Side buckle type aluminum parting strip for hollow glass

An aluminum spacer and glass technology, applied in the direction of windows/doors, building components, buildings, etc., can solve the problems of cumbersome process, aluminum spacer can not be bent, welding port burst, etc., to achieve simple molding process, reduce production costs, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The side buckle-type aluminum spacer for insulating glass provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

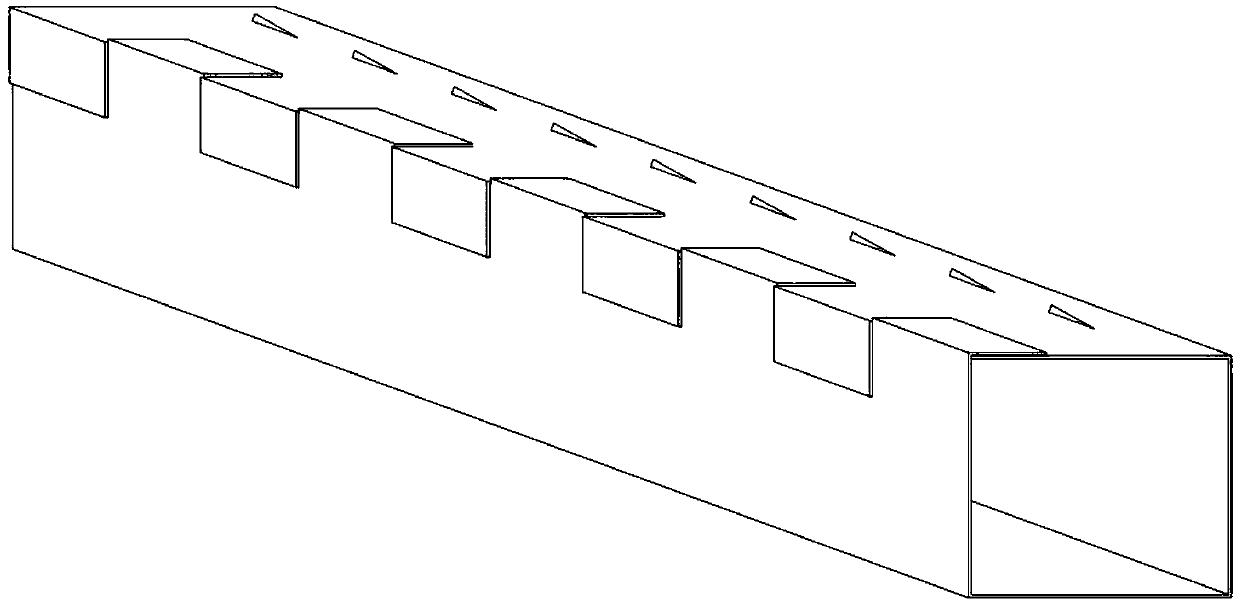

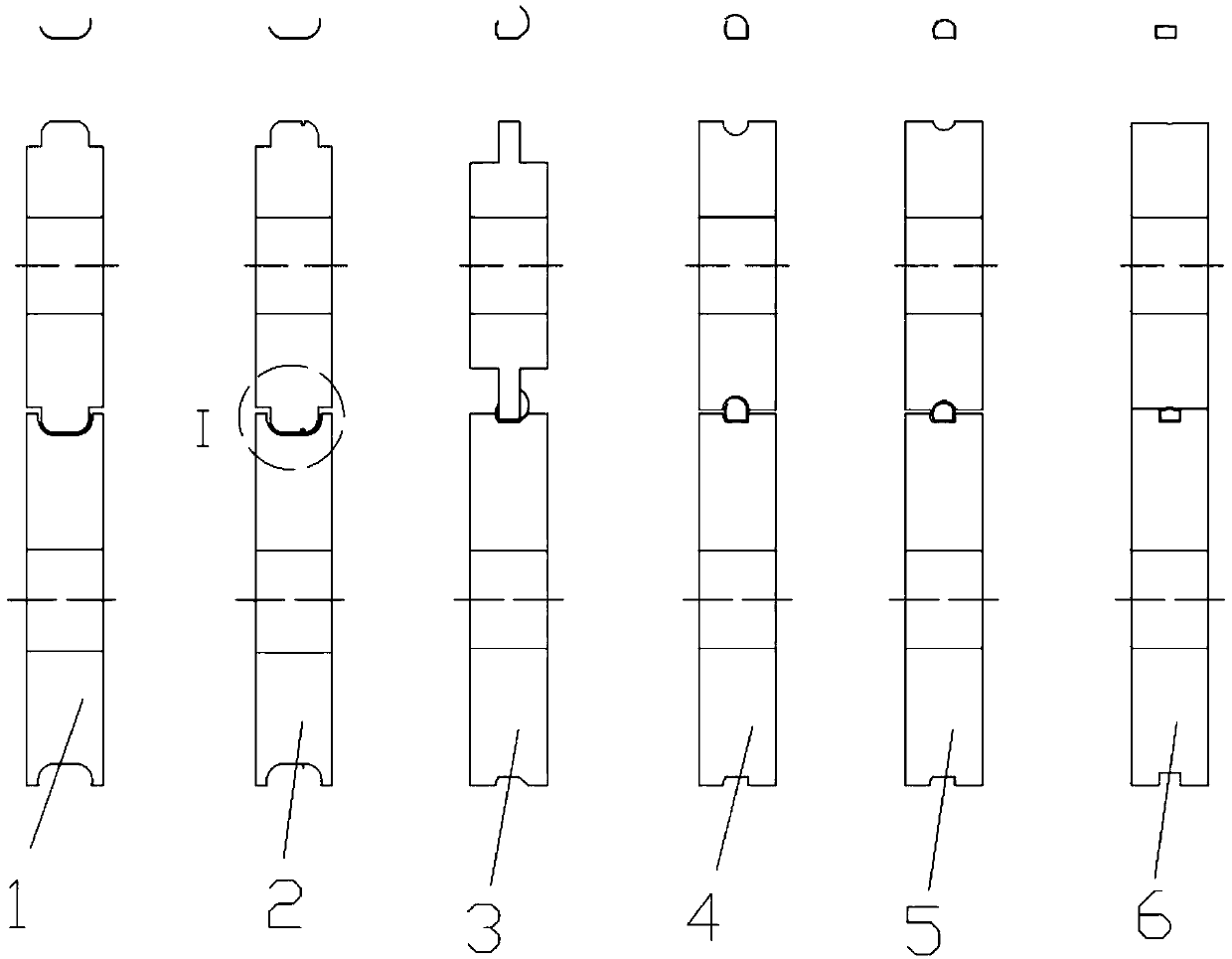

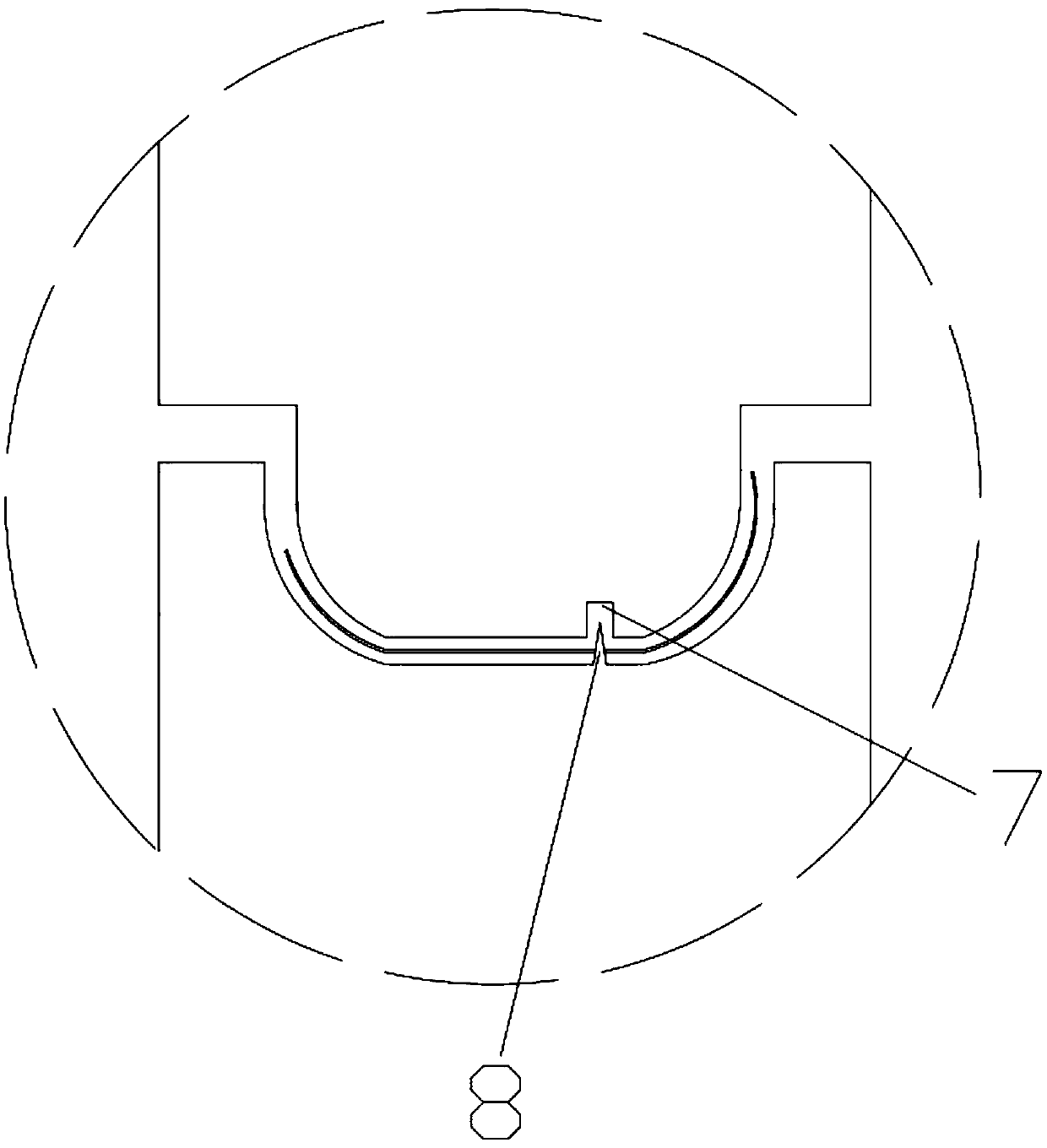

[0017] A side buckle aluminum spacer for insulating glass, the aluminum spacer is formed by rolling an aluminum strip through a forming die wheel set, and then straightening in the front, rear, left and right directions through multiple sets of pressure wheels, and the cross-sectional profile is formed by a straight line It becomes a rectangular frame. The left and right sides of the aluminum strip have concavo-convex shapes. Figure 2-3 As shown, the forming mold wheel set includes a first set of mold wheels 1 formed of upper and lower concave-convex mold wheels that are arc-shaped on both sides, and is composed of an upper mold wheel with a groove 7 and a lower mold wheel with a gear cutter 8 The second group of perforated mold wheels 2, one side is at an angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com