High-precision automatic robot welding device and working method thereof

A technology of automatic welding and working methods, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of increased production costs of components, difficulty in completing the process, and low welding efficiency, so as to achieve stable welding quality, improve efficiency, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

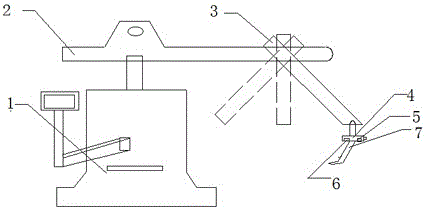

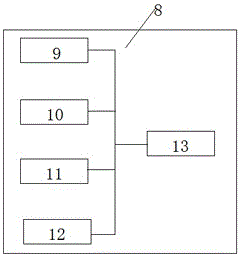

[0040] As shown in the figure, a high-precision robotic automatic welding device includes: a fixed seat 1, a transverse shaft 2, a first joint shaft 3, a second joint shaft 4, a first position sensor 5, a second position sensor 6, and a welding torch 7 And control device 8, wherein, described control device 8 comprises welding device 9, sensor control module 10, executive device 11, alarm system 12 and automatic control system 13, described automatic control system 13 is by adopting single-chip microcomputer control system and control Device composition,.

[0041] The relationship between the above components is as follows:

[0042] The fixed seat 1 is fixed on the ground by anchor screws, the horizontal shaft 2 is fixed on the fixed seat 1 by a positioning pin, and the first joint shaft 3 is set on one end of the horizontal shaft 2 by a positioning pin. The second joint shaft 4 is movably connected with the first joint shaft 3, the first position sensor 5 and the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com