Ensilage harvesting method and ensilage harvester without alfalfa falling to ground

A harvesting method and floor-standing technology, applied in the field of alfalfa non-floor silage harvesting method and harvester, can solve the problems of difficult harvesting of alfalfa and large silage loss, and achieve the effects of reducing machinery input costs, reducing operating procedures, and small packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

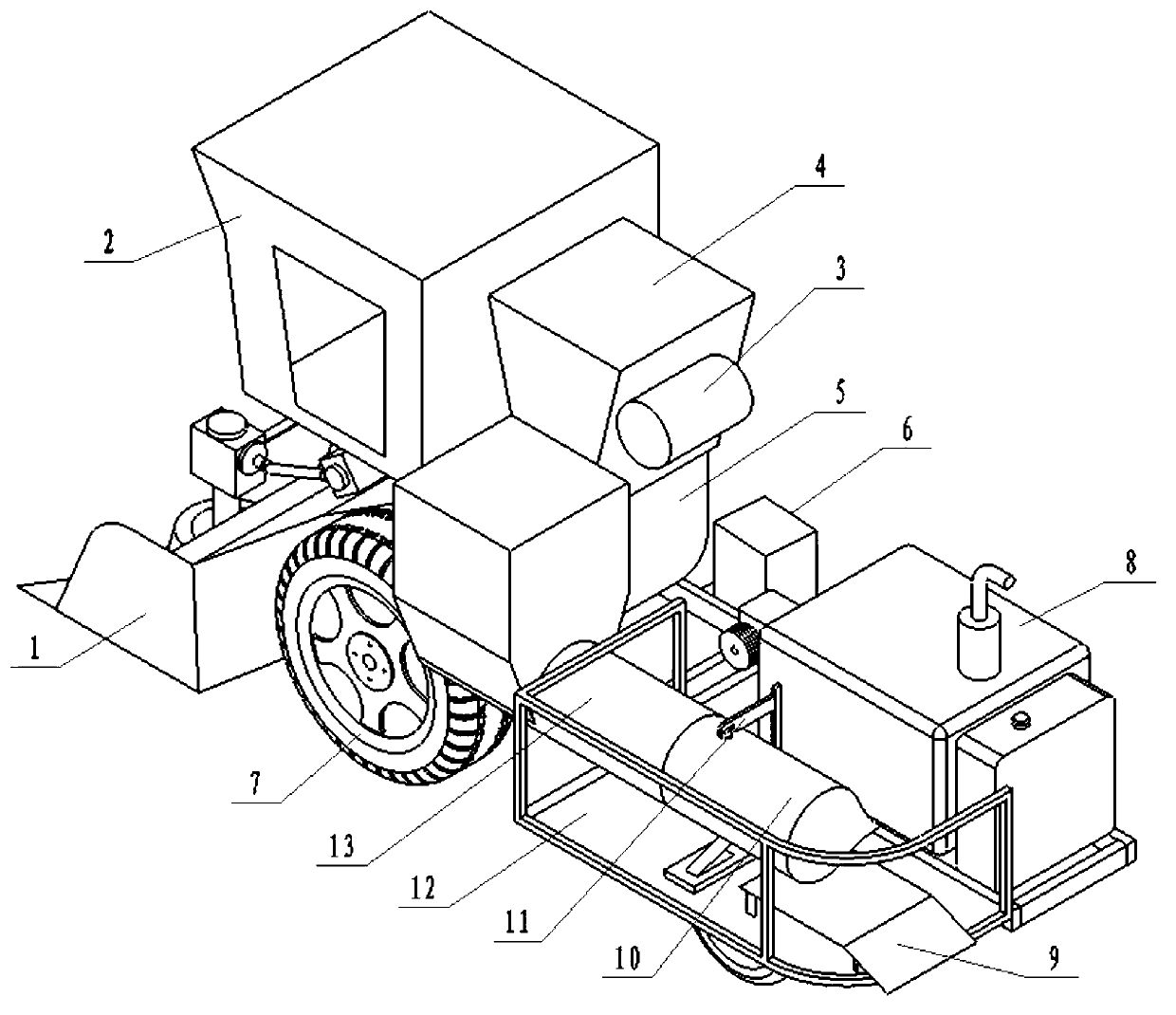

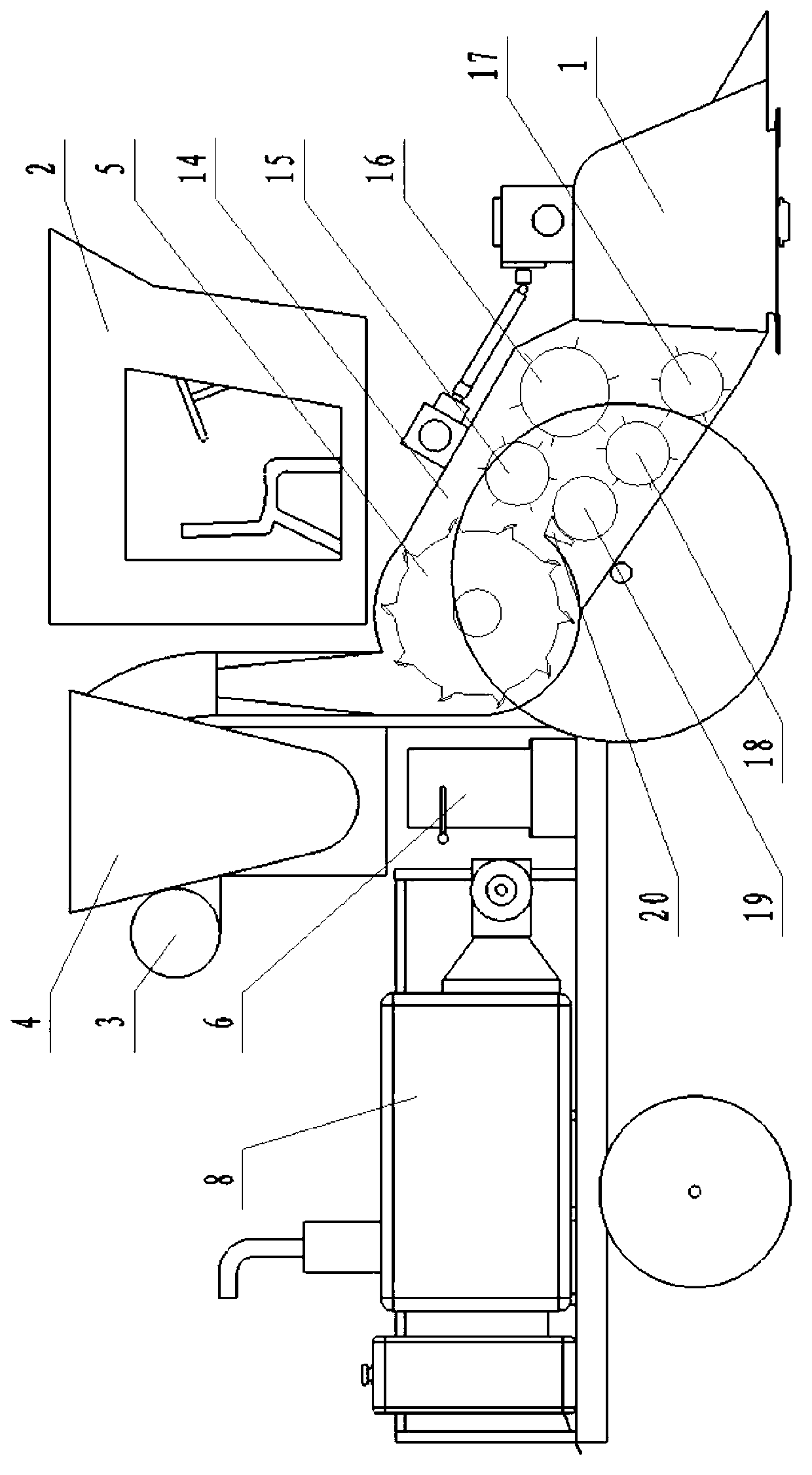

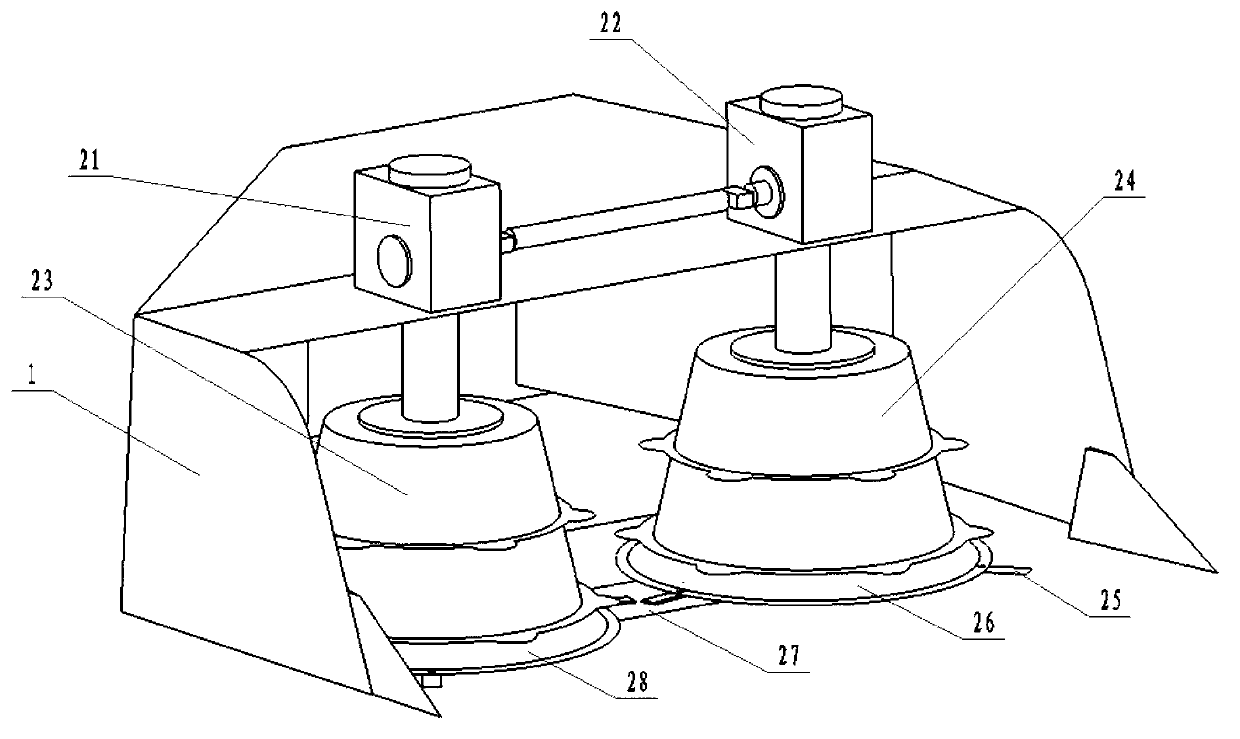

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] A kind of alfalfa non-ground type silage harvesting method is as follows:

[0033] Harvesting: Harvesting at the early flowering stage of alfalfa, when the alfalfa has high protein content and high water content;

[0034] Chopping: the harvested fresh alfalfa grass is cut directly without drying, and the fresh alfalfa grass is chopped into small pieces of 2~4cm;

[0035] Mixing: the chopped alfalfa material is added with silage additives and mixed evenly;

[0036] Compaction: the uniformly mixed alfalfa material is compacted, and the compaction density is greater than 500kg / m 3 , during the harvesting period of alfalfa, the leaves are fresh and tender, the pressure should be properly controlled, and the pressure should not form "pulp";

[0037] Bagging: the compacted alfalfa material is put into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com