Patents

Literature

101results about How to "Meet high precision requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

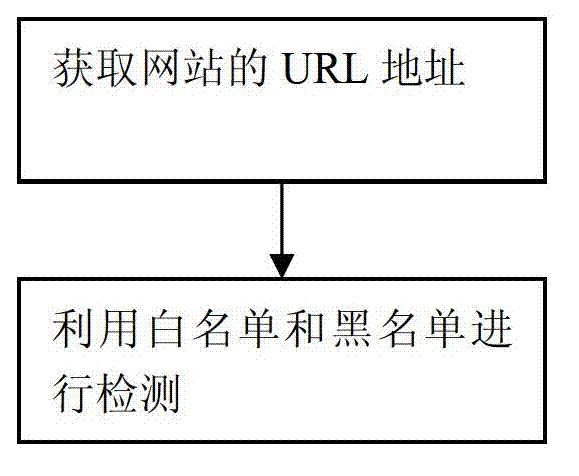

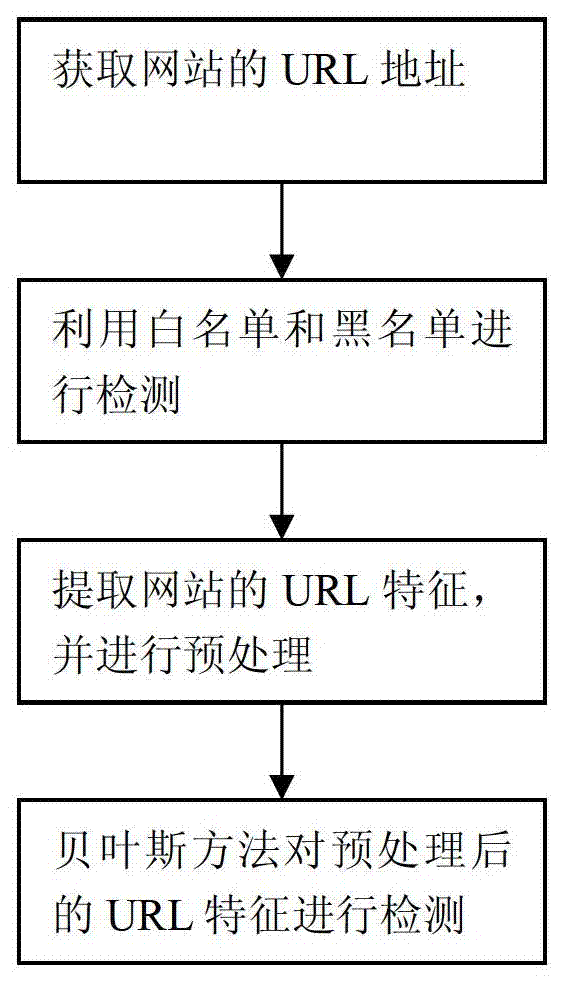

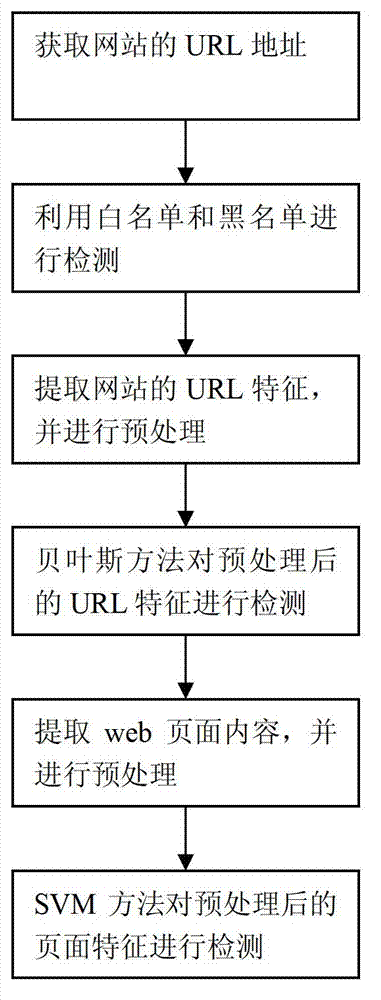

Real-time detection method and system of phishing website

InactiveCN102932348AEasy extractionMeet the requirements for rapid classificationData switching networksLeast squares support vector machineClient-side

The invention relates to a real-time detection method and system of a phishing website. The method comprises the following steps of: obtaining the URL (uniform resource locator) address of the current website; detecting the URL address of the website by use of a white list and a black list; extracting the URL features of the website URL not in the white list and the black list, and performing pretreatment; detecting the URL features after the pretreatment by a Bayesian method, and judging whether the website is a phishing website; if the website can not be clearly determined, determining the website to be a suspicious website; extracting the web page content of the suspicious website, and performing pretreatment; and detecting the page features after the pretreatment by a least square support vector machine method, and judging whether the website is a phishing website. The system consists of a system server and a system client, wherein the system server comprises a white list and black list module and the like; and the system client comprises a URL fingerprint list and the like. Compared with the prior art, the method and system provided by the invention improve the detection rate and the accuracy.

Owner:CHANGZHOU UNIV

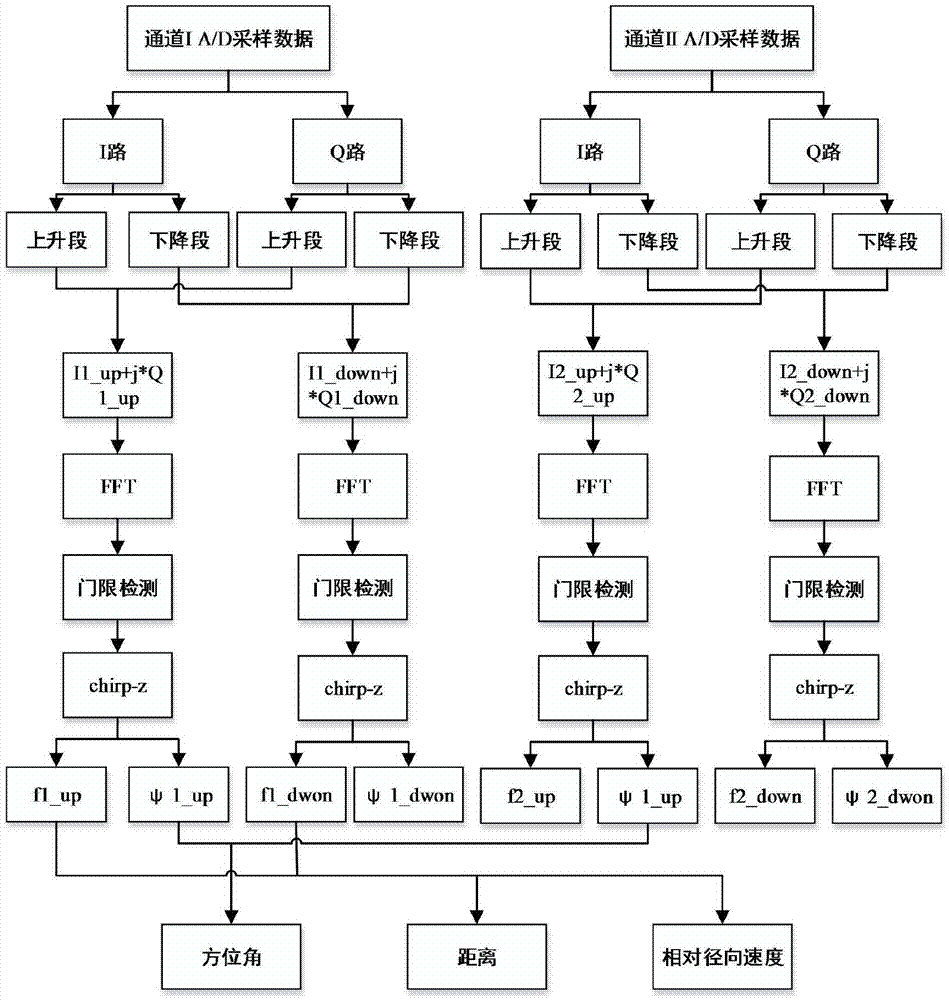

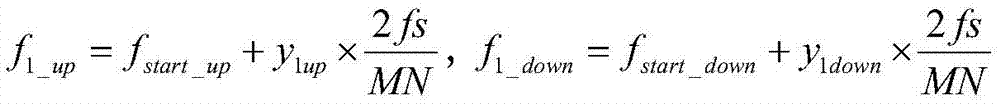

Automobile forward direction anticollision system signal processing method

ActiveCN105445714AMeet high precision requirementsRealize functionRadio wave reradiation/reflectionFast Fourier transformPeak value

The invention discloses an automobile forward direction anticollision system signal processing method. In each frequency sweep cycle, the following processes which are performed on upper sweep frequency IQ data and lower sweep frequency IQ data of each channel comprise steps of performing fast Fourier transform FFT on N points of IQ data, performing adaptive threshold detection on transformed plural module value data after transmission, outputting an over-threshold point position, taking an interval between two points as a transformation interval, wherein one point is positioned before the threshold point position and the other one is positioned after the threshold point position, performing chirp-z transformation on M points, performing peak value searching on the data after chirp-z transformation, outputting a peak value point position, calculating a difference frequency and a phase according to the peak value point, outputting an object distance, relative radial speed and an azimuth according to the difference frequency and the phase output distance. The invention enables the system to respond fast through processing and optimizing the signal, is good in practicability and faster.

Owner:DALIAN ROILAND SCI & TECH CO LTD

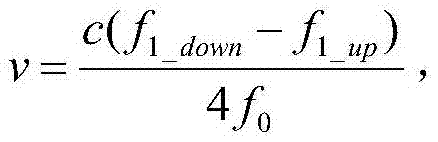

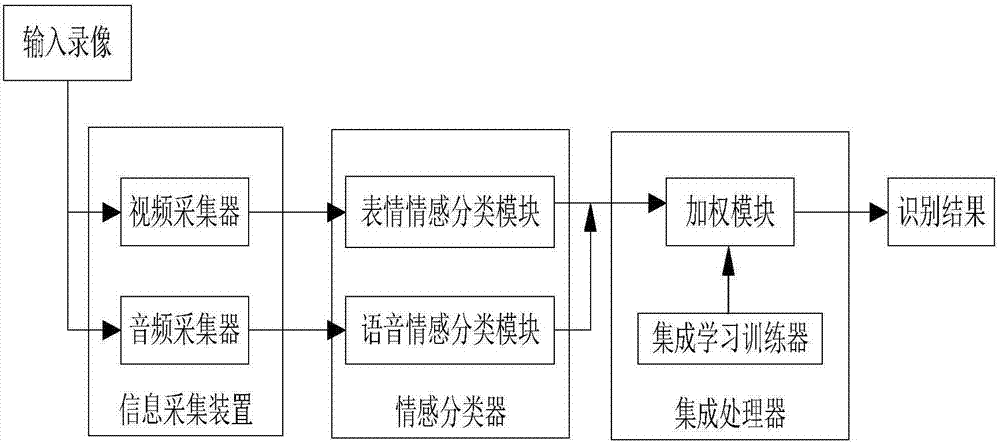

Overall emotion recognition method combining image and speech

PendingCN107256392AAdaptableImprove noise immunitySpeech analysisAcquiring/recognising facial featuresEmotion identificationEmotion classification

The present invention discloses an overall emotion recognition method and system combining an image and speech. The process of recognition comprises: after acquiring a corresponding speech and video signal from an input video, an information acquisition apparatus transmits the corresponding speech and video signal to corresponding emotion classification modules respectively, and after classification, an integrated learning trainer allocates weights, and after weighting, a recognition result is output to complete a recognition process. The system comprises an information acquisition apparatus, an emotion classifier and an integrated processor. The information acquisition apparatus comprises a video acquisition device and an audio acquisition device; the emotion classifier comprises an expression emotion classification module for performing emotion classification on acquired video information and a speech emotion classification module for performing emotion classification on acquired audio information; and the integrated processor comprises a weighting module and an integrated learning trainer. The method and system provided by the present invention have the advantages of higher emotion classification reliability, flexible adjustment on confidence parameters and high precision; and through bi-directional recognition of expression and speech, the human emotion recognition process is simulated to a large extent.

Owner:NANJING UNIV OF POSTS & TELECOMM

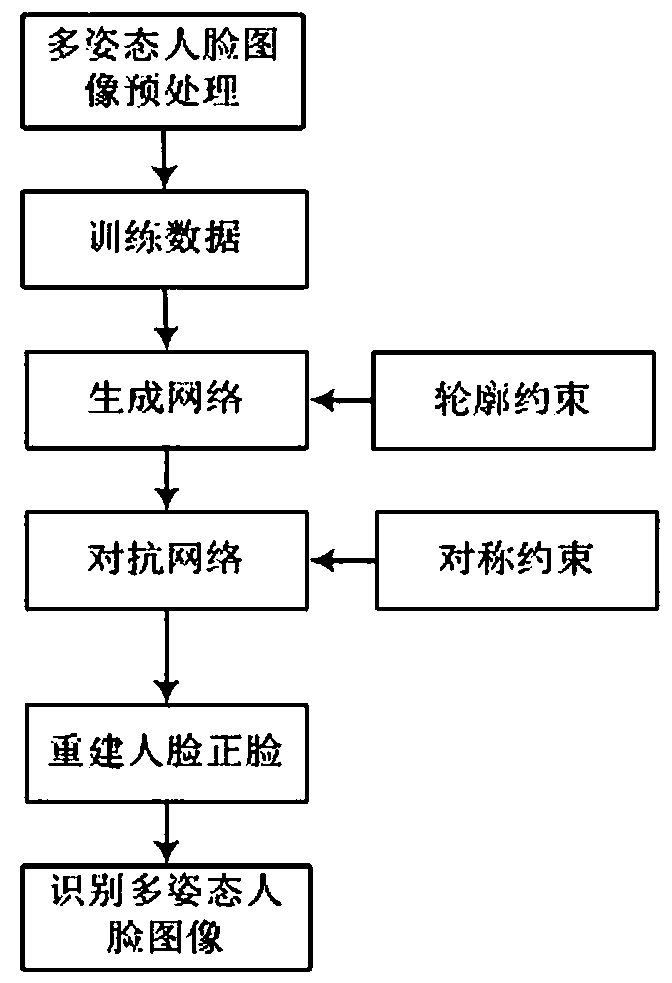

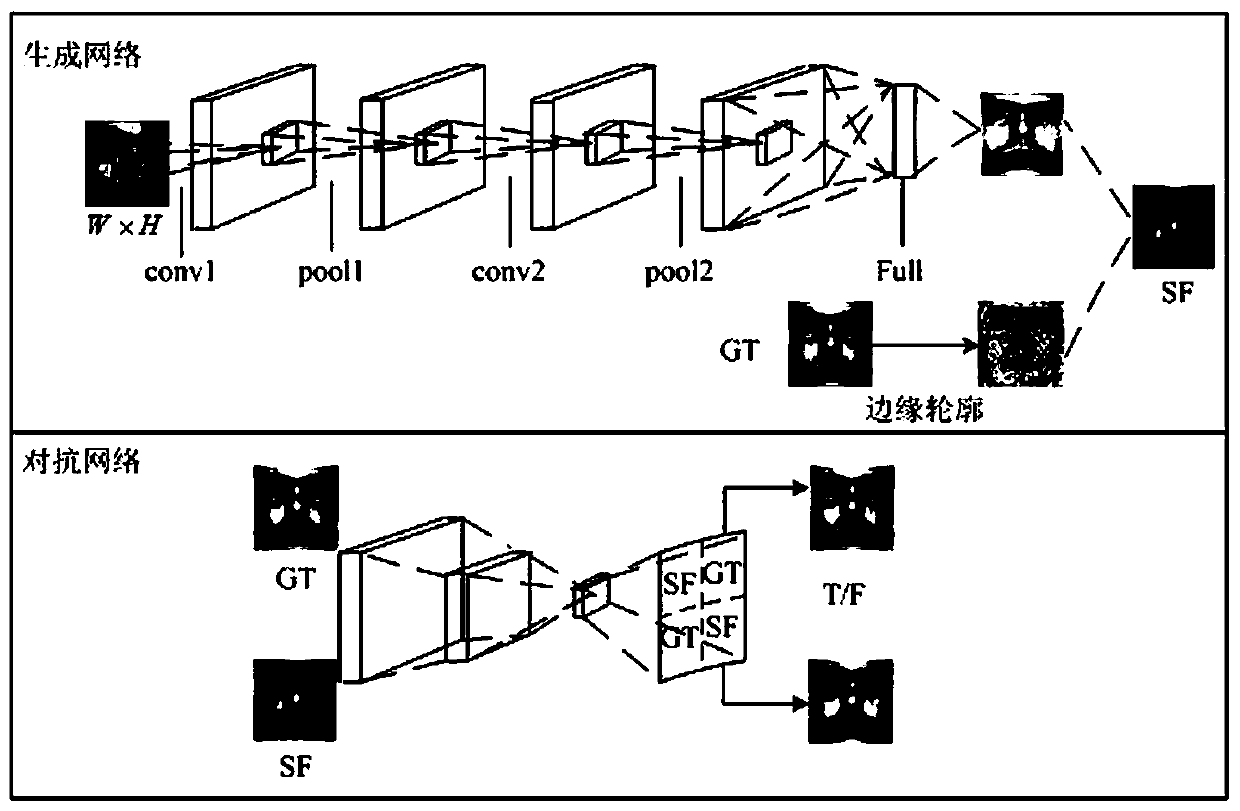

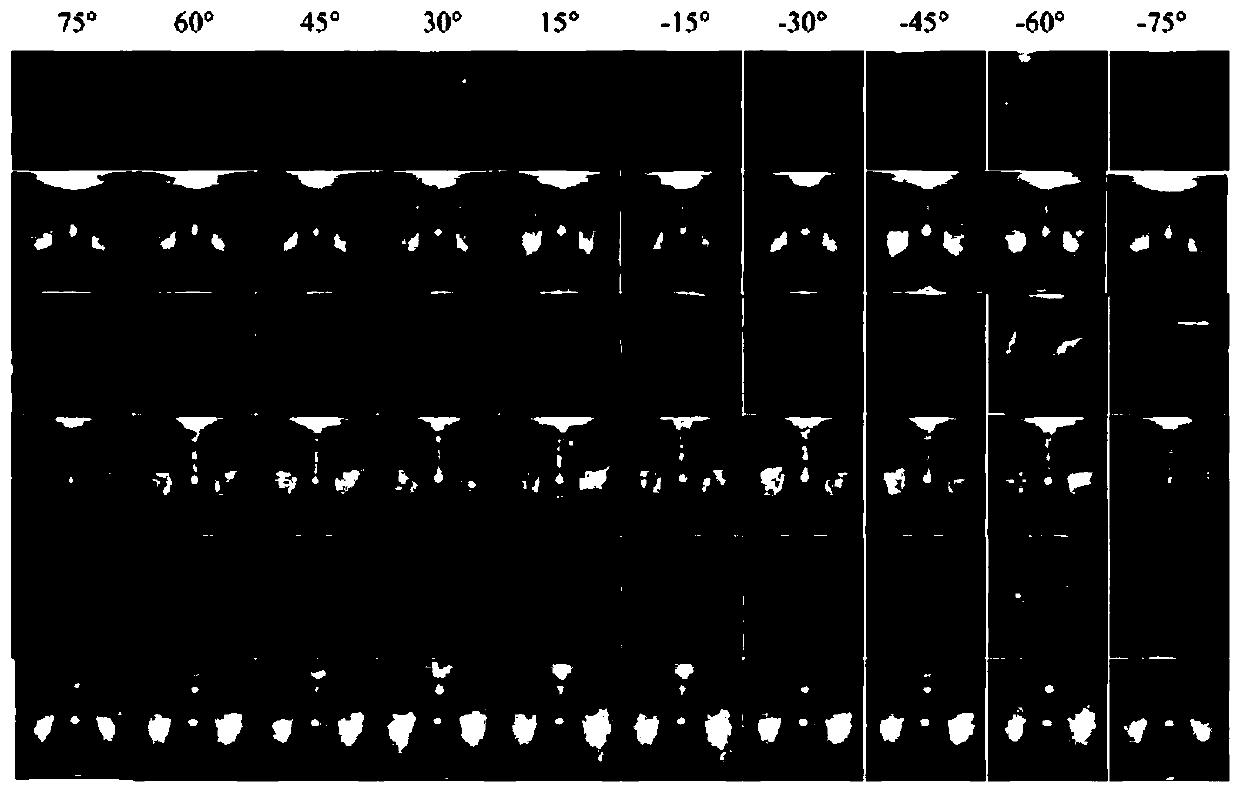

Contour symmetry constraint generative adversarial network-based multi-pose face recognition method

ActiveCN108334816AMeet high precision requirementsSolve the influence of attitude angle deflectionCharacter and pattern recognitionComputer visionGenerative adversarial network

The invention discloses a contour symmetry constraint generative adversarial network-based multi-pose face recognition method. The method is characterized by comprising the following steps of 1) performing data preprocessing; 2) creating a contour constraint generative network; 3) creating a symmetry constraint adversarial network; 4) training and balancing the networks; and 5) performing reconstruction and recognition. According to the method, the pose angle deflection influence of a face image can be effectively eliminated; a characteristic that a face is robuster under multiple poses is extracted; especially global quality and local details are mutually constrained under large-angle pose reconstruction; contour characteristic information of the front face is kept; and the high-precisiondemand on the multi-pose face recognition in actual application can be met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Production technology of high-precision deep groove ball bearing

InactiveCN104162766AEliminate internal stressHigh hardnessFurnace typesHeat treatment furnacesBall bearingEngineering

The invention provides a production technology of a high-precision deep groove ball bearing. The production technology includes the steps of (1) ferrule (inner ring and outer ring) machining, (2) rolling body machining, (3) cage machining and (4) assembling. The ferrule (inner ring and outer ring) machining procedure includes the steps of blanking, annealing treatment on blanks, turning, thermal treatment and grinding, wherein in the turning step, the blanks are basically machined and formed. The rolling body machining procedure includes the steps that forging forming is conducted on 9Cr18Mo stainless steel blanks; carburizing treatment is conducted; grinding is conducted; polishing and inspection are conducted. The cage machining procedure includes the steps of workpiece turning, drilling, lubrication hole machining, surface treatment, washing and rust prevention. The assembling procedure includes the steps that a heated bearing outer ring and a cage are placed on assembling equipment, and a rolling body is pressed into a pocket in the cage; a heated bearing inner ring is placed at the corresponding position of the assembly equipment, and the inner ring is pressed slightly to enable the rolling body to be pressed into a groove of the outer ring; the outer ring is taken down, and assembly of the whole bearing is completed. Through the production technology, the precision of the deep groove ball bearing is improved.

Owner:ANQING YINTAI BEARING

Pressure casting aluminium aluminium alloy for cylinder of minicar engine

InactiveCN1483847AGood casting process performanceHigh leak inspection pass rateChemical compositionPressure casting

The present invention relates to a mnicar engine cylinder pressure casting aluminium alloy, and its chemical component composition includes (wt%) Cu 1.5-3.0%, Si 10.0-12.0%, Mg 0.15-0.35%, the rest is al and the other is impurity. Said alloy tensile strength Qb is greater than or equal to 300MP. Said alloy has enough strength and rigidity and good size stability. Said alloy can meet the requirements for minicar engine cylinder body high-pressure casting process and mechanical working process.

Owner:重庆长安汽车有限责任公司

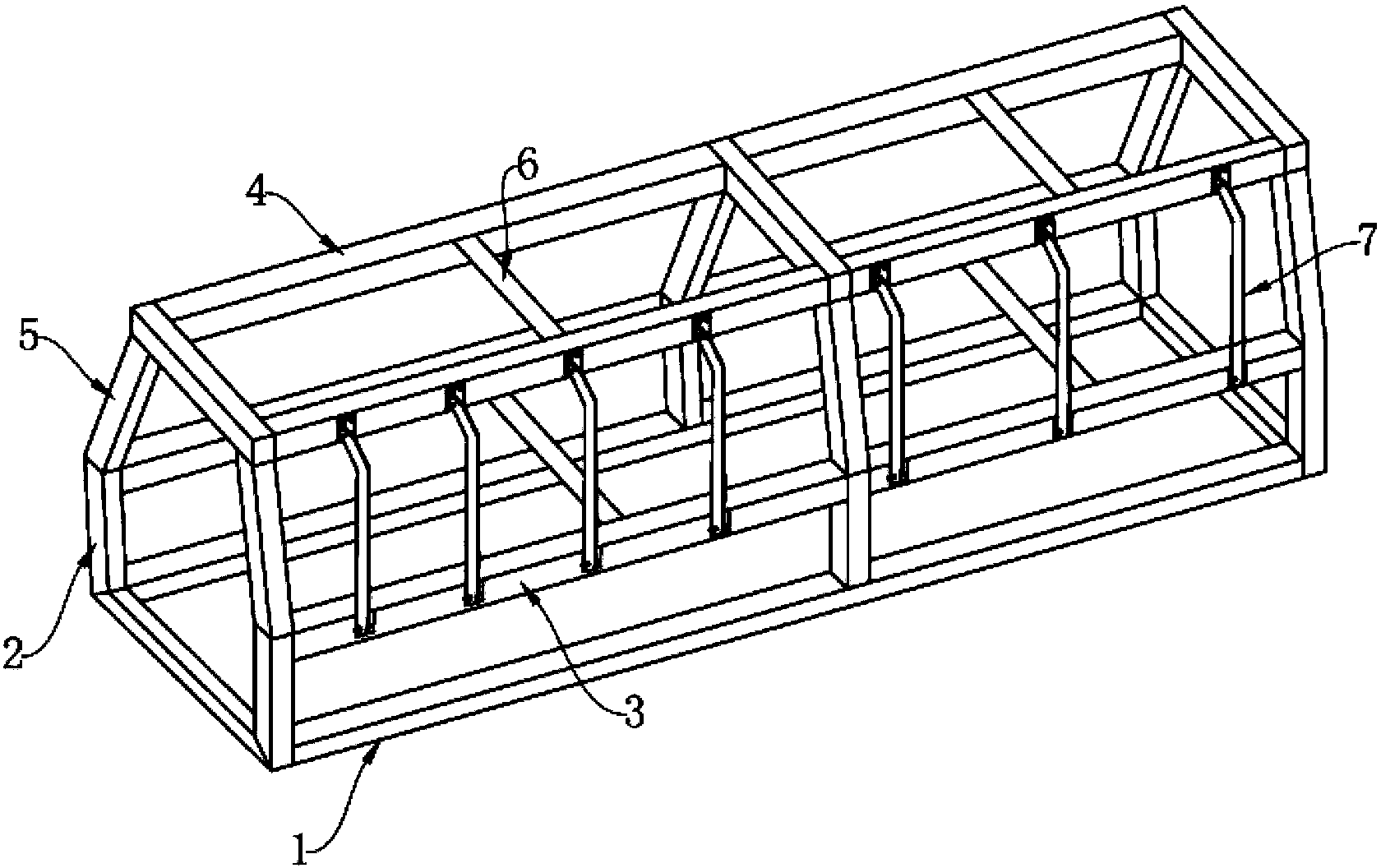

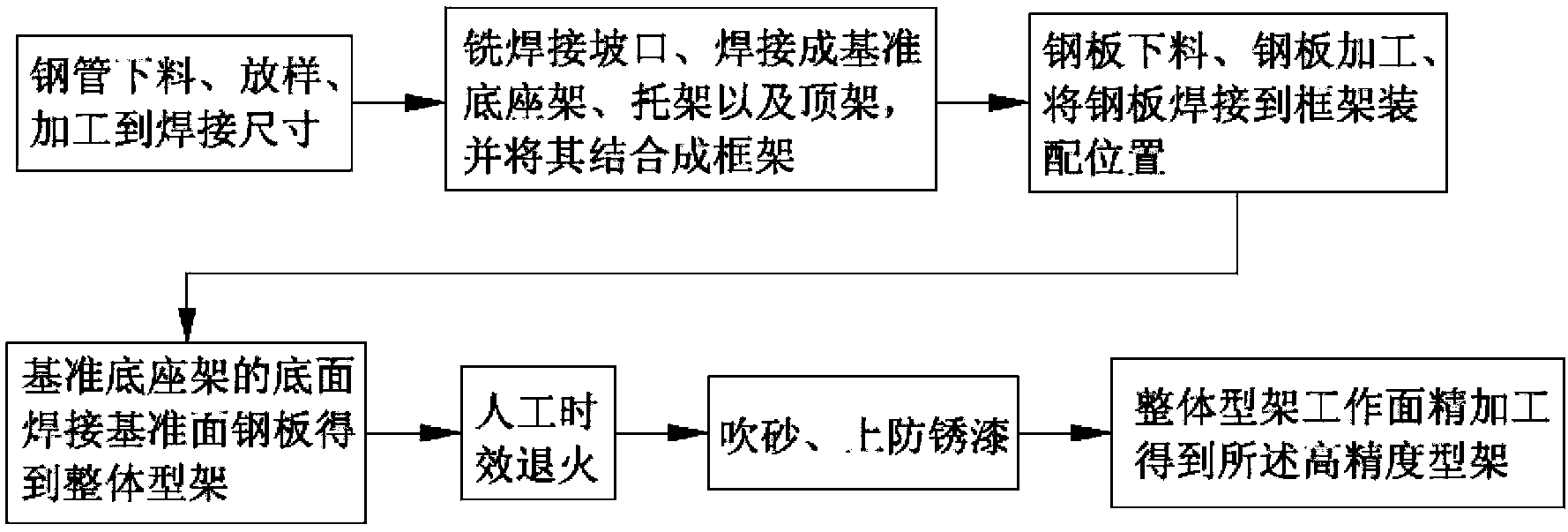

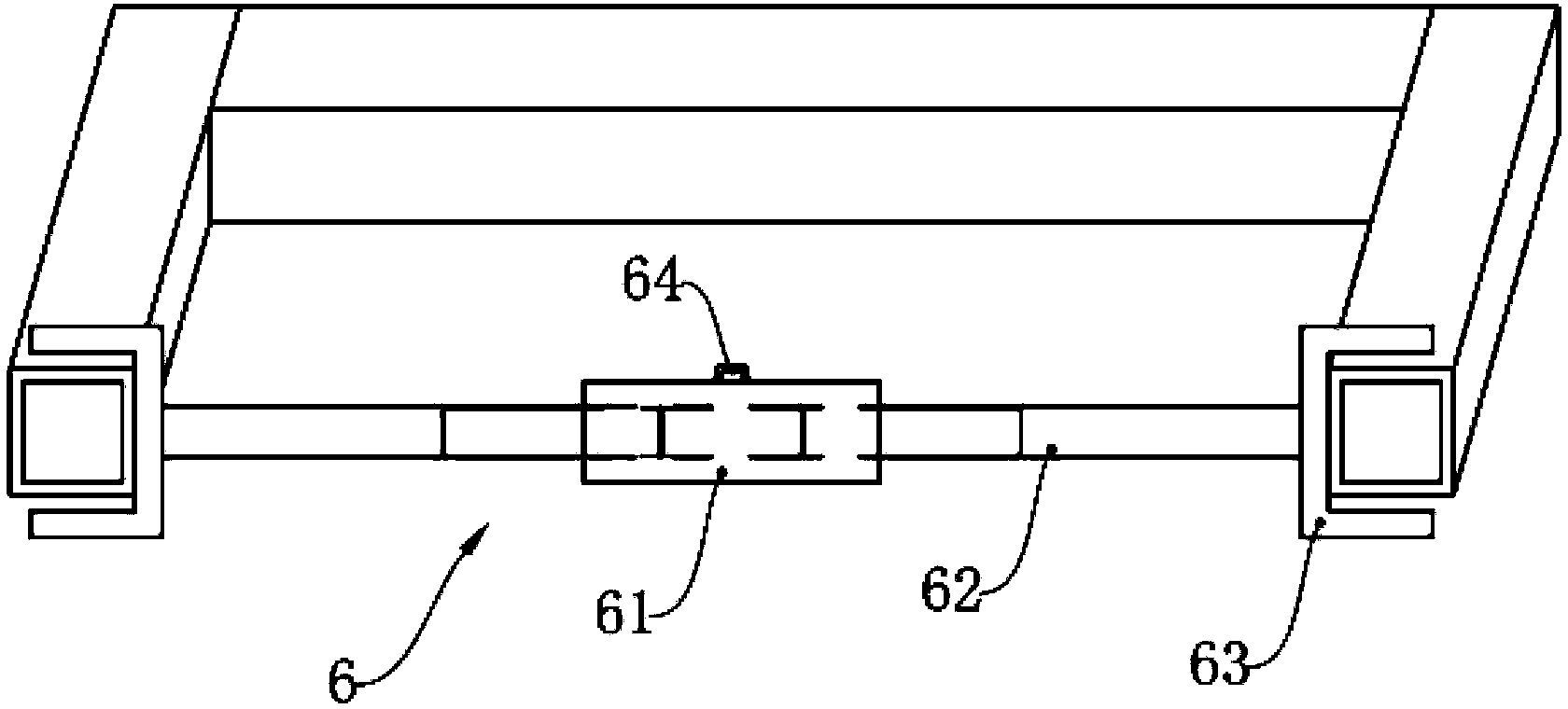

High accuracy frame for aircraft assembling tool and machining method thereof

ActiveCN103770046AGood interchangeabilityHigh precisionWork holdersAircraft assemblyEngineeringMachining

A high accuracy frame for an aircraft assembling tool comprises a benchmark base frame which is arranged at the bottom of the integral frame, a supporting frame and a top frame; the benchmark base frame is a rectangular frame which is formed by two long rods and two short rods; a plurality of vertical bearing rods are oppositely arranged on the two long rods; the supporting frame is provided with two supporting rods; the two supporting rods which are fixed at upper ends of the vertical bearing rods are parallel to the two long rods; the top frame is a rectangular frame; the length of two short rods of the rectangular frame is less than that of the two short rods of the benchmark base frame; the length of two long rods is identical to that of the two long rods of the benchmark base frame; a projection of the top frame is in the center of the benchmark base frame; the plurality of inclined bearing rods are arranged between the top frame and the supporting frame. The invention also provides a high accuracy frame machining method. According to the high accuracy frame for the aircraft assembling tool, the frame achieves a hard connection requirement, no filler is arranged between gaps, and stability and non-deformation is guaranteed.

Owner:CHANGSHA TIANYING MACHINERY MFG

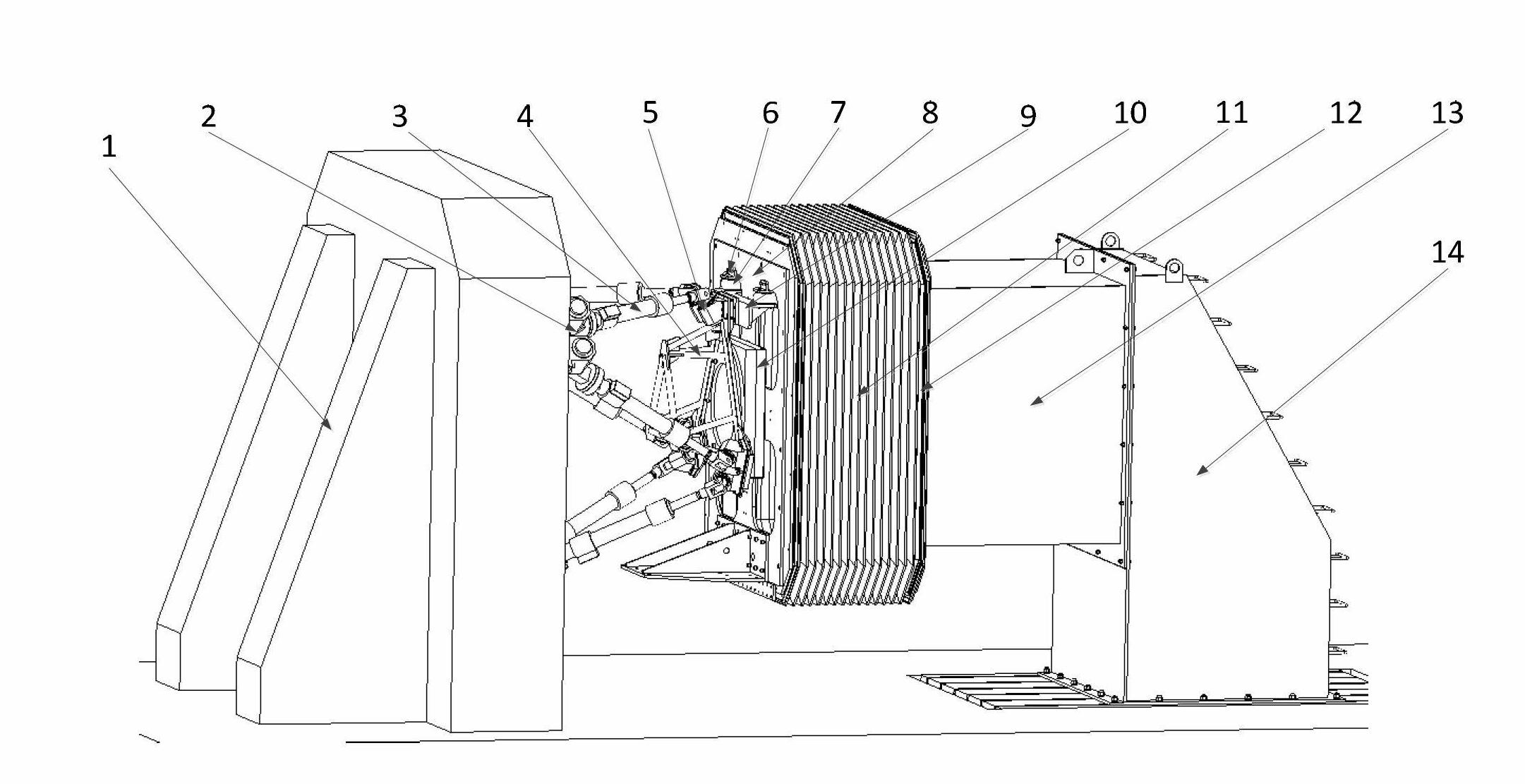

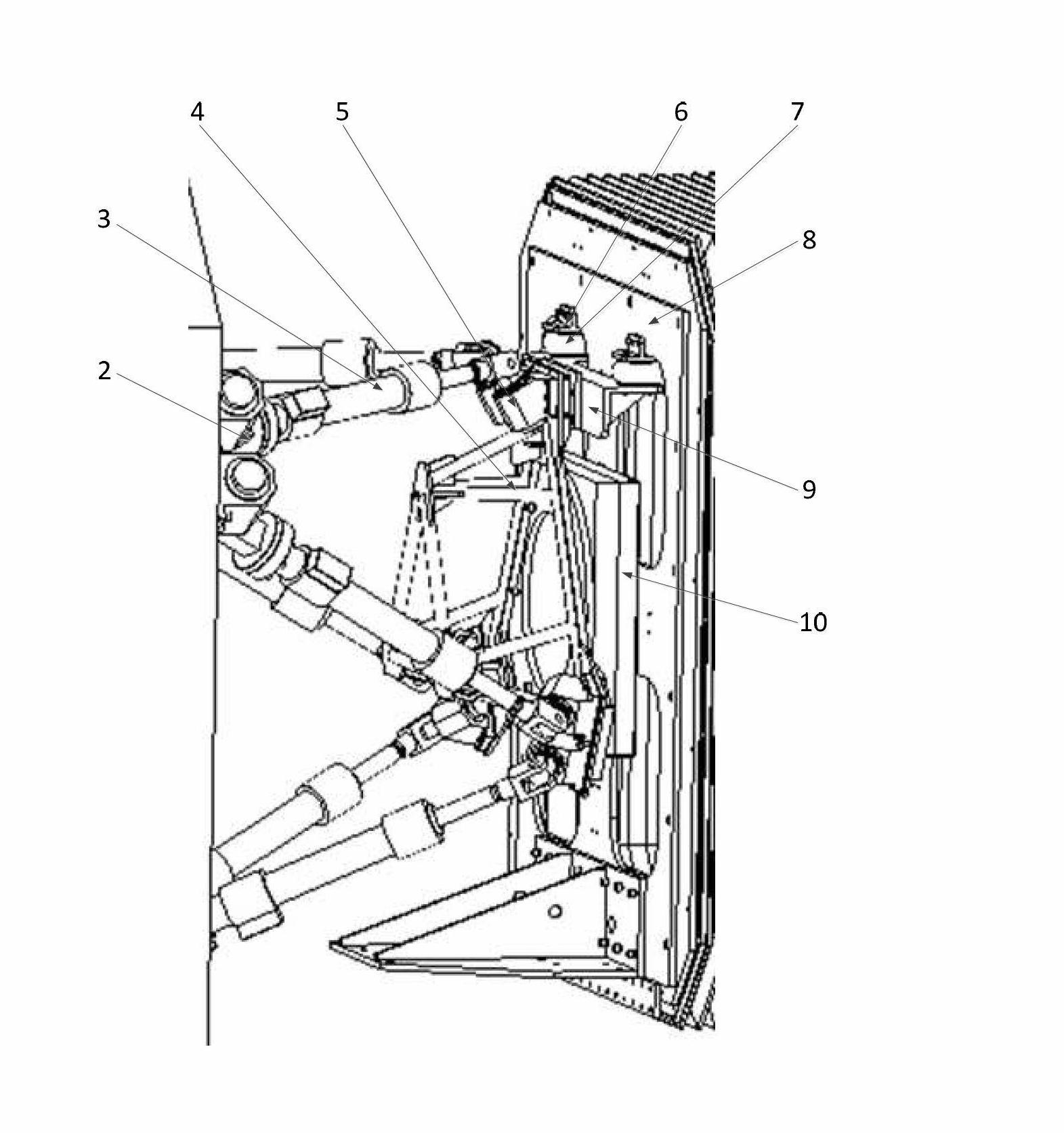

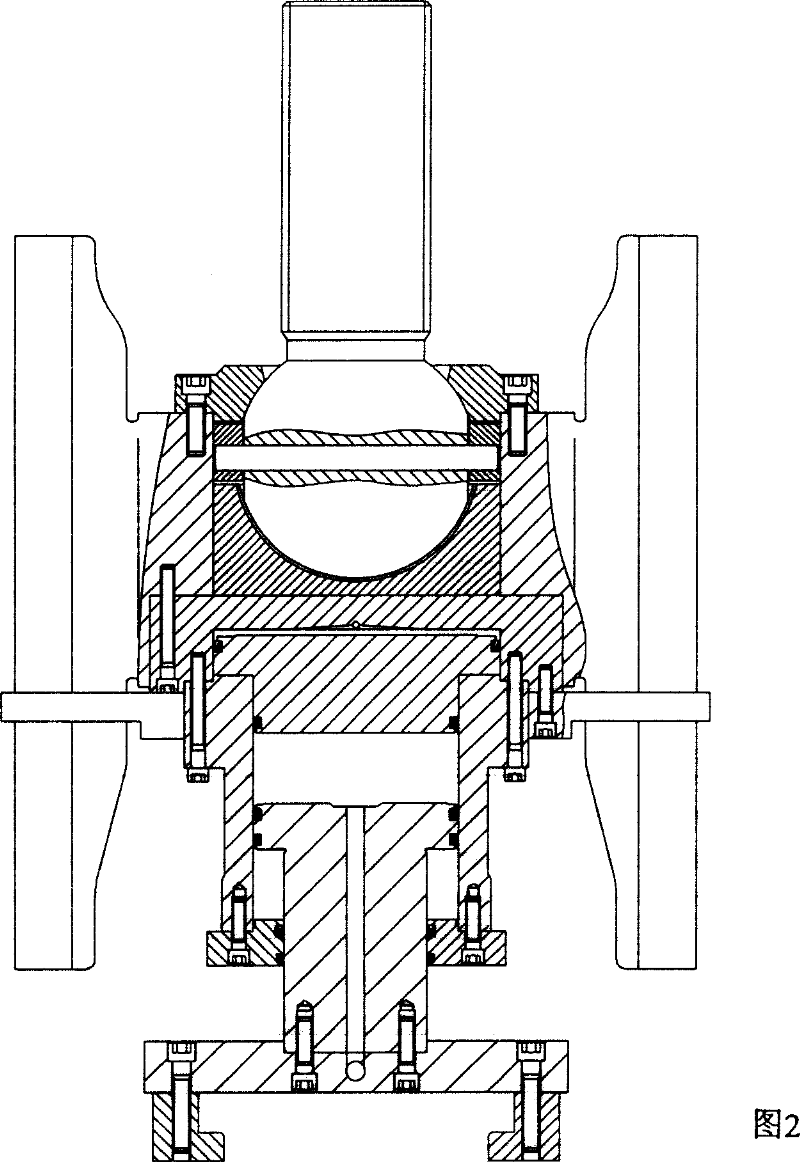

Loading device based on six-degree-of-freedom parallel mechanisms

InactiveCN102680257AHigh measurement accuracyEasy to put inRailway vehicle testingAir springEngineering

The invention provides a loading device based on six-degree-of-freedom parallel mechanisms. The device is mounted on a base and comprises a front counter-force base, a six-degree-of-freedom parallel mechanism, a gravity balancing mechanism, a force measuring mechanism and a back counter-force base. The six-degree-of-freedom parallel mechanism comprises a lower hinge support connected with the front counter-force base, a hydraulic actuating mechanism connected with the lower hinge support and a moving platform connected with the hydraulic actuating mechanism; the gravity balancing mechanism comprises an air spring connected with the moving platform and a front end transition board connected with the air spring through a connecting support; the force measuring mechanism comprises a sensor on the moving platform; and the back counter-force base is in an adjustable connection with the base. The loading device has the advantages that parallel mechanism kinematic positive solution is used for measuring the output pose, investment for measurement equipment is simplified, measurement accuracy of the output pose is effectively improved; force measurement accuracy is effectively improved, and high-accuracy requirement for force measurement is met; and six-degree-of-freedom motion simulation and force loading test of parts can be performed.

Owner:天津福云天翼科技有限公司

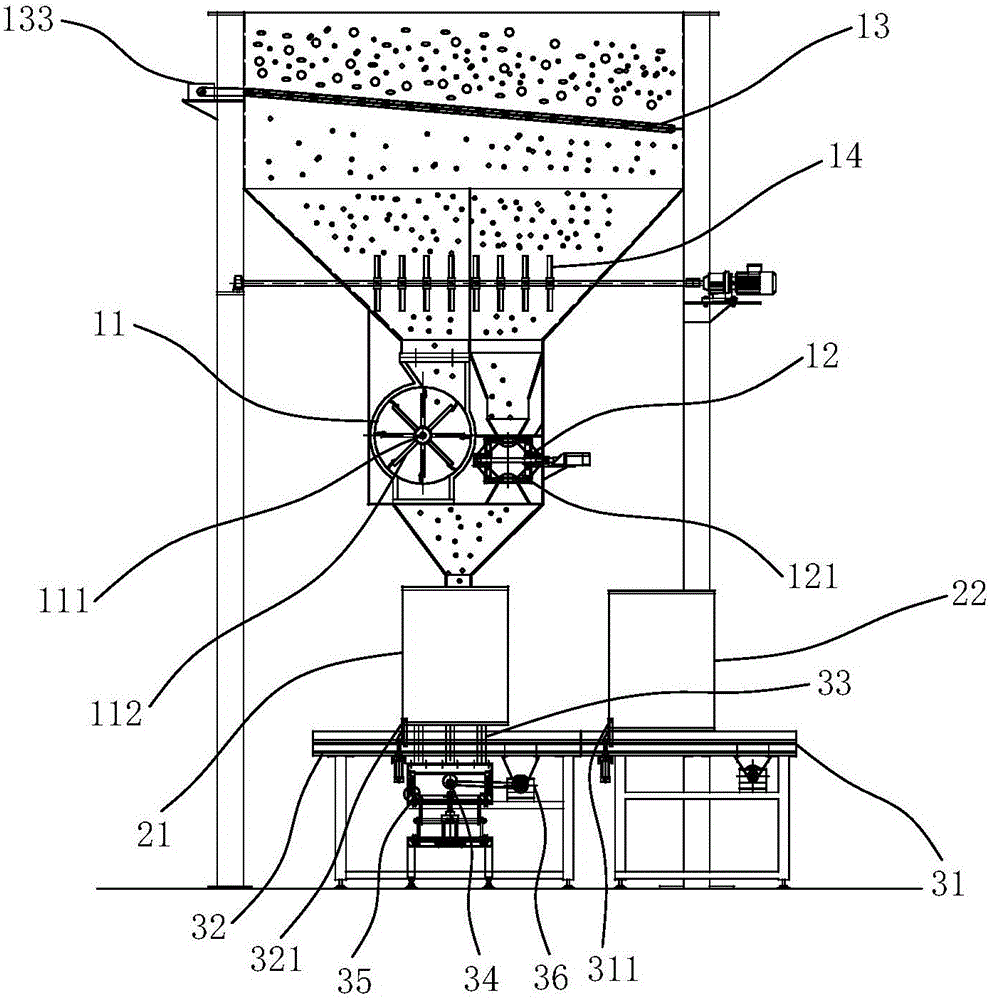

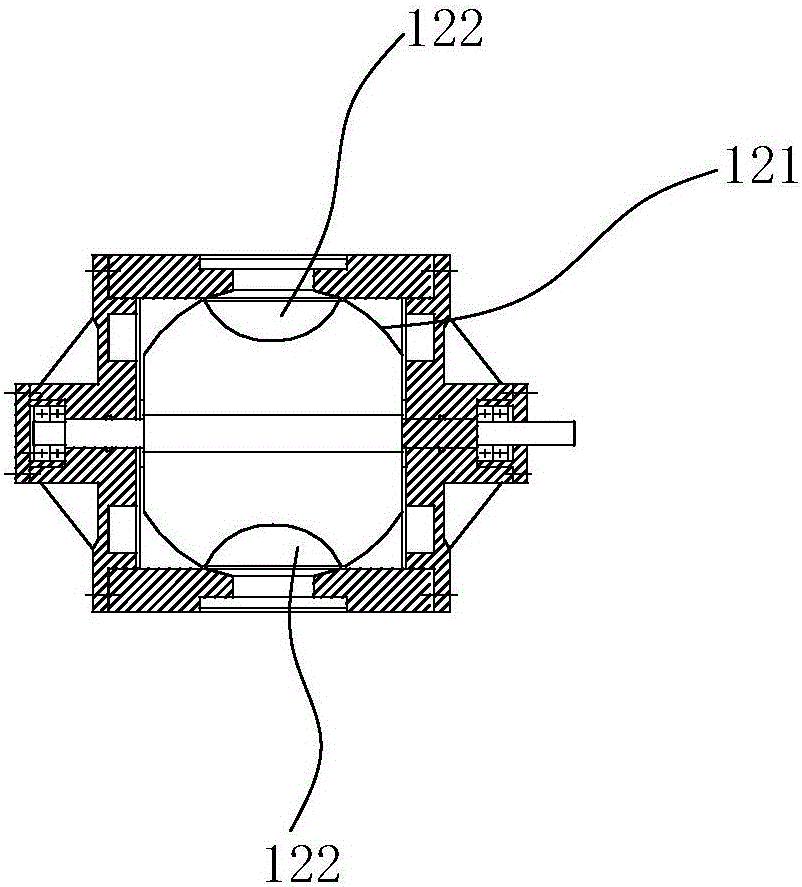

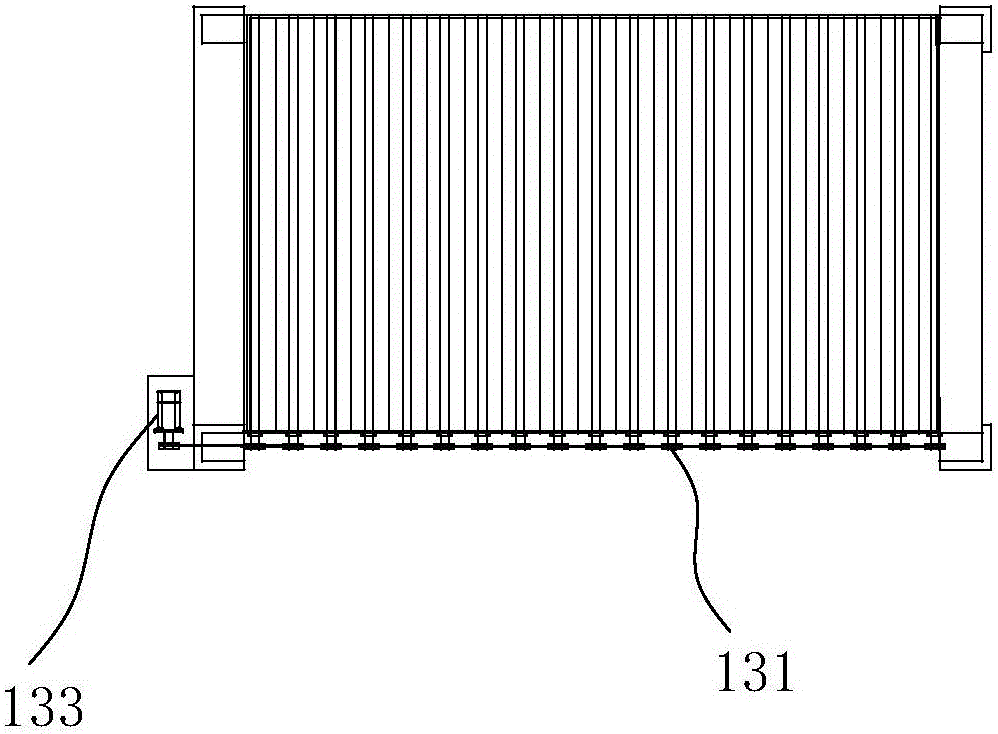

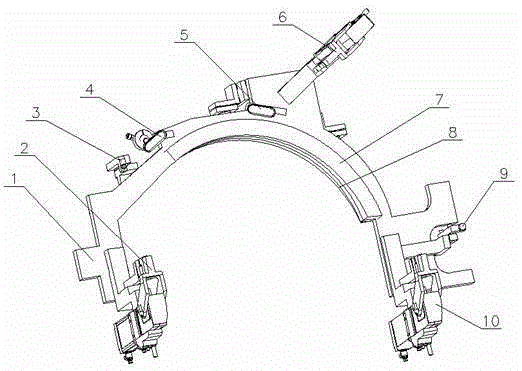

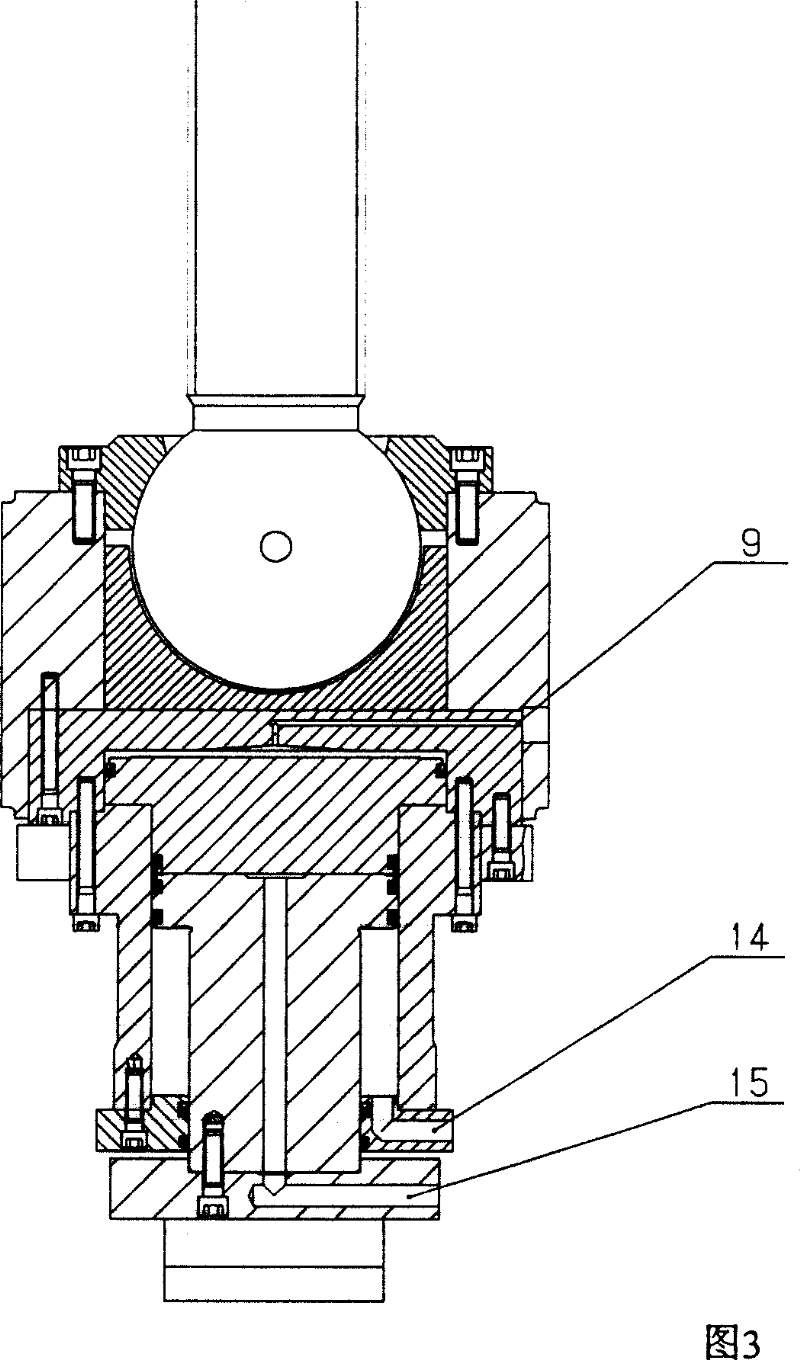

Weighing system having high precision quantification process

ActiveCN106052815AMeet high precision requirementsAccuracy controllableWeighing apparatus with automatic feed/dischargeLoading/unloadingControl systemEngineering

The invention relates to a weighing system having high precision quantification process. The system includes a first feeding mechanism which controls feeding to an initially set weighing value, and a second feeding mechanism which controls feeding to an object set weighing value. The second feeding mechanism includes a spherical spool part which is arranged inside a second feeding channel and conducts radial self-rotation around the second feeding channel. The spherical spool part is provided with a recessed part for receiving a material on the spherical surface most distant from a self-rotating shaft. The weight of the material received in the recessed part is smaller than the error range of the set weighing value. According to the invention, the system realizes fine feeding by rotating the spherical spool part, and when the object set weighing value is arrived, the spherical spool part immediately stops the rotation, and the error of the set weighing value is smaller than the weight received by the recessed part, and the weighing value that is within the set error range is realized. The process weighing control system enables the precision of the weighing process to be easy to control and has a precision which reaches the requirement for high precision of national industries.

Owner:HEFEI GENERAL MACHINERY RES INST

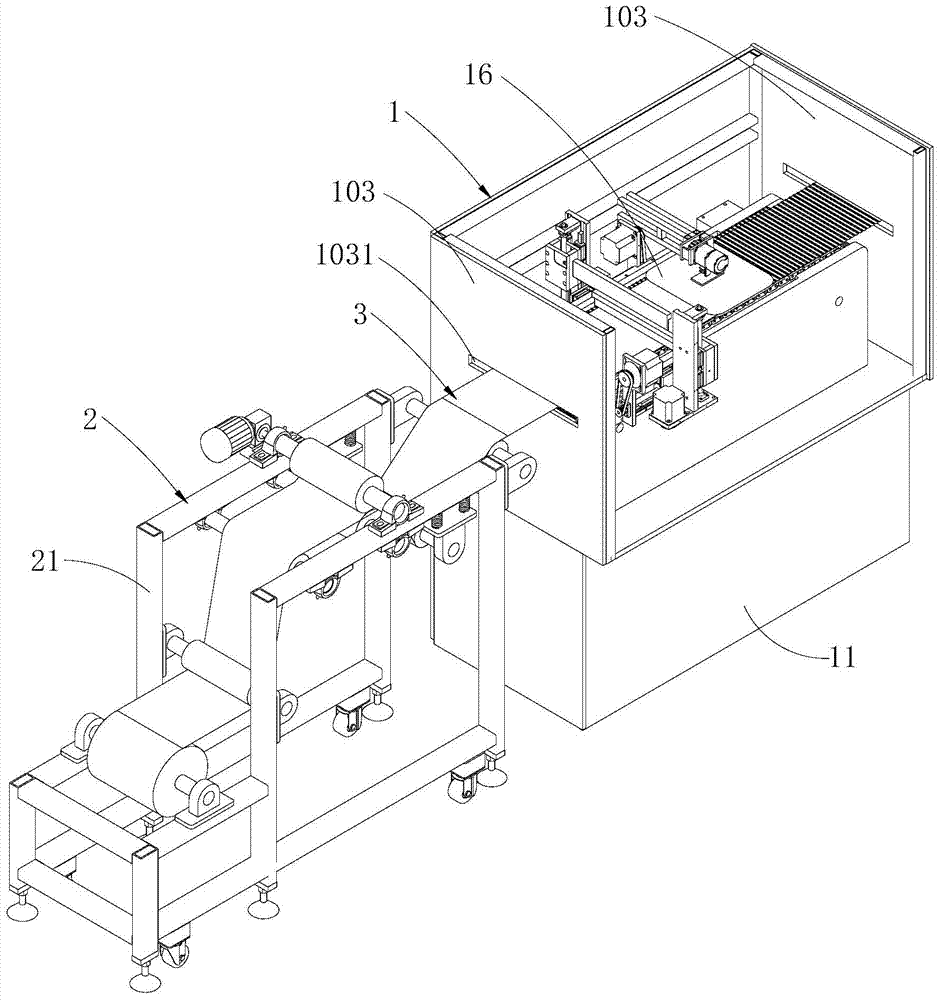

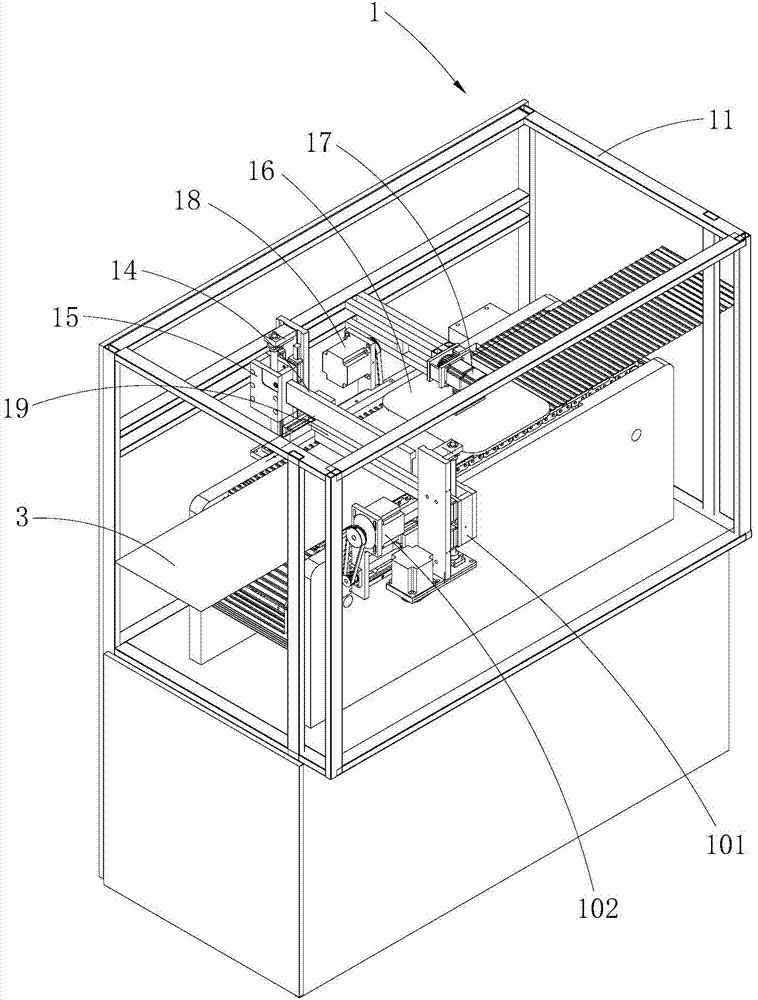

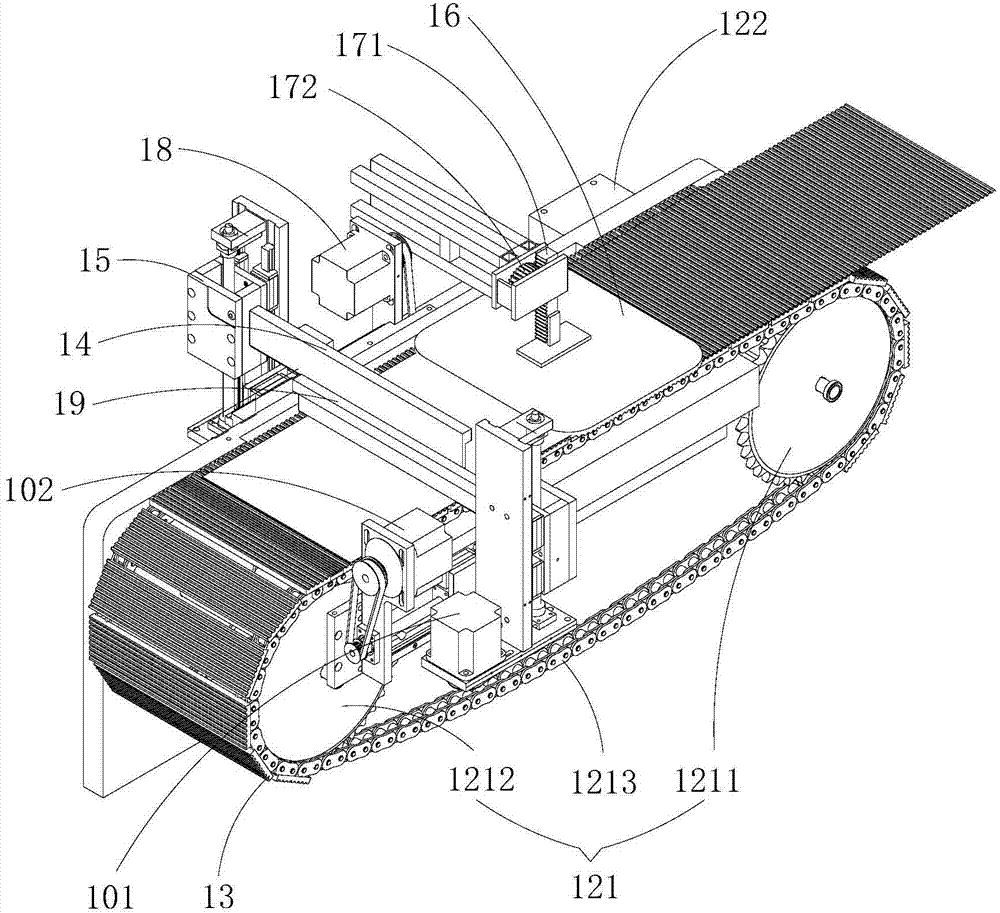

Stamping device of corrugated foils and production device of corrugated foils

ActiveCN103537539AStamping is effectiveEffective realization of stamping formingShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention is applied to the field of production equipment of corrugated foils and discloses a stamping device of corrugated foils. The stamping device comprises a first frame, a conveying mechanism, a forming die, a stamping head, a first lifting component, a pressure-holding shaping plate, and a second lifting component, wherein the conveying mechanism having a conveying component is mounted on the first frame, the forming die having a forming recess is mounted on the conveying component and capable of conveying and moving foils, the stamping head disposed above the forming die is used for pressing one foil into the forming recess to shape the foil, the first lifting component is used for driving the stamping head to ascend and descend, the pressure-holding shaping plate disposed above the forming die is used for pressure-held shaping of the shaped foil, and the second lifting component is used for driving the pressure-holding shaping plate to ascend and descend. A conveying direction of the pressure-holding shaping plate is behind the stamping head. The invention further discloses a production device of the corrugated foils. The production device comprises a shaping device of the corrugated foils and a conveying device used for conveying the foils to the stamping die. The stamping device and the production device have the advantages that production efficiency is high and shaping quality of the corrugated foils is good.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

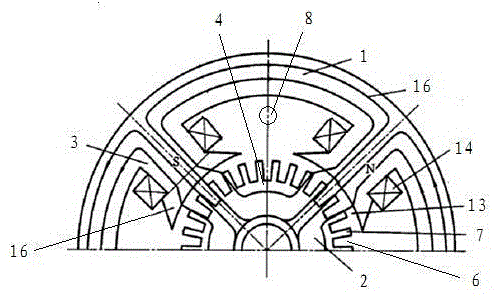

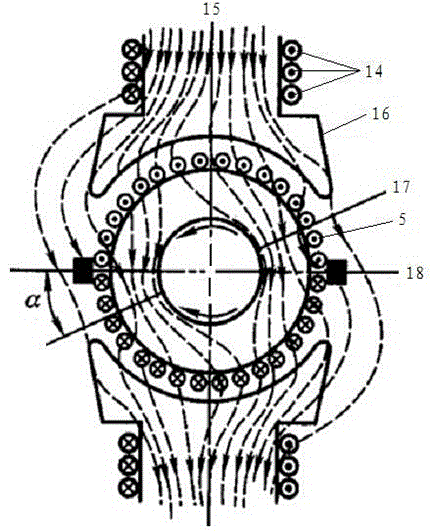

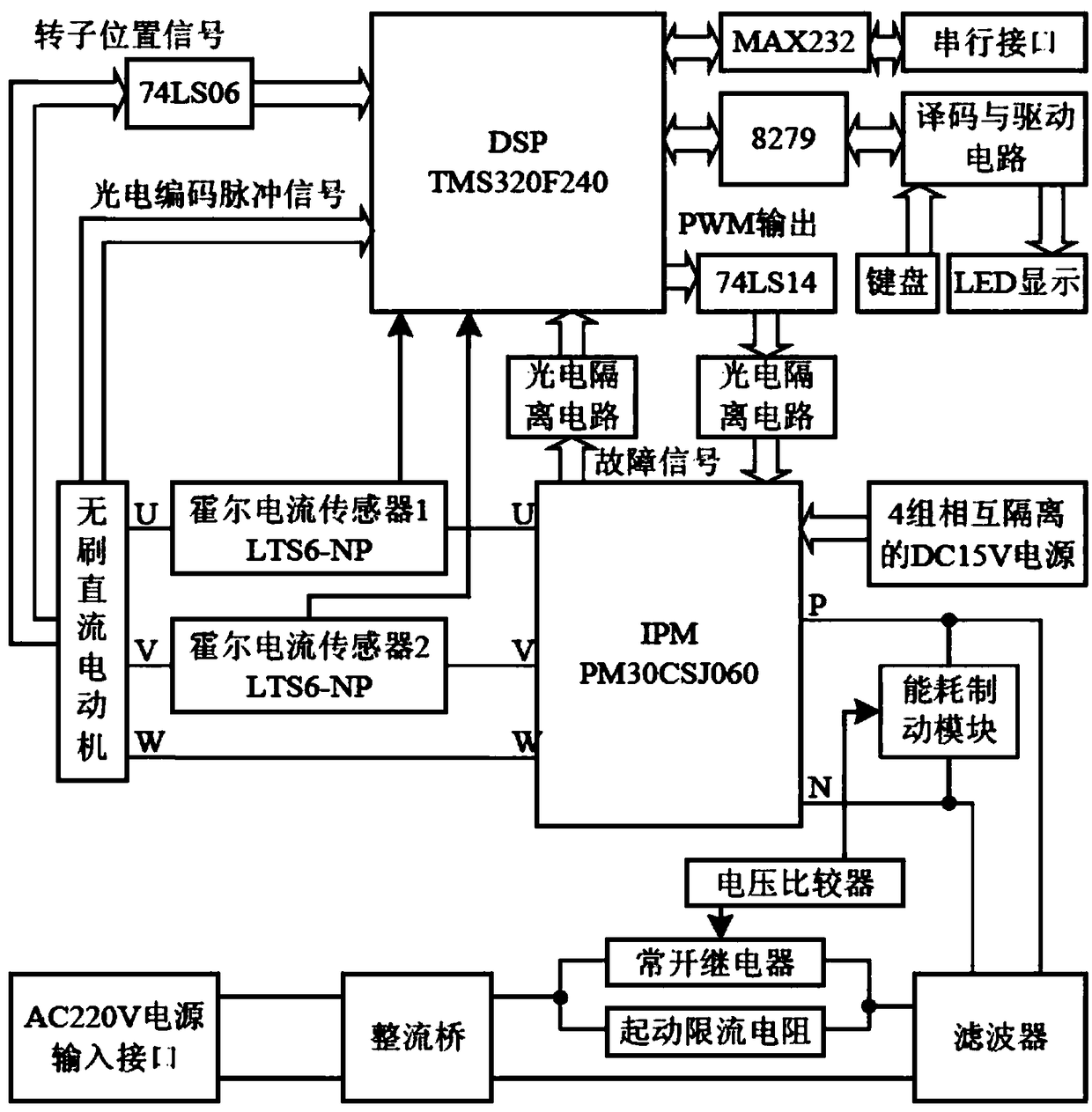

Motor with residual magnetization detection revolution/angle sensor and method for measuring revolution/angle thereof

ActiveCN104319947AReduce volumeLow costUsing electrical meansLinear/angular speed measurementElectric machineHall element

The invention discloses a motor with a residual magnetization detection revolution / angle sensor and a method for measuring revolution / angle thereof. In the motor, the residual magnetization detection revolution / angle sensor is embedded between one pair of adjacent electrical pole shoes, the motor is characterized in that the gap between the pole shoes is utilized, a small-size Hall element is also served as a magnetic flux sensor, besides, and the cycle rule variation characteristics of a residual magnetization flux curve and the corresponding numerical relationship among the angle, the revolution and the slotted tooth are also adopted, through calculation, the revolution or the angle can be precisely measured when the motor has the advantages of the small size and the low cost.

Owner:广东戈兰玛汽车系统有限公司

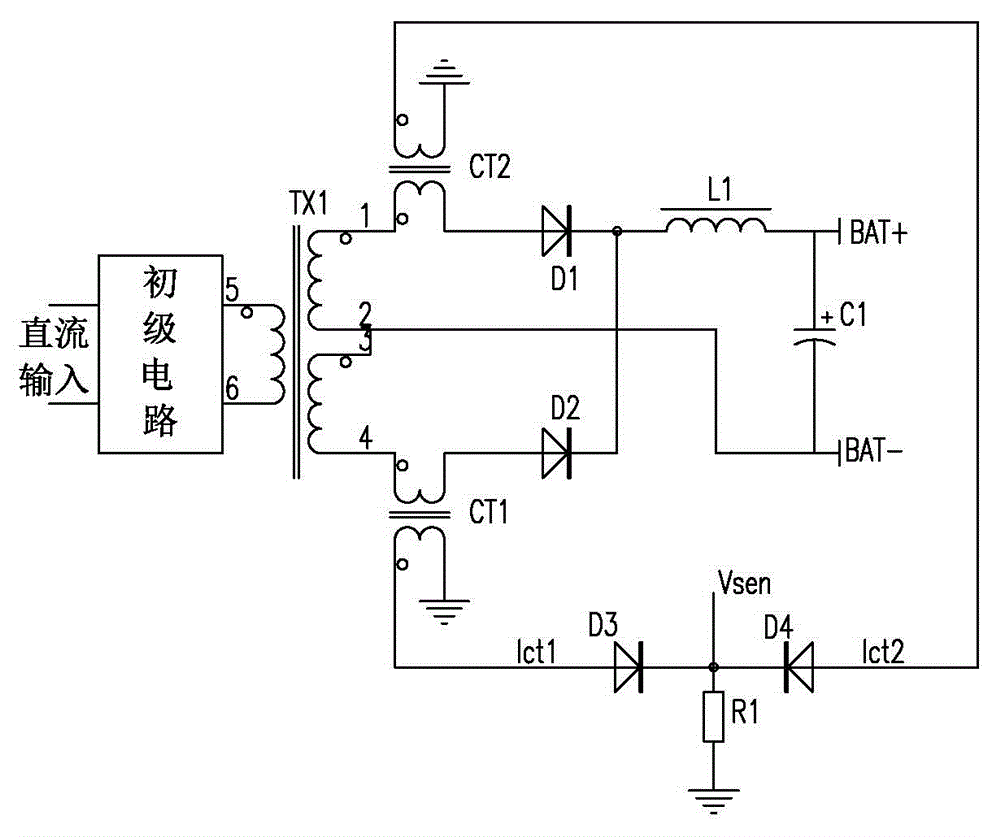

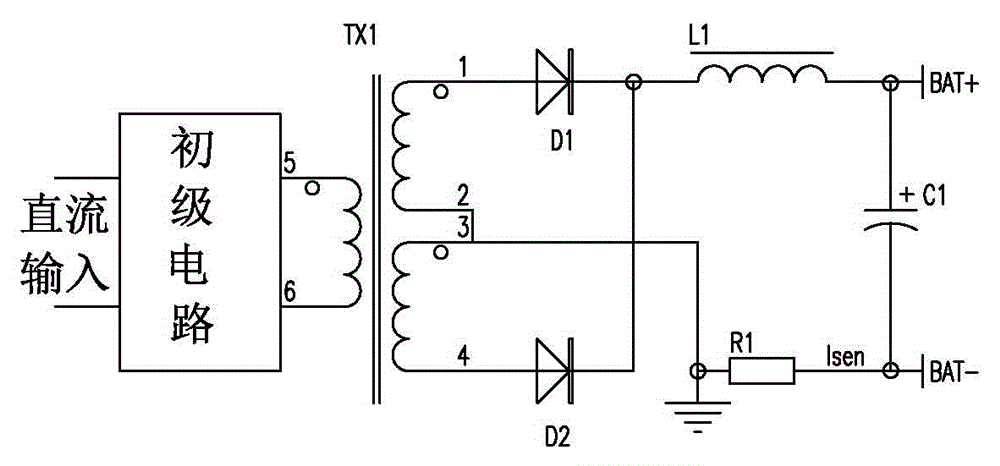

Current detection circuit of switch power supply and switch power supply

InactiveCN105137153ASimple designReduce lossCurrent/voltage measurementDc-dc conversionElectrical resistance and conductanceCharge current

The invention discloses a current detection circuit of a switch power supply and a switch power supply, relating to the current detection technology field. The current detection circuit of the switch power supply comprises a first current mutual inductor, a second current mutual inductor, a sampling resistor and a control system; the second current mutual inductor converts second current which is transmitted from the secondary of a transformer TX1 to an upper side diode to small current which is then supplied to a sampling resistor; the second current mutual inductor converts second current which is transmitted from the secondary of a transformer to an upper side diode to small current which is then supplied to the sampling resistor; and the control system obtain voltage on two ends of the sampling resistor which is converted to corresponding current. Through the clever choice of the current detection point, the current mutual inductor can be used to participate in current detection, the current mutual inductor can convert big current to the small current, and the small current can be supplied to the sampling resistor, which greatly reduce the loss of the sampling resistor, reduces the cost, and improves the precision and design difficulty. Besides, the switch power supply can realize the detection of the charging current, which can benefit the control of the charging current.

Owner:EAST GRP CO LTD

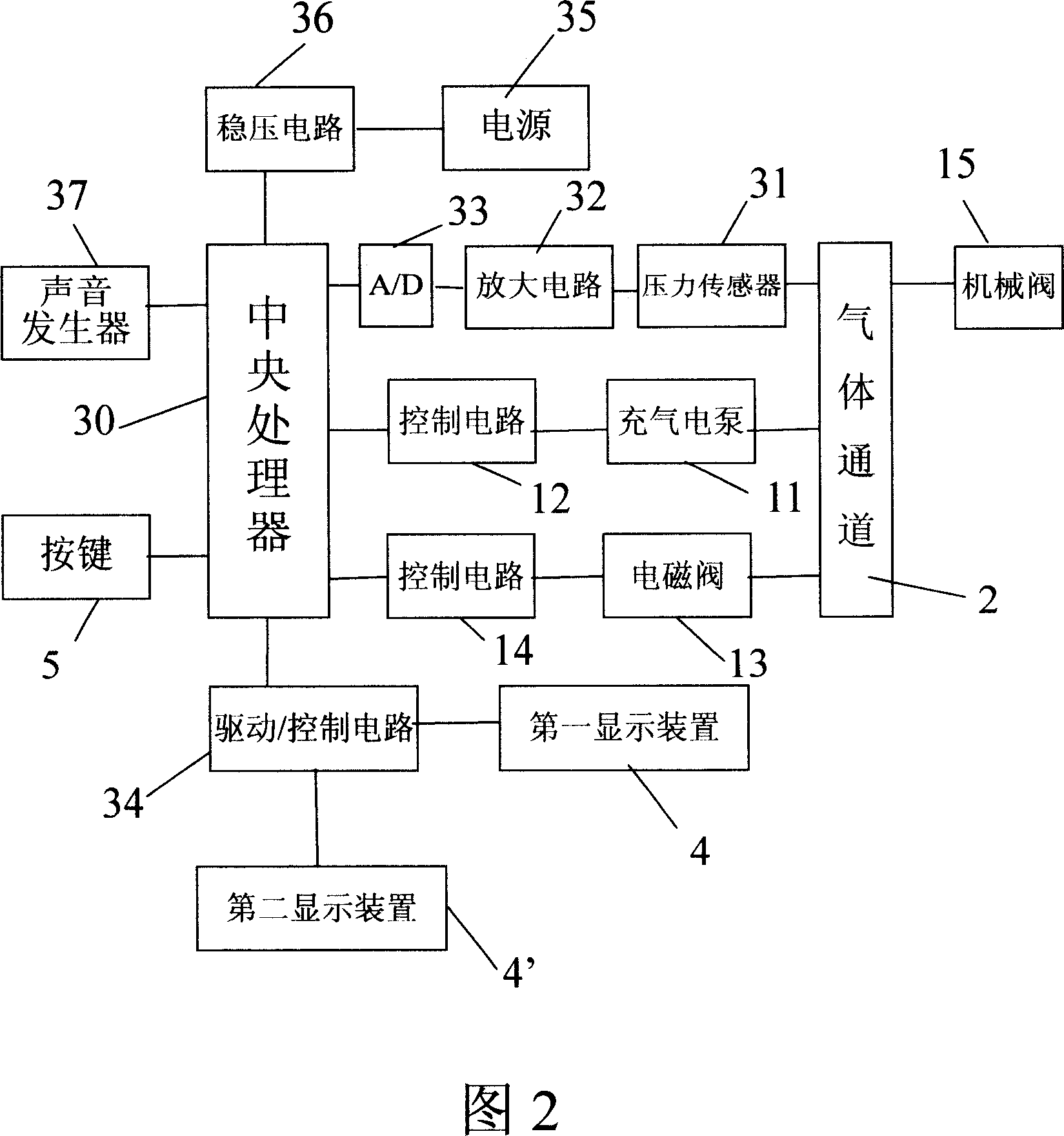

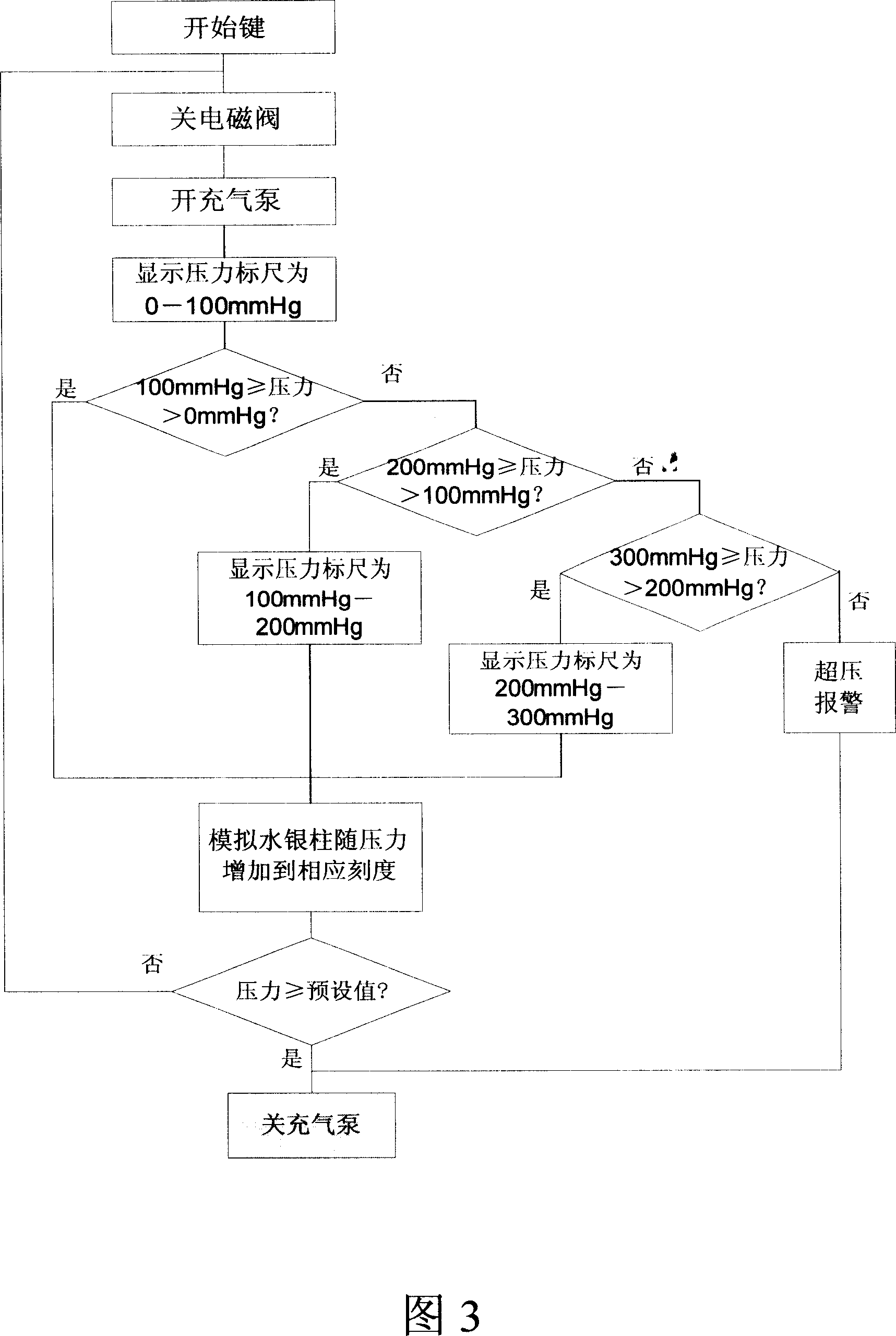

Electronic sphygmomanometer

ActiveCN1923135ALow costMeet high precision requirementsEvaluation of blood vesselsAngiographyOscillometryMeasurement device

The invention relates to an electric blood pressure meter, which comprises automatic aerator, pressure device, measurer, controller, first and second displays. wherein, the aerator can aerates the pressure device; the sensor senses the pressure signal of air bubble to obtain pressure value, to display said value on the analogue mercury ruler of first display; said ruler is divided into several segments, to display the section at said pressure value at least, and indicate the analogue mercury post to relative ruler scale, to be detected by doctor to obtain blood pressure value; and the invention can use oscillography to automatically calculate out the measure result to display it on second display as numbers; therefore, the electric blood pressure meter can avoid display whole mercury ruler, but display segmented, to reduce the cost and avoid hand-operated aerating, to simplify the operation, and uses the automatic discharge valve to uniformly discharge air to improve the accuracy.

Owner:潘卫江 +1

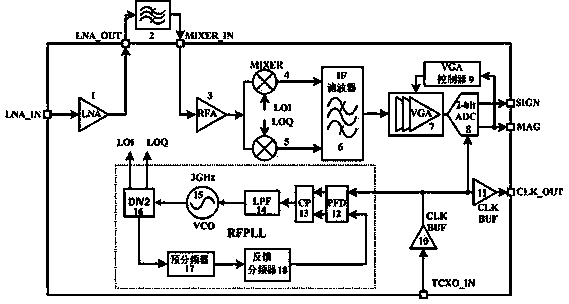

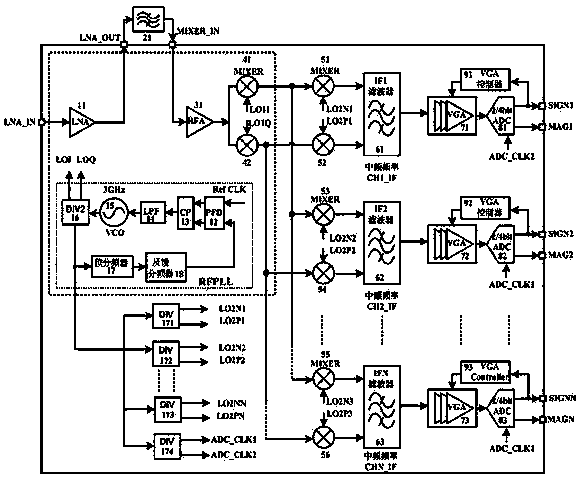

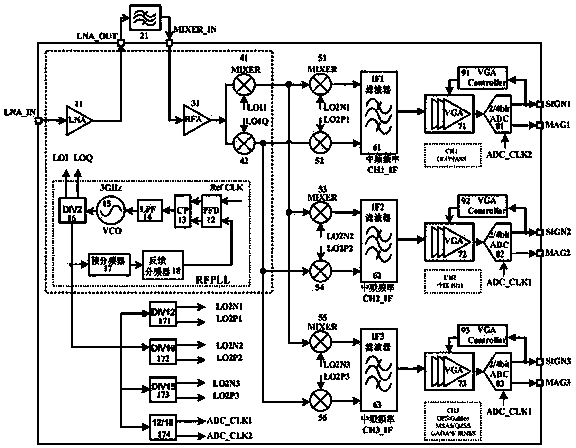

Multi-channel navigation radio frequency receiver

InactiveCN104237910AImprove navigation accuracyHigh positioning accuracySatellite radio beaconingFrequency changerLocal oscillator signal

The invention provides a multi-channel navigation radio frequency receiver. Multiple channels are arranged to correspondingly receive signals of multiple different navigation satellites; the multiple channels share a radio frequency front end and a radio frequency phase-locked loop of a frequency synthesizer, wherein the radio frequency front end carries out down-conversion on radio frequency signals received by the radio frequency front end for the first time through a primary orthogonal down converter, obtains one path of medium-frequency signals and outputs the signals to the multiple channels; corresponding secondary orthogonal down converters are arranged in the multiple channels respectively, and down-conversion is carried out on the medium-frequency signals for the second time to obtain medium-frequency conversion signals corresponding to the channels; the frequency synthesizer provides orthogonal local oscillator signals needed by the first time of down-conversion for the primary orthogonal down converter and provides orthogonal local oscillator signals needed by the second time of down-conversion for the secondary orthogonal down converters in the channels through frequency dividers different in frequency division coefficient. The multi-channel navigation radio frequency receiver not only saves power consumption, but also reduces the cost.

Owner:上海迦美信芯通讯技术有限公司

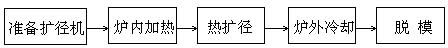

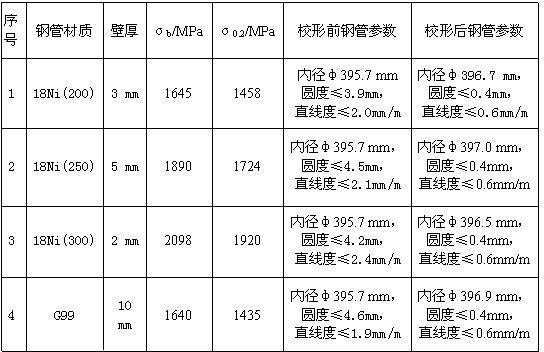

High-precision thermal expanding method for high-strength steel pipes

The invention discloses a high-precision thermal expanding method for high-strength steel pipes. The method comprises the processing steps of preparation of an expanding machine, furnace heating, thermal expanding, external furnace cooling and stripping. The steel pipes to be expanded are charged into a heating furnace and heated to the temperature of between 600 and 800 DEG C, wherein according to the steel pipes, the tensile strength sigma b is between 1,640 and 2,100MPa, the yielding strength sigma 0.2 is 1,400 to 1,950MPa, the wall thickness is 1 to 10 millimeters, the steel pipes are made of different materials, and the inside diameters of the steel pipes are conical or cylindrical; after expanding, the steel pipes are processed into the high-precision steel pipes, the roundness of which is less than or equal to 0.4 millimeter and the linearity of which is less than or equal to 0.6 millimeters per meter; and the method overcomes the defect that the normal temperature expanding process cannot meet the high-precision expanding requirements of the high-strength steel pipes. The method is suitable for expanding various high-strength steel pipes with different chemical components.The expanded high-strength steel pipes produced by using the method are widely applied in the fields of petroleum and natural gas delivery, aerospace and military affairs.

Owner:湘潭华进重装科技股份有限公司

Hydraulic control system of extruder and control method implemented by hydraulic control system

The invention provides a hydraulic control system of an extruder and a control method implemented by the hydraulic control system. The hydraulic control system comprises high-pressure air tanks, piston energy accumulators, an energy accumulator isolating valve, a proportional flow valve, an energy accumulator oil supply liquid inlet valve, a high-frequency-response proportional valve, a master cylinder liquid inlet valve, a side cylinder liquid inlet valve, a liquid replenishing variable pump and a plurality of parallel liquid inlet variable pumps; the high-pressure air tanks are communicated with air inlets of the piston energy accumulators via pipelines; oil outlets of the piston energy accumulators are communicated with a master cylinder of the extruder by pipelines via the energy accumulator oil supply liquid inlet valve, the proportional flow valve and the energy accumulator isolating valve sequentially; the liquid replenishing variable pump is communicated with the oil outlets of the piston energy accumulators via check valves by pipelines; one channel of a main oil outlet of the parallel liquid inlet variable pumps is communicated with a large cavity with the master cylinder of the extruder and side cylinders of the extruder via the high-frequency-response proportional valve, the master cylinder liquid inlet valve and the side cylinder liquid inlet valve respectively; and another channel of the main oil outlet of the parallel liquid inlet variable pumps is respectively communicated with the master cylinder of the extruder and the side cylinders of the extruder via another master cylinder liquid inlet valve and other side cylinder liquid inlet valves. The hydraulic control system has the advantages of large extrusion speed variation range, capability of meeting high precision requirements, and the like.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

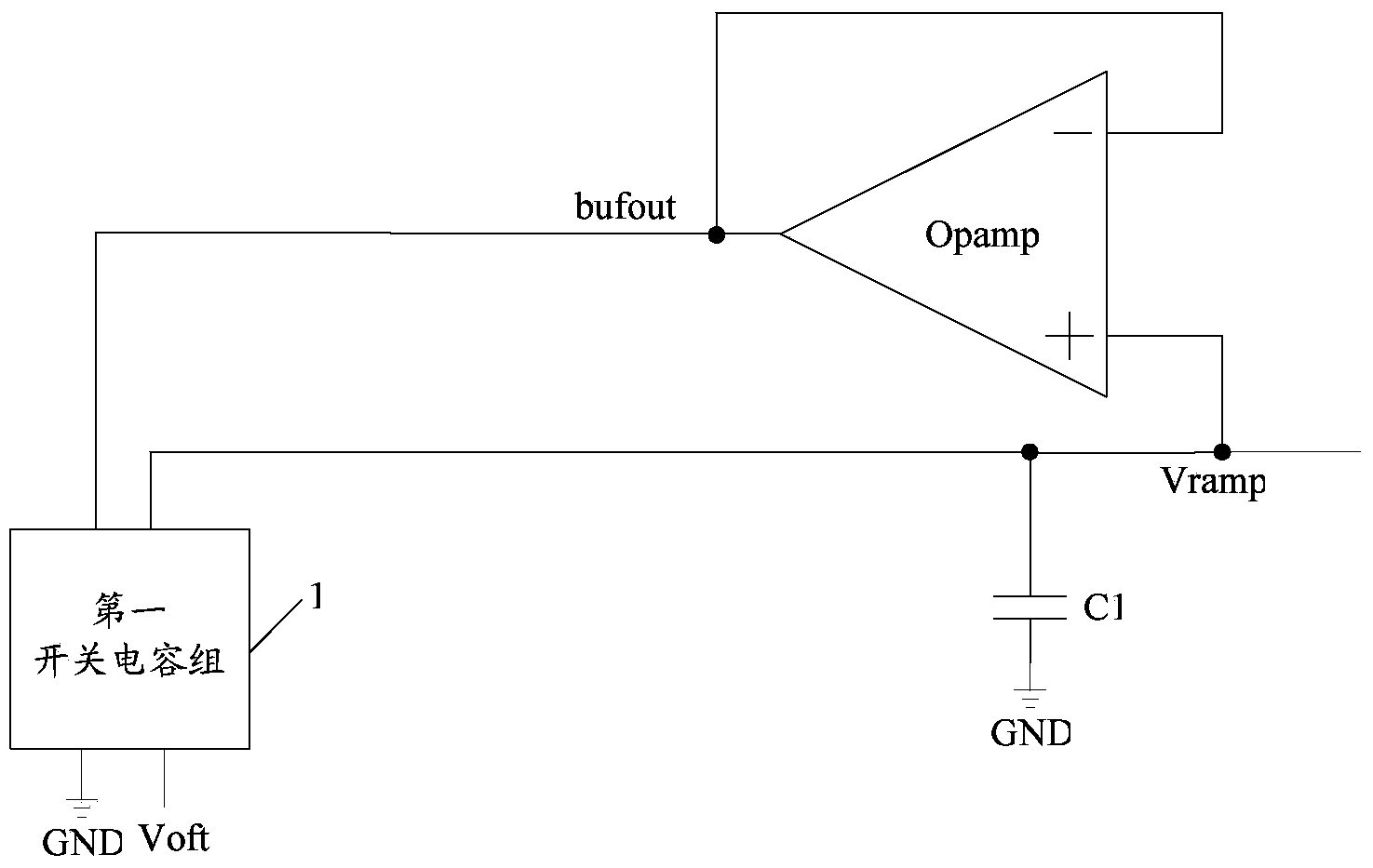

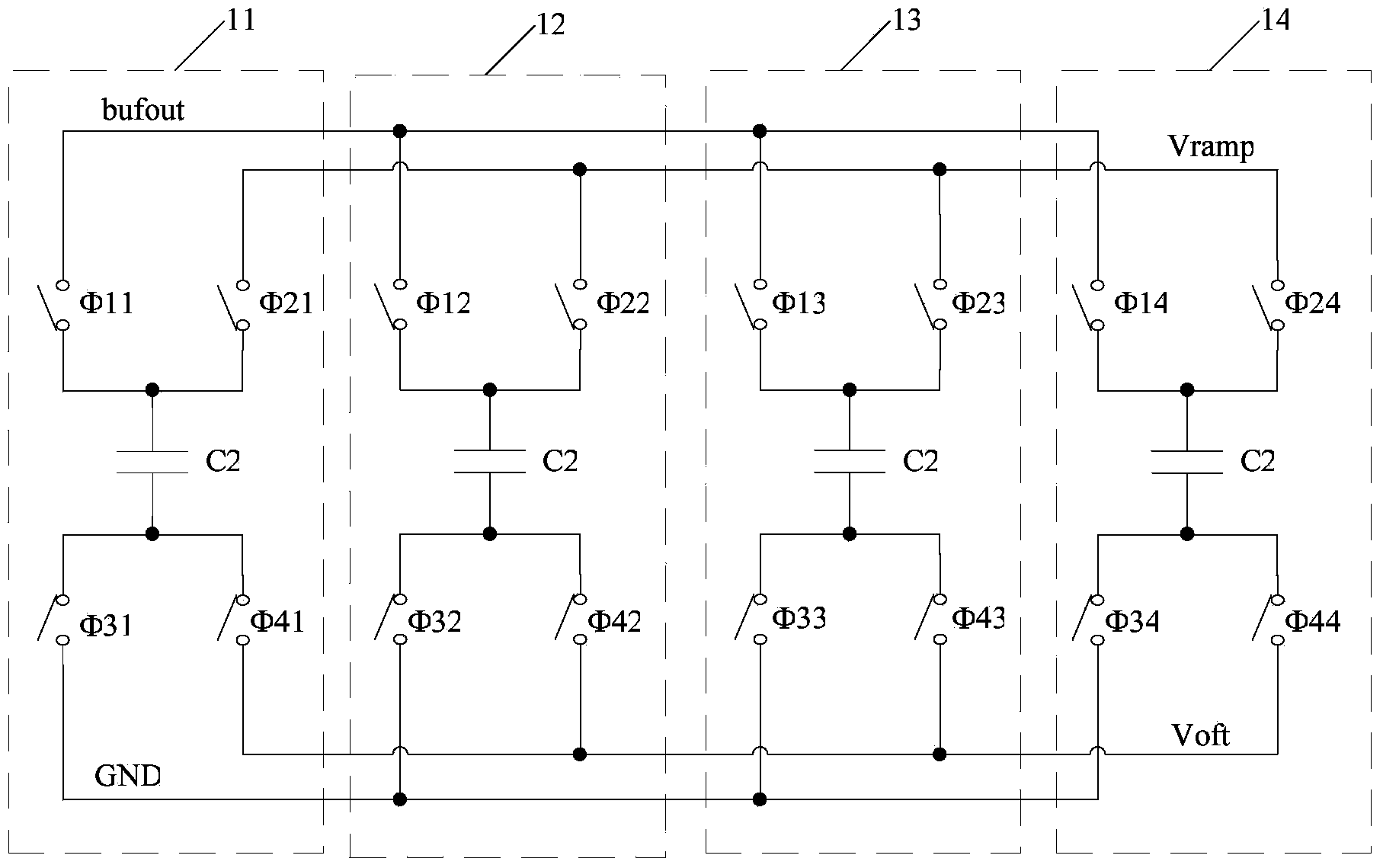

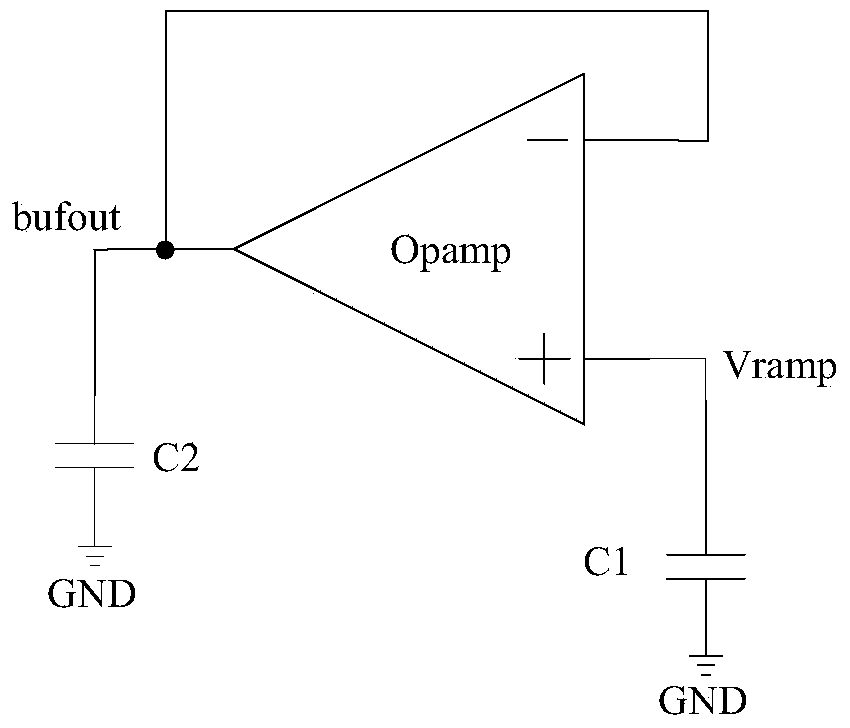

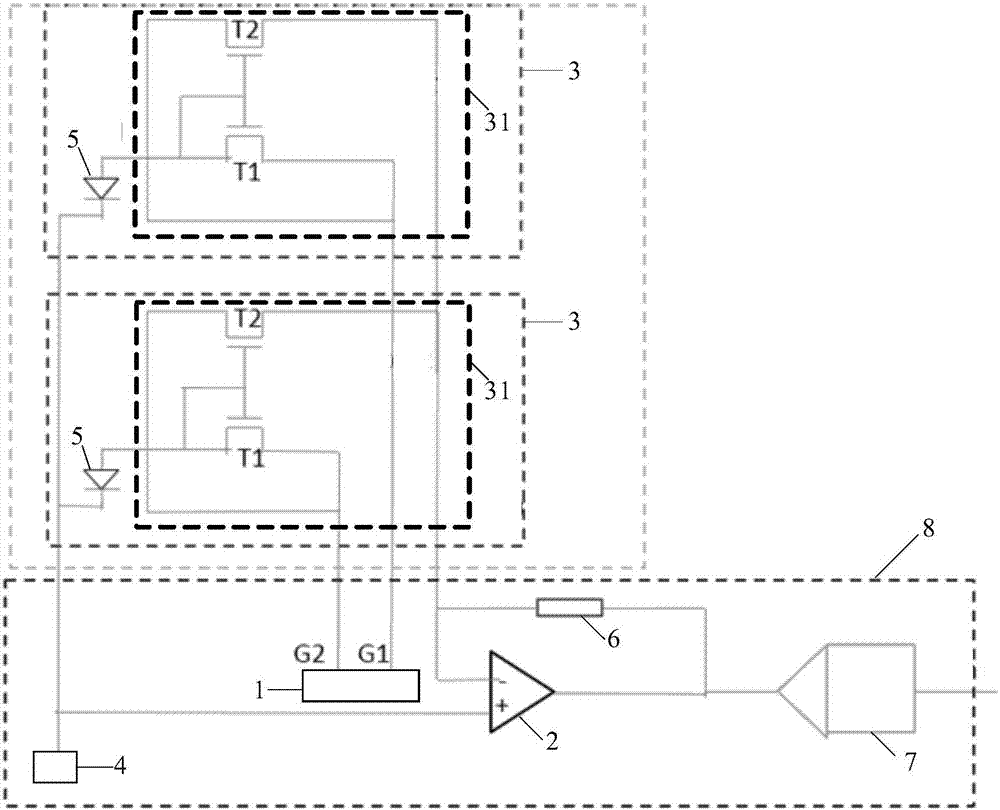

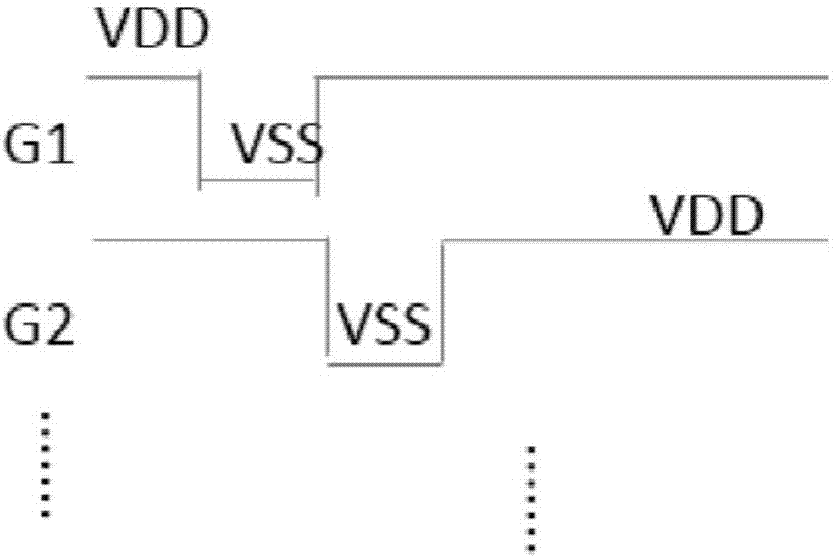

Ramp signal generating circuit and image sensor

ActiveCN104333352AReduced settling timeHigh precision requirementsTelevision system detailsPulse generatorCapacitanceImage sensor

The invention discloses a ramp signal generating circuit and an image sensor, the ramp signal generating circuit comprises an operational amplifier, a first capacitor and at least one first switch capacitance unit, the first switch capacitance unit comprises a first switch, a second switch, a third switch, a fourth switch and a second capacitor; the first end of the first switch is connected to the negative phase input end and the output end of the operational amplifier, the first end of the second switch is connected to the positive phase input end of the operational amplifier and the first end of the first capacitor, the second end of the third switch is applied to input the first voltage, the second end of the fourth switch is applied to input the second voltage, which is unequal to the first voltage on voltage value; in the same first switch capacitance unit, the second end of the first switch is connected to the second end of the second switch and the first end of the second capacitor, the first end of the third switch is connected to the first end of the fourth switch and the second end of the second capacitor; the second end of the first capacitor is connected to the ground; the capacitance value of the first capacitor is greater than that of the second capacitor.

Owner:GALAXYCORE SHANGHAI

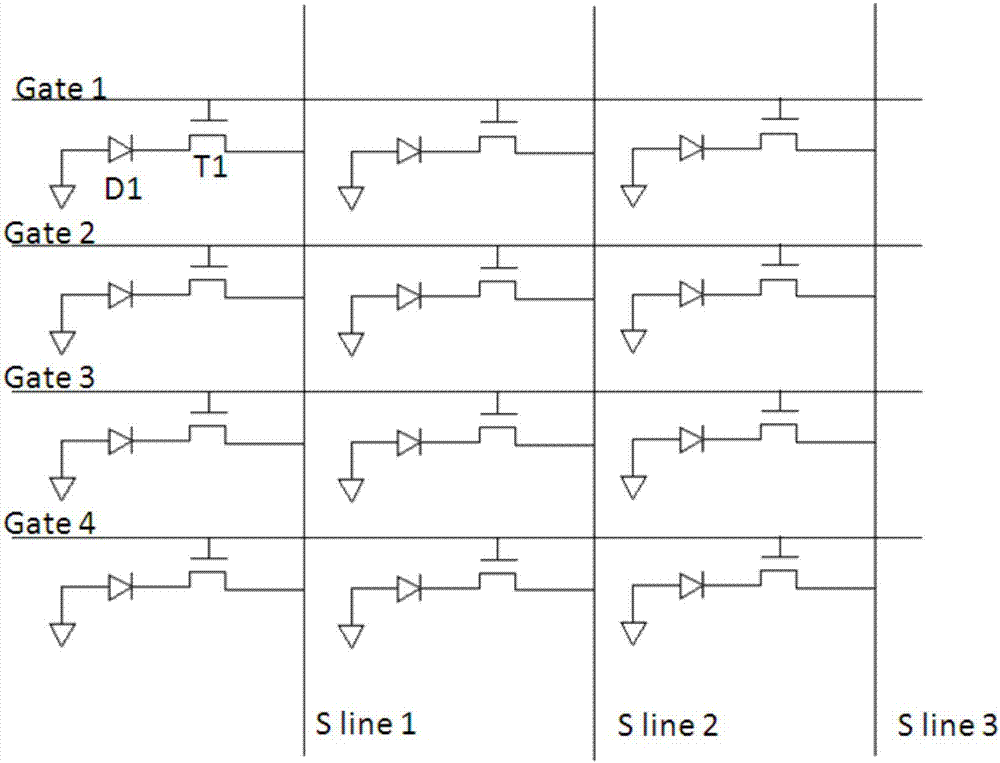

Current amplification circuit, fingerprint detection device and control method of current amplification circuit

ActiveCN107330409ALower resistanceMeet high precision requirementsCharge amplifiersAmplifiers controlled by lightAudio power amplifierFingerprint detection

The invention provides a current amplification circuit, a fingerprint detection device and a control method of the current amplification circuit. The current amplification circuit comprises a voltage control unit, a current amplifier and current amplification units arranged in an array, each current amplification unit comprises a current mirror, each current mirror is separately and electrically connected with a voltage input end, the voltage control unit and a reverse-phase input end of the current amplifier, a positive-phase input end of the current amplifier and the voltage input end are electrically connected, and the voltage control unit outputs voltage control signals to the current mirrors respectively controlling the current mirrors to amplify currents input from the voltage input end. Primary amplification processing is performed on the currents flowing from the voltage input end by using the current mirrors, so a current amplification times needed when secondary amplification processing for the currents is performed by the current amplifier is effectively reduced; and, the current amplification circuit provided in the invention can effectively reduce a resistance value of a resistor for amplifying a current in a current amplifier on an integrated circuit chip on the basis that the current amplifier is usually integrated onto the integrated circuit chip.

Owner:BOE TECH GRP CO LTD

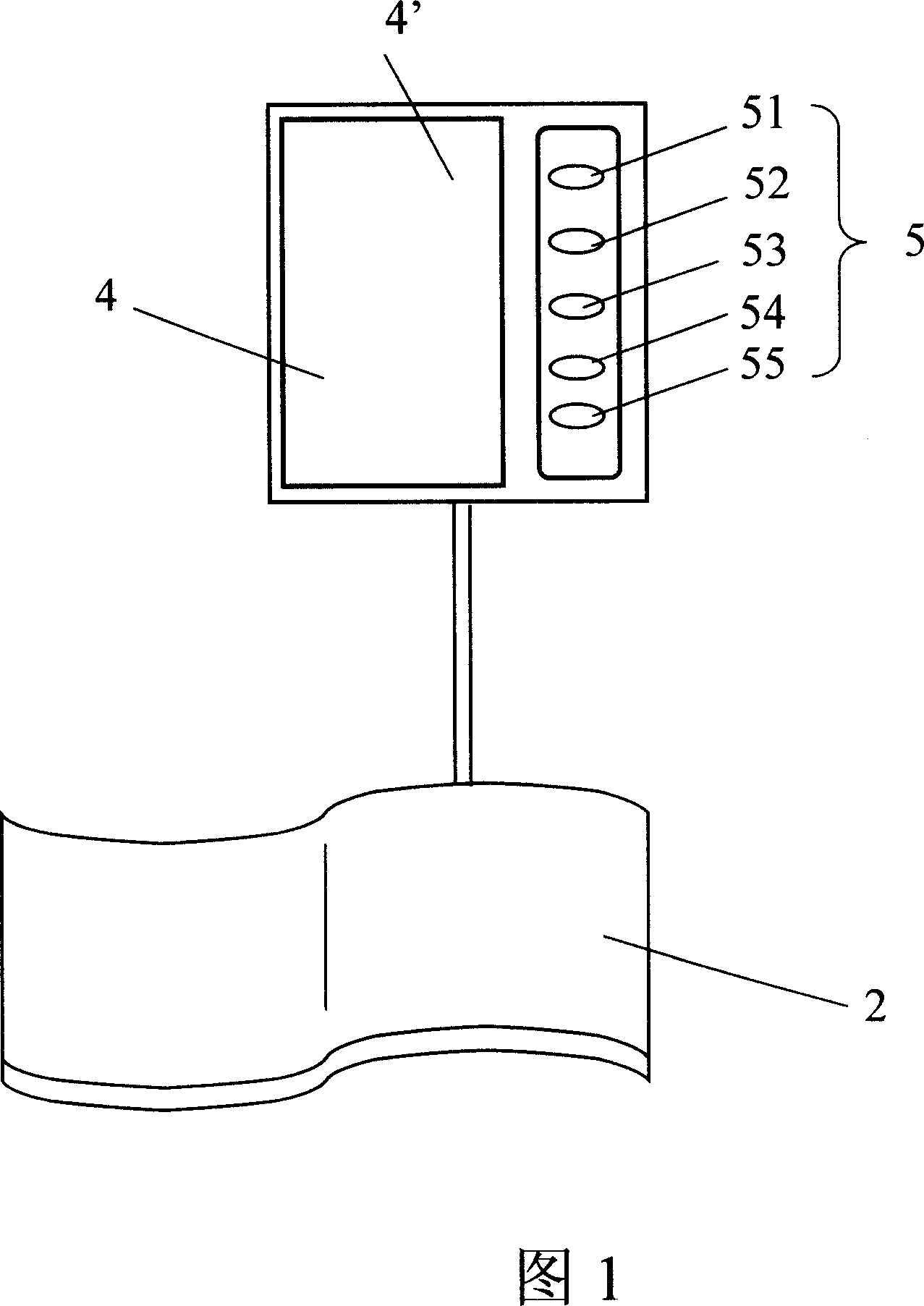

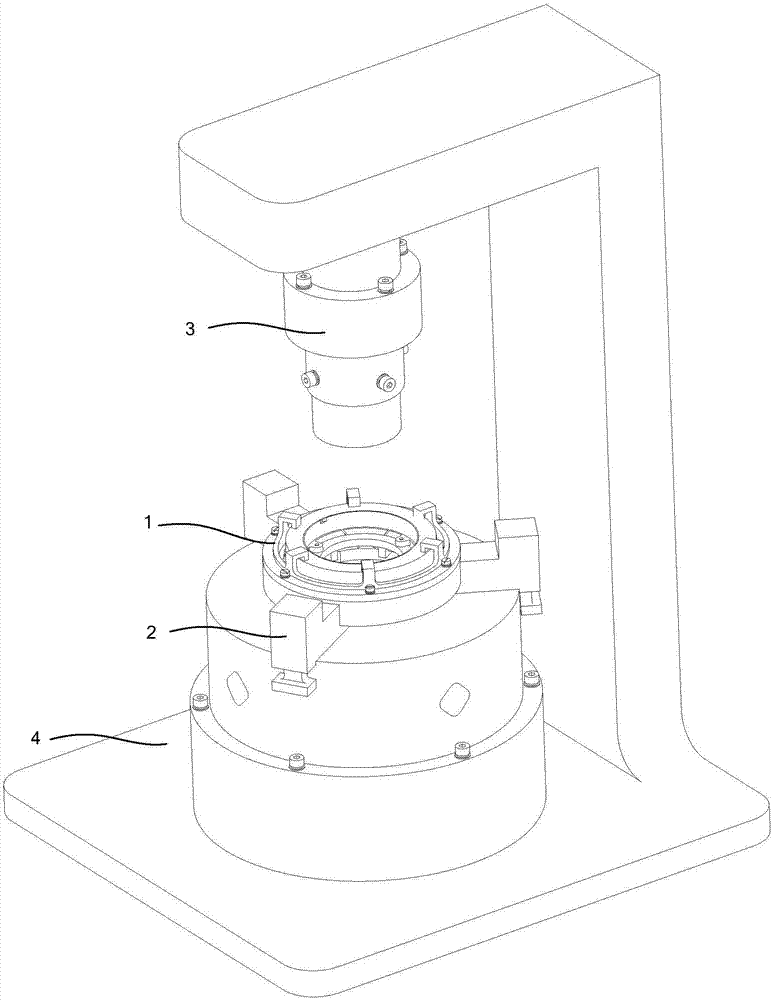

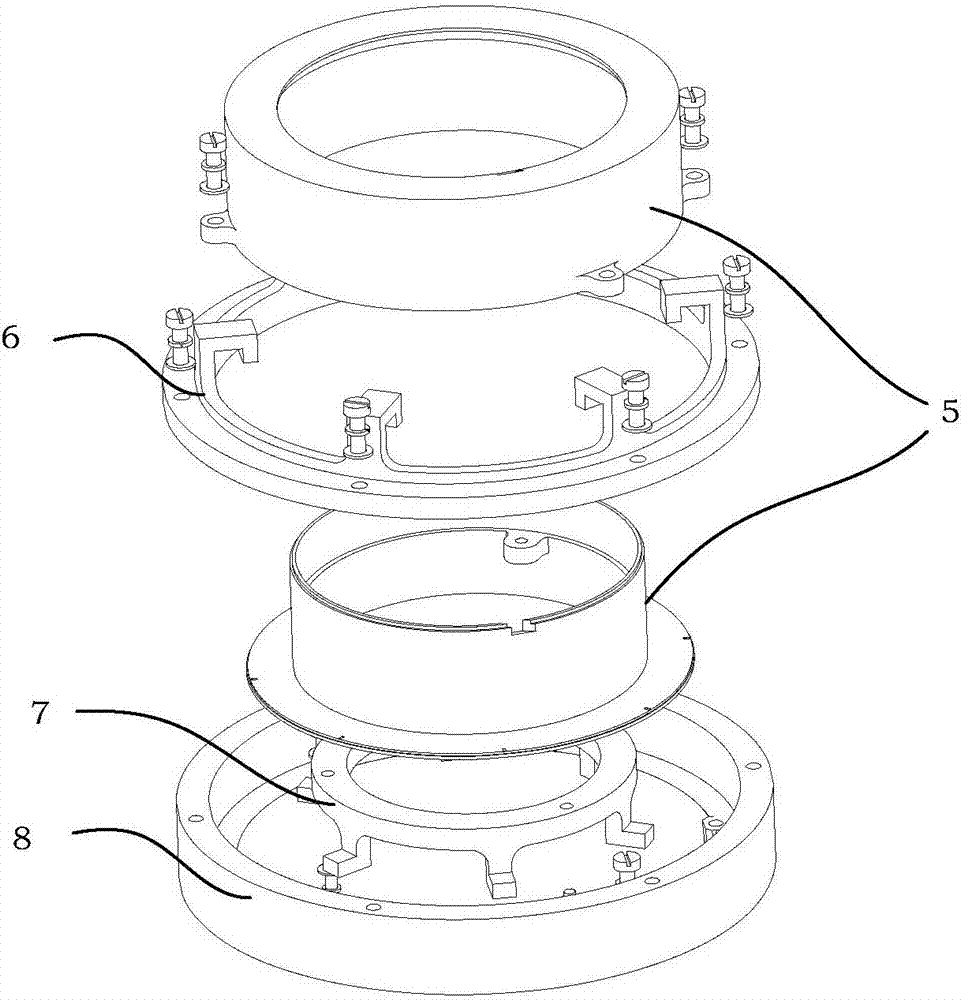

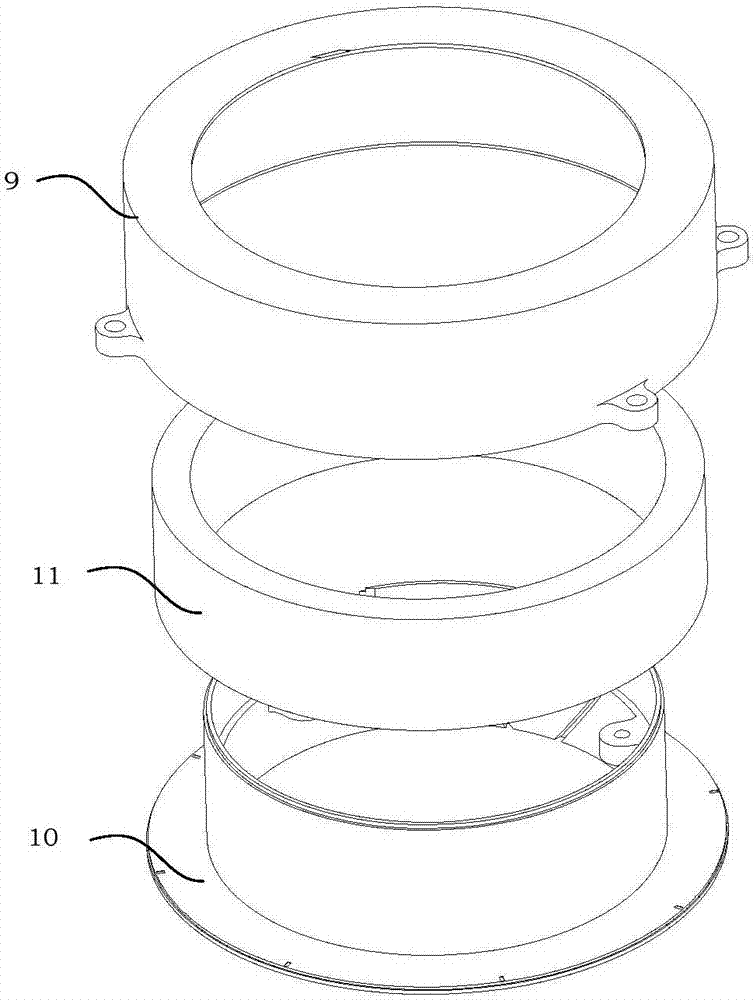

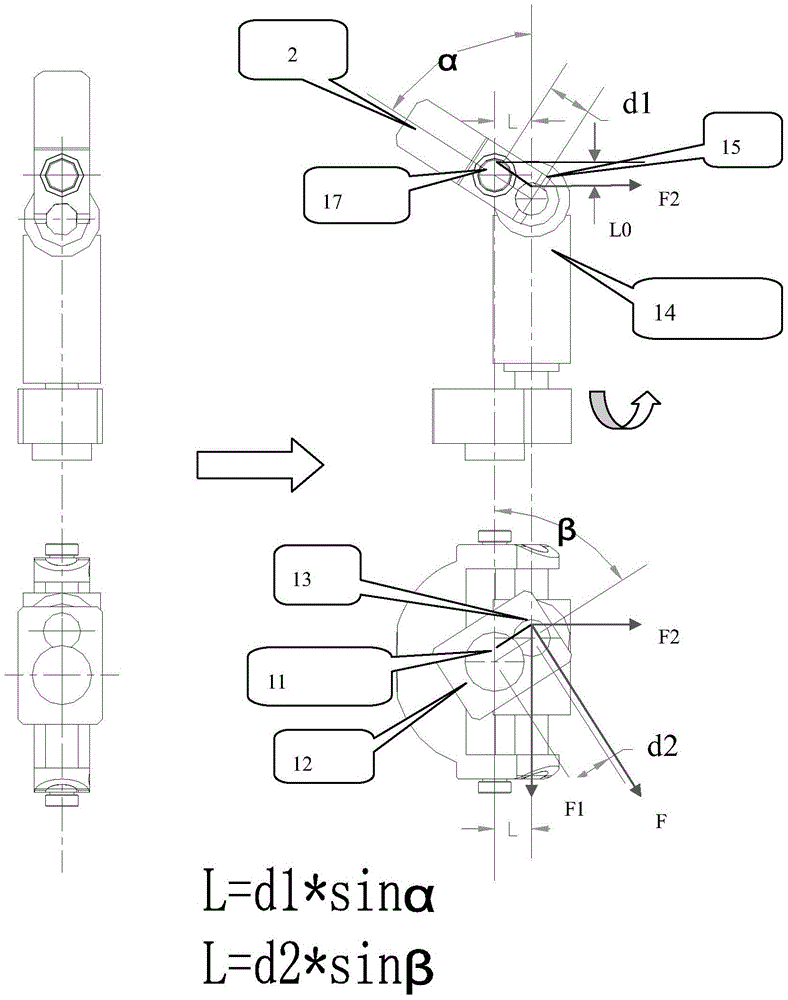

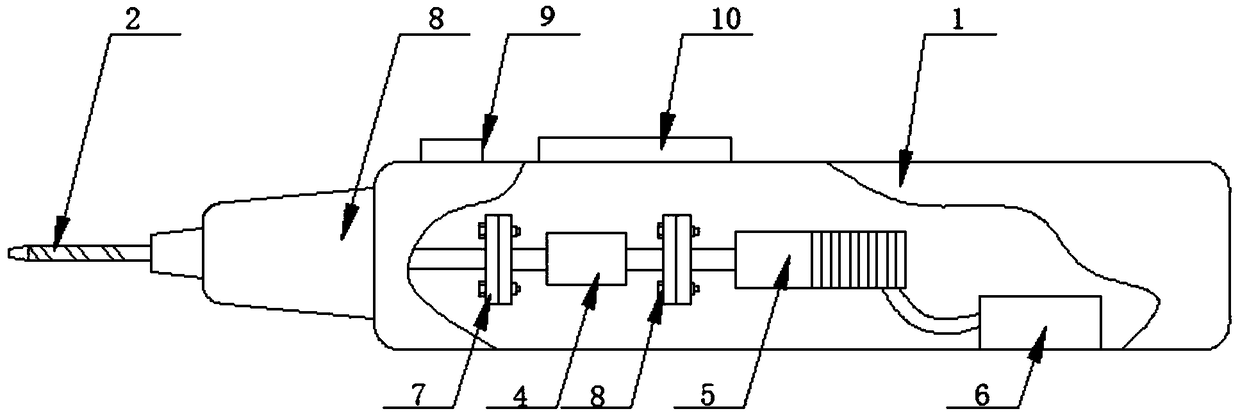

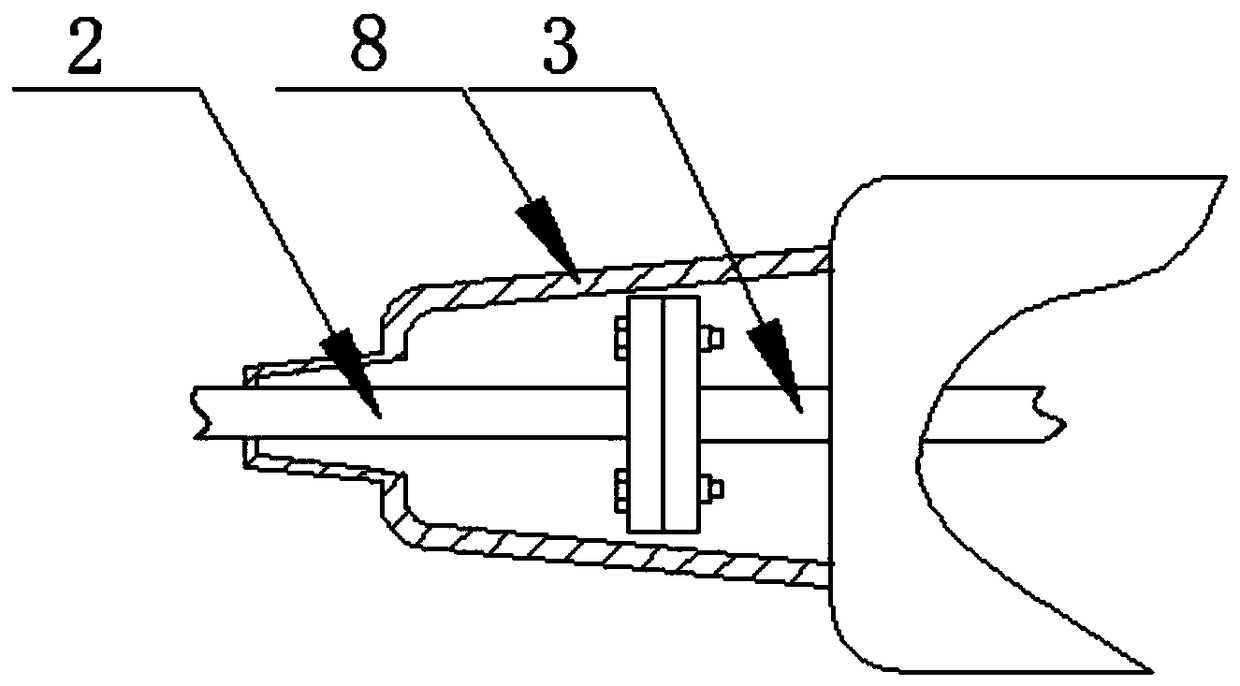

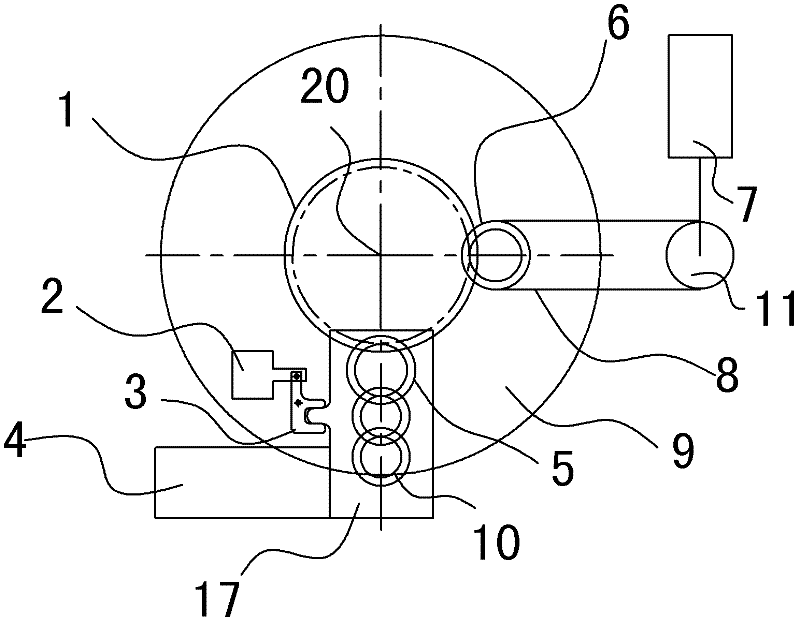

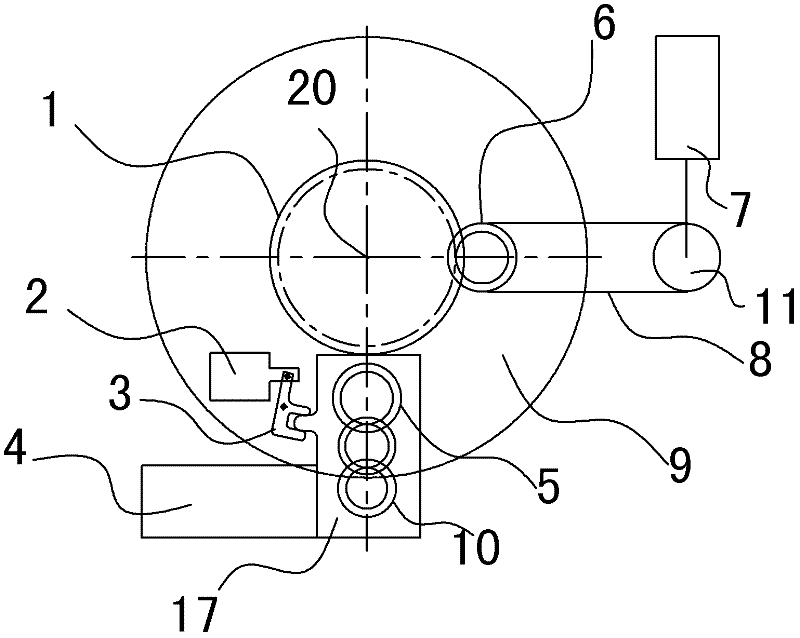

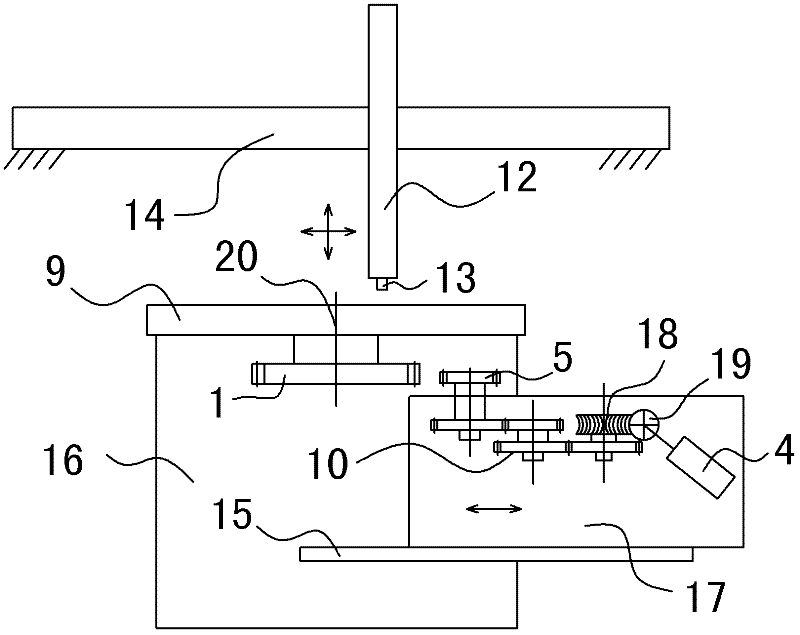

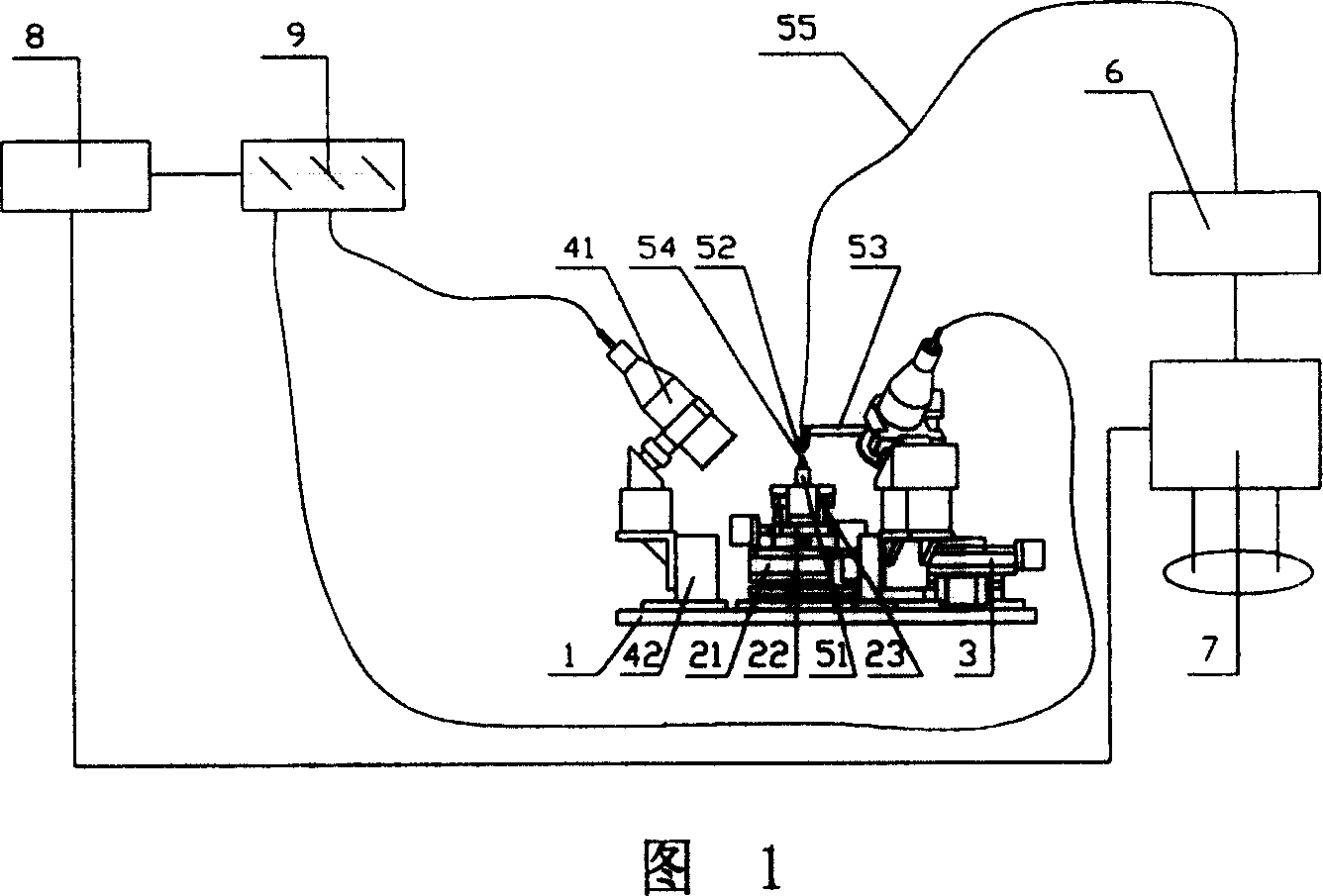

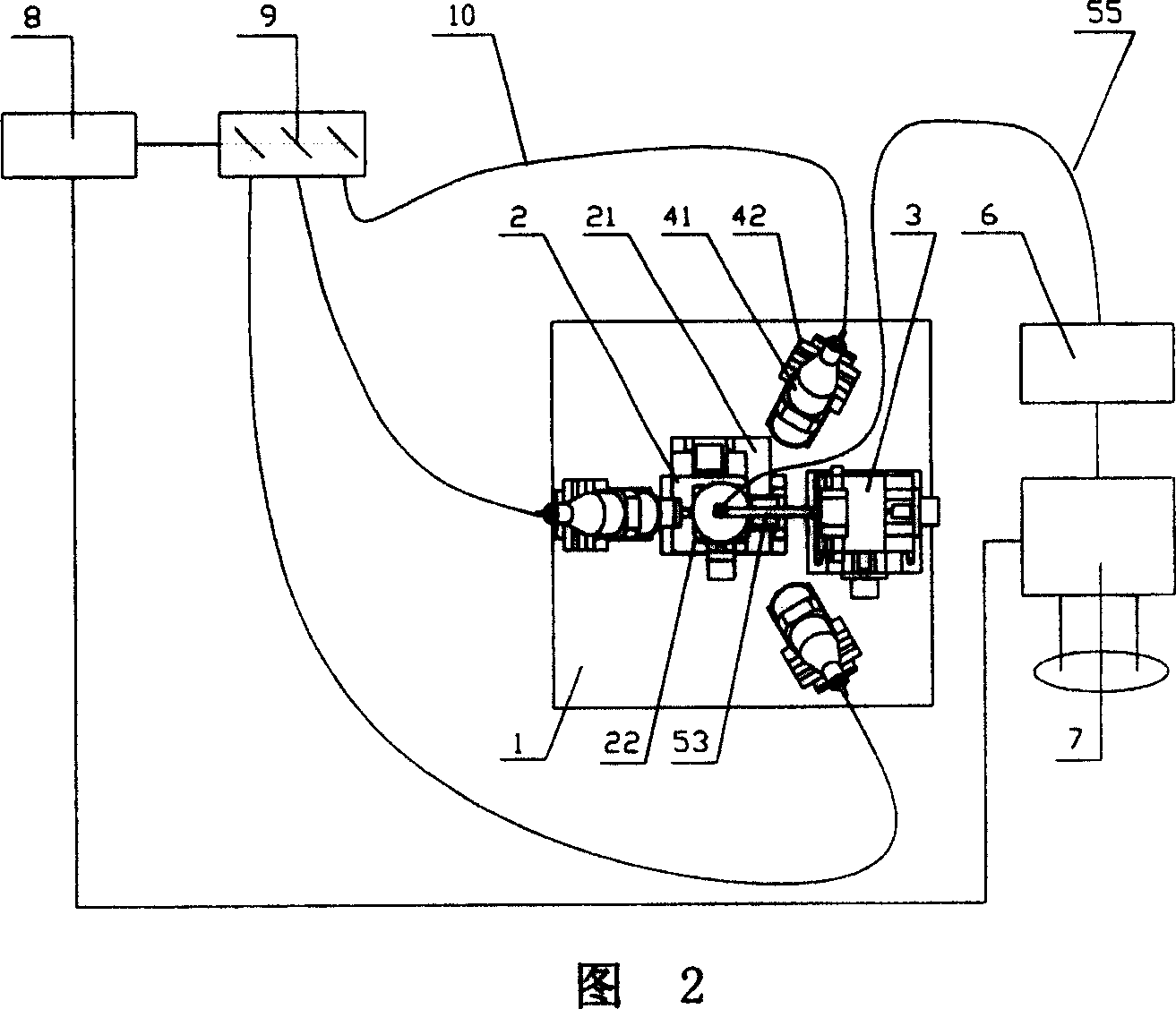

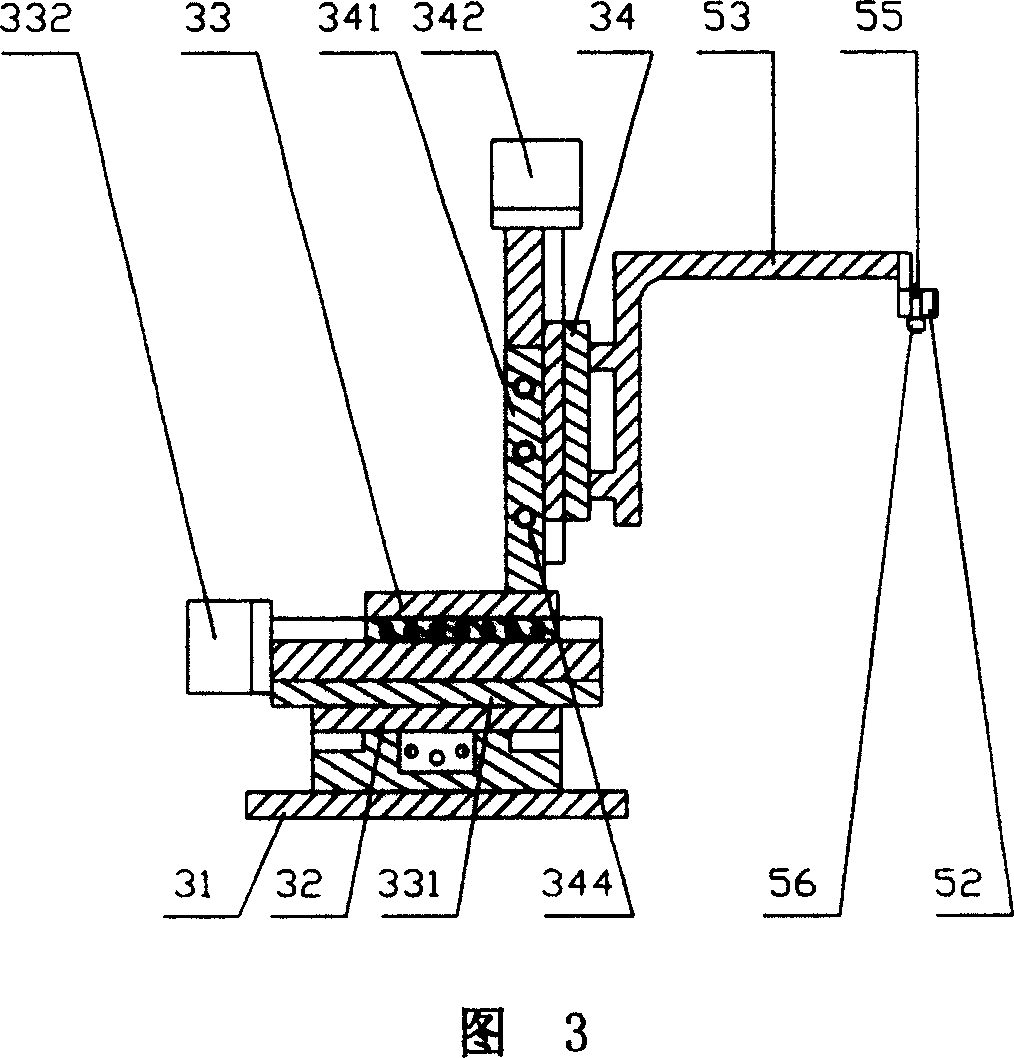

Welding device and method for assembling optical fiber gyro

ActiveCN107088705AImprove matchCompact structureLaser beam welding apparatusEngineeringFibre optic gyroscope

The invention provides a welding device and method for assembling an optical fiber gyro. The deice comprises an optical fiber gyro welding assembly (1), chucks (2), a laser assembly (3) and a platform (4). When the device is adopted for welding an optical fiber gyro, an optical fiber gyro assembly (5) is assembled firstly, an assembled gyro upper cover (9) needs to be welded to the upper side and the lower side of a gyro base (10), and the optical fiber gyro welding assembly (1) is used for pressing the connected gyro upper cover (9) and the gyro base (10). An industrial camera (13) of the laser assembly (3) is used for obtaining weld joint position and images in real time, and a laser (12) is used for completing welding. By means of the welding device and method for assembling the optical fiber gyro, the work efficiency and welding accuracy for structure sealing are improved.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

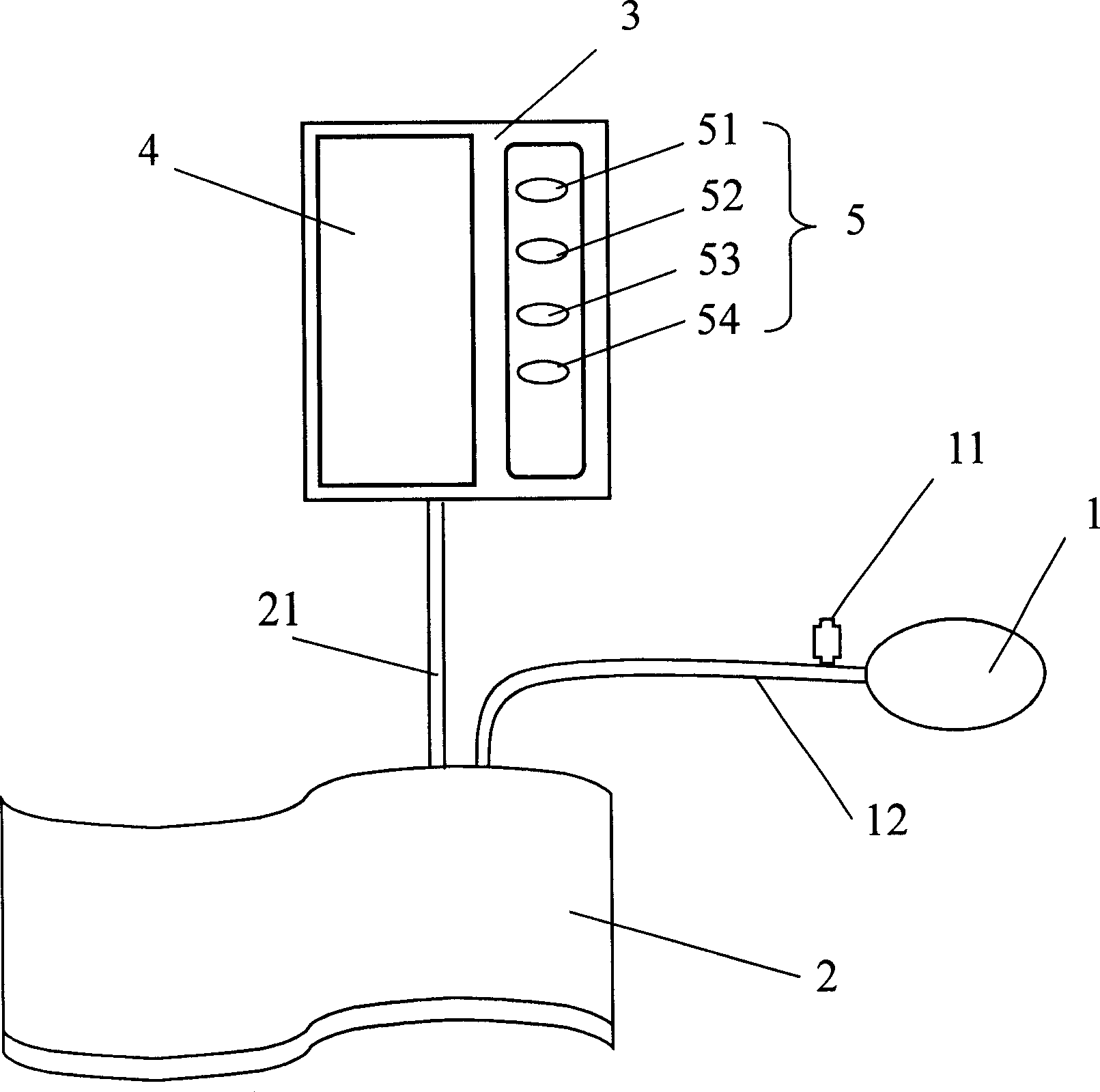

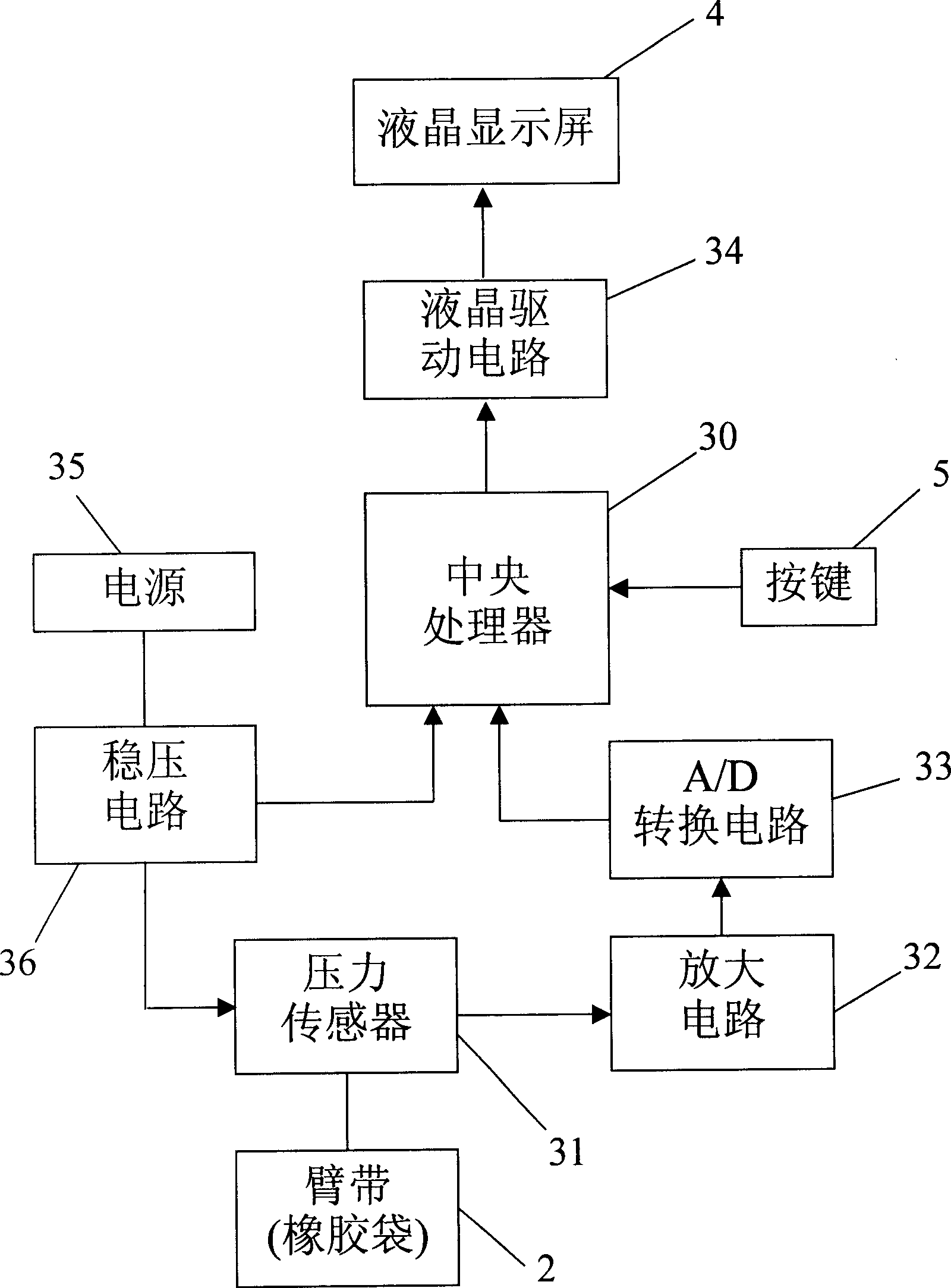

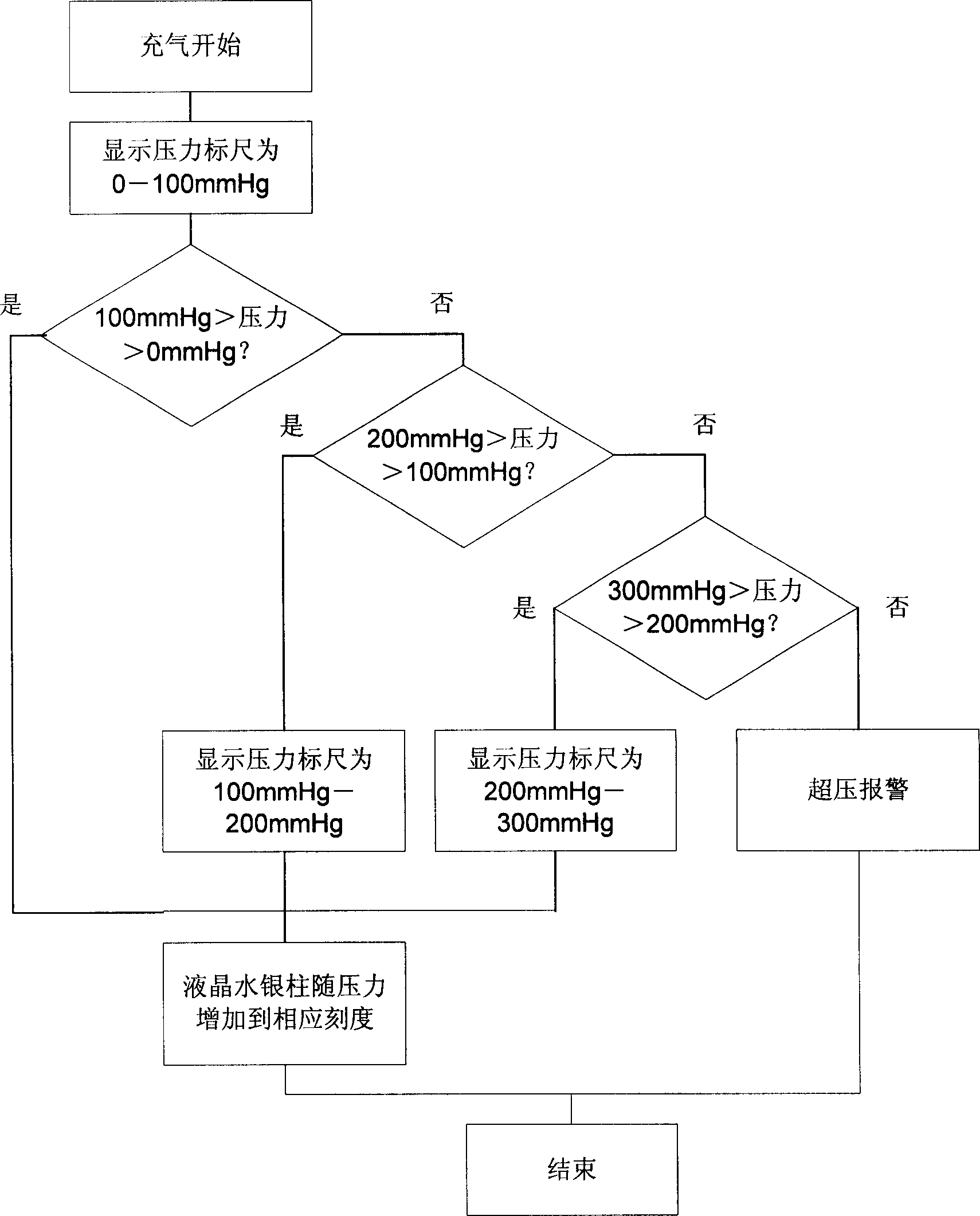

Electronic blood manometer and its display method

ActiveCN1839752AFix oversizeLow costEvaluation of blood vesselsCatheterElectronic sphygmomanometerLiquid-crystal display

This invention discloses a kind of electronic sphygmomanometer and its displaying technique: a sensor senses gasbag pressure signal and educe pressure value after operation process, and outputs the value to a displaying unit to display it by means of a simulated quicksilver column scale. Wherein, the scale is divvied into sections according to designed program, and the scale mark is set by pressure comparison and judgment. In this way, pressure values can be displayed by a subsection manner instead of a full and consistent long column shape. So liquid crystalline display screen of the sphygmomanometer can be smaller and cheaper, at the same time, the resolution ratio of this invention is enough to meet high accuracy need of the scale mark.

Owner:潘卫江

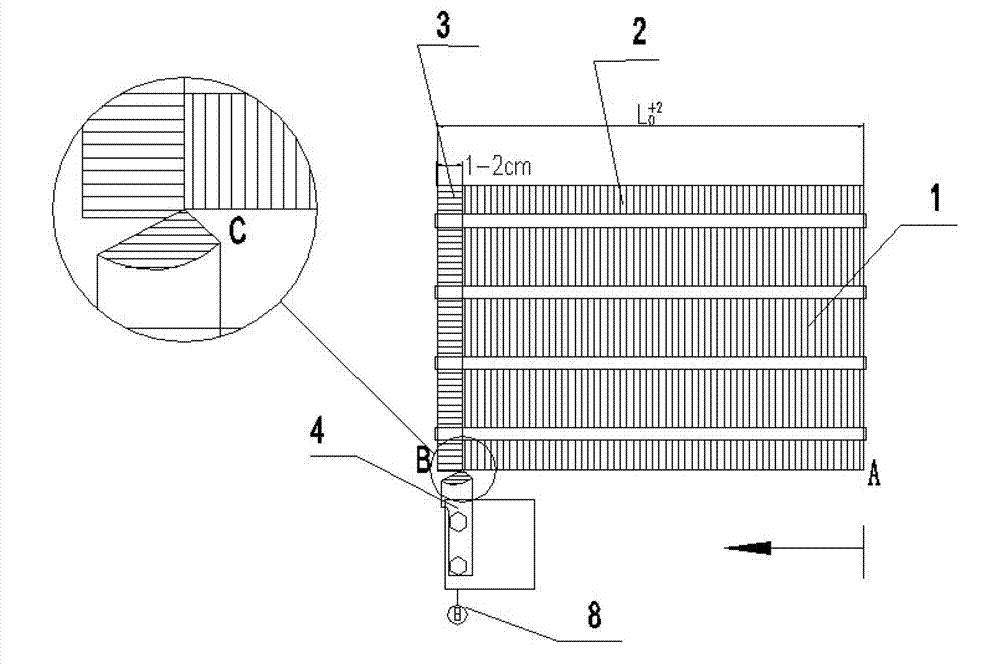

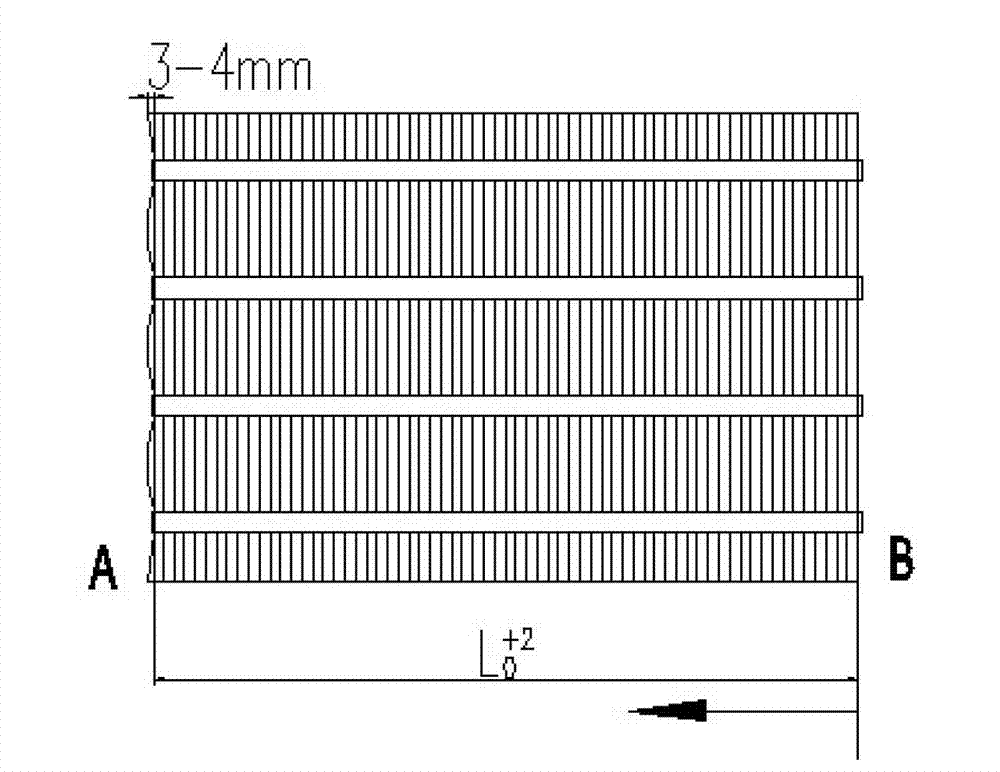

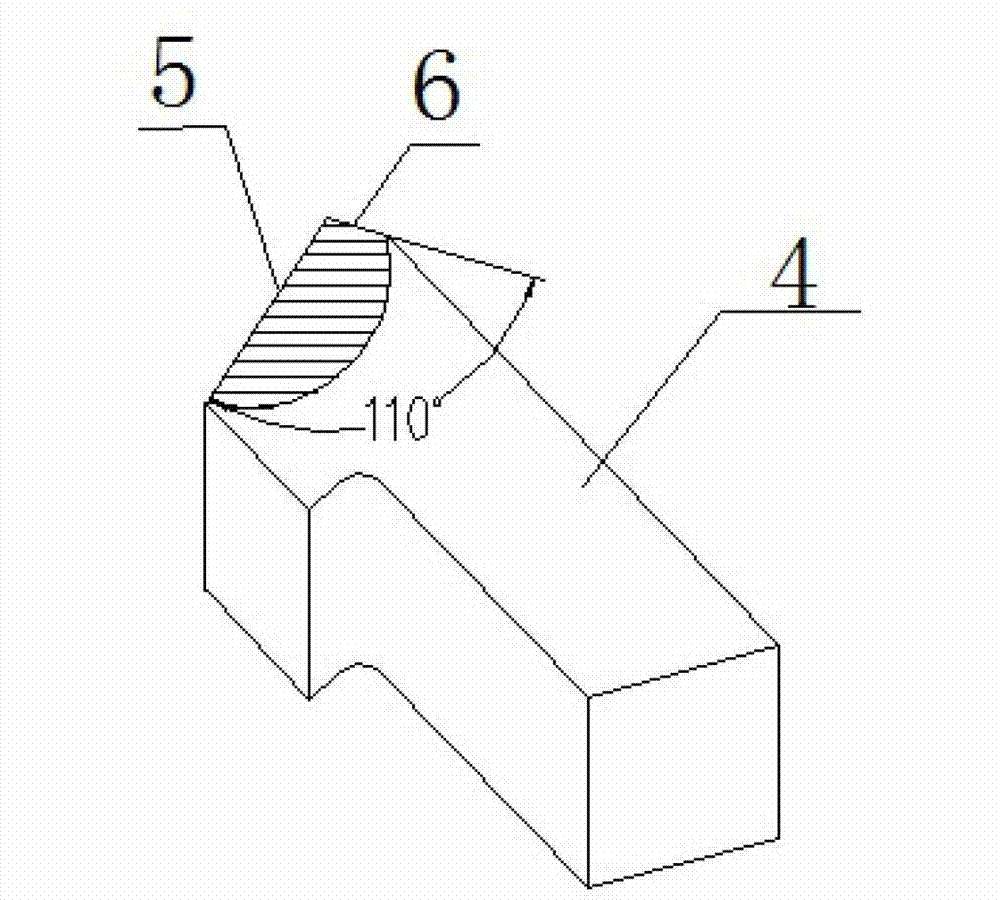

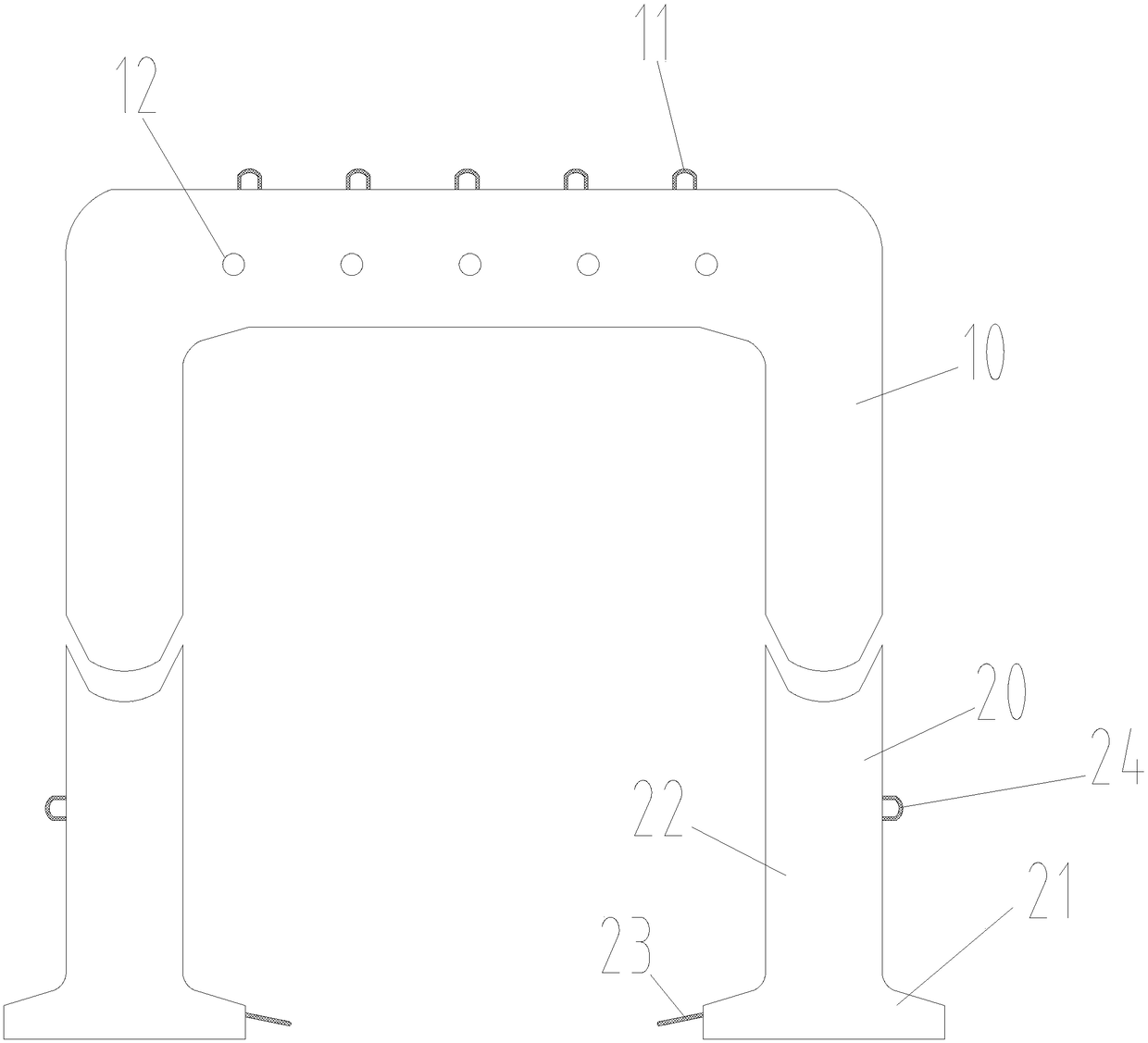

Lathing device for iron core of efficient motor without end plate at two ends and machining method thereof

ActiveCN103203472ANot easy to damageIncrease productivityManufacturing stator/rotor bodiesTurning machinesEngineeringMachining process

The invention discloses a lathing device for an iron core of an efficient motor without an end plate at two ends and a machining method thereof. The lathing device comprises a lathe, two thimbles and a clamping fixture, wherein the thimbles clamp the iron core of the motor through the clamping fixture; correspondingly, the iron core of the motor is provided with a knife rest; the knife rest is provided with a lathe tool which includes a first cutting edge and a second cutting edge; the included angle between the two cutting edges is 100-115 degrees; and the machining steps are as follows: step A, machining by using the first cutting edge, and when the knife is moved from an A end face to have a distance of 1-2 cm to a B end face, retracting the knife to a B end; step B, machining by using the second cutting edge, and when the knife is moved from the B end to have a distance of 1-2 cm to the A end face, retracting the knife to an A end; and carrying out the Step A and the Step B alternately until a set qualified size is obtained. The machining process improves production efficiency, increases product quality, avoids machining risk, realizes requirements on aesthetic sense and high precision of products, saves production cost and increases production benefits as repeated manual subsequent arrangement is unnecessary and the lathe tool is not easy to damage.

Owner:NANTONG TONGDA SILICON STEEL STAMPING TECH CO LTD

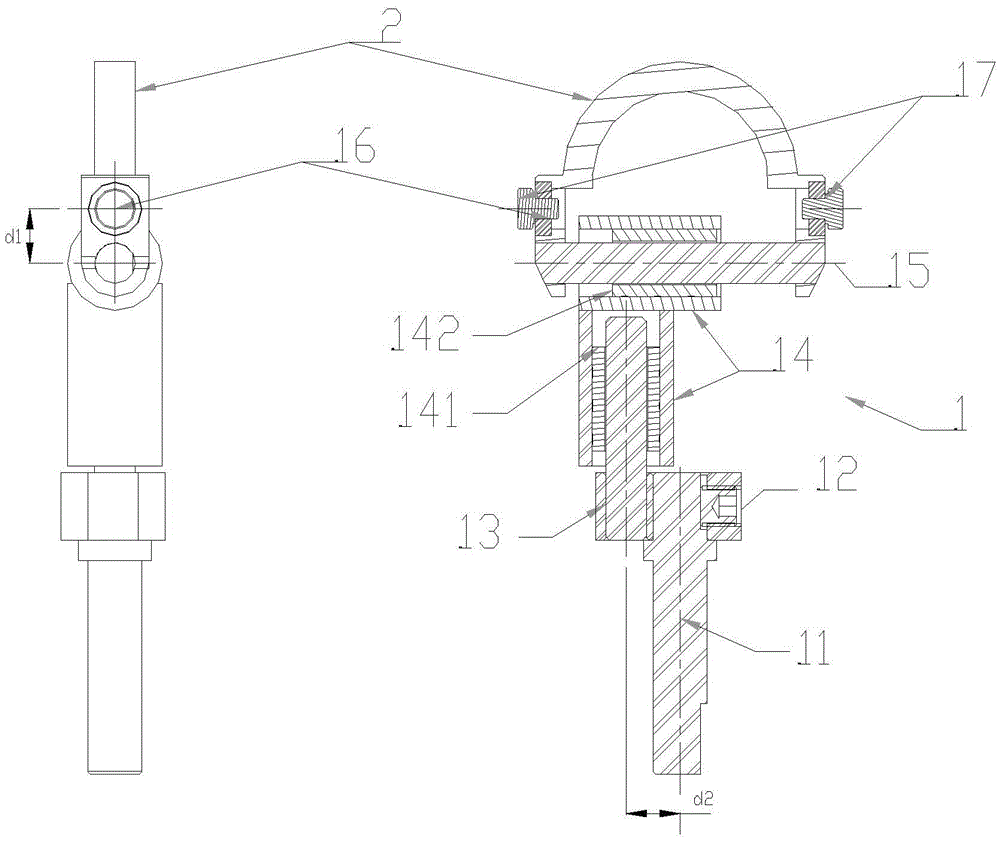

Transmission mechanism and 4D probe thereof

ActiveCN105465308ARealize synchronous transmissionMeet high precision requirementsGearingEnergy converterElectrical and Electronics engineering

The invention provides a transmission mechanism. A motor is driven by the transmission mechanism to drive a core part of an energy converter to swing. The transmission mechanism comprises a first transmission shaft, an eccentric connecting piece, a second transmission shaft, a sliding sleeve, a third transmission shaft, at least one connecting piece and at least one fixing shaft. A corresponding 4D probe is provided. By means of the transmission mechanism and the 4D probe, synchronous transmission of the motor and the core part of the energy converter is achieved, and therefore the requirement for high precision of the probe is met.

Owner:SONOSCAPE MEDICAL CORP

Online robot rolloff device for side body wheel covers

InactiveCN105312381AReduce manufacturing costGuaranteed positional relationshipMetal-working feeding devicesPositioning devicesGeneral assemblyEngineering

The invention relates to an online robot rolloff device for side body wheel covers. The device comprises a base, three clamping mechanisms, two locating pin mechanisms, two sucking disks, an upper bottom die and a lower bottom die, wherein the clamping mechanisms are mounted on the base; the locating pin mechanisms are arranged at the corresponding location holes corresponding to the a body in white; the arc upper bottom die is mounted at the upper part of the base; the sucking disks are mounted adjacent to the arc upper bottom die; the arc lower bottom die is mounted at the lower part of the base; all mounting mechanisms are mounted through pins and screws in a cooperating manner; and meet meanwhile, the rolloff accuracy requirement is metat the same time. The device provided by the invention can realize the fixation of positional relation between tire membranes and wheel covers under the condition that no other external mechanism is required; through the cooperation with the robot and a rolloff head, the device can complete the rolloff work of rear wheel covers on the general assembly welding line of the body in white; the device adopts the car body as a locating basis, and directly fixes the wheel cover rolloff mechanism to the car body; as no extra fixture is required to locate the side body, the device occupies smaller space, is easy to arrange, more accurate in locating and shorter in debugging time.

Owner:TIANJIN FUZHEN IND EQUIP

Processing method of power senary shunting rotary frame of large-scale vertical mill reducer

The invention discloses a processing method of a power senary shunting rotary frame of a large-scale vertical mill reducer. A power senary shunting rotary frame with the porous system and parallel hole system processing accuracy standard of DIN3961 10a27 and the surface roughness of RaO.4 is adopted in the method. The method comprises the processes of rough finishing, heat treatment, multi-procedure semi-finishing, simultation processing, fine finishing and finishing. The method is a novel processing technology of a high precision porous system workpiece, which combines an ordinary machine tool with a precision numerical control machine, combines a traditional technological method with a new technological method, i.e. a computer simulation technology, combines an ordinary technological process with a special technological process, and has the advantages of less geometric tolerance, high processing accuracy, uniform planet hole distribution and low noise after assembly.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

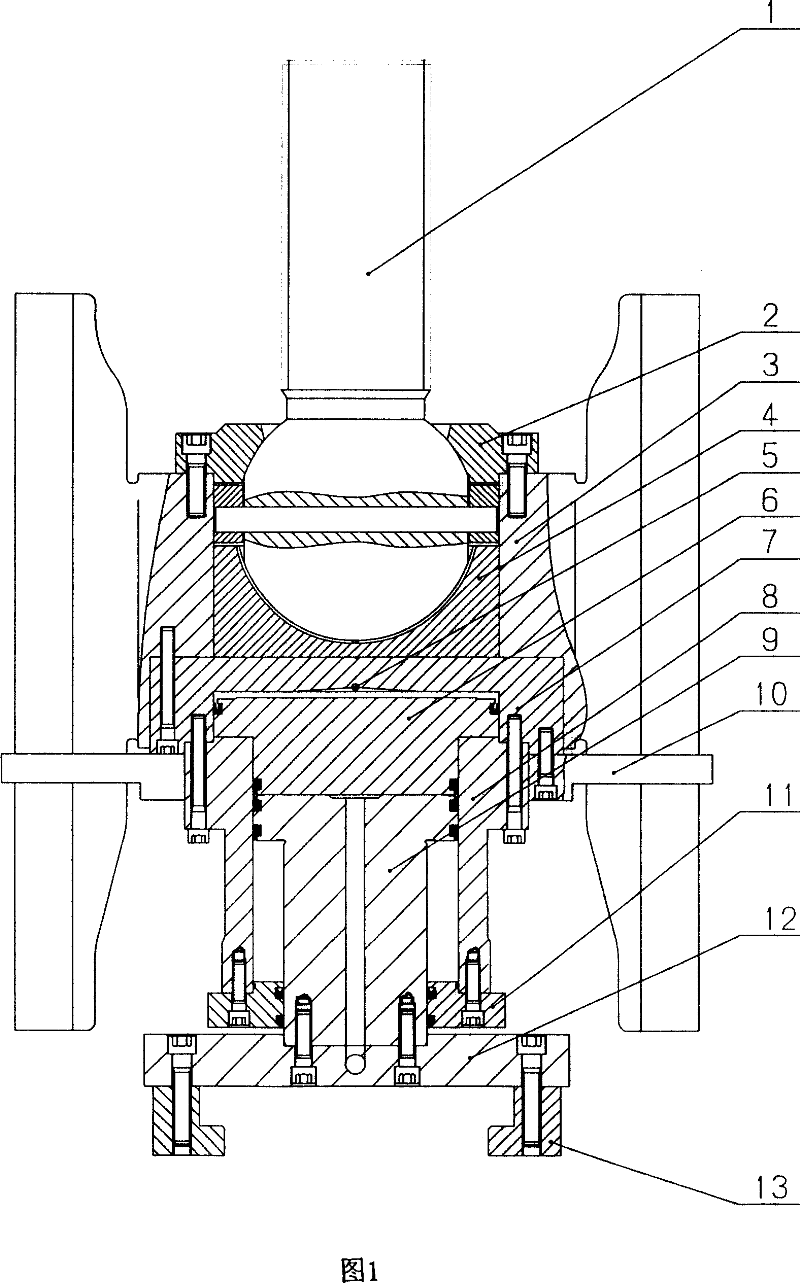

Powder forming machine pressure measuring oil cylinder mechanism

ActiveCN101038225AGuarantee product qualityMeet high precision requirementsFluid pressure measurementPressesPressure controllerOil pressure

The present invention provides a pressure testing oil cylinder mechanism of a powder shaping machine consisting of a driving screw matching with a ball seat in the sliding block, an oil cylinder fixed on the sliding block and the soleplate, an air cylinder body with a piston is fixed on the oil cylinder, an air cylinder piston matching with a guider actively and that is fixed on a connection board. Said oil cylinder is a cylinder for measuring that is fixed on the sliding block and the soleplate, and a measuring piston is provided in the inner chamber, and also the oil cylinder matches with the air cylinder piston and the air cylinder body. The pressure of the powder shaping machine can be measured accurately by the oil pressure sensor of the pressure controller positioned on the soleplate, even though moving direction of the measuring piston is converted from the upper to the lower comparing the original moving direction and all the air in the measuring oil cylinder is discharged in the moving state. As a result, the pressure of the pressed objects is controlled by a pressure controller for adjusting, controlling and inputting the pressure of the measuring oil cylinder.

Owner:严俏敏

Pen-type hand-pressed fine bone drill for orthopedic surgery

InactiveCN109223093AEasy to operateRealize speed regulation functionSurgeryModelling/simulations for controlCouplingIndex finger

The invention belongs to the technical field of orthopaedic surgical equipment, and discloses a pen-type hand-pressed fine bone drill for orthopaedic surgery, wherein the pen-type hand-pressed fine bone drill for orthopaedic surgery is provided with a shell. A transmission rod, a miniature gearbox, a motor and a storage battery are sequentially arranged from the front end to the rear end inside the shell; A drill bit is arranged in front of the shell; A transmission rod is arranged behind the drill bit, and the front end of the transmission rod is connected with the drill bit through a coupling; The transmission rod is connected with a micro transmission through a coupling; The micro-gearbox is connected with an electric motor through a coupling; A motor switch and a speed regulating button are arranged on the outside of the housing, and a fixing bracket is fixed on the front screw. The bone drill realizes the speed regulating function of the fine bone drill when in use. A switch of that motor is arranged at the position of the index finger, which is convenient to operate; meanwhile, the invention has the advantage of simple structure, strong structure and convenient operation.

Owner:黄鲁豫

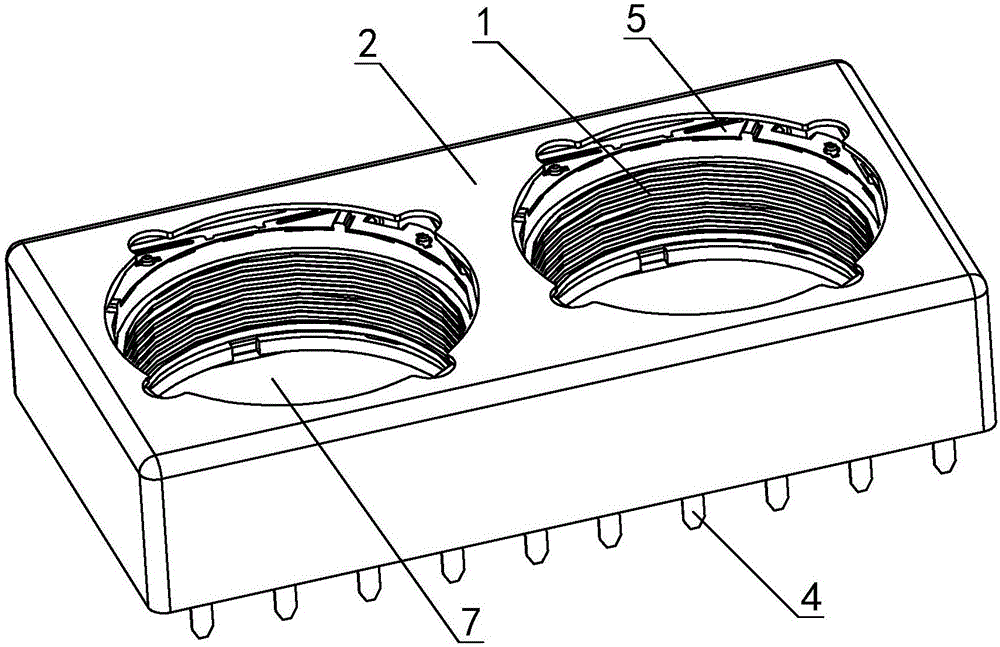

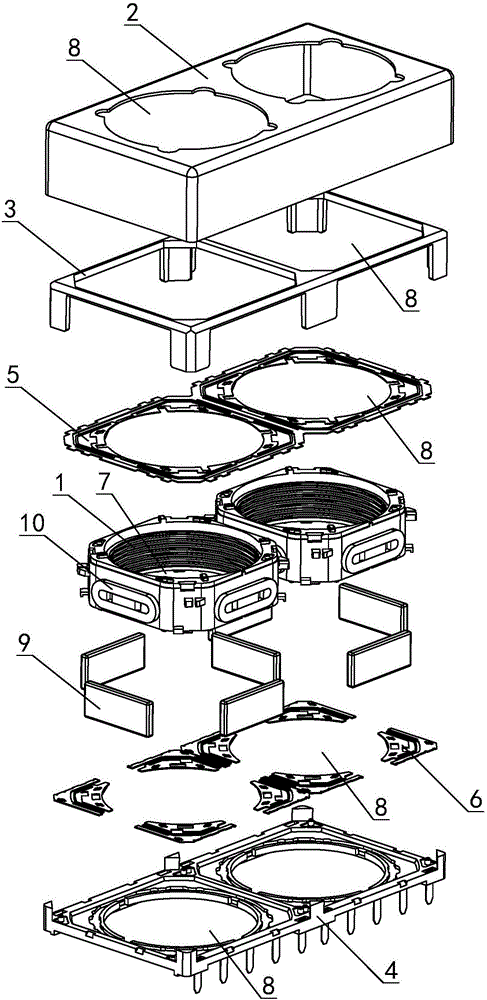

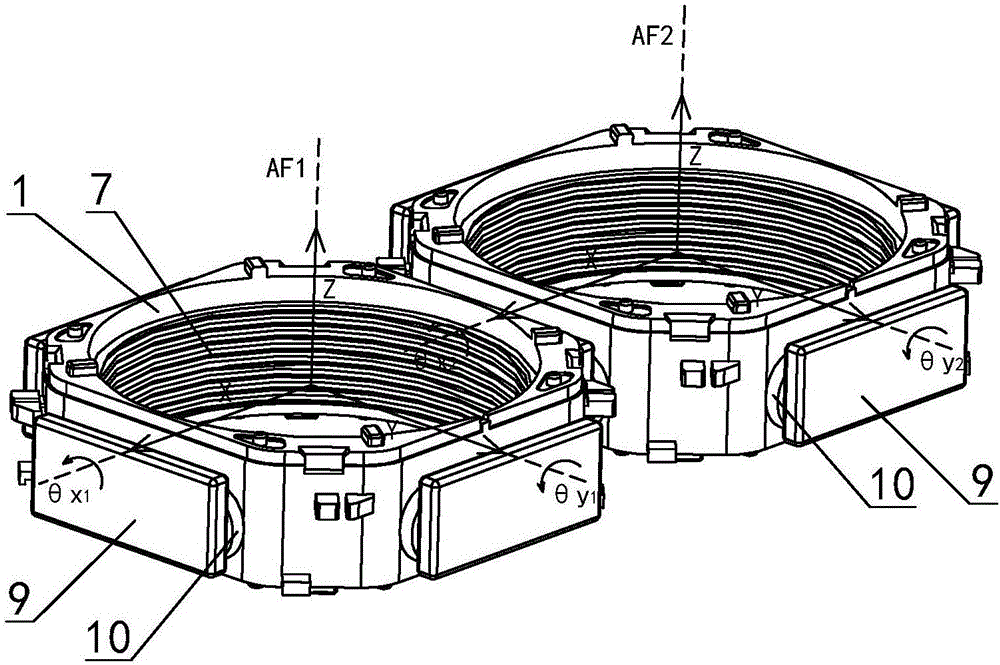

Photographing module with multiple camera lenses focusing respectively

A photographing module with multiple camera lenses focusing respectively comprises a shell, elastic pieces, at least two lens seats, a plurality of magnetic stones or magnets, a plurality of coils and a plurality of leads. Each lens seat is provided with a lens assembling hole, and each elastic piece is positioned between the inner side of the shell and the corresponding lens seat in an abutted manner. Four coils are fixedly arranged on the outer sides of the four horizontal directions of each lens seat respectively, the magnetic stones or the magnets are fixedly arranged in the shell, and one magnetic stone or magnet is arranged on the outer side of each coil correspondingly. When being electrified, the coils generate magnetism mutually repelling with that of the magnetic stones or magnets. The leads are electrically connected with the coils to enable the coils to be electrified and generate magnetism. The photographing module with the multiple camera lenses focusing respectively has the advantages that except for a traditional focusing function in a Z-axis direction, each lens seat has a fine adjustment function in two angles of theta x and theta y, so that high-precision requirements on focusing during photographing is met, production efficiency and yield are increased because of structural simplification, and cost is lowered.

Owner:SUZHOU FORCECON ELECTRIC

Pre-assembled box culvert for high-speed road and bridge construction and construction process thereof

InactiveCN108729366AEasy to installMeet high precision requirementsGround-workSealed roadArchitectural engineering

The invention relates to a pre-assembled box culvert for high-speed road and bridge construction, which comprises a top formwork and a side wall board supporting the top formwork, the side wall boardcomprises a base and a support platform on the base, the base and the support platform is formed into an inverted T-shape, and the inner side of the base is provided with cast steel bars, the upper end of the support platform is provided with a V-shaped groove or a U-shaped groove, and the outer side of the support platform is provided with a lower hanging steel bar hook, and the lower hanging steel bar hook and the cast steel bars are arranged in parallel; the lower end of the top formwork is provided with an engaging portion conforming to the groove type of the V-shaped groove or the U-shaped grooved, and the upper plate surface of the top formwork is provided with an upper hanging steel bar hook, which is provided with a connection hole along the long direction of the top formwork platefor the connection and fixation of the bend bolts .

Owner:安徽巢湖路桥建设集团有限公司

C-axis device of CNC vertical lathe

ActiveCN102284880AImprove processing efficiencyImprove machining accuracyMetal working apparatusNumerical controlThin walled

The invention relates to a C-axis device of a numerical control vertical lathe. The device is characterized in that: the C-axis device is arranged beside a first gear which drives a worktable to rotate and is fixedly connected with a spindle and mainly comprises a servo motor, a transmission mechanism, a slide rail, a slide seat and a linear driving mechanism. The C-axis device can finish turning, drilling and milling actions through one-time clamping, is multipurpose, comprehensively improves processing efficiency, and particularly has superior processing performance for thin-wall parts withhigh requirements.

Owner:YOUJI MACHINE IND CHINA COMPANY

Automatic laser welding device for fibre-optical active component

InactiveCN100351033CAdaptableIncrease flexibilityLaser beam welding apparatusFiberOptical power meter

The automatic laser welding apparatus for active fiber device includes a work table, a control unit, a laser welding mechanism and a precise butt jointing mechanism, and the laser welding mechanism and the precise butt jointing mechanism are installed on the work table. The precise butt jointing mechanism includes a fiber position regulating mechanism and a light source device position regulating mechanism, the fiber position regulating mechanism includes three successively superposed 1D translation stages and one fiber device fixture on the stages, and the light source device position regulating mechanism includes one 2D inclined stage and two orthogonal micro platforms in the same structure and on the inclined stage. The control unit includes one host control computer and one light power meter and is connected via cables to other mechanisms. The present invention has the advantages of simple structure, simple control, low cost, great stroke, high resolution, etc.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com