Derivative weld solder skips mistake prevention device and method

An error-proofing and welding-leakage technology, which is applied in the field of lead-out welding leakage prevention and welding error prevention and lead-out welding leakage-welding error prevention device, can solve the problems of customers' troubles, losses, and welding leakage, and achieve the effect of saving human resources and preventing welding leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

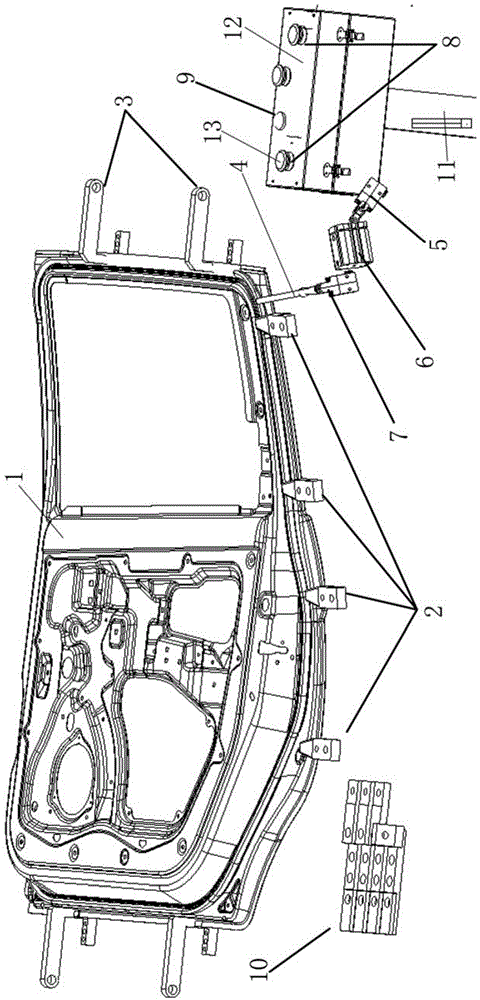

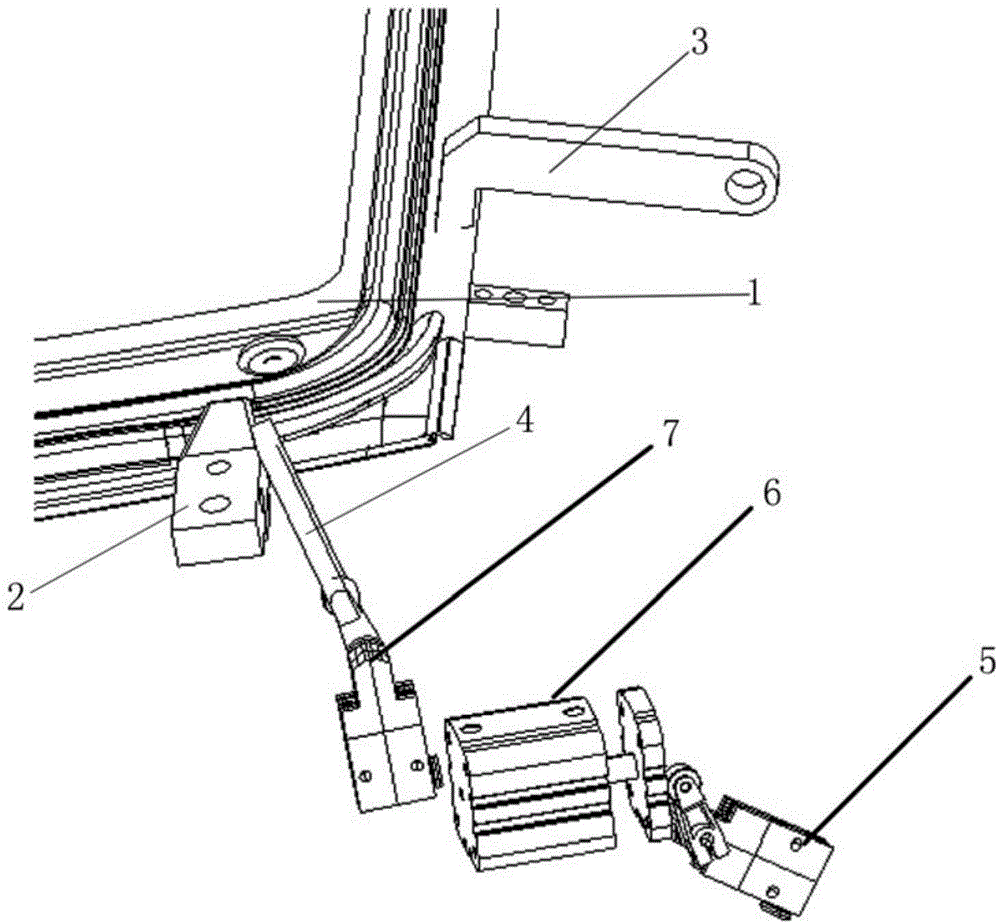

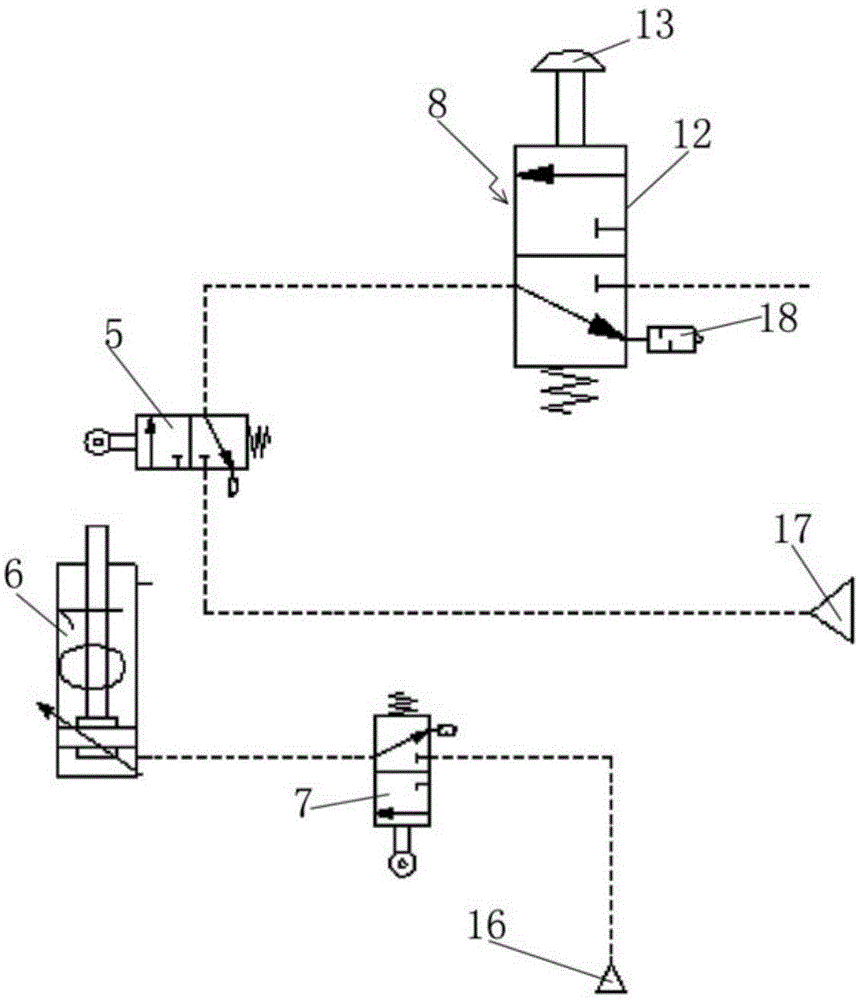

[0033] The following with attached Figure 1 to Figure 4 A device and method for preventing errors of lead-out soldering leakage according to the present invention will be further described in detail.

[0034] An error prevention device for lead-out soldering leakage welding according to the present invention, please refer to Figure 1 to Figure 4 , including a lever valve 7, a detection swing rod 4, a cylinder 6, a travel switch 5 and clamps 3 air circuits, the lever valve 7 is connected with the detection swing rod 4, the lever valve 7 is connected with the cylinder 6, and the The travel switch 5 is connected to the lever valve 7, the travel switch 5 is connected to the clamp 3 through the air circuit, and the detection end of the detection pendulum 4 is located on the side of at least one welding clamp head 2 in each group of repair welding clamps. 3. The air circuit is electronically connected to the fixture 3 clamped on the part 1. The lever valve 7, the cylinder 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com