Automatic variable-speed motor transmission mechanism for electric tricycle and electric vehicle

A technology for electric tricycles and electric vehicles, which is applied in the directions of gear transmissions, transmissions, transmission parts, etc., can solve the problems of energy waste, motor power amplification, climbing and lack of speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

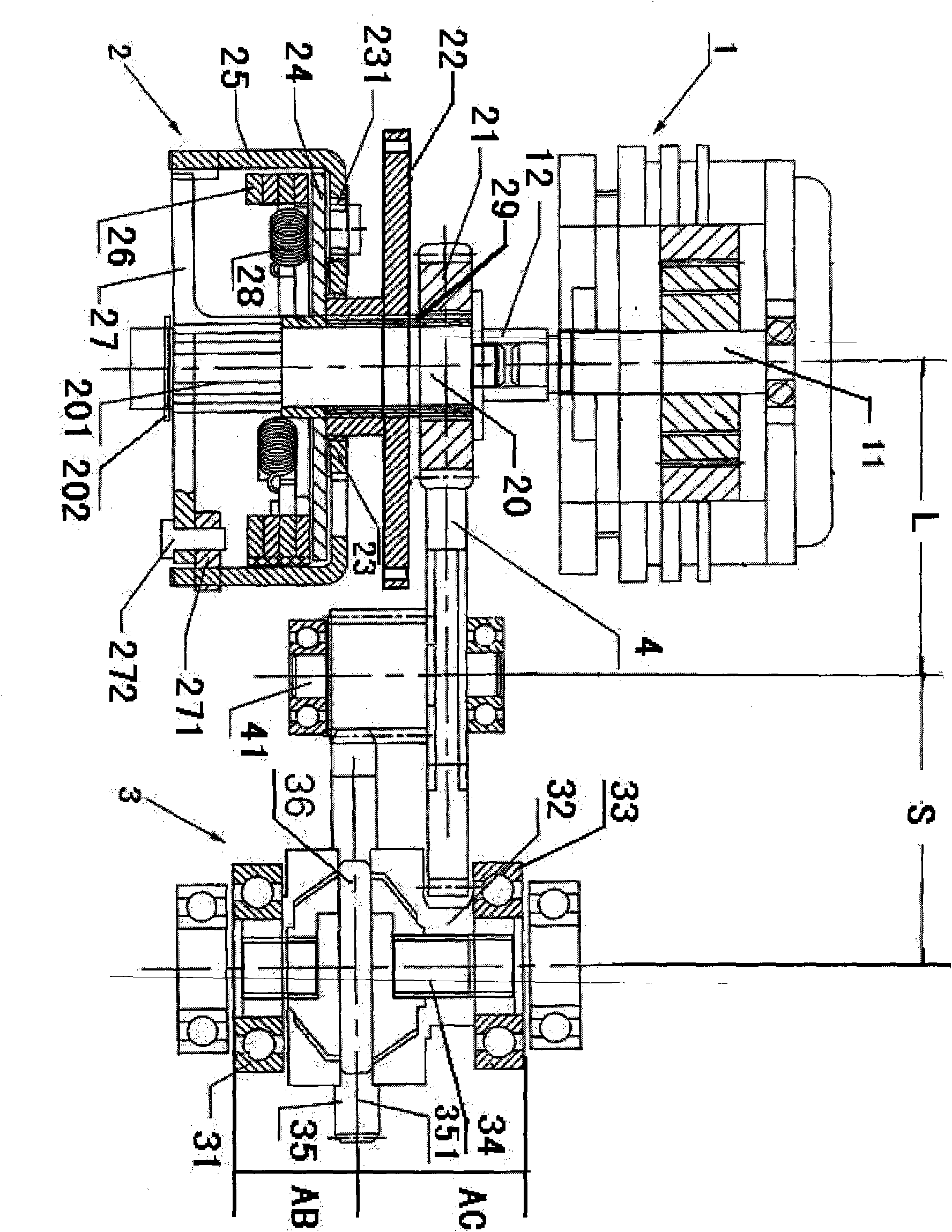

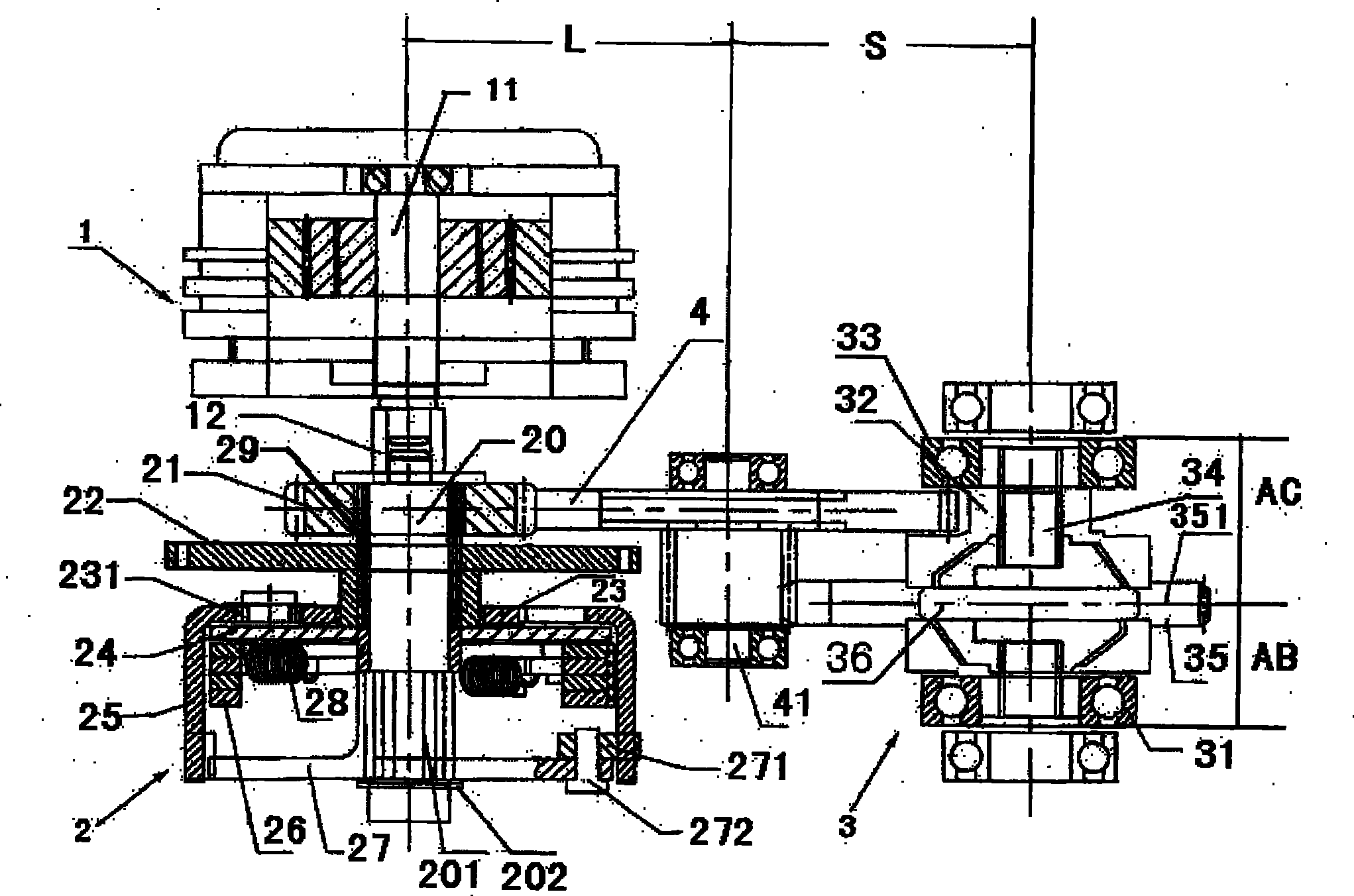

[0008] The invention discloses an automatic transmission motor transmission mechanism for an electric tricycle and an electric automobile, such as figure 1 As shown, there are a motor 1, an automatic transmission 2 and a differential system 3. The automatic transmission 2 is characterized in that the automatic transmission 2 includes a transmission shaft 20, a driving gear 21, a sun gear fixing plate 22, a driving disc 24, a cover 25 and a connecting plate 27. The motor shaft 11 of the motor 1 drives the transmission shaft 20. The other end of the transmission shaft spline 201 is equipped with a connecting plate 27, which is connected to the housing 25. A planetary gear 231 is installed in the upper part of the housing 25. The lower part is fixedly connected to the driving disc 24 with the snapping block 26. The snapping block 26 is connected with a tension spring 28. The driving disc 24 is sleeved outside the transmission shaft 20 through the spline 29 of the driving disc. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com