Patents

Literature

257 results about "Automatic variable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computer programming, an automatic variable is a local variable which is allocated and deallocated automatically when program flow enters and leaves the variable's scope. The scope is the lexical context, particularly the function or block in which a variable is defined. Local data is typically (in most languages) invisible outside the function or lexical context where it is defined. Local data is also invisible and inaccessible to a called function, but is not deallocated, coming back in scope as the execution thread returns to the caller.

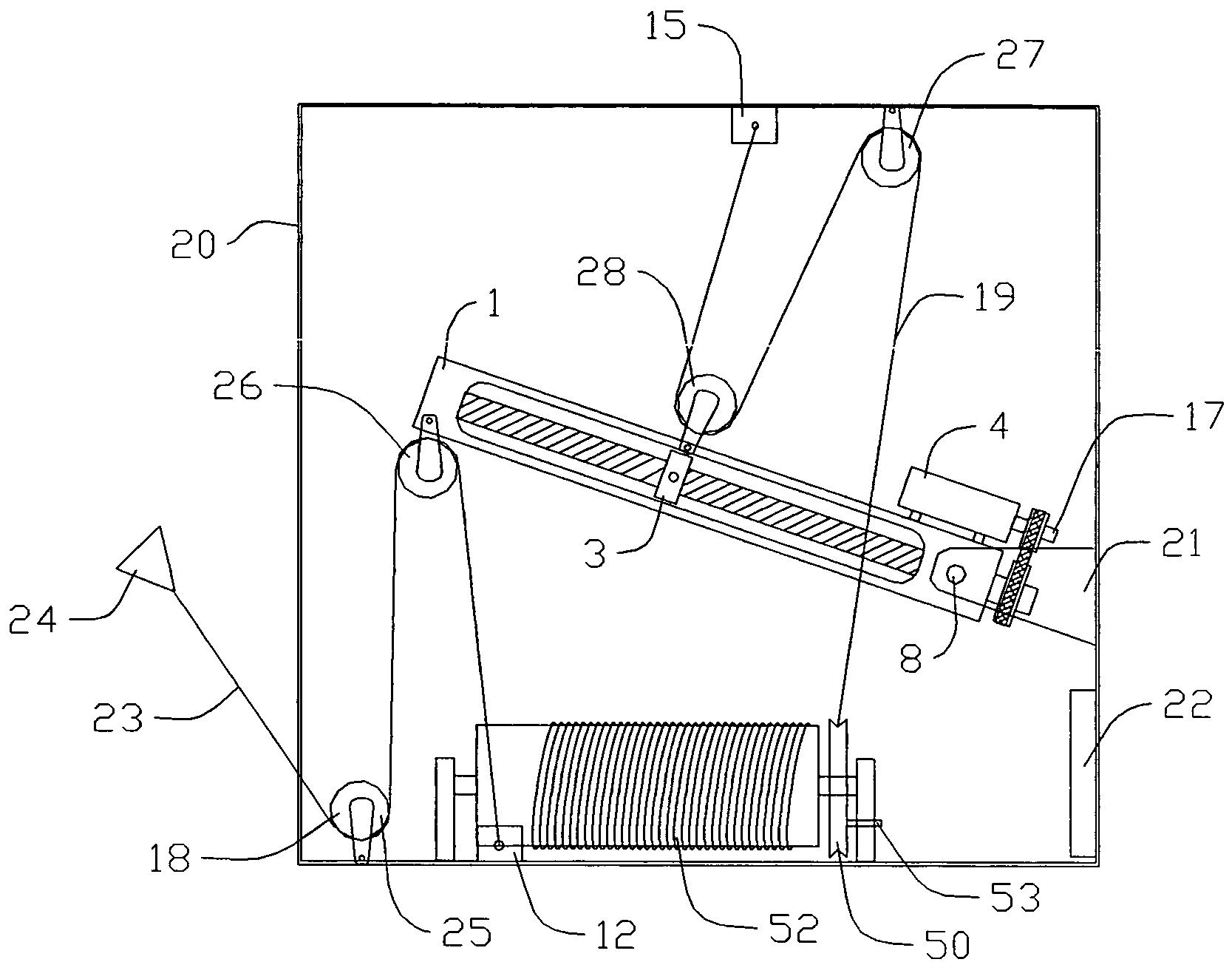

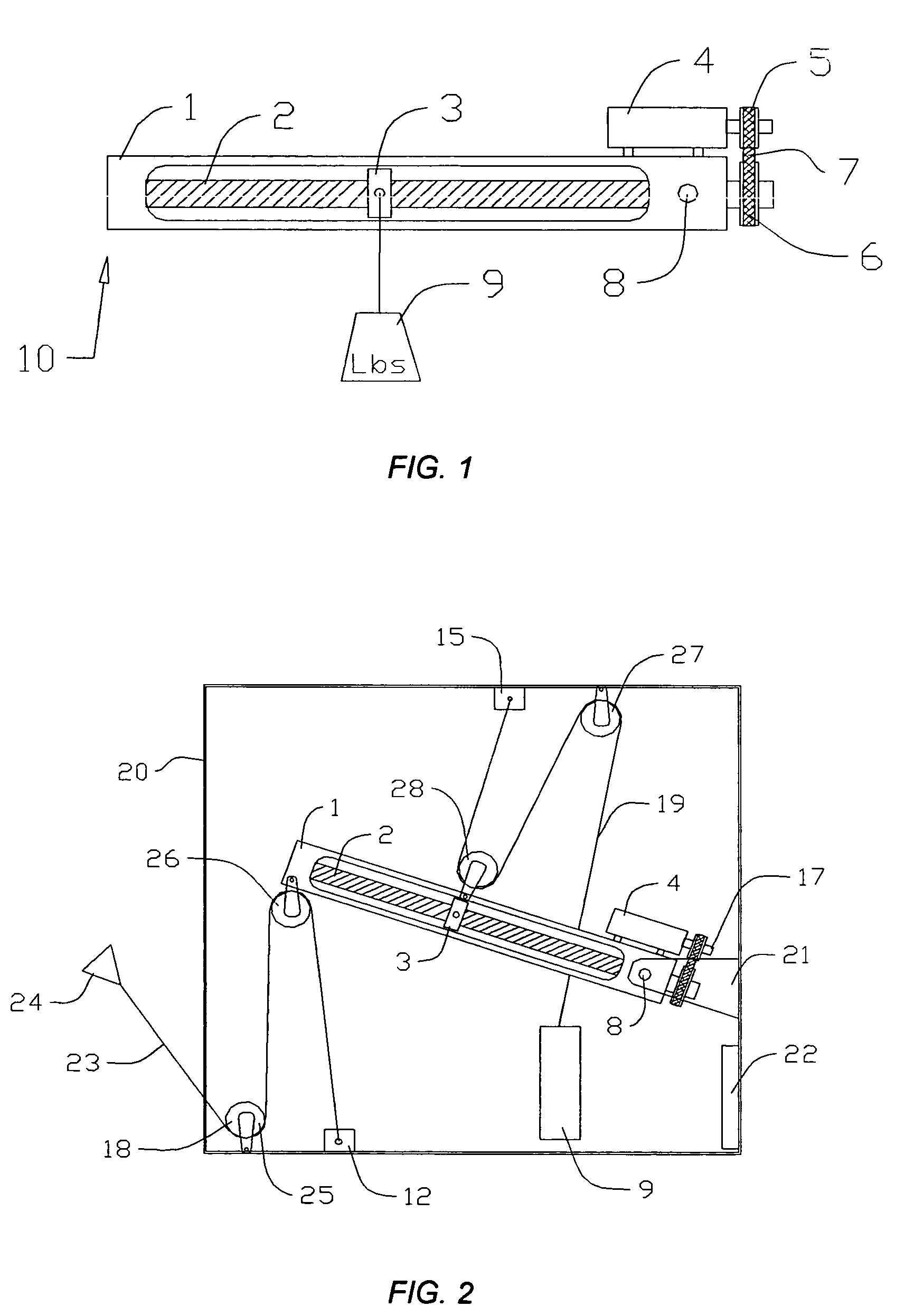

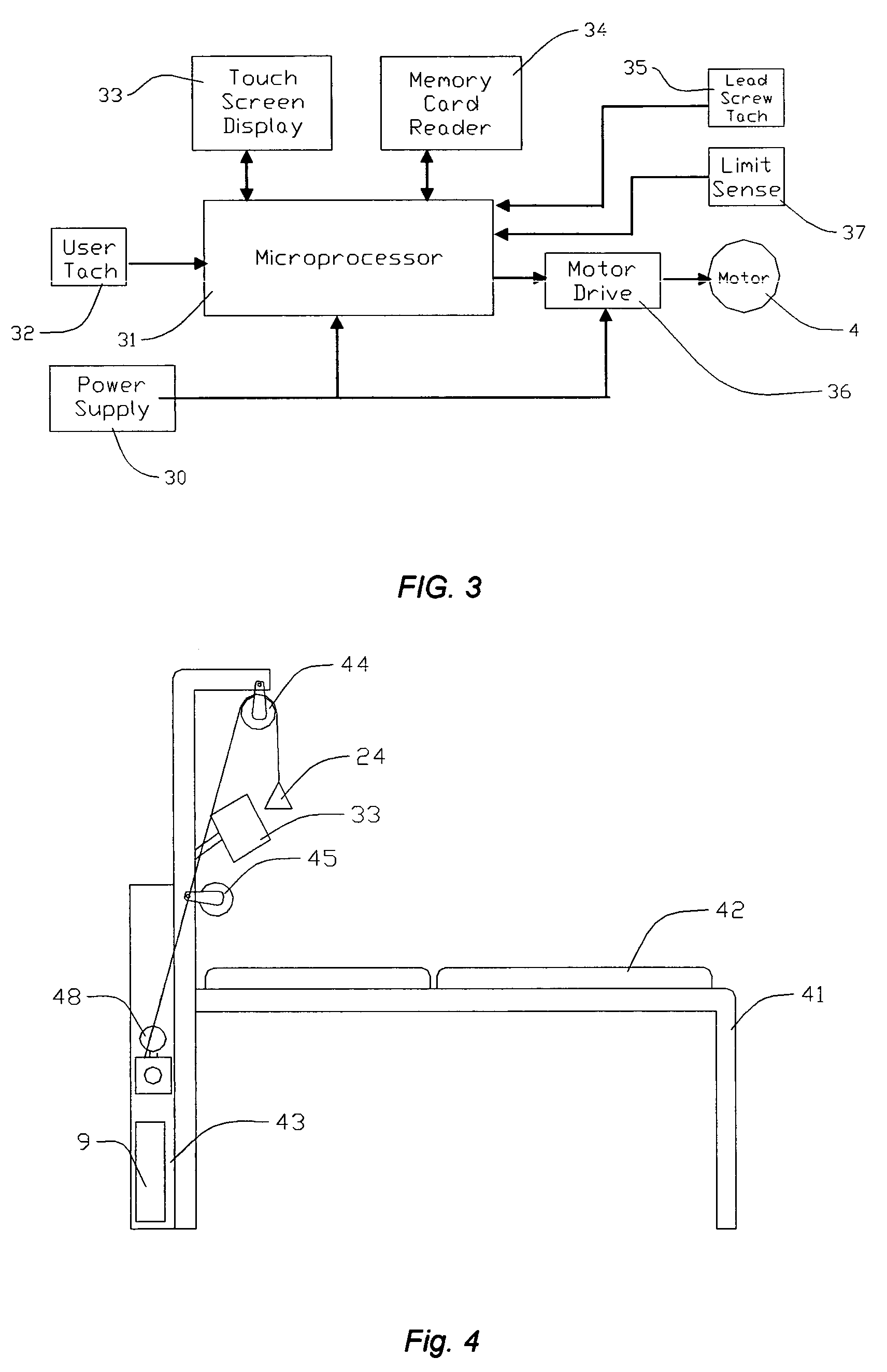

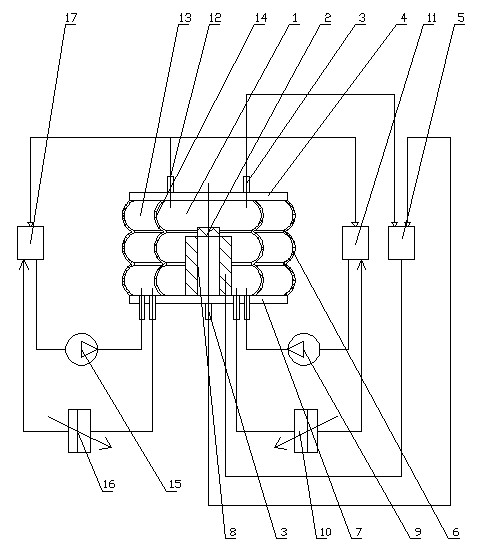

Automatic variable resistance exercise system

InactiveUS7278958B2Continuous regulationRealize automatic adjustmentResilient force resistorsWeightsMotor driveEffective length

A variable resistance physical exercise apparatus is provided which provides improved features over prior art devices in that it is more compact, provides a linear resistance profile to the user and provides a variety of modes of operation. The device comprises a motor driven bi-directional linear translation mechanism to vary the effective length of a lever arm and therefore vary the weight of resistance to the user. An alternative embodiment includes a spring winder drum pulley combination.

Owner:MORGAN CURTIS WAYNE

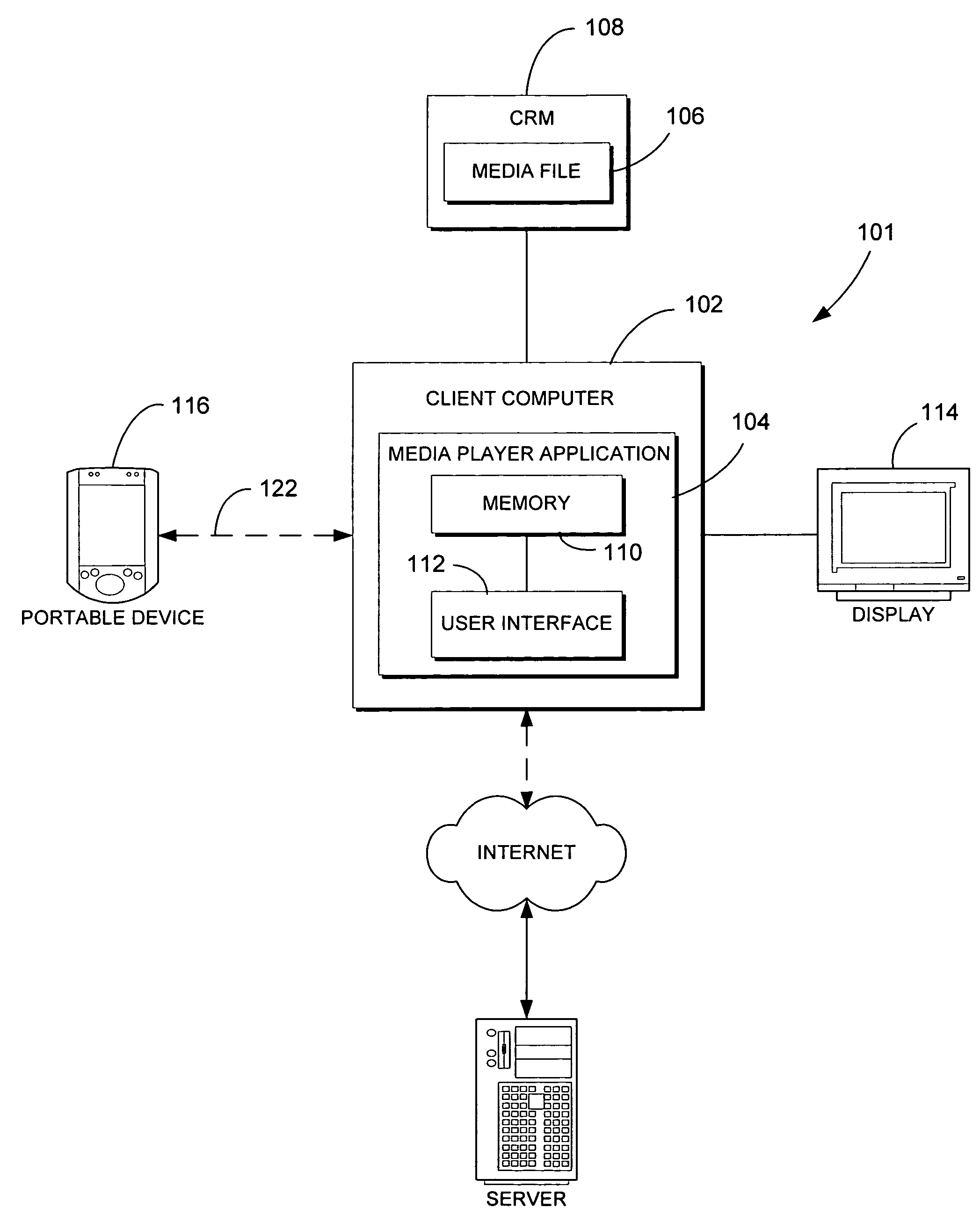

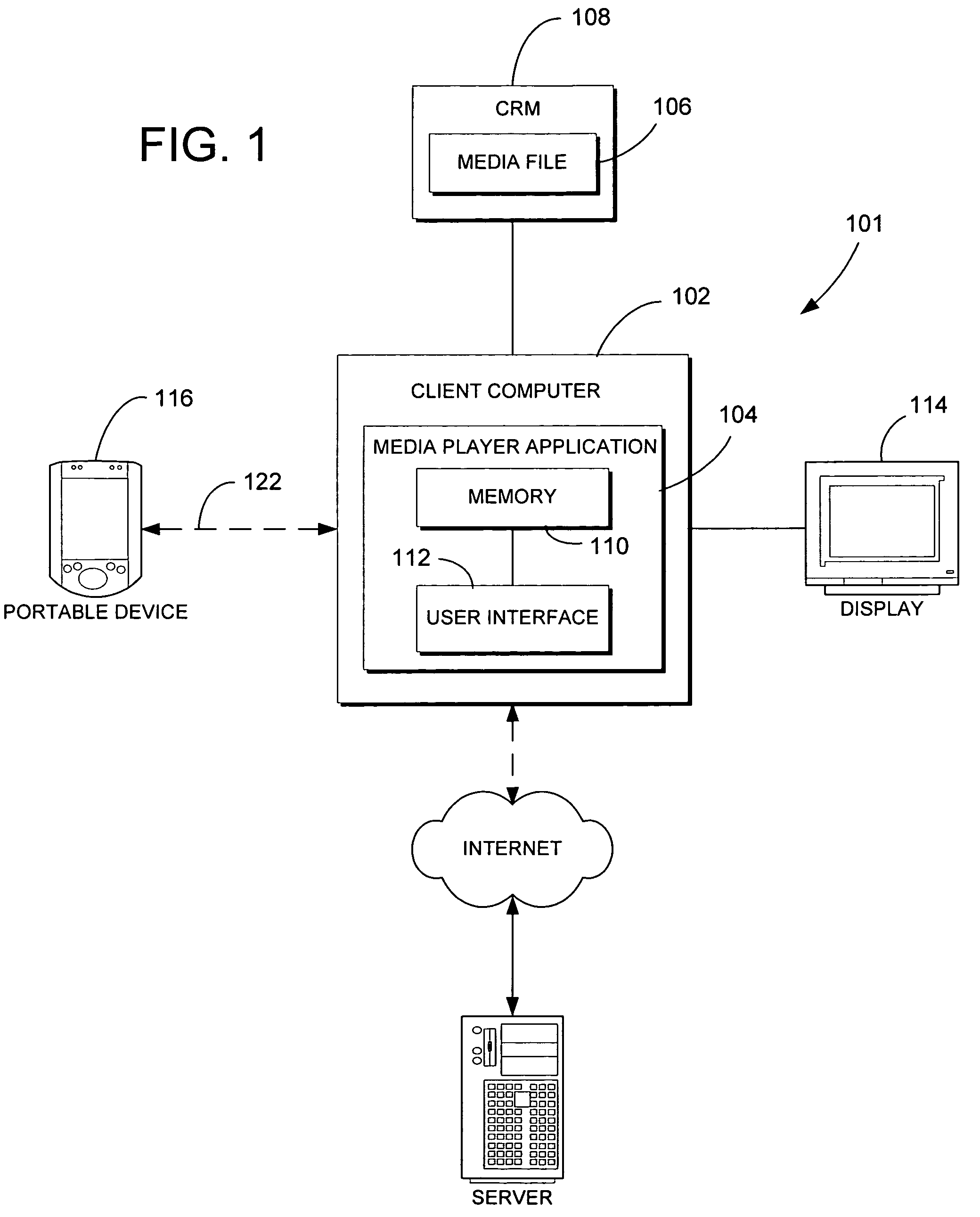

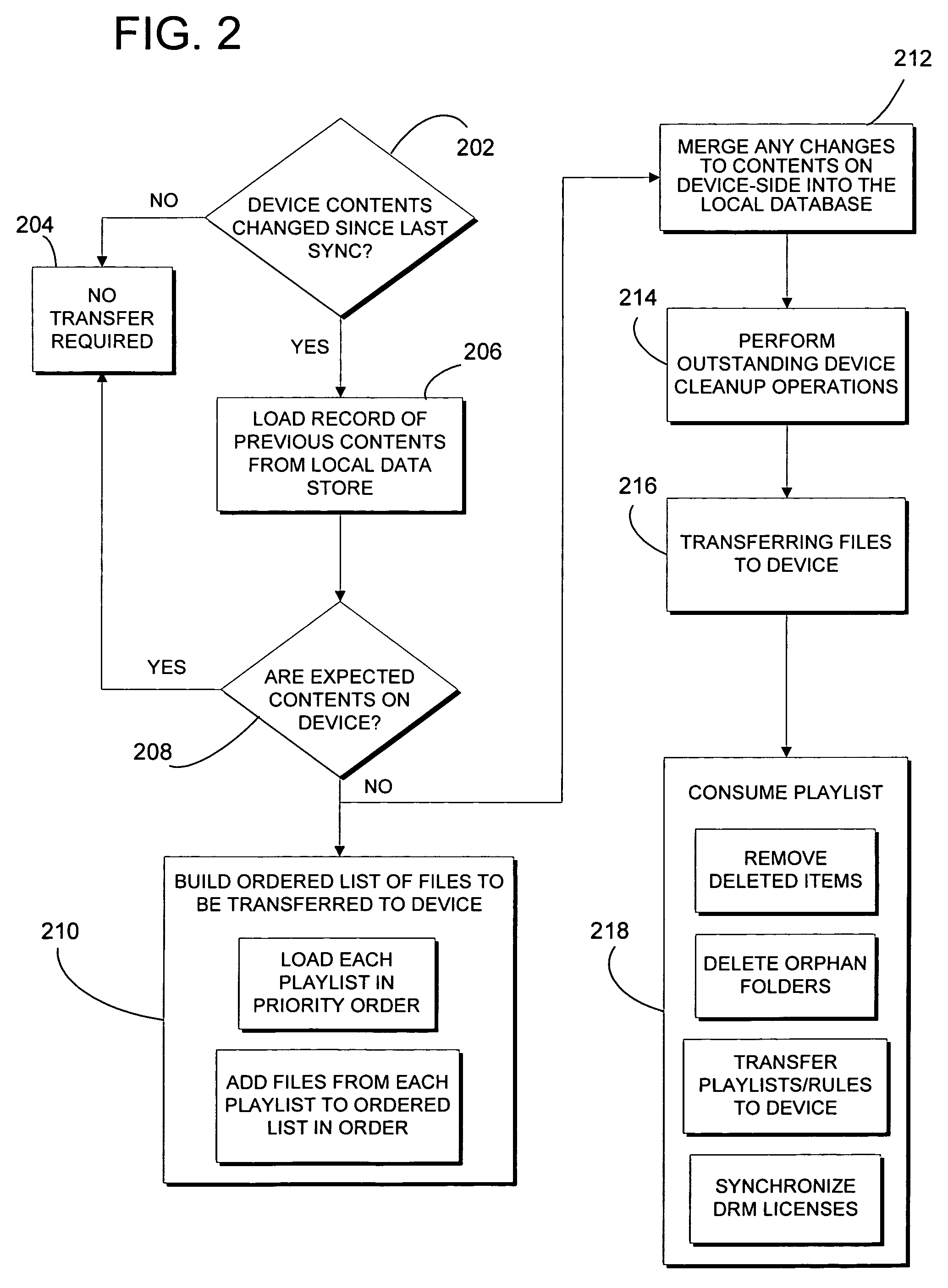

Automatic rules-based device synchronization

ActiveUS7647346B2Improve experienceDigital data information retrievalData processing applicationsData synchronizationFile synchronization

Owner:MICROSOFT TECH LICENSING LLC

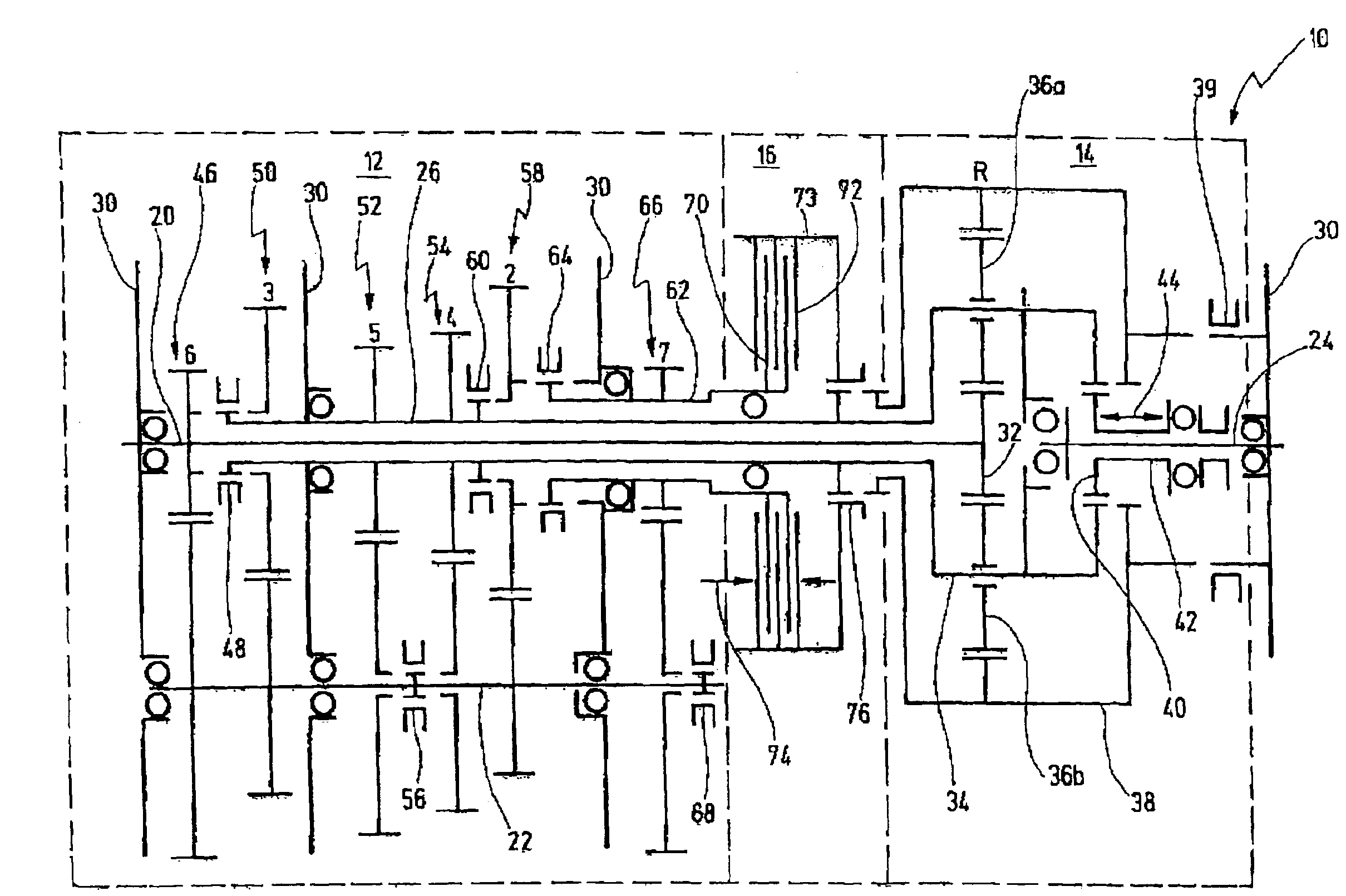

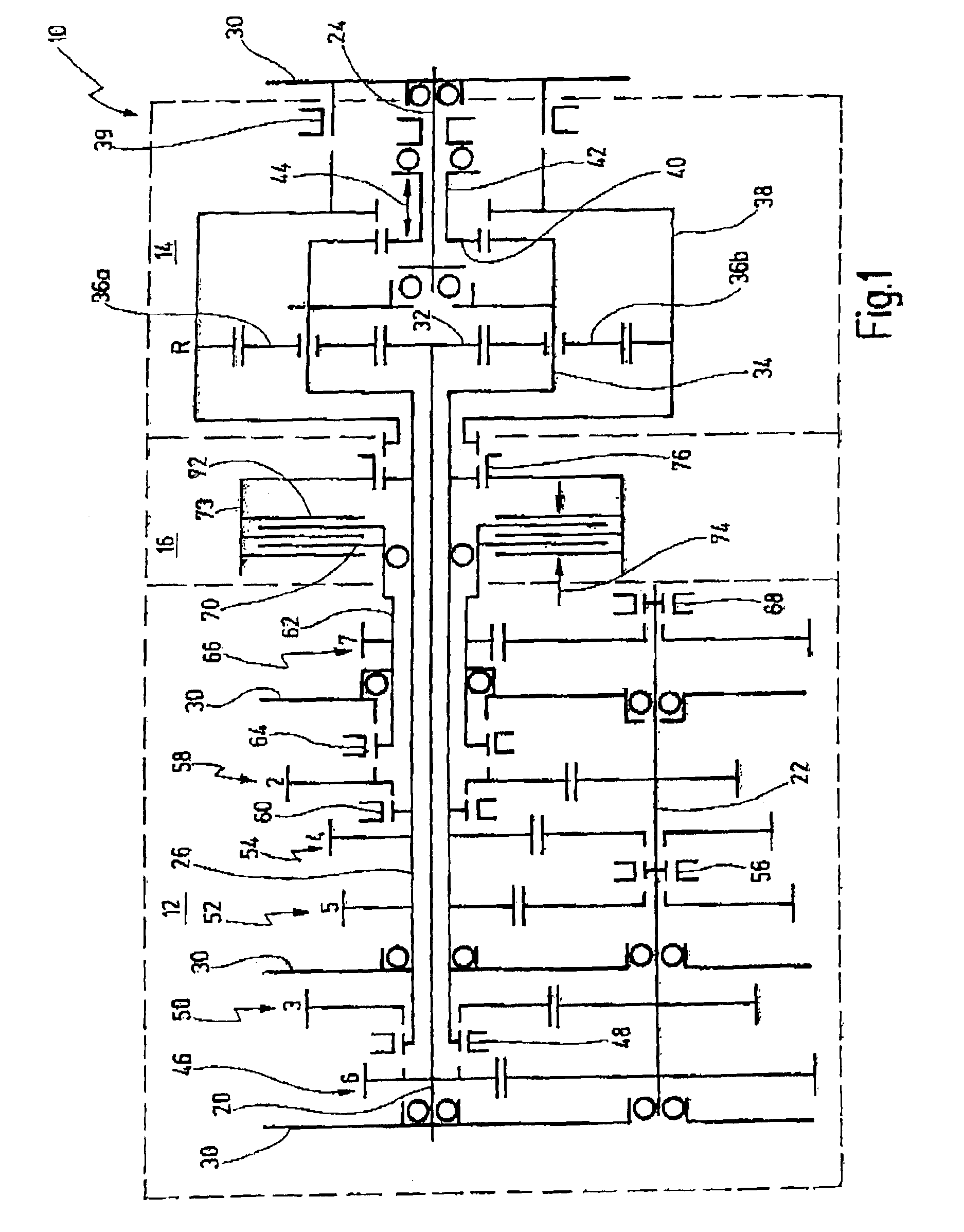

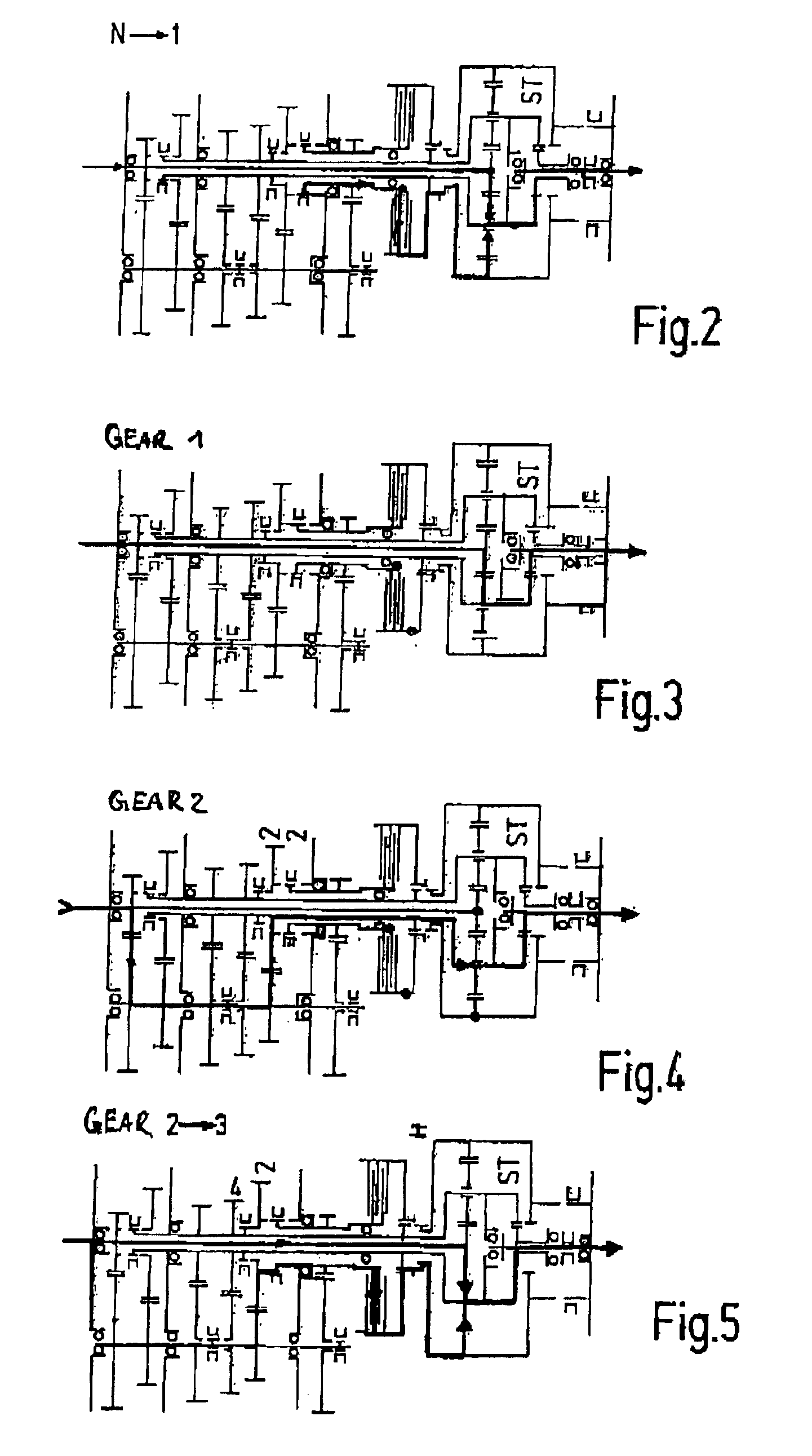

Automatic variable-speed transmission

InactiveUS6869379B2Compact structureSimple structurePeptide librariesNucleotide librariesPower flowEngineering

An automatic variable-speed transmission for setting up a plurality of gear steps with an input shaft, an output shaft and two transmission units which form two parallel branches. One branch has a multi-step transmission and the other a summing transmission with a friction clutch for starting and for central synchronization, the friction clutch having a first friction element and a second friction element, one of the friction elements being connectable to various transmission elements by means of at least one shift element, with at least one first power command range for gear-step changes between low gear steps and at least one second power command range for at least the gear change into the highest gear step and for the highest gear step. In this case, the at least one shift element connects the one friction element to transmission elements such that there is reduced reactive-power flow in any operating mode.

Owner:GETRAG INNOVATIONS

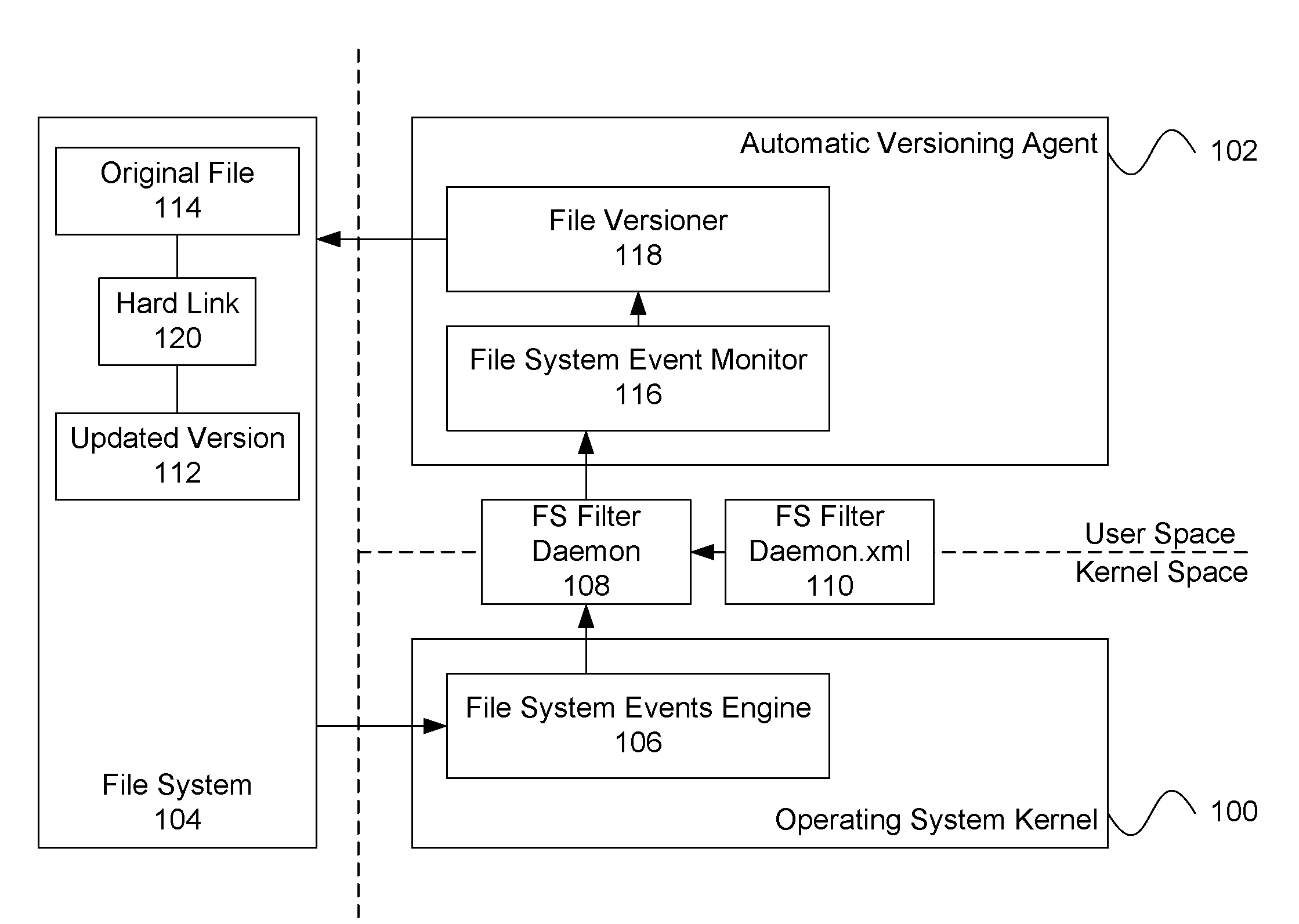

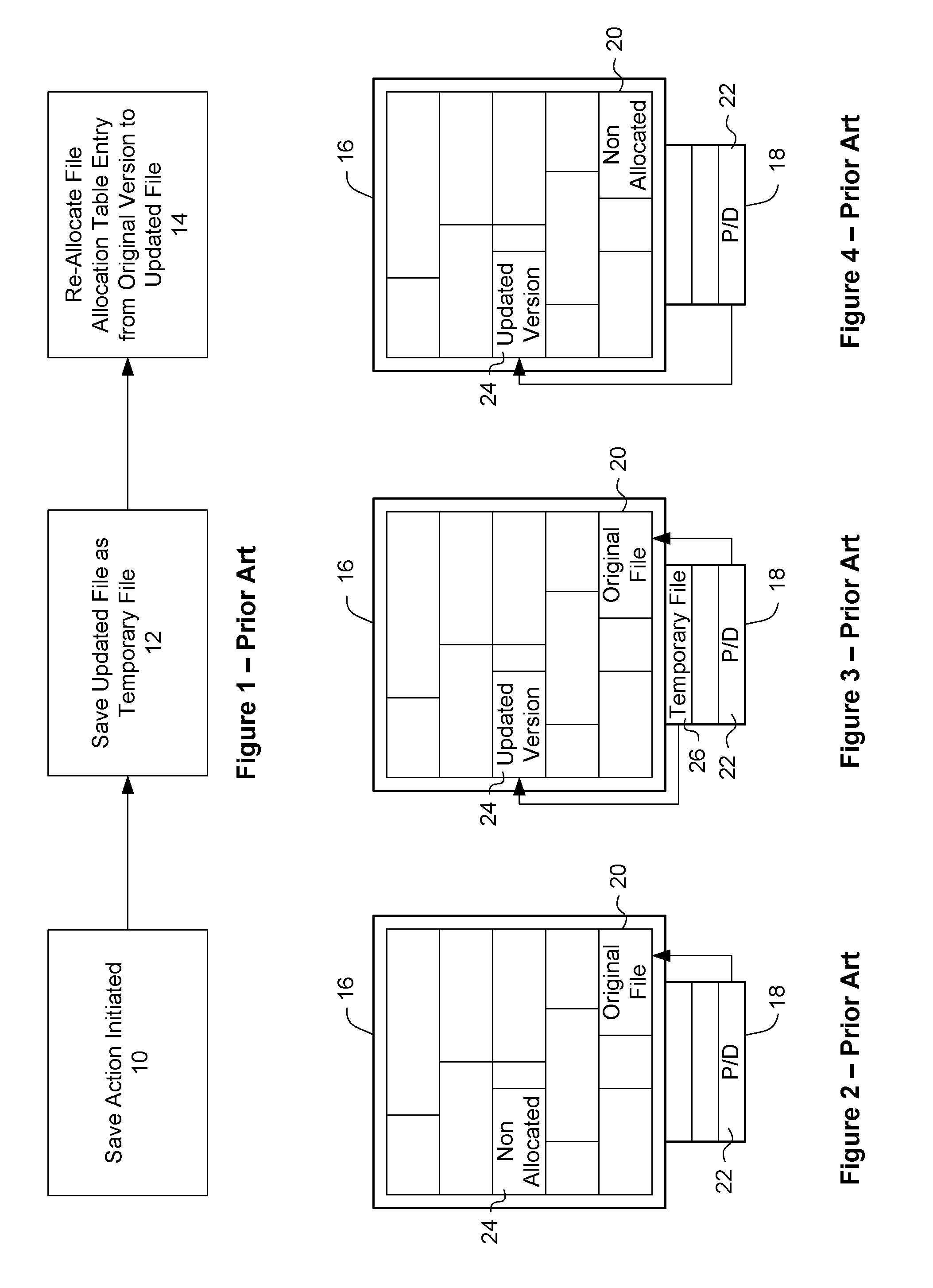

Automatic file versioning

InactiveUS20090024674A1Reduce disadvantagesDigital data information retrievalNatural language data processingDocumentation procedureHard link

A method and system are provided to automatically and transparently version files across many desktop applications without requiring the user to take specific action to cause the versioning to occur. Previous versions and versioning information can both be stored using hard links, and the versioning information can be used to determine a version history for a file. Embodiments of the present invention do not require applications to be modified to support this versioning method. Further, using one approach, the application does not even know that the versioning is occurring. The present invention provides an automatic versioning solution that is completely transparent to the user, which causes overwrite operations to be seamlessly co-opted into versioning operations which retain previous document versions instead of overwriting them.

Owner:GRIDIRON SOFTWARE

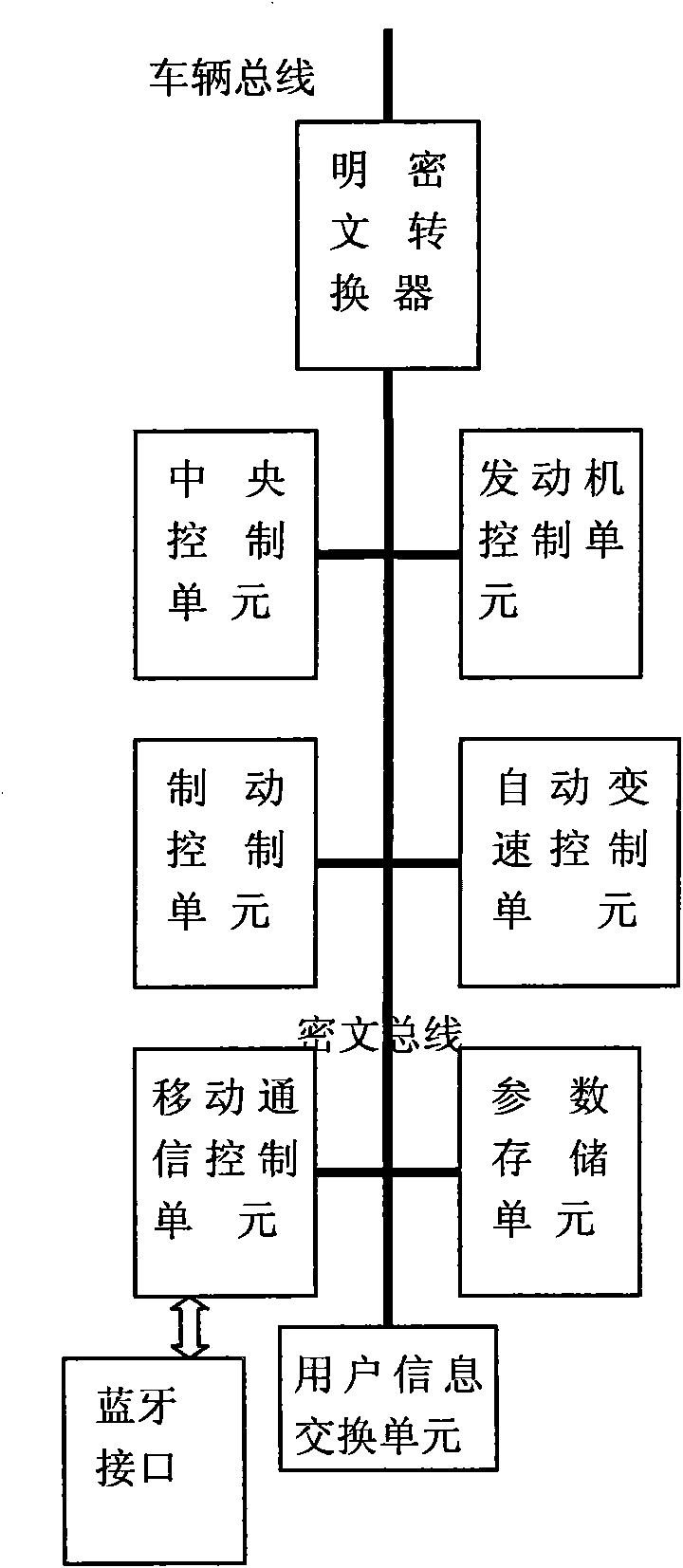

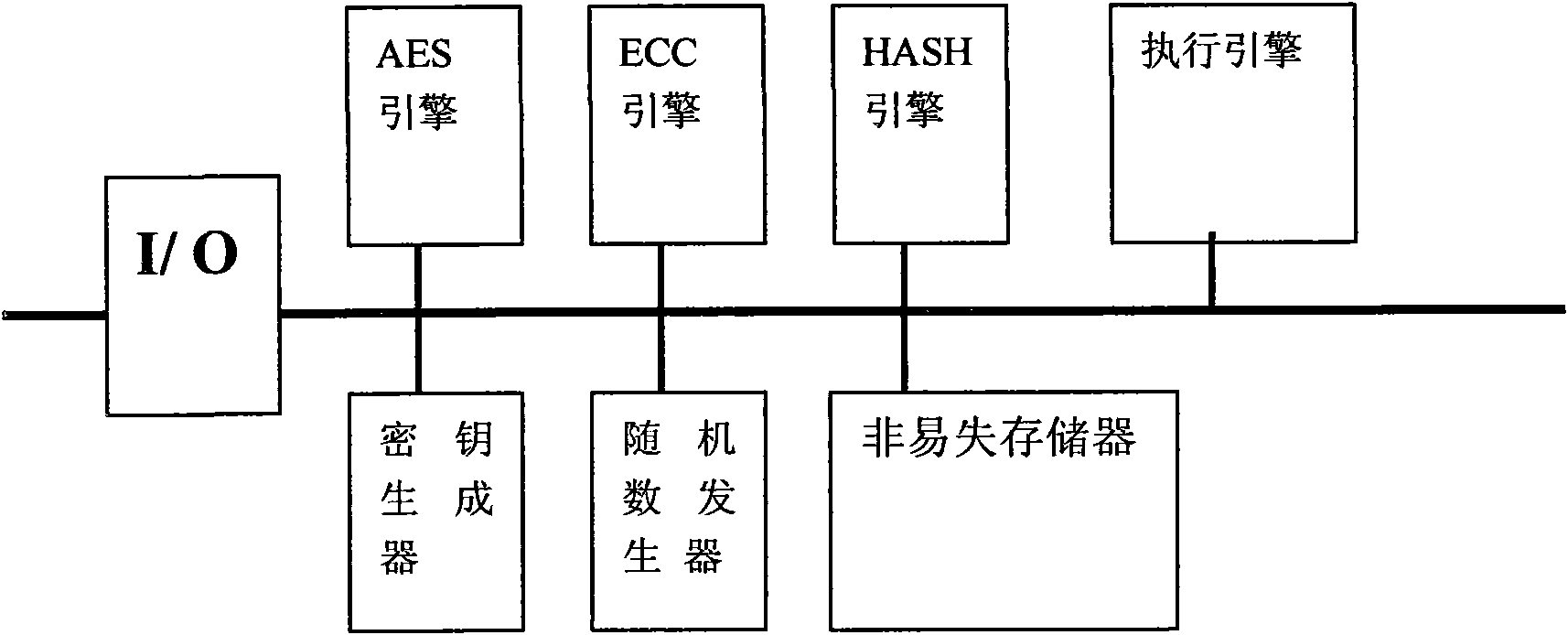

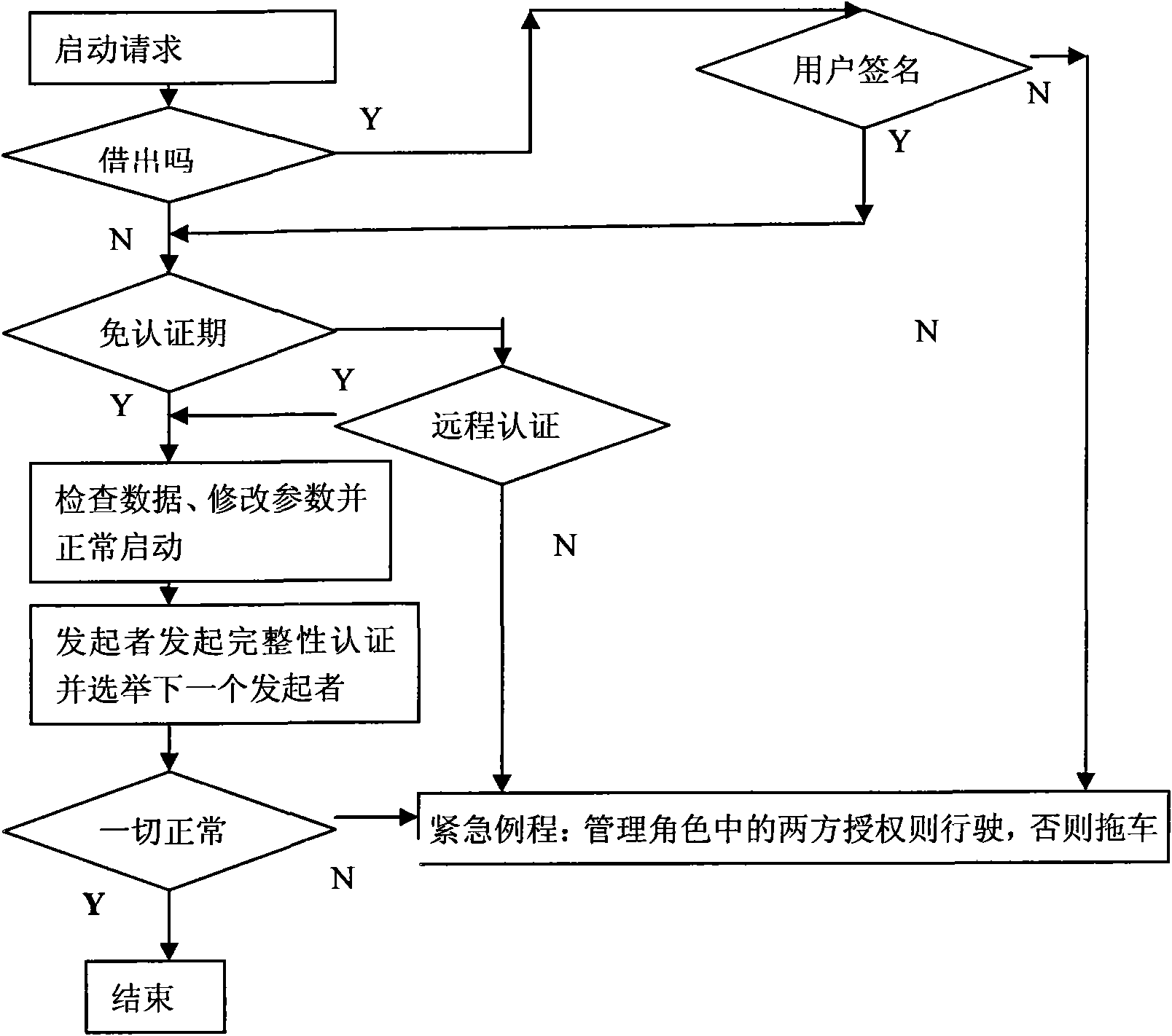

Vehicle control system for preventing stealing and robbery and implementation method thereof

InactiveCN101559745AMileage limitStart limitPublic key for secure communicationAnti-theft devicesPlaintextConfidentiality

The invention discloses a vehicle control system for preventing stealing and robbery, comprising a central control unit, an engine control unit, an automatic variable speed control unit, a brake control unit, a mobile communication control unit, a parameter storage unit, a user information exchange unit and a vehicle owner key, which are all provided with an encode processing module; besides, the vehicle control system also comprises a plaintext and ciphertext converter, a ciphertext bus, an ordinary vehicle key and a vehicle owner key; and the invention has another purpose of providing a method for implementing the vehicle control system, and the method includes the steps of (1) initialization; (2) start-up process; and (3) emergent verification. By adopting the technologies of confidentiality, verification and threshold, the invention effectively improves the safety of vehicles, prevents other people from illegally driving the vehicle and illegally changing elements on the ciphertext bus, and the method for handling the case of loss of an ordinary vehicle key is simple.

Owner:SOUTH CHINA UNIV OF TECH

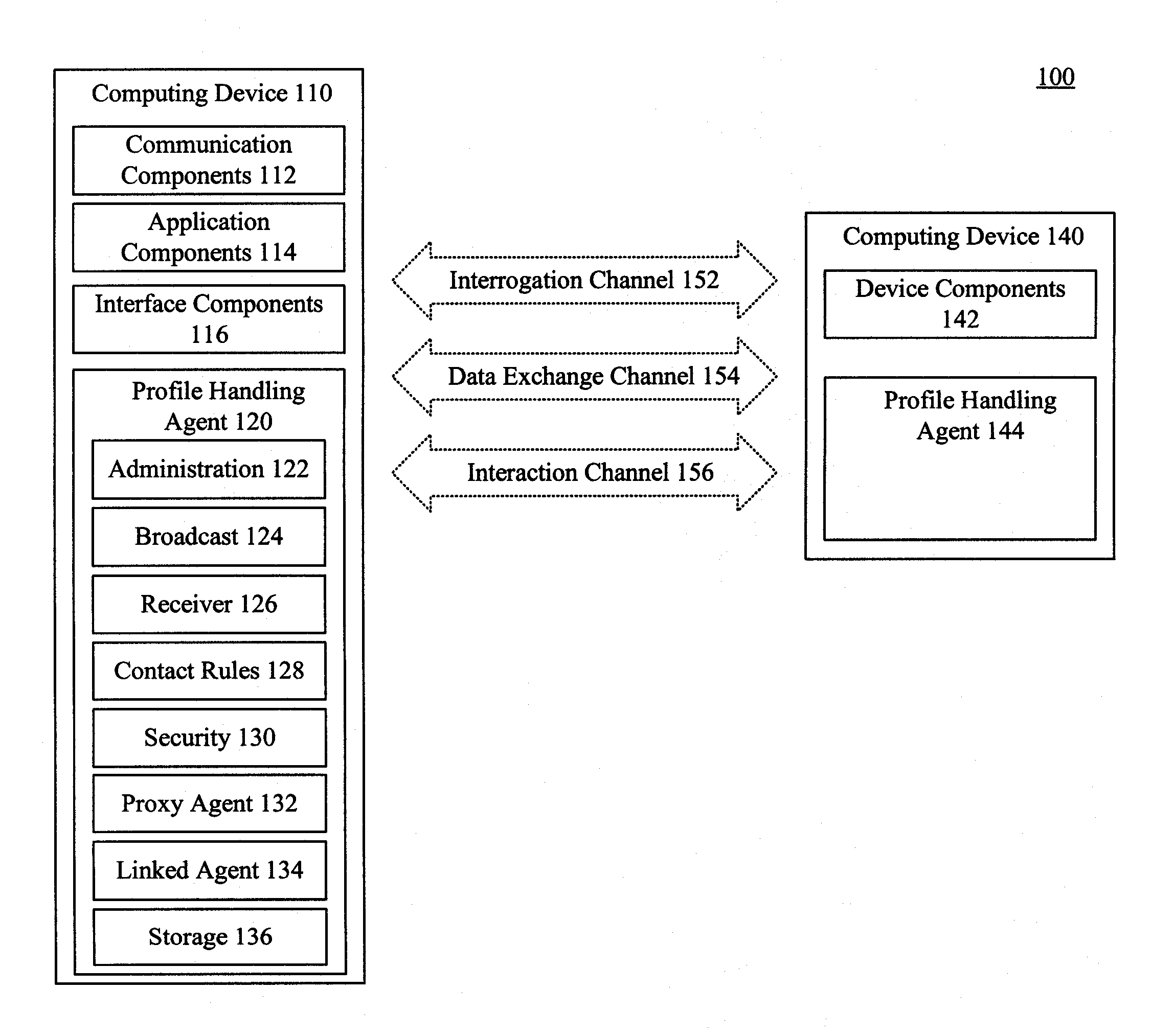

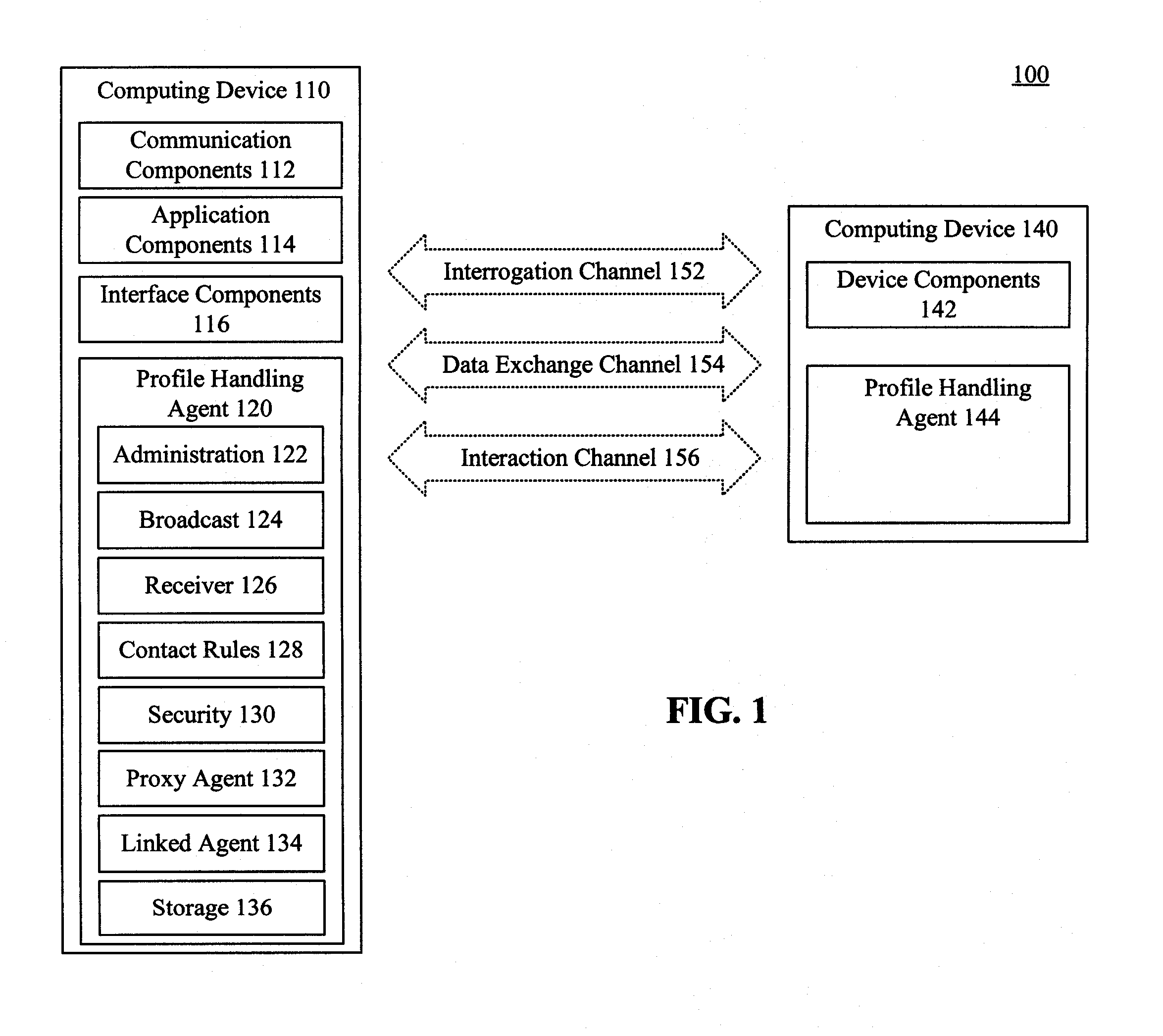

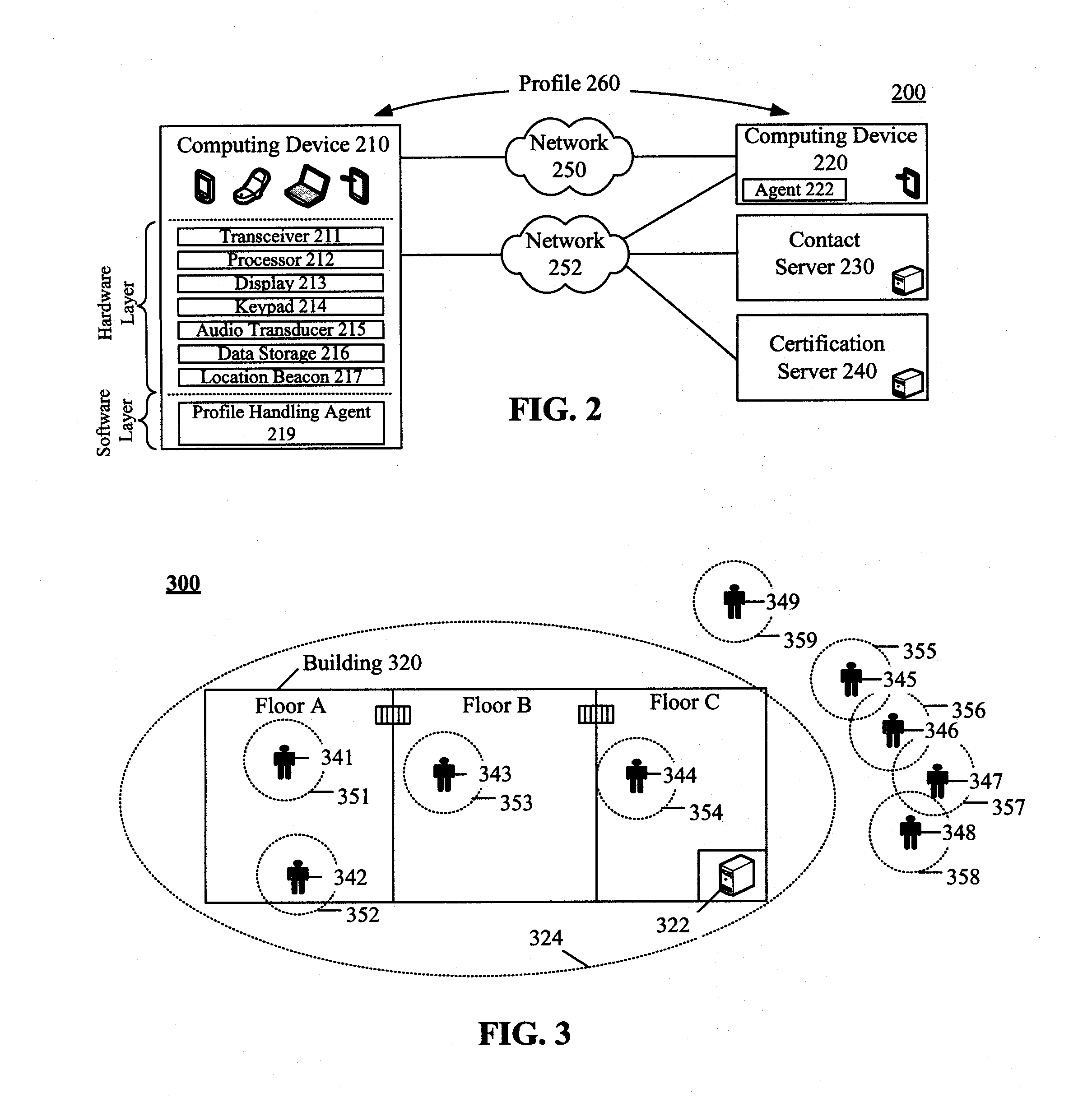

Contact initialization based upon automatic profile sharing between computing devices

ActiveUS8346863B2Interconnection arrangementsTime-division multiplexInternet privacyAutomatic variable

Owner:INT BUSINESS MASCH CORP

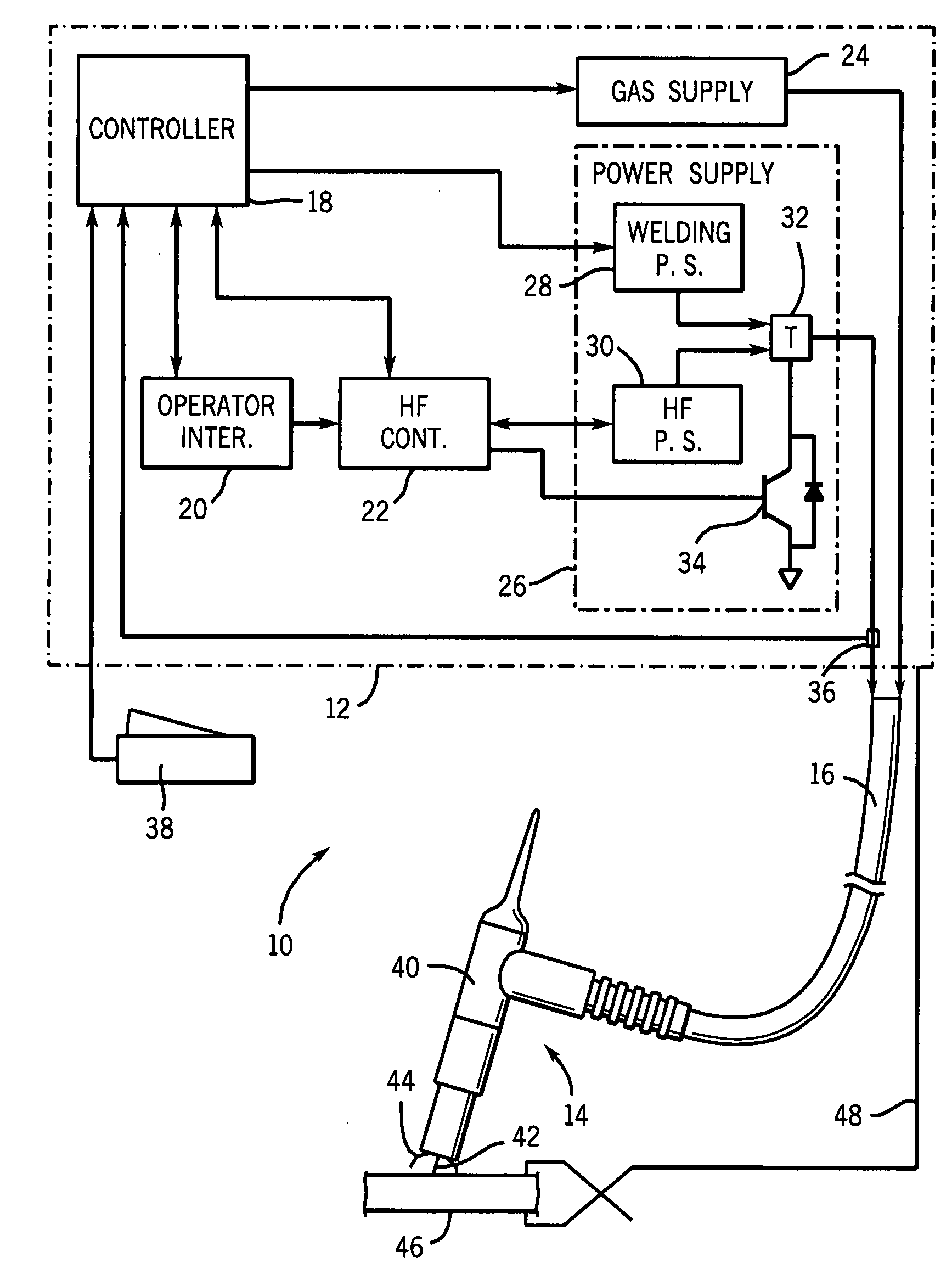

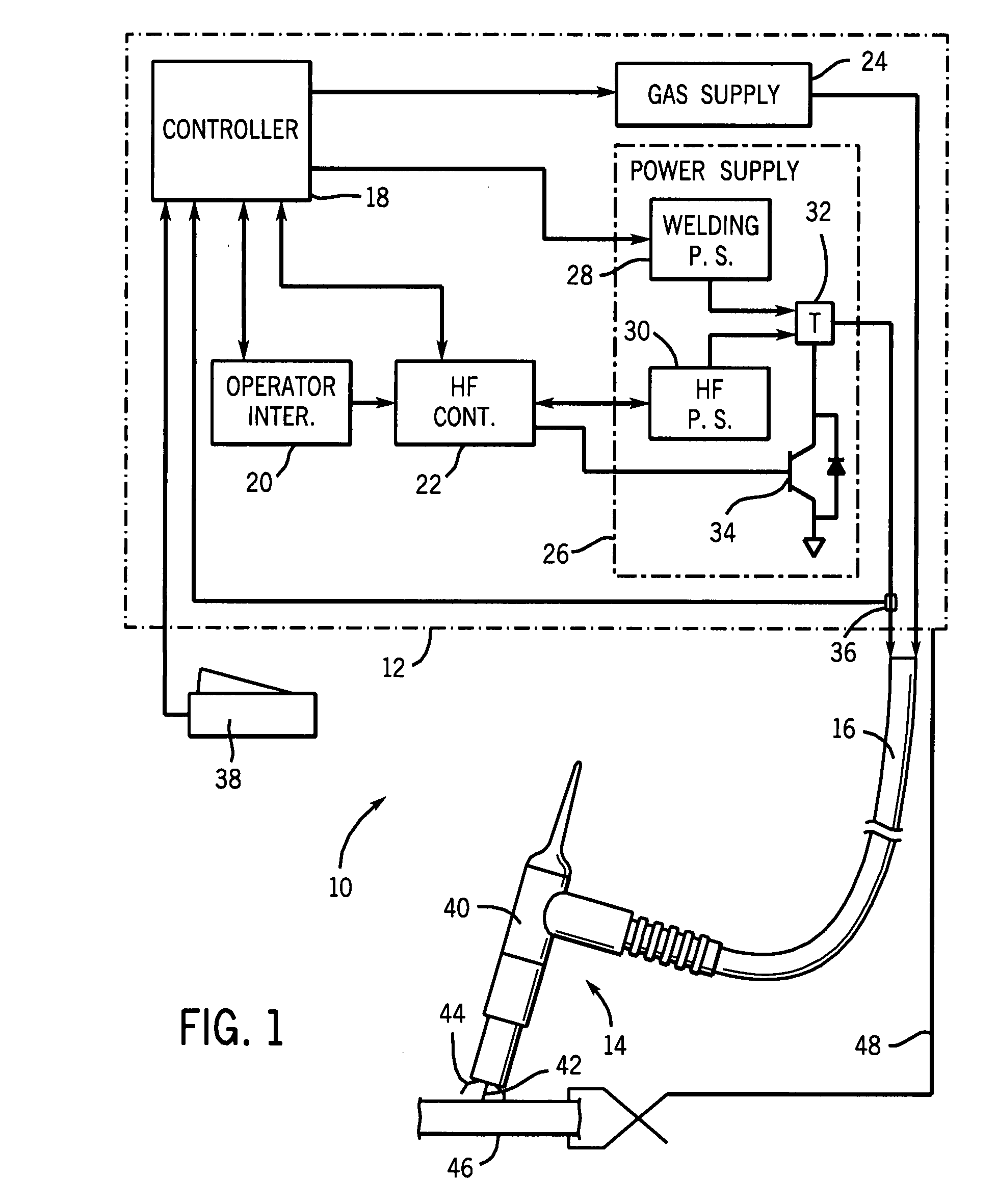

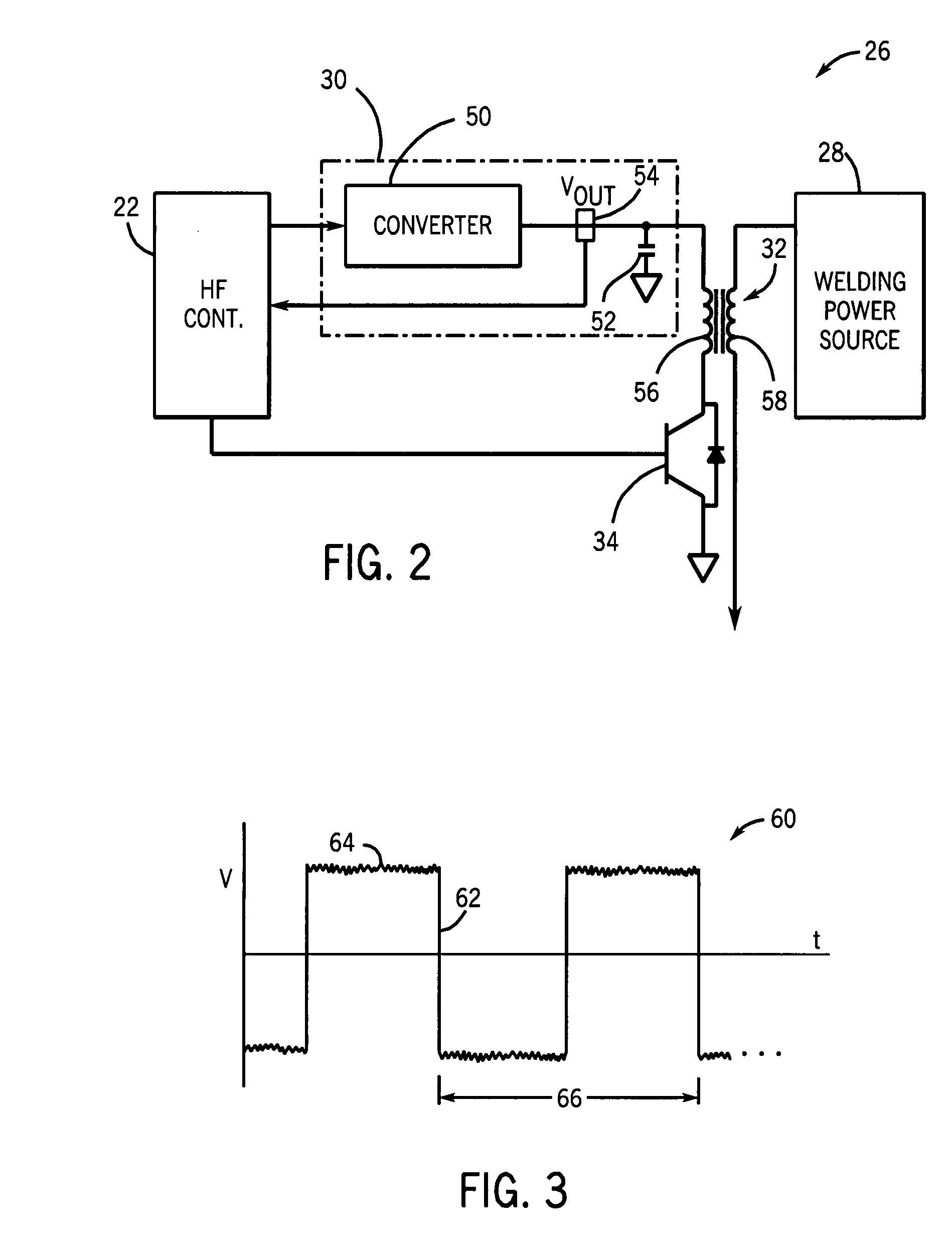

Welding power source with automatic variable high frequency

ActiveUS20080264915A1Improve the level ofImproved arc performanceArc welding apparatusCapacitanceCapacitive storage

A high frequency power source configured to provide a variable voltage output is described such as for use in welding systems. The high frequency power source charges a capacitive storage device. A transformer having a primary winding coupled to the output of the high frequency power source and establishing a resonant frequency signal with the capacitive storage device, and a secondary winding coupled to the welding power supply, superimposes the resonant frequency signals onto the welding power signal of the welding power supply during periods of the resonant rings. By varying the voltage output from the high frequency power source, the high frequency energy delivered to the welding torch can be optimized for a variety of welding applications.

Owner:ILLINOIS TOOL WORKS INC

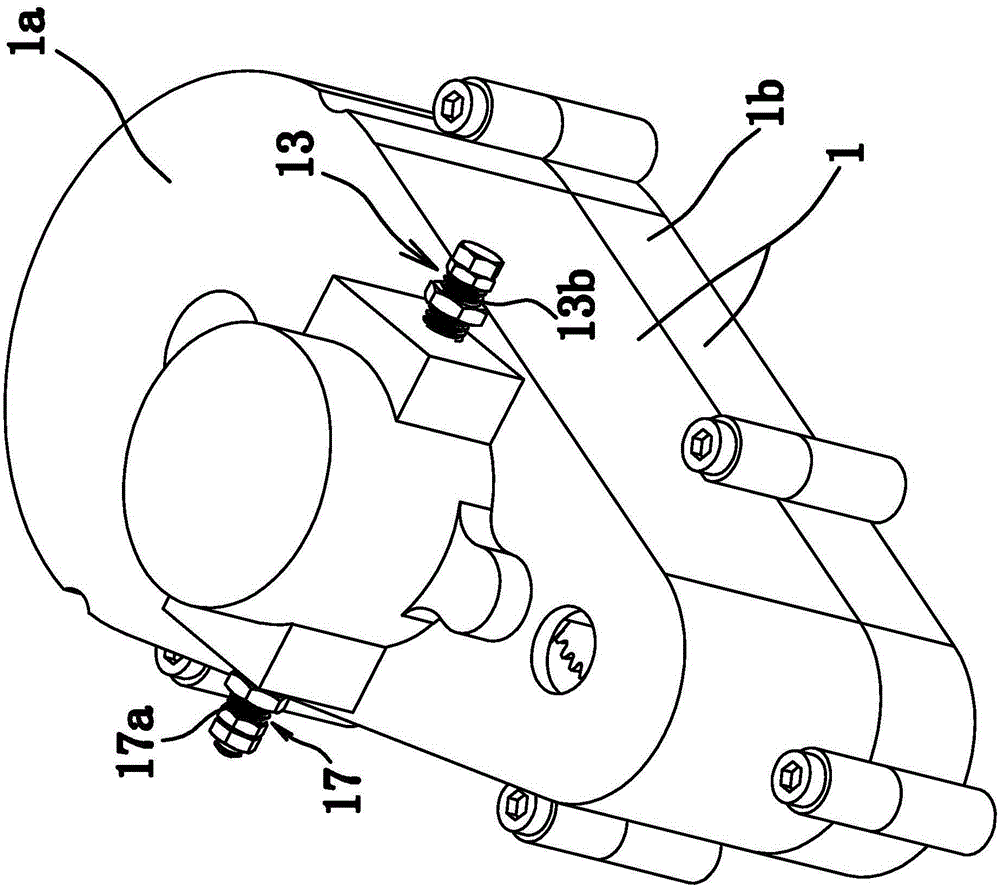

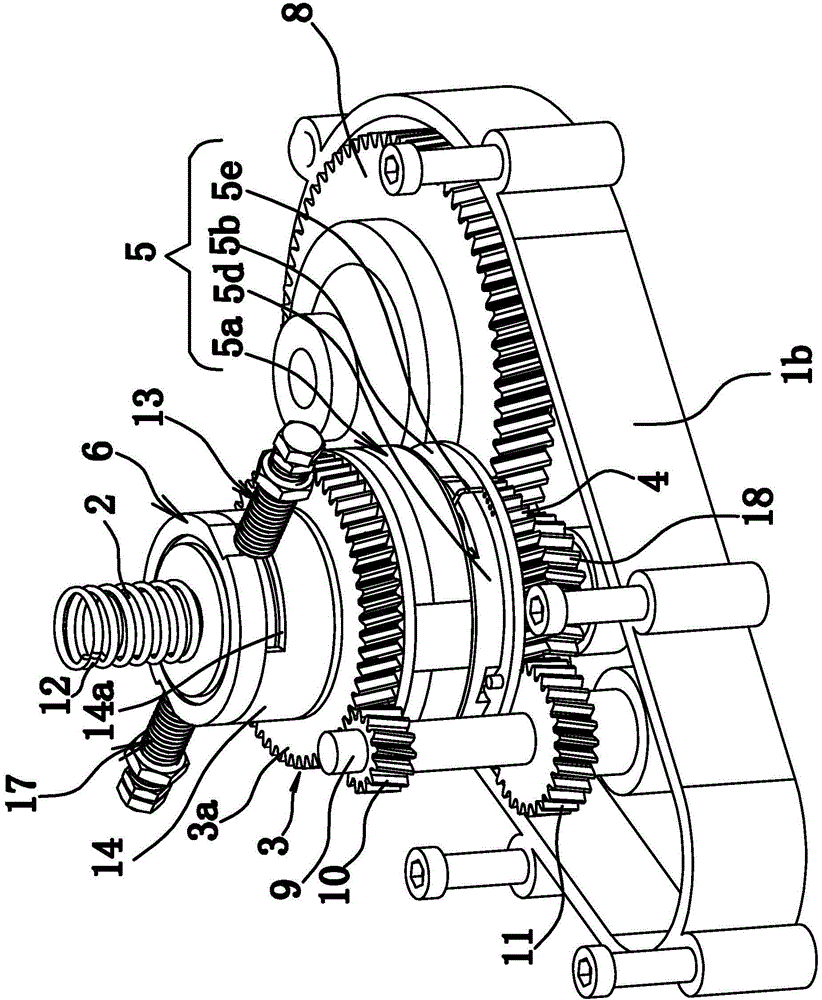

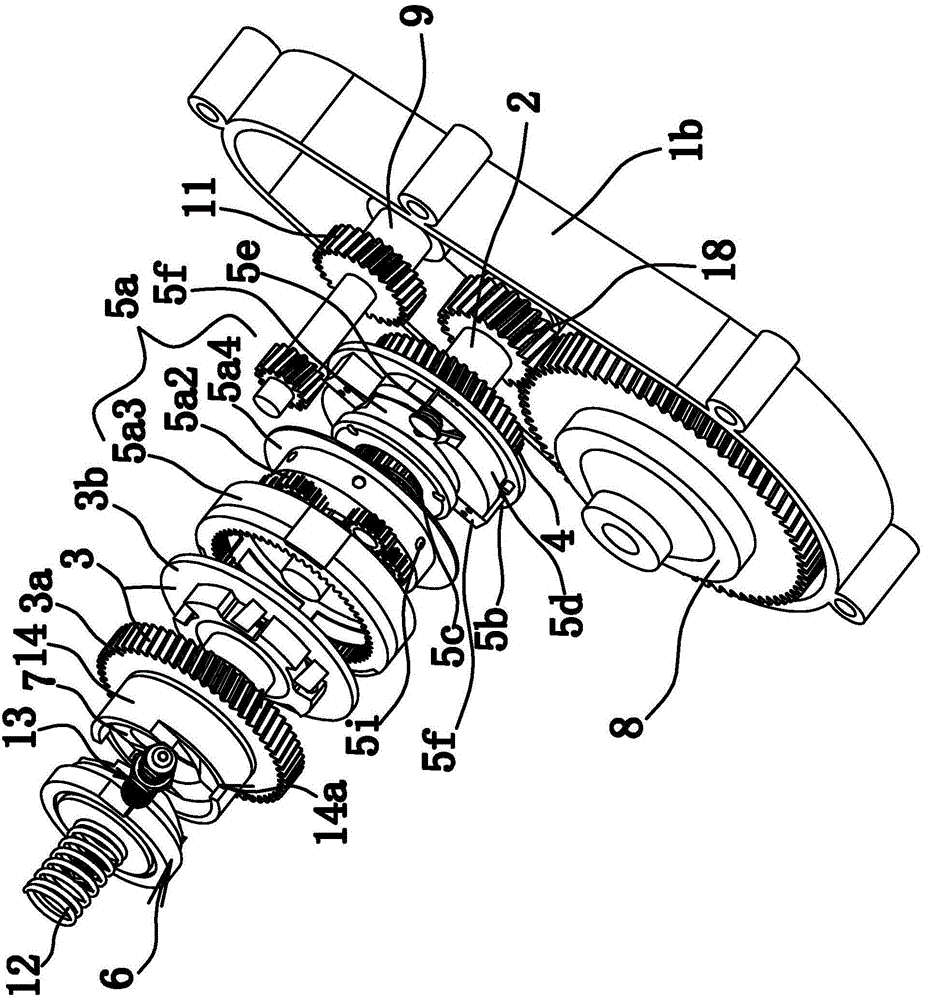

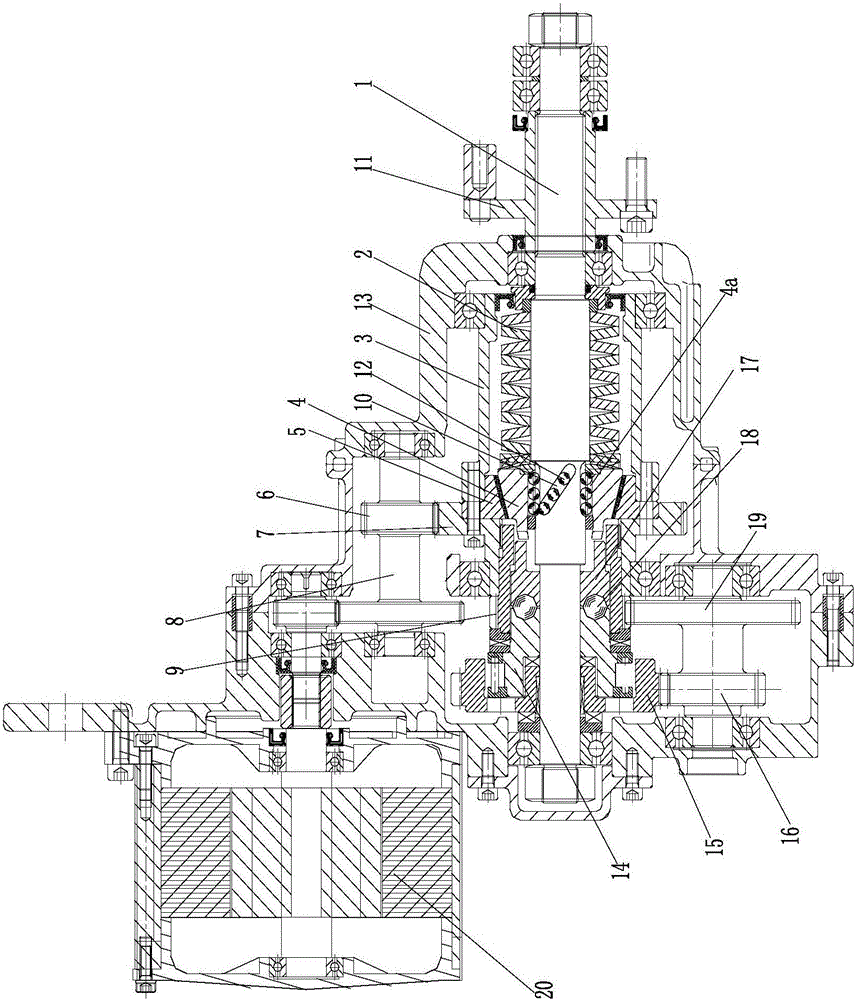

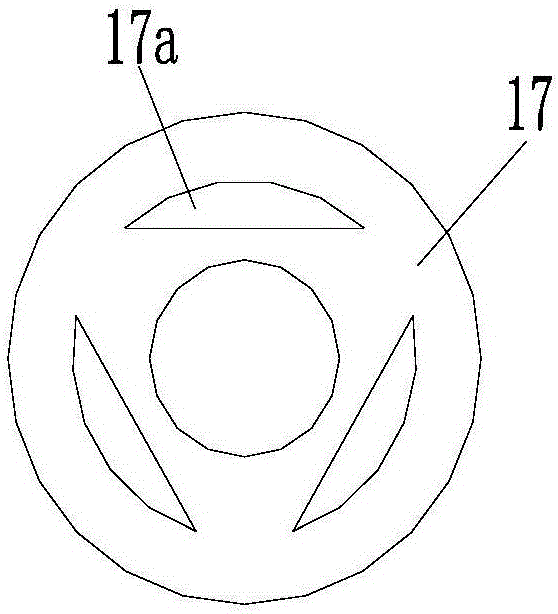

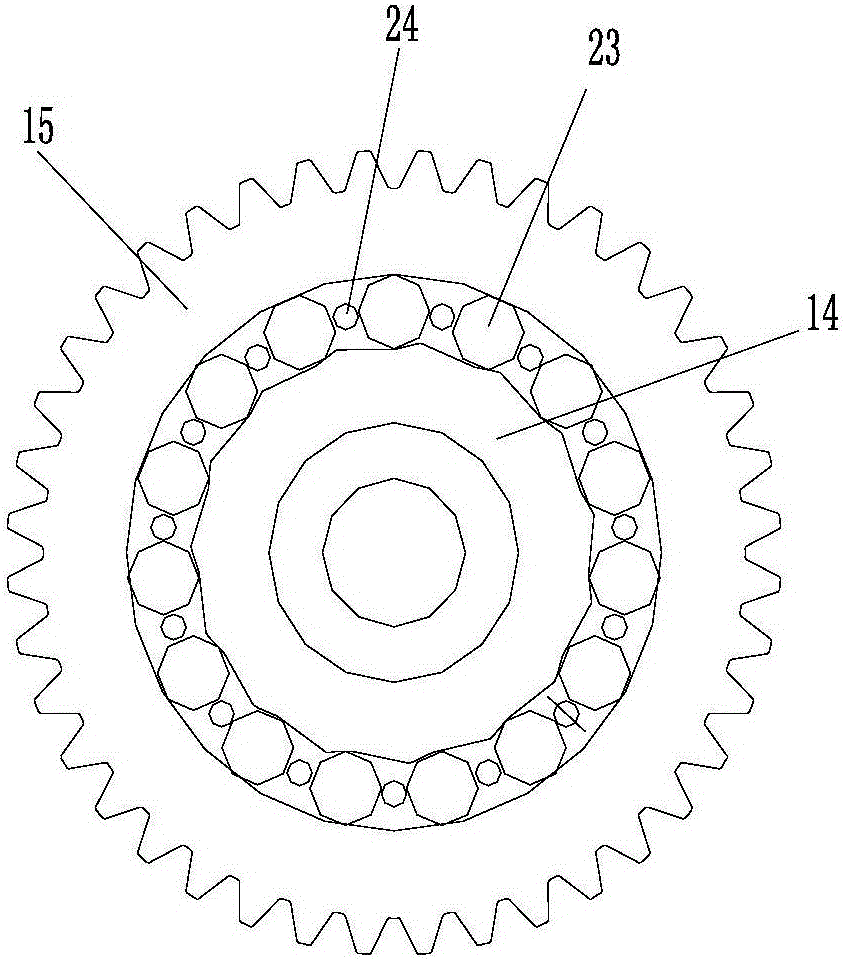

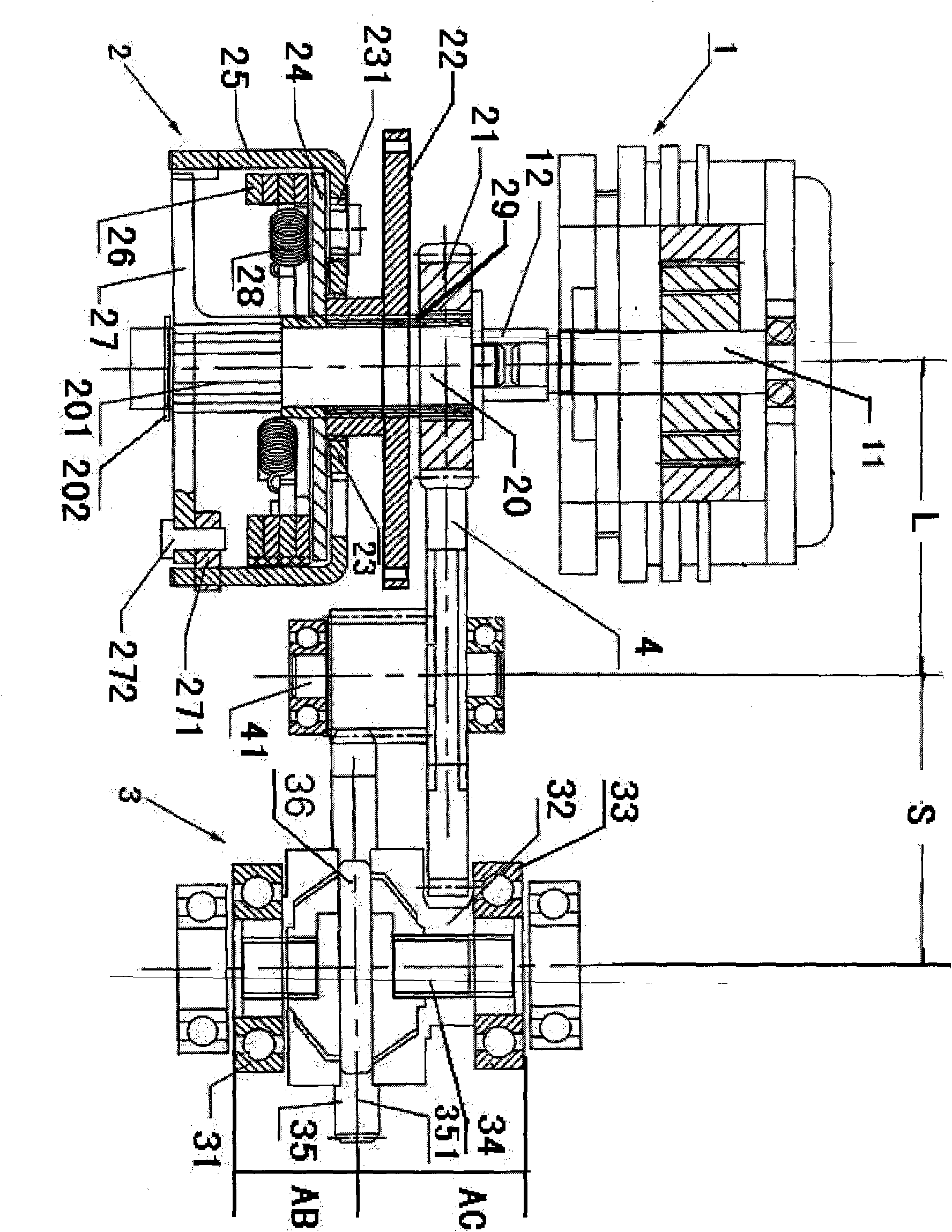

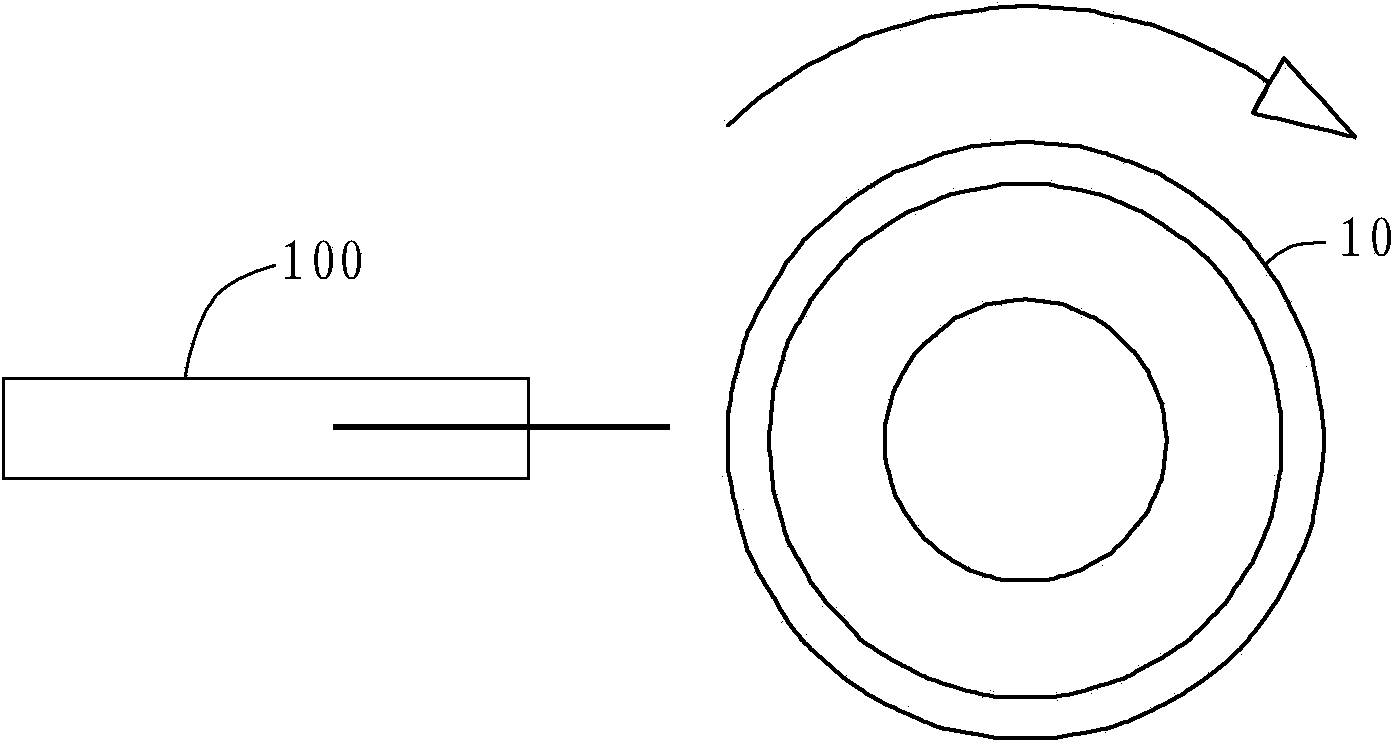

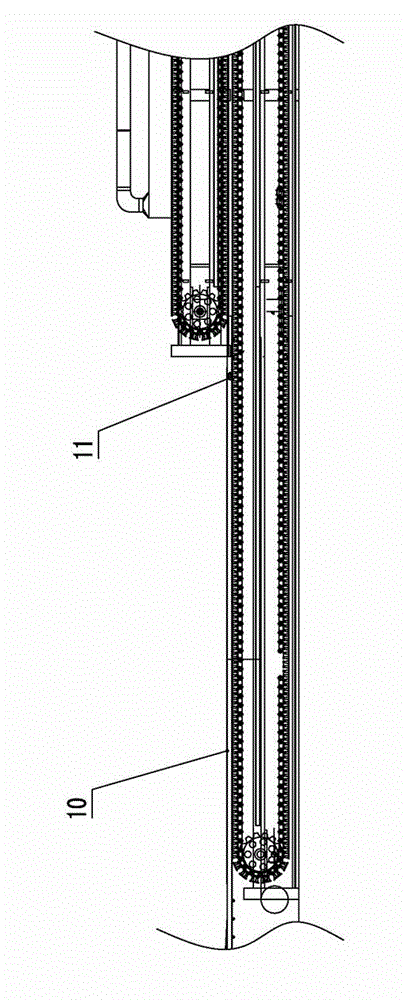

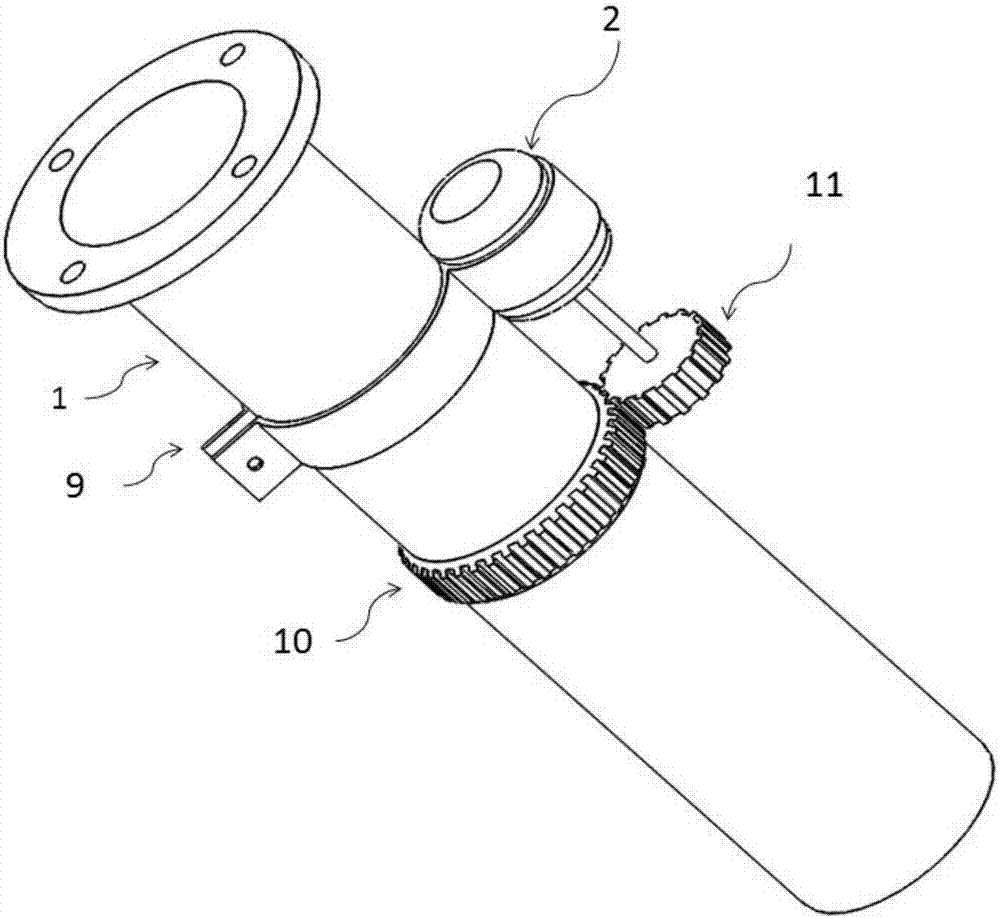

Bidirectional automatic variable-speed motor transmission device

ActiveCN104976292AImplement reversing functionReduce distanceToothed gearingsTransmission elementsAutomatic variableTransmission ratio

The invention provides a bidirectional automatic variable-speed motor transmission device and belongs to the technical field of machines. The bidirectional automatic variable-speed motor transmission device solves the problem that an existing bidirectional automatic variable-speed motor transmission device is incompact in structure. The bidirectional automatic variable-speed motor transmission device comprises a shell, a main shaft and a rotary shaft, wherein both the main shaft and the rotary shaft are fixed in the shell in the axial direction. The main shaft is sleeved with a one-way device. The one-way device comprises an outer ring and an inner ring which is fixed to the main shaft. A gear is fixed to the main shaft in the axial direction. A connecting piece is fixed to the outer ring. A transmission piece is fixed to the main shaft in the circumferential direction. The rotary shaft drives the outer ring and the gear to rotate at the same time through a transmission mechanism. The transmission ratio of the rotary shaft to the outer ring is lager than that of the rotary shaft to the gear. When the rotary shaft rotates anticlockwise, the one-way device slips, and the connecting piece is in linkage with the transmission piece through a combining mechanism; when the rotary shaft rotates clockwise, the connecting piece and the transmission piece are separated from each other through a separating mechanism; when the rotary shaft rotates clockwise at a high speed, the gear is in linkage with the inner ring through a speed change mechanism. The bidirectional automatic variable-speed motor transmission device has the advantage of being compact in structure.

Owner:屠申富 +1

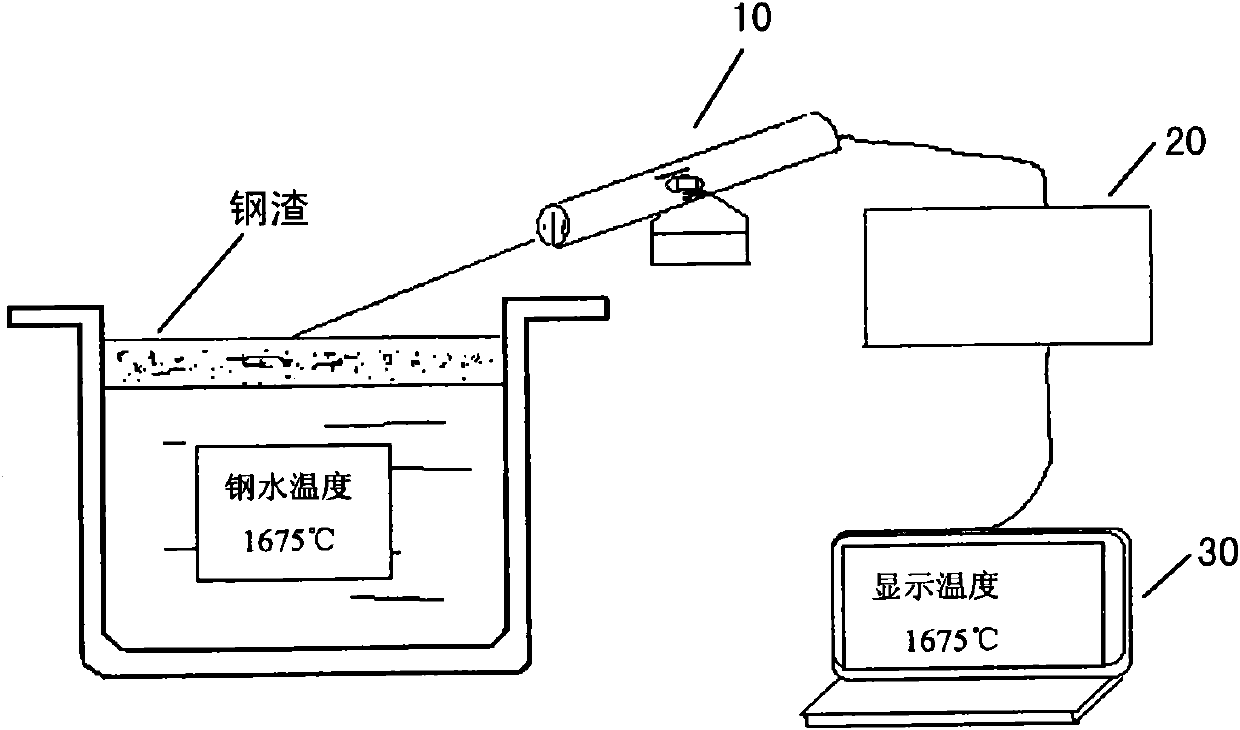

Infrared temperature measurement method and infrared temperature measurement system

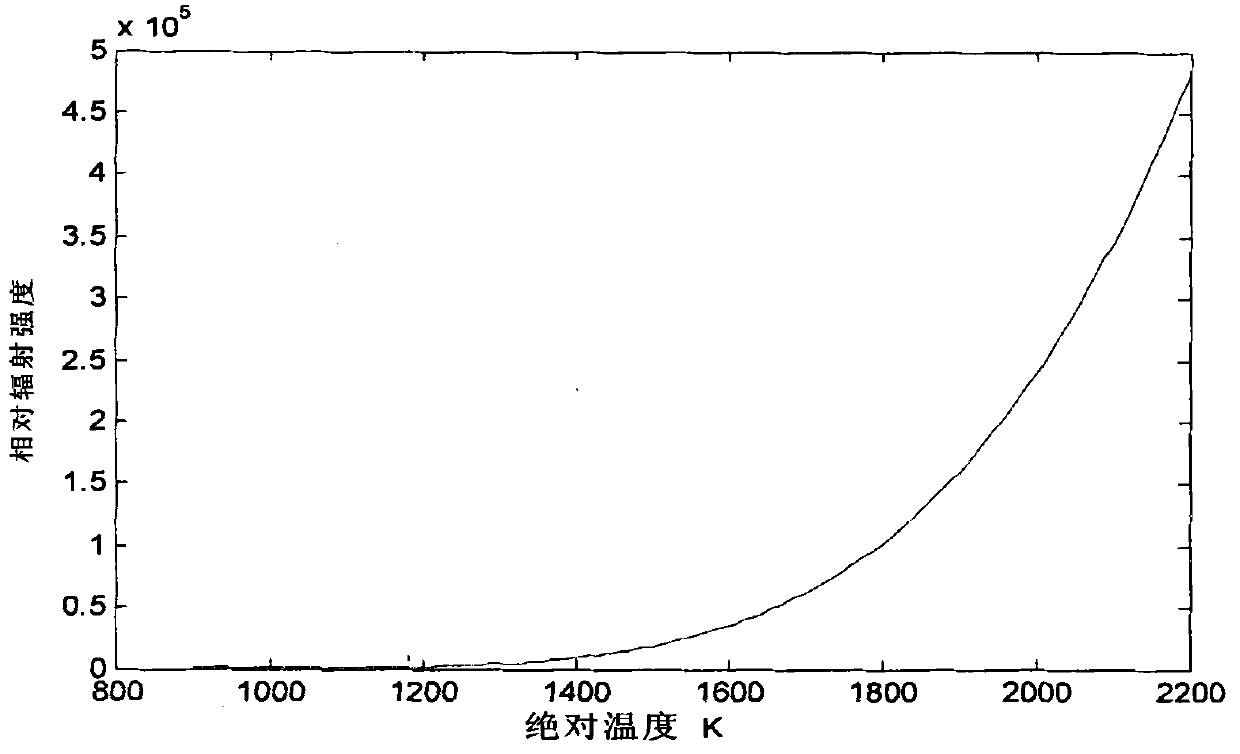

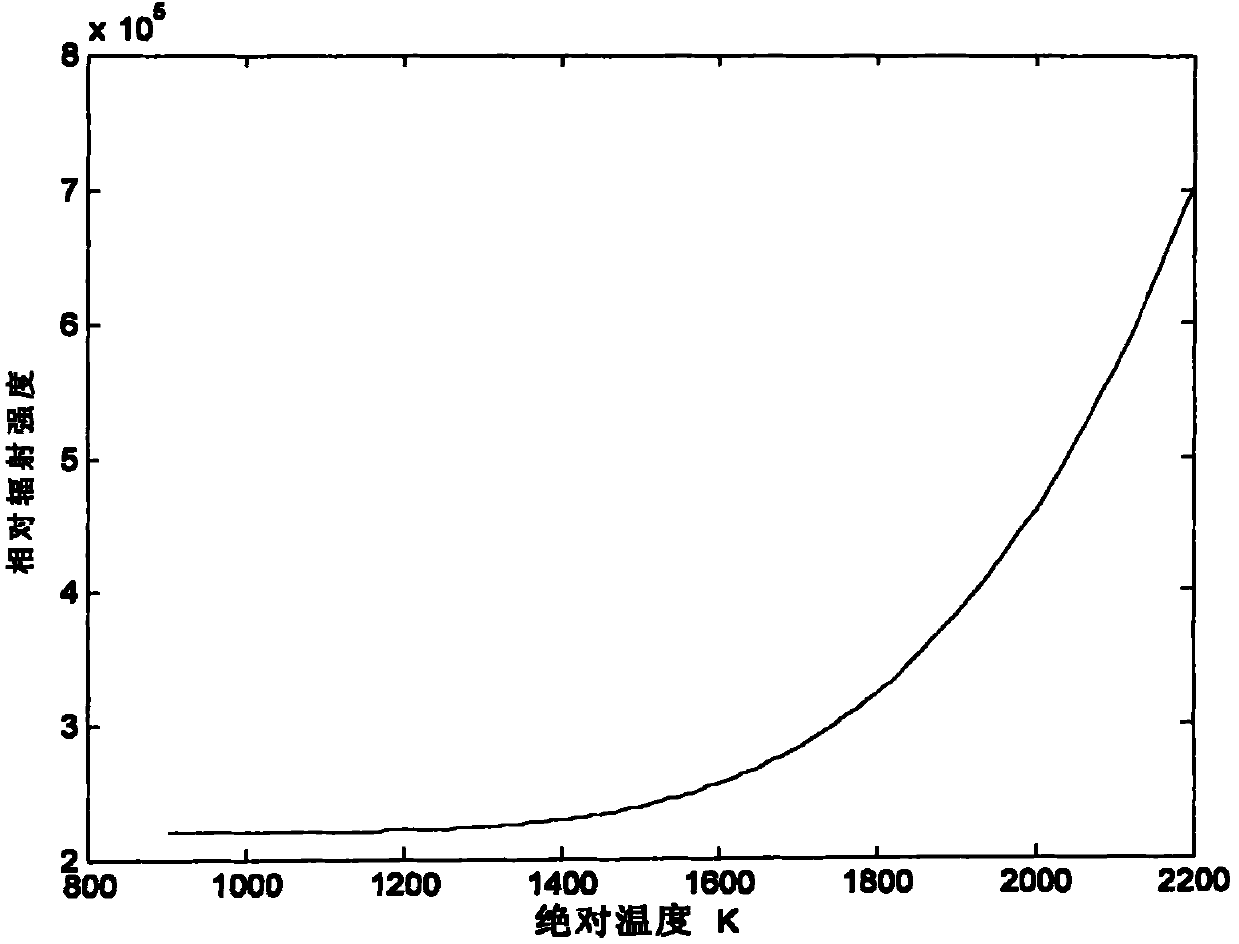

An infrared temperature measurement method comprises the following steps of: (1) when a temperature of a measured object in actual measurement is t, utilizing an automatic variable double wavelength infrared detector to measure radiation intensity E1 (lambda 1, t) and E2 (lambda 2, t) of the measured object, wherein E1 (lambda 1, t) is corresponding to the radiation intensity of the measured object when a wavelength is lambda 1, and E2 (lambda 2, t) is corresponding to the radiation intensity of the measured object when the wavelength is lambda 2; (2) substituting the measured E1 (lambda 1, t) and E2 (lambda 2, t) into a formula E1 (lambda 1, t)=alpha lambda[1]<-5> (e<delta / lambda[1]t>-1)<-1> and a formula E2 (lambda 2, t)=alpha lambda[2]<-5> (e<delta / lambda[2]t>-1)<-1>, and calculating values of coefficients alpha and delta, wherein alpha and delta are coefficients which are changed with material composition, temperature and measurement wavelength of the measured object; (3) substituting the calculated values of the coefficients alpha and delta into a measured object radiation intensity formula E(lambda, t) = alpha lambda-5(e delta / lambda t-1)-1 to obtain a corresponding relation curve between the radiation intensity and the temperature of the measured object with a given wavelength; (4) utilizing the automatic variable double wavelength infrared detector to measure the radiation intensity of the measured object with the given wavelength, and obtaining the temperature of the measured object based on the corresponding relation curve between the radiation intensity and the temperature of the measured object with the given wavelength. According to the infrared temperature measurement method, the temperature of the measured object can be accurately measured.

Owner:田乃良 +1

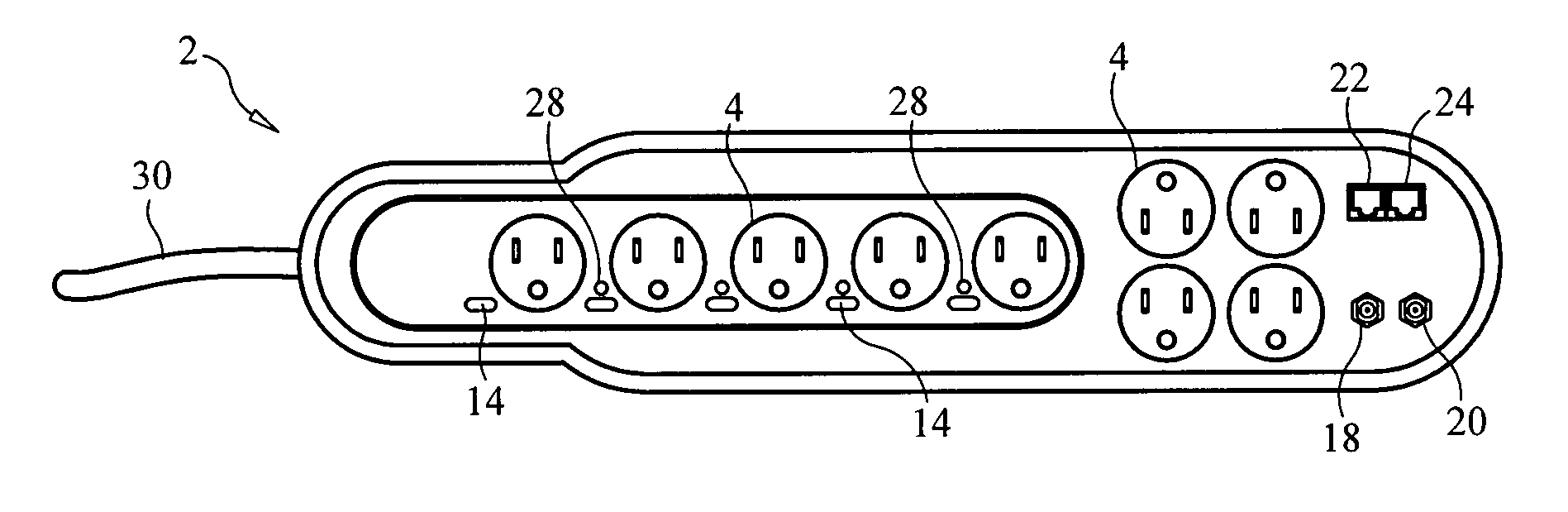

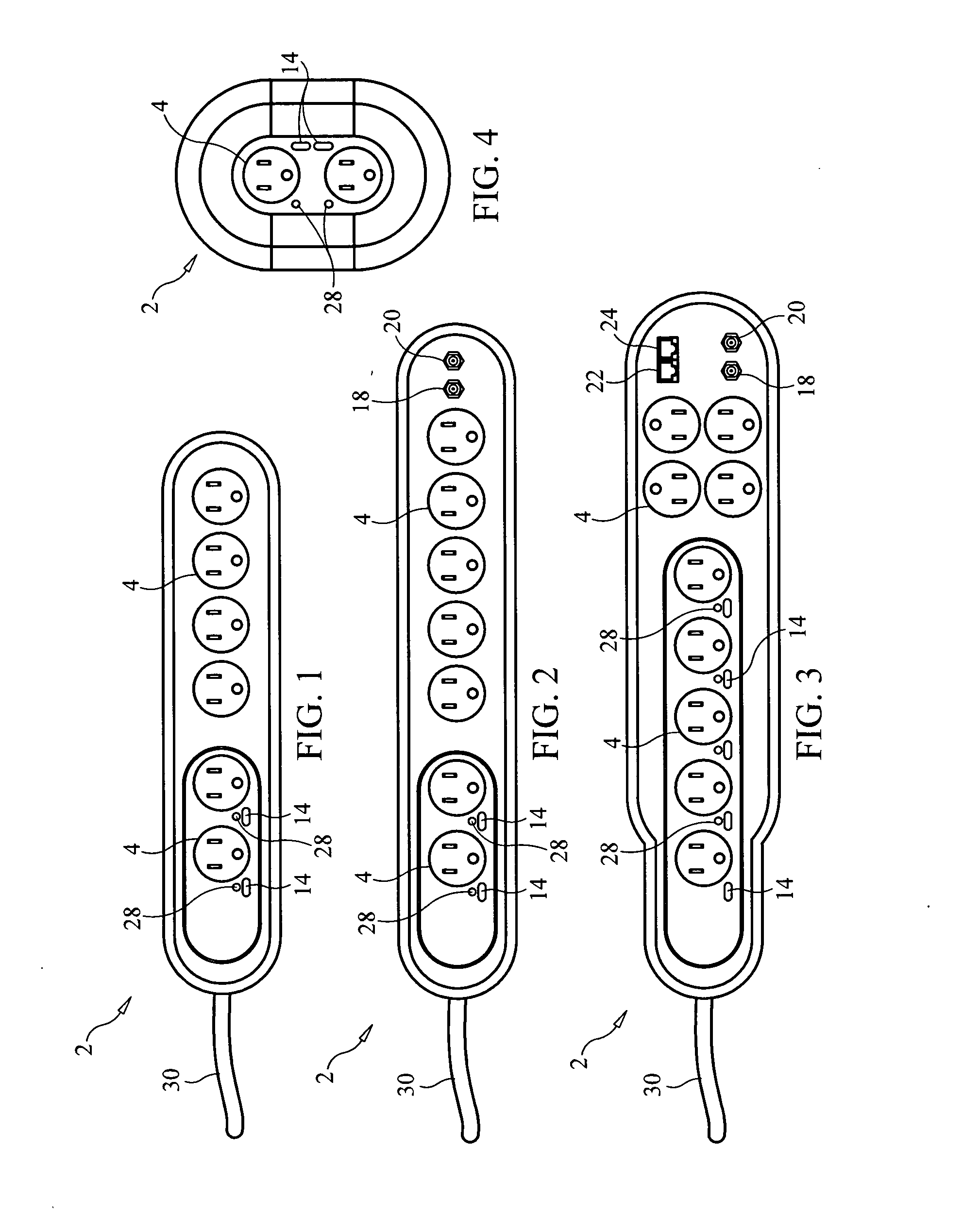

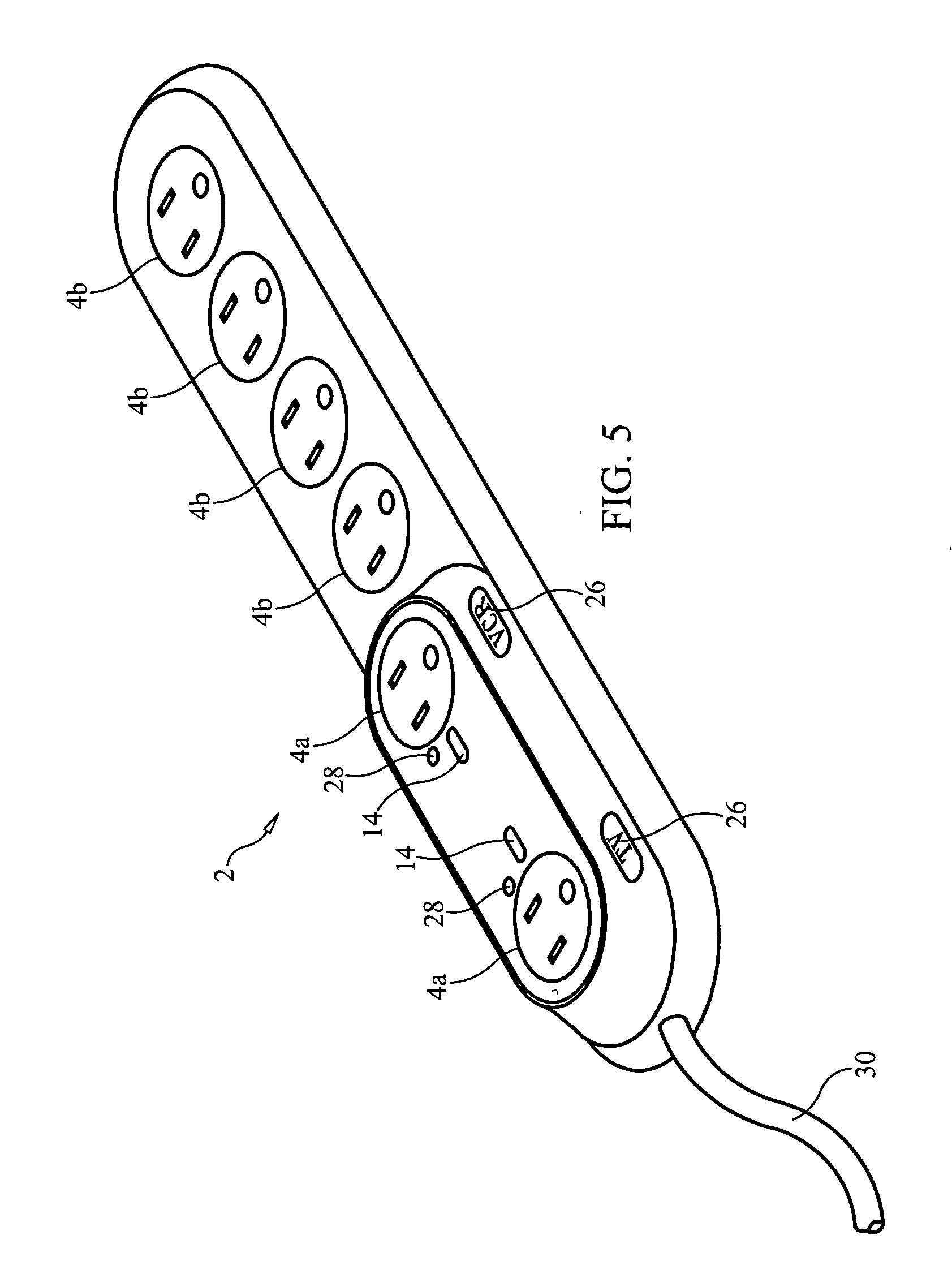

Automatic variable power outlet for energy saving power source

ActiveUS20110169342A1Reduce line voltagePrecise functionEnergy efficient ICTBoards/switchyards circuit arrangementsElectricityElectrical devices

A variable power device in a form of a power strip includes a plurality of power outlets for powering electrical devices connected thereto. A current sensing circuit is electrically coupled to each power outlet and senses current flowing through the power outlet and drawn by an electrical device connected to the outlet. A power control circuit selectively provides one of a standby mode power signal and an active mode power signal to a respective power outlet in response to the feedback signal from the current sensing circuit associated with the power outlet.

Owner:VOXX INTERNATIONAL

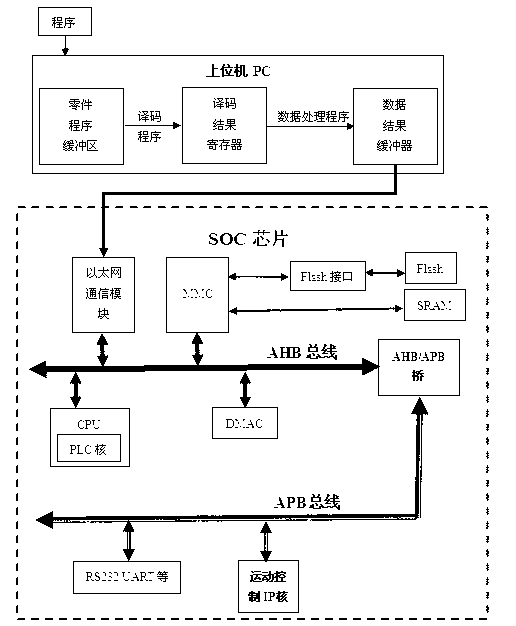

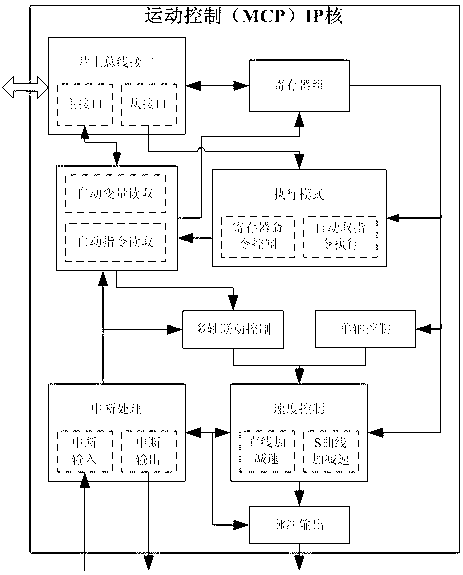

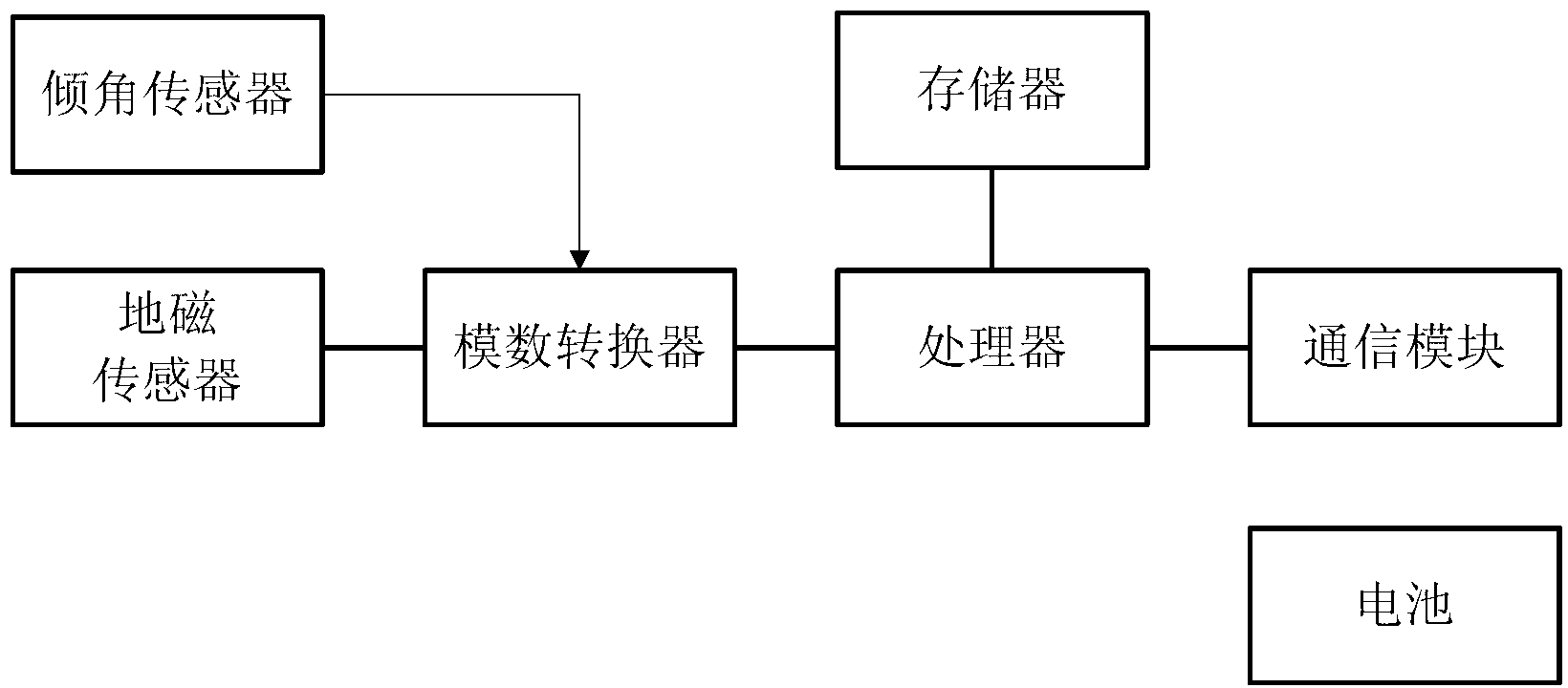

Motion control on-chip system

ActiveCN103226344AReduce overheadFlexible switchingNumerical controlDirect memory accessMovement control

A motion control on-chip system comprises an embedded processor core, a memory system, a DMA (Direct Memory Access) controller, a communication module IP (Internet Protocol) core, a motion control IP core and a plurality of peripheral interfaces, wherein the motion control IP core comprises an on-chip bus, an automatic instruction reading module, an automatic variable reading module, a register block, an interpolation control module, a single-axis control module, a speed control module, a pulse output module and an interruption processing module; the automatic instruction reading module of the motion control IP core autonomously reads a numeric control instruction and acquires an instruction parameter or variable from a register system through the on-chip bus, transmits relevant data of interpolation position to the interpolation control module and transmits the relevant data of speed control to the speed control module; when the instruction which can be immediately executed is read, corresponding actions are automatically started to execute according to current parameters; and pulses generated by the processing of interpolation control and speed control generate driving pulses with specified forms through the pulse output module.

Owner:宁波中控微电子有限公司

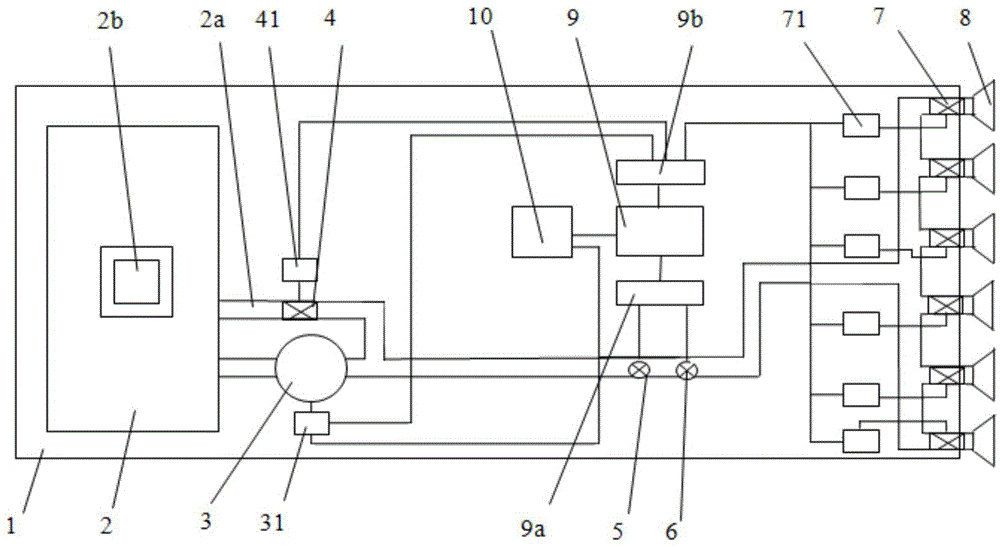

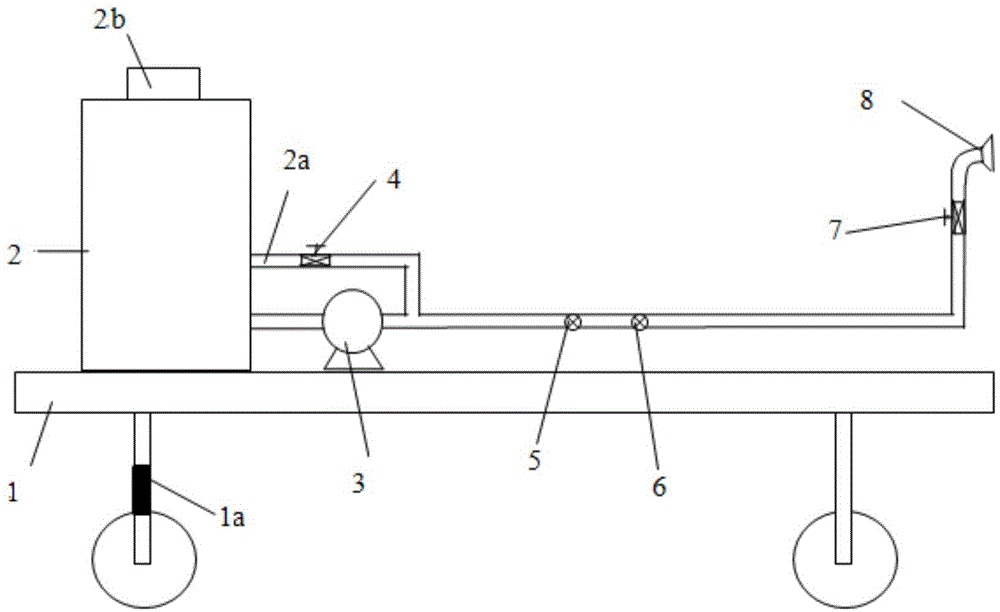

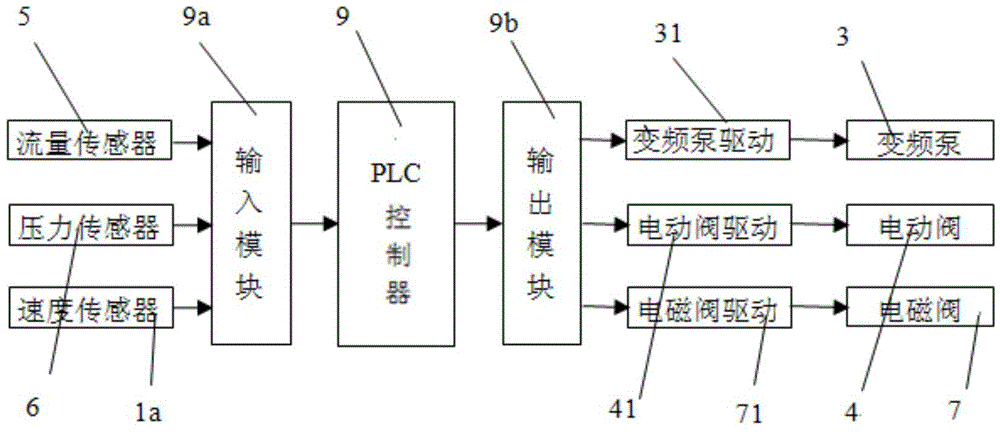

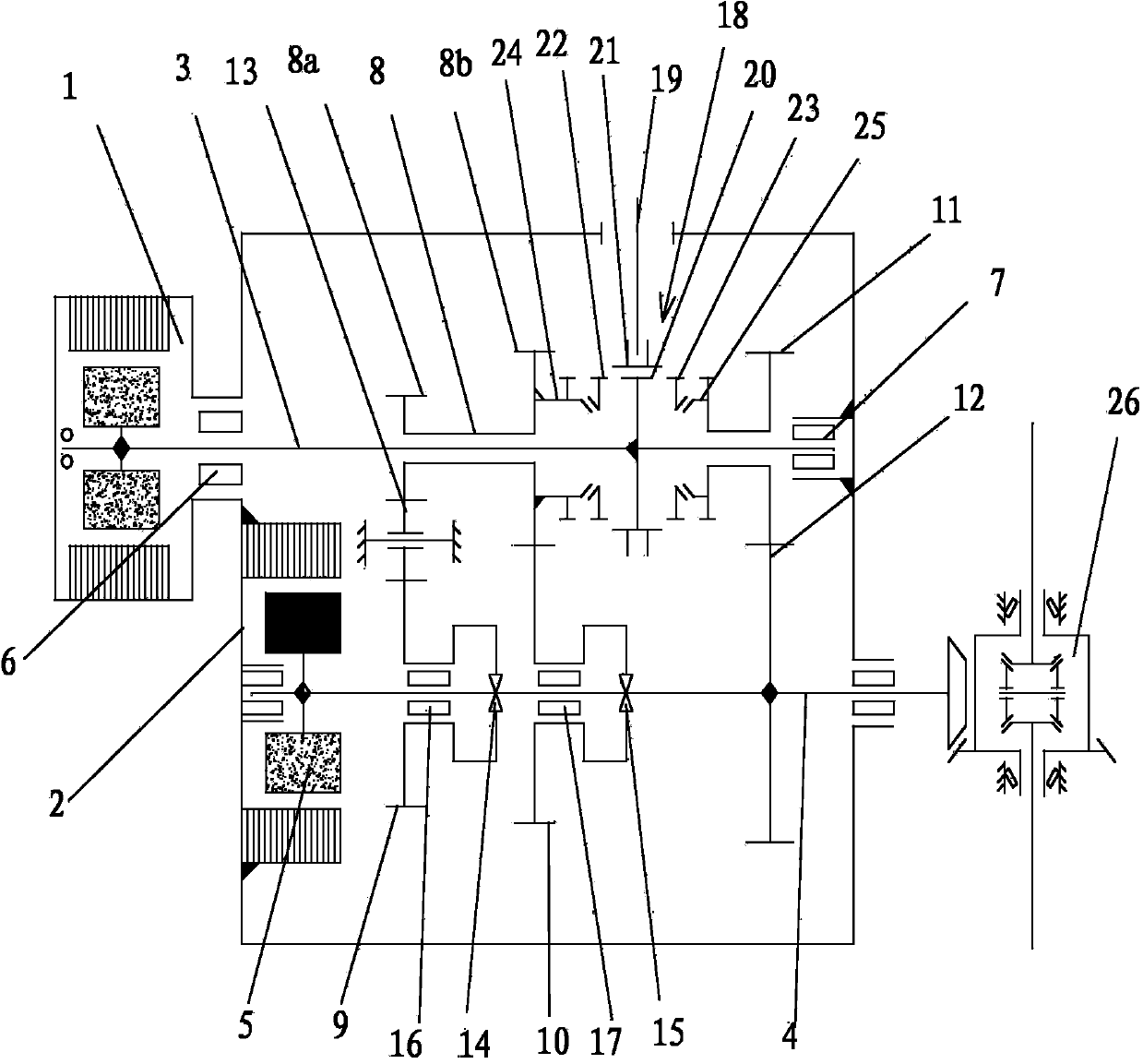

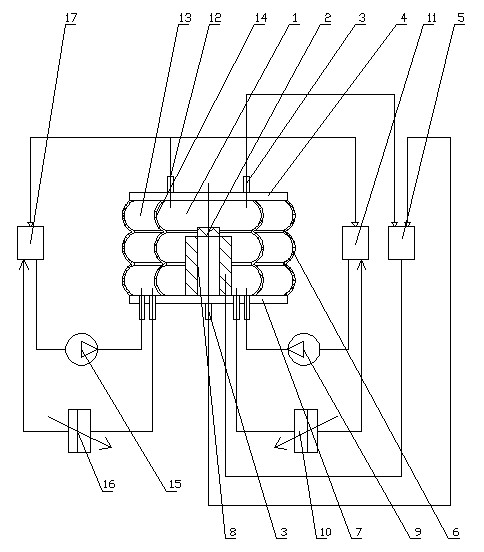

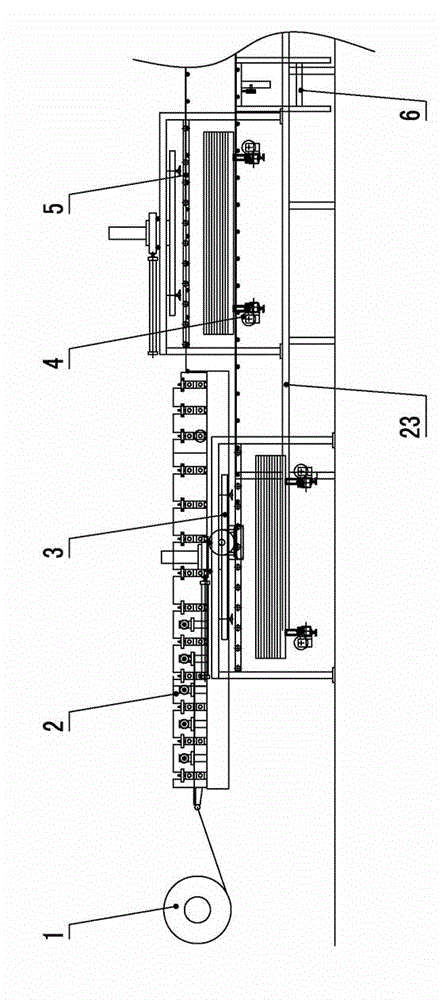

Automatic variable pesticide spraying system and control method thereof

ActiveCN104082267ANo wasteFavorable ecological developmentPump controlPositive-displacement liquid enginesEngineeringAutomatic variable

The invention discloses an automatic variable pesticide spraying system and a control method thereof. The automatic variable pesticide spraying system comprises a moving trolley, a pesticide box and a variable frequency pump, wherein the pesticide box and the variable frequency pump are mounted on the moving trolley. The pesticide box is connected with an inlet of the variable frequency pump through a pesticide conveying pipeline, an outlet of the variable frequency pump is connected with N pesticide conveying branch pipes through a pesticide conveying main pipe, and a shower nozzle is mounted at the end of each pesticide conveying branch pipe. Liquid pesticide output by the variable frequency pump can be further conveyed back into the pesticide box through a return pipe, the return pipe is provided with a first flow valve, and a flow sensor and a pressure sensor are further arranged on the pesticide conveying main pipe between the return pipe and each pesticide conveying branch pipe. A second flow valve is arranged on each pesticide conveying branch pipe. The automatic variable pesticide spraying system and the control method thereof have the obvious advantages that a variable pesticide application technology can be used for spraying pesticide as required according to acquired small-area difference information of farmland injurious insects, the pesticide spraying amount can be controlled accurately, pesticide waste can be avoided, the environment can be prevented from being polluted, and the system is even in pesticide spraying and good in atomization effect.

Owner:重庆帝勒金驰通用机械股份有限公司

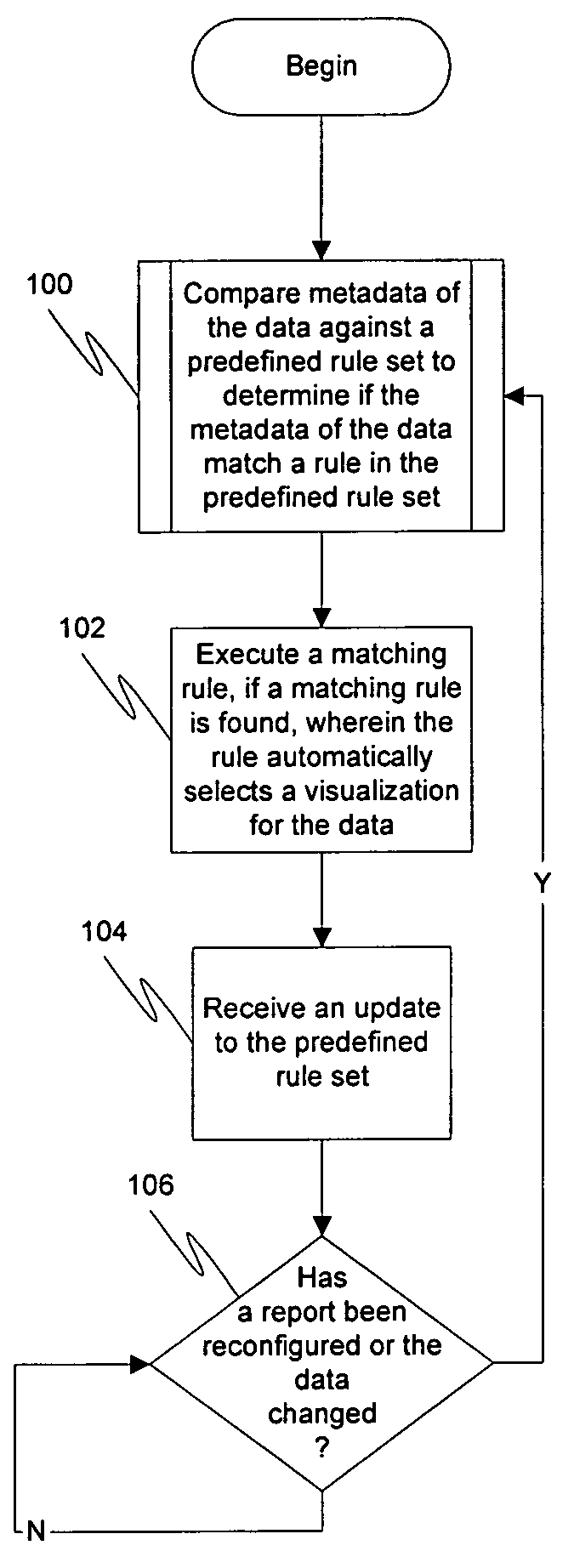

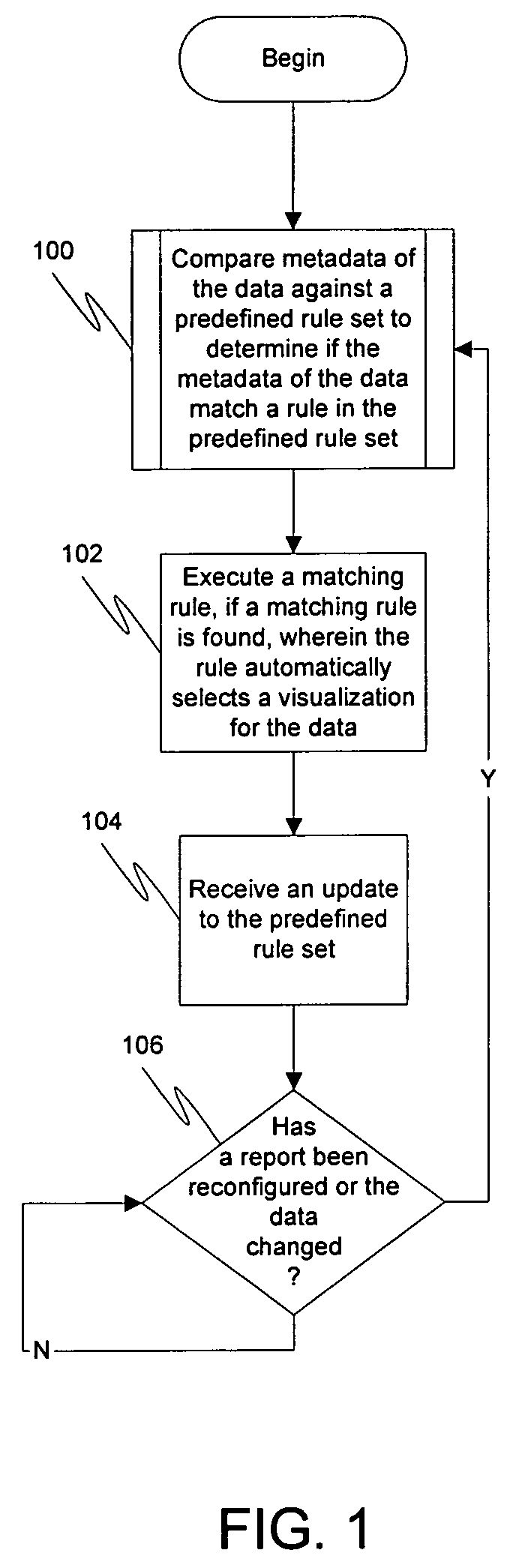

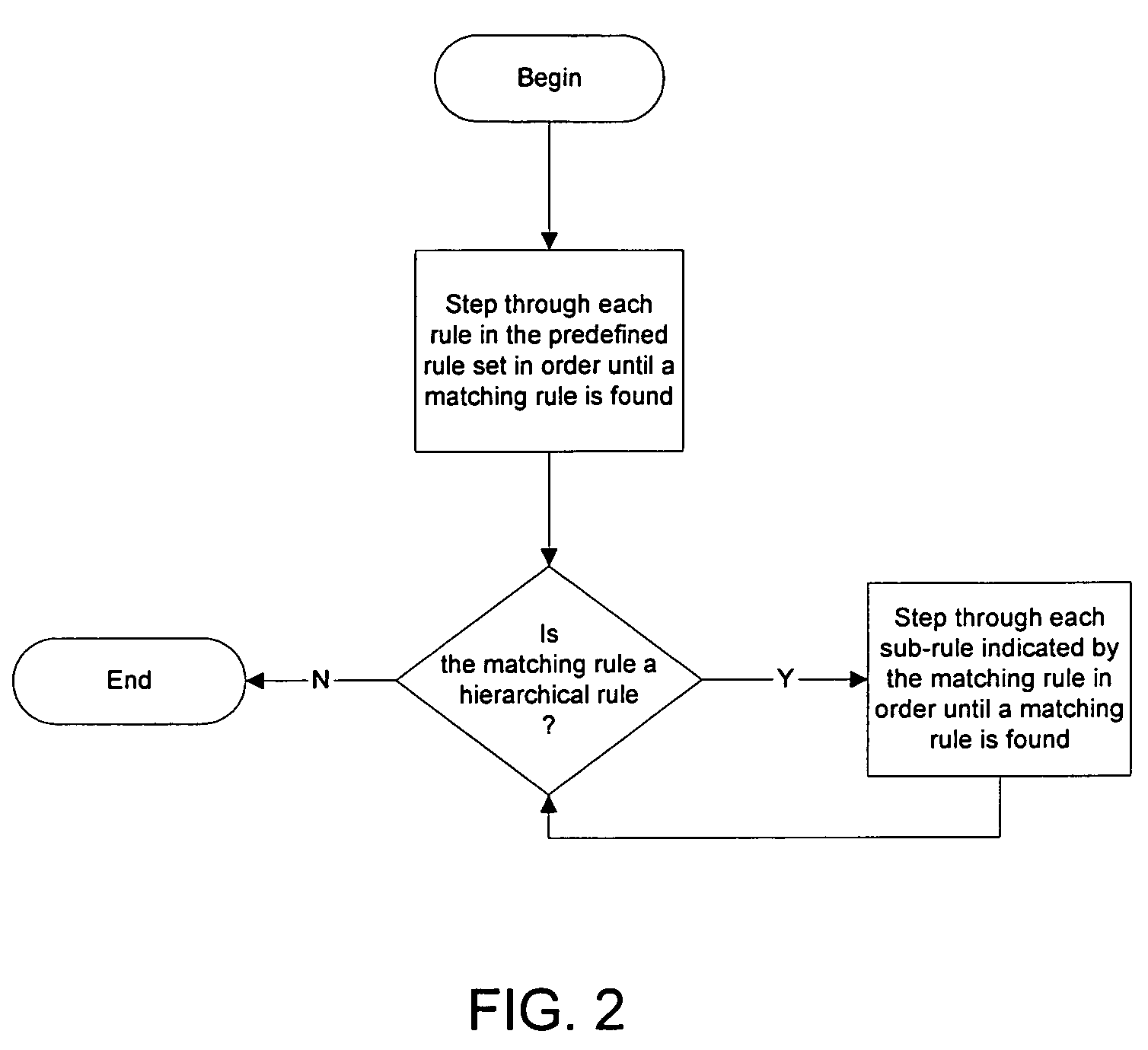

Automatic rules driven data visualization selection

ActiveUS7606835B2Office automationSpecial data processing applicationsData visualizationRule-based system

A solution is provided that automatically decides what visualization is best suited to present specified data. This is accomplished using a rules-based system that determines the type and properties of a visualization based on data and its corresponding metadata. The data and metadata may be checked against one or more rules, and depending upon which rule or rules match, a corresponding visualization and option combination may be utilized.

Owner:ORACLE INT CORP

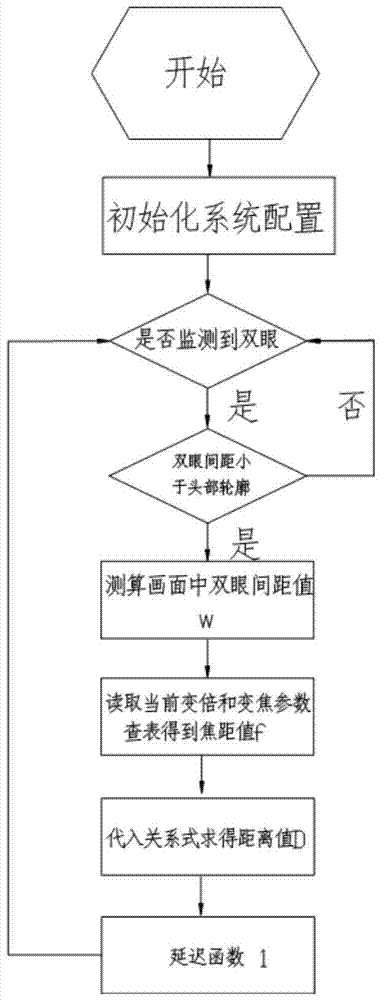

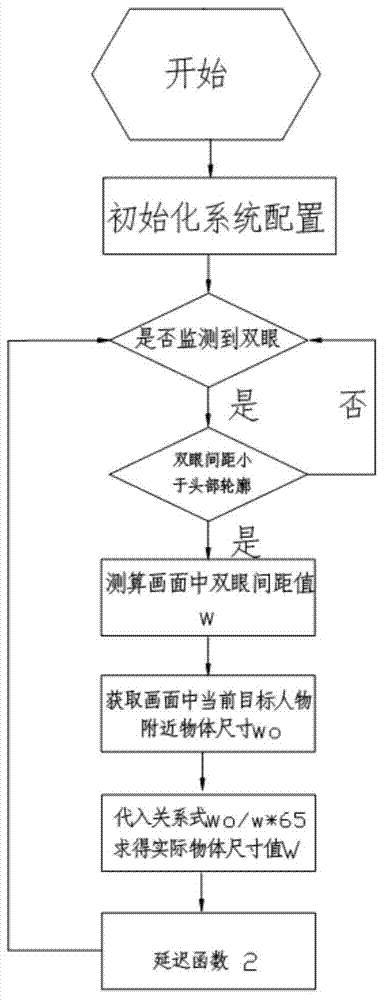

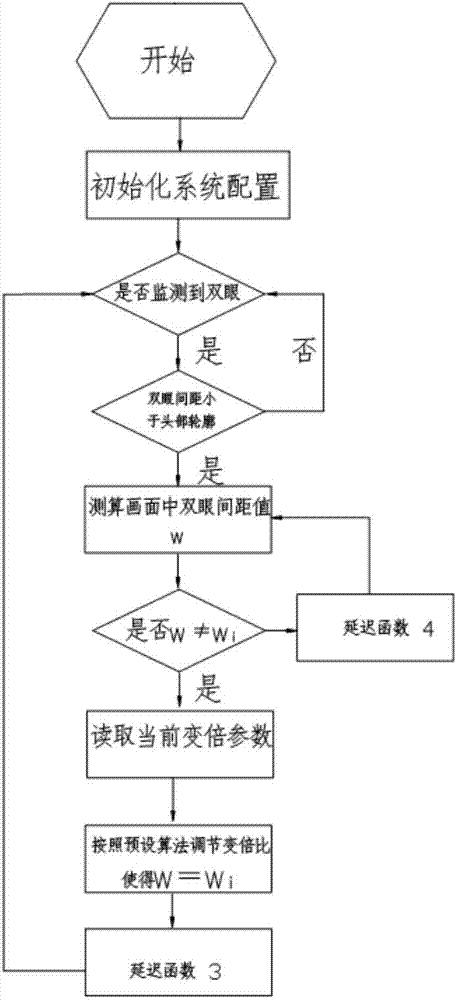

Camera automatic variable-time control method based on human eye space

InactiveCN104506773ASimple compositionCalculate the sizeTelevision system detailsColor television detailsPrime lensFace size

The invention provides a camera automatic variable-time control method based on the human eye space. According to the method, a zoom lens and / or zoom driving motor or a prime lens, an image sensor and a video analysis processing unit are mainly used, the front side of a person enters a shooting view field, the two eyes in the video are locked, the space w of the two eyes is measured and calculated, at the moment, the lens focus f and the human eye general space W and the human eye space w in the video are known quantities, the values are substituted into a formula, the distance of an object to be shot can be calculated, the expected human face size is set in a monitoring image, the space between the two eyes in the image is wi, the space w of the two eyes in an actual image is measured and calculated, the ratio of the w to the wi is calculated, the zoom power of the lens is regulated according to a preset relational expression in accordance to the proportion relationship, so that the regulated w equals to the wi, the steps are repeated when the distance between the human face and the lens is changed, and the w is enabled to be equal to the wi, so that the human face can be enabled to be always displayed in the image in the preset size in a certain distance range.

Owner:TIANJIN YAAN TECH CO LTD

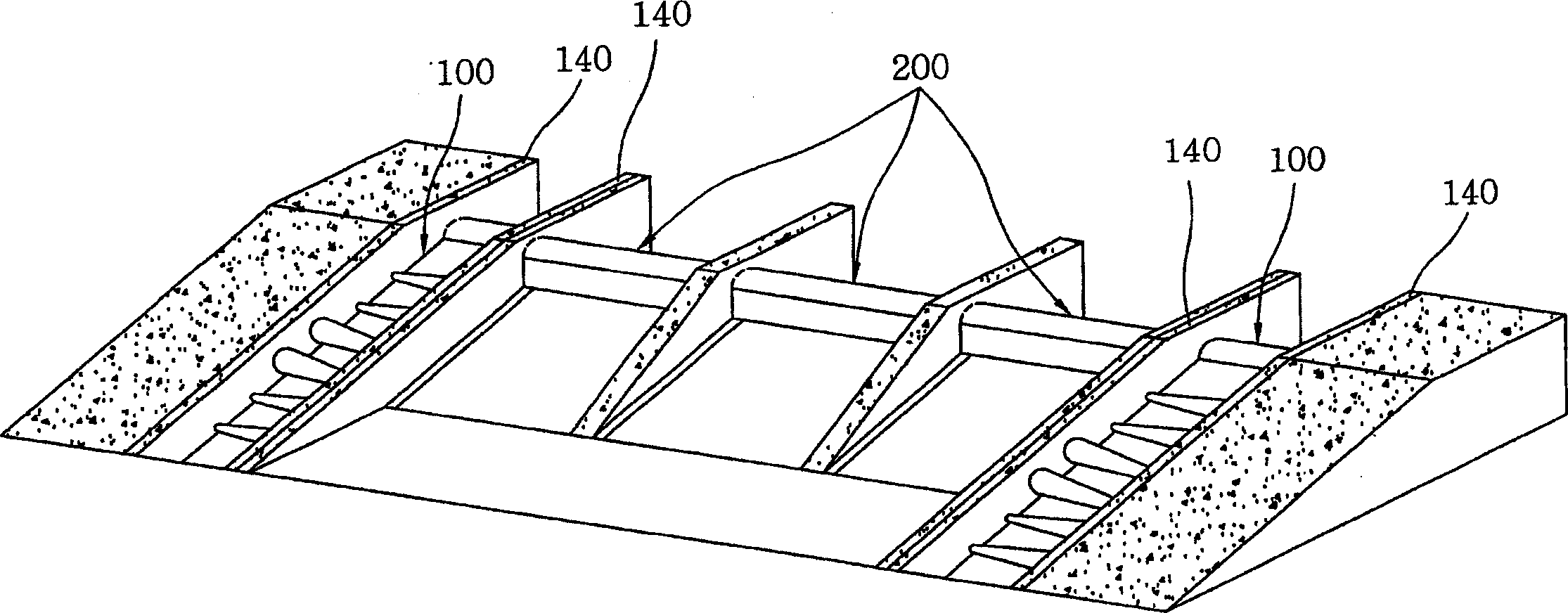

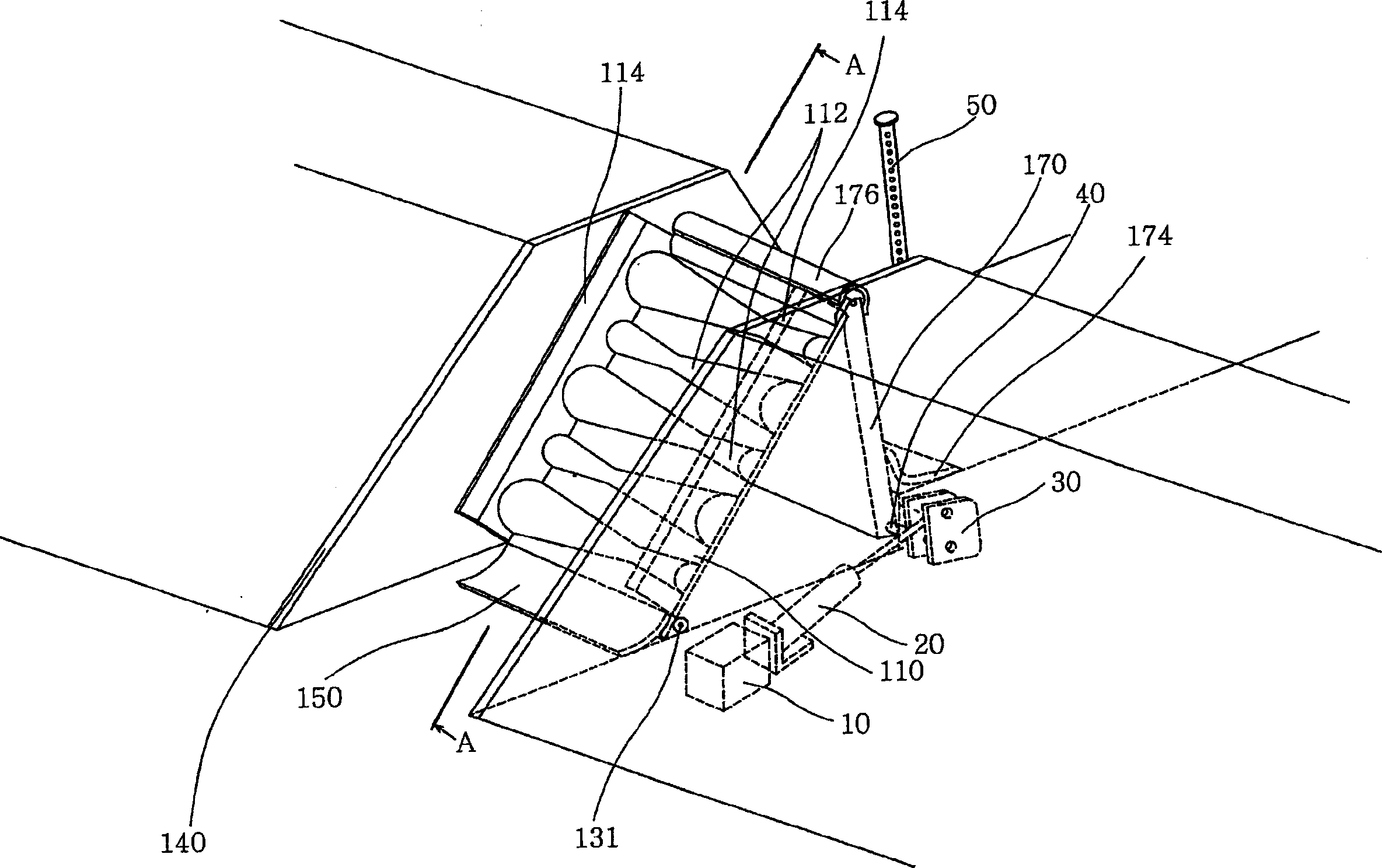

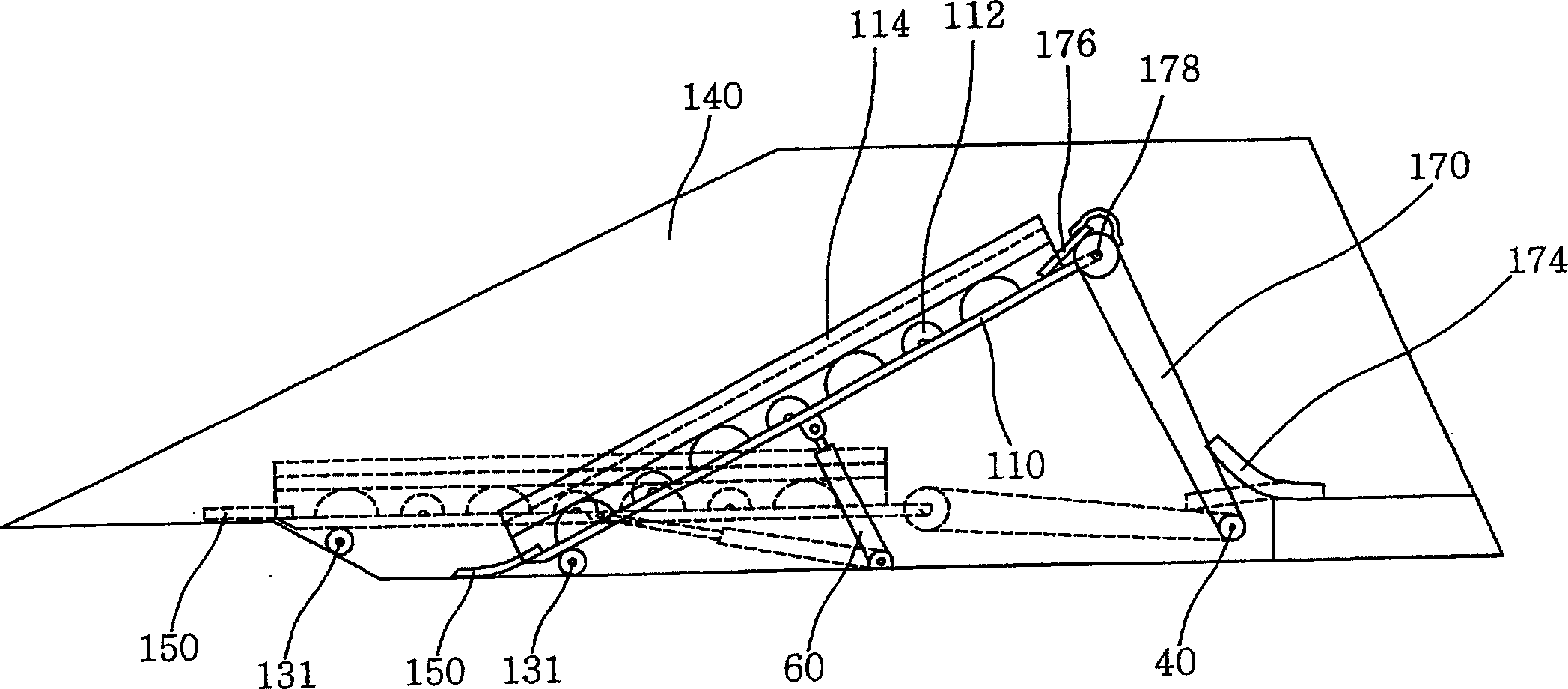

Automatic variable fishway by water level sensed

InactiveCN1863970AProtect the ecosystemGuaranteed normal displacementBarrages/weirsClimate change adaptationEngineeringWater level

The present invention relates to an automatic variable fishway. More particularly, an automatic variable fishway by water level sensed of the invention can automatically vary its height to uniformly maintain the quantity of water drained through the fishway so that migratory animals can freely move through the fishway to upstream or downstream of a dam regardless of the quantity of storage water. The automatic variable fishway by water level sensed of the invention is installed in a bank for storing a predetermined quantity of water to allow migration of fish, and comprises: an underwater gate 170 for being erected or laid by a drive means which is operative in response to a signal from a water level detecting sensor 50 for detecting the level of storage water; and a fishway plate 110 connected with a top of the underwater gate 170 to form a migration path for fish.

Owner:寄寅舒

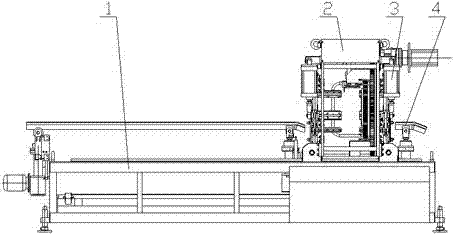

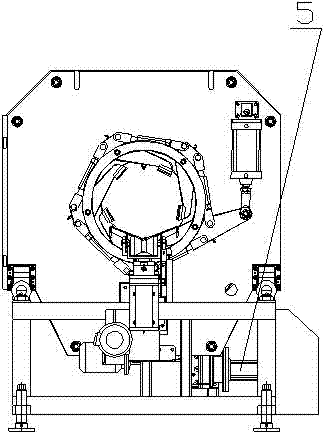

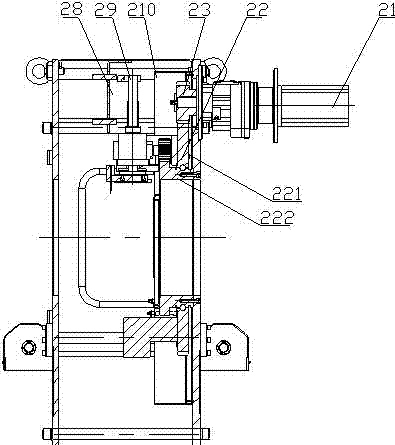

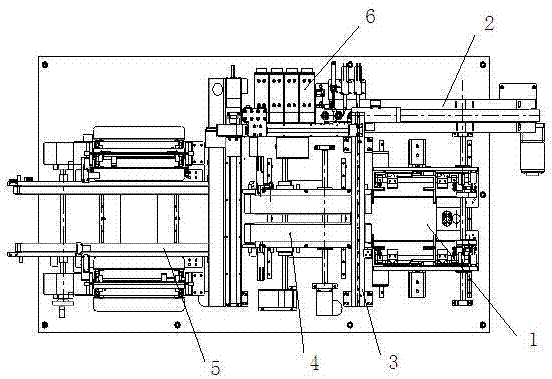

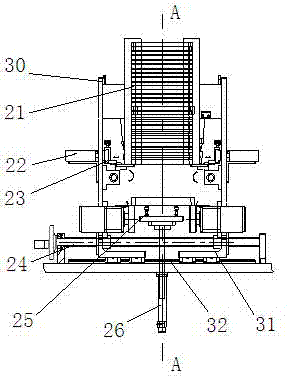

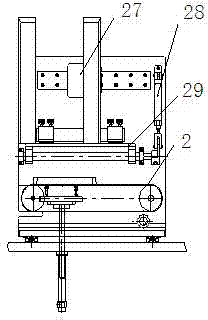

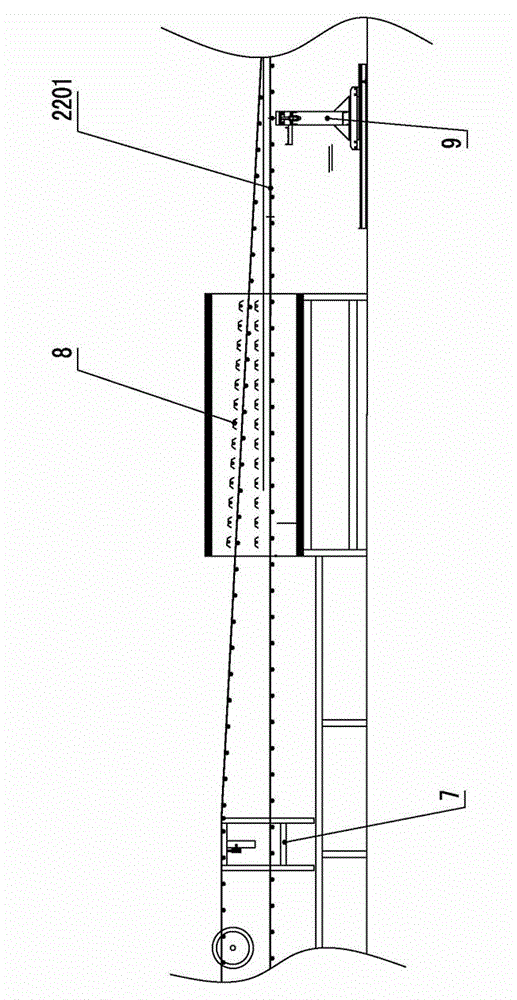

Automatic variable diameter chipless cutting machine

InactiveCN102452097AHigh degree of full automationCompact structureMetal working apparatusSpiteHuman–machine interface

The invention relates to the related technical field of pipe cutting equipment, in particular to an automatic variable diameter chipless cutting machine, which comprises a frame, and a supporting mechanism, a clamping mechanism and a rotating mechanism arranged on the frame in turn, wherein the clamping mechanism comprises a clamping bottom plate with a clamping through hole, and a clamping cylinder, a front turning arm and a plurality of clamping force arms, which are arranged on the clamping bottom plate; and the front end of each clamping force arm is provided with a clamping block, and the rear end of each clamping force arm is provided with a clamping rotating shaft, a force applying shaft and a stressed shaft. In spite of the change of specifications of pipes, the clamping device can adapt to a pipe clamping range; and clamp blocks are not required to be changed, and a clamping cylinder mounting position design ensures that force generated by the cylinder is exerted maximally in a linked multi-point clamping mechanism, so that pipes with the maximum diameter are clamped. The machine has high full automation degree, compact and concise structure, safe and reliable electric control and ideal human-computer interface, and is easy and convenient to operate; and the online automation of the cutting machine is realized by a programmable logic controller (PLC).

Owner:GUANGDONG LIANSU MACHINERY MFG

Automatic pallet filler of commutator

InactiveCN103569637AImprove general performanceEasy to installConveyor partsEngineeringAutomatic variable

Owner:SHANGHAI ZHAOCHENG COMMUTATOR TECH

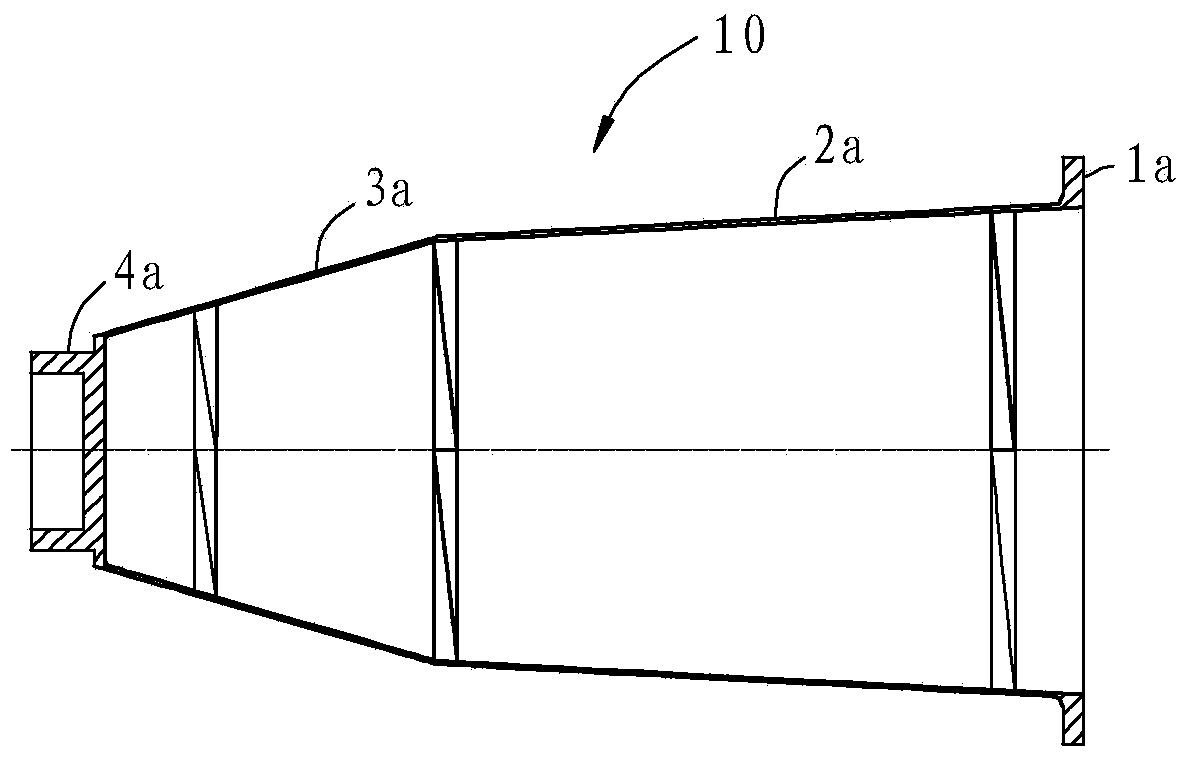

Side-hung bow cone swing type self-adaption automatic variable-speed drive assembly for electric motorcycle

ActiveCN105129016ASmooth load changeAchieve balance controlWheel based transmissionDrive shaftEngineering

The invention discloses a side-hung bow cone swing type self-adaption automatic variable-speed drive assembly for an electric motorcycle. The side-hung bow cone swing type self-adaption automatic variable-speed drive assembly comprises a box body, a transmission shaft, a slow-gear transmission mechanism and a mechanical and intelligent self-adaption variable-speed assembly. An annular concave part is formed in the axial end face of the outer ring of an overrun clutch of the slow-gear transmission mechanism. The inner ring of the overrun clutch of the slow-gear transmission mechanism is arranged in the annular concave part. A meshing space is formed between the outer circle of the inner ring and the inner wall of the radial outer side of the annular concave part. The slow-gear transmission mechanism outputs power and locks a variable-speed elastic part through a swing type end face cam meshing pair. By means of the side-hung bow cone swing type self-adaption automatic variable-speed drive assembly, a traditional structure that the inner ring is directly supported by the transmission shaft is avoided, the problem that the transmission error is amplified on the overrun clutch is solved as well, the overall stability of the overrun clutch is ensured, stable supporting can still be ensured after a transmission runs for a long period, the running noise is reduced, the running comfort is ensured, the transmission efficiency is improved, and therefore the energy consumption is lowered; the service life is prolonged, the running accuracy is improved, and the side-hung bow cone swing type self-adaption automatic variable-speed drive assembly is suitable for heavy-load and high-speed use environments.

Owner:SOUTHWEST UNIVERSITY

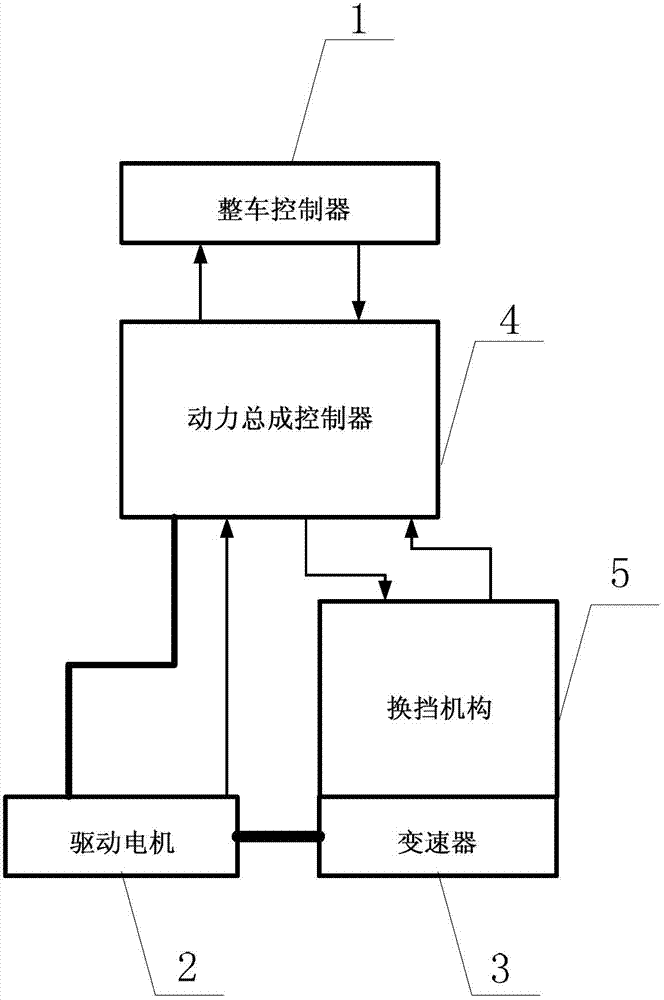

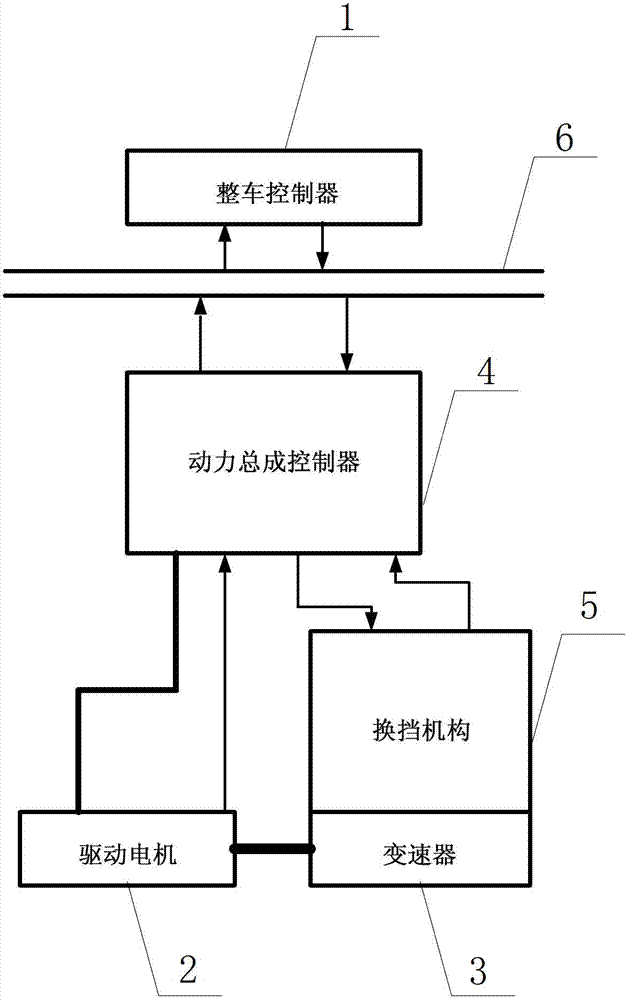

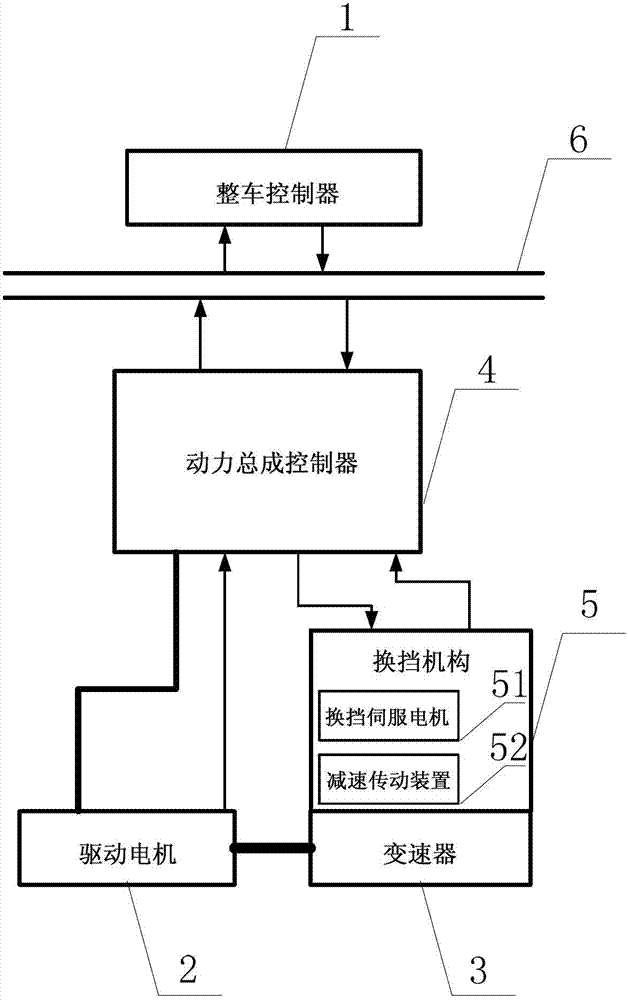

Automatic variable speed control system of pure electric vehicle and pure electric vehicle

The embodiment of the invention provides an automatic variable speed control system of a pure electric vehicle and a pure electric vehicle. The automatic variable speed control system comprises an entire vehicle controller, a drive motor, a transmission, a power assembly controller and a gearshift, wherein the entire vehicle controller is used for generating control information, and the control information comprises a target torque and a target gear; the power assembly controller is used for obtaining the control information, controlling the target torque to control the drive motor to output a torque and a rotating speed, and controlling the gearshift to drive the transmission to adjust a gear according to the target gear; and the drive motor drives the transmission to operate according to the torque and the rotating speed. According to the technical scheme provided by the embodiment of the invention, requirements of large starting torque of the vehicle, high motor operating efficiency and wide working range can be satisfied.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

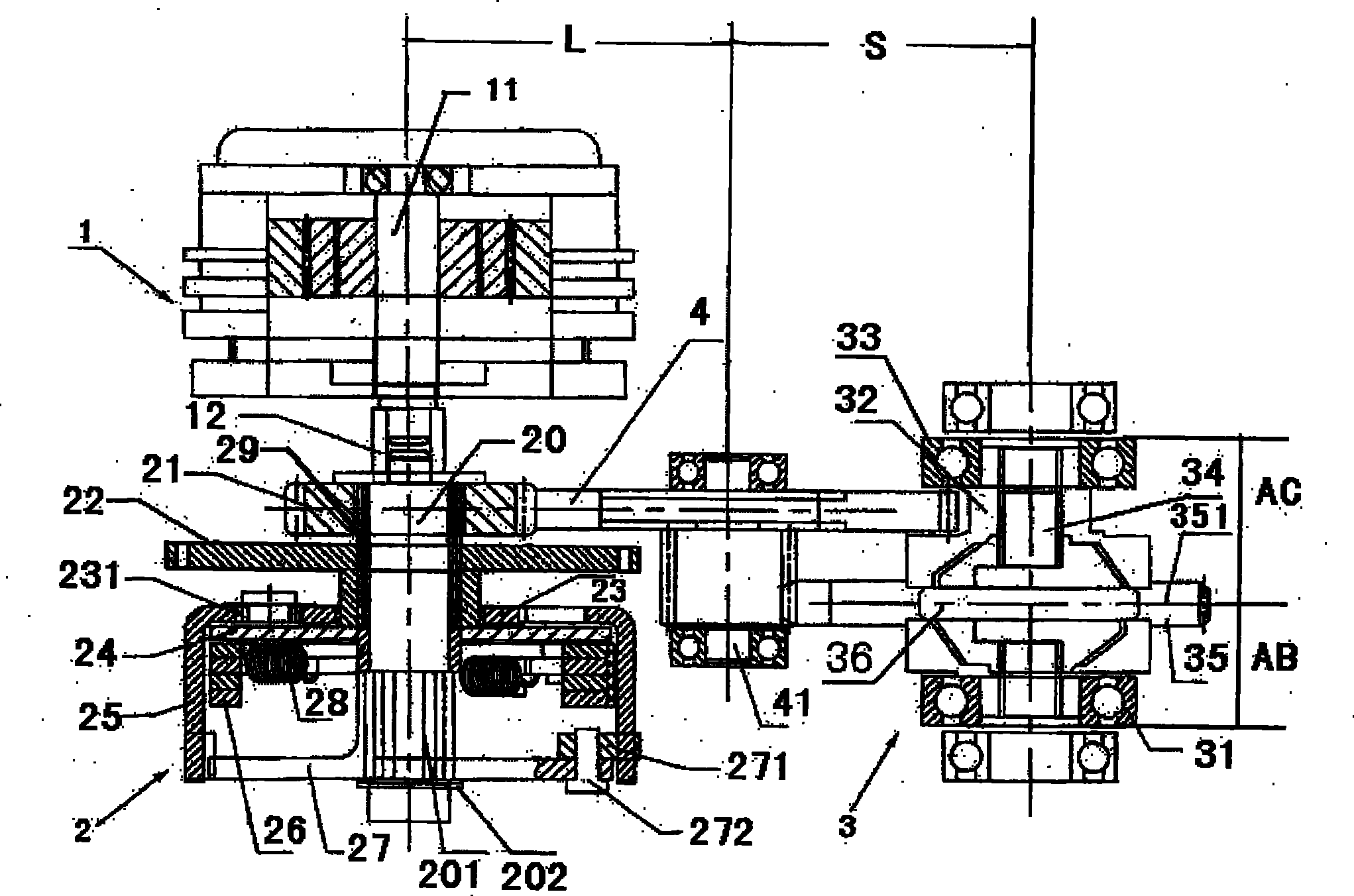

Automatic variable-speed motor transmission mechanism for electric tricycle and electric vehicle

ActiveCN102606689ASimple structureRealize automatic switching gear ratioToothed gearingsGearing detailsAutomatic transmissionMotor drive

An automatic variable-speed motor transmission mechanism for an electric tricycle and an electric vehicle comprises a motor, an automatic speed changer and a differential system. The automatic variable-speed motor transmission mechanism is characterized in that the automatic speed changer consists of a speed changer shaft, a driving gear, a sun gear fixing plate, a driving disc, a housing and a connecting plate, a motor shaft of the motor drives the speed changer shaft, the connecting plate is mounted at the other end of the speed changer shaft and connected with the housing, a planetary gear is mounted on the upper portion of the housing, the driving disc with a shoe is fixedly connected to the lower portion of the planetary gear, a tension spring is connected with the shoe, the driving disc is sleeved on the outside of the speed changer shaft by a driving disc spline, the planetary gear matches with a sun gear, the sun gear matches with the sun gear fixing plate, through holes on two sides of the sun gear fixing plate are fixed on a body of a gearbox, the driving disc is connected with the driving gear by a driving gear spline, the driving gear drives an intermediate gear, an intermediate driven gear drives a driven gear, the driven gear is connected with the differential system, and a differential spline sleeve is connected to a rear axle shaft of the electric vehicle.

Owner:台州市皓仔邦工业设计有限公司

Dual-motor automatic variable-speed drive system of electric vehicle

InactiveCN103434379AEnsure safetyImprove powerElectrodynamic brake systemsElectric propulsion mountingEngineeringElectric power

The invention discloses a dual-motor automatic variable-speed drive system of an electric vehicle. The dual-motor automatic variable-speed drive system comprises a main motor and a transmission variable speed assembly. The transmission variable speed assembly comprises a box body, a power input shaft and a power output shaft, wherein the power input shaft and the power output shaft are arranged on the box body in the mode that the power input shaft and the power output shaft can rotate around the axis of the power input shaft and the axis of the power output shaft. The main motor can input power into the power input shaft to achieve gear shifting and speed changing, wherein the power can switched in the positive direction and the negative direction. The dual-motor automatic variable-speed drive system of the electric vehicle further comprises an auxiliary motor which provides auxiliary output power for the power output shaft when the main motor switches the rotation direction. The auxiliary motor in transmission connection with the power output shaft is arranged to provide the auxiliary output power for the power output shaft when the main motor switches the rotation direction to cause power failure in the gear shifting process, and smoothness of gear shifting and dynamic property of running of the vehicle are improved. In addition, in the vehicle regenerative brake process, the auxiliary motor can be used as an engine, part of the kinetic energy of the vehicle is converted into electric energy, part of electricity is stored, and therefore the driving range is prolonged.

Owner:SOUTHWEST UNIVERSITY

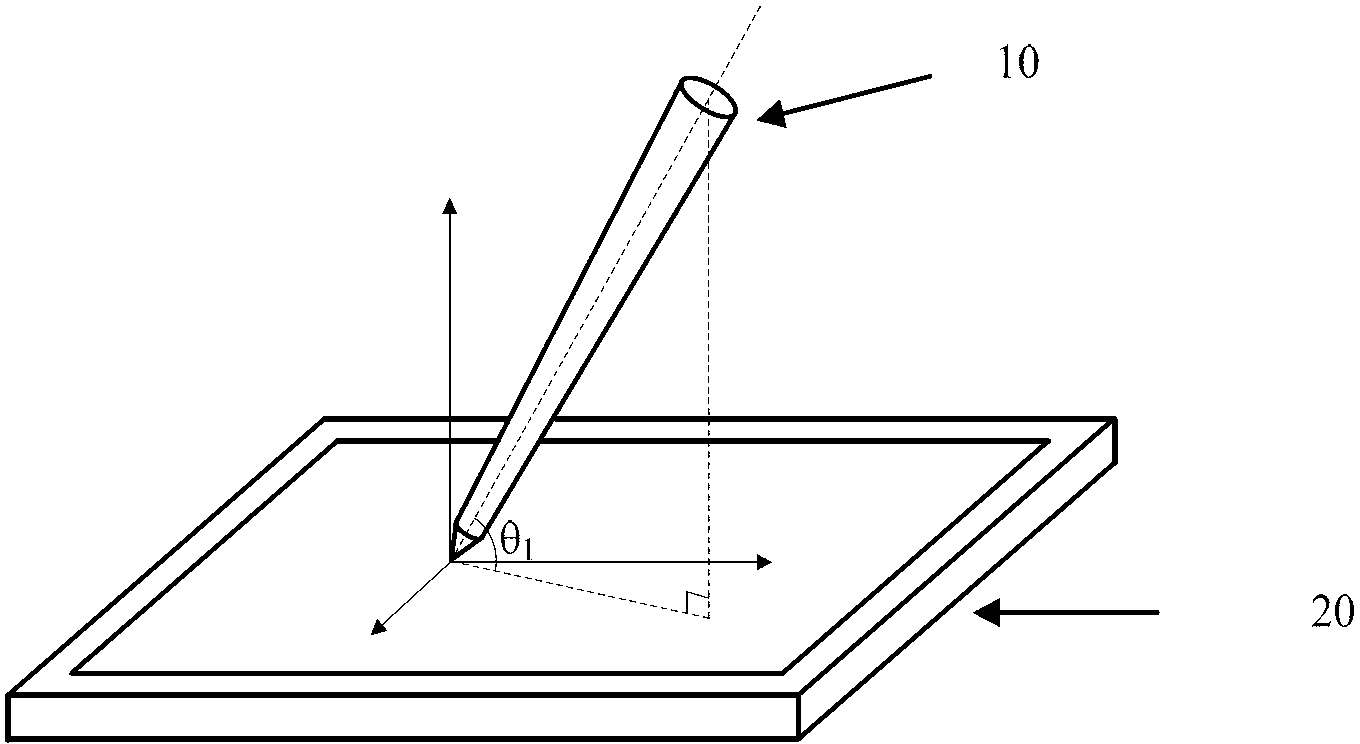

Automatic variable stroke type handwriting input device

ActiveCN103218065AReduce stepsImprove experienceInput/output processes for data processingHandwritingPhysical medicine and rehabilitation

The invention provides an automatic variable stroke type handwriting input device. The device comprises portable electronic equipment and a handwriting pen, wherein the stroke type of the handwriting pen is automatically changed according to a relative included angle between the handwriting pen and a handwriting plane of the portable electronic equipment. The stroke type is set to be changed under the following conditions: the handwriting pen is in a handwriting state; and the handwriting pen is in three angle scopes and is continuously maintained for T seconds. The device has the advantages that the stroke type of the handwriting input can be automatically varied, so that the additional operations of users can be reduced, and user experiences are improved; and the stroke type variation based on relative included angle variation satisfies the pen holding habits of the users, and the users can be adapt to the use without additional learning.

Owner:BEIJING SHUNYUAN KAIHUA TECH LTD

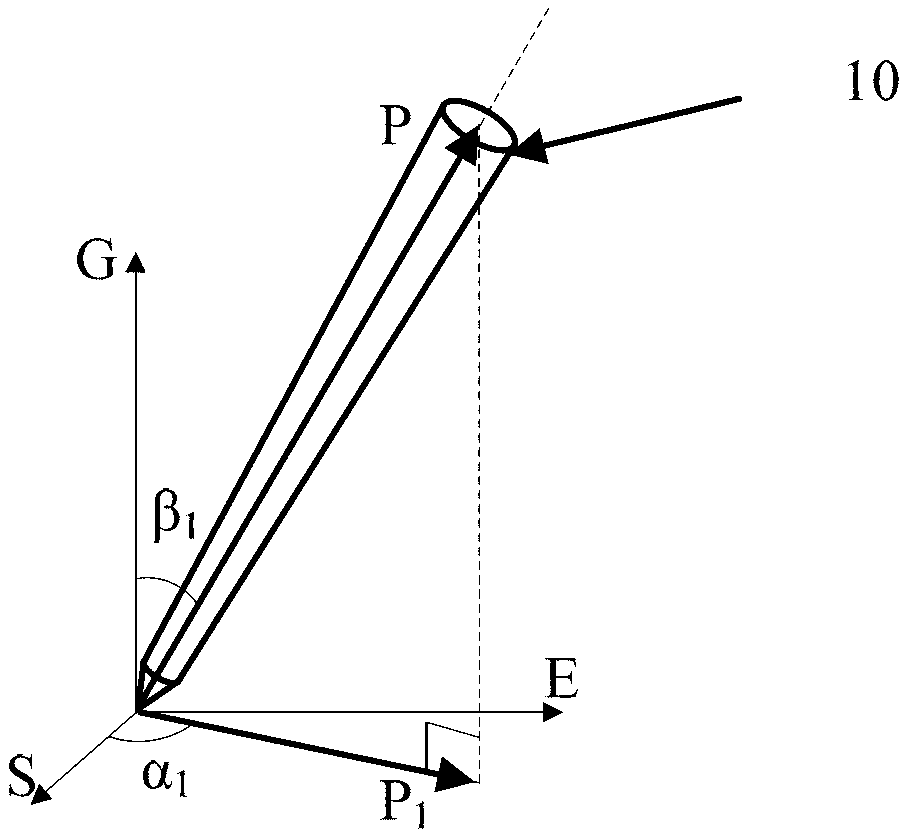

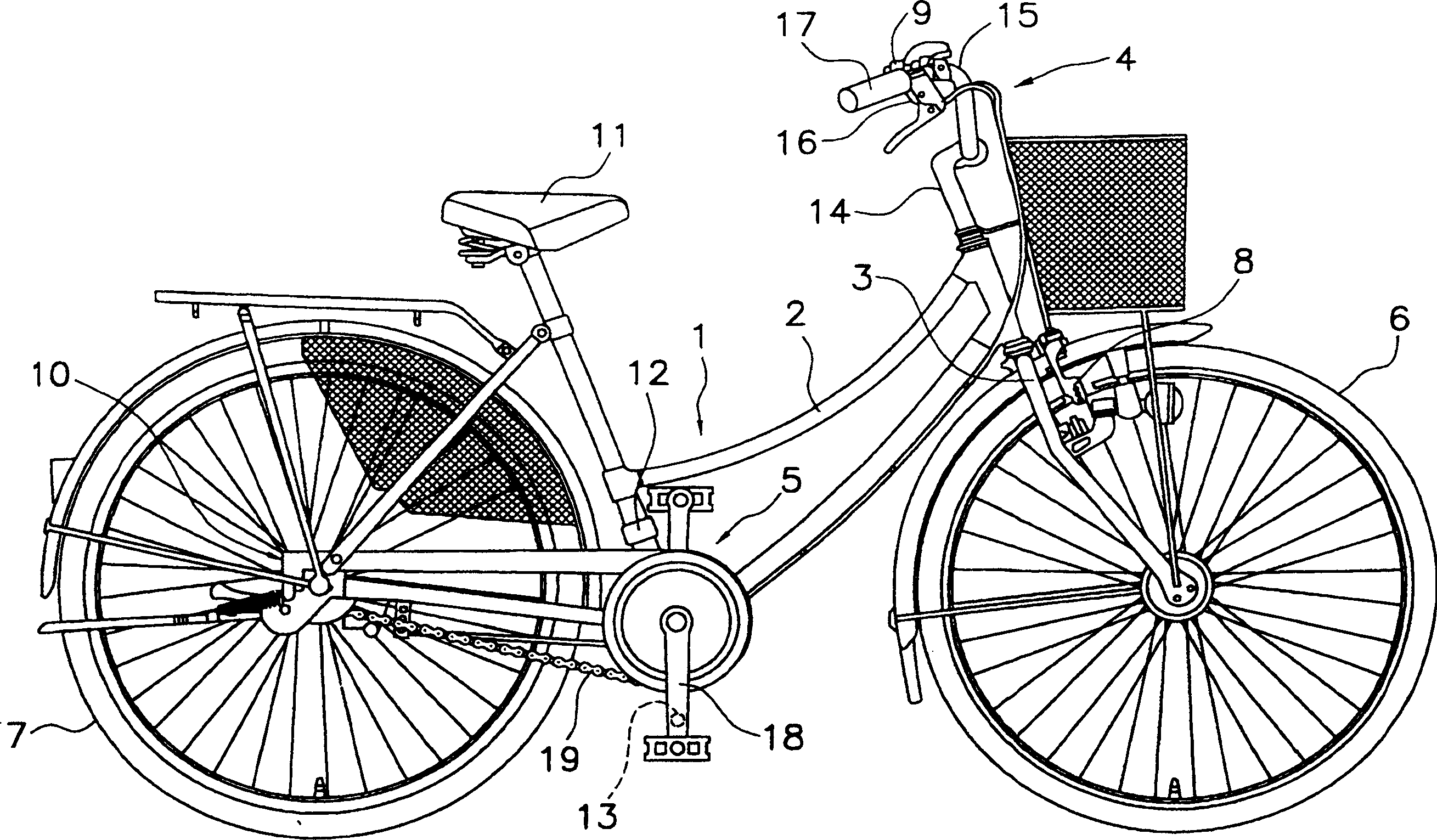

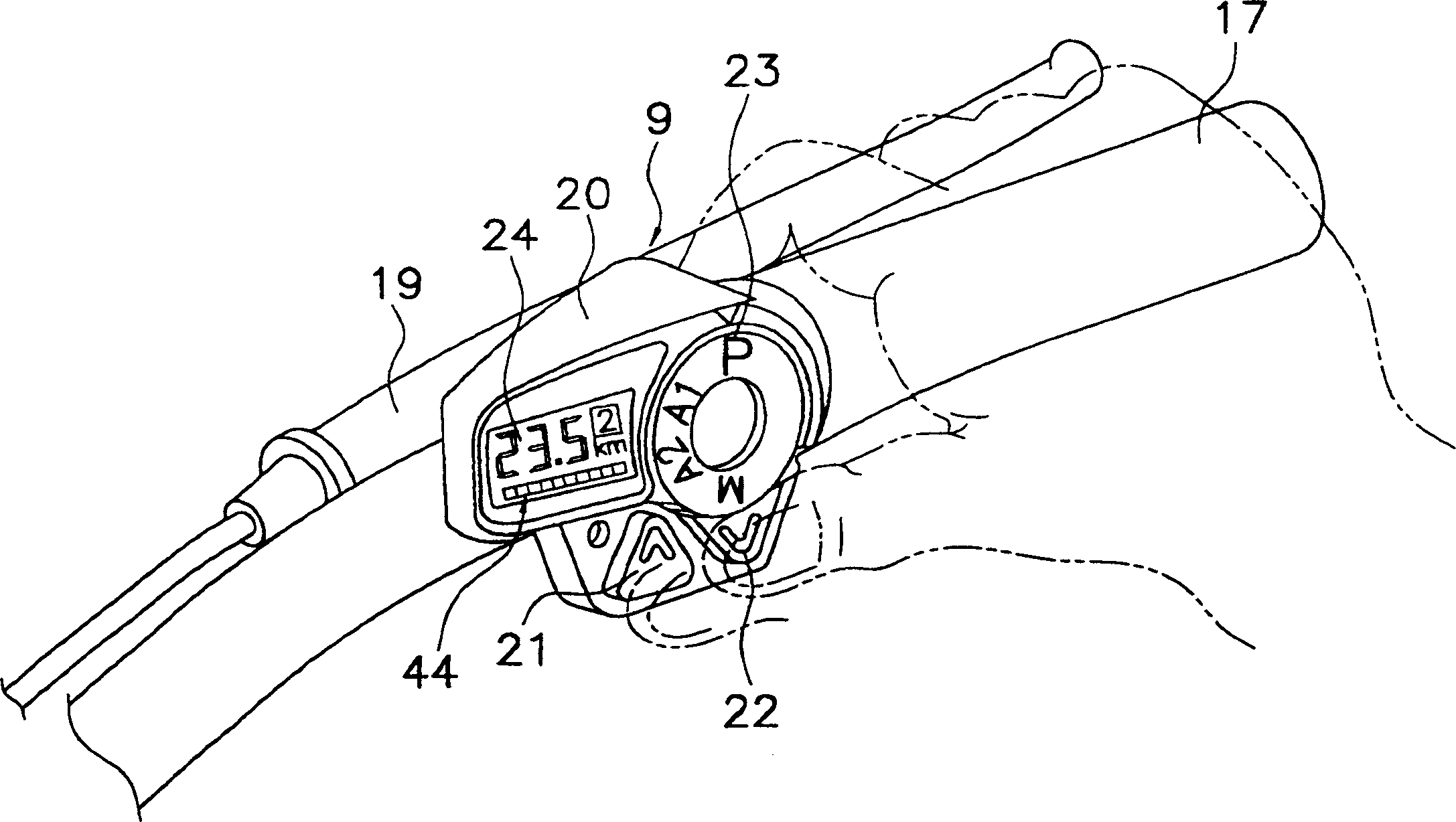

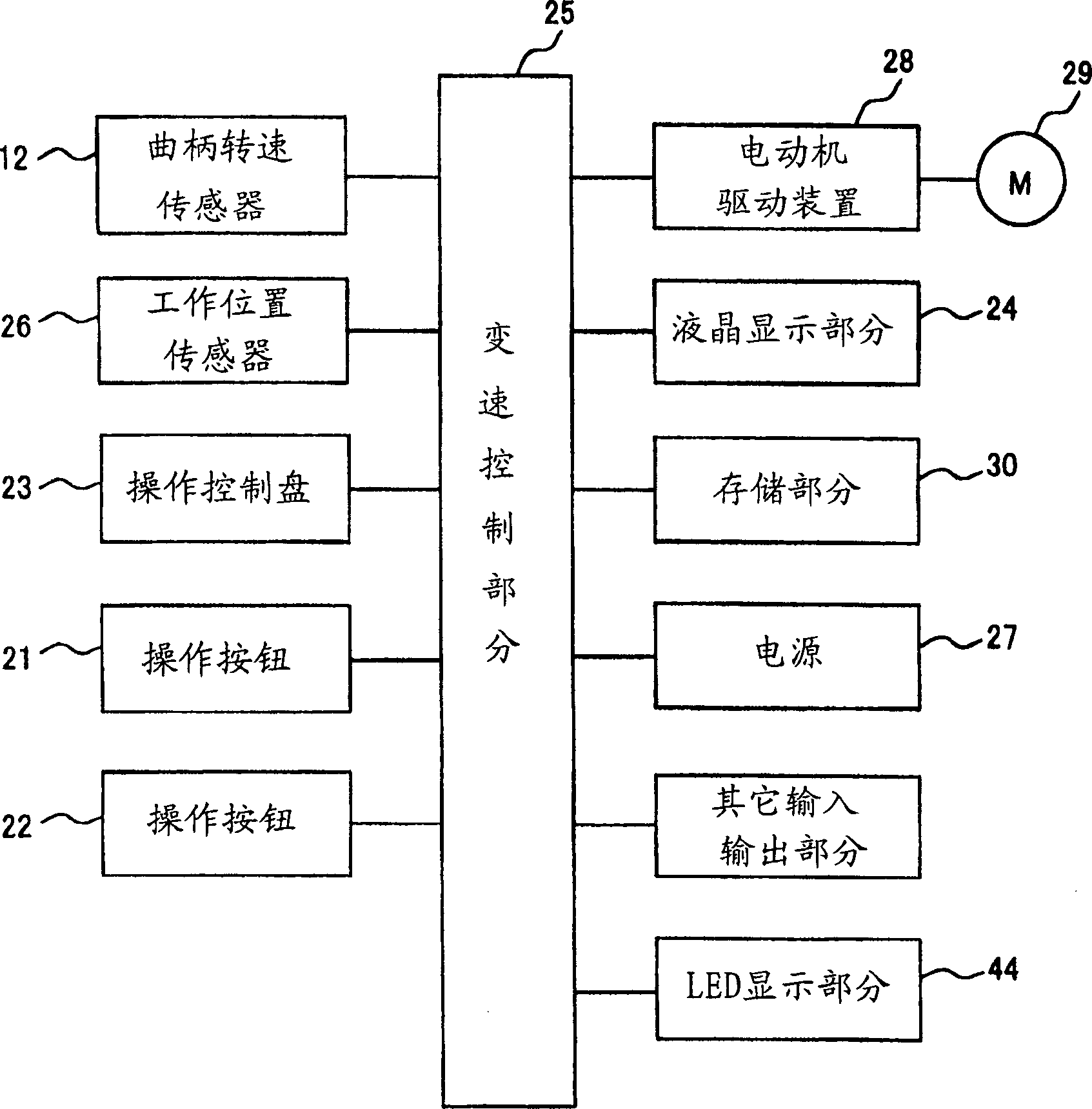

Automatic variable speed controller and method for bicycle

The invention provides an automatic gear shifting controller for a bicycle and a method and the same, capable of informing the gear shifting in advance to a rider. This gear shifting controller for the bicycle is used for driving a transmission every gear shifting timing on the basis of a traveling condition of the bicycle, and comprises a crank rotating speed sensor 12, a gear shifting motor 29, and an LED display part 44. The crank rotating speed sensor 12 is a means for detecting the traveling condition of the bicycle. The gear shifting motor 29 is a means for driving the transmission on the basis of a result of the detection by the crank rotating speed sensor 12. The LED display part 44 is a means for informing the gear shifting in advance before the gear is shifted when the traveling condition of the bicycle approaches the gear shifting timing.

Owner:SHIMANO INC

Welding method for multistage circular welds of medium and thin wall variable-diameter aluminum alloy shell

InactiveCN103551717AGuarantee welding qualityGuaranteed weld shapeWelding/cutting auxillary devicesAuxillary welding devicesFree coolingWelding defect

A welding method for multistage circular welds of a medium and thin wall variable-diameter aluminum alloy shell is characterized by including the steps: designing a welding connector; performing primary cleaning; protecting weld backs; performing assembly; performing secondary cleaning; preheating and welding the aluminum alloy shell by the aid of an automatic variable polarity plasma welding machine; reducing the temperature of the shell to the indoor temperature in a natural cooling mode after the multistage circular welds are welded. Compared with a traditional tungsten argon arc welding process, a variable polarity plasma welding process has the advantages that a groove is omitted or a small groove is formed, particularly, a welding groove is omitted when the wall thickness of the aluminum alloy shell is smaller than 10mm, the aluminum alloy shell can be welded once, so that heat input is reduced, the probability of welding defects is decreased, preheating and welding are realized by the aid of the same device, preheating and welding efficiency is improved, and welding cost is reduced.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH +1

Magneto-rheological hydraulic rubber air spring

InactiveCN101968097AGood oil resistanceLarge adjustment rangeNon-rotating vibration suppressionGas and liquid based dampersControl systemMagneto rheological damper

The invention relates to a magneto-rheological hydraulic rubber air spring, which comprises an upper fixed sealing plate, a lower fixed sealing plate and a rubber outer bag. Magneto-rheological liquid is filled in the rubber outer bag, a rubber bag is arranged in the rubber outer bag, the rubber bag is connected with the upper and lower fixed sealing plates, and the magneto-rheological liquid is connected with a magneto-rheological hydraulic adjusting system. The air spring solves the problem of automatically adjusting the height and the rigidity in real time, has the characteristics of high oil resistance, wide adjustment range, strong temperature adaptability, high response speed, simple structure, small volume and low cost, and can be used for an automobile active suspension system; and if the air spring is integrated with a magneto-rheological damper, the automobile active suspension system with real-time automatic variable height, variable rigidity and variable damping can be formed; and the air spring also can be applied to other vibrating active control systems.

Owner:游世辉 +3

Continuous automatic production equipment of structural thermal-insulating composite wall boards for buildings

ActiveCN102975473AImplement automatic connectionHigh degree of automationLamination plant layoutLaminationAssembly lineHigh pressure

The invention relates to continuous automatic production equipment of structural thermal-insulating composite wall boards for buildings. The continuous automatic production equipment comprises a lateral edge steel belt unreeling machine, a lateral edge tongue-and-groove side stopping forming machine, a crown-block-type vacuum sucker transferring machine, an automatic sticking machine, an automatic variable-frequency speed adjustment transmission line, an infrared preheating device, a foaming and pouring platform, a PLC (Programmable Logic Controller) control operation table, a thermosetting high-pressure foaming machine, a raw material premixing device, a hydraulic double-track lamination assembly line, a hot-air-circulation temperature control device, an automatic tracking cutter and an automatic packaging device. The continuous automatic production equipment provided by the invention has the beneficial effects that inorganic panels and core materials can be continuously produced and once formed; automatic connection and non-dislocation juncture can be realized by a double-faced panel, so that not only can metal-faced composite boards be produced, but also non-metal-faced double-faced composite wall boards further can be produced; and the continuous automatic production equipment has the advantages of high automatic degree, high production efficiency and low production cost.

Owner:HUIZHOU HECHENG MECHANICAL EQUIP CO LTD

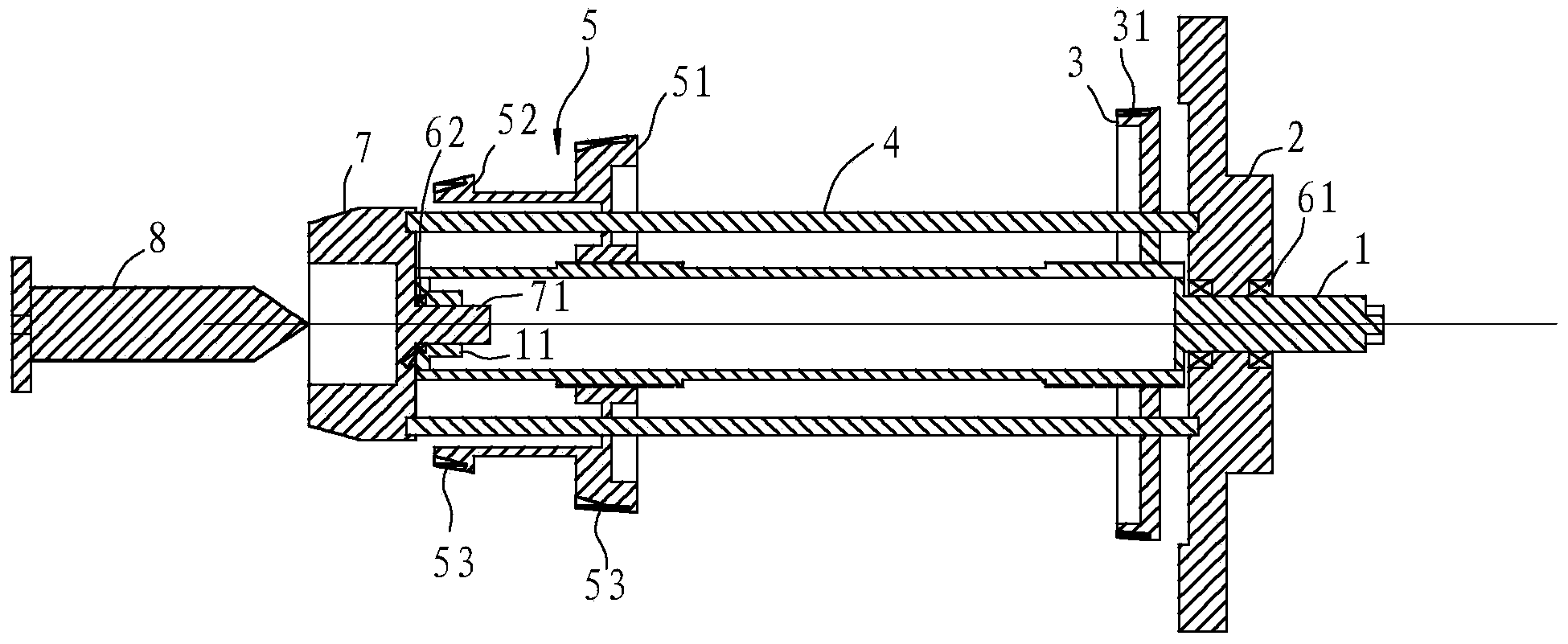

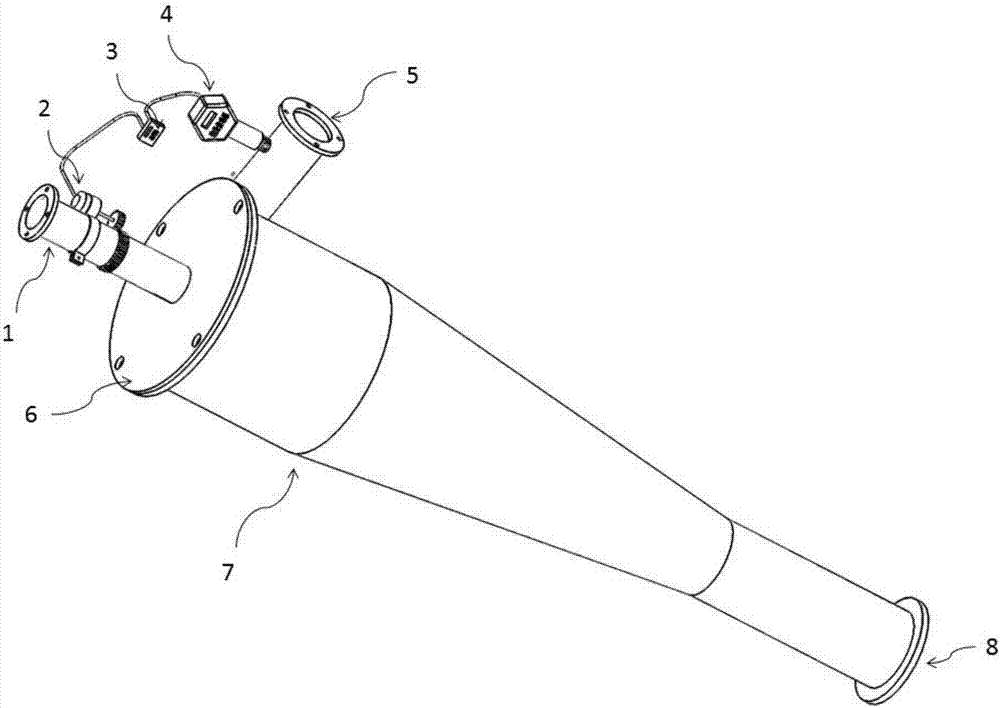

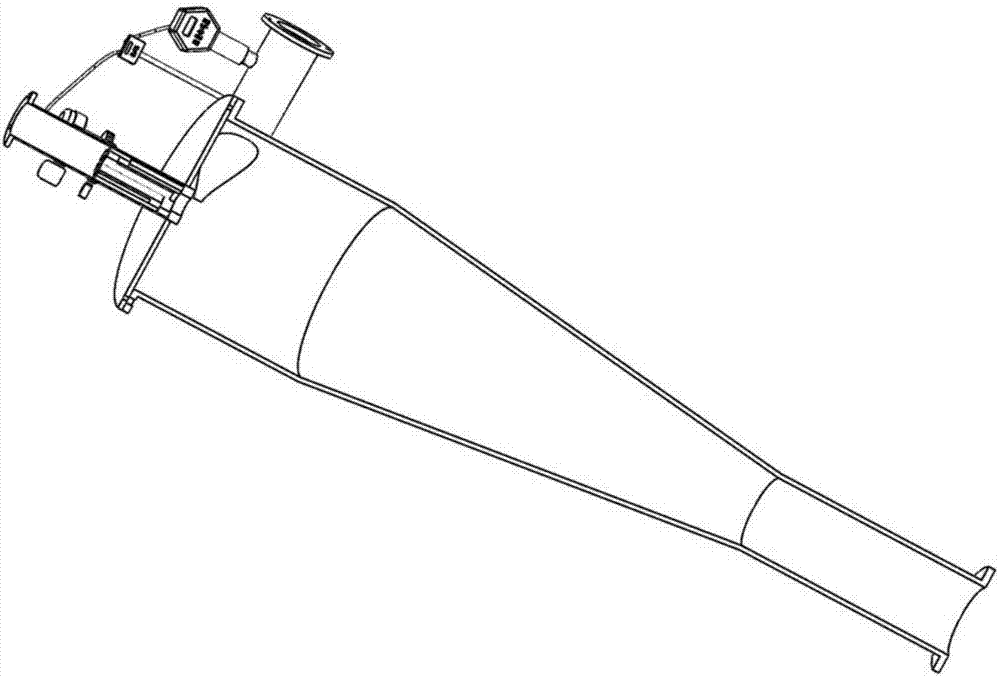

Overflow pipe automatic variable-diameter type cyclone separation device

ActiveCN106944268AEfficient running stateEasy to separateReversed direction vortexPressure senseEngineering

The invention provides an overflow pipe automatic variable-diameter type cyclone separation device mainly to solve the problem that since the structure of a cyclone separation device is fixed, the optimum separation ratio of the cyclone separation device can not be immediately adjusted along with the working condition. The overflow pipe automatic variable-diameter type cyclone separation device is characterized in that the cyclone separation device further comprises a diameter adjustment motor, a controller and a pressure sensing device; the pressure sensing device (4) is mounted into a device inlet pipe through threaded connection to monitor the pressure at an inlet and meanwhile synchronously transmits the measured pressure to the controller; the controller converts a pressure signal into the number of rotating laps of the diameter adjustment motor to conduct variable-diameter adjustment on a variable-diameter overflow pipe through a variable-diameter piece set; and the variable-diameter piece set is formed by common surrounding and staggering of six curved pieces, positioning is completed through an upper positioning pin, a lower positioning pin and an overflow pipe shell, and under the adjustment effect of a variable-diameter adjustment valve, all the curved pieces rotate and deviate according to a certain track to complete immediate diameter variation of the whole overflow pipe.

Owner:NORTHEAST GASOLINEEUM UNIV

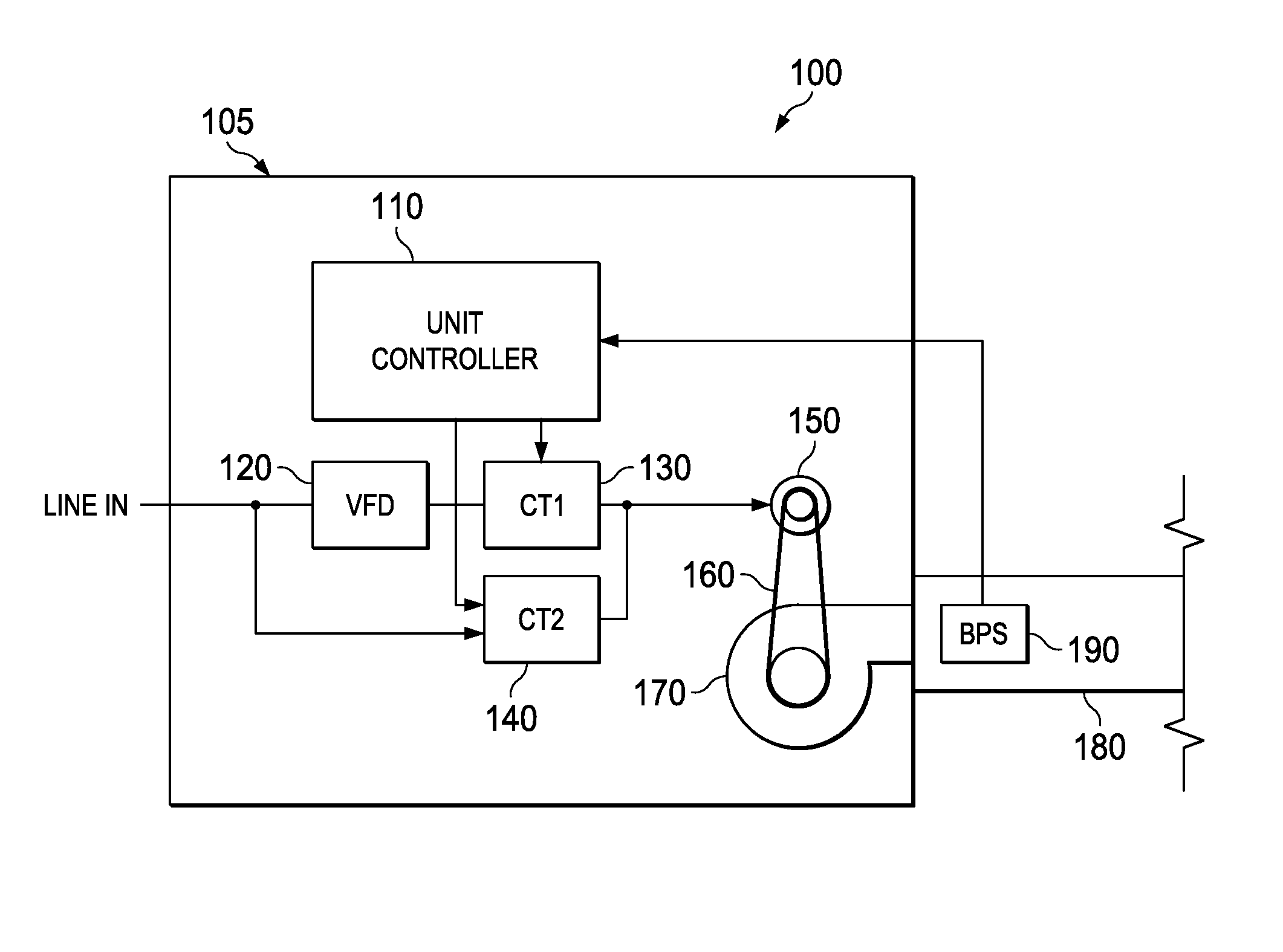

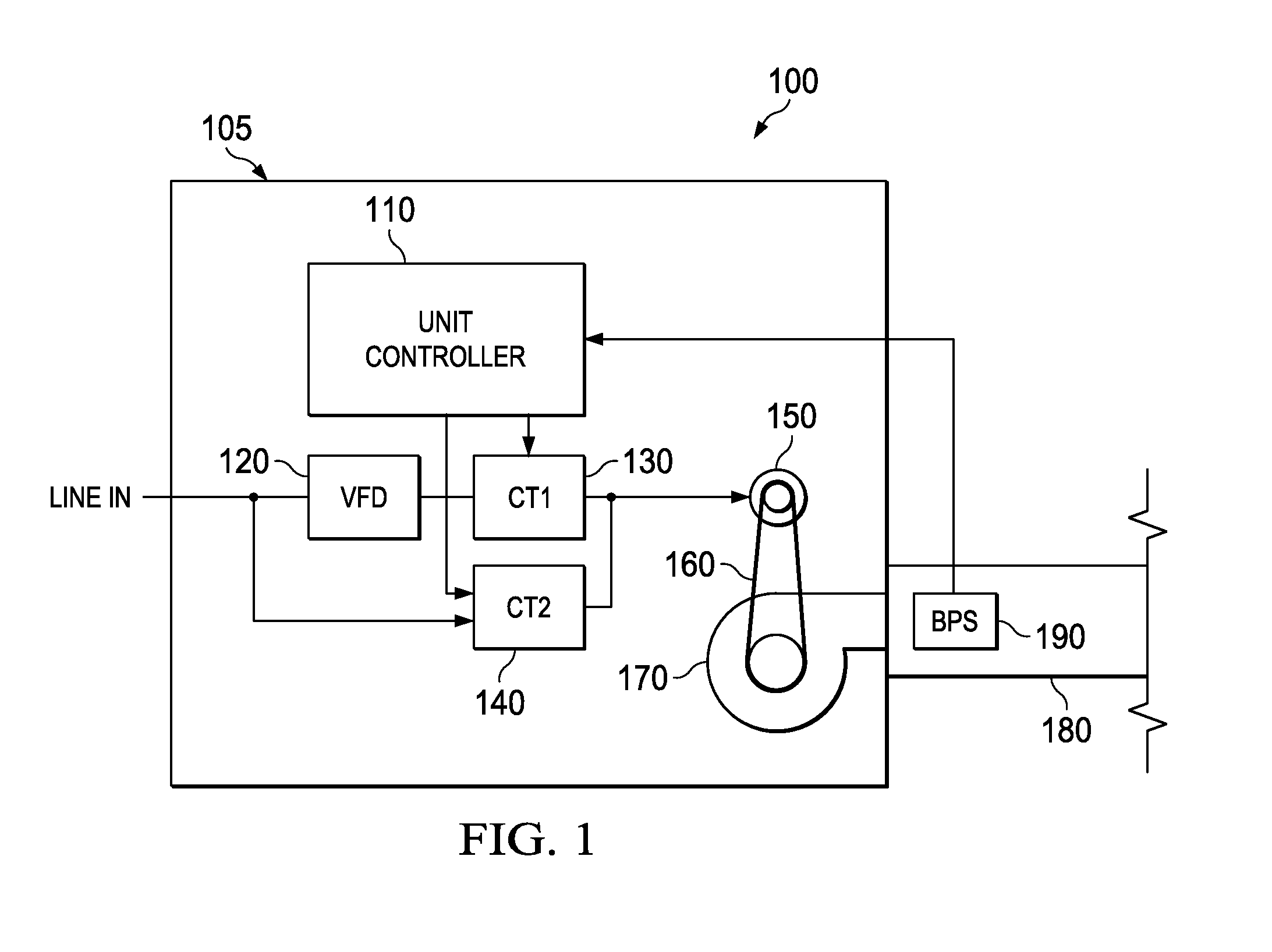

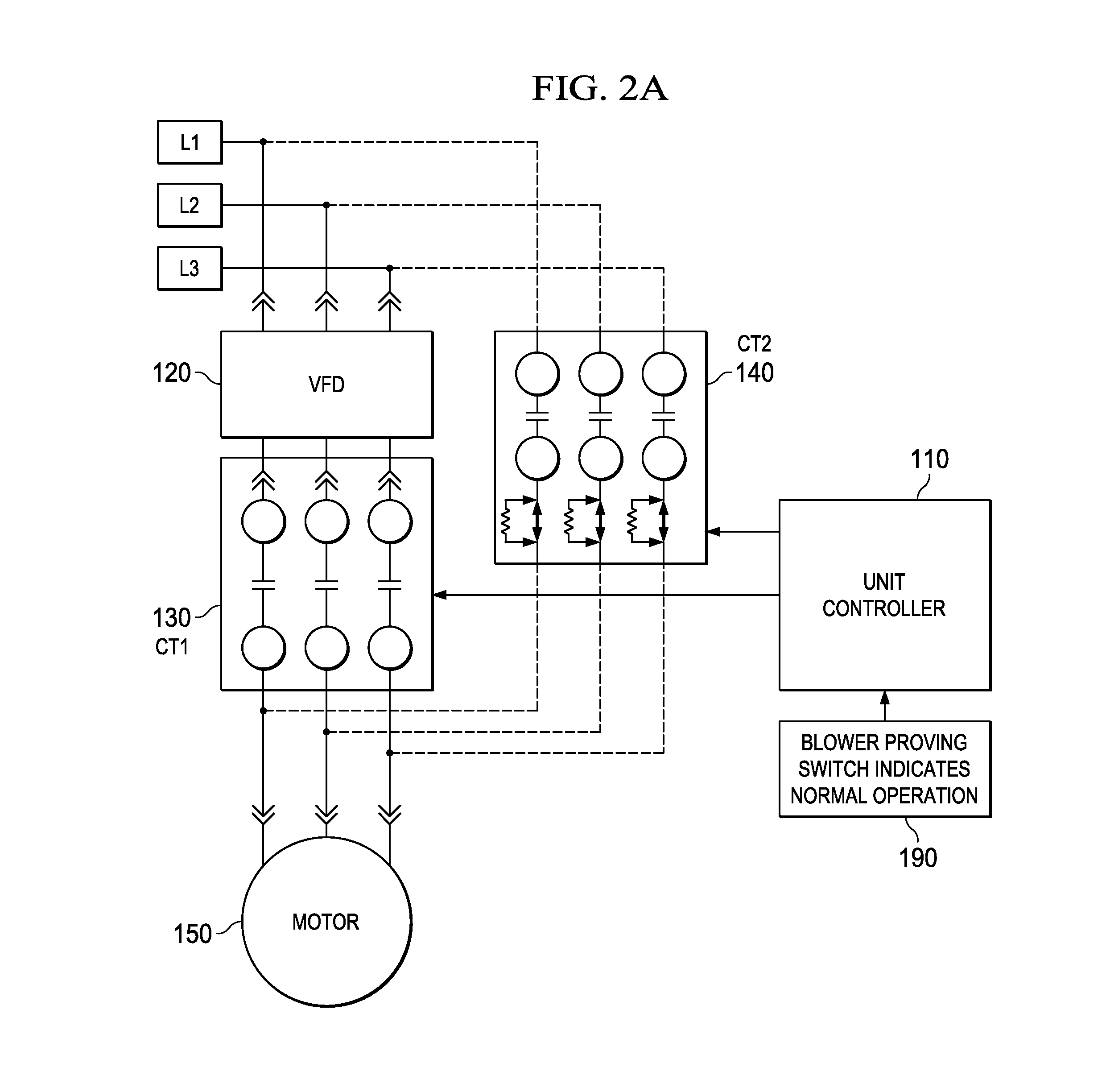

Automatic variable speed motor drive bypass

An HVAC system includes a blower motor and a variable speed motor drive. The variable speed motor drive is configured to receive line power and provide modulated power to the motor. The blower motor is configured to produce airflow in response to the modulated power. A unit controller is configured to bypass the variable speed motor drive to provide the line power directly to the blower motor in the event that a measured airflow is less than a predetermined value.

Owner:LENNOX IND

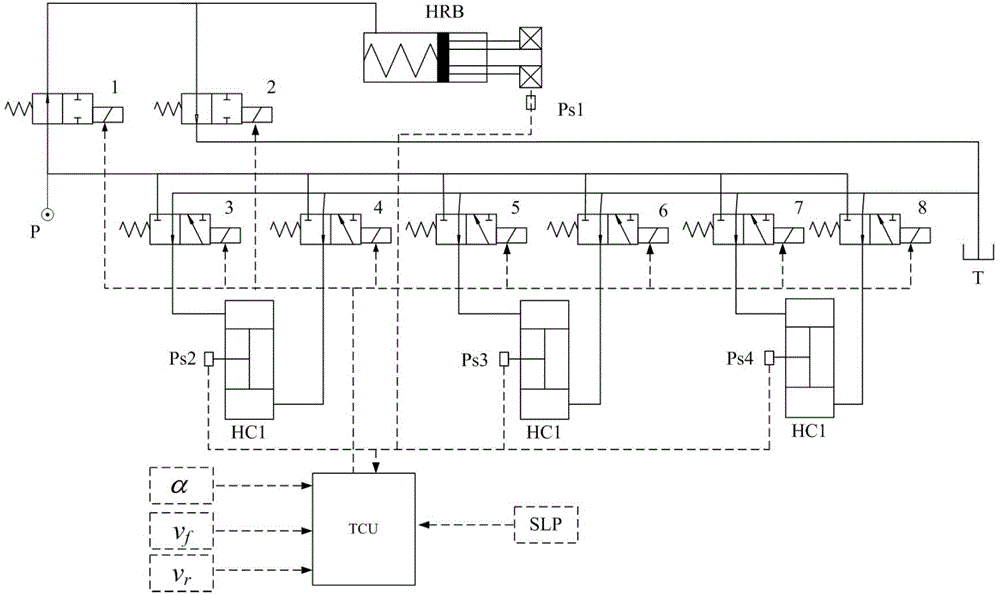

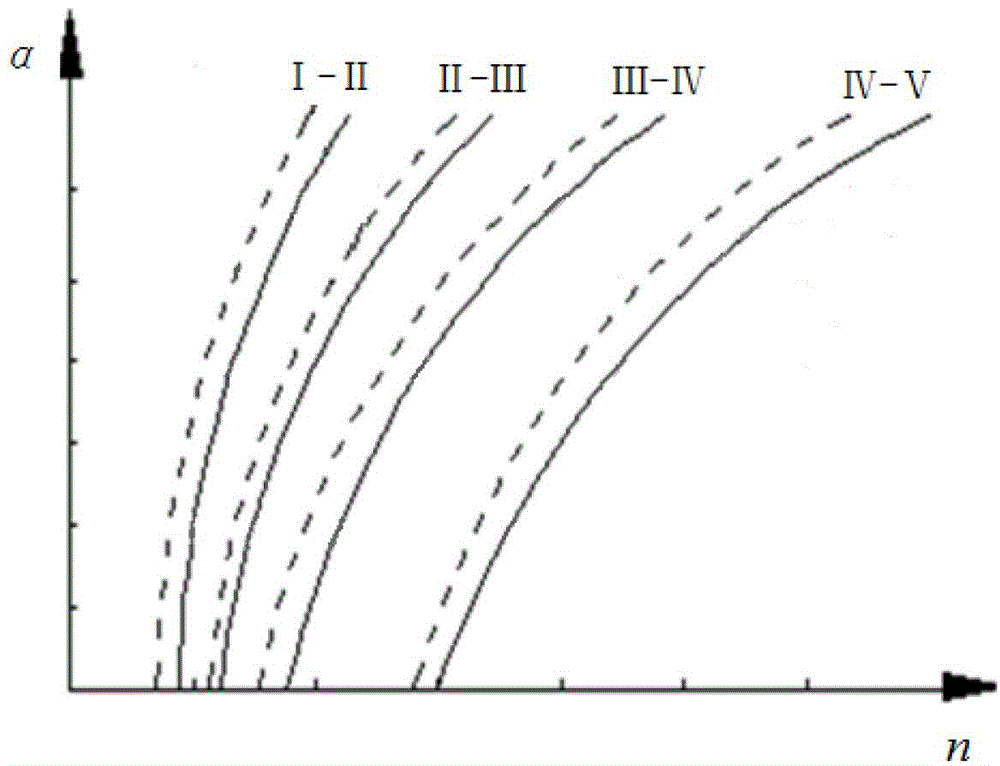

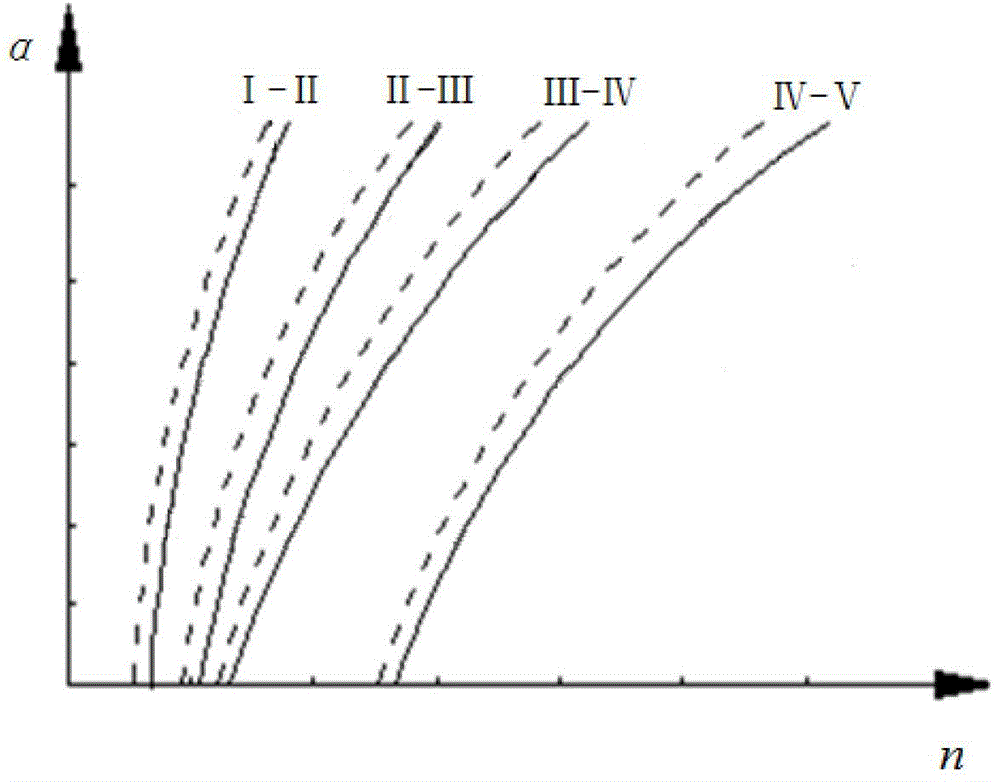

Gear-shifting schedule curve measuring method and corresponding gear-shifting control method for off-road vehicles

The invention relates to a gear-shifting schedule curve measuring method and a corresponding gear-shifting control method for off-road vehicles, and belongs to the technical field of automatic variable speed control of the off-road vehicles. According to the methods, a gear-shifting schedule curve equation of an AMT (automated mechanical transmission) of an off-road vehicle is calculated firstly; a corresponding gear-shifting schedule curve is drawn; the current practical vehicle speed, the slip ratio and the throttle opening degree are collected, and corresponding target gears are determined; control signals for electromagnetic valves of actuating mechanisms are output through an logical operation; therefore, the electromagnetic valves of the actuating mechanisms are enabled to perform corresponding actions, and the automatic gear shifting is achieved. The gear-shifting schedule curve measuring method and the corresponding gear-shifting control method can guarantee the tractive efficiency and the fuel oil economic efficiency of the AMT of the off-road vehicles, reduces the work intensity of a driver, and enables the vehicles to travel more smoothly; meanwhile the gear-shifting actuating mechanisms are improved, a gear selecting process is omitted, the gear-shifting time is reduced and the gear-shifting efficiency is improved due to the direct gear shifting; and the methods can be used for AMT of off-road engineering vehicles, agricultural vehicles and military motor vehicles.

Owner:HENAN UNIV OF SCI & TECH

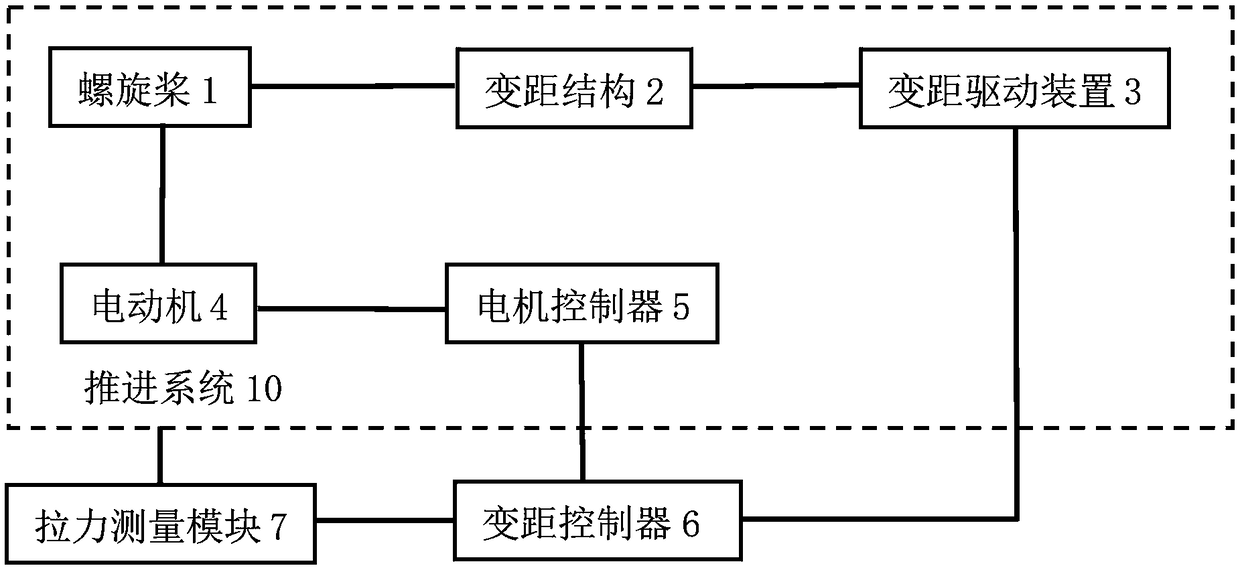

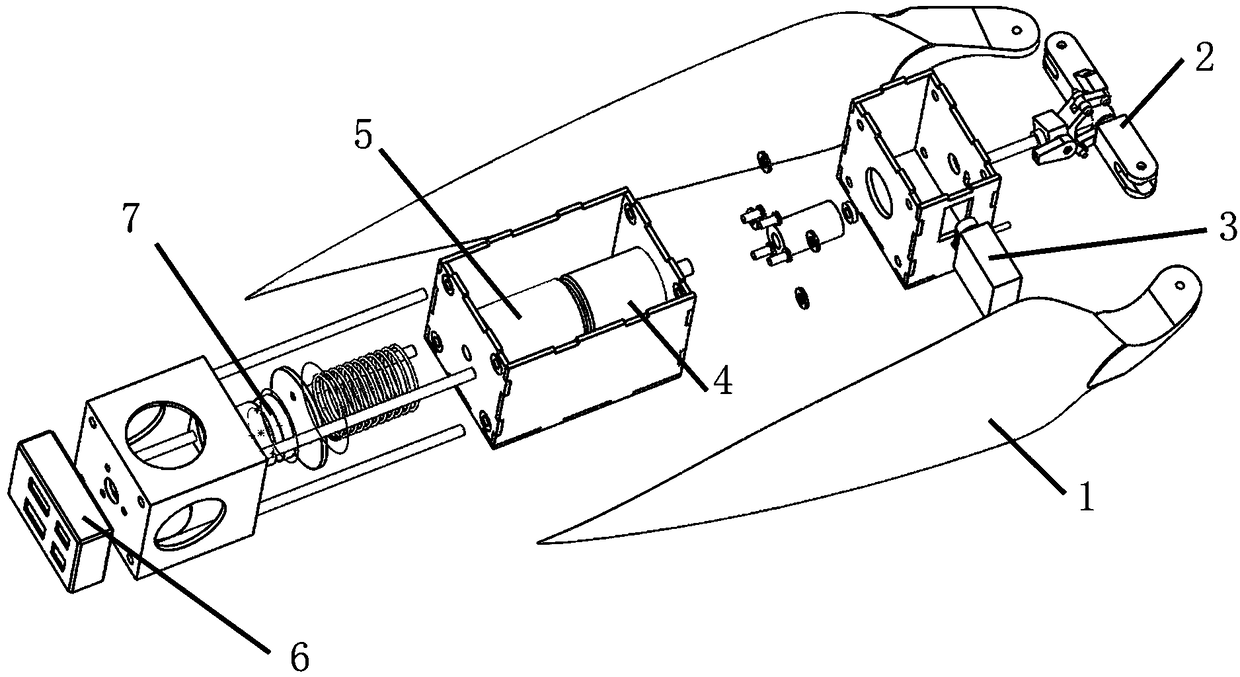

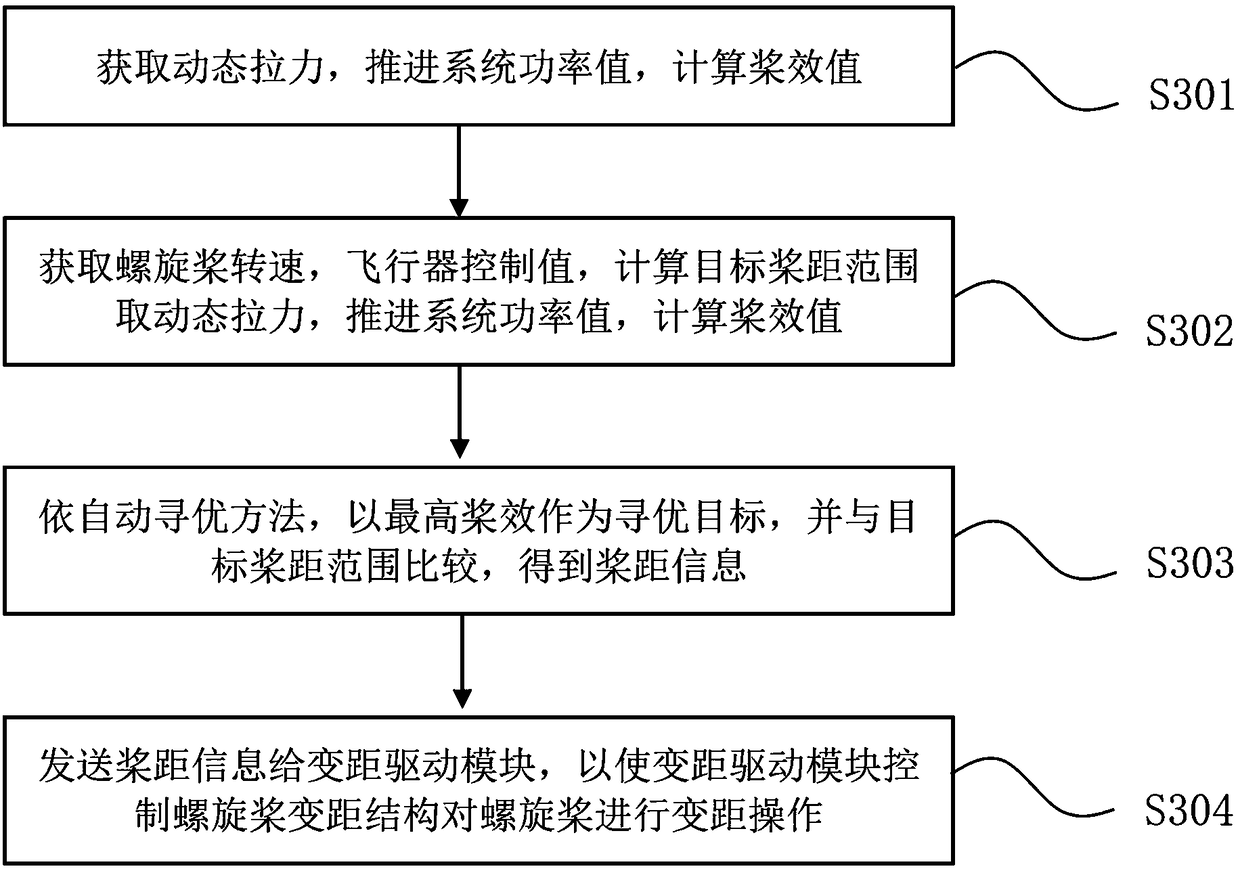

Automatic variable-pitch propeller device, control method thereof and aircraft

The invention discloses an automatic variable-pitch propeller device, a control method thereof and an aircraft. A variable-pitch driving device is connected with a propeller through a variable-pitch structure, and the pitch of the propeller is adjusted by operating the variable-pitch structure; a tension measuring module is connected with a propulsion system and is used for measuring the dynamic tension of the propulsion system; a variable pitch controller determines real-time propeller efficacy value information according to the dynamic tension and input power, determines a target pitch rangeaccording to the propeller rotating speed and airspeed information, and provides a pitch value in the target pitch range by using an automatic optimization method according to the propeller efficacydata, and the propeller performs variable pitch operation. The device can calculate the propeller efficacy value of the propulsion system in real time, automatically optimizes and matches the optimalpitch based on propeller efficacy, and improves the efficiency of the propulsion system of the aircraft.

Owner:陈俊胤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com