Photographing module with multiple camera lenses focusing respectively

A multi-lens and module technology, applied in installation, optics, instruments, etc., can solve the problems of low yield rate and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

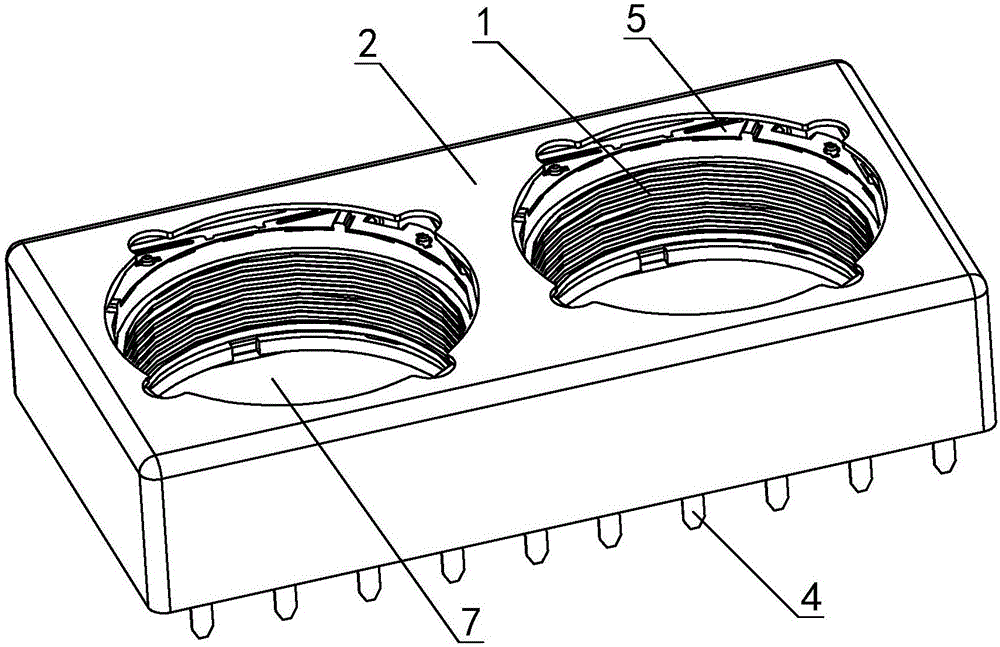

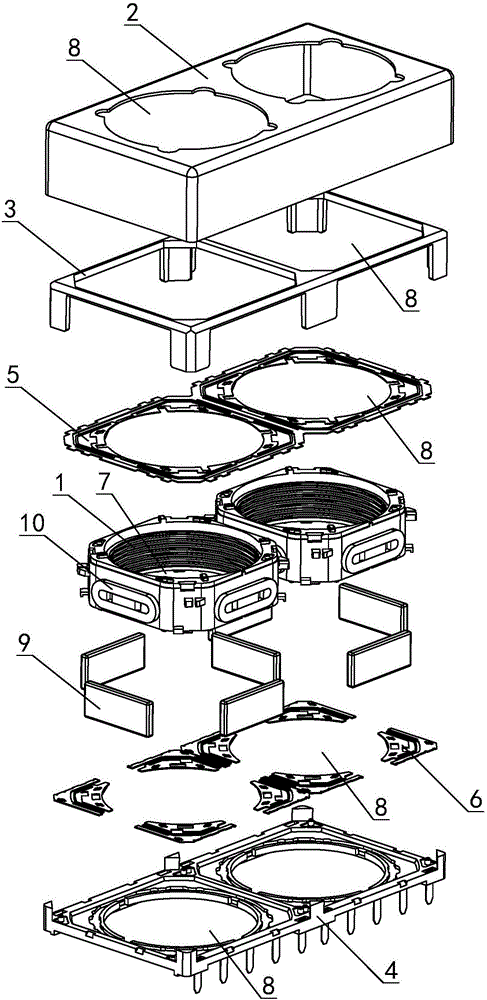

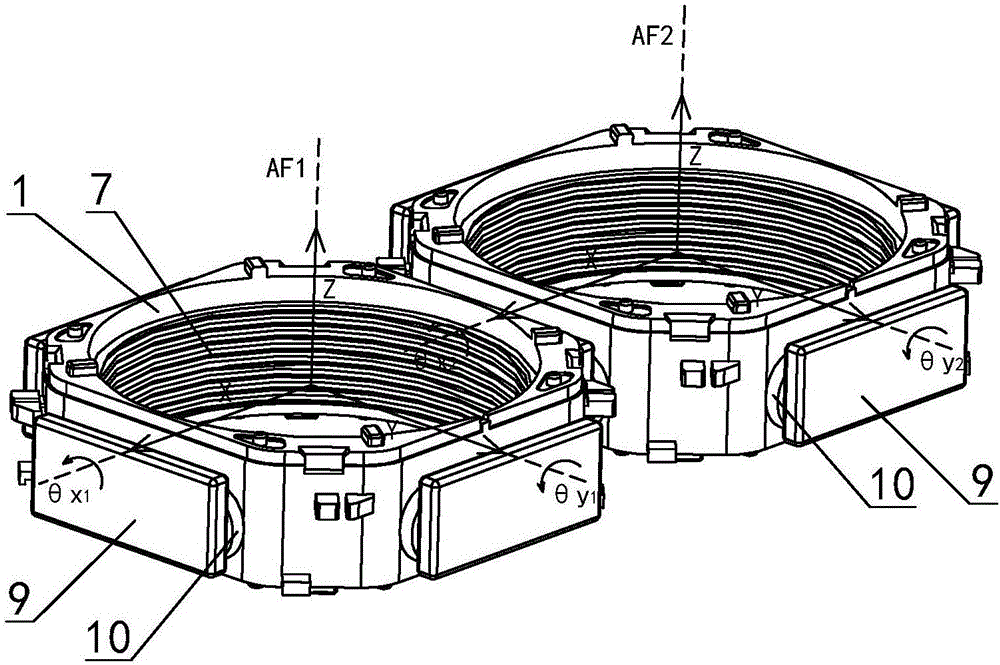

[0028] Example: see attached Figure 1~4 As shown, a camera module with multi-lens focusing separately includes a casing, an elastic sheet and a lens holder 1, the casing includes a yoke 2, a bracket 3 and a base 4; the elastic sheet includes an upper elastic sheet 5 and a lower elastic sheet 6; The yoke 2 is covered on the outside of the bracket 3;

[0029] The lens holder 1 is arranged in the bracket 3, the bottom of the lens holder 1 is supported by the base 4, and the upper elastic piece 5 is elastically supported on the underside of the upper surface of the bracket 3 and the upper part of the lens holder 1 , the lower elastic piece 6 is elastically supported on the upper side of the base 4 and the lower part of the lens holder 1, through the design of the upper elastic piece 5 and the lower elastic piece 6, the support of the lens holder 1 can be better, and it is also easier to restore Location.

[0030] Wherein, there are two lens holders 1, each lens holder 1 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com