Multi-machine collaborated wheat harvest system

A multi-machine and wheat technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of low efficiency and inability to meet the needs of harvesting, and achieve the goals of avoiding complicated processes, improving harvesting efficiency, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further describe in detail below in conjunction with accompanying drawing and specific embodiment:

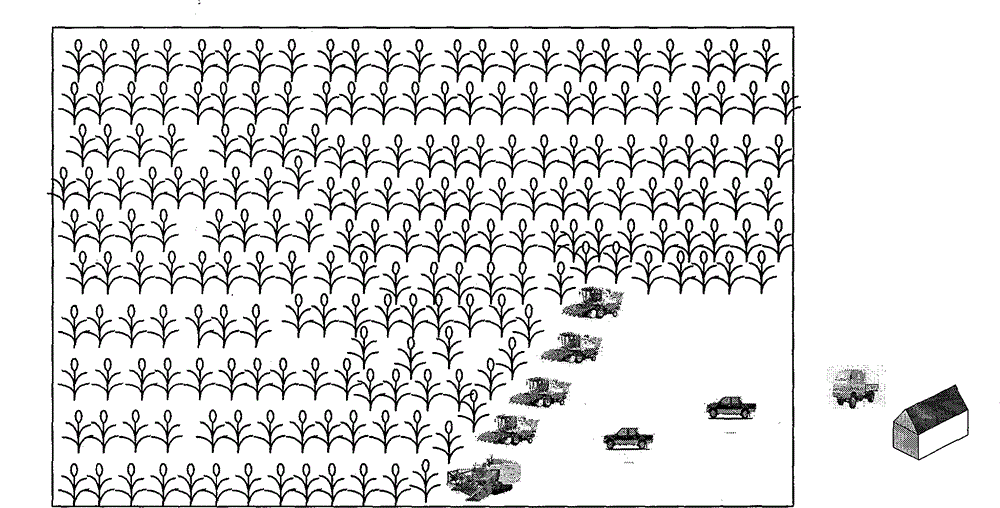

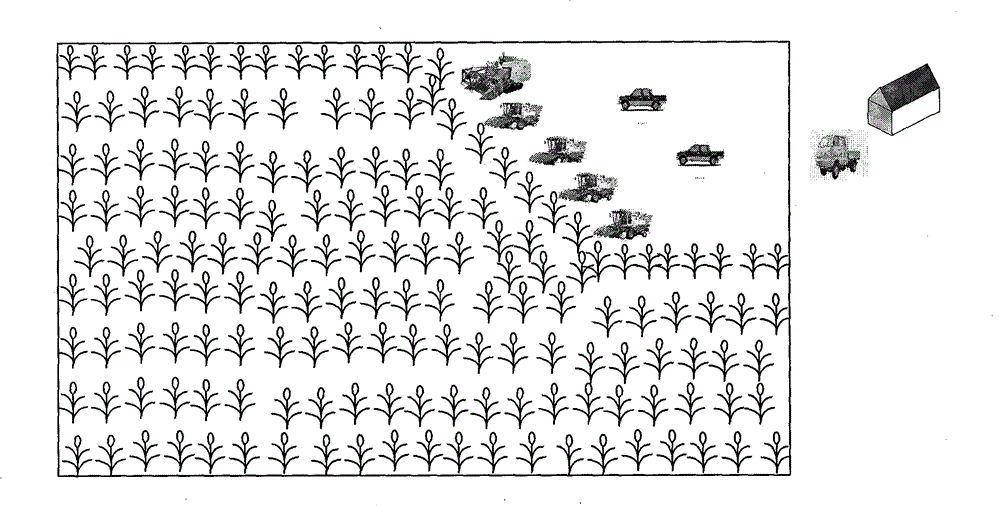

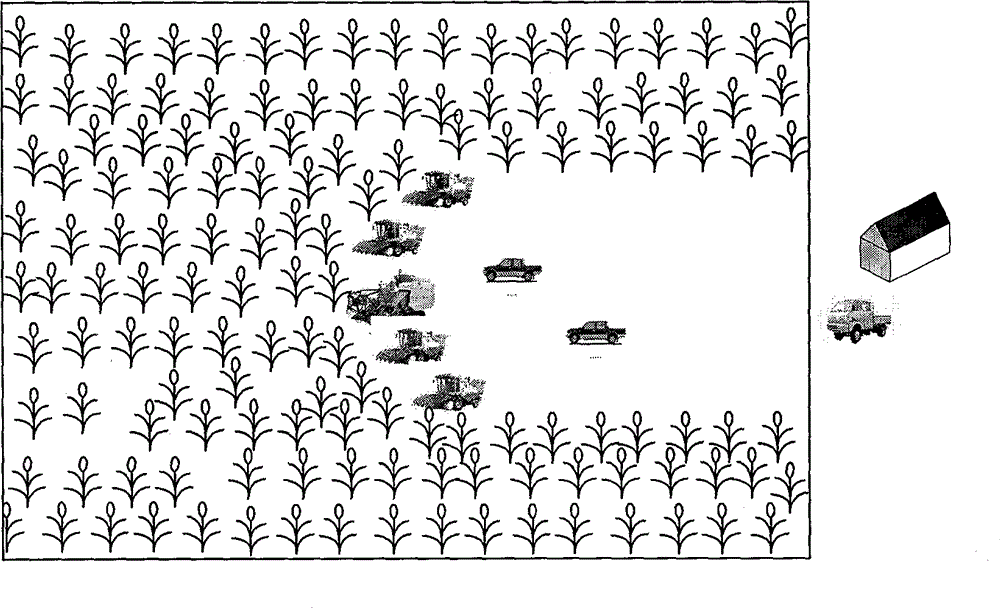

[0013] Such as figure 1 , the present embodiment includes: a leading wheat harvester, several following wheat harvesters, several wheat transport vehicles, a wireless communication system and a failure maintenance vehicle. Wherein, the pilot wheat harvester is manually driven, and it leads the vehicle formation while harvesting wheat. Several follower wheat harvesters form a certain formation and follow the lead harvester to move synchronously according to the received state information, control information and state information of adjacent robots. A number of wheat transport vehicles (the number of which is generally less than the number of harvesters) is close to the harvester and cooperates with each harvester according to the wheat harvesting amount of each harvester, loads, transports and unloads wheat, and follows the wheat harvester and wheat transport vehicle th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com