Method for treating waste incineration flue gas by using phosphate

A technology for incinerating flue gas and waste, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of rising equipment investment and operating costs, increasing fly ash treatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

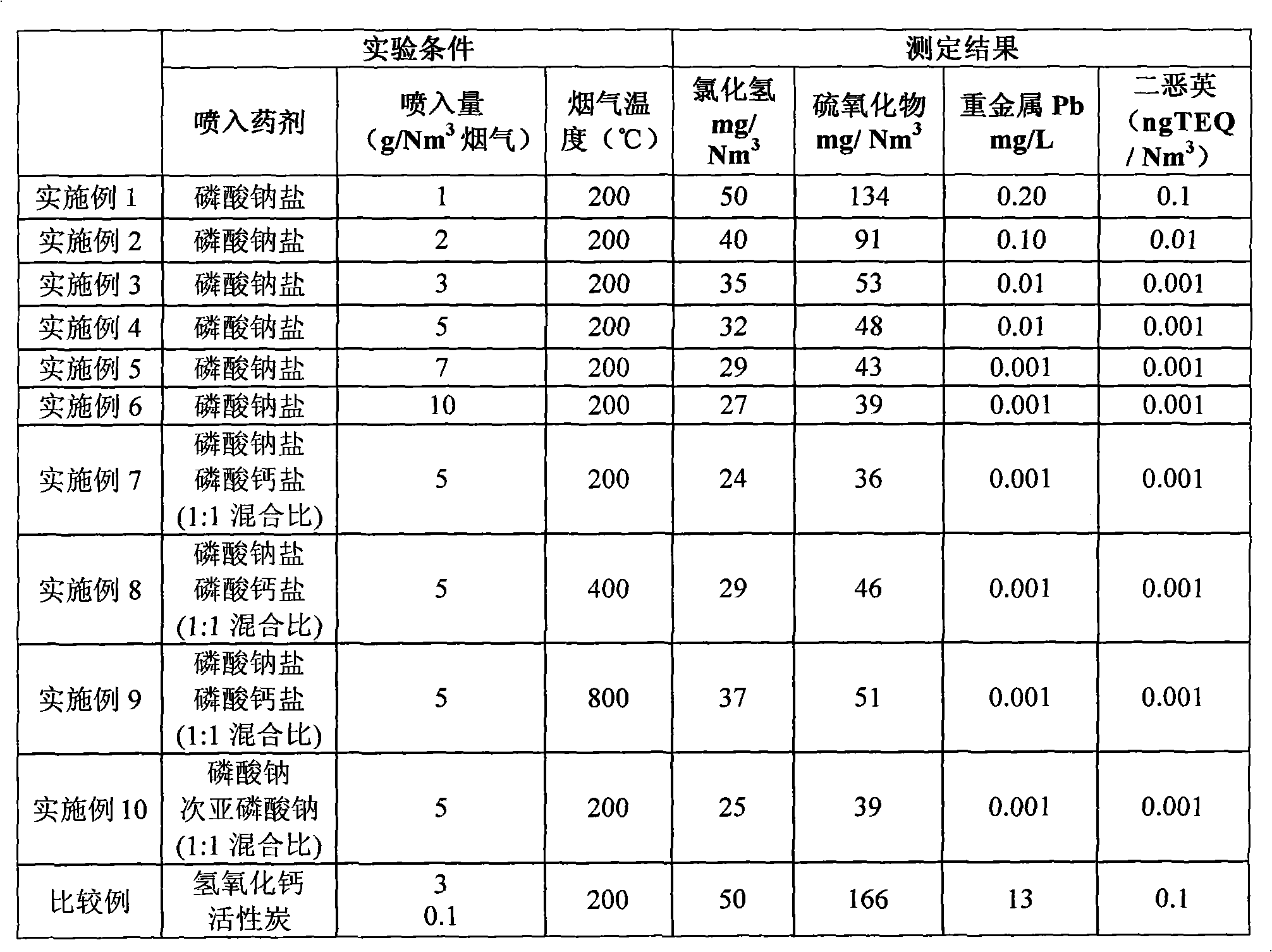

[0019] To waste incineration flue gas (flue gas flow rate 30,000m 3 / h-wet) into the exhaust flue, spray sodium phosphate or a mixture of sodium phosphate and calcium phosphate. Measure the content of sulfur oxides, hydrogen chloride and dioxin in the flue gas at the outlet of the dust collector, and measure the dissolution of heavy metals in the fly ash collected by the dust collector.

[0020] Change the injection amount and injection position of phosphate to achieve different treatment effects. And the original flue gas treatment method, that is, spraying calcium hydroxide and activated carbon into the flue gas, was taken as a comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com