Gas pipeline welding device for integrated stove

A gas pipeline and welding device technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of poor sealing of gas pipe welding, risk, gas leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

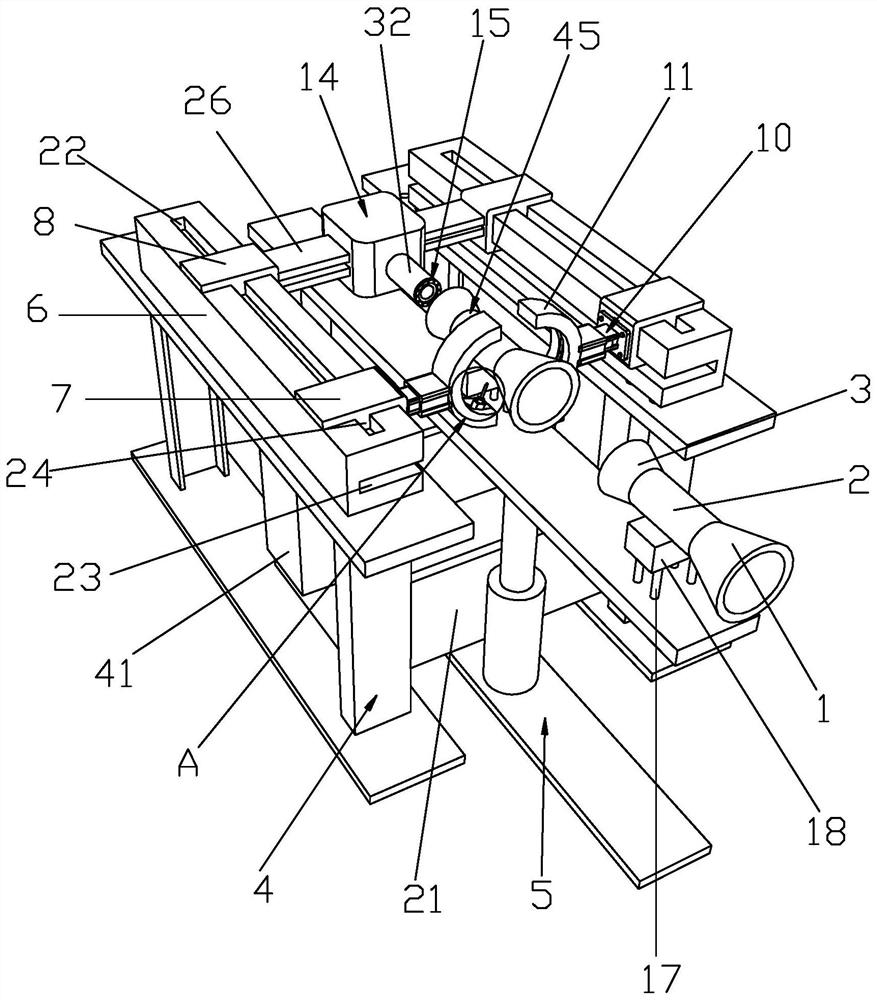

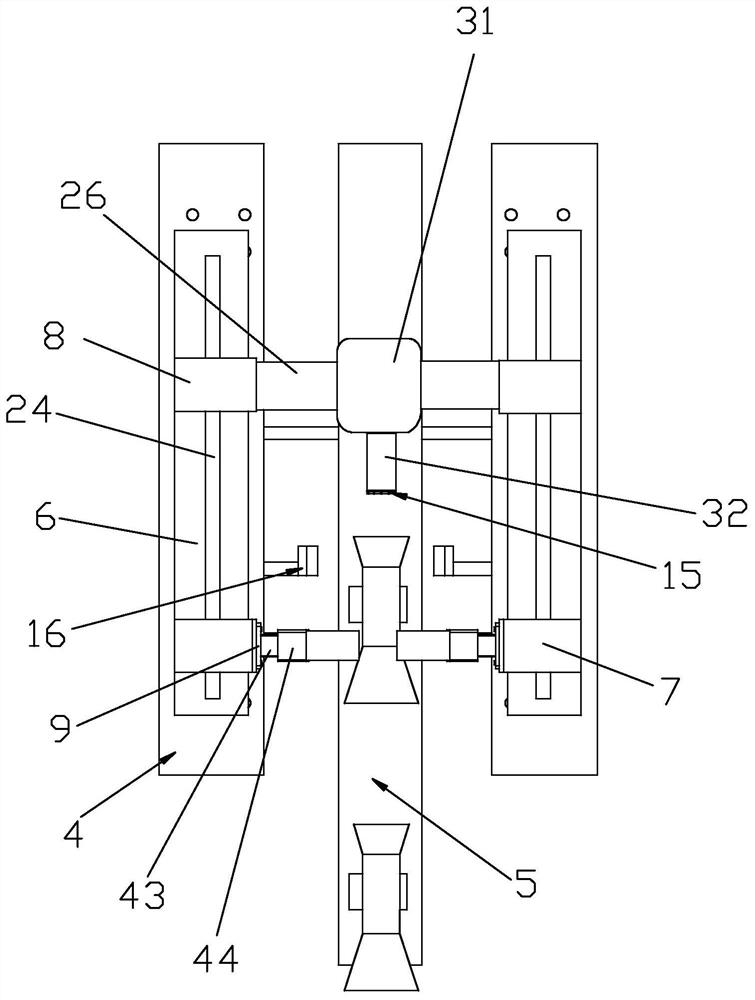

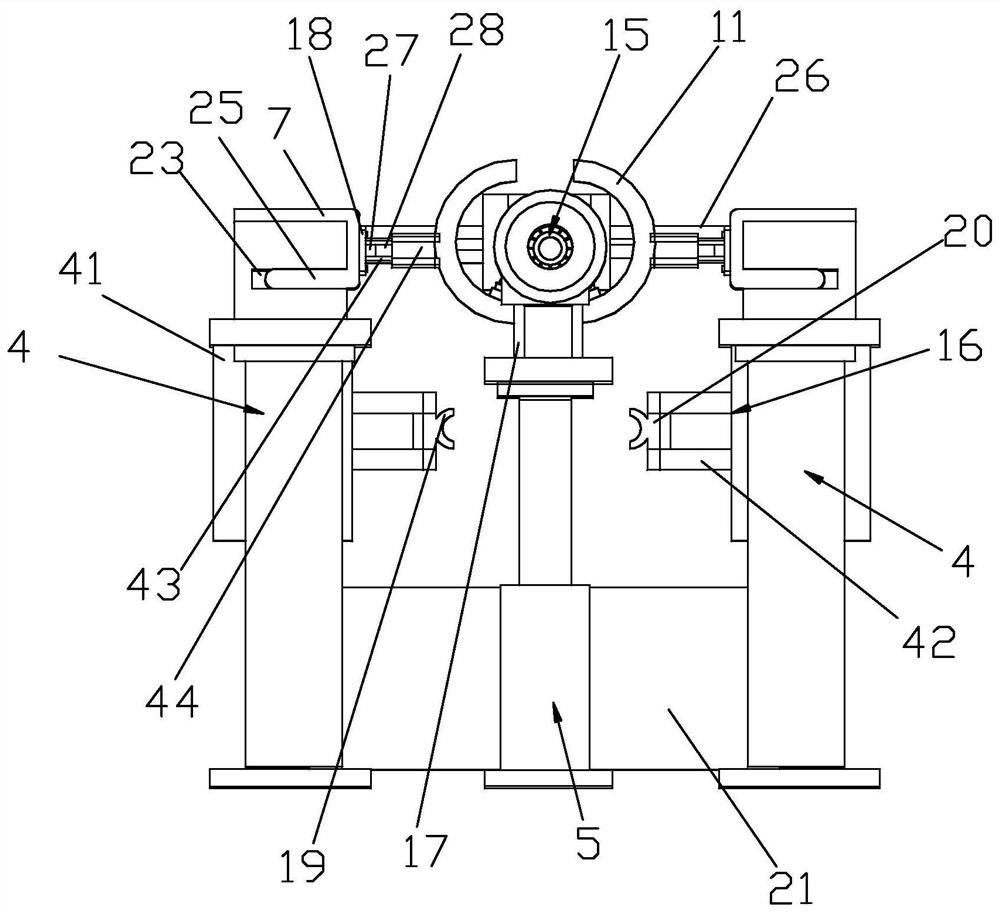

[0032] The specific embodiment of the present invention: the gas pipe 45 is placed on the fixed block 18, the first sliding block 7 and the second sliding block 8 are opened, the first sliding block 7 slides to the joint of the mixing tube 2 and the diffuser tube 3, and the connection The mechanism 10 is started, so that the position of the welding mechanism 13 is located at the splicing place. The second sliding block 8 slides at the same time, driving the rotation mechanism 14 and the fixed mechanism 15 to move, the fixed mechanism 15 is plugged with the mixing tube 2, the rotation mechanism 14 rotates, and the welding mechanism 13 performs welding at the same time, so that the pipes are evenly welded. After the welding is completed, rotate The mechanism 14 stops rotating, and the first sliding block 7 slides to the joint of the mixing tube 2 and the suction shrink tube 1, and the above operation is performed, and the rotating mechanism 14 continues to rotate. After welding i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com