Pre-assembled box culvert for high-speed road and bridge construction and construction process thereof

A high-speed road and bridge, prefabricated assembly technology, applied in the direction of the road bottom, buildings, etc., can solve the problems of low construction and installation accuracy, large installation deviation, and easy formation of wrong side wall panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

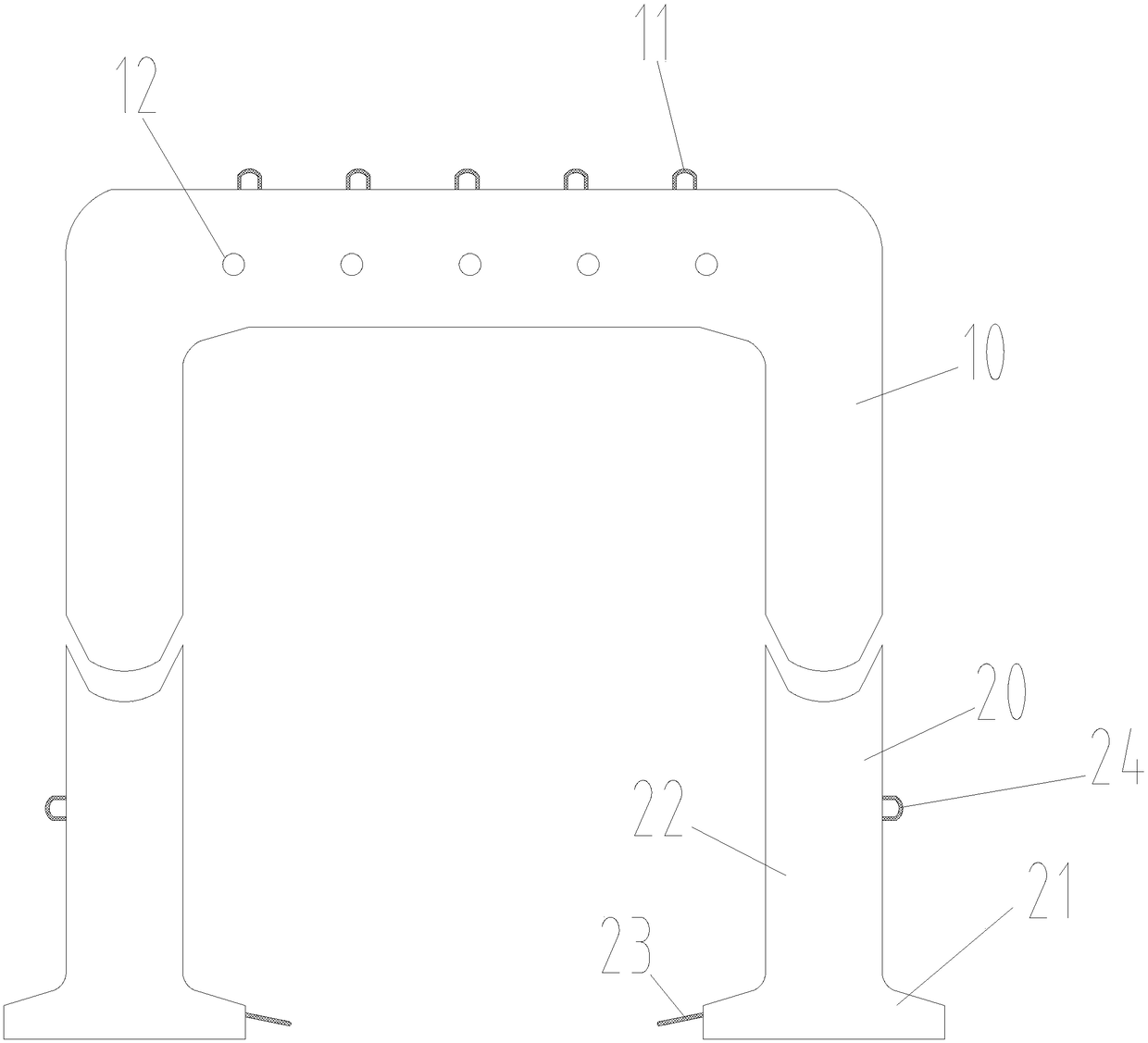

[0015] With reference to the drawings, a prefabricated box culvert for highway and bridge construction includes a top form 10 and a side wall panel 20 supporting the top form 10. The side wall panel 20 includes a base 21 and a support platform on the base 21 22. The base 21 and the support 22 form an inverted T shape, the inner side of the base 21 is provided with pouring steel bars 23, the upper end of the support 22 is provided with V-shaped grooves or U-shaped grooves, and the outer side of the support platform 22 is provided with hanging steel bars. Hook 24, the lower hanging steel bar hook 24 is arranged in parallel with the pouring steel bar 23; the lower end of the top template 10 is provided with a joint portion consistent with the V-shaped groove or U-shaped groove, and the top template The upper plate surface of 10 is provided with an upper hanging steel hook 11, and a connecting hole 12 for bending bolt connection and fixation is opened along the longitudinal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com