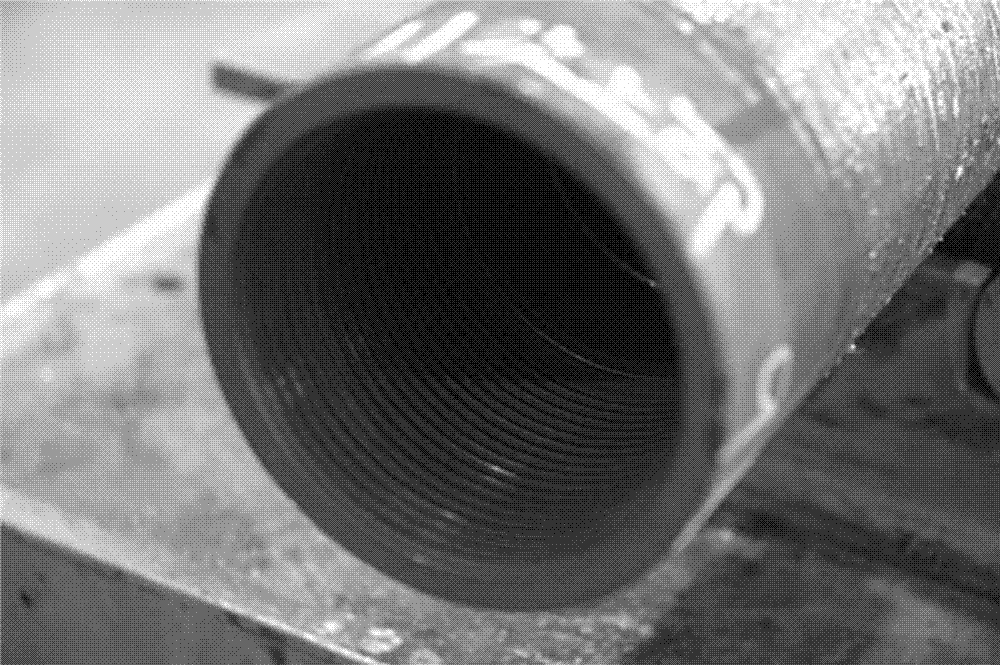

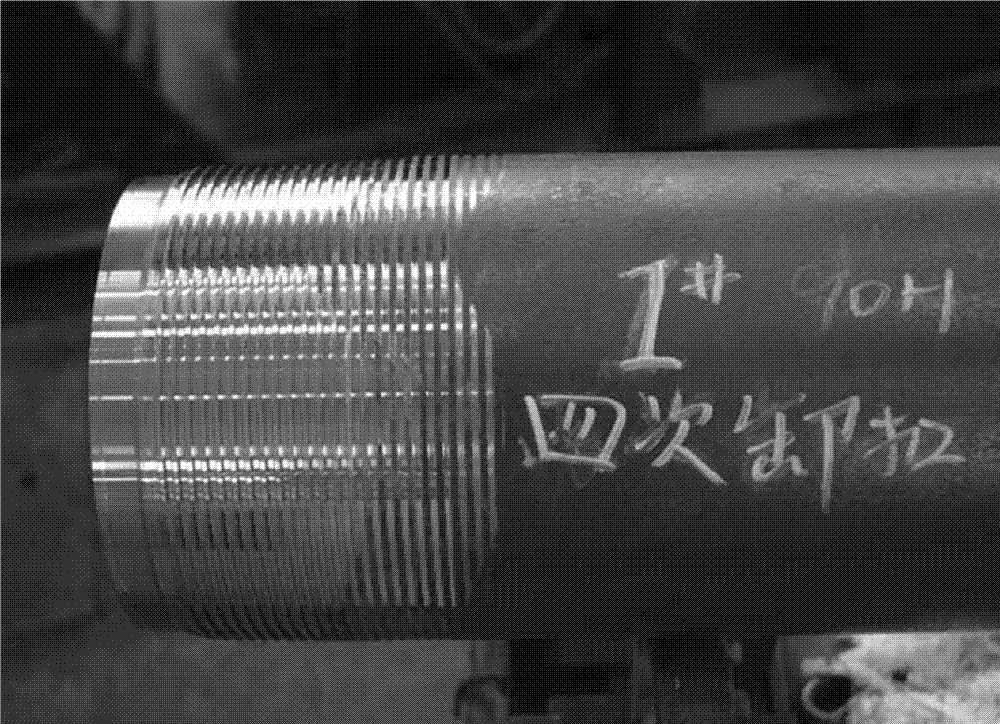

Oil casing pipe joint anti-thread-gluing coating and preparation method thereof

A oil casing, anti-sticking technology, applied in the direction of pipes/pipe joints/fittings, coatings, anti-corrosion coatings, etc., can solve problems such as heavy metal powder pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Coating composition (weight percent)

[0052] 49.8% polyamideimide, 10% polytetrafluoroethylene, 30% modified molybdenum disulfide, 5% modified titanium dioxide, 5% calcium stearate, 0.1% leveling agent, 0.1% wetting agent, mixed solvent The dosage is 3 times the mass of the above components.

[0053] Coating process: the pressure of the spray gun is 0.25MPa, and the temperature is kept at 280°C for 0.3 hours in a drying oven.

[0054] Results: After the above treatment, the bonding strength between the coating and the oil pipe joint of P110 steel grade is grade 1; there is no sticking phenomenon in the make-up and breakout 11 times; there is no rust point in the neutral salt spray test for 100 hours.

Embodiment 2

[0056] 30.89% polyamideimide, 7% polytetrafluoroethylene, 49% modified molybdenum disulfide, 10% modified titanium dioxide, 3% calcium stearate, 0.01% leveling agent, 0.1% wetting agent, mixed solvent The dosage is 4 times the mass of the above components.

[0057] Coating process: the pressure of the spray gun is 0.25MPa, and the temperature is kept at 280°C for 0.1 hour in a drying oven.

[0058] Results: After the above treatment, the bonding strength between the coating and the oil pipe joint of P110 steel grade is grade 1; there is no sticking phenomenon in the make-up and breakout 11 times; there is no rust point in the neutral salt spray test for 100 hours.

Embodiment 3

[0060] 57.89% polyamideimide, 4% polytetrafluoroethylene, 32% modified molybdenum disulfide, 5% modified titanium dioxide, 1% calcium stearate, 0.1% leveling agent, 0.01% wetting agent, mixed solvent The dosage is 3.5 times the mass of the above components.

[0061] Coating process: the pressure of the spray gun is 0.25MPa, and the temperature is kept at 250°C for 0.1 hour in a drying oven.

[0062] Results: After the above treatment, the bonding strength between the coating and the oil pipe joint of BG110SS steel grade was grade 1; there was no sticking phenomenon in the make-up and breakout 11 times; there was no rust point in the neutral salt spray test for 100 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com