Screw cap with solid lubricating coating and production method of screw cap

A solid lubrication and coating technology, applied in the direction of coating, lubricating composition, device for coating liquid on the surface, etc., can solve problems such as the influence of nut suppliers on exports, improve reliability and facilitate maintenance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

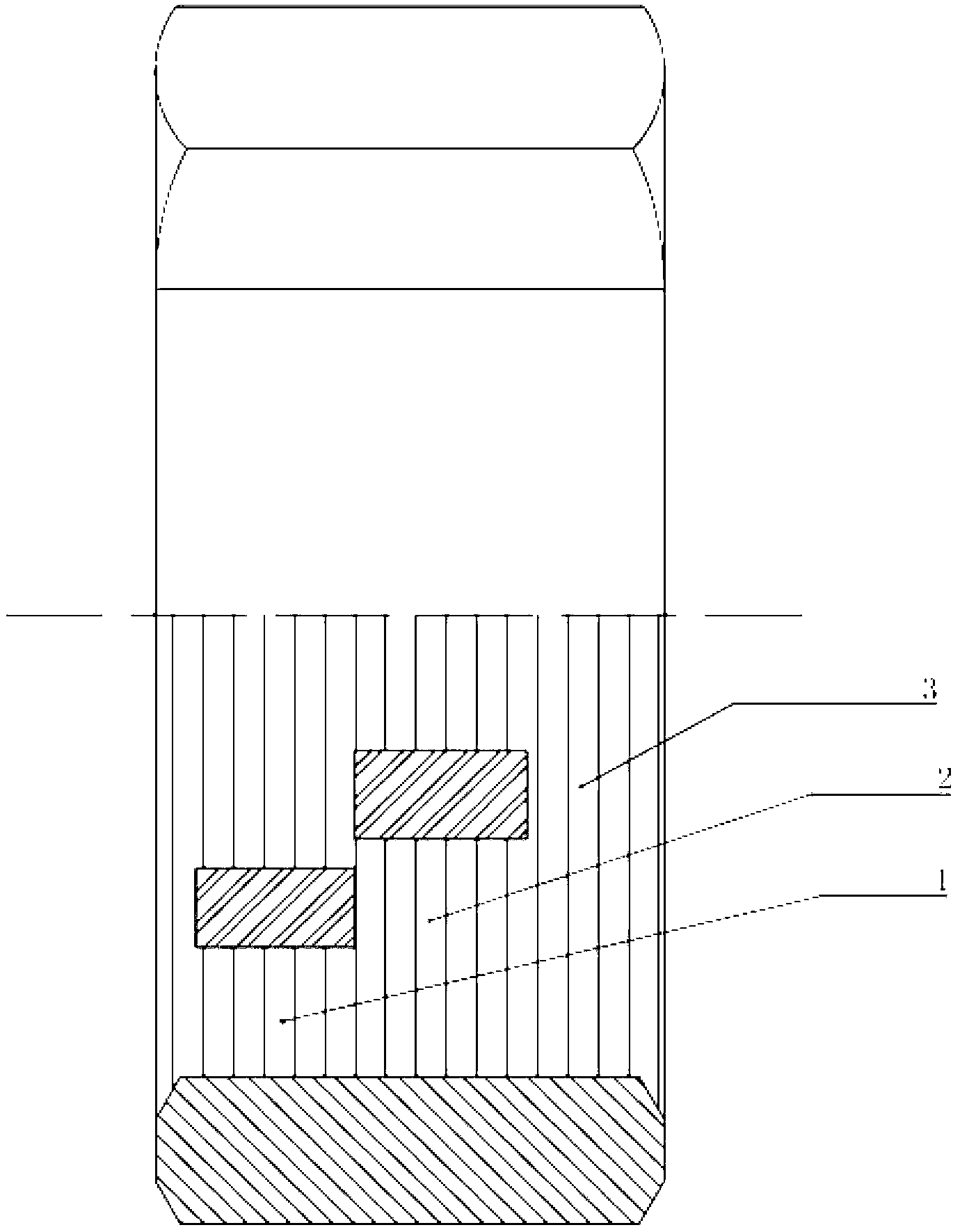

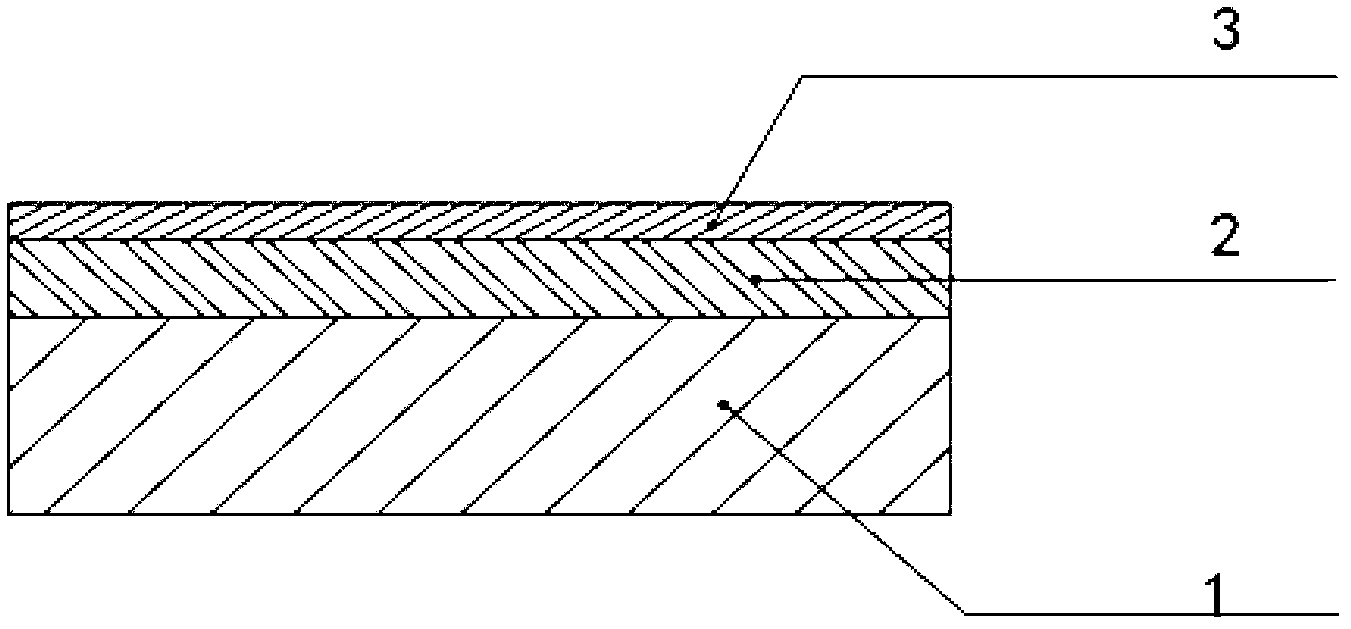

Image

Examples

Embodiment

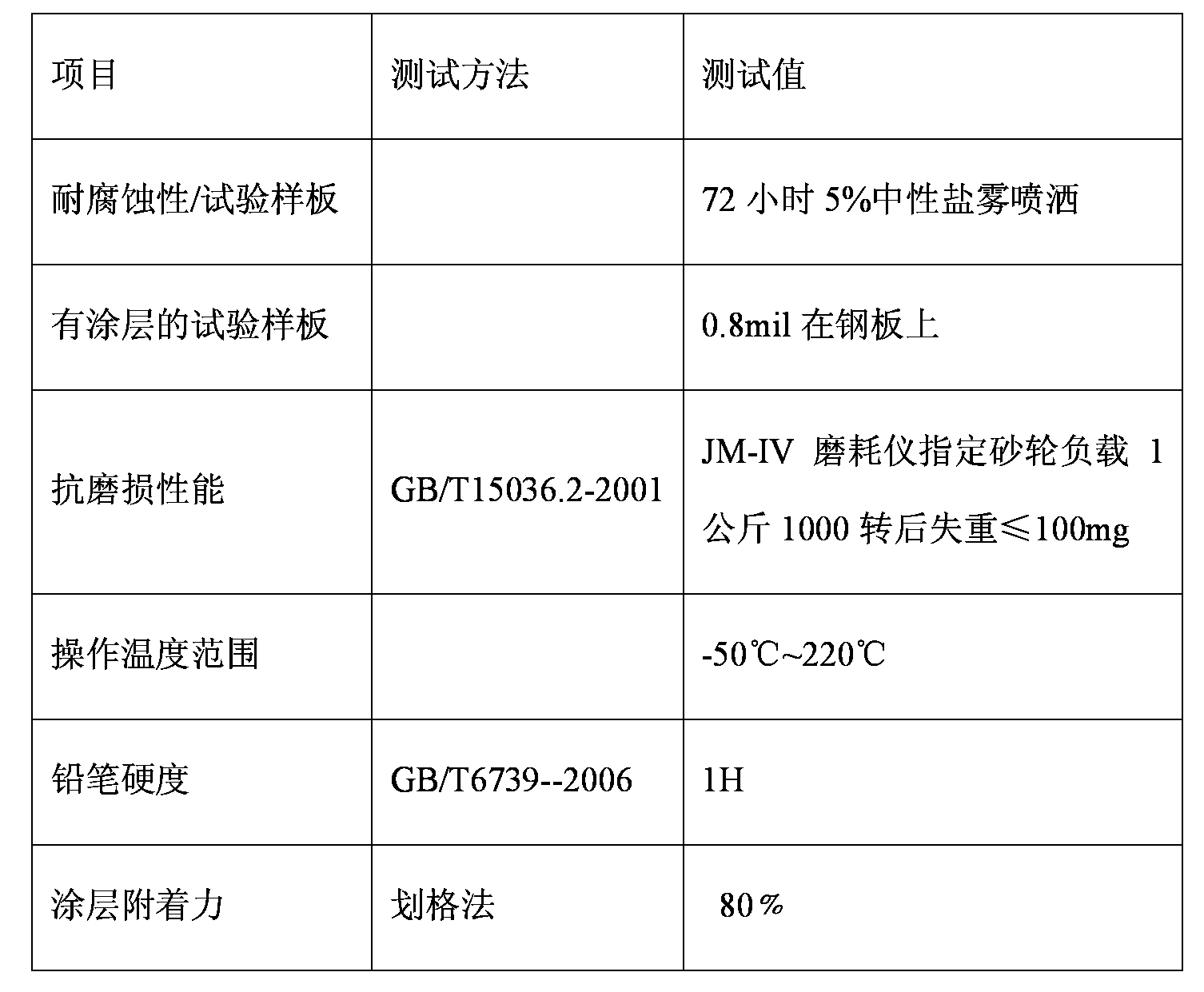

[0020] The formula of solid lubricating coating is as follows:

[0021] Solid lubricant: 10% molybdenum disulfide, 3% polytetrafluoroethylene, 5% graphite, 1% graphene, 16% tungsten disulfide, 10% graphite fluoride;

[0022] Adhesive: 30% epoxy resin, 19% nitro resin;

[0023] Additive: powder surface treatment agent 6%;

[0024] Active additives are added to the solid lubricant to activate the surface of the solid lubricant so that it can better combine with the polymer material.

[0025] After mixing, the specific gravity is 1100±60 g / L, it is black, and the flash point is 100°C.

[0026] The specific steps of coating the solid lubricating coating on the nut are as follows:

[0027] The first step is to use a normal temperature neutral degreasing agent to thoroughly remove all kinds of grease, dust, oil stains and other micro-garbage on the nut during the machining process, and wash it with water. After washing with water, dry the surface of the workpiece with high-press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com