Switch component

A technology of switch components and parts, which can be used in electrical switches, electrical components, contacts, etc., to solve problems such as poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

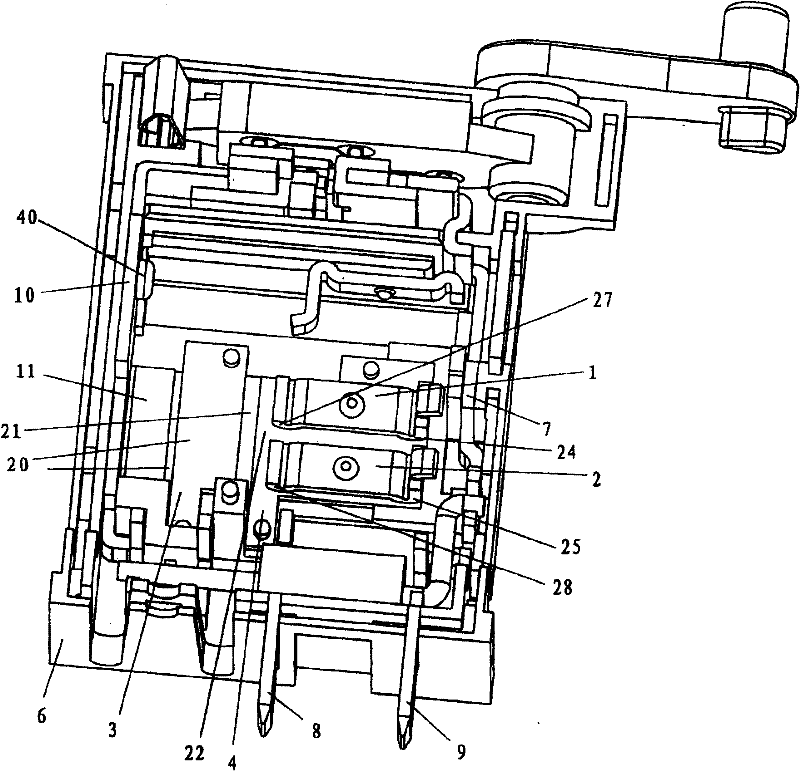

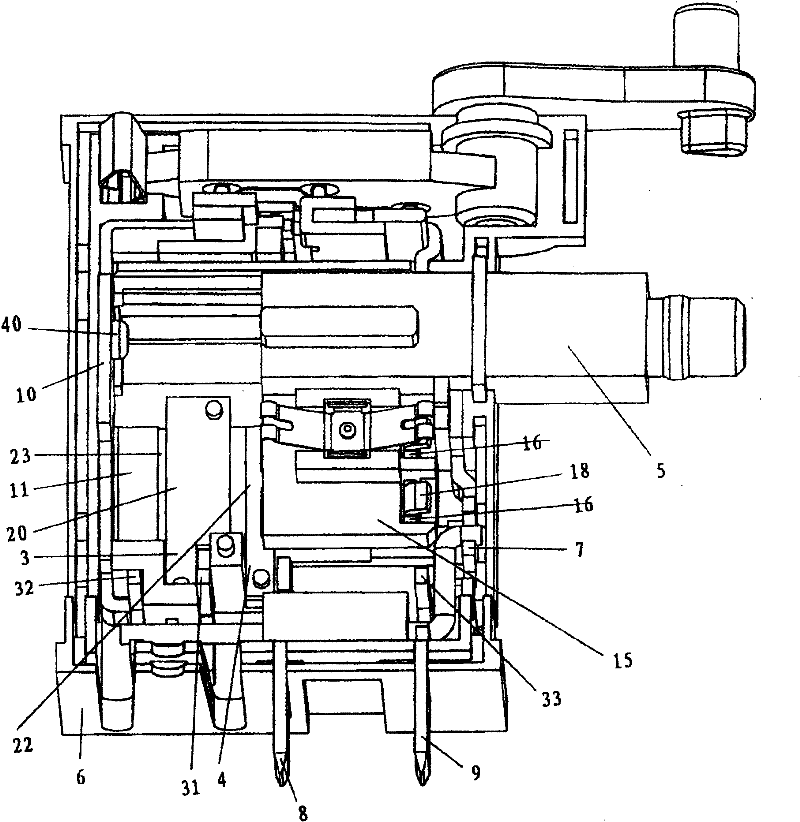

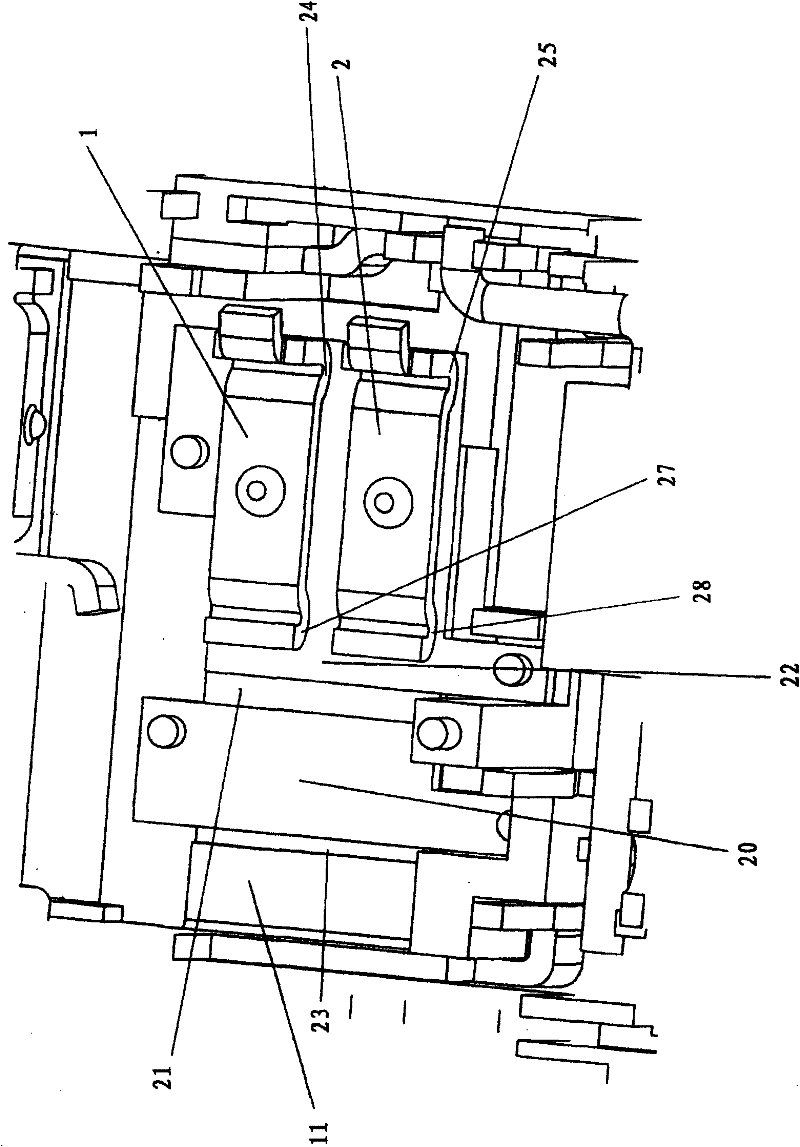

[0210] Figure 1-20 as well as Figure 77 A first embodiment of the invention is shown. Such as Figure 1-3 , 13-15 and 18-19, the switch assembly according to this embodiment includes a housing 6. The housing 6 is equipped with a power negative input fixed contact part 4 as an input part and a power positive input fixed contact part 7 as another input part. Both the power negative input fixed contact part 4 and the power positive input fixed contact part 7 with the power negative input fixed contact piece 22 are fixed on the housing 6 . One end 8 of the negative pole input fixed contact part 4 of the power supply is used for electrical connection with the negative pole of the power supply. One end 9 of the positive input fixed contact part 7 of the power supply is used for electrical connection with the positive pole of the power supply. A straight-through fixed contact part 10 is also fixed on the housing 6 . Especially as Figure 11 As shown, the through-fixed contact...

Embodiment 1

[0224] Embodiment 1 adopts the contact method of double sliding contact pieces, that is, from the start of work to the speed regulation state, and then to the straight-through state, two same sliding contact pieces are used, that is, all the working contact surfaces are double. Compared with products using single sliding contact sheet moving contact, this product adds a current channel during operation, which reduces the current flowing through each current channel, reduces the total contact resistance, and improves the current carrying capacity of the switch. It will increase accordingly.

Embodiment 2

[0226] Figure 21-46 The second embodiment of the present invention is shown. The main difference between embodiment 2 and embodiment 1 is that in embodiment 1, the through function of the switch is through the sliding contact pieces 1 and 2 and the power supply negative input fixed contact piece 22 at the same time It is realized by contacting with the straight-through fixed contact piece 11 on the straight-through fixed contact part 10 . And in embodiment 2, straight-through fixed contact piece 11 is not provided with through-through fixed contact piece 211 on the straight-through fixed contact part 10, and the sliding contact piece is still contacted with speed-regulating fixed contact piece in the rear part of the stroke of push rod or It may not be in contact with the speed regulating fixed contact piece, but it must not be in contact with the straight-through fixed contact part. The through function of the switch is realized by at least two pivoting contact parts connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com