Stalk chopping and pickup square baler

A technology of bundling mechanism and straw, which is applied in the direction of baler, harvester, digging harvester, etc., to achieve the effect of convenient adjustment of working height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

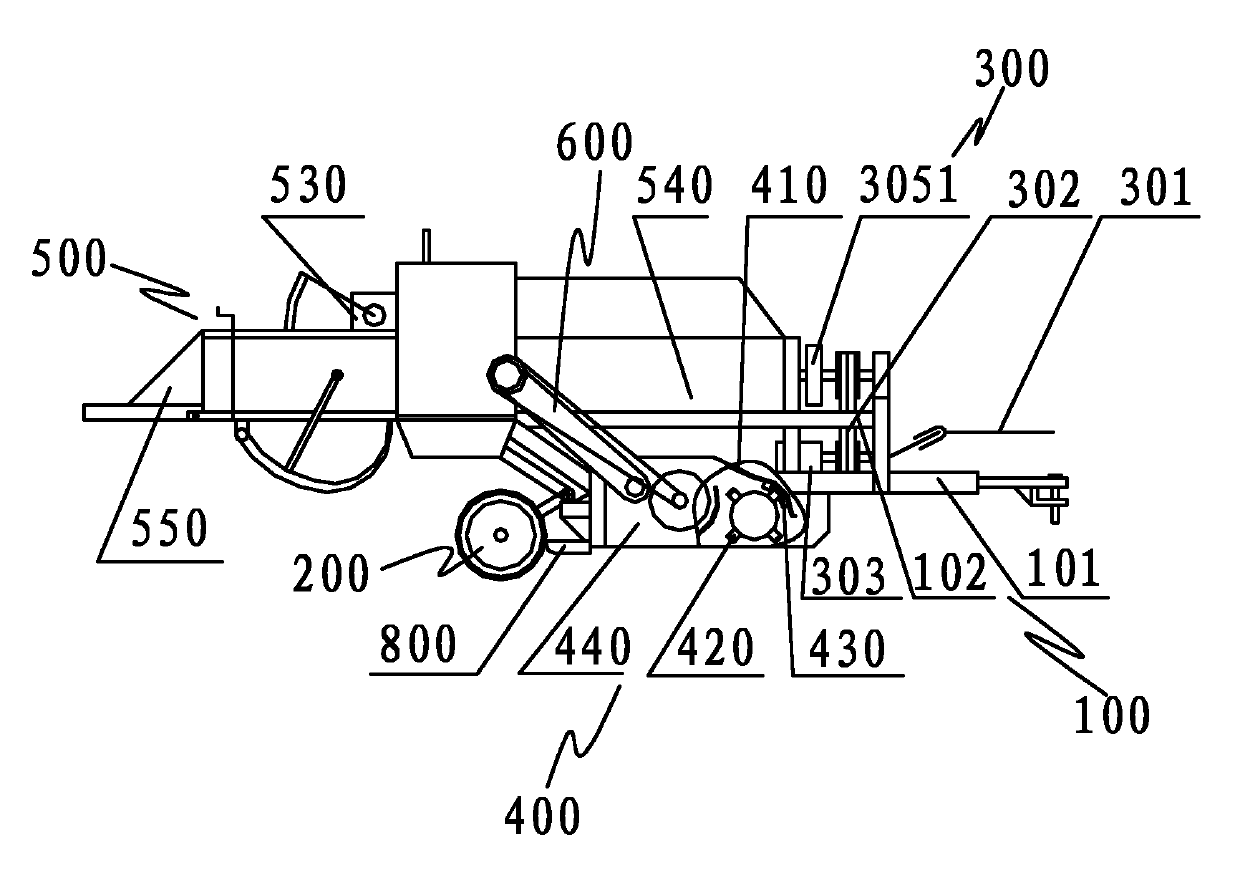

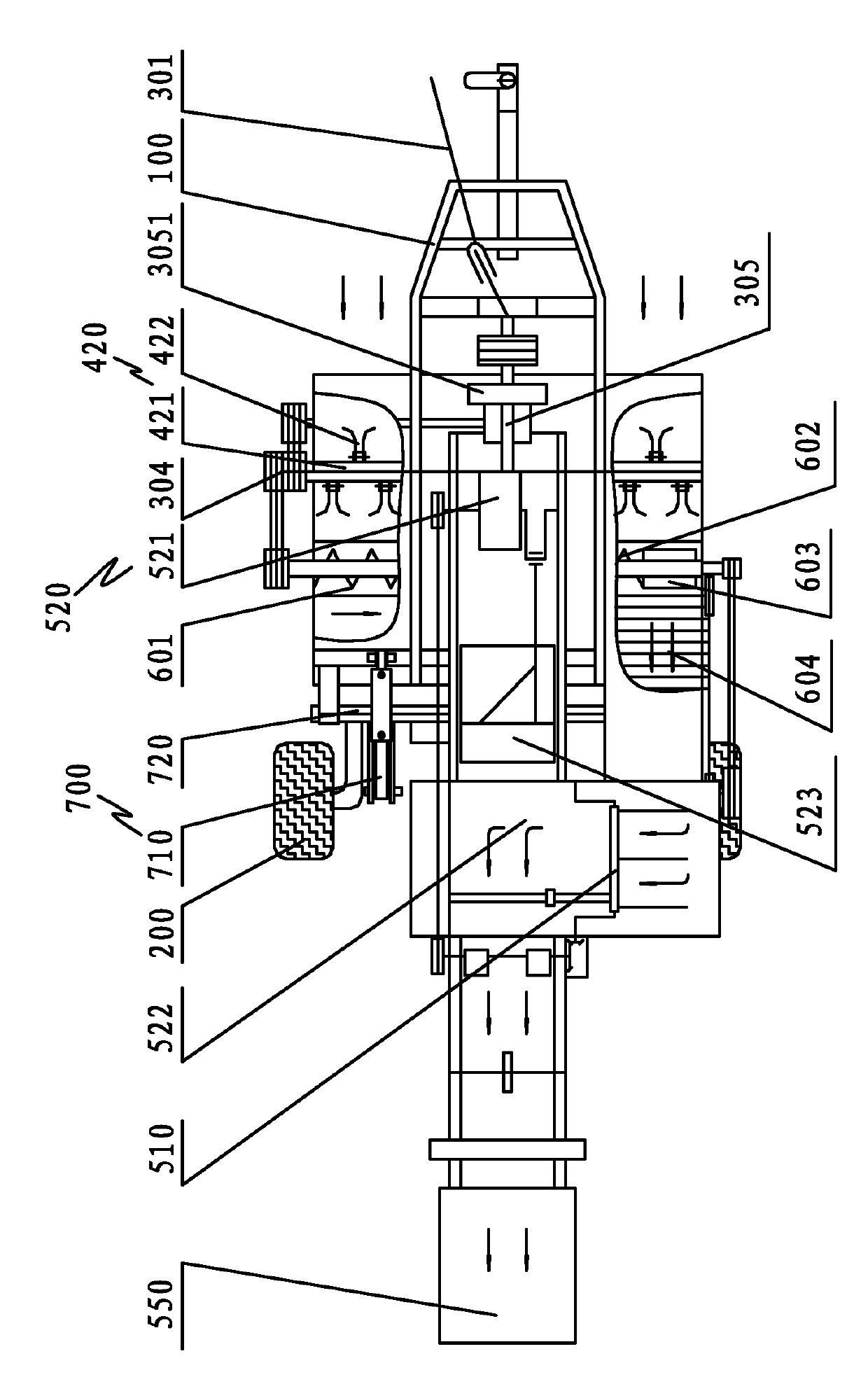

[0069] refer to figure 1 and figure 2 , as shown in the figure, the straw chopping, collecting and bundling machine of the present invention is used to be arranged directly behind the tractor, and includes a traction frame 100, a walking wheel 200, a power transmission mechanism 300, a cutting and crushing mechanism 400, and a collection and transmission mechanism 600 And compression bundling mechanism 500.

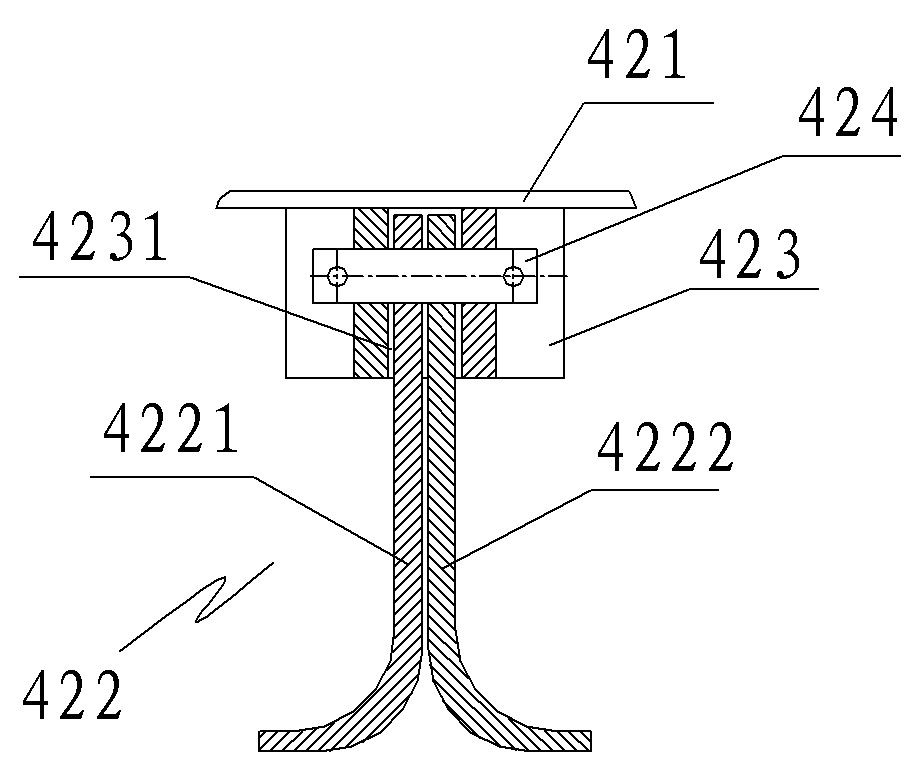

[0070] The draw frame 100 comprises a first draw frame part 101 and a second draw frame part 102, wherein the second draw frame part 102 is positioned above the first draw frame part 101, and the cutting and crushing mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com