Patents

Literature

282results about "Reaper-binders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

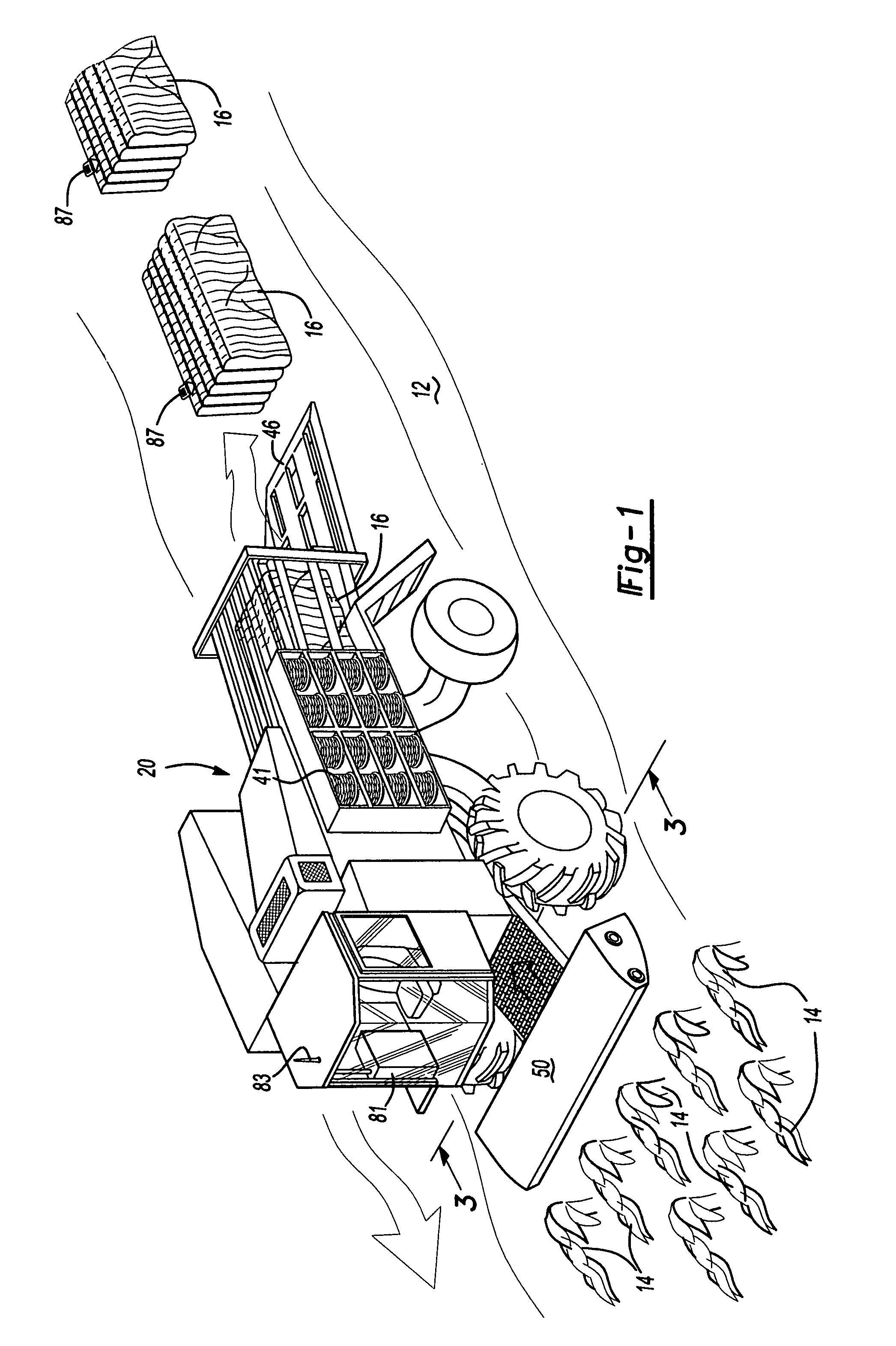

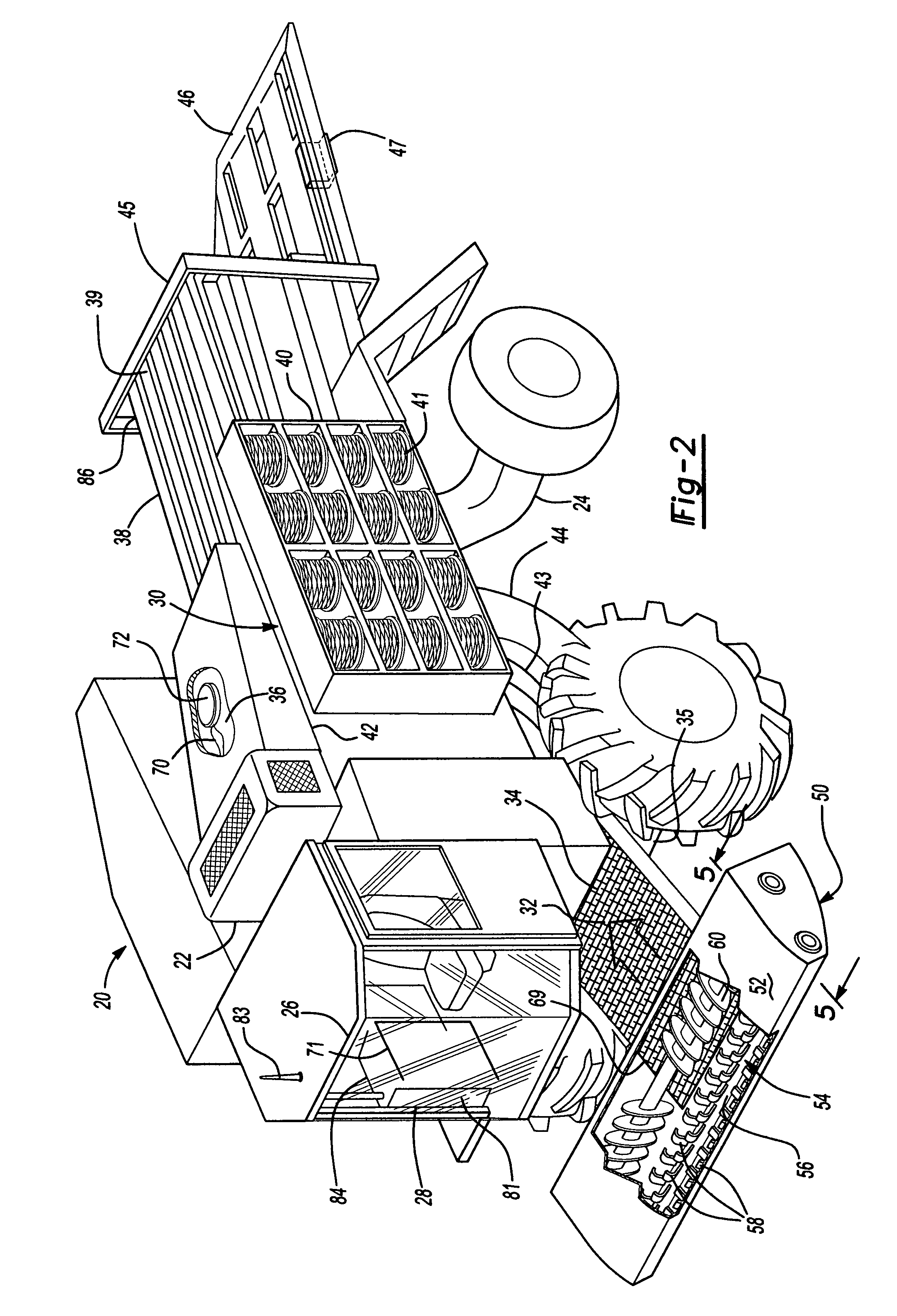

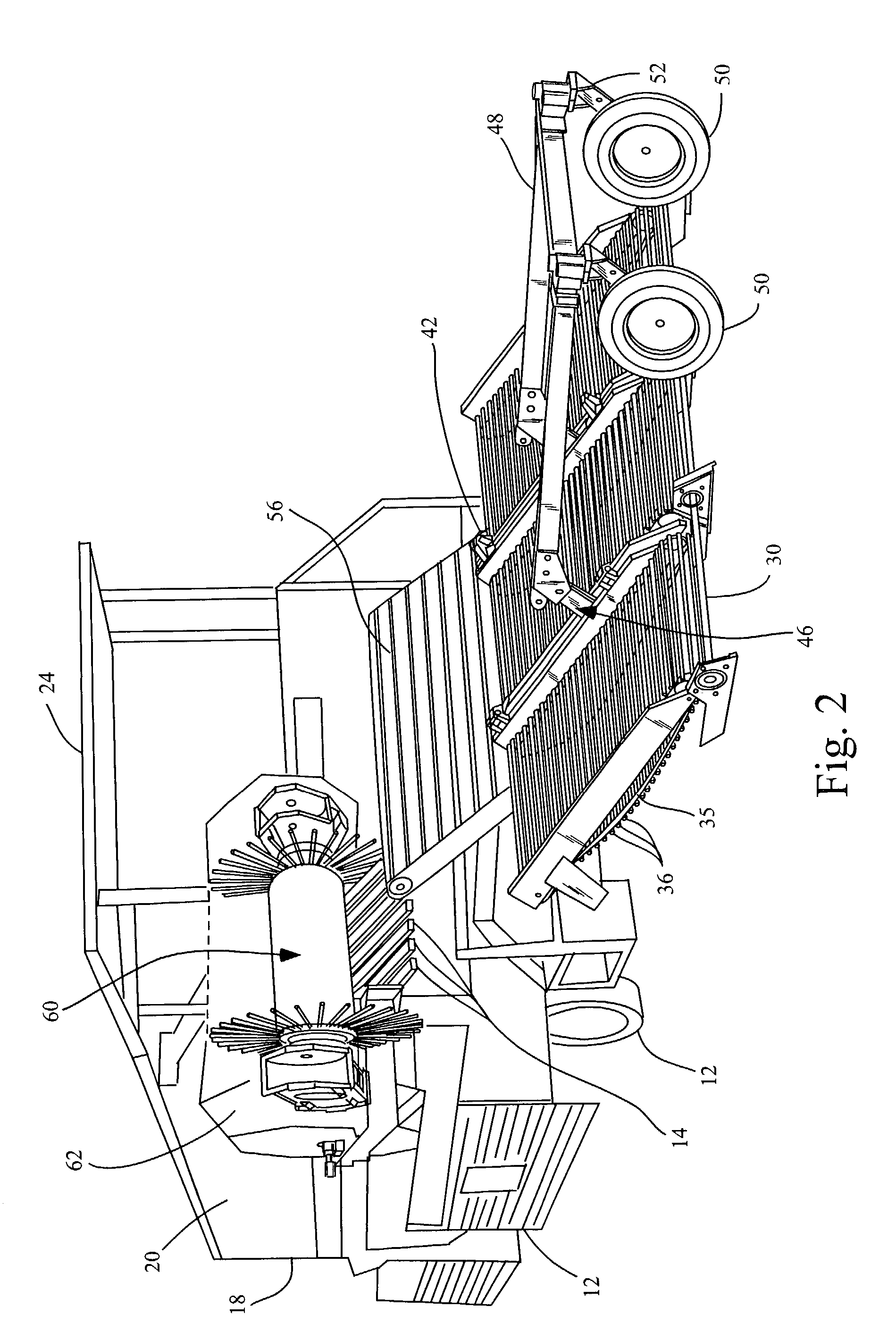

Biomass harvesting system

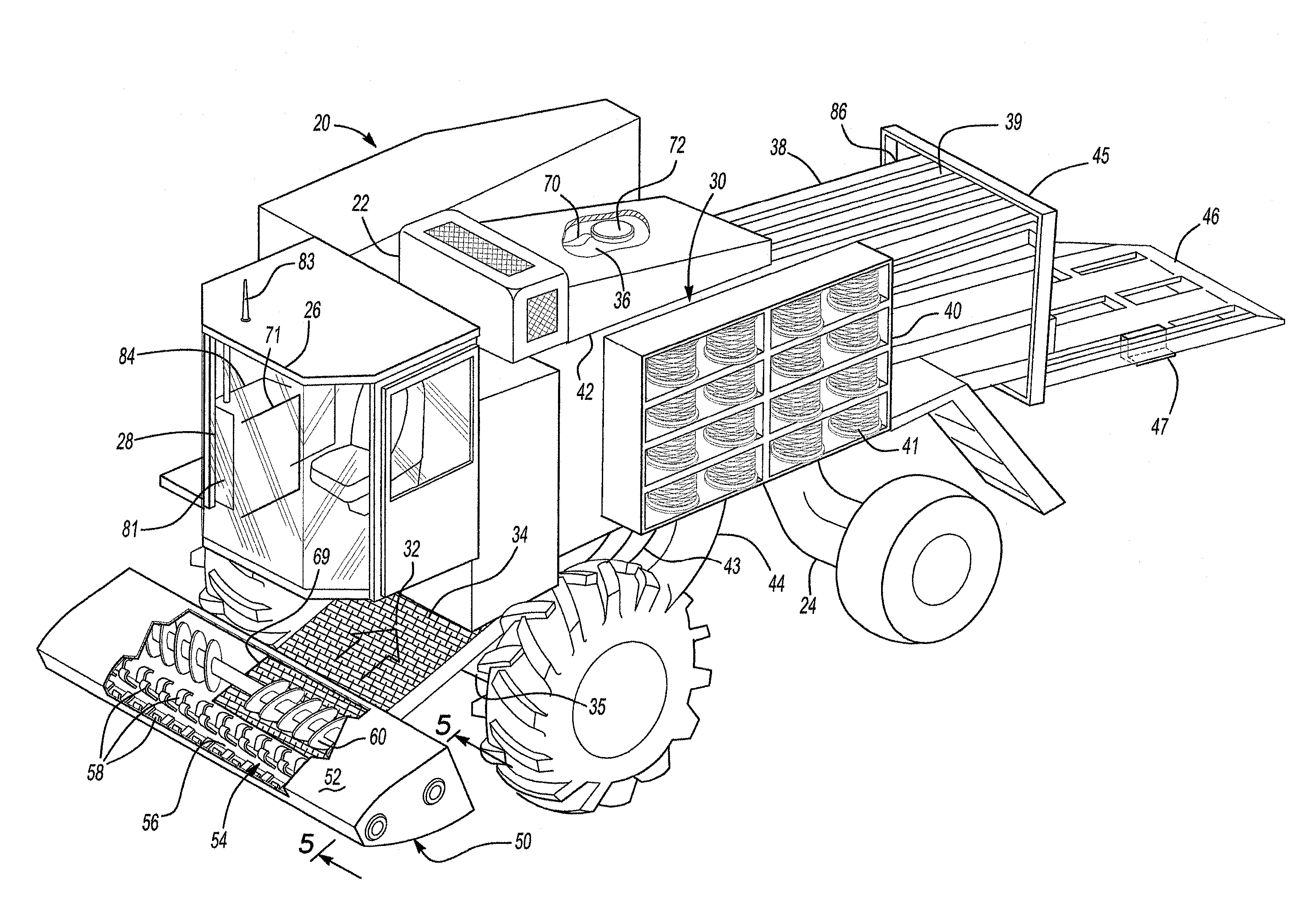

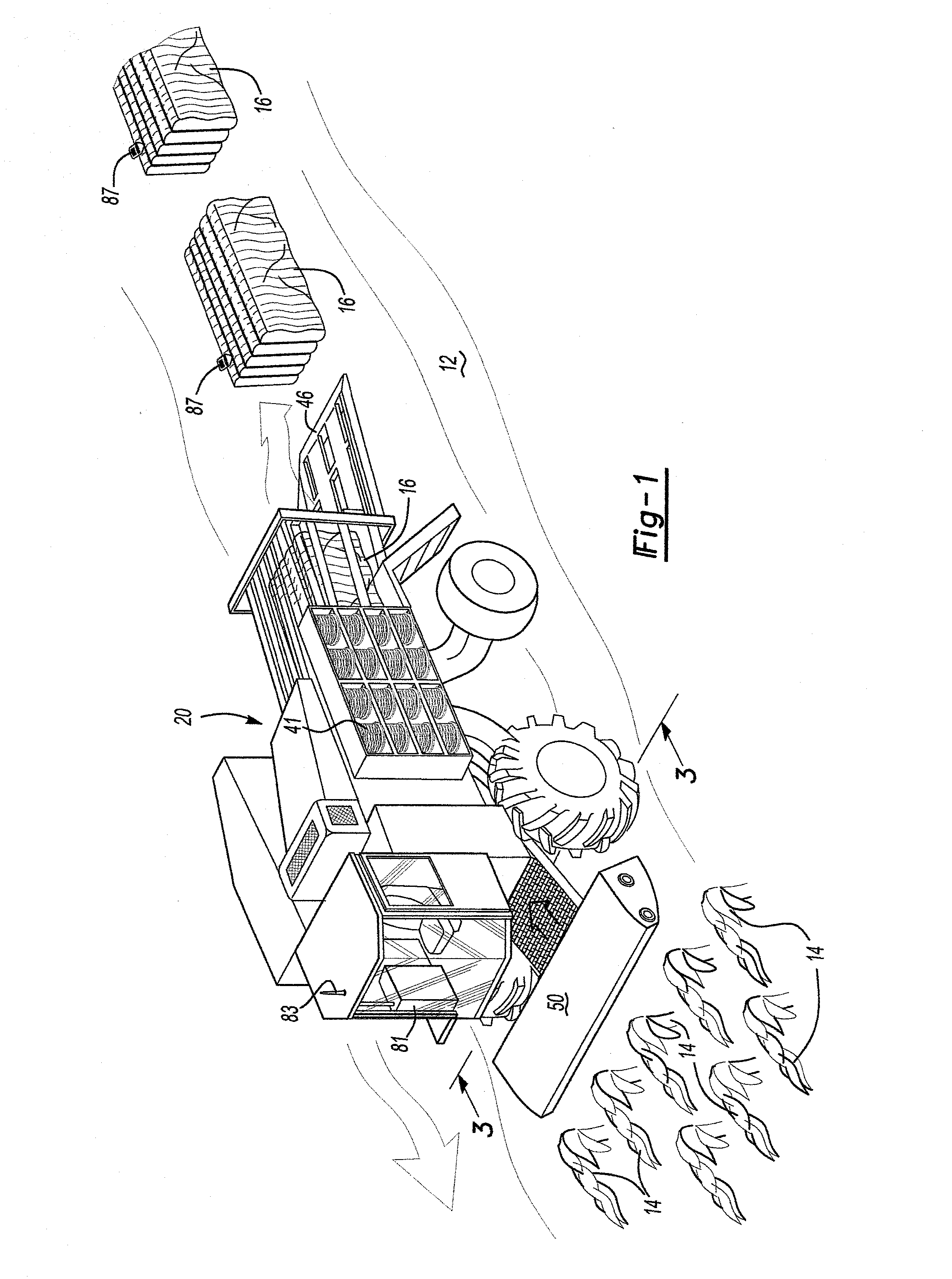

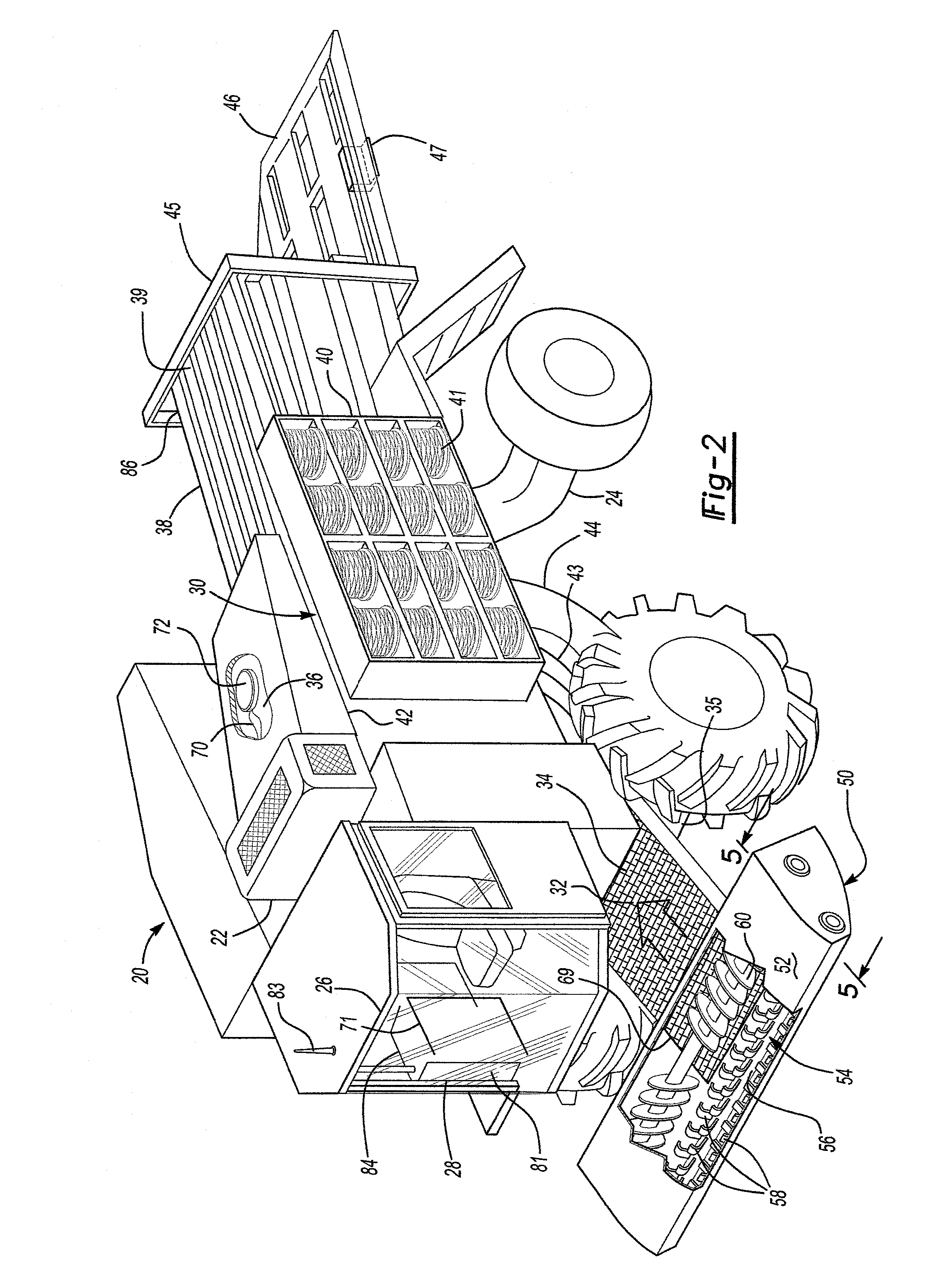

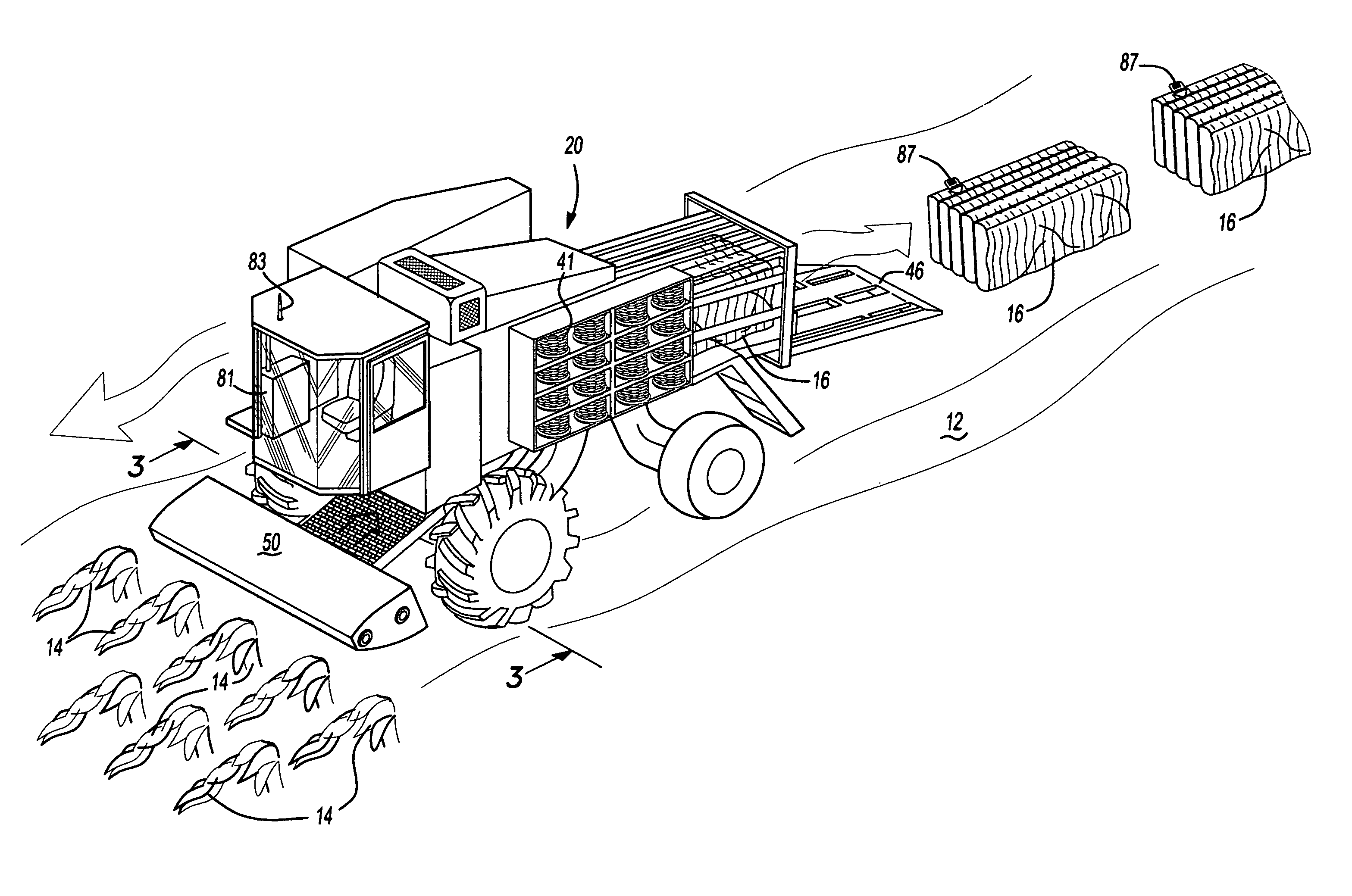

A biomass harvesting system for harvesting agricultural plant growth from agricultural fields comprises a power source for providing mechanical and electric power to the system, a biomass accumulator for producing discrete units of accumulated biomass, a windrower for feeding biomass to the accumulator, a biomass quality analyzer for sensing and transmitting a set of quality characteristics of the biomass, a ground cover residue monitor for sensing and transmitting an optimal quantity of biomass residue to remain on the field, an active tracking system for identifying individual ones of the discrete units of accumulated biomass, and a central processing unit including a memory module storing an executable instruction set therein. The central processing unit executes the instruction set and integrates the sensed biomass quality characteristics and the sensed optimal quantity of biomass residue to remain on the field to determine a biomass quality index of the discrete units of accumulated biomass.

Owner:CROSBY LON OWEN

Biomass harvesting system

A biomass harvesting system for harvesting agricultural plant growth from agricultural fields comprises in operative combination a power source for providing mechanical and electric power to the system, a biomass accumulator for producing discrete units of accumulated biomass and a windrower for feeding biomass to the biomass accumulator. The system also includes a biomass quality analyzer for determining a set of quality characteristics of the accumulated biomass, a dirt control system for controlling the quantity of dirt in the accumulated biomass, and a ground cover residue monitor for determining on optimal quantity of biomass residue to remain on the agricultural field. An active tracking system identifies individual ones of the discrete units of accumulated biomass.

Owner:CROSBY LON OWEN

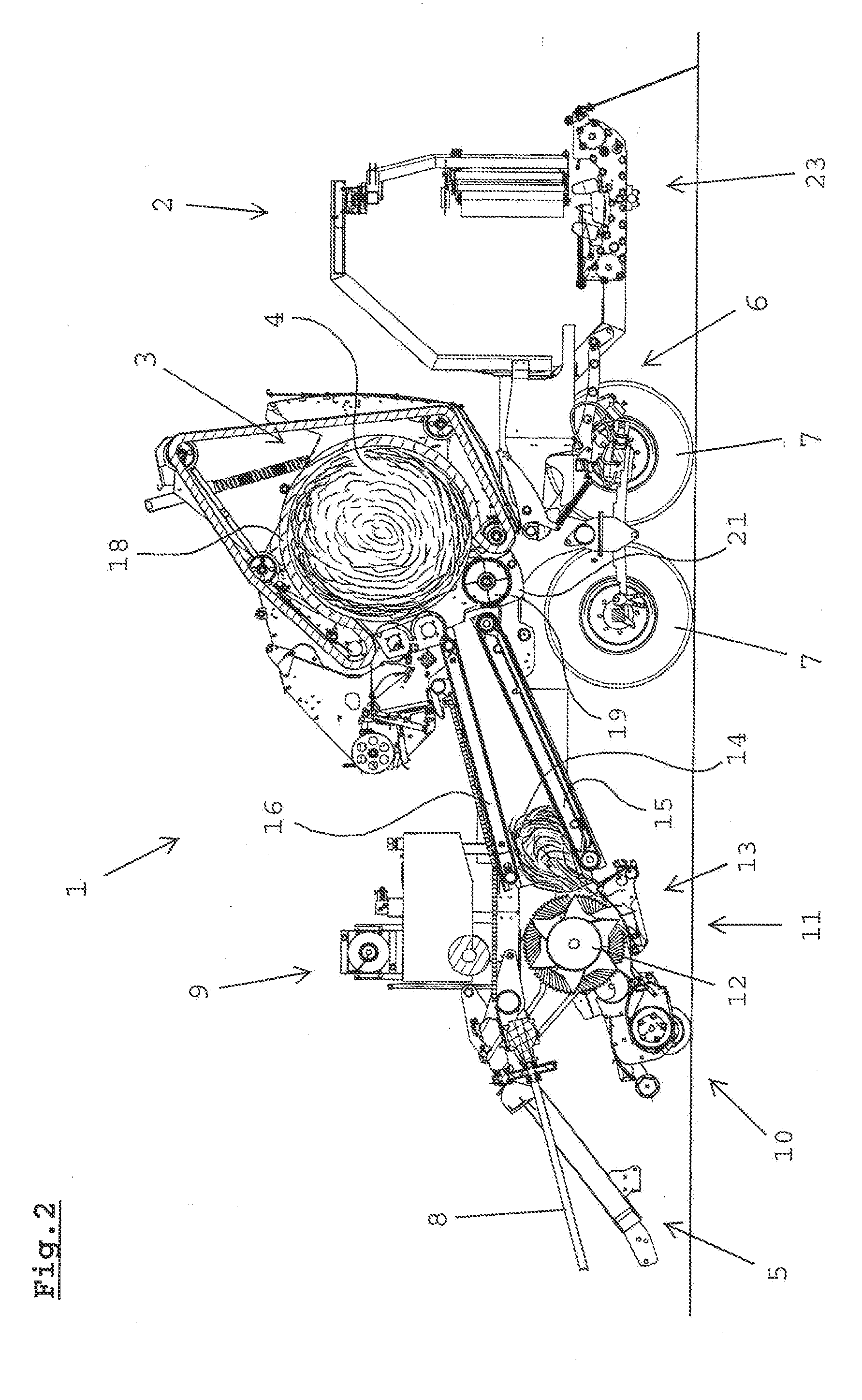

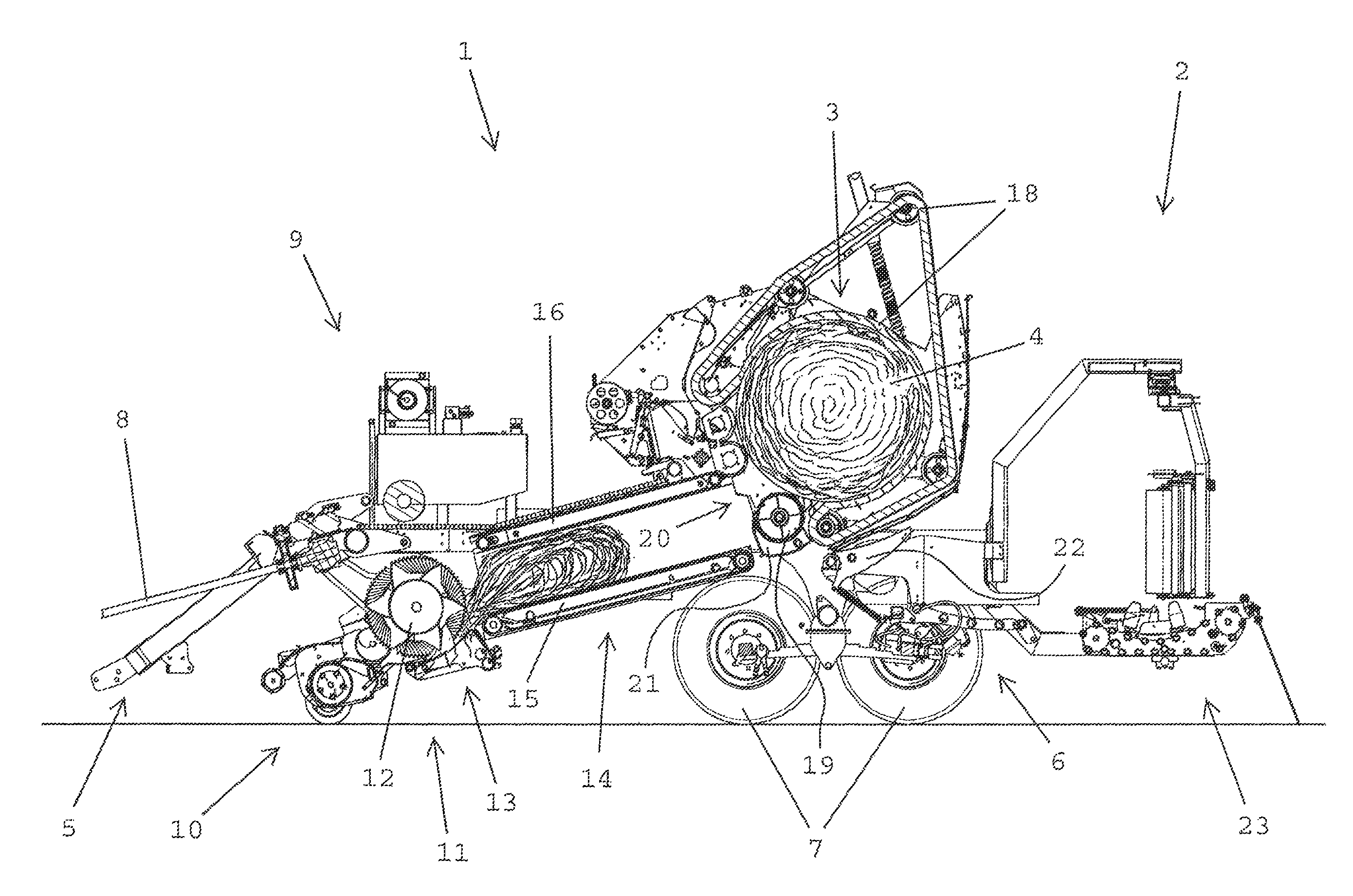

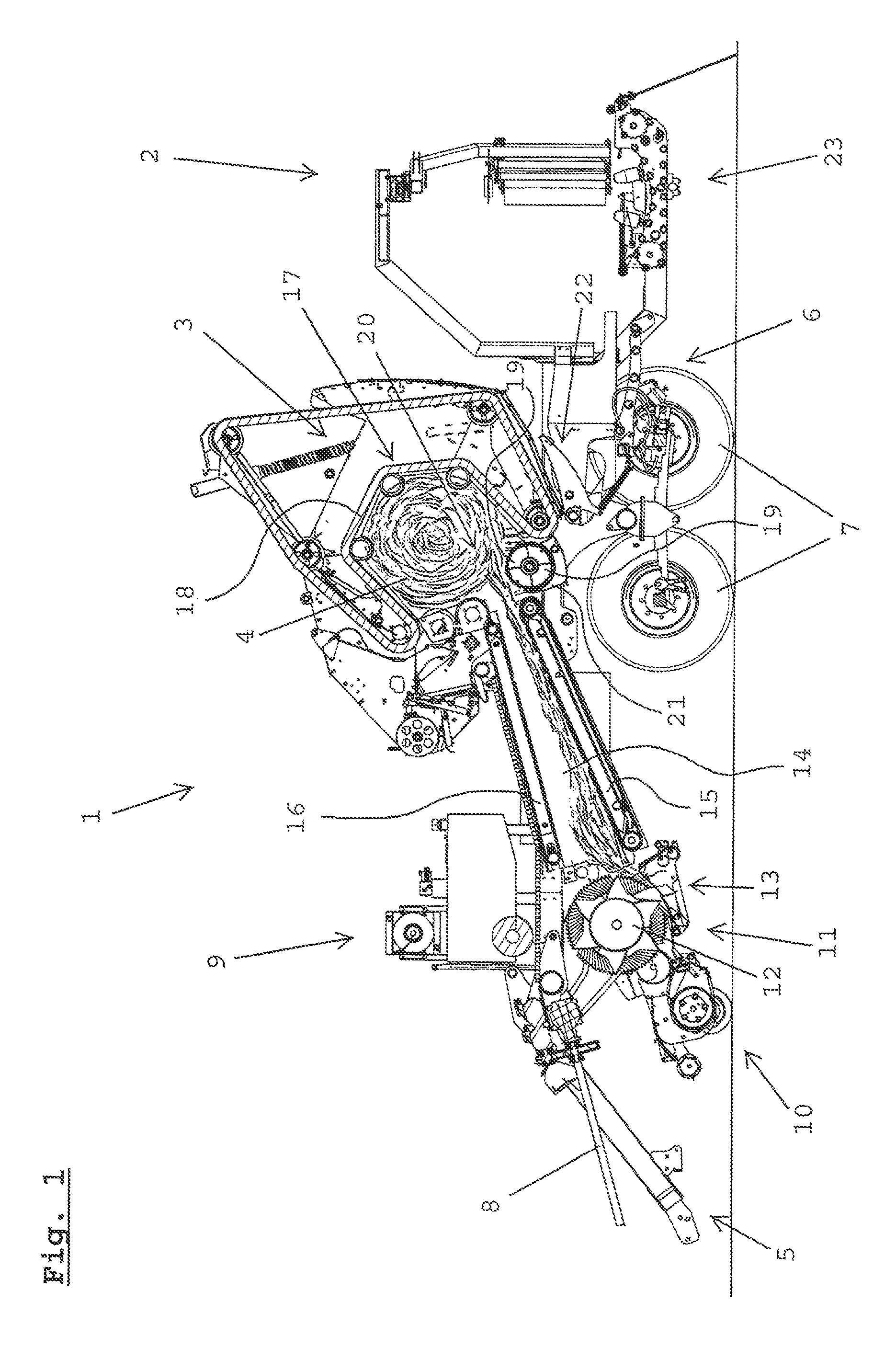

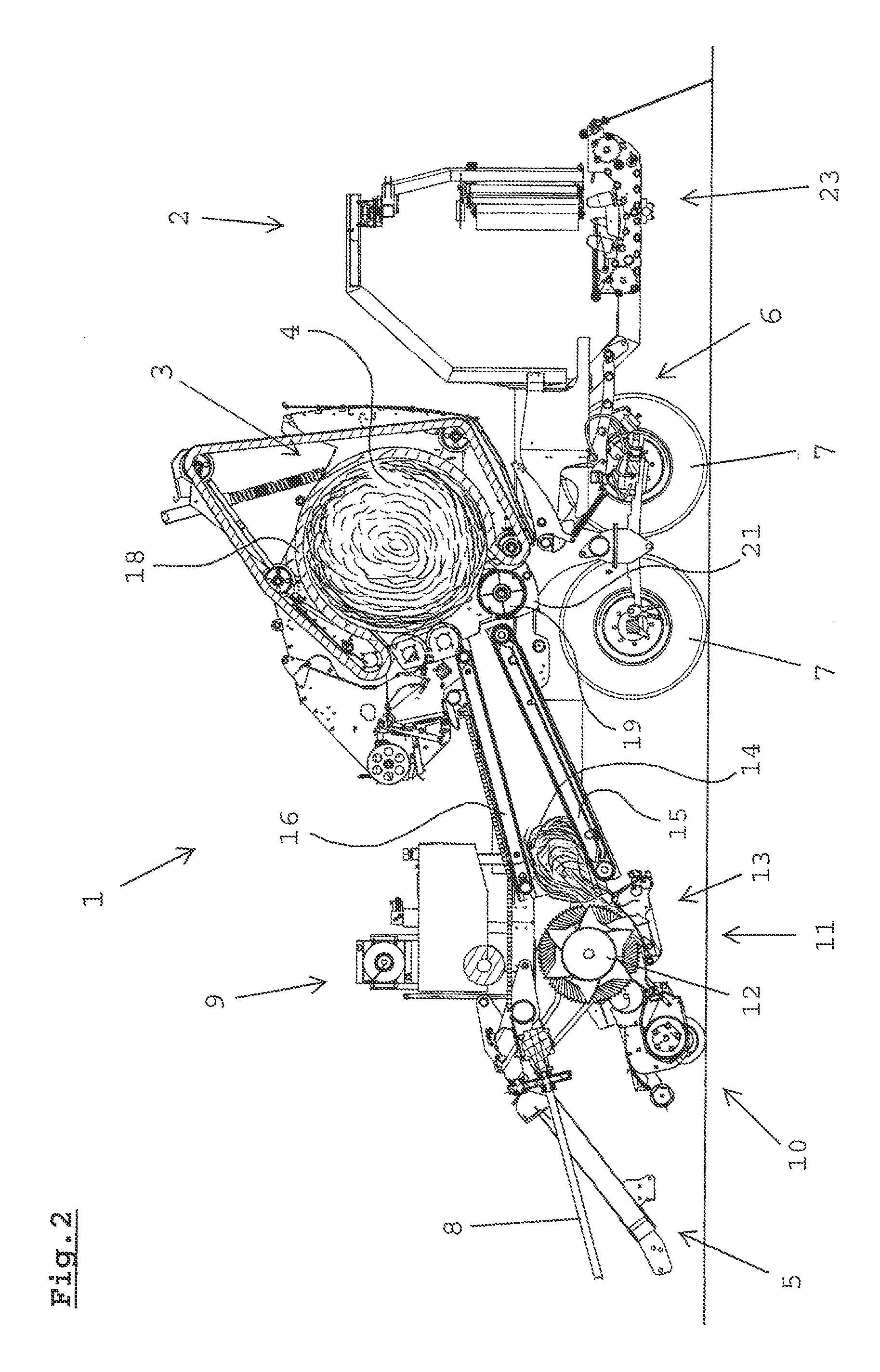

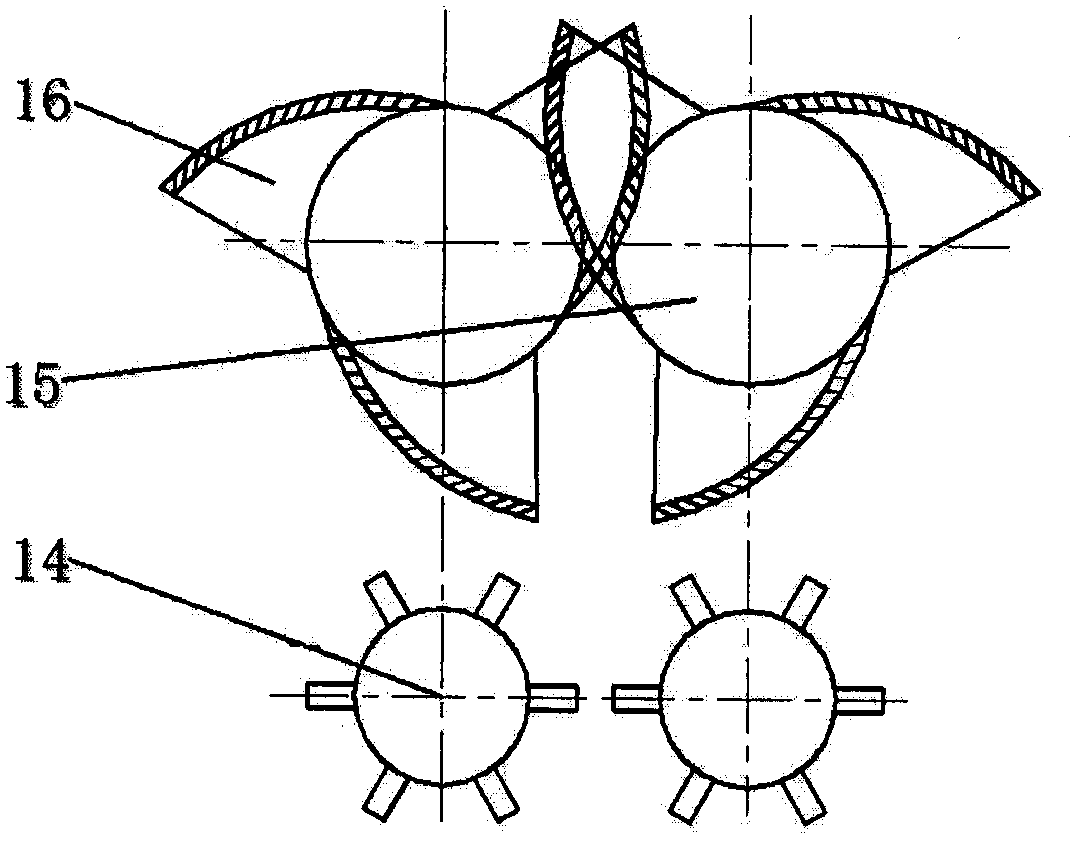

Agricultural Round Baler

InactiveUS20130036921A1Disadvantageous qualityDisadvantageous throughputBalingPackagingEngineeringCrop

An agricultural round baler has a press chamber with inlet and rear outlet for ejecting a bale. A pressing device in the press chamber causes the harvested crop to rotate. A pickup device and a conveying and cutting device are provided upstream of a storage chamber that extends to the inlet of the press chamber and receives harvested crop in a storage phase of the baler. An element that interrupts or releases flow of harvested crop from the storage chamber to the press chamber is provided and acted on by a control and governing device. The storage chamber is a flat shaping and pressing channel for the harvested crop conveyed in the storage phase of the baler operation. The channel has a height-adjustable end and a cross-section that at least temporarily in the storage phase tapers in flow direction of harvested crop to the press chamber.

Owner:KRONE AGRI SE

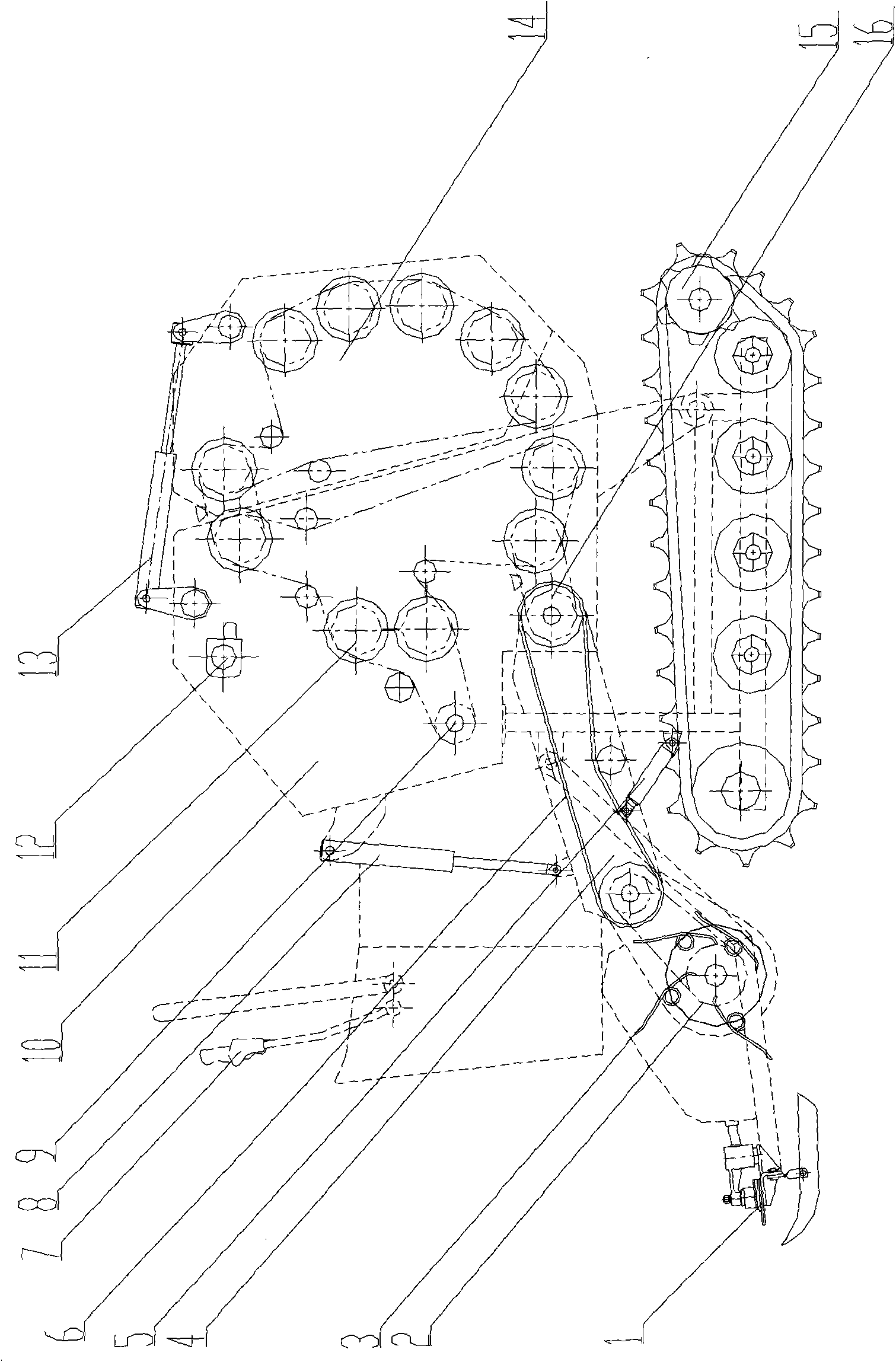

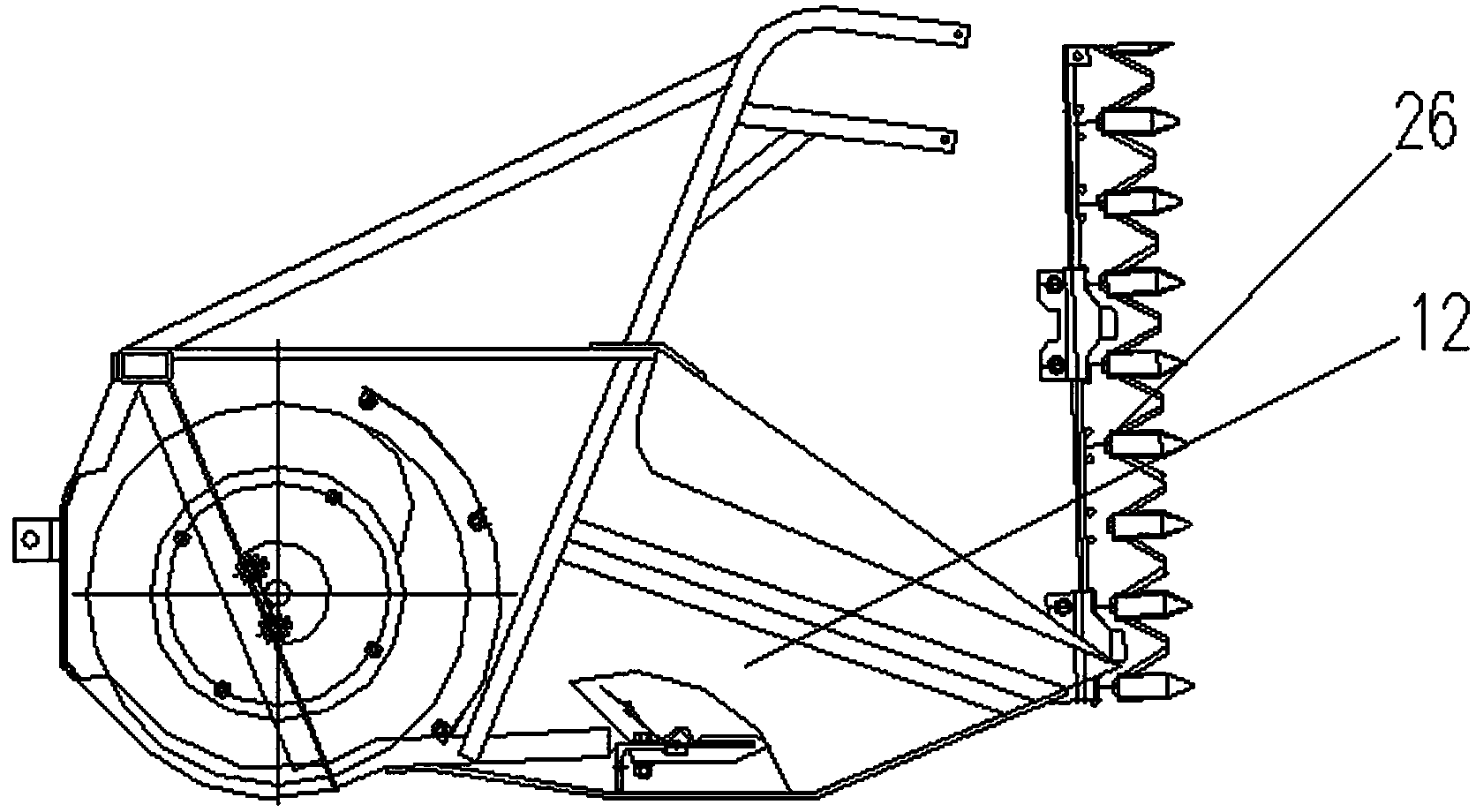

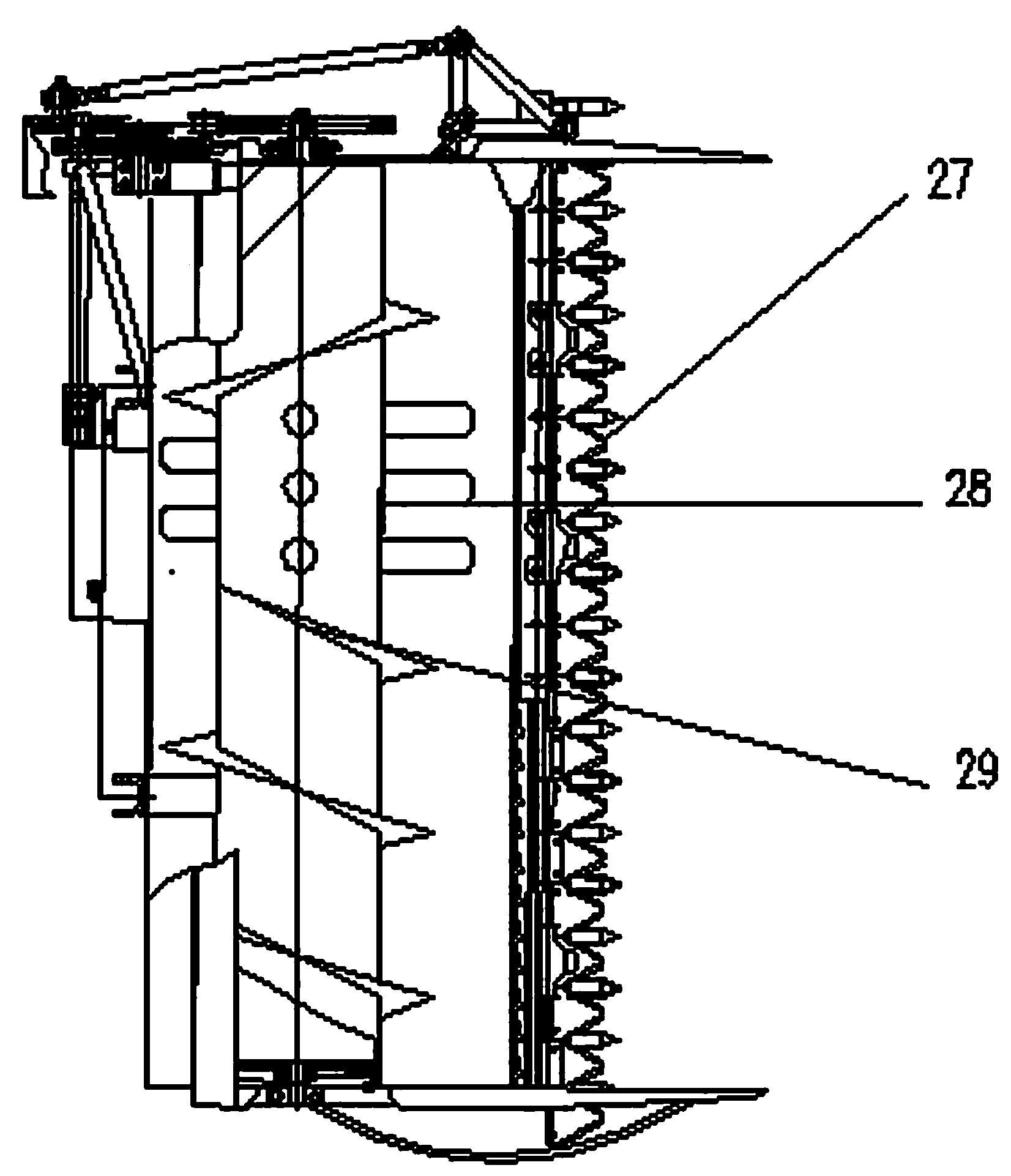

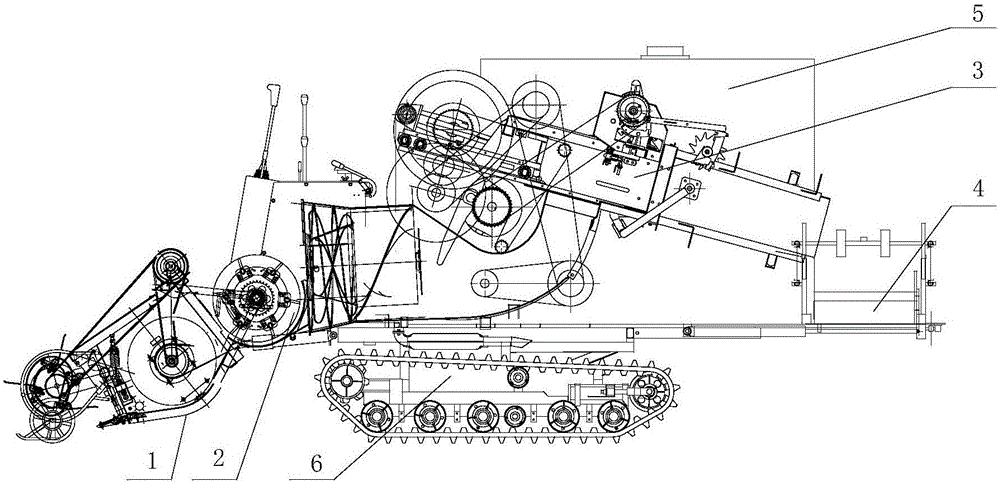

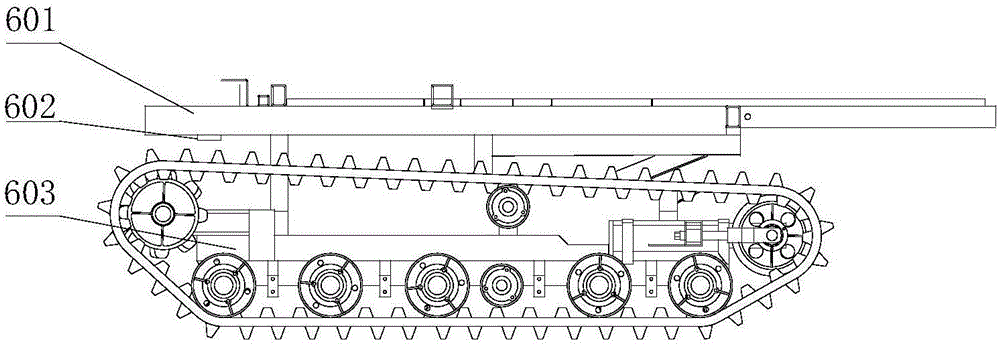

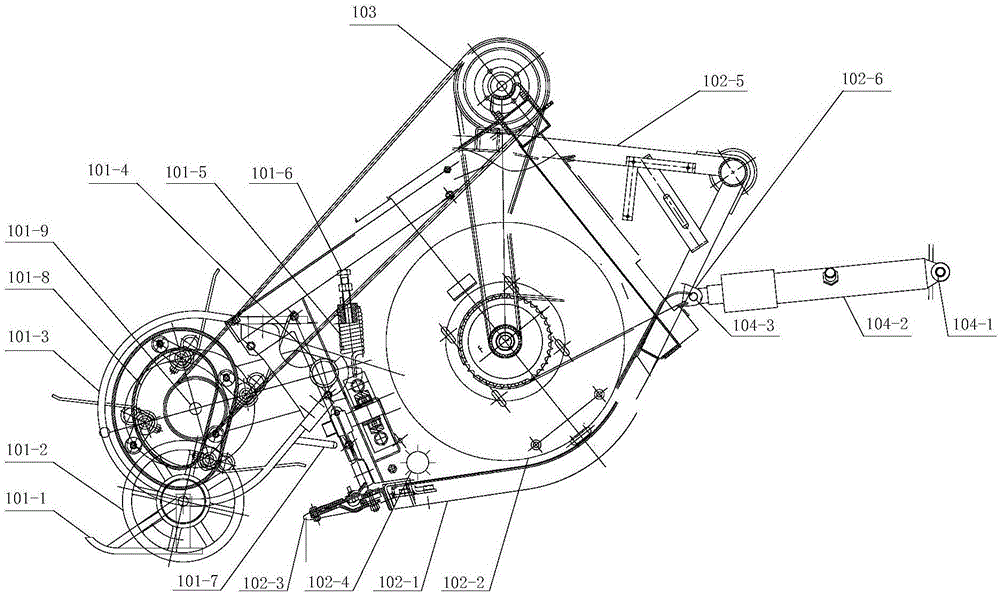

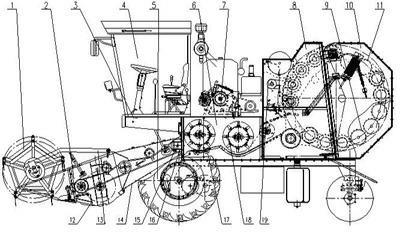

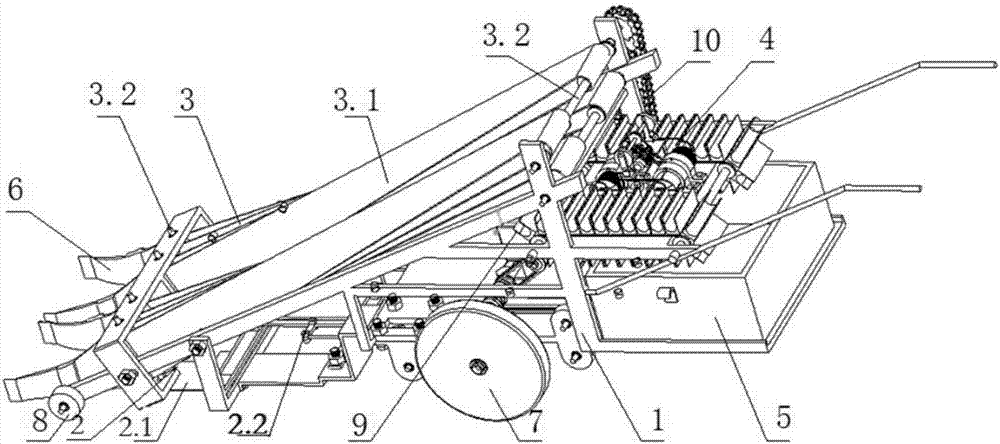

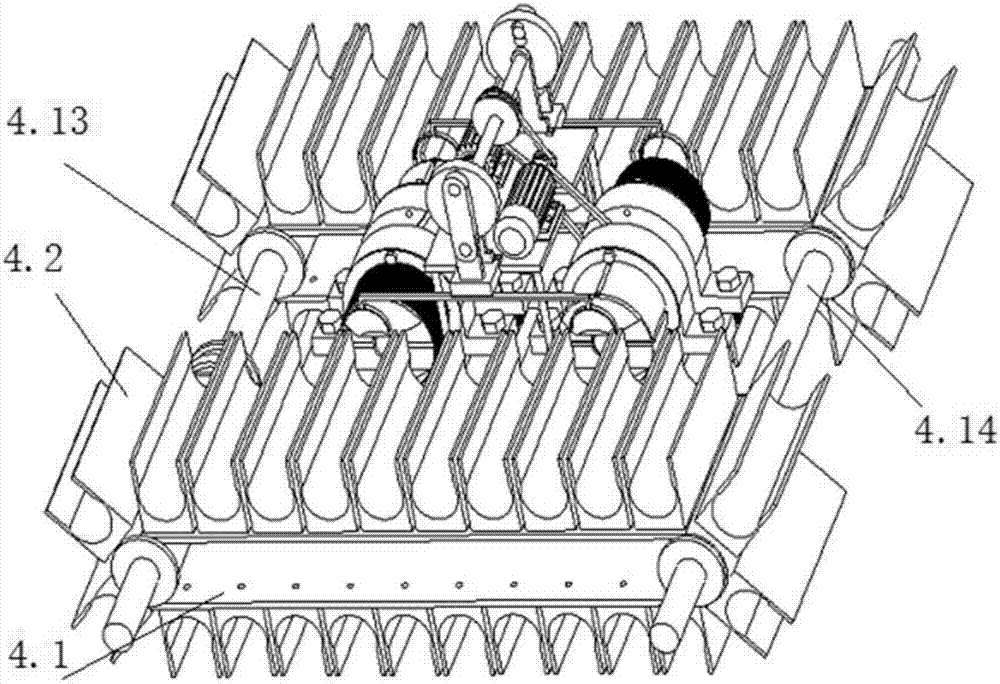

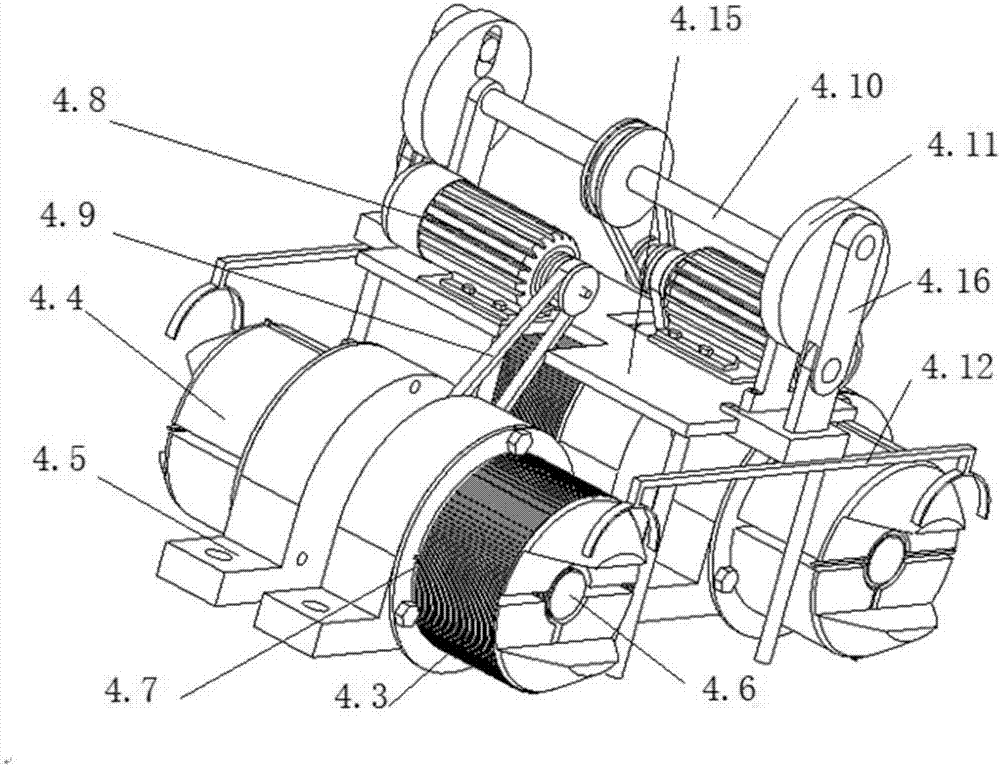

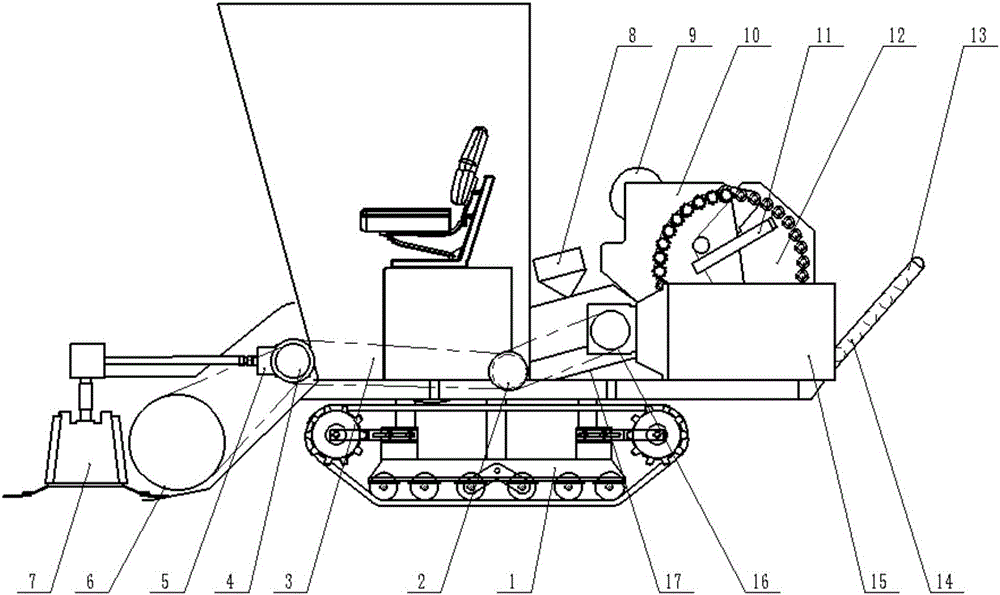

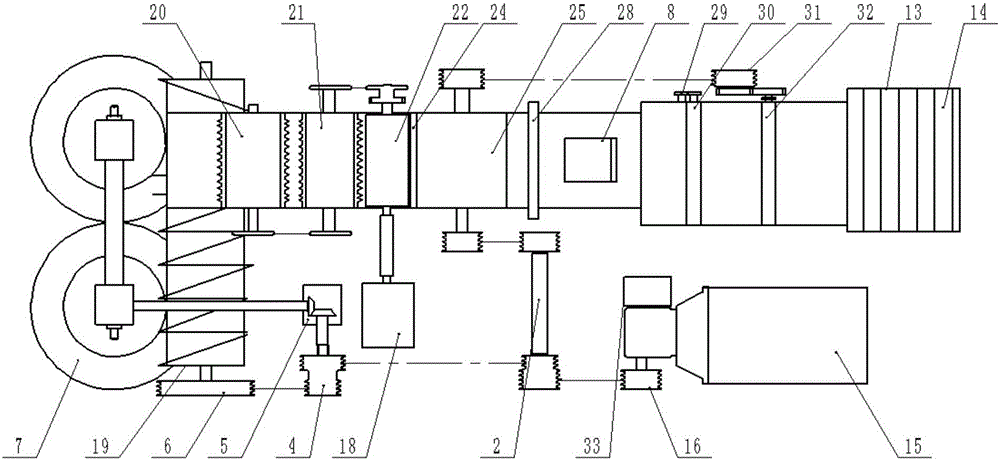

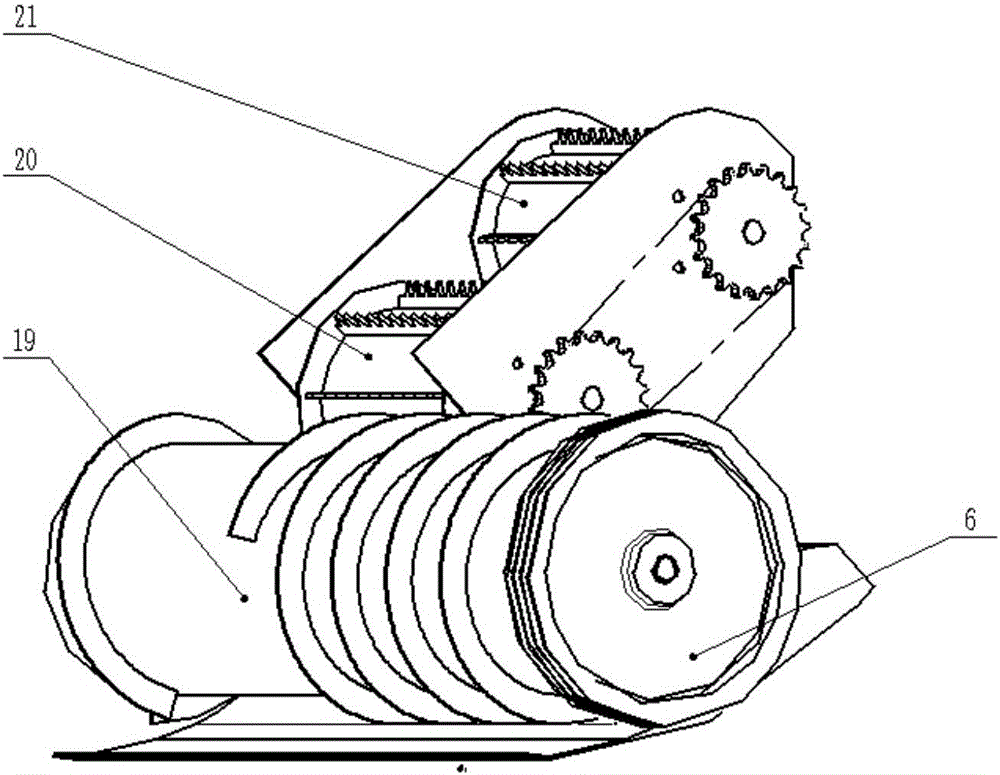

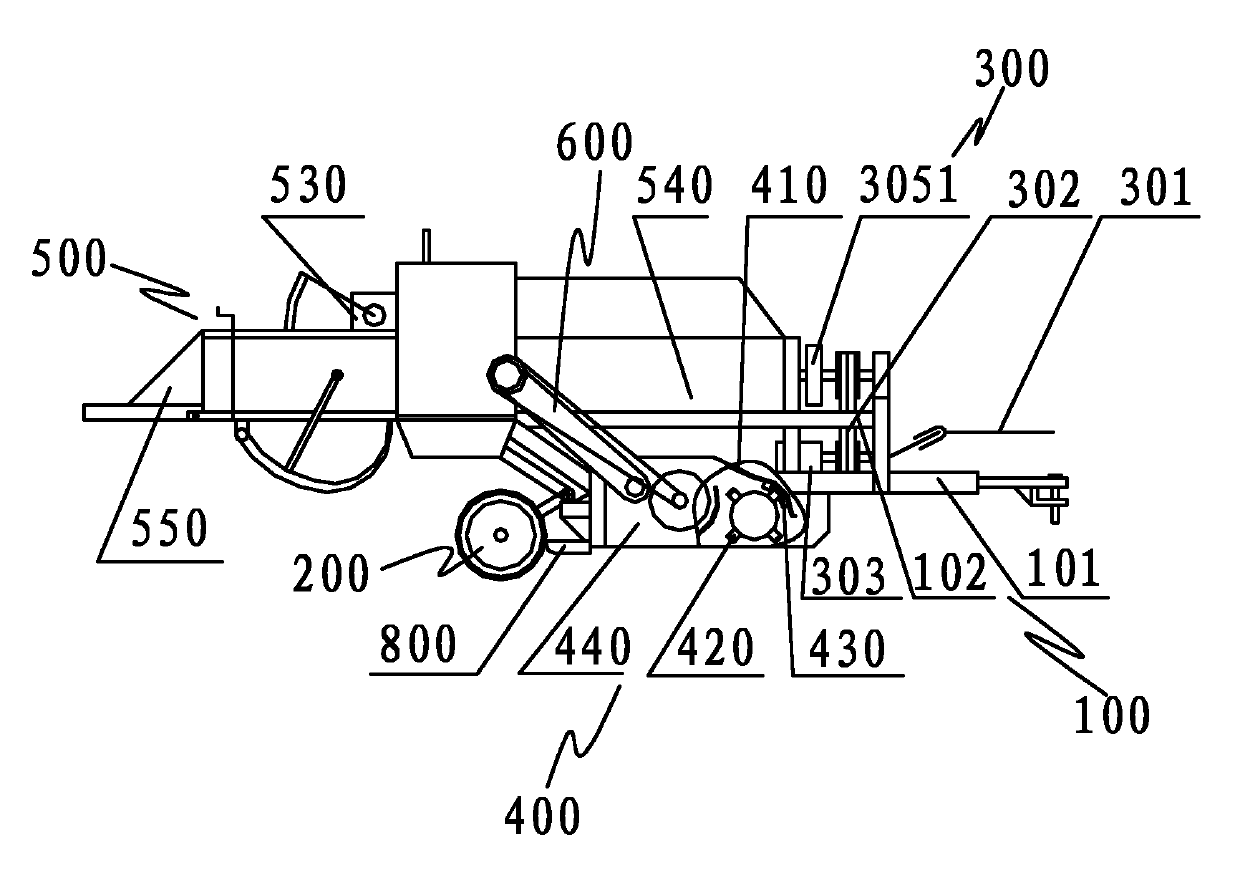

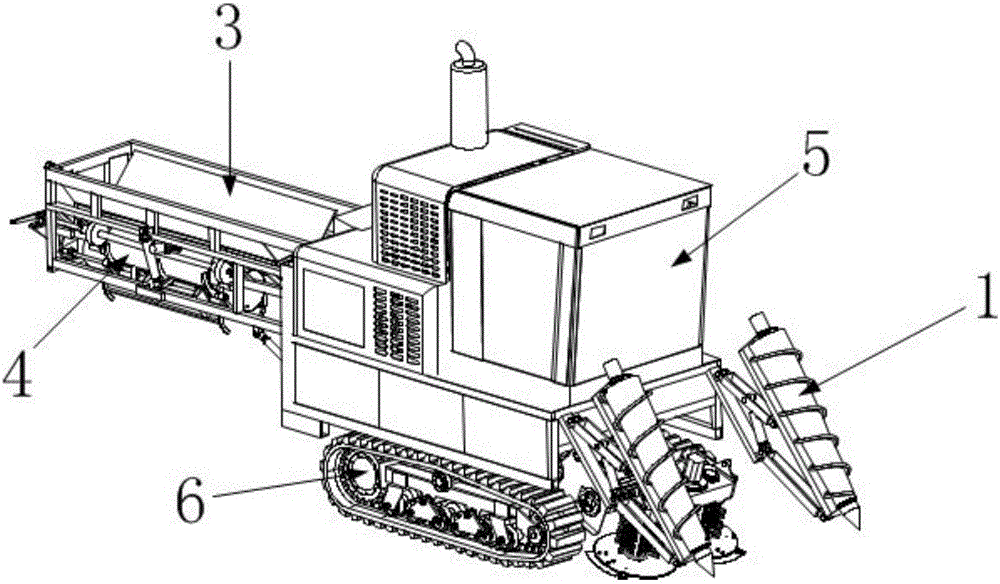

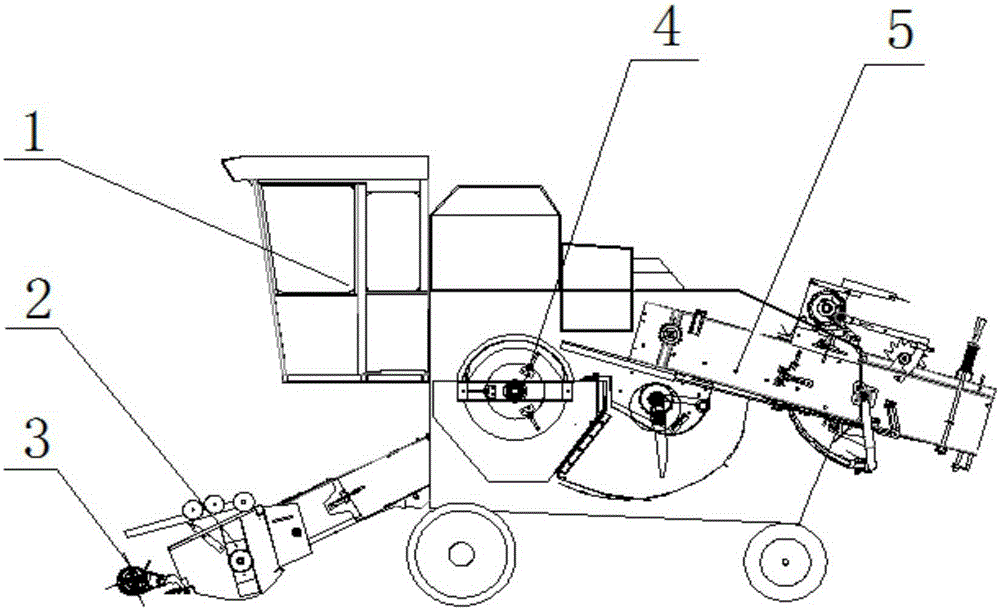

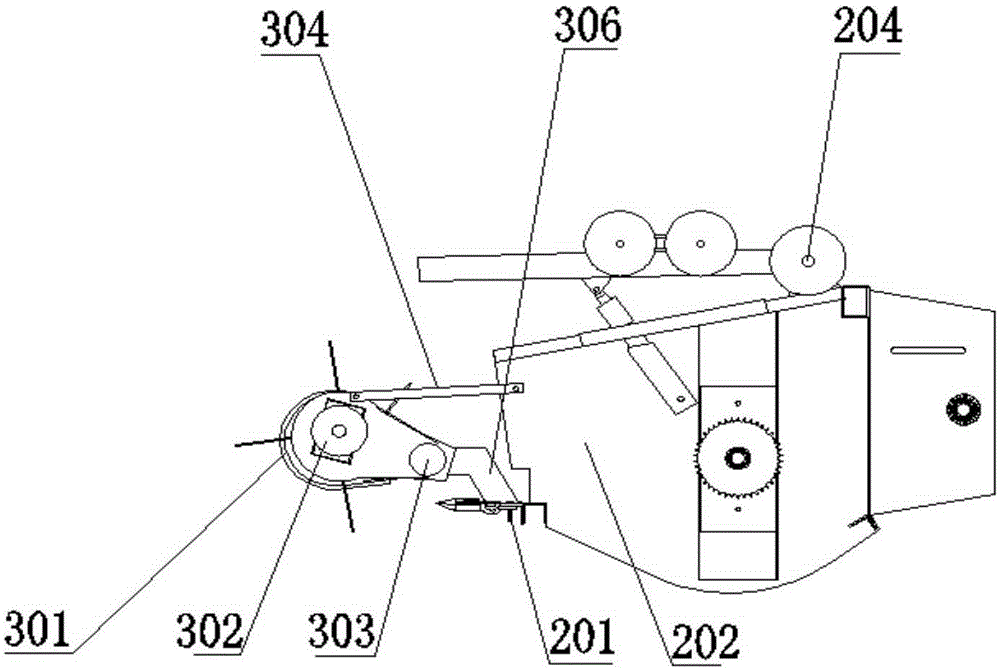

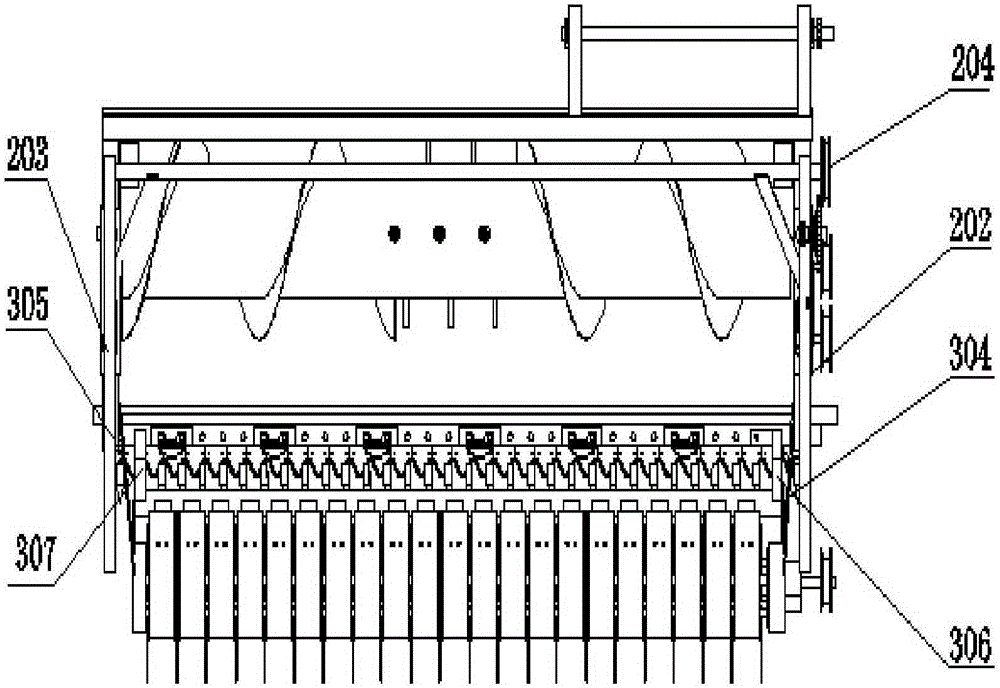

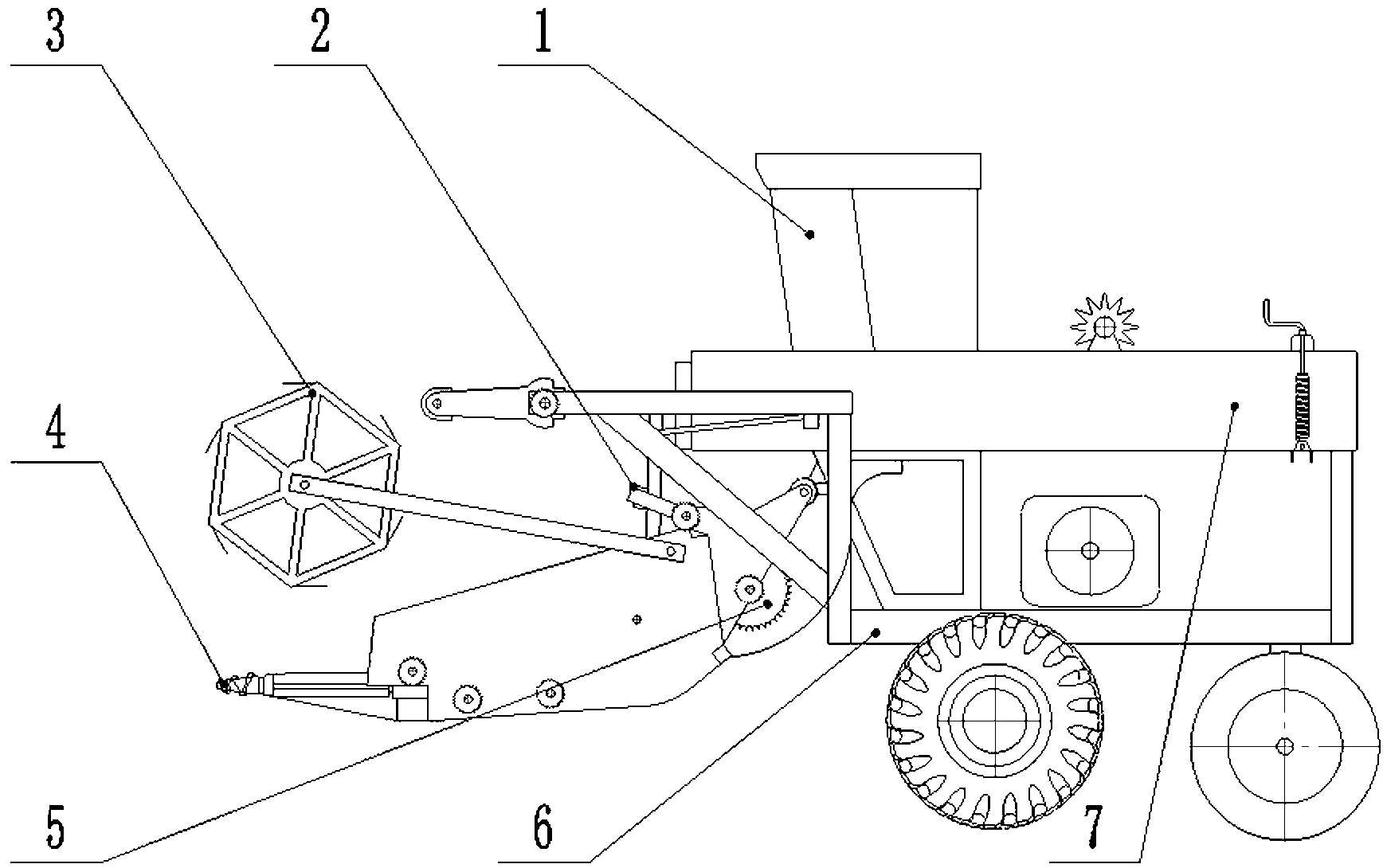

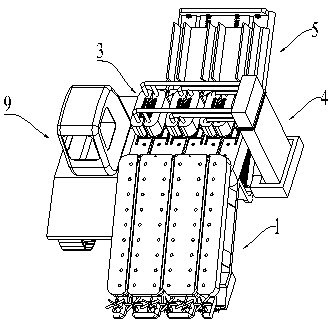

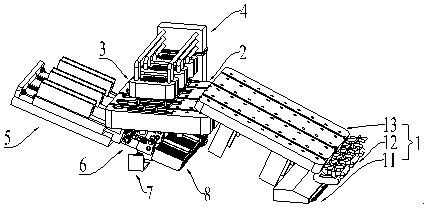

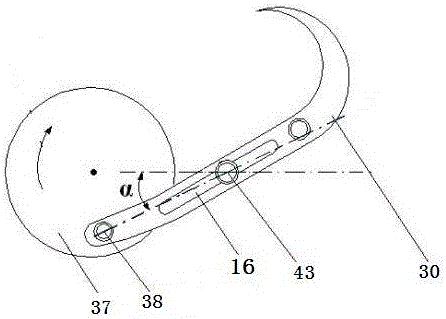

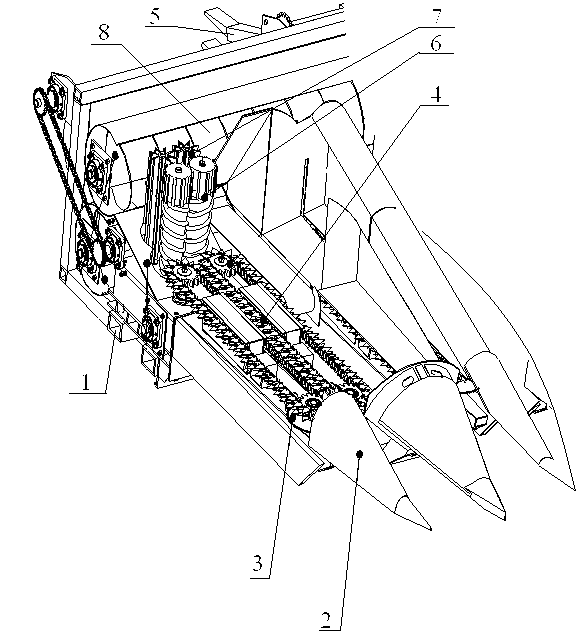

Method for cutting, picking up and bundling straw stalks and device thereof

InactiveCN101622927AImprove work efficiencyReduce labor intensityLoadersAgricultural undercarriagesAgricultural engineeringControl theory

The invention discloses a method for cutting, picking up and bundling straw stalks and a device thereof. The invention is characterized of adopting a self propelled chassis which takes a rubber track as a walk part, and installing a set of device for cutting, picking up and bundling the straw stalks especially for recycling the straw stalks on the chassis. The device for cutting, picking up and bundling the straw stalks adopts the self propelled chassis which takes the rubber track as the walk part; the chassis is provided with a stander; the stander is provided with an engine; the output shaft of the engine is provided with two sets of belts; one set of belt is connected with a walk speed changer by a rubber belt; the other set of rubber belt on the engine is connected with a work speed changer of the device for cutting, picking up and bundling the straw stalks; one end of the output shaft of the a work speed changer is provided with a belt wheel and is connected with the device for cutting, picking up and bundling the straw stalks by the belt; and the output shaft of the other end of the work speed changer is connected with a device for picking up and bundling by means of chain drive.

Owner:株洲联合收割机有限公司

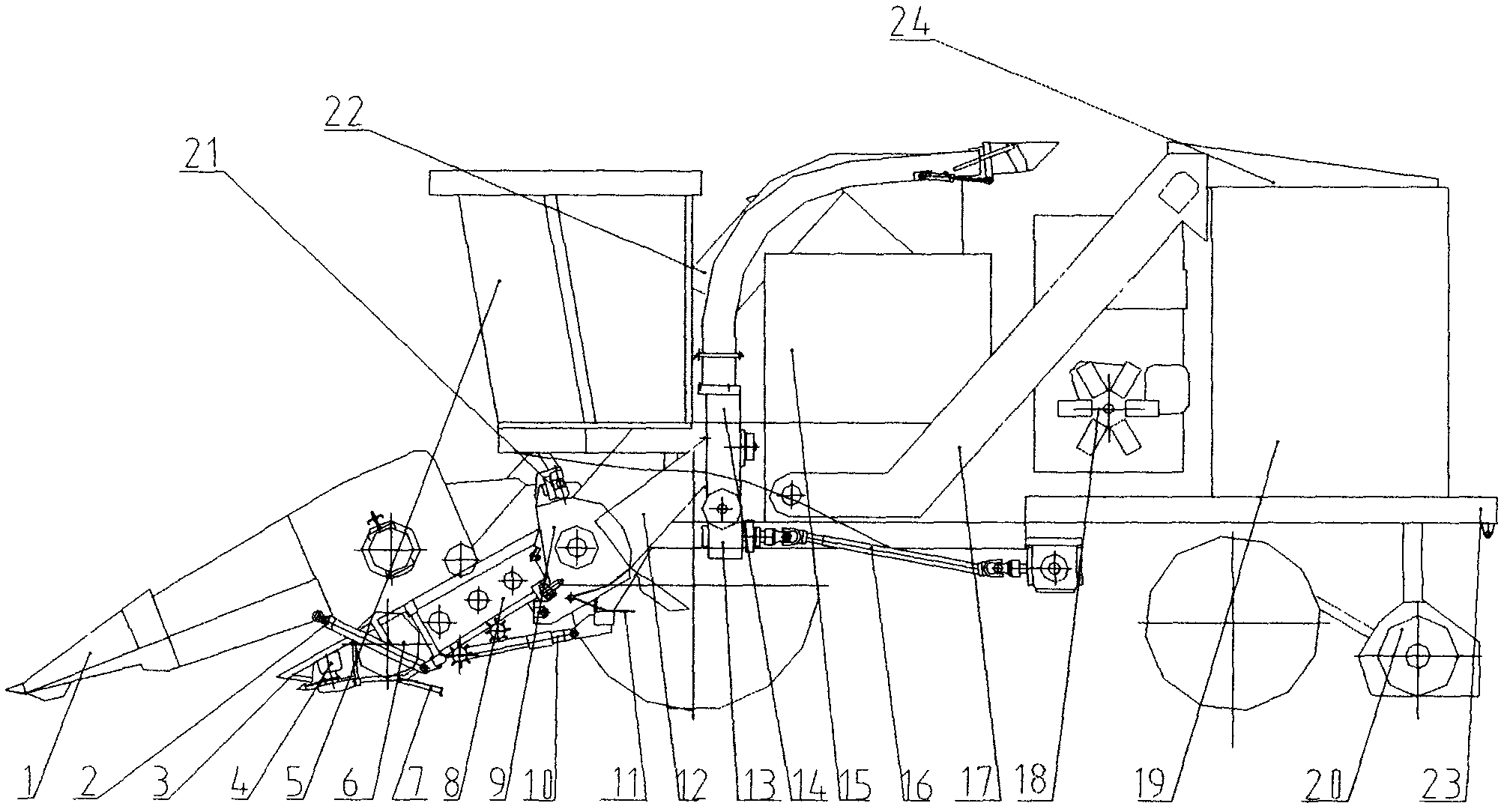

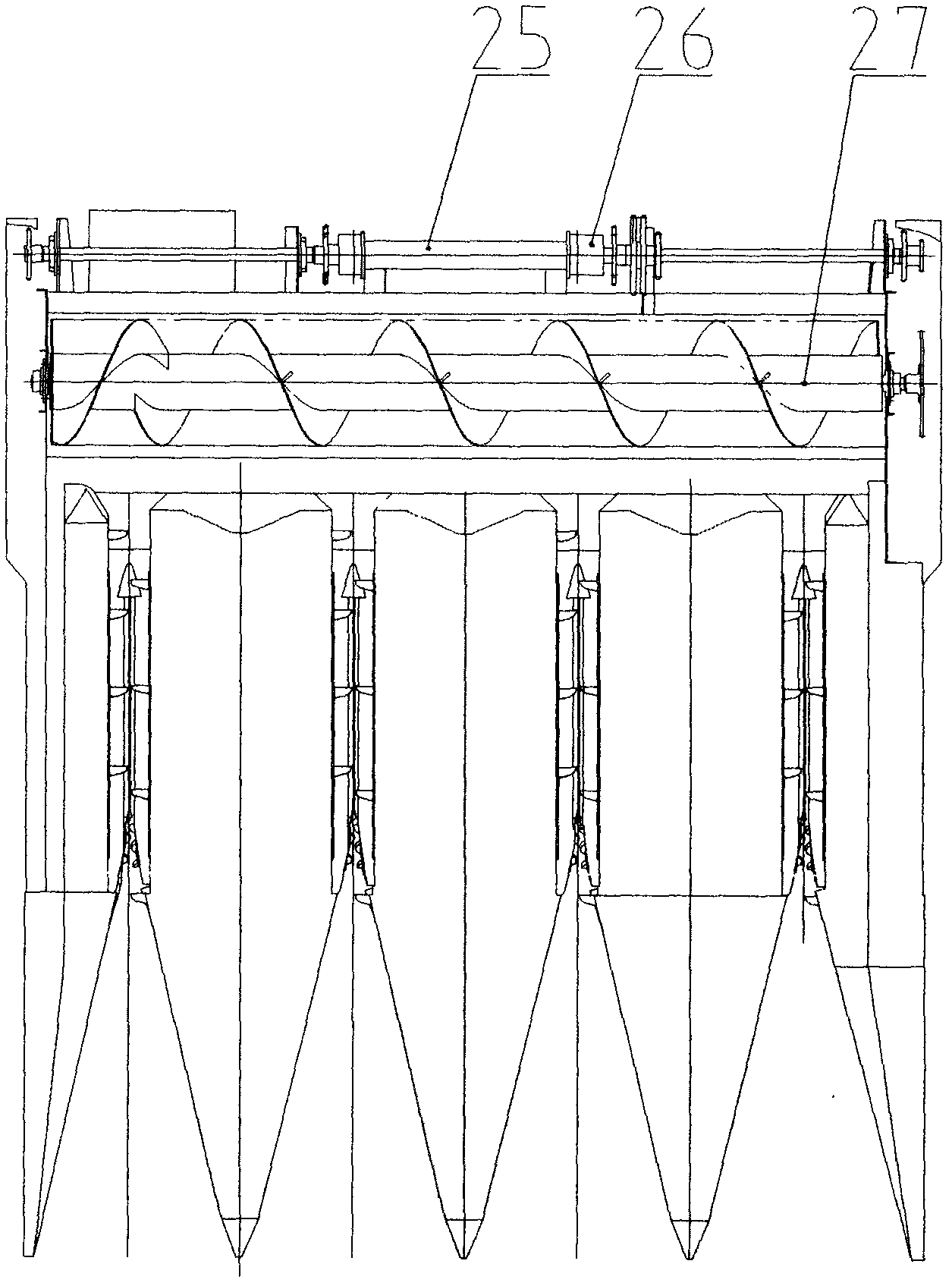

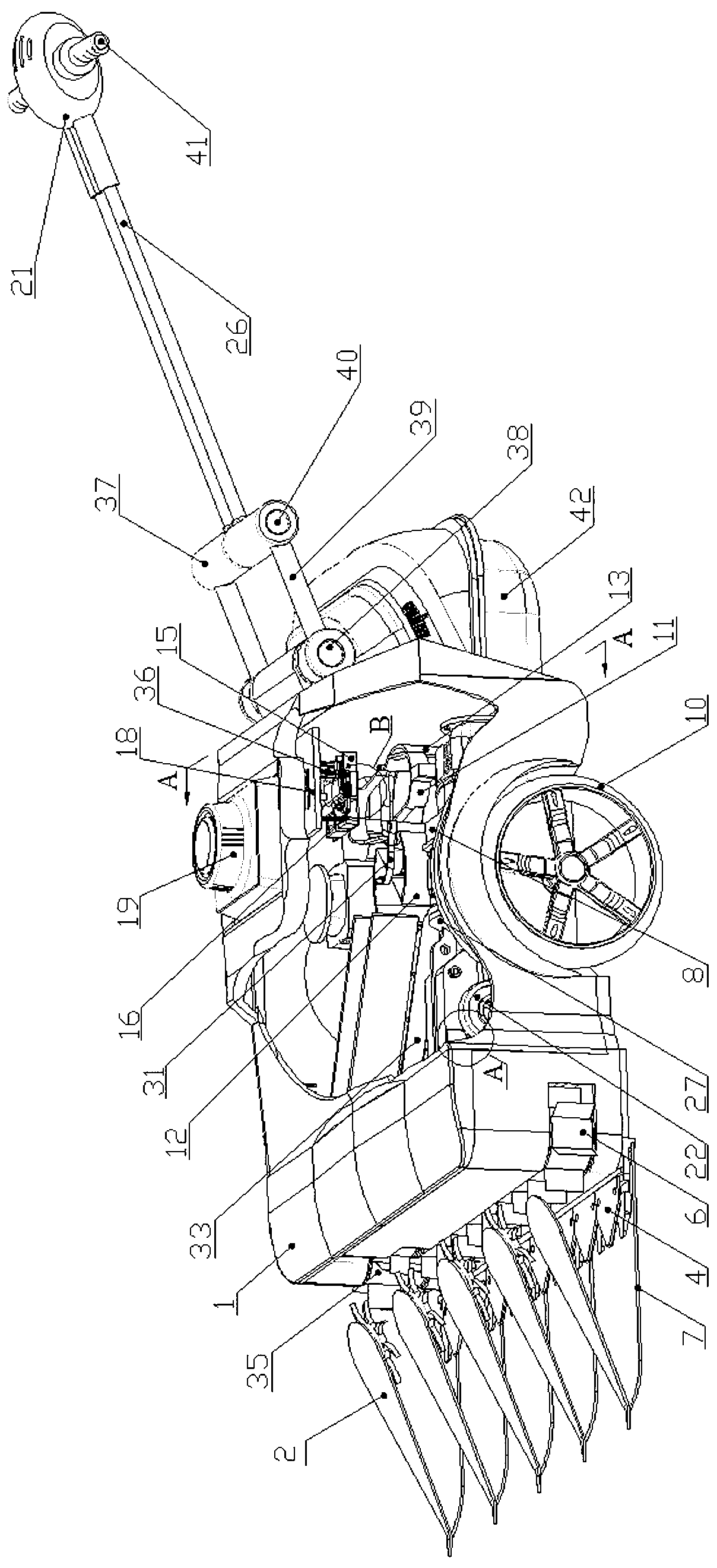

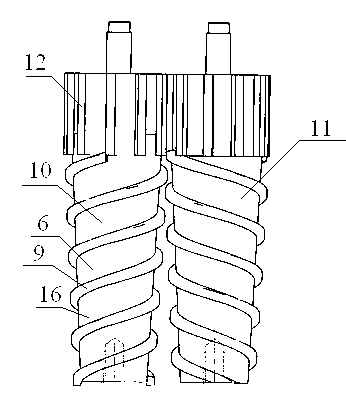

Corn combine harvester for both ears and stalks

InactiveCN102523827AStrong pulling powerPull the stem quicklyMowersThreshersEngineeringCombine harvester

The invention relates to agricultural machinery, in particular to a multifunctional corn combine harvester for both ears and stalks, which comprises a header including an upper layer and a lower layer. The upper header is an ear picking table, and the lower header is a stalk header. The corn combine harvester for both ears and stalks further comprises an ear harvesting collection box device, a stalk crushing device, a stalk thrower, a stalk baler, an intermediate drive device and a stalk stubble cleaning and returning device mounted on the rear lower portion of a frame and the like. Compared with the prior art, the corn combine harvester for both ears and stalks has the advantages that the functions of corn ear picking, husking and collection, stalk laying, stalk crushing and returning, stalk crushing for feed or industrial materials, and stalk stubble cleaning and returning are achieved on the corn combine harvester, the requirements of different users in different areas can be met, operation functions and cross-area operational adaptability of the corn combine harvester are improved greatly, comprehensive usability of corn stalks is improved greatly.

Owner:SHANDONG AGRI MACHINERY RES INST

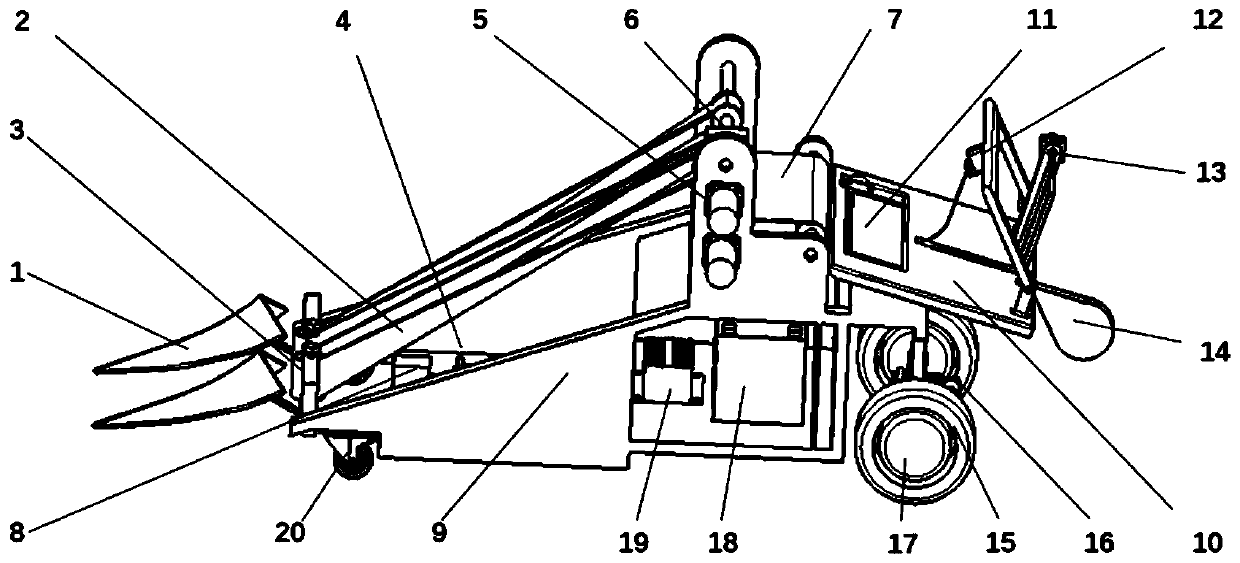

Crop reaping and binding machine

The invention discloses a crop reaping and binding machine. The crop reaping and binding machine comprises a reaping table, a conveying groove, a feeding device, a binding mechanism and a dynamic travelling system, wherein the reaping table pulls crops to the conveying groove after reaping the crops, the conveying groove conveys the crops to the feeding device, the feeding device feeds the crops into the binding mechanism, and the binding mechanism binds the crops, bound crops fall into a storage box after being discharged and then are concentratedly transported to an appointed place, and the dynamic travelling system is used for realizing a travelling function of the binding machine and providing power for the conveying groove and the binding mechanism. The crop reaping and binding machine has the advantages that by means of finishing the processes of reaping, picking, binding, storing and the like at a time, a cropland is emptied for next-stubble crops immediately, and crop rotation contradiction is relieved; in addition, the crops are transported to the fixed places for concentrated after-ripening, so that crop seeds are protected from mildewing loss caused by overcast and rainy weather, and the economic benefit for crop production is increased.

Owner:HUNAN AGRICULTURAL UNIV

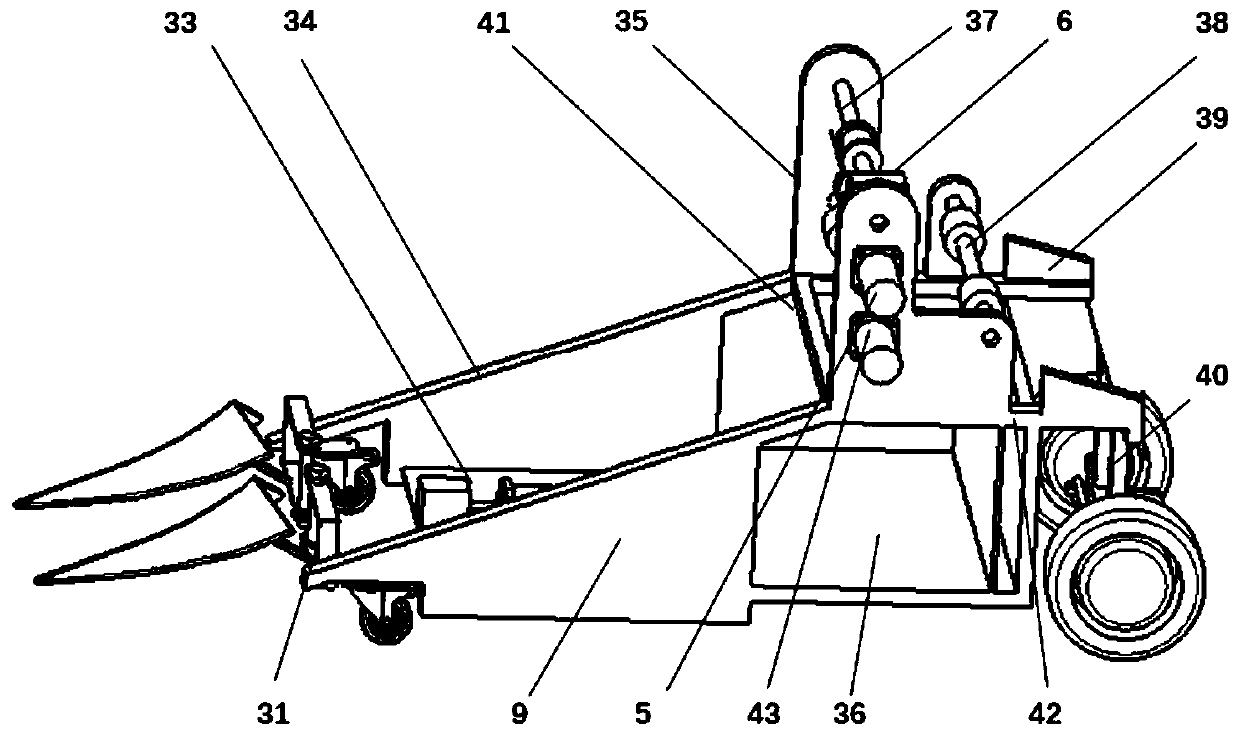

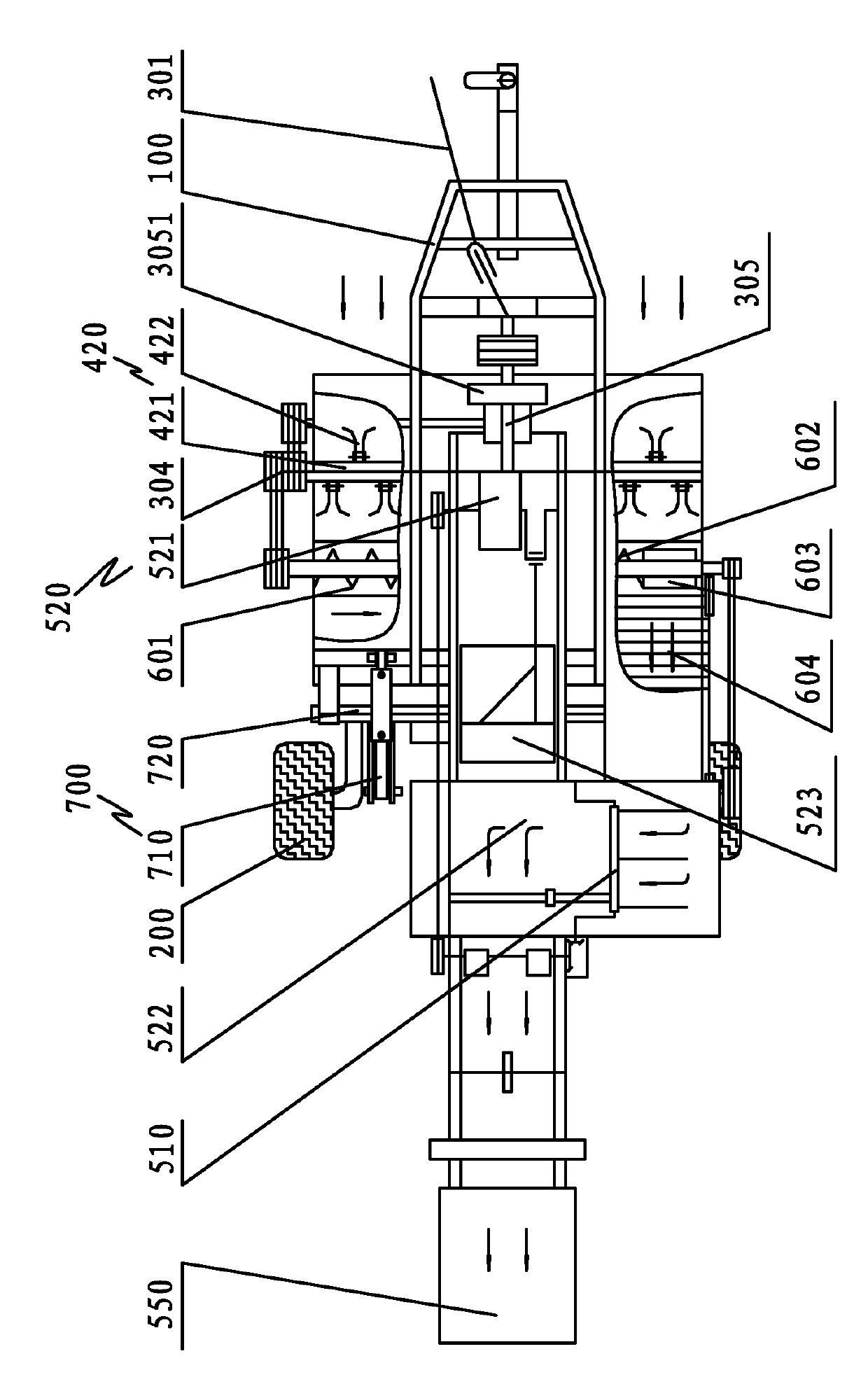

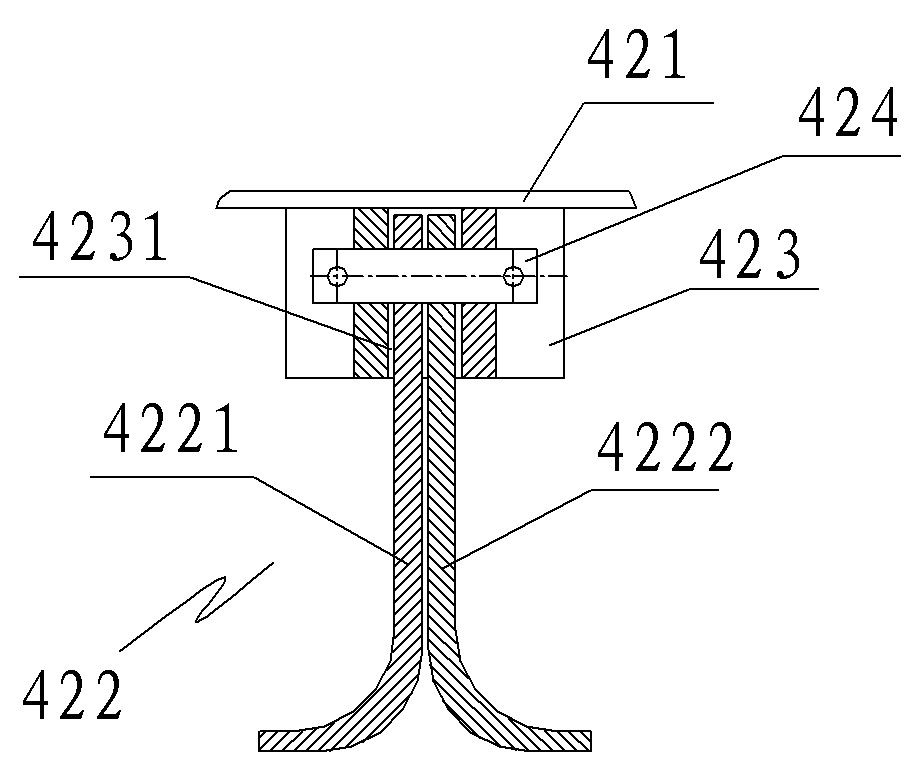

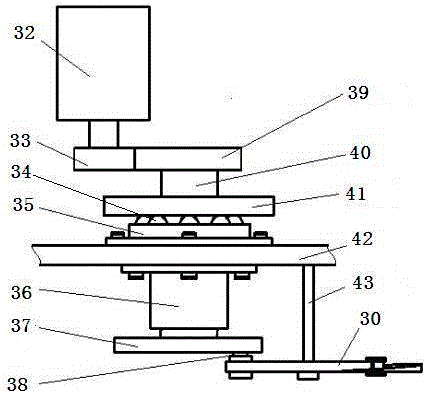

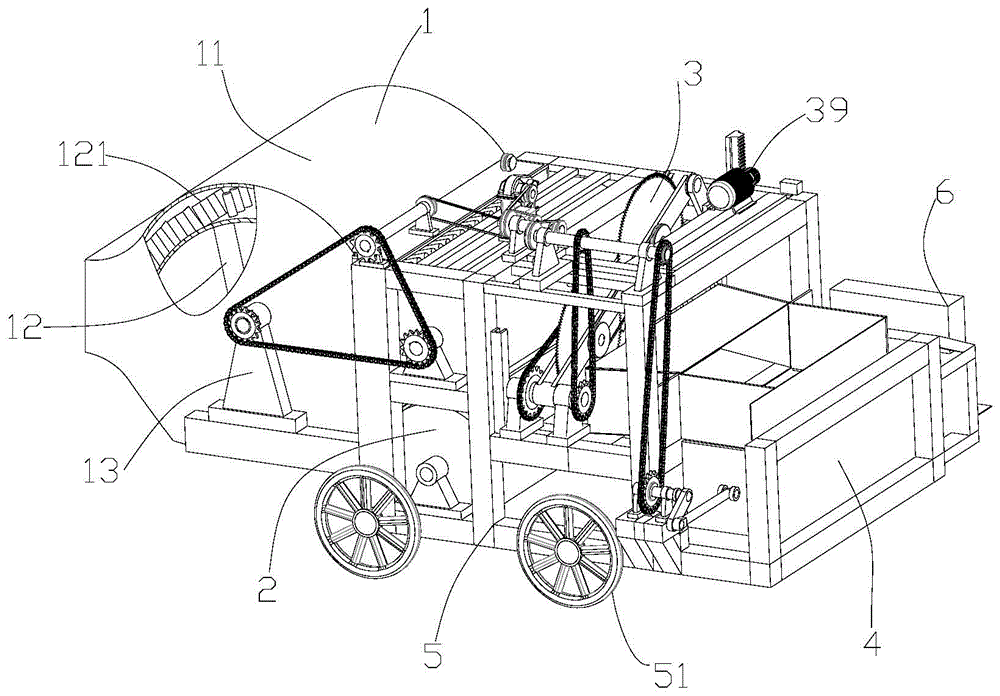

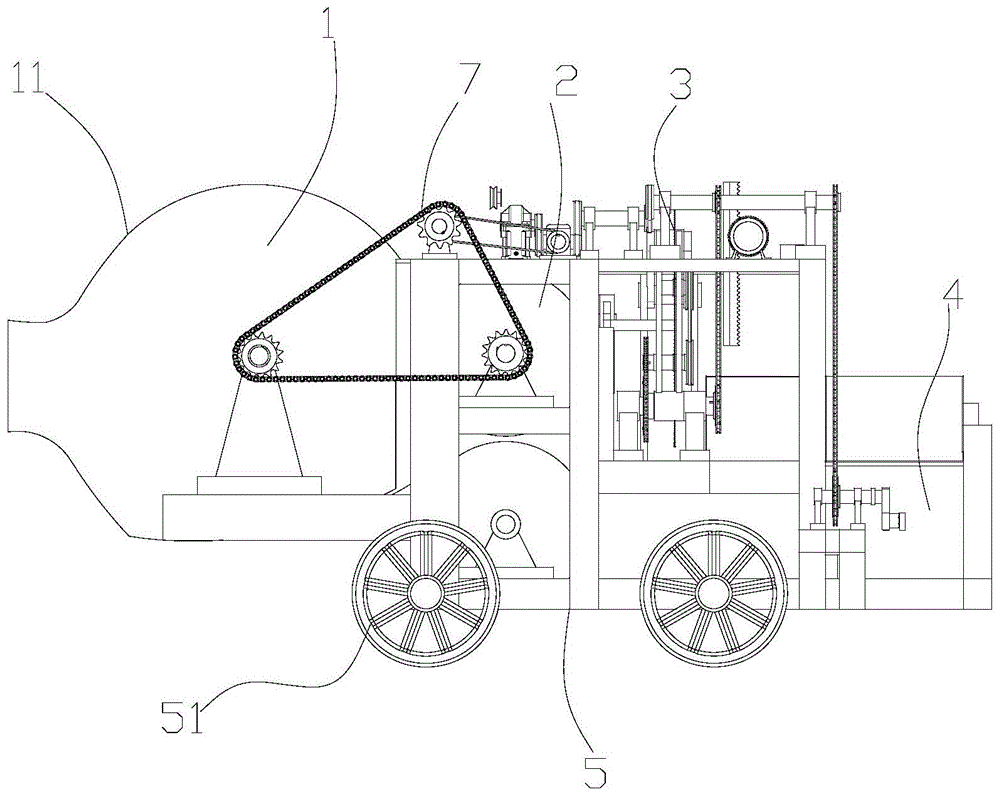

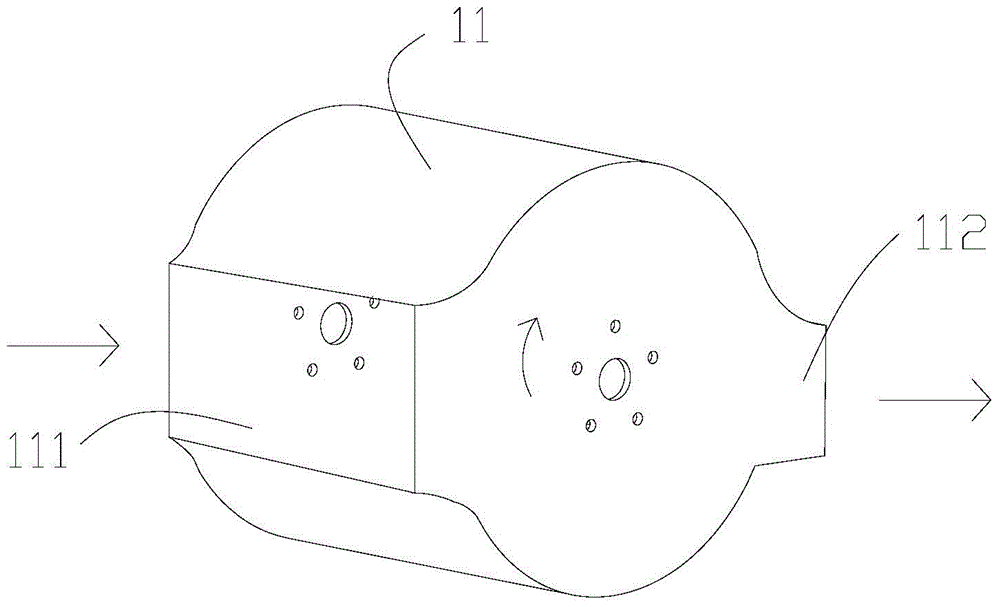

High-efficiency crawler-type pick-up baler and bale automatic stacking system thereof

ActiveCN106358605AImprove efficiencyImprove work efficiencyLoadersMowersDelivery PerformanceControl system

Owner:JIANGSU UNIV

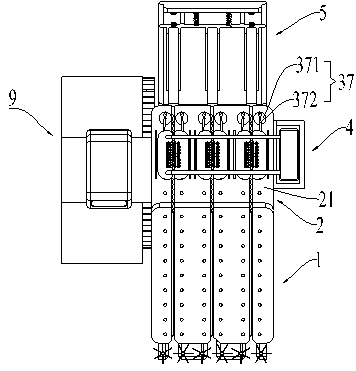

Small-sized fragrant-flowered garlic harvesting and binding machine

InactiveCN103181264ASolve the problem of manual bundlingEliminate physical hazardsReaper-bindersDrive shaftEngineering

The invention mainly relates to a small-sized fragrant-flowered garlic harvesting and binding machine which comprises a self-walking rack. Storage batteries and a program control device are arranged at the right side of the rear of the self-walking rack. An adjustable handle and a storage are arranged at the rear end of the self-walking rack. An engine, a traveling box, a header clutch, a header gearbox and a main transmission box are arranged at the left side of the self-walking rack, wherein a main transmission shaft which is in power connection with the engine and two walking half shafts which are in transmission connection with the transmission shaft are arranged in the walking box. Two walking half shafts are connected by a differential mechanism and traveling wheels are arranged at the end parts of the two traveling half shafts. Dividers are horizontally and uniformly arranged at the front end of the self-waling rack. A cutting device is arranged at the lower side of the front end of the self-walking rack. The small-sized fragrant-flowered garlic harvesting and binding machine disclosed by the invention can be used for cutting and binding fragrant-flowered garlic, so that the efficiency of labor is greatly increased, the labor intensity is reduced and the small-sized fragrant-flowered garlic harvesting and binding machine is applicable to popularization and application.

Owner:SHENYANG POLYTECHNIC UNIV

Intelligent vegetable harvester

ActiveCN109874496ARealize automatic harvestingImprove harvesting efficiencyReaper-bindersLoss rateVehicle frame

The invention relates to an intelligent vegetable harvester. The intelligent vegetable harvester comprises a driving unit, a vehicle frame unit, a harvesting unit, a transportation unit, a bundling unit and an electric control unit. The intelligent vegetable harvester can automatically walk under the control of a mobile phone; automatic harvesting of vegetables such as Chinese chives and swamp cabbages can be achieved, the harvesting efficiency is high, and the loss rate is low; a belt adopts a sponge conveyor belt, the sponge conveyor belt is used for vegetable transportation, the transportation is stable, and damage to vegetables cannot be caused; automatic bundling of the vegetables can be achieved, the bundling efficiency is high, the bundled vegetables are transported and slide to space in rear of the vegetable harvester, and later picking and other subsequent operation steps are facilitated.

Owner:CHINA AGRI UNIV

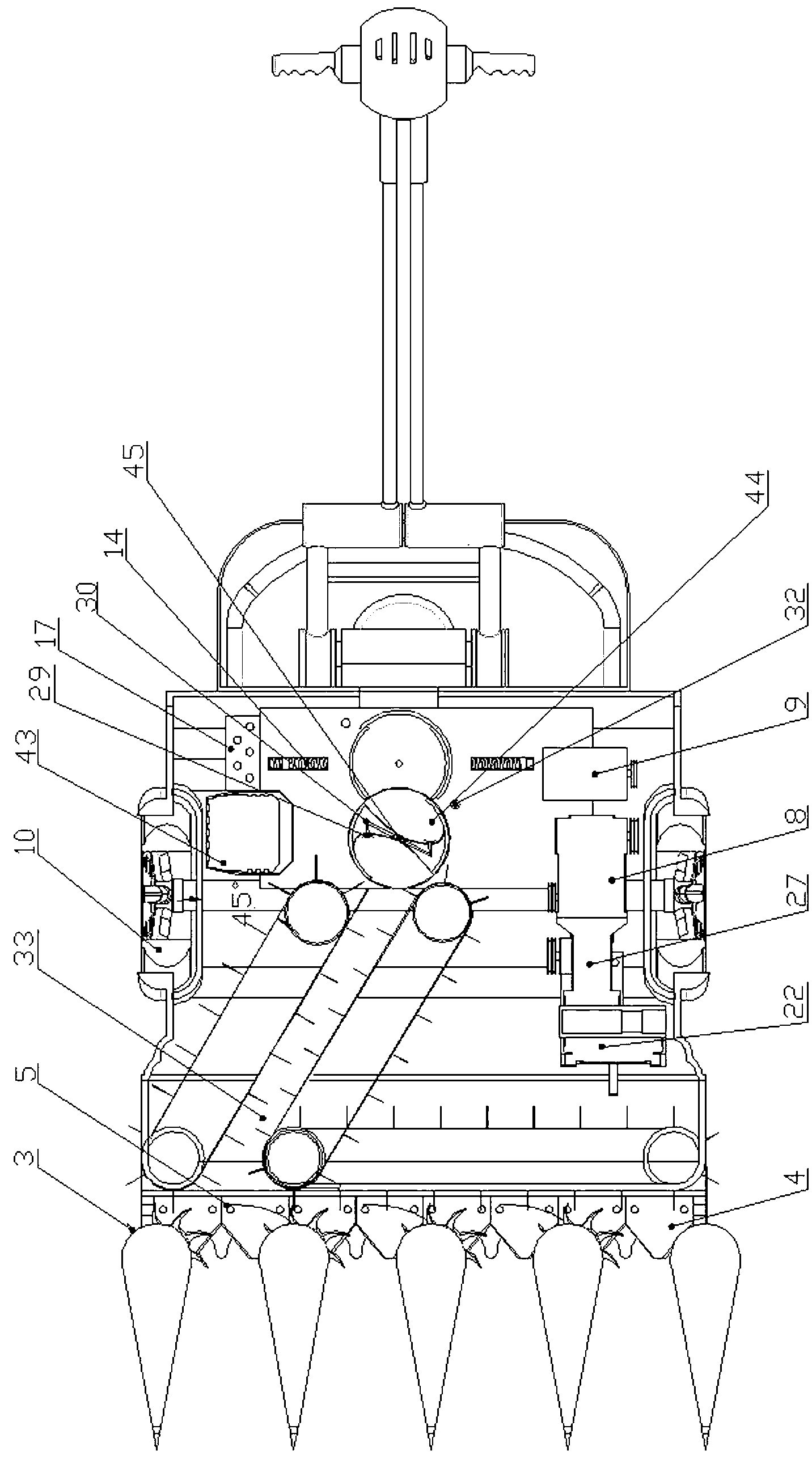

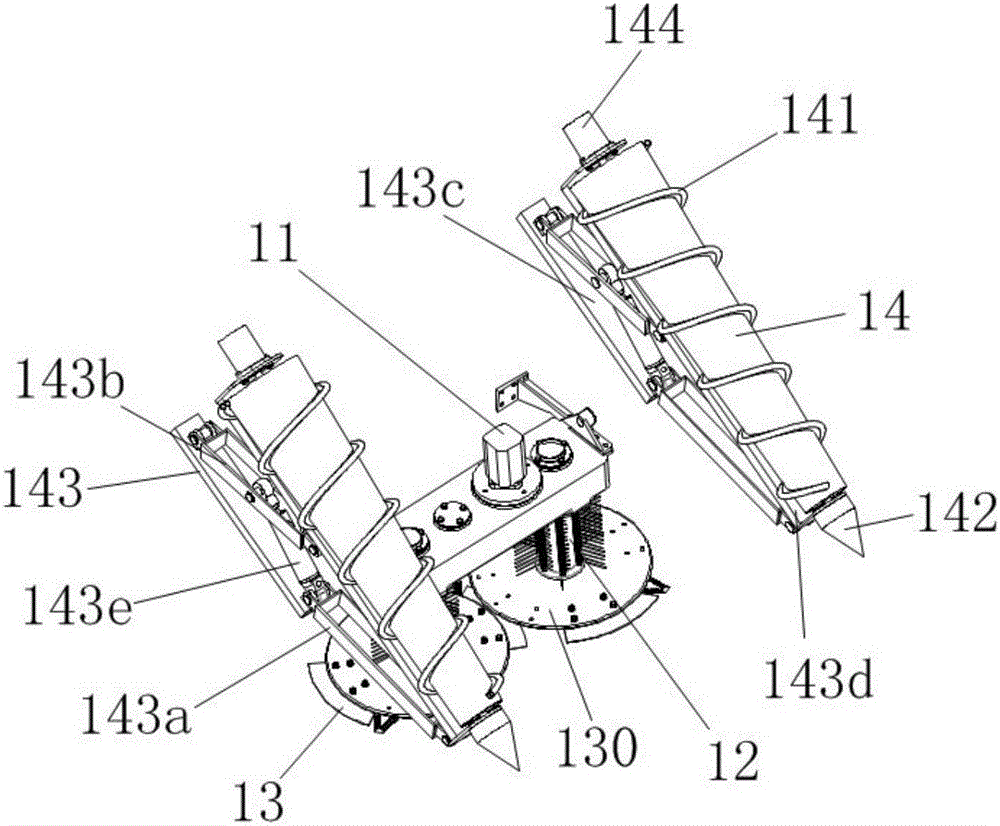

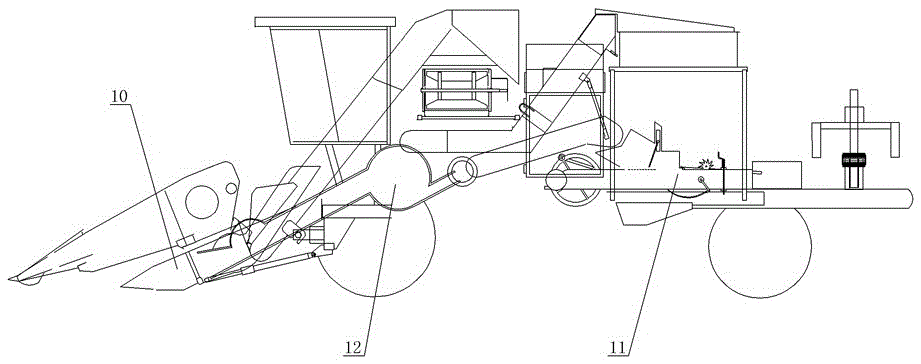

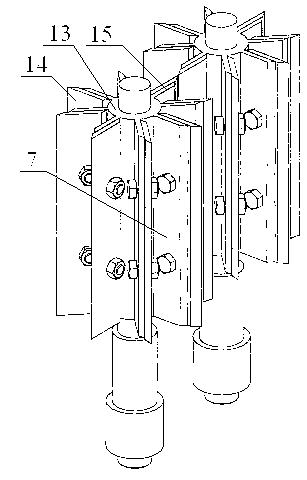

Shunting harvester of highland barley stalks and ears

ActiveCN106034554AIncrease profitSolve the problem of feeding valueMowersReaper-bindersEngineeringMechanical engineering

The invention discloses a shunting harvester of highland barley stalks and ears. The harvester comprises a rack and a walking mechanism, wherein a power system, an upper-layer cutting table, a lower-layer cutting table, a driving cab and a threshing device are disposed on the rack; multiple dividers are disposed on the lower-layer cutting table, and a clamping chain of which rotation is driven by a drive device is disposed on each divider; multiple poking fingers are uniformly disposed on the clamping chain; two seedling poking star wheels which are disposed correspondingly up and down and can conduct synchronous rotation are disposed on each divider; stalks are cut down by a cutting device under clamping and opposite-direction poking of the poking fingers as well as transmission of the clamping chains and are then conveyed to a first conveying roller through clamping and opposite-direction poking of the seedling poking star wheels and the poking fingers; the rear end of the first conveying roller is connected to a second conveying roller; the rear end of the second conveying roller is connected to a smashing device; and the rear end of the smashing device is connected to a bundling room. According to the invention, the harvesting mode comprises shunting harvesting of the stalks and ears and separate treatments of the stalks and ears; and the stalks are treated through one-time cutting, smashing and bundling, so that a utilization rate of the stalks is increased.

Owner:HENAN UNIV OF SCI & TECH

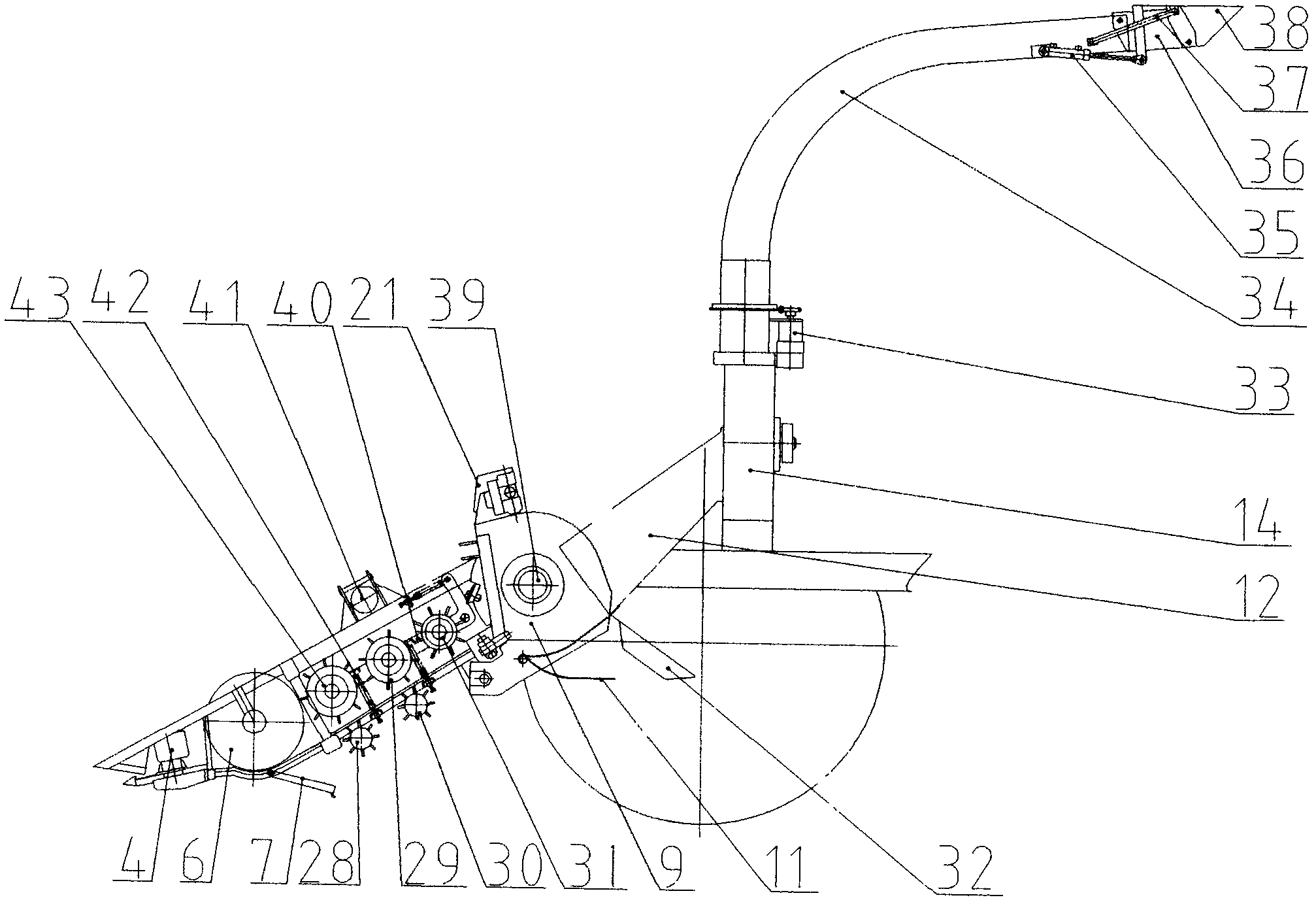

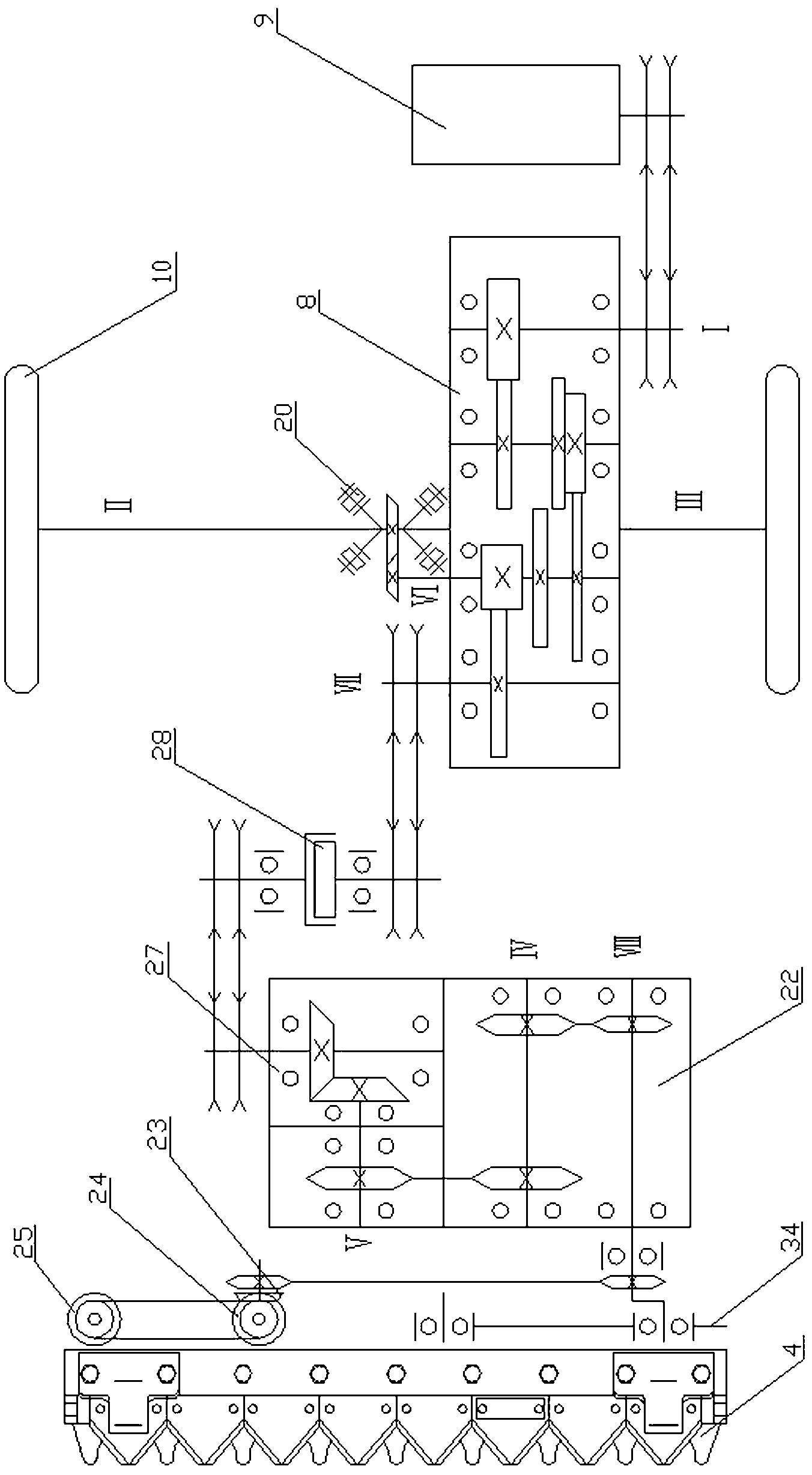

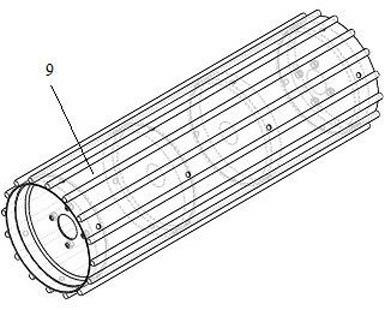

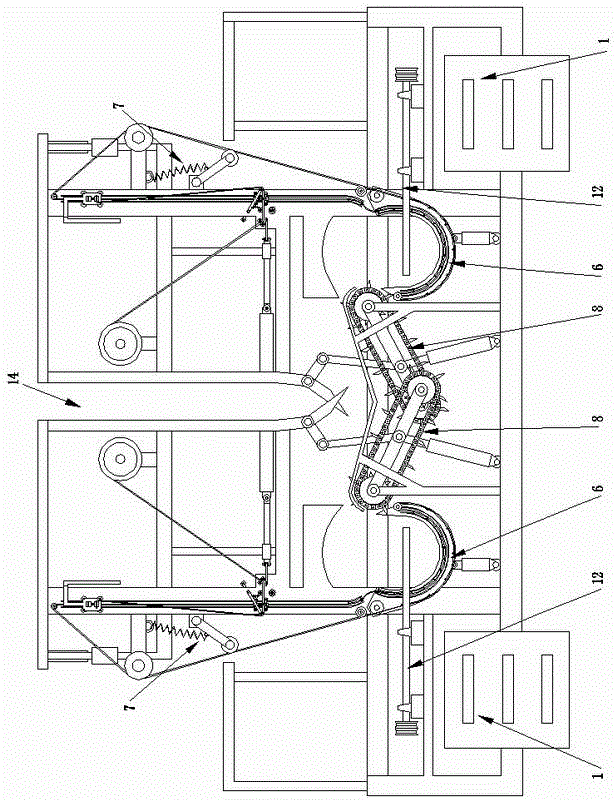

Self-propelled multifunctional straw harvest bundling machine

The invention discloses a self-propelled multifunctional straw harvest bundling machine which comprises a winder, a header assembly, an operating device, a chassis assembling assembly, a kneading room, a power device, a front bundling room and a rear bundling rood, wherein the header assembly and the winder are positioned at right ahead of the whole bundling machine; the winder is hooked on a lifting arm of the header assembly, and can be lifted around a rotational shaft of the lifting arm at the action of an oil cylinder; the header assembly is hinged on a support seat at the front of the kneading room, and can be lifted around a hooking shaft; the kneading rood is positioned at the front end on the upper part of the chassis assembling assembly, and the front part of the kneading part is connected with the operating device; a cab is connected with the operating device; the kneading room is connected with the power device, and the rear part of the kneading room is connected with the front bundling room which is positioned at the rear end on the upper part of the chassis assembling assembly, and is hinged with the rear bundling room; a bundling room is formed by the front bundling room and the rear bundling room; bundling rollers are arranged in the bundling room in circumference; and a rope bundling device is arranged at the front of the front bundling room.

Owner:LUOYANG ZHONGSHOU MACHINERY & EQUIP

Double-row fragrant-flowered garlic harvesting equipment

The invention discloses a two-row leek harvesting equipment, comprising a frame, a driving device, a cutting device for cutting leeks installed on the frame, a transmission device for conveying leeks, a binding device for binding leeks, A collection box and a walking device for collecting leeks; the cutting device includes a reciprocating cutting knife and a crank connecting rod-slider mechanism driven by the driving device; the transmission device includes two torsion belts The transmission channel and the distance between the two twisted belts remain unchanged, one end of the twisted belt is vertically arranged at the cutting mechanism through the driven shaft, and the other end of the twisted belt is horizontally arranged at the said cutting mechanism through the driving shaft. At the strapping device, the driving shaft is power-connected with the driving device; the running device includes a driving wheel arranged at the rear end of the frame driven by the driving device and a guide wheel arranged at the front end of the frame.

Owner:HUNAN UNIV OF ARTS & SCI

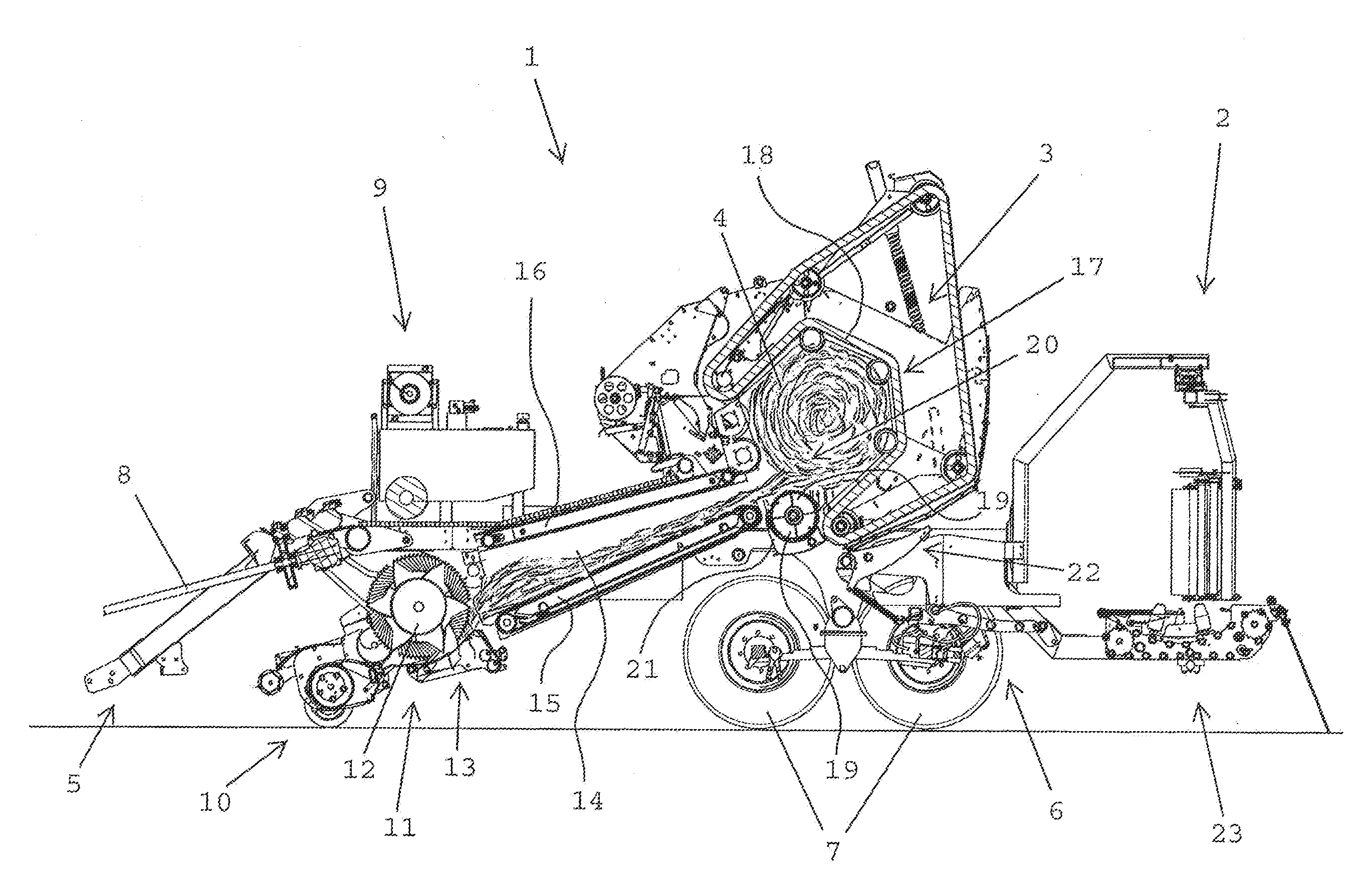

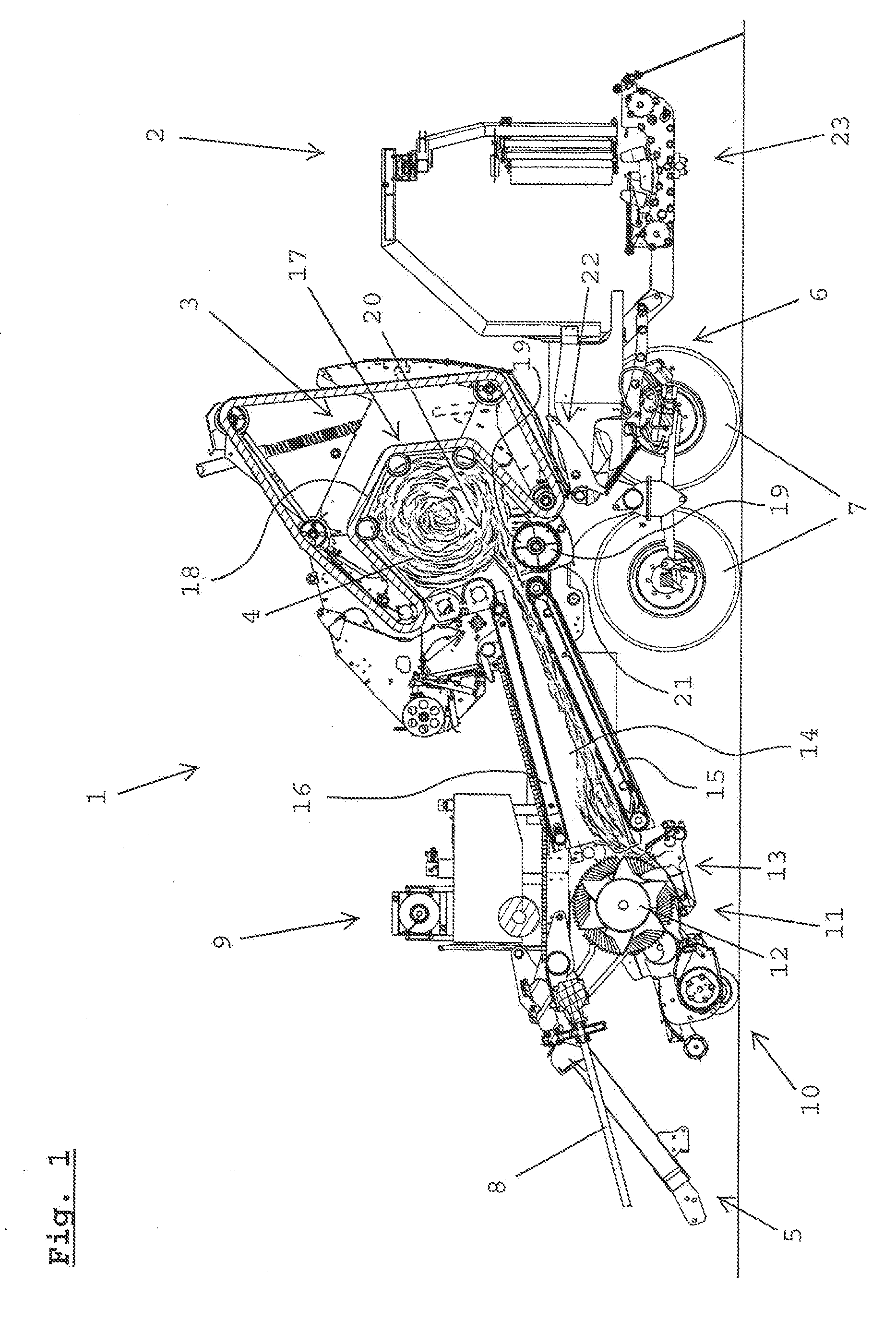

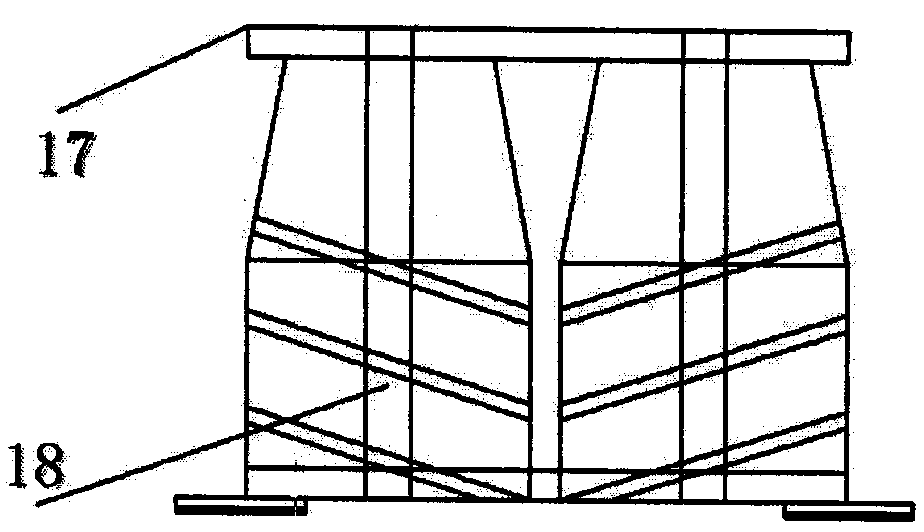

Argricultural round baler with height-adjustable shaping and pressing channel

An agricultural round baler has a press chamber with inlet and rear outlet for ejecting a bale. A pressing device in the press chamber causes the harvested crop to rotate. A pickup device and a conveying and cutting device are provided upstream of a storage chamber that extends to the inlet of the press chamber and receives harvested crop in a storage phase of the baler. An element that interrupts or releases flow of harvested crop from the storage chamber to the press chamber is provided and acted on by a control and governing device. The storage chamber is a flat shaping and pressing channel for the harvested crop conveyed in the storage phase of the baler operation. The channel has a height-adjustable end and a cross-section that at least temporarily in the storage phase tapers in flow direction of harvested crop to the press chamber.

Owner:KRONE AGRI SE

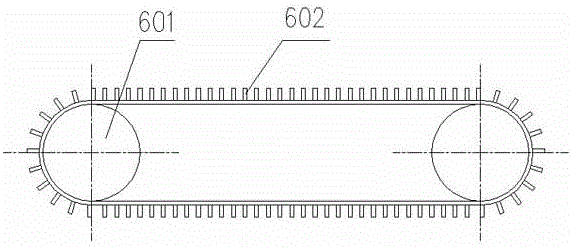

Self-propelled round herbage bale baler

ActiveCN106105546AAvoid problems such as pollutionIncrease productivityReaper-bindersIntegrated operationsEngineering

The invention relates to a self-propelled round herbage bale baler which comprises a walking device, a cab, a baling device, a baling net, a bale unloading device and a dynamic system, wherein a cutting table at the front mows and conveys herbage to a feeding device; the feeding device comprises an auger, a first feeding roller and a second feeding roller in sequence from front to back; a flattening device is arranged thereafter and comprises an upper flattening roller and a lower flattening roller; the feeding device feeds the herbage to the flattening device to be flattened and conveyed to a crushing device at the back; the crushing device comprises a fixed blade and a movable blade, cuts the herbage into small pieces and then throws the small pieces into a stirring and conveying device at the back; the stirring and conveying device comprises a conveying belt; an additive spraying system and a stirring roller are arranged above the conveying belt to spray additives to the herbage and stir the herbage uniformly. The self-propelled round herbage bale baler provided by the invention can realize integrated operation of harvesting, flattening, crushing, additive spraying, baling, net winding and bale unloading of the herbage, and improves production efficiency and quality of herbage bales.

Owner:CHINA AGRI UNIV

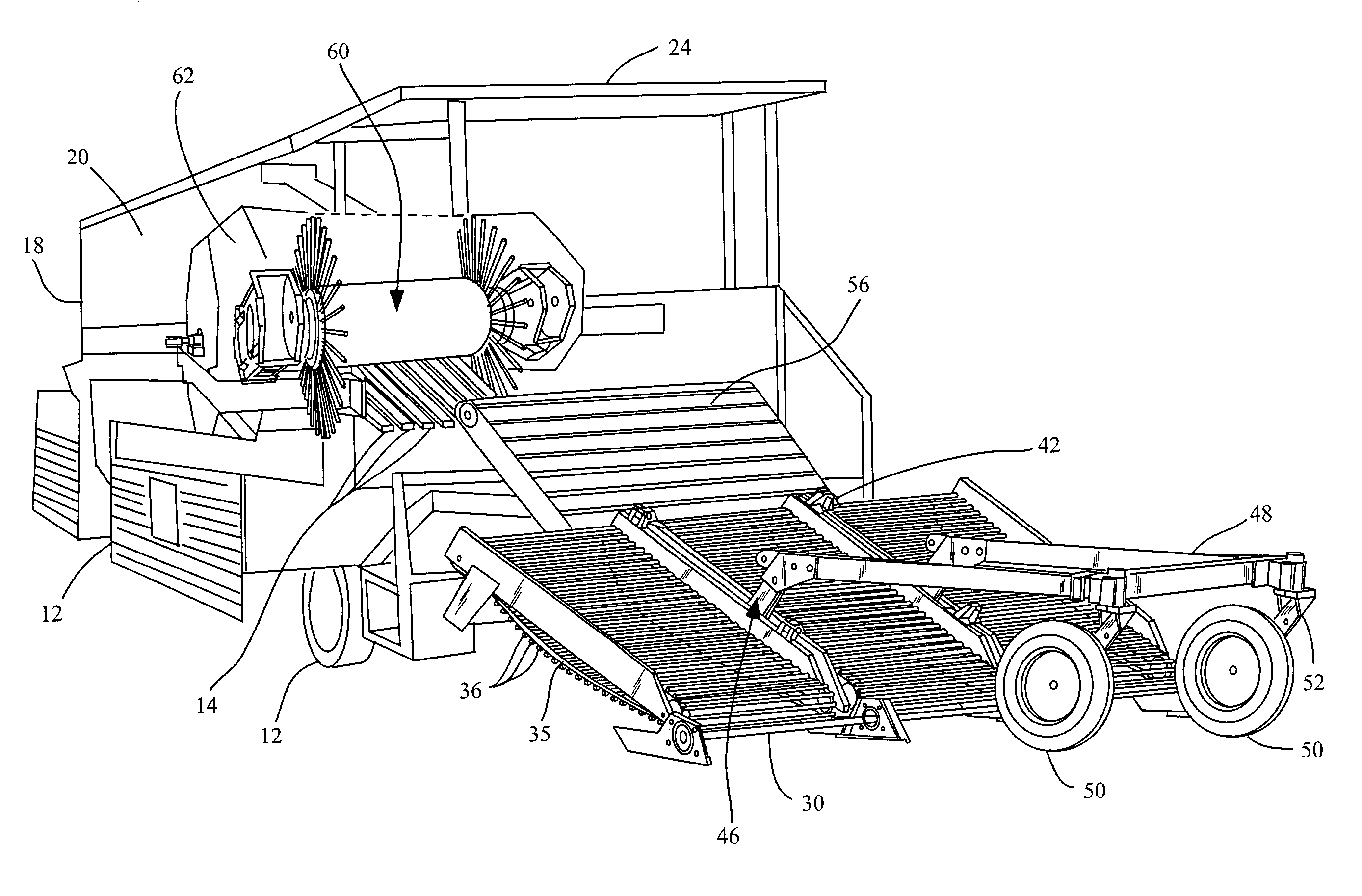

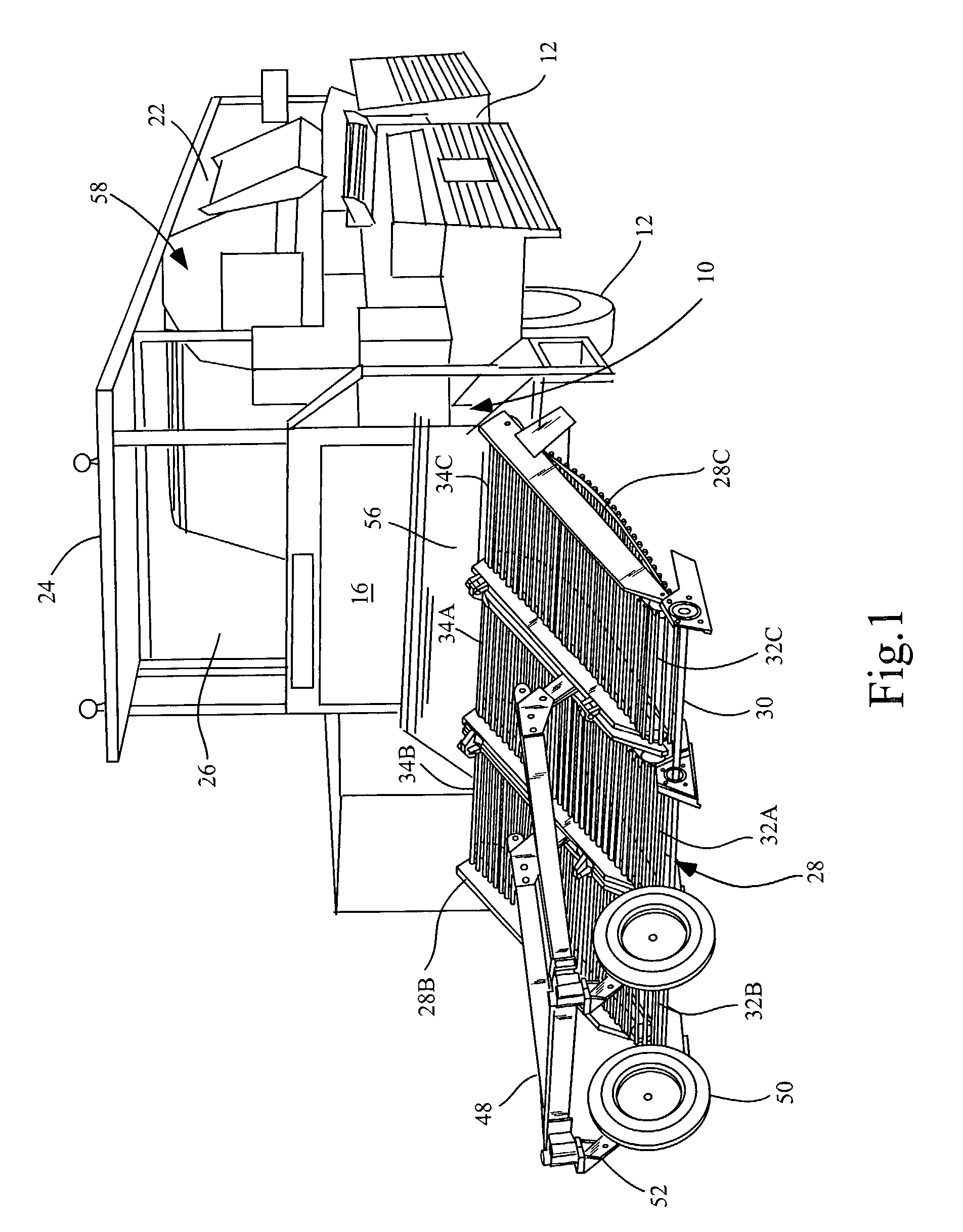

Tomato harvester

A new and more efficient tomato harvesting machine is capable of simultaneously severing up to three (3) rows of tomato vines or other similar crops. The harvesting machine comprises pick up means adjacent to the forward end of the machine for picking up and severing vinous crops from the field, where the crops remain attached to the vines, as the vines are severed. The pick up means carry the crops and vines rearwardly and upwardly. The harvesting machine further comprises separating means for separating crops from the vines. The present invention comprises improvements to the pickup means and the separating means. These improvements allow a harvester to gather vines and crops from up to three adjacent rows simultaneously, and to process the increased volume of vines and crops without overloading the processing equipment.

Owner:BRANNSTROM GREG

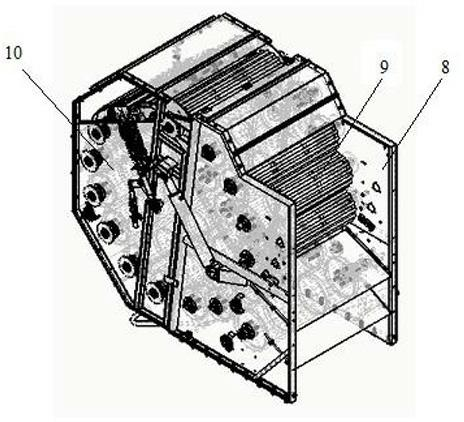

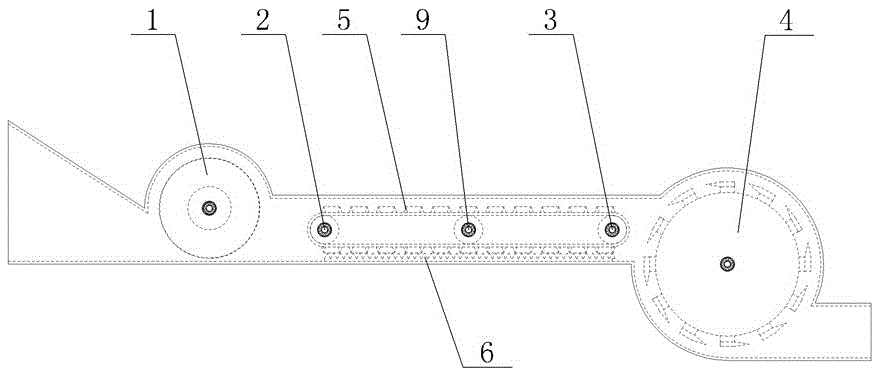

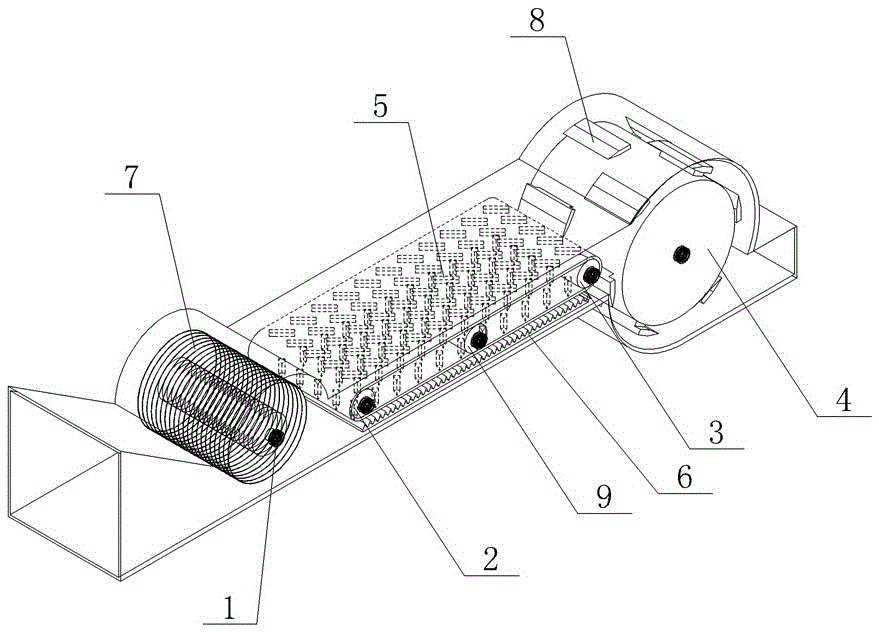

Stalk chopping and pickup square baler

The invention discloses a stalk chopping and pickup square baler which is arranged right behind a tractor. The square baler comprises a cutting and grinding mechanism and a compressing and baling mechanism, wherein the compressing and baling mechanism is arranged above the cutting and grinding mechanism; a pickup transport mechanism is arranged between the cutting and grinding mechanism and the compressing and baling mechanism; the pickup transport mechanism contains a pickup cavity arranged on the back of the casing of the grinder; an auger arranged in the pickup cavity, a fan arranged on one end of the auger and a scraper conveying mechanism arranged in an inclined manner; and the scraper conveying mechanism is arranged between the air outlet of the fan and the feeding fork. By adopting the invention, the stalks of corn and cotton can be cut, grinded, picked up, conveyed, compressed and baled conveniently once; and the square baler has strong functions, stable operation, high operation efficiency and low harvest cost.

Owner:MODERN AGRI EQUIP

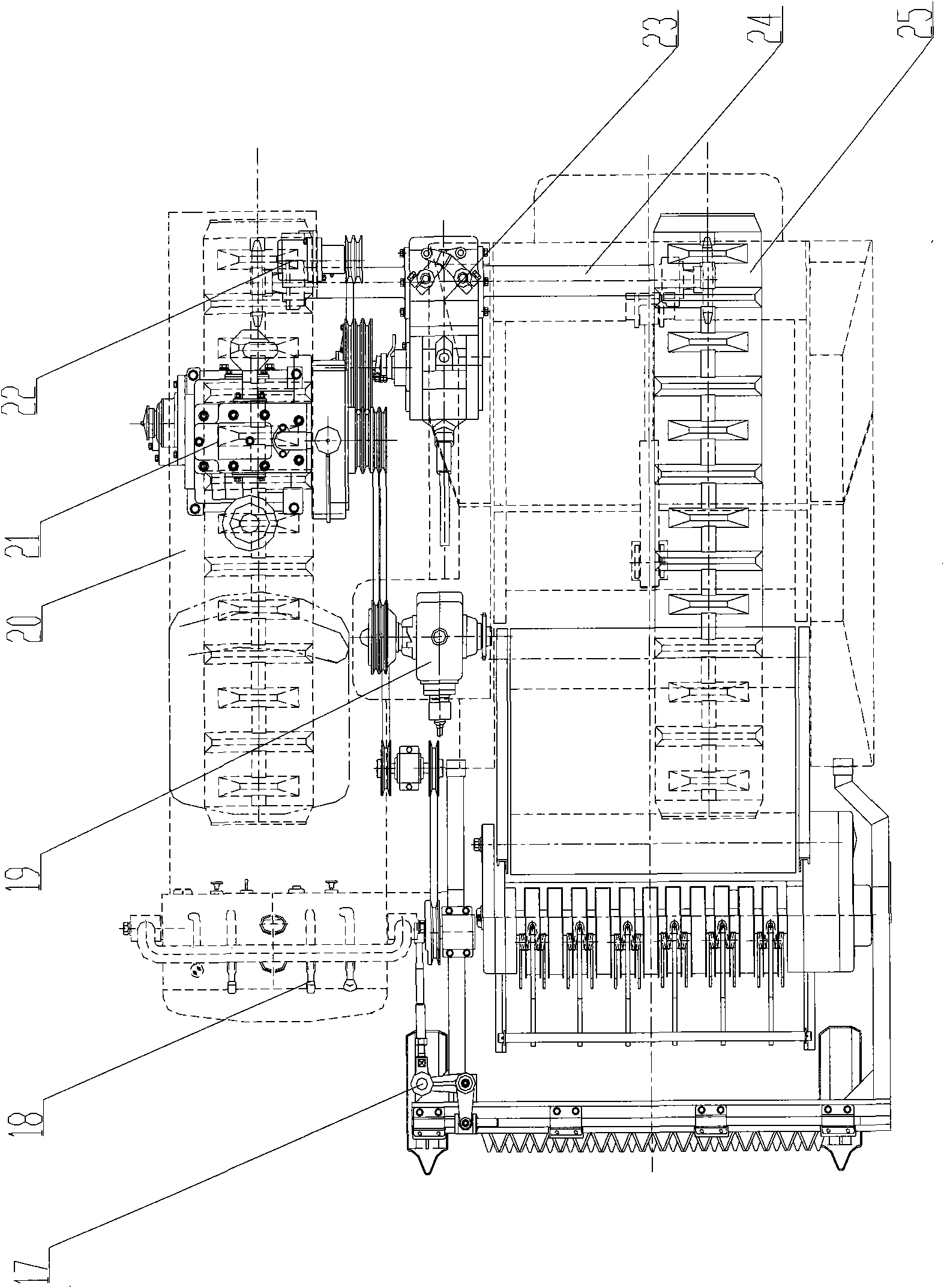

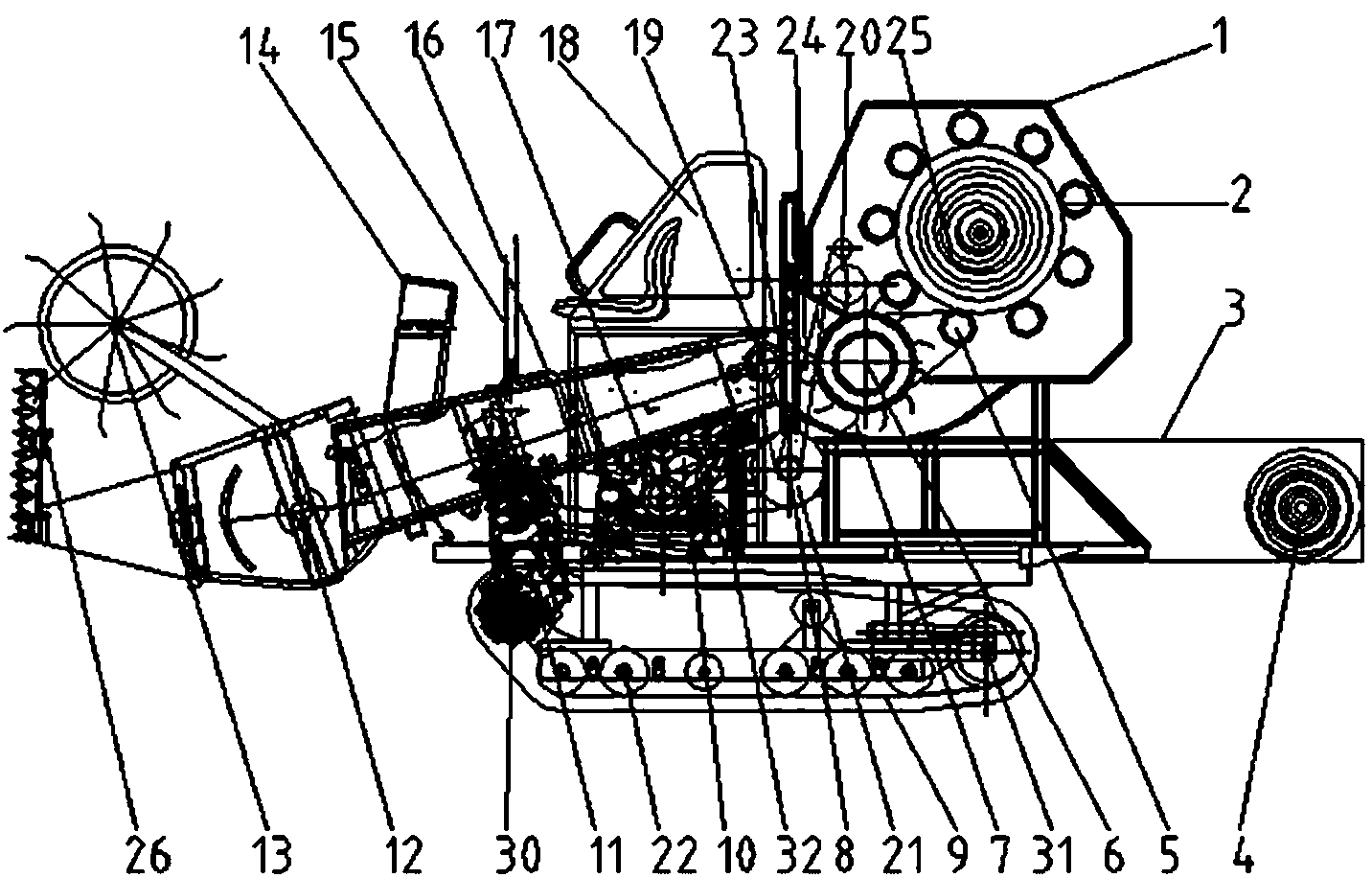

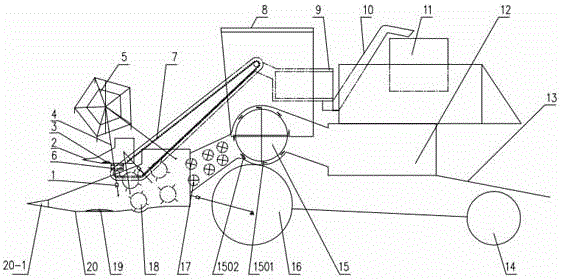

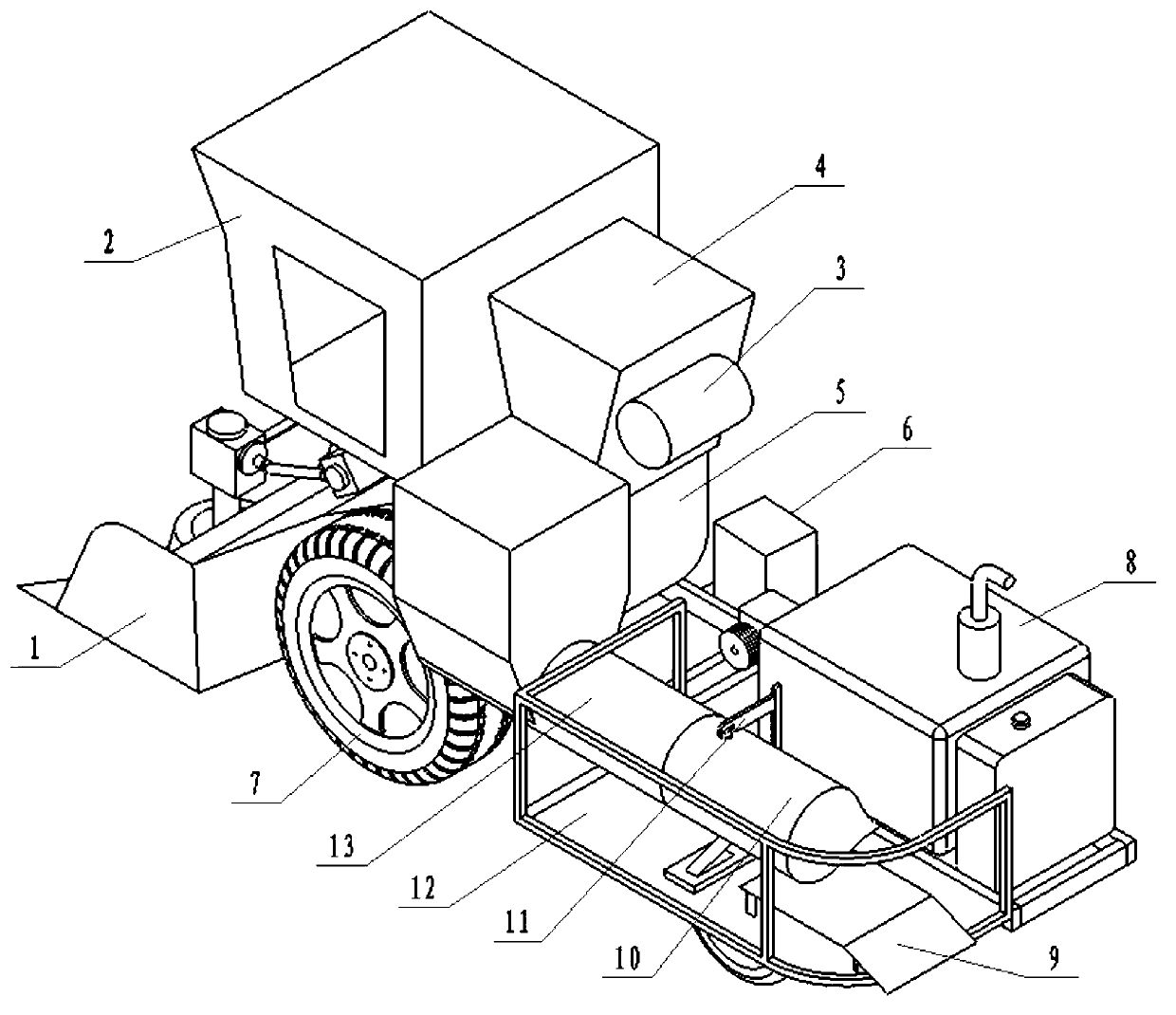

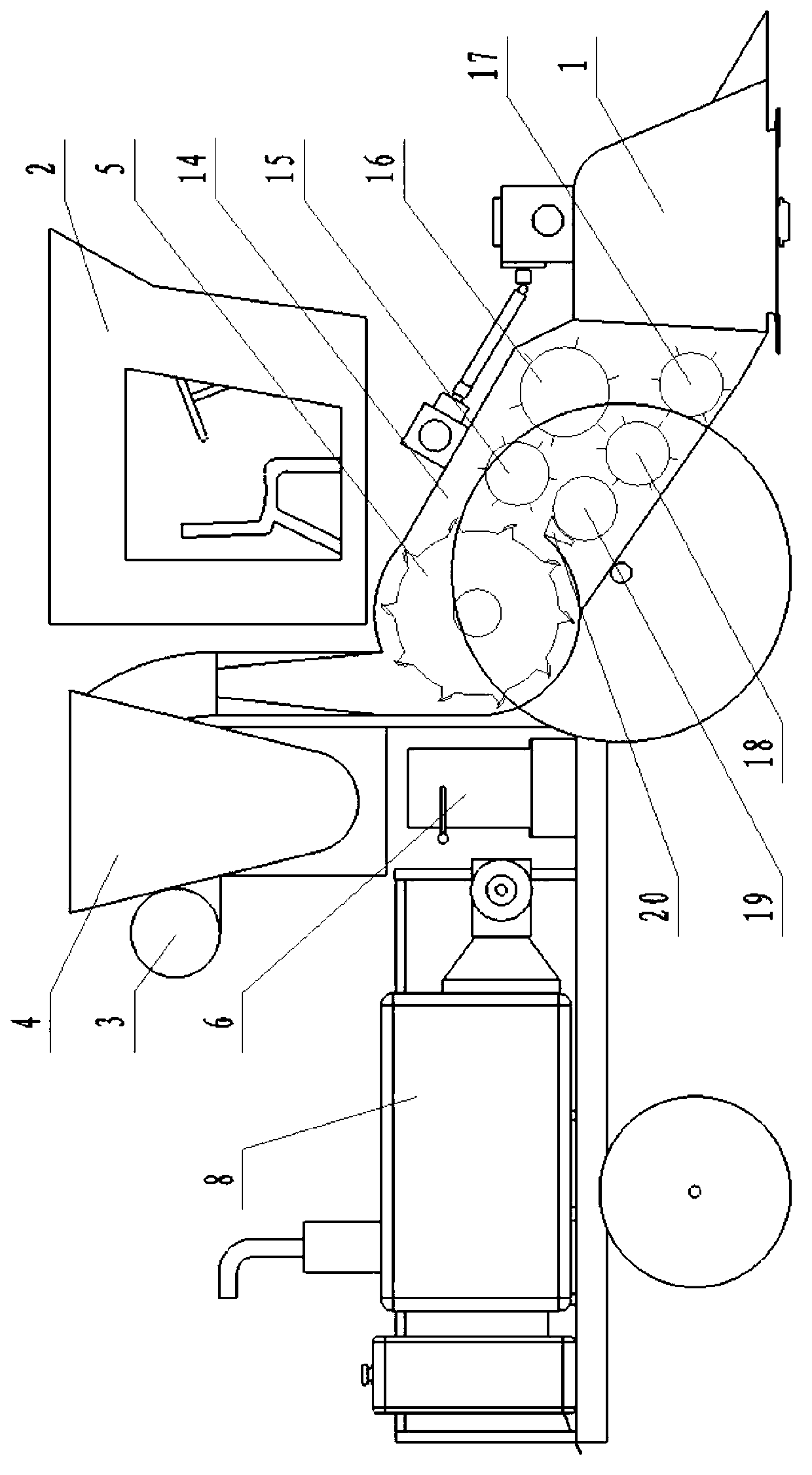

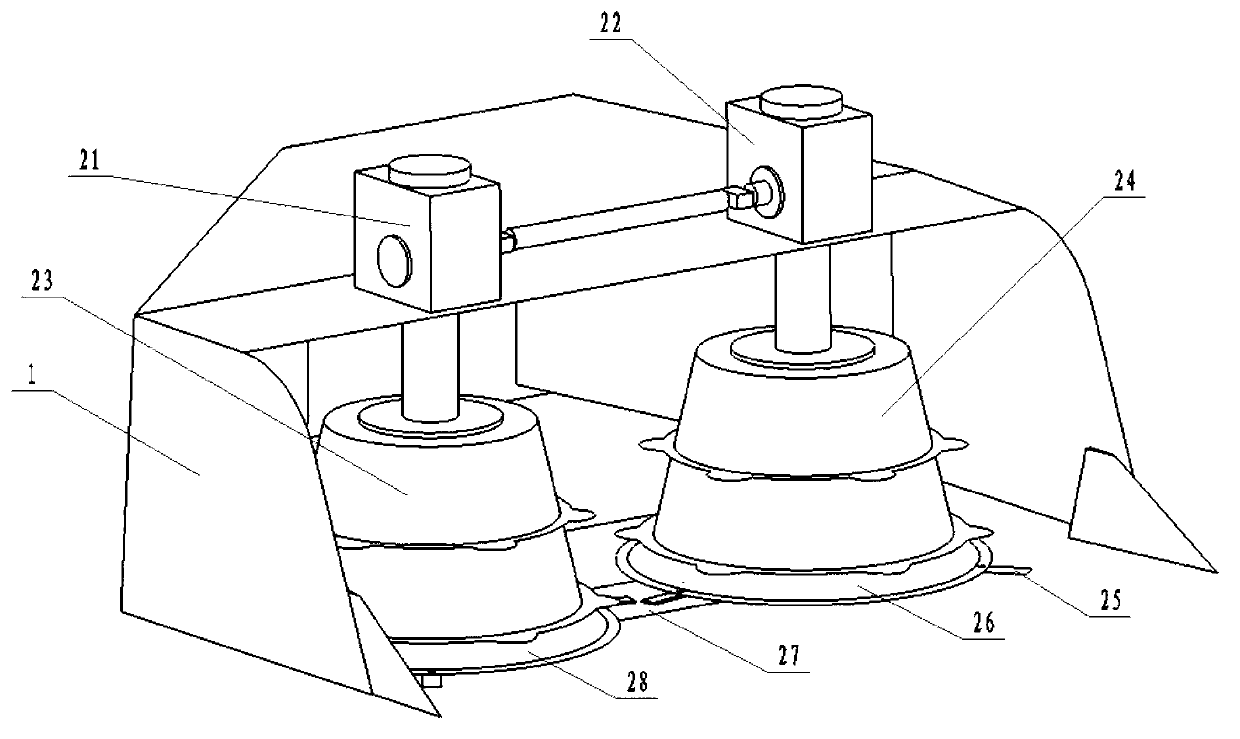

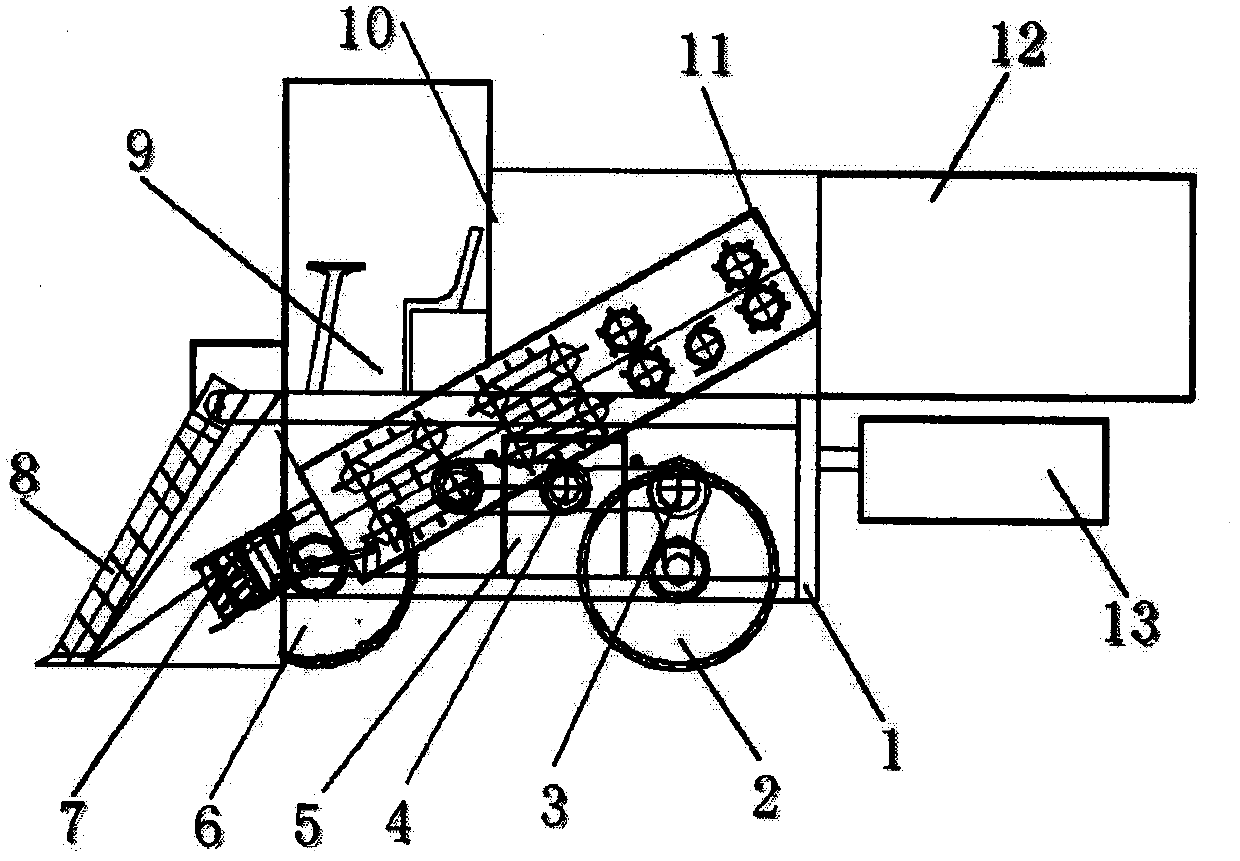

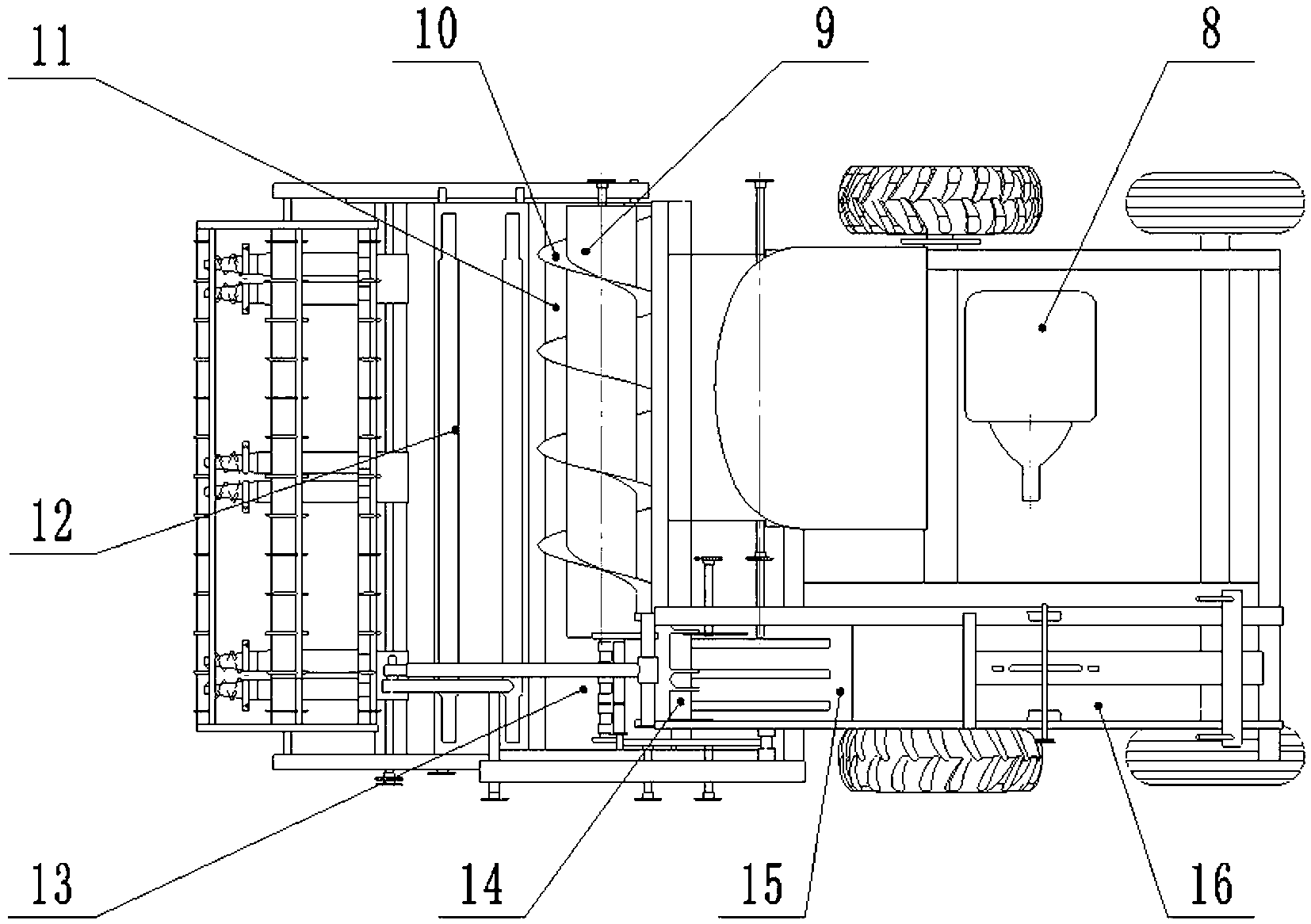

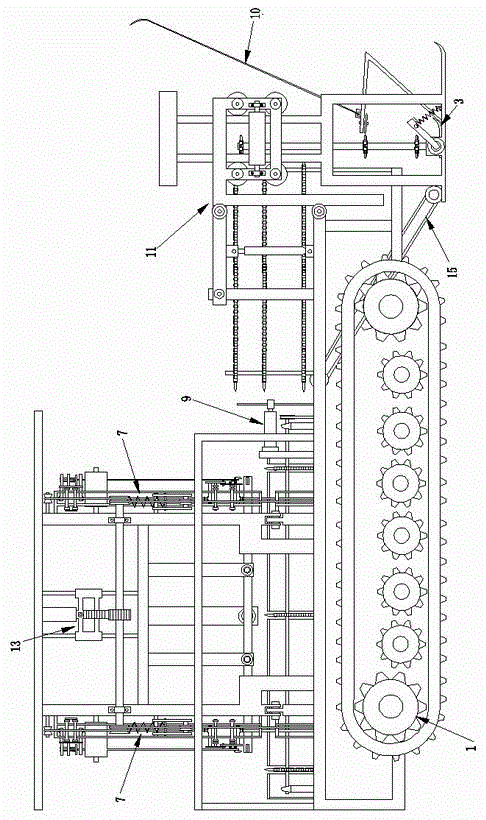

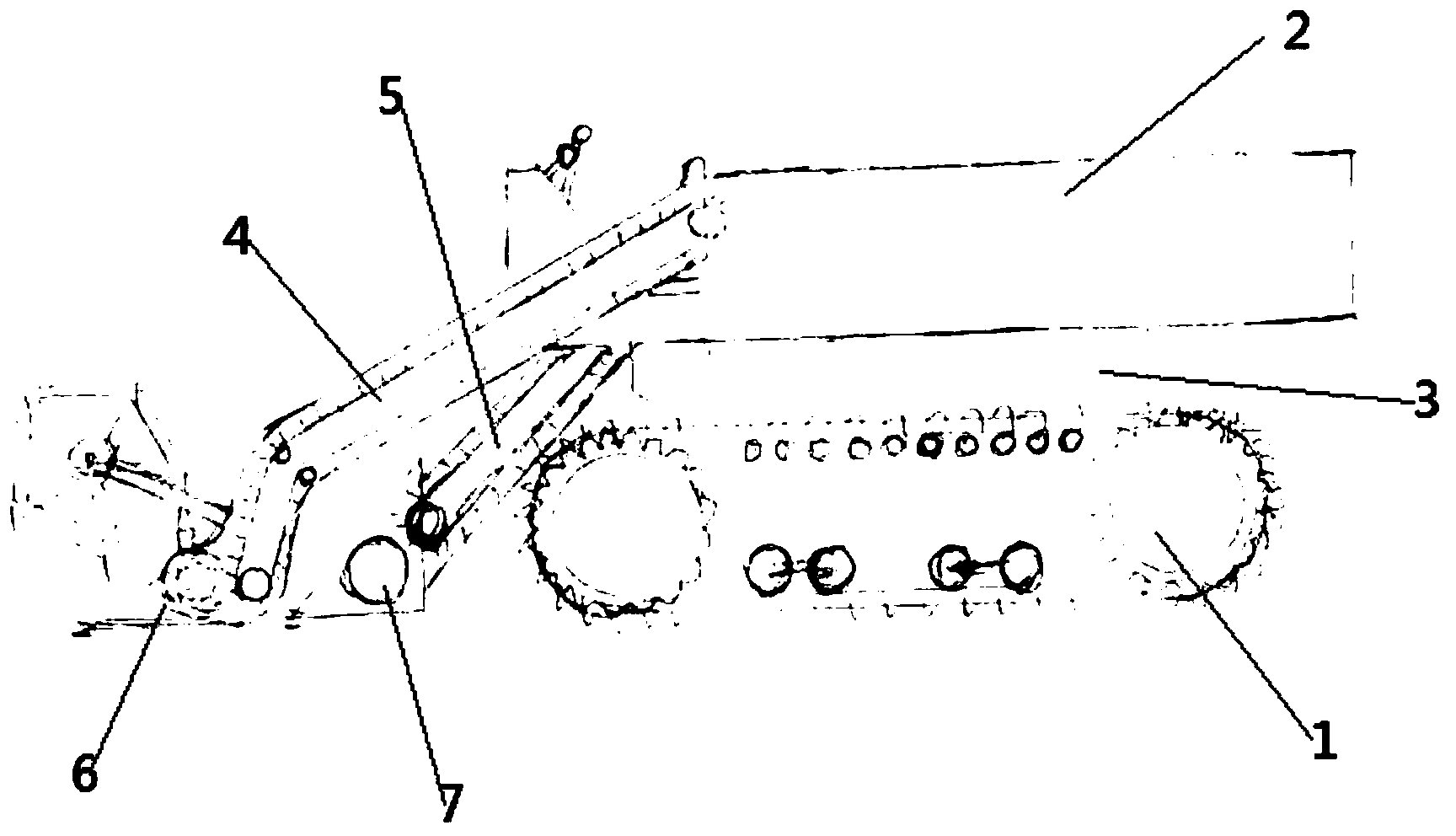

Ensilage harvesting method and ensilage harvester without alfalfa falling to ground

InactiveCN103004383AHigh protein contentGuaranteed qualityAnimal fodder preservationWrapper twisting/gatheringMedicago sativaIndustrial engineering

The invention belongs to the field of stockbreeding machinery and particularly relates to an ensilage harvesting method and an ensilage harvester without alfalfa falling to the ground. The harvester mainly comprises traveling wheels (7), a cab (2), a cutting table (1), a conveyor (14), a chopper (5), a pesticide spaying device (3), a material collector (4), a compressor (13), a sealing device (11), a working table (12) and a discharging table (9). Multiple operation links of cutting, chopping, compacting and bagging can be completed at a time, operation procedures are reduced, harvesting time is shortened, mechanical input cost is lowered, and labor forces are saved. The ensilage harvesting method is unlimited by the weather and can achieve harvesting as long as machines and tools can be operated in fields, so that the problems of difficulty in alfalfa harvesting in rainy seasons, large ensilage loss and the like are solved, prepared alfalfa ensilage is small in package and convenient to transport, and commercial production is achieved easily.

Owner:CHINA AGRI UNIV

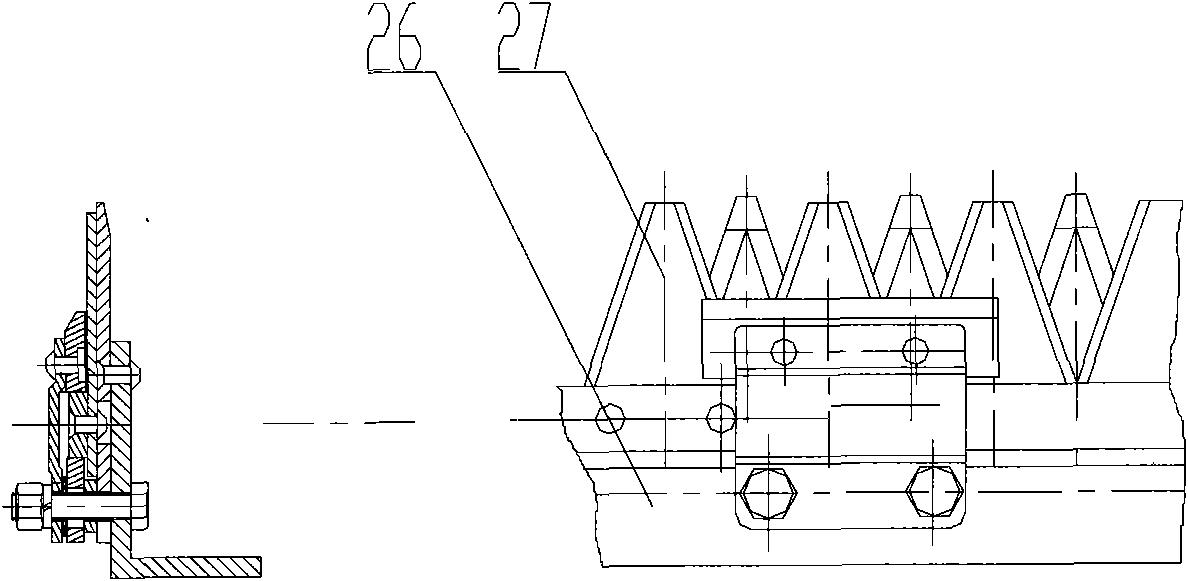

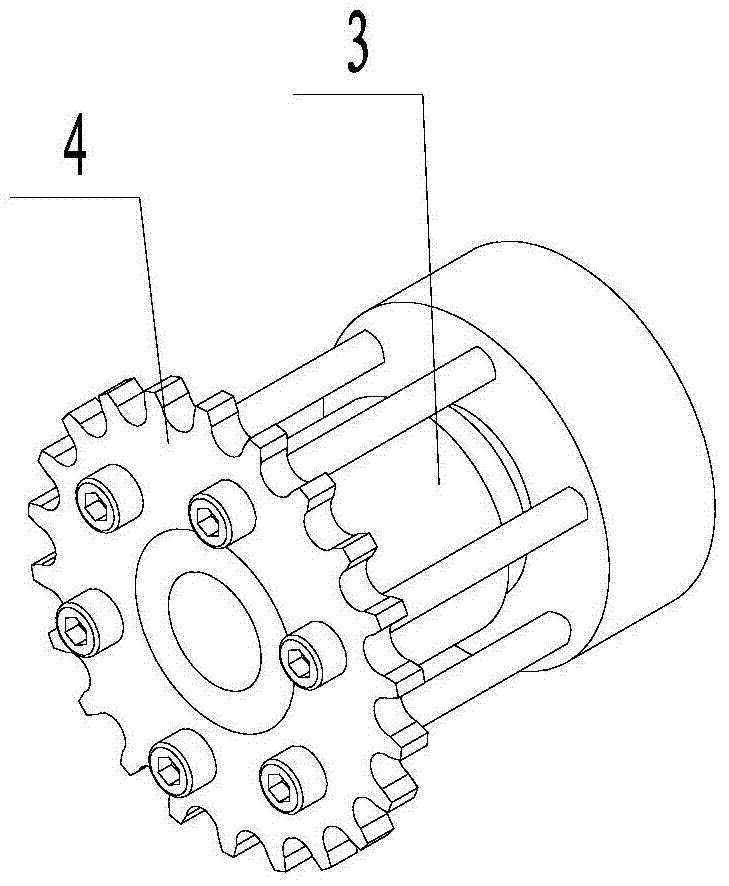

Straw baler matched with wheel type harvester

The invention discloses a straw baler matched with a wheel type harvester. The defects that an existing combined harvester is high in cost, prone to being entangled with straw and high in fault rate are overcome. The straw baler comprises the harvester and a baler body arranged on the harvester, a roller shaft is arranged on the harvester, and the roller shaft is connected with a drive chain wheel through a plurality of fastening screws. The baler body comprises a baling box, a speed reducer, a transmission mechanism, a straw conveying box, a straw shifting device, a longitudinal straw pressing device and a twine knotter, the baling box is arranged by inclining upwards from front to back, a material inlet is formed in the position, close to the front portion, of the upper end of the baling box, a material outlet is formed in the rear end of the baling box, a piston is arranged in the baling box, a push rod is movably connected with the front end of the piston, front movable cutters are connected with the edge, close to the rear portion, of the upper end of the piston, fixed cutters correspondingly matched with the front movable cutters are connected with the rear edge of the material inlet in the baling box, blades of the front movable cutters are of a linear structure, and blades of the fixed cutters are of a sawtooth-shaped structure.

Owner:陈孝中 +1

Collecting and bundling device of cane harvesting machine

InactiveCN106818032AImprove harvesting efficiencyNo need for manual bundlingMowersReaper-bindersEngineeringKnot tying

The invention relates to a collecting and bundling device of a cane harvesting machine. The collecting and bundling device comprises a collecting mechanism and a bundling mechanism. The collecting mechanism comprises a collecting frame, a supporting frame, baffles and two side plates; the bundling mechanism comprises a pressing plate, supporting claws, threading needles and knot tying devices. The collecting and bundling device is used in the cane harvesting process, and canes can be collected and bundled; after the canes are completely harvested, farmers can directly load the canes to vehicles to be carried away, manual bundling is not required, the cane harvesting efficiency is improved, and the labor cost is reduced.

Owner:广东金庄液压设备有限公司

Corn straw crushing device

The invention relates to a corn straw crushing device and belongs to the technical field of crop processors for agricultural harvesting. The crushing device comprises a shell, wherein the shell is internally provided with a first rotary shaft, a driving shaft, a driven shaft, a second rotary shaft, a movable rubbing plate and a fixed rubbing plate; the first rotary shaft, the driving shaft, the driven shaft and the second rotary shaft are arranged in a manner of being parallel to each other; the movable rubbing plate and the fixed rubbing plate are arranged relatively up and down; the first rotary shaft and the second rotary shaft are located at the inlet and the outlet of the crushing device respectively; the driving shaft and the driven shaft are located between the first rotary shaft and the second rotary shaft; a longitudinal cutter is fixedly arranged on the first rotary shaft and a transverse cutter is fixedly arranged on the second rotary shaft; the movable rubbing plate is a conveyor-belt-shaped rubbing plate formed by mutually connecting plate-shaped rubbing plates; the front and rear ends of the movable rubbing plate sleeve the driving shaft and the driven shaft respectively; a straw rubbing channel is formed between the movable rubbing plate and the fixed rubbing plate. With the adoption of the crushing device, corn straws can be conveniently and rapidly crushed to specific sizes so that subsequent bundling and film packaging work can be conveniently carried out.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

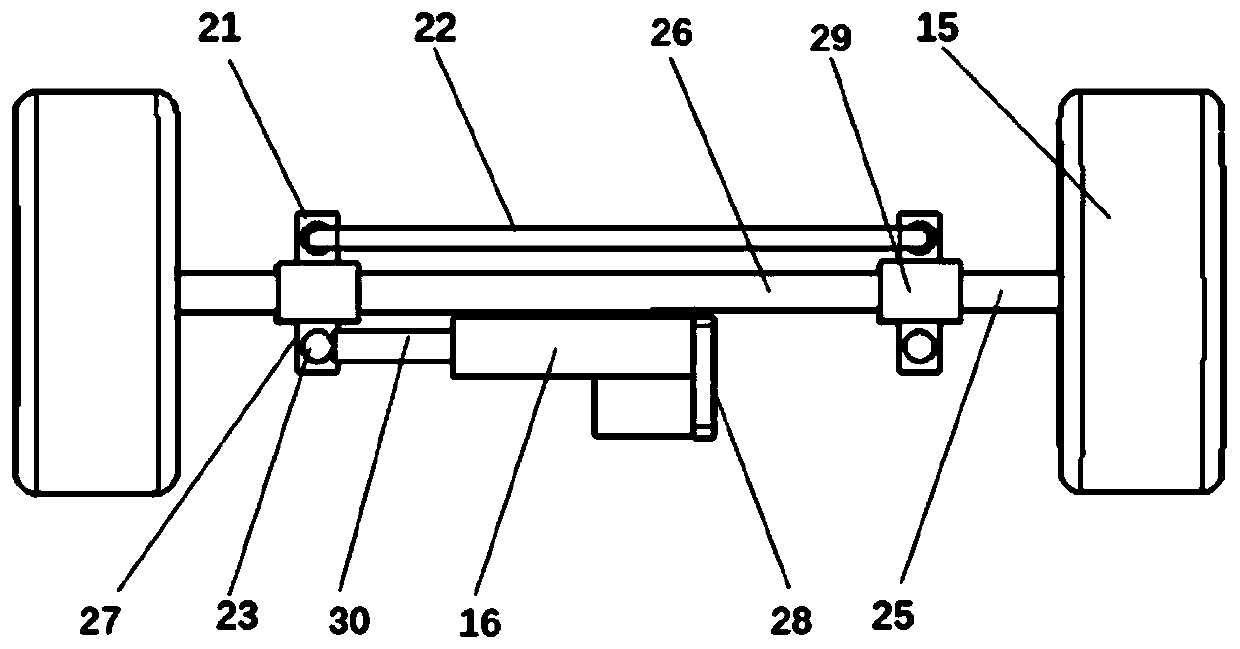

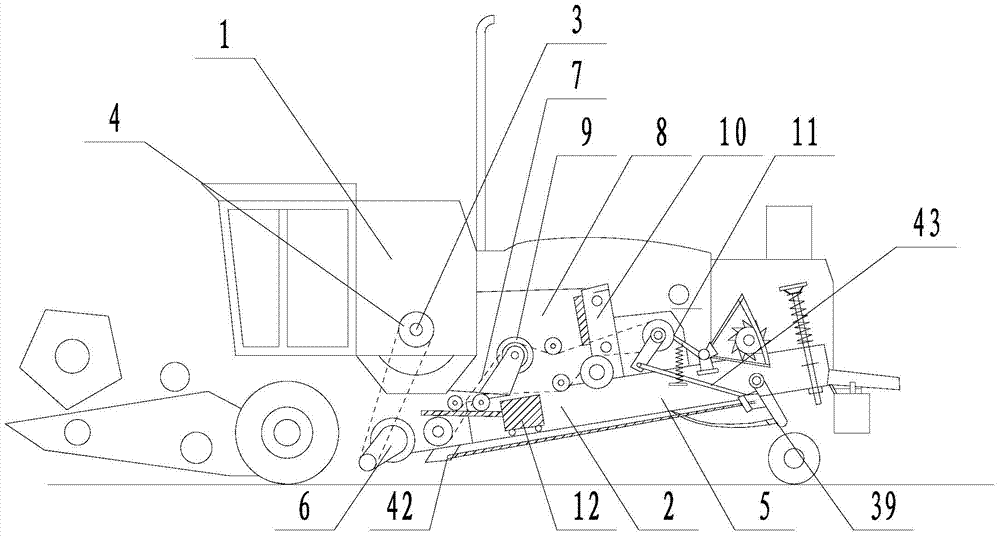

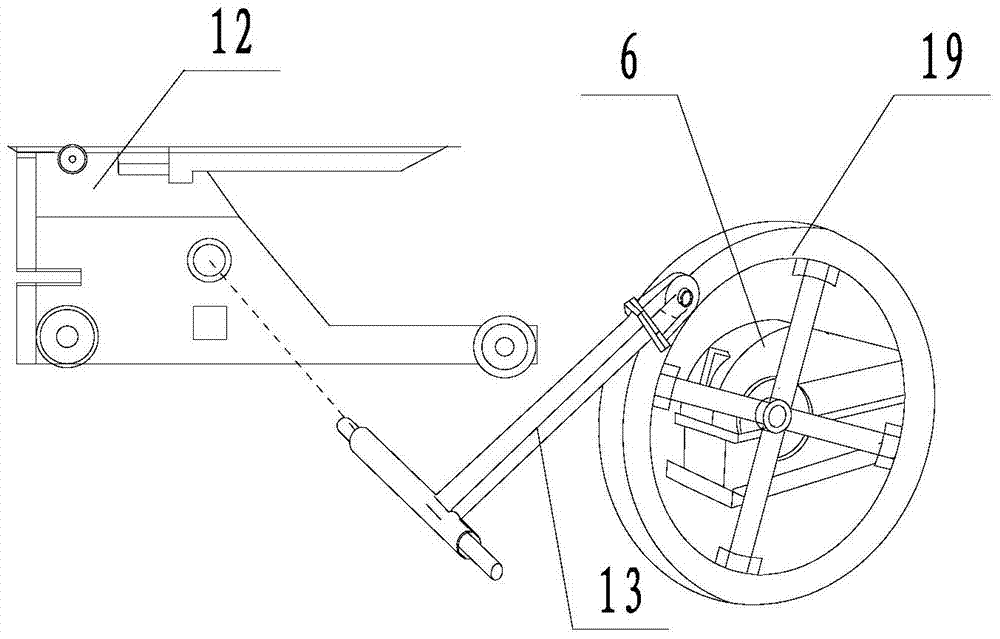

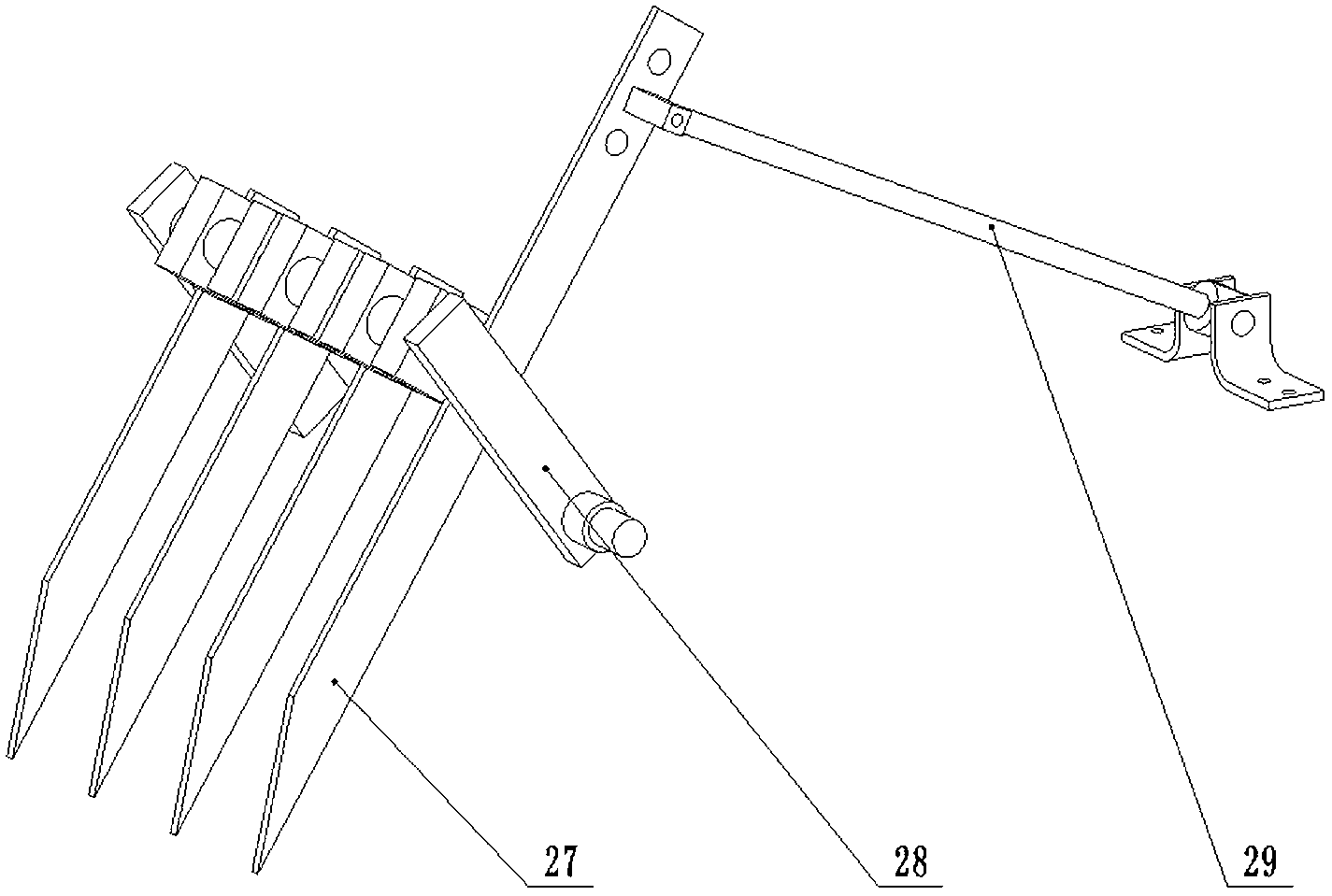

Self-walking wheel type picking and bundling device

The invention provides a self-walking wheel type picking and bundling device which comprises a combined harvester, a cutting table, a picking device and a roller conveying device, wherein the picking device comprises an elastic claw picker, a belt wheel and a picking rack; the elastic claw picker is fixedly arranged on the picking rack; a straight gear a is arranged on the side surface of the picking rack and is coaxial with the elastic claw picker; a straight gear b is positioned at the lower part of the straight gear and is meshed with the straight gear b; the belt wheel is coaxial with the straight gear a and is positioned at the outer side of the straight gear a; the belt wheel is in power connection with a middle stepless speed-variable output belt wheel by virtue of a belt; certain ends of a connecting rack a and a connecting b are respectively welded at two sides of the picking rack, and the other ends of the connecting rack a and the connecting b are respectively and fixedly connected with the cutting device; a connecting rod a and a connecting rod b are respectively positioned at the upper parts of the connecting rack a and the connecting rack b; one ends of the connecting rod a and the connecting rod b are fixedly connected with two sides of the picking rack, and the other ends of the connecting rod a and the connecting rod are respectively and fixedly connected with a side plate a of the cutting table and a side plate b of the cutting table. The self-walking wheel type picking and bundling device is capable of picking up and bundling straw materials scattered in a field, and cutting and harvesting higher-stubble crops.

Owner:JIANGSU UNIV

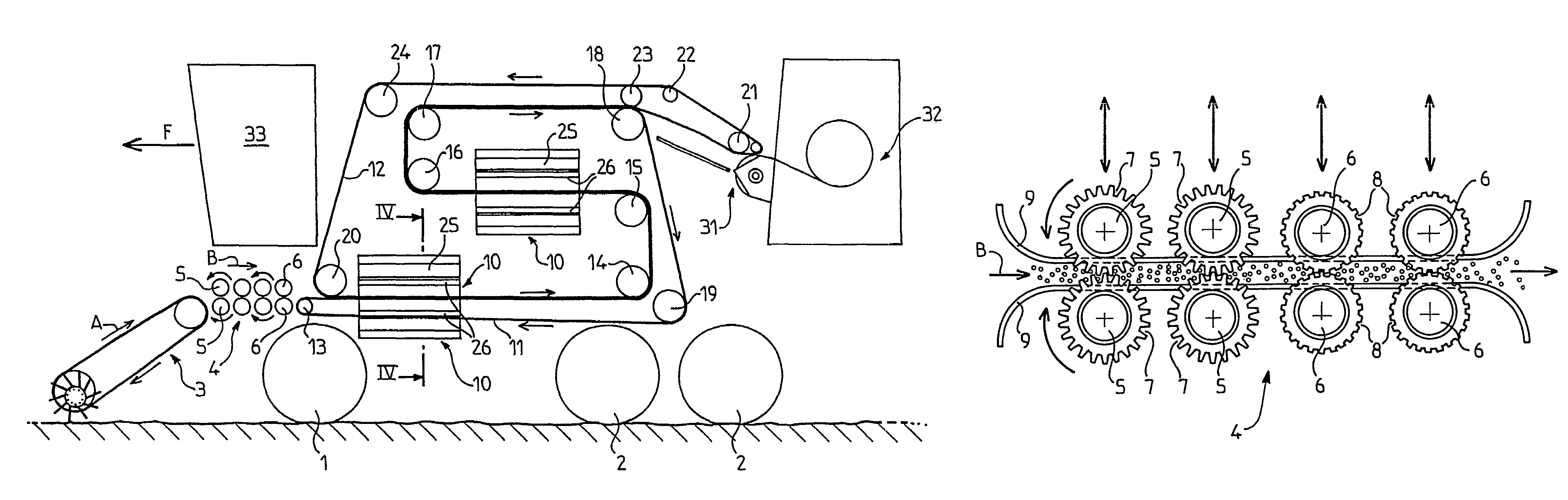

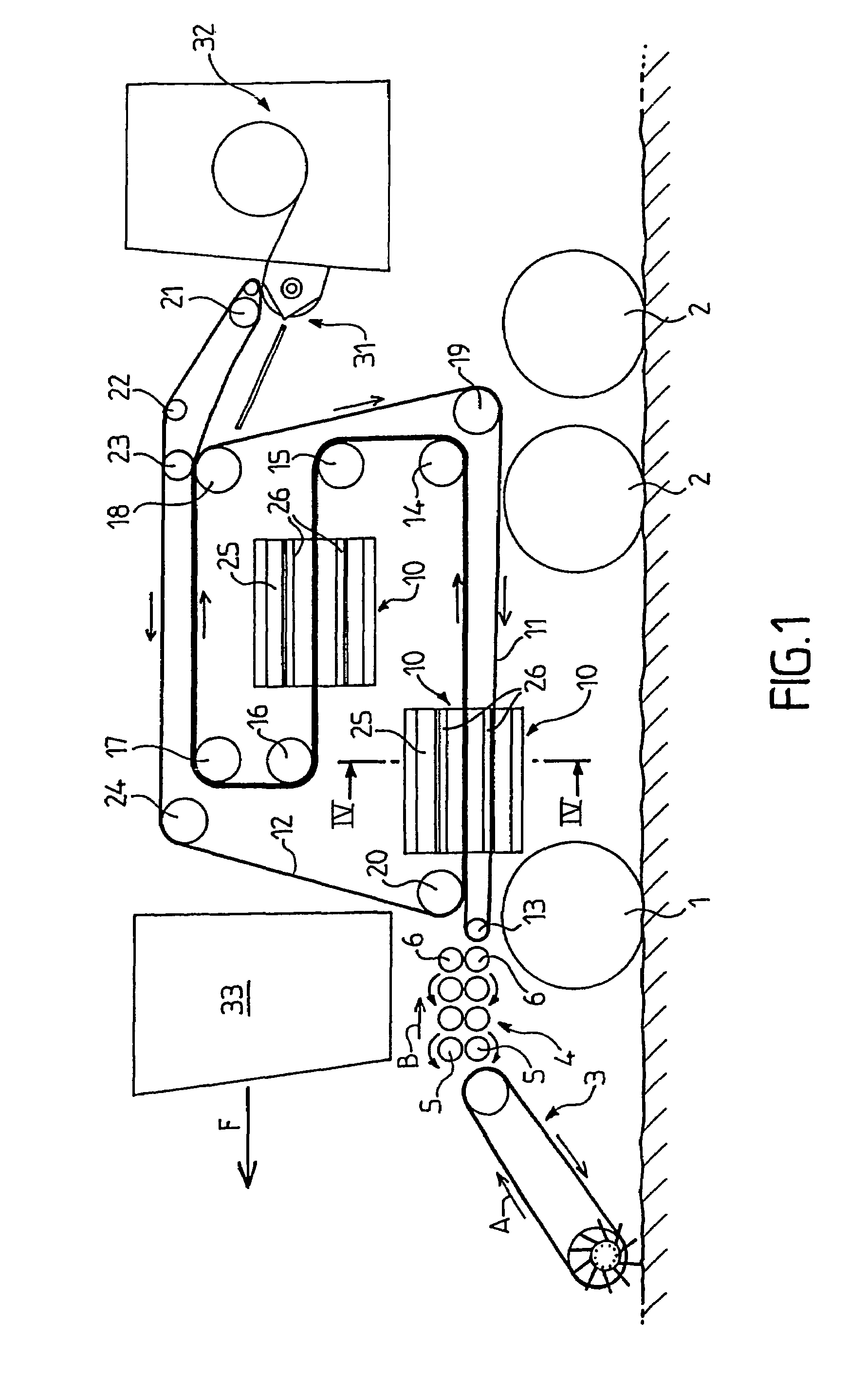

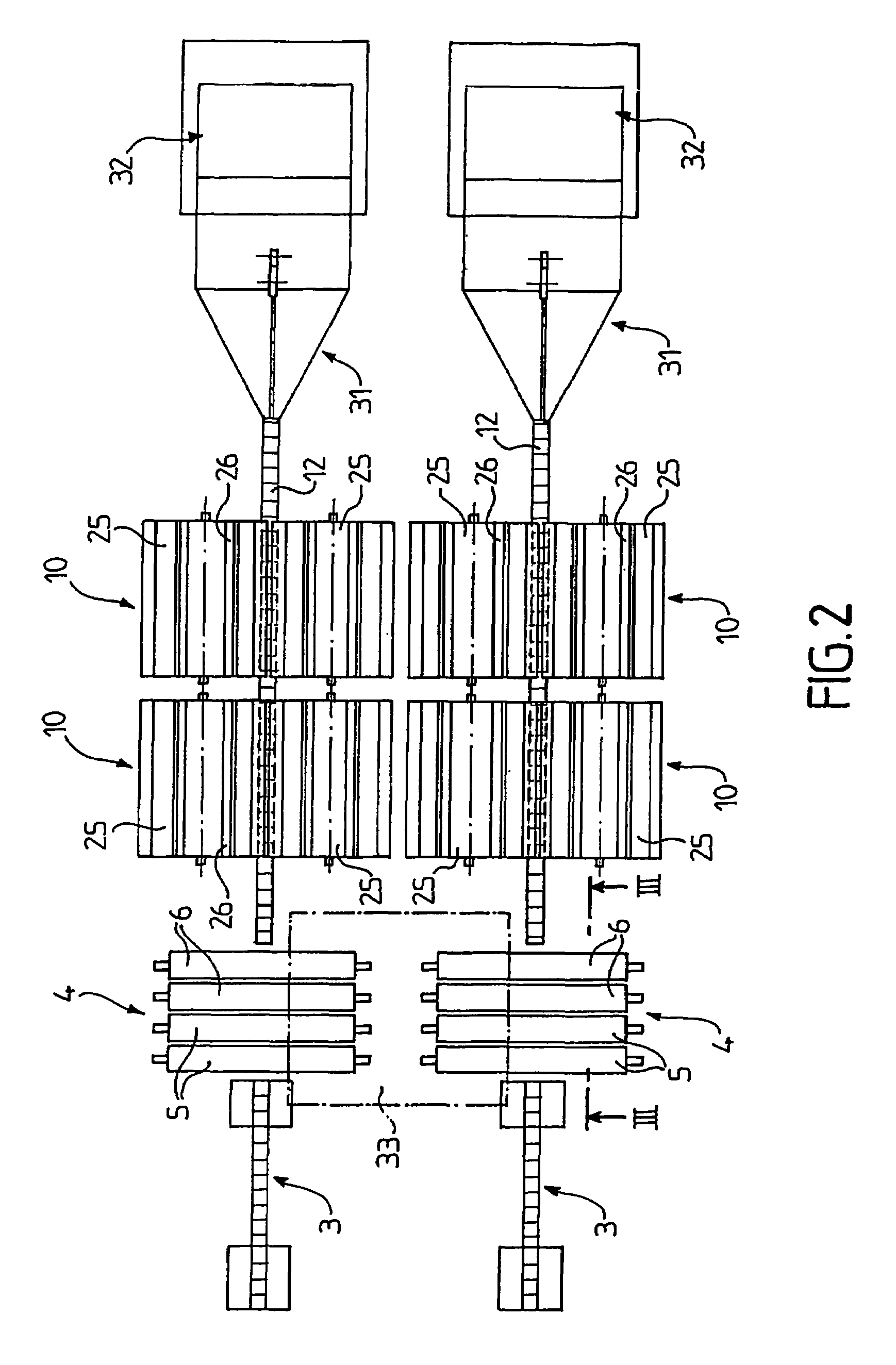

Method and machine for packing fibrous plants into balls especially common flax, hemp plant and sisal

InactiveUS7520214B2Combed more easily and more quicklyLess expensivelyMowersCuttersHemp plantPulp and paper industry

A method is provided for collecting at least partially retted plants and winding them into bales. The method is characterised in that the collected and wound plants are fibrous plants with previously cut tops and bottoms. A machine to perform the method has a gatherer (3) for collecting at least partially retted plants with previously cut tops and bottoms, a crusher (4) for grinding the stems of the plants without tops and bottoms to break the wood filaments therein, a decorticator (10) for scarifying the ground stems to release the wood filaments and shives, a unit (31) for laying flat the fibres scutched in this way, and a baler (32) for winding the same into bales.

Owner:DEHONDT GUY

Novel whole-rod-type sugarcane combine harvester and leaf peeling conveying device thereof

The invention discloses a novel whole-rod-type sugarcane combine harvester and a leaf peeling conveying device thereof. The novel whole-rod-type sugarcane combine harvester comprises a machine frame, a mechanical transmission part, a sugarcane supporting device, a knife disc device, the leaf peeling conveying device and a sugarcane collecting device. A gradually-opening type combined knife structure is used for chopping sugarcanes, a knife is arranged on a knife disc in a gradually-opening-line shape, along with rotating of the knife disc, the contact face of a blade and a sugarcane can be expanded gradually, the cutting face becomes larger and deeper and is expanded gradually, the blade is provided with teeth, so that common sugarcane chopping is changed into sugarcane cutting, sugarcane head breaking is lowered, in addition, a leaf jaw formed by a spiral spring rod or a rubber plate is arranged on a leaf peeling belt, compared with a common leaf removing device, efficiency is higher, and effect is better. The novel whole-rod-type sugarcane combine harvester can complete all the work in the whole process from sugarcane chopping to sugarcane collecting conveying, and the labor intensity of people is greatly lowered.

Owner:广西丰港农业科技发展有限责任公司

Bundling harvester for cotton firewood

The invention relates to a bundling harvester for cotton firewood. The bundling harvester comprises a rack, a cab, a stalk pulling device, a seedling pulling device, a chain harrow conveying device, an auger conveying device, cut-off devices, a feeding device and a bundling device. The bundling harvester is characterized in that the stalk pulling device is positioned at the most front end of the whole harvester, the seedling pulling device is located above the stalk pulling device, the chain harrow conveying device is arranged between the seedling pulling device and the auger conveying device, the cut-off devices are disposed on two sides of an auger outlet, the feeding device is arranged above the auger outlet, the bundling device is positioned on one side of the rack, a grid plate is arranged between the auger outlet and a bundling device inlet, and an engine is arranged behind the cab. Compared with the prior art, the bundling harvester is provided with functions of stalk pulling, conveying, cutting-off, bundling and the like, the cotton firewood can be pulled out, cut into sections and bundled in square shapes, storage and transportation of the cotton firewood are facilitated, and the utilization rate of the cotton firewood is improved.

Owner:SHANDONG UNIV OF TECH

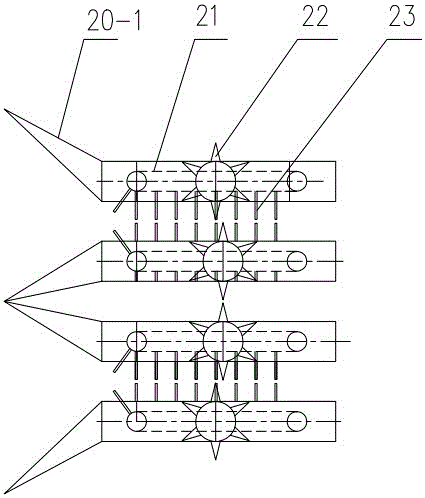

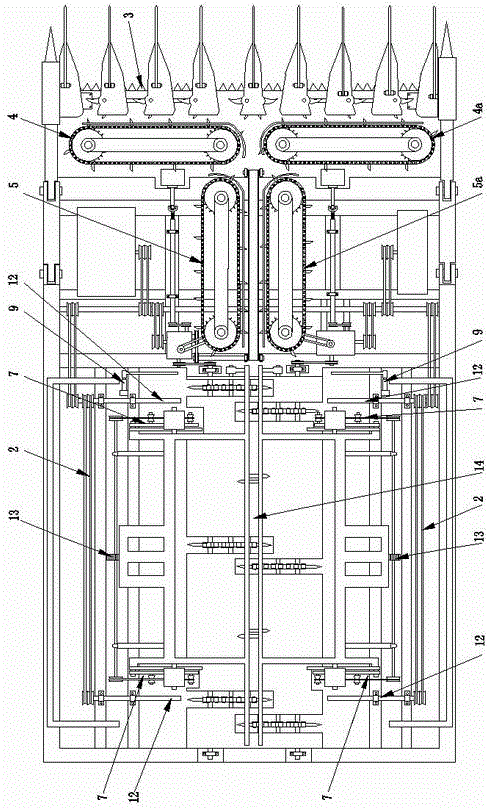

Reed/crop straw harvesting bundler

The invention discloses a reed / crop straw harvesting bundler, and belongs to the technical field of harvesters. The harvesting bundler mainly comprises a cutting knife mechanism, feeding mechanisms, distributing mechanisms, bundling mechanisms, rope conveying mechanisms, rope conveying gear mechanisms, aligning mechanisms, bundle conveying mechanisms and a lifting mechanism. The transverse feeding mechanisms, the longitudinal feeding mechanisms, the distributing mechanisms, the bundling mechanisms, the rope conveying mechanisms, the rope conveying gear mechanisms, the aligning mechanisms and the bundle conveying mechanisms are symmetric about the center of a travelling mechanism. After materials harvested by the harvesting bundler are conveyed to the distributing mechanisms by the feeding mechanisms, the left distributing mechanism and the right distributing mechanism alternately distribute the materials to the two bundling mechanisms, the materials are aligned by the aligning mechanisms and then bundled by the bundling mechanisms, the rope conveying mechanisms convey ropes, and the materials are manually fastened, conveyed out, loaded and carried away by the bundle conveying mechanisms. According to the harvesting bundler, harvesting is combined with bundling, harvesting operation is completed once, labor is saved, transportation is facilitated, production efficiency is improved, and production cost is reduced.

Owner:韩志玉 +1

Fully automated kenaf harvesting integrated machine

ActiveCN108064545AAchieve smashGuaranteed safe and reliable useMowersThreshersFiberComputer engineering

The invention relates to a fully automated kenaf harvesting integrated machine comprising a harvesting device, a second clamping and conveying device, a branch and leaf treatment device, a residue discharge device, a feeding device, a kenaf stem-fiber separation device, a collecting and bundling device, a smashing device and a transport vehicle. The harvesting device, the second clamping and conveying device, the branch and leaf treatment device, the residue discharge device, the feeding device, the kenaf stem-fiber separation device, the collecting and bundling device and the smashing deviceare arranged on the transport vehicle. The fully automated kenaf harvesting integrated machine completes kenaf harvesting, branch and leaf removal and kenaf stem-fiber separation, the kenaf stem-fiberseparation treatment is completed automatically in the whole process, kenaf stem-fibers are bundled after the kenaf stem-fiber separation, the treatment efficiency is high, the treatment automation can be achieved, follow-up processes are reduced, and the cost is reduced. Through the compact layout of the overall machine, operations by workers are facilitated, and the fully automated kenaf harvesting integrated machine is complete in function, saves labor and is environmentally friendly.

Owner:振林建设集团股份有限公司

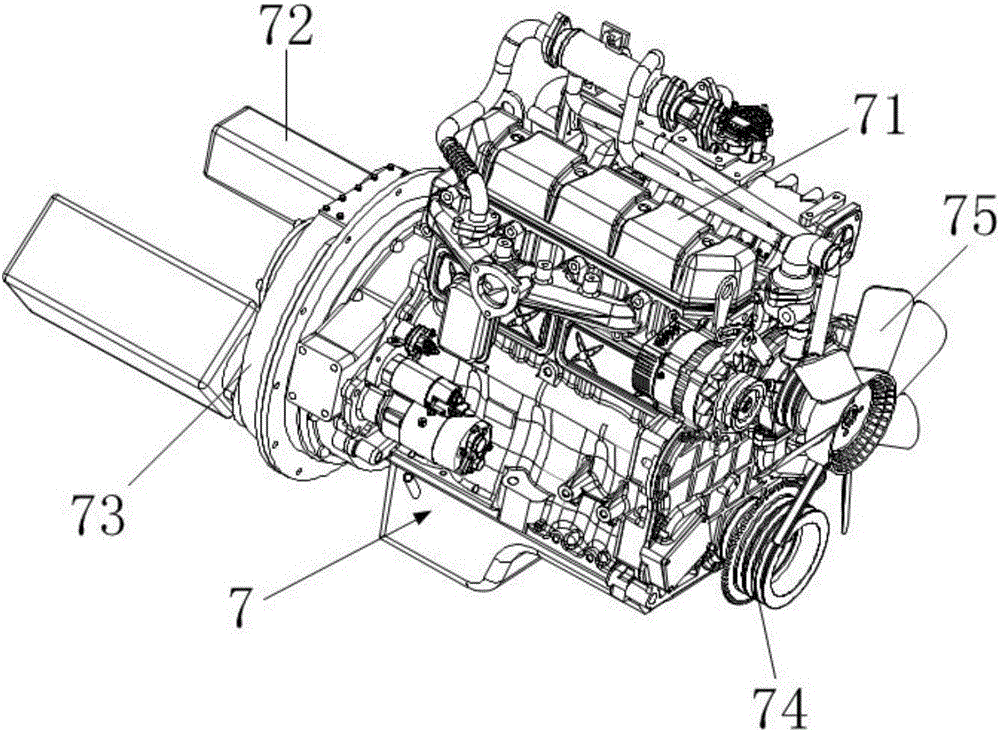

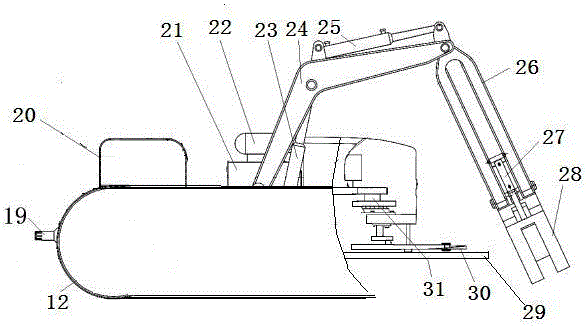

Corn straw harvester

InactiveCN106258182AAvoid safety hazardsReduce labor intensityMowersFluid steeringHydraulic motorAutomatic control

The invention discloses a corn straw harvester, and belongs to agricultural machines. The corn straw harvester comprises a rack, an engine, a crawler-type walking device, a mechanical arm and a hydraulic system, wherein the engine, the crawler-type walking device and the hydraulic system are all connected with the rack; the mechanical arm is mounted on a mechanical arm rotary device; the mechanical arm rotary device is mounted on the rack; the corn straw harvester is characterized in that a cutting device is further mounted on the rack; the cutting device is positioned at the front part of the rack; the cutting device comprises a hydraulic motor, a support ring and a shaft sleeve. By adopting the corn straw harvester, integral automatic control on cutting and bundling is achieved, the potential safety hazard of arm bruising is avoided, and the working intensity is alleviated.

Owner:CROP SCI RES INST SHANXI ACADEMY OF AGRI SCI

Cotton stalk cutting bundling machine

InactiveCN104429317AImprove general performanceQuick cutReaper-bindersAnimal ForagingTraction system

The invention discloses a cotton stalk cutting bundling machine. The cotton stalk cutting bundling machine comprises a feeding system, a traction system, a cutting system and a compressing and bundling system, arranged on a frame in sequence. Cotton stalks are cut through the rapid rotation motion of a lifting circular saw blade and the downward movement of a cutting device, lengths of the cut cotton stalks are uniform, subsequent compressing and bundling are convenient, the cotton stalk cutting bundling machine has high universality for other straws with different physical characters, particularly for soft woody materials, for example forage grass, the cutting speed is high, the cut effect is obvious, and compressing and bundling are convenient. The cotton stalk cutting bundling machine can be directly towed to the rear part of a cotton stalk harvesting machine, realizes large-area cotton stalk harvesting and bundling operation, is low in cost, is beneficial to the subsequent transportation of compressed and bundled cotton stalks, and further effectively enhances the utilization efficiency of cotton stalks in other industries.

Owner:HUNAN AGRICULTURAL UNIV

Maize harvester capable of bundling stalks continuously

A maize harvester capable of bundling stalks continuously belongs to the technical field of machinery manufacturing. The harvester is formed by a harvester body, a plant pulling device, a cutting saw, a clamping chain and a bundling machine. A stalk pulling extruding roller group and a section cutting knife roller group are installed on the harvester body between the tail end of the clamping chain and the bundling machine. A section cutting knife roller group is formed by two roller columns perpendicular to a harvester body chassis, and blades are arranged on the roller columns and fixed on the roller columns axially and are in a radial shape seen from the top. The section cutting knife roller group is arranged on the back portion of the stalk pulling extruding roller group. When the harvester works, the two roller columns of the section cutting roller group rotate inwards oppositely, the cut-off stalks are delivered to the position of the stalk pulling extruding roller group through the clamping chain and pulled in quickly by the stalk pulling extruding roller group, and the stalks delivered by the stalk pulling extruding roller group are cut into a plurality of small sections mutually connected through the section cutting roller group and delivered into the bundling machine to be bundled. Due to the fact that the stalks are cut into the small sections mutually connected by the section cutting roller group and mixed into an intersection state in the delivery process, stalk loss and bundle loose do not happen after the stalks are bundled, multi-time transportation and long-distance transportation storage are facilitated, and the problem of stalk loss and bundling loosening and happening after the stalks are smashed is solved.

Owner:杨野

Dual cutting bench mechanism for harvester

The invention discloses a dual cutting bench mechanism for a harvester. The dual cutting bench mechanism comprises a harvester rack, wherein the rack is provided with a threshing mechanism and a straw binding mechanism and comprises a front conveying channel and a rear conveying channel; the front conveying channel and the rear conveying channel are internally and rotatably provided with conveying mechanisms respectively; the output ports of the front and rear conveying channels are respectively communicated with a threshing screening mechanism and the straw binding mechanism; the input port of the front conveying channel is provided with a crop head cutting mechanism; the input port of the rear conveying channel is provided with a crop straw cutting mechanism; the height of a cutter in the crop head cutting mechanism is matched with that of a crop head, and the cutter in the crop straw cutting mechanism is tightly attached to the ground. The dual cutting bench mechanism is reasonable in structural design; the crop heads and crop straws are separately processed, so that cereal grains can be prevented from being mixed into the straws, grain losses are avoided, and the use requirements of farmers are met.

Owner:管中林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com