Composition for metal surface treatment, metal surface treatment method and coating method of metal material

A metal surface treatment and metal material technology, applied in the direction of metal material coating process, etc., can solve the problems of inability to obtain corrosion resistance, insufficient coating film adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0079] In a 1L round bottom flask equipped with a reflux condenser, a thermometer, a nitrogen inlet tube, and a stirrer, add 200 g of isopropanol and 200 g of deionized water, and start stirring. Nitrogen gas was supplied in a gaseous phase, and 90 g of 3-aminopropyltrimethoxysilane and 10 g of bis(triethoxysilyl)ethane were thrown in at once while stirring. After stirring at normal temperature for 1 hour, the mixture was reacted at 60°C for 6 hours, and then the fraction was removed, and the temperature was raised to 120°C while exchanging with propylene glycol monomethyl ether. After cooling to 60° C., it was concentrated by vacuum distillation to obtain 120 g of a product (P1) of a solution having a non-volatile content of 40%. The obtained product (P1) was a colorless transparent viscous liquid with a non-volatile content of 40%.

manufacture example 2~12

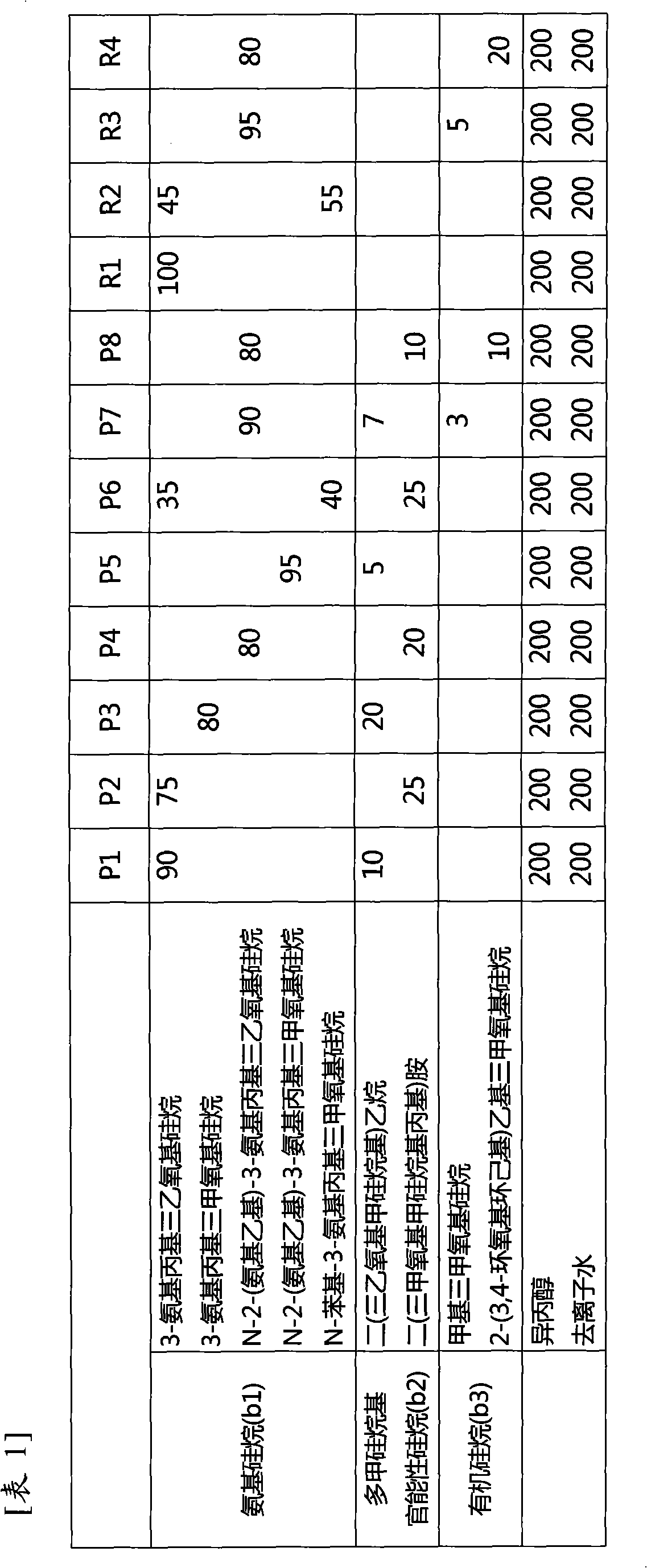

[0081] Except that in Production Example 1, the raw material composition was as shown in Table 1, it carried out similarly to Production Example 1, and each product (P1)-(P8) and (R1)-(R4) was obtained.

[0082]

Embodiment 1~26 and comparative example 1~4

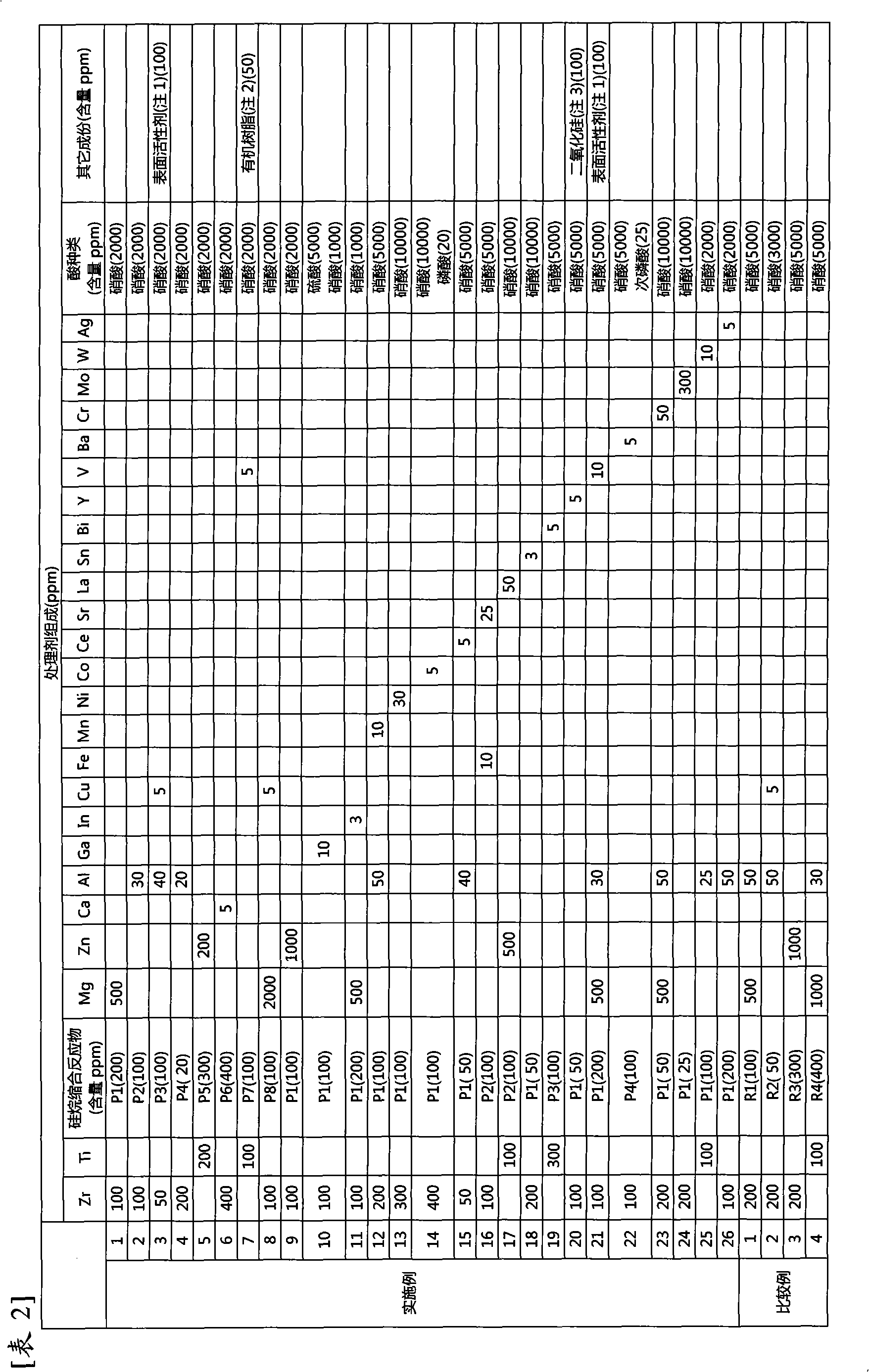

[0084] Production of compositions for metal surface treatment

[0085] In (P1) to (P8) and (R1) to (R4) prepared above, use fluozirconic acid, fluotitanic acid, and nitrates of each metal, etc., to adjust the combination for metal surface treatment with the composition shown in Table 2. thing. In Table 2, the concentration of each metal component is expressed in terms of metal elements, and the other component concentrations represent the solid content concentration.

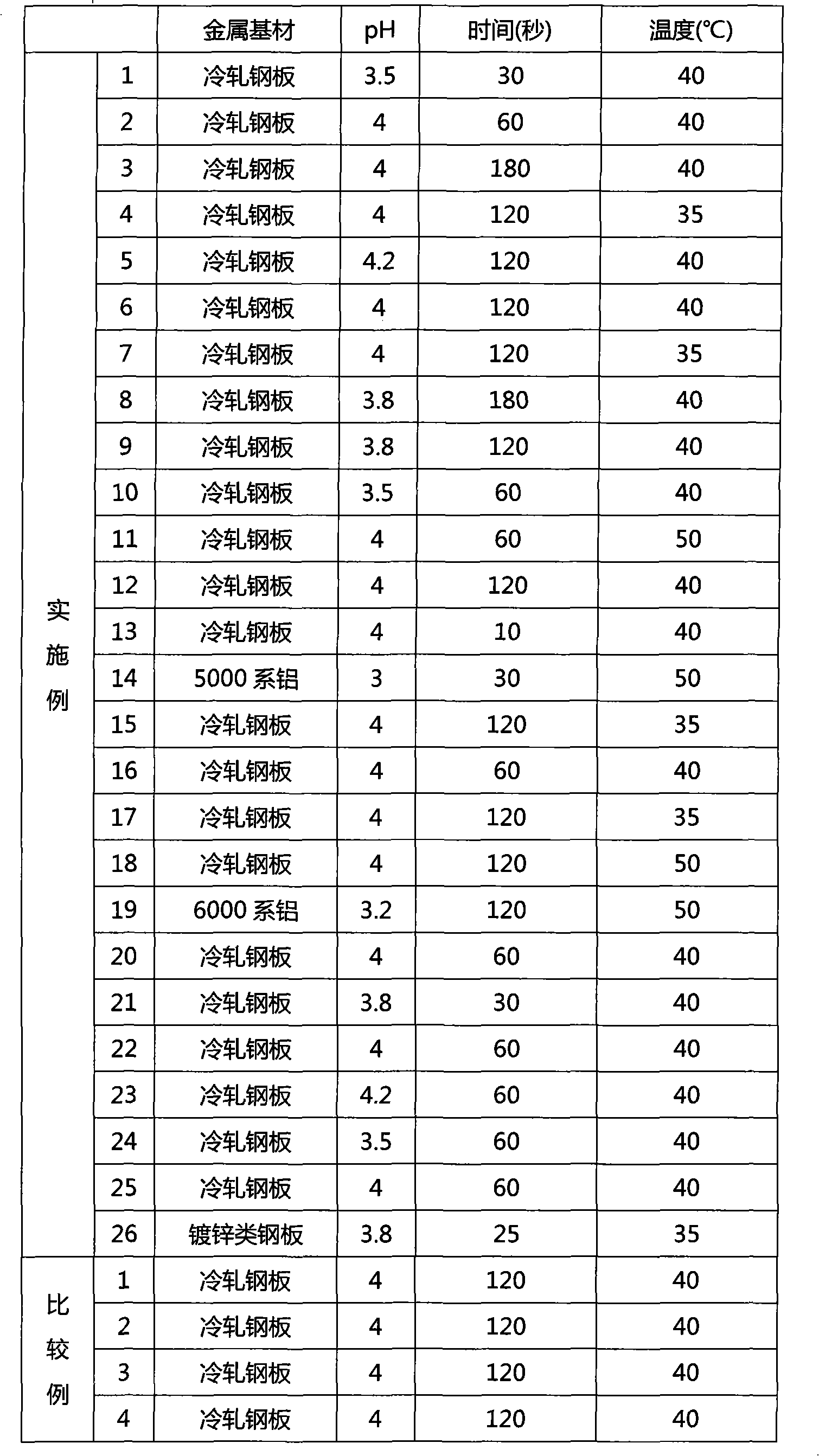

[0086] Chemical conversion treatment and finishing

[0087] Commercially available cold-rolled steel sheets (SPCC-SD, manufactured by Testpanel Corporation of Japan, 70mm×150mm×0.8mm), galvanized steel sheets (GA steel sheets, manufactured by Testpanel Corporation of Japan, 70mm×150mm×0.8mm), 5000 series Aluminum (manufactured by Japan Testopanel Corporation, 70mm × 150mm × 0.8mm) or 6000 series aluminum (manufactured by Japan Testopanel Corporation, 70mm × 150mm × 0.8mm) was used as a base material, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com