Self-propelled multifunctional straw harvest bundling machine

A multi-functional, self-propelled technology, applied to balers, harvesters, agricultural machinery and implements, etc., can solve the problems of cumbersome work, low efficiency, and not being widely used, so as to improve harvesting efficiency and reduce Fuel consumption and power saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

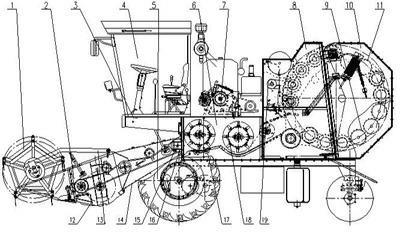

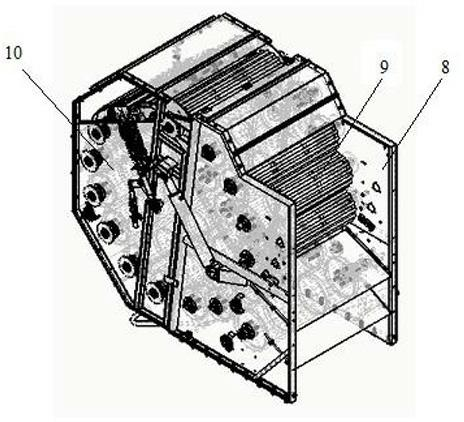

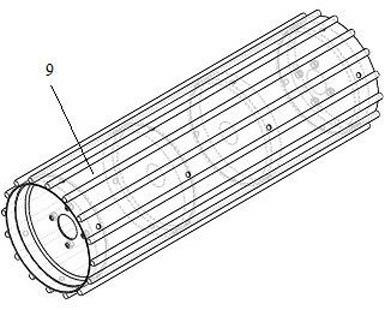

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1~Figure 5 As shown, the self-propelled multifunctional straw harvesting and bundling machine consists of a reel 1, a header assembly 2, a manipulation device 3, a chassis assembly assembly 5, a kneading chamber 6, a power unit 7, a front bundling chamber 8, Rear bundling room 10, binding rope mechanism 19 etc. are formed.

[0018] The header assembly 2 and the reel 1 are located directly in front of the vehicle, and the reel 1 is mounted on the lifting arm of the header assembly 2, and can be raised and lowered around the rotary shaft of the lifting arm 13 under the action of the oil cylinder; the main completion Support and promotion of crop straw. The header assembly 2 is hinged on the support 16 in front of the kneading chamber 6 and can be raised and lowered around the articulated shaft 15. It mainly completes the cutting and transportation of crop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com