Double layer standard squirrel cage conductor rotor high torque density permanent magnet governor

A permanent magnet speed governor, conductor rotor technology, applied in the direction of permanent magnet clutches/brakes, electromechanical devices, electrical components, etc., can solve the problem of increasing the axial length of the device, weakening the air gap magnetic field strength, increasing the magnetic circuit reluctance problem, to reduce the axial length and solve the effect of local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

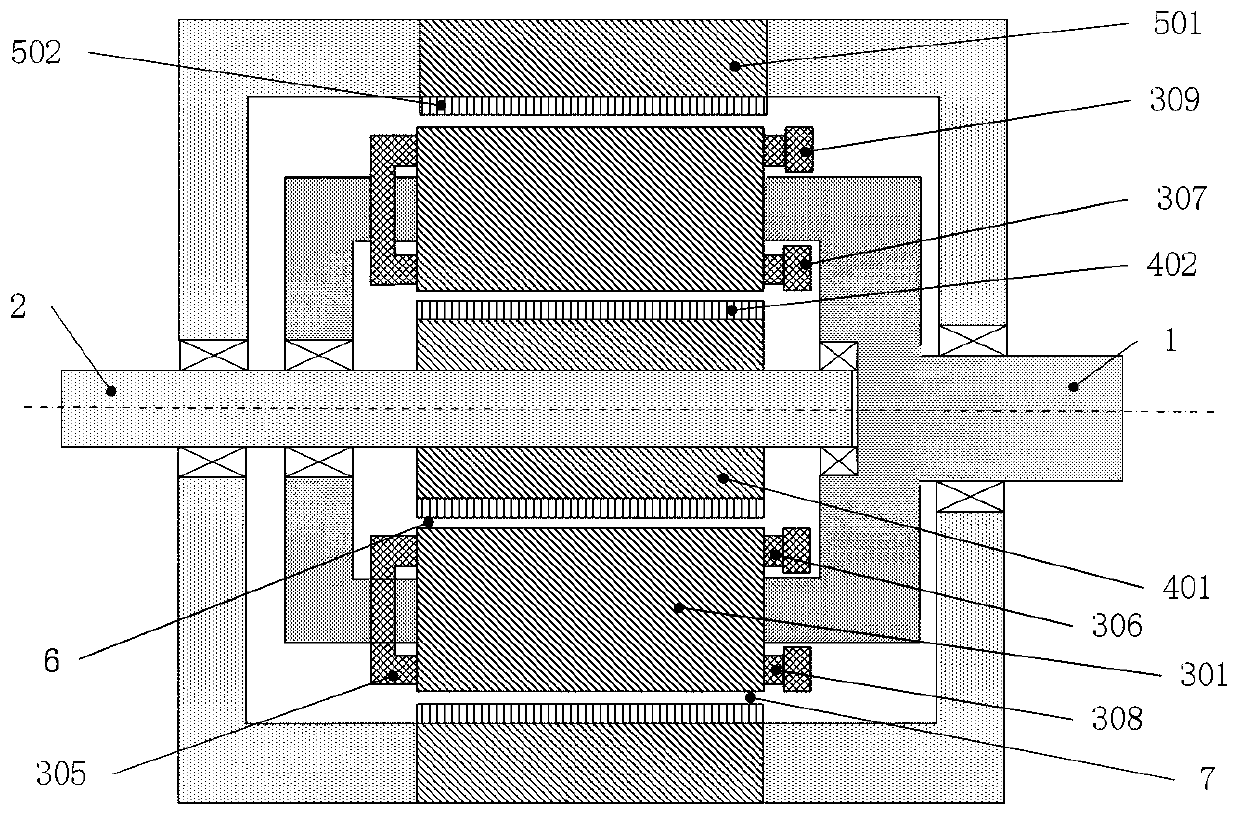

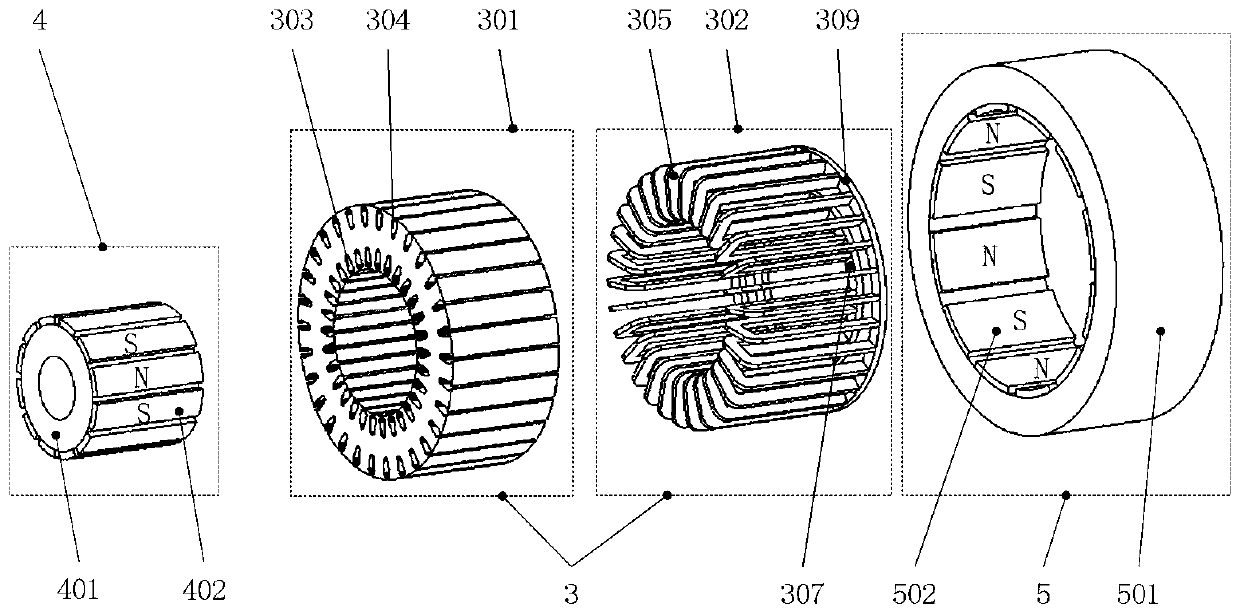

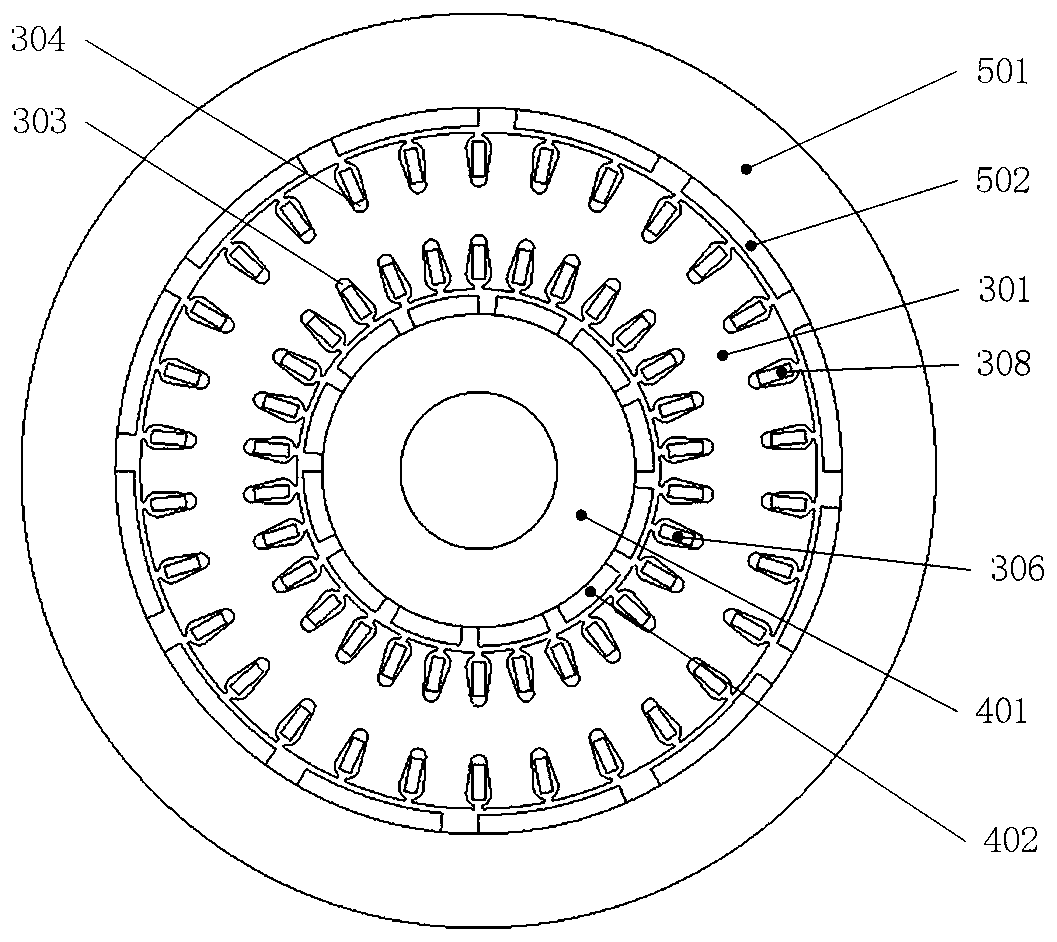

Embodiment 1

[0031] Such as figure 1 with figure 2 As shown, the present invention discloses a double-layer standard squirrel-cage conductor rotor high torque density permanent magnet speed governor, which includes an input shaft 1 and an output shaft 2 arranged on the same central axis, and a gap between the input shaft 1 and the output shaft 2 Fixed connection with bearings. In the present invention, the input shaft 1 includes a central uniaxial body and a cylindrical shaft body for passing the conductor rotor 3 . In the present invention, the first permanent magnet rotor 4 and the second permanent magnet rotor 5 pass through the output shaft 2 and provide torque for the first permanent magnet rotor 4 and the second permanent magnet rotor 5 . The present invention also includes a bracket 8 for passing through the second permanent magnet rotor 5 , one end of the bracket 8 is connected to the output shaft 2 through a bearing, and the other end is also connected to the input shaft 1 thro...

Embodiment 2

[0036] Such as Image 6 with Figure 7 As shown, the present invention discloses a double-layer standard squirrel-cage conductor rotor high torque density permanent magnet speed governor, which includes an input shaft 1 and an output shaft 2 arranged on the same central axis, and a gap between the input shaft 1 and the output shaft 2 Fixed connection with bearings. In the present invention, the input shaft 1 includes a central thin uniaxial body and a disk-shaped shaft body for passing the conductor rotor 3 . In the present invention, the first permanent magnet rotor 4 and the second permanent magnet rotor 5 pass through the output shaft 2 and provide torque for the first permanent magnet rotor 4 and the second permanent magnet rotor 5 . The output shaft 2 of the present invention is erected with a bracket 8 for passing through the second permanent magnet rotor 5 , one end of the bracket 8 is connected with the output shaft 2 through a bearing, and the other end is also conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com