Patents

Literature

47results about How to "Avoid missing solder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

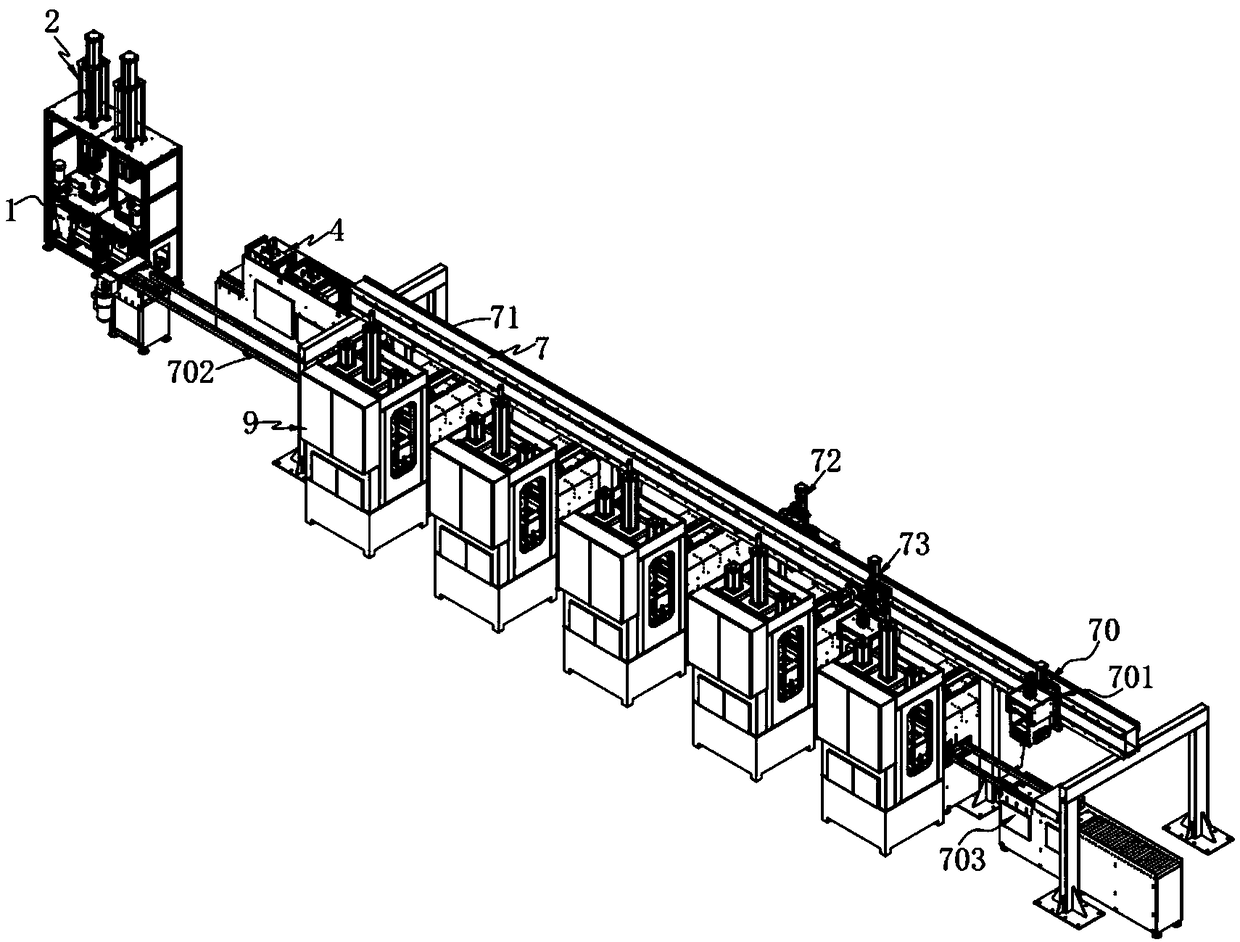

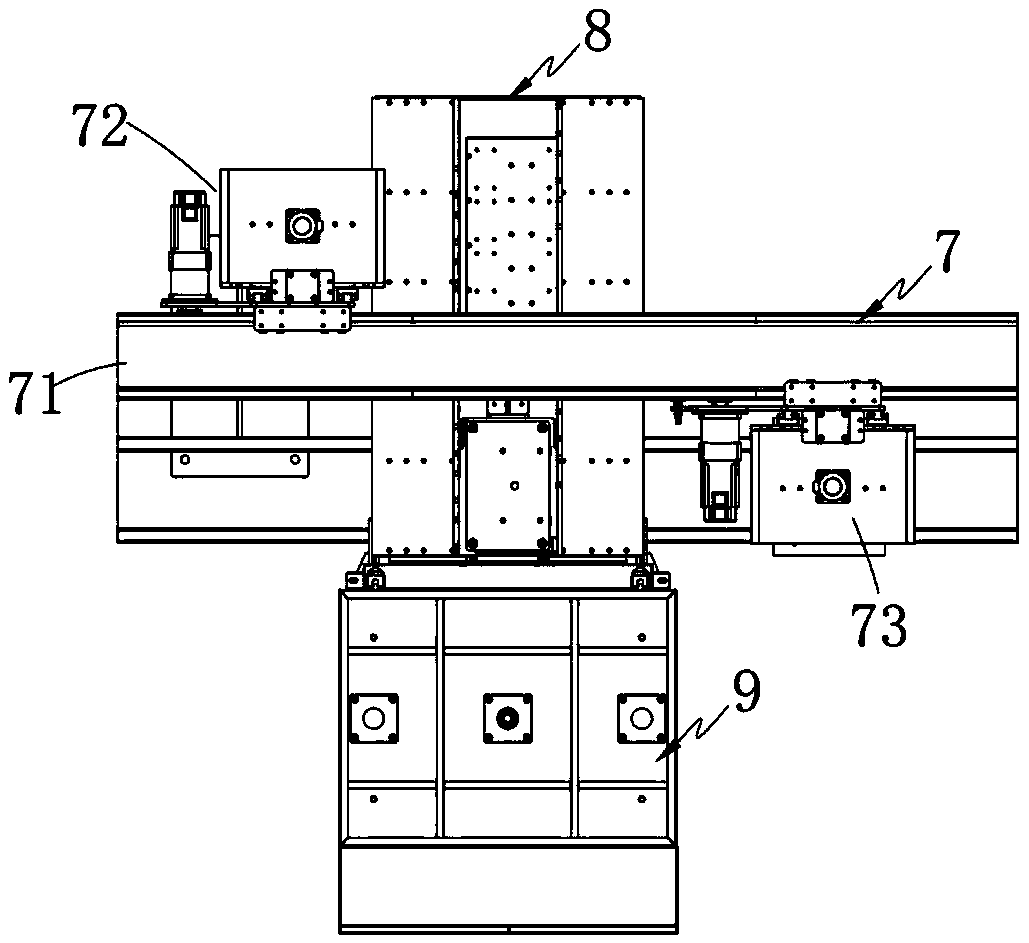

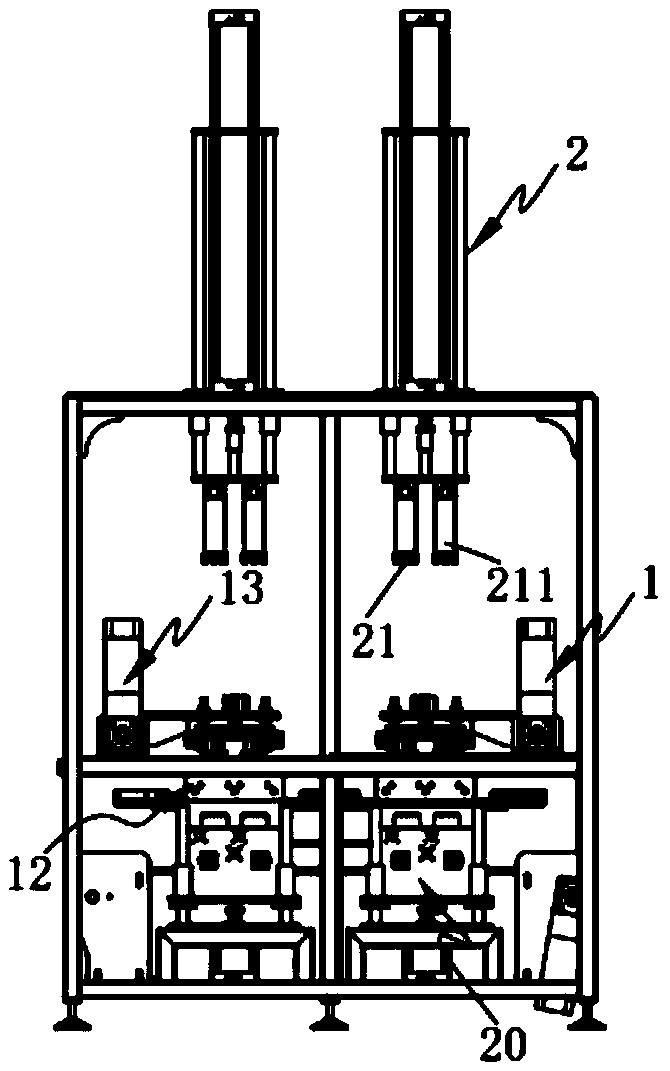

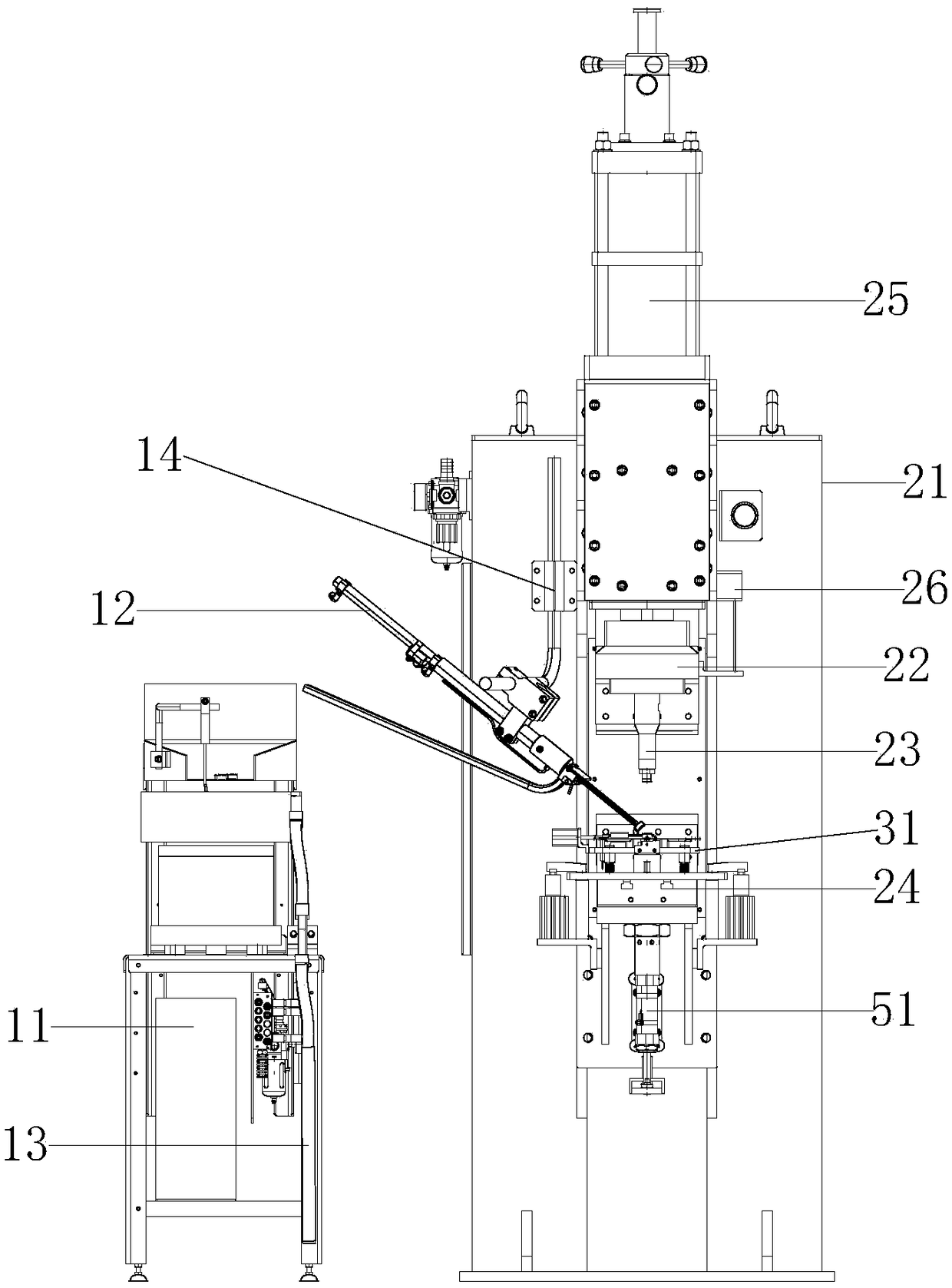

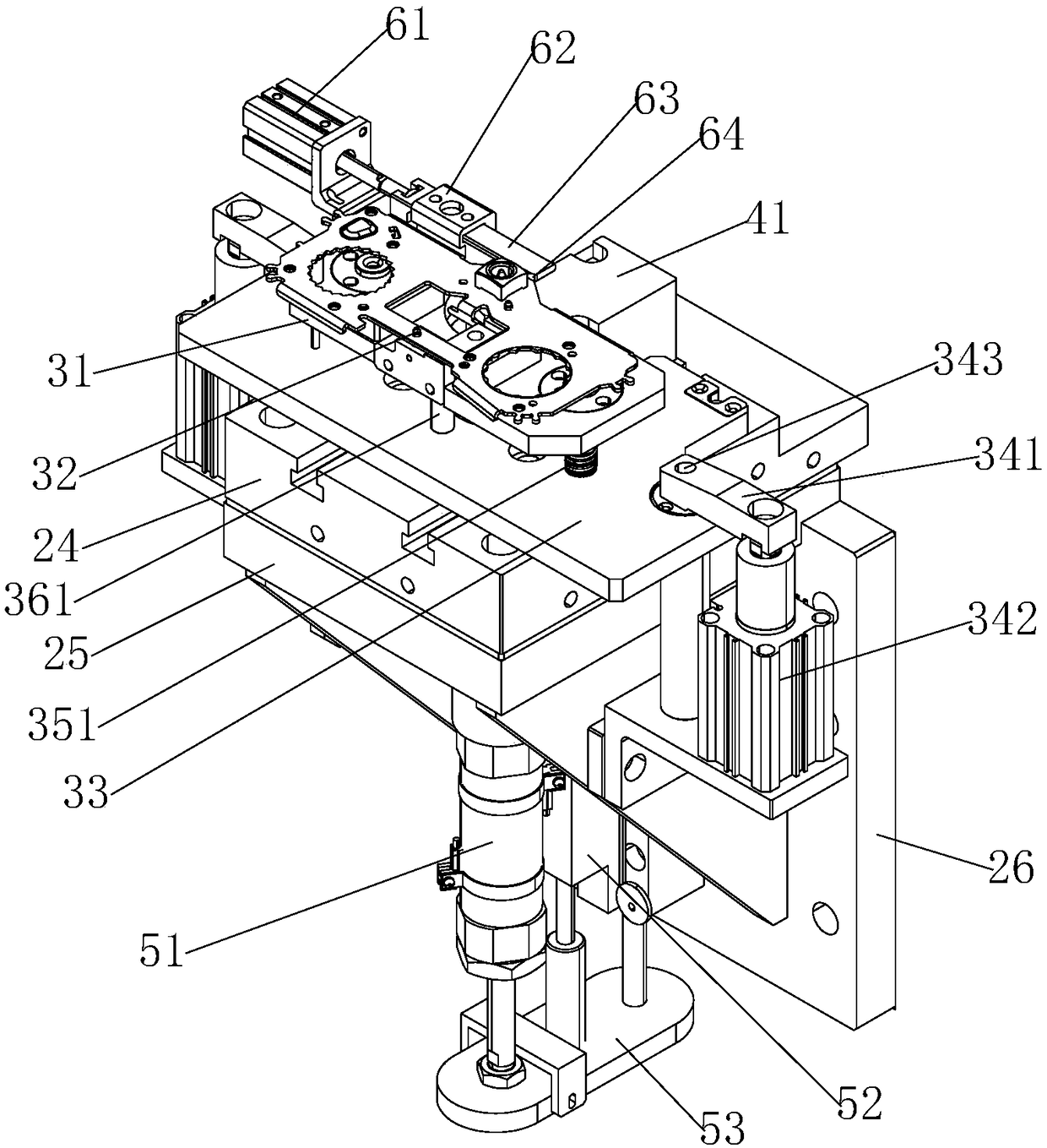

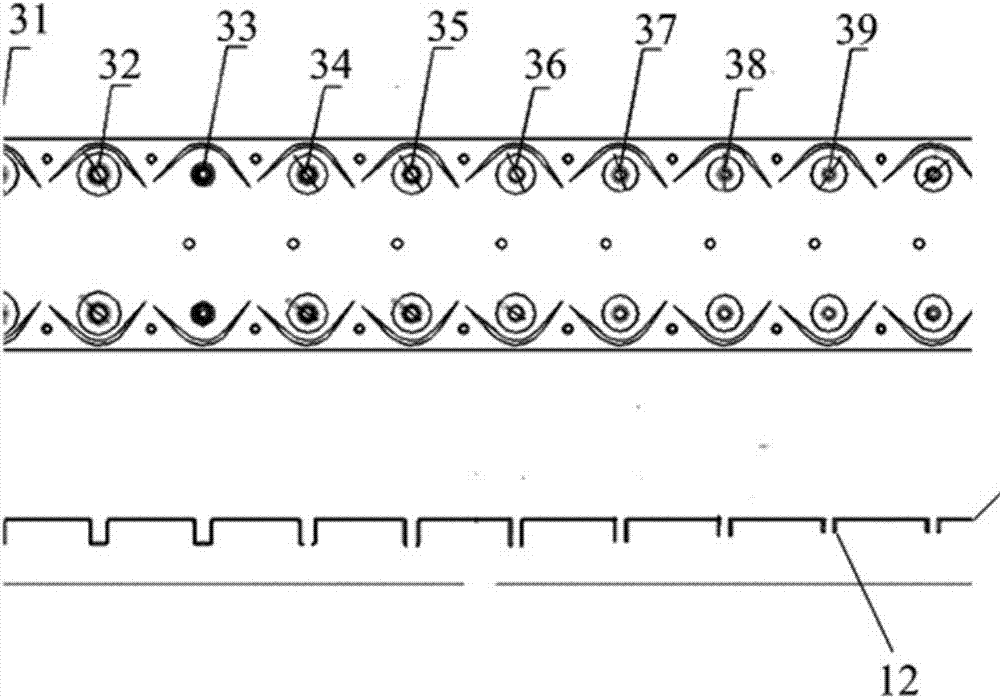

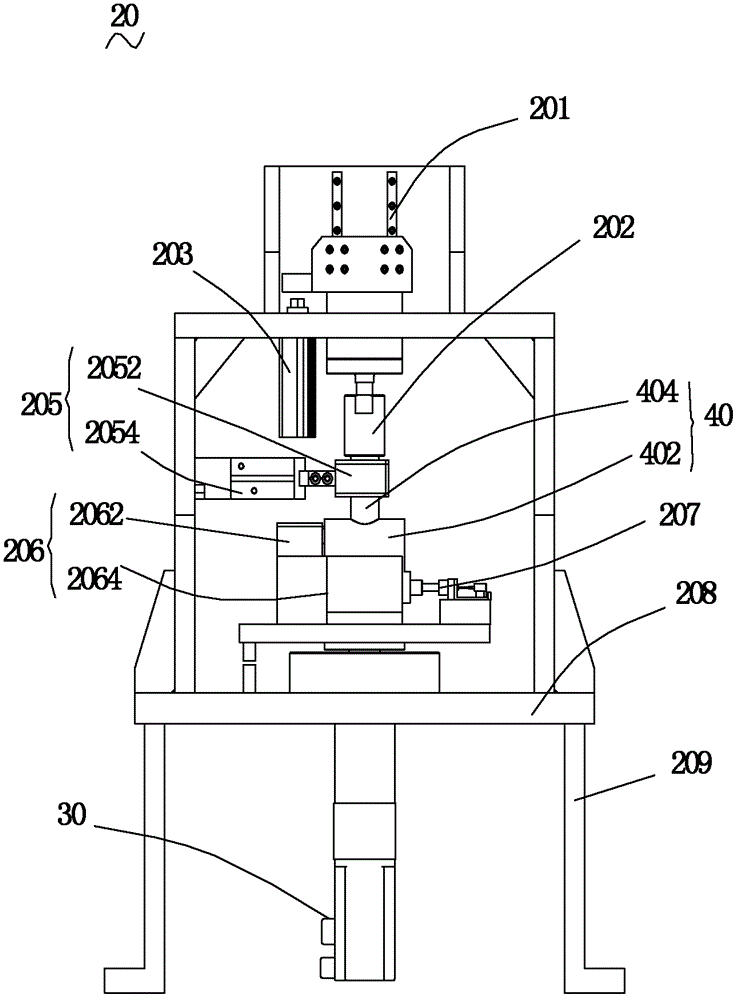

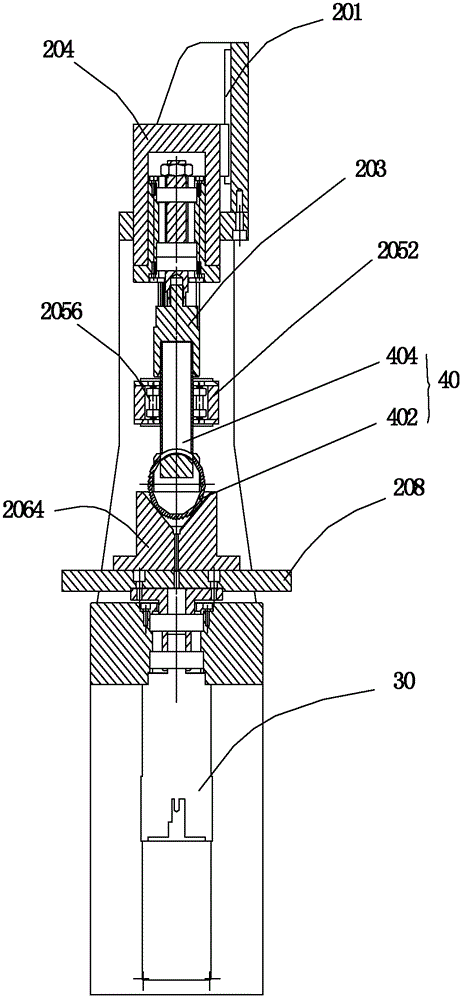

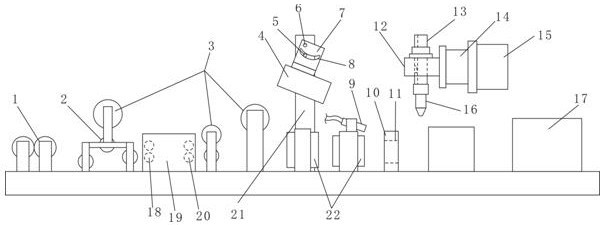

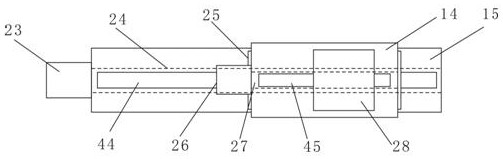

Automatic processing production line and production process of lead-acid batteries

ActiveCN108808126ASolve the technical problems of fully automatic processingLabor savingFinal product manufactureLead-acid accumulators constructionProduction lineBiochemical engineering

The invention provides an automatic processing production line and a production process of lead-acid batteries. On the automatic processing production line, electrode groups are automatically cased through a clamping device and a casing device in cooperation, inverted plastic battery cases loaded with the electrode groups are automatically conveyed through a square tray, cutting brushing and fluximpregnation are completed sequentially during the conveying process, and finally, a horizontal grabbing conveying device is used for realizing automatic input and output during a battery cast-weldding process, and automatic production of multiple cast-welding devices connected is realized, thereby realizing fully automatic processing of battery cast-welding and pre-cast-welding processing. The automatic processing production process of the lead-acid batteries has the beneficial effects that the automatic casing of the battery electrode groups is realized by an electrode group clamping procedure, an electrode group lugging procedure and a casing procedure, the automatic output of the plastic battery cases and the recycling of the square tray are realized by an output procedure, and the fully automatic processing in battery cast-welding and pre-cast-welding processing is realized.

Owner:长兴玖佳机械股份有限公司

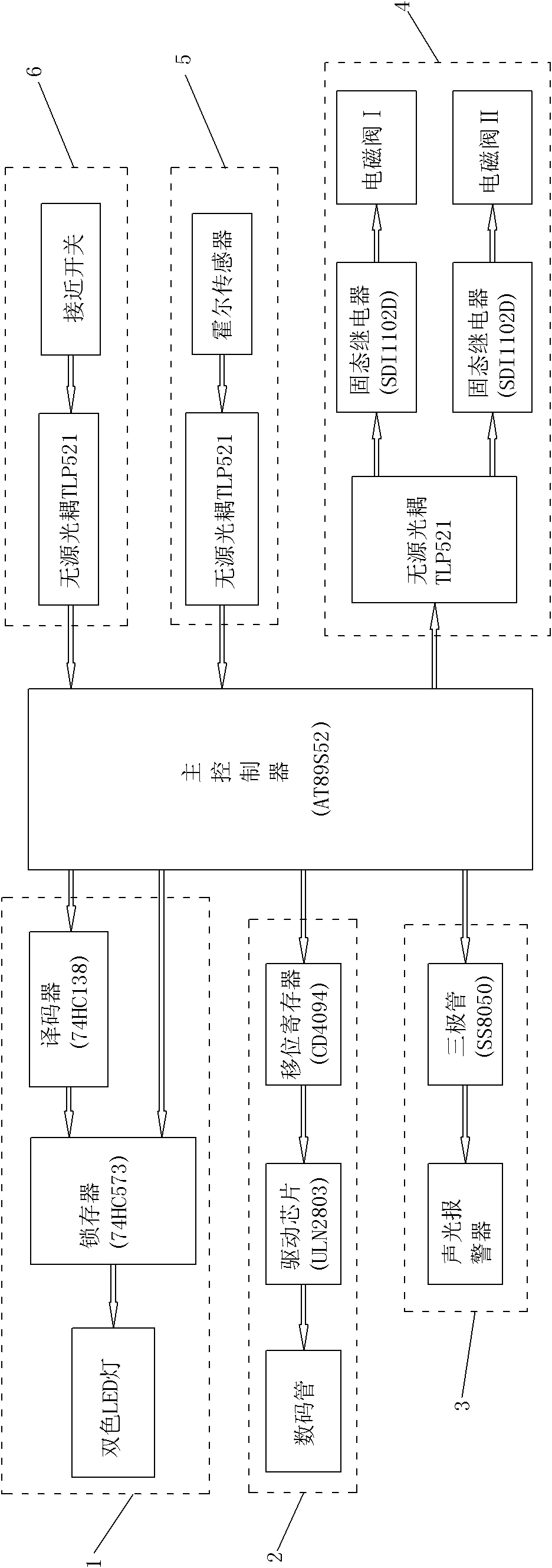

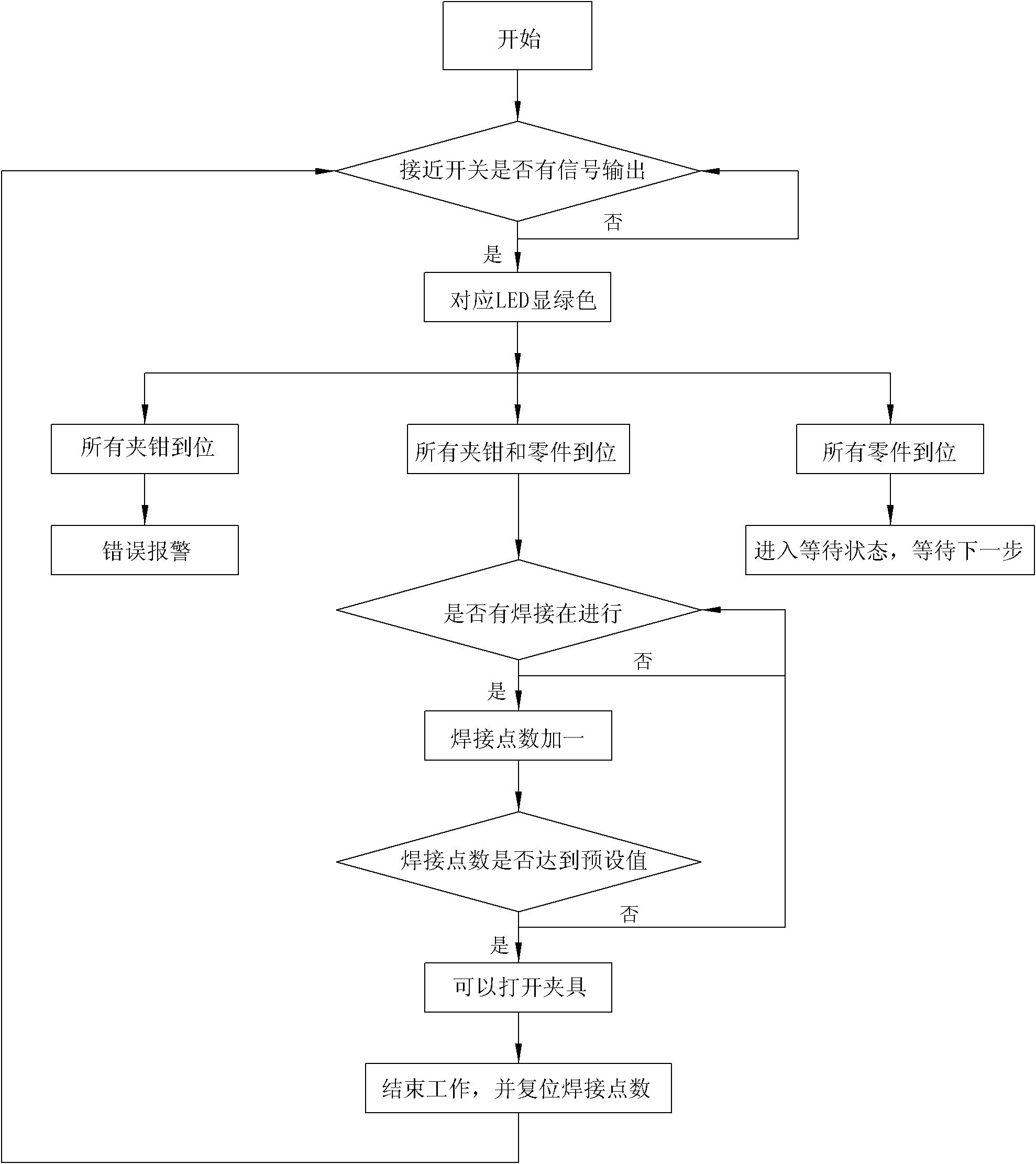

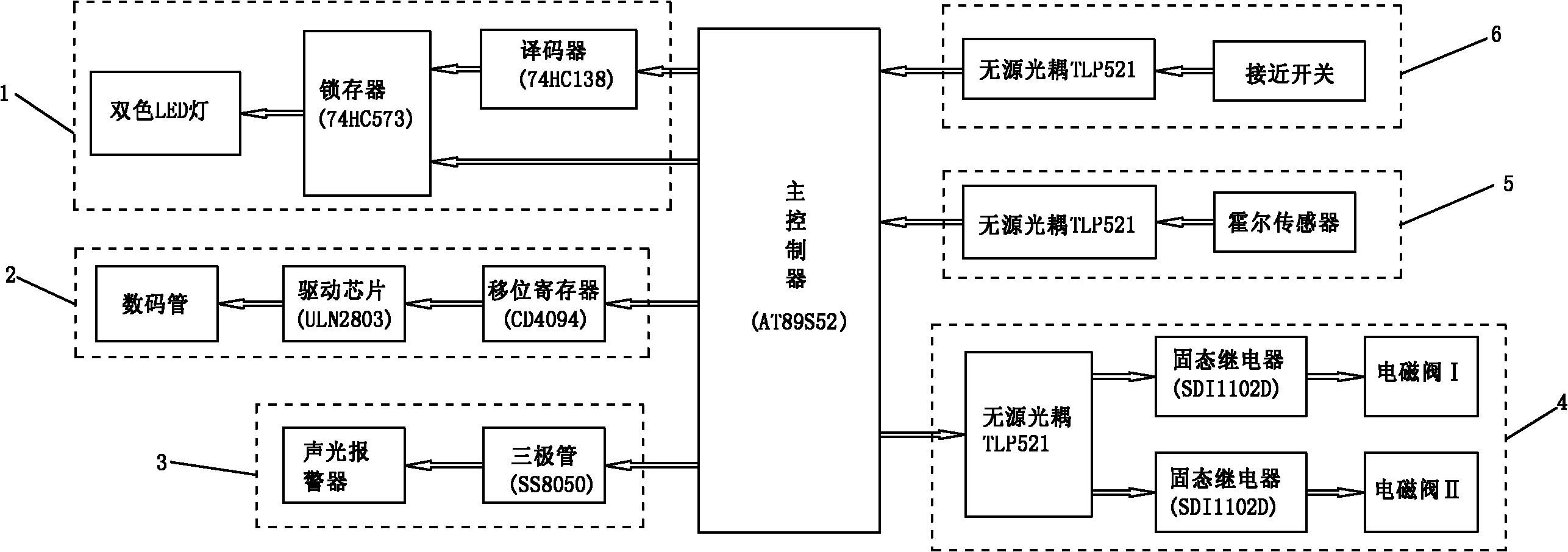

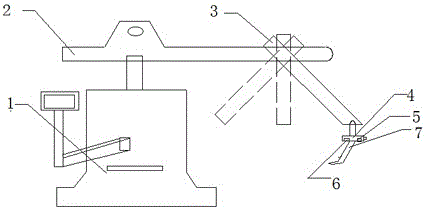

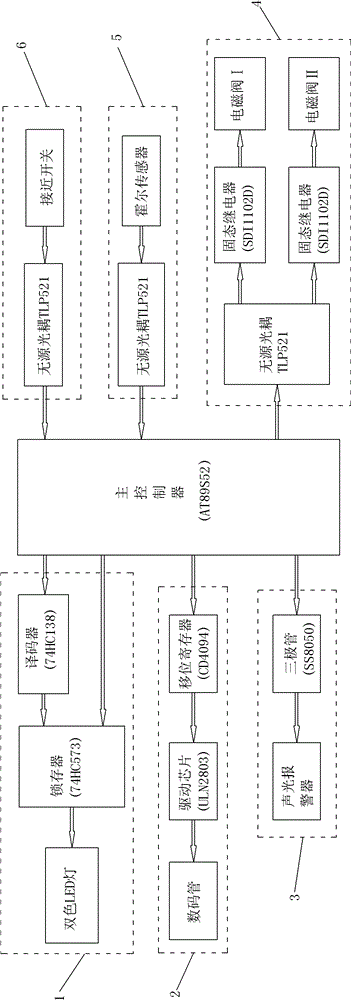

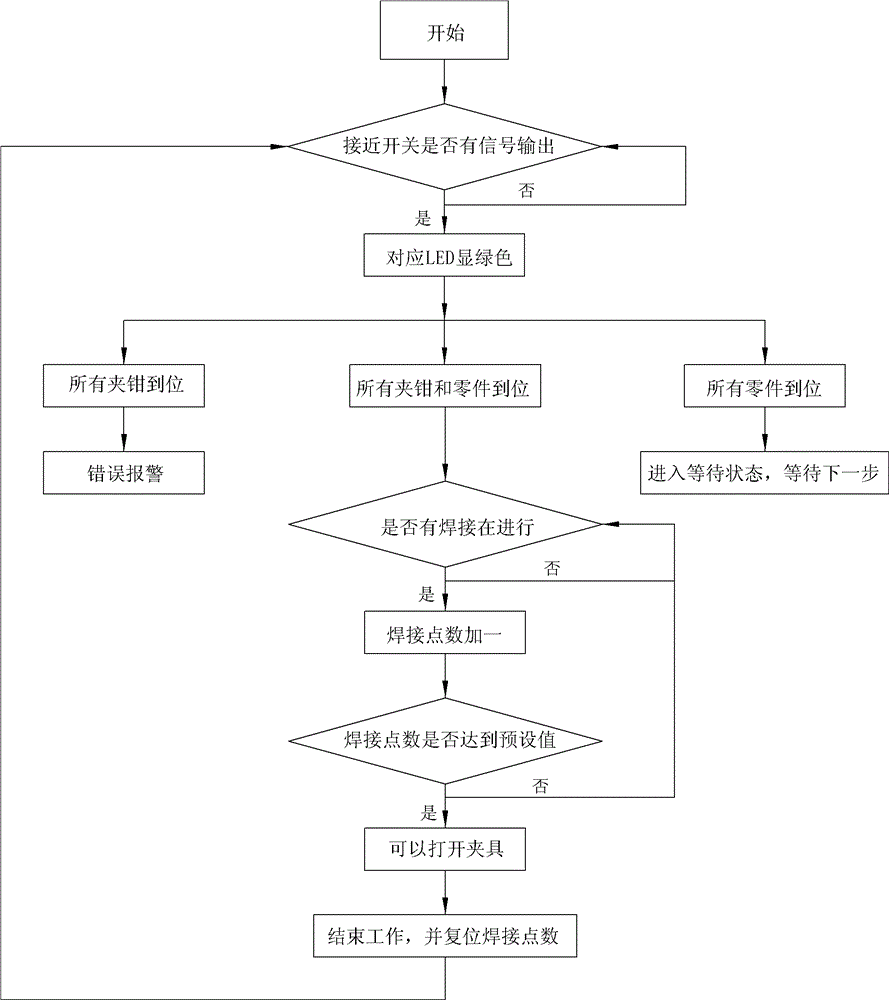

Welding online monitoring system

InactiveCN102430883AAchieve positioningImplementation statusWelding/cutting auxillary devicesAuxillary welding devicesMonitoring systemManufacturing line

The welding online monitoring system of the invention relates to a welding monitoring system. The welding online monitoring system comprises a main controller and a positioning detecting module, a welding gun magnetism detecting module, an alarming module, a fixture controlling module, a panel LED module and a digitron display module respectively connected with the main controller. The positioning detecting module can position precisely, the positioning information can be displayed by the panel LED module, if the positioning is not accurate, the alarming module will alarm, number of the welding points can be detected by the welding gun magnetism detecting module, and the number and the process state can be displayed by the digitron display module. Thereof, the invention can realize precise positioning and state indicating of parts placed on the fixture of the welding production line to prevent missed welding and mistaken welding during the welding process. The fixture controlling module can control automatic opening or closing of the welding fixture before and after the welding to improve the automatic degree of the welding production line and to relieve the working intensity of workers at the production line.

Owner:LIUZHOU GAOHUA MACHINE

High-precision automatic robot welding device and working method thereof

ActiveCN104999202AImprove securityImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlAutomated control system

The invention discloses a high-precision automatic robot welding device, which comprises a fixing seat, a horizontal shaft, a first joint shaft, a second joint shaft, a first position sensor, a second position sensor, a welding gun and a control device, wherein the control device comprises a welding device, a sensor control module, an execution device, an alarming system and an automatic control system; the first position sensor and the second position sensor are arranged on the second joint shaft and are connected with the sensor control module; and the horizontal shaft, the first joint shaft and the second joint shaft form an arm of the robot. According to the high-precision automatic robot welding device, the first position sensor and the second position sensor are arranged on the arm of the robot, the position of a welding point is calculated via detection values of the two sensors, automatic calibration of the welding position is realized, accuracy of the welding gun position and the welding port position can be effectively ensured, accuracy of the welding position is greatly improved, and stability of the welding quality is ensured.

Owner:SUZHOU WST ROBOT AUTOMATION CO LTD

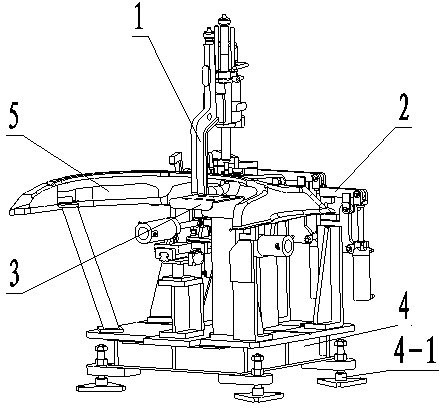

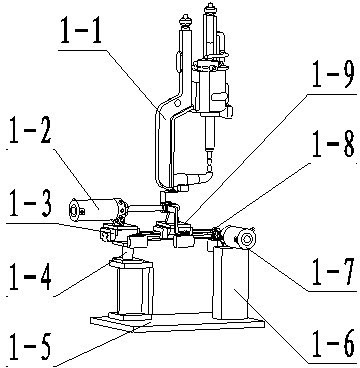

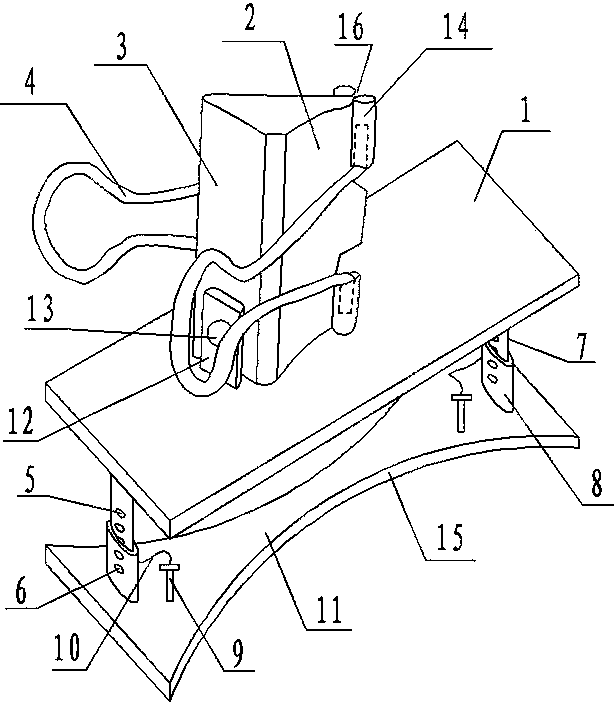

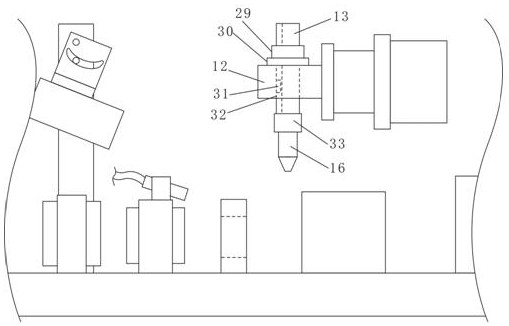

Automatic spot-welding equipment

ActiveCN102554529AShort time spentAvoid missing solderWelding/cutting auxillary devicesAuxillary welding devicesProgrammable logic controllerEngineering

Automatic spot-welding equipment is used for solving the problem of automated welding of sheet metal workpieces and comprises a welding execution mechanism, a workpiece positioning and clamping mechanism, a PLC (programmable logic controller) control system and a base. The welding execution mechanism comprises a welder, a translation cylinder, a rotary seat, a translation sliding rail, a sidesway cylinder and a bottom plate, wherein the translation cylinder is fixed onto the rotary seat through a translation cylinder support, the rotary seat is fixed onto the bottom plate and fixedly connected with one end of the translation sliding rail, the other end of the translation sliding rail is connected with a telescopic arm of the sidesway cylinder, the sidesway cylinder is fixed onto the bottom plate through a sidesway cylinder support, the bottom plate is fixedly mounted on a base, the welder is fixed onto a welder support fixedly connected with the telescopic arm of the translation cylinder, and the bottom of the welder support is provided with a sliding groove matched with the translation sliding rail. By the aid of the automatic spot-welding equipment, the labor intensity of operators can be greatly reduced, and working efficiency and workpiece welding quality can be remarkably improved.

Owner:长城汽车股份有限公司平湖分公司

Welding technology for rear automobile frame assembly shaped like Chinese character 'jing'

InactiveCN105252154AGood size consistencyImprove welding qualityVehicle componentsMetal working apparatusChinese charactersVehicle frame

A welding technology for a rear automobile frame assembly shaped like a Chinese character 'jing' is characterized in that all installed and welded parts to be installed and welded are firstly clamped on a special welding clamp for locating and clamping, gas shielded welding is adopted for carrying out manual spot welding on all spot welding positions, the rear automobile frame assembly obtained after spot welding is finished is arranged on a full welding clamp of a robot to be located, then a pneumatic clamp is used for clamping, and the robot is started for sequence welding; and full welding is carried out on a bracket assembly and a supporting plate, full welding is carried out on a stabilization rod support assembly and an auxiliary arm support assembly, the bracket assembly is mounted in a full welding manner, gas shielded welding is manually utilized for carrying out welding supplementary on missing welded positions of the robot, re-tapping is carried out on nuts, and welding slag around a welding seam is cleared away. The weld penetration rate completely reaches the standard, the frame size consistency is good after welding, the quality of the welding seam is good, missing welding is avoided, operation by workers is convenient, labor intensity is low, production efficiency is high, cost is low, and wide application value is achieved in production of products of the same kind.

Owner:HENGYANG FENGSHUN AXLE CO LTD

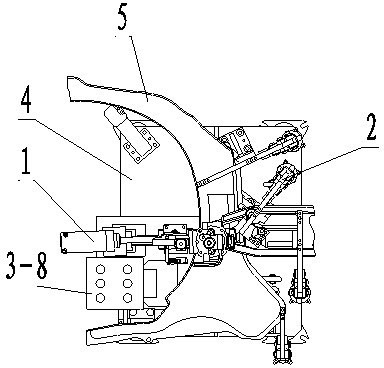

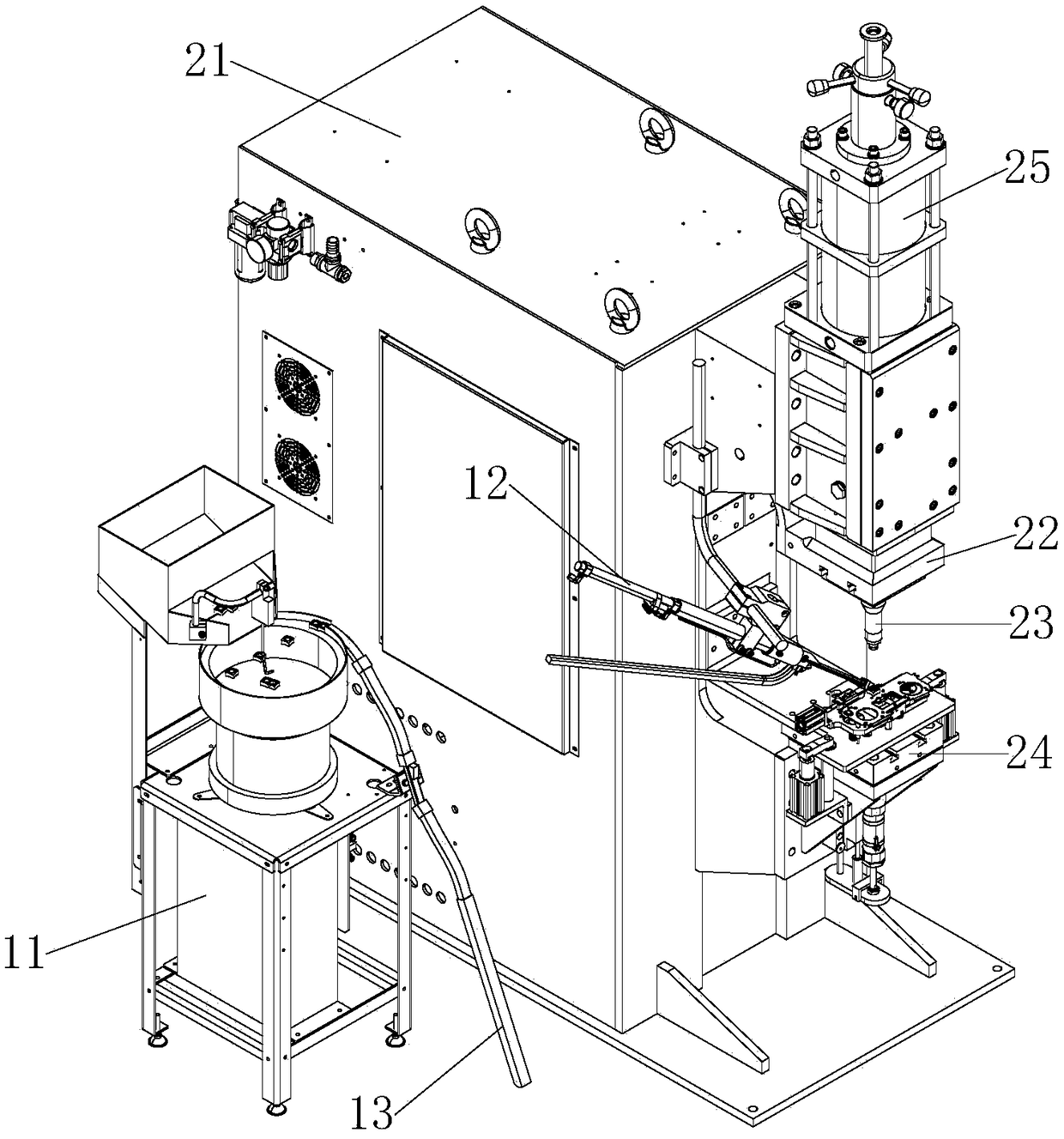

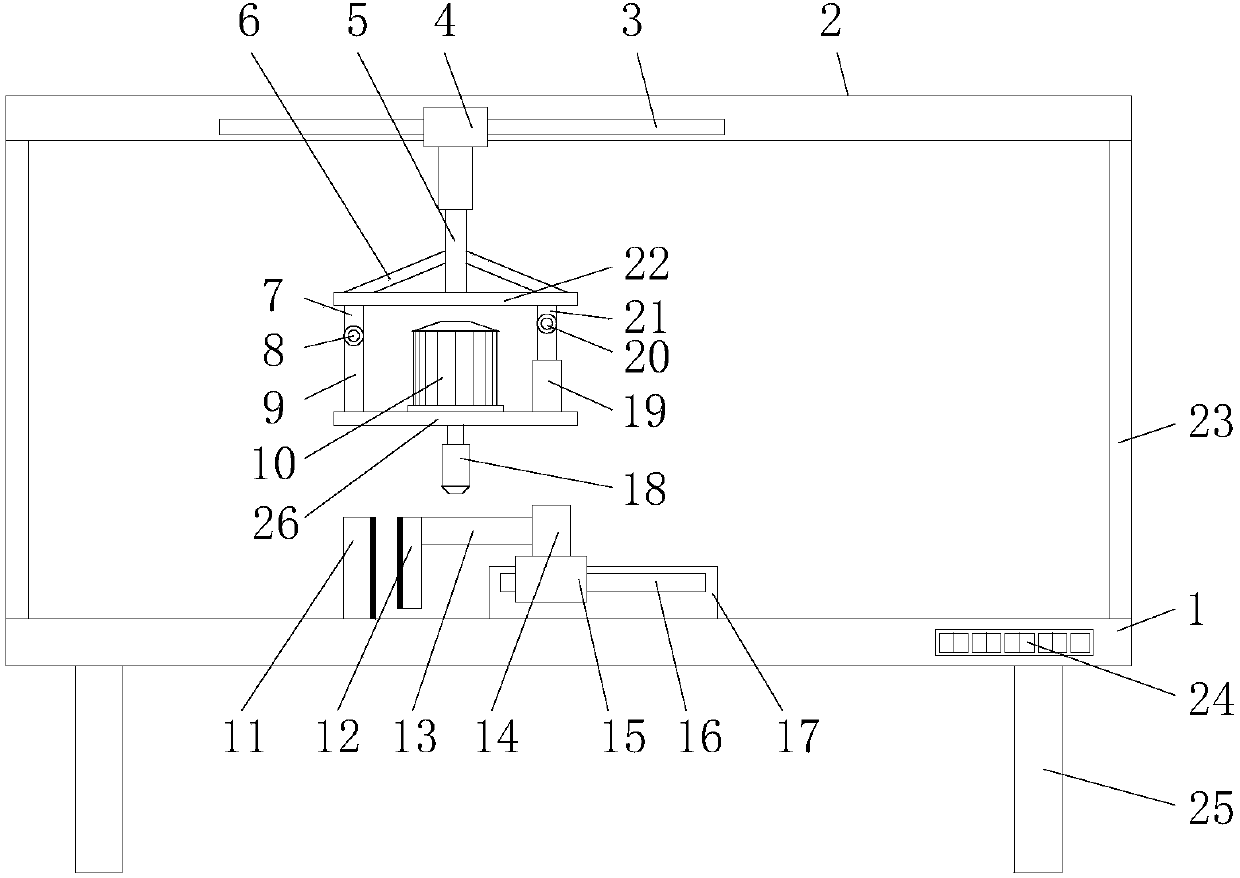

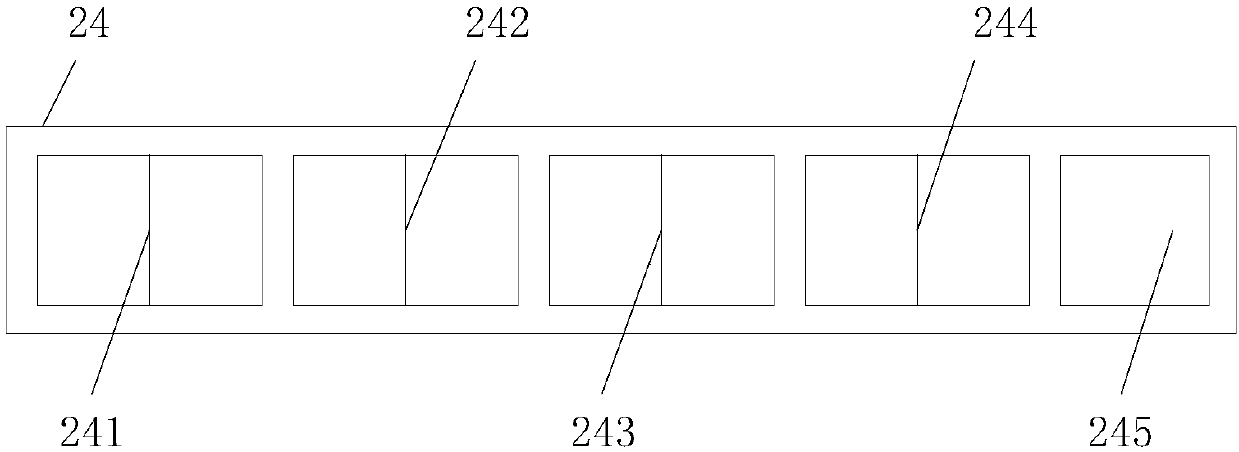

Welding nut automatic welding device

ActiveCN109079305AAvoid missing solderEliminate multi-weldingResistance electrode holdersWelding/cutting auxillary devicesEngineeringWelding

The invention relates to a welding device, in particular to a welding nut automatic welding device which comprises a nut vibration conveying device and a nut conveying rod and further comprises a workpiece positioning device and a nut positioning device. The nut vibration conveying device is connected with the nut conveying rod through a hose. The workpiece positioning device and the nut positioning device are both installed on a welding base. The workpiece positioning device is used for placing a workpiece. The nut positioning device is provided with a lower electrode which is located at thebottom of the workpiece. The nut positioning device is used for limiting the position of a welding nut. An upper electrode is arranged over the lower electrode and installed on an electric resistancewelding lifting table. The nut conveying rod is fixed to one side of a machine frame. One end of the nut conveying rod is located above the nut positioning device when extending out. By means of the welding device, the clamping time of the workpiece and the welding nut is shortened, work efficiency is improved, labor cost and labor intensity are reduced, omitted welding and excessive welding of the nut can be eradicated, and the welding quality is good.

Owner:LEMTECH PRECISION MATERIAL (CHINA) CO LTD

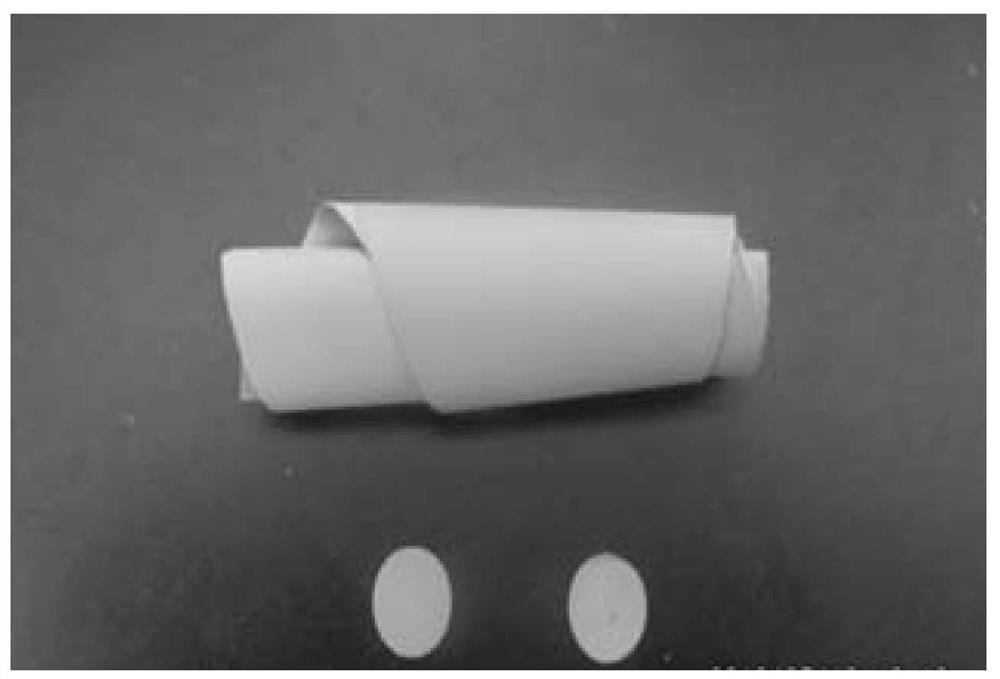

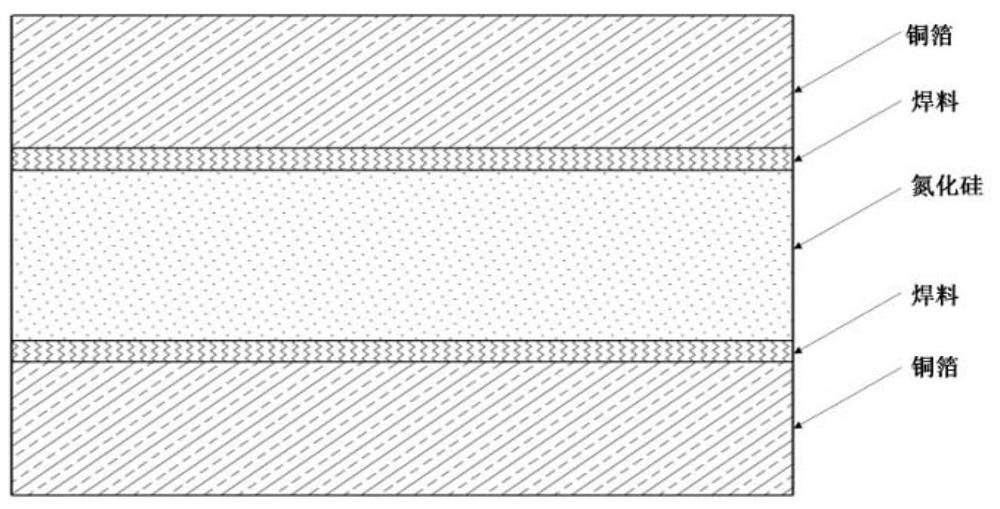

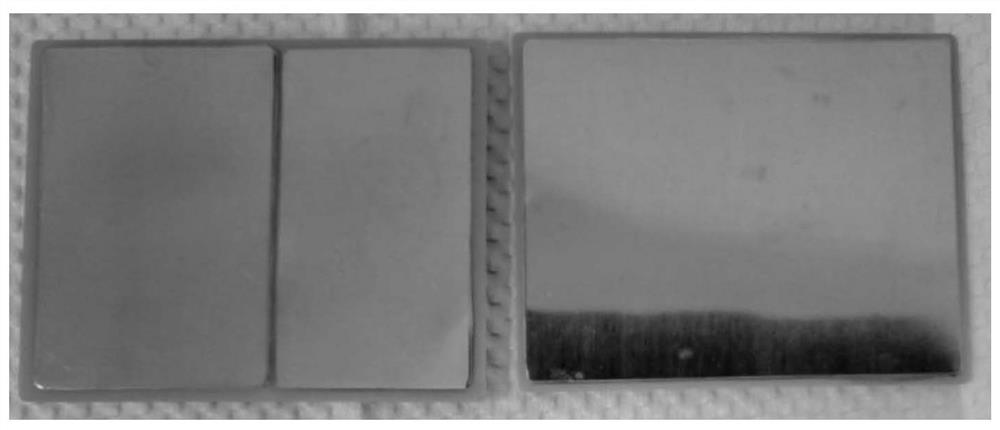

Silicon nitride ceramic substrate of copper-clad plate and preparation method thereof

The invention relates to a silicon nitride ceramic substrate of a copper-clad plate and a preparation method thereof. The silicon nitride ceramic substrate of the copper-clad plate structurally comprises a silicon nitride ceramic substrate, copper plates distributed on the upper side and the lower side of the silicon nitride ceramic substrate, and welding layers distributed between the copper plates and the silicon nitride ceramic substrate. The components of the ceramic nitride silicon ceramic substrate comprise a silicon nitride phase and a grain boundary phase; the content of the silicon nitride phase is greater than or equal to 95 wt%; the grain boundary phase is a mixture at least containing three elements of Y, Mg and O; the content of the grain boundary phase is less than or equal to 5wt%, and the content of the crystal phase in the grain boundary phase is greater than or equal to 40vol%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

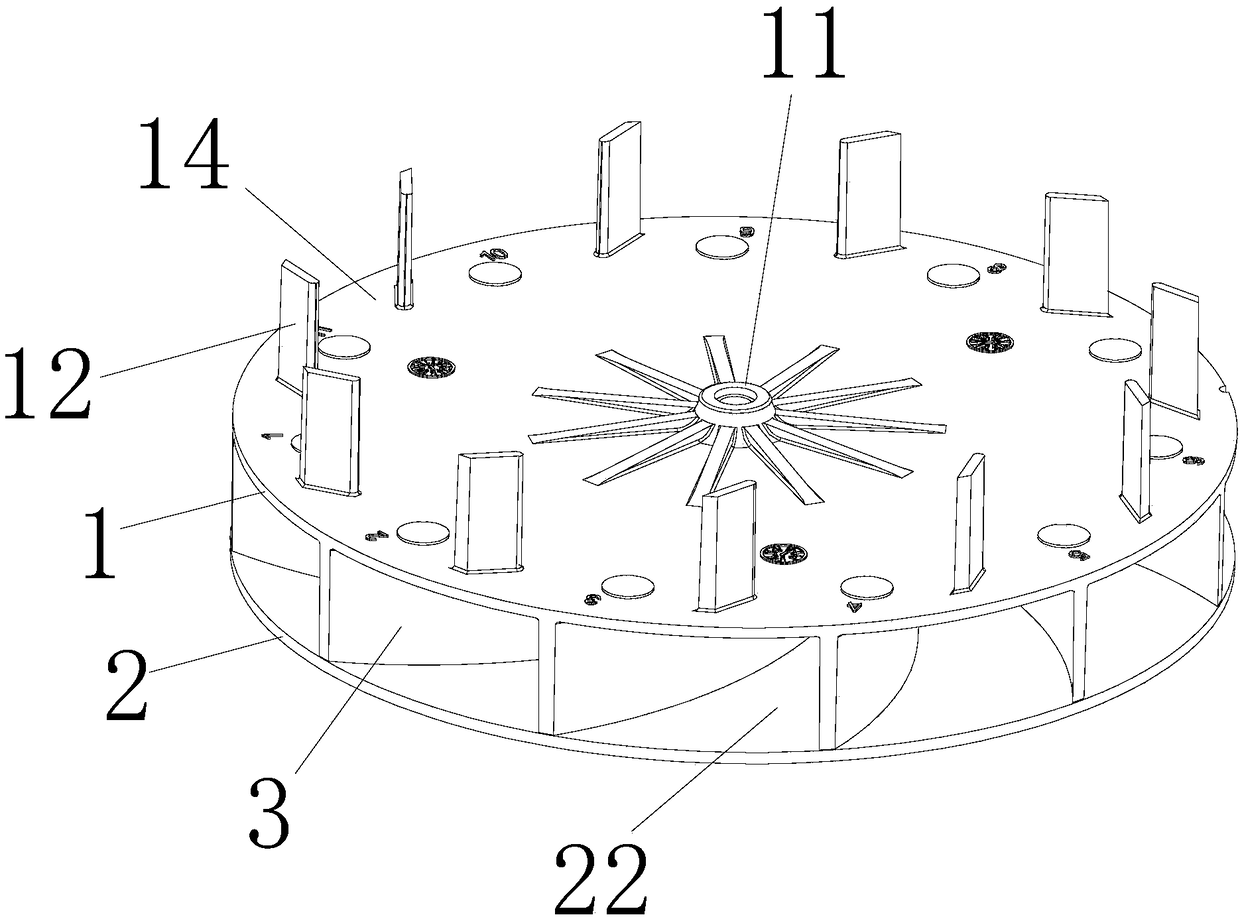

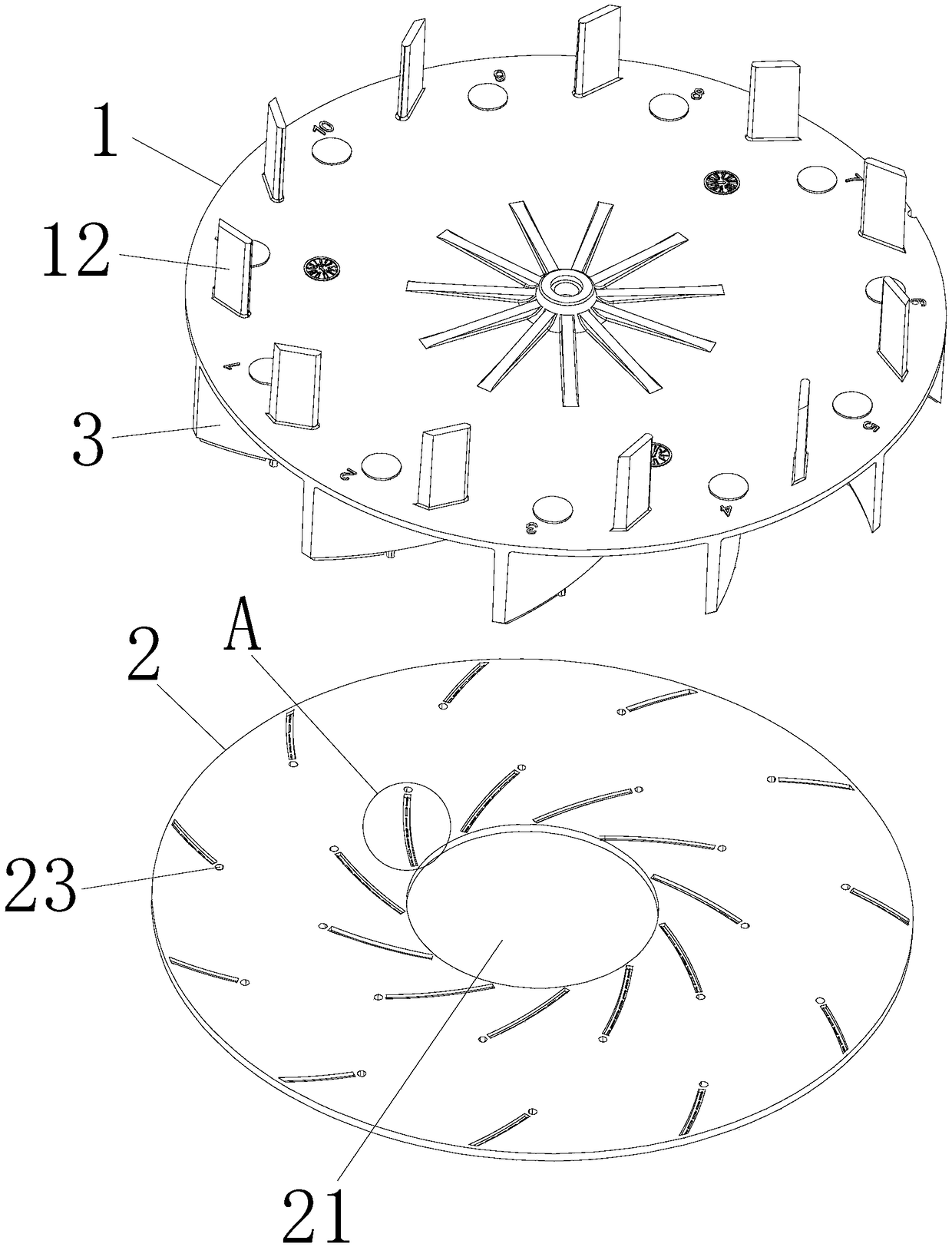

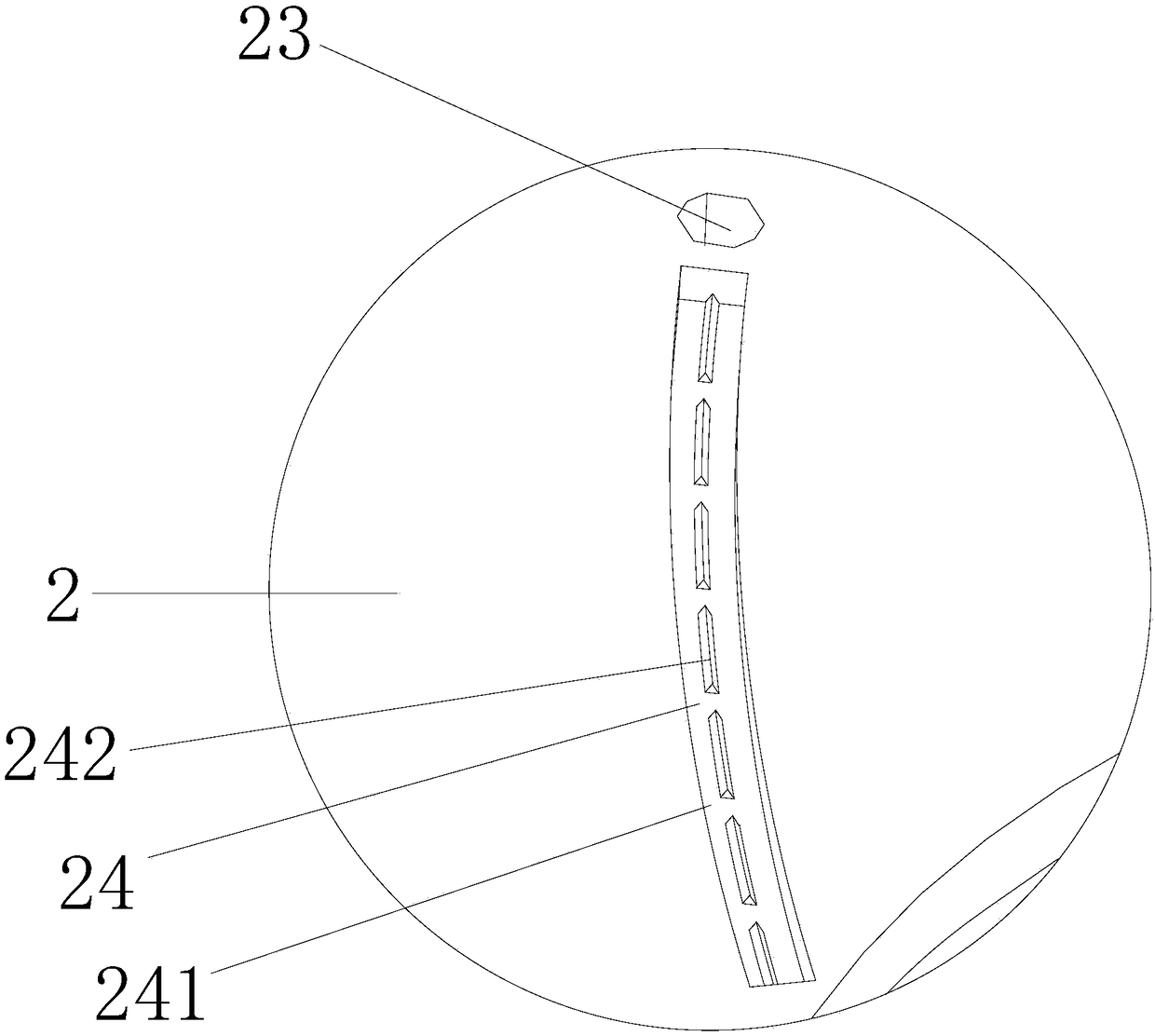

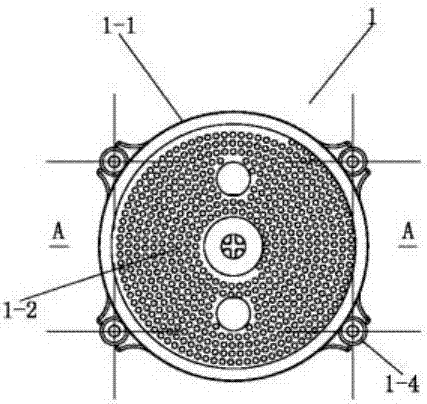

Wind wheel and air blower applying wind wheel

PendingCN108223443ASolve the big jumpSolve the problem of poor horizontalityPump componentsPumpsEngineeringInjection moulding

The invention discloses a wind wheel and an air blower applying the wind wheel. The wind wheel comprises a top panel provided with a plurality of wind blades and a bottom panel. The multiple wind blades protrude out of the lower end face of the top panel, and the multiple wind blades and the top panel are integrally formed through injection molding. The multiple wind blades are located between thetop panel and the bottom panel. An air inlet is formed in the middle of the bottom panel. An air flue is formed between every two adjacent wind blades. A connecting base connected with a motor shaftis arranged in the center of the top panel. A plurality of positioning columns protrude out of the end faces, connected with the bottom panel, of the wind blades. The bottom panel is provided with installing holes for the positioning columns to penetrate, and the wind blades and the bottom panel are fixed together through welding. The end faces of the wind blades are further provided with a plurality of first bosses. The bottom panel is provided with grooves matched with the first bosses. The first bosses are embedded in the grooves, the first bosses and the grooves are combined together through welding, welding points are reduced, and the problem about solder skips is reduced; and the welding precision is improved, welding is firm, and the problems that during wind wheel running, jumpingis great, and balance performance is poor are effectively solved.

Owner:ZHONGSHAN BROAD OCEAN

High-precise efficient nut plate and forming method thereof

Owner:ZHEJIANG CHANGHUA AUTO PARTS

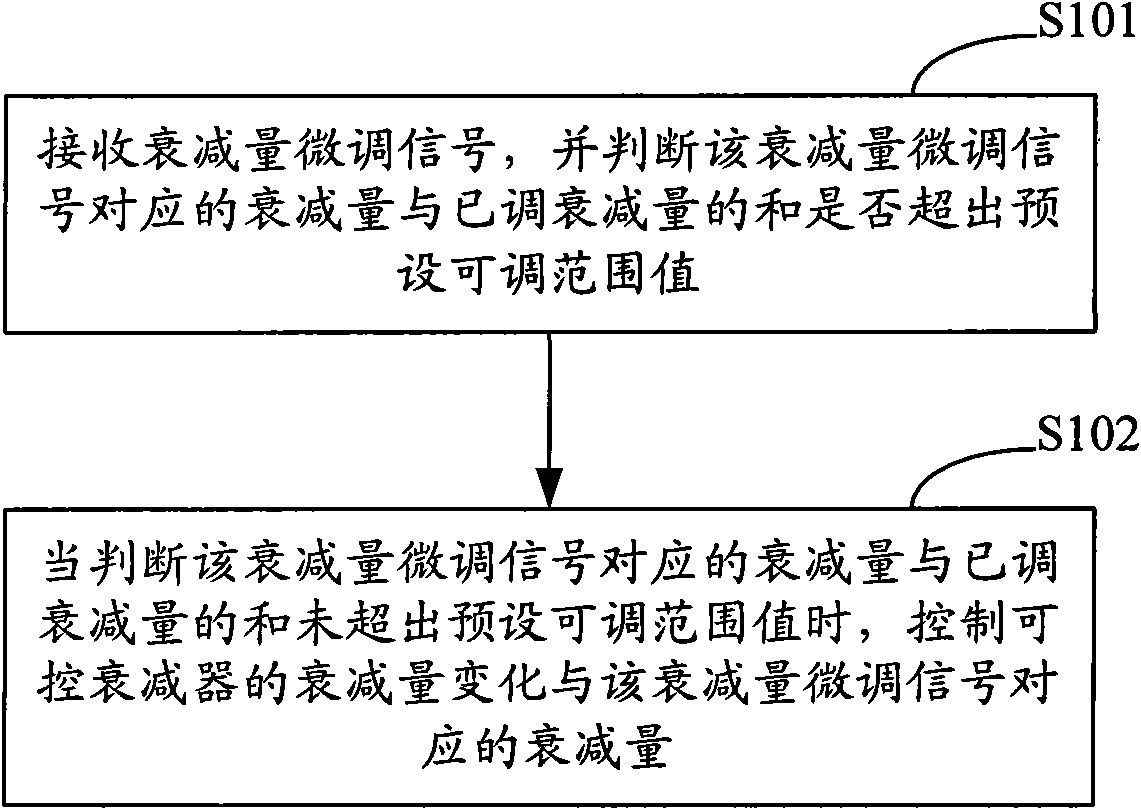

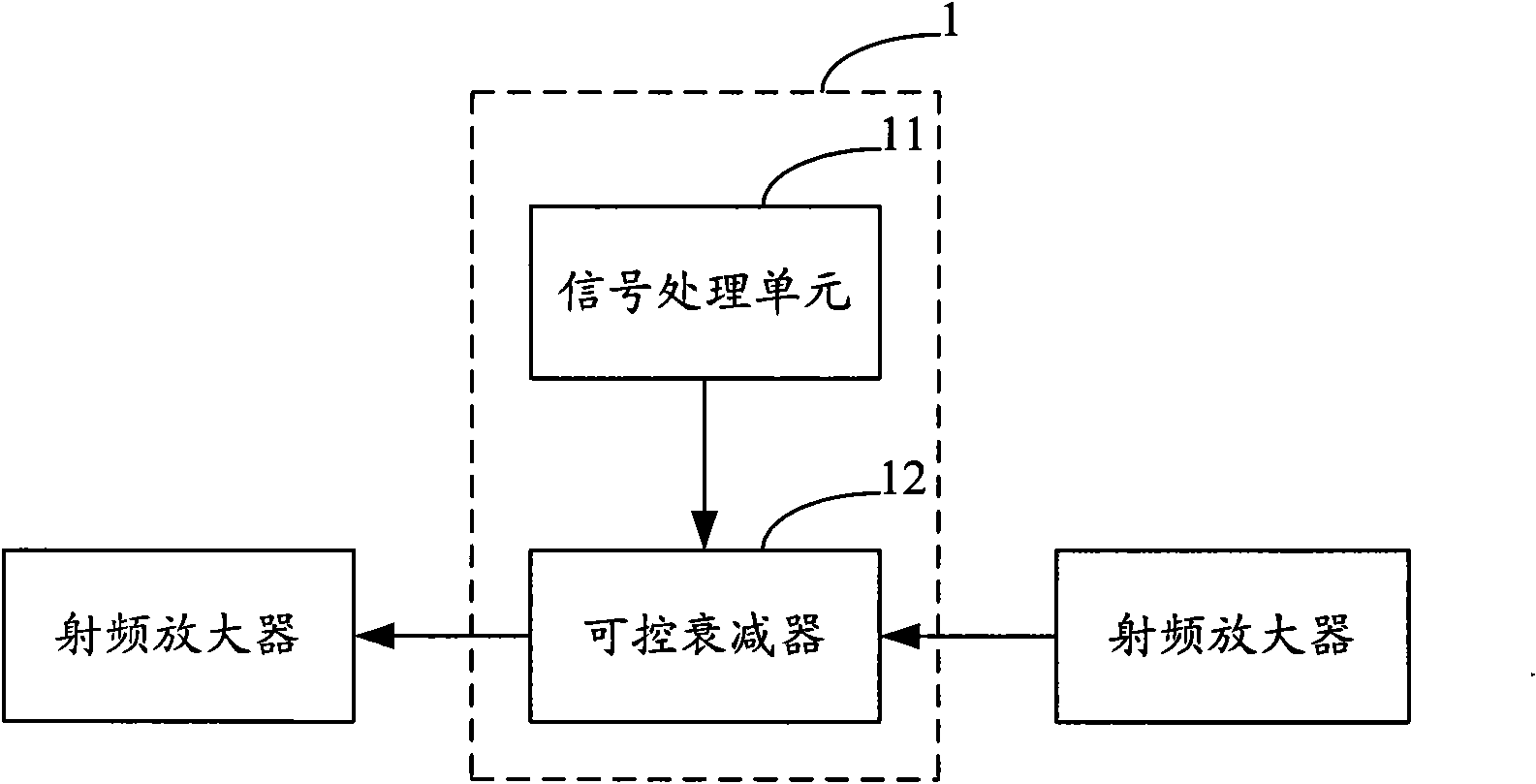

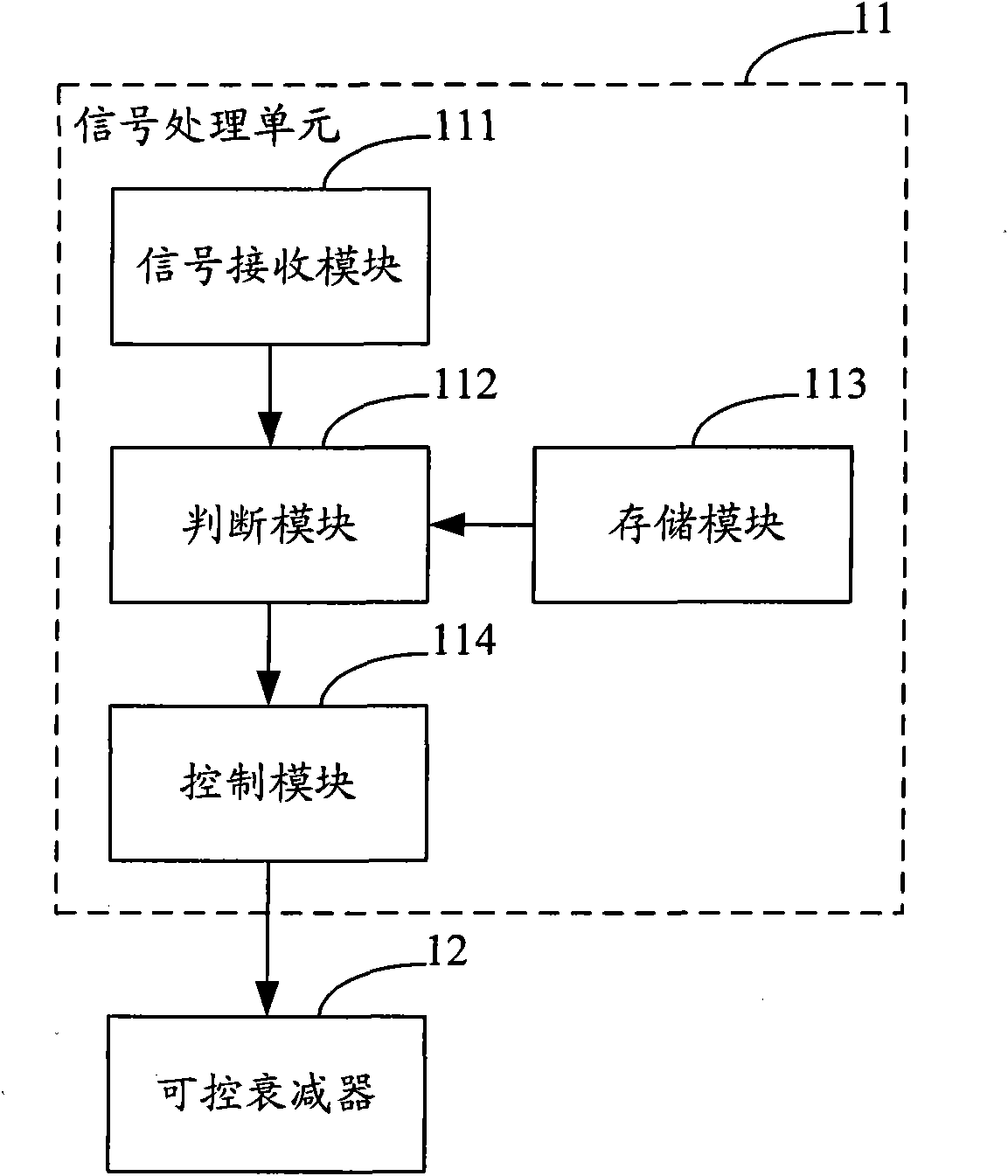

Radio frequency front-end device, gain control method and system thereof

The invention provides a radio frequency front-end device, a gain control method and a system thereof, which are applicable to the technical filed of radio frequency signal processing, wherein the method comprises the following steps: receiving decrement fine adjustment signals; judging whether the sum of the decrement corresponding to the decrement fine adjustment signals and the finely adjusted decrement exceeds a preset adjustable range value or not; and controlling the decrement of the current decrement change of a controllable attenuator corresponding to the decrement fine adjustment signals without using a traditional pi type attenuator for realizing the fine adjustment on the gain of the radio frequency front-end device when the judgment result shows that the sum of the decrement corresponding to the decrement fine adjustment signals and the finely adjusted decrement does not exceed the preset adjustable range value. Thereby, the invention avoids the phenomena such as rosin welding joint, leak welding joint or false welding joint and the like caused by resistor change are avoided, the repeated welding operation is not needed, and the reliability and the pass rate of products are improved.

Owner:MOBILE ANTENNA TECH SHENZHEN +5

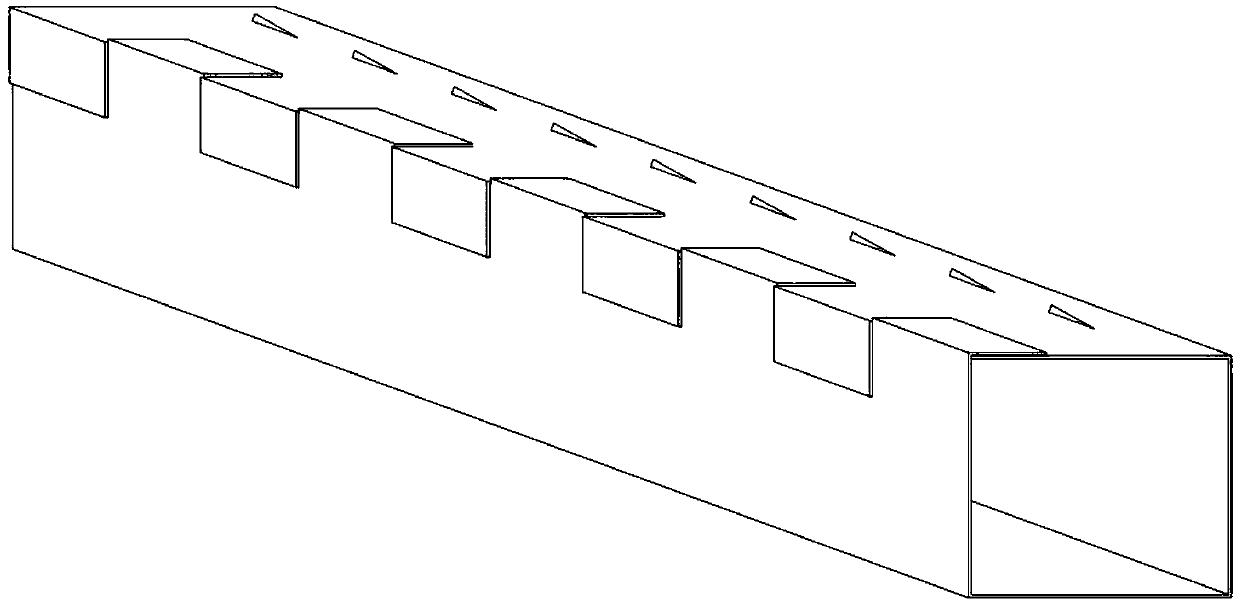

Side buckle type aluminum parting strip for hollow glass

The invention discloses a side buckling type aluminum parting strip for hollow glass. The aluminum parting strip is formed by processing an aluminum strip through rolling of a forming die wheel set and straightening of a plurality of groups of press wheels in the front-back direction and left-right direction, the section outline is changed into a rectangular frame from a straight line shape, the left side edge and the right side edge of the aluminum strip are provided with concave-convex shapes, and the concave-convex shapes of the left side edge and the right side edge are distributed in a staggered mode. The aluminum parting strip is formed by buckling the concave-convex shapes of the aluminum strip at the joint of two adjacent faces through engaging, a row of vent holes are formed in one buckling face, and the other three faces are airtight. The aluminum parting strip is molded through rolling and straightening through the forming die wheel set, and is formed by side buckling of theconcave-convex shapes through engaging, the structure is firm, welding forming of a high-frequency welding machine is not needed, the vent holes are also formed through rolling of the mold wheels, noadditional vent hole is needed, a main isolation face is not welded, the phenomena of cracking, welding leakage and air leakage of welded junctions are avoided, the sealing performance of the aluminum parting strip is guaranteed, and the service life of the hollow glass is prolonged.

Owner:广西加一米科技有限公司

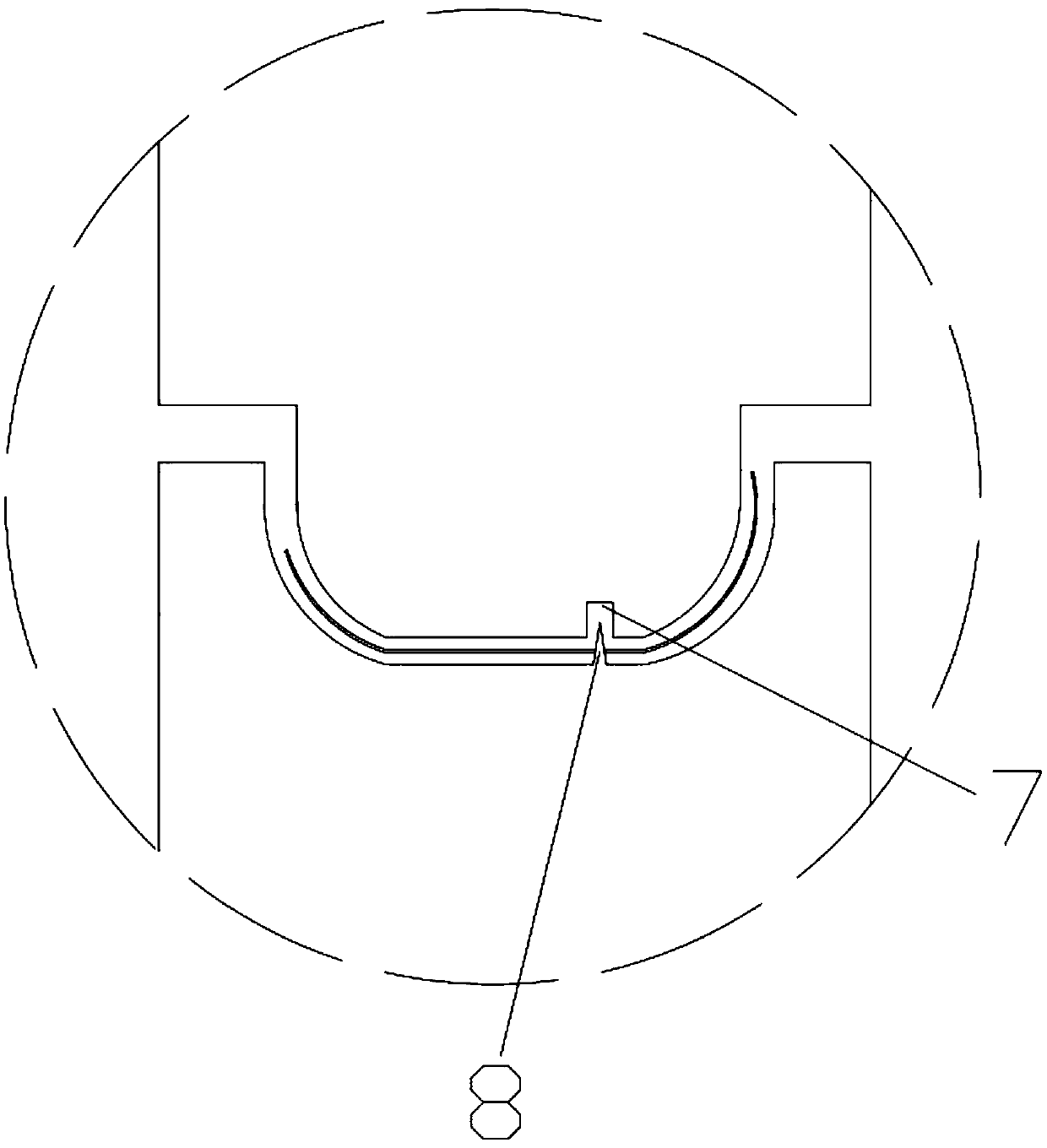

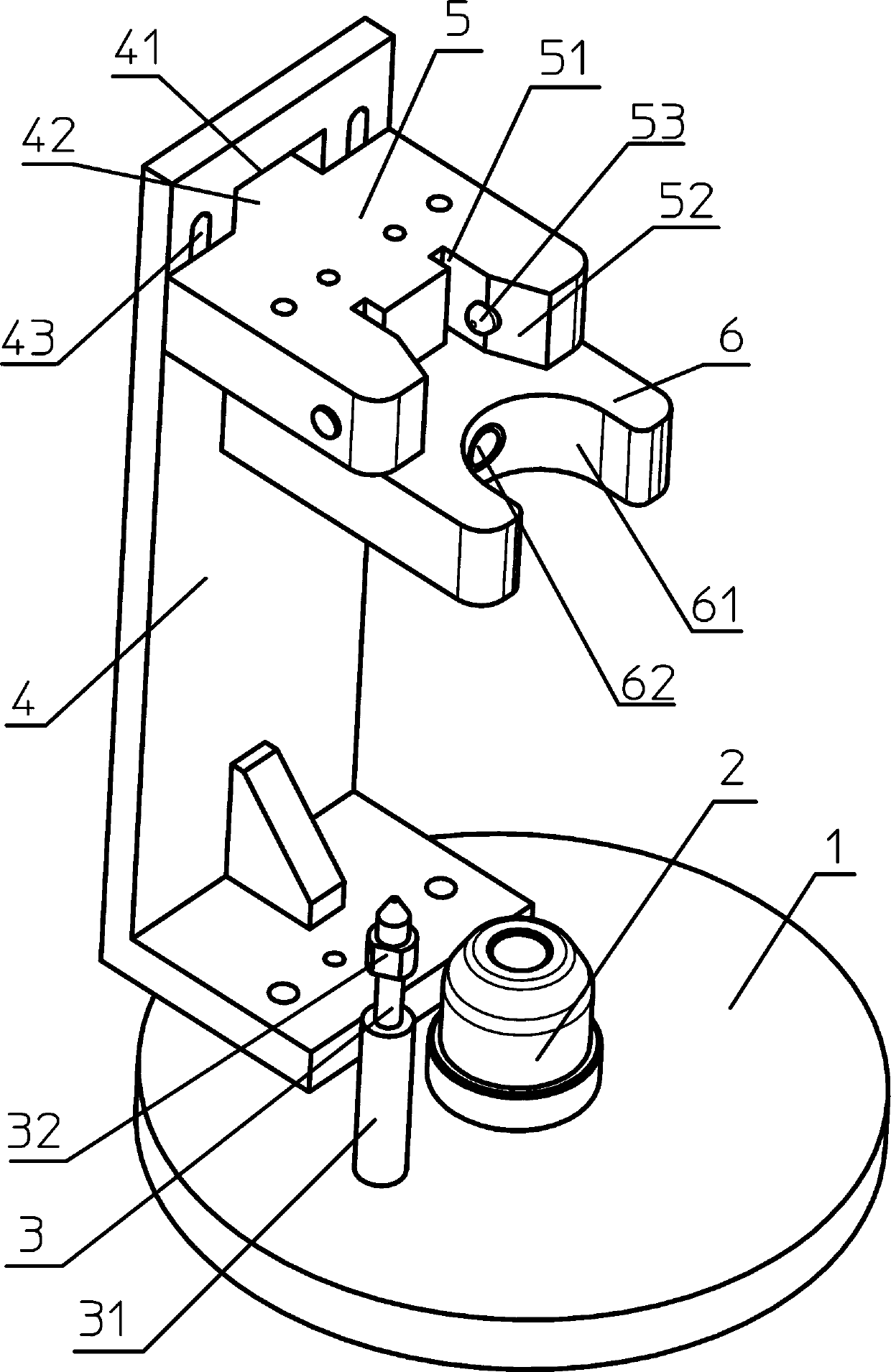

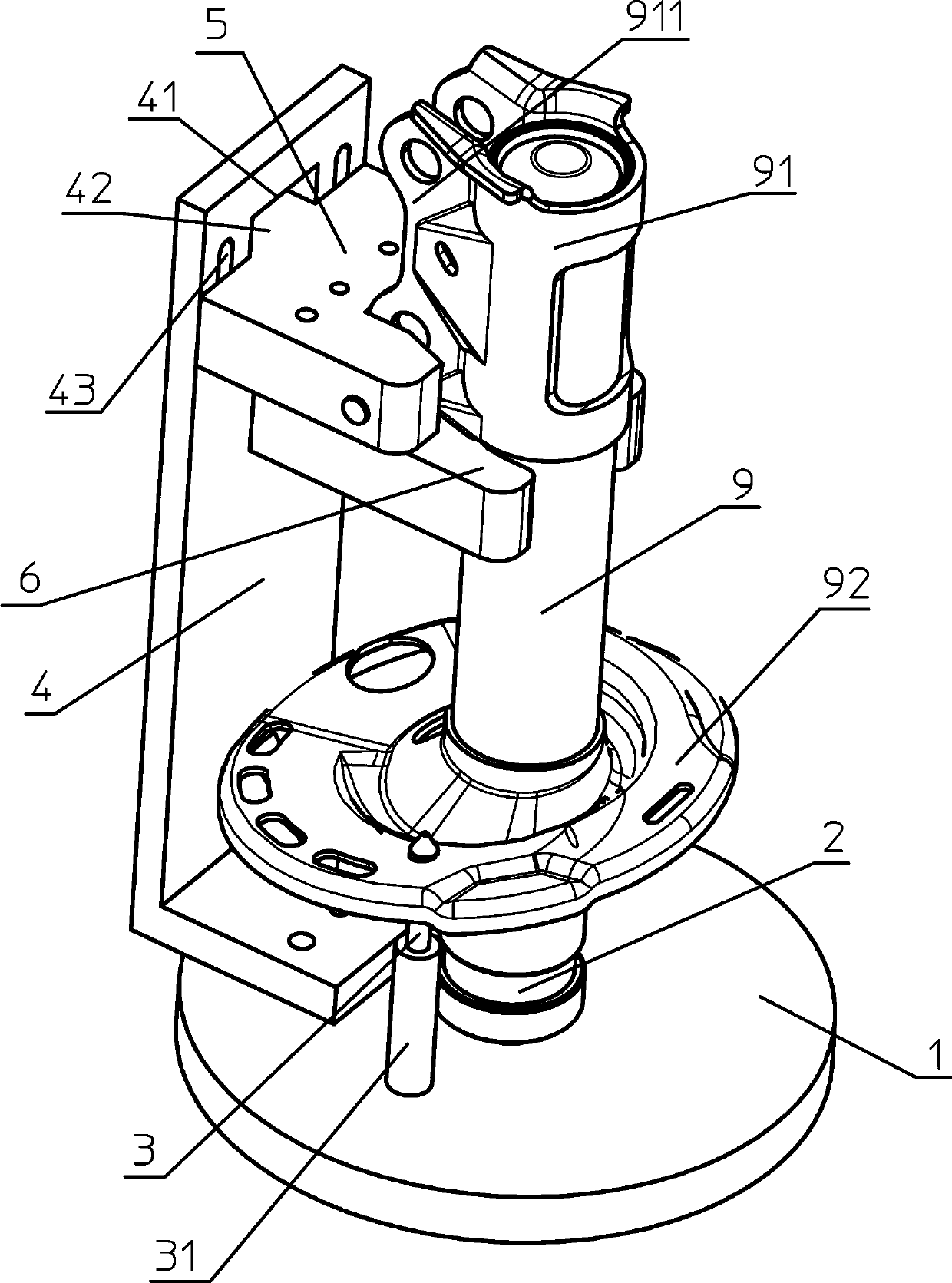

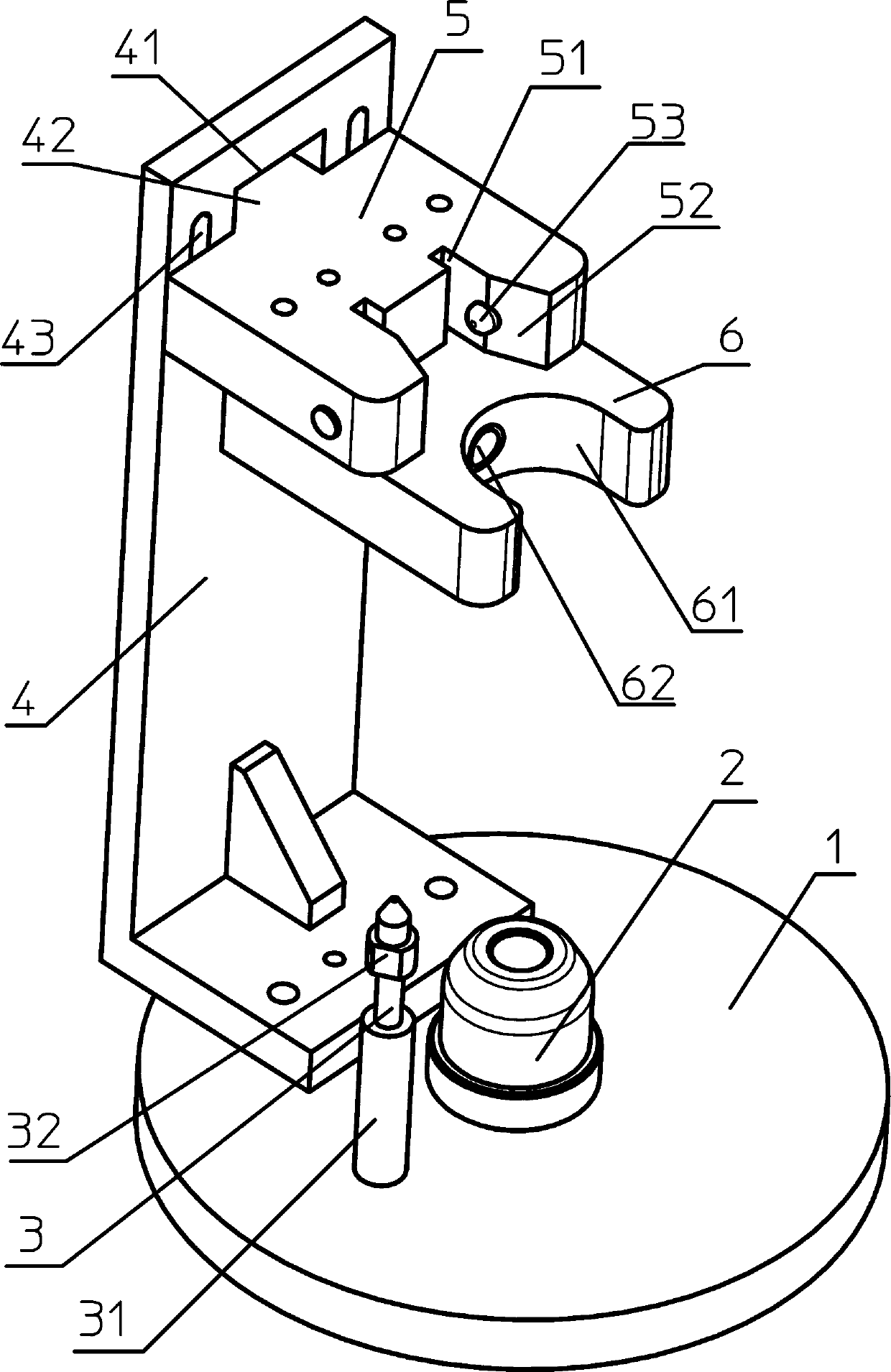

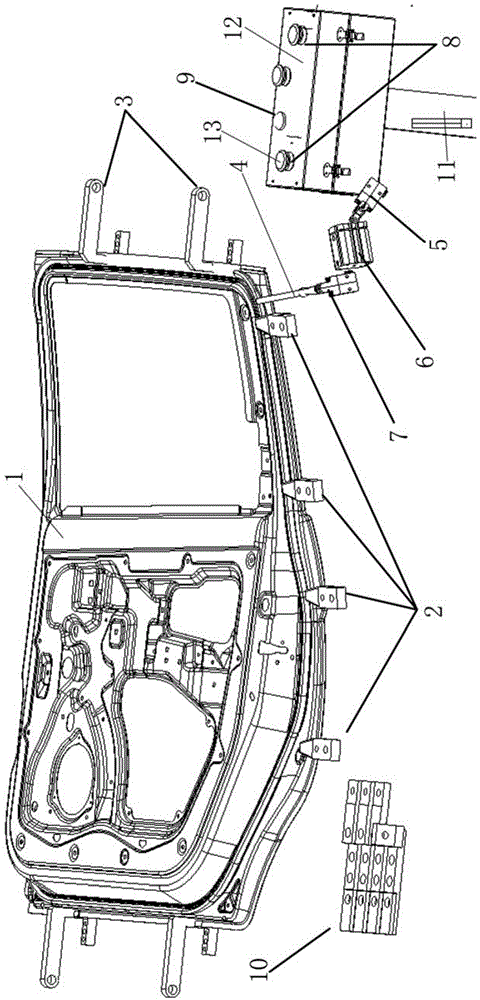

Welding tool for bracket on car shock absorber outer cylinder

PendingCN110000502AImprove welding efficiencyEliminate missing solderWelding/cutting auxillary devicesAuxillary welding devicesManipulatorMagnet

The invention discloses a welding tool for a bracket on a car shock absorber outer cylinder. The welding tool comprises a base. A locating column, a locating pin and a locating frame are arranged on the base. The locating column is used for being inserted into the tail end of the outer cylinder to locate the tail end of the outer cylinder. The locating pin is used for being inserted into a springdisc through hole in the outer cylinder, and locating the outer cylinder in the peripheral direction through a spring disc. The locating plate is arranged on the locating frame. A carrier plate is arranged on the lower portion of the locating plate. The locating plate is provided with two clamping grooves, wherein two connecting plates of the bracket installed on the outer cylinder in a sleeved manner are clamped into the clamping grooves in a one-to-one manner. The carrier plate is provided with a locating groove used for clamping the outer cylinder and locating the outer cylinder. A magnet is arranged on the groove bottom of the locating groove. According to the welding tool, the outer cylinder with which the bracket is sleeved can be located rapidly and reliably, the bracket installed on the outer cylinder in a sleeved manner can be welded automatically through a welding mechanical hand, thus the welding efficiency can be improved greatly, welding skips are eradicated completely, and the welding quality can also be guaranteed.

Owner:ZHANGJIAGANG BONDED ZONE YAXIN PRECISION PIPE MAKING

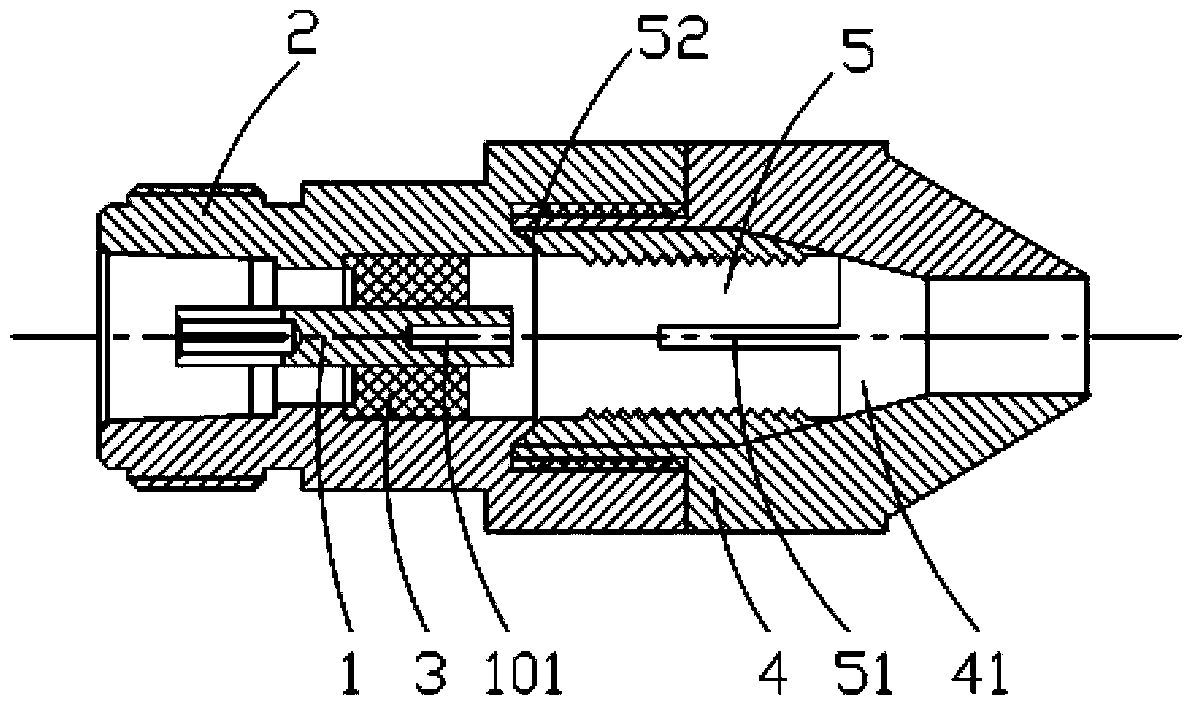

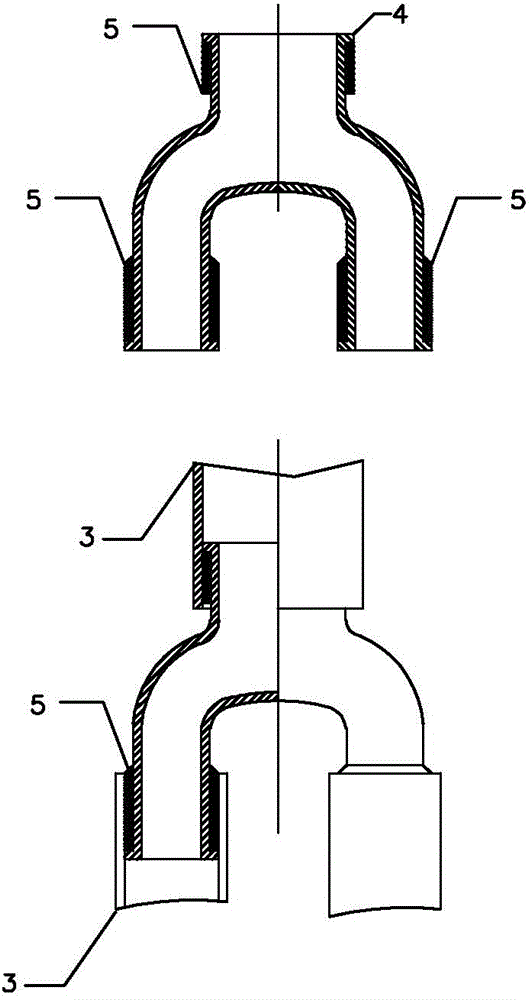

Hot melting connector capable of being quickly positioned, and water dissolving core injection molding process thereof

ActiveCN108312550AHeating evenlyAvoid leaningBio-packagingDomestic articlesPlastics industryPipe fitting

The invention belongs to the technical field of pipe fitting plastics, and particularly relates to a hot melting connector capable of being quickly positioned, and a water dissolving core injection molding process thereof. The hot melting connector comprises a connector body provided with at least one installing end, wherein an installing site is arranged on an inner wall of the connector body; aguiding core is arranged on the installing site; an outer side wall of the guiding core is a guiding surface; a hot melting guiding part adaptive to the wall thickness of a hot melting pipe is formedbetween the guiding surface and an inner wall of the installing end; a guiding opening is formed in the outer end of the hot melting guiding part. The guiding core provided by the invention has the following effects that a, during heating, the guiding core can be prevented from being inclinedly or one-sidedly heated; b, during hot melting, a pipeline and the connector keep in a straight line, so that an annular fusion welding surface is uniformly fusion-welded, and the occurrence of the phenomenon of one-sided fusion welding is avoided.The injection molding process provided by the invention isapplied to the plastic industry and is mainly aimed at the plastic products which have complex inner cavity larger than the outer port and are not suitable for the core demoulding treatment. The plastic products produced by the injection molding process can integrally form a complex inner cavity, the core demoulding is not needed, the manufacturing cost is low and the water dissolving core can beeasily removed by water washing.

Owner:陈奎宏

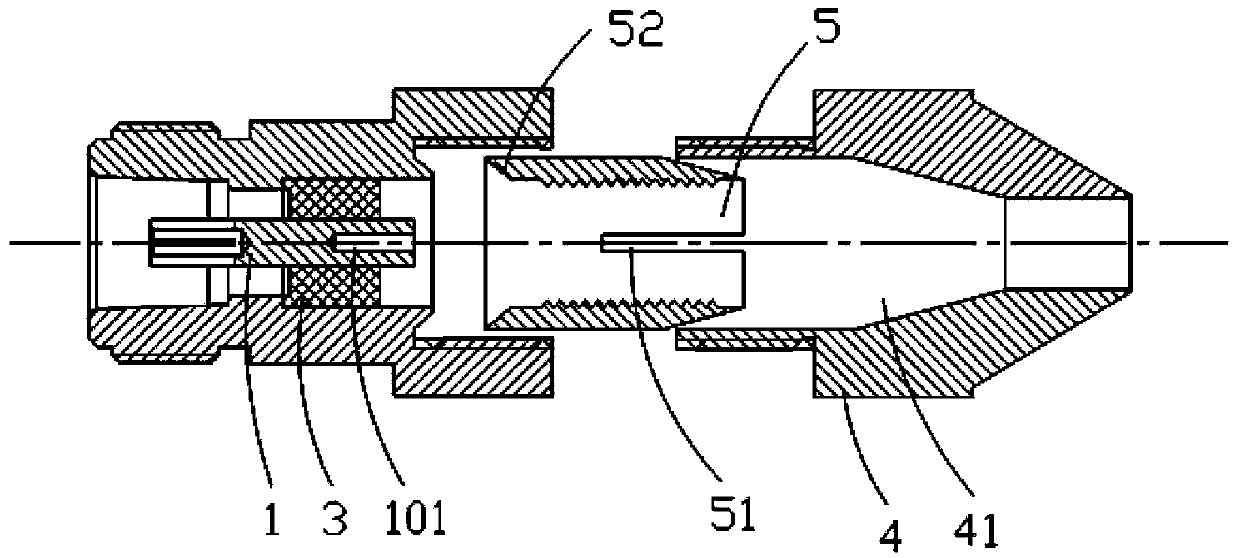

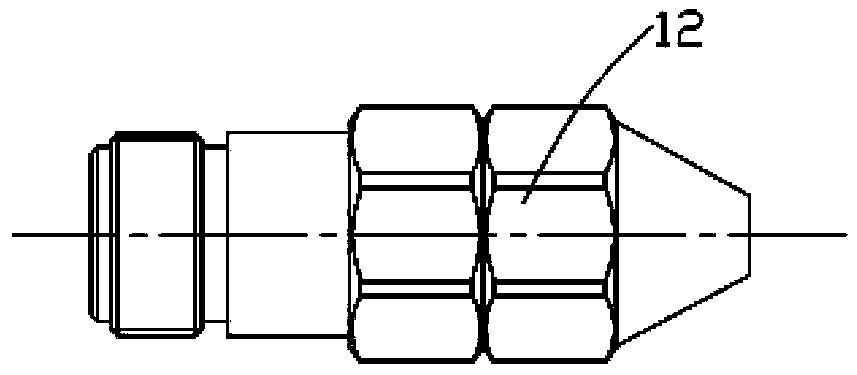

Radio frequency cable connector suitable to be assembled outdoors

ActiveCN103427258ASimple structureBroaden the limits of the environmentCoupling contact membersTwo-part coupling devicesElectrical conductorEngineering

The invention discloses a radio frequency cable connector suitable to be assembled outdoors. The radio frequency cable connector suitable to be assembled outdoors comprises an outer conductor and an inner conductor coaxially arranged in the inner cavity of the outer conductor, wherein an insulating medium is sleeved at the periphery of the inner conductor coaxially; the insulating medium is in close fit with the inner cavity wall of the outer conductor; a central fixed hole is formed in the tail end part of the inner conductor; a threaded inner hole is formed in the tail end of the outer conductor; a backseat in threaded connection with the outer conductor is arranged; the backseat has a tapered hollow inner cavity and a tapered sleeve which matches the tapered hollow inner cavity; the big end of the tapered sleeve points to one side of the inner conductor. The radio frequency cable connector suitable to be assembled outdoors has the advantages of reliable performances, excellent indexes, a simple structure, easy installation, simple assembling tools, a strong adaptability to the environment, a capability of being suitable for operation outdoors and high above the ground, and the like.

Owner:安徽蓝麦通信股份有限公司

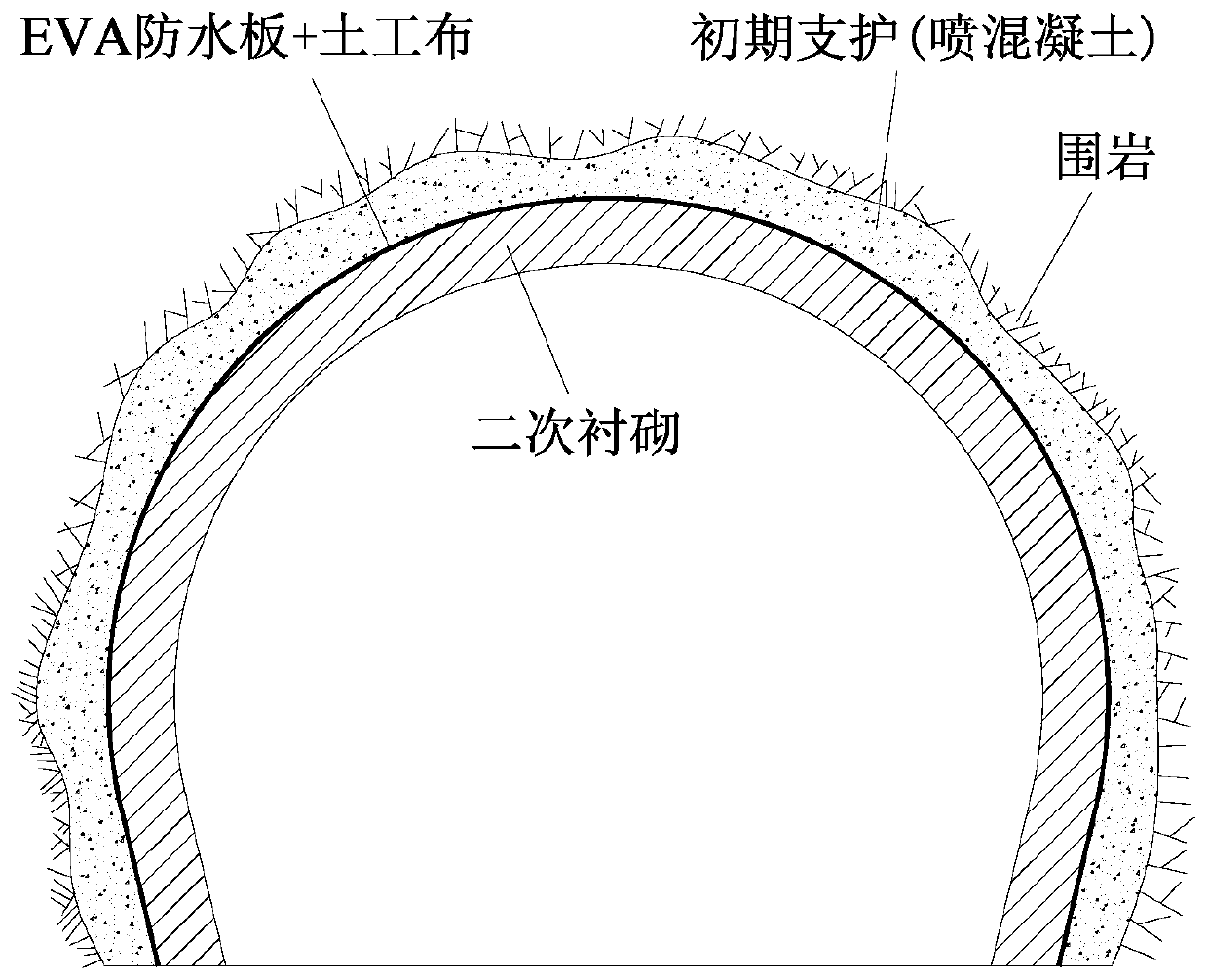

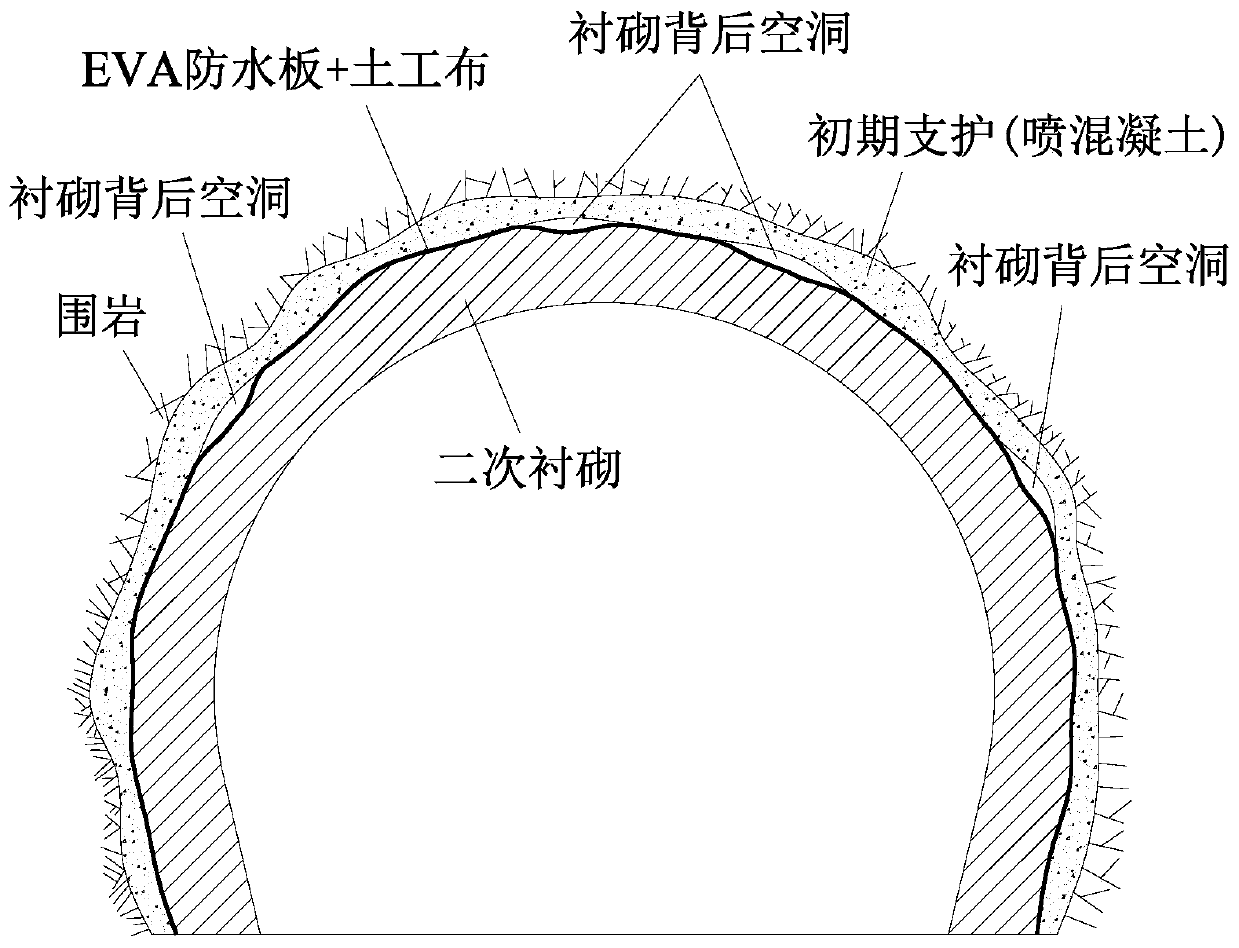

Tunnel waterproof layer, model board trolley and construction method

PendingCN111335926AImprove waterproof performanceImproving the quality of secondary lining pouringUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel waterproof layer, a model board trolley and a construction method. The waterproof layer comprises EVA waterproof boards and foam boards. The side surfaces of the foamboards are bonded to the side surfaces of the EVA waterproof boards, the EVA waterproof boards are used for facing the inner side of a tunnel, and the foam boards are used for facing the surrounding rock side. By applying the tunnel waterproof layer, the model board trolley and the construction method provided by the invention, the waterproof performance of a tunnel structure can be greatly improved, the secondary lining casting quality and the construction efficiency are greatly improved, and the construction cost is lowered.

Owner:中铁二院成都勘察设计研究院有限责任公司

Leak repairing method of phase connection lines of stator winding in turbonator

ActiveCN105033422AImprove sealingAvoid missing solderArc welding apparatusWelding/cutting media/materialsWorkloadRepair method

The invention discloses a leak repairing method of phase connection lines of a stator winding in a turbonator. The leak repairing method includes the steps that leak points are heated through two welding guns with the 180-degree inclined angle, meanwhile, the temperature is detected through a silver solder, when the silver solder is melting, the leak points are evenly coated with the silver welding powder, the silver solder is placed on the silver welding powder, welding-all-around is conducted on the leak points on the phase connection lines, and the surfaces of the welded parts are coated with the silver welding powder again 1-2 minutes after welding is completed, then the portions where plated silver is exfoliated are grinded through abrasive cloth to be smooth, the two welding guns with the 180-degree inclined angle heat the tin-enameled portions while the temperature is detected through tin bars, when the tin bars are melting, the tin-enameled portions are evenly coated with soldering paste so that immunities can be removed, and then the tin bars are boned onto the soldering paste. The leak repairing method is simple in operation, the workload of inspectors is lowered, and working efficiency is improved.

Owner:大唐桂冠合山发电有限公司

Coaxial cable welding and fixing device

InactiveCN104184017ALow welding technical requirementsSave human effortLine/current collector detailsCoaxial cableEngineering

The invention provides a coaxial cable welding and fixing device, which comprises a supporting table, wherein the supporting table is provided with a clamping part used for clamping a connector of a coaxial cable; the clamping part is a sleeve-shaped component with an opening, and the cross section of the sleeve-shaped component is triangular; the sleeve-shaped component comprises a supporting part and two clamping pieces, the two clamping pieces are arranged at two sides of the supporting part respectively, the ends, which are away from the supporting part, of the two clamping pieces form the opening, and the outer sides of the two clamping pieces are respectively provided with handles used for opening the sleeve-shaped component; the bottom part of the supporting table is provided with supporting rods; the ends, which are away from the supporting table, of the supporting rods are provided with a base; and the supporting rods are retractable rods. The coaxial cable welding and fixing device can limit the connector of the coaxial cable, improve the work efficiency, avoid a defect of a phenomenon of shaking which easily occurs when the connector of the coaxial cable is limited mutually in the prior art, and avoid occurrence of conditions such as false welding, missed welding, short circuit and the like; and furthermore, the height of the supporting table can be adjusted, working fatigue can be alleviated, and the welding efficiency is improved.

Owner:STATE GRID CORP OF CHINA +1

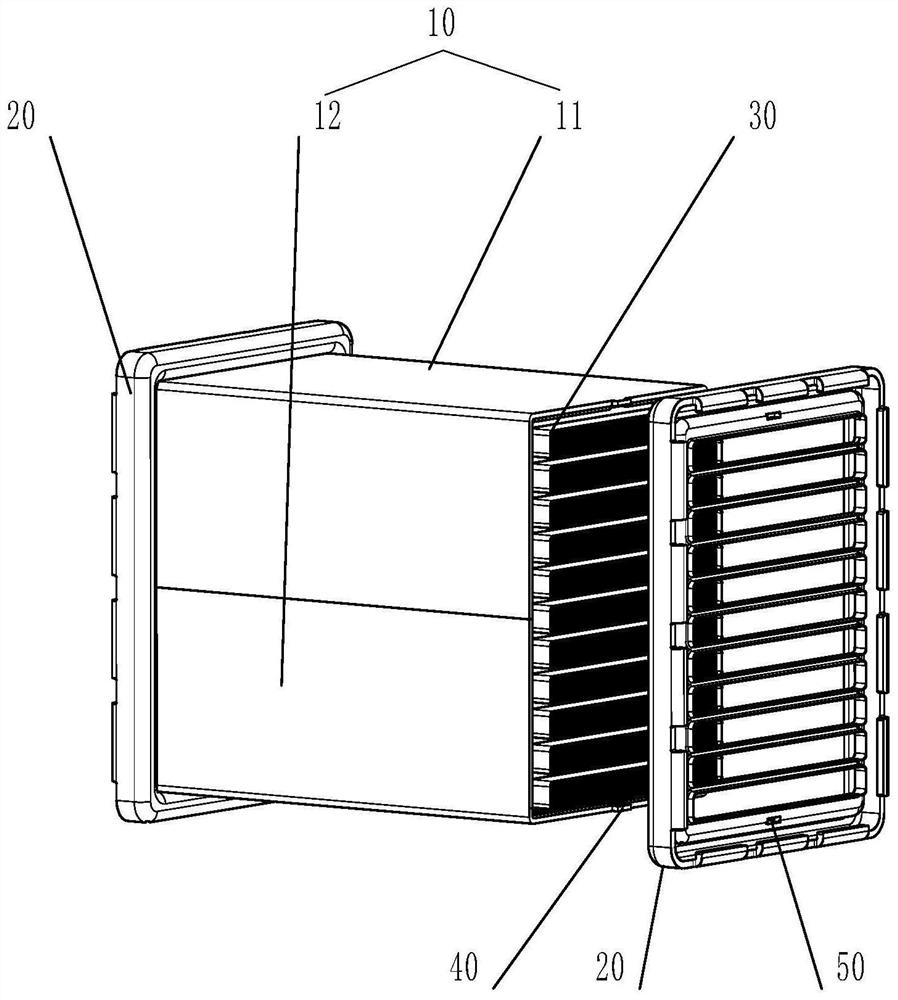

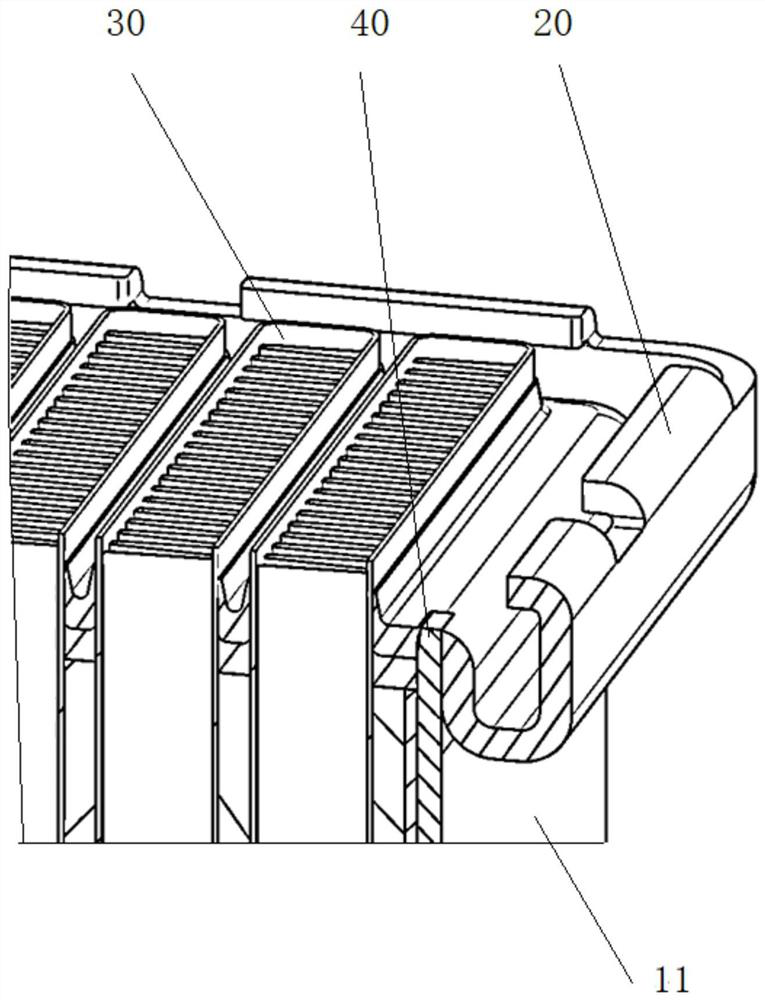

Core assembly and water-air intercooler

PendingCN111854505AAvoid LeakageImprove reliabilityHeat exchanger casingsStationary tubular conduit assembliesEngineeringIntercooler

The invention relates to the technical field of heat exchange devices, in particular to a core assembly and a water-air intercooler. The core assembly is applied to the water-air intercooler, and comprises a mainboard, a shell, a limiting structure and a matching structure, wherein two ends of the shell are respectively connected with the mainboard; one of the limiting structure and the matching structure is arranged on the mainboard; the other one of the limiting structure and the matching structure is arranged on the shell; and the limiting structure is connected with the matching structure,so that the welding part of the shell and the mainboard is prevented from being separated. According to the core assembly provided by the invention, in the welding process, each part is expanded at high temperature and retracted after being cooled, but the limiting structure is connected with the matching structure, so that the occurrence of the phenomenon that a gap appears between the shell andthe mainboard due to the inconformity of the cold contraction amount of the shell and the cold contraction amount of the mainboard in one same contraction direction is avoided, the occurrence of insufficient welding and the lack of welding between the mainboard and the shell is avoided, the occurrence of leakage of the core assembly is further avoided, and the reliability of the core assembly isimproved.

Owner:ZHEJIANG YINLUN MACHINERY

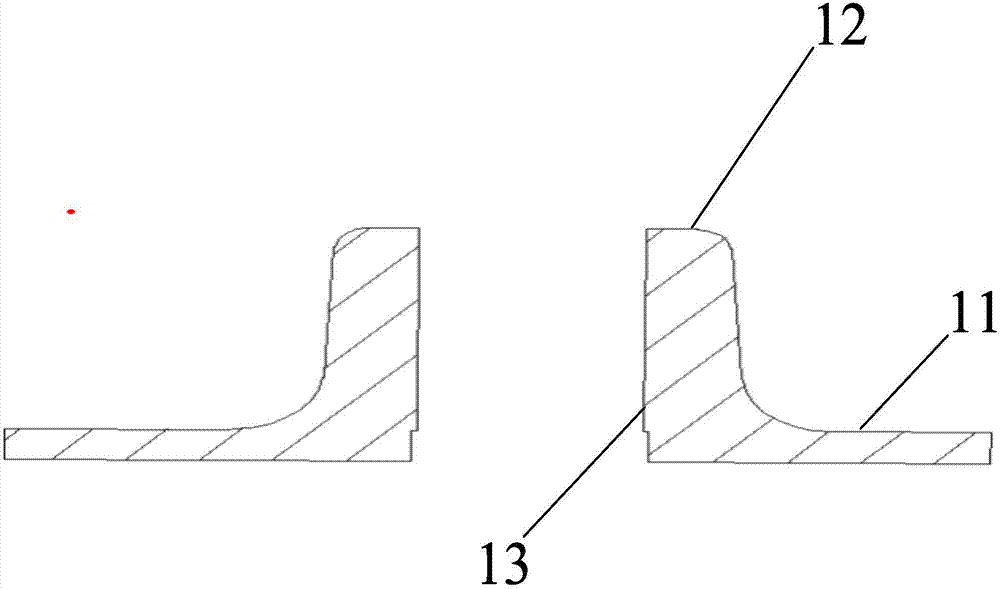

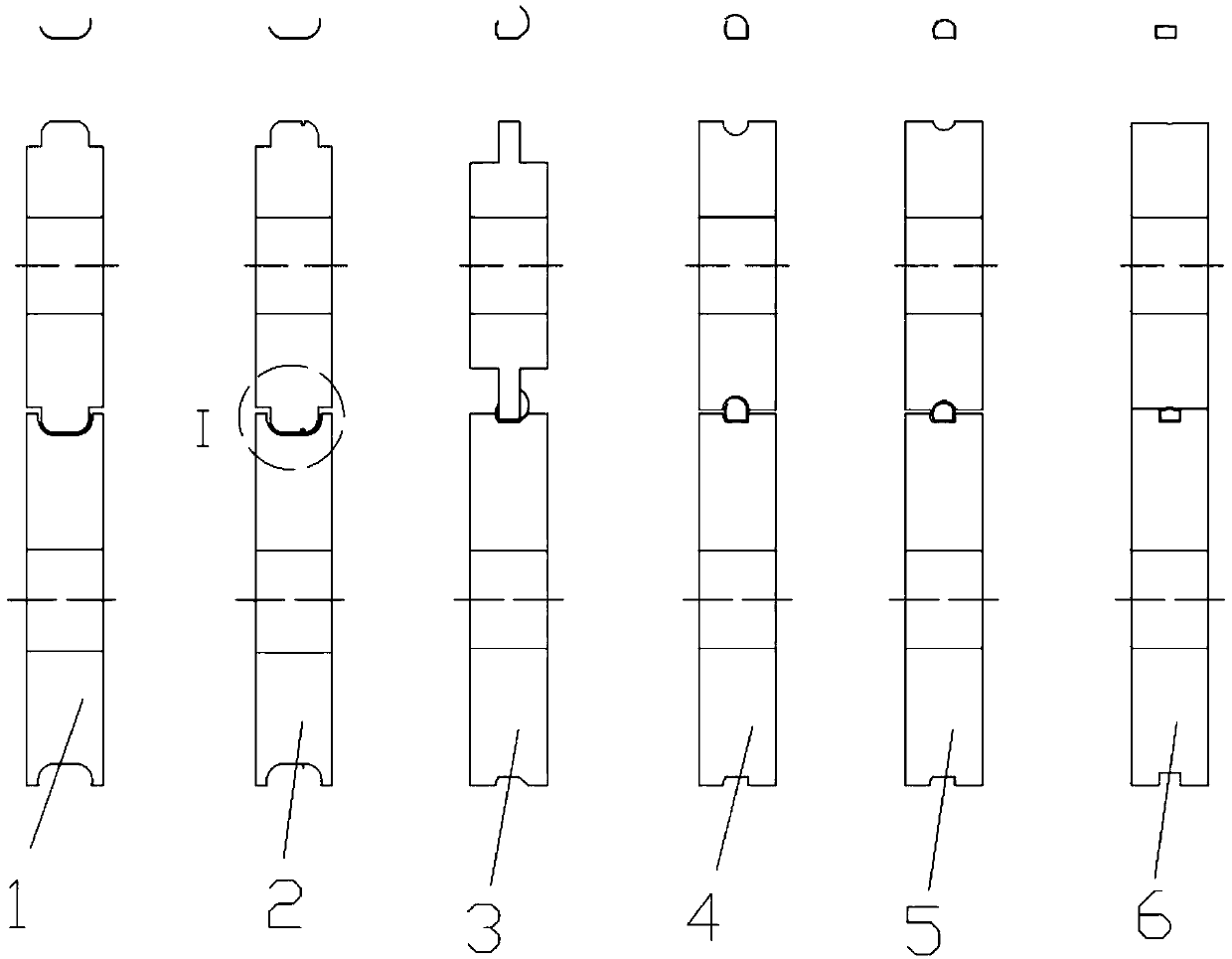

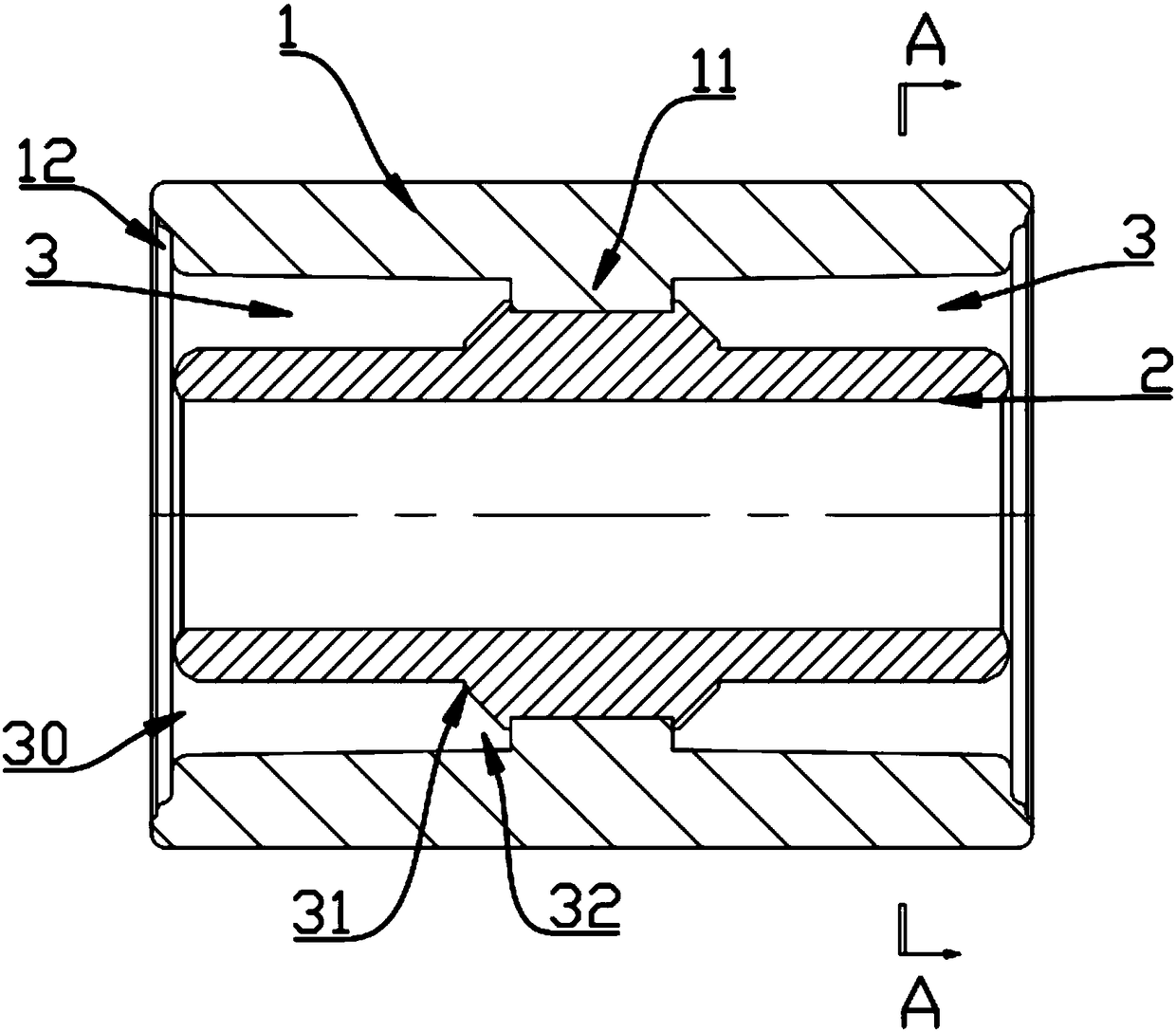

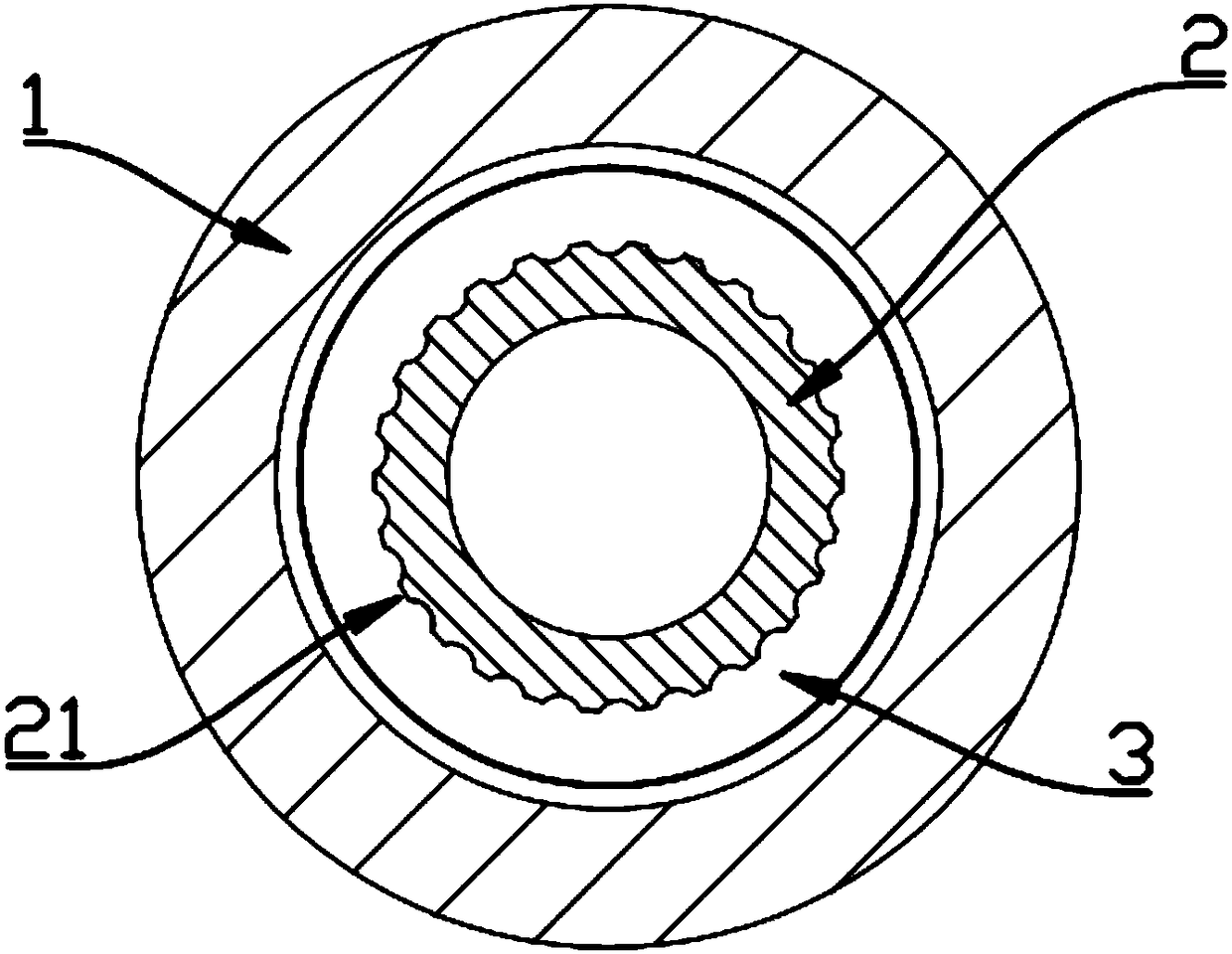

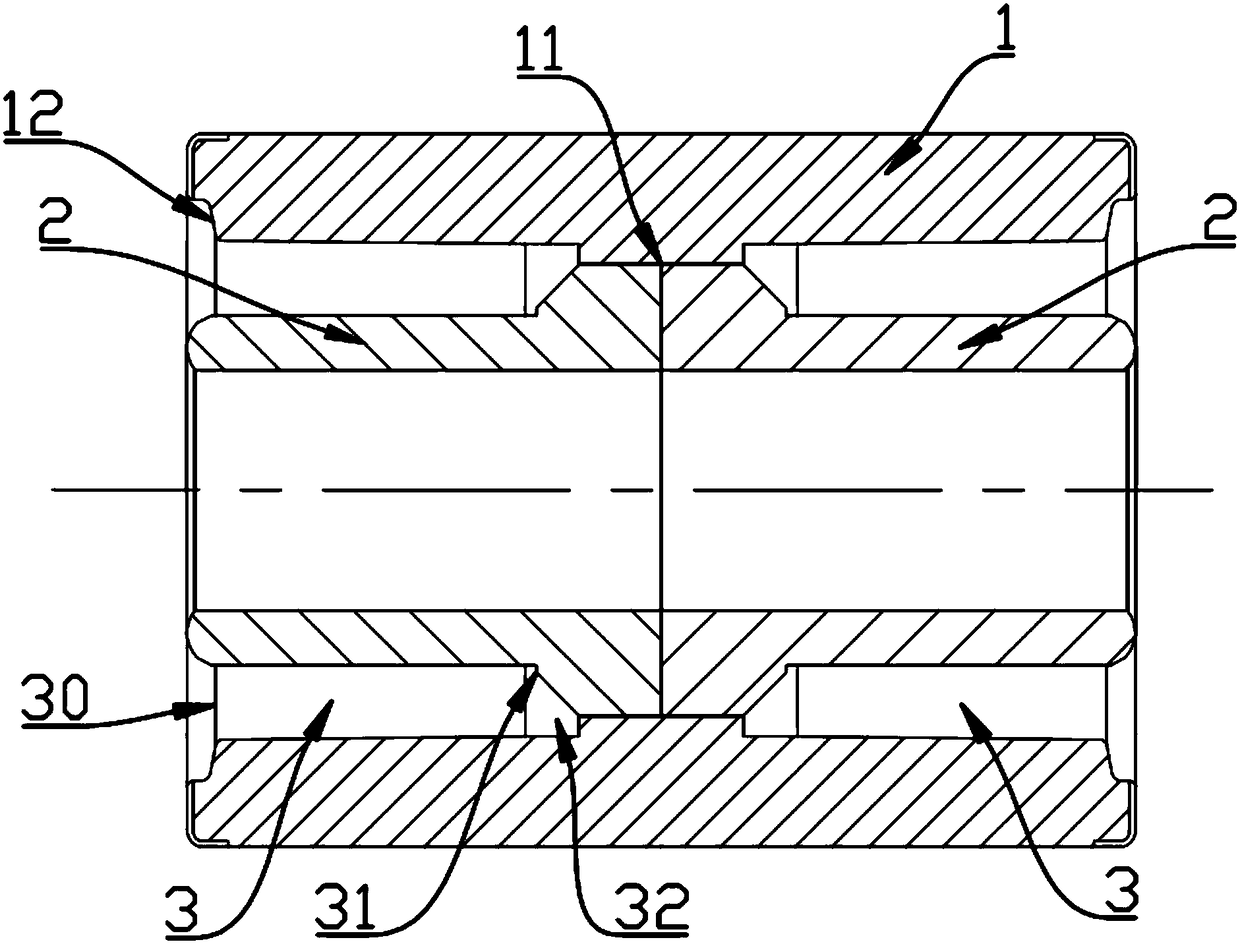

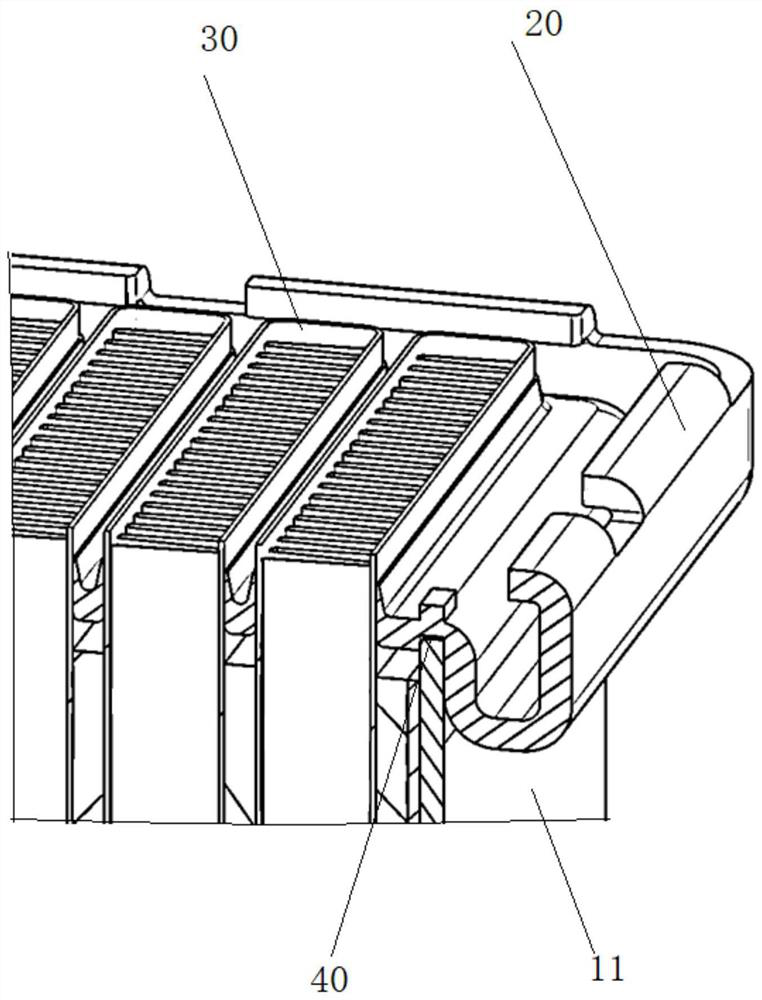

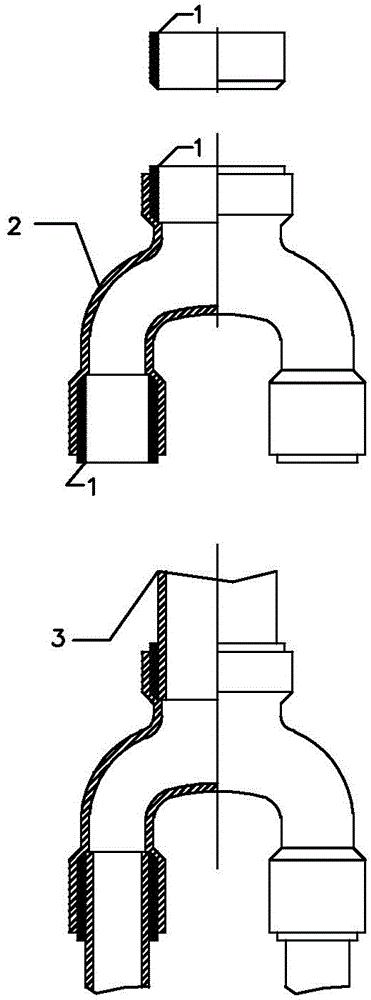

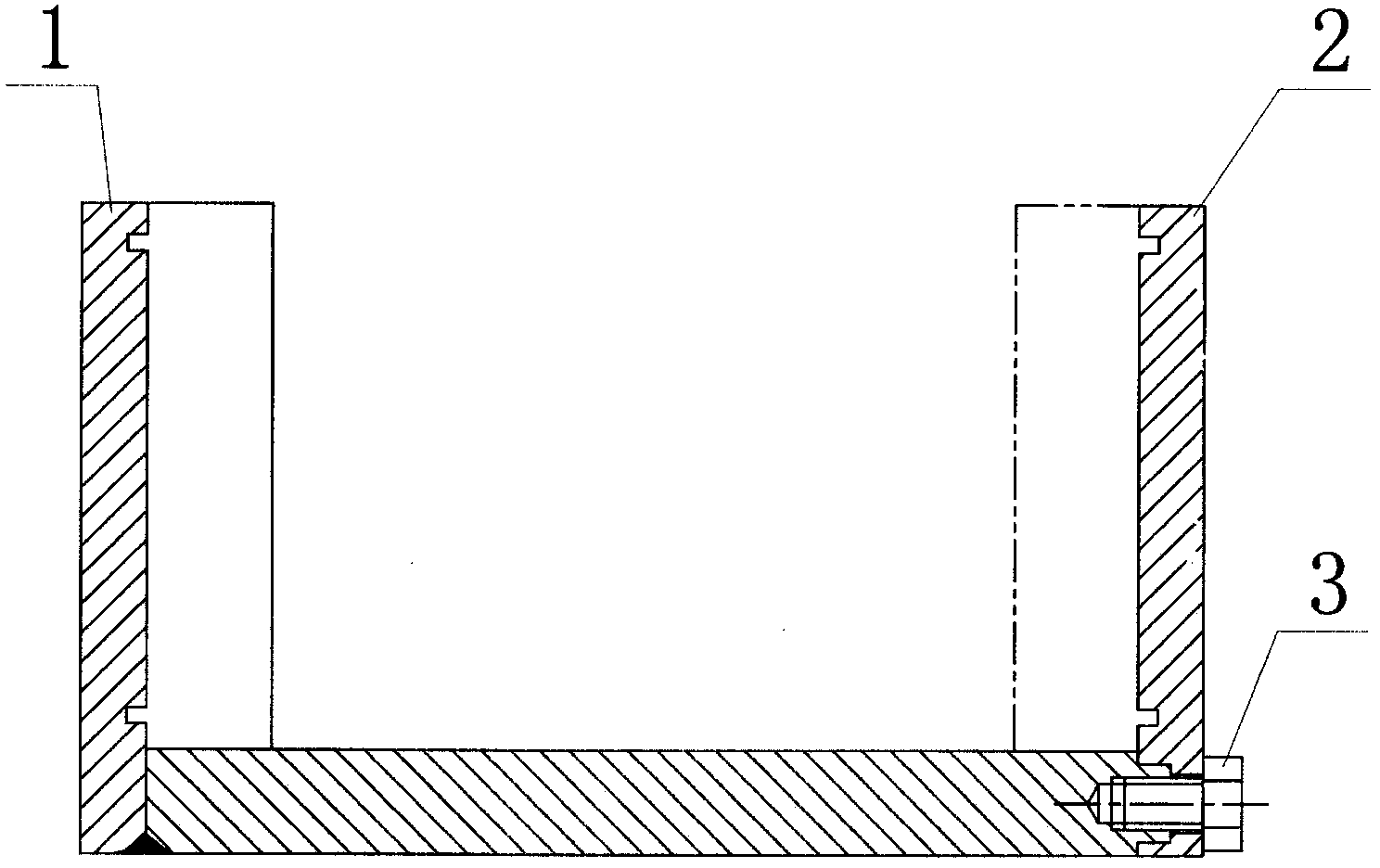

Tube connector with preset brazing filler metal

InactiveCN105983746AAvoid missing solderImprove brazing qualitySolder feeding devicesSoldering auxillary devicesFiller metalBrazing

A pipe joint pre-soldered. In order to overcome the inconvenience of inhomogeneous melting of brazing material and adding brazing material in the brazing process, the present invention adopts the scheme of presetting brazing material at the socket position of the pipe joint, making it a pipe joint with pre-set brazing material . During the brazing process of the pipe connection, the socket part of the pipe joint 2 is heated by the flame, and the brazing material 1 preset at the socket position of the pipe joint 2 first melts and is evenly fused, and the connected pipe 3 and The connecting portion of the pipe joint 2 is uniformly contained by the brazing material. This not only avoids missing welding caused by uneven distribution of brazing material, but also frees up the operator to do other things, which not only improves the welding quality but also improves the production efficiency.

Owner:叶东来

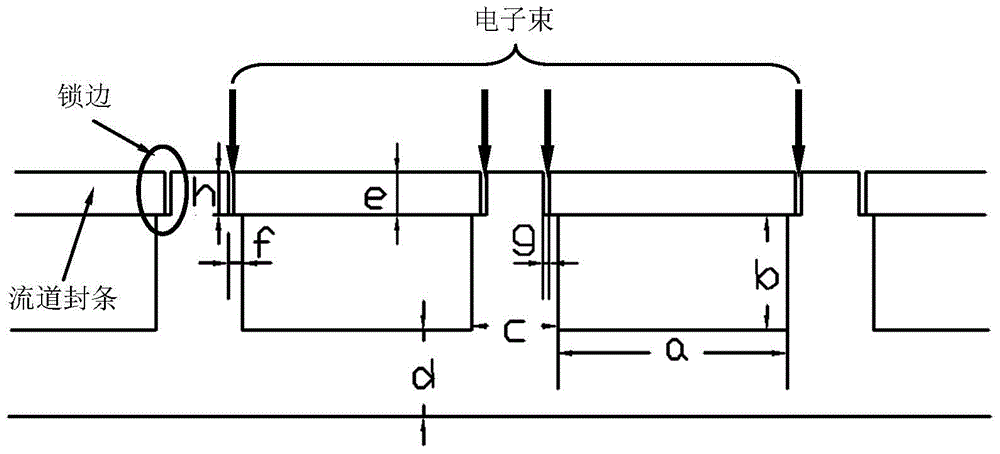

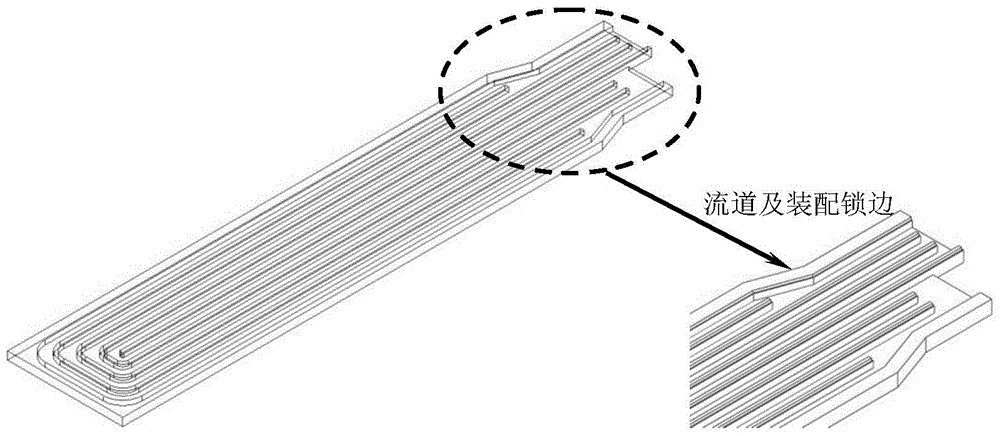

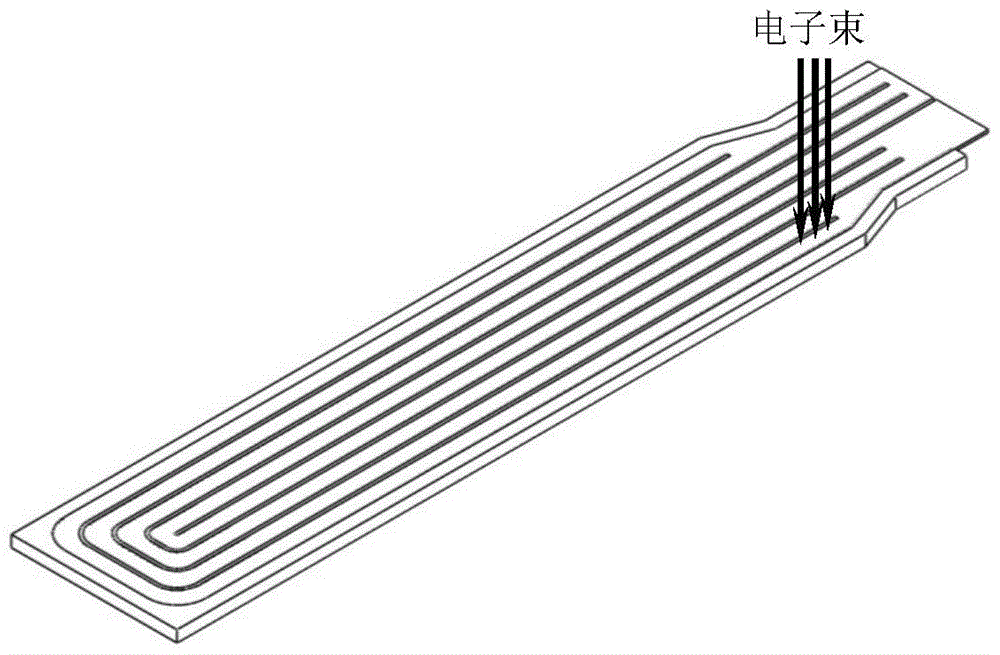

An Electron Beam Welding Process Suitable for Martensitic Steel High-Density Runner Package Forming

ActiveCN104400203BImprove performanceLarge amount of deformationElectron beam welding apparatusWelding/soldering/cutting articlesHigh densityBiological activation

The invention discloses an electron beam welding process suitable for encapsulation molding of a martensitic steel high-density runner. The process comprises such steps as size design of a runner seal and an assembly lockrand, demagnetization and cleaning of parts, weld preheating, electron beam welding of the seal, excess weld metal processing of the seal and annealing heat treatment. The electron beam welding process suitable for encapsulation molding of a cooling part runner of the martensitic steel high-density runner has such advantages as good runner molding, no such defects as air holes and cold / hot cracks and small welding deformation, solves the problems of easy cracking of an encapsulation welding line and big welding deformation of the martensitic steel high-density runner, and can be suitable for encapsulation molding of low-activation martensitic steel high-density and narrow-gap runners.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

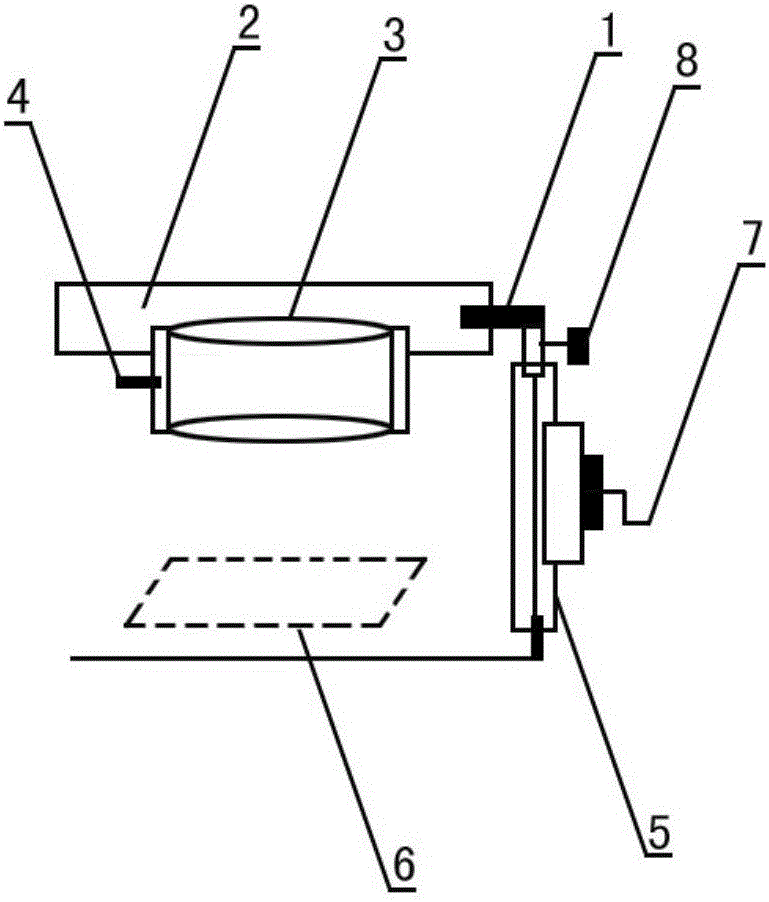

Lifting type tin soldering device for wiring harnesses

InactiveCN105689841ASimple structure designReduce outputSoldering auxillary devicesEngineeringSoldering

The invention discloses a lifting type tin soldering device for wiring harnesses. The device comprises a rack (1), wherein the rack (1) adopts a half-open mode design integrally; a supporting frame device (2), a coil fixing device (3) and a button pulling structure (4) are arranged at the upper portion; the rack is connected with a positioning platform (6) through a lifting component (5); a manual operating device (7) is installed at the outer side end of the lifting component (5); during use, a tin soldering furnace is located on the positioning platform (6); after wiring harnesses which need to be tin-soldered are positioned quantitatively, the height of the supporting frame device (2) is adjusted manually, and lifting type tin soldering operation is carried out; a prompting device (8) is arranged on one side of the rack (1), and the device gives different prompts according to the fastening state or the operating state; a mode of prompting is LED light display, and the light colors are divided into yellow, red and green according to operating states; phenomena of solder skips, inconsistent tin soldering depths and the like which are caused by manual operation are effectively avoided; output of manual labor is reduced; the product quality is guaranteed to be uniform; and the operation is simple.

Owner:ANHUI KANGCHENG IND PROD DESIGN

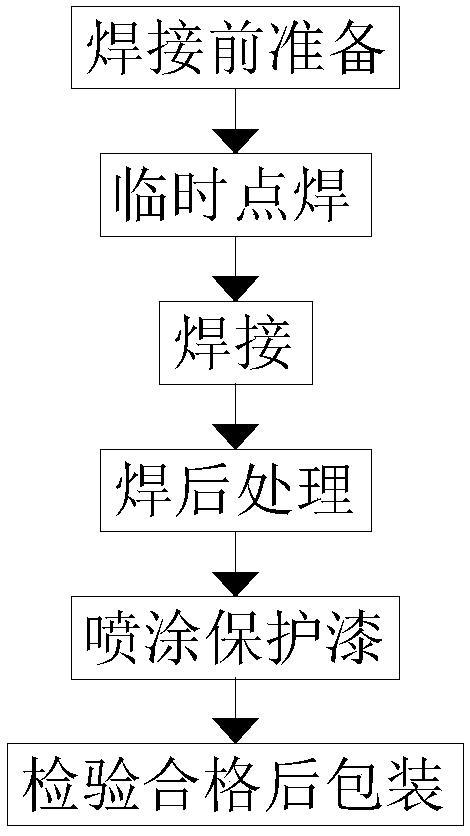

Environment-friendly carbon-gold battery horizontal terminal cast welding method

InactiveCN109967837AAvoid missing solderImprove welding efficiencyFinal product manufactureArc welding apparatusOxideVoltage

The invention discloses an environment-friendly carbon-gold battery horizontal terminal cast welding method. The environment-friendly carbon-gold battery horizontal terminal cast welding method comprises the following steps that A, preparation before welding is carried out; B, temporary spot welding is carried out; C, the welding is carried out; D, post-welding treatment is carried out; E, protective paint is sprayed; and F, packaging is carried out after passing inspection. The preparation before the welding includes the following steps that (1), accumulated water and accumulated snow on thebattery shell surface are removed completely to ensure dryness of the battery shell surface; (2), dirt of blocked rust oxide, greasy dirt, and the like on the surface of an horizontal terminal is cleaned up; and (3), a welding mode and a welding material are selected, Tungsten inert gas arc welding (TIG) is adopted, the type of the welding material is an ER CuNi-7 welding wire with phi 3.0mm, thewelding current is 250-300A, the welding voltage is 20-24V. According to the environment-friendly carbon-gold battery horizontal terminal cast welding method, a welding technology is adopted, the occurring of the phenomena of leakage welding, multi-welding, incomplete cleaning of welding slag and unqualified welding seams can be effectively avoided, the welding efficiency of the horizontal terminal is improved, the welding quality is ensured at the same time, and the environment-friendly carbon-gold battery horizontal terminal cast welding method is in line with self interests of enterprises.

Owner:GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

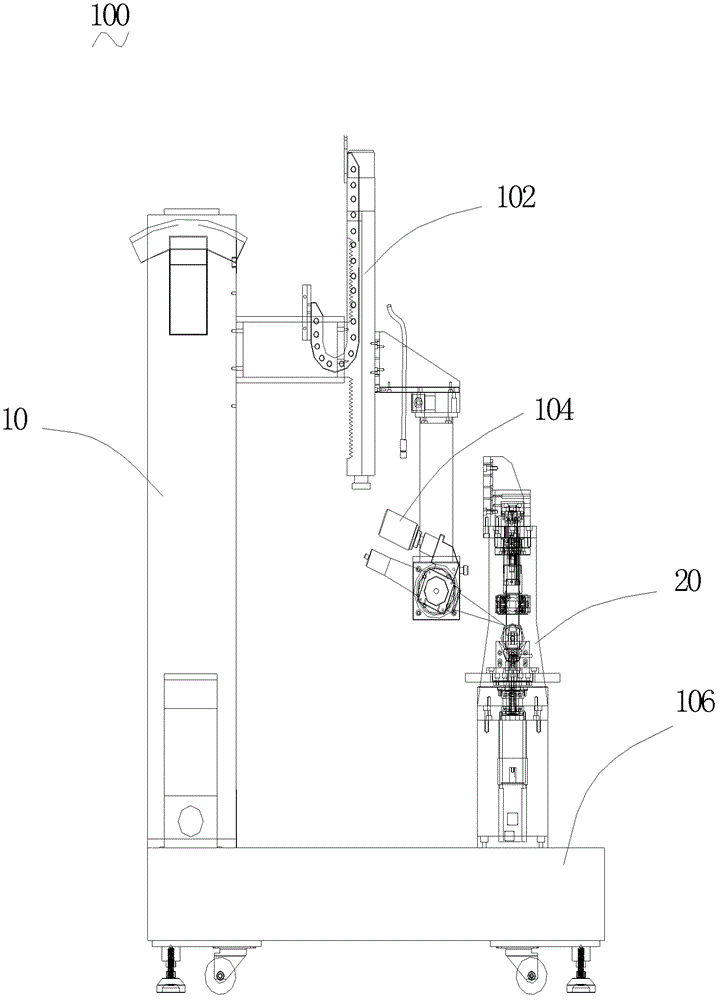

Laser welding method and device

InactiveCN102363247BRealize differential weldingAvoid missing solderWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionEngineering

The invention discloses a laser welding method, which is suitable for welding a main tube and a branch tube of a metal three-way tube. The method comprises the following steps of: setting the main tube and the branch tube of the metal three-way tube in a to-be-welded state, and rotating the main tube and the branch tube; and welding the main tube and the branch tube together by using a laser welding head which moves linearly in a reciprocating way relative to the rotating plane of the main tube. In the laser welding method, the metal three-way tube is rotated, and the laser welding head moves in a reciprocating way relative to the metal three-way tube simultaneously, so that the difference compensating welding of the metal three-way tube is realized, lack of weld is prevented, and the welding quality is improved. Moreover, the invention further provides a laser welding device.

Owner:HANS LASER TECH IND GRP CO LTD

High-precision welding system for metal sheath for fireproof cable

InactiveCN113245740AAvoid missing solderQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPhysicsWeld seam

The invention relates to a high-precision welding system for a metal sheath for a fireproof cable, which comprises a workbench, and an edge trimming device, a wire wrapping device, a welding joint device and a cooling device which are sequentially arranged on the upper surface of the workbench. The welding joint device comprises a detection mechanism and a welding mechanism. The welding mechanism comprises an adjuster fixedly connected to the workbench, a fine adjustment component connected with the adjuster and a welding head connected with the fine adjustment component. The detection mechanism comprises a visual tracking system, the visual tracking system can drive the fine adjustment component to drive the welding head to reciprocate in the horizontal direction, and a welding edge line cleaning device is arranged on the front side of the welding joint device. Before welding, the side edge of a metal band is treated and deburred through the welding edge line cleaning device, the situation that since powder accumulation occurs at the butt welding joint position, the welding quality is affected is avoided, the butt joint position of the metal band is tracked through the visual tracking system in the welding process and fed back to the fine adjustment component for real-time adjustment, and the phenomenon of weld skip is avoided.

Owner:NANYANG CABLE TIANJIN

Welding online monitoring system

InactiveCN102430883BAchieve positioningImplementation statusWelding/cutting auxillary devicesAuxillary welding devicesProduction lineMonitoring system

The welding online monitoring system of the invention relates to a welding monitoring system. The welding online monitoring system comprises a main controller and a positioning detecting module, a welding gun magnetism detecting module, an alarming module, a fixture controlling module, a panel LED module and a digitron display module respectively connected with the main controller. The positioning detecting module can position precisely, the positioning information can be displayed by the panel LED module, if the positioning is not accurate, the alarming module will alarm, number of the welding points can be detected by the welding gun magnetism detecting module, and the number and the process state can be displayed by the digitron display module. Thereof, the invention can realize precise positioning and state indicating of parts placed on the fixture of the welding production line to prevent missed welding and mistaken welding during the welding process. The fixture controlling module can control automatic opening or closing of the welding fixture before and after the welding to improve the automatic degree of the welding production line and to relieve the working intensity of workers at the production line.

Owner:LIUZHOU GAOHUA MACHINE

Heating head capable of detecting hot-melting piece and heater

PendingCN107580382AEasy to find the correct positionAvoid missing solderInduction heating apparatusType metalElectromagnetic induction

The invention discloses a heating head capable of detecting a hot-melting piece. The heating head is provided with at least one hot-melting piece detector. The hot-melting piece detectors are metal detectors. The metal detectors are electro-magnetic inducted metal detectors or X-ray detection type metal detectors or ultrasonic detection type metal detectors. The hot-melting piece detectors are cylindrical. The number of the hot-melting piece detectors is four. The four hot-melting piece detectors are distributed on the side face of the heating head. The distribution shape of the four hot-melting piece detectors is rectangular. The detection heads of the hot-melting piece detectors are fixedly connected with the heating head through fixing racks. The hot-melting piece detectors are identical to the heating head in orientation. A heater comprises a heating head, wherein the heating head is the heating head capable of detecting the hot-melting piece. The correct position of the hot-melting piece is easy to find, and caused solder skips, false solder and solder deviations are avoided.

Owner:高雄

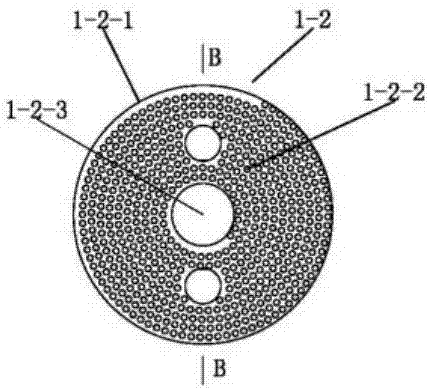

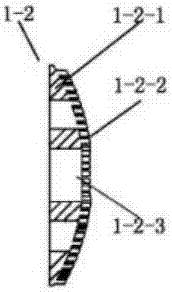

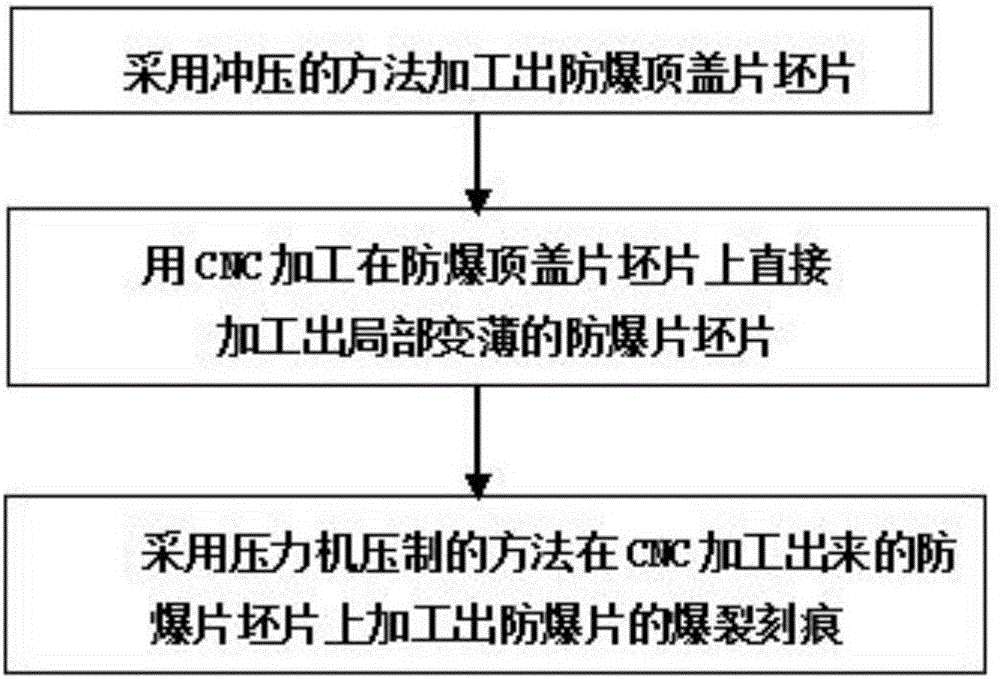

Manufacturing method of explosion-proof head cover plate

InactiveCN106025115AImprove reliabilityImprove stabilityCell lids/coversIntegrated processingProcessing cost

The invention discloses a manufacturing method of an explosion-proof head cover plate. Manufacturing is carried out by an integrated processing and molding method of an explosion-proof plate and the explosion-proof head cover plate. Firstly, an explosion-proof head cover plate blank is machined by a stamping method; secondly, an explosion-proof plate blank which is locally thinned is directly machined on the explosion-proof head cover plate blank through CNC machining; and finally, a burst score of the explosion-proof plate is machined on the explosion-proof plate blank obtained through CNC machining by a press compacting method. By the manufacturing method of the explosion-proof head cover plate, stamping, thermal treatment and detection procedures of the individual explosion-proof plate, a welding procedure of the explosion-proof plate and the head cover plate, a seal testing procedure of a welding line and the like are omitted; and the material and processing cost are reduced.

Owner:广州力电宝电子科技有限公司

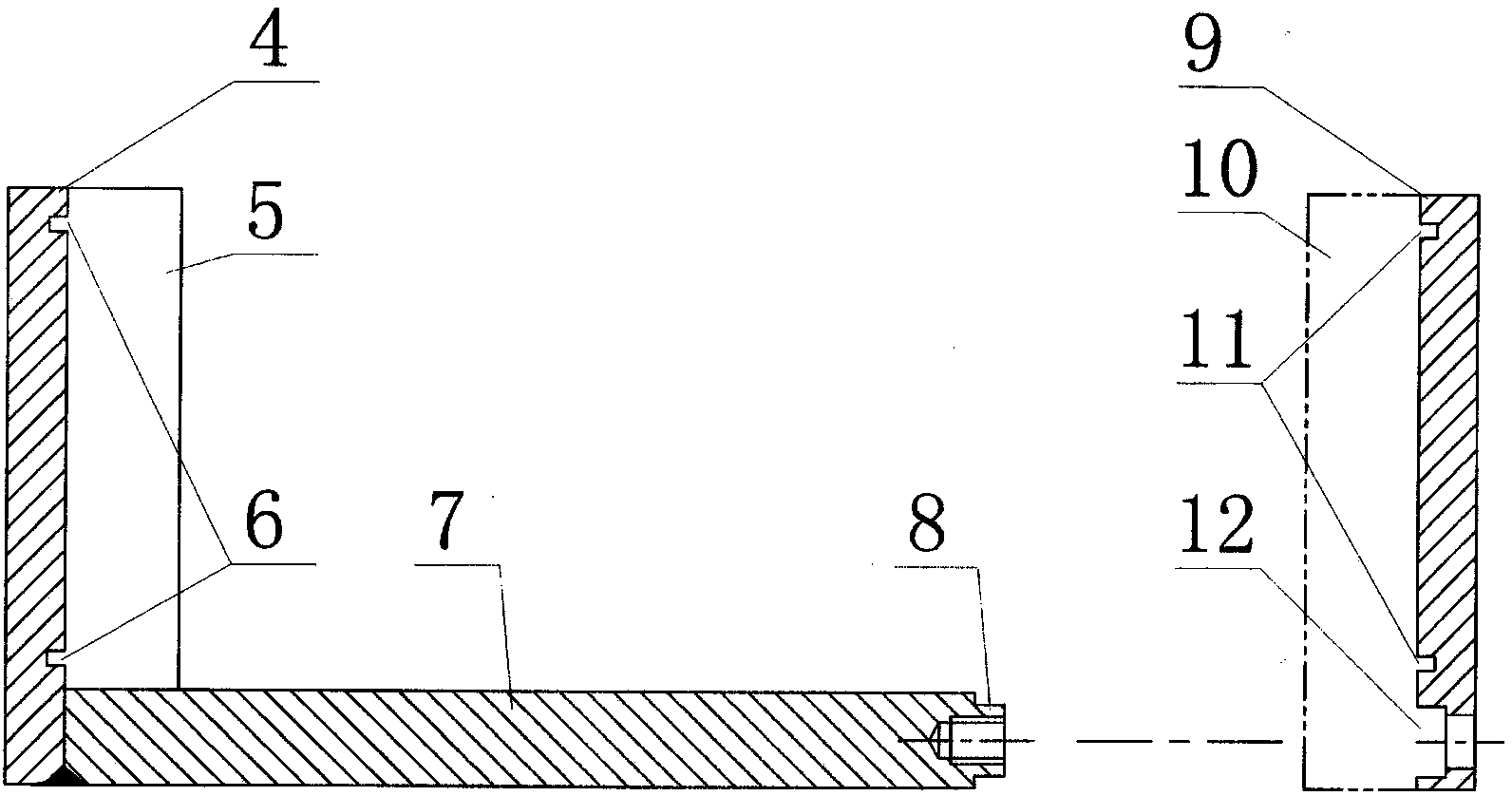

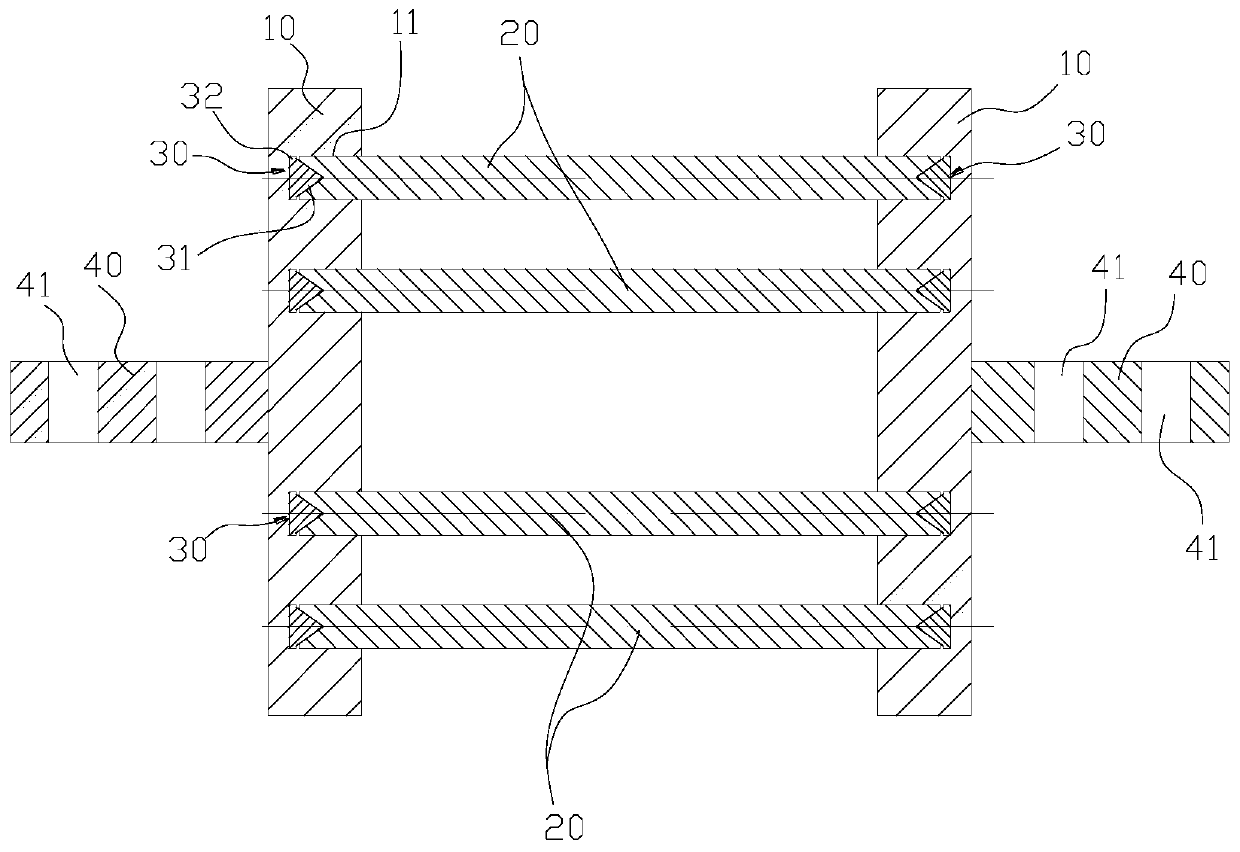

Welding fixture and welding process for magnetic medium box

ActiveCN102350608BGuaranteed Spacing RequirementsGuaranteed Parallelism RequirementsWelding/cutting auxillary devicesArc welding apparatusMagnetic mediaFixed frame

The invention relates to a welding fixture and a welding process for a magnetic medium box. The welding fixture is an integrated fixture with baffles on two sides and an opening at the top. A main formwork and a side formwork are fastened through connecting bolts to form the integrated fixture. The welding process comprises the following steps: 1) preparing the welding fixture, and inserting magnetic medium sticks in two angular holes at external ends of two pored plates of the magnetic medium box, thereby forming a fixed frame; 2) inserting all the magnetic medium sticks in turn; 3) aligning mortises of the side formwork to rabbets of the main formwork, assembling and fastening the side formwork and the main formwork; 4) beating exposed ends of the magnetic medium sticks so that the lower end faces of the magnetic medium sticks fit a base plate tightly; 5) placing into a cooling water tank for argon arc melting welding; 6) welding the bottom; and 7) finishing the welding. A special welding fixture is used for integrally melting and welding exposed parts at two ends of the magnetic medium sticks and the pored plates into a whole by directly utilizing argon arc welding, and the effect of even, smooth and firm welding is achieved. The welding process is performed in the cooling water tank, thereby greatly reducing the welding thermal deformation and improving working condition of welding operators.

Owner:岳阳大力神电磁机械有限公司

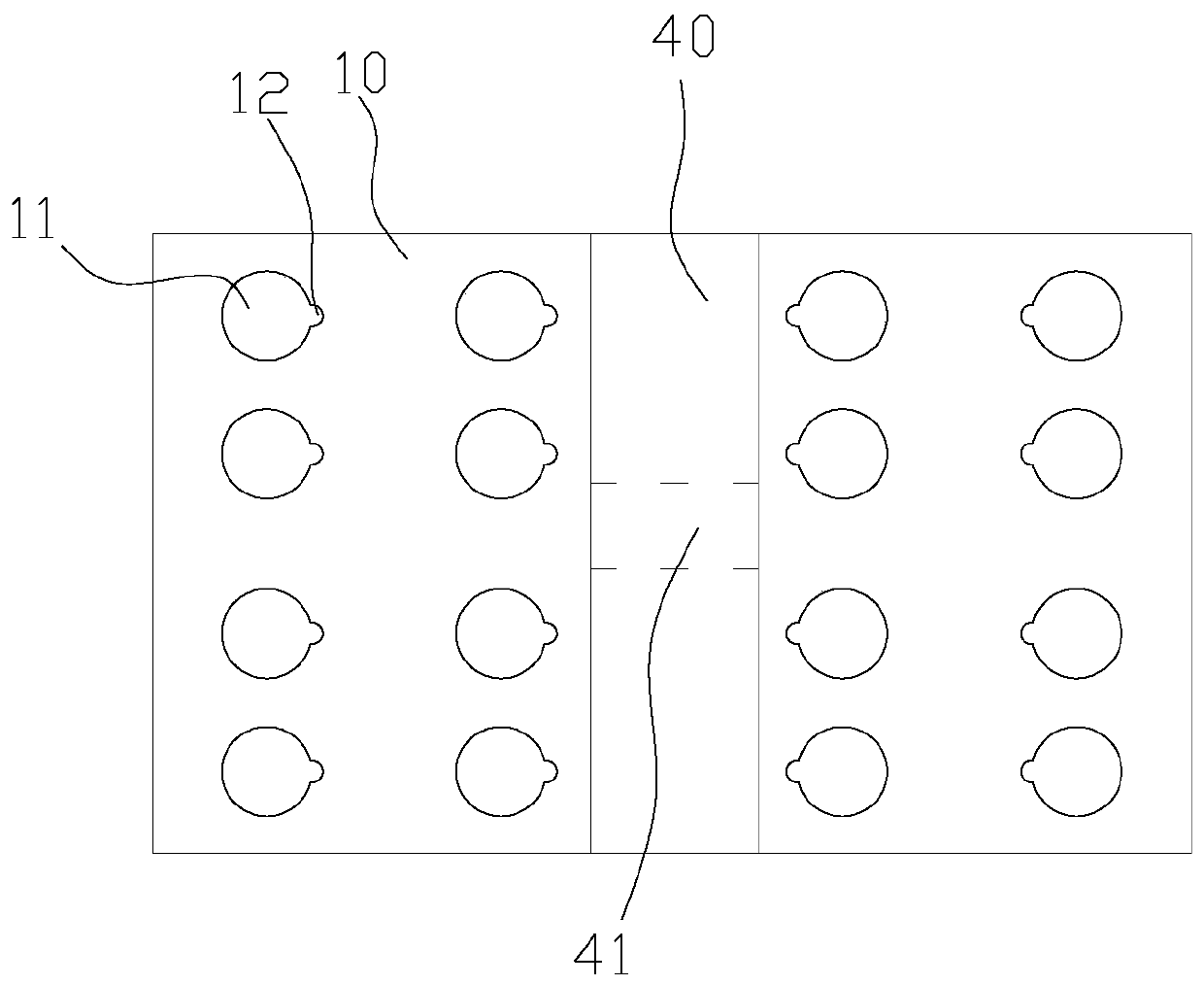

Shunt and manufacturing method thereof

ActiveCN110034418AQuick connectionFirmly connectedContact member manufacturingRiveted connectionsEngineeringRivet

The invention discloses a shunt and a manufacturing method thereof. The shunt comprises plate-shaped wiring terminals, resistance rods and rivets, wherein the two plate-shaped wiring terminals are oppositely arranged; the two plate-shaped wiring terminals are provided with insertion holes in matrix arrangement, and the insertion holes are blind holes formed in the inner side plate surfaces of theplate-shaped wiring terminals; the multiple resistance rods are in one-to-one correspondence with the insertion holes, wherein the two ends of each resistance rod are provided with mortise holes respectively, and the mortise holes are conical; each rivet comprises a head part and a cap part, wherein the head part of the rivet extends into the corresponding mortise hole; and the two ends of each resistance rod are pressed into corresponding insertion holes of the two plate-shaped wiring terminals respectively, so that the tail part of the rivet is extruded by the hole bottom of the corresponding insertion hole.

Owner:陈敏

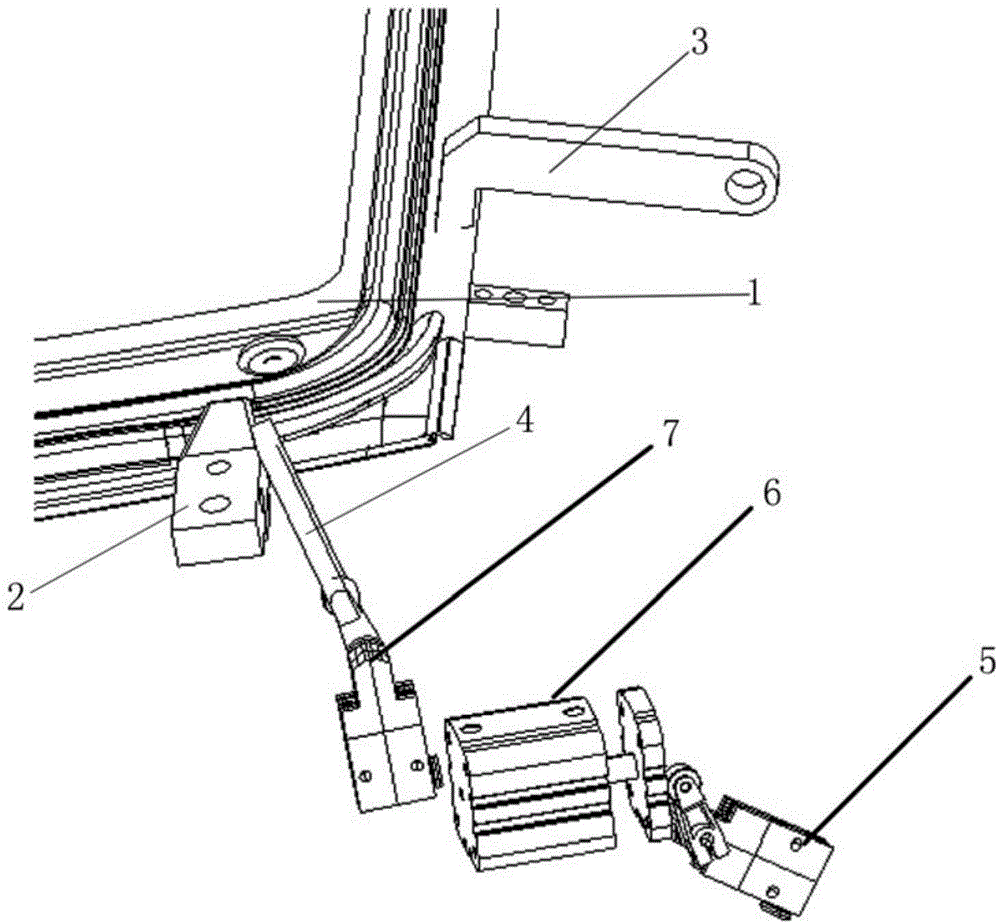

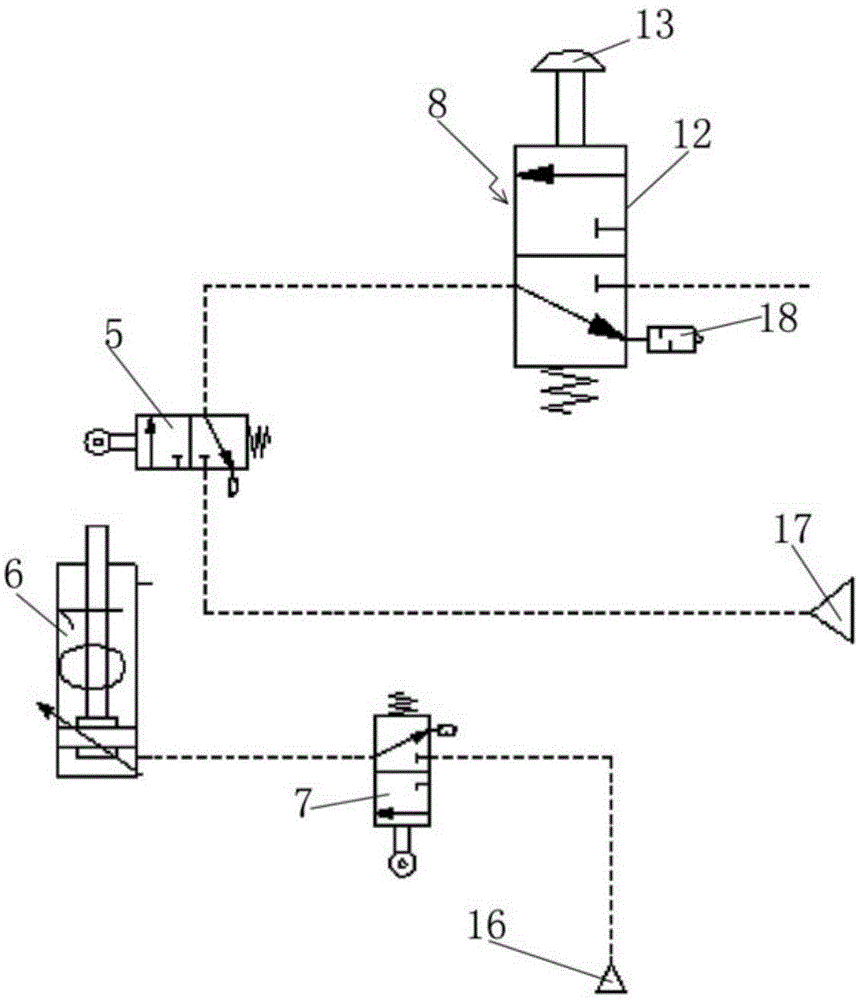

Derivative weld solder skips mistake prevention device and method

ActiveCN105728996ASave human resourcesAvoid missing solderWelding/cutting auxillary devicesAuxillary welding devicesElectric controlPetroleum engineering

The invention discloses derivative weld solder skips mistake prevention device and method, wherein the device comprises a lever type valve, a detection oscillating bar, a cylinder, a travel switch and a fixture gas circuit; the lever type valve is connected with the detection oscillating bar and the cylinder, the travel switch is connected with the cylinder, the travel switch is connected with the fixture gas circuit, the detection end of the detection oscillating bar is located at one side of at least one welding tong head in each group of repair welding tongs, the fixture gas circuit is in electric control connection with a fixture clamped on a component; the lever type valve, the cylinder and the travel switch form a detection loop; and the detection loop is connected in series with the fixture gas circuit. The derivative weld solder skips mistake prevention device is simple in structure, low in cost, and small in occupation space, can be repeatedly used, can reduce checking personnel and can completely realize prevention on solder skips.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com