Patents

Literature

777 results about "Tungsten disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten disulfide is an inorganic chemical compound composed of tungsten and sulfur with the chemical formula WS₂. This compound is part of the group of materials called the transition metal dichalcogenides. It occurs naturally as the rare mineral tungstenite. This material is a component of certain catalysts used for hydrodesulfurization and hydrodenitrification.

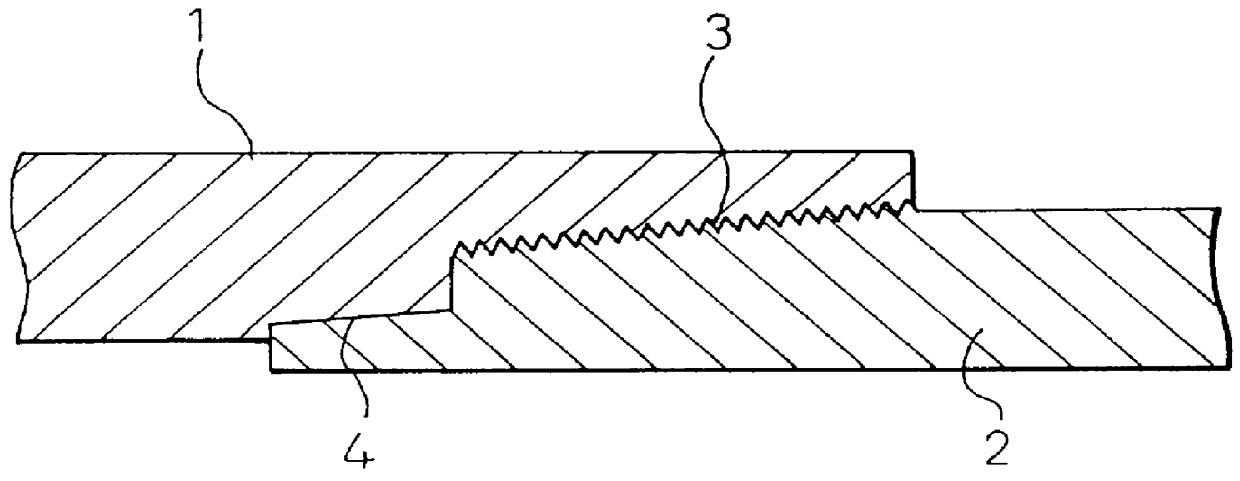

Joint for steel pipe having high galling resistance and surface treatment method thereof

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

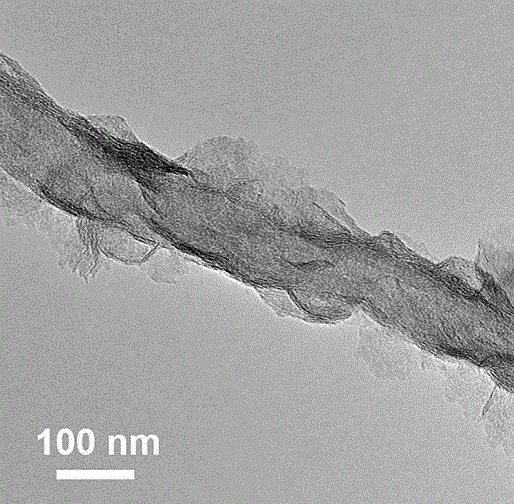

Compound nano material of graphene nano slice and WS2 and preparation method thereof

InactiveCN102142550AMild reaction conditionsSimple preparation processMaterial nanotechnologyCell electrodesSynthesis methodsNew energy

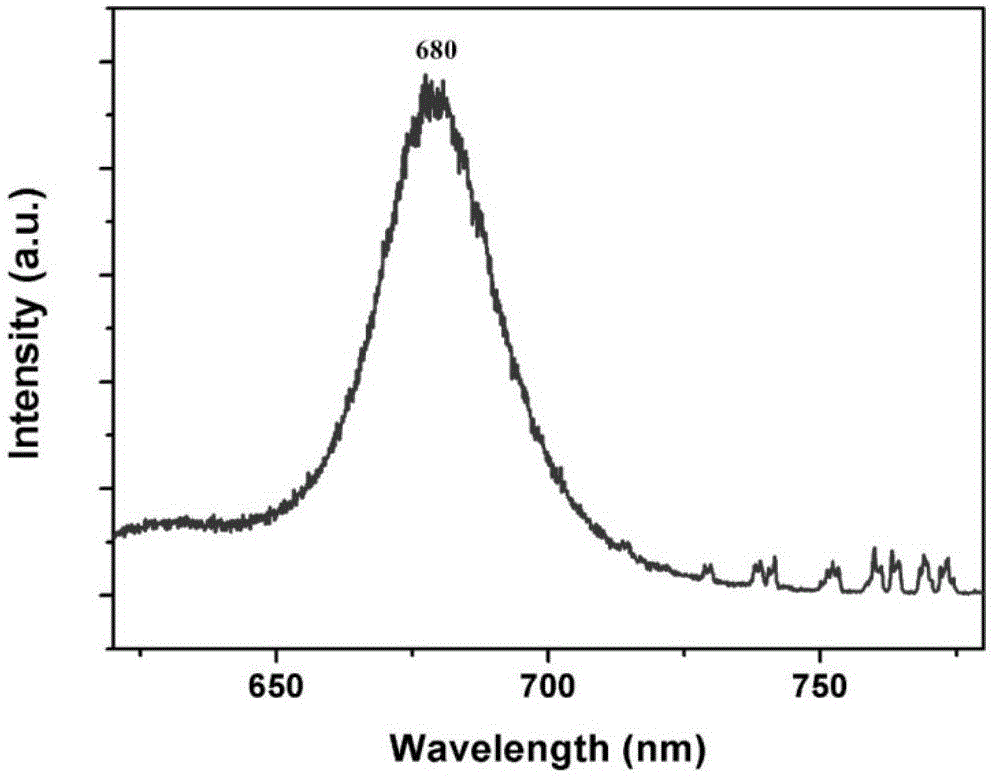

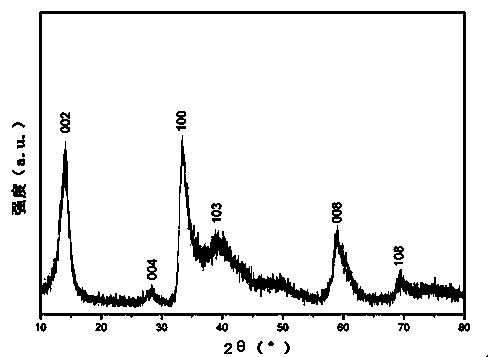

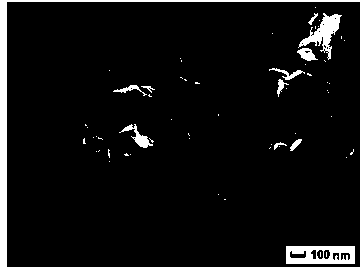

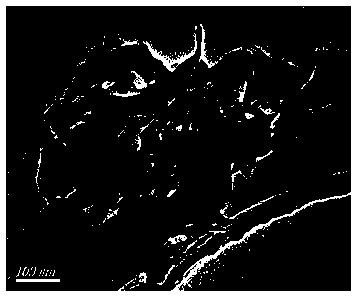

The invention discloses a compound nano material of graphene nano slice and tungsten disulfide (WS2), and a synthesis method and a preparation method thereof. The compound material is formed by mixing graphene and a WS2 nano material in a mass ratio of (1 to 1)-(4 to 1). The preparation method comprises the following steps of: preparing an oxidized graphite nano slice from graphite by a chemical oxidization method; then dissolving tungstic acid into deionized water so as to form 0.02 to 0.07M of solution; adding L-cysteine serving as a sulfur source and a reduction agent, wherein the mass ratio of the L-cysteine to the tungstic acid is (5 to 1)-(12 to 1); adding the oxidized graphite nano slice into the solution, and ultrasonically treating so that the oxidized graphite nano slice can be fully dispersed in the hydrothermal reaction solution; transferring the mixture into a hydrothermal reaction kettle and sealing; and synthesizing by a one-step hydrothermal method to obtain the compound nano material of graphene and WS2, wherein the mass ratio of the graphene nano slice to the WS2 is (1 to 1)-(4 to 1). The method has the characteristics of mild reaction condition and simple process. The compound nano material of graphene and WS2 synthesized by the method can be widely used as electrode materials of new energy batteries, high-performance national lubricants, catalyst carriers and the like.

Owner:ZHEJIANG UNIV

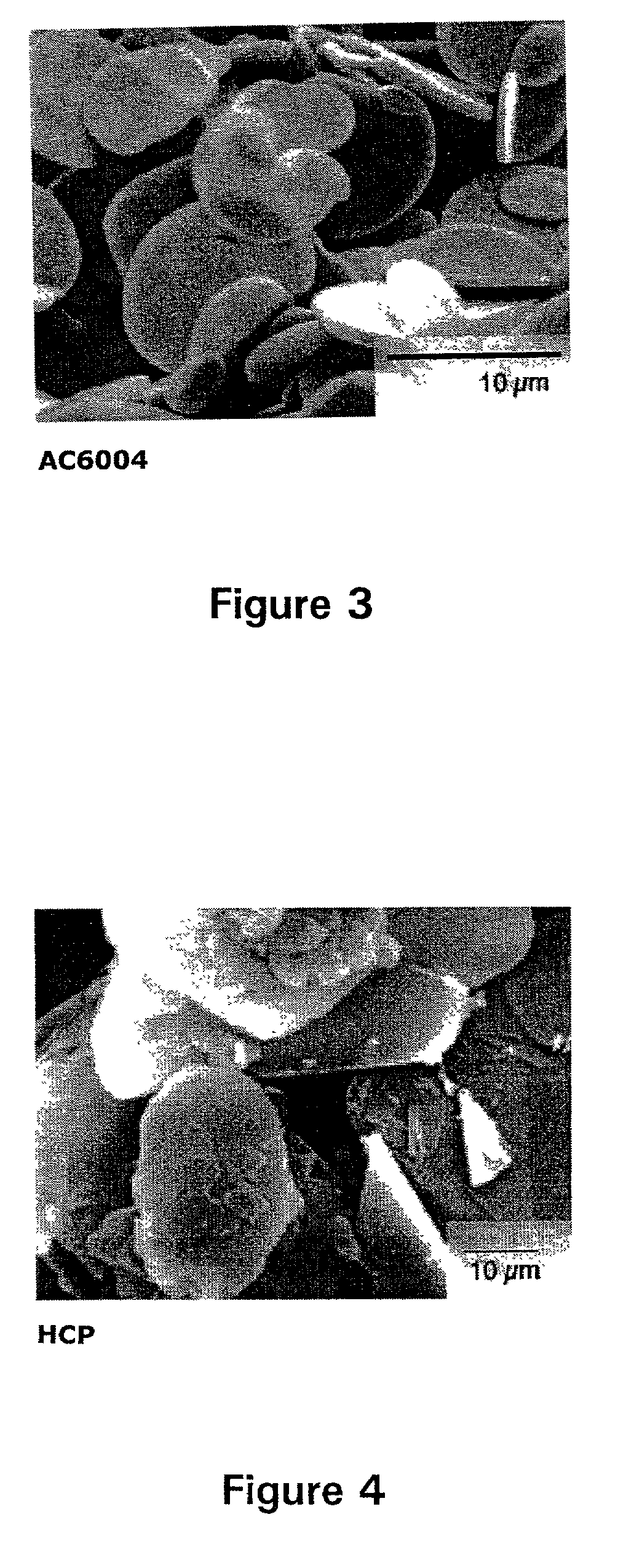

Thermal spray compositions for abradable seals

Owner:SULZER METCO CANADA INC

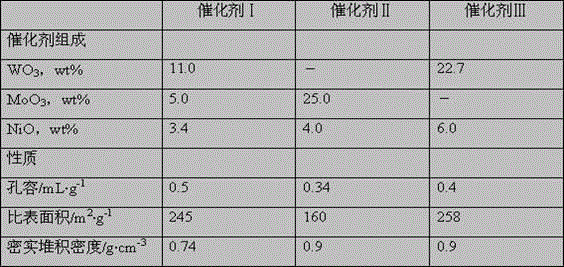

Operating method for vulcanized hydrogenation catalyst

ActiveCN104593050ANo self-heatingNo flammability issuesMolecular sieve catalystsHydrotreatment operations starting-upHydrogenation reactionReaction temperature

The invention discloses an operating method for a vulcanized hydrogenation catalyst. The method comprises the following steps: impregnating the vulcanized hydrogenation catalyst with an organic complex solution of a group-VIII metal; carrying out heat treatment so as to allow a layer of a protective film to form on the surface of the vulcanized hydrogenation catalyst; carrying out treatment in the presence of inert gas so as to allow the group-VIII metal to be inlaid in the defect of molybdenum disulfide or tungsten disulfide, thereby forming a high-activity hydrogenation active phase; and then carrying out switching into hydrogen, adjusting pressure and temperature to reaction pressure and reaction temperature after air current is steady, feeding raw oil and beginning a hydrogenation reaction. The method provided by the invention can passivate the vulcanized catalyst, facilitates transportation, storage and filling of the catalyst and can improve hydrogenation performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid lubricating high-temperature anti-wearing powder composition and preparation method of compound coating of composition

InactiveCN102836996ASignificant progressImprove high temperature wear resistance and friction reduction performanceLiquid/solution decomposition chemical coatingDecompositionEvaporation

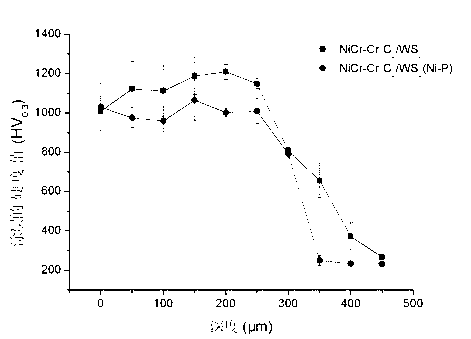

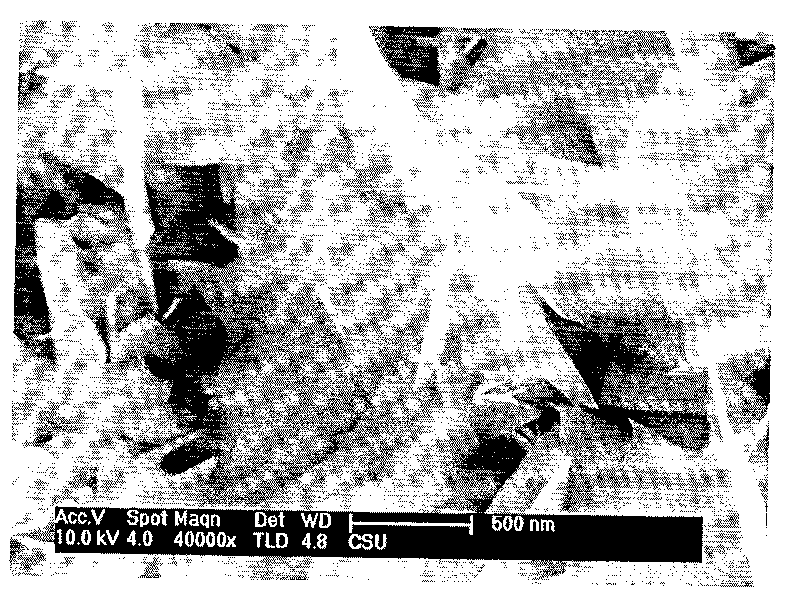

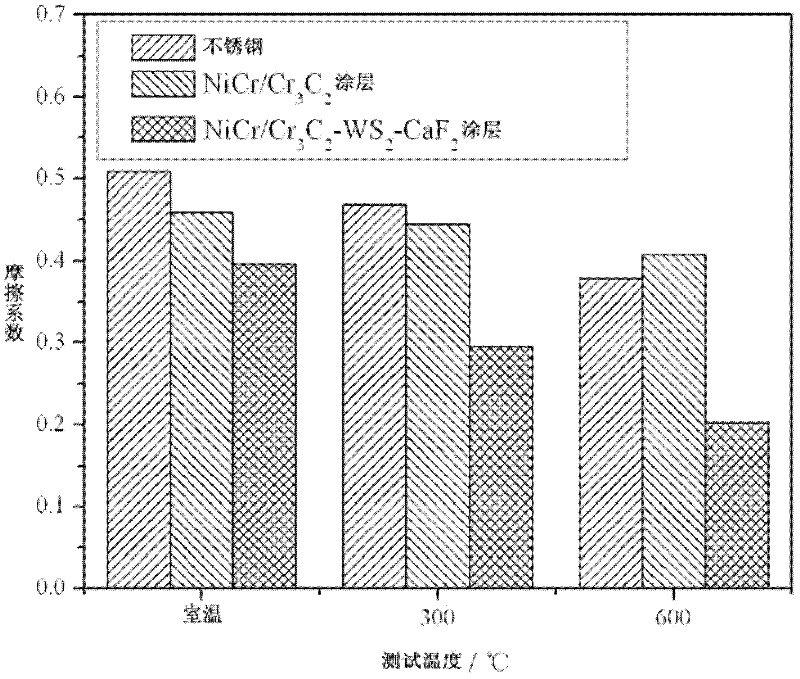

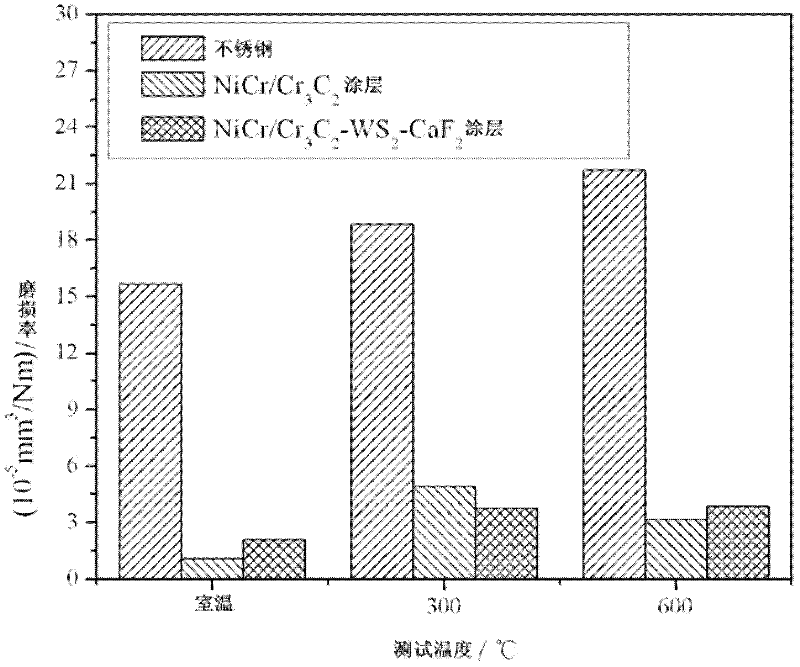

The invention relates to a solid lubricating high-temperature anti-wearing powder composition and a preparation method of a compound coating of the composition. The powder composition comprises the following components in percentage by mass: 14-17.5% of nickel, 3-3.5% of chromium, 49-52.5% of chromium carbide and 25-30% of tungsten disulfide with a surface coated by an alloy-phosphorus alloy. A solid self-lubricating high-temperature anti-wearing compound coating is prepared by the powder composition through utilizing a laser smelting technology. According to the invention, NiCr-Cr3C2 compound powder is used as a metal substrate and the compound coating is formed by a ceramic anti-wearing phase and a metal toughening phase; WS2 is a solid lubricating phase and one layer of a micron-grade Ni-P alloy is coated on the surface of a WS2 powder grain by utilizing a chemical plating method, so that the thermal stability and the chemical stability of WS2 are increased, the decomposition and evaporation of the WS2 in a laser smelting process are effectively inhibited and the compatibility of the WS2 and the metal substrate is increased; and the compound material coating has the characteristic of high-temperature self-lubricating wearing resistance.

Owner:SUZHOU UNIV

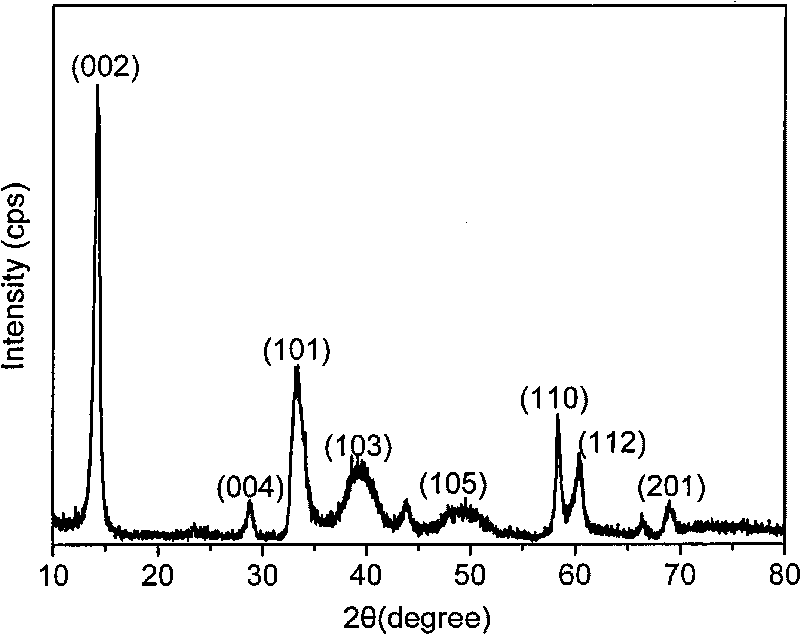

Method for preparing mono-disperse tungsten disulfide nano slices

InactiveCN101723464ASimple processLow costNanostructure manufactureTungsten compoundsChemical synthesisSulfur

The invention discloses a method for preparing mono-disperse tungsten disulfide nano slices. The method comprises the following steps: ball-milling, mixing and activating tungsten oxide and sulfur serving as raw materials, and annealing for 30 to 120 minutes at the constant temperature of between 600 and 700 DEG C in a protective atmosphere; during annealing at the constant temperature, preposing a part of sulfur powder as a complementary sulfur source, wherein the mass ratio of the complementary sulfur powder to the reaction mixture is between 0.05 and 10; and then, cooling a reaction product to below 250 DEG C along with a furnace in the protective atmosphere to obtain the mono-disperse tungsten disulfide nano slices. The method prepares a large amount of mono-disperse slice tungsten disulfide material by a simple and effective chemical synthesis method; and the method is simple and quick, has low production cost, and can be widely used in the aspects of lubrication and catalysis.

Owner:CENT SOUTH UNIV

Self-lubricating solid composite material and preparation method of self-lubricating solid coating

ActiveCN102363853AImprove wear resistanceReduce coefficient of frictionMetallic material coating processesMelting tankChromium carbide

The invention provides a self-lubricating solid composite material, which comprises 15-30 wt% of nickel-chromium alloy, 40-60 wt% of chromium carbide, 10-20 wt% of tungsten disulfide and 10-20 wt% of calcium fluoride. The invention also provides a preparation method of a self-lubricating solid coating. By a laser cladding method, the self-lubricating solid coating is formed on a matrix material. The self-lubricating solid composite material can be firstly coated on the matrix material and forms a coating by laser cladding; and also the matrix material can be firstly irradiated by a laser beam to form a molten pool, and then the self-lubricating solid composite material is sent into the molten pool and is continuously irradiated to form the coating. The prepared self-lubricating solid coating has excellent wear resistance and good lubrication performance within the temperature range of room temperature to 600 DEG C, and can satisfy the usage requirement under severe working conditions.

Owner:SUZHOU UNIV

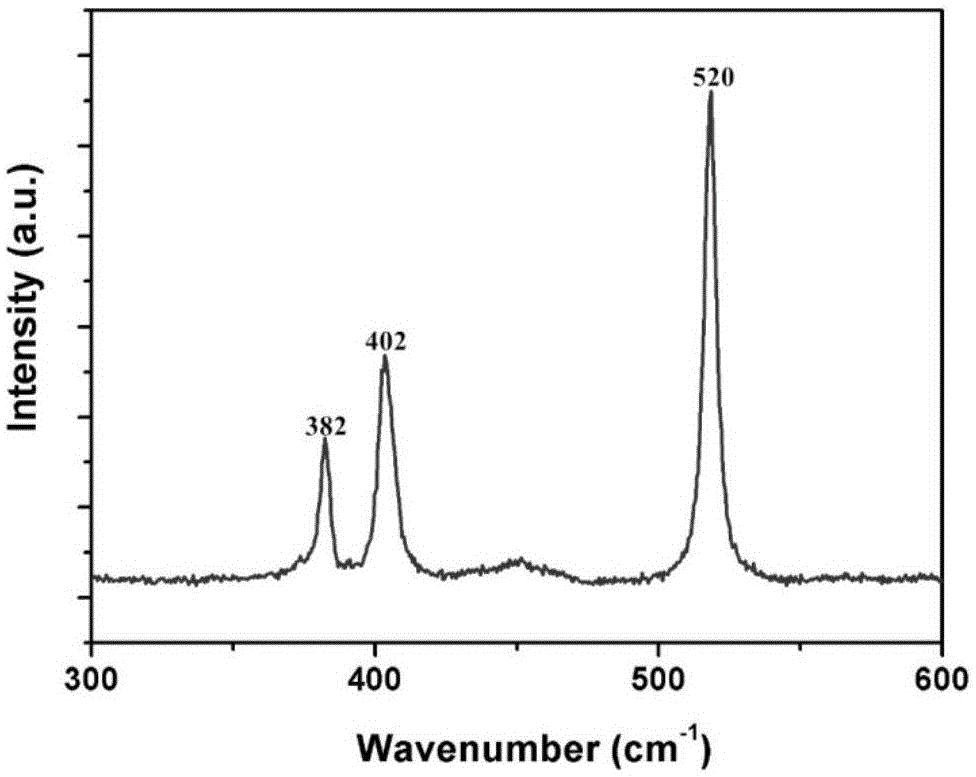

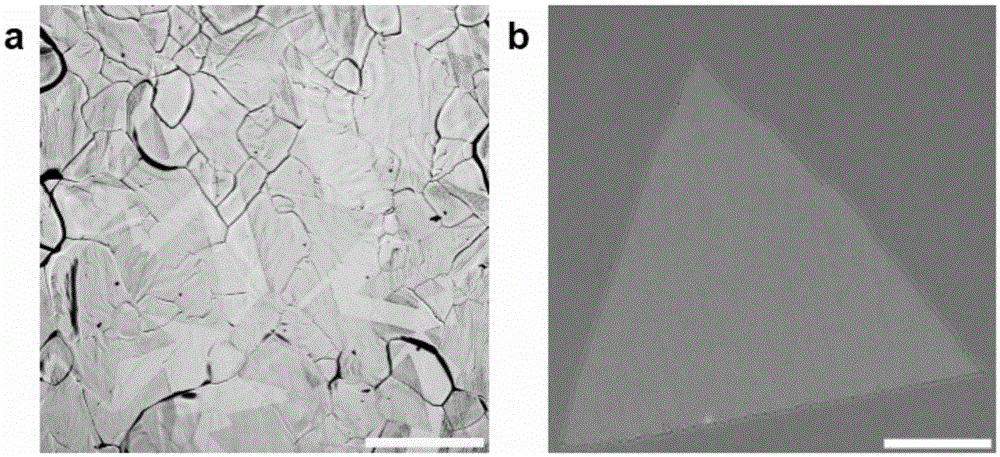

Method for growing substrate-modified large-size monolayer molybdenum disulfide film through chemical vapor deposition

ActiveCN105002476AEfficient preparationChemical vapor deposition coatingSemiconductor materialsGas phase

The invention proposes a method for growing a substrate-modified large-size monolayer molybdenum disulfide film through chemical vapor deposition. Ammonium sulfide serves as a substrate surface modifying agent; a nucleation rate is controlled through such methods as control of a concentration of the modifying agent, a dipping time and a cleaning method; and a film thickness is controlled through such methods as control of a growing temperature, a growing time and an air flow of the chemical vapor deposition. The method can efficiently grow the large-size monolayer molybdenum disulfide film under the condition of a relatively lower growing temperature on the basis of traditional growth chemical vapor deposition equipment. The method for growing large-size monolayer molybdenum disulfide, provided by the invention, is suitable for the growth of large-size monolayer tungsten disulfide, molybdenum diselenide, tungsten diselenide and the like similar to two-dimensional semiconductor materials in structure.

Owner:NANJING UNIV

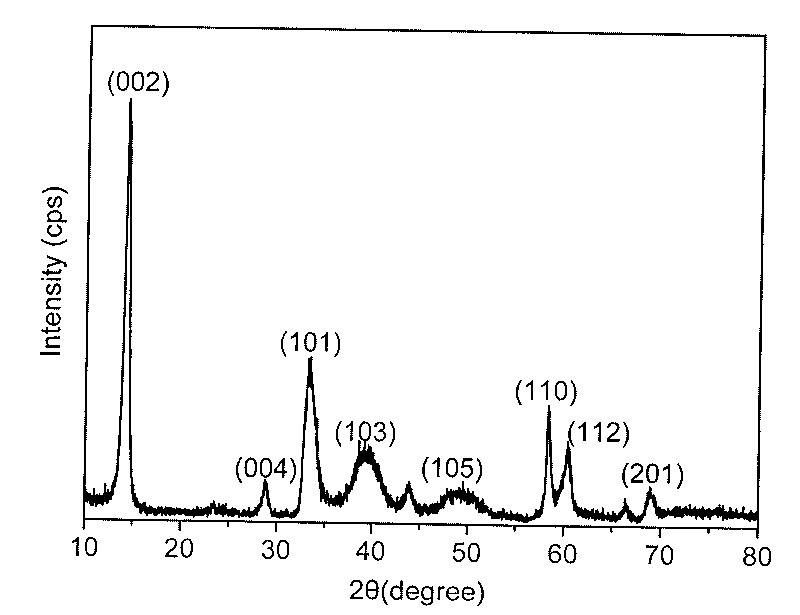

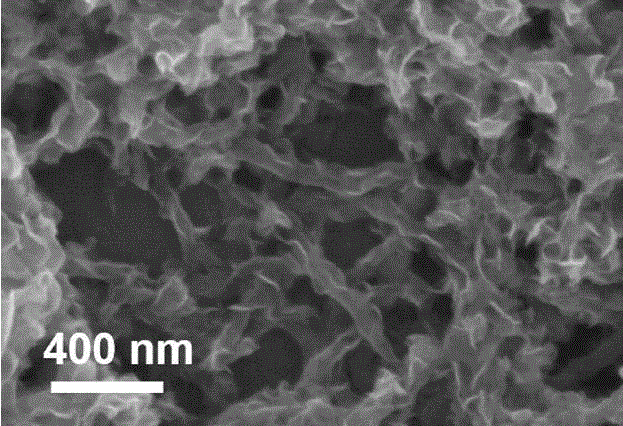

Preparation method of graphite alkene like tungsten disulfide nanometer sheet

InactiveCN103641173AThe overall thickness is thinLarge side dimensionsMaterial nanotechnologyTungsten compoundsThioureaTube furnace

The invention discloses a preparation method of graphite alkene like tungsten disulfide nanometer sheet, which employs a high temperature solid phase synthesis method, and the method comprises the following steps: mixing thiourea and WO3 according to mol ratio 20:1-41:1 and fully grinding, and containing the grinded powder into a porcelain boat; heating a tubular furnace to 800-900 DEG C and letting nitrogen in; quickly pushing the porcelain boat into a central heat zone position of the tubular furnace and processing for 30-60 min at constant temperature; then, the mixture is naturally cooled to room temperature, and the graphite alkene like tungsten disulfide nanometer sheet is obtained. The invention has the advantages of simple technology and low cost, and the obtained product has high purity and yield, and is hopeful to be used in large scale industrial production.

Owner:JIANGSU UNIV

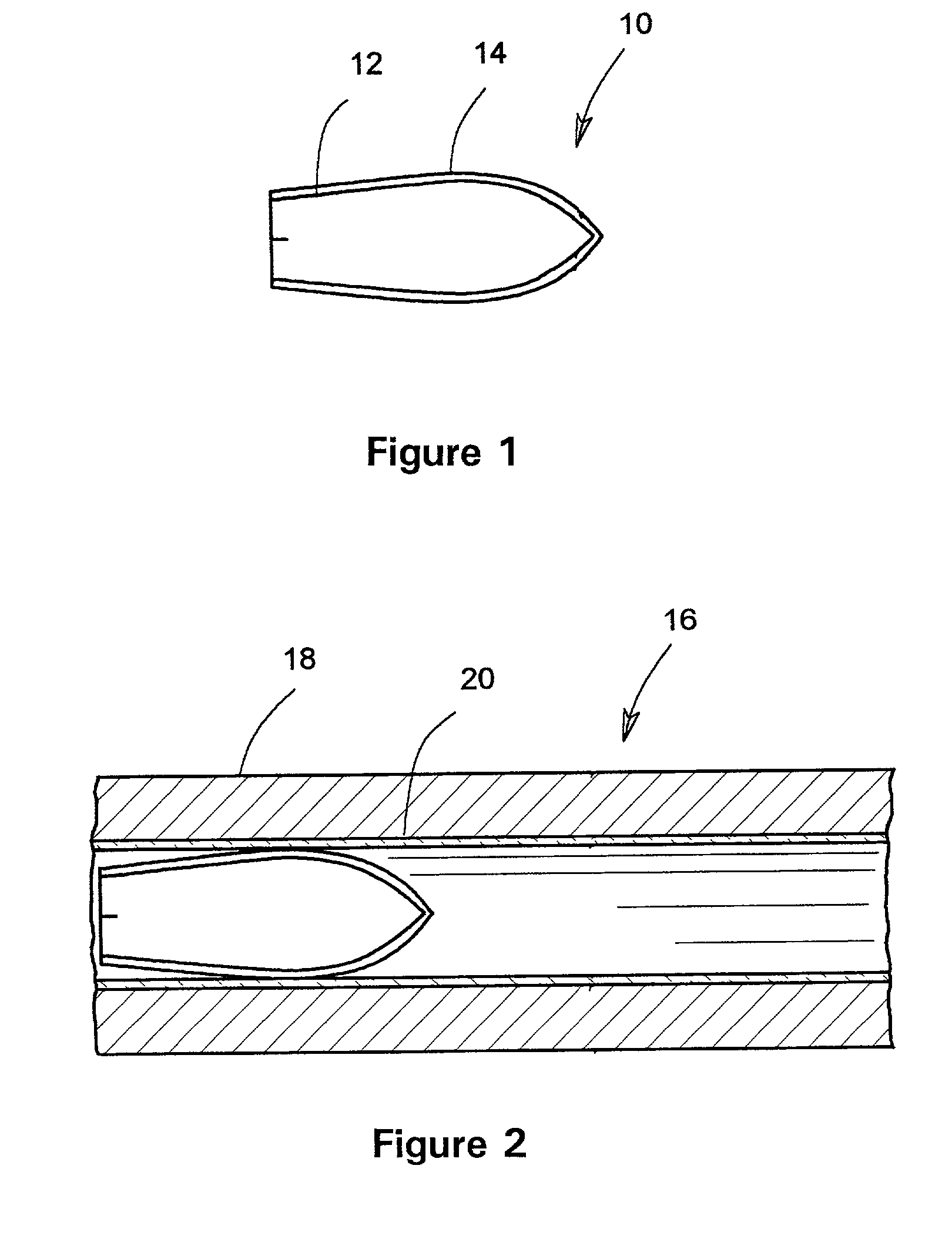

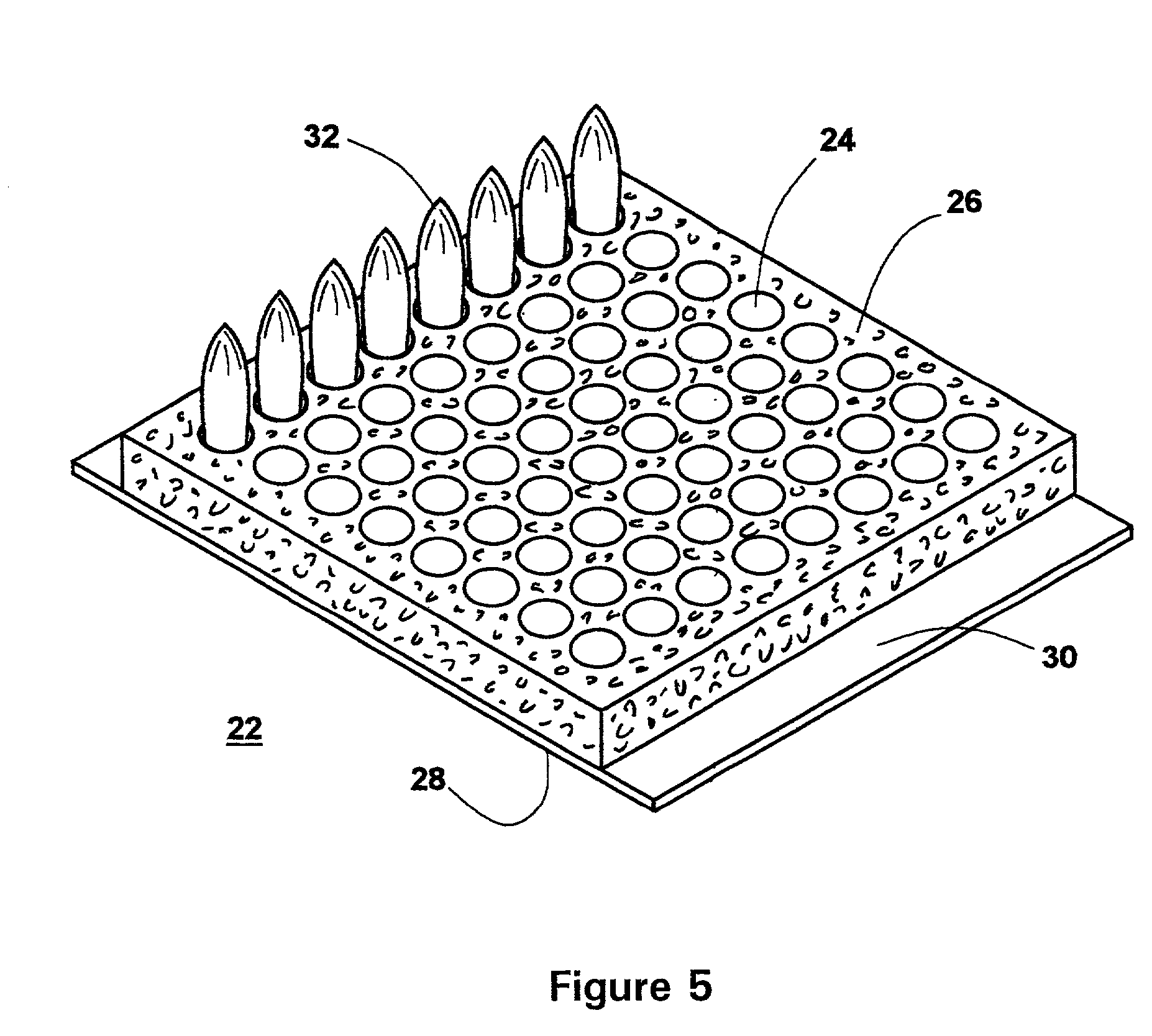

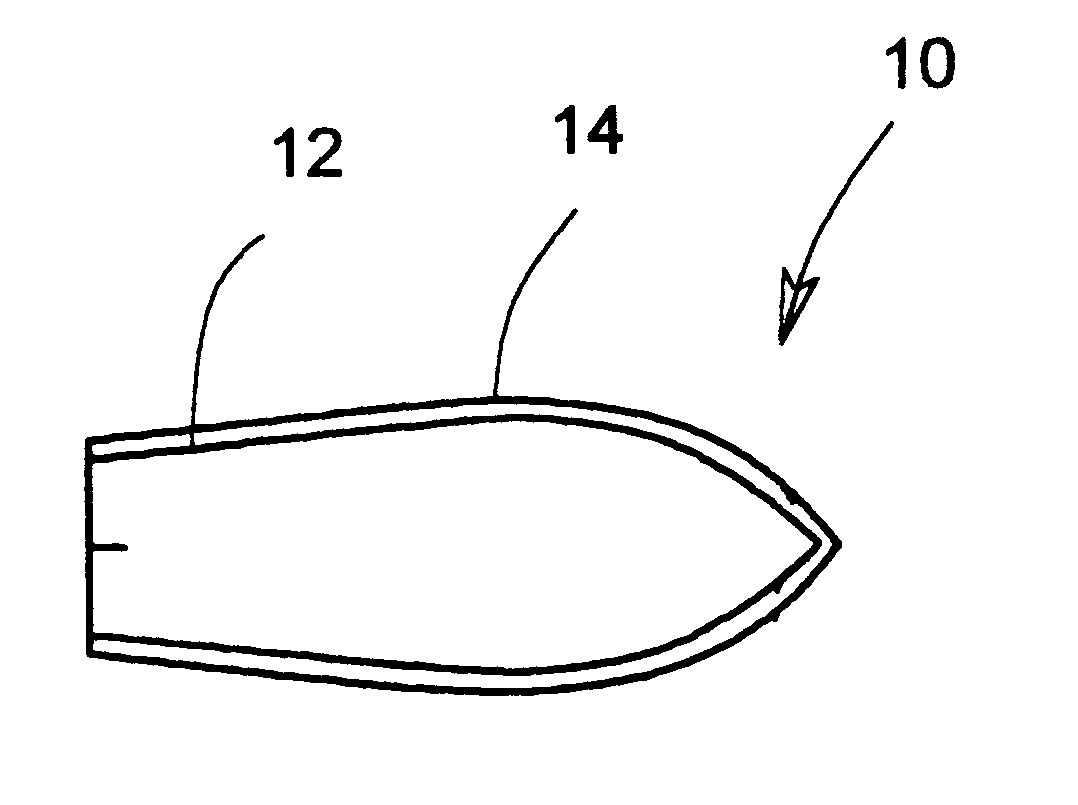

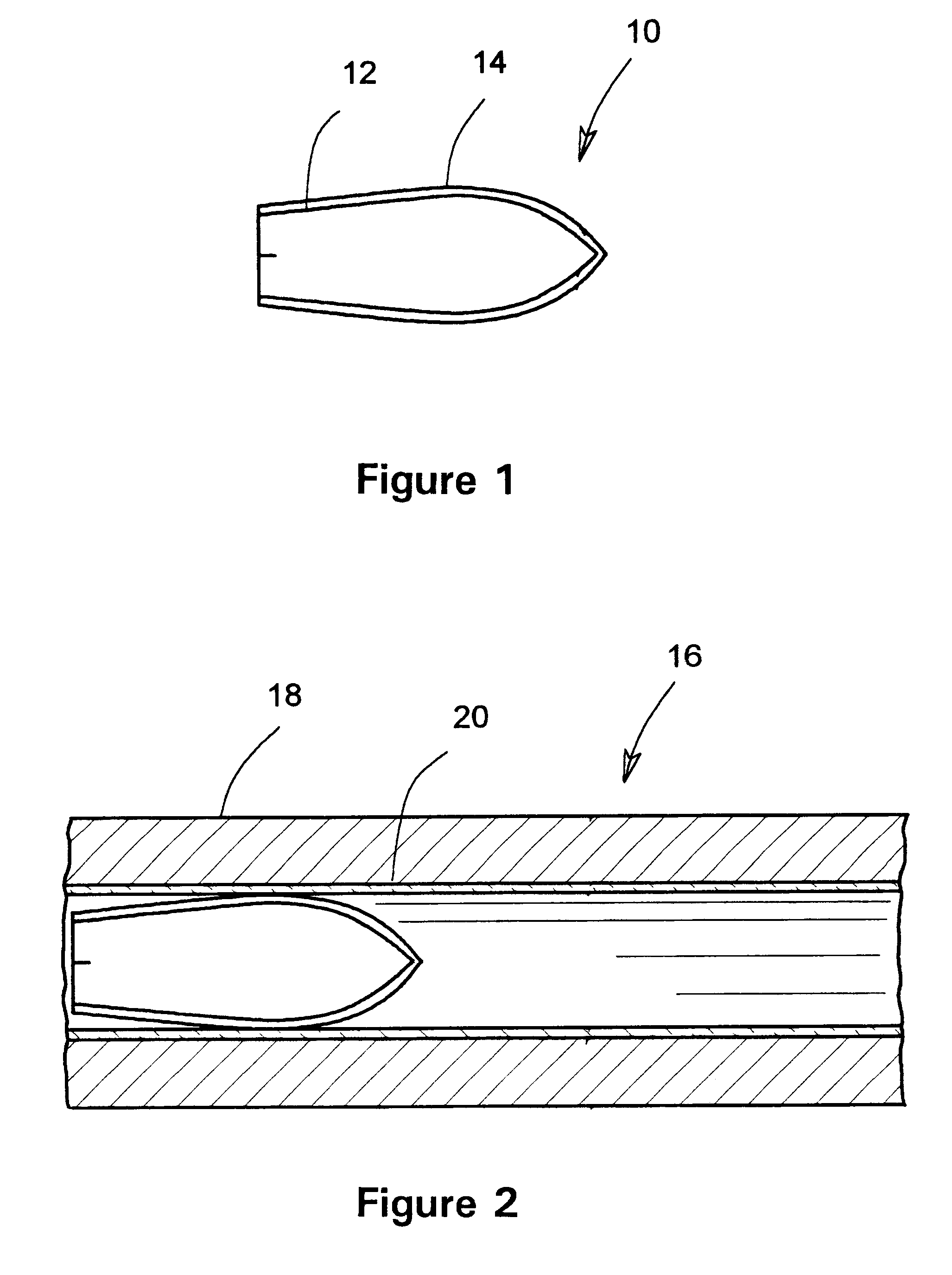

Ballistics conditioning

InactiveUS20030078170A1Quick and easy spray-coatingHigh hardnessAmmunition projectilesMoulding toolsHexagonal boron nitrideAcrylic resin

Compositions and methods for ballistic conditioning firearm projectiles, firearms, and firearm components such as bores of barrels, by applying to such items a conditioning composition selected from the group consisting of hexagonal boron nitride, graphite, tungsten disulfide, antimony trioxide, talc, mica, and mixtures thereof, suspended in a carrier comprising a volatile solvent, and a binder selected from the group consisting of cellulosic-, alkyd- and acrylic-resins.

Owner:BROWN DAVID THOMAS

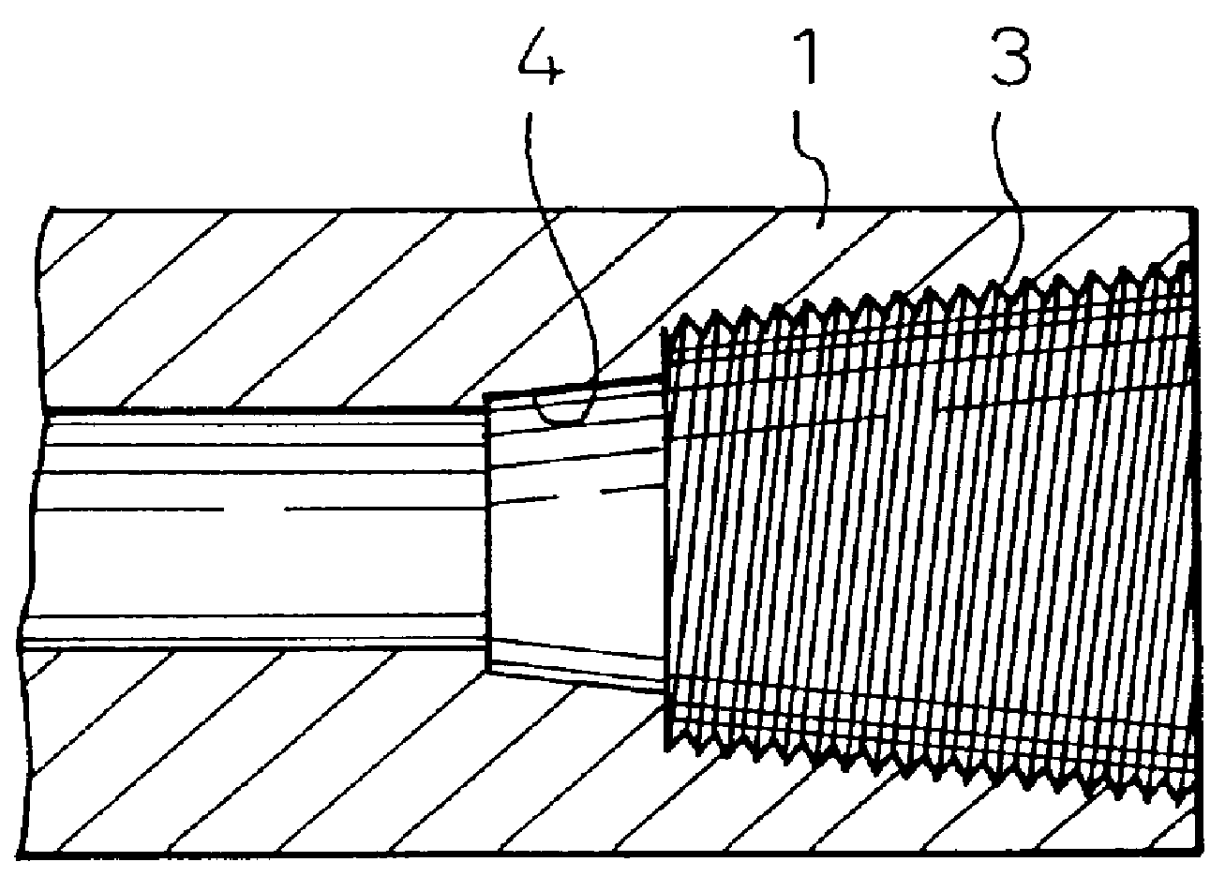

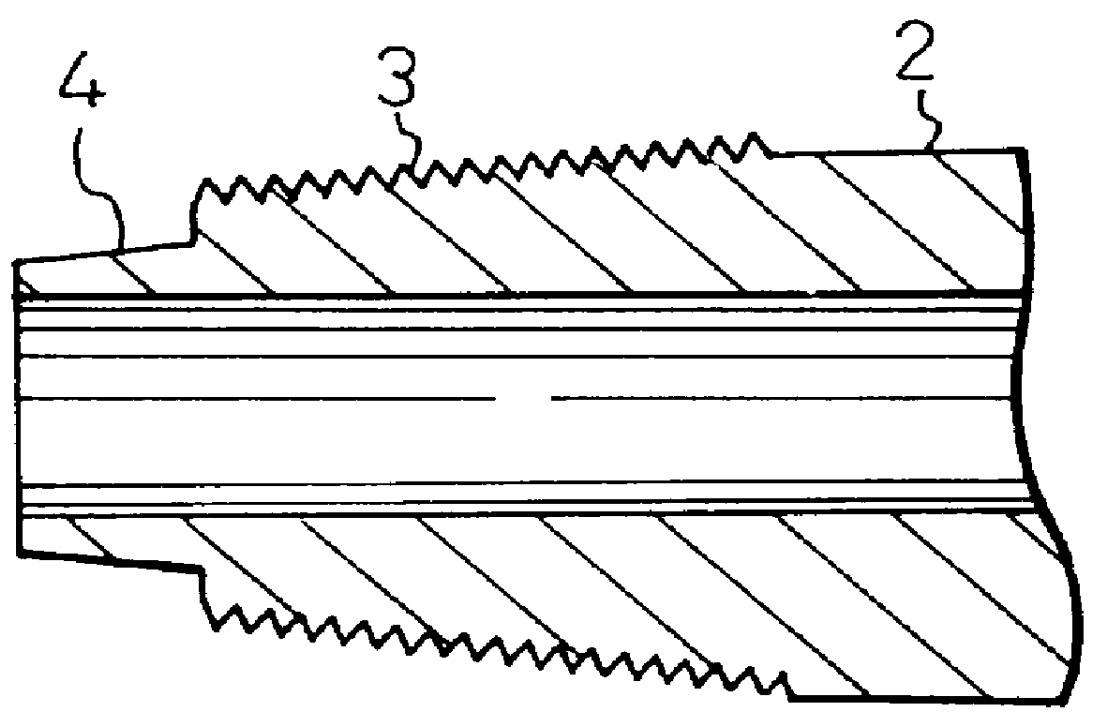

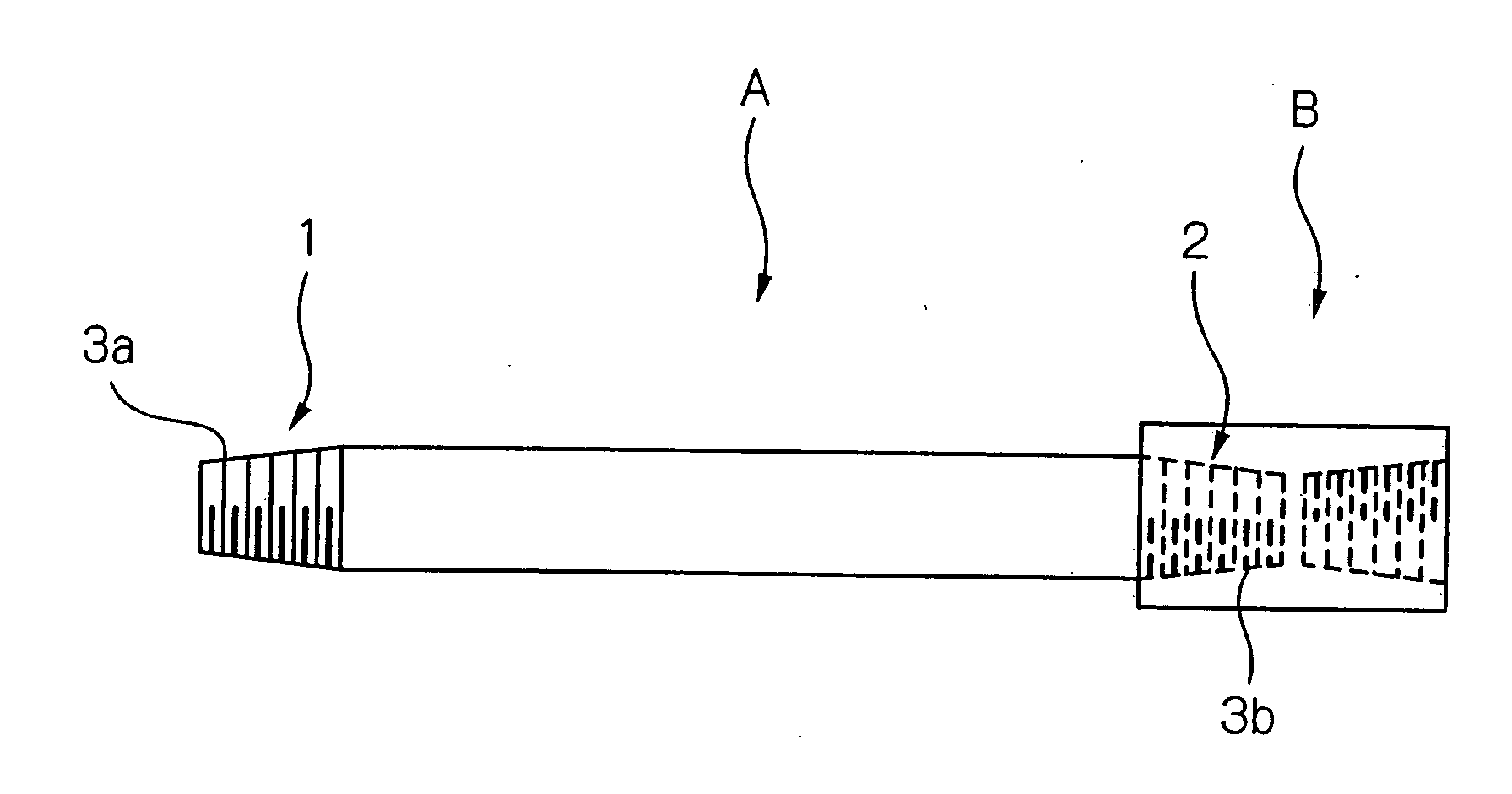

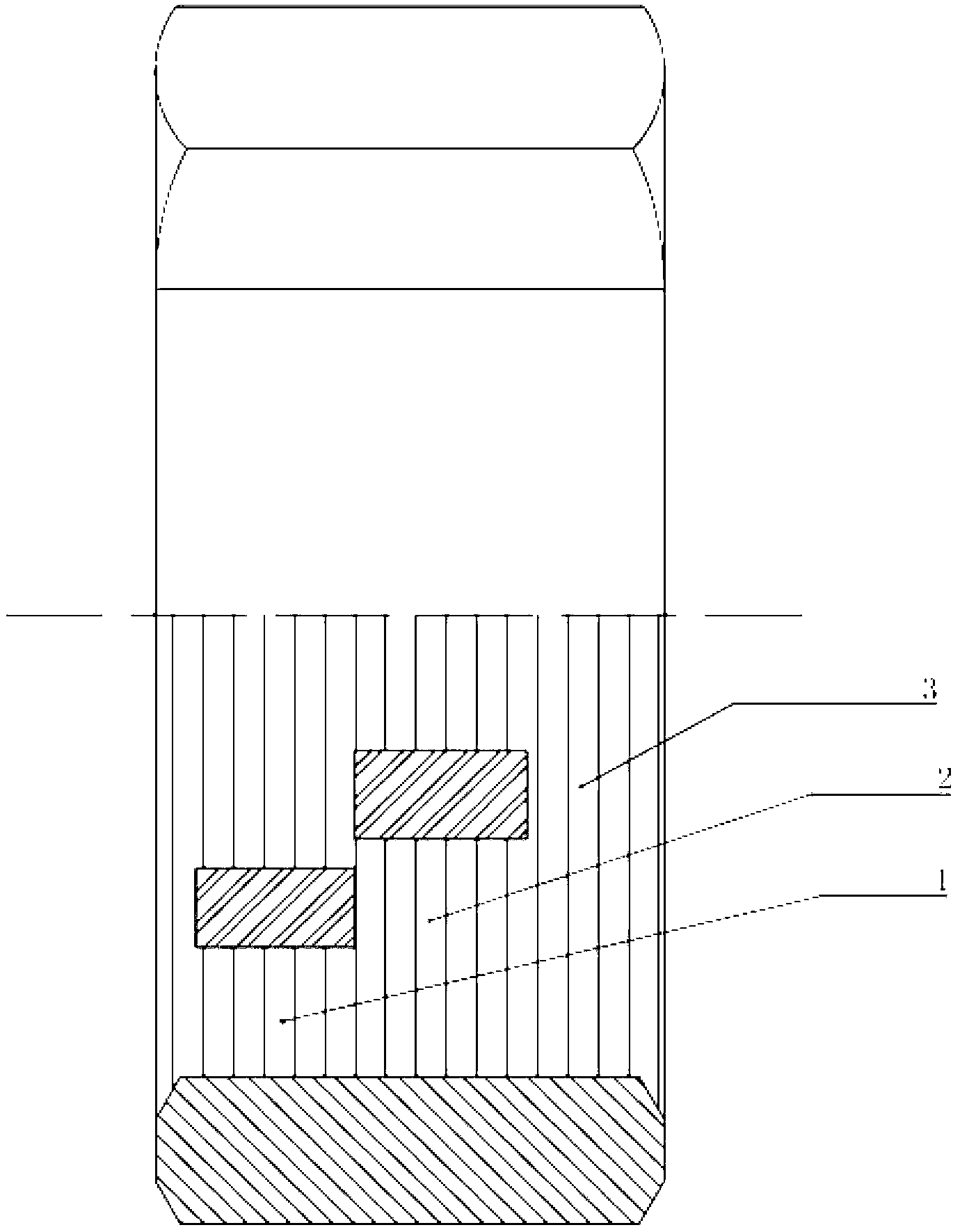

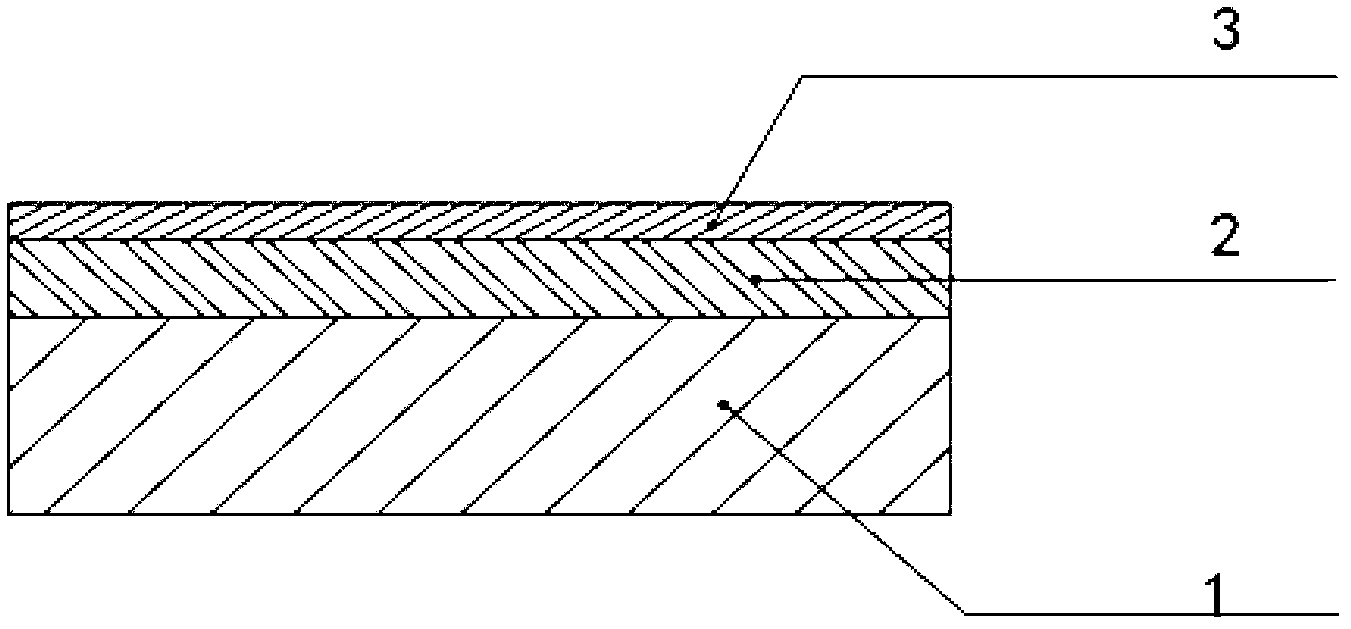

Threaded joint for steel pipes

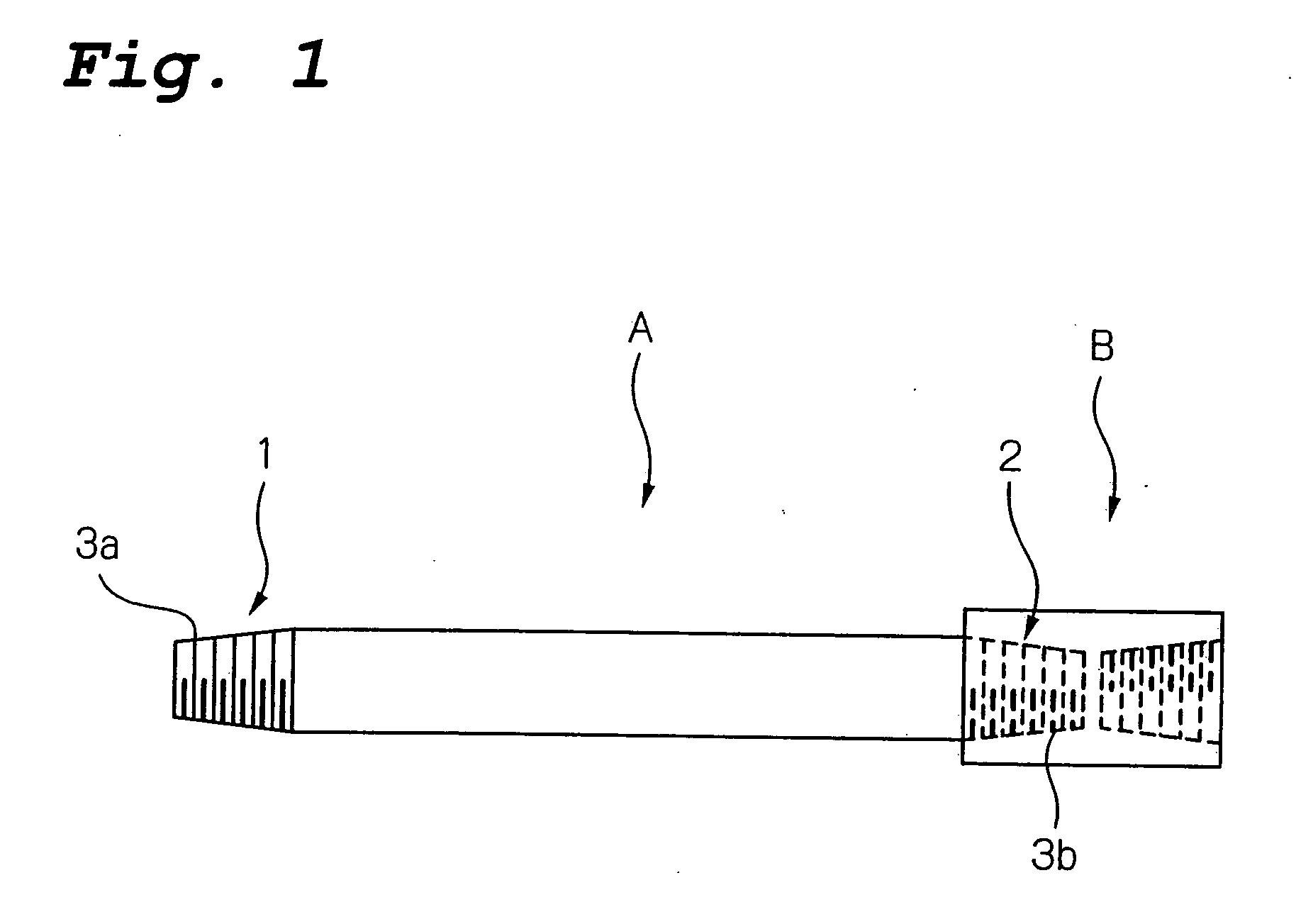

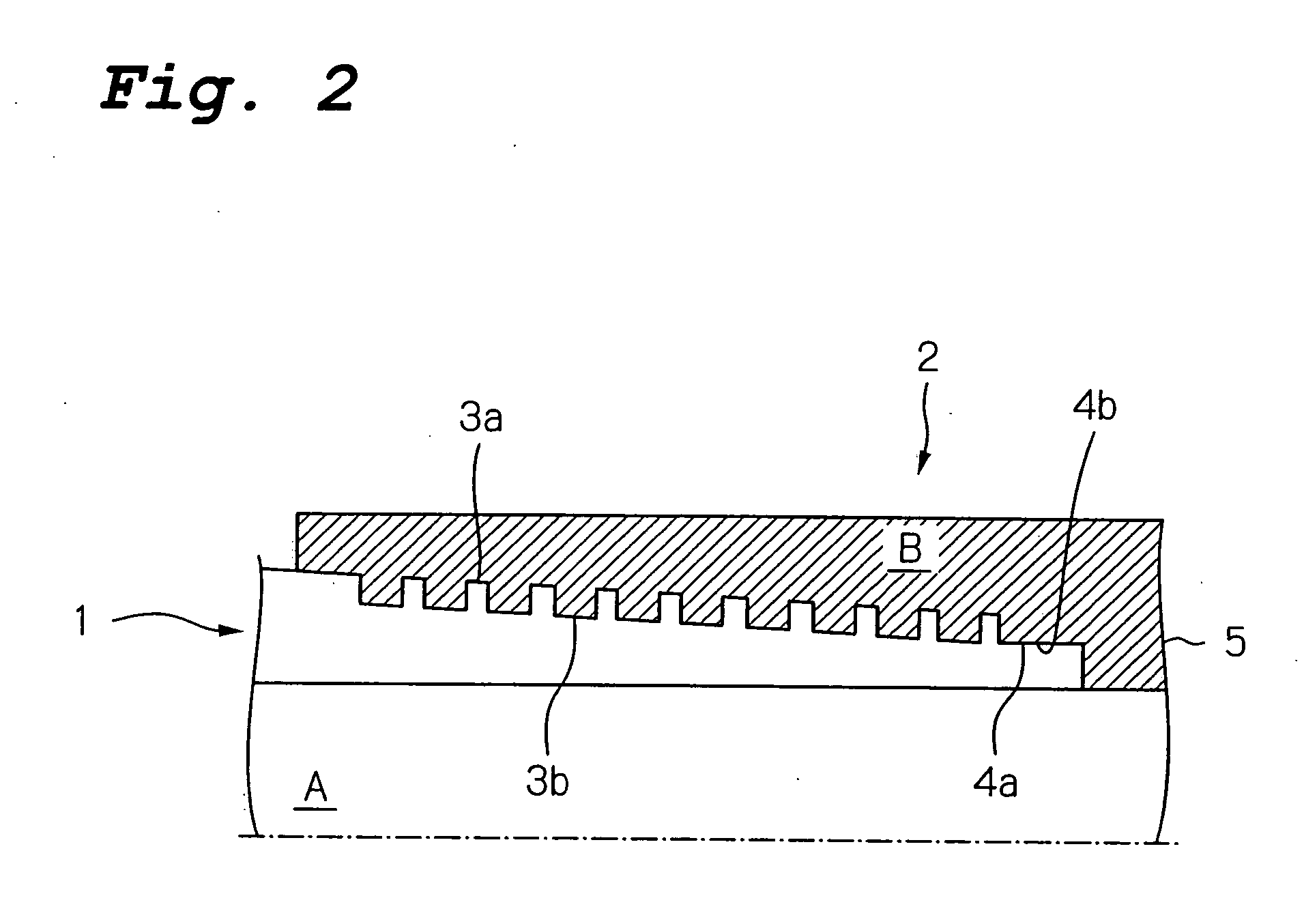

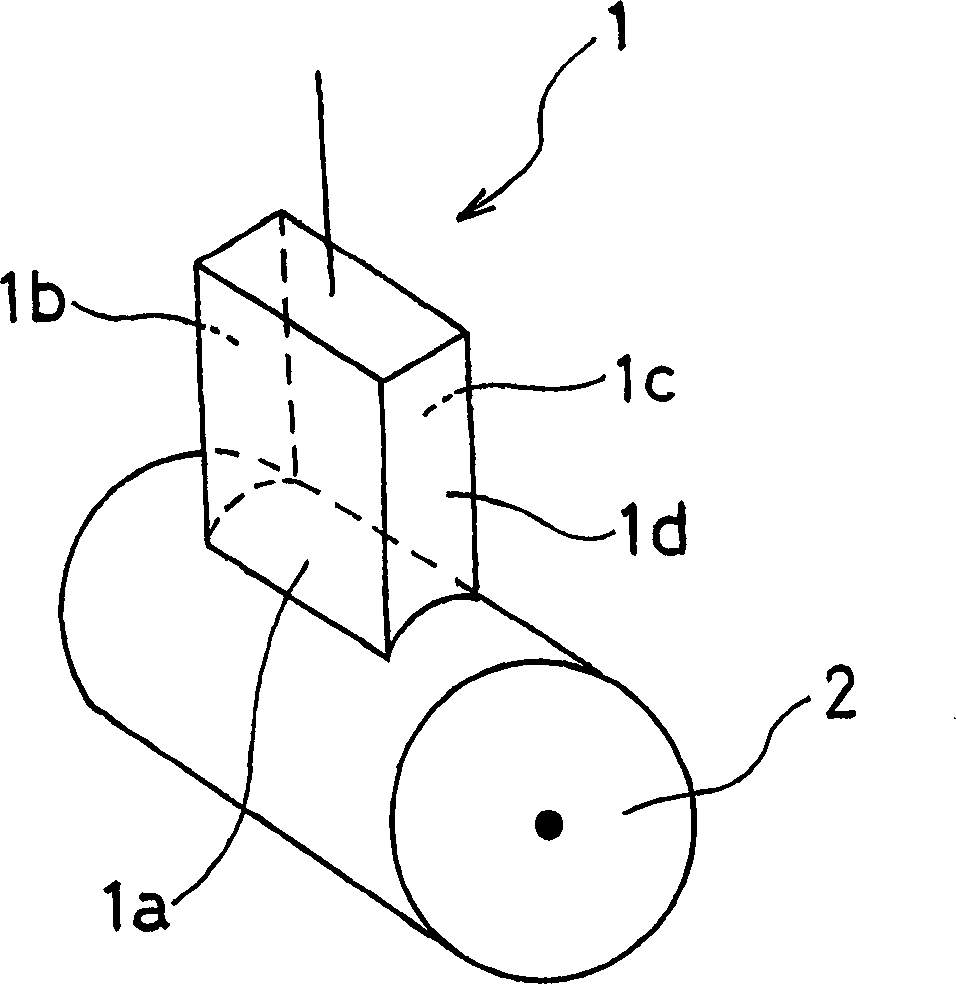

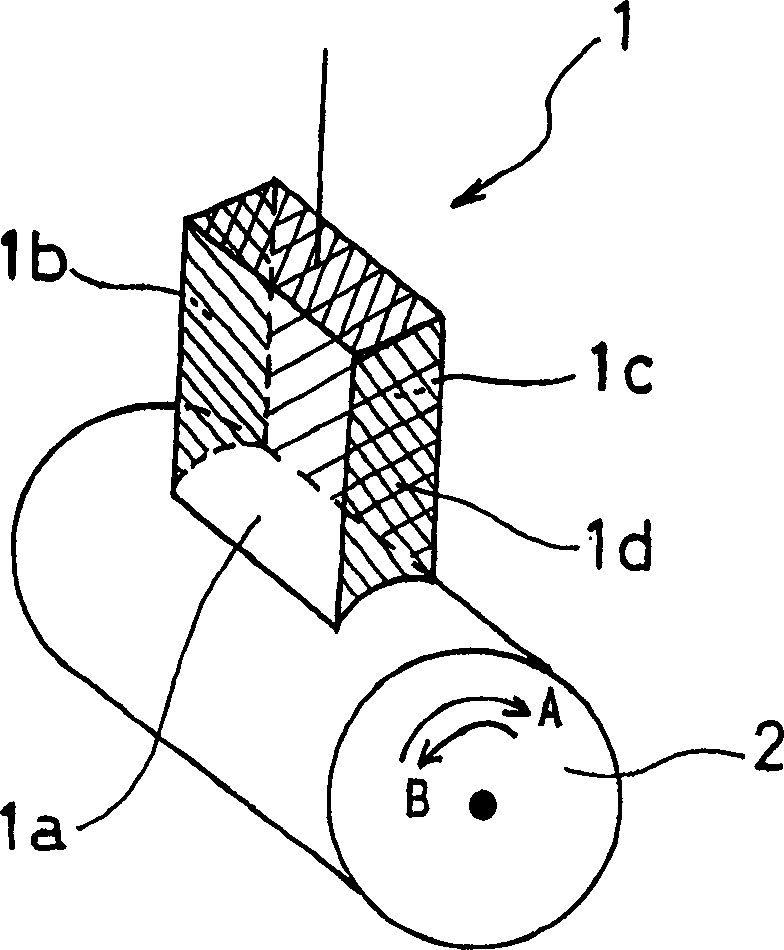

InactiveUS20060197343A1Improve adhesionImprove the immunitySleeve/socket jointsPipe supportsEpoxyEngineering

A threaded joint for steel pipes comprises a pin (1) and a box (2) each having a threaded portion (3a or 3b) and an unthreaded metal-to-metal contact portion (4a or 4b) as contact surfaces which contact each other when the joint is fastened. The contact surfaces (3a and 4a and / or 3b and 4b) of at least one of the pin (1) and the box (2) are coated with a lower layer of a solid lubricating coating containing a solid lubricating powder (e.g., molybdenum disulfide, tungsten disulfide, or graphite) and a binder (e.g., an epoxy or other organic resin) and an upper layer of a solid corrosion protective coating formed by an organic resin which does not contain solid particles.

Owner:NIPPON STEEL CORP

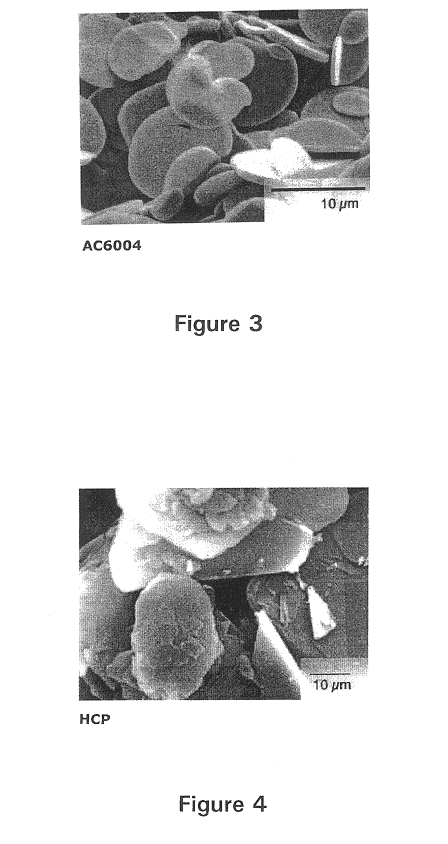

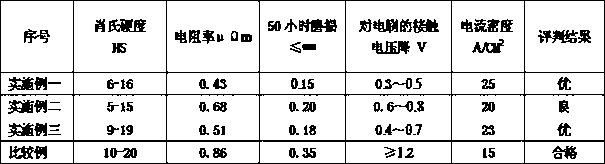

Carbon brush for electric machine

InactiveCN1439187AFriction loss rate is smallLong-term rectification characteristicsRotary current collectorDynamo-electric machinesTectorial membraneMetal coating

Owner:TOTANKAKO

Electrochemical preparation method for two-dimensional molybdenum disulfide and tungsten disulfide nanosheet

InactiveCN106086919AHigh yieldLower potentialElectrolysis componentsNanotechnologySulfideChemical stability

Molybdenum disulfide or tungsten disulfide is good in catalytic hydrogen evolution activity, lithium storage performance, thermal stability and chemical stability. In order to increase the utilization rate of the molybdenum disulfide or the tungsten disulfide and improve the catalytic hydrogen evolution catalytic activity and the lithium storage specific capacity, sulfide needs to be prepared into a monomolecular layer or polymolecular layer two-dimensional material. An electrochemical method is adopted, a molybdenum disulfide (or tungsten disulfide)-metal composite material serves as an anode, graphite or a platinum electrode serves as a cathode, sulfate serves as an electrolyte, and thus two-dimensional molybdenum disulfide or tungsten disulfide with the thickness being 1-20 nm is successfully stripped out. By means of the two-dimensional sulfide, the electrocatalytic hydrogen evolution activity is good, and the lithium storage performance is excellent.

Owner:ANYANG INST OF TECH

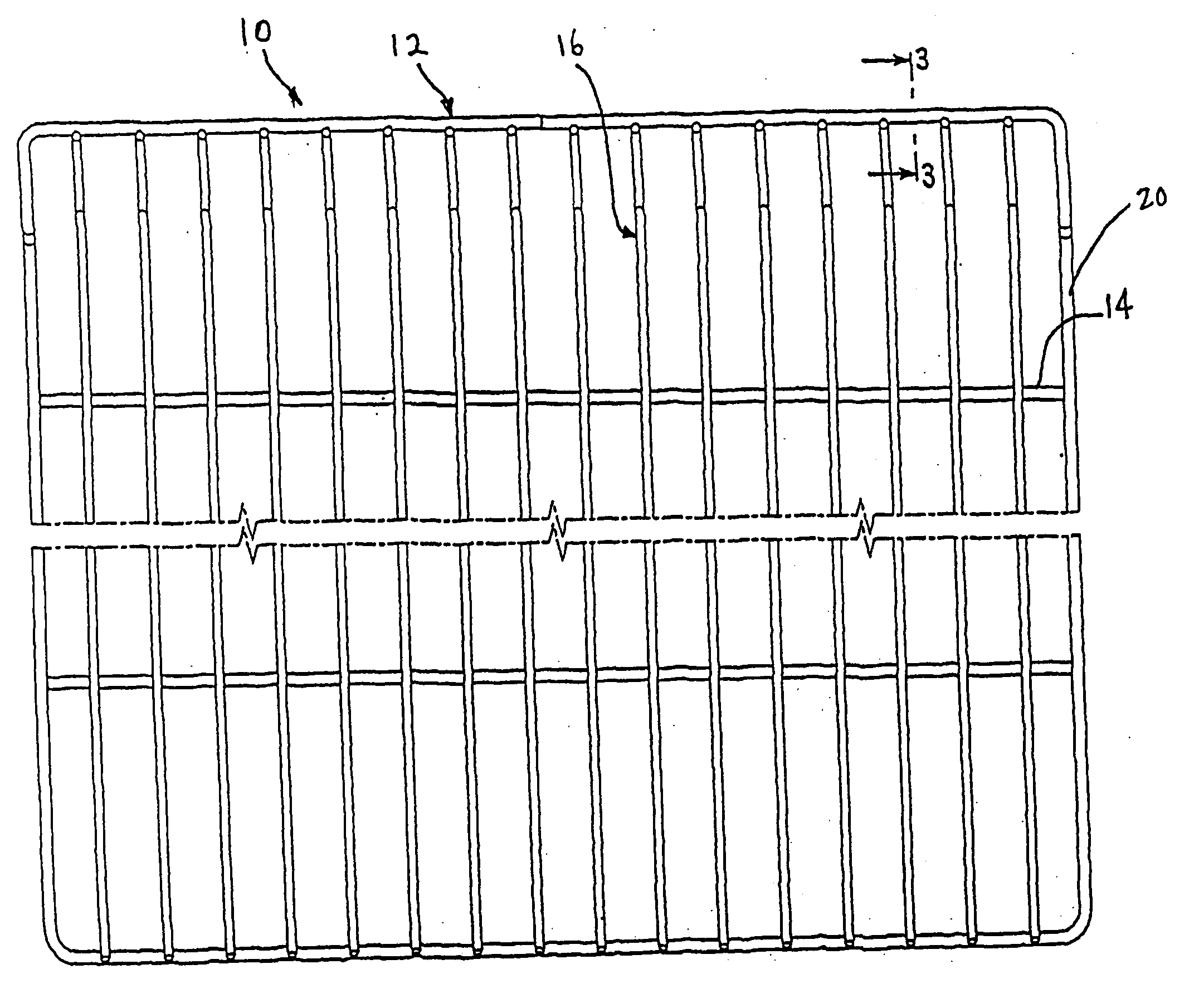

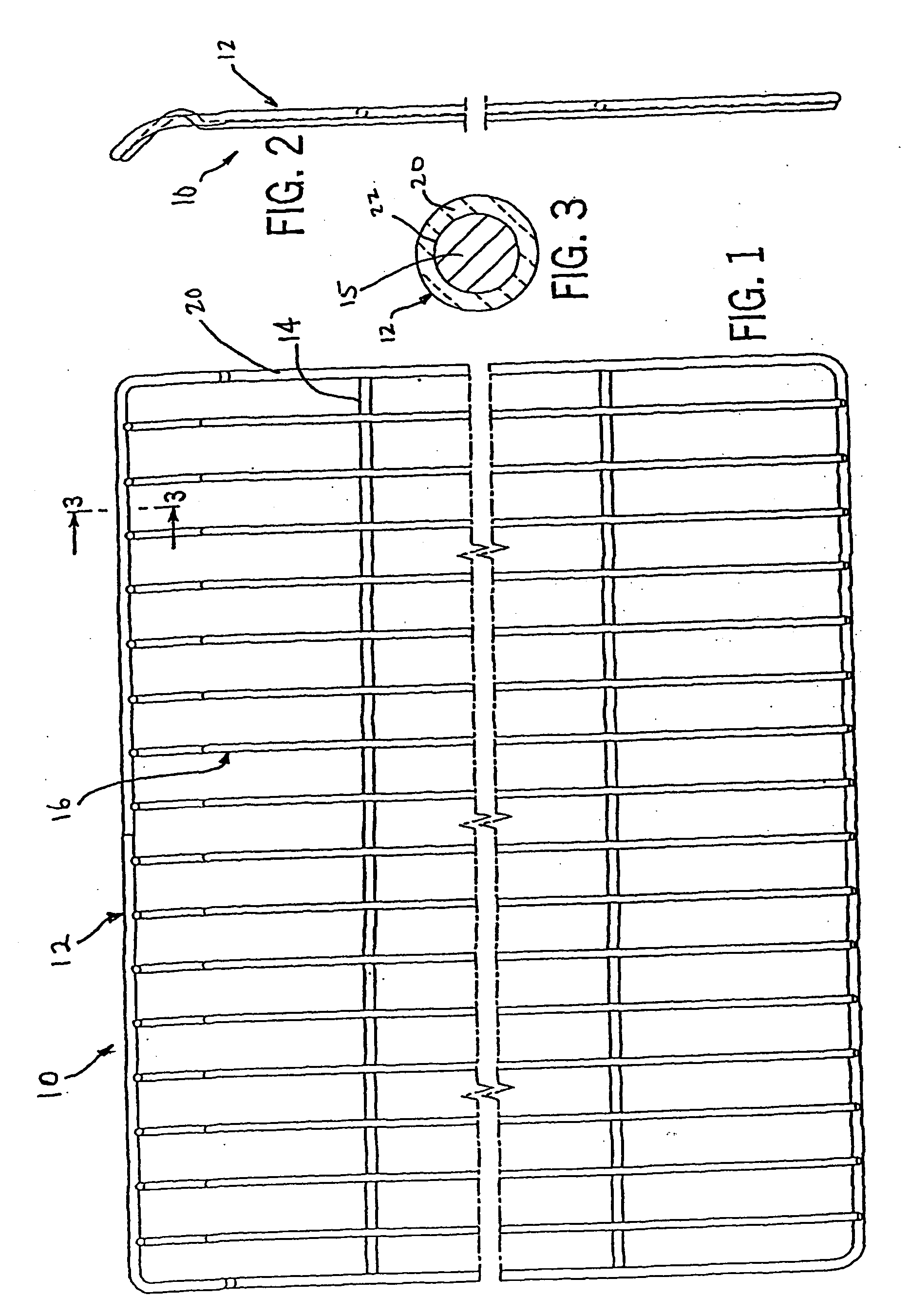

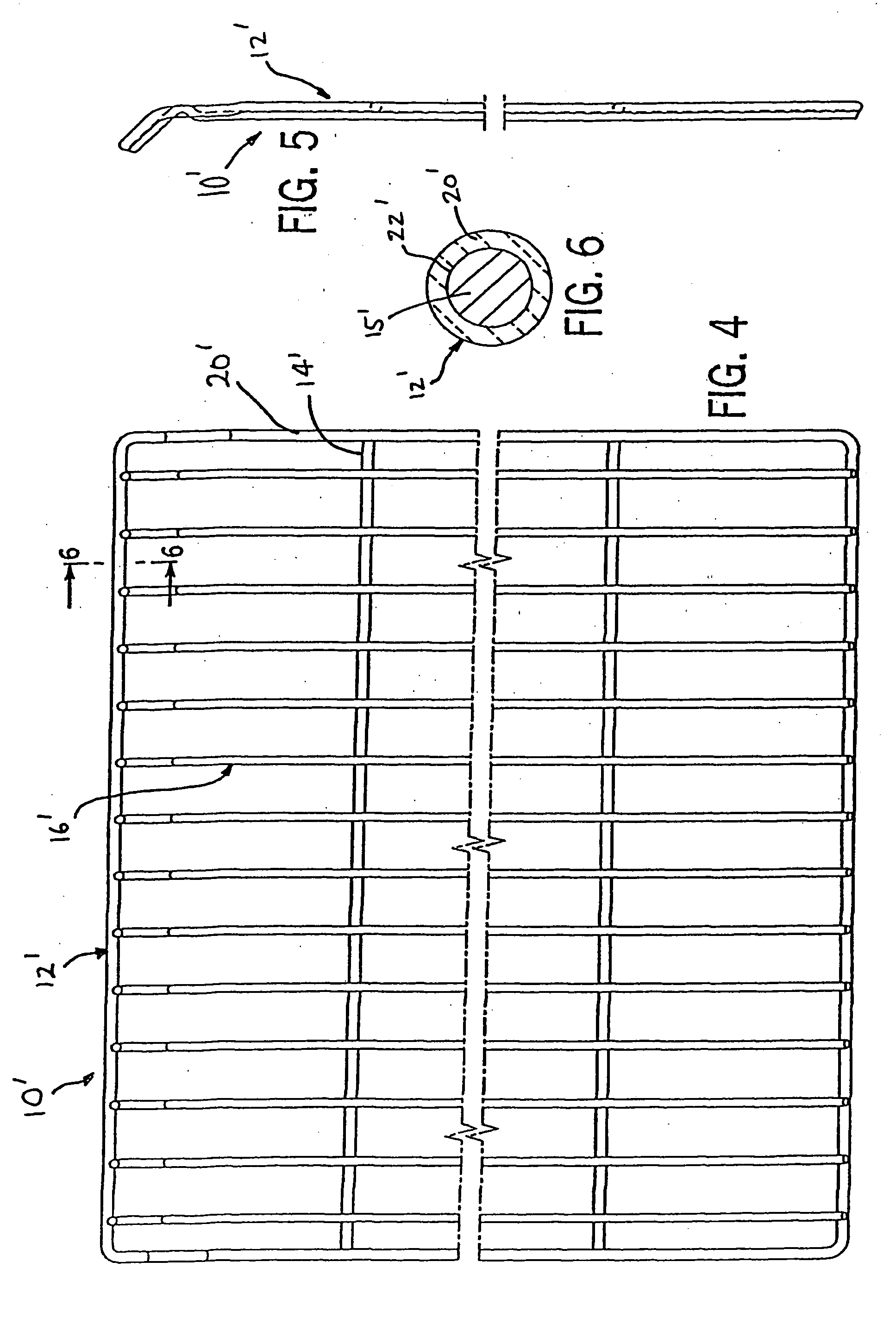

Oven rack having an integral lubricious, dry porcelain surface

InactiveUS20070272231A1Avoid chippingReduce the overall diameterDomestic stoves or rangesStoves/ranges shelves or racksDiamond-like carbonAntimony trioxide

A lubricious porcelain coated steel wire oven rack. The preferred coated steel wire oven rack includes a plurality of elongated steel wire members joined together to form an oven rack having an outer surface. The plurality of elongated steel wire members are made from a cold drawn steel rod material containing from about 80 to about 99.9% by weight of iron, up to about 0.08% by weight of carbon and from about 0.001 to about 0.2% by weight of a carbon stabilizing transition metal, preferably selected from the group consisting of Vanadium, Tantalum, Titanium and Niobium. In a preferred embodiment, the porcelain surface of the oven rack includes a dry lubricant selected from carbon; graphite; boron nitride; cubic boron nitride; molybdenum (IV) sulfide; molybdenum disulfide; molybdenum sulfide; molybdenum (IV) selenide; molybdenum selenide; tungsten (IV) sulfide; tungsten disulfide; tungsten sulfide; silicon nitride (Si3N4); TiN; TiC; TiCN; TiO2; TiAlN; CrN; SiC; diamond-like carbon; tungsten carbide (WC); zirconium oxide (ZrO2); zirconium oxide and 0.1 to 40 weight % aluminum oxide; alumina-zirconia; antimony; antimony oxide; antimony trioxide; and mixtures thereof.

Owner:SSW ADVANCED TECH LLC

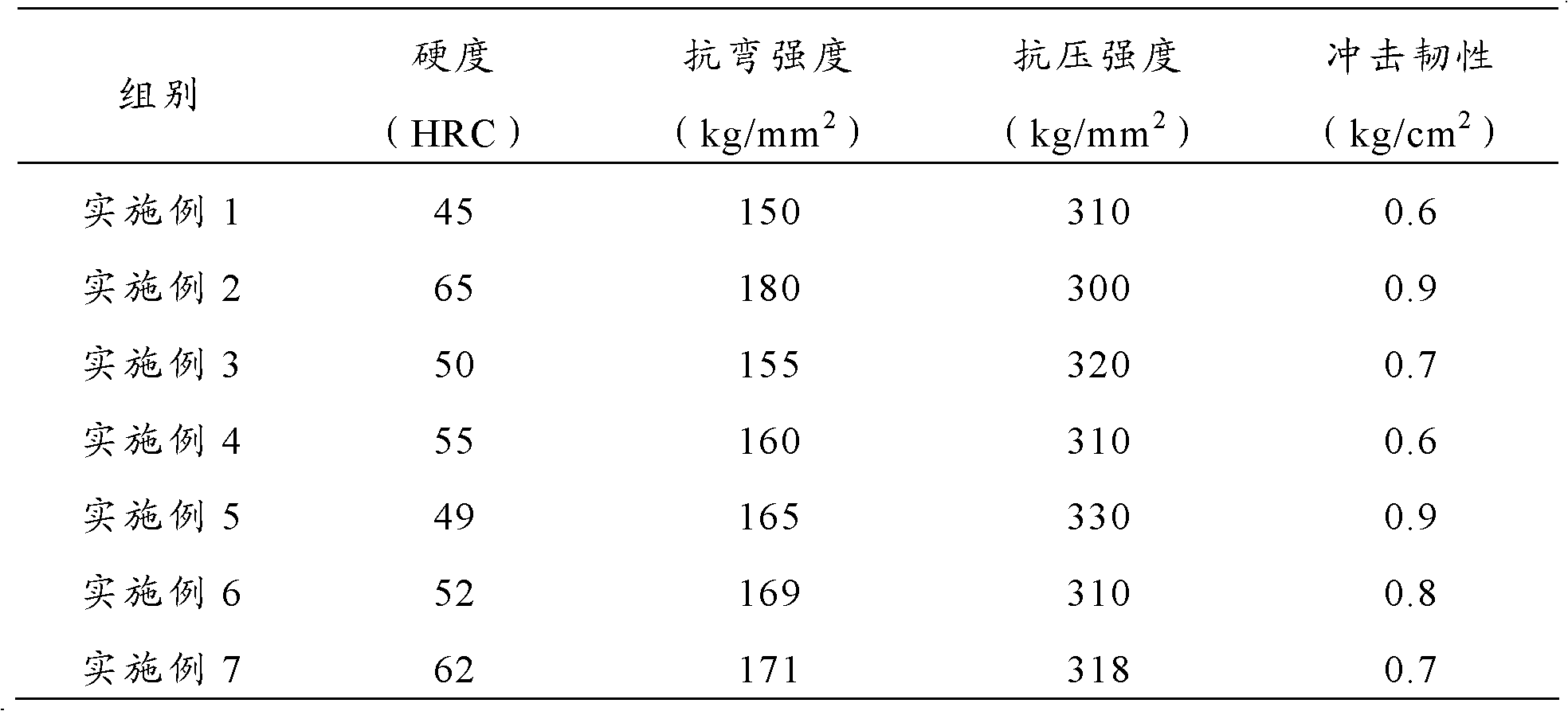

Steel bonded hard alloy and preparation method thereof

The invention provides steel bonded hard alloy which comprises the following components: 1.5wt%-6.0wt% of refractory carbide, 1.0wt%-3.0wt% of WS2, 1.0wt%-3.0wt% of C, 0.1wt%-0.5wt% of Mn, 10.0wt%-18.0wt% of Cr, 1.0wt%-5.0wt% of Mo, more than 0 but less than or equal to 1.8wt% of Si, more than 0 but less than or equal to 5.0wt% of Ni, and the balance of Fe. The invention also provides a preparation method for the steel bonded hard alloy. The raw materials, such as refractory carbide, tungsten disulfide, carbon and chromium are added in the steel bonded hard alloy, and a powder metallurgy sintering technology and a thermal treatment technology are adopted, so that the strength and hardness of the steel bonded hard alloy are increased, the abrasive resistance of the steel bonded hard alloy is increased and the service life of a stirring shaft abrasion-resisting sleeve prepared from the steel bonded hard alloy is prolonged.

Owner:CHANGSHA WEISITAN METALLURGY PRODS

Self-repairing multi-soap based composite bearing lubricating grease and preparation method thereof

ActiveCN1804016AAvoid underperformanceStable structureDrill bitsAdditivesStructural ModifierPetroleum

The related composite poly-soap self-repair bearing lubricating grease comprises the basic liquid, composite calcium sulfonate, composite Ca-Li-base thickener, non-oxidizing anti-corrosion additive, metal deactivator, tungsten disulfide extreme pressure additive, wear-well additive, self-repair additive, and structural modifier; has well anti-oxidation ability and bearing capacity, can repair wore part on condition of extreme pressure and high temperature to supply the silver-plating lacking on bearing radial surface effectively, prolongs bearing service time on maximum limit, and has special application in oil drilling exploration.

Owner:SINOPEC OILFIELD EQUIP CORP +1

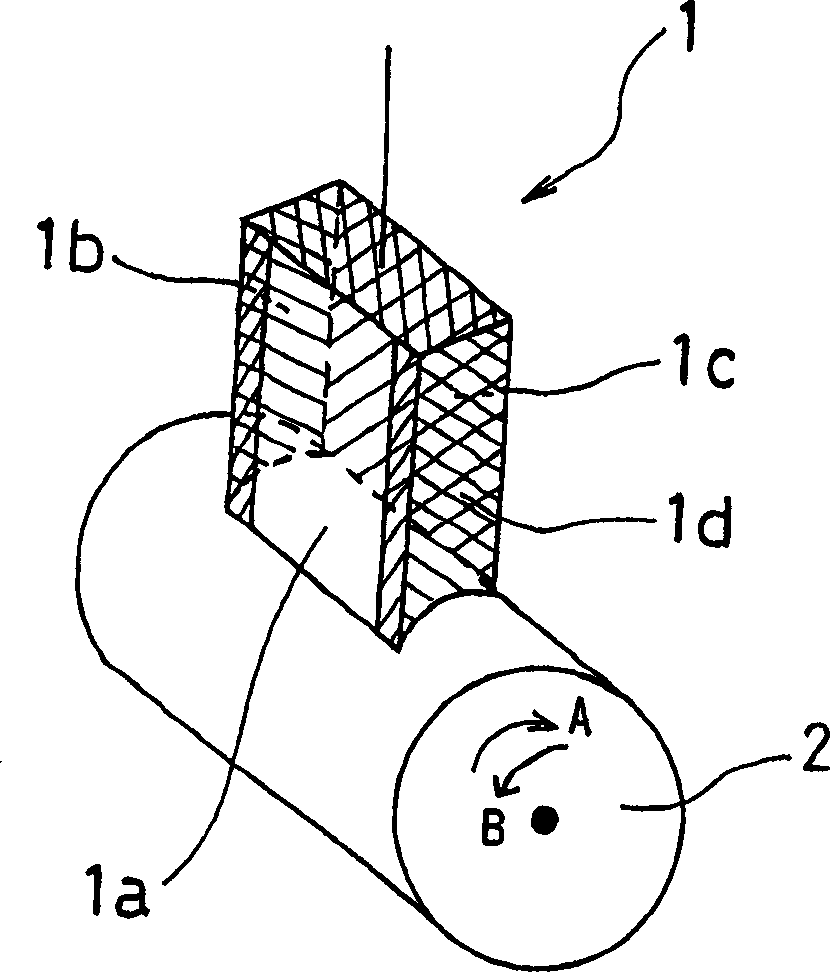

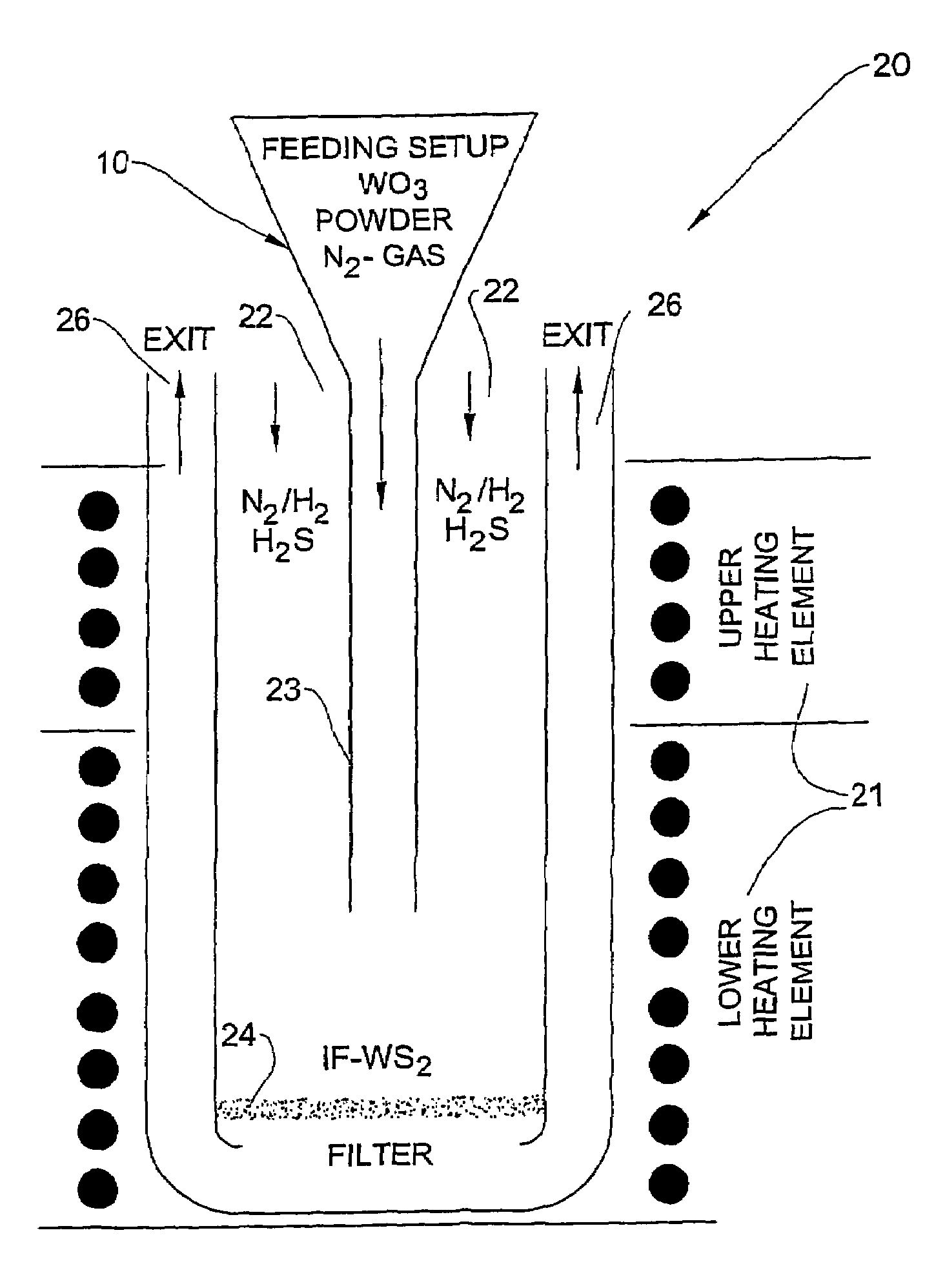

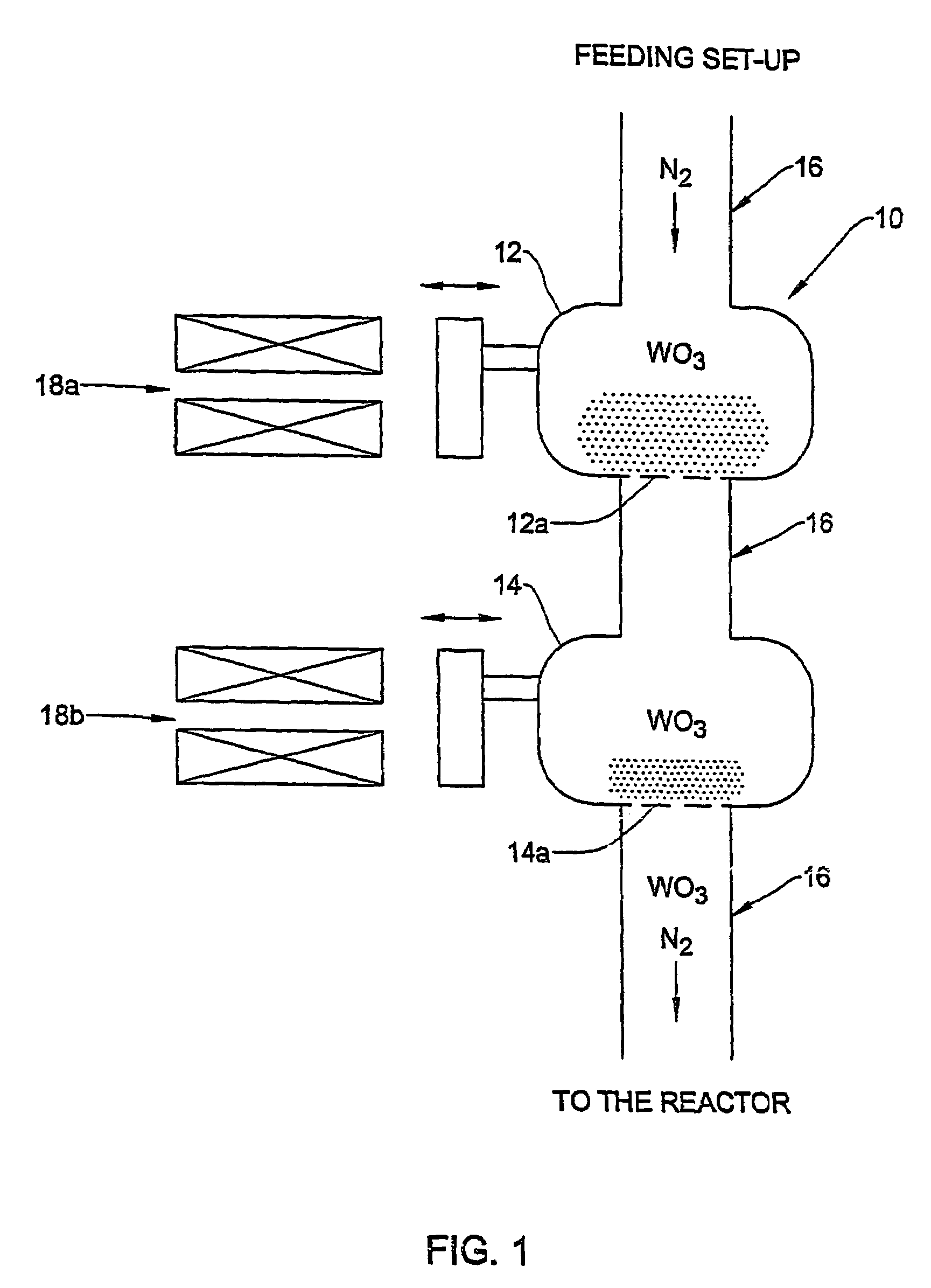

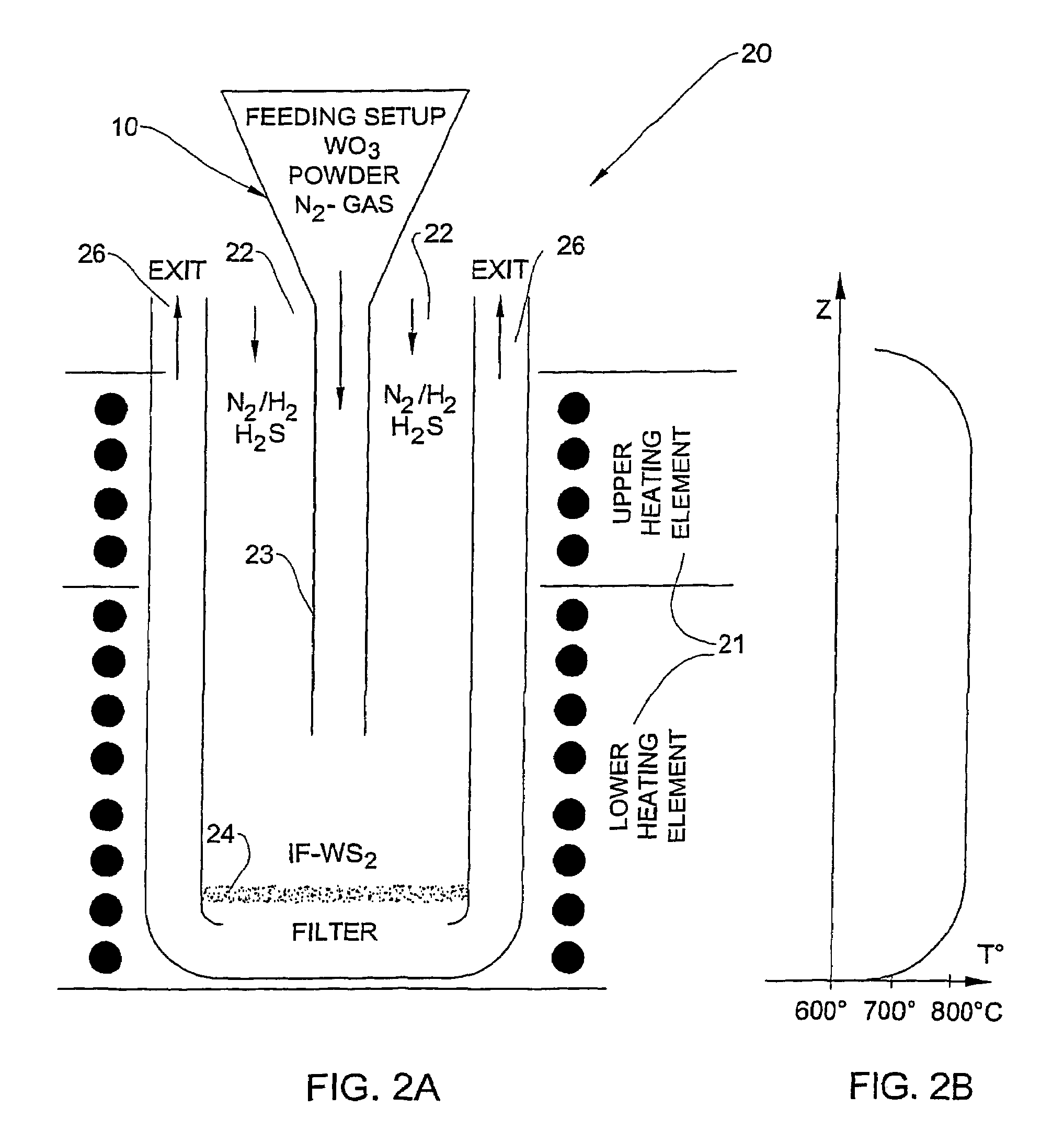

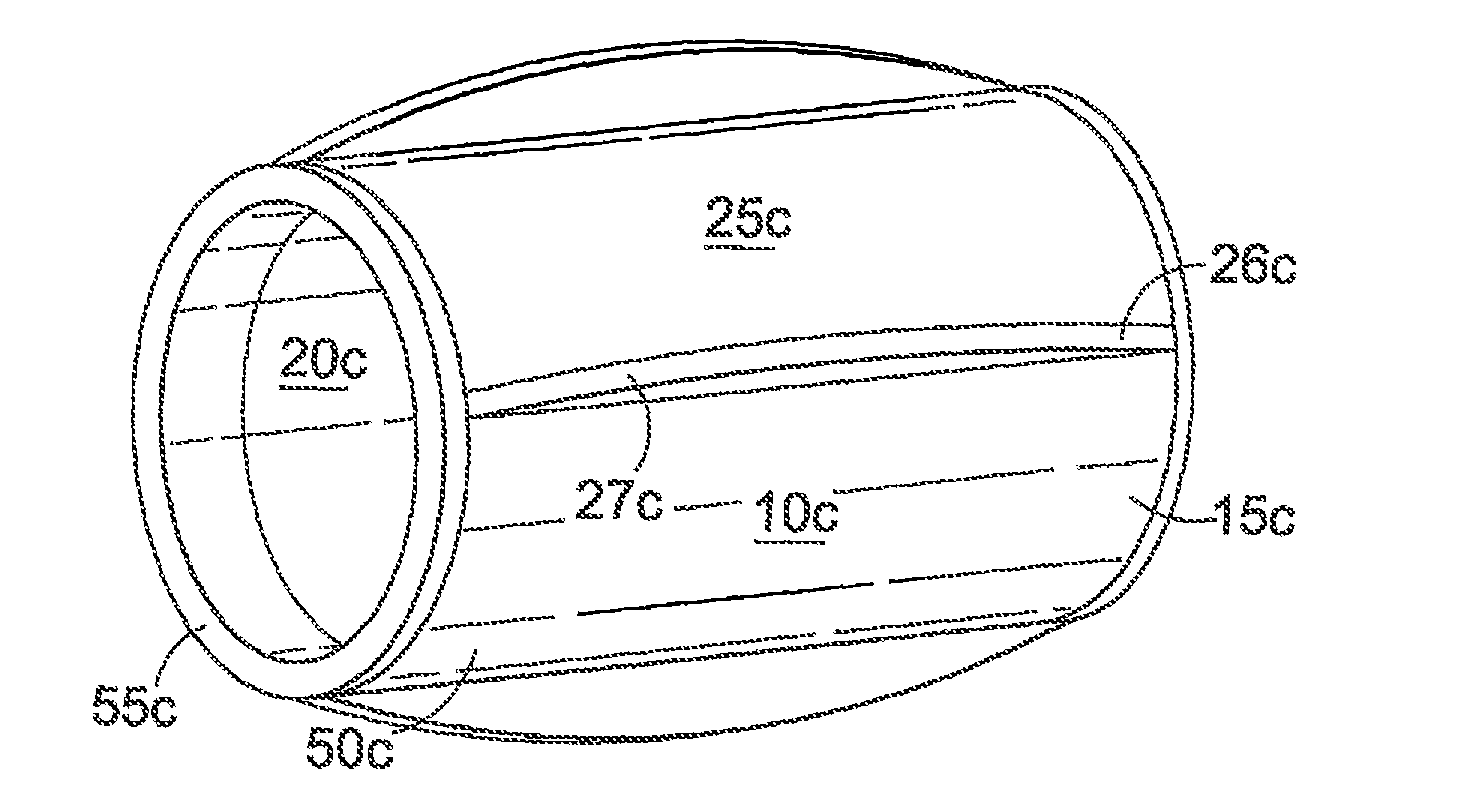

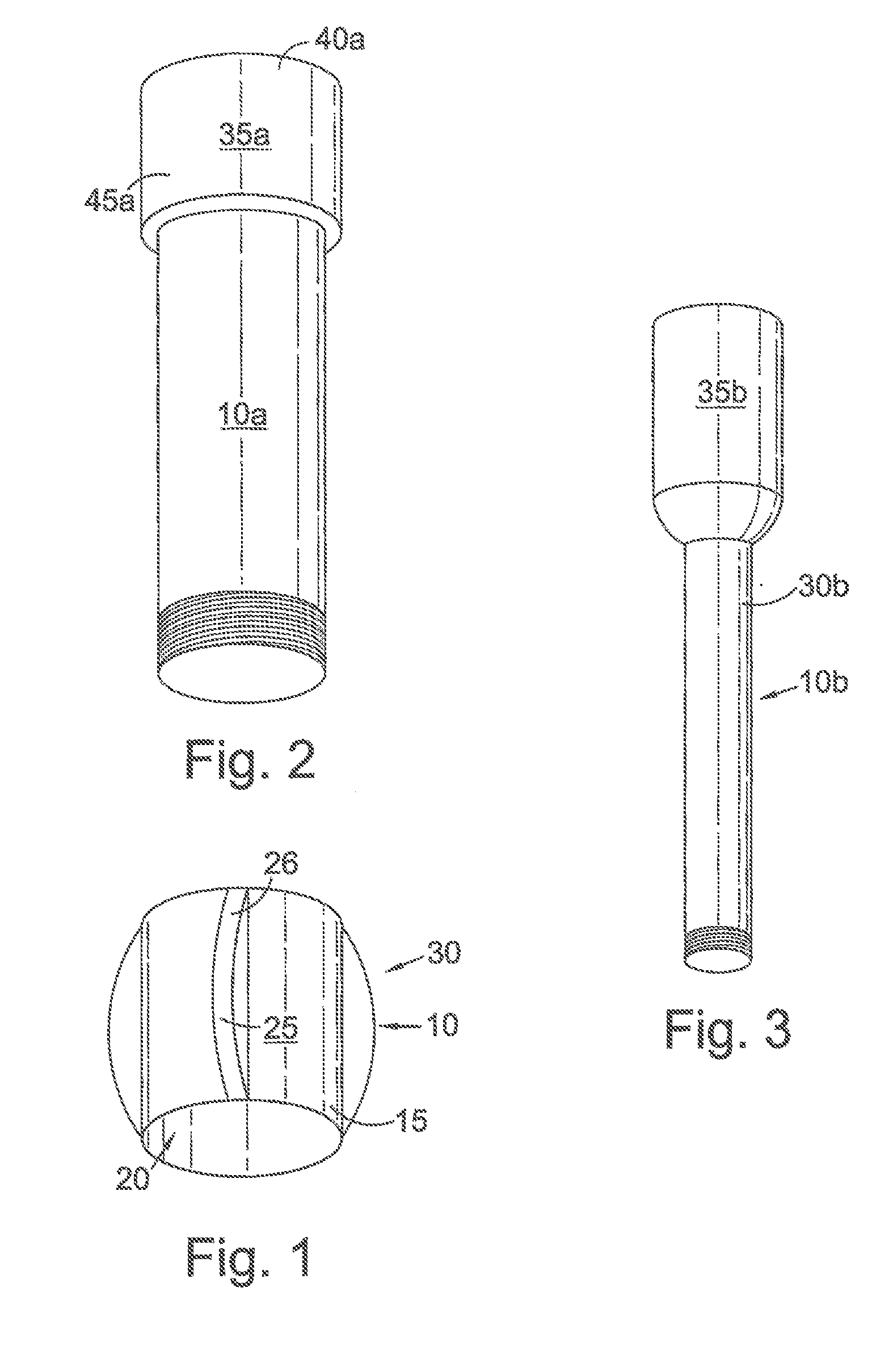

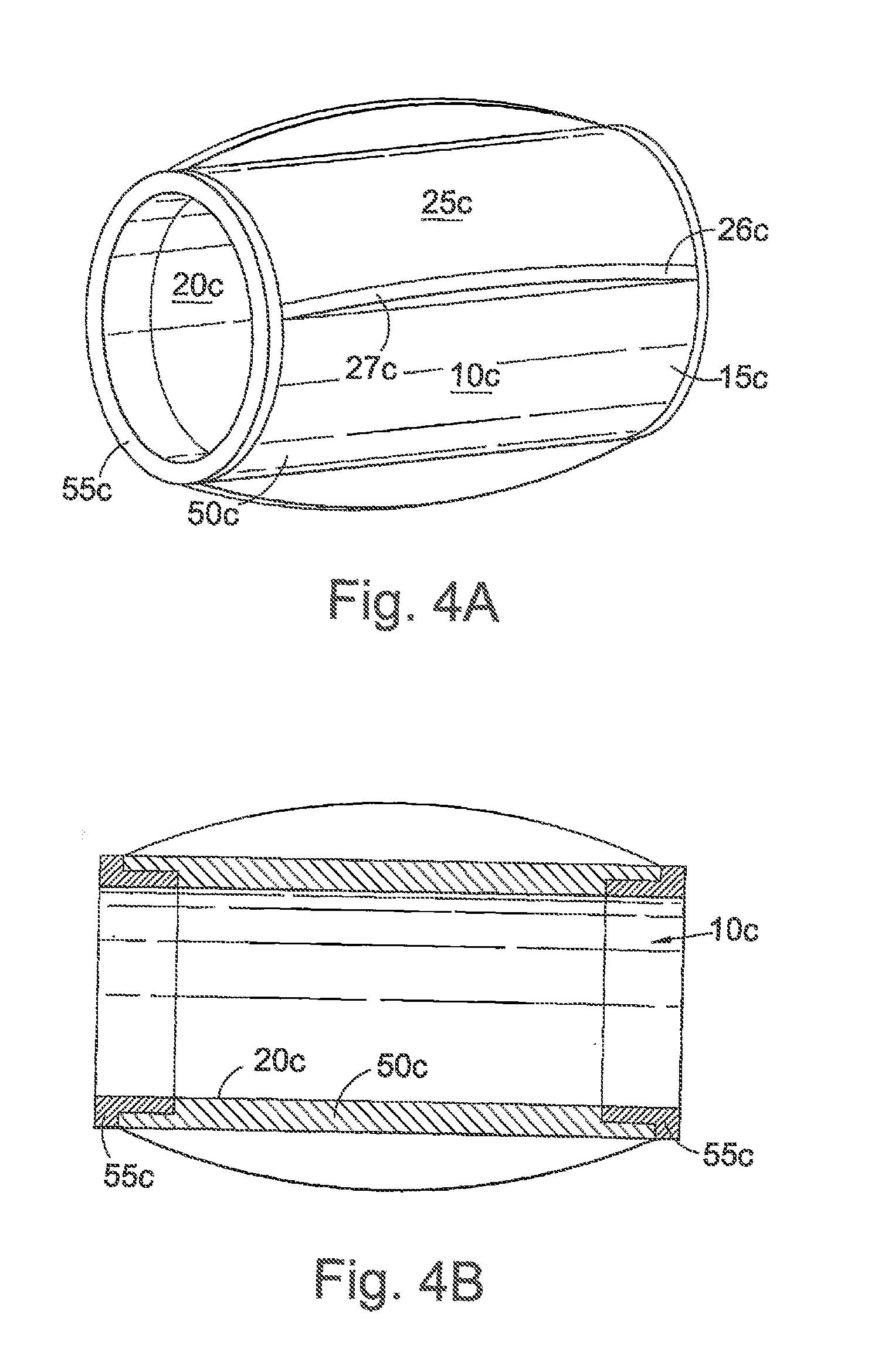

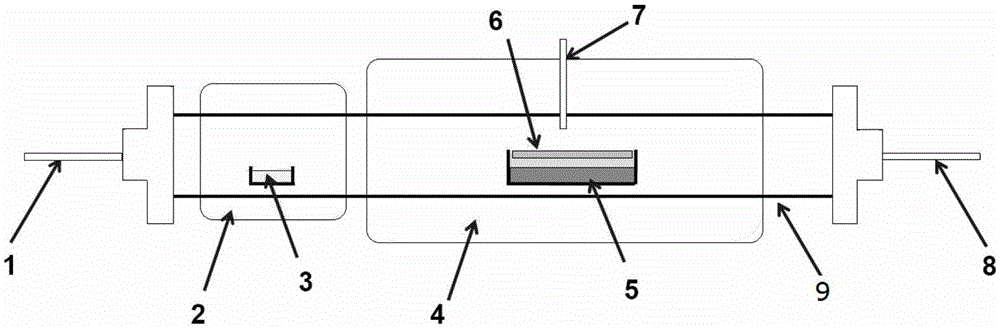

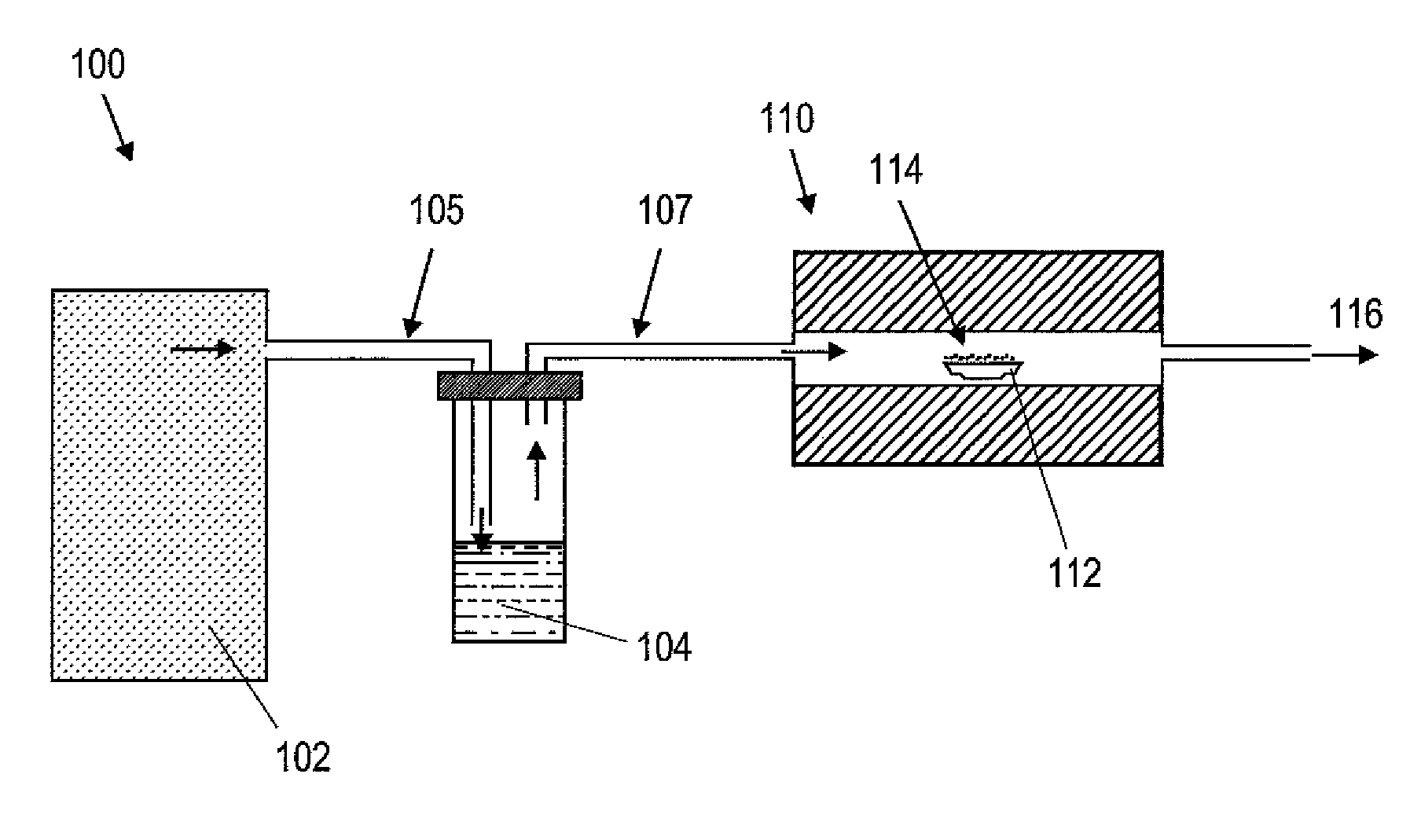

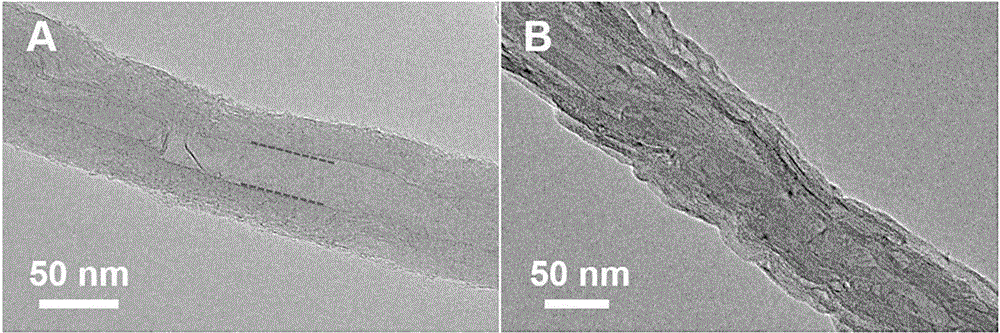

Reactors for producing inorganic fullerene-like tungsten disulfide hollow nanoparticles and nanotubes

InactiveUS7524481B2Uniform spherical shapeUniform size distributionMaterial nanotechnologyNanostructure manufactureTemperature controlNanoparticle

The present invention is related to an apparatus for the production of inorganic fullerene-like (IF) nanoparticles and nanotubes. The apparatus comprises a chemical reactor, and is further associated with a feeding set up and with a temperature control means for controlling the temperature along the reaction path inside the reactor so as to maintain the temperature to be substantially constant. The invention is further directed to a method for the synthesis of IF-WO3 nanoparticles having spherical shape and having a size up to 0.5 mu m and nanotubes having a length of up to several hundred mu m and a cross-sectional dimension of up to 200 nanometer.

Owner:YEDA RES & DEV CO LTD

Downhole tools

There is disclosed a downhole tool or device adapted to include at least part of a well completion assembly or well drilling assembly. For example, an improved centraliser is provided for centralisation of tubulars such as casings, liners, production screens, production tubing and the like in oil / gas wells in other wells, e.g. water wells. An improved downhole tool device is coated with at least first and second coatings, wherein the second coating layer is molecularly bonded to the first coating layer. The first coating comprises at least partly a material selected from the group consisting of Titanium Nitride (TiN), Diamond Like Carbon (DLC) or Carbon, and wherein the second coating at least partly comprises Tungsten Disulfide (WS2). There is also provided a method of manufacturing a downhole tool or device, wherein the second coating is applied at ambient temperature.

Owner:VOLNAY ENG SERVICES

Ballistics conditioning

Compositions and methods for ballistic conditioning firearm projectiles, firearms, and firearm components such as bores of barrels, by applying to such items a conditioning composition selected from the group consisting of hexagonal boron nitride, graphite, tungsten disulfide, antimony trioxide, talc, mica, and mixtures thereof, suspended in a carrier comprising a volatile solvent, and a binder selected from the group consisting of cellulosic-, alkyd- and acrylic-resins.

Owner:BROWN DAVID THOMAS

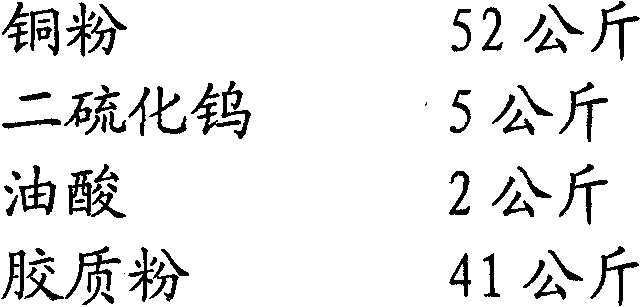

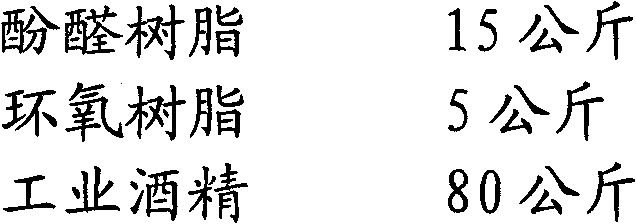

Method for manufacturing electric brush used for industrial motor

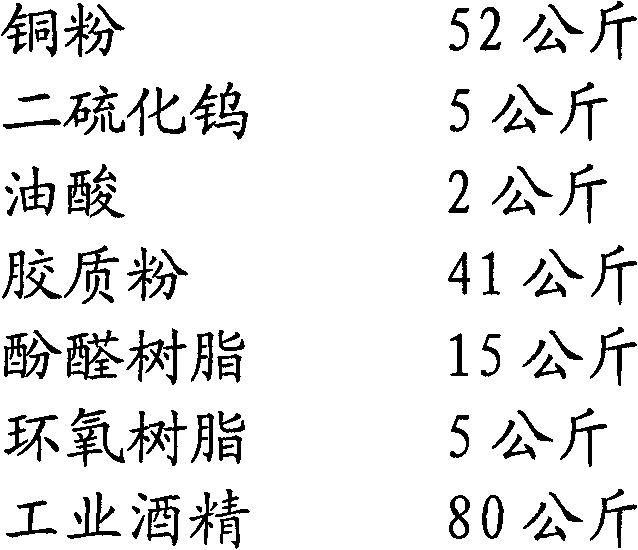

InactiveCN102074875AGuaranteed uniformityImprove the lubrication effectBrushes manufactureEpoxyCopper

The invention discloses a method for manufacturing an electric brush used for an industrial motor. In the method, a main material is formed by proportioning 52 kilograms of copper powder, 5 kilograms of tungsten disulfide, 2 kilograms of surfactant oleic acid, 41 kilograms of rubber powder, 15 kilograms of phenolic resin, 5 kilograms of epoxy resin and 80 kilograms of industrial alcohol. The invention also discloses a preparation process for the electric brush used for the industrial motor. The method has the advantages of high abrasion resistance, prolonged service lives of the electric brush and a motor slip ring and the like.

Owner:杨长根

Preparation method of tungsten disulfide nanorods

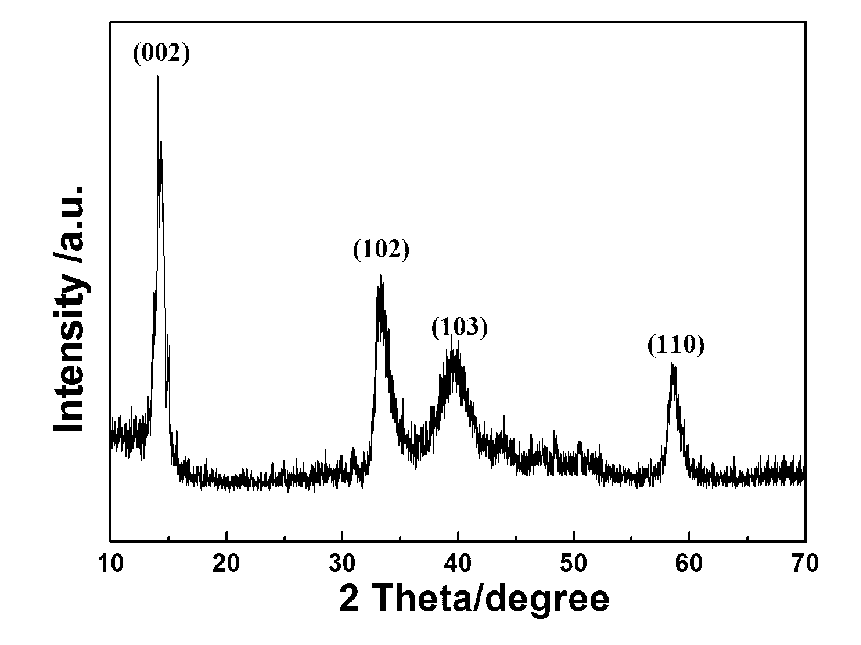

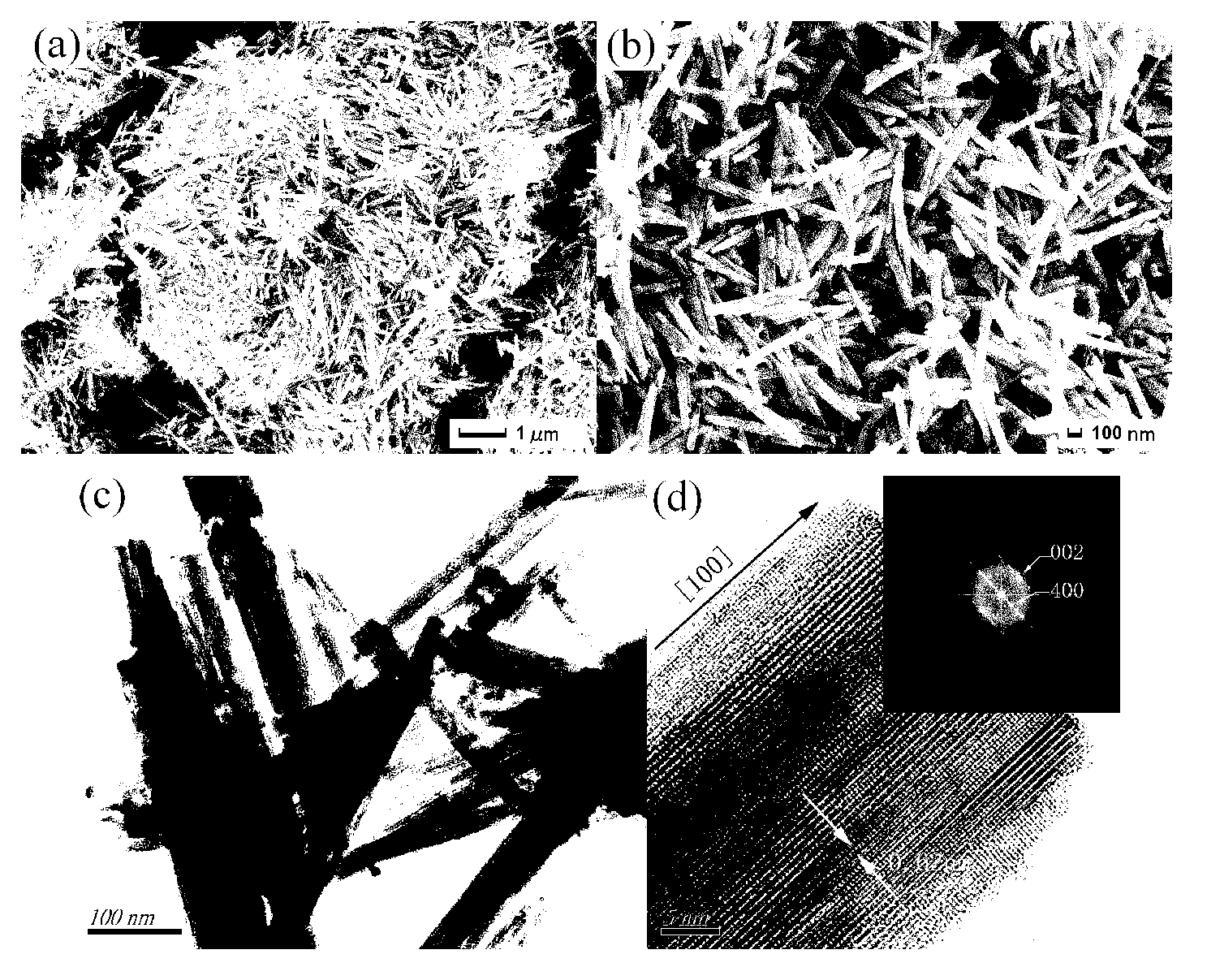

InactiveCN102701283AClear hexagonal layered structureFully crystallizedNanotechnologyTungsten compoundsMaterials preparationRoom temperature

Owner:无锡润鹏复合新材料有限公司

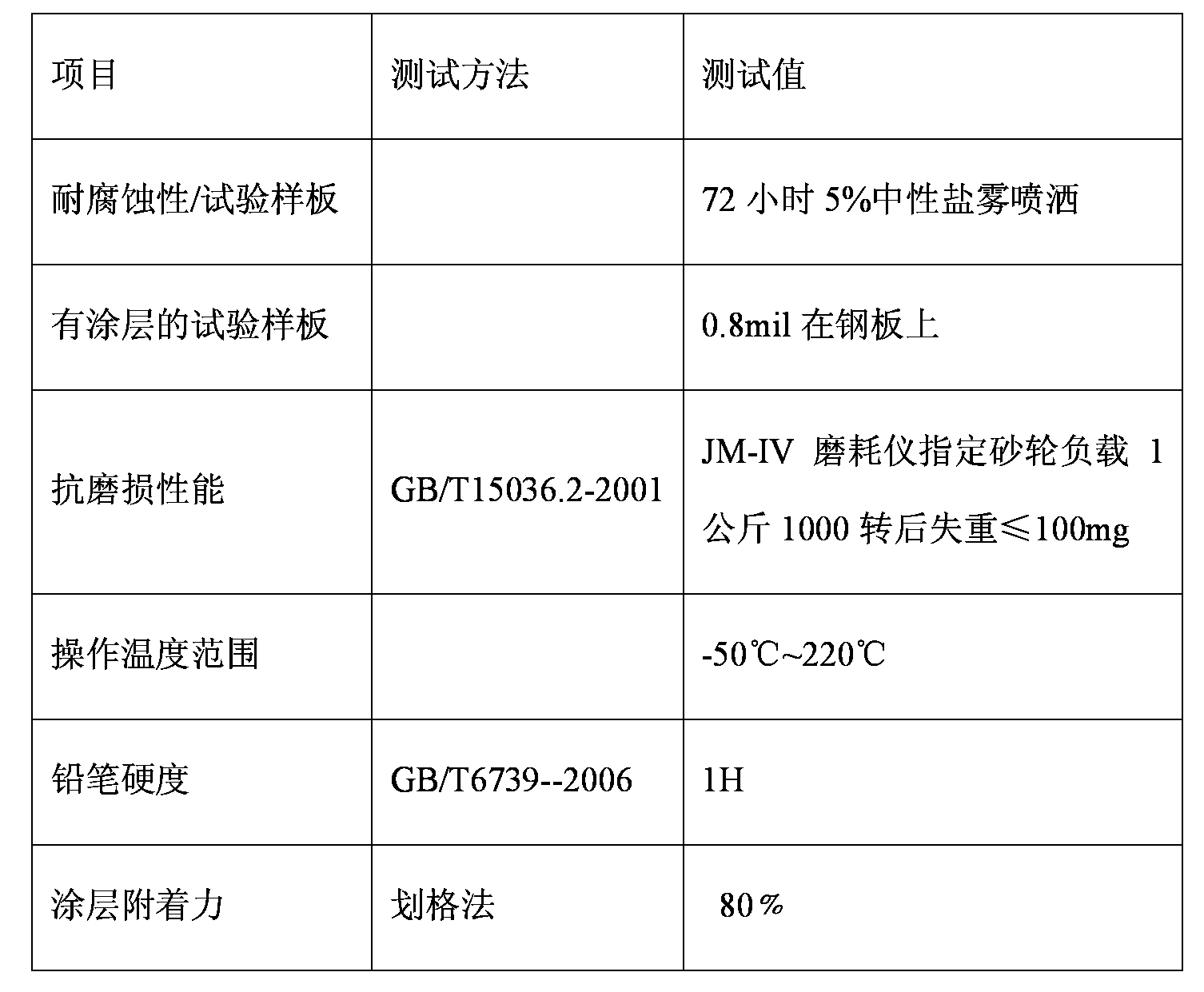

Screw cap with solid lubricating coating and production method of screw cap

ActiveCN103214911AMeet demanding requirementsImprove reliabilityNutsPretreated surfacesEpoxyCarbon monofluoride

The invention relates to a screw cap with a solid lubricating coating. The lubricating coating is 15-30mum thick, and the solid lubricating paint comprises the following ingredients in percentage by weight: 2-12% of molybdenum disulfide, 3-6% of polytetrafluorethylene, 1-7% of graphite, 0-3% of graphene, 12-18% of tungsten disulfide, 8-12% of carbon monofluoride, 16-34% of epoxy resin, 18-29% of nitroresin, and 3-9% of paint additives. The lubricating coating has excellent self-lubricating property, and anti-loosening and anti-occlusion properties. The screw cap with the solid lubricating coating realizes low torque coefficient of 0.1-0.13, and high torque coefficient of 0.14-0.17, thereby meeting the special requirements of automobiles, shipbuilding, power generation and other industries on the screw cap.

Owner:SHANGHAI YILIN LUBRICATING MATERIAL

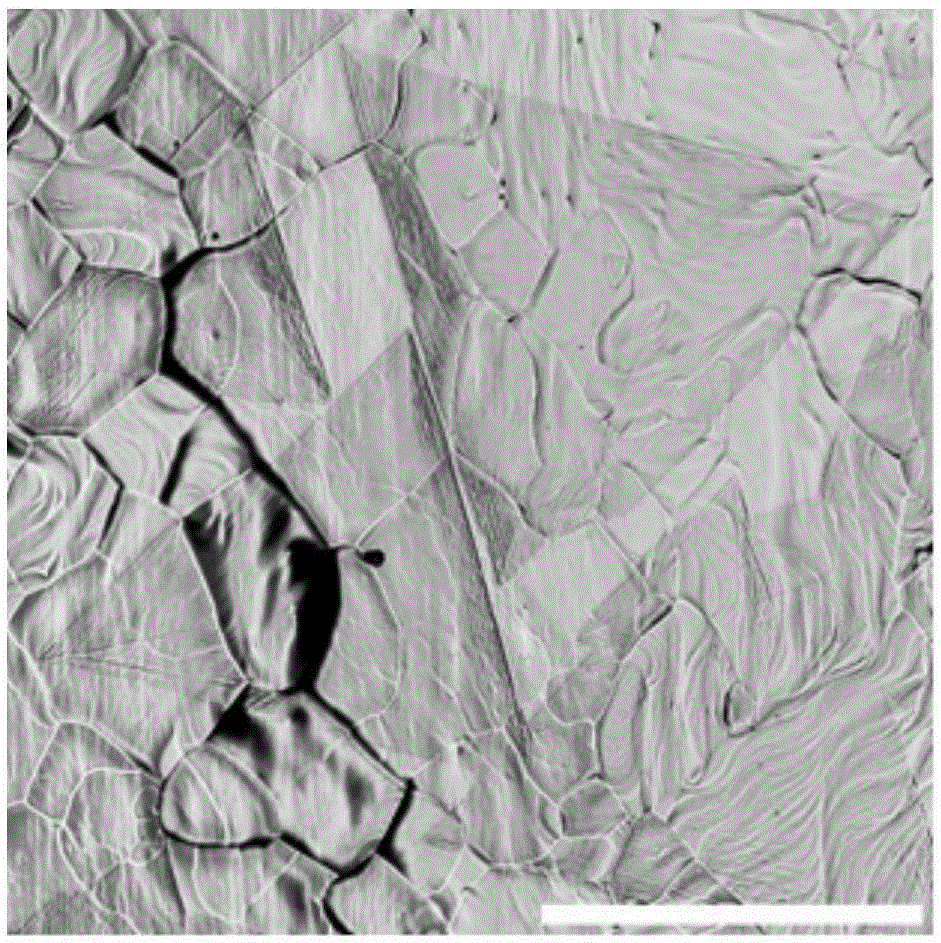

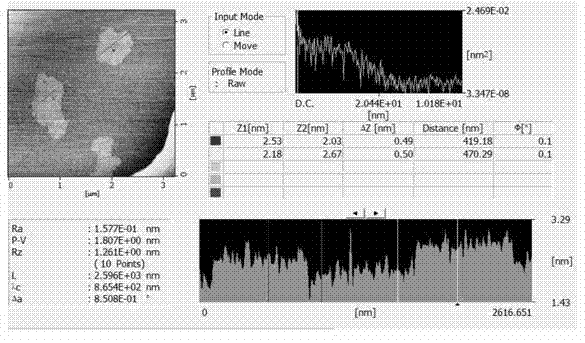

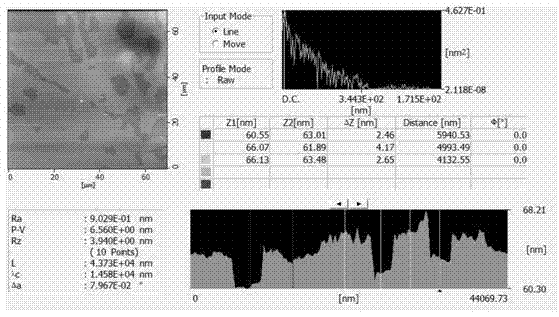

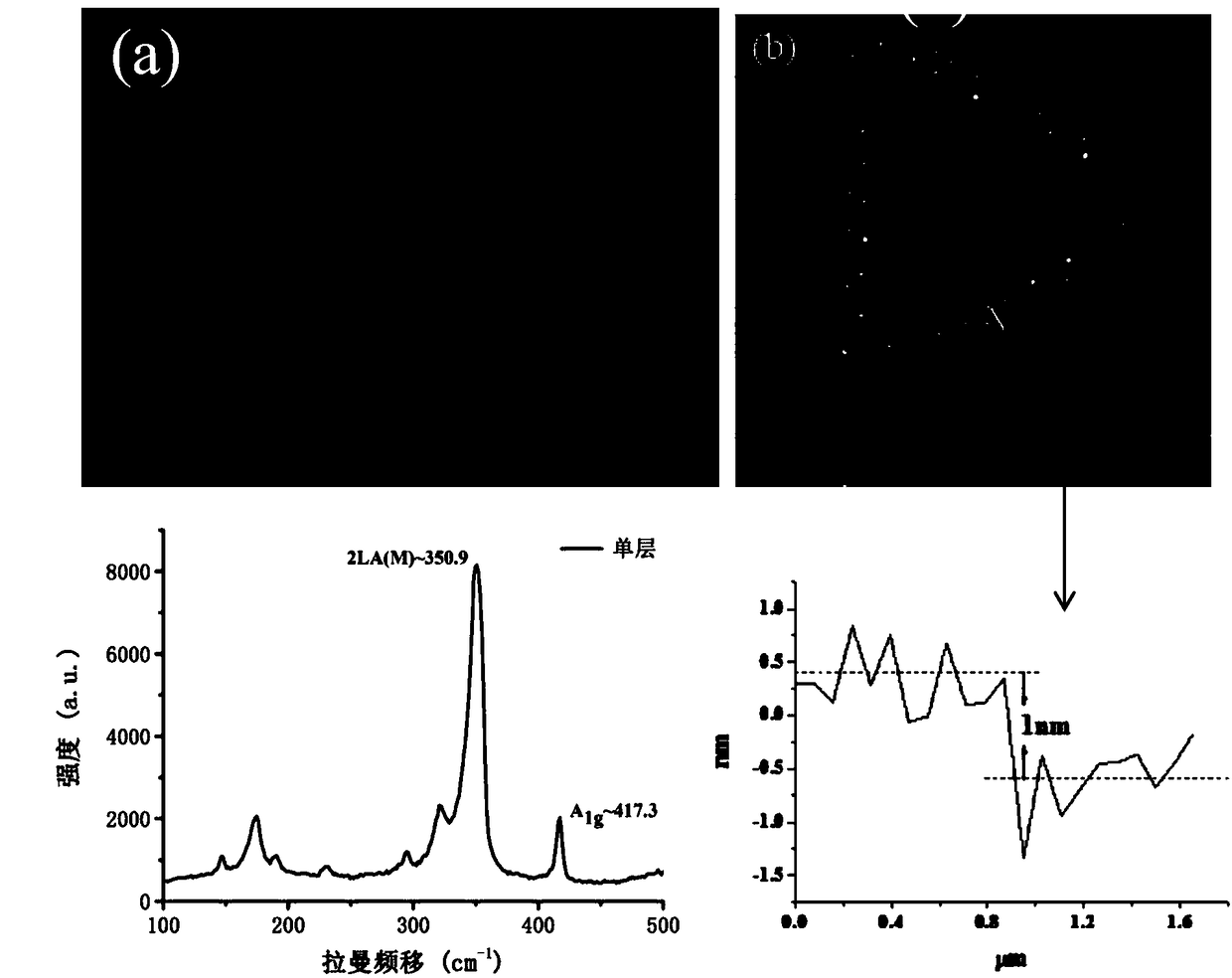

A method of preparing large-area high-quality completely single-layered tungsten disulfide

InactiveCN106567055AQuality improvementImprove uniformityPolycrystalline material growthFrom chemically reactive gasesSolubilitySelf limiting

The invention relates to the field of tungsten disulfide, and particularly relates to a method of preparing large-area high-quality completely single-layered tungsten disulfide. A chemical vapor deposition technique is adopted. Gold the tungsten solubility of which is extremely low is adopted as a growth substrate, and a tungsten source and a sulfur source under atmospheric pressure at high temperature are subjected to a catalytic reaction on the surface of the gold substrate to grow, in a self-limiting manner, completely single-layered tungsten disulfide large-size monocrystalline and large-area continuous film. The characteristic that bonding between the prepared tungsten disulfide and the gold substrate under atmospheric pressure is weak is utilized, a bubbling transferring process and a process combining bubbling and reel-to-reel transferring are respectively adopted to transfer the large-area completely single-layered tungsten disulfide to rigid and flexible substrates under the premise of not destroying the gold substrate. The completely single-layered high-quality millimeter-level tungsten disulfide monocrystalline and large-area continuous film can be prepared through the method, thus laying foundations for application of single-layered tungsten disulfide in the fields of electron / optoelectronic devices, spinning devices, solar cells, gas / light sensors, flexible film electronic / optoelectronic devices, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing two-dimensional atomic crystal new material by supercritical fluid

ActiveCN102732966AControl layer distributionReduce forcePolycrystalline material growthSingle crystal growth detailsHexagonal boron nitrideBoron nitride

The invention relates to method for preparing a two-dimensional atomic crystal new material by supercritical fluid. The method comprises the steps of: by taking laminated structure materials such as boron nitride (BN), molybdenum disulfide (MoS2), tungsten disulfide (WS2) as raw materials, and taking supercritical fluid (carbon dioxide CO2) as a stripping agent, successfully stripping new two-dimensional atomic crystal material for preparing BN film, MoS2 film, WS2 film and the like, wherein each film exists in a form of a single layer (monoatomic layer) and a few thin layers (a few atomic layers). The two-dimensional atomic crystal film prepared by the method has the same or similar structure with graphene, and has excellent mechanical property and transmittance property. Each film has excellent electrical, magnetic, thermal and optical performance, and has important application prospect in many fields; and by the technology of preparing the two-dimensional atomic crystal film by supercritical fluid in a stripping way, the product film has the advantages of controllable layers, excellent structure, high yield, simple process and low cost.

Owner:SHANGHAI JIAO TONG UNIV

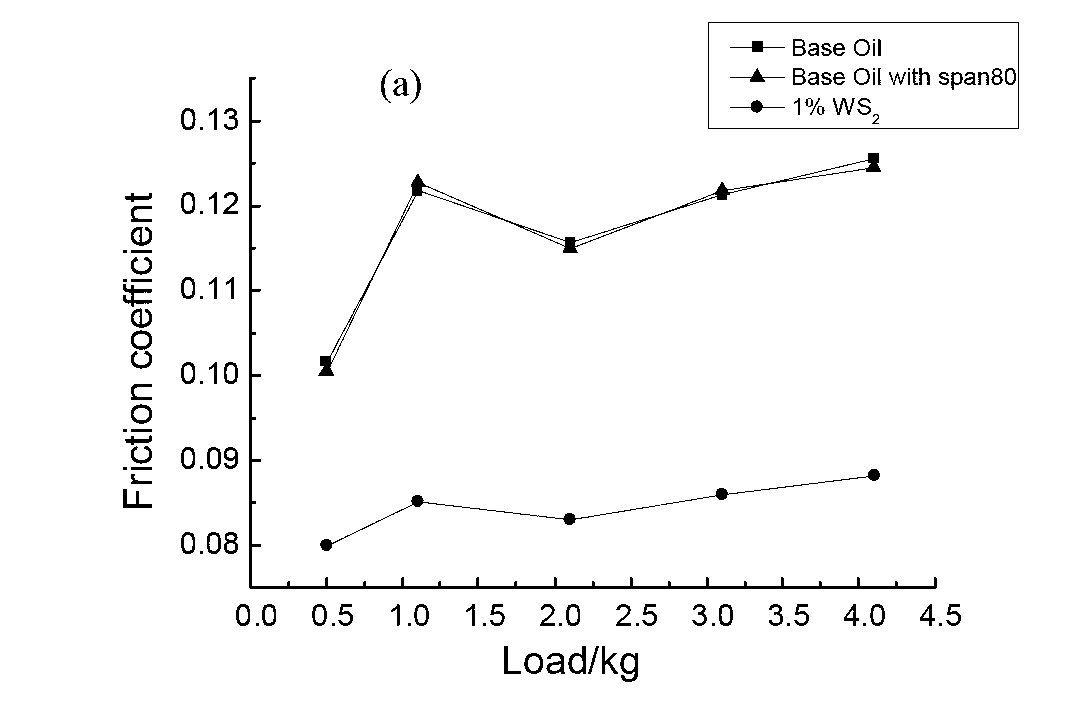

Water-based lubricant and preparing method of the same based on nanometer tungsten disulfide

The invention discloses a water-based lubricant based on nanometer tungsten disulfide, which comprises the following components and contents, by weight, 1% to 15% of nanometer tungsten disulfide, 1% to 10% of solid lubricant, 0.2% to 3% of antirust agent, 10% to 40% of aqueous stearic acid, 10% to 20% of waterborne zinc stearate, 0.4% to 4% of emulsifying stabilizer, 0.01% to 0.05% of defoaming agent, and 8% to 77% of water. The constituent content of the components sums up to 100%. The preparing method of the water-based lubricant and a usage method thereof are disclosed. The water-based lubricant based on the nanometer tungsten disulfide has the advantages of being good in the lubrication effect of the water-based lubricant, large in elongation coefficient, environment-friendly and unpolluted, and wide in applying scope. In addition, the preparing method of the water-based lubricant and the use method and process steps thereof are simple and fast so as to improve the production efficiency and benefit the environmental protection.

Owner:HENAN HUIER NANO TECH

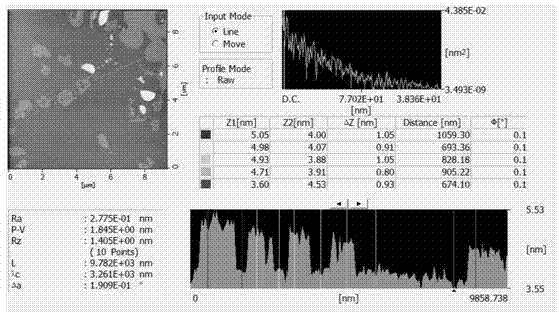

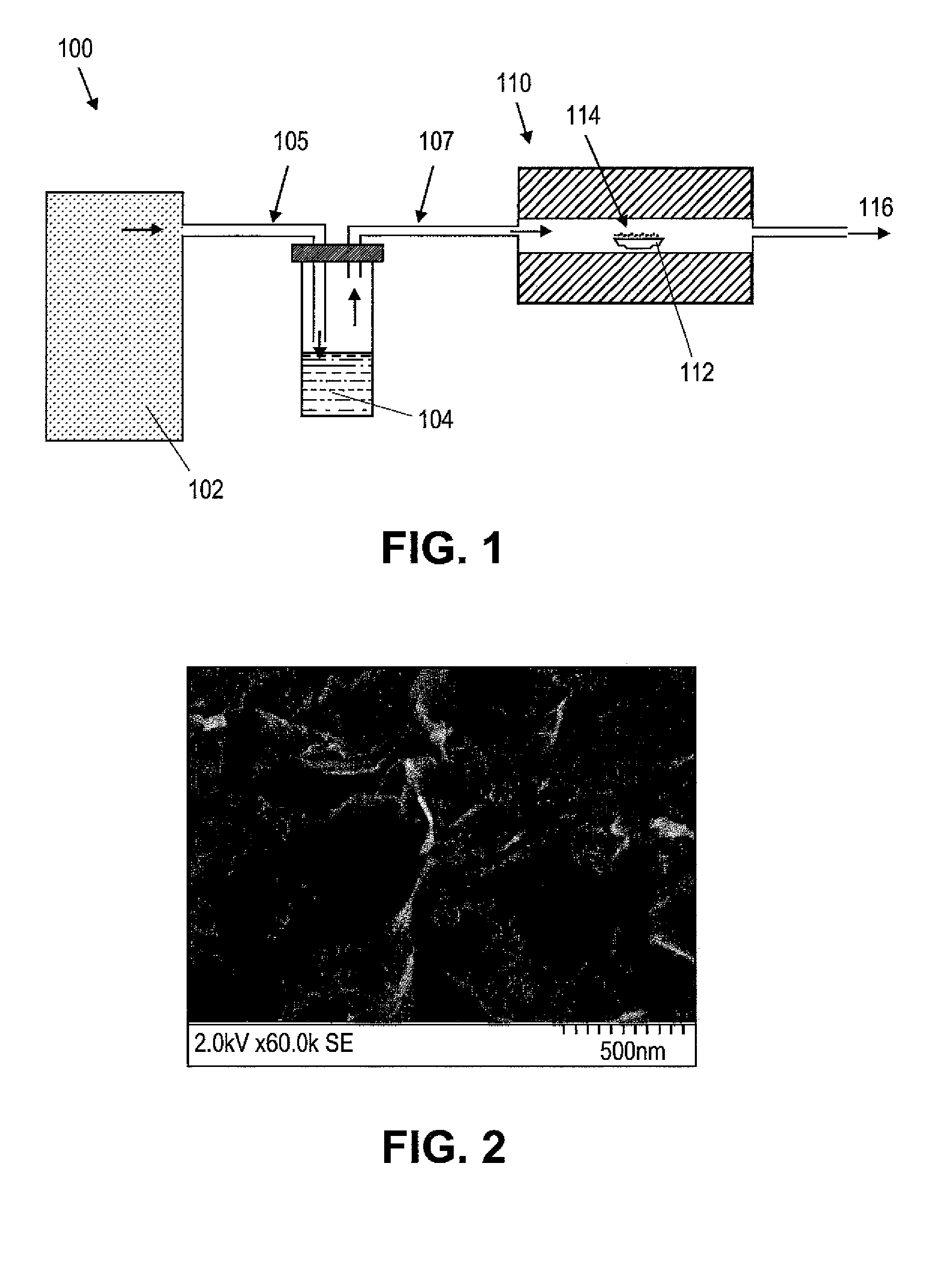

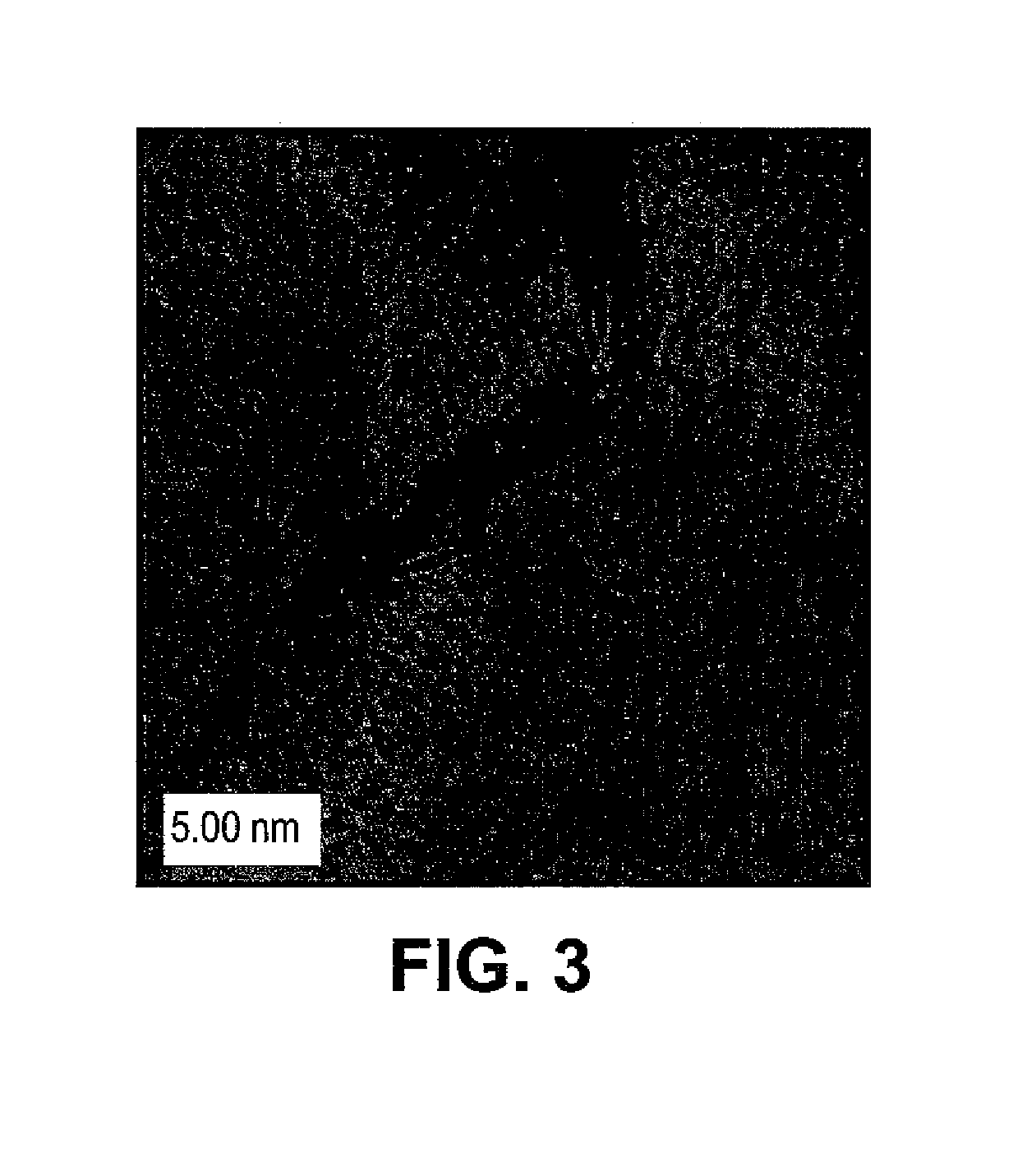

Synthetic methods for generating WS2 nanostructured materials

InactiveUS8303926B1Cell electrodesSulfide/polysulfide preparationSynthesis methodsNanostructured materials

In accordance with various embodiments, there are nanostructured materials including WS2 nanostructures and composites of WS2 nanostructures and other materials and methods for synthesizing nanostructured materials. The method can include providing a plurality of precursor materials, wherein each of the plurality of precursor materials can include a tungsten reactant. The method can also include flowing, for a reaction time, a substantially continuous stream of carbon disulfide (CS2) vapor in a carrier gas over the plurality of precursor materials at a temperature in the range of about 700° C. to about 1000 C, wherein the reaction time is sufficient to permit the tungsten reactant to react with carbon disulfide to form a plurality of tungsten disulfide (WS2) nanostructures.

Owner:STC UNM

Electric brush for ABS system and preparation method thereof

ActiveCN102856758AFrictional stabilityStable service lifeRotary current collectorBrushes manufactureFiberElectrolysis

An electric brush for ABS (Anti-skid Brake System) comprises a brush body and a lead-out wire, wherein the brush body comprises 46 to 52 parts by weight of superfine electrolytic copper powder, 52 to 46 parts by weight of cementing powder and 2 parts by weight of modifier at; the cementing powder comprises 1.0 to 3.0 parts of high-purity carbon fiber powder, 23 to 27 parts of artificial graphite powder, 25 to 35 parts of high-purity sub-nanometer graphite powder, 18 to 22 parts of crystal graphite powder, 3 to 8 parts of graphitized carbon black powder, 2.5 to 4.5 parts of rare-earth tungsten disulfide composites and 5 to 15 parts of high-temperature resistant phenolic resin; and the modifier comprises 0.20 to 1.30 parts of vulcanization silver powder, 0.20 to 1.5 parts of stibonium powder and 0.5 to 1.5 parts of zinc powder. The chemical stability, the lubricating property, the electrical conductivity, the high-temperature resistance and the abrasion resistance of the electric brush provided by the invention are much better than that of the existing products.

Owner:丽水市长新电器制造有限公司

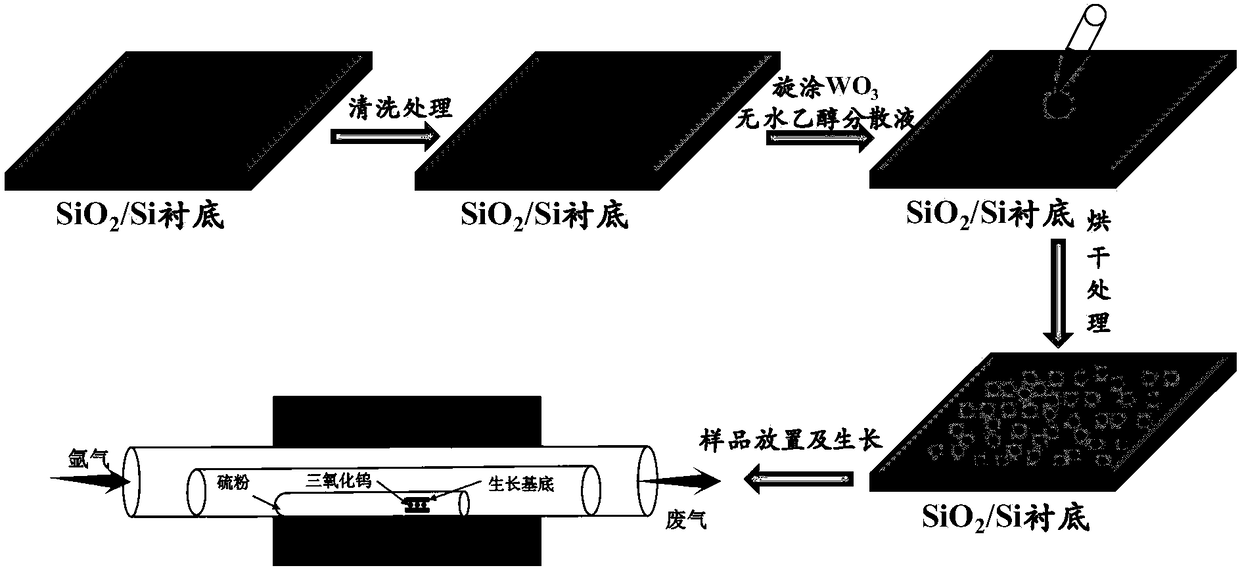

Preparation method for large-area single-layer tungsten disulfide film based on atmospheric pressure chemical vapor deposition and product

ActiveCN108559972AFast preparationPrepare to repeatChemical vapor deposition coatingFilm baseGas phase

The invention relates to a preparation method for a large-area single-layer tungsten disulfide film based on atmospheric pressure chemical vapor deposition and a product. The preparation process comprises SiO2 / Si substrate cleaning, spin coating of a WO3 anhydrous ethanol dispersion solution, substrate drying treatment, sample placement and tungsten disulfide film growth. By the adoption of the method, WO3 precursor is uniformly dispersed on a substrate by spin coating of the WO3 anhydrous ethanol dispersion solution, a single-ended-closed small-caliber quartz tube is placed in a quartz tube growth chamber, and the amount of S powder and WO3 precursor participating in a nucleation and film growth process is effectively controlled, so that the prepared tungsten disulfide film has the largearea, single layer and large size. The method has the beneficial effects of being quick and repeatable and is significant in preparation of the large-area single-layer tungsten disulfide film.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Tungsten disulfide/graphene nanobelt composite material and preparation method thereof

InactiveCN105280900AEasy to makeEasy to operateMaterial nanotechnologyPhysical/chemical process catalystsNew energySolar battery

The invention belongs to the technical field of transition metal sulfide-carbon materials, and particularly discloses a tungsten disulfide / graphene nanobelt composite material and a preparation method thereof. A graphene nanobelt disclosed by the invention is prepared through solution oxidation, and the tungsten disulfide / graphene nanobelt composite material is formed by tungsten disulfide nanosheets in an in-situ growth manner on the graphene nanobelt through a one-step solvothermal method. The graphene nanobelt prepared by the invention has the advantages of stable chemical property, high conductivity and the like; and the composite material prepared by the invention has the characteristic of morphology controllability, and the tungsten disulfide nanosheets are uniformly loaded on the graphene nanobelt, so that the adhesion of tungsten disulfide is effectively inhibited, and unique high specific surface area and high conductivity of the graphene nanobelt are fully utilized. The tungsten disulfide / graphene nanobelt composite material prepared by the invention can become an ideal high-performance electrocatalytic material and an electrode material of new energy devices such as lithium ion batteries and solar cells.

Owner:FUDAN UNIV

Arc extinction brush and method for eliminating electric arc of power generator with this arc-extinction brush

InactiveCN101237108ADoes not affect productionNo need to shed loadRotary current collectorCurrent collector maintenanceIndiumSilver iodide

The present invention relates to an arc extinction brush, comprising a solid mixture brush body, wherein, the solid mixture brush body consists of a solid lubricant, wax, and a fast film formation substance; the solid lubricant is any of tin, lead, indium, cadmium, silver and oxides thereof; the fast film formation substance is any of molybdenum disulfide, tungsten disulfide, silver iodide, lithium carbonate, barium carbonate or sodium silicate. The present invention also comprises a method of using the arc extinction brush to eliminate electric arc of brushes for generators. The arc extinction brush is used to replace a brush to participate in motor operation and is matched with the operation of eliminating a bad oxide film, and after the arc extinction brush is repeatedly put into operation, the arc extinction brush can help form a good oxide film, so as to eliminate electric arc of brushes for generators and to reduce the sliding friction and self-vibration of brushes.

Owner:黄继林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com