Patents

Literature

59results about How to "Realize speed regulation function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

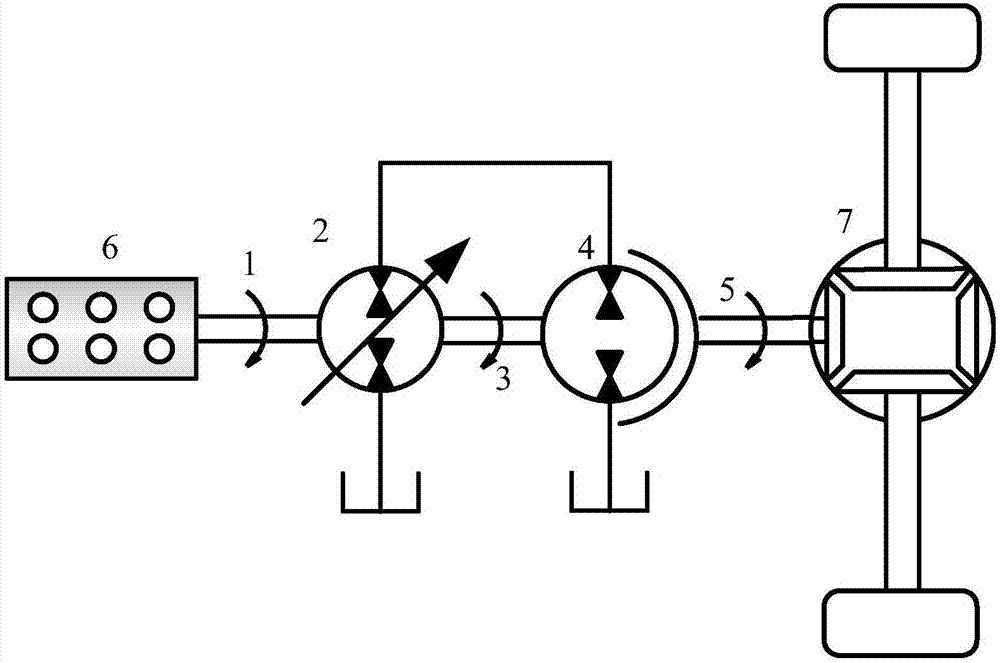

Oil-electric hybrid electric vehicle multi-mode drive system

ActiveCN103660905AEnabling pure engine drive modeImplement drive modeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingMotor driveCoupling

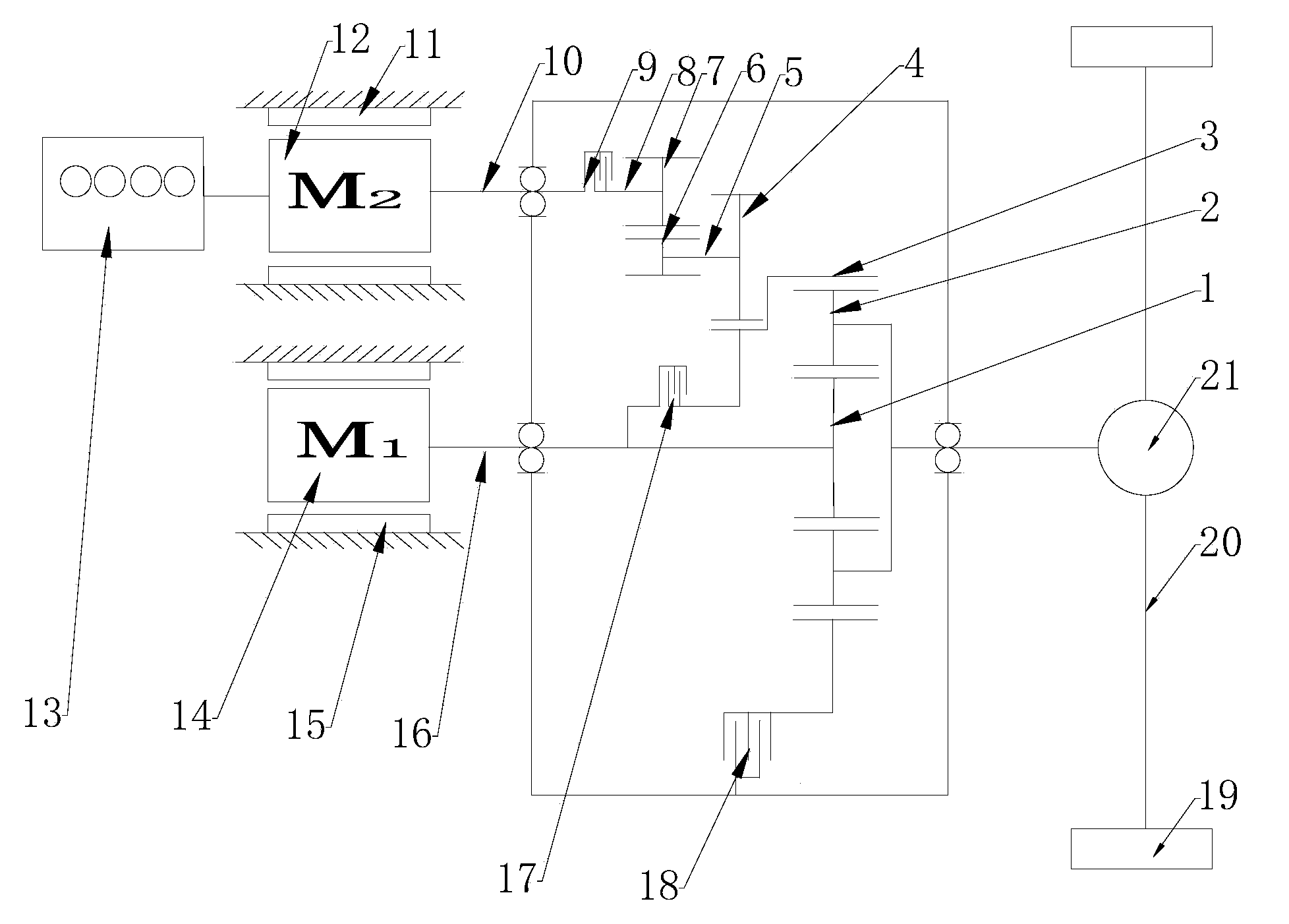

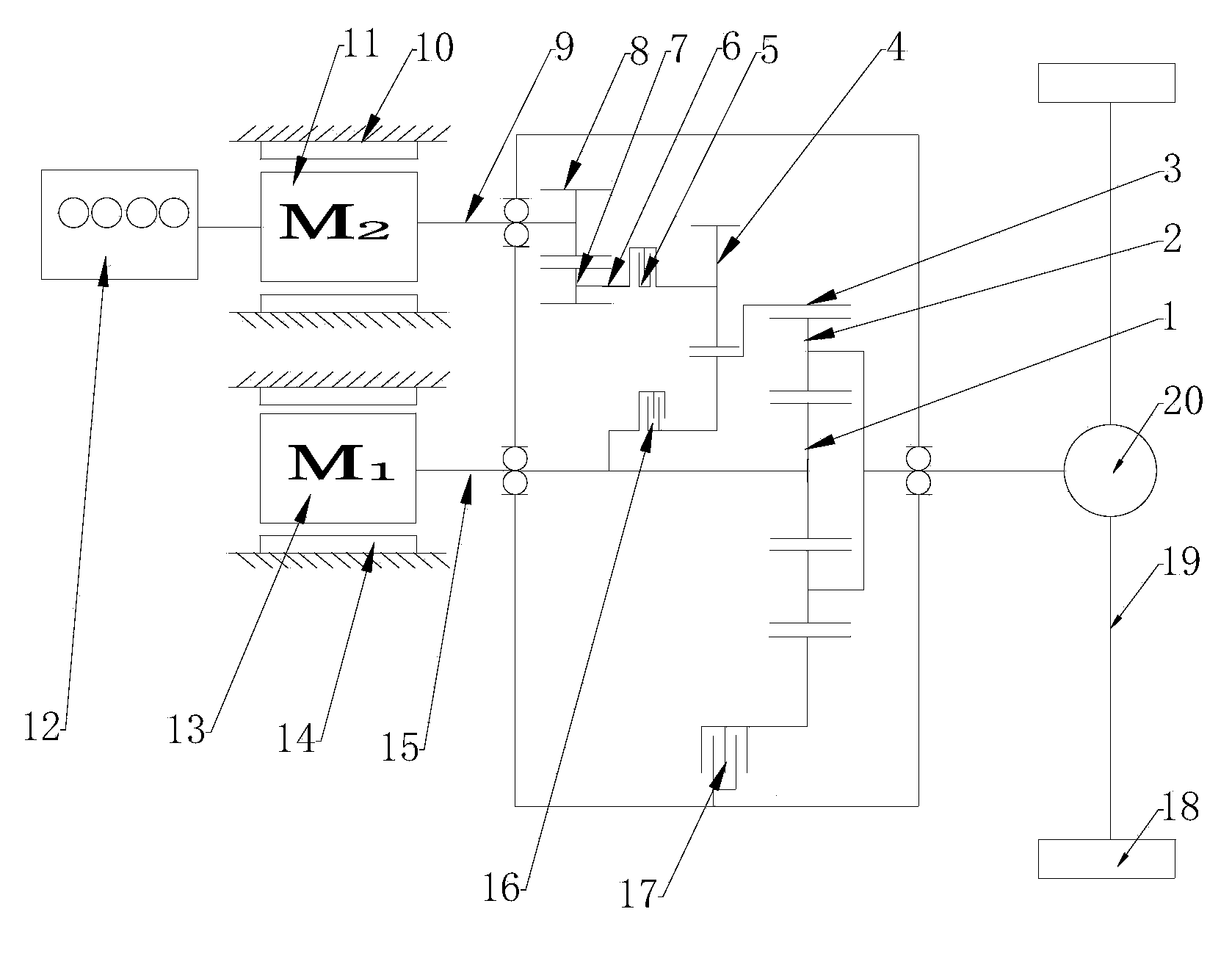

The invention discloses an oil-electric hybrid electric vehicle multi-mode drive system. One end of a second motor of the drive system is connected with an engine, and the other end of the second motor of the drive system is connected with a second motor rotor shaft. One end of a first clutch is connected with the second motor rotor shaft, and the other end of the first clutch is connected with a gear ring through a transmission device. A second clutch and a solar wheel are respectively connected with a first motor through a first motor shaft. The second clutch is connected with the gear ring. A brake is connected with the gear ring. A planet carrier is connected with a drive axle. The drive axle is connected with two wheels respectively through two half shafts. An ECU is connected with a motor controller. The motor controller is connected with the first motor and the second motor respectively. The ECU is further connected with the first clutch, the second clutch and the brake respectively. According to the drive system, a planet mechanism, the clutches and the brake are used in a matching mode, so that a drive mode of pure motor drive and coupling of a motor and an engine is realized, and a multi-power transmission mode is formed.

Owner:SOUTH CHINA UNIV OF TECH

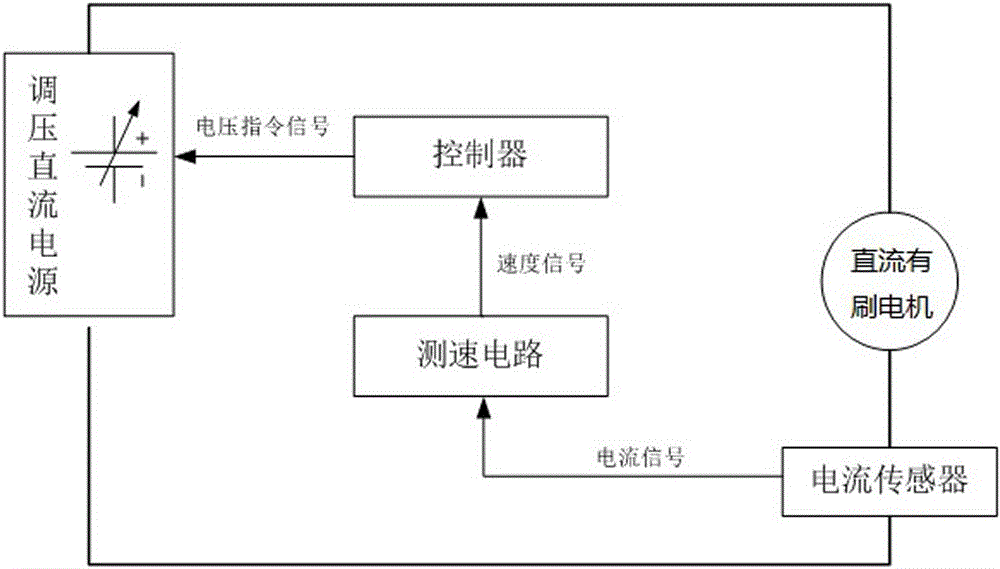

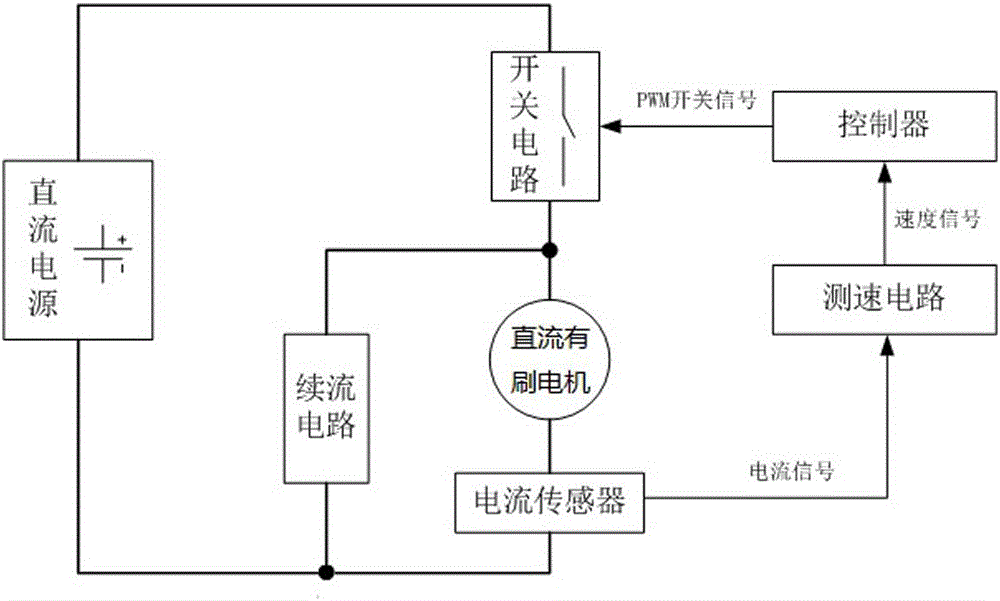

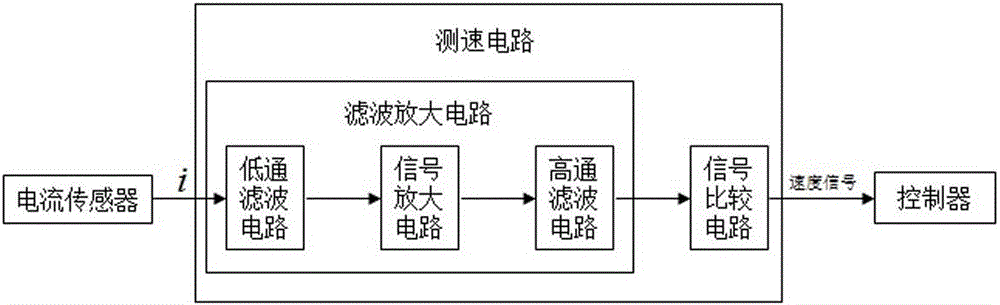

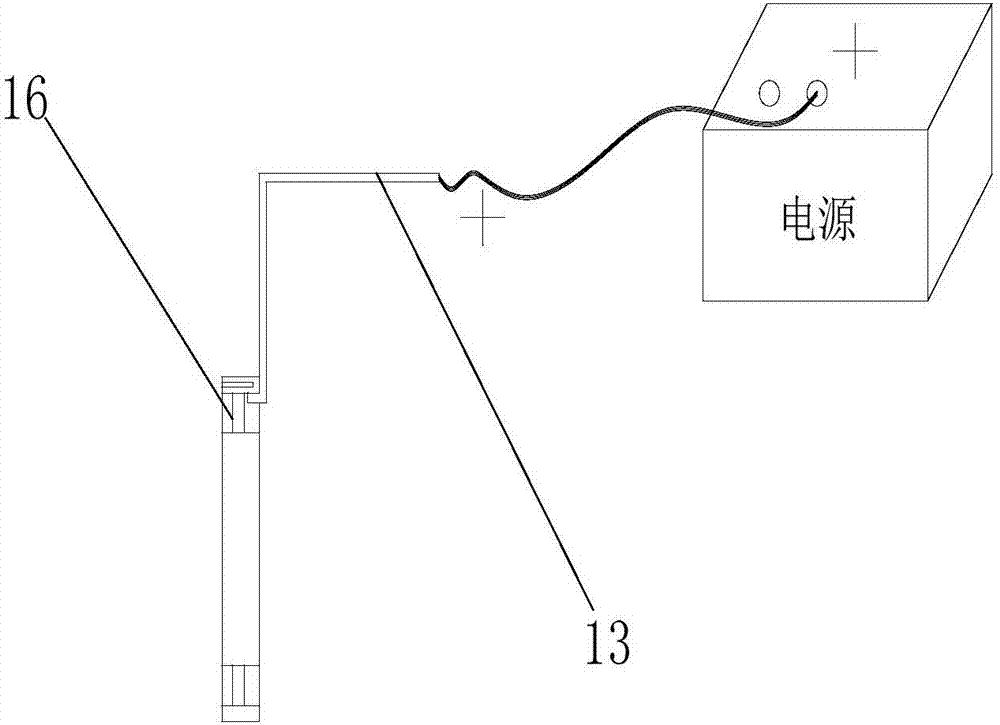

Speed regulation device and speed regulation method of DC brush motor

InactiveCN105680744ARev easySpeed adjustmentField or armature current controlPower flowSquare waveform

The invention relates to a speed regulation device and speed regulation method of a DC brush motor. The speed regulation device and the speed regulation method are characterized in that a current signal of the DC brush motor is acquired by a current sensor; the current signal is filtered and amplified by a filtering amplification circuit; the current signal is converted to a high-low alternating square wave speed signal by a single comparison circuit; the rotational speed of the motor is obtained through calculation by a controller according to the period or the frequency of the speed signal combined with the number of mica plates in a motor commutator; and finally, an instruction signal is sent to an adjustable power supply from the controller, and the purpose of adjusting the rotational speed of the motor is achieved by controlling the DC voltage amplitude of the motor. With the speed regulation device and the speed regulation method, the speed of the motor can be measured and adjusted by single circuit combination, an extra large-scaled device is not needed, and the speed regulation device and the speed regulation method are relatively low in cost; and moreover, no limitation is generated to an application environment and a mechanical structure of the motor, the speed measurement result is more accurate, and the rotational speed of the motor can be adjusted and controlled better.

Owner:JIANGSU REYA ELECTRIC

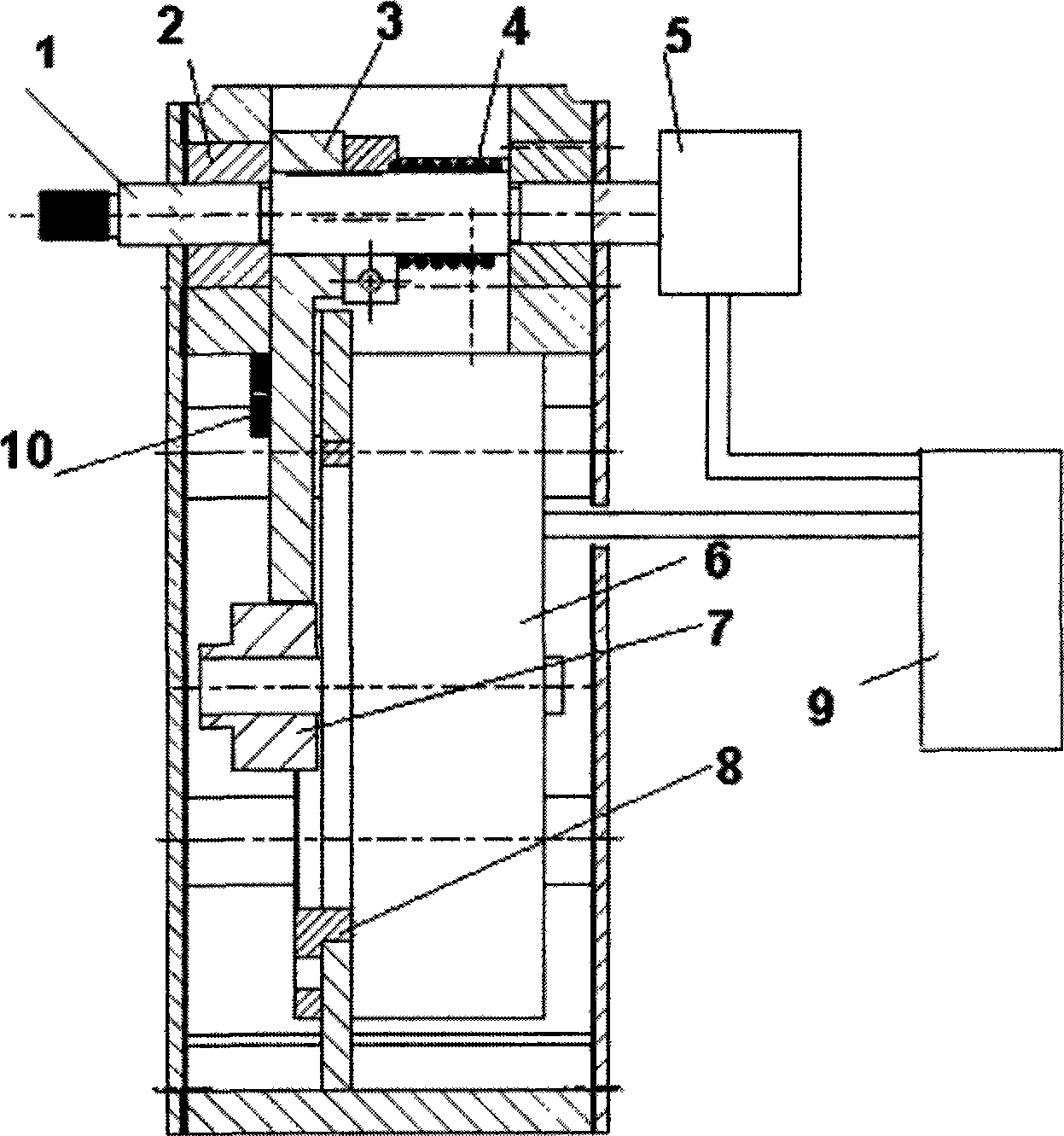

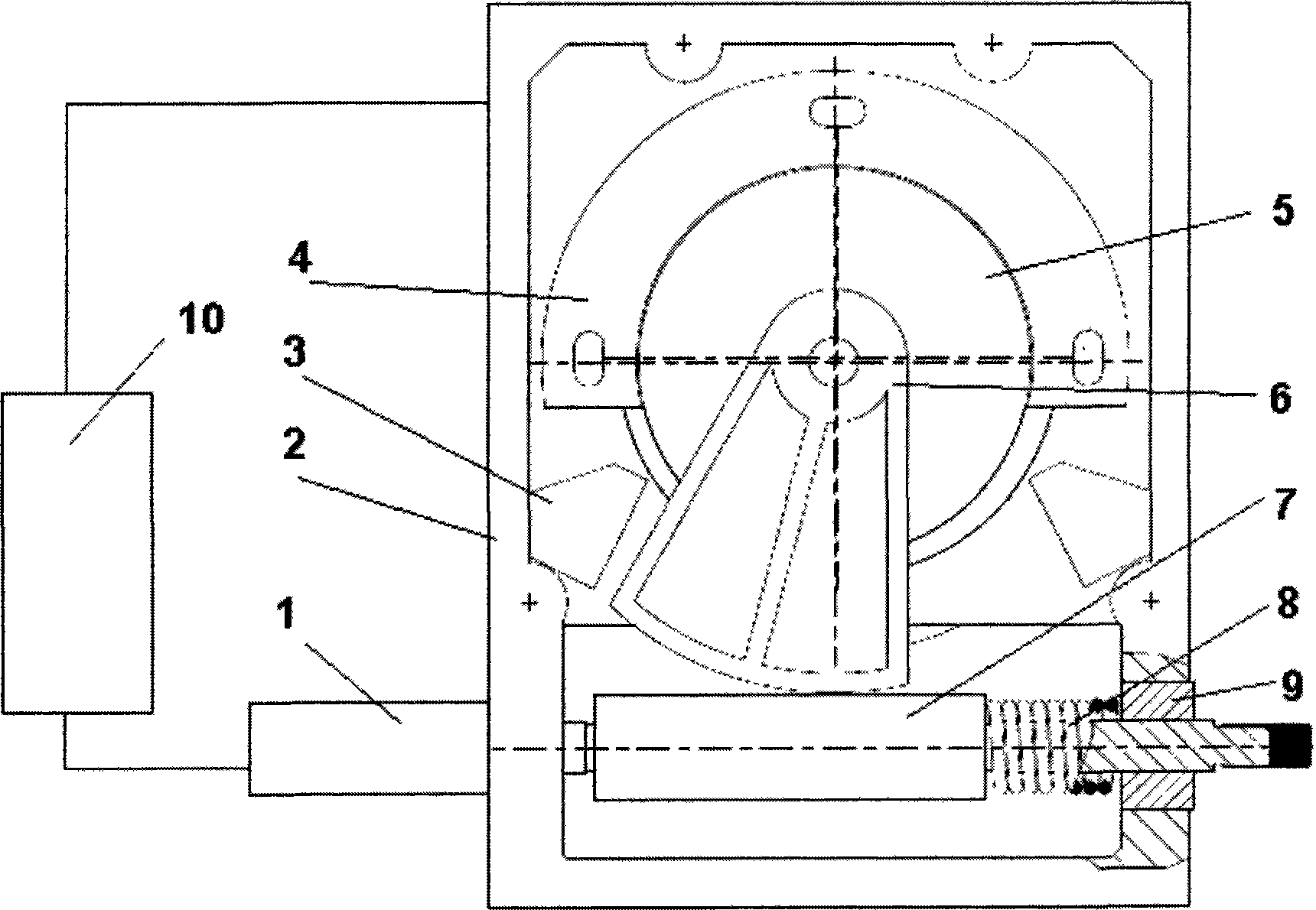

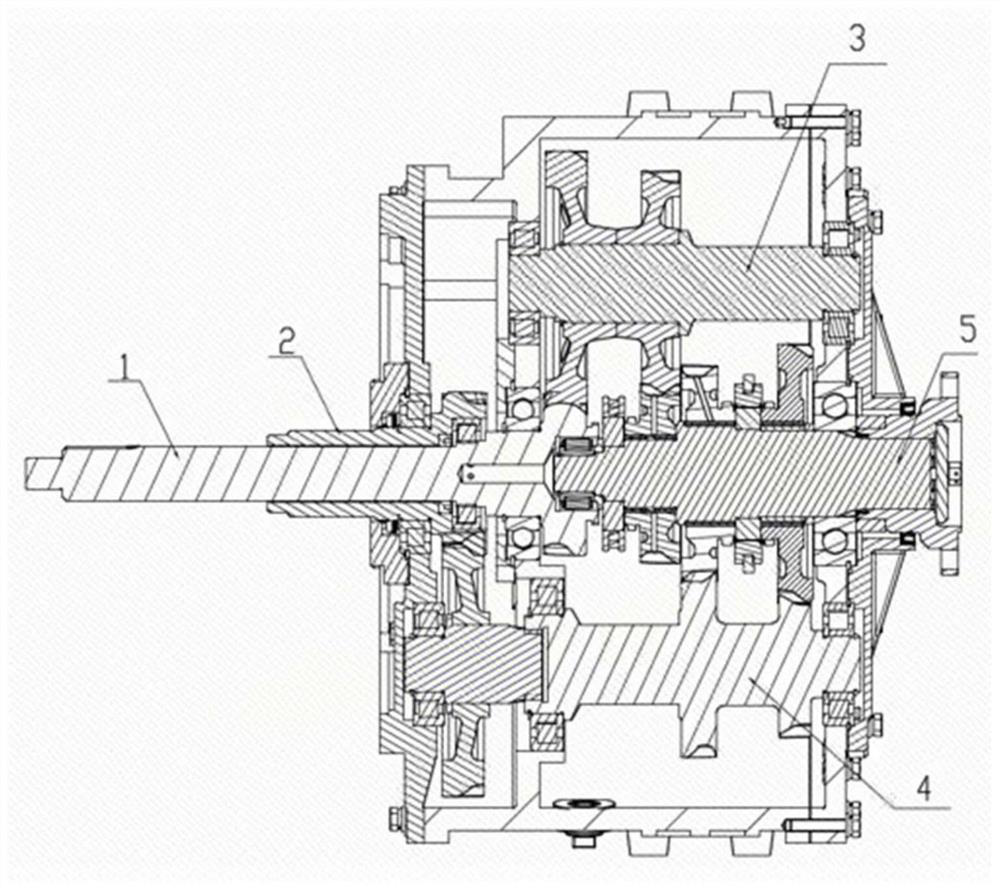

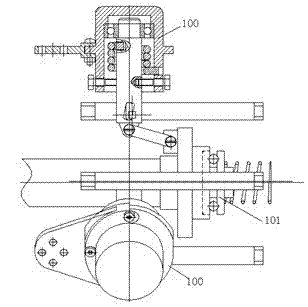

Torque motor actuator of rotary diesel engine

InactiveCN101532435AControl speedQuick responseEngine controllersMachines/enginesGear wheelTorque motor

The invention provides a torque motor actuator of a rotary diesel engine, comprising a shaft, a bearing, a gearwheel, an angle sensor, a torque motor, a pinion, an eccenter, a controller and the like. The torque motor is arranged on the eccenter and is provided with the pinion; the pinion is mutually meshed with the gearwheel installed on the shaft; one end of the shaft is provided with the angle sensor which is connected with the controller to feed back the shaft angle to the controller; the output of the controller controls the torque motor. In the invention, the torque motor with small torque is adopted for torque amplification via a gear mechanism, which can realize larger torque, and a backlash eliminating mechanism and an angle position-limit mechanism are installed, which can better realize controlled electronic speed regulating function of diesel engine position.

Owner:HARBIN ENG UNIV

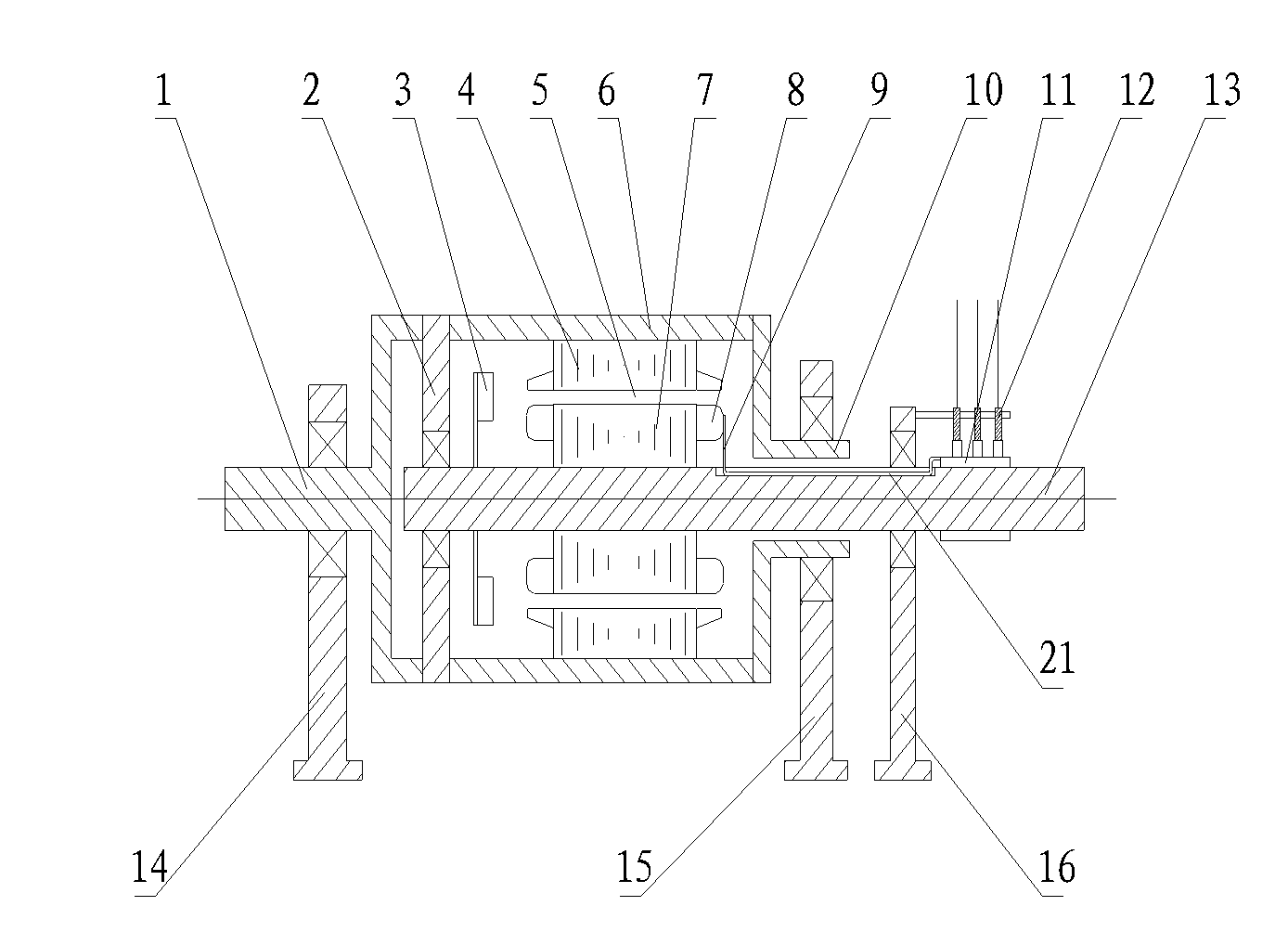

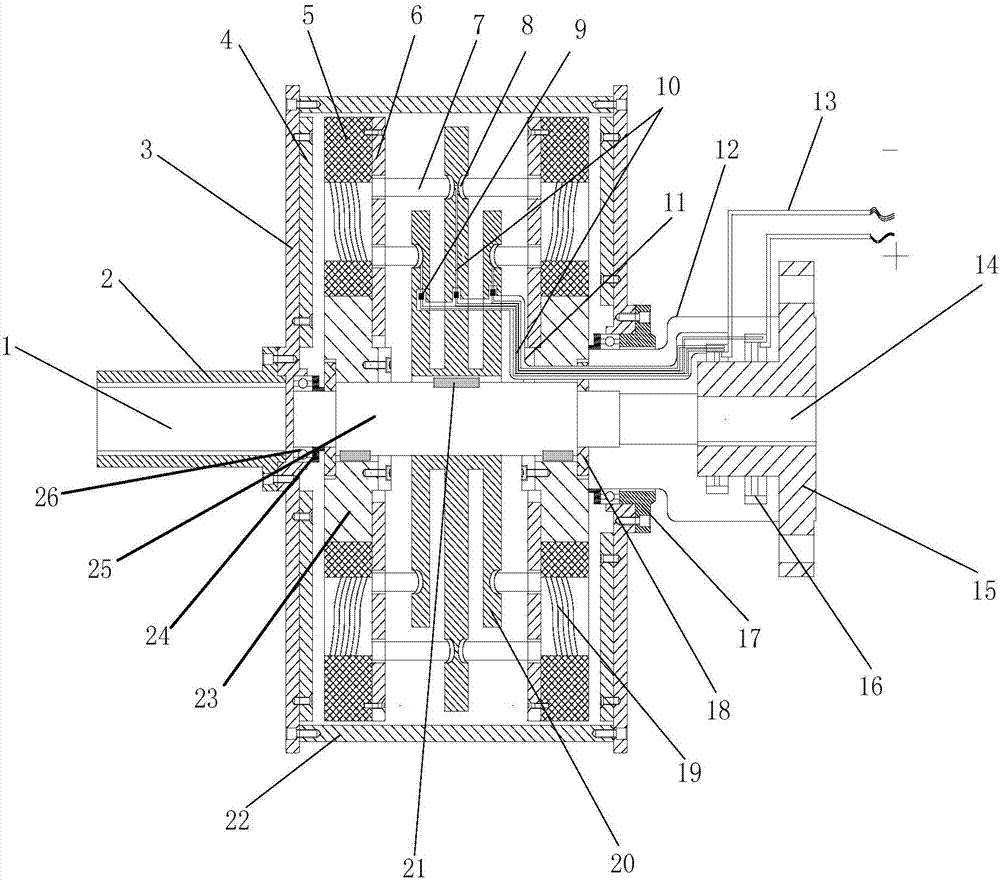

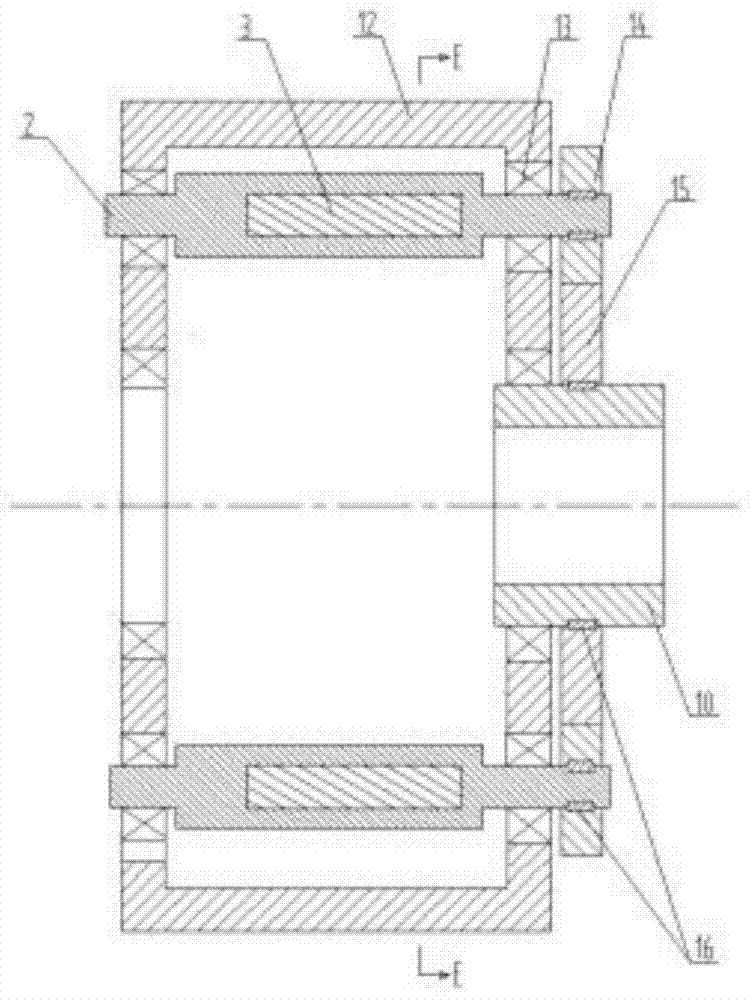

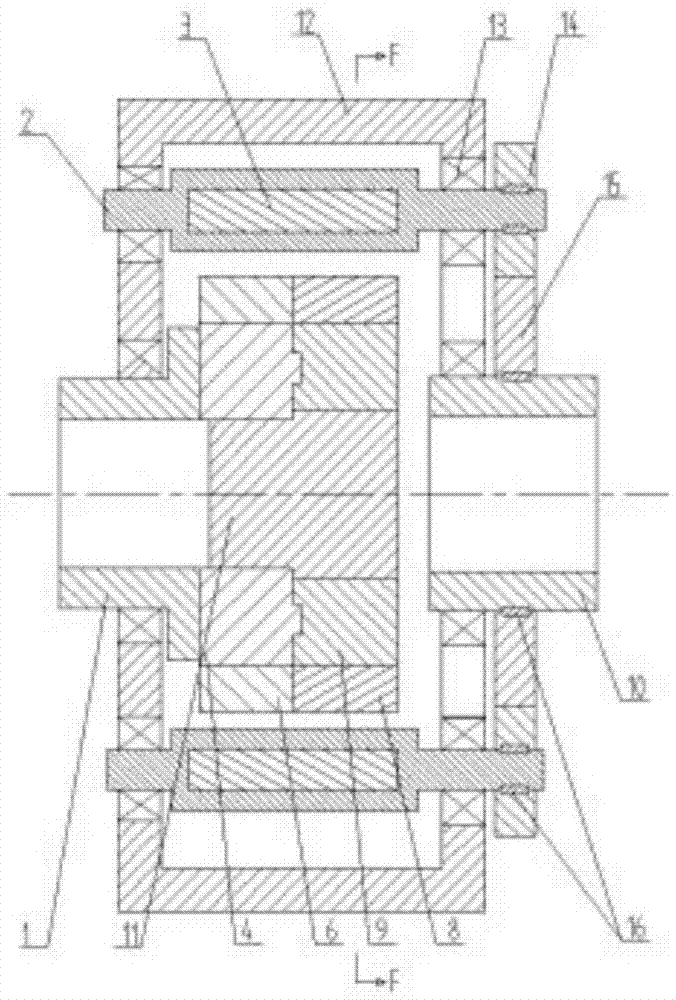

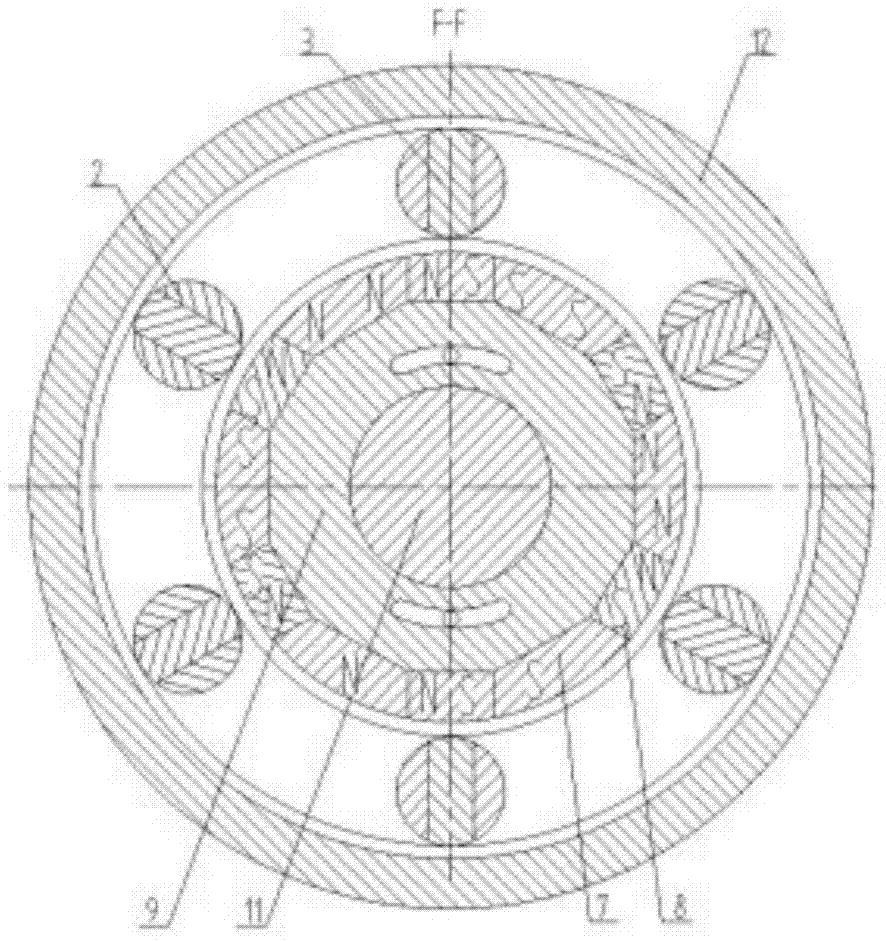

Non-contact type speed-adjustable electromagnetic coupler

InactiveCN101944826ARealize contactless connectionPlay the role of energy transferDynamo-electric gearsDynamo-electric gear controlElectromagnetic couplingFluid coupling

The invention relates to a non-contact type speed-adjustable electromagnetic coupler which comprises an outer rotor assembly, an inner rotor assembly and a conducting assembly, wherein the inner rotor assembly and the outer rotor assembly are mutually and electromagnetically coupled in a power-on state; the conducting assembly comprises three lead slots arranged on the side face of an inner rotor shaft, three leads respectively arranged in the lead slots, three conducting rings fixed on the side face of the rear end part of the inner rotor shaft and a three-phase static electric brush respectively in fitting contact with the three conducting rings; one end of each lead is respectively connected with an inner rotor armature winding, while the other ends are respectively connected with the three conducting rings; and the three-phase static electric brush is respectively connected with a three-phase alternating current power supply. The invention solves the technical problem that the speed of the traditional hydraulic coupler cannot be adjusted. The non-contact type speed-adjustable electromagnetic coupler can be used for realizing mechanical energy transmission, meanwhile, the speed can be adjusted, thus the non-contact type speed-adjustable electromagnetic coupler can be used for replacing the traditional coupler in a transmission system to realize the non-contact connection of the mechanical transmission system.

Owner:XIAN DUNAN ELECTRIC

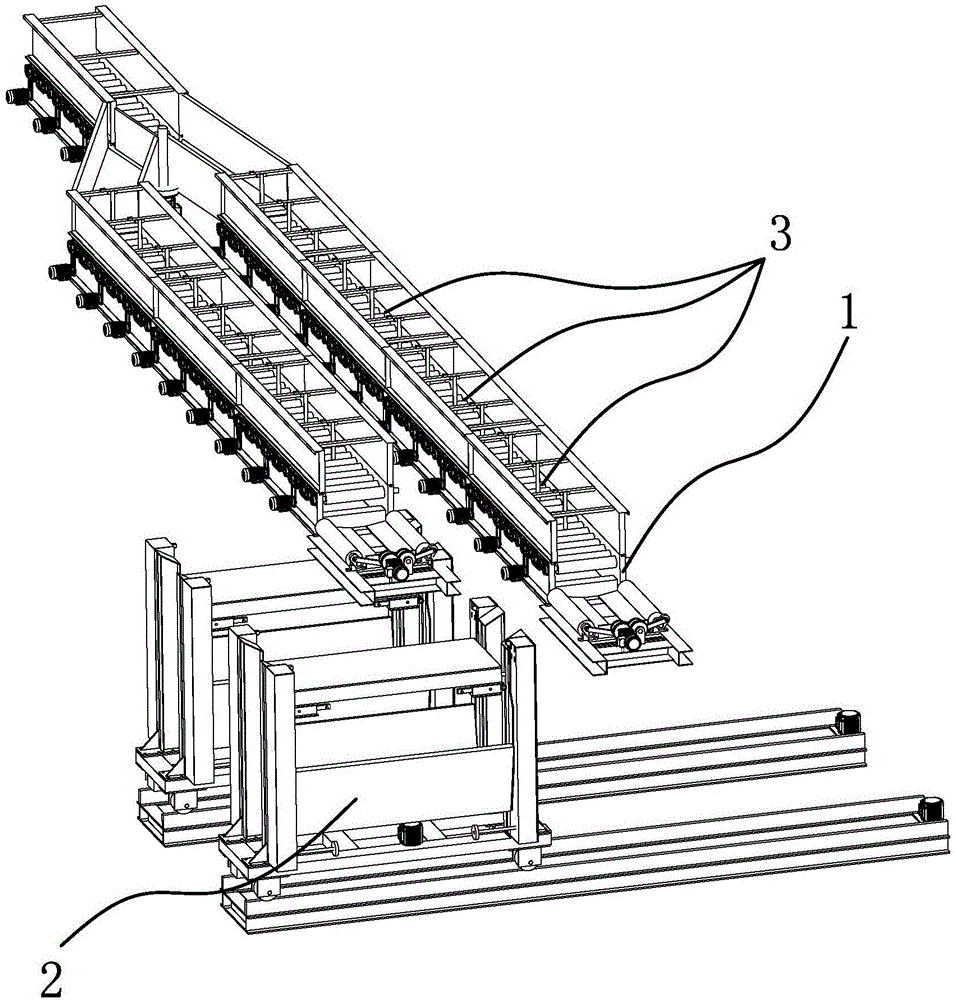

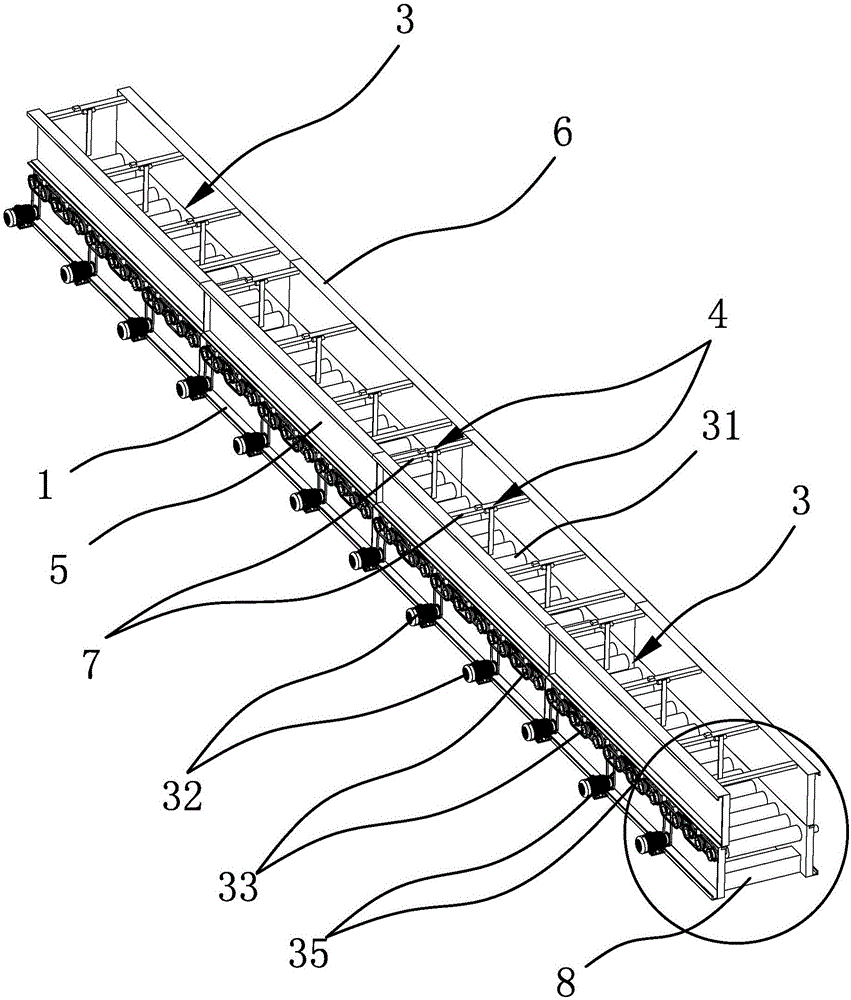

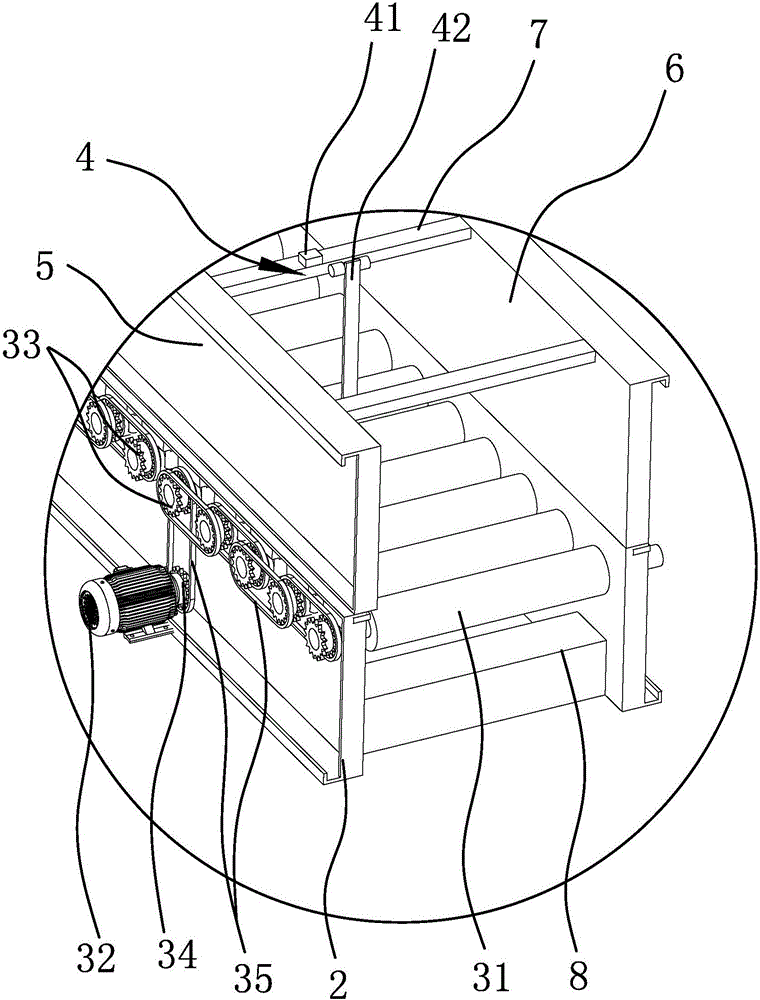

Conveying track for bagged goods stacking production line

InactiveCN106395281AMeasure distanceMeasure movement speedControl devices for conveyorsMechanical conveyorsProduction lineDrive motor

The invention provides a conveying track for a bagged goods stacking production line, and belongs to the technical field of conveying equipment. The conveying track solves the technical problem that a conveying track on an existing bagged goods stacking production line cannot be adjusted. The conveying track comprises two parallel strip-shaped installing frames arranged in a spaced manner. At least three sets of drive units are sequentially arranged between the two strip-shaped installing frames in the length direction of the strip-shaped installing frames. Each drive unit comprises a plurality of parallel rollers arranged at intervals and a drive motor capable of driving the rollers to rotate. A sensing device capable of inducting whether bagged goods are arranged in place or not is arranged above each drive unit. According to the conveying track, the sensing device above each drive unit can detect whether the bagged goods exist on the corresponding drive unit or not, the distance between every two adjacent bagged goods and the moving speed of the bagged goods can be measured and calculated.

Owner:吴江南

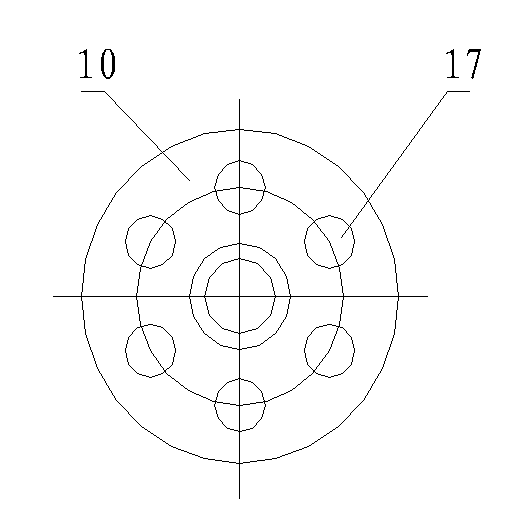

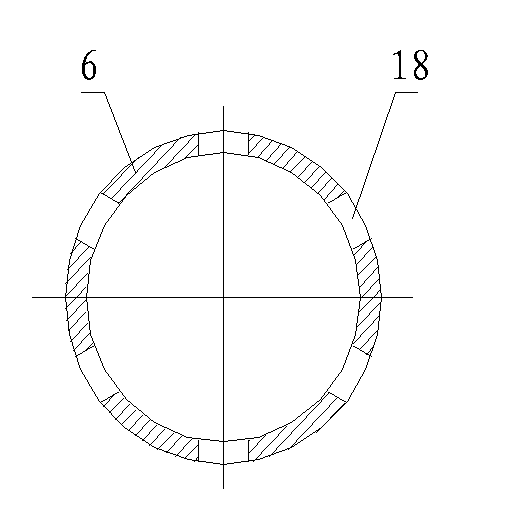

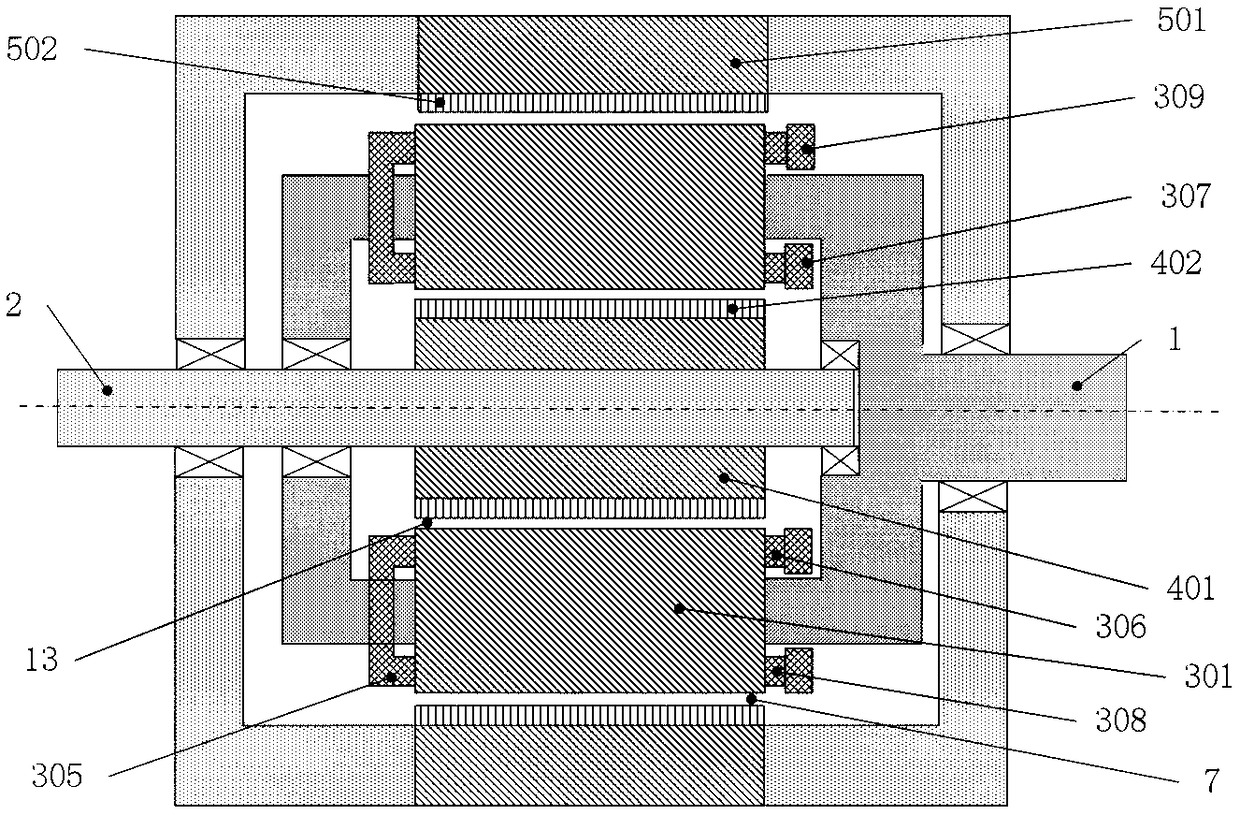

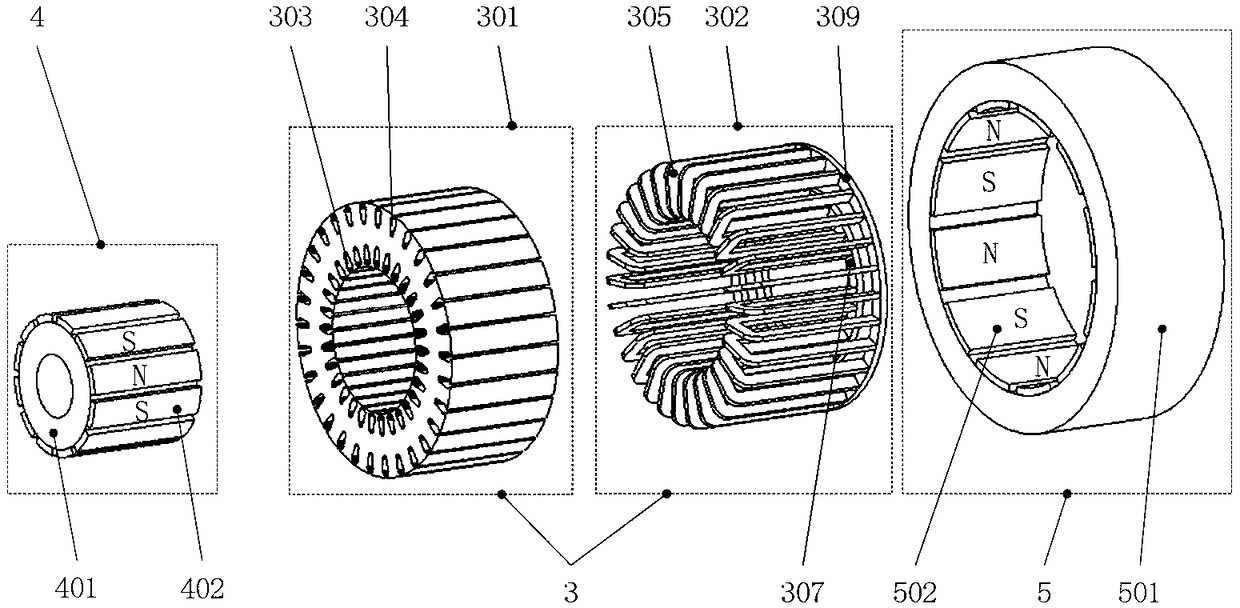

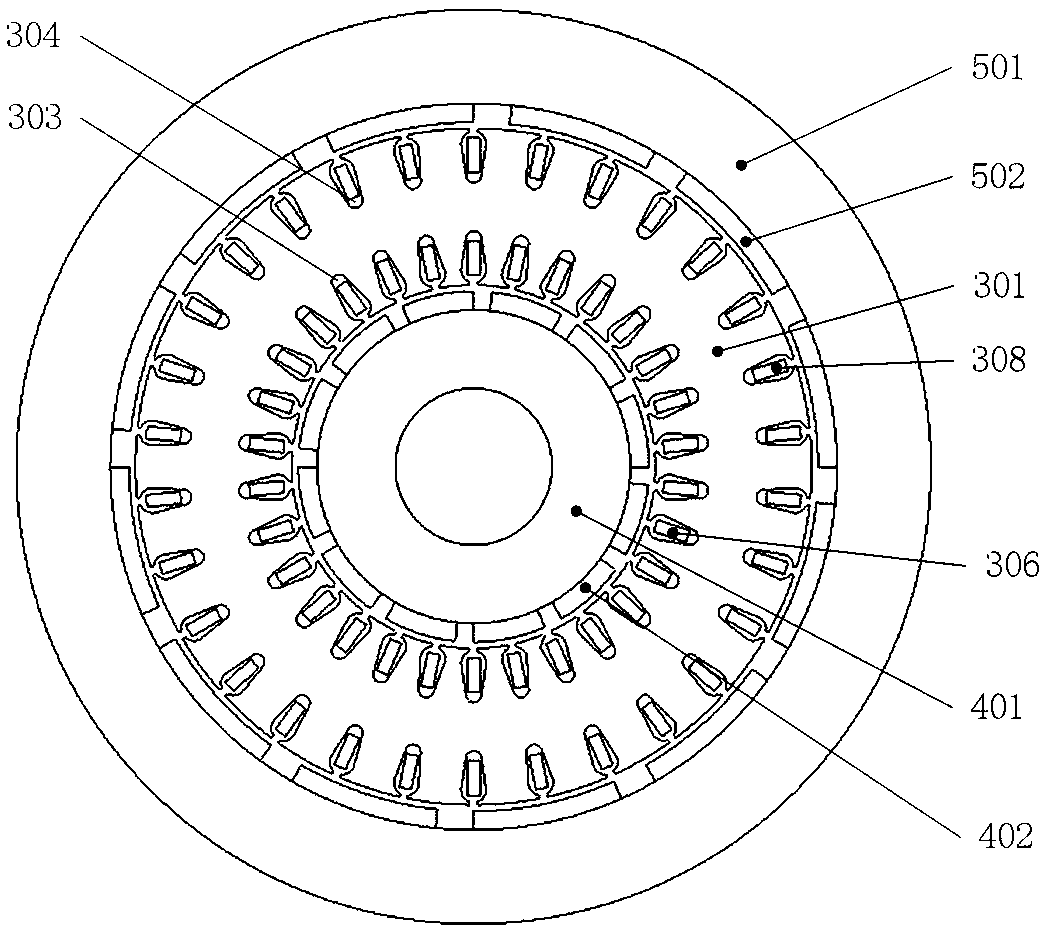

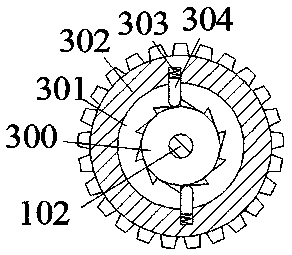

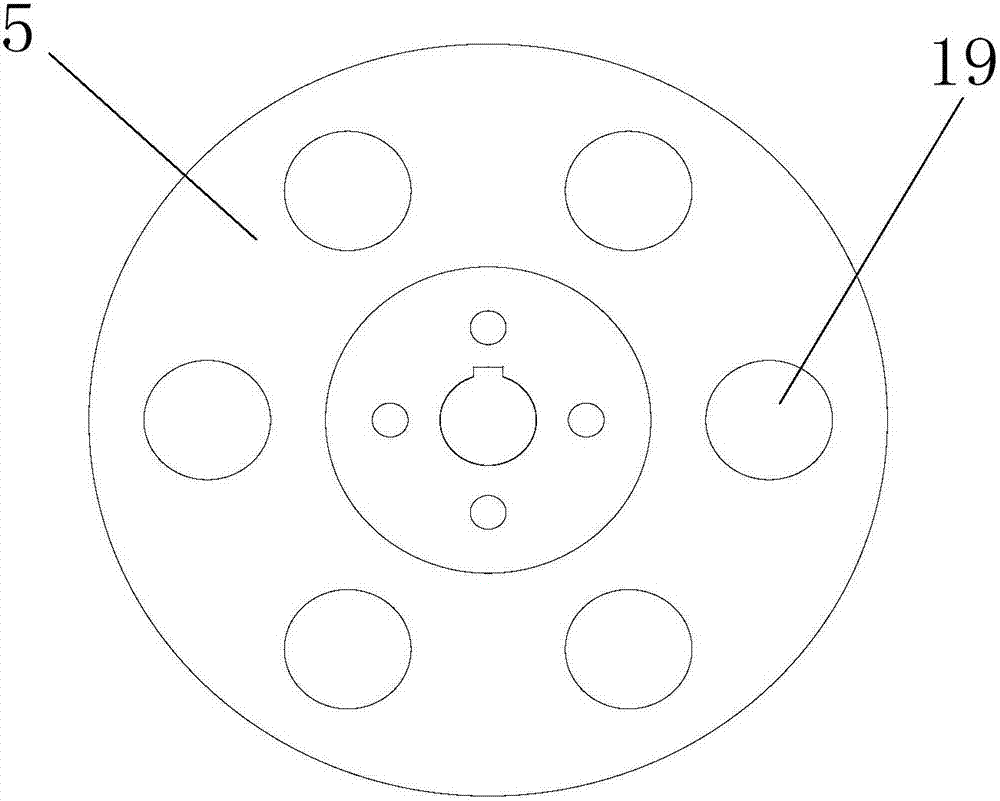

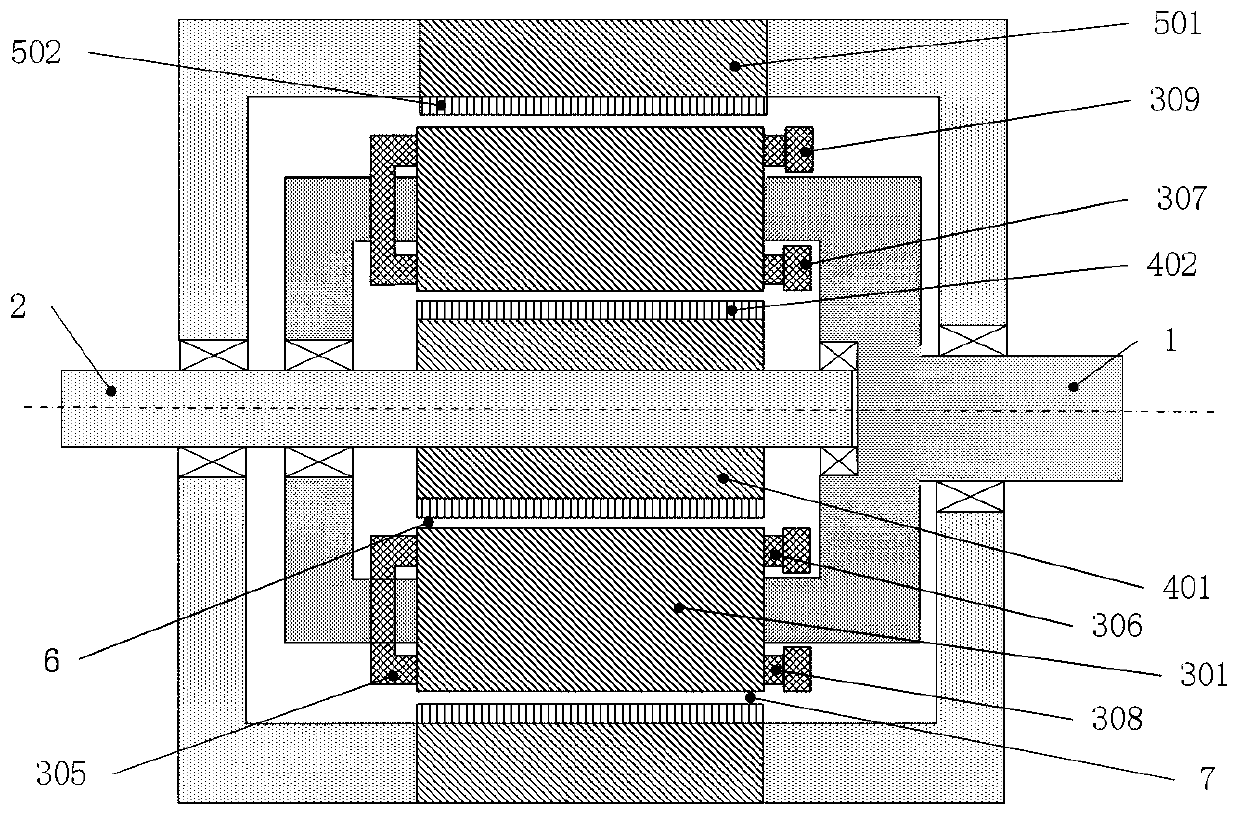

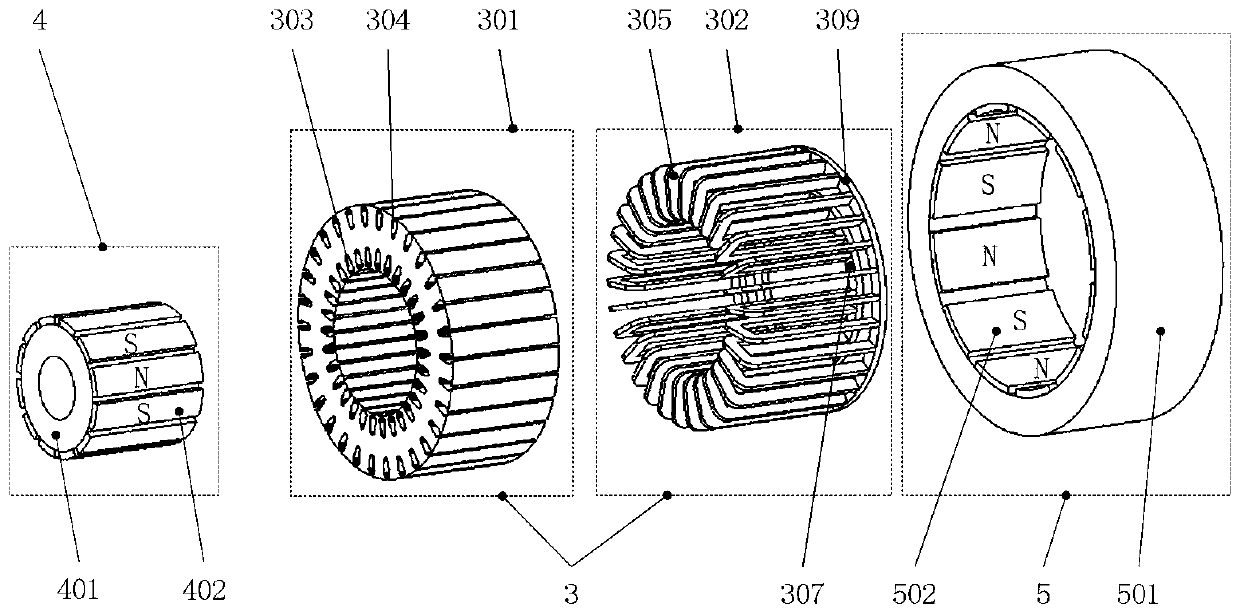

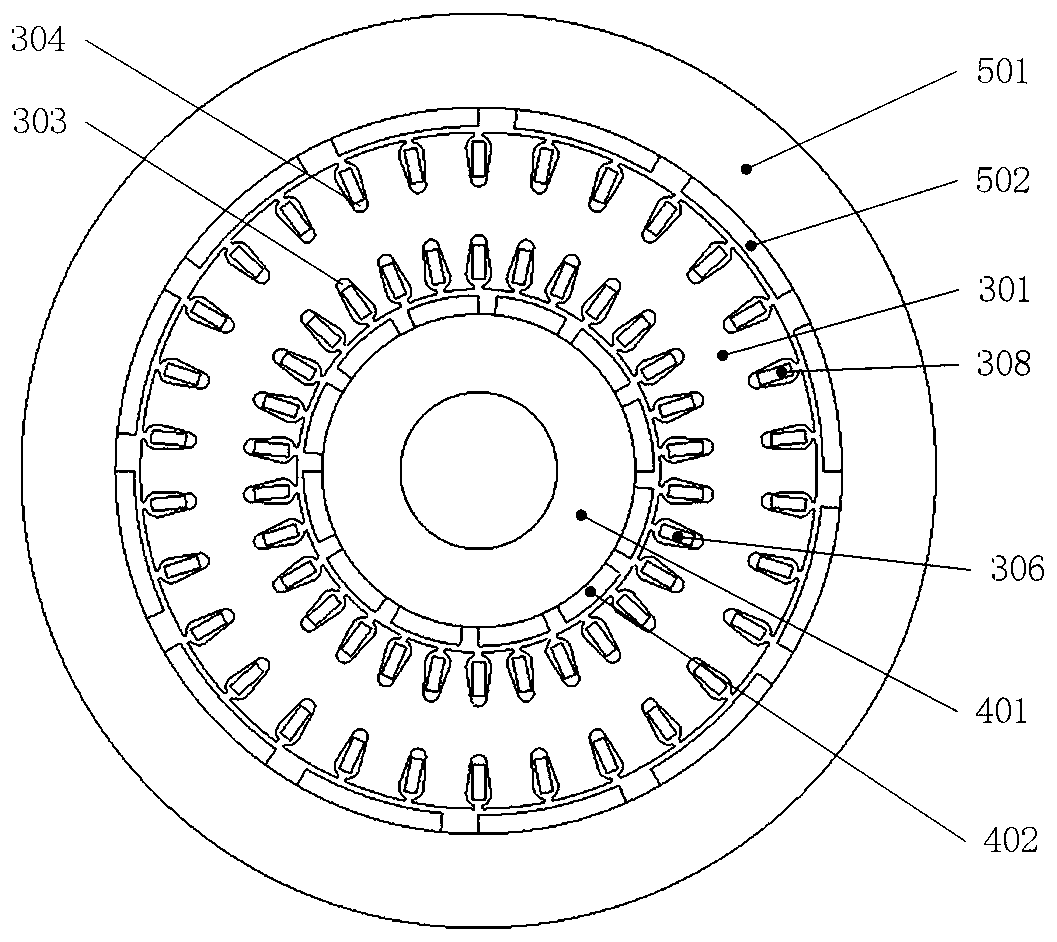

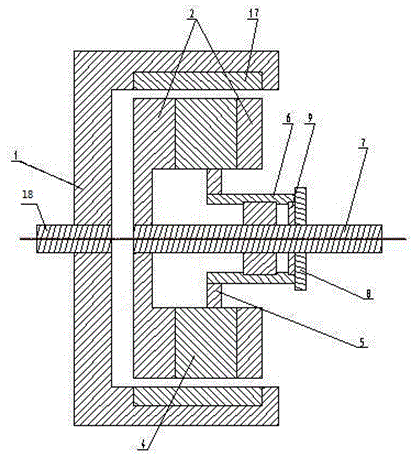

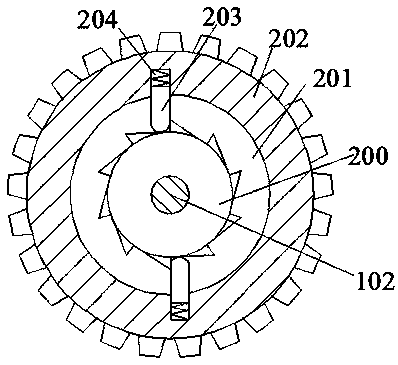

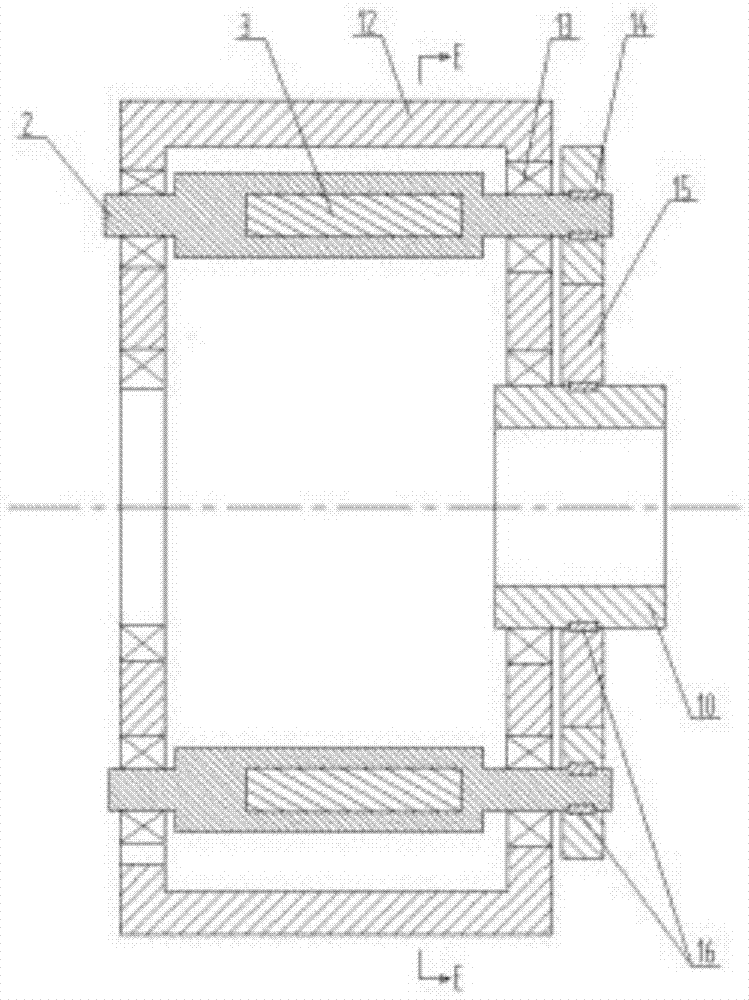

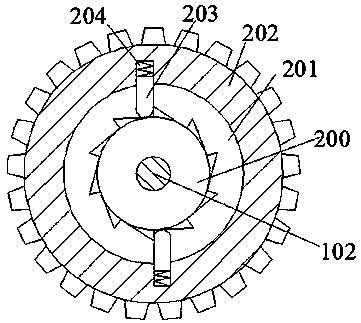

Double-layer standard squirrel cage conductor rotor high torque density permanent magnetic speed controller

ActiveCN108964387ARealize speed regulation functionShorten the axial lengthPermanent-magnet clutches/brakesPermanent magnet rotorElectrical conductor

The invention discloses a double-layer standard squirrel cage conductor rotor high torque density permanent magnetic speed controller. The permanent magnetic speed controller comprises an input shaftand an output shaft set on the same central axis, wherein the input shaft is provided with a conductor rotor in a penetration mode, the output shaft is provided with a first permanent magnet rotor anda second permanent magnet rotor in a penetration mode, the first permanent magnet rotor and the second permanent magnet rotor can rotate with relative concentricity, the first permanent magnet rotor,the conductor rotor and the second permanent magnet rotor are sequentially concentrically sleeved in the radial direction, a first air gap is between the first permanent magnet rotor and the conductor rotor, and a second air gap is between the conductor rotor and the second permanent magnet rotor. The permanent magnetic speed controller is advantaged in that through rotation of the first permanent magnet rotor or the second permanent magnet rotor, the relative rotation angle between the first permanent magnet rotor and the second permanent magnet rotor is changed, the speed control function of the speed controller is achieved, in the speed control process, overcoming the cogging torque is only required, the function of the speed controller is different from the speed control function achieved through adjusting an axial air gap between a magnetic rotor and a conductor rotor in the prior art, and axial length of the permanent magnetic speed controller is effectively reduced.

Owner:SOUTHEAST UNIV

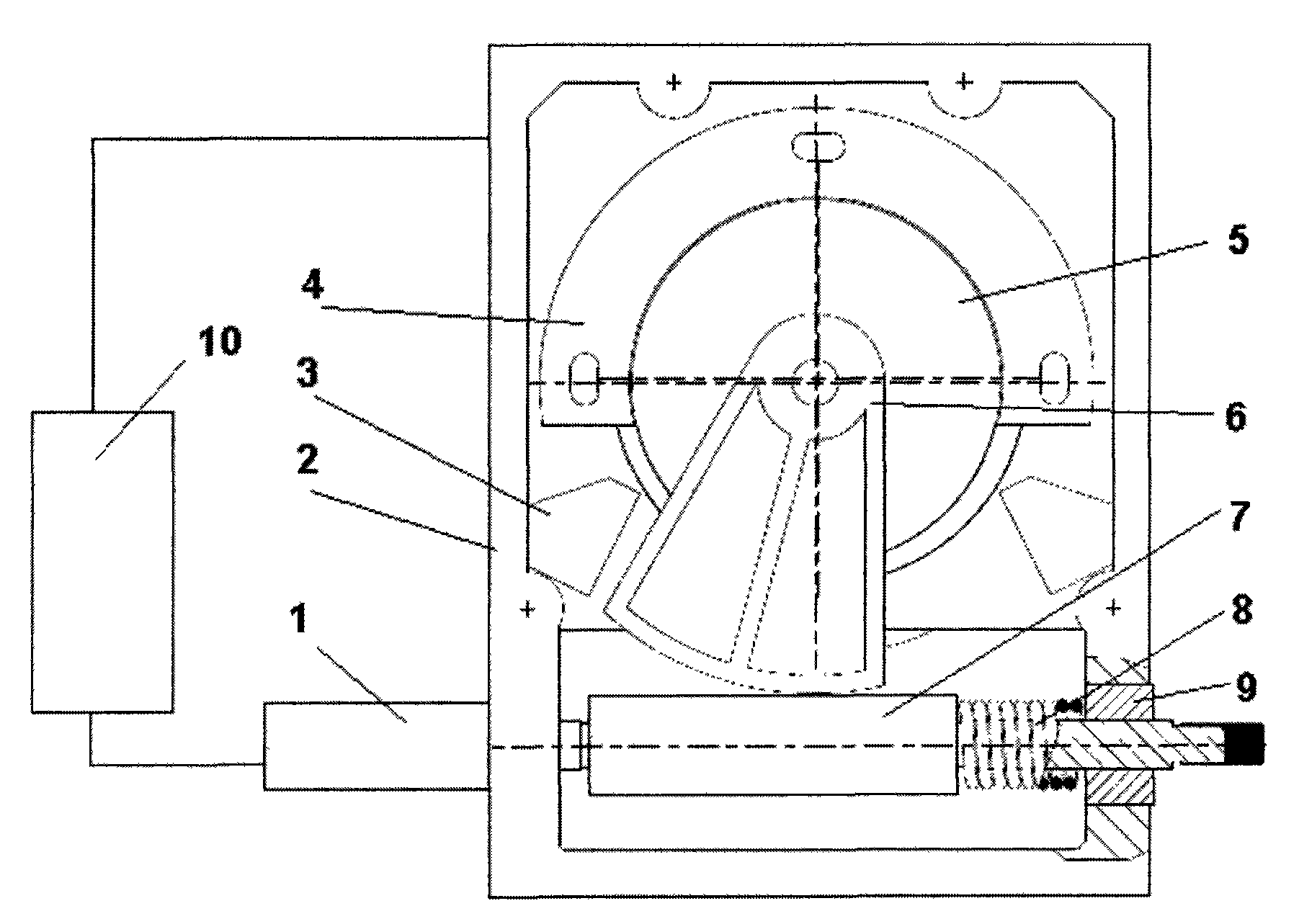

Torque motor actuator of linear diesel engine

InactiveCN101520005AControl speedQuick responseEngine controllersMachines/enginesElectric machineTorque motor

The invention provides a torque motor actuator of a linear diesel engine, comprising a torque motor, a displacement sensor, a stroke control locating iron, a shell, a controller, and the like, wherein the torque motor is mounted on an eccentric wheel which is adjusted and fastened in the shell, and a segment gear is mounted on the torque motor; a rack shaft is mounted on the shell by two linear bearings, and a spring is mounted at one end of the rack shaft; a displacement sensor is mounted at one terminal of the rack shaft, is connected with the controller and feeds offset of the rack shaft back to the controller, and the output of the controller controls the torque motor. The torque motor actuator of the linear diesel engine can reliably control the rotating speed of the diesel engine, has higher response speed and is suitable for controlling the rotating speeds of middle-powder or small-powder diesel engines.

Owner:HARBIN ENG UNIV

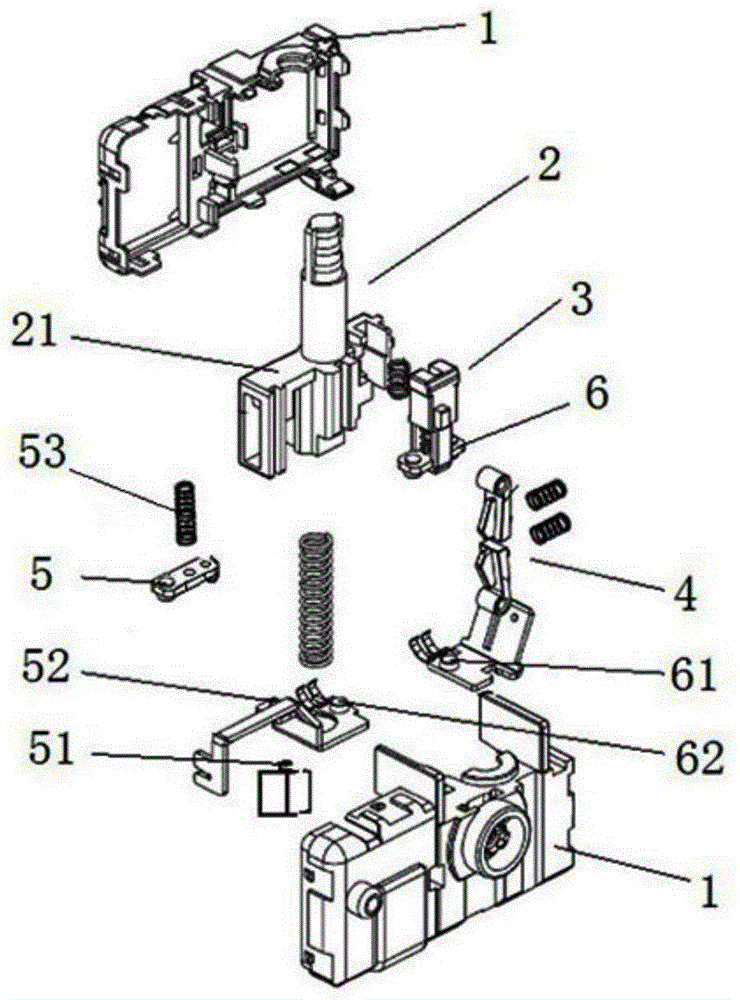

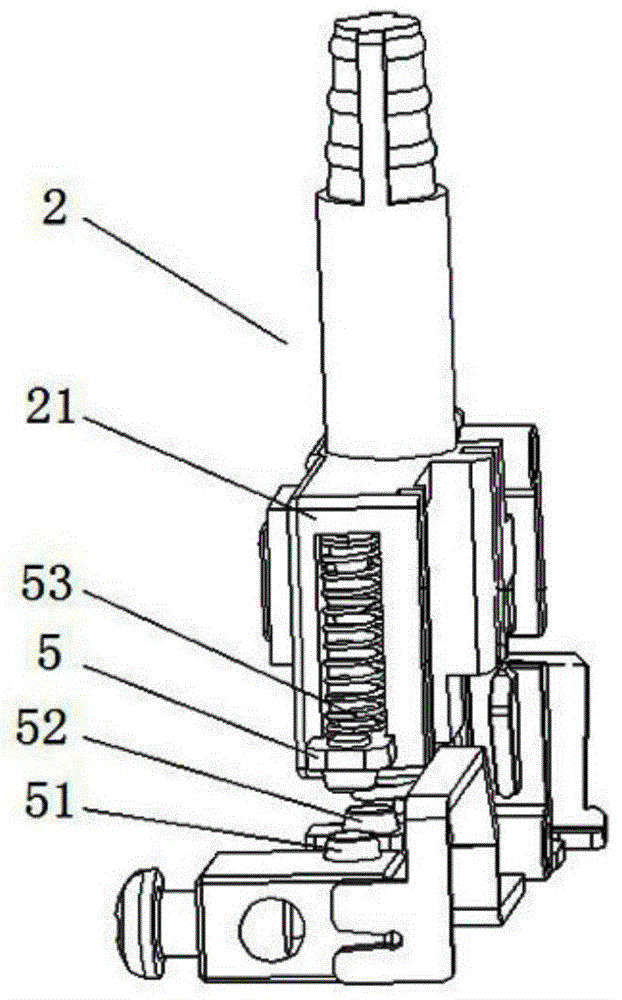

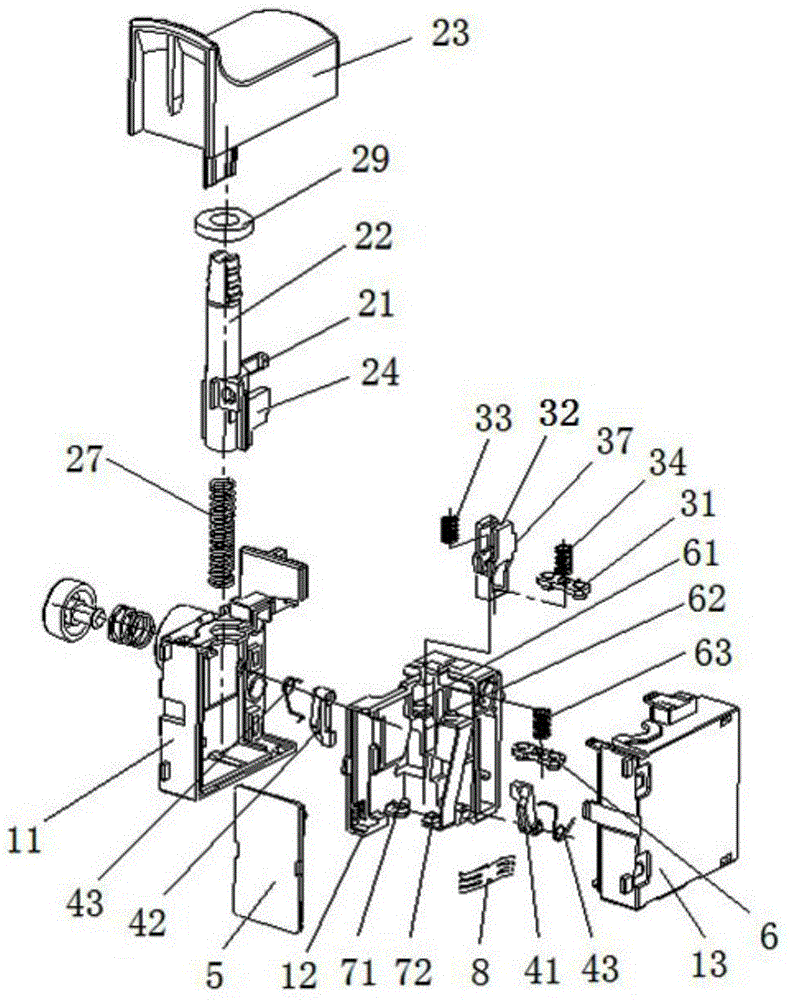

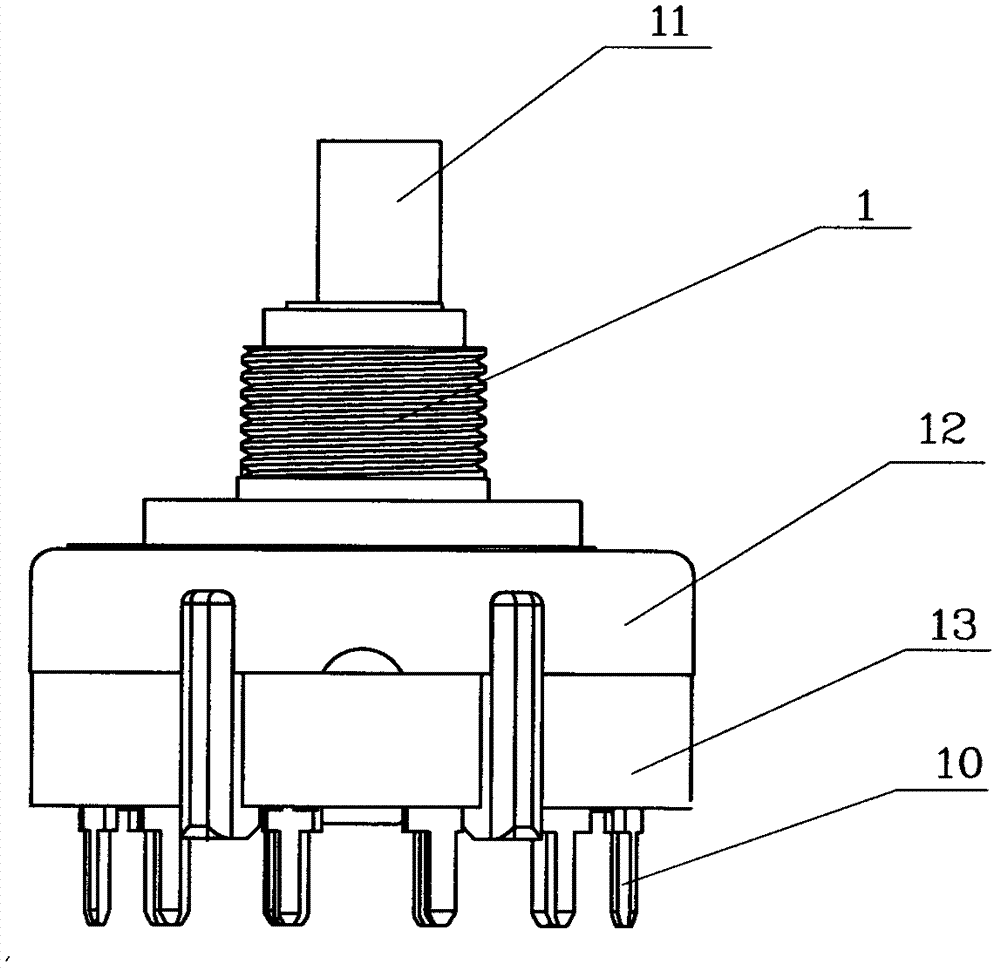

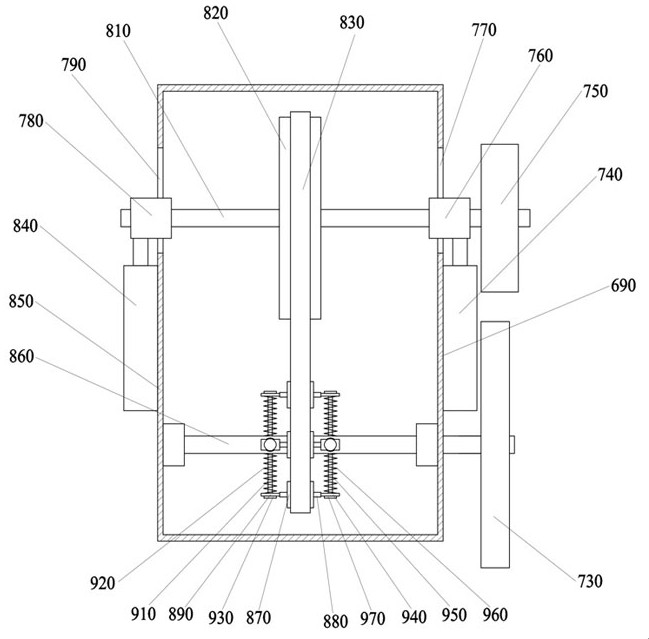

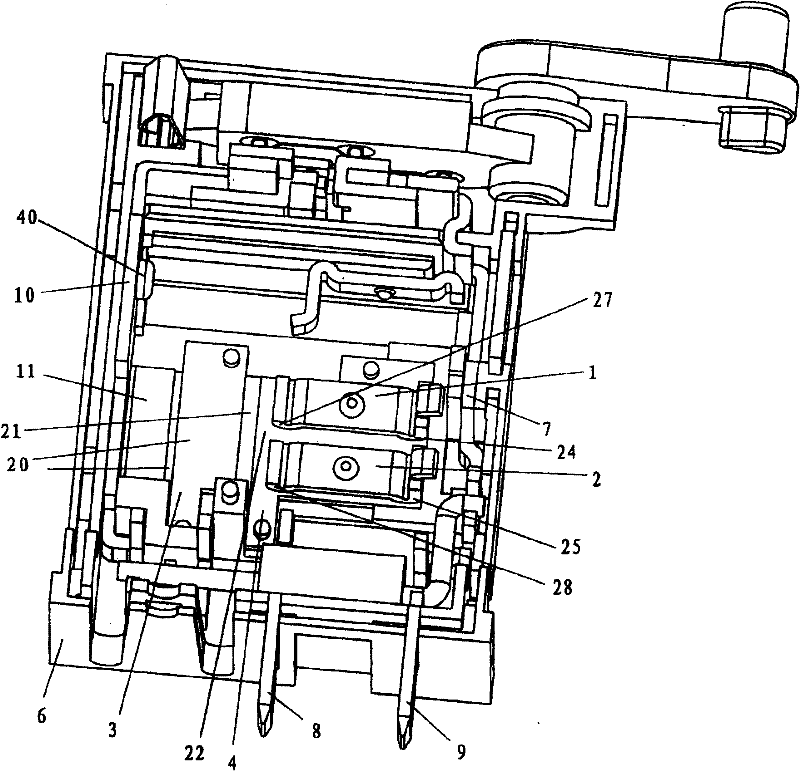

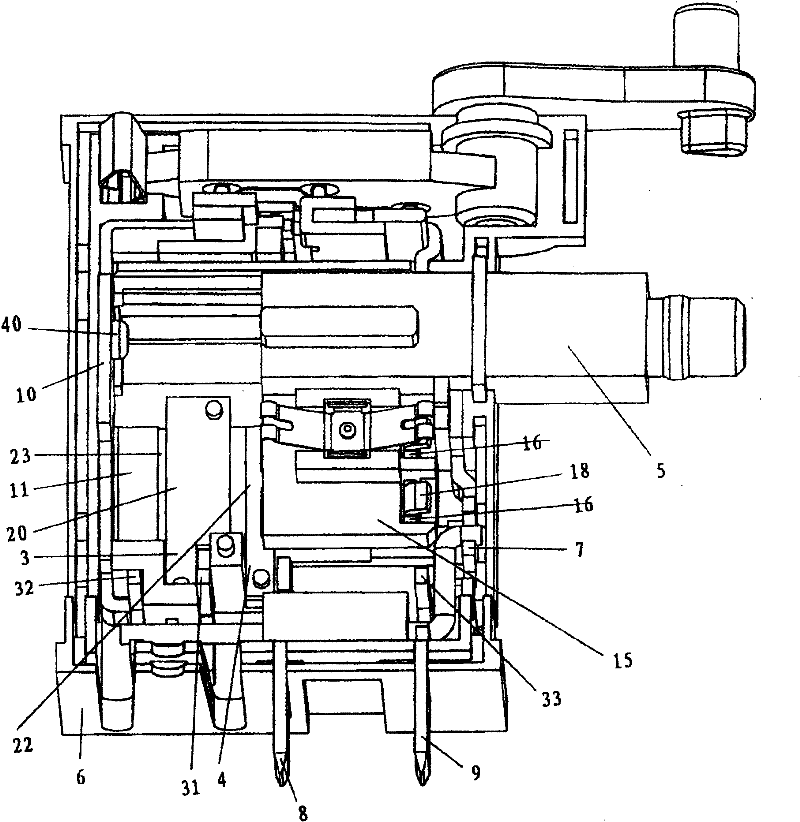

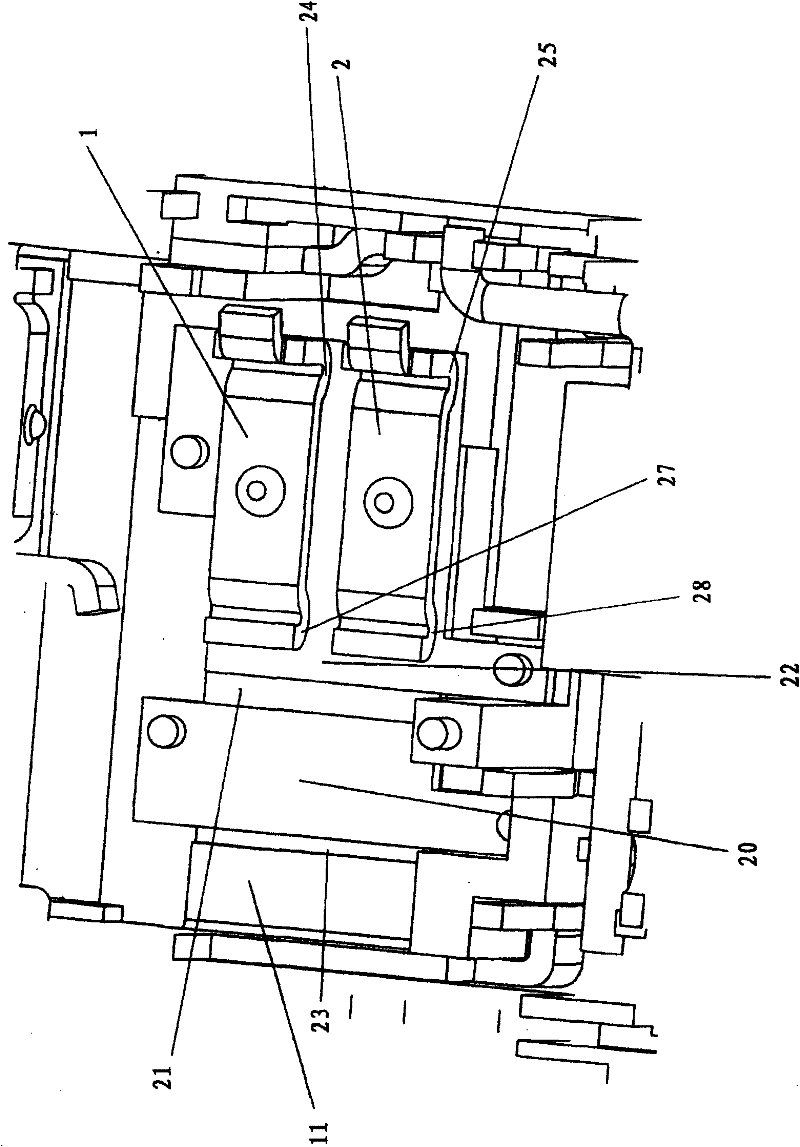

Speed-control switch with kick device

ActiveCN103337396AShort lifeRealize speed regulation functionElectric switchesElectric arcEngineering

The invention discloses a speed-control switch with a kick device, which comprises a casing and a button component arranged at the inner part of the casing, a contact terminal component driven by the button component and a locking block component used for matching the button component to realize the up and down kick of the second moving contact component, wherein the contact terminal component comprises a first contact terminal component used for controlling the make-and-break of a speed regulation circuit board and a second contact terminal component used for short-connecting a speed regulation circuit of the speed regulation circuit board; a first moving contact in the first contact terminal component is connected with the casing through a spring; a protruding pole with the capability of pushing the first moving contact upward to compress the spring is arranged on the button component. After the first moving contact is contacted with a first fixed contact, the pressure between the first moving contact and the first fixed contact is constant and relatively static; the first moving contact and the first fixed contact can be in contact with each other tightly and are communicated well; the happening of the burning loss of the contact terminals by an electric arc when the speed regulation switch with the kick function communicates the speed regulation switch in the prior art is avoided; the shortening of the switch service life due to the frequent excessive compression of the spring connected with the first moving contact can be avoided.

Owner:KEDU ELECTRIC CO LTD

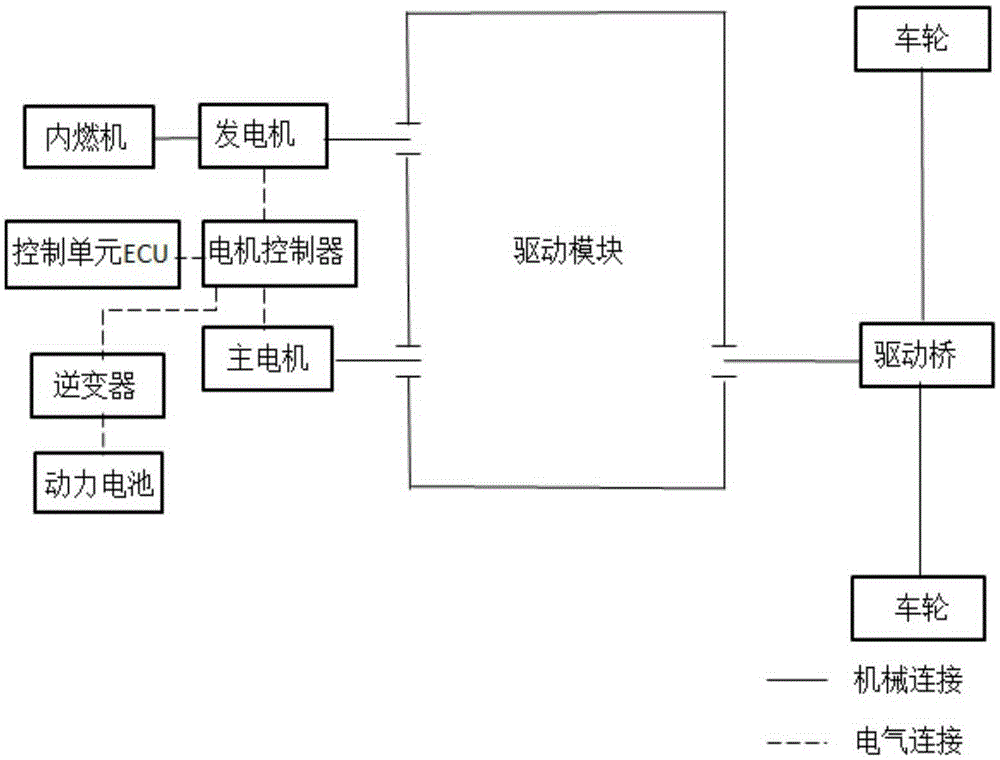

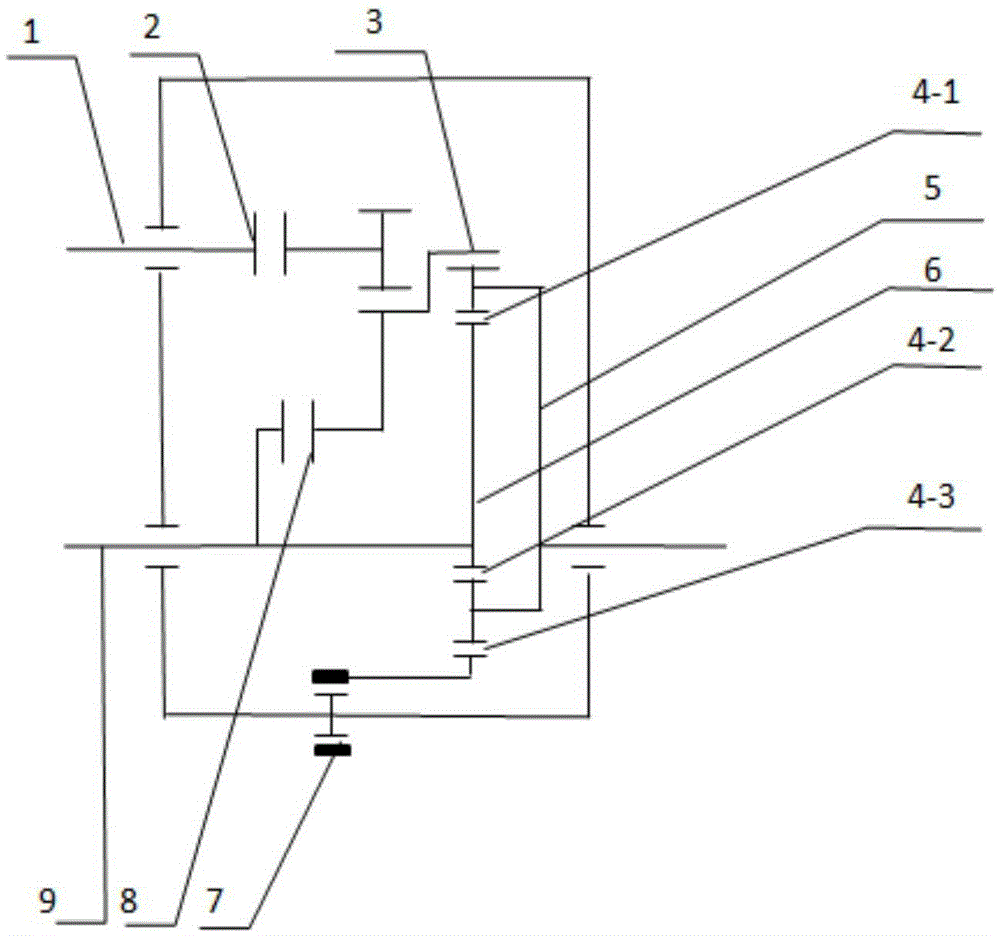

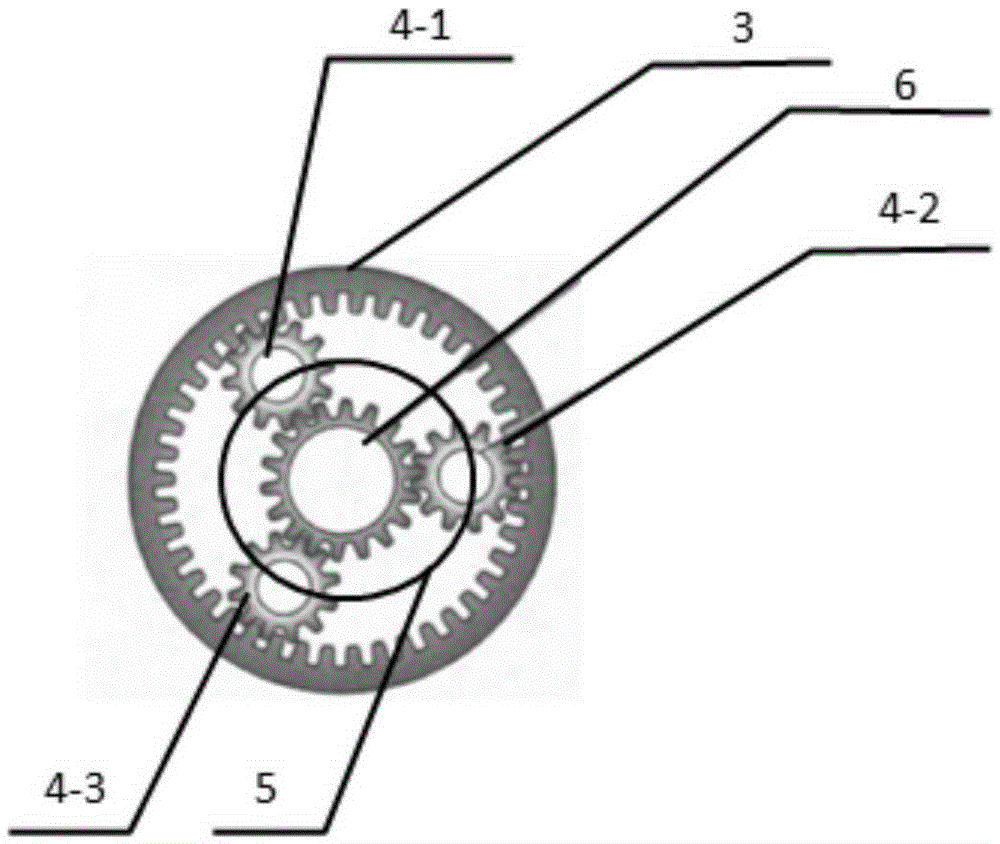

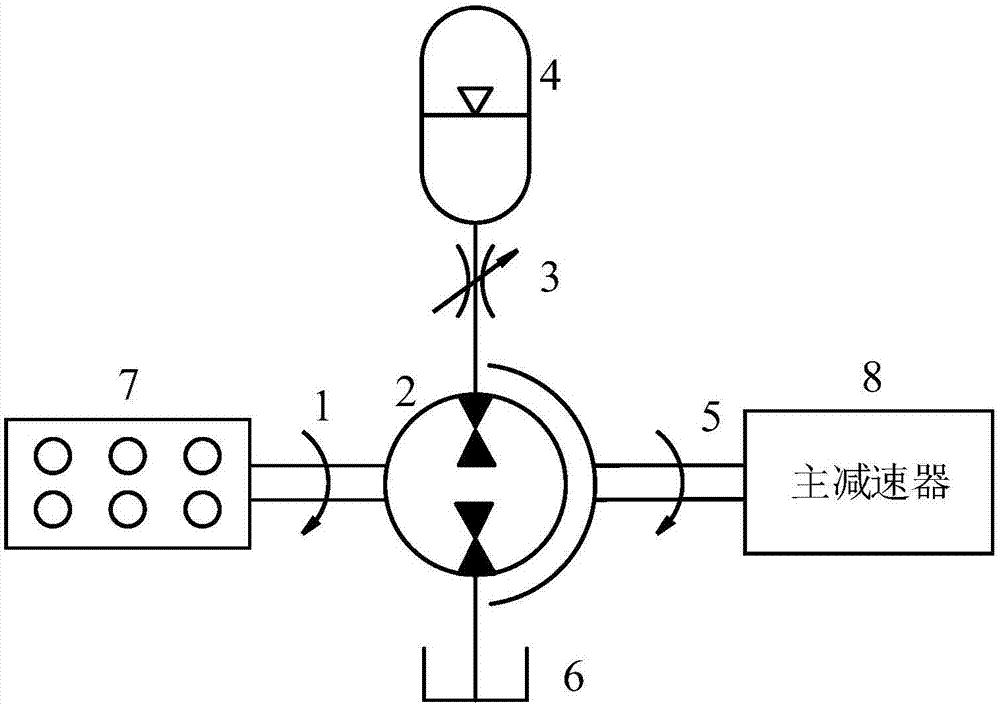

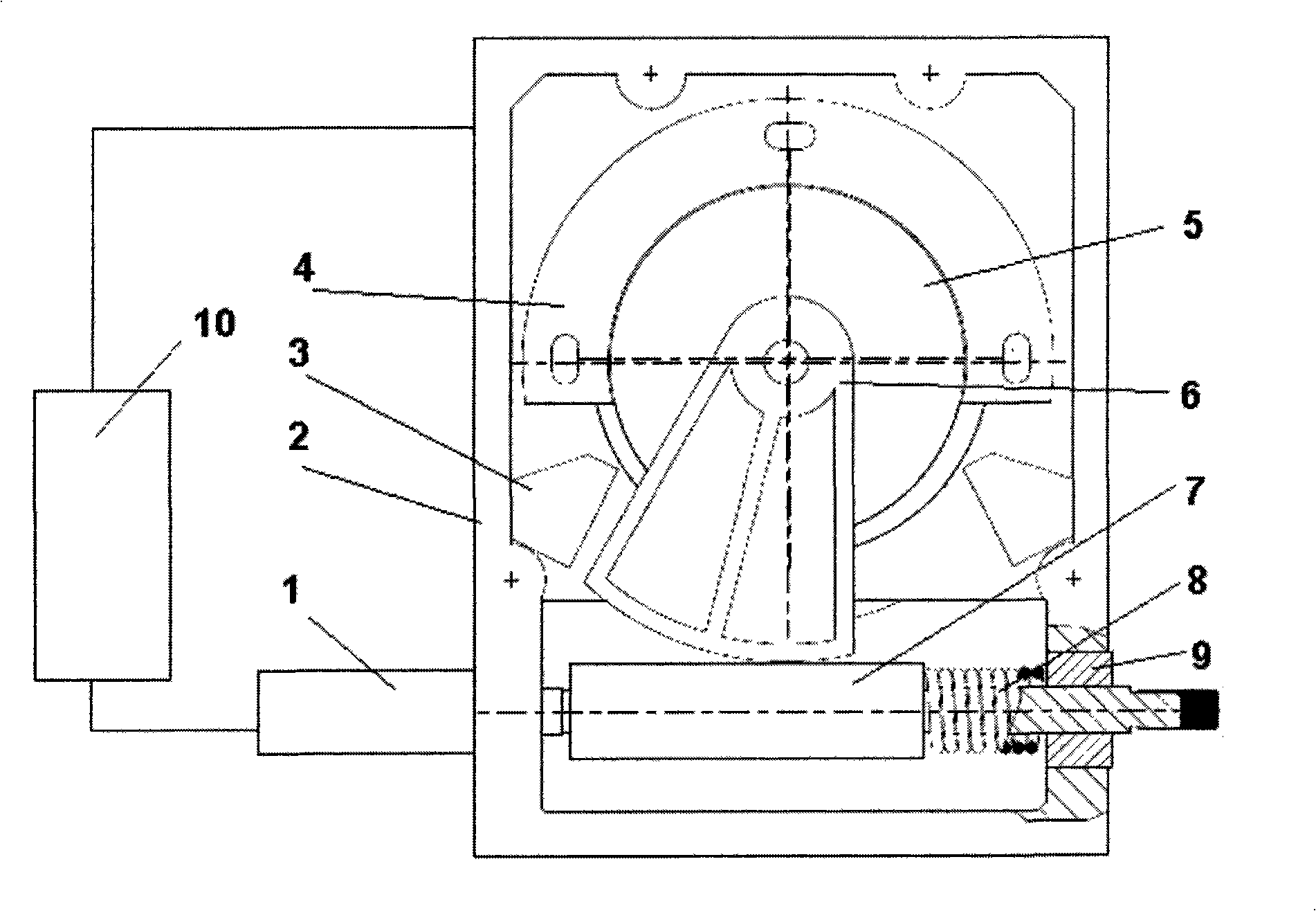

Hybrid power electric car driving system based on planetary gear mechanism

InactiveCN106608177AImprove powerImprove fuel economyHybrid vehiclesGas pressure propulsion mountingPower batteryElectric machine

The invention relates to a hybrid power electric car driving system based on a planetary gear mechanism. The hybrid power electric car driving system comprises an internal-combustion engine, a main motor, a power generator, a first clutch, a second clutch, a brake, a control unit ECU, a drive axle, axle shafts, wheels, a motor controller, a power battery, an inverter and a planetary mechanism. The drive axle is connected with the wheels through the two axle shafts; the planetary mechanism comprises a sun gear, a planet carrier, a gear ring and a planetary gear; the sun gear is connected with a rotor shaft of the main motor, and the planet carrier serves as the output end to be connected with the drive axle; the brake is connected with the gear ring; one end of the power generator is connected with the internal-combustion engine, and the other end of the power generator is connected with the motor controller; and the control unit ECU is connected with the motor controller, and the motor controller is connected with the main motor and the power generator. According to the hybrid power electric car driving system, the planetary gear mechanism and the multiple clutches are used in cooperation, multiple driving manners can be switched in good time, and the travelling distance is increased.

Owner:NANJING UNIV OF SCI & TECH

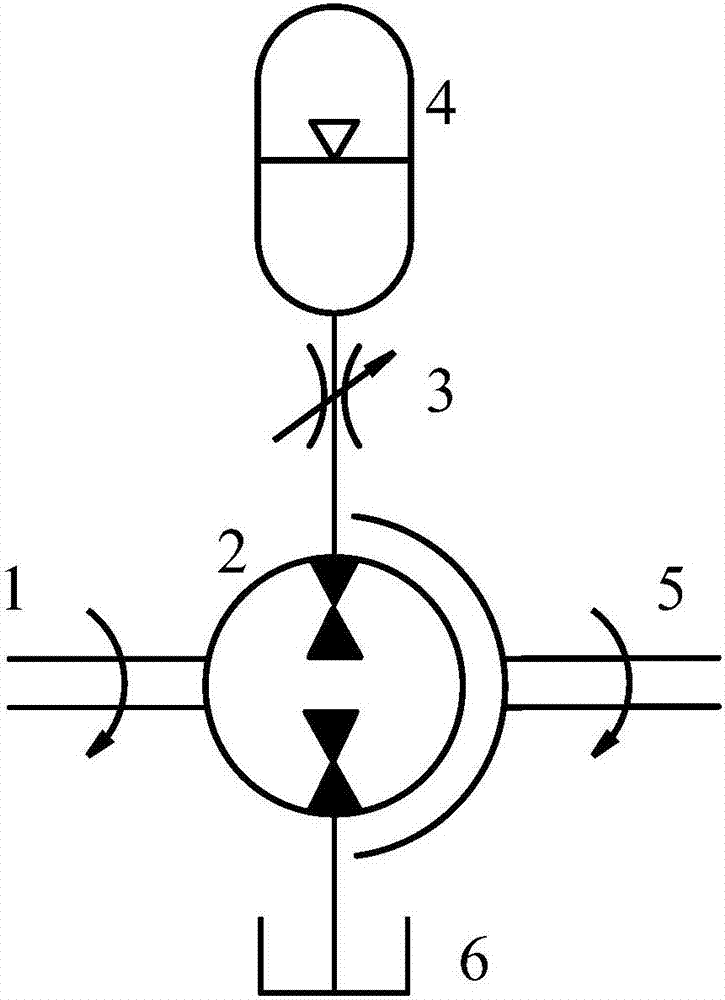

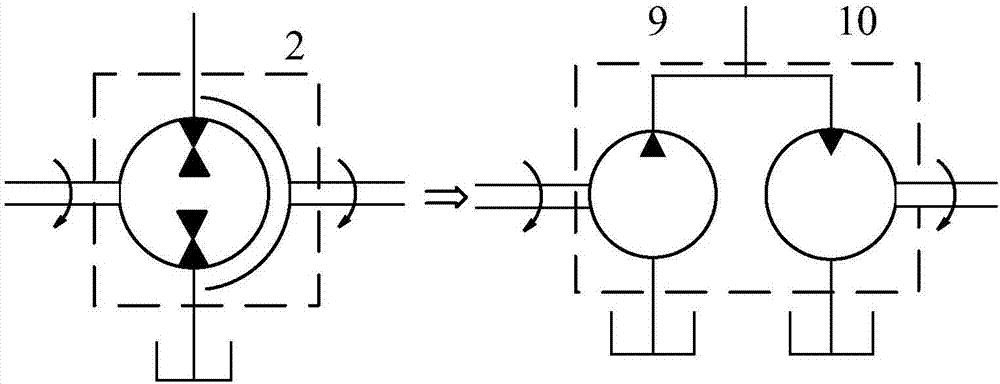

Integrated hydraulic transformer based on energy recovery

ActiveCN107131181AIncrease profitRealize speed regulation functionFluid-pressure actuator componentsHydraulic structureEnergy based

The invention discloses an integrated hydraulic transformer based on energy recovery. The integrated hydraulic transformer comprises a novel hydraulic transformer, an adjustable throttling valve, a hydraulic accumulator and a hydraulic oil tank, wherein the novel hydraulic transformer is provided with two oil liquid openings, an input shaft and an output shaft; the input shaft and the output shaft are driven by the transmission of a hydraulic structure; one oil liquid opening of the novel hydraulic transformer is connected with the hydraulic accumulator through the adjustable throttling valve, and the other oil liquid opening of the novel hydraulic transformer is connected with the hydraulic oil tank. According to the integrated hydraulic transformer disclosed by the invention, the functions of decelerating and accelerating can be realized; through charging and discharging of the energy of the accumulator, deceleration or acceleration of an output end is realized. Compared with a conventional hydraulic transformer, the integrated hydraulic transformer not only can realize the function of speed adjusting, but also can recover the braking energy; and the utilization rate of the energy is increased.

Owner:ZHEJIANG UNIV

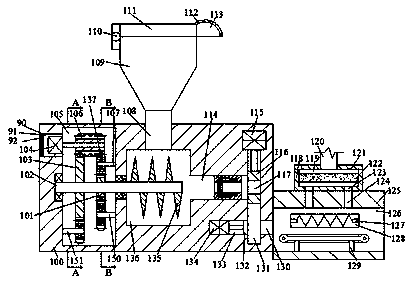

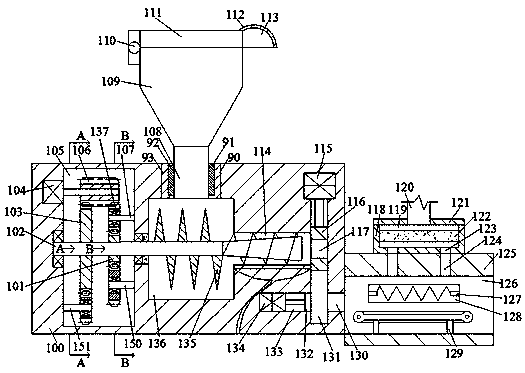

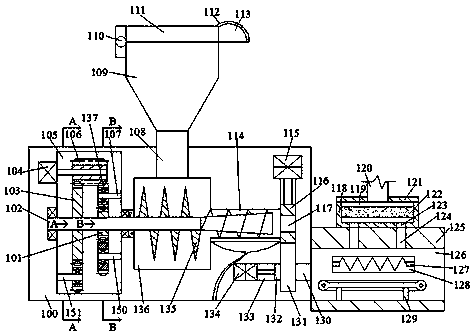

Novel bio-fertilizer device

InactiveCN108395321AImprove transmission efficiencyImprove work coordinationFertilizer mixturesHeat sinkEquipment use

The invention discloses a novel bio-fertilizer device, which comprises an accommodating box fixedly arranged on the ground, wherein a power cavity is fixedly arranged in the accommodating box; an electric motor cavity is arranged in the left end wall of the power cavity; the left side end surface of the electric motor cavity is provided with a dismountable heat radiation plate; heat radiation finsare fixedly arranged in the heat radiation plate; an electric motor is fixedly arranged in the electric motor cavity; a conveying cavity positioned in the accommodating box is arranged at the right side of the power cavity; a force conveying gear is fixedly arranged at the outer surface of a force conveying shaft of the electric motor; a fixing rod A is fixedly arranged at the right end wall of the power cavity; a force transfer gear engaged with the force conveying gear is rotatably arranged at the outer surface of the fixing rod A; a guide wheel mechanism B is arranged under the force transfer gear; a guide wheel mechanism A is arranged under the force conveying gear; a rotating shaft rightwards extending into the conveying cavity is rotatably arranged between the left and right end walls of the power cavity; the guide wheel mechanism B comprises an inverse wheel A in fixed and matched connection with the rotating shaft. The novel bio-fertilizer device has the advantages that the structure is simple; the use is convenient; the equipment uses a ratchet wheel type structure for driving the spiral conveying structure; the regulation production efficiency at different speed ratios is realized; the production efficiency is effectively improved.

Owner:嵊州市林美生物科技有限公司

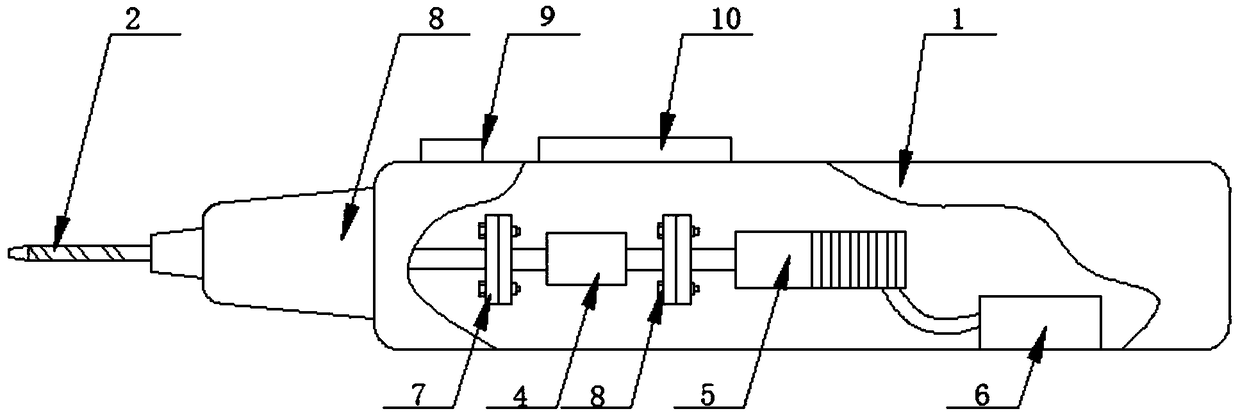

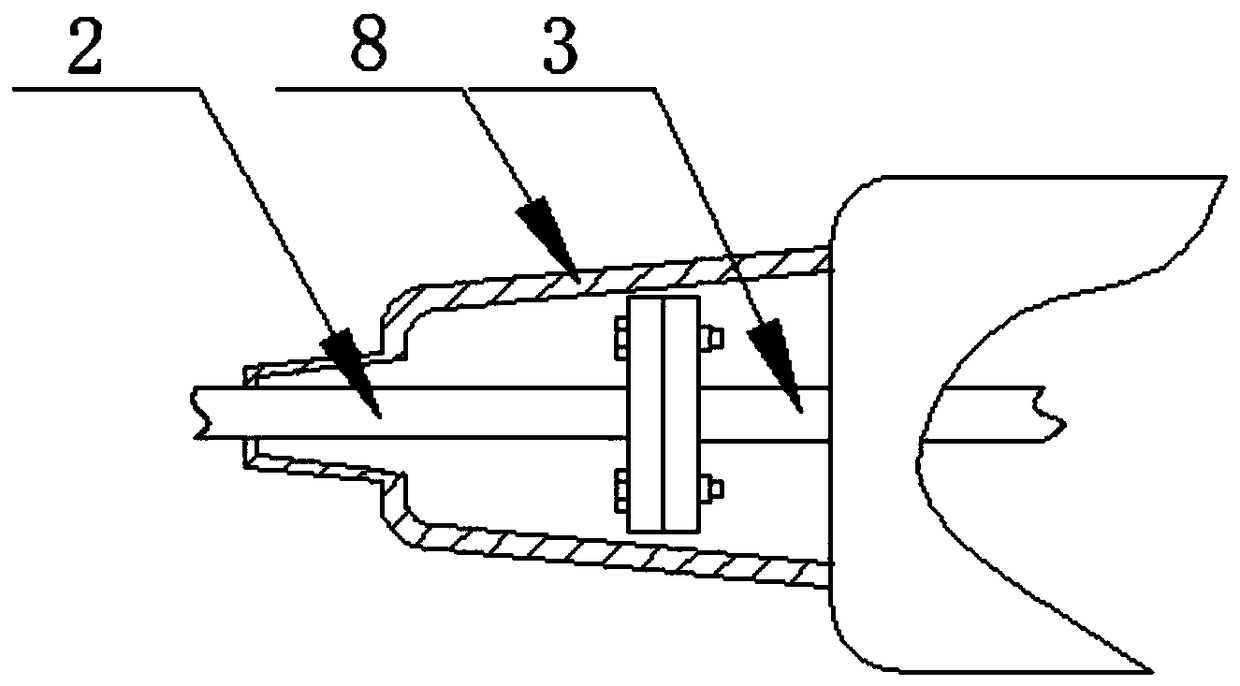

Pen-type hand-pressed fine bone drill for orthopedic surgery

InactiveCN109223093AEasy to operateRealize speed regulation functionSurgeryModelling/simulations for controlCouplingIndex finger

The invention belongs to the technical field of orthopaedic surgical equipment, and discloses a pen-type hand-pressed fine bone drill for orthopaedic surgery, wherein the pen-type hand-pressed fine bone drill for orthopaedic surgery is provided with a shell. A transmission rod, a miniature gearbox, a motor and a storage battery are sequentially arranged from the front end to the rear end inside the shell; A drill bit is arranged in front of the shell; A transmission rod is arranged behind the drill bit, and the front end of the transmission rod is connected with the drill bit through a coupling; The transmission rod is connected with a micro transmission through a coupling; The micro-gearbox is connected with an electric motor through a coupling; A motor switch and a speed regulating button are arranged on the outside of the housing, and a fixing bracket is fixed on the front screw. The bone drill realizes the speed regulating function of the fine bone drill when in use. A switch of that motor is arranged at the position of the index finger, which is convenient to operate; meanwhile, the invention has the advantage of simple structure, strong structure and convenient operation.

Owner:黄鲁豫

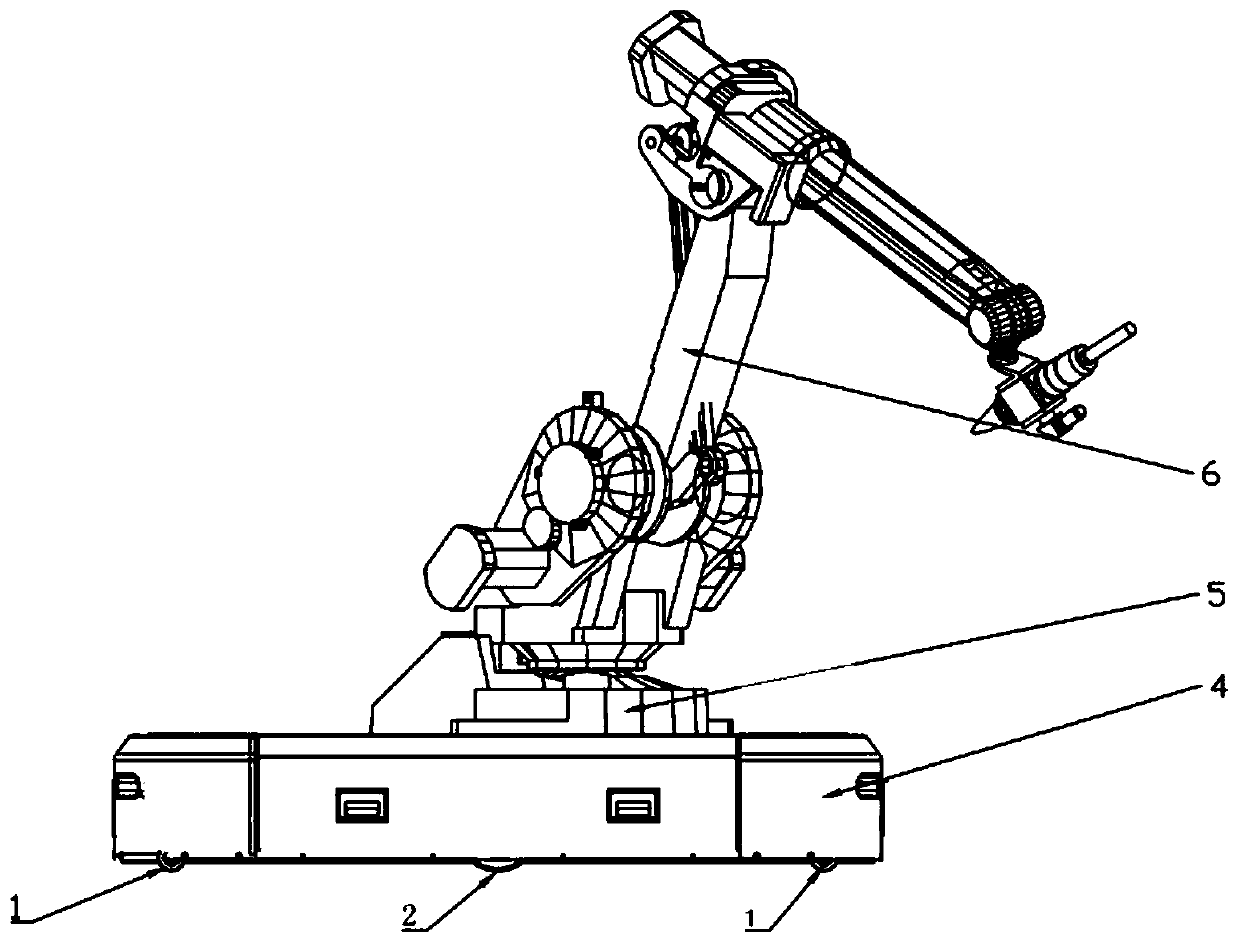

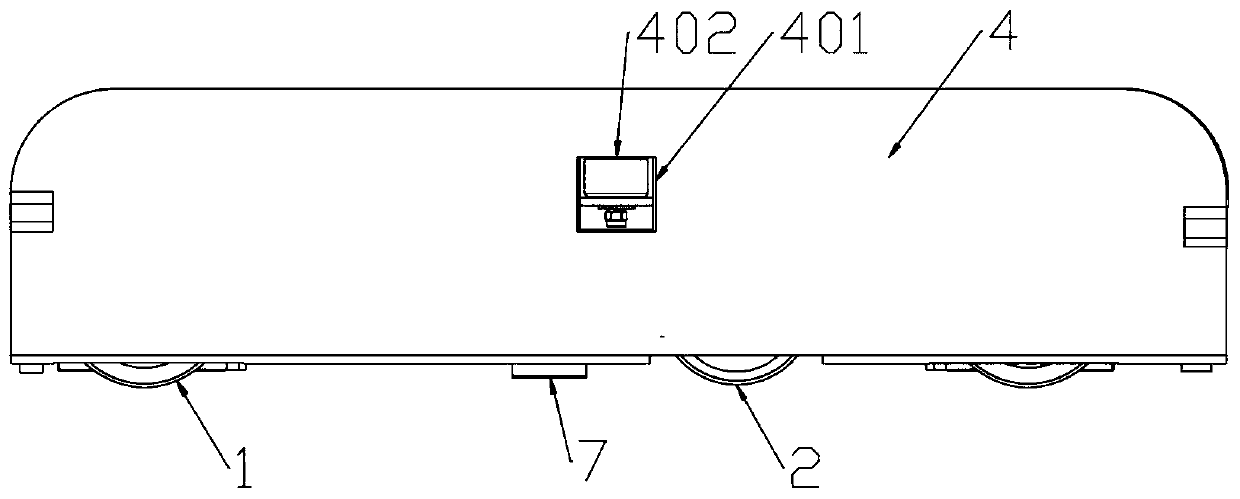

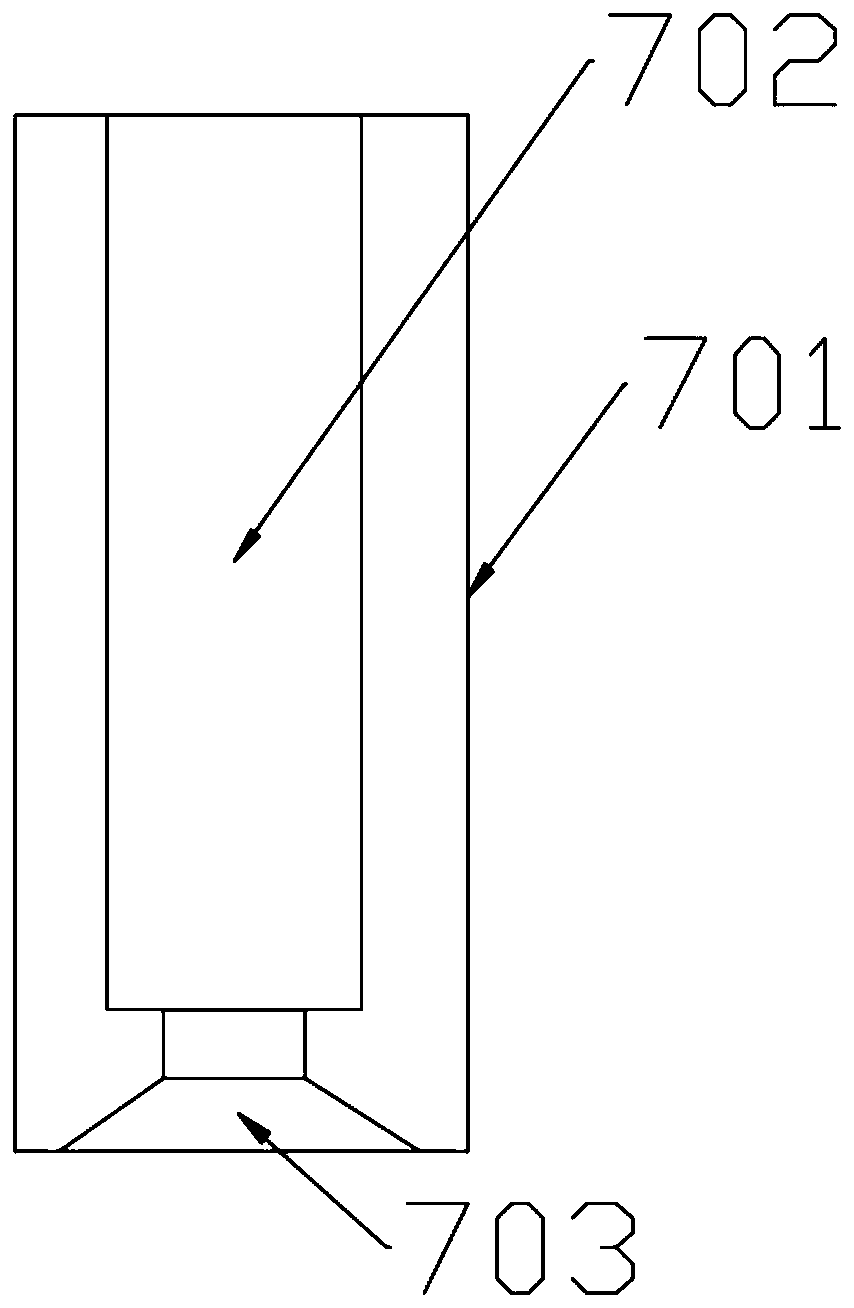

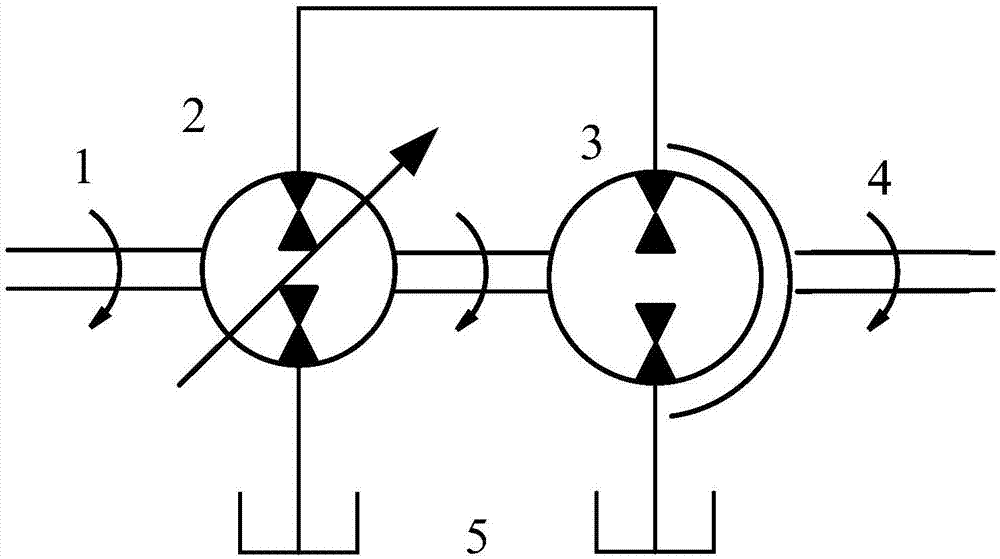

Welding robot capable of moving in all directions

InactiveCN109732254AMeet the needs of useRealize speed regulation functionWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelGear wheel

The invention discloses a welding robot capable of moving in all directions. A vehicle body and a welding robot assembly installed on the vehicle body are included; the vehicle body comprises a shell,and a chassis is arranged at the bottom of the shell, and is provided with driving wheel assemblies and driven wheel assemblies; a first driving motor and a second driving motor are further arrangedon the chassis; a gear is connected to an output shaft of the first driving motor, and is engaged with a rack which is movably connected to the chassis; a connection block is fixed to each of the twoends of the rack; each connection block is movably connected with a transmission shaft, and the transmission shafts are connected with the driven wheel assemblies; a main gear is connected to an output shaft of the second driving motor, and is engaged with a slave gear; the driving wheel assemblies are each provided with a driving shaft, and the slave gear is fixed to one of the driving shafts; and a differential mechanism is connected between the driving shafts. The welding robot can move in all directions in a narrow space, better meets the using requirement of a user, and is compact in structure, convenient to manipulate and high in practicability.

Owner:航天通用技术(北京)有限公司 +1

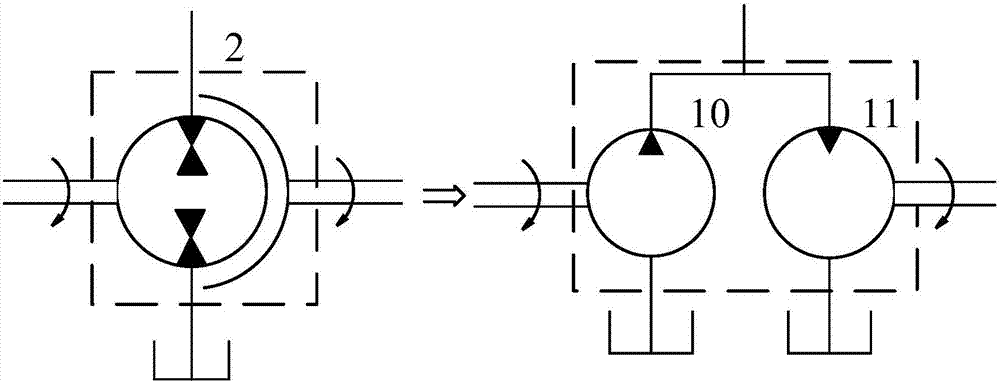

Machine liquid composite transmission system based on pressure control

PendingCN107131277ARealize speed regulation functionSimple structureFluid gearingsHydraulic pumpEngineering

The invention discloses a machine liquid composite transmission system based on pressure control. The system comprises a variable pump / motor unit, a novel hydraulic transmission and a hydraulic oil tank; the novel hydraulic transmission is provided with two oil liquid ports, an input shaft and an output shaft, and the input shaft and the output shaft are driven through a hydraulic structure in a transmission mode; and the variable pump / motor unit adopts a through-shaft type, the variable pump / motor unit and the input shaft of the novel hydraulic transmission are coaxially connected, the variable pump / motor unit communicates with one oil liquid port of the novel hydraulic transmission in a connected mode, and the variable pump / motor unit and the other oil liquid port of the novel hydraulic transmission are both connected to the hydraulic oil tank. According to the system, the speed increasing and reducing functions can be achieved so as to be matched with the rotating speed and the torque which are needed by the load. Compared with a traditional hydrostatic transmission, repeated assemblies and pipeline connection in a hydraulic pump control motor system are omitted, so that the structure is simpler, and the transmission efficiency is higher.

Owner:ZHEJIANG UNIV

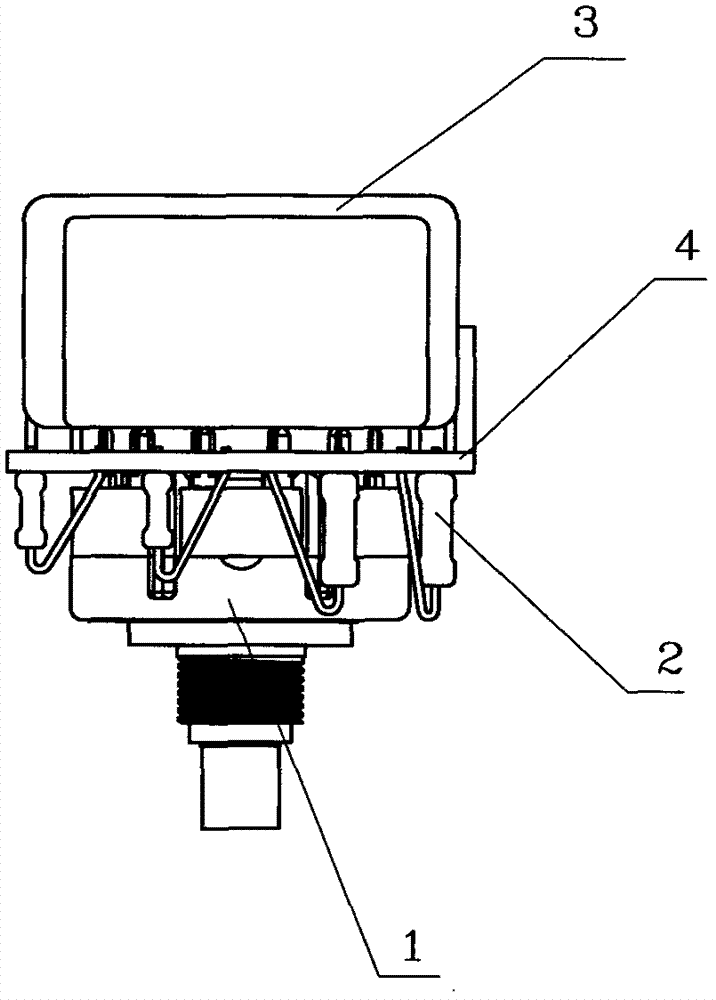

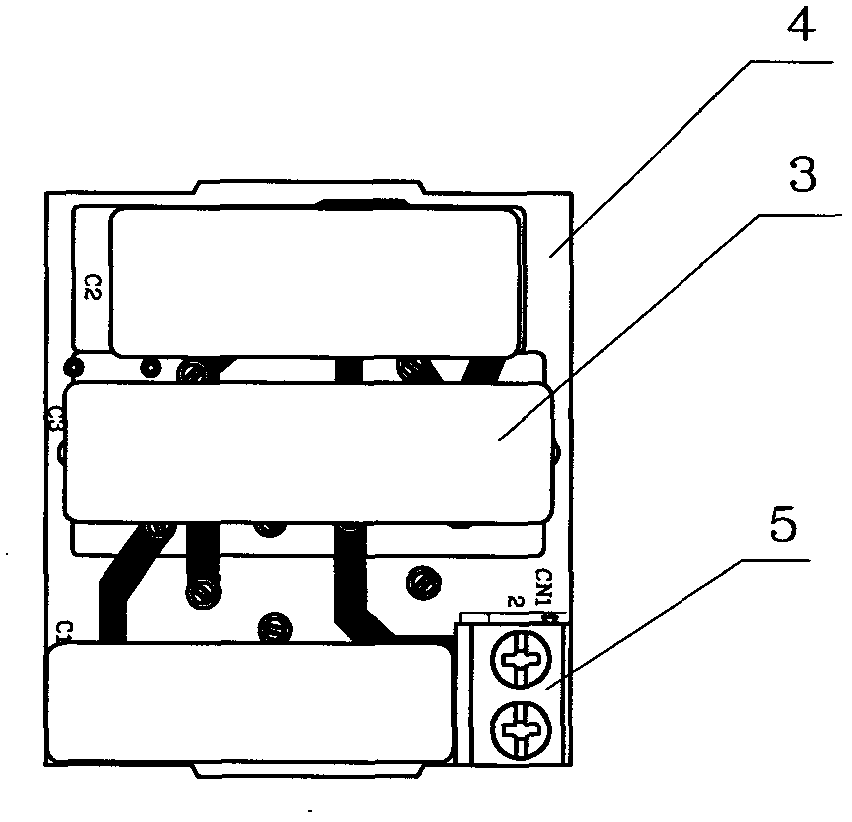

Voltage adjusting switch

InactiveCN103500679AReduce volumeImprove cooling conditionsElectric switchesPump controlCapacitanceElectrical resistance and conductance

The invention relates to a voltage adjusting switch, which comprises an adjusting switch, capacitors, resistors and a circuit board, wherein the capacitors and the resistors are welded on the circuit board, the circuit board is welded on the adjusting switch, the adjusting switch comprises an upper cover and a lower cover, the upper part of the upper cover is provided with an adjusting shaft, the inner plane of the upper cover is symmetrically provided with two movable contacts with double contacts in the circumferential direction, and the lower cover is provided with two groups of static contacts and conductive rings in the circumferential direction. The voltage adjusting switch has the advantages that when the voltage is adjusted, different resistors and capacitors are sequentially switched through the rotation of each baffle contact, the different line impedances are formed in a loop of a controlled motor, and then the working rotation speed of the controlled motor is changed; meanwhile, the power factor of the lines is improved; as a power supply is accessed into the loop in a two-path parallel way, and the loading current is shunted, the heat radiating conditions of the resistors and the capacitors are improved, the capacities of the resistors and the capacitors are reduced, and the size of the voltage adjusting switch is only one half of the size of the traditional speed adjusting switch.

Owner:YUEQING JINLONG ELECTRONICS INDAL

Novel speed-regulation electromagnetic coupler

InactiveCN106981971ARealize high power transmissionSimple structurePermanent-magnet clutches/brakesSlide plateRelative motion

The invention provides a new type of speed-regulating electromagnetic coupler. When the electromagnet is fed with current and the input shaft of the motor drives the copper disc to rotate, the copper disc and the electromagnet disc will move relative to each other, forming a slip between the copper disc and the electromagnet disc. Poor, the electromagnet passing the current will generate a magnetic field. According to Faraday's electromagnetic induction principle, an eddy current is generated between the copper disk and the electromagnet disk, and the induced magnetic field generated by the eddy current interacts with the magnetic field generated by the electromagnet. Due to the slip angle The magnetic force generated by the displacement drives the electromagnet disk to rotate with the copper disk in the same direction, and transmits the torque of the driving shaft to the load end, and then drives the load to do work. By changing the magnitude of the external access current and changing the strength of the electromagnet, the speed regulation function is realized. .

Owner:ANHUI UNIV OF SCI & TECH

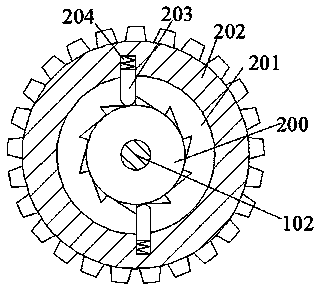

Double layer standard squirrel cage conductor rotor high torque density permanent magnet governor

ActiveCN108964387BRealize speed regulation functionShorten the axial lengthPermanent-magnet clutches/brakesPermanent magnet rotorElectrical conductor

The invention discloses a double-layer standard squirrel cage conductor rotor high torque density permanent magnetic speed controller. The permanent magnetic speed controller comprises an input shaftand an output shaft set on the same central axis, wherein the input shaft is provided with a conductor rotor in a penetration mode, the output shaft is provided with a first permanent magnet rotor anda second permanent magnet rotor in a penetration mode, the first permanent magnet rotor and the second permanent magnet rotor can rotate with relative concentricity, the first permanent magnet rotor,the conductor rotor and the second permanent magnet rotor are sequentially concentrically sleeved in the radial direction, a first air gap is between the first permanent magnet rotor and the conductor rotor, and a second air gap is between the conductor rotor and the second permanent magnet rotor. The permanent magnetic speed controller is advantaged in that through rotation of the first permanent magnet rotor or the second permanent magnet rotor, the relative rotation angle between the first permanent magnet rotor and the second permanent magnet rotor is changed, the speed control function of the speed controller is achieved, in the speed control process, overcoming the cogging torque is only required, the function of the speed controller is different from the speed control function achieved through adjusting an axial air gap between a magnetic rotor and a conductor rotor in the prior art, and axial length of the permanent magnetic speed controller is effectively reduced.

Owner:SOUTHEAST UNIV

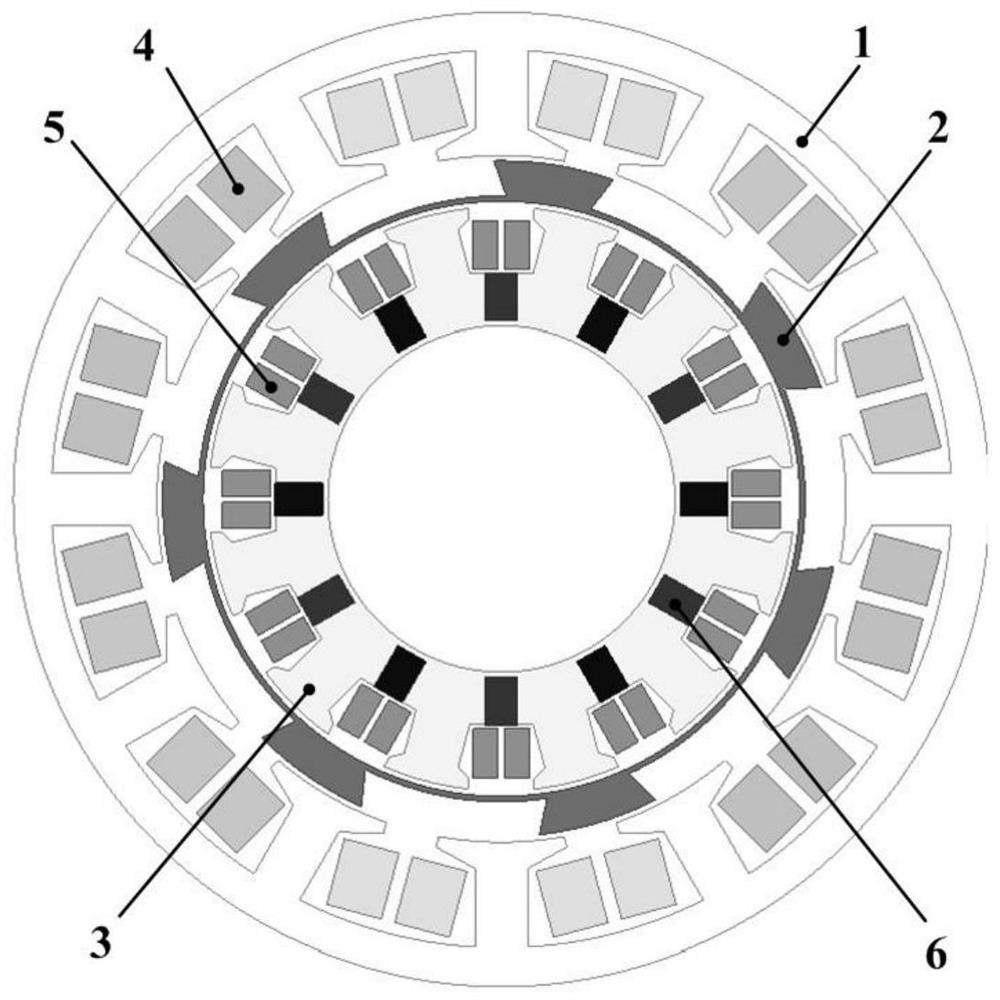

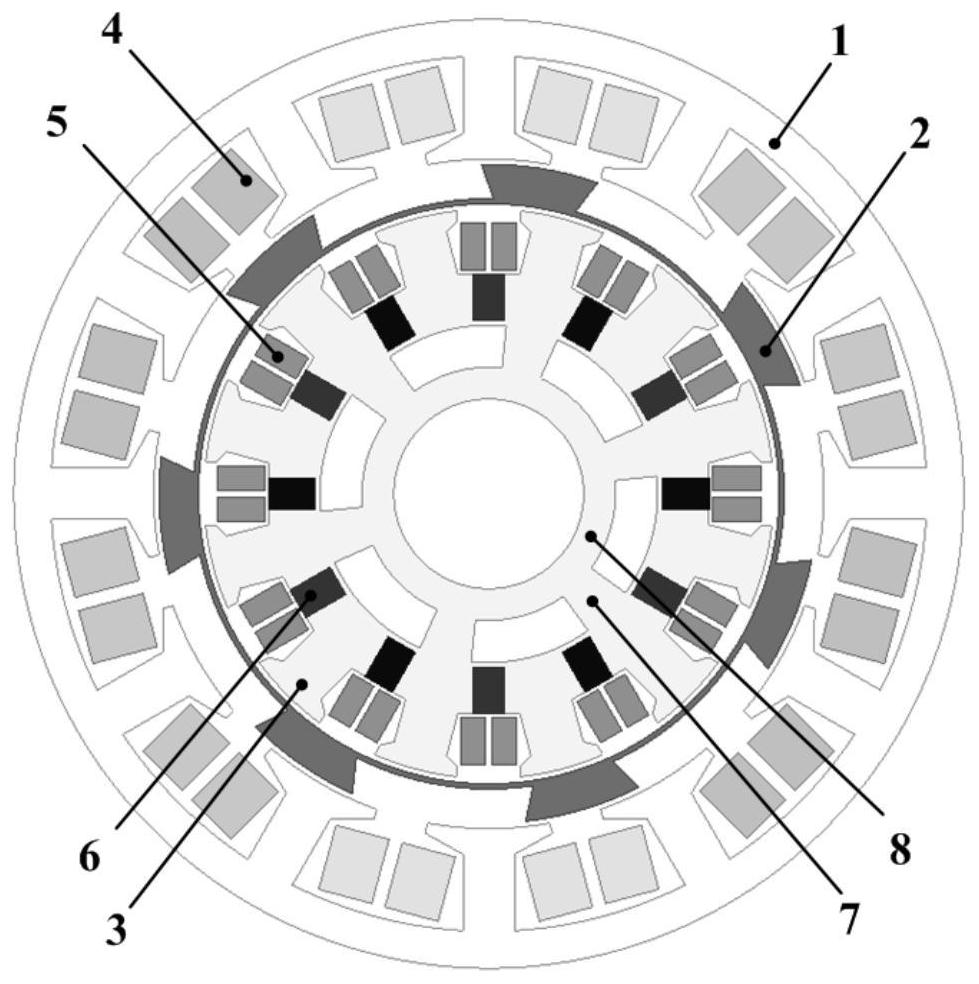

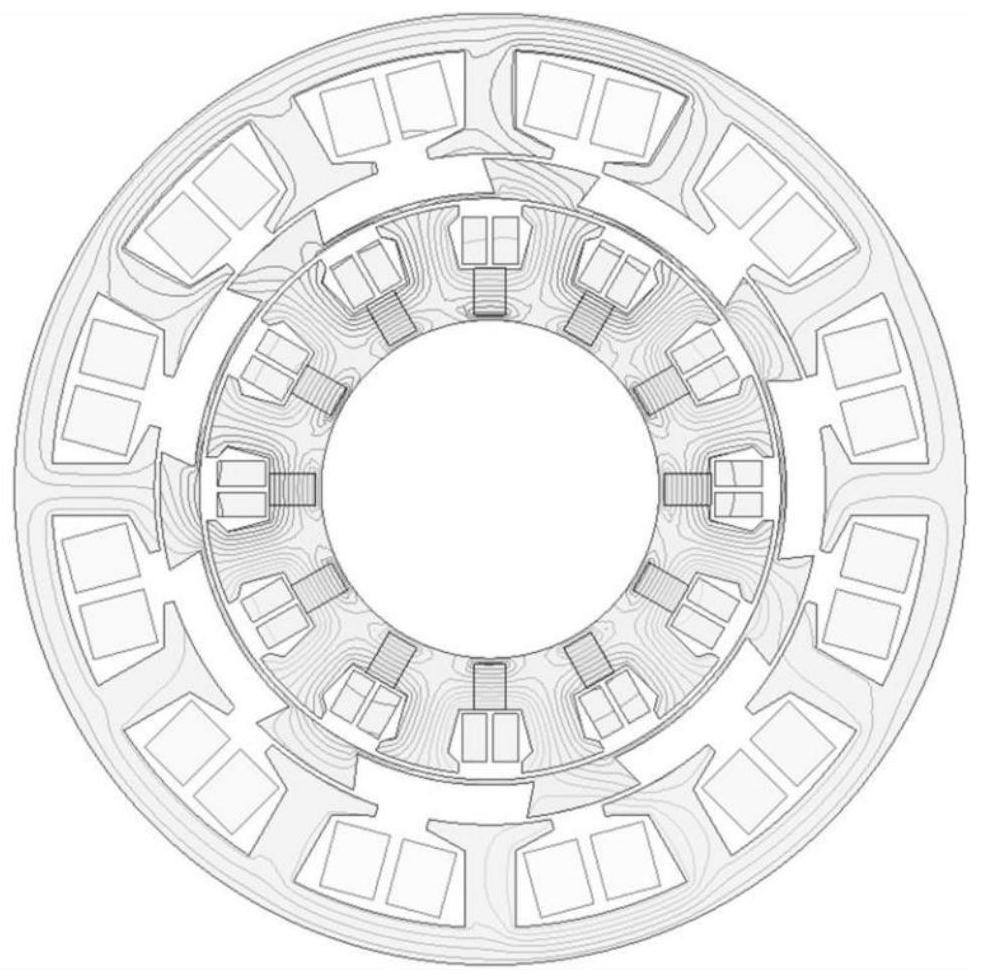

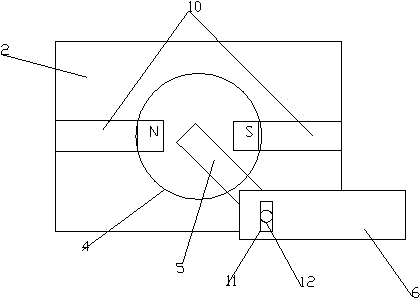

Stator partition type hybrid excitation motor with built-in magnetic field adjusting ring structure

ActiveCN113078789AImprove space utilizationPreserve high power densityMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineCondensed matter physics

The invention discloses a stator partition type hybrid excitation motor with a built-in adjustable magnetic ring structure. The motor comprises an outer stator, a rotor and an inner stator, the outer stator (1) and the rotor (2) are separated by an air gap, and the inner stator (3) and the rotor (2) are separated by an air gap; 12 outer stator teeth are uniformly arranged on the outer stator (1) along the circumferential direction, and armature windings (4) are wound on the outer stator teeth; 12 inner stator teeth are uniformly arranged on the inner stator (3) along the circumferential direction, a centralized excitation winding (5) is wound on the inner stator teeth, 12 permanent magnets (6) are uniformly inserted into a yoke part of the inner stator along the circumferential direction, each permanent magnet is magnetized in the tangential direction, the difference between the magnetizing directions of the two adjacent permanent magnets is 90 degrees, and 6 alternating magnetic bridges (7) are uniformly arranged on the inner side of the inner stator (3) and connected with a magnetism adjusting ring (8); and the middle rotor is composed of seven magnetism adjusting blocks which are evenly arranged. According to the invention, the output torque can be adjusted up and down according to the requirements of application occasions, and the flexibility is high.

Owner:JIANGSU UNIV

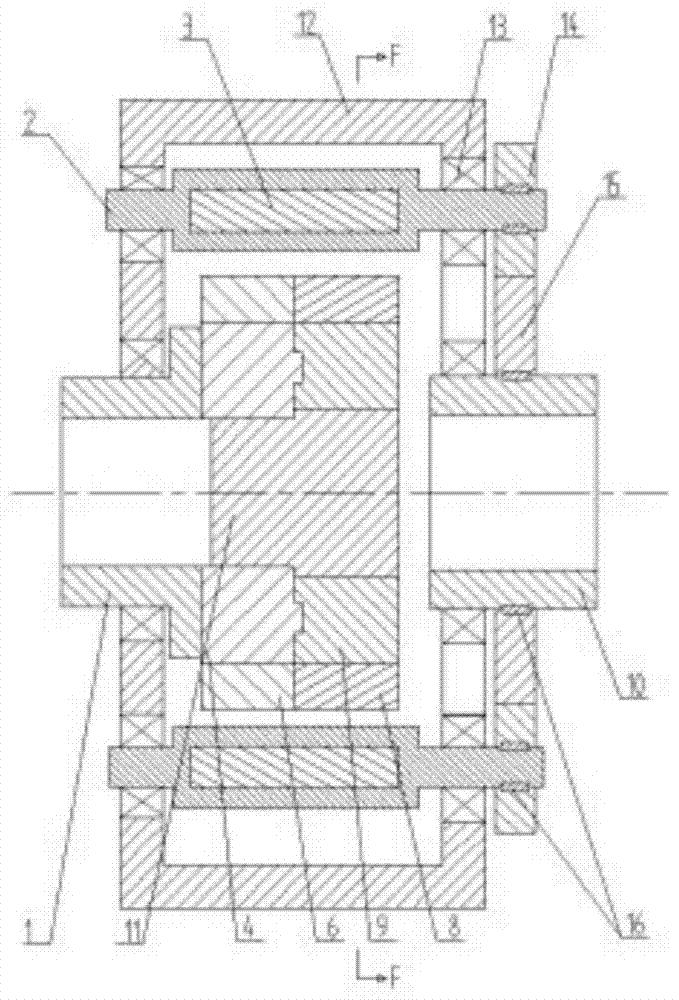

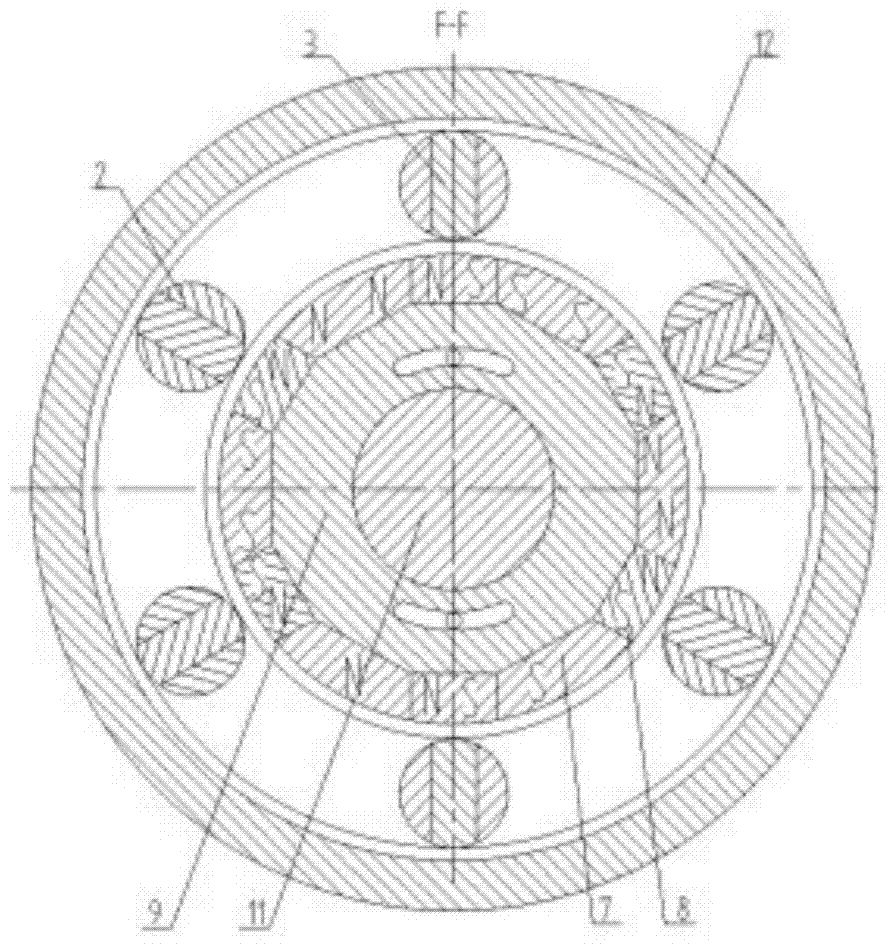

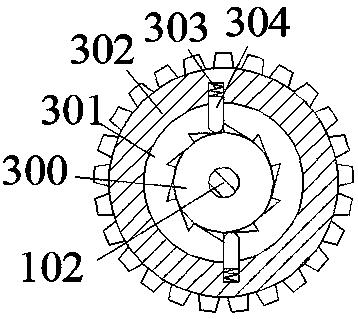

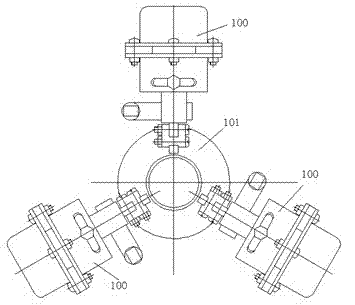

A permanent magnet governor with fixed magnetic gap

ActiveCN105449980BRealize speed regulation functionBroaden the fieldPermanent-magnet clutches/brakesDrive shaftRare earth

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap, and the speed regulator comprises a first internal magnetic rotor, a second internal magnetic rotor, and an external magnet rotor frame, wherein a driving shaft coaxially passes through the first and second internal magnetic rotors, and the external magnet rotor frame is connected with a driven shaft. The external magnet rotor frame is provided with an external magnetic rotor through a bearing. In addition, one end, close to the driven shaft, of the external magnetic rotor is provided with an external magnetic rotor planetary gear. A driven shaft planetary gear is disposed between the external magnetic rotor planetary gear and the driven shaft. The speed regulator employs a fixed magnetic gap structure, so the speed regulator greatly increases the engagement area, reduces the assembly difficulty, reduces the generated heat, enlarges the range of speed regulation, saves rare earth materials, and greatly improves the capability of torque transmission. Because the speed regulator employs a planetary gear transmission structure, the speed regulator achieves a function of 0-%N speed regulation of input and output rotating speeds through changing the gear ratio of the external magnetic rotor planetary gear to the driven shaft planetary gear. In addition, the speed regulator employs a bearing structure, and prevents the continuous shaking of the driven shaft in two directions from causing that the driven shaft cannot rotate normally in one direction to drive a load.

Owner:刁俊起

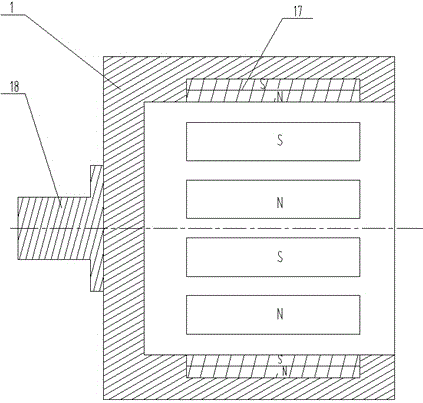

Permanent magnet speed controller with fixed magnetic gap

InactiveCN104362829AIncrease meshing areaReduce generationDynamo-electric brakes/clutchesElectric motor controlMagnetic polesTorque transmission

The invention relates to a permanent magnet speed controller with a fixed magnetic gap. The permanent magnet speed controller comprises an outer magnet rotor and an inner magnet rotor, wherein at least two outer permanent magnets are uniformly distributed along the circumferential direction of the inner circumferential surface of the outer magnet rotor; the magnetic poles of the outer permanent magnets are arranged along the radial direction, and the magnetisms of exposed magnetic pole surfaces of every two adjacent outer permanent magnets are different; at least one rotatable permanent magnet is distributed along the circumferential direction of the outer circumferential surface of the inner magnet rotor; the rotatable permanent magnet is cylindrical, and the pole N and the pole S are arranged along the diameter direction; and one end of the rotatable permanent magnet is provided with a magnetic circuit regulator. Due to the adoption of the fixed magnetic gap, the meshing area of the speed controller is greatly increased, the assembling difficulty is lowered, the heat generation is reduced, the speed control range is widened, rare earth materials are saved, the torque transfer capacity is greatly improved, the function of controlling the speed at the input and output rotating speed of 0-N% is achieved, the material consumption is reduced, the mounting space is saved, and more importantly, the convenience is brought for field installation and construction.

Owner:刁俊起

Convenient sludge treatment device

InactiveCN108503190AImprove transmission efficiencyImprove work coordinationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeSprocket

The invention discloses a convenient sludge treatment device, comprising a treatment box fixedly arranged on the ground; a driving cavity is fixedly arranged in the treatment box; a cavity C, positioned in the treatment box, is arranged at the right side of the driving cavity; a driver is fixedly arranged in the left end wall of the driving cavity; a chain wheel A is fixedly arranged on the outersurface of a rotating shaft of the driver; a fixed shaft A is fixedly arranged on the right end wall of the driving cavity; a chain wheel B, meshed with the chain wheel A, is rotatably arranged on theouter surface of the fixed shaft A; a rotating wheel group B is arranged under the chain wheel B, and a rotating wheel group A is arranged under the chain wheel A; a rotating shaft, extending into the cavity C rightwards, is rotatably arranged between the left end wall and the right end wall of the driving cavity; the rotating wheel group B comprises a reverse gear A which is in fixed fit connection with the rotating shaft. The convenient sludge treatment device is simple in structure and convenient to use; the device adopts a ratchet type structure to drive a screw conveying structure, so that the production efficiency can be adjusted at different speed ratios, and the production efficiency is effectively improved.

Owner:练酉均

Permanent magnet speed regulator with fixed magnetic gap

ActiveCN105449980ARealize speed regulation functionExpand the scope of usePermanent-magnet clutches/brakesDrive shaftRare earth

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap, and the speed regulator comprises a first internal magnetic rotor, a second internal magnetic rotor, and an external magnet rotor frame, wherein a driving shaft coaxially passes through the first and second internal magnetic rotors, and the external magnet rotor frame is connected with a driven shaft. The external magnet rotor frame is provided with an external magnetic rotor through a bearing. In addition, one end, close to the driven shaft, of the external magnetic rotor is provided with an external magnetic rotor planetary gear. A driven shaft planetary gear is disposed between the external magnetic rotor planetary gear and the driven shaft. The speed regulator employs a fixed magnetic gap structure, so the speed regulator greatly increases the engagement area, reduces the assembly difficulty, reduces the generated heat, enlarges the range of speed regulation, saves rare earth materials, and greatly improves the capability of torque transmission. Because the speed regulator employs a planetary gear transmission structure, the speed regulator achieves a function of 0-%N speed regulation of input and output rotating speeds through changing the gear ratio of the external magnetic rotor planetary gear to the driven shaft planetary gear. In addition, the speed regulator employs a bearing structure, and prevents the continuous shaking of the driven shaft in two directions from causing that the driven shaft cannot rotate normally in one direction to drive a load.

Owner:刁俊起

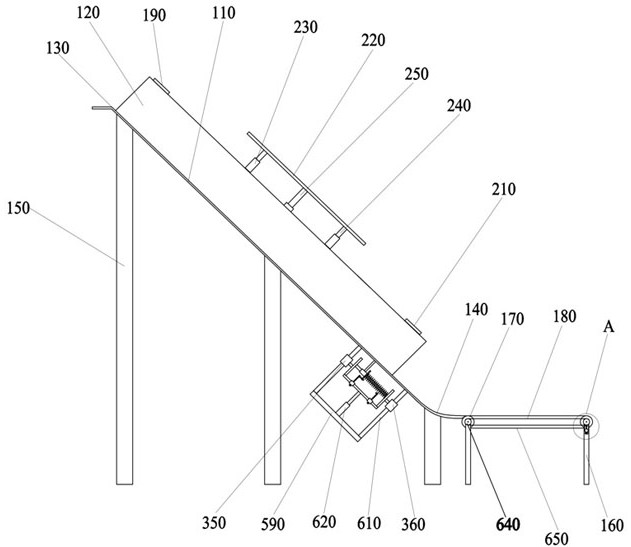

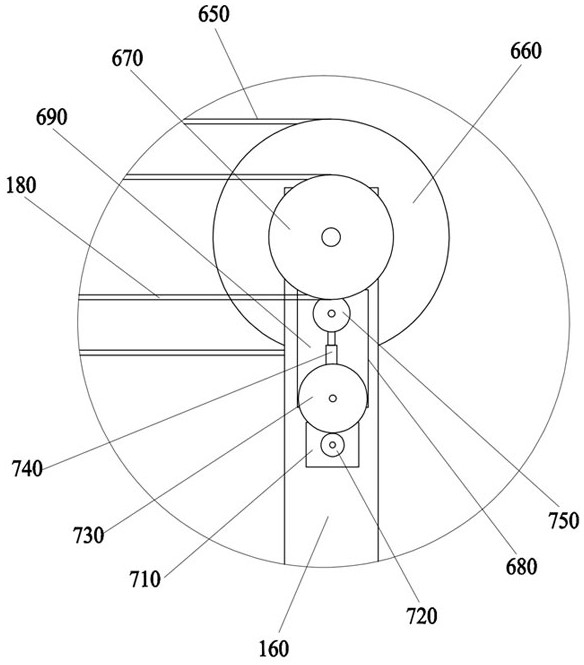

Descending loading conveying device with speed reducer

ActiveCN112499125AImprove practicalityAdjust the running speedConveyorsConveyor partsProduction lineGear wheel

The invention discloses a descending loading conveying device with a speed reducer. The descending loading conveying device comprises a slideway, a conveying belt, a driving roller, a driven roller, amotor and the speed reducer, wherein the slideway comprises an upper end and a lower end; the upper end is arranged at an output port of a production line; the lower end is close to one end of the conveying belt; the slideway is obliquely arranged; the conveying belt is arranged on the driving roller and the driven roller in a sleeving manner; and the speed reducer comprises a box body, a first rotating shaft, a second rotating shaft, a second gear, a third grooved wheel, a telescopic assembly, a second grooved wheel, a first belt, a first bearing, a second bearing, a first air cylinder and asecond air cylinder. According to the descending loading conveying device with the speed reducer, the speed reducer has the speed changing capacity, products enter the conveying belt after sliding down from the slideway, and the running speed of the conveying belt can be adjusted according to the frequency of fallen product packaging boxes.

Owner:WANSHSIN SEIKOU HUNAN CO LTD

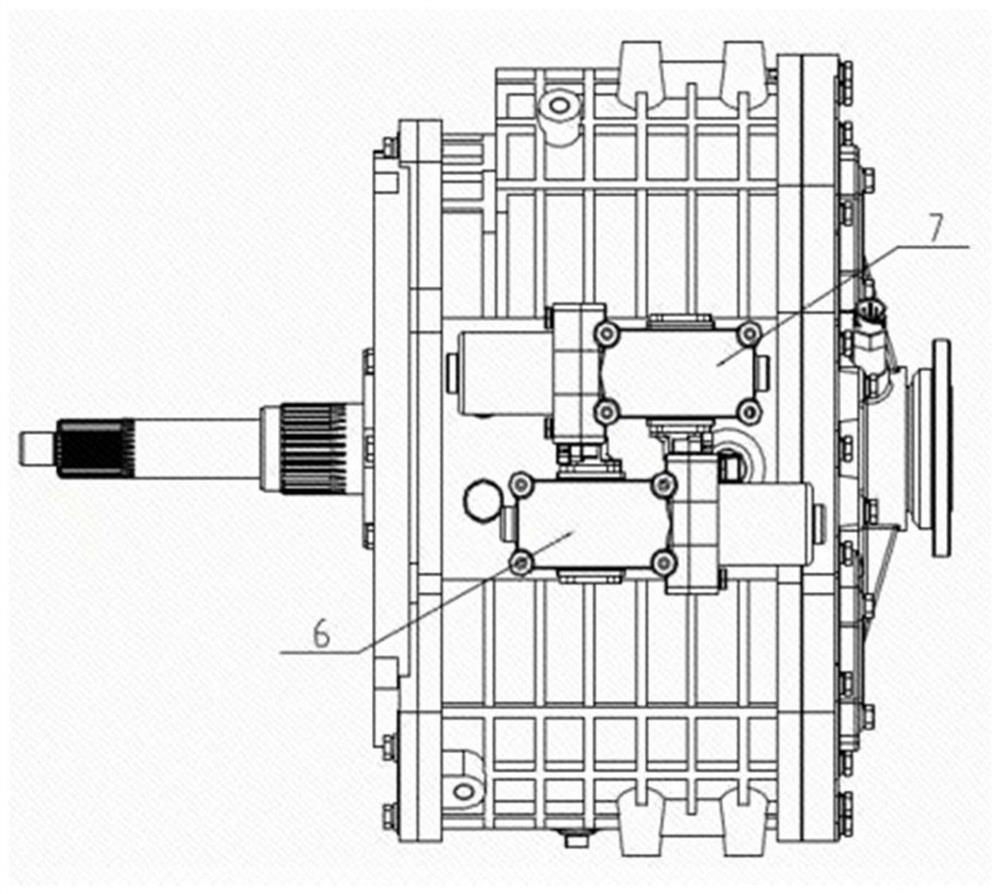

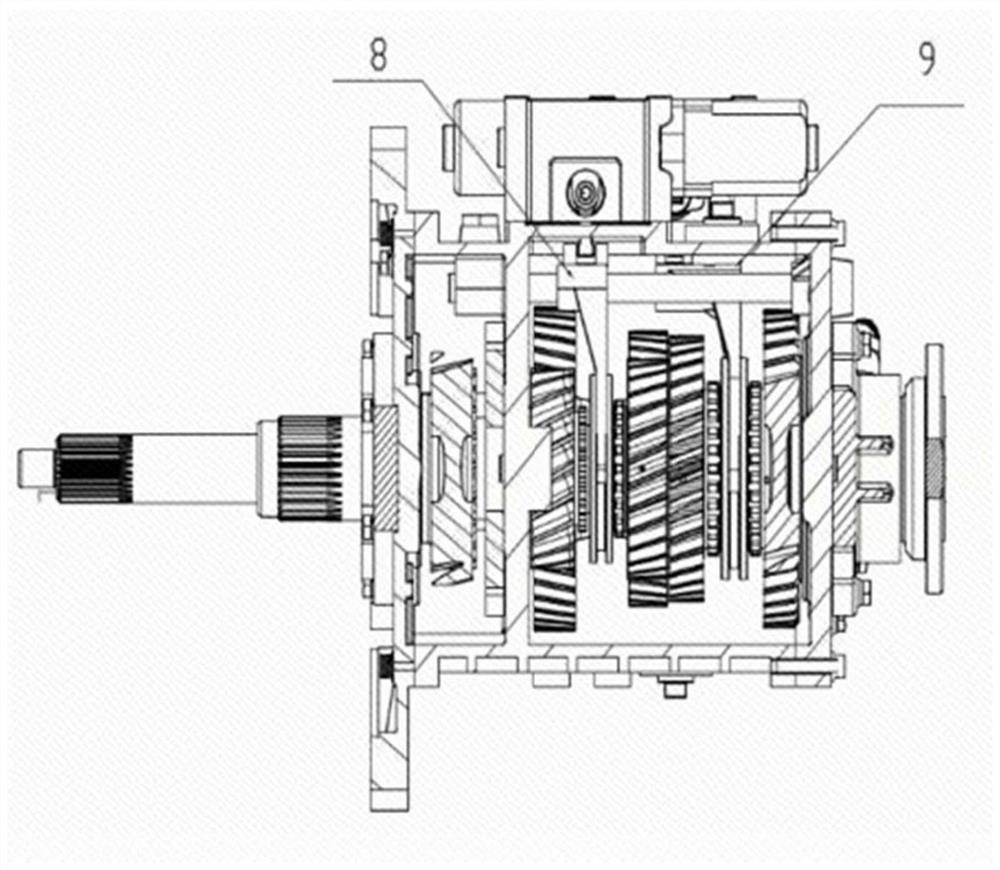

Double-input gearbox assembly and operation method thereof

PendingCN114810955ADifficulty of SimplificationLess intrusiveControlled membersToothed gearingsPower couplingMotor speed

The invention discloses a double-input gearbox assembly and an operation method thereof. The double-input gearbox assembly comprises a first input shaft, a second input shaft, a first intermediate shaft assembly, a second intermediate shaft assembly and an output shaft. The first input shaft is sleeved with a second input shaft, the first input shaft is connected with the output shaft, one side of the output shaft is provided with a first intermediate shaft assembly, the other side of the output shaft is provided with a second intermediate shaft assembly, the first input shaft and the second input shaft are connected with a power structure, and the power structure is connected with the gearbox. The gear force needing to be provided is selected firstly; the two independently-arranged input systems are used for carrying out gear shifting and speed regulation on the gearbox; a motor controller is used for reading the rotating speed in real time; the motor rotating speed device adjusts the rotating speeds of the two motors, gear coupling is achieved, it can be effectively guaranteed that the device adjusts the speed through the motors, simultaneous input of the two motors is achieved, it is guaranteed that the device can be engaged with the two gears, power coupling is achieved, and therefore the effects of saving energy, reducing consumption and saving cost are achieved.

Owner:SHAANXI FAST GEAR CO

Switch component

ActiveCN101699594BGood effectVoltage polarity is differentContact electric connectionContact failureEngineering

The invention particularly relates to a switch and is used to improve the structure at the contact part used for turning on and off in a switch to reduce current in each contact point and total contact resistance. The problem of poor contact at the pin joint position of a pin joint contact rod and a supporting part in the conventional switch is solved by arranging an additional elastic metal plate on the pin joint contact rod. Due to the contact part arranged on a rotary contact device at the position of a forward / reverse conversion mechanism, the total contact area is increased, current in each contact point is further reduced, and the total contact resistance and heat generation between the rotary contact device at the position of the forward / reverse conversion mechanism and an internalinput and an external output are reduced.

Owner:SHANGHAI BAICHENG ELECTRONICS

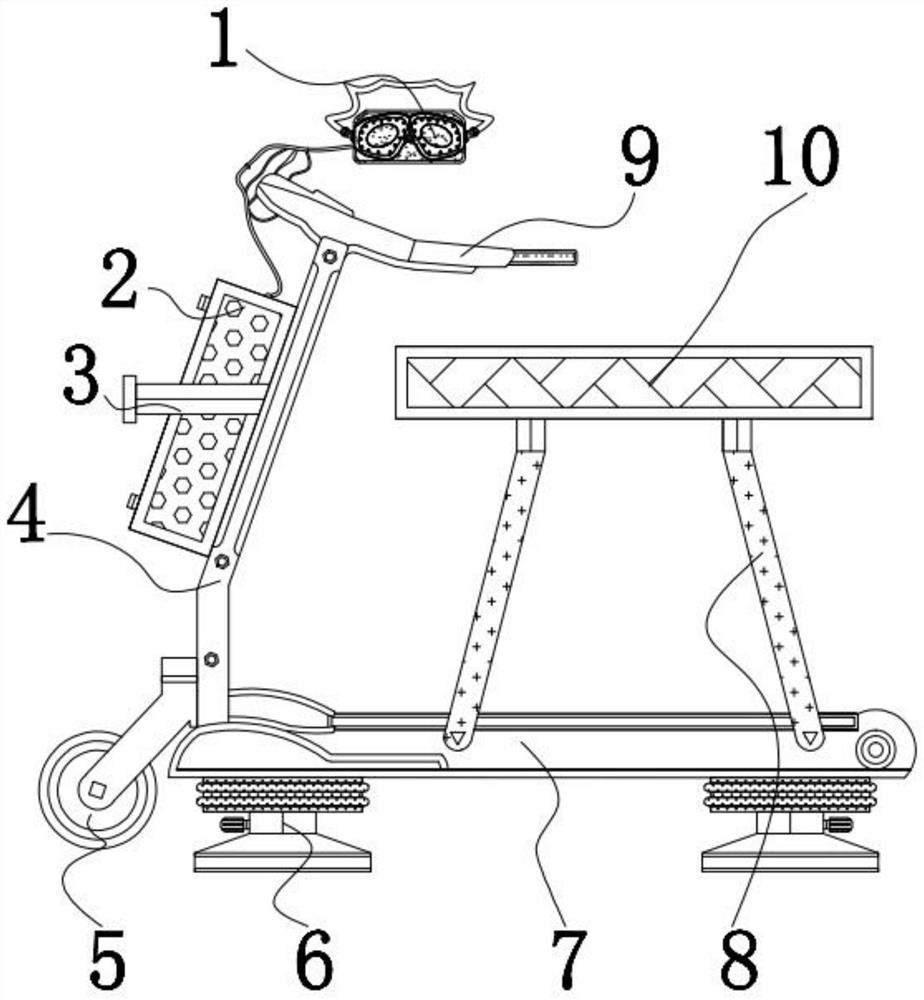

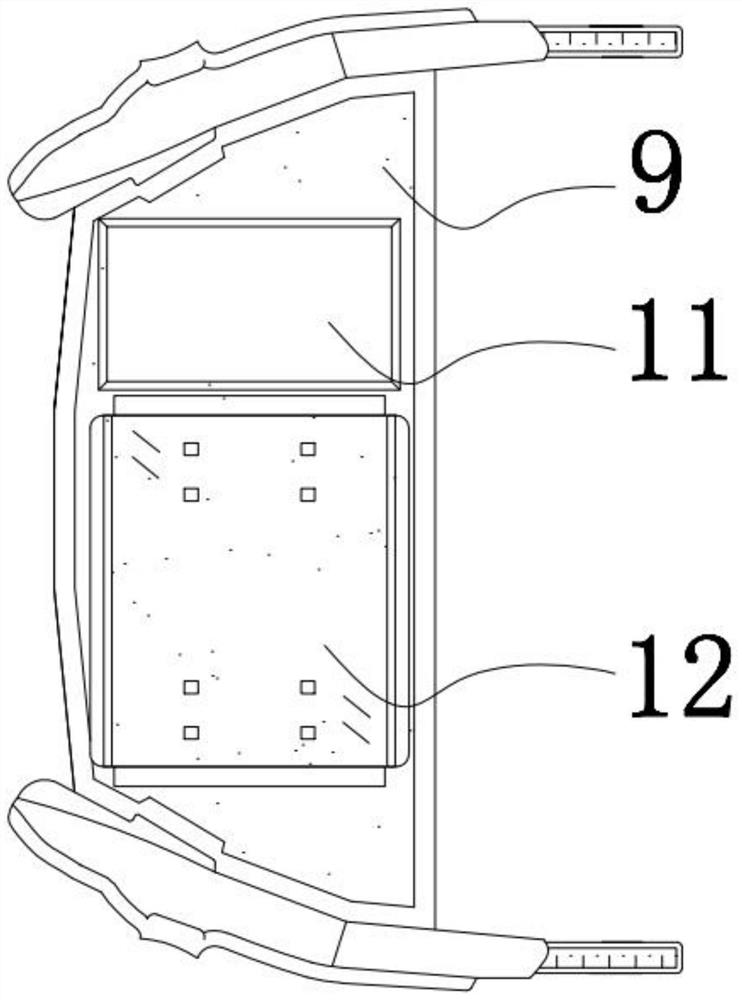

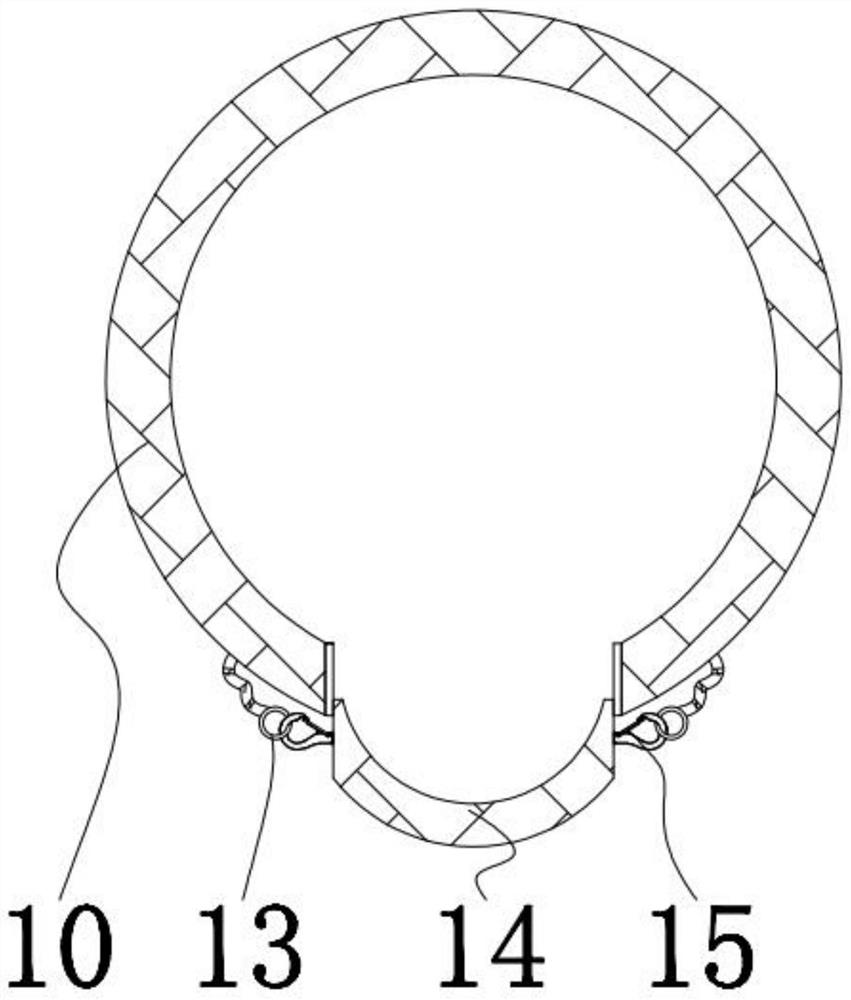

Treadmill with VR interaction function

InactiveCN113713325AHigh intelligenceOptimize structureNon-rotating vibration suppressionMovement coordination devicesTreadmill runningEngineering

The invention discloses a treadmill with a VR interaction function. The treadmill comprises VR glasses, a controller, a rack and a base, wherein the base is welded to the bottom of the rack, rubber damping plates are bonded to two ends of the bottom of the base, fixing discs are arranged on the two sides of the bottom of each rubber damping plate, trundles are uniformly mounted at the bottom of one end of the rack, the controller is installed at an end, close to the trundles, of the rack. By installing an operation handle, trundles and VR glasses, when the device is specifically used, on one hand, a user can grasp the operation handle and incline the device to enable the trundles to conveniently push the device to move, on the other hand, the user can open a sealing plug on a reserved air pipe and then extract air in a fixed disc through an air extracting pump; and negative pressure is generated in the adsorption holes in the bottom of the fixing disc, the corresponding operation ground is firmly adsorbed, then the device is conveniently fixed, and stability of the device is enhanced.

Owner:江西伊启实业有限公司

Sludge treatment device

InactiveCN108503177AImprove transmission efficiencyImprove work coordinationSludge treatment by de-watering/drying/thickeningSludgeSprocket

The invention discloses a sludge treatment device, which comprises a treatment box fixedly arranged at the ground, wherein a driving cavity is fixedly arranged in the treatment box; a cavity C positioned in the treatment box is arranged at the right side of the driving cavity; a driving machine is fixedly arranged in the left end wall of the driving cavity; a chain wheel A is fixedly arranged at the outer surface of a rotating shaft of the driving machine; the right end wall of the driving cavity is fixedly provided with a fixed shaft A; the outer surface of the fixed shaft A is rotatably provided with a chain wheel B engaged with the chain wheel A; a rotating wheel group B is arranged under the chain wheel B; a rotating wheel group A is arranged under the chain wheel A; a rotating shaft rightwards extending into the cavity C is rotatably arranged between the left and right end walls of the driving cavity; the rotating wheel group B comprises a reverse gear A in fixed matched connection with the rotating shaft. The sludge treatment device has the advantages that the structure is simple; the use is convenient; the equipment uses a ratchet wheel type structure for driving a spiral conveying structure; the goal of regulating the production efficiency at different speed ratios is realized; the production efficiency is effectively improved.

Owner:练酉均

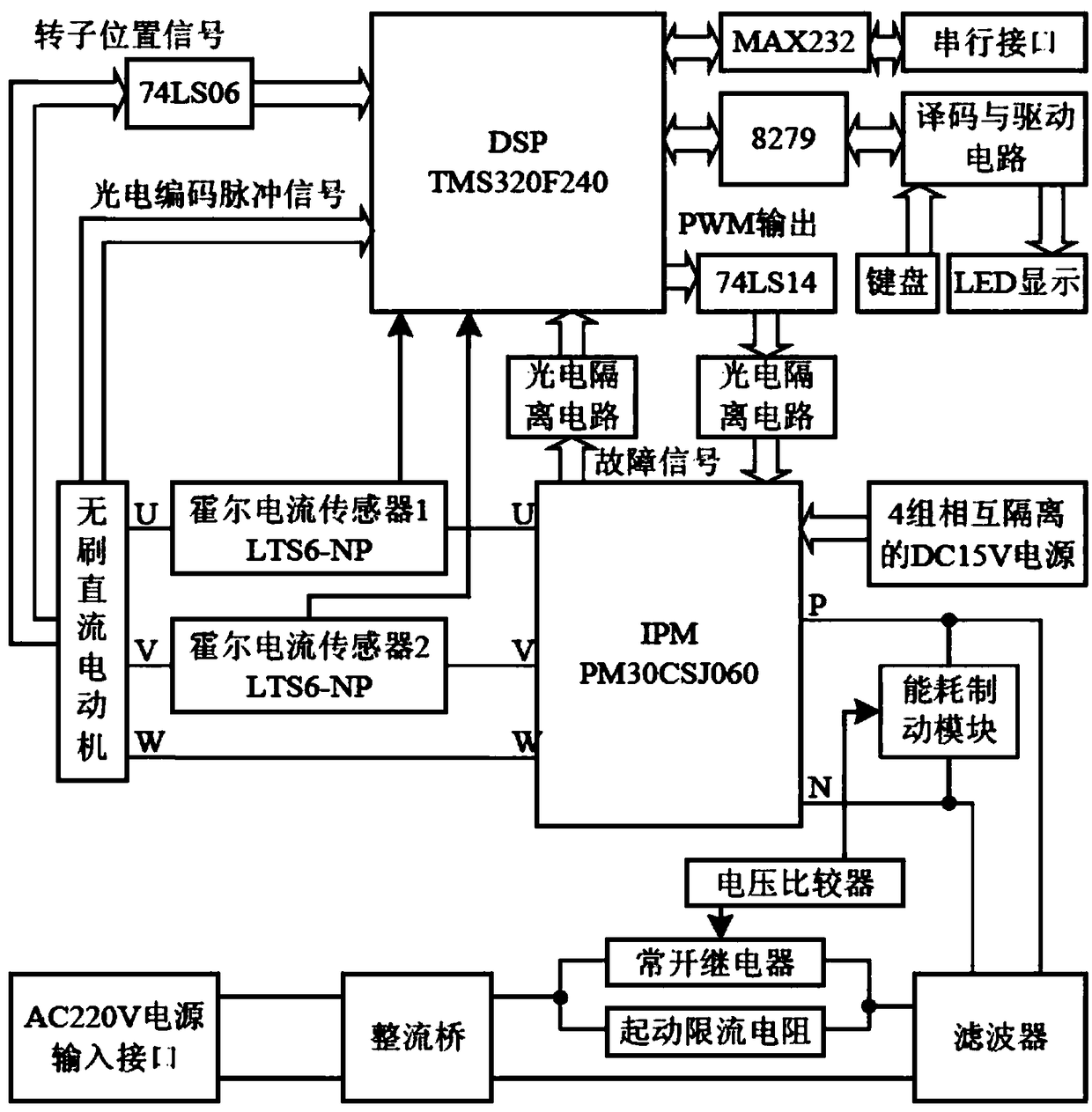

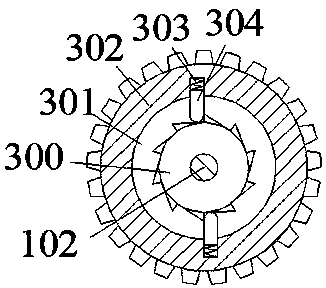

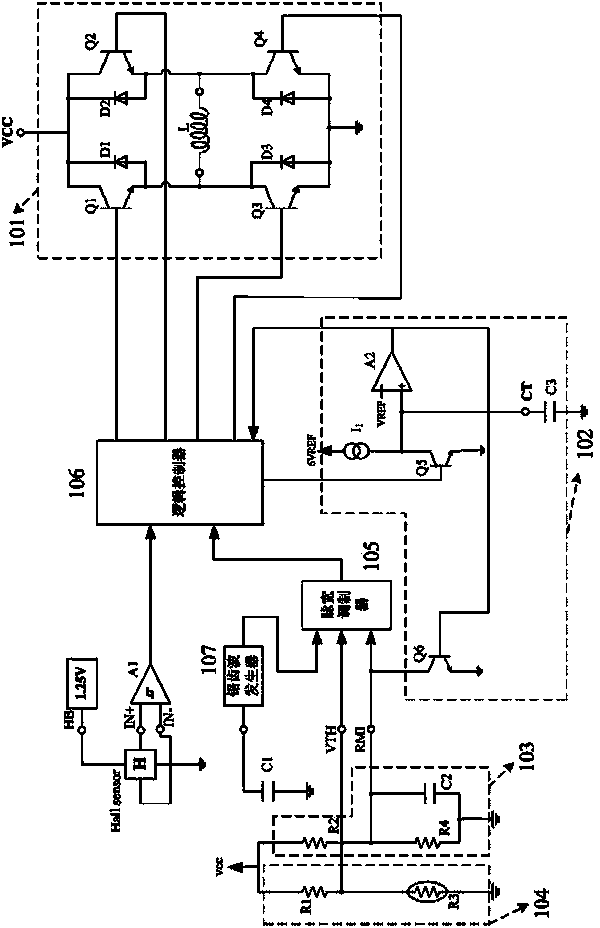

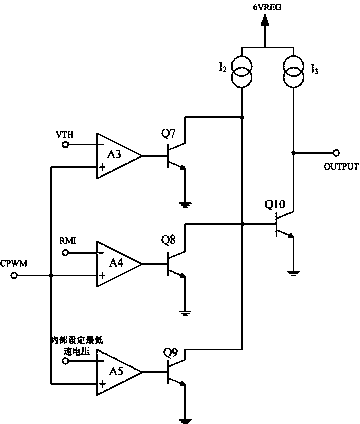

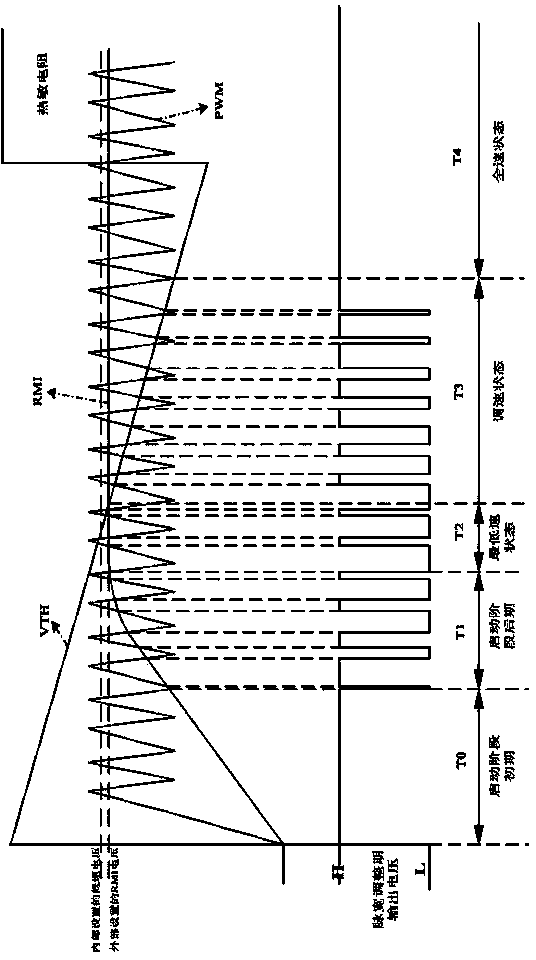

Speed regulation driving integrated circuit for single-phase brushless direct current fan

ActiveCN102594234BLow costRealize speed regulation functionEmergency protective circuit arrangementsField or armature current controlAmplifierDirect current

The invention relates to the field of integrated circuits, in particular to a speed regulation driving integrated circuit for a single-phase brushless direct current fan. An acquired temperature signal and an internal sawtooth generator signal are controlled through a pulse width modulator to realize automatic speed regulation. A reversing function is realized through the processing of a Hall amplifier and a logic controller according to a Hall sensor signal. A locking alarming function, a locked-rotor protection function and an automatic restarting function are realized by utilizing an internal locked-rotor detection and automatic restarting circuit. According to the integrated circuit, an automatic speed regulation function is realized, the auxiliary functions of rotating speed detection, locking alarming, locked-rotor protection, automatic restarting and the like are also realized, the complexity of a peripheral circuit is lowered, peripheral devices are reduced, and cost in the speed regulation of the fan is greatly decreased.

Owner:DALIAN LIANSHUN ELECTRONICS +3

Torque motor actuator of linear diesel engine

InactiveCN101520005BRealize speed regulation functionControl speedEngine controllersMachines/enginesElectric machineTorque motor

The invention provides a torque motor actuator of a linear diesel engine, comprising a torque motor, a displacement sensor, a stroke control locating iron, a shell, a controller, and the like, whereinThe invention provides a torque motor actuator of a linear diesel engine, comprising a torque motor, a displacement sensor, a stroke control locating iron, a shell, a controller, and the like, wherein the torque motor is mounted on an eccentric wheel which is adjusted and fastened in the shell, and a segment gear is mounted on the torque motor; a rack shaft is mounted on the shell by two linear bethe torque motor is mounted on an eccentric wheel which is adjusted and fastened in the shell, and a segment gear is mounted on the torque motor; a rack shaft is mounted on the shell by two linear bearings, and a spring is mounted at one end of the rack shaft; a displacement sensor is mounted at one terminal of the rack shaft, is connected with the controller and feeds offset of the rack shaft baarings, and a spring is mounted at one end of the rack shaft; a displacement sensor is mounted at one terminal of the rack shaft, is connected with the controller and feeds offset of the rack shaft back to the controller, and the output of the controller controls the torque motor. The torque motor actuator of the linear diesel engine can reliably control the rotating speed of the diesel engine, hack to the controller, and the output of the controller controls the torque motor. The torque motor actuator of the linear diesel engine can reliably control the rotating speed of the diesel engine, has higher response speed and is suitable for controlling the rotating speeds of middle-powder or small-powder diesel engines.s higher response speed and is suitable for controlling the rotating speeds of middle-powder or small-powder diesel engines.

Owner:HARBIN ENG UNIV

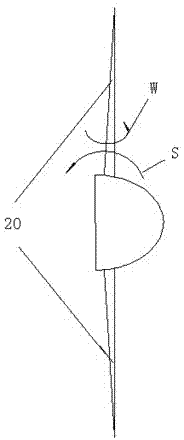

Automatic blade-changing speed-regulating device based on wind speed

InactiveCN102926932BRealize speed regulation functionSimple structureWind motor controlMachines/enginesDrive shaftEngineering

The invention provides an automatic variable-pitch speed regulating device based on an air speed, which is formed by a variable mounting angle mechanism and a variable inclined angle mechanism. A blade mounting plate is fixedly connected with an outer step of a sleeve of the variable mounting angle mechanism and a mandrel is mounted at the upper end of the sleeve through a radial bearing; the mandrel is positioned by a positioning screw at the lower end; the mandrel is connected with the sleeve through a torsional spring; the lower end of the mandrel is fixedly connected with a positioning rod on a machine shell and is connected with the variable inclined angle mechanism through a connecting rod; a spline transmission shaft of the variable inclined angle mechanism is slidingly connected with a rotary table; an axial bearing is mounted at the front end of the rotary table; the axial bearing is connected with the machine shell through a compression spring; the back end of the rotary table is connected with the connecting rod. Under the effect of wind power, an automatic variable pitch blade mounting angle is realizing by the torsional spring and a rotary mechanism, and an automatic variable pitch blade inclined angle is realized by using the compression spring and a connecting rod mechanism. According to the device, the structure is simpler, the installation is convenient, other auxiliary energy sources and counter weight mechanisms are not needed and the function can be automatically realized according to the size of the wind power.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com