Hydraulic device

A water conservancy and long-cavity technology, applied in hoisting devices, portable lifting devices, etc., can solve problems such as troublesome users, resistance encountered in retracting well ropes, and low degree of automation, so as to improve stability and slide stability , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

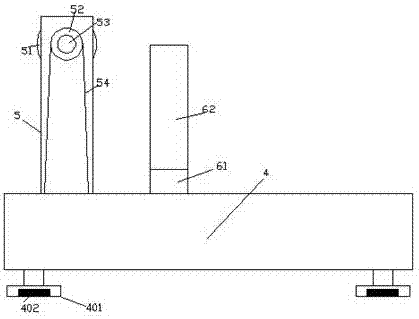

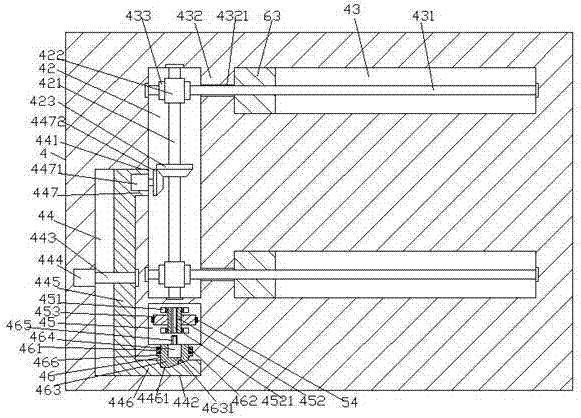

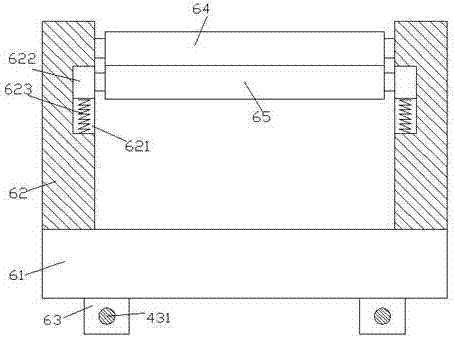

[0022] Such as Figure 1-Figure 5 As shown, a water conservancy device of the present invention includes a base 4 and a rope winding frame 5 fixed on the top left side of the base 4, and the inside of the left side of the base 4 is provided with a first long cavity extending from front to back 42, the abutment 4 on the right side of the first long cavity 42 is provided with guide grooves 43 that correspond up and down and extend left and right, and the left tail of each guide groove 43 is connected with the first long cavity Plates 432 are arranged between the right sides of 42, each of the plates 432 is provided with a through hole 4321, and each of the through holes 4321 is equipped with a first extending to the left and right sides. Screw rod 431, the left side extension tail of the first screw rod 431 extends into the first long cavity 42 and is connected with the left inner wall of the first long cavity 42 in a rotational fit, the first screw rod 431 The extended tail on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com