Full flexible three-translational series-parallel connection fine motion device of scanning electron microscope home position observation

A micro-movement device, scanning electron microscope technology, applied in the direction of measurement device, mechanical device, strength characteristics, etc., can solve the problems of inability to meet high-precision requirements, lubricant pollution, etc., to avoid vibration shock and avoid the accumulation of various errors , The effect of meeting high precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

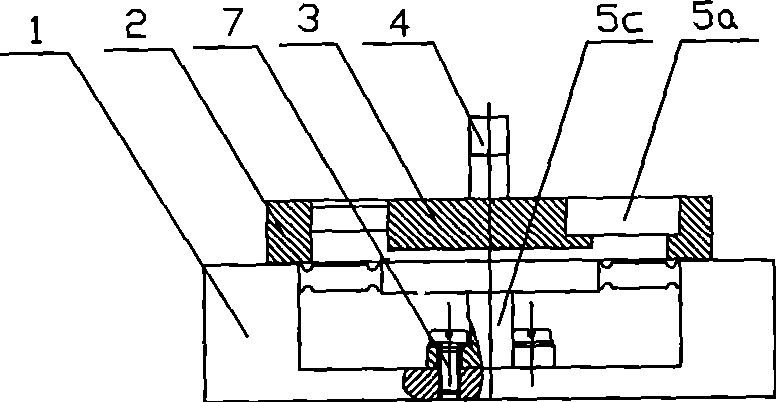

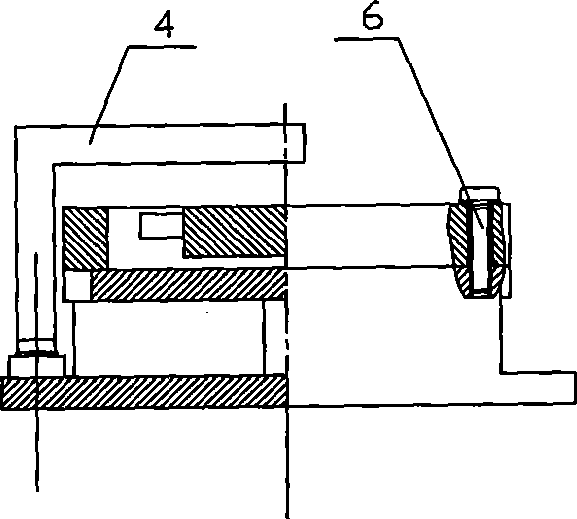

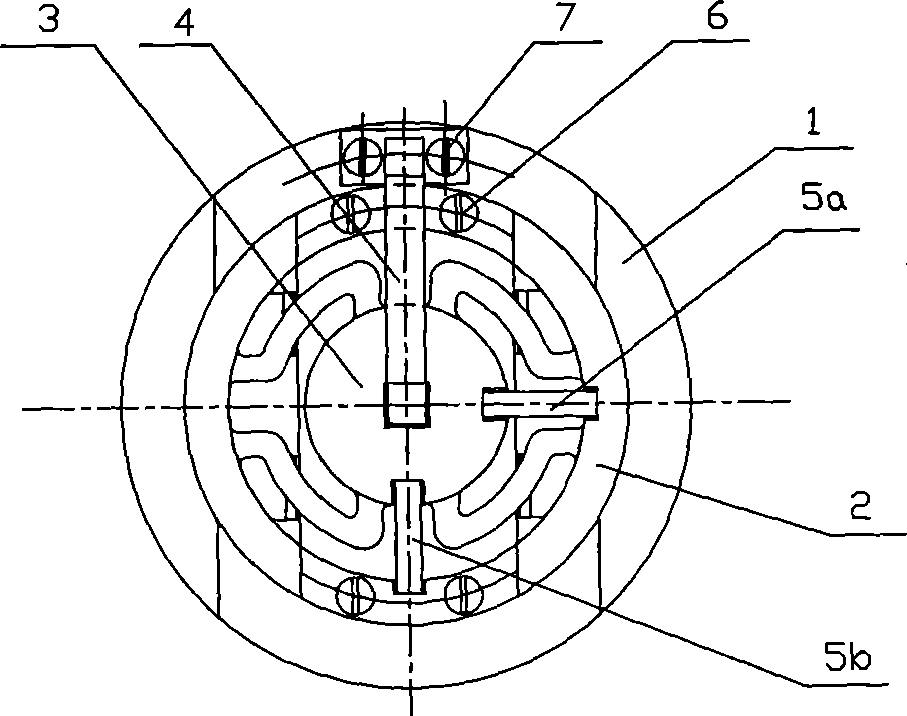

[0015] As shown in the figure, the present invention includes a base 1, 2, a sample stage 3, a microindenter support 4, and piezoelectric ceramic micro-drivers 5a, 5b, 5c. The microindenter support 4 is located above the sample stage 3 and can be fastened. Installed on the base 1, the microindenter bracket 4 is installed on the base 1 with screws 7 as shown in the figure, and the microindenter can be a diamond microindenter. The fully flexible three-translation hybrid micro-motion device is composed of a two-degree-of-freedom fully-flexible planar parallel mechanism and a single-degree-of-freedom fully-flexible mechanism connected in series to form a hybrid mechanism. The two-degree-of-freedom fully-flexible planar parallel mechanism is x, y A micro-motion translation structure in the z-direction, and a fully flexible mechanism with a single degree of freedom is a micro-motion translation structure in the z direction. The described x, y direction micro-motion translation struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com