Continuous automatic production equipment of structural thermal-insulating composite wall boards for buildings

A technology for structural thermal insulation and composite wallboard, applied in the direction of layered products, lamination, lamination systems, etc., can solve the problems of low production efficiency, high production cost, low degree of automation, etc., and achieve high production efficiency and low production cost. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

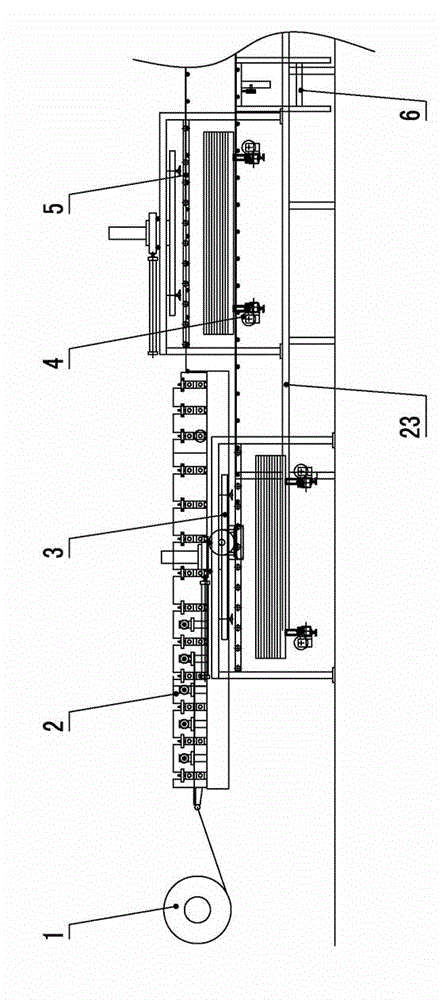

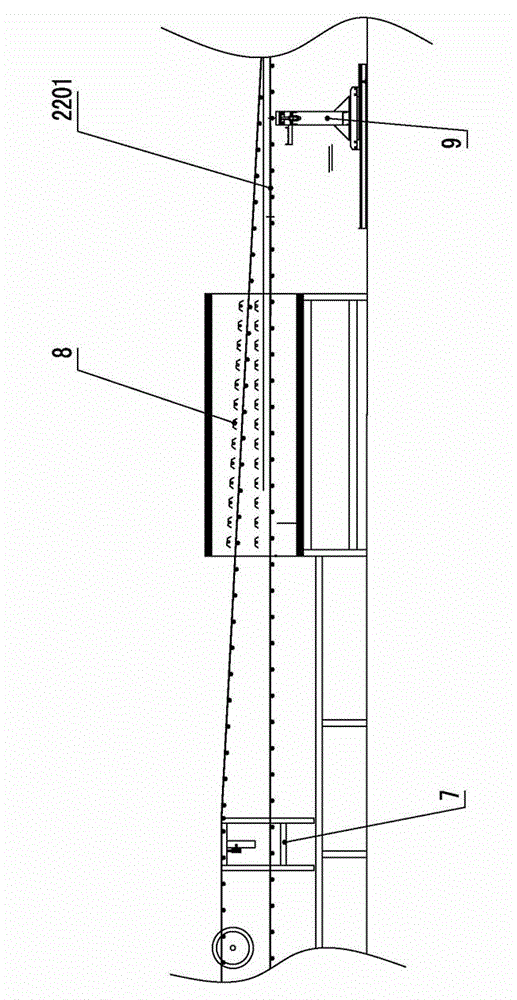

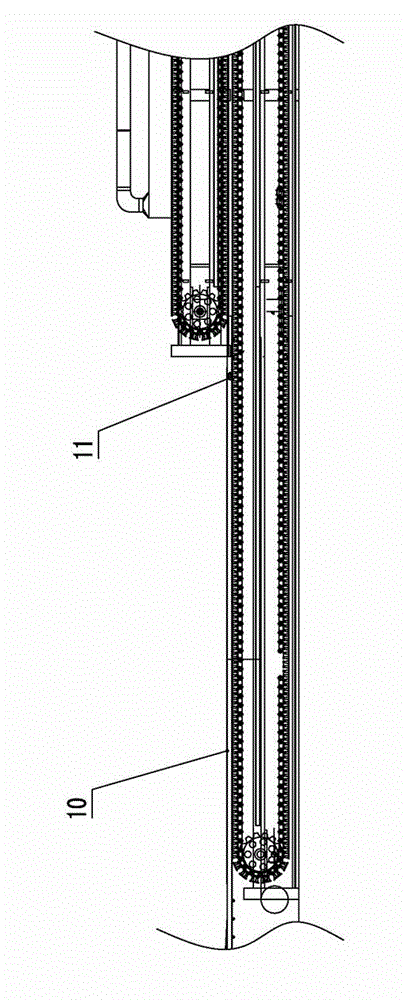

[0032] Such as Figure 1 to Figure 12 As shown, side steel strip unwinding machine 1; upper color steel coil unwinding machine 101; lower color steel coil unwinding machine 102; side tenon and groove side stop forming machine 2; left tenon and groove side stop member forming machine 201; Right mortise and groove side member forming machine 202; lower crane type vacuum suction cup transfer machine 3; automatic frequency conversion speed regulation conveyor line 4; upper automatic frequency conversion speed regulation conveyor line 401; lower automatic frequency conversion speed regulation conveyor line 402; upper layer crane type Vacuum suction cup transfer machine 5; lower plate automatic sticker machine 6; upper plate automatic sticker machine 7; infrared preheating device 8; 12; hot air circulation pipeline 13; automatic tracking cutting mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com