Production method and die of cold-drawing transmission shaft

A transmission shaft and mold technology, applied in metal drawing forming tools, manufacturing tools, metal wire drawing, etc., can solve the problem of inability to produce transmission shaft tolerance, precision cold-drawn section steel, cold-drawn round steel tolerance and high precision, size Problems such as inability to be precisely controlled to achieve the effects of excellent comprehensive mechanical properties, saving raw material resources, and stable dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

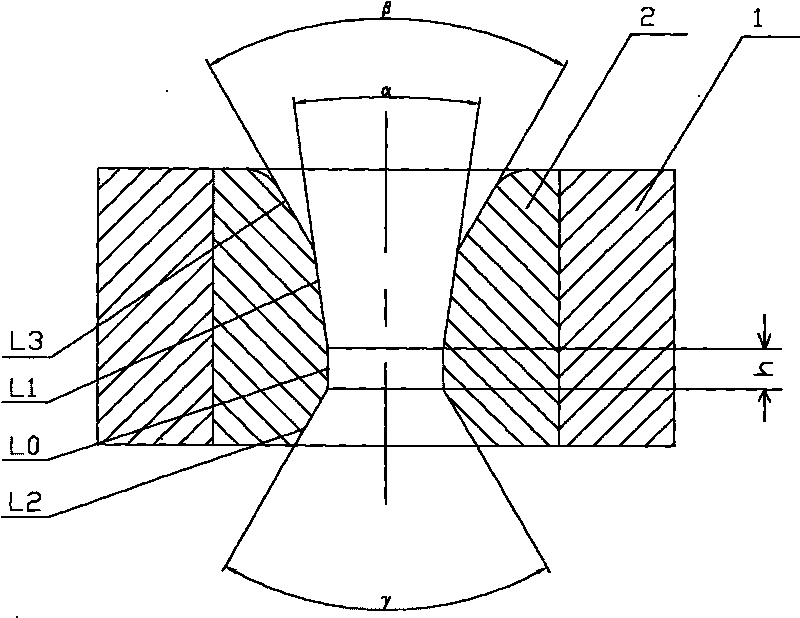

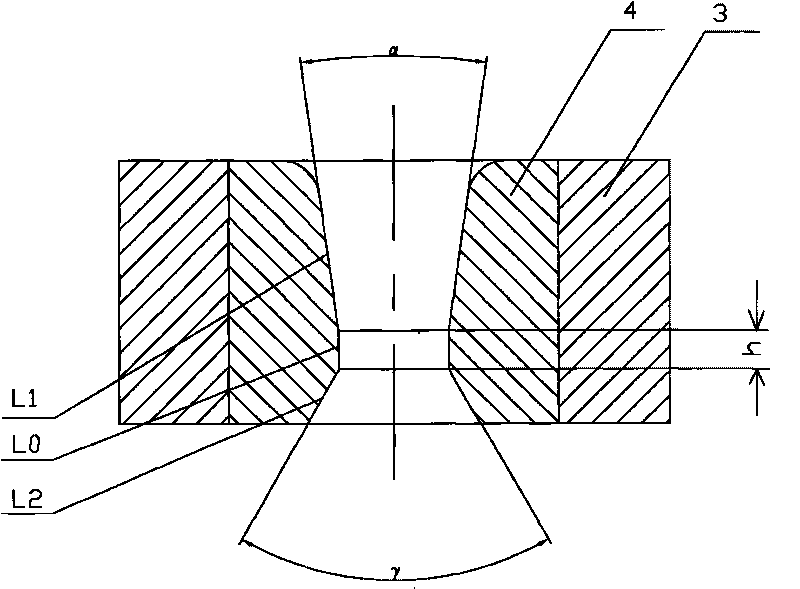

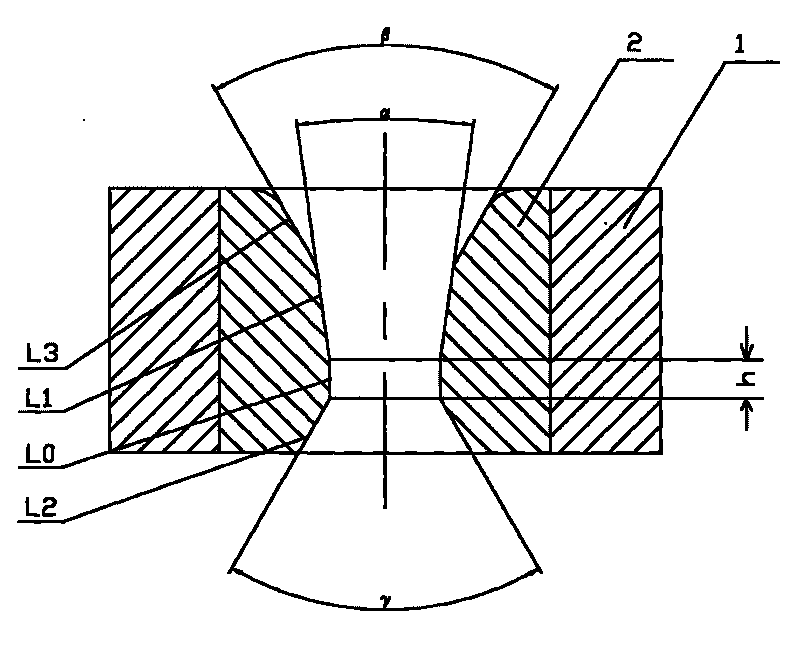

Image

Examples

Embodiment Construction

[0031] A method for producing a transmission shaft by a cold drawing process, the specific production method is as follows:

[0032] A. Inspection and classification of billets: Classify billets according to their hardness and divide them into 5 interval categories, namely HB≤170, HB170~200, HB200~230, HB230~250, and HB250 and above.

[0033] B. Pretreatment before drawing, the pretreatment before drawing includes:

[0034] 1. Pickling treatment: Soak the blank with 10-15% sulfuric acid at a temperature of 70-80°C for 25-30 minutes.

[0035] 2. Neutralization treatment: Soak the billet after pickling treatment in 5% N a In OH aqueous solution, the soaking temperature is 40°C, the soaking time is 10 minutes, and then rinsed with clean water.

[0036] 3. Phosphating treatment: Soak the neutralized billet in phosphating solution at 70-80°C for 10-15 minutes.

[0037] The phosphating solution is composed of the following raw materials, the parts are parts by weight, wherein: zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com