Patents

Literature

975results about How to "Improve harvesting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

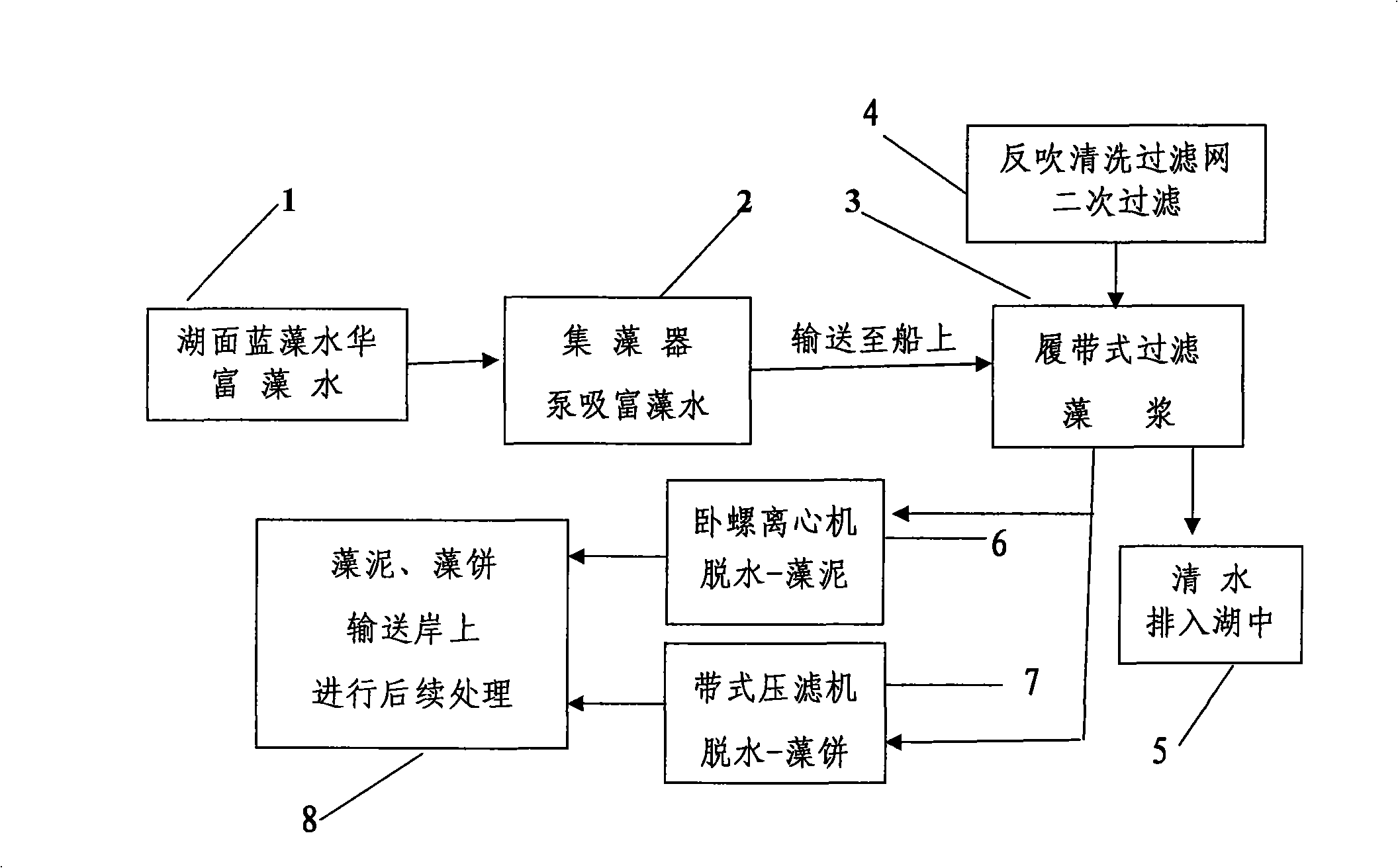

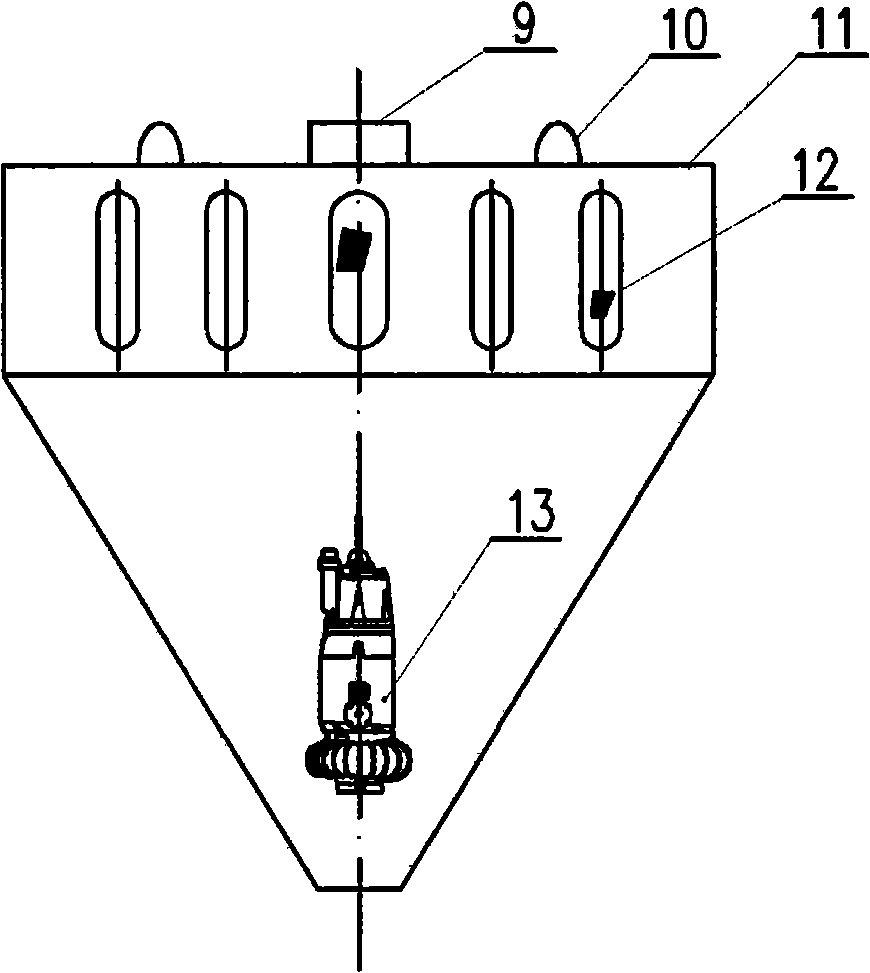

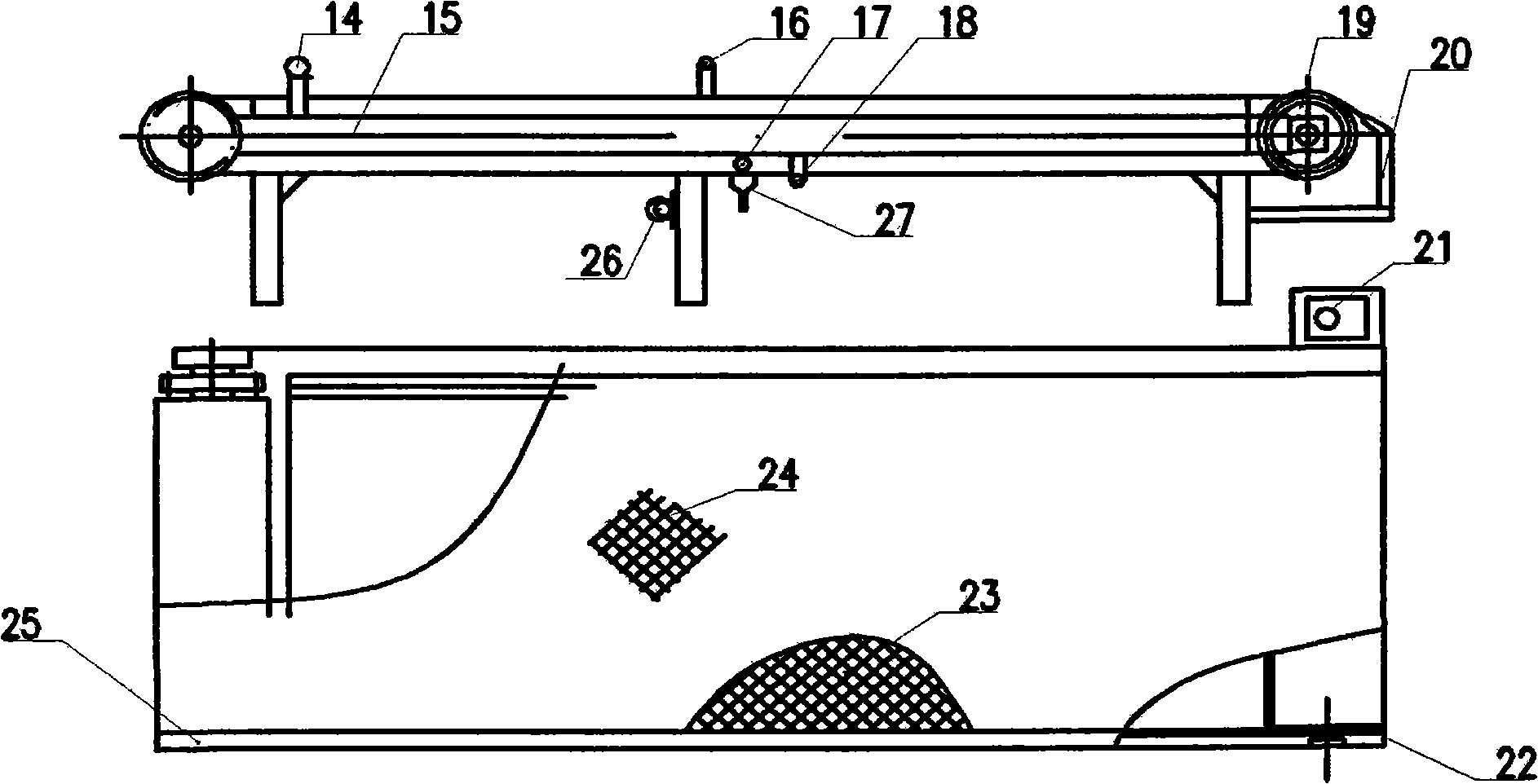

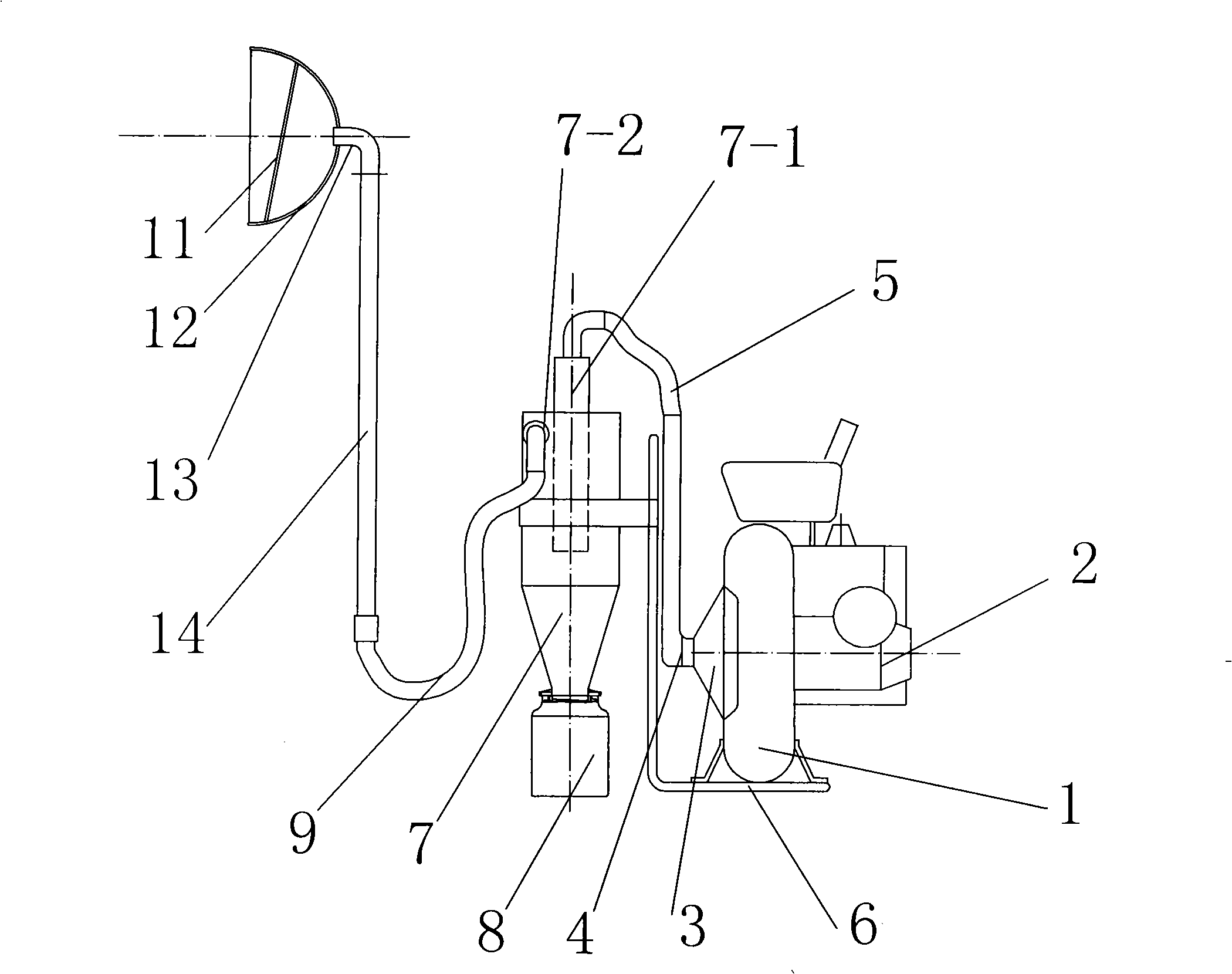

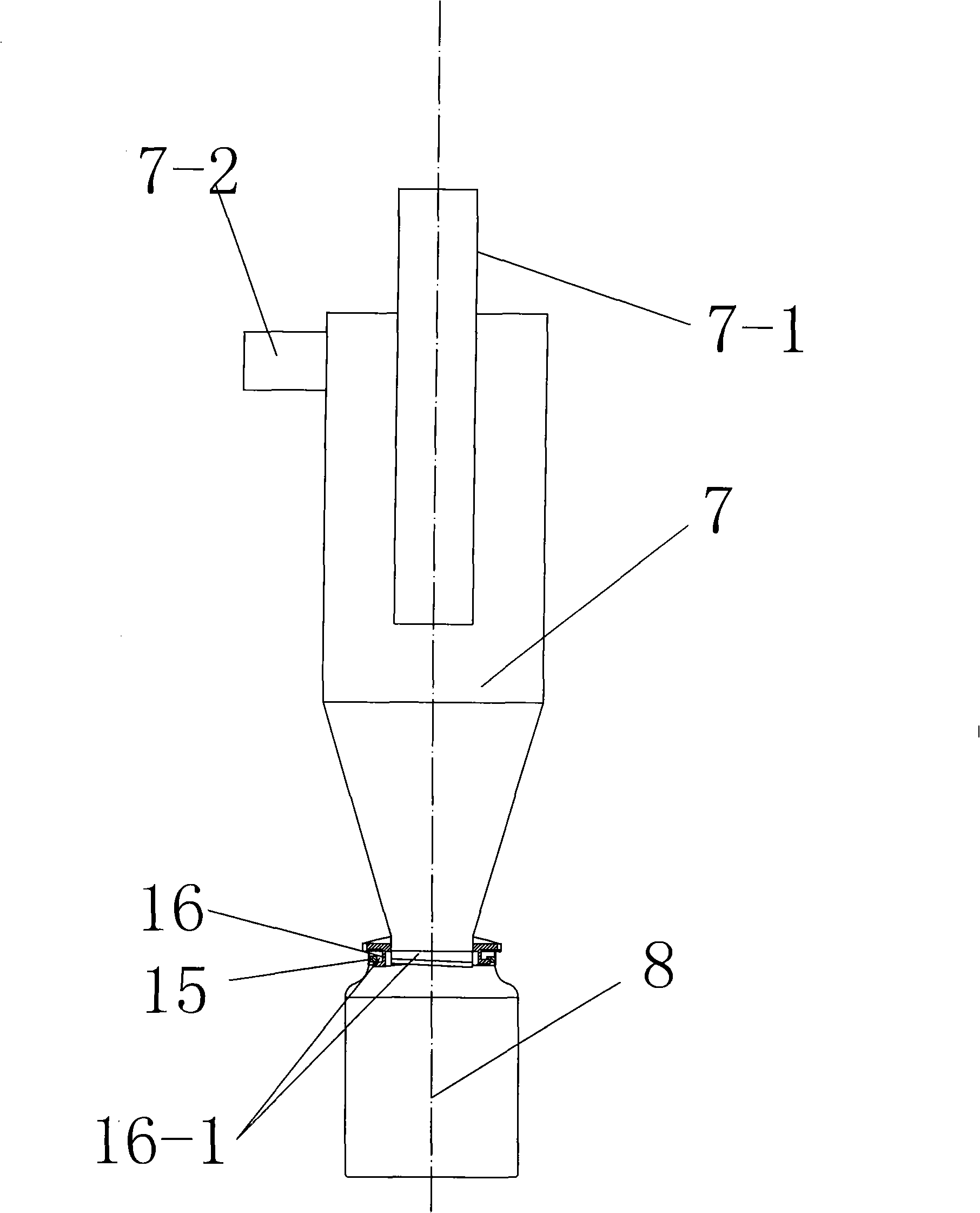

Method and apparatus for harvesting water bloom blue algae

InactiveCN101318714ASimple methodSimple and fast operationWater cleaningWater/sewage treatmentPhylum CyanobacteriaFiltration

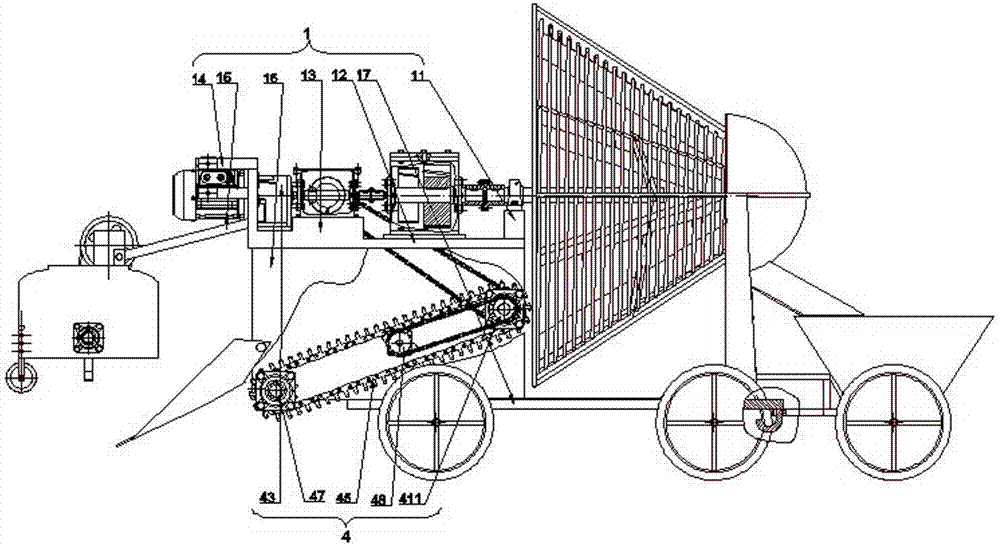

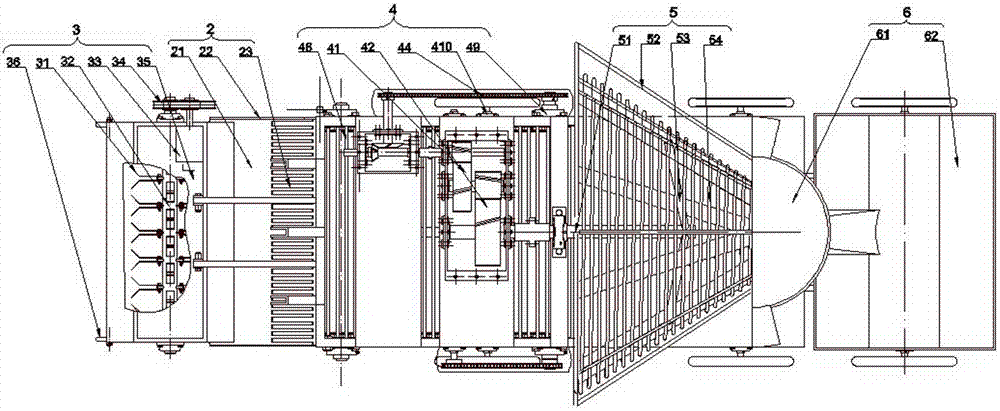

The invention discloses a method and a device for harvesting water-blooming cyanobacteria. The method comprises the following steps that: A. the water-blooming cyanobacteria is enriched into algae-rich water on water surfaces of lakes, reservoirs and riverways; B. an algae sucker pump is used to suck the algae-rich water; C. the algae-rich water is conveyed to a filtering system of a caterpillar system on a ship and is filtered into algae pulp; D. the algae pulp is subject to reverse purging and then secondary filtration; and E. the algae pulp is concentrated and dehydrated into algal biscuits or algae mud through a belt filter press or a horizontal screw decanter. The device for harvesting the water-blooming cyanobacteria comprises an algae sucker, a caterpillar algae-laden water filtering device, the belt filter press and the horizontal screw decanter, wherein, the fore of the ship is provided with the algae sucker, a non-clogging pump or a membrane pump is arranged in the algae sucker, the upper end of the algae sucker is provided with an impurity prevention net, and a cover plate is provided with a hoisting ring; and the caterpillar filtering device is fixed on a main frame body, and a stainless steel foraminous conveyer is arranged below a filter screen. The method is easy to operate, saves the energy, has low cost, a simple structure and convenient use, and effectively solves the problems of harvesting, concentration and dehydration of the water-blooming cyanobacteria accumulated in the lakes, reservoirs and riverways.

Owner:INST OF AQUATIC LIFE ACAD SINICA

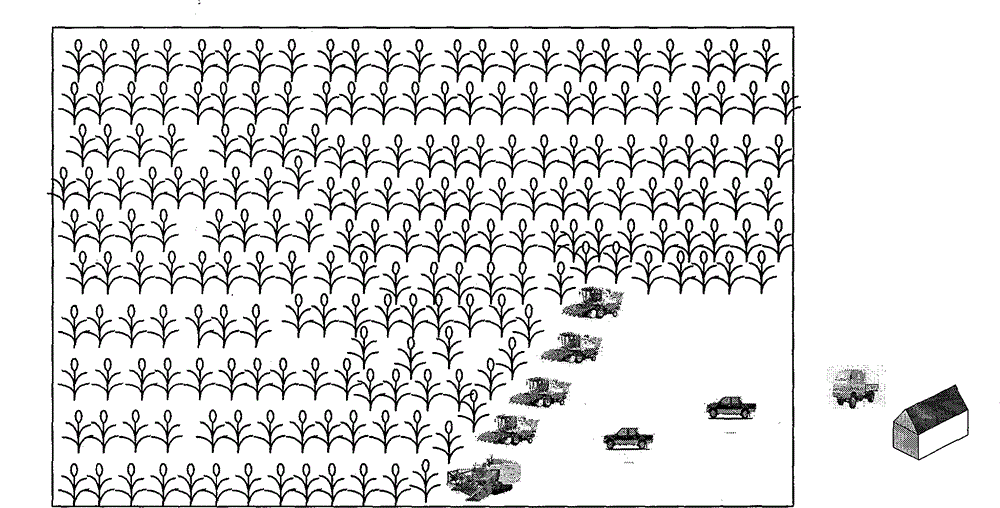

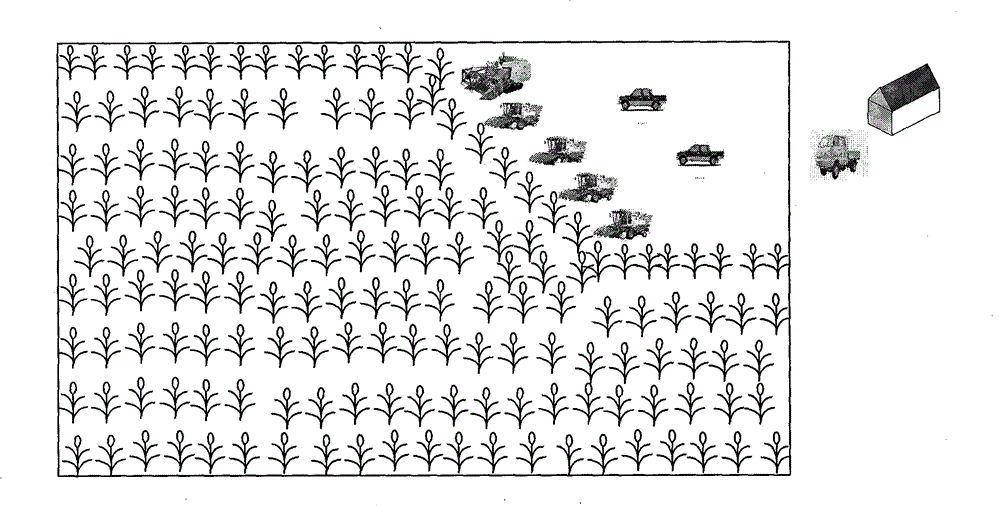

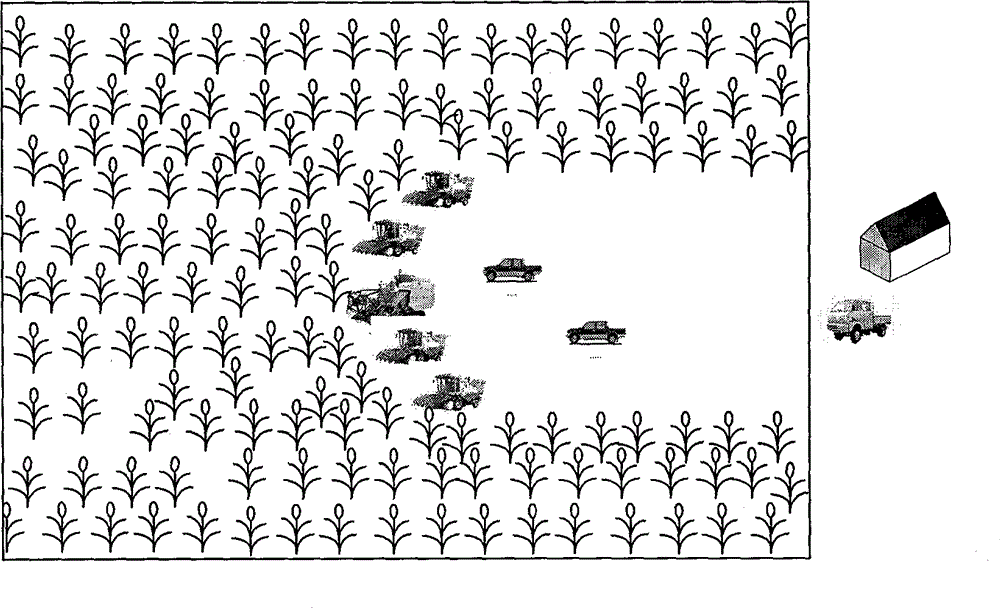

Multi-machine collaborated wheat harvest system

InactiveCN103181263ASave human resourcesReduce labor costsMowersProgramme total factory controlMulti machineCommunications system

The invention relates to a multi-machine collaborated wheat harvest system. The system comprises one piloting wheat harvester, a plurality of following wheat harvesters, a plurality of wheat transport carts, one maintenance truck and a wireless communication system. The multi-machine collaborated wheat harvest system uses one manually-driving harvester for piloting, and the plurality of automatically-driving harvesters follow to harvest wheat; and the wheat transport carts are adopted to be matched with the harvesters for operation, so as to automatically load, transport and unload harvested wheat. The multi-machine collaborated wheat harvest system has the advantages that the multiple machines are driven by one person, so that labor cost is saved; complex design for a single large-scale wheat harvester is avoided; collaboration of multiple machines enables the harvest efficiency to be improved exponentially, and great significance is realized for rush-harvesting in the farming season; and the harvesters and the transport carts are matched for operation, which further reduces labor intensity of people, and has certain practical value.

Owner:NORTHWEST A & F UNIV

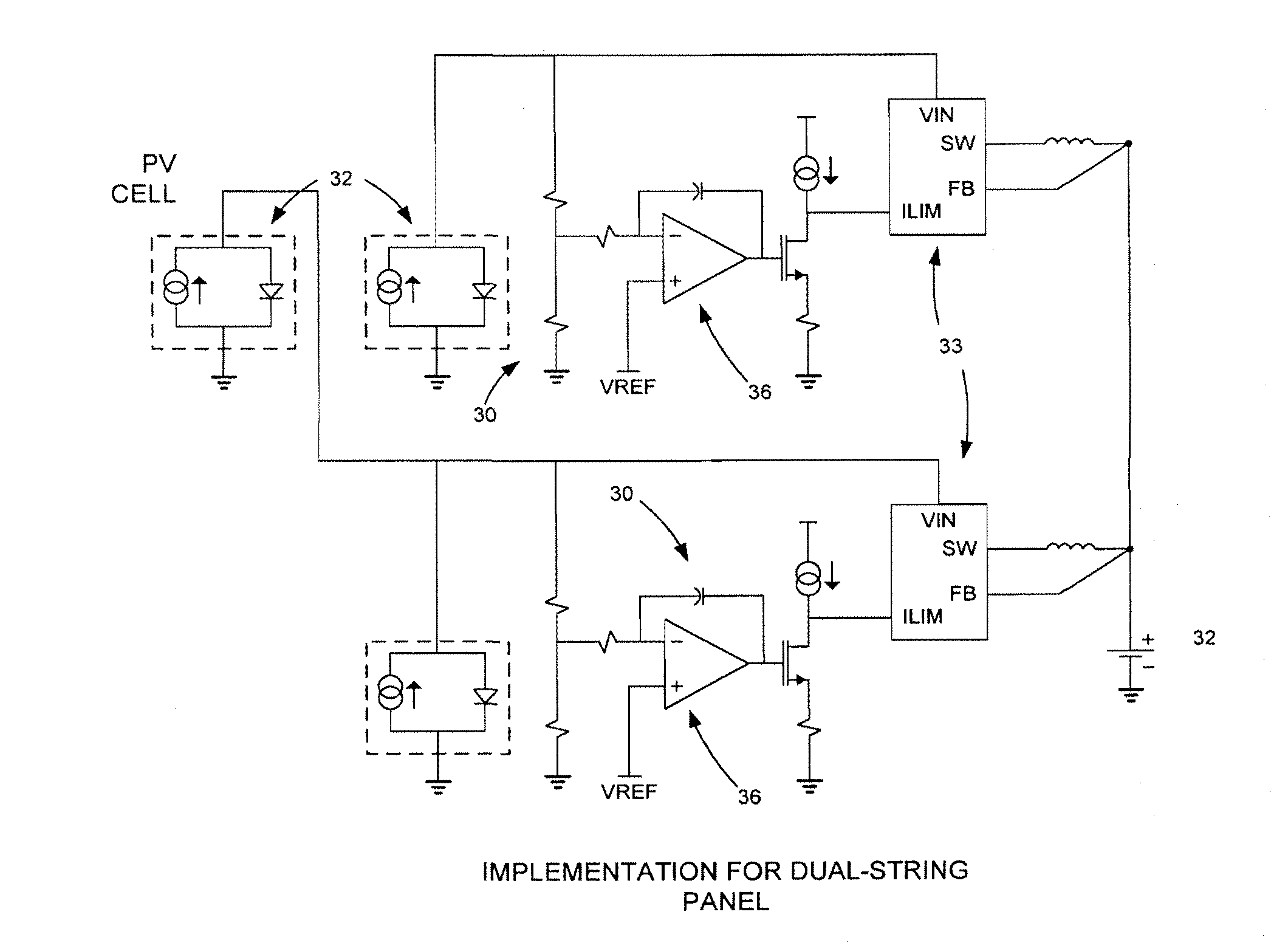

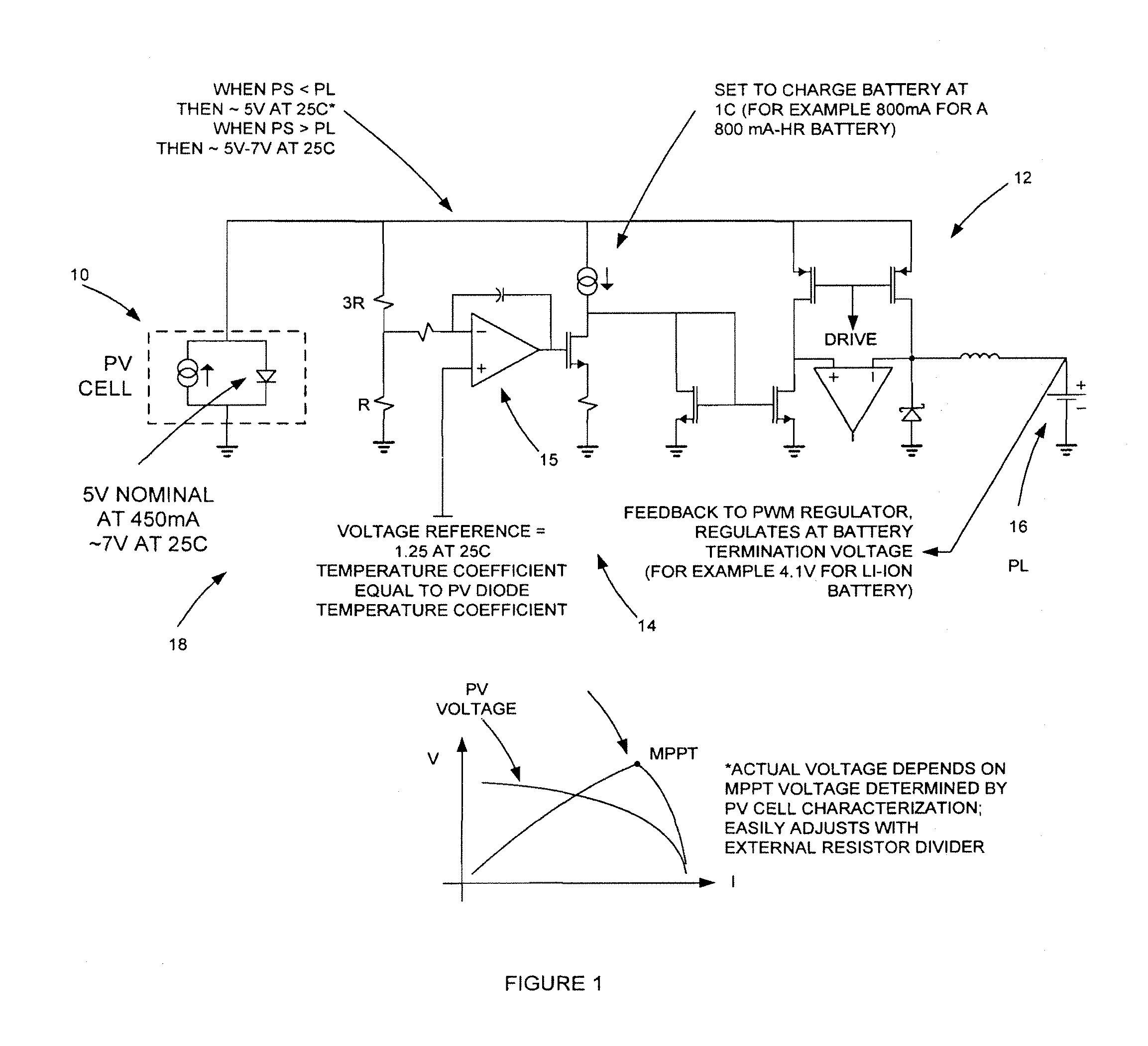

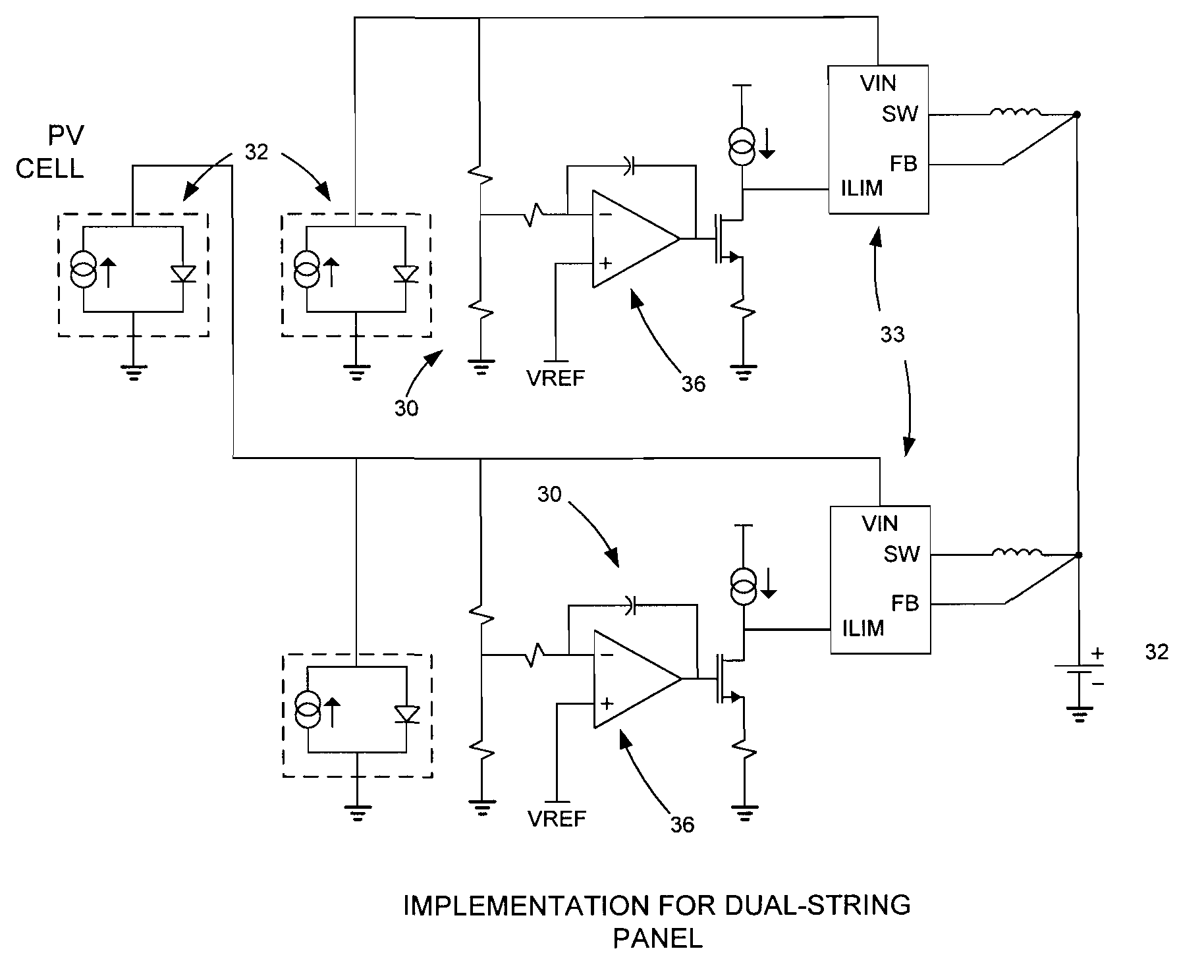

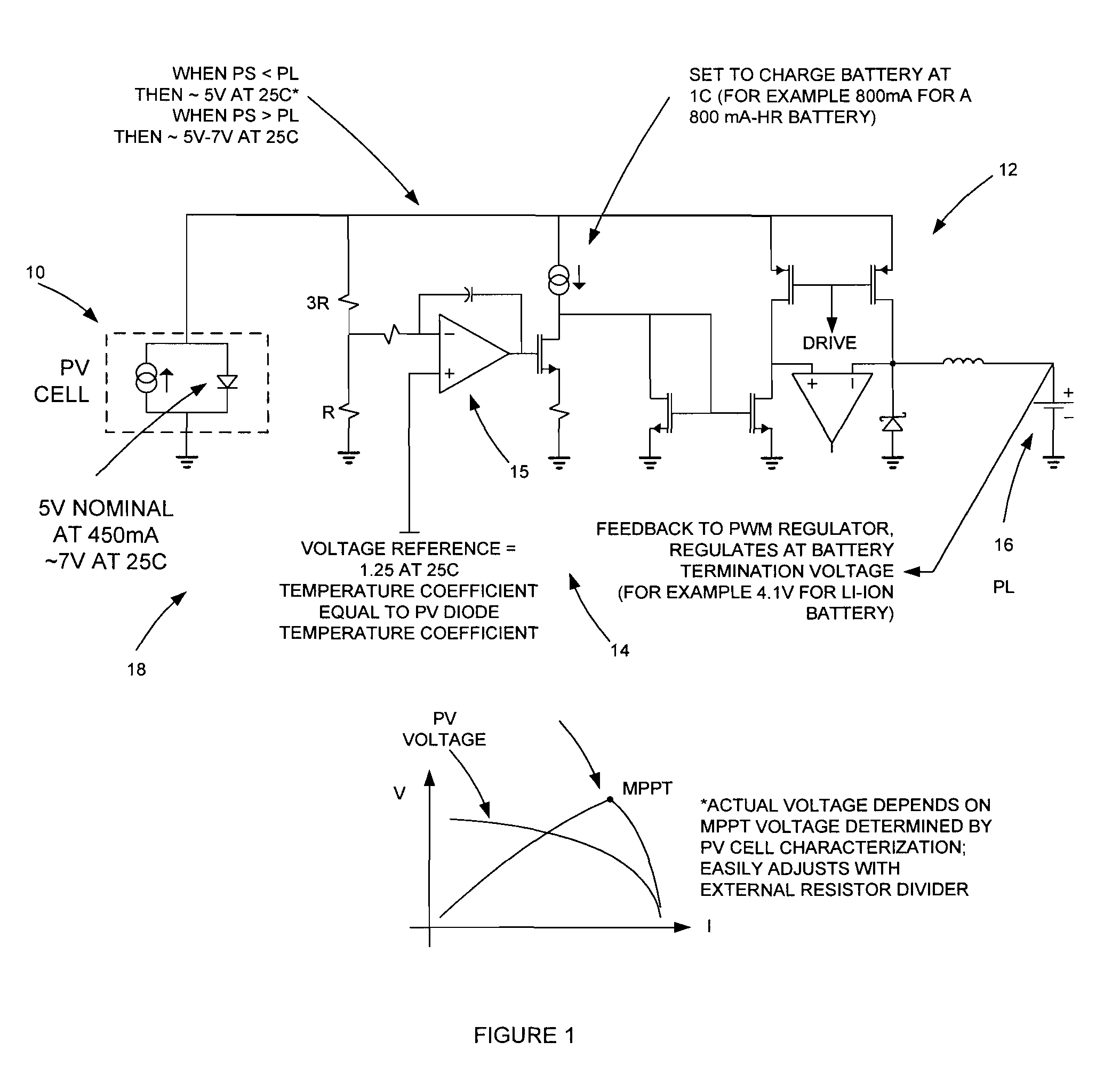

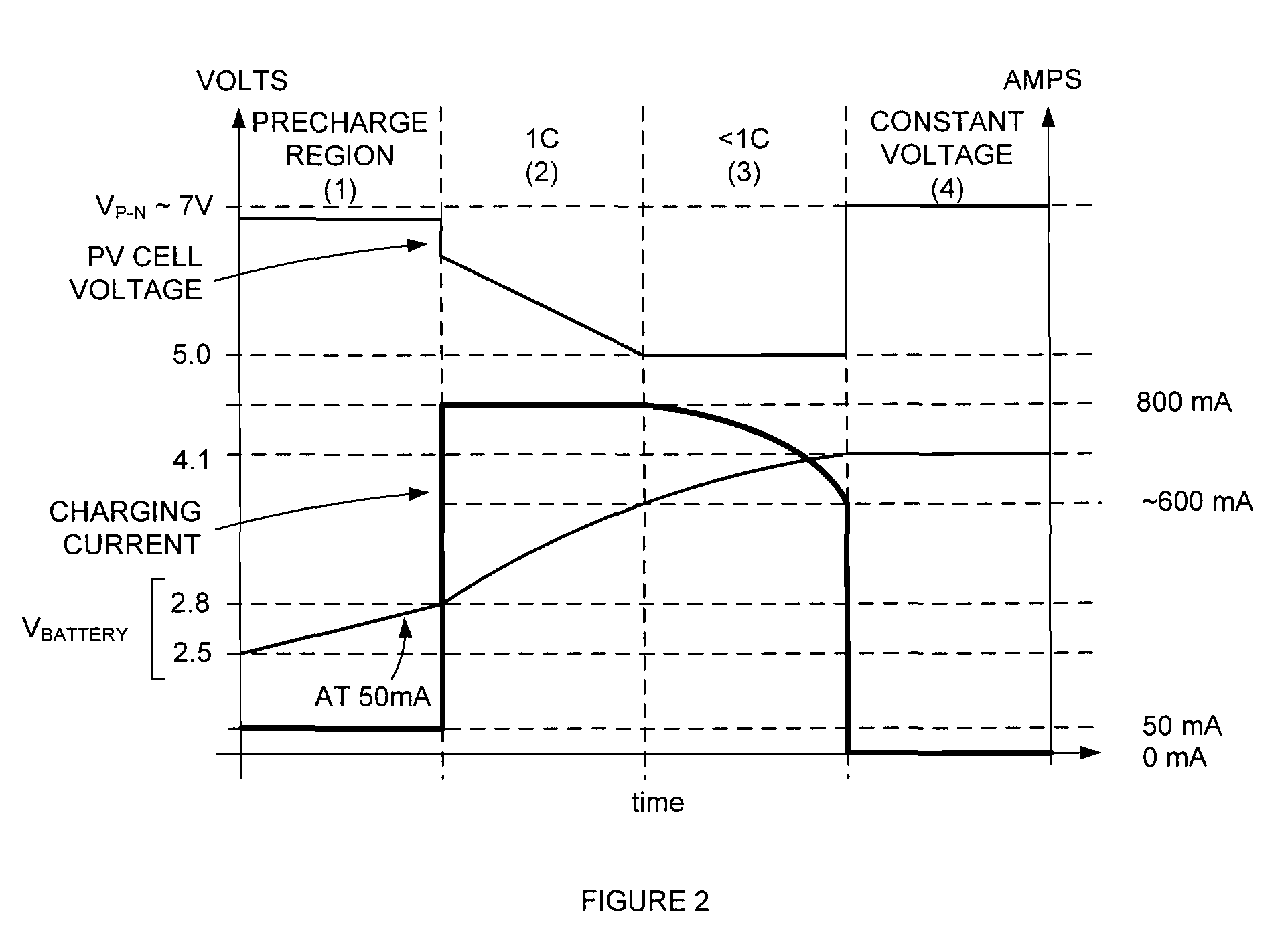

Adaptive power control for energy harvesting

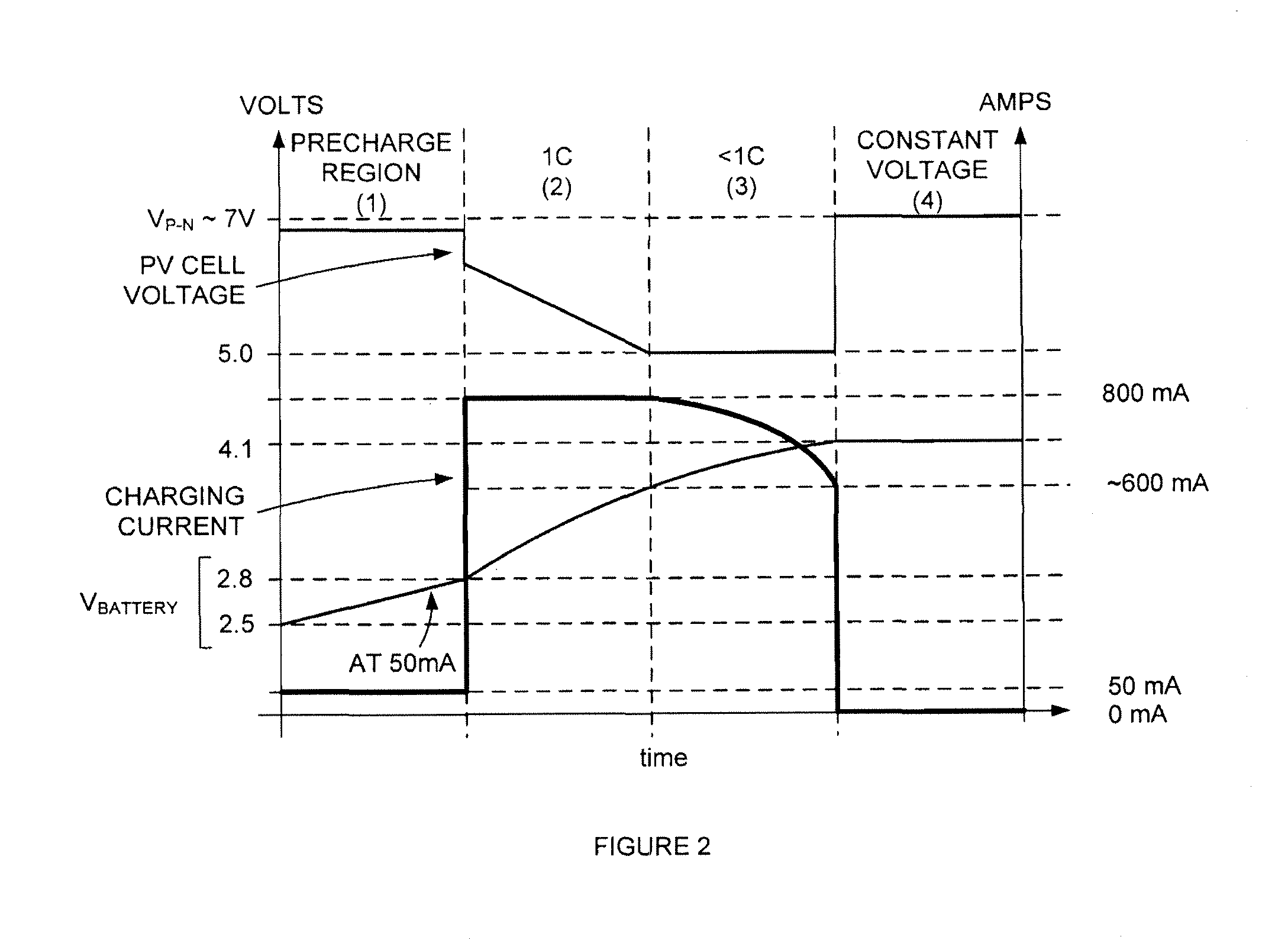

InactiveUS20130241465A1Improve harvesting efficiencyLow costBatteries circuit arrangementsDc source parallel operationPower parameterSelf adaptive

Advances in the arts are disclosed with novel methods and circuit systems for controlling power in an energy harvesting system. Techniques and related systems for controlling power output of an energy harvesting device provide for monitoring at least one power parameter at a power source and monitoring at least one power parameter at a load such as a storage medium. The power source output is adjusted in order to optimize energy harvesting and / or storage based on real-time performance parameters.

Owner:TRIUNE IP

Energy harvesting system

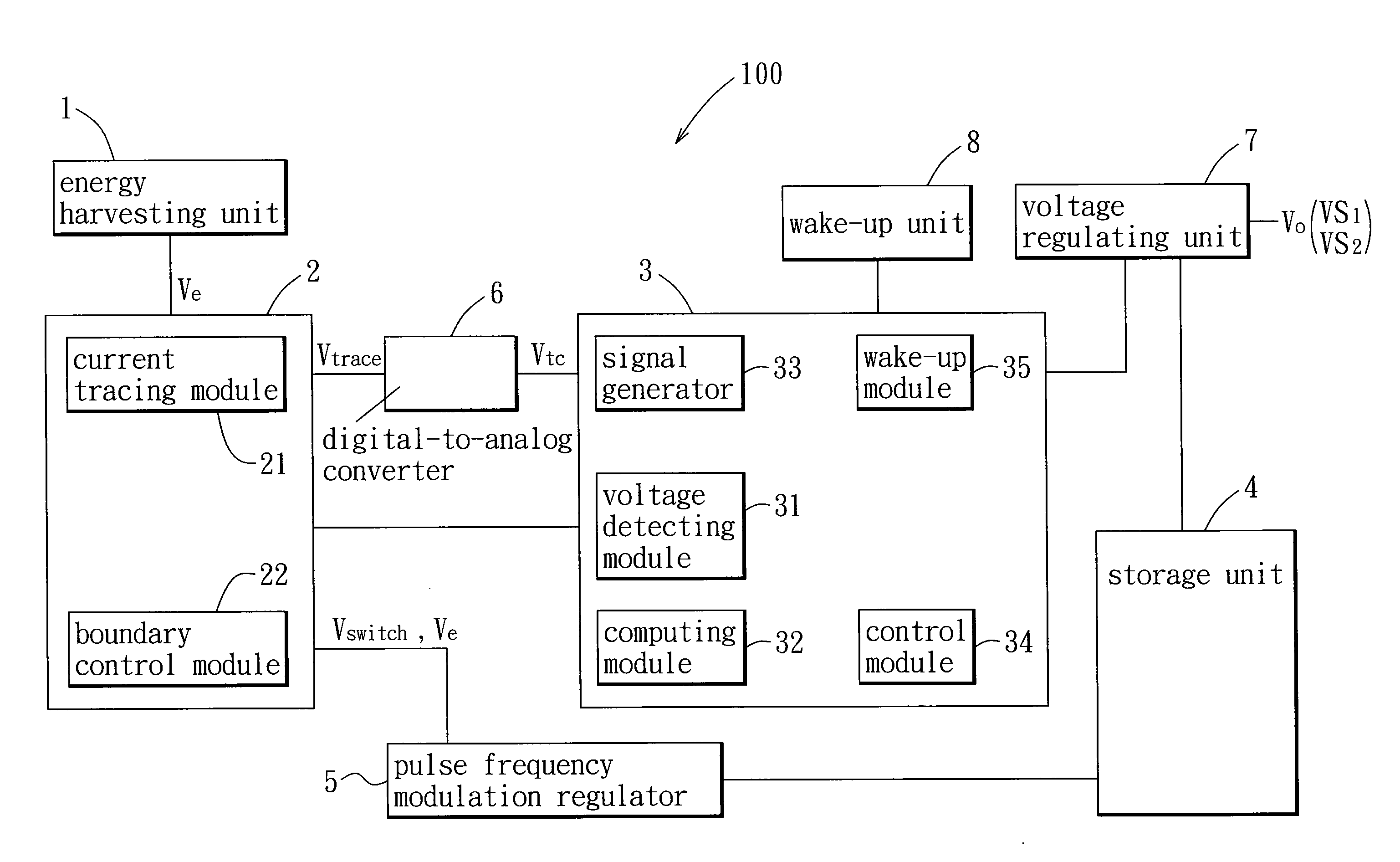

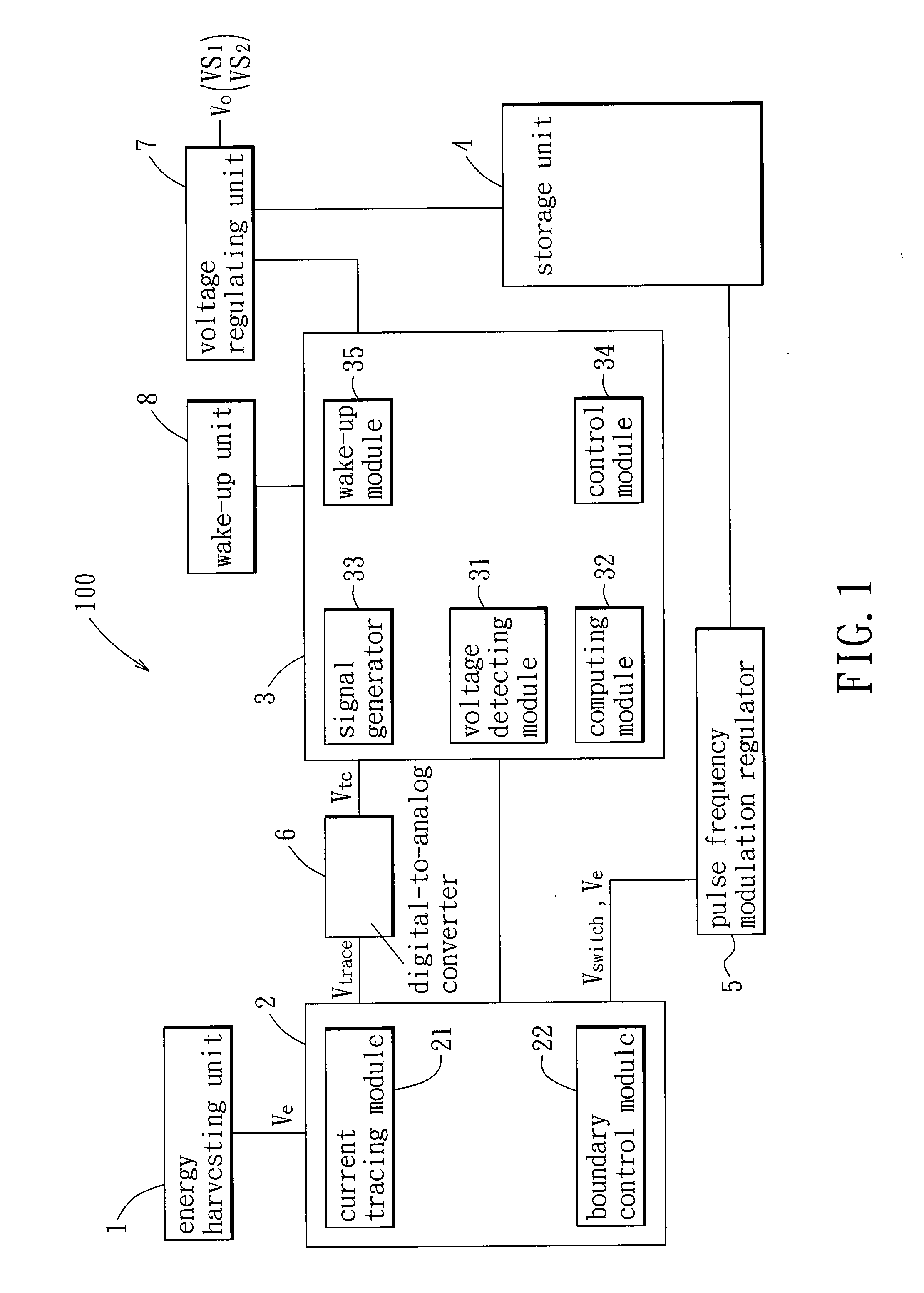

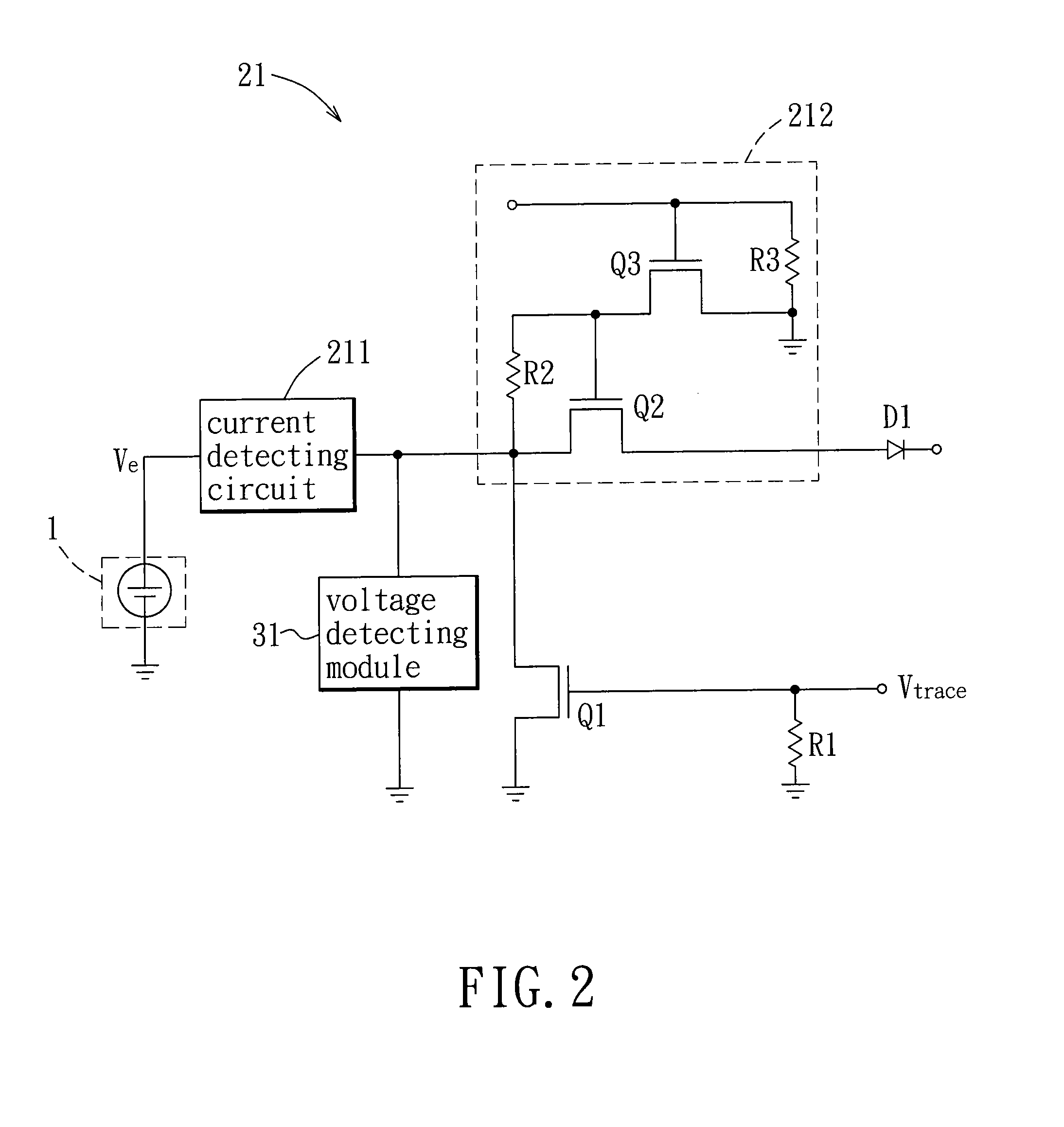

ActiveUS20110172847A1Drawback can be obviatedImprove energy efficiencyEnergy efficient ICTBatteries circuit arrangementsMicrocontrollerMaximum power point tracking

An energy harvesting system includes: an energy harvesting unit for converting energy from a natural energy source into an electrical power signal; a power point tracking unit including a current tracing module capable of detecting a current of the electrical power signal, and a boundary control module; a microcontroller including a voltage detecting module capable of detecting a voltage of the electrical power signal, and a computing module for determining a maximum power point with reference to the voltage and the current of the electrical power signal, the boundary control module generating a switch control voltage signal with reference to the maximum power point; a storage unit capable of storing energy; and a pulse frequency modulation regulator for converting the electrical power signal into an intermediate signal with reference to the switch control voltage signal for subsequent storage of energy of the intermediate signal in the storage unit.

Owner:NATIONAL TSING HUA UNIVERSITY

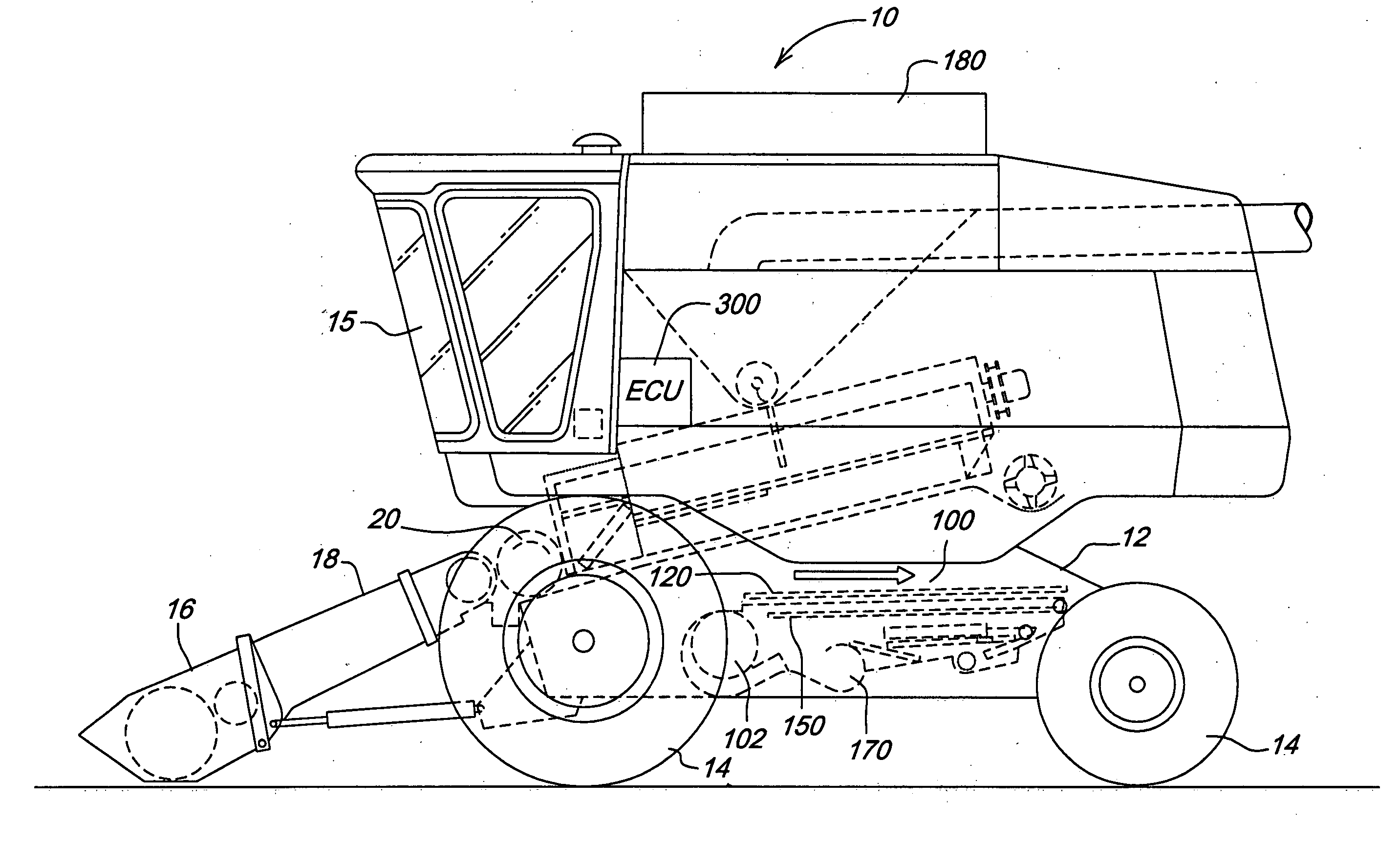

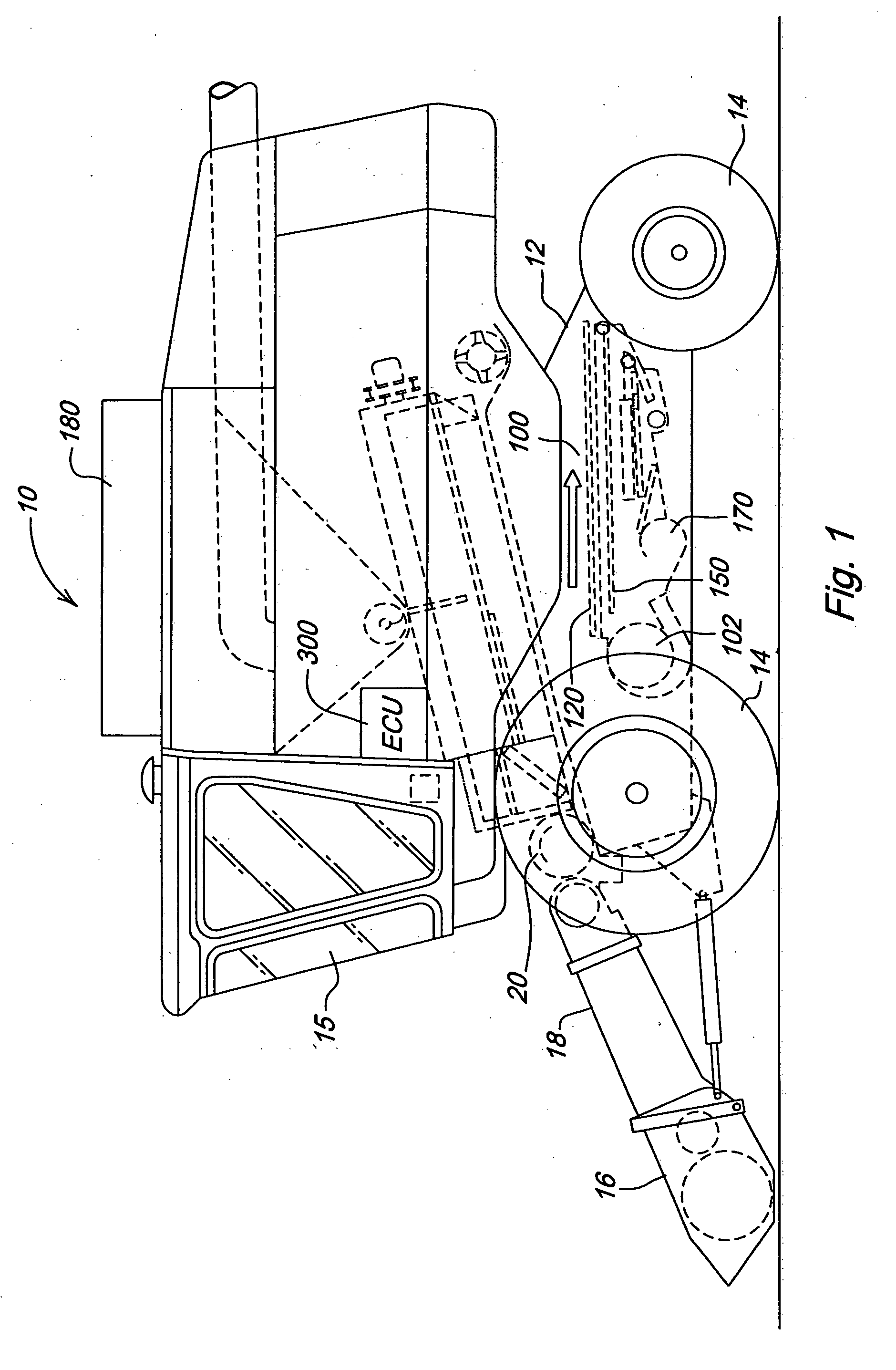

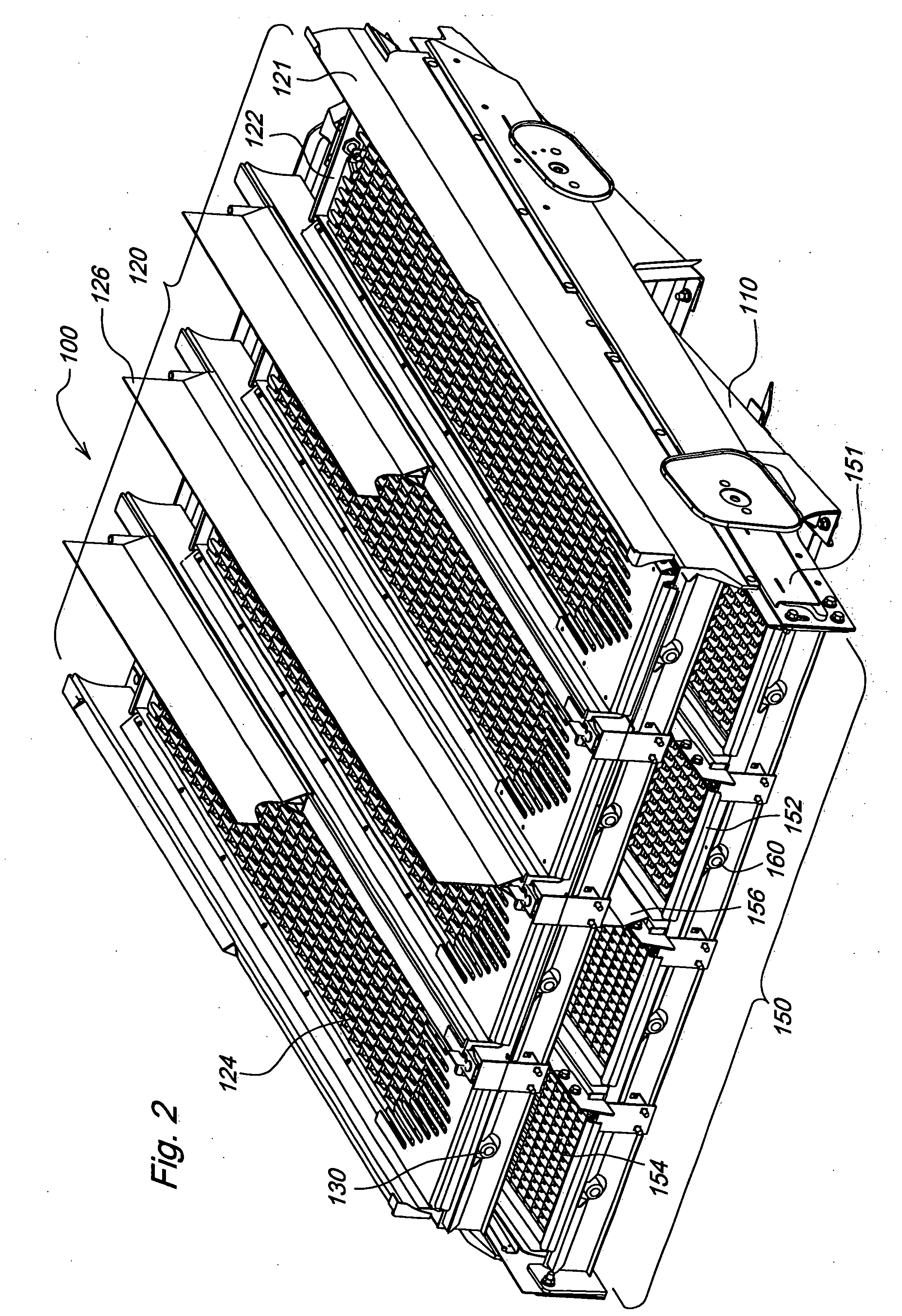

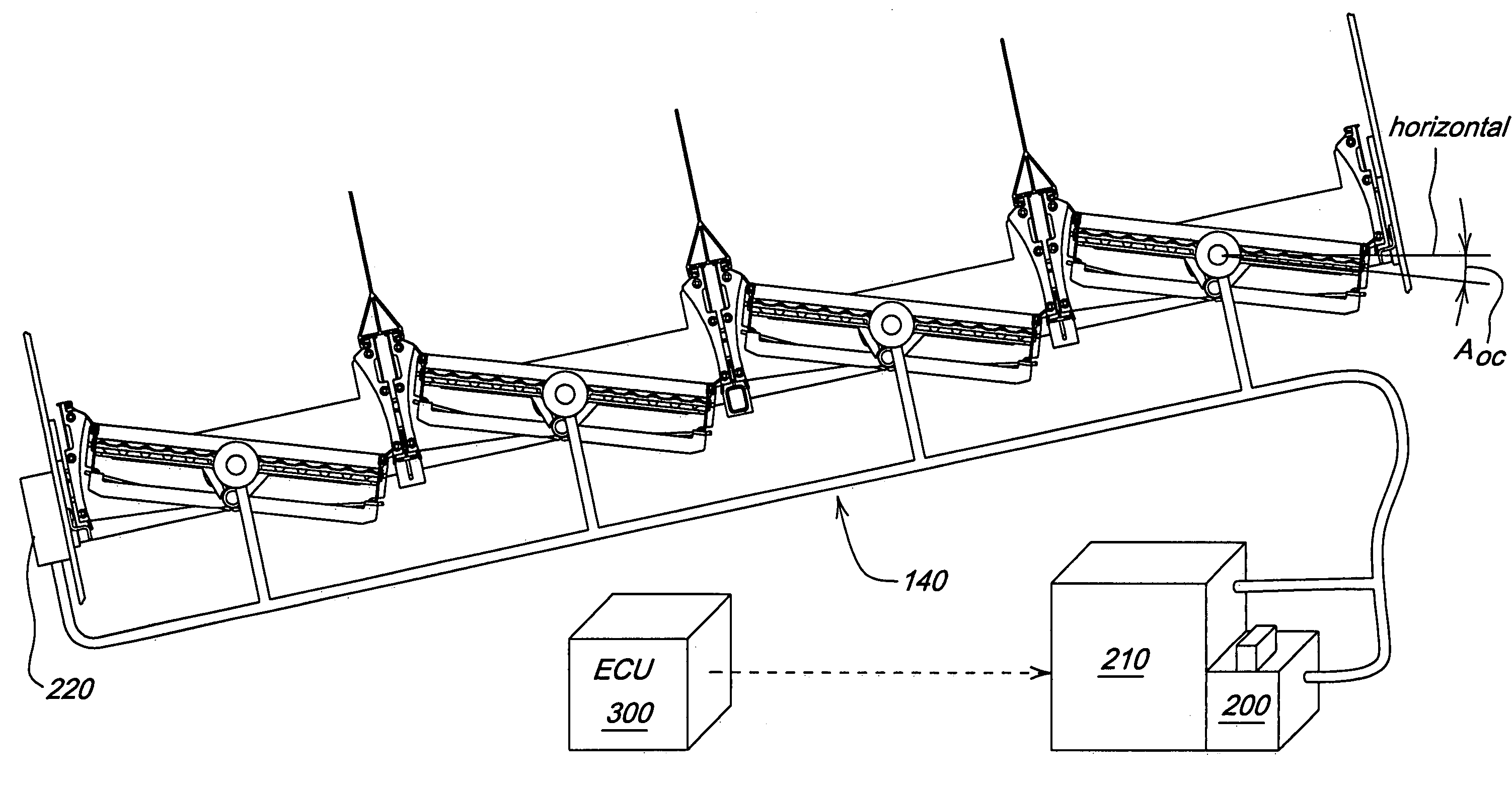

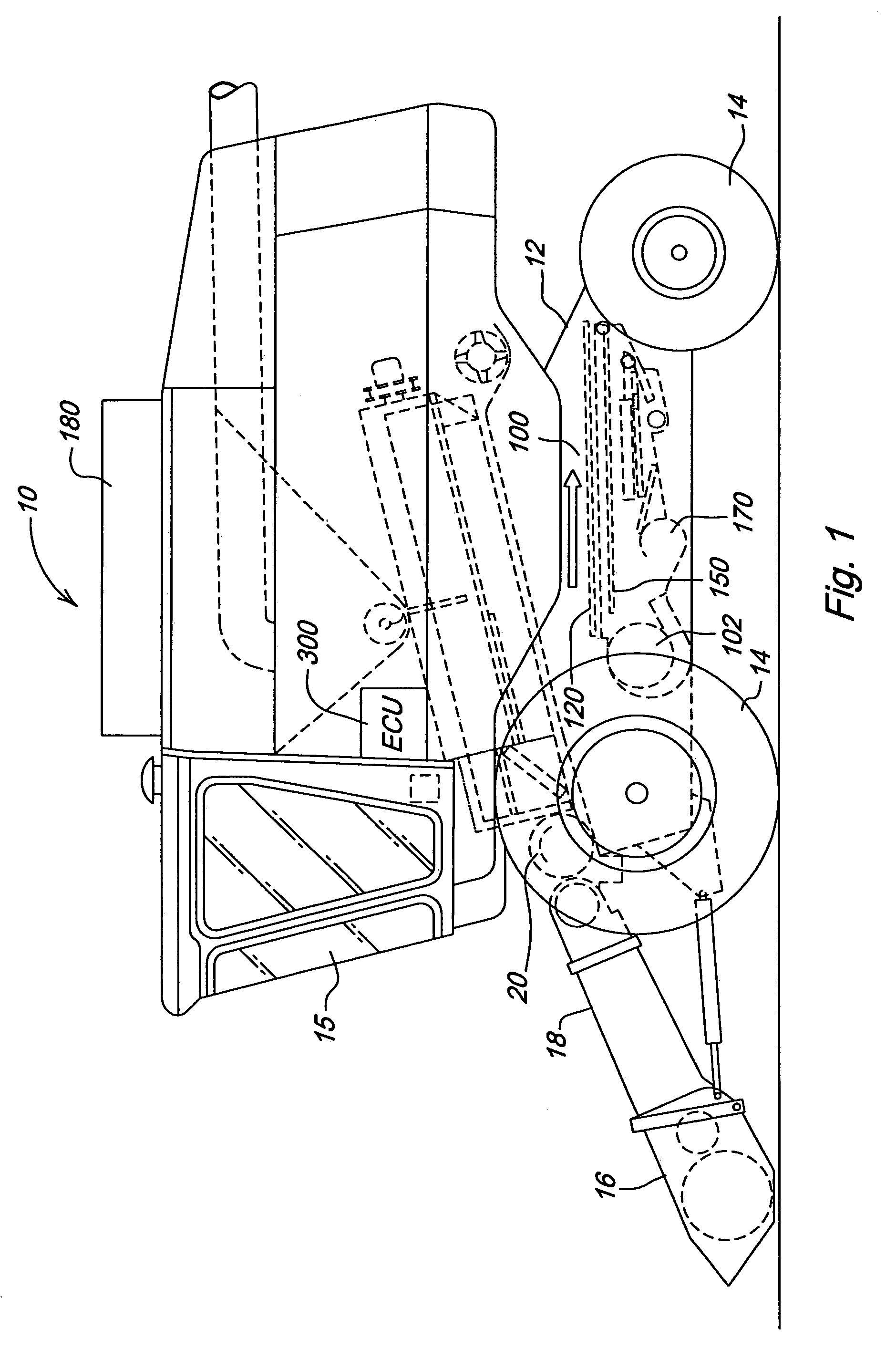

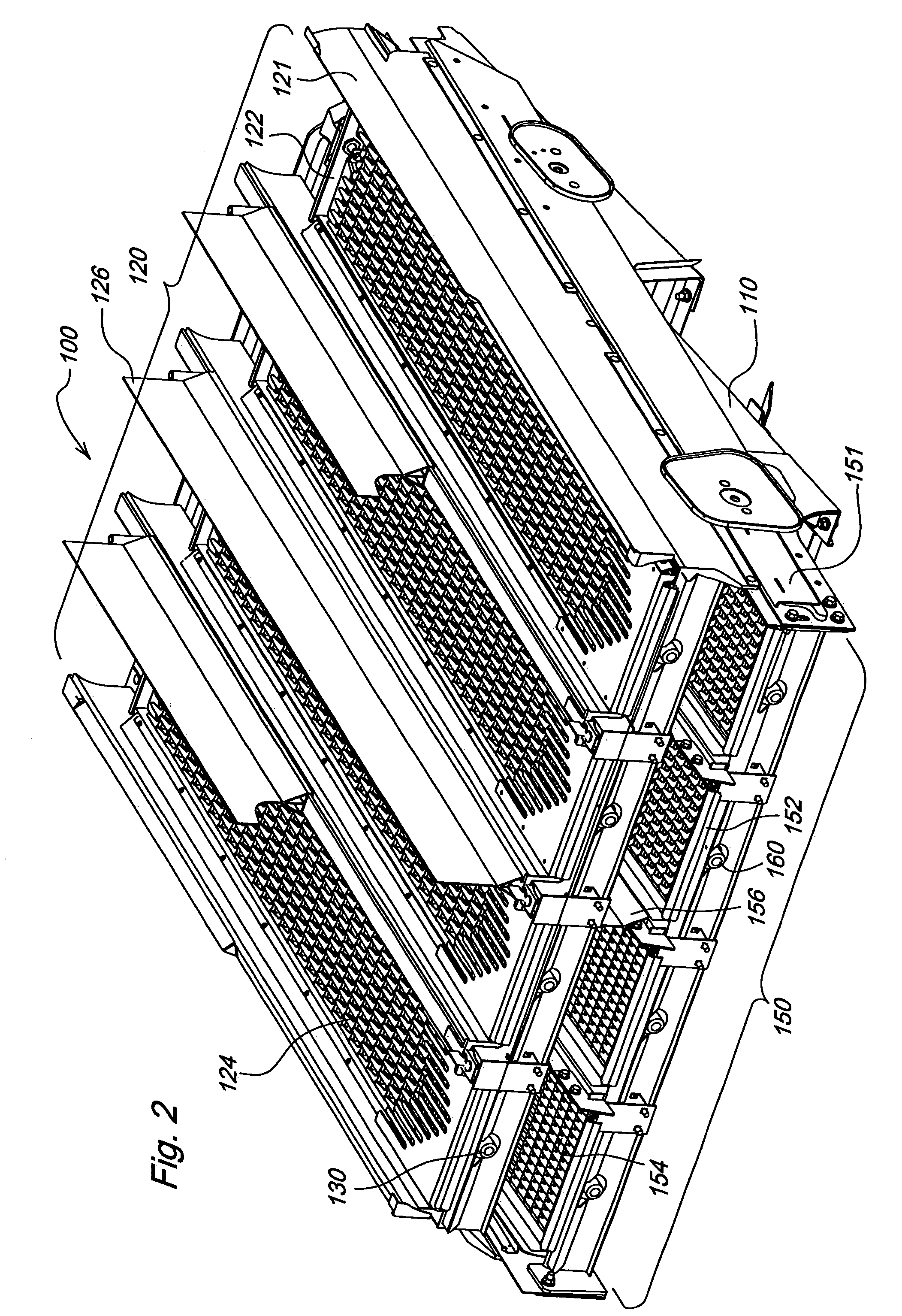

Leveling by over-compensation

ActiveUS20070123326A1Limiting crop lossIncreased crop harvesting efficiencySievingScreeningEngineeringCombine harvester

A system and method for limiting crop loss when harvesting on sloped or rolling ground by adjusting the chaffer and / or sieve, or longitudinal sections thereof, so as to overcompensate for the ground slope so that the chaffer and / or sieve sections are actually inclined away from horizontal opposite the direction of ground slope at a selected angle. Such overcompensation increases crop harvesting efficiencies over systems that simply work to level the chaffer and / or sieve sections, without the high expenses associated with a combine having a pivoting axle.

Owner:DEERE & CO

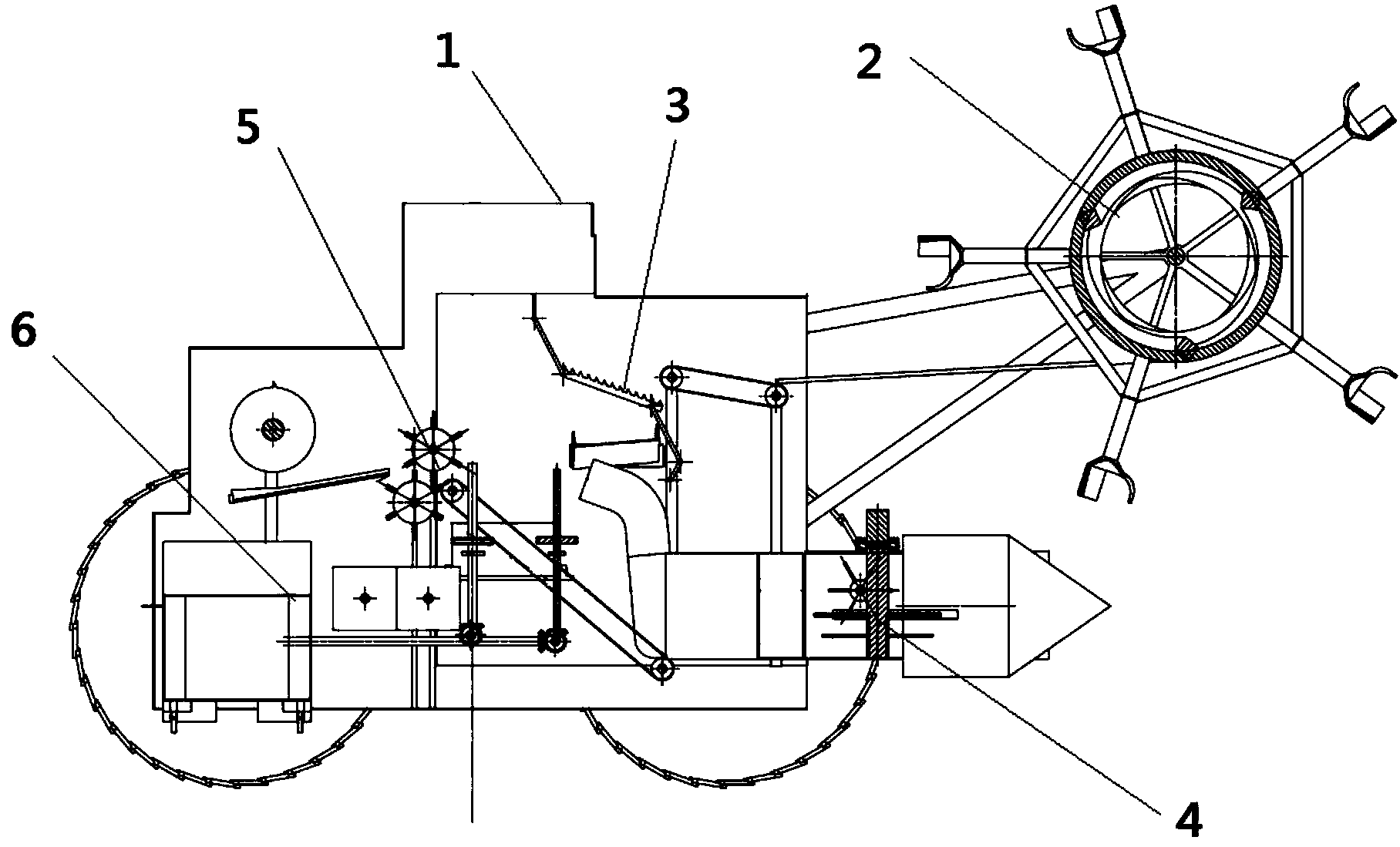

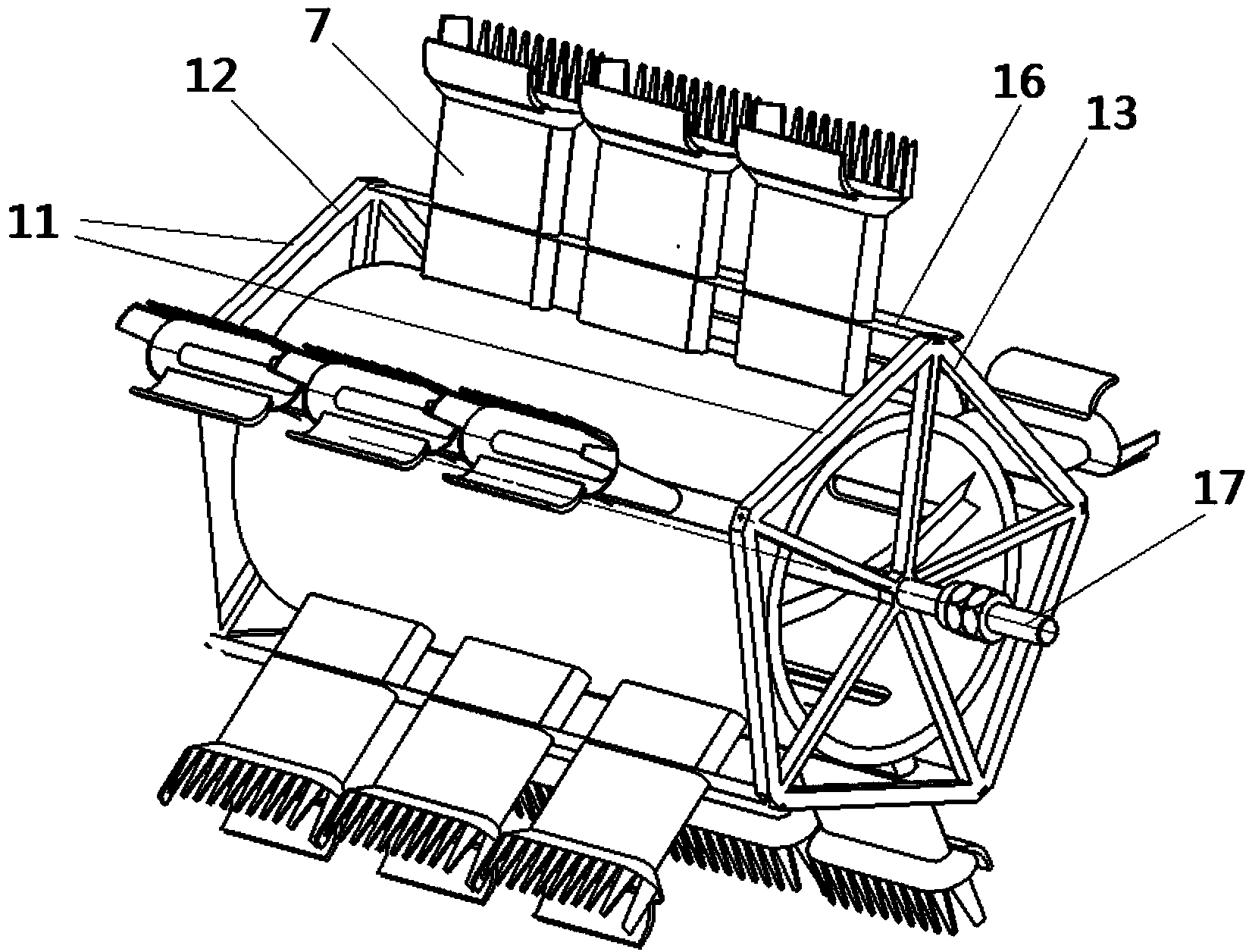

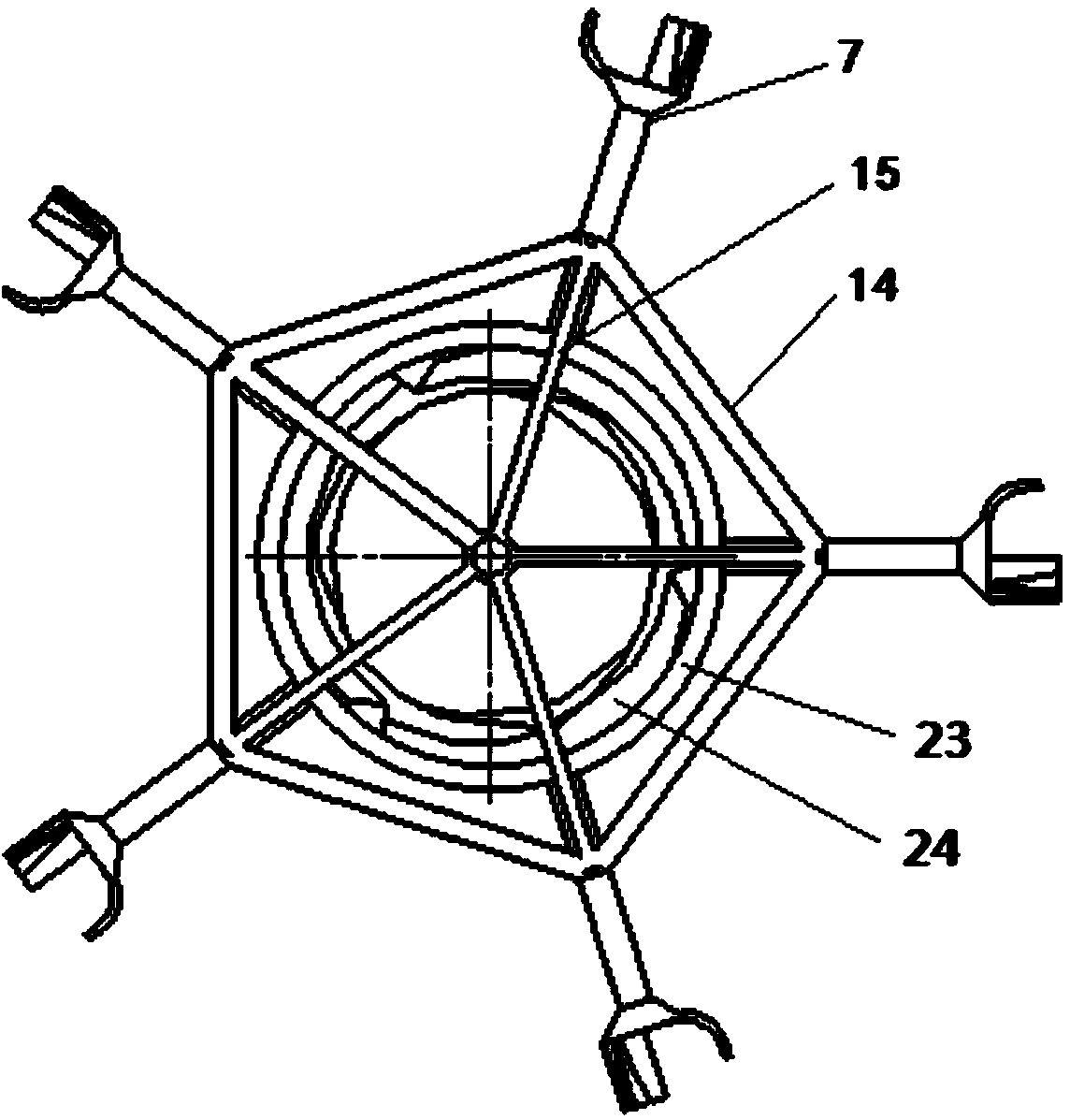

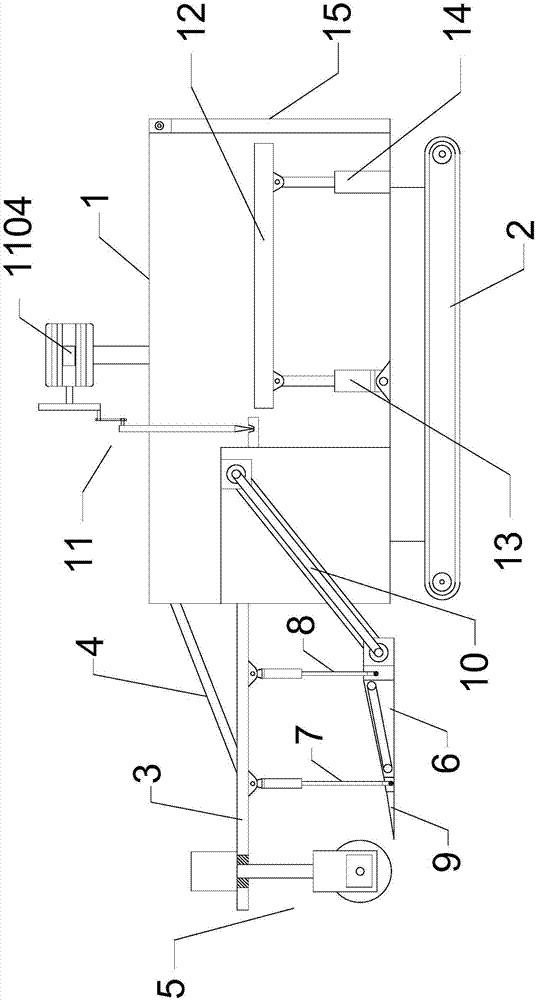

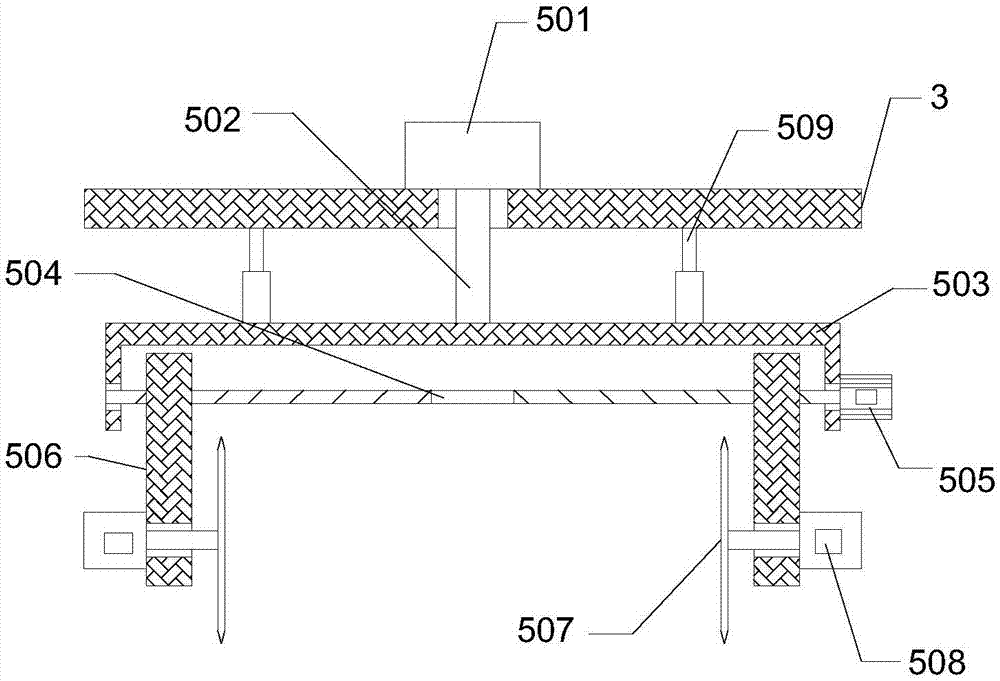

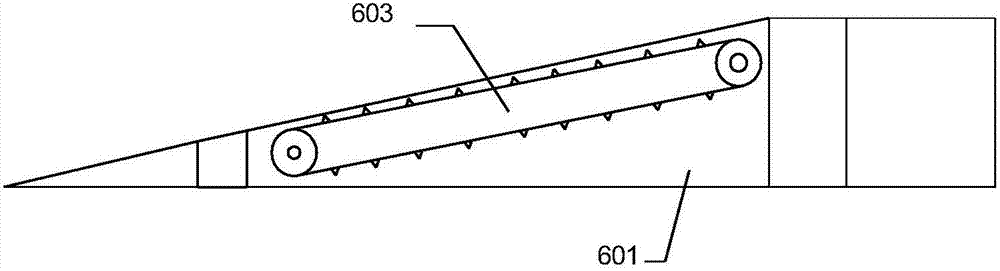

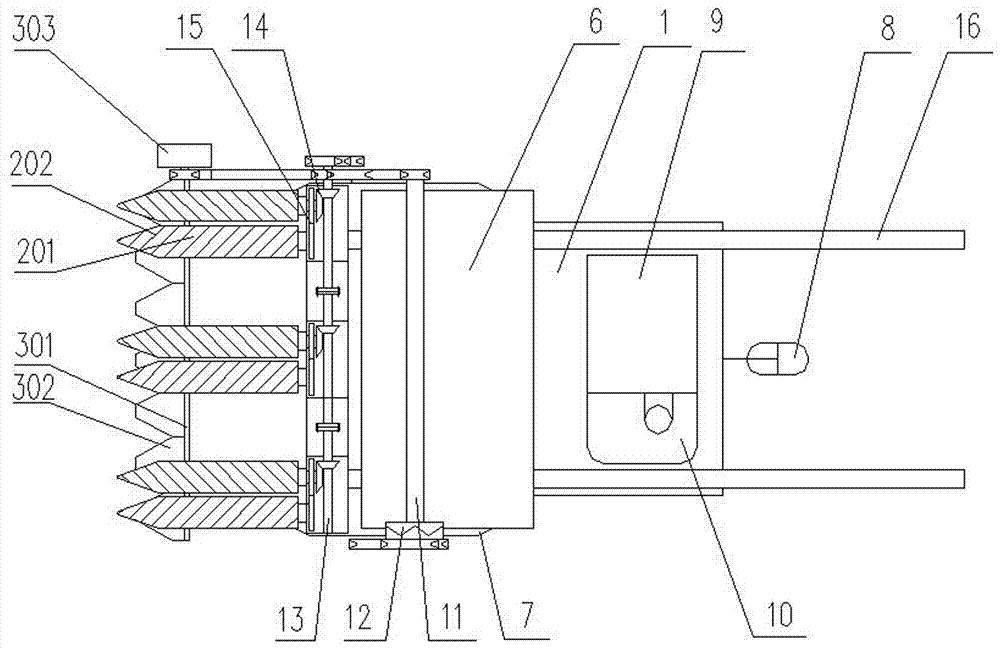

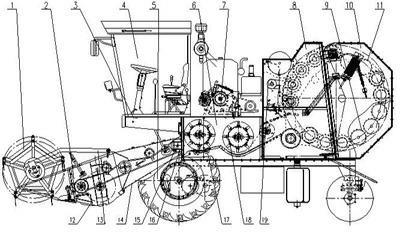

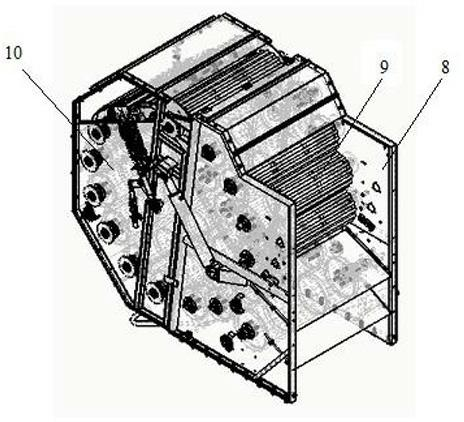

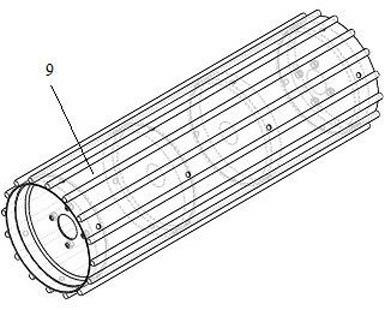

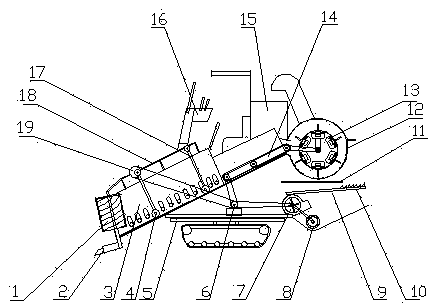

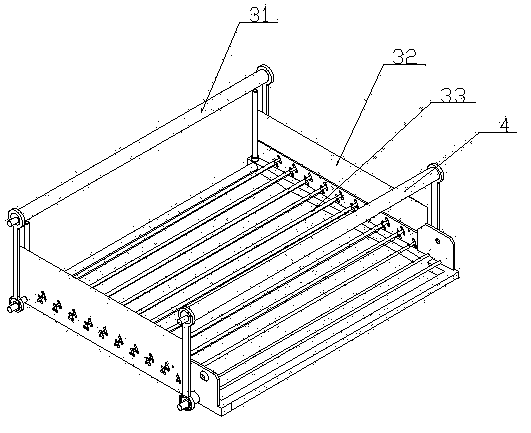

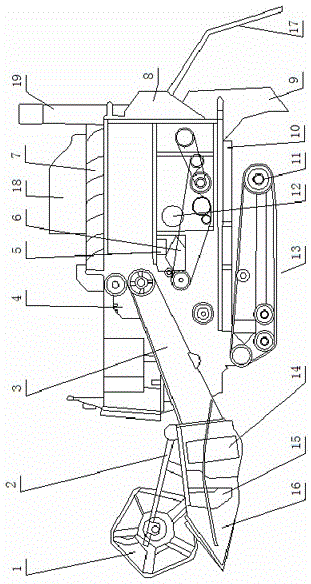

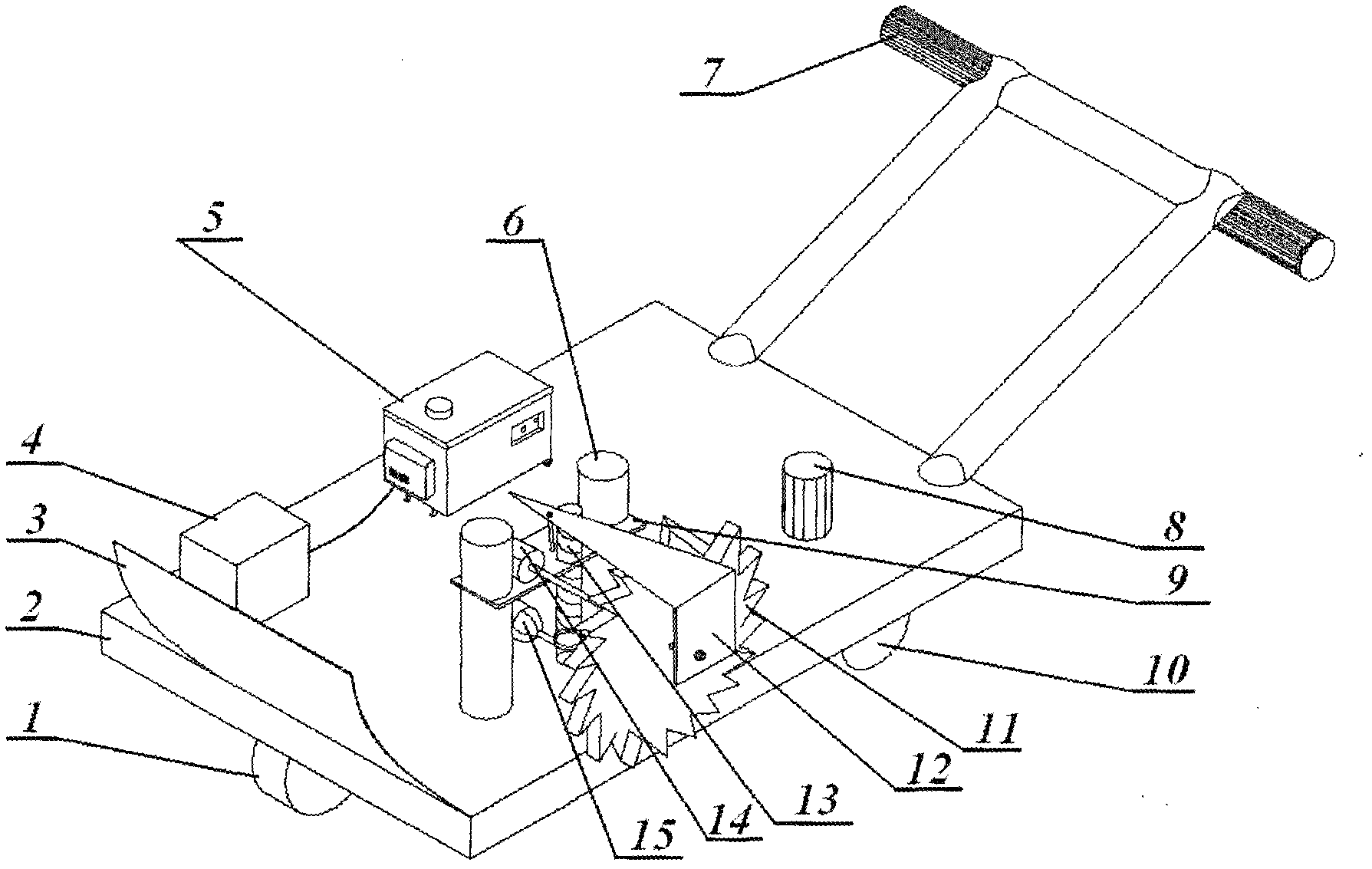

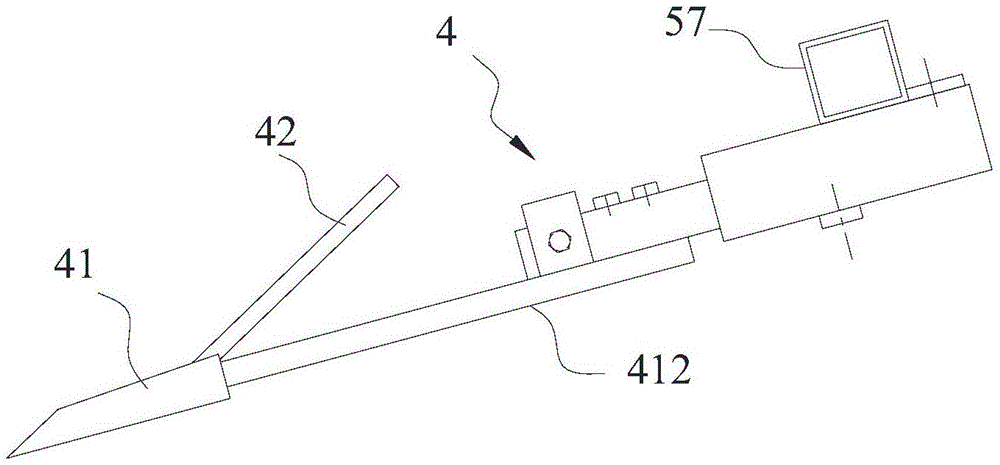

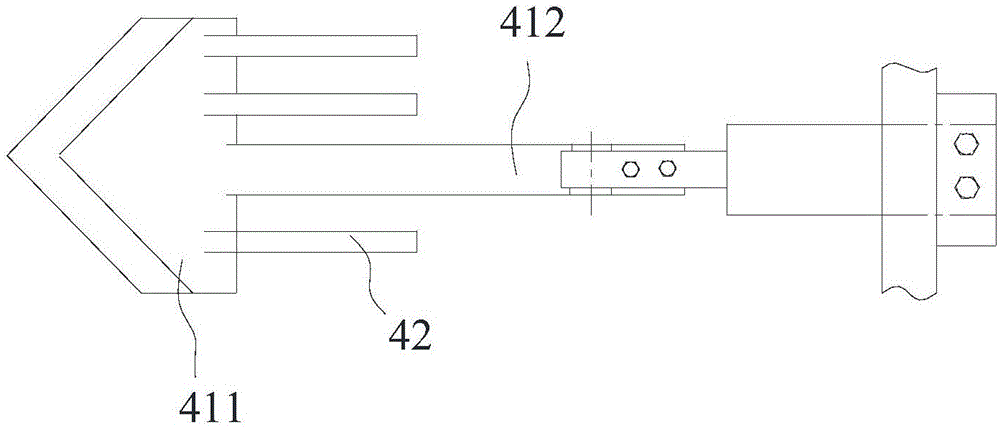

Comb tooth type ricinus communis combine harvester with fruit picking and straw fixed length fixed quantity and bundling functions

The invention relates to a comb tooth type ricinus communis combine harvester with fruit picking and straw fixed length fixed quantity and bundling functions. The combine harvester is reasonable in structure and integrates picking, separating and cleaning of castor seeds with fixed length segmentation, fixed quantity compaction and automatic bundling of straw. A comb tooth picking system and a feed-in disc type header system are located at the front end of a harvester body, a separating and cleaning system and a hob type fixed length segmentation system are located at the middle end of the harvester body, and fixed quantity compaction and bundling systems are located at the rear end of the harvester body; a comb tooth picking device which rotates anticlockwise is adopted for the comb tooth picking system to pick off the castor seeds and send the castor seeds to the separating and cleaning system, the castor seeds after being collected and separated through a grain collection bin are arranged below an outlet of the separating and cleaning system, a divider is arranged in the front of the harvester body, ricinus communis straw is fed into the disc type header system, the cutoff straw is fed into the hob type fixed length segmentation system through a stalk lifting conveyer belt, and an outlet of the hob type fixed length segmentation system is connected with the fixed quantity compaction and bundling systems; all the systems are driven by a power device through corresponding transmission devices.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

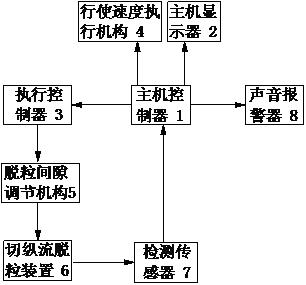

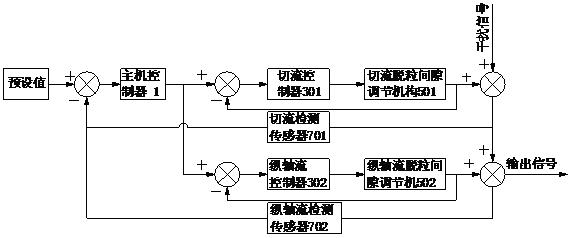

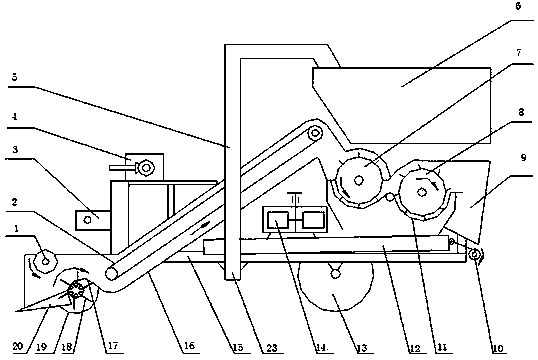

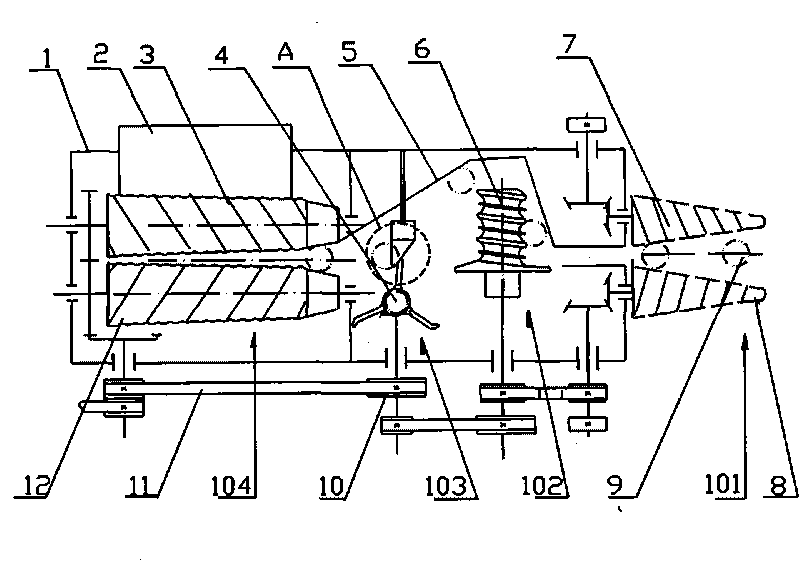

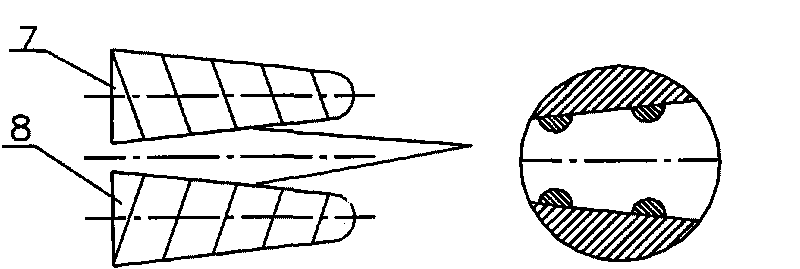

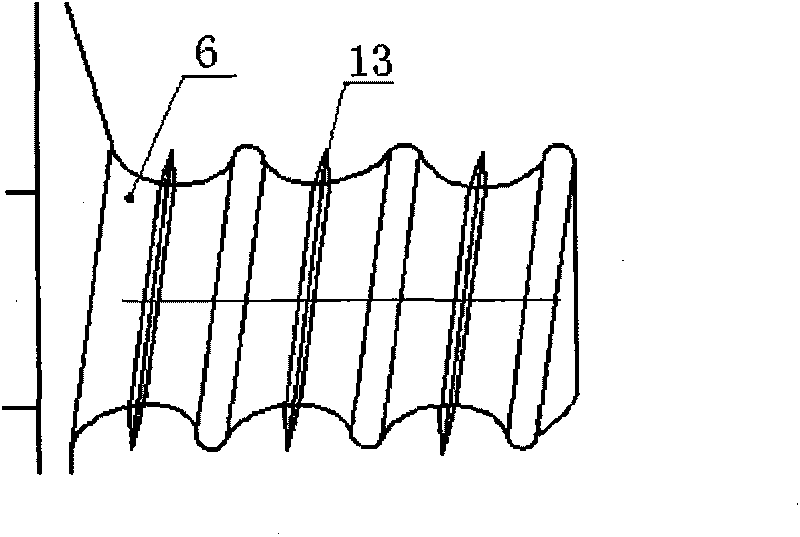

Adaptive anti-clogging control system and control method for cutting longitudinal flow combine harvester

ActiveCN102273359AHigh degree of automationImprove harvesting efficiencyMowersSelf adaptiveEngineering

The invention relates to a self-adaptive anti-blocking control system for a tangential and longitudinal flow combine harvester. The self-adaptive anti-blocking control system is mainly applied to harvesting machines for crops so as to solve the problem that materials are blocked, overloaded and the like in the process of crop harvesting of the tangential and longitudinal flow combine harvester at present. A self-adaptive anti-blocking control method comprises the following steps of: detecting the working load of a tangential and longitudinal flow threshing device by using a host controller; in the threshing and separating process, detecting the rotating speed and the torque of a tangential flow roller and a longitudinal shaft flow roller by using a detection sensor; calculating a change deviation value; comparing the change deviation value with a prestored standard value and judging; and controlling working parameters of a threshing separation device of the tangential and longitudinal flow combine harvester according to the change of the rotating speed and the torque. By the self-adaptive anti-blocking control system and the self-adaptive anti-blocking control method, the harvesting efficiency of the tangential and longitudinal flow combine harvester is improved; failure rate is reduced; harvesting cost is saved; and labor intensity of workers is greatly reduced. The self-adaptive anti-blocking control system and the self-adaptive anti-blocking control method are also suitable for other kinds of combine harvesters.

Owner:JIANGSU UNIV

Adaptive Power Control for Energy Harvesting

InactiveUS20100259225A1Improve harvesting efficiencyLow costDc network circuit arrangementsBatteries circuit arrangementsPower parameterSelf adaptive

Advances in the arts are disclosed with novel methods and circuit systems for controlling power in an energy harvesting system. Techniques and related systems for controlling power output of an energy harvesting device provide for monitoring at least one power parameter at a power source and monitoring at least one power parameter at a load such as a storage medium. The power source output is adjusted in order to optimize energy harvesting and / or storage based on real-time performance parameters.

Owner:TRIUNE IP

Leveling by over-compensation

ActiveUS7306513B2Improve harvesting efficiencyIncrease costSievingScreeningEngineeringCombine harvester

A system and method for limiting crop loss when harvesting on sloped or rolling ground by adjusting the chaffer and / or sieve, or longitudinal sections thereof, so as to overcompensate for the ground slope so that the chaffer and / or sieve sections are actually inclined away from horizontal opposite the direction of ground slope at a selected angle. Such overcompensation increases crop harvesting efficiencies over systems that simply work to level the chaffer and / or sieve sections, without the high expenses associated with a combine having a pivoting axle.

Owner:DEERE & CO

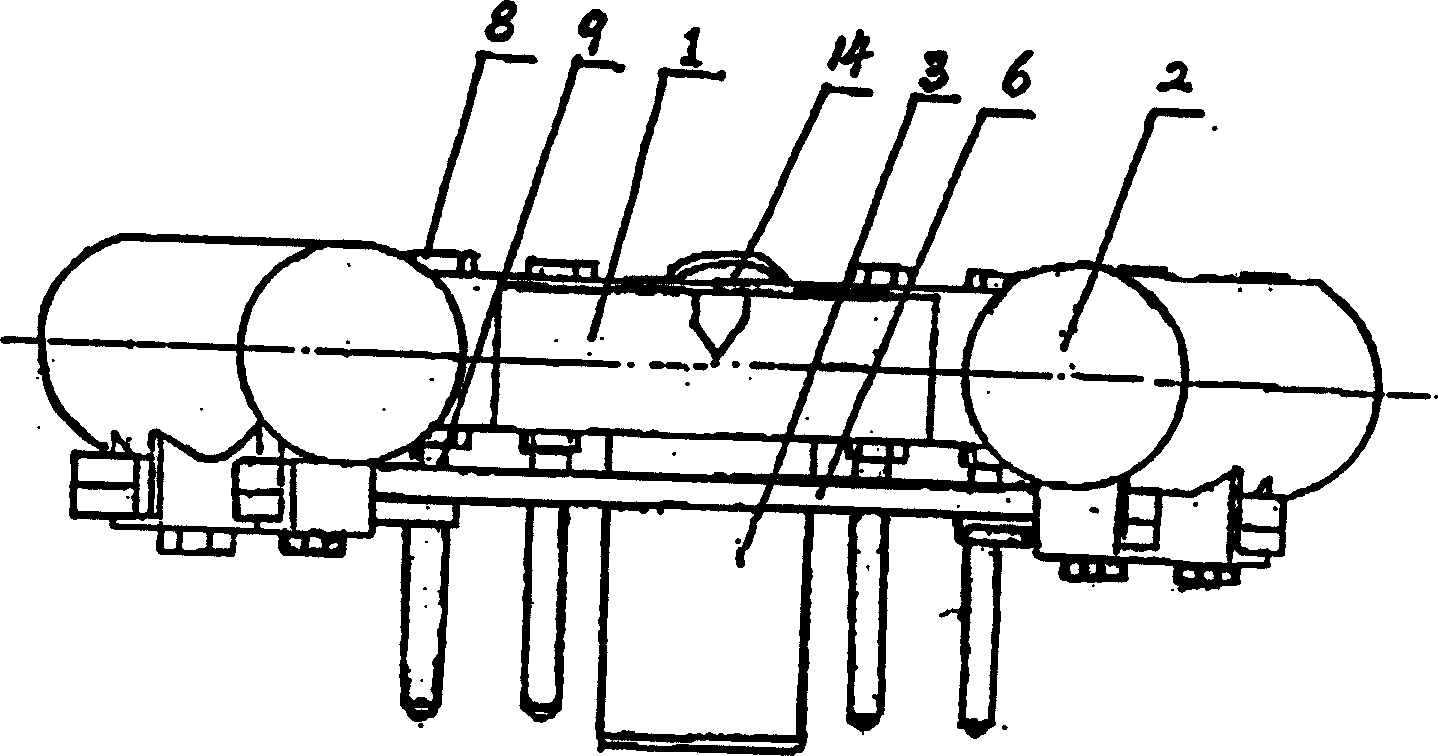

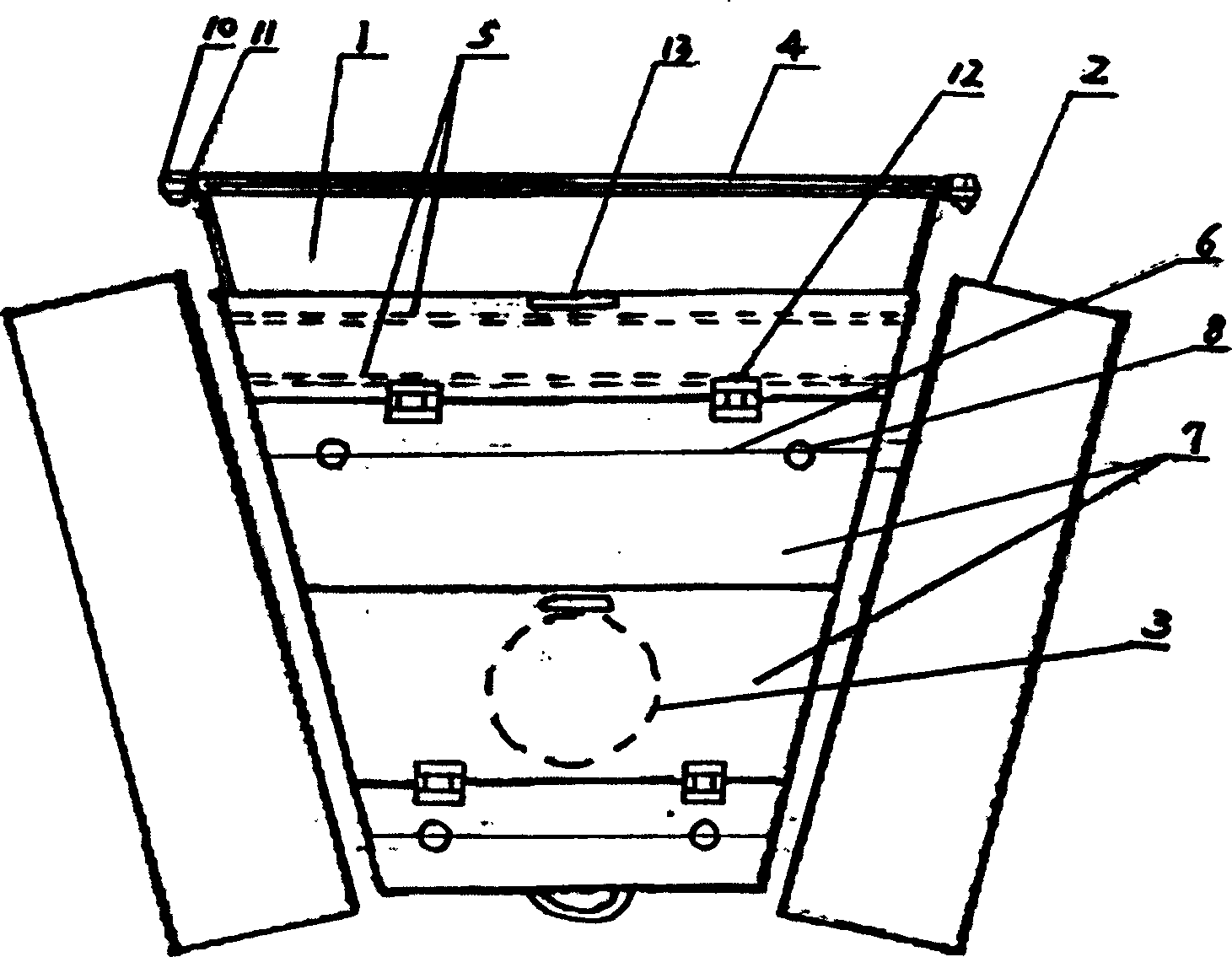

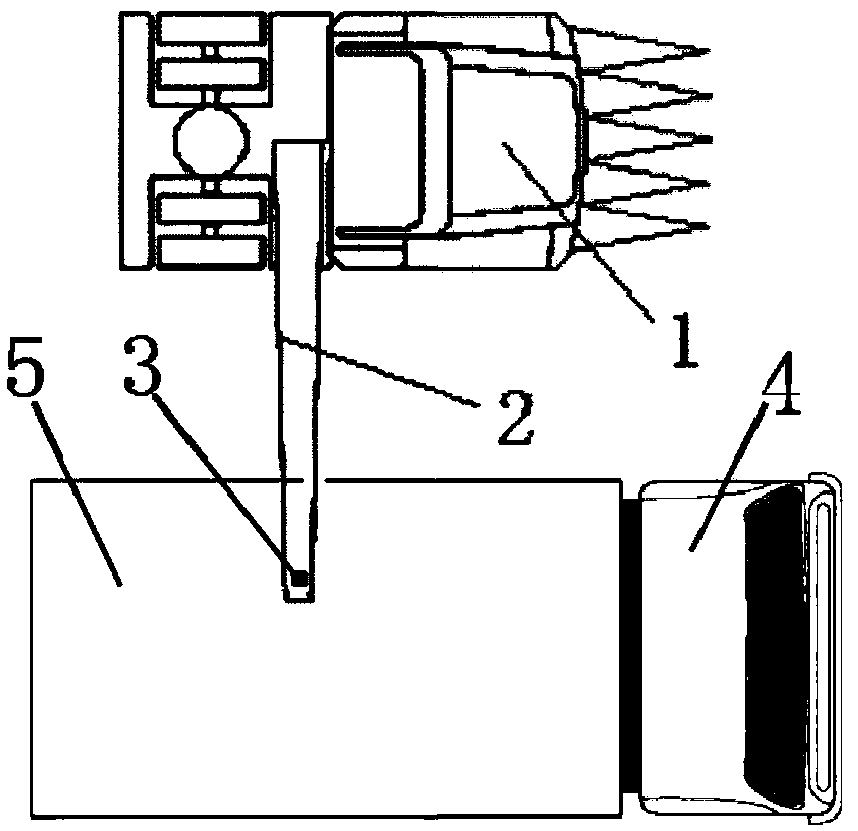

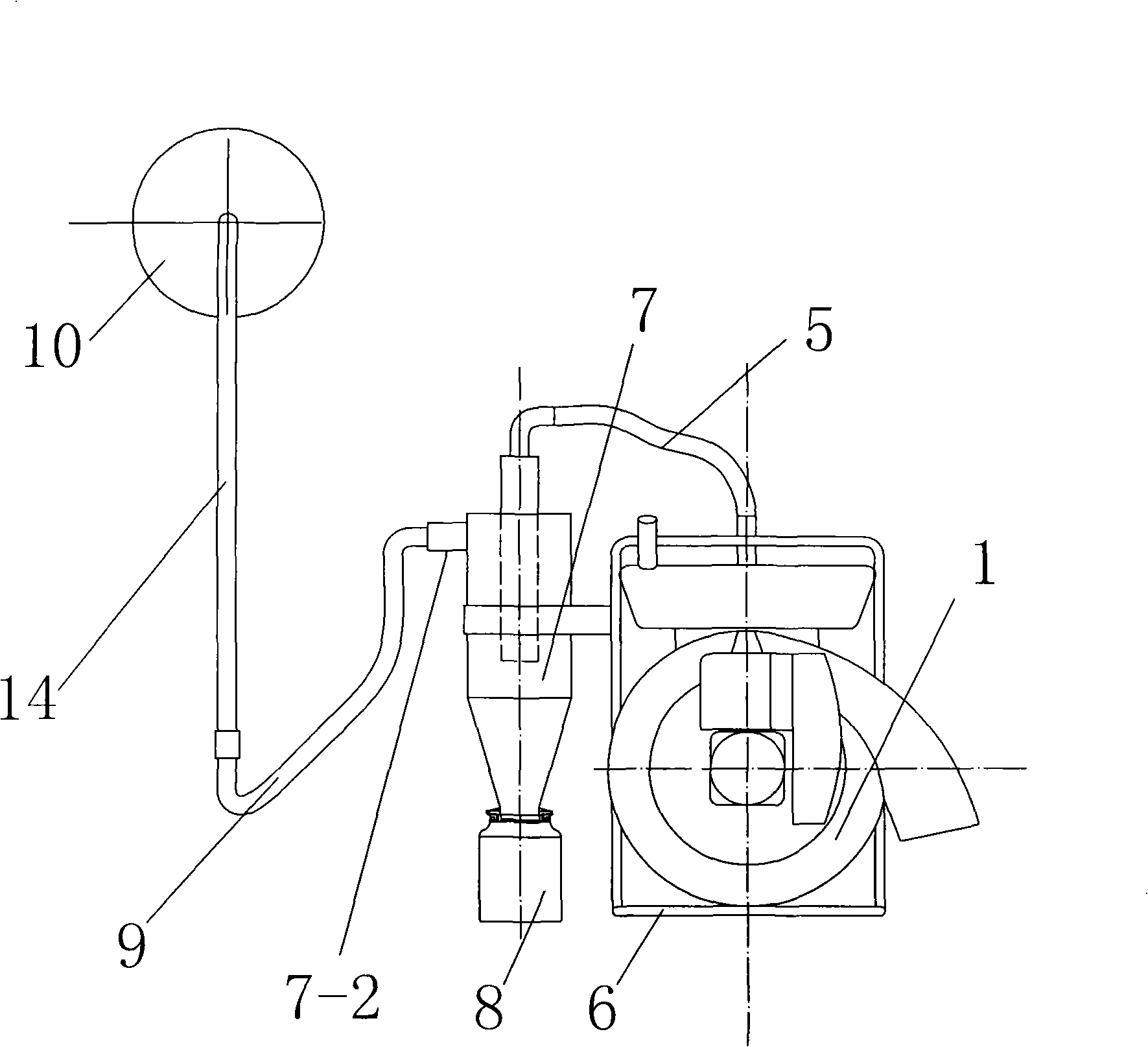

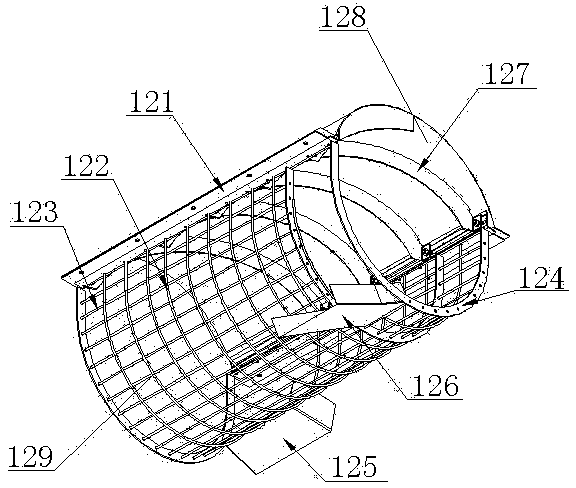

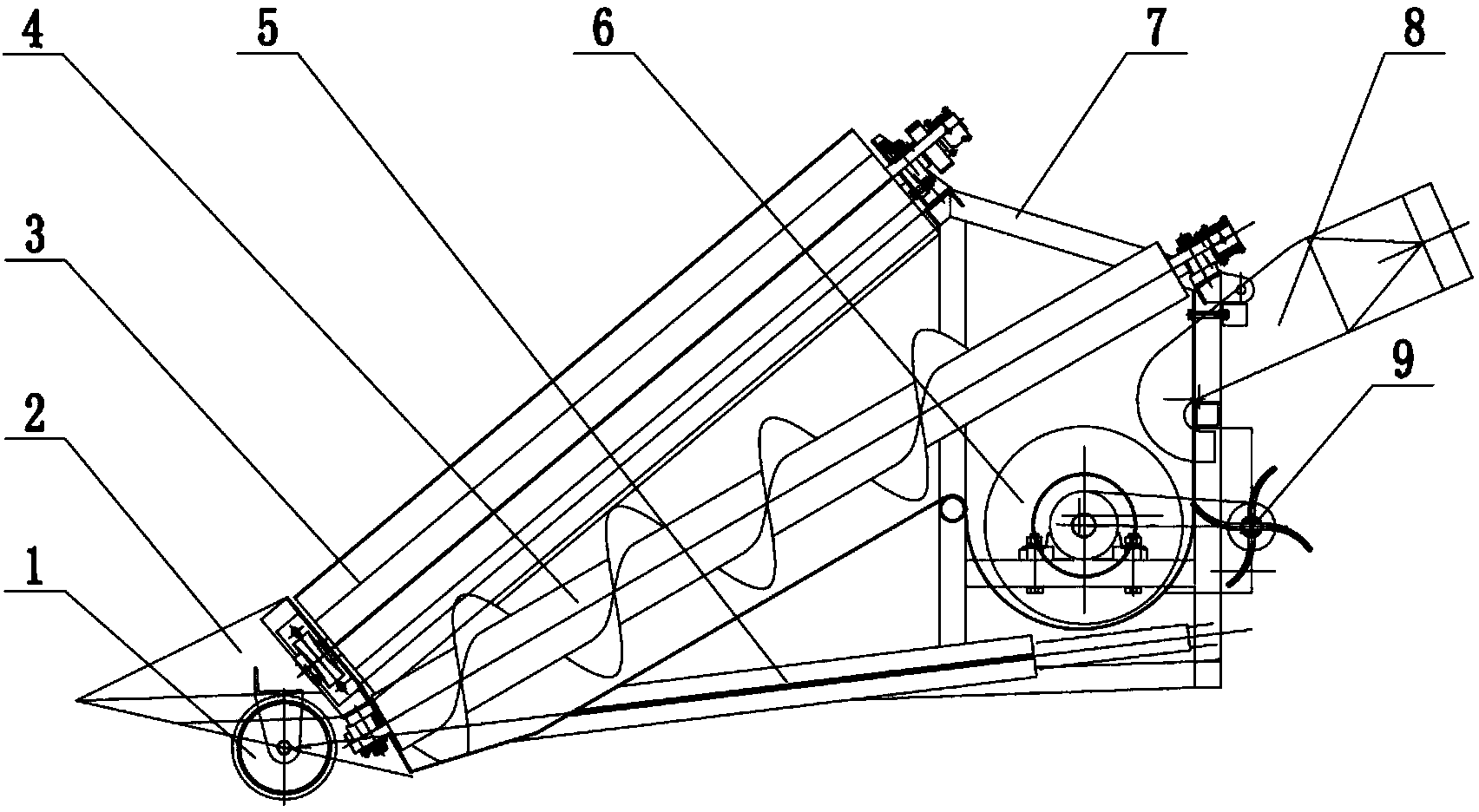

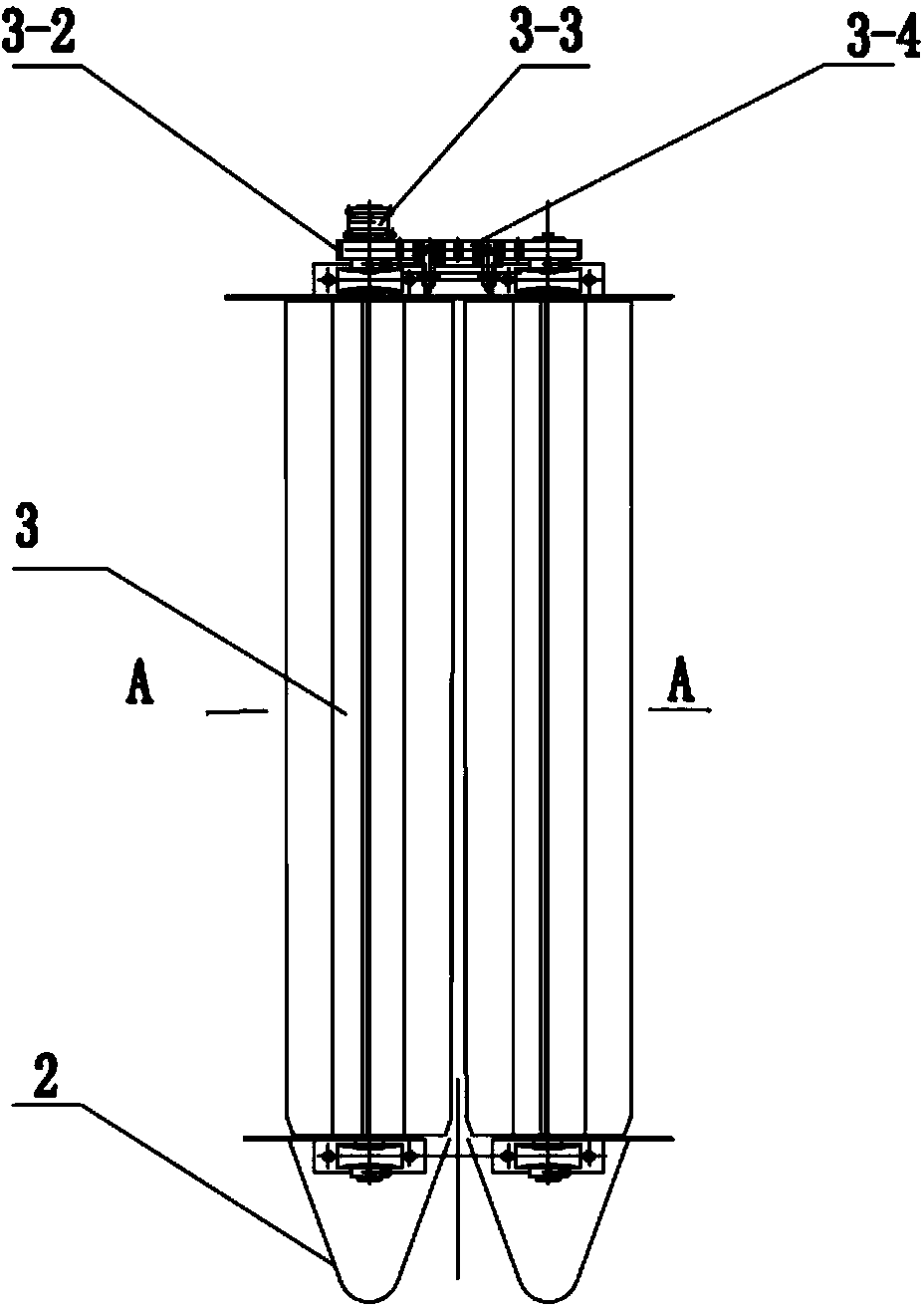

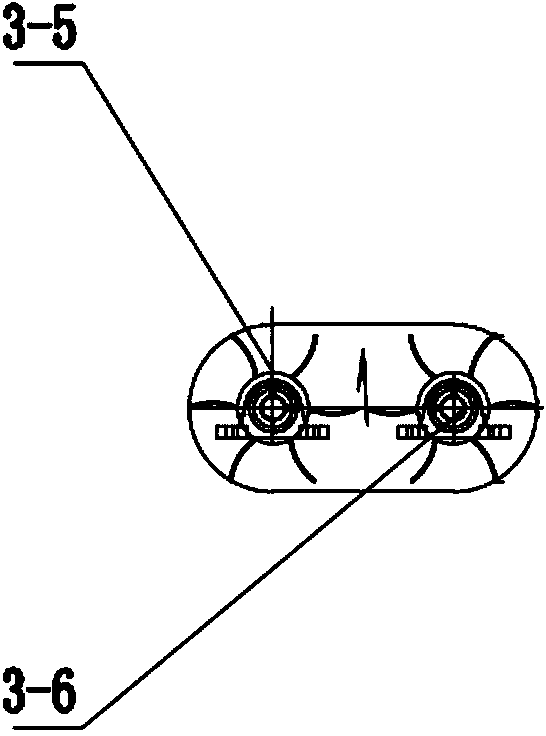

Sorption algae apparatus of collecting blue algae water bloom

InactiveCN1559928AImprove harvesting efficiencyLow priceWater/sewage treatment by centrifugal separationWater cleaningAgricultural engineeringAlgae

The invention discloses an algae absorber of collecting water blooms and blue-green alga, using a ladder type pontoon to collect water blooms and blue-green alga enriched on water surface by a absorbing pump. It is composed of ladder type tank component, bracket, cover plate, hinge and water pump pipe, where there is the ladder type tank component installed in the ladder type tank, the component, the float, a pump tube, a regulator, and a two-layer filter net fence are fixed through the bracket and the cover plate by using connecting nuts and bolts, the front end of the ladder type tank is provided with the regulator, it uses a sheet with two ends fixed with active nut and active bolt to fix a socket on two sides of the ladder type tank, and the two-layer filter net fence is inserted in the socket. It is widely applied to the harvest of water blooms and blue-green alga in lakes, riverways, reservoirs and lake bends in gardens.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Adjustable turf harvester

InactiveCN107347274AImprove harvesting efficiencyImprove cutting accuracyHops/wine cultivationTurf growingEngineeringSoil horizon

The invention discloses an adjustable turf harvester, which comprises a car body; the left side wall of the car body is fixedly connected with a beam plate; the left side of the beam plate is provided with a turf cutting device; the right side of the turf cutting device is provided There is a shovel device. The present invention is equipped with a turf cutting device and a turf shoveling device with an adjustable width, which can cut the turf into a specified width according to the needs and efficiently shovel and collect it, greatly improving the harvesting efficiency and cutting accuracy of the turf, and ensuring the turf block The thickness of the soil layer is consistent; the invention is equipped with a turf cutting device, which can cut out a specified area of turf according to the needs, so as to realize accurate harvesting; the invention is equipped with a rotatable lifting plate, which is convenient for unloading the turf, and is convenient for shipment and subsequent laying.

Owner:ZHENGZHOU BINGTONG LIZHI ELECTRONICS TECH CO LTD

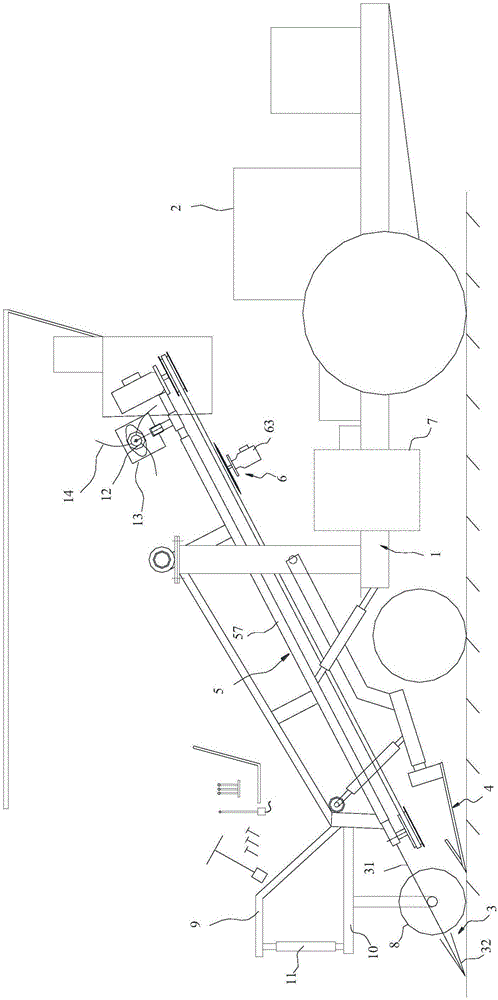

Peanut combine

ActiveCN104025794ASolve the harvesting problem of continuous plantingImprove harvesting efficiencyDigger harvestersTraction frameEngineering

The invention discloses a peanut combine. The peanut combine comprises a machine frame, a traction frame, a transmission gearbox, a peanut picking device, a conveying and collecting device, a peanut collection box, a cleaning and separating device and a peanut collecting trough. The peanut combine is characterized in that the machine frame is supported by land wheels, the front end of the machine frame is provided with a picking-up and conveying device communicated to the peanut picking device, the peanut collection box is arranged on the upper portion of the peanut picking device, and the cleaning and separating device is arranged on the lower portion of the peanut picking device and is communicated to the peanut collecting box through a peanut lifter. The peanut combine automatically picks and collects seedlings and peanuts through the steps of picking-up and conveying, picking, cleaning and separating, and conveying and collecting, is high in harvesting efficiency, makes the harvested peanuts be clean and have few impurities like straw, and is very suitable for management of family farms and cooperatives in China, wide in use range and free of influence of soil texture and planting modes.

Owner:王刚

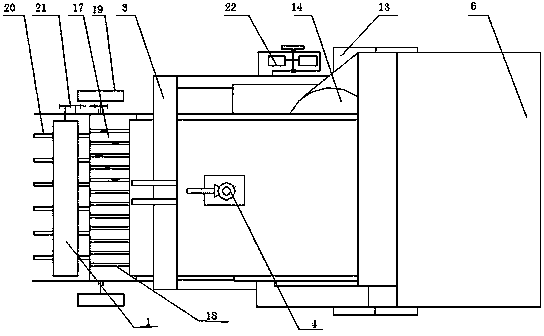

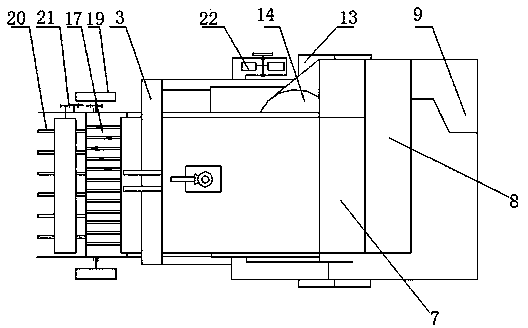

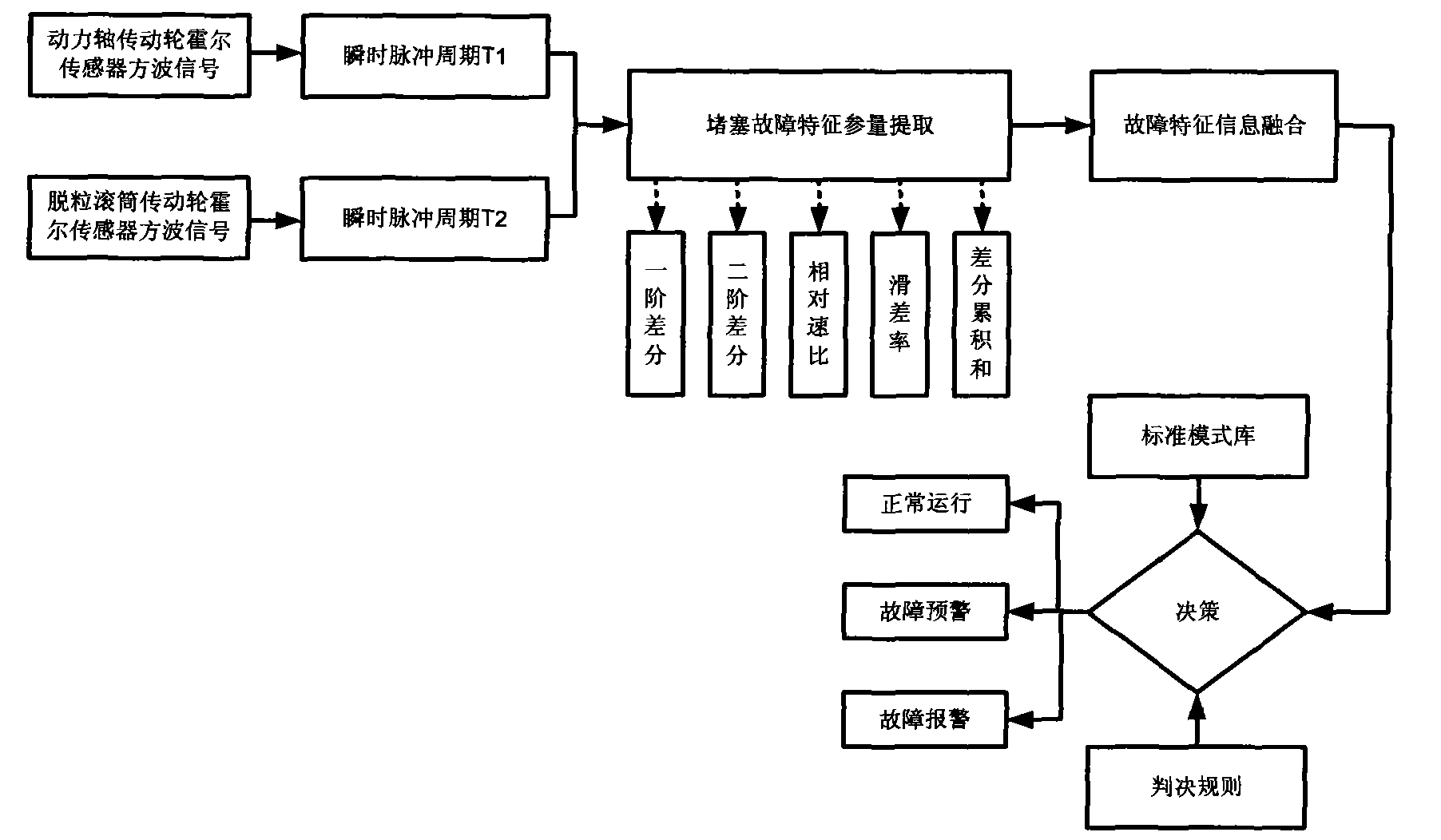

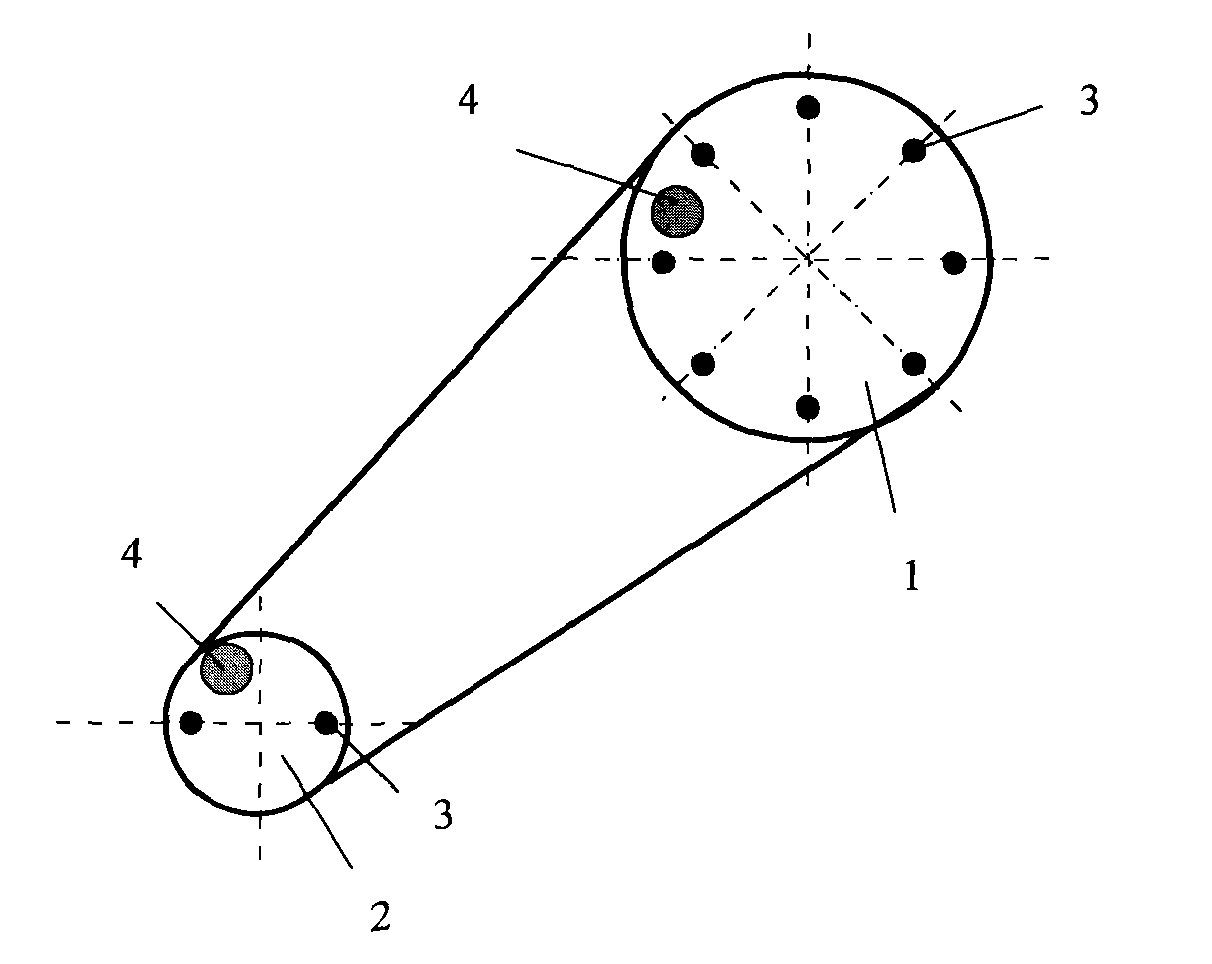

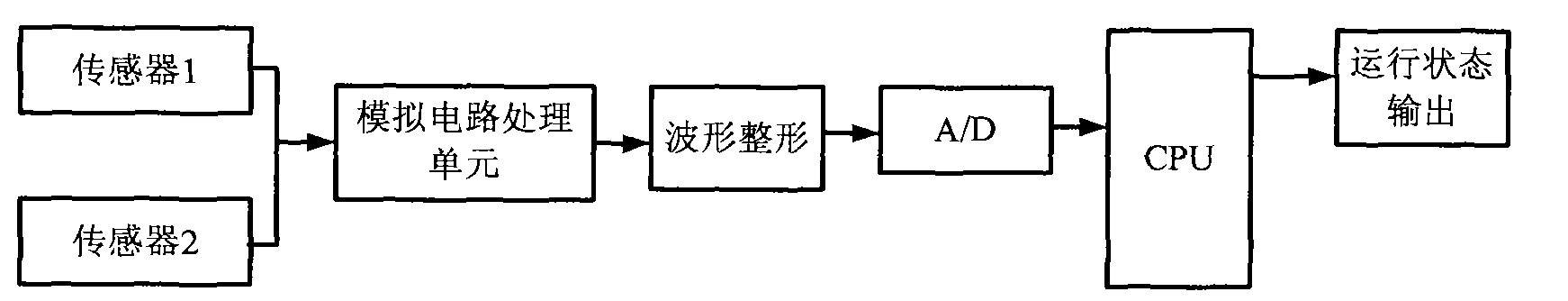

Precaution and alarming method for combined harvester threshing cylinder plugging fault

InactiveCN101595786AAvoid clogging failureImprove the level of intelligenceMowersPower beltEngineering

The invention relates to a precaution and alarming method for preventing a combined harvester threshing cylinder from plugging fault. In the method, two Hall sensors are used, one sensor is arranged on a belt pulley of an output power shaft, and the other sensor is arranged on an input power belt pulley of the threshing cylinder; transient impulse cycles of upper wave of the two wheels are synchronously measured to extract a first order difference, a second order difference, a relative speed ratio, a slip ratio, difference cumulative sum to as plugging fault portent characteristic quantity of transient impulse cycle; priority and weight are endowed on the characteristic quantity according to the contribution in identifying plugging fault; the three decisions of normal operation, plugging precaution and alarming are made on the premise of combining the plugging default portent characteristic standard model bank with judgment rules; sound and light are used for prompting the driver to carry out correct measurement in time. The invention has the advantages of automatically adapting to the forwarding speed and change of feeding quantity of the harvester, thus effectively preventing the combined harvester from plugging default to improve intelligent level and harvesting efficiency of the combined harvester and reduce loss caused by plugging.

Owner:JIANGSU UNIV

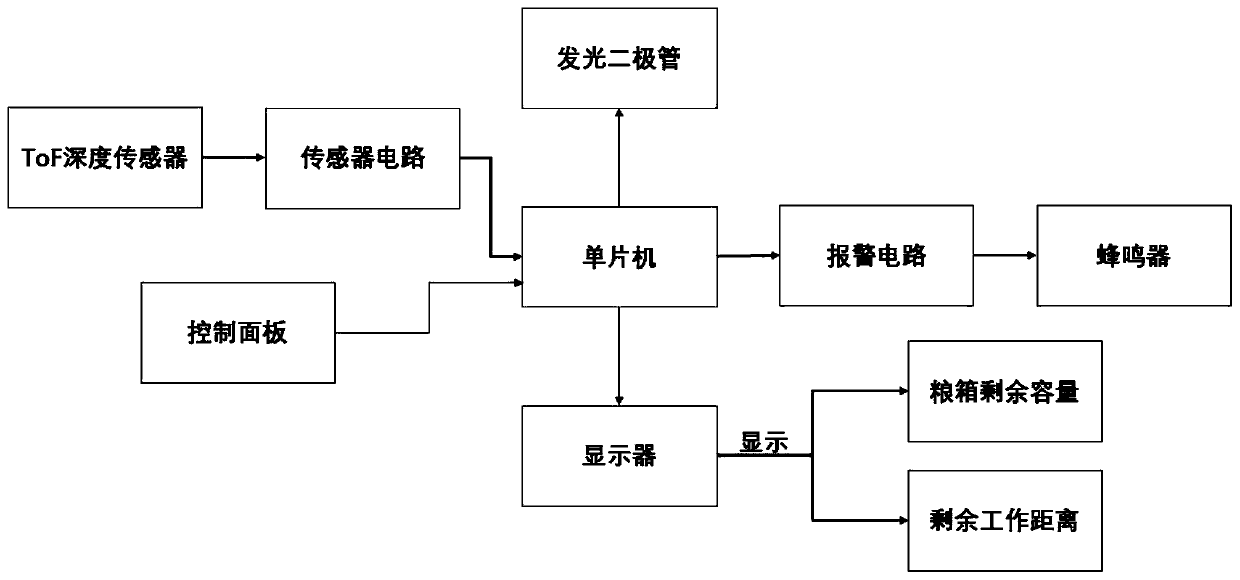

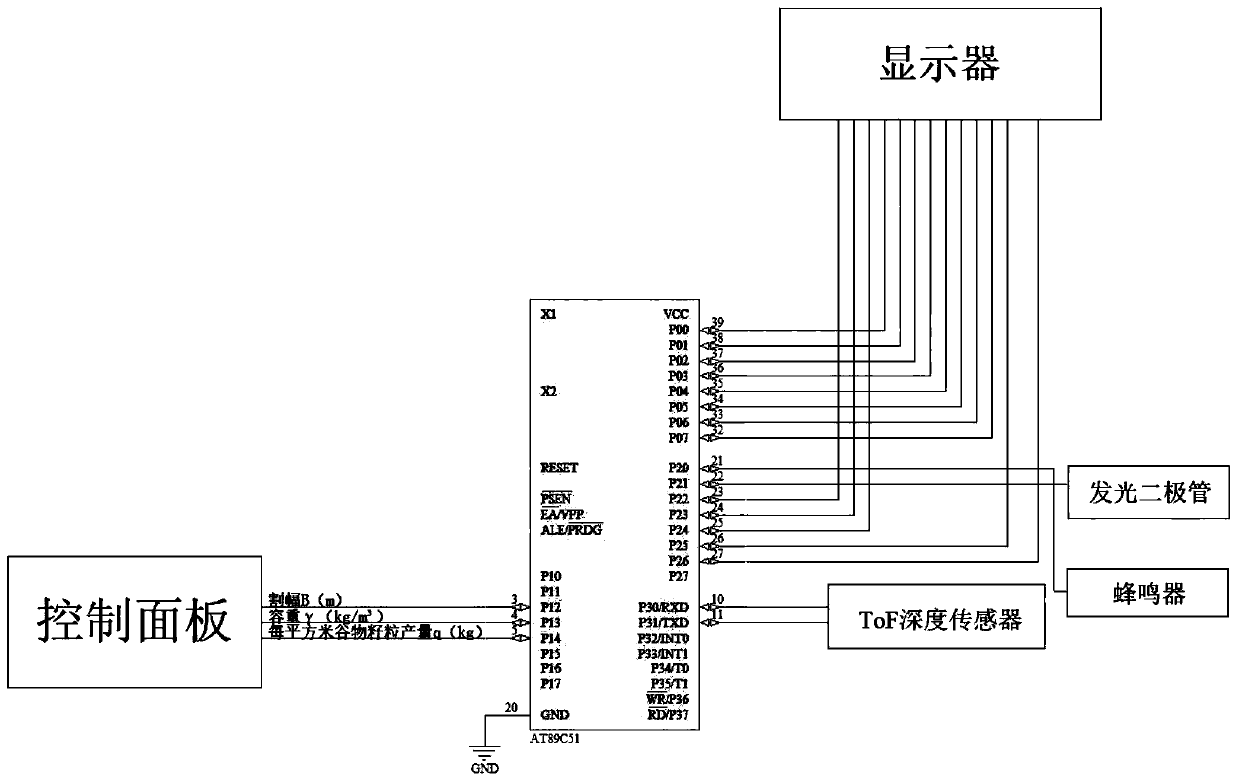

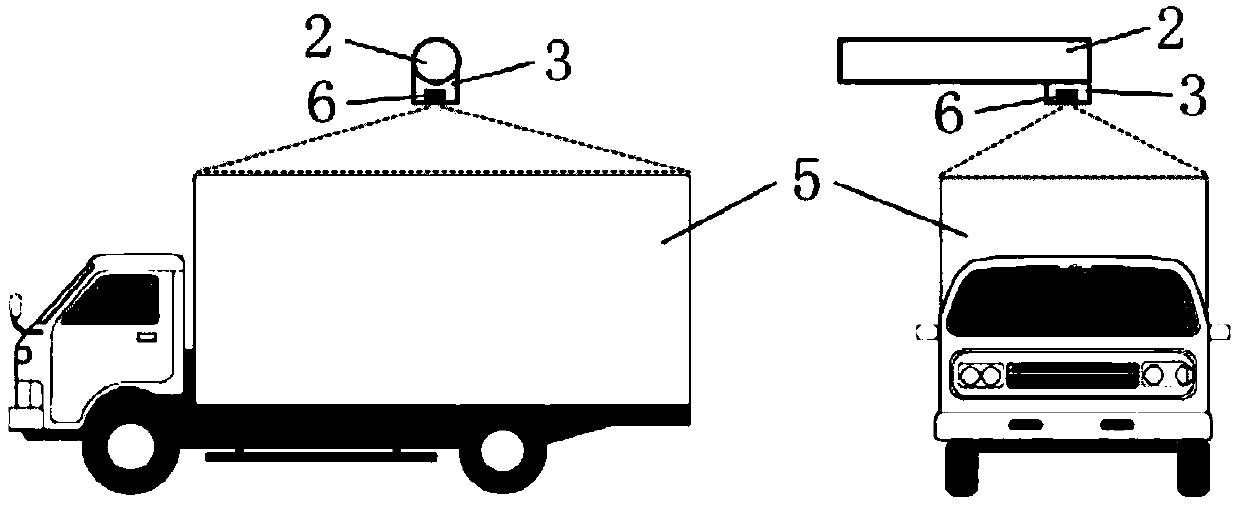

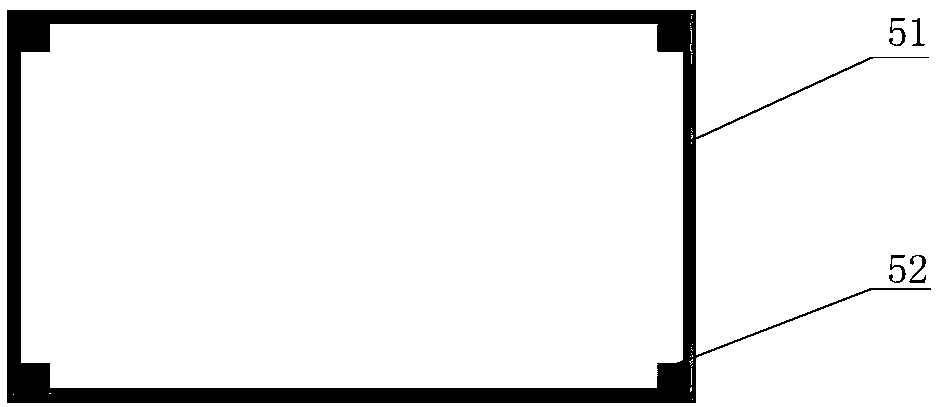

Device and method for monitoring residual capacity of grain tank and residual walking distance of combine harvester

PendingCN111406505AGrasp the accumulation status in real timePrevent leakageProgramme controlComputer controlAgricultural engineeringControl cell

The invention provides a device and method for monitoring the residual capacity of a grain tank and the residual walking distance of a combine harvester. The device comprises the grain tank, a detection device, a control panel, a control unit and a warning device, wherein the detection device is used for detecting average distance information from the stacking surface of grains in the grain tank to the top of the grain tank and transferring the average distance information to the control unit; and the control panel is used for at least inputting information including a cross section area of the grain tank, the height of the grain tank, the cutting width of the harvester, the grain yield per square meter and the unit weight of cereal grains and transferring the information to the control unit. By monitoring the residual space in the grain tank in real time, the residual walking distance of the combine harvester during harvesting working is calculated and is displayed in a display in a cab in real time, so that a tractor driver can be assisted to plan a harvesting route and an unloading route, the idle stroke of the combine harvester during field walking is shortened, and the harvesting working efficiency is improved; and when the capacity of the grain tank is about to be used up, a light-emitting diode cooperates with a buzzer to raise the alarm to remind the tractor driver to timely unload the grains, so that the loss caused due to leakage of the grains is avoided.

Owner:JIANGSU UNIV

Garlic sprout harvester

InactiveCN101697677AAchieve mechanized harvestingImprove harvesting efficiencyPicking devicesProduction rateCuticle

The invention relates to a garlic sprout harvester and belongs to the field of agricultural machinery. The garlic sprout harvester can erect a single row of garlic sprout stems and gather the garlic sprout stems into a bundle, vertically gash the epidermis of each garlic sprout stem at certain height, transversely make a cut with certain depth in the gashed epidermis and draw the garlic sprouts by using a drawing device. The invention solves the problem of mechanized harvesting of garlic sprouts. The technical proposal of the invention can increase the production rate for harvesting garlic sprouts, reduce the labor intensity for harvesting garlic sprouts and enhance the mechanization level of garlic planting.

Owner:NORTHWEST A & F UNIV

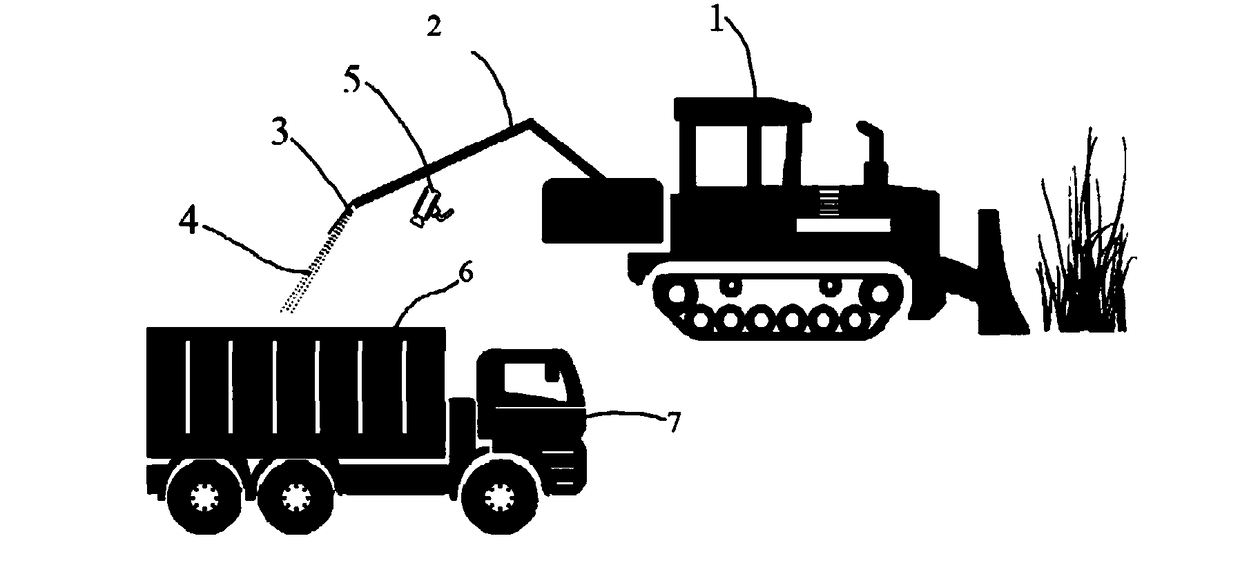

Grain harvesting and transporting integrated loading device and method based on image recognition

PendingCN111201879AAchieve horizontalChieve vertical controlMowersImage feed-backKinematic controllerAgricultural science

The invention discloses a grain harvesting and transporting integrated loading device and method based on image recognition, and relates to the technical fields of depth vision, image recognition, agricultural harvesting and internet of vehicle (IOV). Farm implements and agriculture are improved by a stereoscopic vision technology, the automation and agricultural informatization level of a harvester and a grain unloading vehicle is enhanced, and grain or equipment waste caused by human misoperation is avoided while the harvesting efficiency is improved. A self-adaptive operation manner of an existing combine harvester and a following skip car is effectively improved, a skip car human driver (driving robot) can be guided to make more accurately and effectively operation response for the current working condition, and advantageous improvement is made to avoid leakage waste, filling insufficiency and low efficiency in the operation process; and environmental information or decision instructions can be directly imported into a vehicle movement controller to realize transverse or longitudinal control on unmanned farming machinery so as to realize unmanned agricultural operation in the whole process.

Owner:金华中科艾特智能科技研究所有限公司

Motion hopper automatic identification and positioning method based on depth visual information

InactiveCN108550141AImprove harvesting efficiencyReduce labor intensityImage enhancementImage analysisPoint cloudImaging processing

The invention relates to a motion hopper automatic identification and positioning method based on depth visual sense information; the method comprises the following steps: S1, parsing a rotation matrix R and a translation matrix t between a camera coordinate system and a world coordinate system; S2, reading a frame of depth image that contains depth visual sense information from a camera, and reading a frame of point cloud data; S3, downsampling the point cloud data; 4, converting the point cloud data under the camera coordinate system into the point cloud data under the world coordinate system; S5, carrying out threshold process for the converted point cloud data, keeping a lattice of an approximate height area to which the hopper is located, carrying out dimension reduction process for the point cloud after threshold processing, and projecting same to a two dimensional plane; S6, using an image processing technology to carry out a fitting process for the point cloud after dimension reduction, thus obtaining a hopper edge straight line, and calculating an angle point of the same. The method can automatically identify the outer profile of the hopper of a trailer, can obtain the angle and position of the hopper with respect to a machinery arm nozzle, and can automatically control the nozzle height and angle to make corresponding adjustments.

Owner:SHANGHAI UNIV

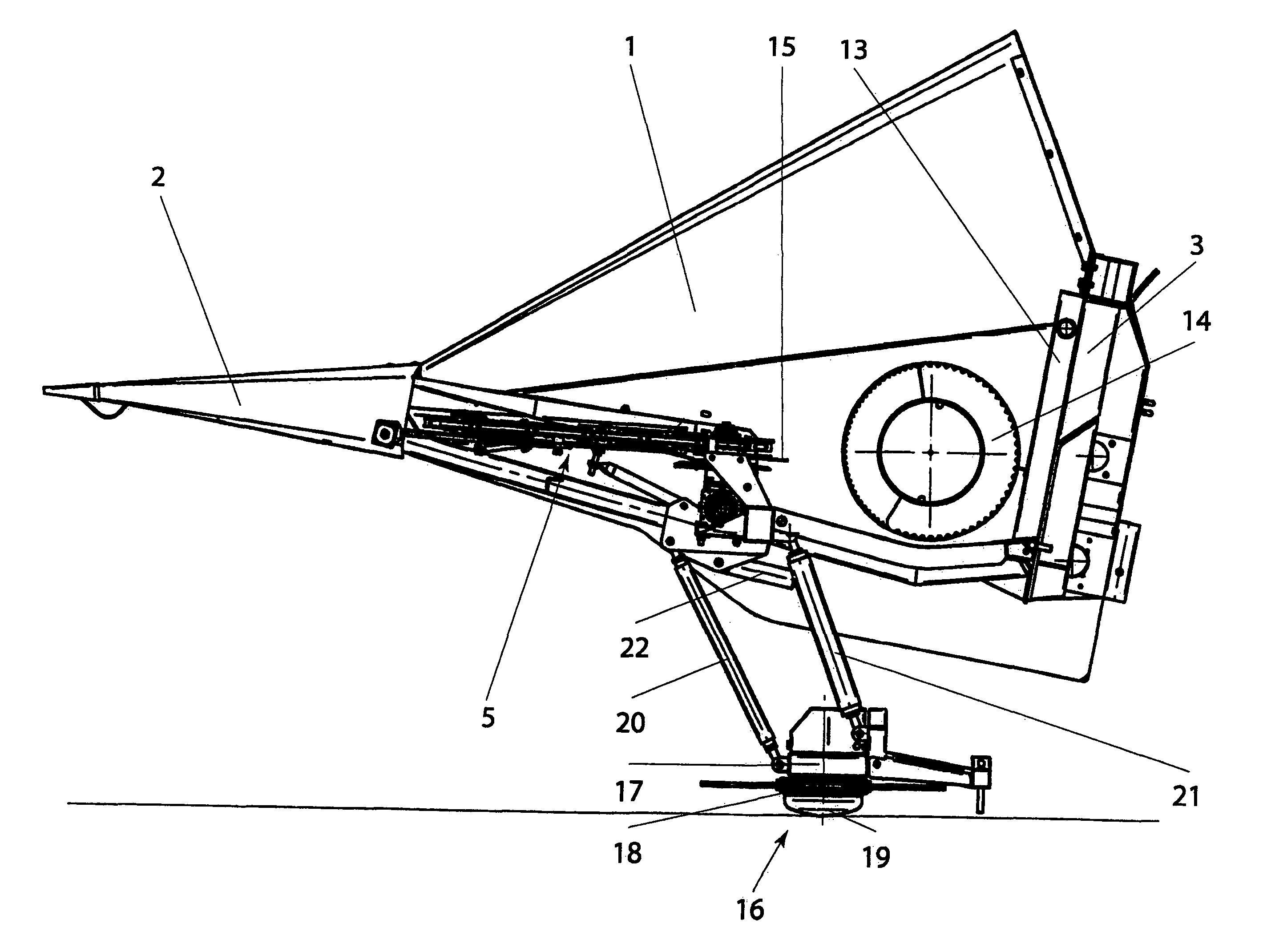

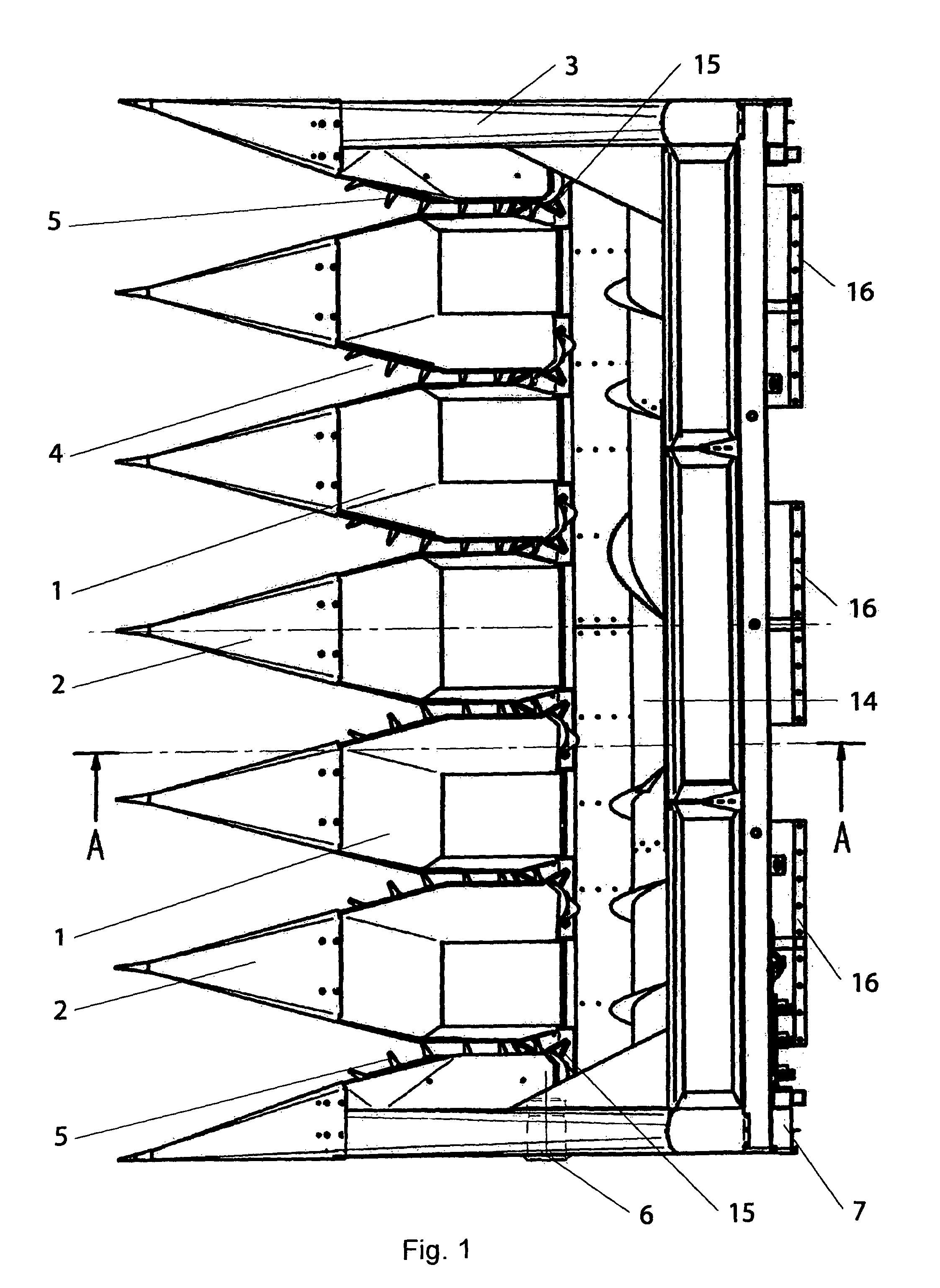

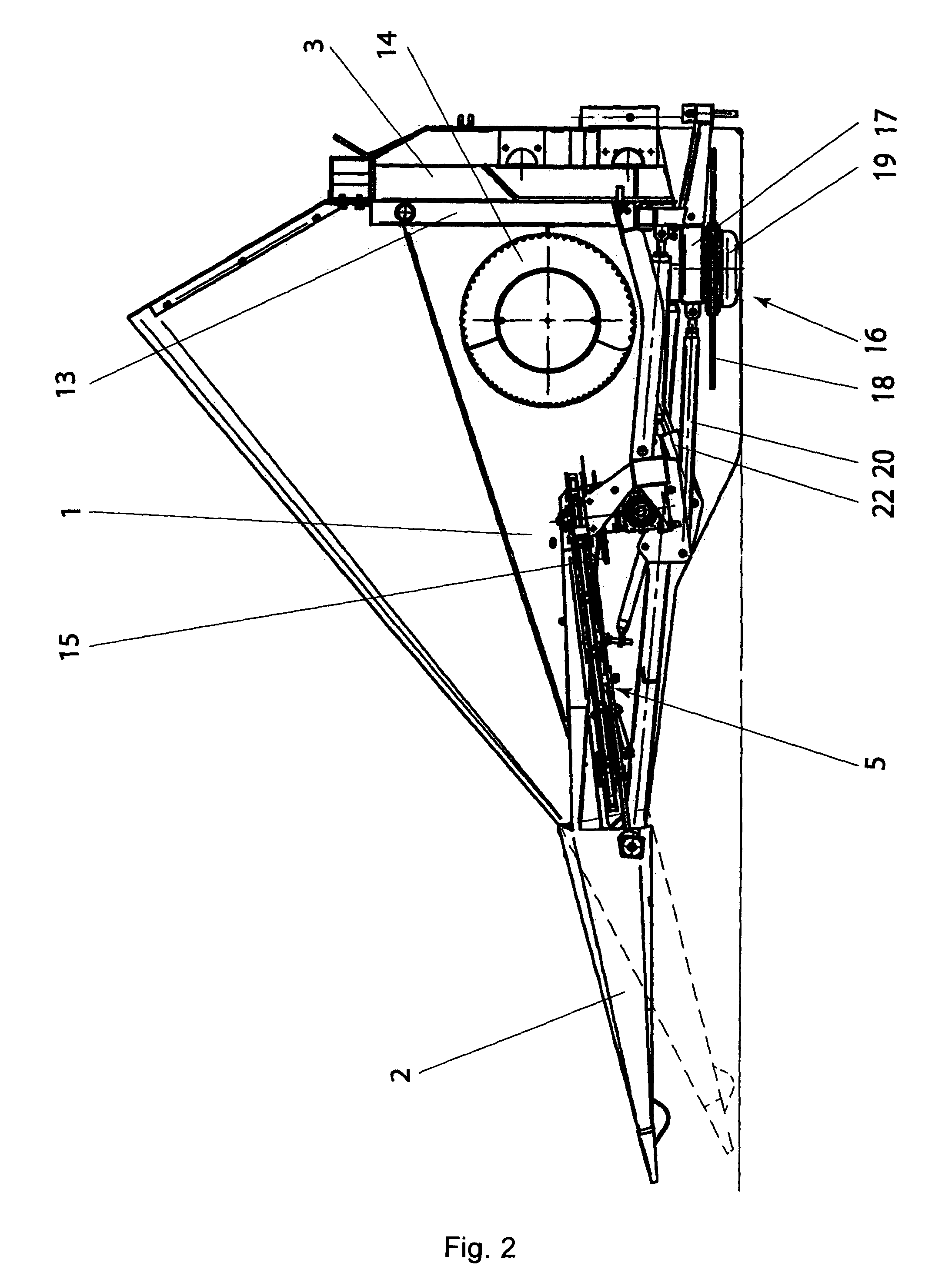

Harvester adapter with stalk shredder for harvesting grain crops, particularly sunflower

The harvester adapter has a frame structure, for attachment to a combine harvester. At least two crop gathering units are secured to the frame structure. Adjacent crop gathering units are arranged such that a channel with an open leading end is formed between them, with a stalk gathering unit being disposed in driving connection with a harvesting mechanism on at least one side of the channels. The adapter has a collecting auger disposed rearward from the harvesting mechanism and at least one stalk shredder unit attached to the frame structure. The speed of the stalk gathering unit is continuously adjustable by control orders given by the combine harvester and / or by a speed meter disposed on the adapter and / or by the operator, and the stalk shredder units are attached to the frame structure such that their position is adjustable in a direction perpendicular to the direction of travel.

Owner:OPTIGEP

Young garlic shoot harvester

ActiveCN106941868ASolving the problem of mechanized harvestingPrecious harvest timeHarvestersShootTurning frames

The invention relates to the field of agricultural machinery, in particular to a young garlic shoot harvester which comprises a car frame. A swing cutter device for cutting down young garlic shoots from bottoms is arranged at the front end of the car frame, a conveying device for conveying the young garlic shoots cut down by the swing cutter device to a harvesting box on the car frame is arranged above the swing cutter device on the car frame, advancing wheels are arranged on the two sides of the car frame, a land supporting drag wheel is arranged at the tail end of the car frame, a young garlic shoot drawing device for gathering and lifting young garlic shoots up in an advancing process of the car frame is arranged on the car frame and between the conveying device and the swing cutter device, and a peeling device for peeling the young garlic shoots in a lifting process through the young garlic shoot drawing device is arranged on the car frame and between the young garlic shoot drawing device and the swing cutter device. The young garlic shoot harvester disclosed by the invention solves the problem of mechanically harvesting the young garlic shoots, further has a reasonable structure, small volume, flexibility and convenience to operate and high work efficiency, wins precious harvesting time for young garlic shoot farmers and effectively reduces harvesting cost.

Owner:HENAN UNIV OF SCI & TECH

Pine pollen collector

The invention relates to a pine pollen collector, which comprises a power-actuated air suction device, a pollen collecting device and a pollen sucking device, wherein the power-actuated air suction device consists of a centrifuge and a power unit, the pollen collecting device consists of a gas-solid separator and a pollen cup, and the pollen sucking device consists of a pollen sucking head and a hollow handle. One end of the hollow handle is communicated with the pollen sucking head, while the other end is communicated with an air inlet of the gas-solid separator through a hose. The air outlet of the gas-solid separator is communicated with a hose port on the centrifuge through a connecting hose. The pollen cup which is detachable is connected with a bottom part of the gas-solid separator. The pine pollen collector has the advantages of: 1. tree damage-free collection and effective protection of forest resources; 2. simple, convenient and safe operation, overall operation and completecollection; 3, high efficiency and high-quality pollen; 4. prolonging collection period; and 5. sustained production of pine pollen.

Owner:浙江亚林生物科技股份有限公司

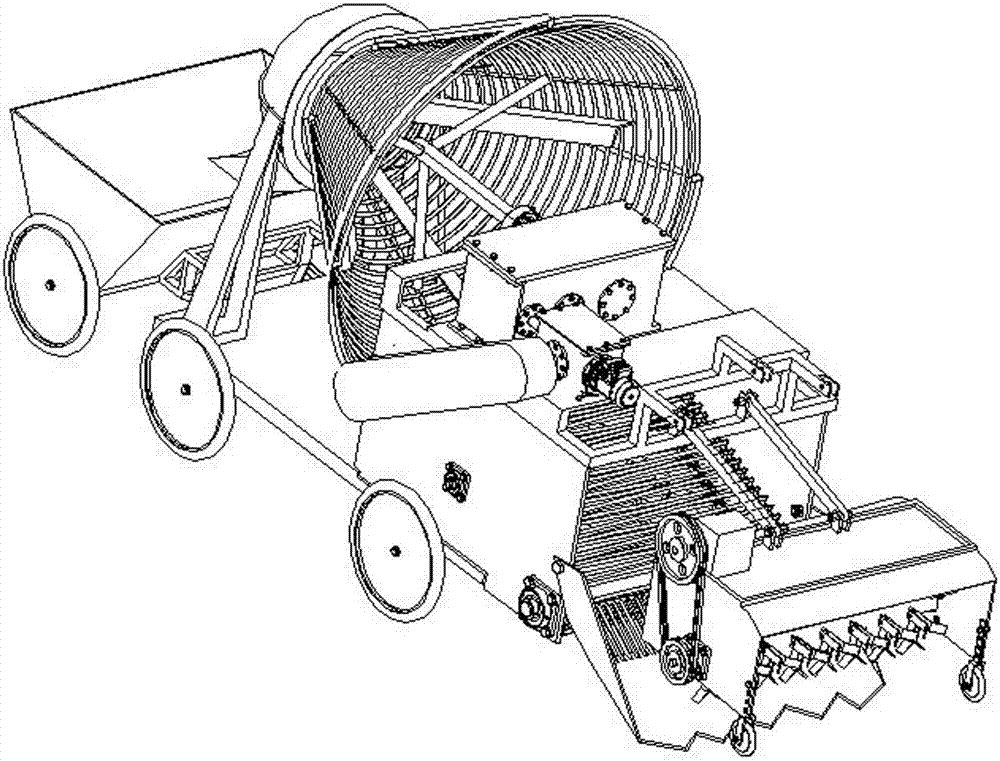

Self-propelled multifunctional straw harvest bundling machine

The invention discloses a self-propelled multifunctional straw harvest bundling machine which comprises a winder, a header assembly, an operating device, a chassis assembling assembly, a kneading room, a power device, a front bundling room and a rear bundling rood, wherein the header assembly and the winder are positioned at right ahead of the whole bundling machine; the winder is hooked on a lifting arm of the header assembly, and can be lifted around a rotational shaft of the lifting arm at the action of an oil cylinder; the header assembly is hinged on a support seat at the front of the kneading room, and can be lifted around a hooking shaft; the kneading rood is positioned at the front end on the upper part of the chassis assembling assembly, and the front part of the kneading part is connected with the operating device; a cab is connected with the operating device; the kneading room is connected with the power device, and the rear part of the kneading room is connected with the front bundling room which is positioned at the rear end on the upper part of the chassis assembling assembly, and is hinged with the rear bundling room; a bundling room is formed by the front bundling room and the rear bundling room; bundling rollers are arranged in the bundling room in circumference; and a rope bundling device is arranged at the front of the front bundling room.

Owner:LUOYANG ZHONGSHOU MACHINERY & EQUIP

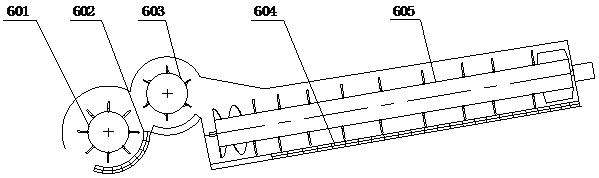

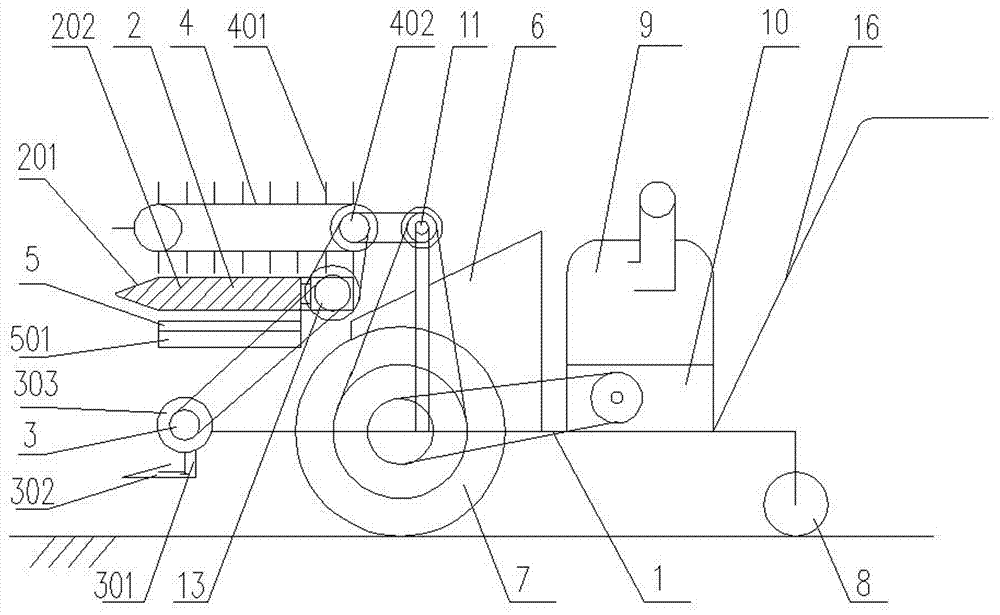

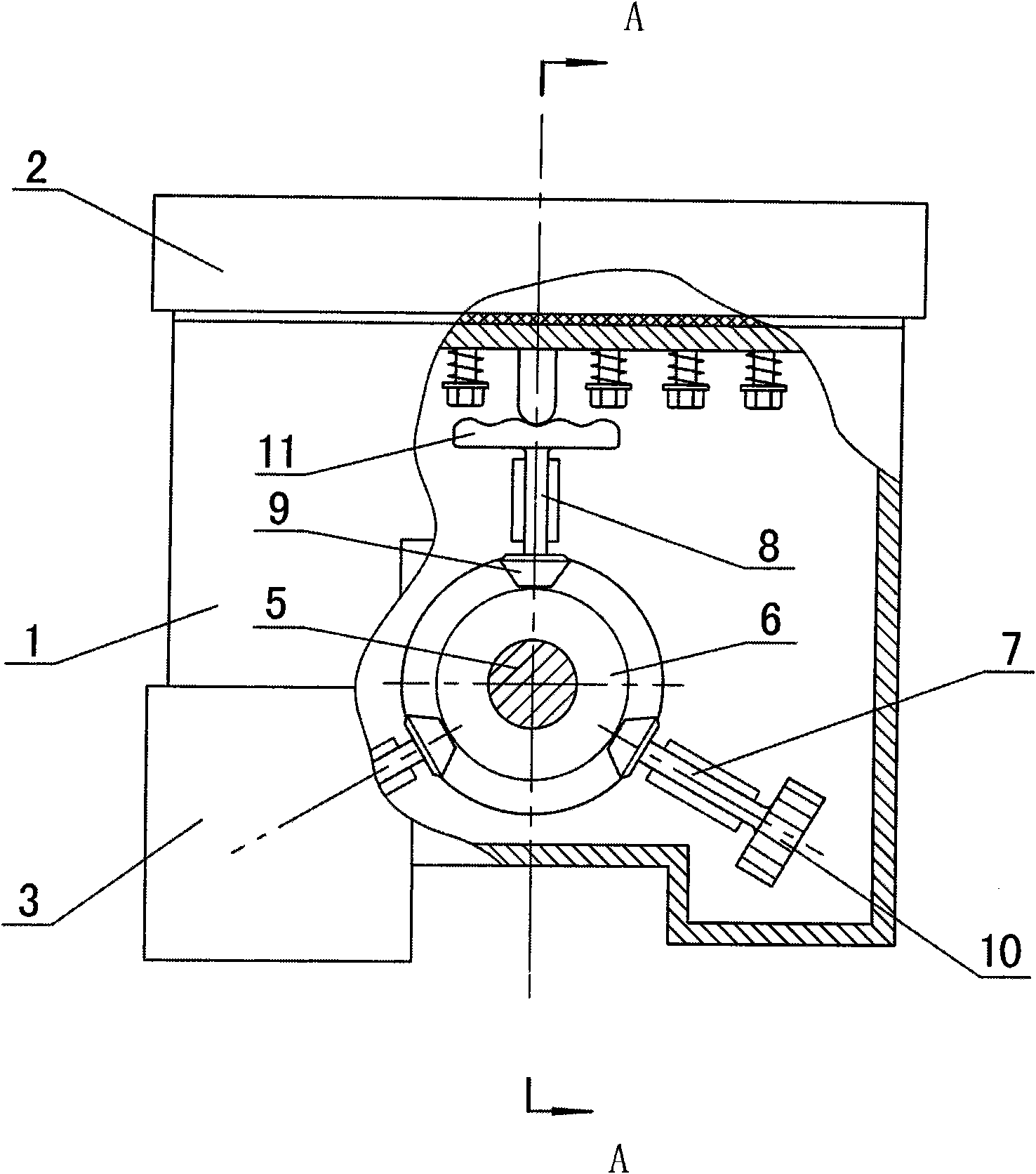

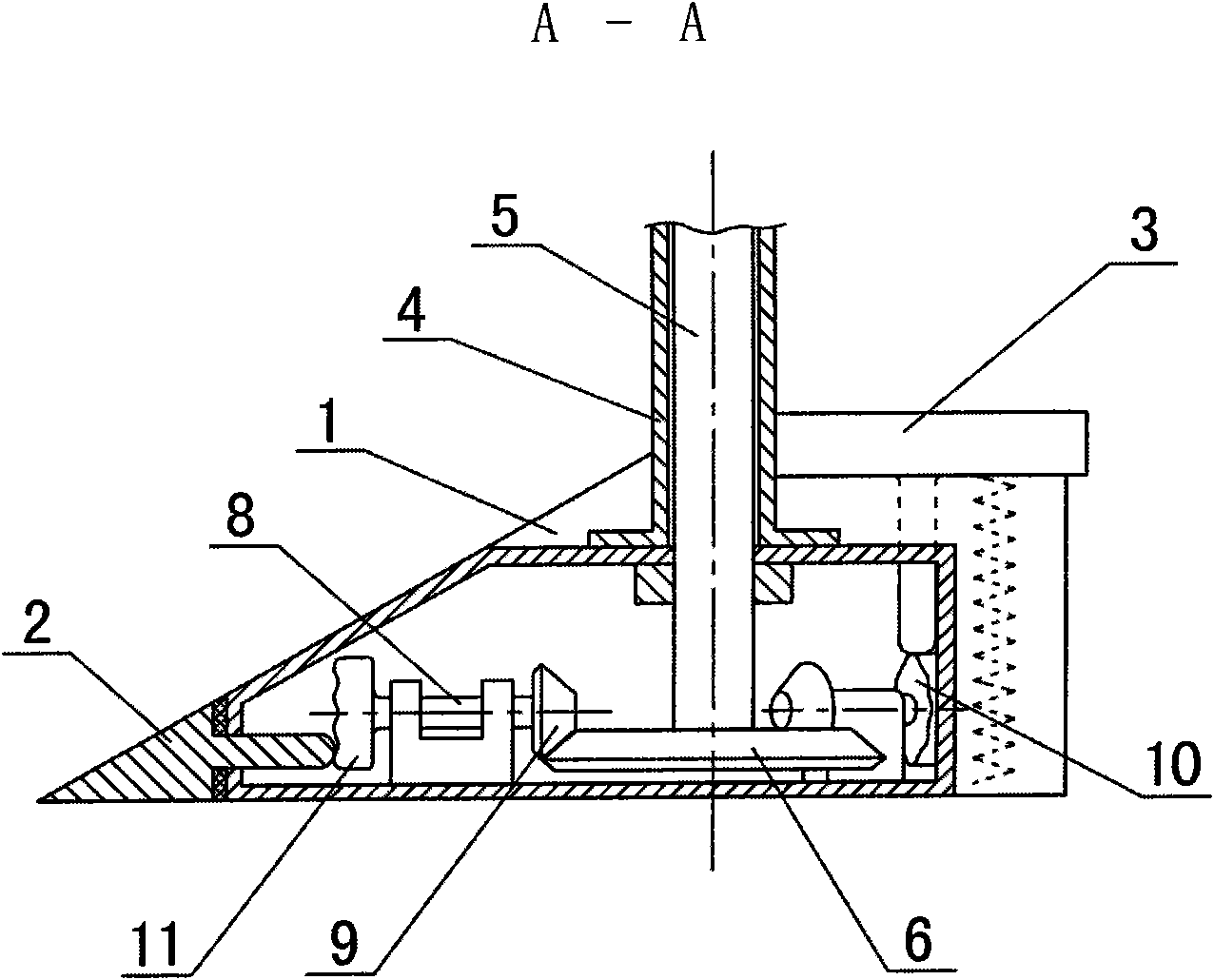

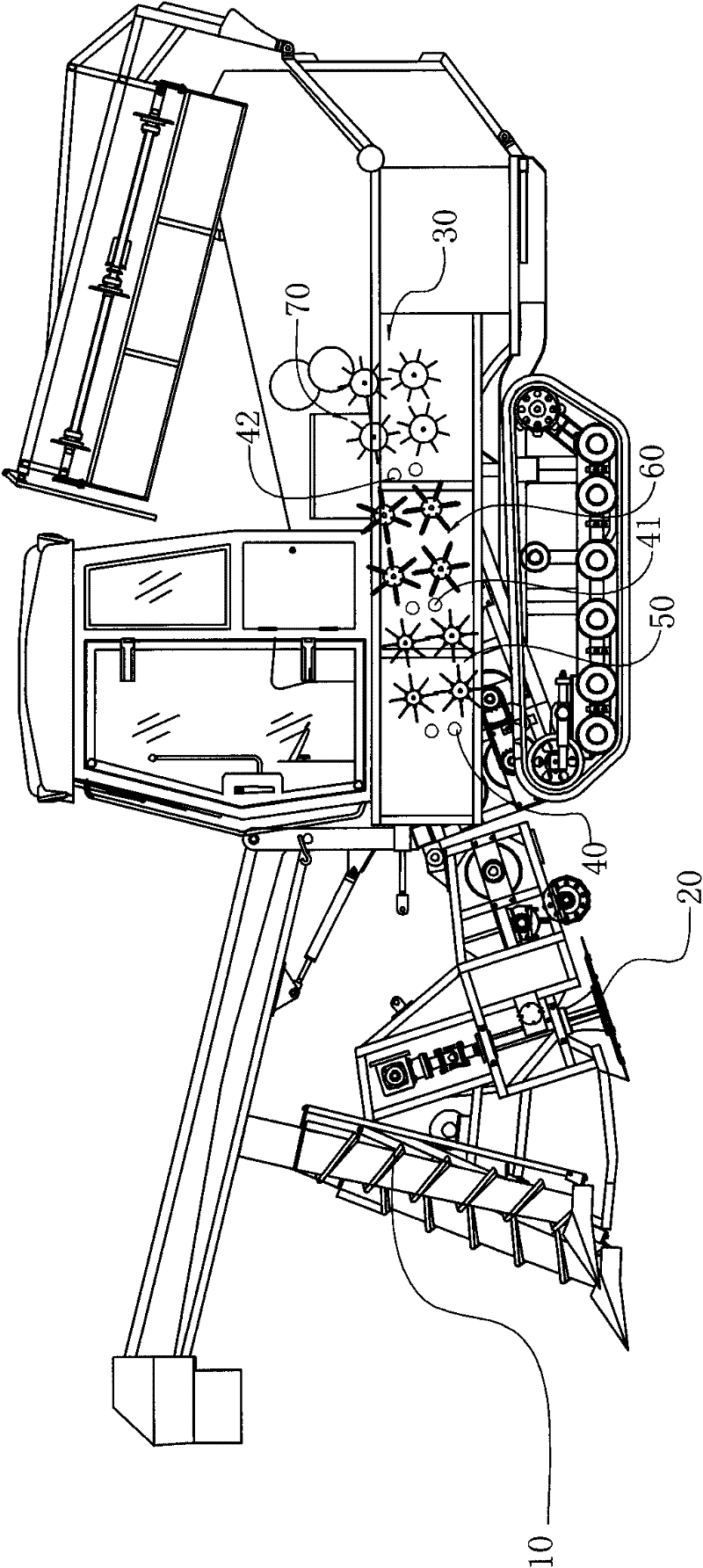

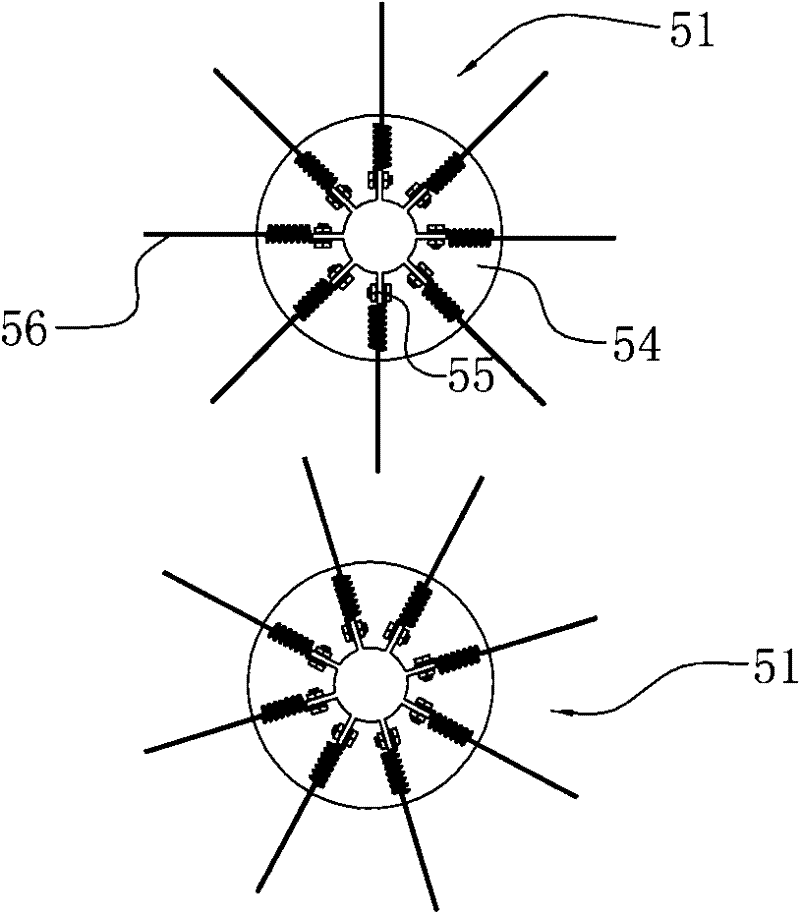

Full-feeding type peanut combined harvester

InactiveCN104160818AReduce impurityQuick and efficient removalDigger harvestersThreshersReciprocating motionAgricultural engineering

The invention discloses a full-feeding type peanut combined harvester and belongs to the field of agricultural harvesting machinery. The full-feeding type peanut combined harvester comprises a vibrating digging shovel, a soil distributing and conveying device, a peanut picking device, a cleaning device, a peanut collecting device and the like. The vibrating digging shovel performs reciprocating vibration and is a sawtooth type vibrating digging shovel, a belt wheel transfers power to the vibrating digging shovel through a crankshaft and a connecting rod to achieve reciprocating vibration of the vibrating digging shovel. The soil distributing and conveying device is located at the rear portion of the digging shovel, and soil on peanut vines is screened while the soil is conveyed backwards. A feeding conveying belt is located under the back of the soil distributing and conveying device, the tail portion of the conveying belt extends into the peanut picking device, and the peanut vines are fed into the peanut picking device through the feeding conveying belt. The full-feeding type peanut combined harvester has the advantages that digging, soil screening, peanut picking, cleaning, peanut collecting and the like are finished in one time, the harvesting efficiency is improved, and peanut picking gaps of peanut picking rollers can be adjusted according to peanut varieties, planting density, maturity and the harvesting speed.

Owner:JIANGSU UNIV

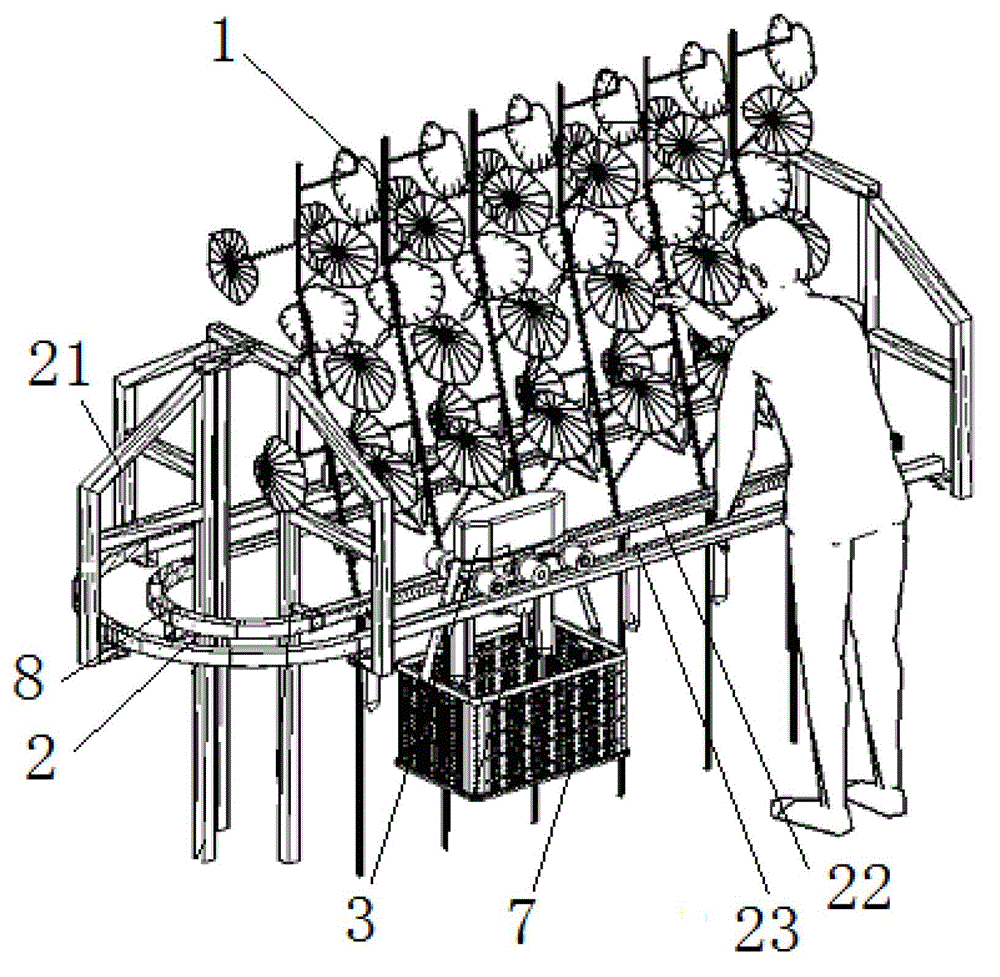

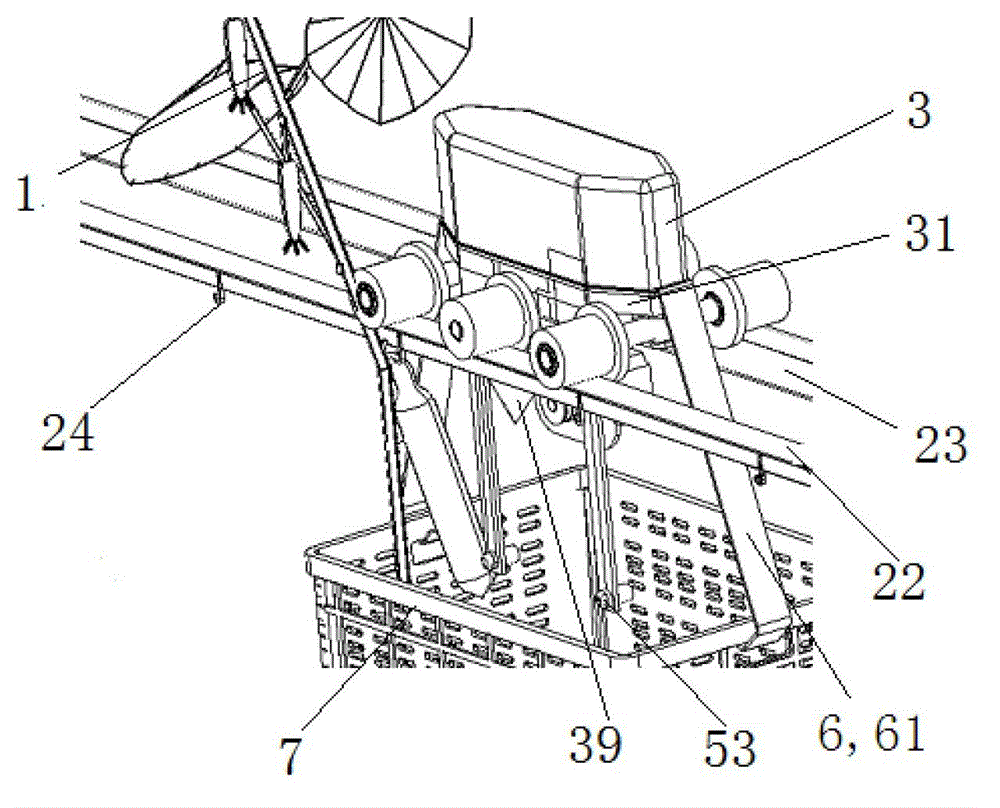

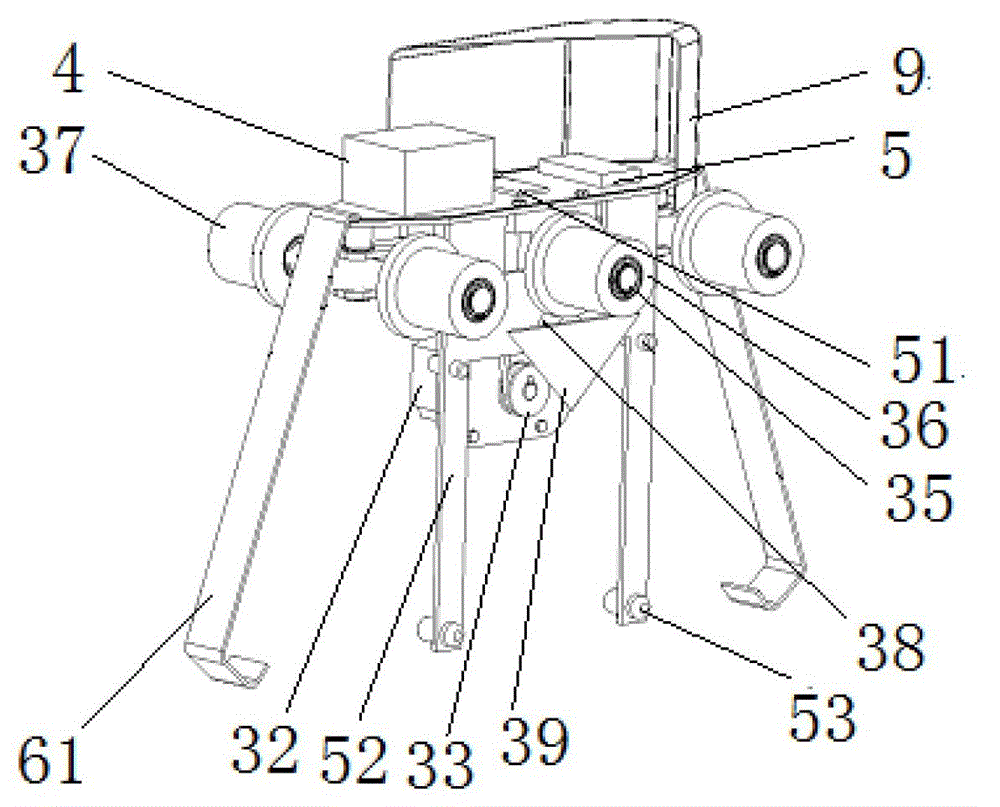

Cucumber harvesting device and using method thereof

The invention relates to a cucumber harvesting device and a using method thereof. The cucumber harvesting device is characterized by comprising an annular rail, wherein an intelligent harvesting vehicle for hanging a harvesting basket is arranged on the annular rail; hooks for hanging cucumber stems are arranged on the inner side of an inner ring straight rail at intervals; the intelligent harvesting vehicle comprises a machine frame; a power supply and a control device are arranged at the top of the machine frame; a motor is arranged at the bottom of the machine frame; the motor is connected with a small belt pulley; the small belt pulley is connected with a big belt pulley through a belt; the big belt pulley is connected with a driving shaft; the driving shaft is rotationally connected to the bottom of the machine frame; one end of the driving shaft is fixedly connected with a driving roller wheel and the other end of the driving shaft is connected with another driving roller wheel; supporting shafts are fixedly connected to the front part and the rear part of the bottom surface of the machine frame respectively; two ends of the supporting shafts are rotationally connected with roller wheels respectively; a rotary electromagnet is arranged at the bottom of the machine frame; the rotary electromagnet is connected with a harvesting cutter; harvest basket hooks are arranged at the front end and the rear end of the machine frame respectively; and infrared sensors are arranged at the bottoms of two detection rods of the machine frame. The cucumber harvesting device can be widely applied to production of fruits and vegetables in greenhouses.

Owner:CHINA AGRI UNIV

Small-size soybean combine harvester

InactiveCN105027813AHigh coordinationImprove adaptabilityCrop conditionersMowersProduction rateBreakage rate

The invention belongs to the field of agricultural machines, and particularly discloses a small-size soybean combine harvester. The small-size soybean combine harvester comprises a harvester frame, a power device assembly, a caterpillar band walking device, a header assembly, a conveying bridge device, a threshing and cleaning assembly, a water tank and a straw smashing device assembly. The small-size soybean combine harvester has the advantages that as the position and the parts of a whole mechanism are adjusted, the whole harvester is simple, compact, convenient to operate and high in harvesting efficiency; the harvester has the functions that a header is small in vibration, the ground clearance is smaller than 50 mm, and straw is smashed to be directly returned to fields, the straw is sprayed to be buried underground, and decomposing and rotting of the straw are facilitated; the functions of collecting the straw and the like are achieved, the header of the harvester is small in cutting width and is specially designed for the soybean intercropping and interplanting mode, and the harvesting speed is higher than 6-7 mu per hour; mixed liquid beneficial for straw decomposing is mixed into the straw returned to the fields, and therefore the decomposing and rotting speed of the straw is increased. According to the small-size soybean combine harvester, the harvesting production speed is high and larger than 6-7 mu per hour, the soybean loss ratio and the soybean breakage rate are smaller than or equal to 2%, and the soybean cleaning rate is larger than 98%.

Owner:SICHUAN AGRI UNIV

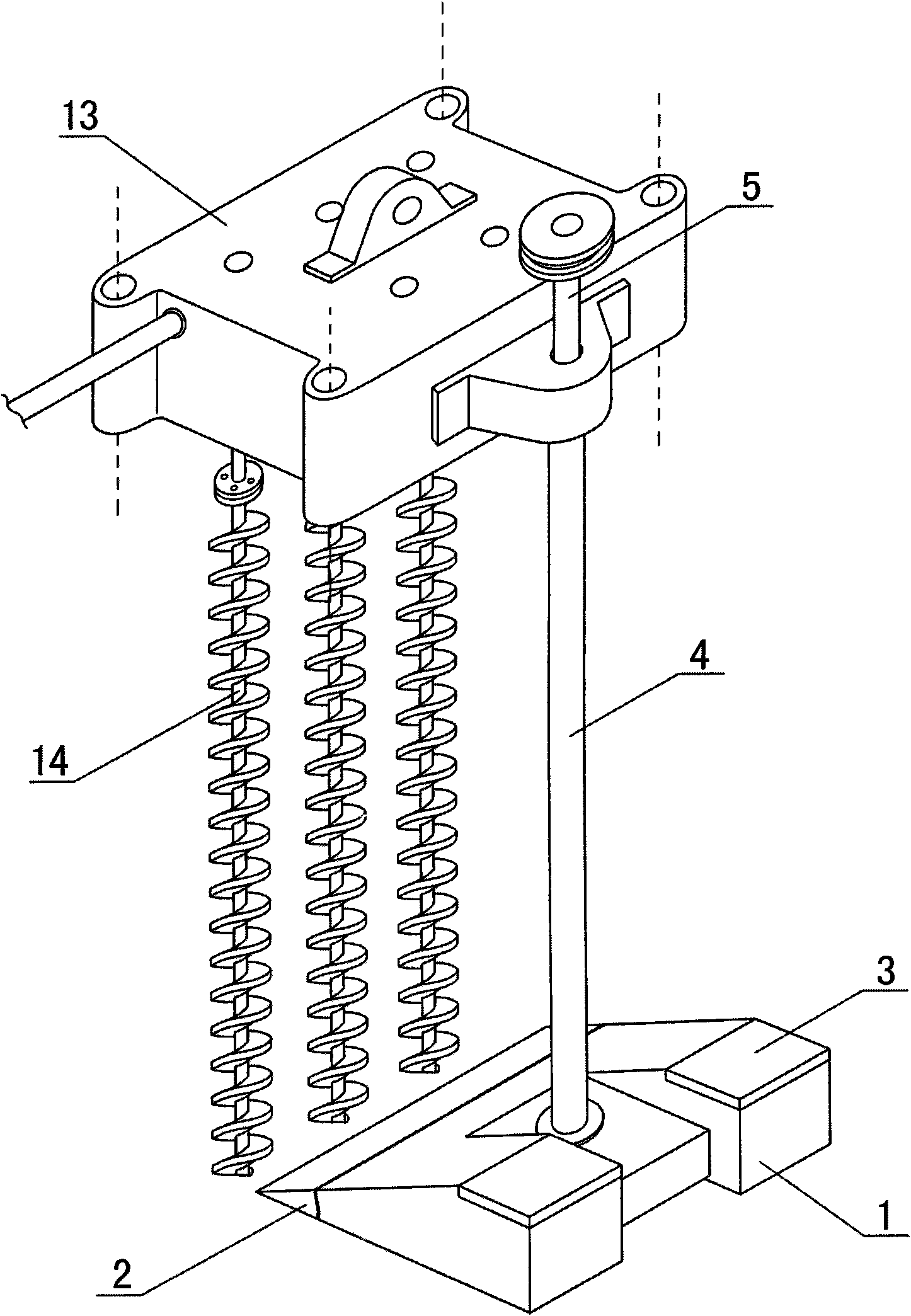

Chinese yam harvesting and planting dual-purpose machine

InactiveCN102144450AEasy to take outImprove planting efficiencyPlantingDigger harvestersRootstockDual purpose

The invention relates to the technical field of harvesting and planting machinery for agricultural products, in particular relates to a Chinese yam harvesting and planting dual-purpose machine. The soil requires to be loosened deeply before the planting of long-rootstock crops; because the crops grow deeply in the soil and especially the growing situations of Chinese yam, burdock and the like are difficultly known, most of the crops are harvested manually so as to avoid damage of the crops during the harvesting, and thus the labour intensity is high and the work efficiency is low. The technical scheme of the Chinese yam harvesting and planting dual-purpose machine disclosed by the invention is characterized by comprising a frame, a power device and a furrowing device; the upper end of a shaft sleeve of a vibrating device is assembled at the rear part of the furrowing device, and the lower end of the shaft sleeve of the vibrating device is fixedly provided with a wedge-shaped vibrating box. During the harvesting of the crops such as Chinese yams and the like, the soil at two sides of a crop ridge is dug to be loose by using the furrowing device, then the soil below or around the crop is vibrated to be loose by using the vibrating device, and finally, the crop is ejected upwards, so that the intactness of the crop in the digging process is guaranteed and the work efficiency is improved greatly. The Chinese yam harvesting and planting dual-purpose machine further can be used for digging the soil to be loose by only using the furrowing device and improves the planting efficiency of the agricultural crops.

Owner:张家口茂盛创新科技有限公司

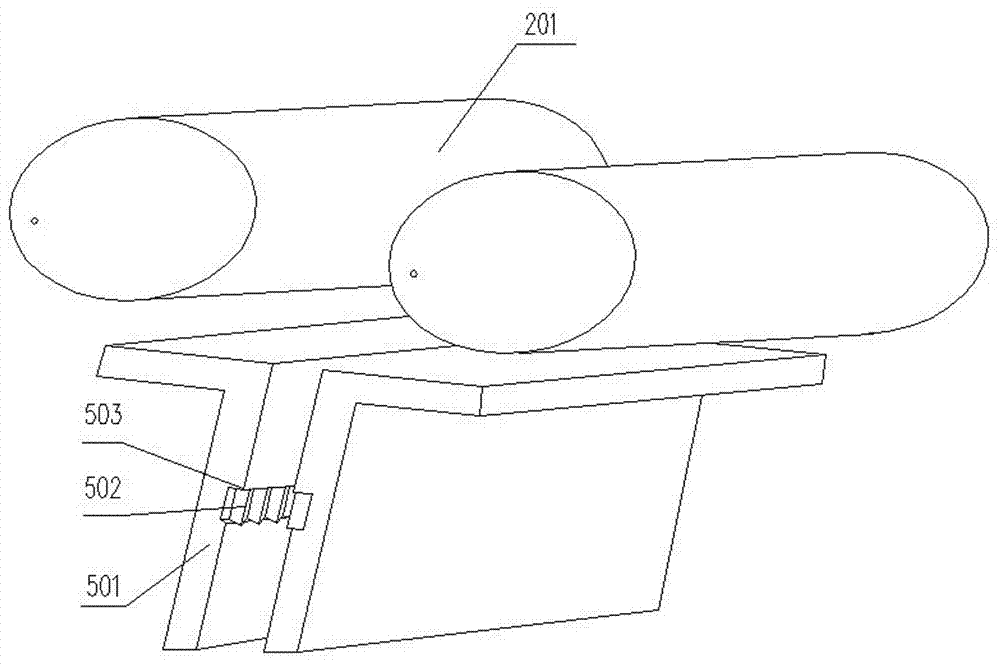

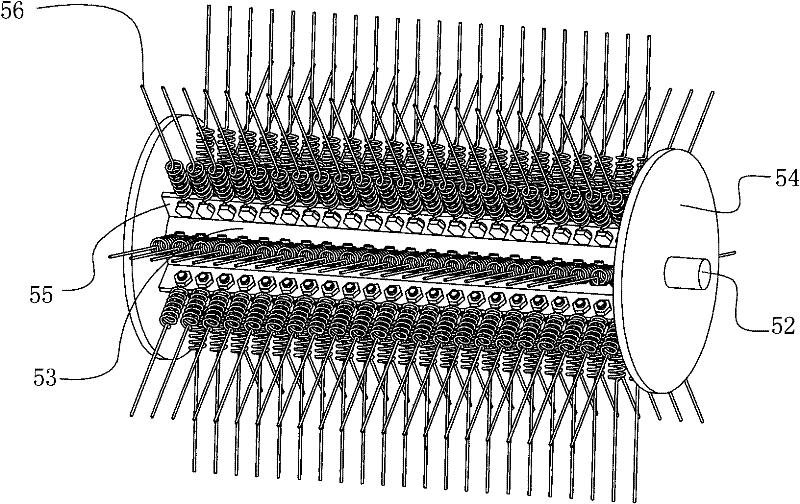

Brush roll type picking table

ActiveCN103858605AImprove harvesting efficiencyPicking devicesAgricultural engineeringAgricultural machinery

The invention relates to a brush roll type picking table and belongs to the technical field of agricultural machinery. The picking table comprises at least one pair of dividers with cone heads, which are arranged at the front end of a picking table frame; picking heads are arranged behind the dividers; each picking head comprises a pair of left and right brush rolls which are provided with low front parts and high rear parts, are supported on the picking table frame and rotate towards the opposite directions at the same speed; a group of brush plates radially extending are peripherally distributed on each of the left and right brush rolls; longitudinal helical conveyors with V-shaped connecting grooves are respectively arranged below the outsides of the left and right brush rolls; a pair of left and right anti-pulling rollers which are basically horizontally supported and rotate towards the opposite directions at the same speed is arranged at the lower part inside each pair of left and right brush rolls; and anti-pulling teeth radially extending are distributed on the peripheries of the left and right anti-pulling rollers. The brush roll type picking table not only solves the problems of low harvesting rate and high loss ratio of a spindle-type cotton picker, but also solves the problem of easiness for pulling a cotton stalk of a compound rod type cotton picker.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Potato secondary soil screening harvesting cart

PendingCN107950168AImprove harvesting efficiencyImprove separation efficiencyDiggersSeedlingScreening effect

The invention provides a potato secondary soil screening harvesting cart. The potato secondary soil screening harvesting cart mainly comprises a rack device, a seedling removing device, a digging device, a soil-potato shaking separating delivering device, a spiral roller separating and screening device and a collecting device, so that the potato secondary soil screening harvesting cart becomes a functional harvesting cart integrating seedling removing, soil digging, delivering, separating and harvesting. The harvesting cart can smoothly complete a series of work of seedling removing, soil digging, conveyance, soil screening, potato collecting and the like, and the harvesting efficiency of the potatoes is improved. By means of the potato secondary soil screening harvesting cart, the purposeof harvesting the potatoes and removing seedlings is achieved, most soil can be separated to the ground, the efficiency of separating soil and the potatoes is greatly improved, the potato damaging rate is lower, the soil screening effect is good, the practicability is high, and the structure is simple.

Owner:XIANGTAN UNIV

Sugarcane combine harvester with tail cutting device

The invention relates to a sugarcane combine harvester with a tail cutting device, which comprises a power system, an operation system, a front furling mechanism, a cutting mechanism and a leaf stripping and tail cutting mechanism arranged behind the cutting mechanism. A sugarcane conveying channel is formed in the leaf stripping and tail cutting mechanism. The leaf stripping and tail cutting mechanism is provided with the tail cutting device. The tail cutting device comprises at least one pair of tail cutting wheels which are positioned in the sugarcane conveying channel and are arranged up and down. The at least one pair of tail cutting wheels comprise first tail cutting wheels and second tail cutting wheels. Both the first and second tail cutting wheels comprise a mounting shaft and a roller. A plurality of elastic ribs which extend along the axial directions and the radial directions of the rollers are uniformly distributed on the outer peripheral surfaces of the rollers. The end faces outside the elastic ribs of the second tail cutting wheels are saw-toothed curved surfaces. The sugarcane combine harvester with the tail cutting device can be used for effectively cutting off tender stem parts on the tail parts of sugarcanes. Moreover, due to the tail cutting device of the combine harvester, the tail cutting effect is good.

Owner:浙江三佳农业机械装备有限公司

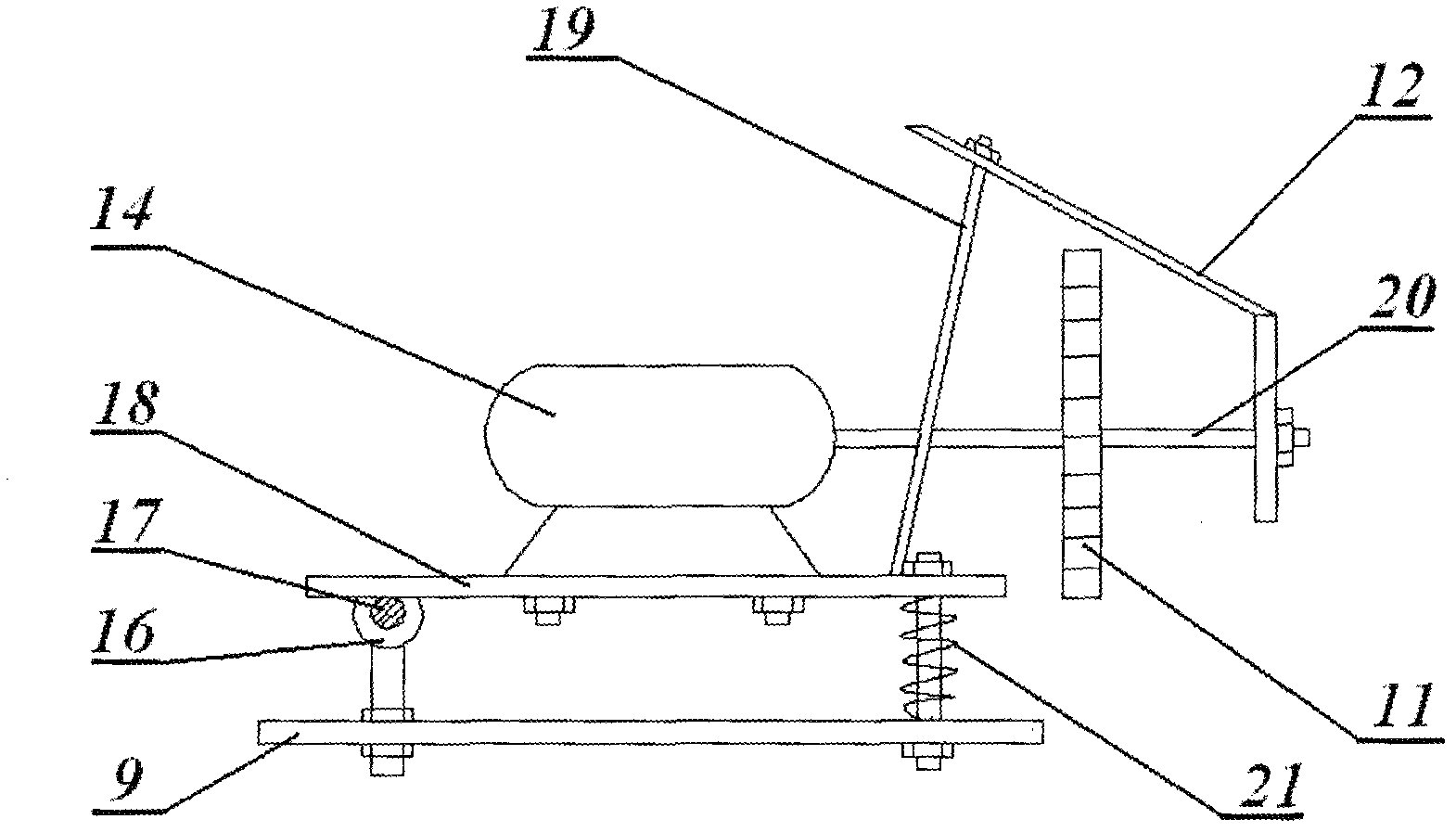

Sisal harvester

The invention discloses a sisal harvester. A small diesel generator (5) is installed on a small platform lorry, which provides power for the whole sisal harvester; the sisal harvester is provided with a dicing saw blade (11); the dicing saw blade (11) is driven through a main servo motor (14) to rotate; the main servo motor (14) is installed on a lifting bottom plate (9), the height of which can be adjusted; the main servo motor (14) is in flexible connection with the lifting bottom plate (9); a guide protective cover (12) is arranged outside the dicing saw blade (11); one end of the guide protective cover (12) is connected with a motor supporting plate (18) through a guide protective cover supporting rod (19); the other end of the guide protective cover (12) is connected with a saw blade shaft (20) through a bearing; and a sisal collector (3) is arranged at the lower front part of the dicing saw blade (11). The sisal harvester is also provided with a lifting servo motor (15), a lead screw (13), a vertical column (6), a control box (4) and a driving servo motor (8). The sisal harvester has the benefits that sisal harvesting mechanization is realized, the sisal harvester is simple and convenient to operate, the harvesting efficiency is high, and the sisal harvesting cost is greatly reduced.

Owner:HAINAN UNIVERSITY

Garlic combine harvester

InactiveCN105123076AAvoid entanglementAvoid congestionLiftersTopping machinesEngineeringCombine harvester

The invention discloses a garlic combine harvester. The garlic combine harvester comprises a harvester body, a driving device, multiple seedling separators, a soil excavation mechanism, a clamping and conveying mechanism, a cutter mechanism and a collecting device, wherein the cutter mechanism is used for cutting off garlic seedlings; the collecting device is used for collecting and conveying garlic bulbs; the driving device is in driving connection with the harvester body; the clamping and conveying mechanism is movably suspended on the harvester body and has at least two clamping and conveying gaps, an inlet for inputting the garlic seedlings and an outlet for outputting the garlic seedlings are formed in two ends of each clamping and conveying gap, and the inlet is lower than the outlet; each seedling separator is fixed at one end, close to the corresponding inlet, of the clamping and conveying mechanism; the soil excavation mechanism is movably mounted on a rack and is located behind the seedling separators; the cutter mechanism is mounted on the clamping and conveying mechanism and located on the lower side of each clamping and conveying gap; the collecting device is fixed on the harvester body and located below the cutter mechanism. According to the garlic combine harvester, seedling separation, soil excavation, clamping, seedling cutting and garlic bulb conveying and collection of multiple rows of garlics can be completed once, and the adaptability and the reliability are high.

Owner:王成文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com