Powder forming machine pressure measuring oil cylinder mechanism

A technology of forming machine and oil cylinder, applied in the direction of press, measuring fluid pressure, measuring device, etc., can solve problems such as failure to meet accuracy requirements, unclean air discharge, errors, etc., and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

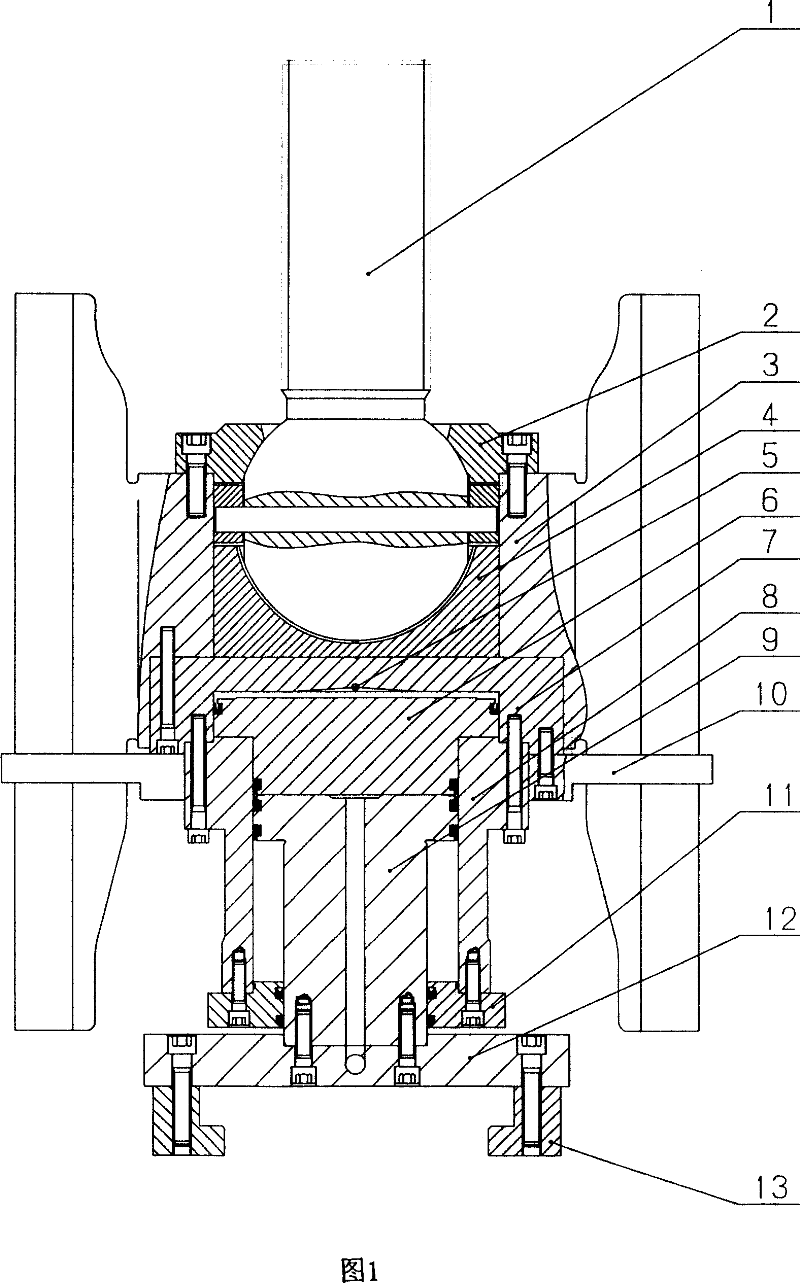

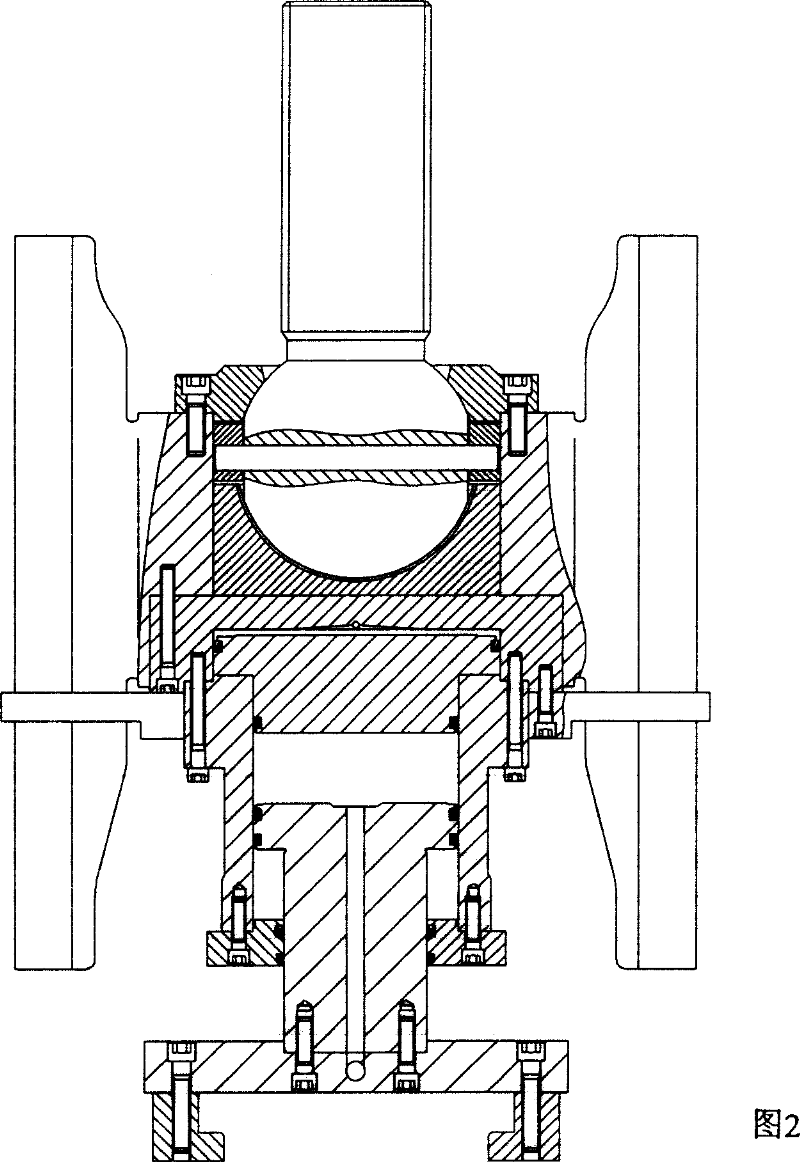

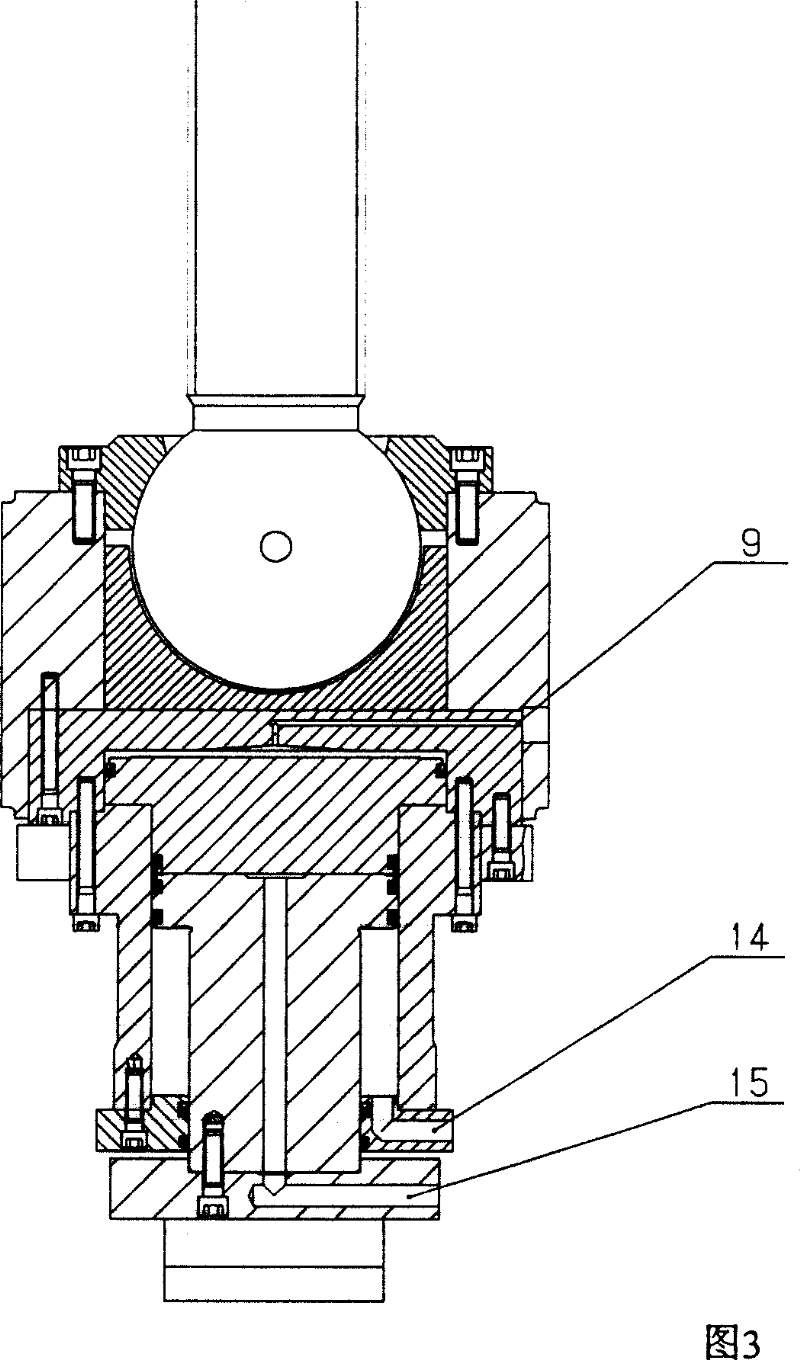

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] The upper end of the screw rod 1 is connected with the power source crank linkage mechanism on the powder forming machine, the ball handle at the lower end of the screw rod 1 is fixed on the two positioning keys through the pin shaft, and the two positioning keys are fixed under the ball cover 2, the lower end of the ball handle Cooperate with the ball seat 4 in the slide block 3, swing forward and backward in the ball seat, can not be killed, and the ball cover 2 is fixed on the upper end surface of the slide block 3 with screws.

[0013] A pressure controller is installed on the base plate 10, and the valve seat on the pressure controller communicates with the measuring oil cylinder 7 (figure not drawn).

[0014] A cavity is machined under the original slider, and the measuring cylinder 7 is fixed on the inner bottom plate 10 of the cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com