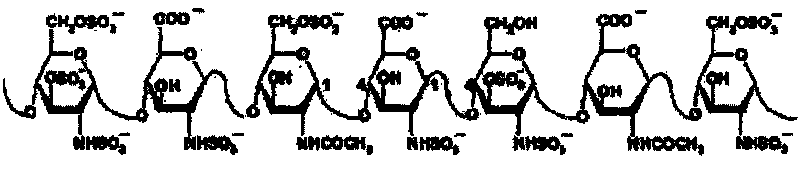

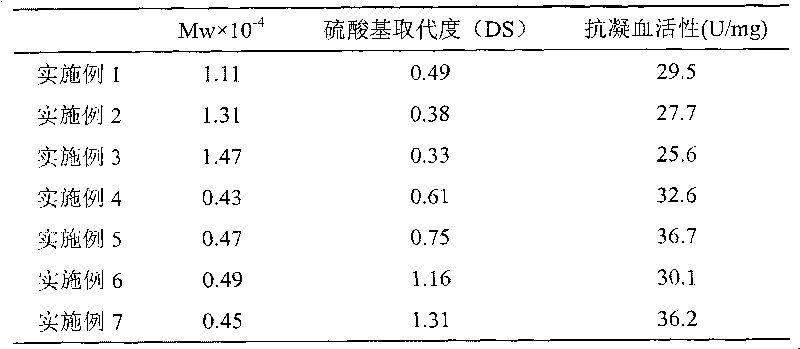

Method for preparing heparinoid polysaccharide

The invention discloses a method for preparing heparinoid polysaccharide. The heparinoid polysaccharide is prepared by chitin through phosphate treatment, a 6-bit selective oxidation reaction, deacetylation reaction, sulfonation reaction and / or a sulfation reaction, the substitution degree of sulfate groups thereof is between 0.3 and 1.35, and the molecular weight is between 0.40*104 and 1.5*104. The method has good repeatability; and the prepared heparinoid polysaccharide has a structure close to that of heparin, has higher anticoagulant activity, and expects to substitute the heparin to serve as an anticoagulant medicament.

Owner:WUHAN UNIV

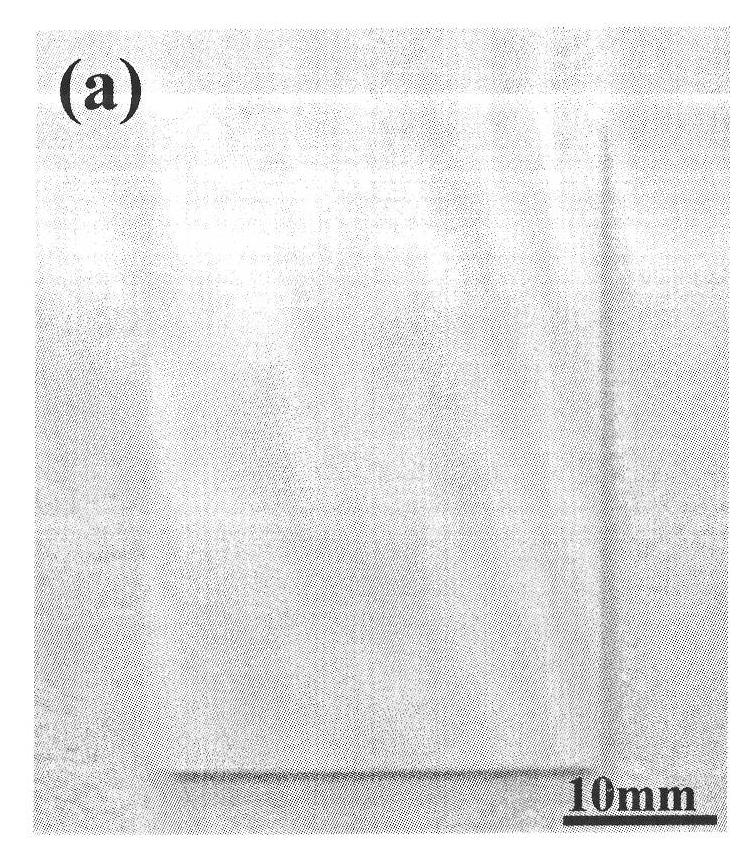

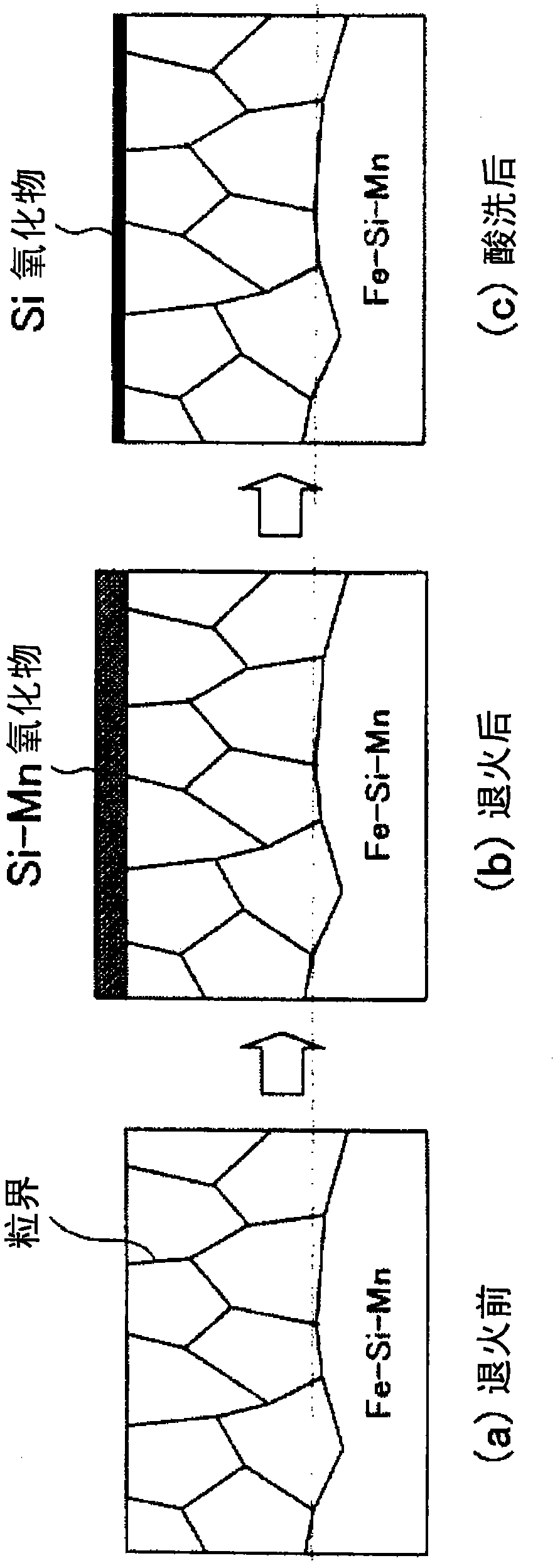

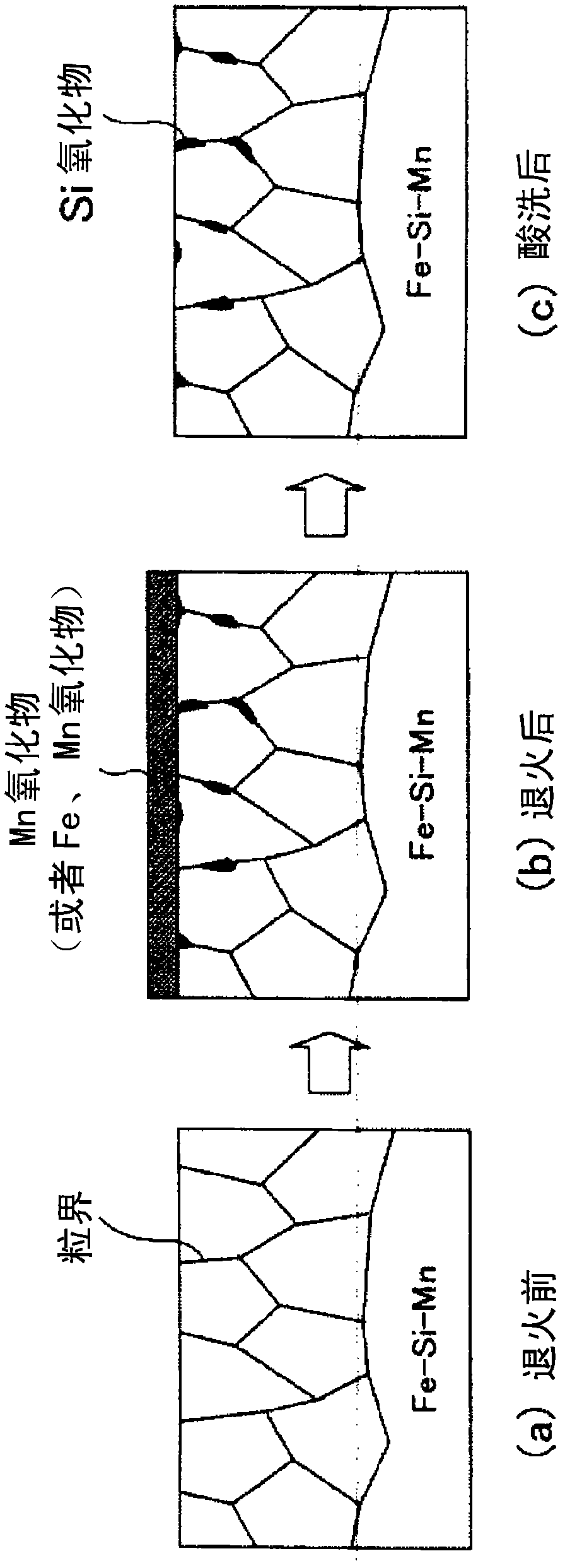

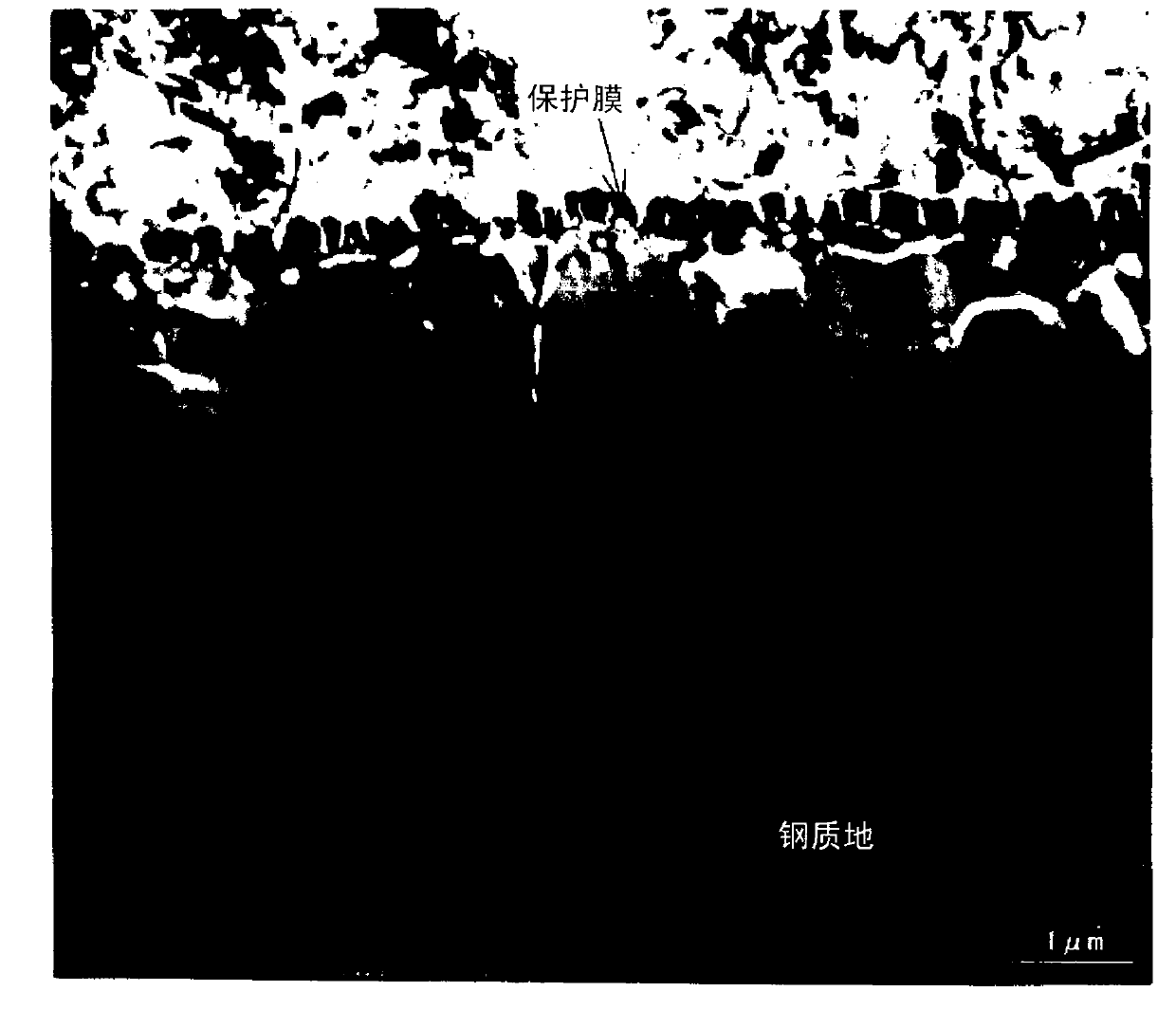

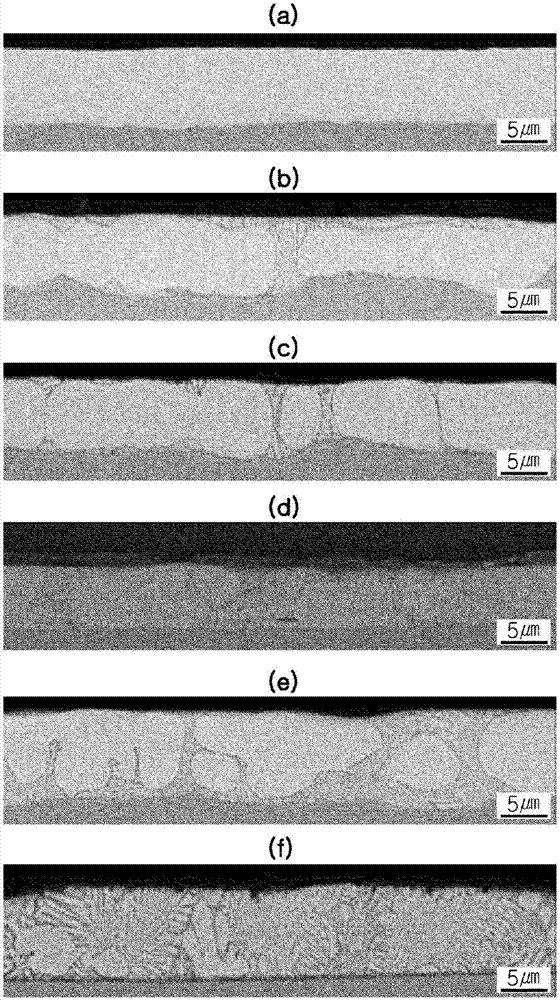

High-strength cold-rolled steel plate and manufacturing method thereof

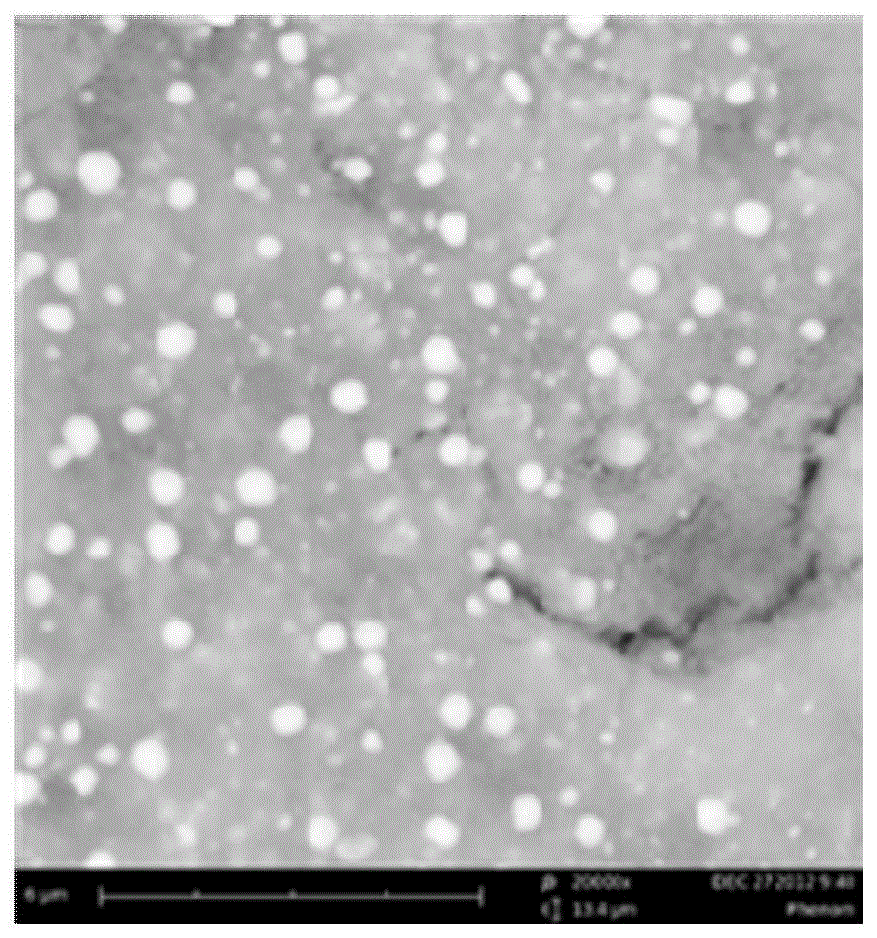

The invention provides a steel plate containing C, Si and Mn, and particularly relates to a high-strength cold-rolled steel plate and a manufacturing method thereof. In case of a high Si content, the high-strength cold-rolled steel plate can be well subjected to phosphate treatment, has favorable appearance with no tiny dents on the surface, and has excellent corrosion resistance. Therefore, when a cross section in a direction perpendicular to the surface of the steel plate is observed through an electron microscope at a multiplying factor of 50000 times or above, the ratio of Si-containing oxide on the surface of the steel plate having a length of 10mu m, based on the average value of five points randomly selected, is 80% or below.

Owner:KOBE STEEL LTD

Method for electrodepositing phosphate/metal composite film on cathode of surface of magnesium alloy

InactiveCN101643928AFacilitates tertiary dissociationContinuous processingPhosphatisationComposite filmAcid washing

The invention relates to a method for electrodepositing phosphate / metal composite film on cathode of surface of magnesium alloy, comprising the following steps: 1) taking magnesium alloy, cleaning surface of the magnesium alloy according to the sequence of mechanically removing dirt, alkaline washing and degreasing, acid washing and activating color temperature, and the cleaning quickly with water; 2) electrifying the magnesium alloy cleaned in step one, and then transferring into phosphate treatment solution to dip with electricity under voltage of 3-5 V, hanging the magnesium alloy on cathode of electrolytic bath, taking zinc as anode, wherein the current density range is between 1 A and 10 A / D2 (ampere / decimeter square), electrifying for 2-10 minutes; 3) taking out the magnesium alloy,blowing with 50-90 DEG C of hot air, forming phosphate / metal composite film on surface of magnesium alloy material, and completing surface treatment of magnesium alloy material. The method of the invention is used to cover phosphate / metal composite film on surface of the magnesium alloy material, and the film has more compact structure than the general phosphating film, thereby having good adhesive force and stronger protection capability; the treatment process has less substrate loss, the treatment solution has wider range, and the solution is convenient to maintain.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Polymer battery module packaging sheet and a method of manufacturing the same

InactiveUS8067113B2Improve the protective effectNon-aqueous electrolyte accumulatorsFinal product manufactureConversion coatingChemical conversion

A polymer battery module packaging sheet includes, as essential components, a base layer (61), an aluminum layer (62), chemical conversion coatings (64a, 64b) coating the opposite surfaces of the aluminum layer (62), and an innermost layer (63). The chemical conversion coatings (64a, 64b) are formed by processing the opposite surfaces of the aluminum layer (62) by a phosphate treatment method. The base layer (61) and the innermost layer (63) are bonded to the chemical conversion coatings (64a, 64b) of the aluminum layer (62) with adhesive layers (65a, 65b), respectively.

Owner:DAI NIPPON PRINTING CO LTD

Method for producing precise linear guide slide seat for machining center

The invention relates to a method for producing a linear guide, in particular to a method for producing a precise linear guide slide seat on a machining center for processing workpieces in machining industries. The method comprises the steps of hot rolling, spheroidizing, head rolling, pickling, phosphate treatment, saponification treatment, cold drawing, process annealing, straightening, cuttingand the like. The method for producing the precise linear guide slide seat for the machining center has the advantages of high efficiency and low production cost.

Owner:WUXI NEWAY STEEL

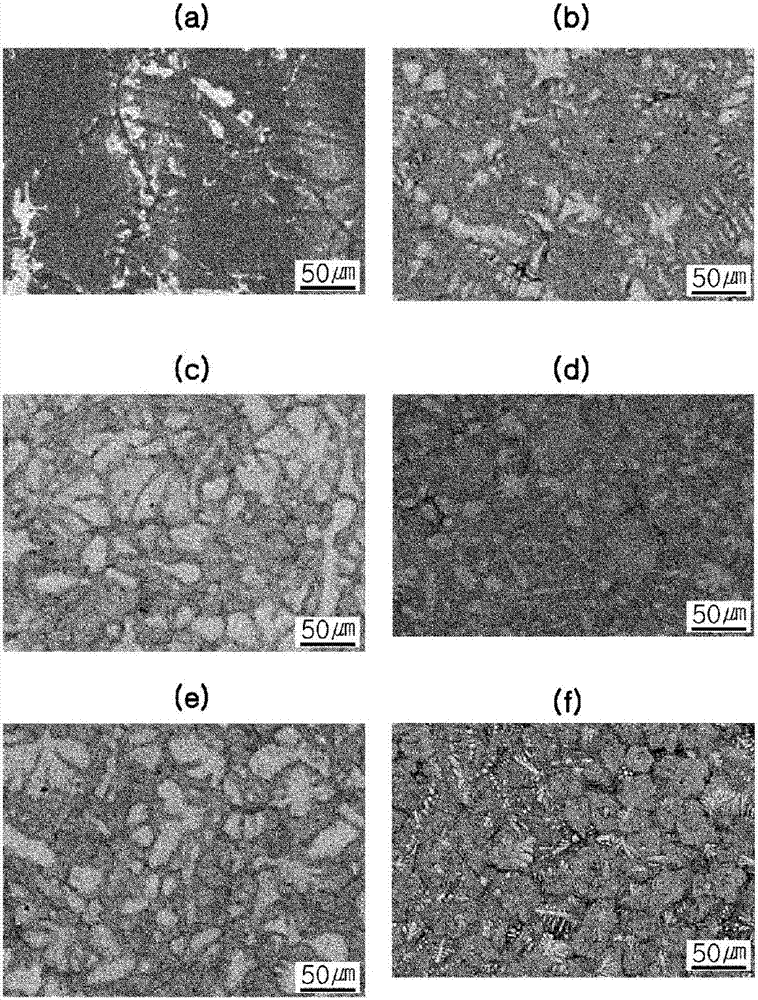

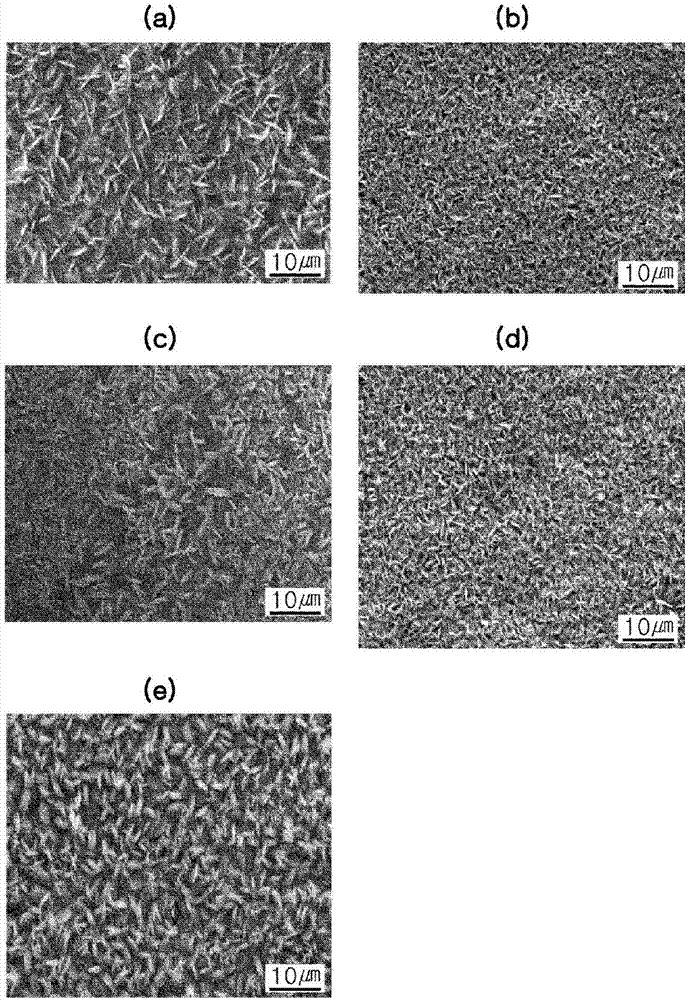

Zn alloy plated steel sheet having excellent phosphatability and spot weldability and method for manufacturing same

ActiveCN107109608AGood spot weldabilityEasy to handleHot-dipping/immersion processesIntermetallicSurface structure

A Zn alloy plated steel sheet having excellent phosphatability and spot weldability and a method for manufacturing the same are provided. In the Zn alloy plated steel sheet including a base steel sheet and a Zn alloy plating layer, the Zn alloy plating layer includes, by wt%, Al: 0.5-2.8%, Mg: 0.5-2.8%, and a remainder of Zn and inevitable impurities, and a cross-sectional structure of the Zn alloy plating layer includes, by area percentage, more than 50% of a Zn single phase structure and less than 50% of a Zn-Al-Mg-based intermetallic compound. A surface structure of the Zn alloy plating layer includes, by area percentage, 40% or less of a Zn single phase structure and 60% or more of a Zn-Al-Mg-based intermetallic compound.

Owner:POSCO CO LTD

Part electrophoretic coating process

InactiveCN109881239AQuality improvementGood adhesionElectrophoretic coatingsElectrophoresisUltrafiltration

The invention relates to the technical field of surface treatment, in particular to a part electrophoretic coating process. According to the technical scheme, the part electrophoretic coating processis mainly characterized by comprising a pretreatment working procedure and an electrophoretic treatment working procedure, wherein the pretreatment working procedure sequentially comprises the following treatment steps of degreasing treatment, phosphating treatment and passivation treatment, the degreasing treatment sequentially comprises the following steps of pre-degreasing spraying treatment, degreasing soaking treatment and main degreasing spraying treatment, the phosphating treatment sequentially comprises the following steps of surface adjusting spraying treatment and phosphate soaking treatment, the passivation treatment sequentially comprises the following steps of passivation soaking treatment, first-time pure water spraying treatment and second-time pure water spraying treatment,and the electrophoretic treatment working procedure sequentially comprises the following treatment steps of anodic electrophoretic treatment, ultrafiltration recovery treatment, pure water soaking treatment and pure water spraying treatment. The part electrophoretic coating process has the advantage of improving the electrophoretic coating quality of automobile parts.

Owner:TONGWEI PRECISION COATING SHANGHAI

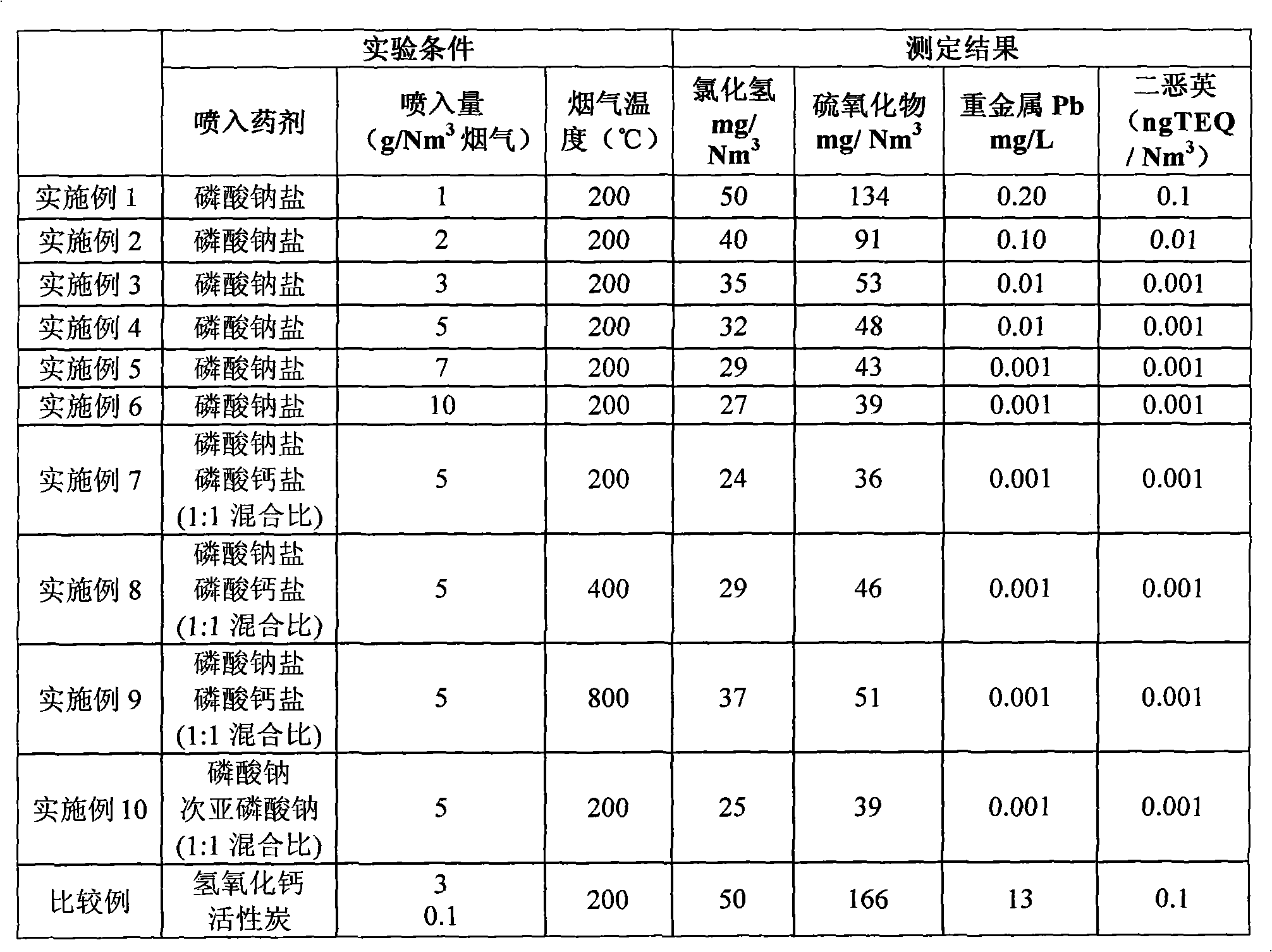

Method for treating waste incineration flue gas by using phosphate

The invention relates to a method for treating waste incineration flue gas by using mixture containing phosphate, comprising: the incineration flue gas with the temperature of below 800 DEG C is sprayed with the mixture containing the phosphate, and the spray quantity is 0.1-10g / Nm<3> of flue gas; the mixture is contacted with the flue gas for reaction, so that the content of oxysulphide, hydrogen chloride and dioxin as well as the dissolving out quantity of heavy metal can be effectively reduced. Compared with the original flue gas purification method, the method has the characteristics of simple technique, low cost, little medicament dosage, remarkable effect, etc.

Owner:SHANGHAI SUS ENVIRONMENT +1

Composite material with excellent antibiotic and preservative performance

InactiveCN106433420AImprove antibacterial and antiseptic effectImprove performanceAntifouling/underwater paintsPaints with biocidesGlycerolCobalt

The invention discloses a composite material with excellent antibiotic and preservative performance. The composite material is prepared from the following raw materials including alkide resin paint, vinyl chloride-vinyl acetate resin, polyphosphoric acid, diacetyl aniline, cobalt manganese rare earth, calcium molybdate, forging white powder, modified aluminum powder, zeolite powder, nitrocotton, iron powder, nanometer antibacterial powder, natrosol, hydrated aluminum oxide, polybutene, hydroxyethyl cellulose, aluminum sulfate solution, glacial acetic acid, lauryl acrylate, ethyl acetate, methyl methacrylate, acrylonitrile, titanate coupling agents, phosphating treatment liquid, xylene, n-butyl alcohol, sulfonated oil and glycerol. The composite material provided by the invention has excellent antibiotic and preservative performance.

Owner:ANHUI SKY EYE INTELLIGENT TECH

Metal surface treating composition and surface treating metal material with metal surface treating film obtained therefrom

The aim of the invention is to provide a non-pollution metal surface treatment composition which has comparative anti-rusting capability with the previous chromate treatment agent and phosphate treatment agent and has excellent alkaline resistance, excellent processability, excellent corrosion resistance, excellent coating property, etc. The invention also provides a surface treatment metal material which has the metal surface treatment layer obtained by the composition. The surface treatment composition provided by the invention is characterized by comprising the following components: (A) peroxide vanadic acid; (B) organic phosphonic acid and (C) water-soluble or water-dispersive organic resin (C) which is included according to requirement.

Owner:KANSAI PAINT CO LTD

Bonderite process before lacquering steel surface

InactiveCN101063201AImprove protectionLess investmentMetallic material coating processesPhosphoric acidZinc nitrate

The invention discloses a phosphating additive before tinting of metallic surface in surface chemical technical domain, which comprises the following steps: allocating with mass ratio as 3-7 phosphoric acid, 2-8 zinc dihydrogenphosphate, 1-6 zinc nitrate, 1-3 nickel nitrate, 0. 1-3 sodium fluoroborate, 0. 5-4 sodium chlorate, 1-3 citric acid, 1-4 sodium nitrite and 50-65 soften water; getting the product. This invention can be used to proceed phosphate treatment for metallic surface.

Owner:宋晨玮

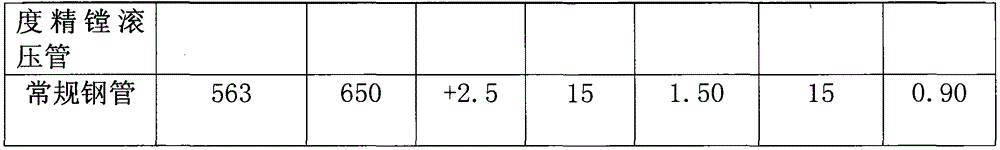

Manufacturing method of cold-drawn high-strength fine-boring rolled pipe

The invention relates to a manufacturing method of a cold-drawn high-strength fine-boring rolled pipe. The manufacturing method comprises the following steps of heating, wherein a pipe blank is heated in a circular furnace; perforating, wherein the heated pipe blank is perforated by a perforating machine; annealing, wherein the pipe blank is annealed; borax spraying, wherein oxide skin is removed; hot rolling, wherein the annealed pipe blank is guided into a pipe rolling machine for hot rolling; sizing, wherein the rolled pipe formed after continuous rolling is subjected to sizing through a sizing mill; stress relief annealing, wherein the rolled pipe is guided into a heating furnace to be heated to obtain the annealed pipe blank; acid pickling treatment, wherein rust scales on the surface are removed; phosphating treatment, wherein a chemical generation film of zinc phosphate is formed on the surface; saponification treatment, wherein metallic soap and the like are formed to lubricate the film; primary cold-drawing, wherein the pipe blank to be cold-drawn is cold-drawn; secondary cold-drawing, wherein the cold-drawn pipe subjected to primary cold-drawing is subjected to secondary cold-drawing to obtain the cold-drawn pipe; normalizing and air cooling treatment; straightening treatment; induction furnace quenching treatment; and fine-boring rolling. Thus, the fine-boring rolled pipe is obtained. The fine-boring rolled pipe obtained through the method is high in yield strength and tensile strength.

Owner:WUXI SHENLU HYDRAULIC PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com