Patents

Literature

1062results about How to "Crushed fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing neodymium iron boron through regenerating waste material containing neodymium, iron and boron

ActiveCN103866127AFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementMetallurgyEconomic benefits

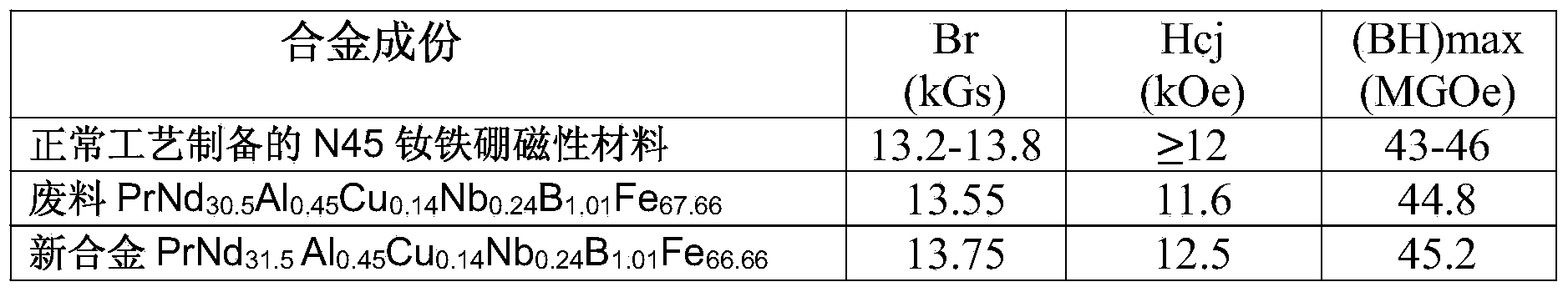

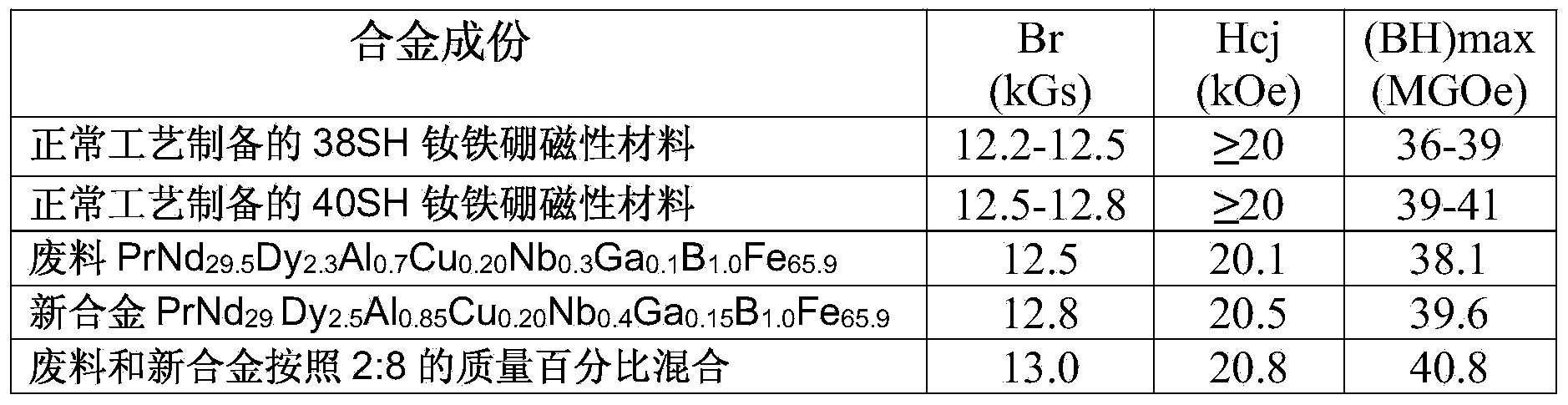

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

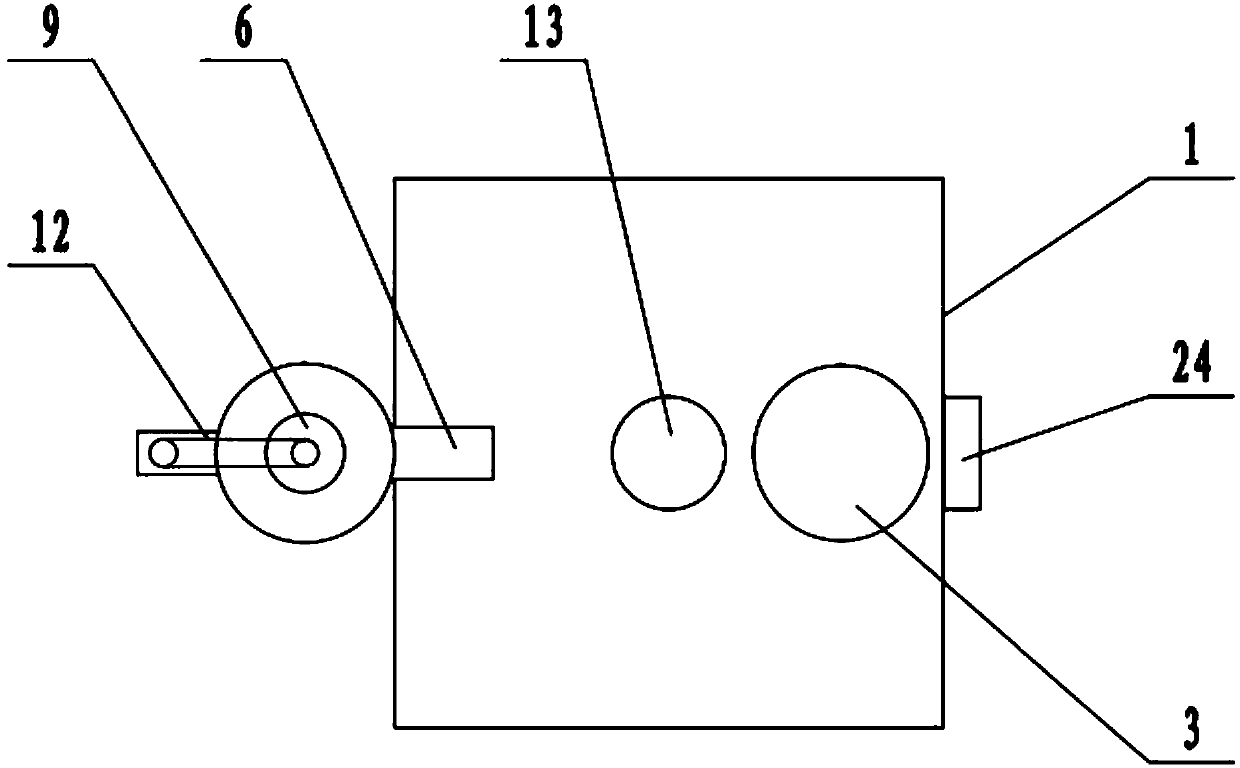

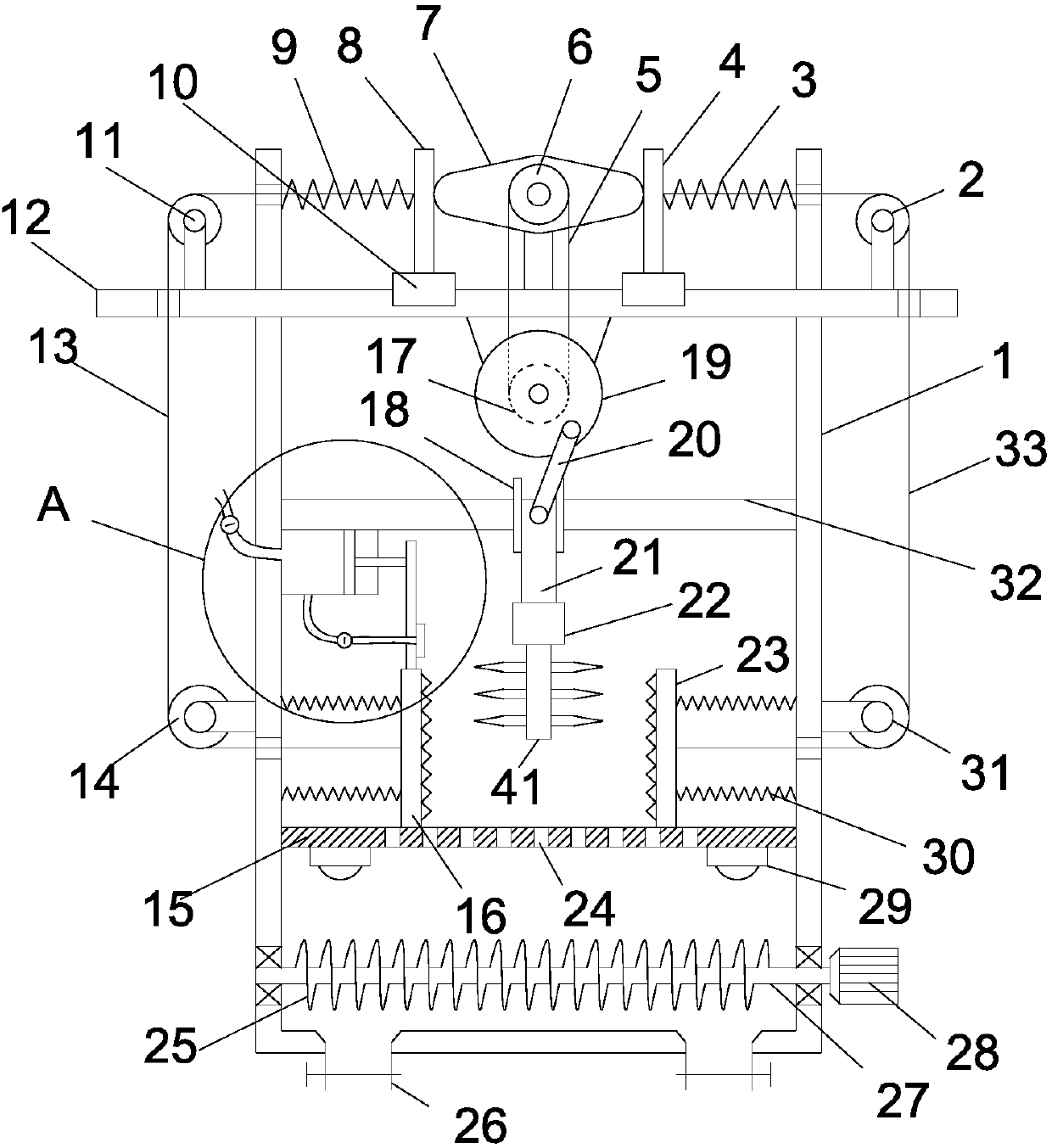

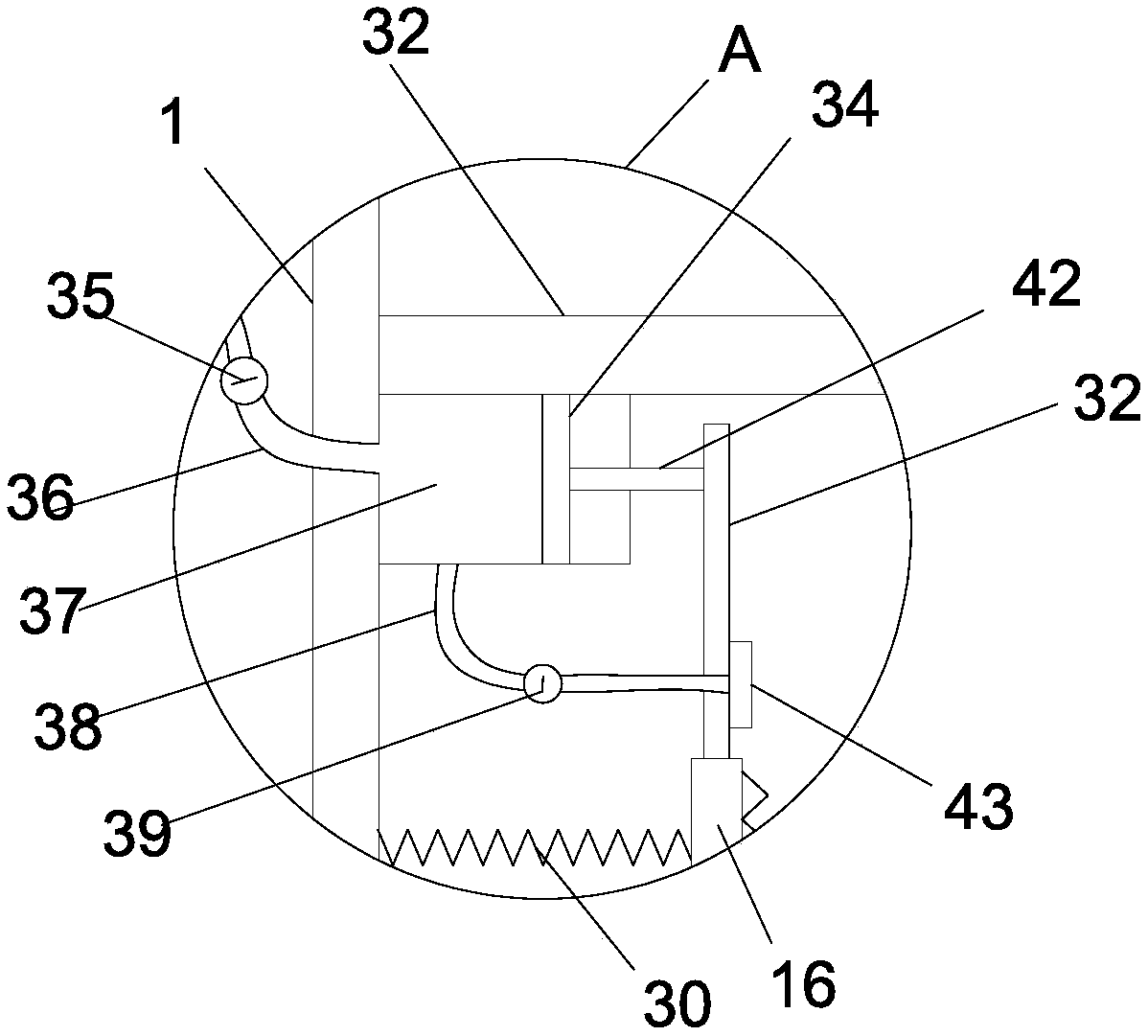

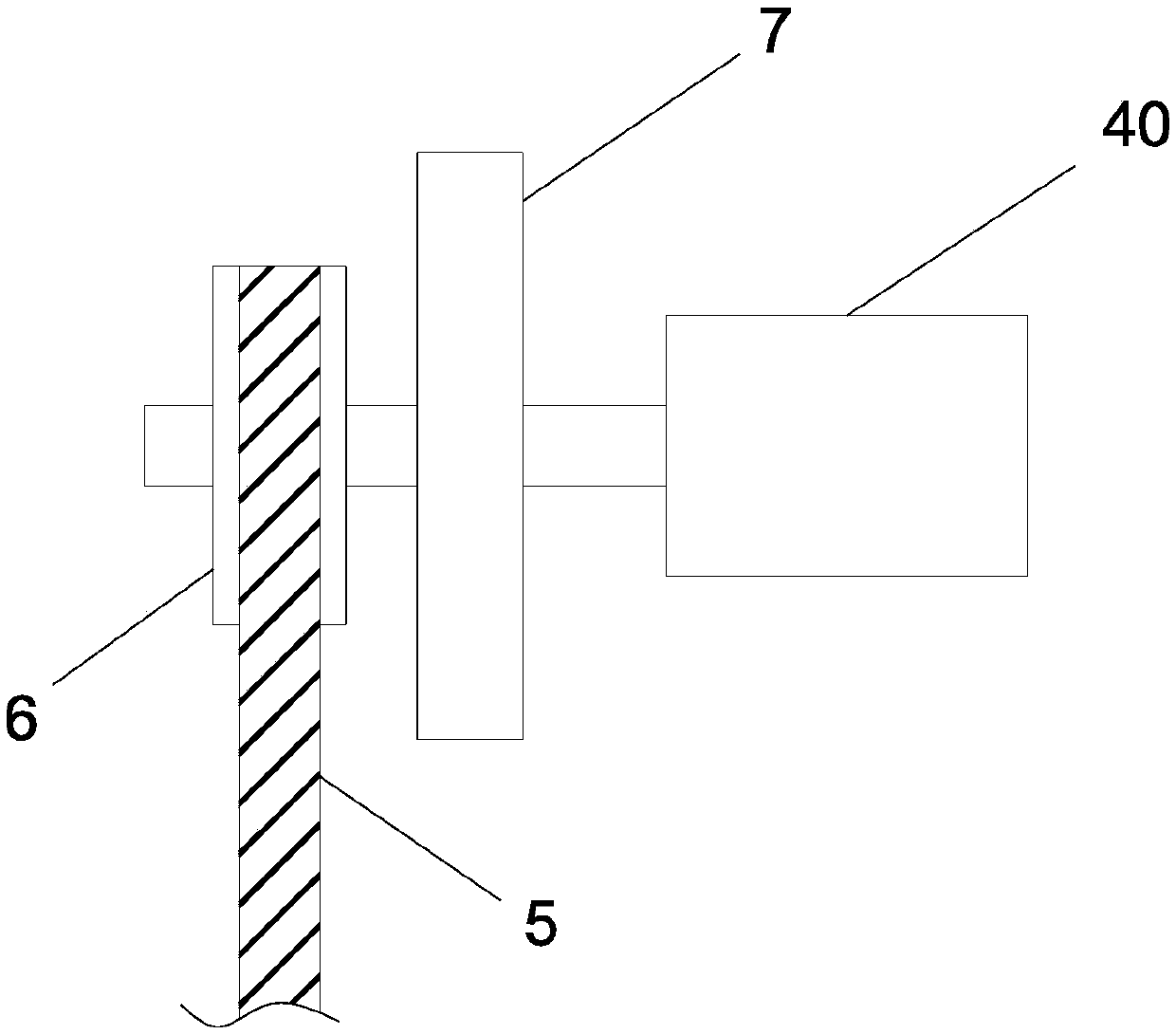

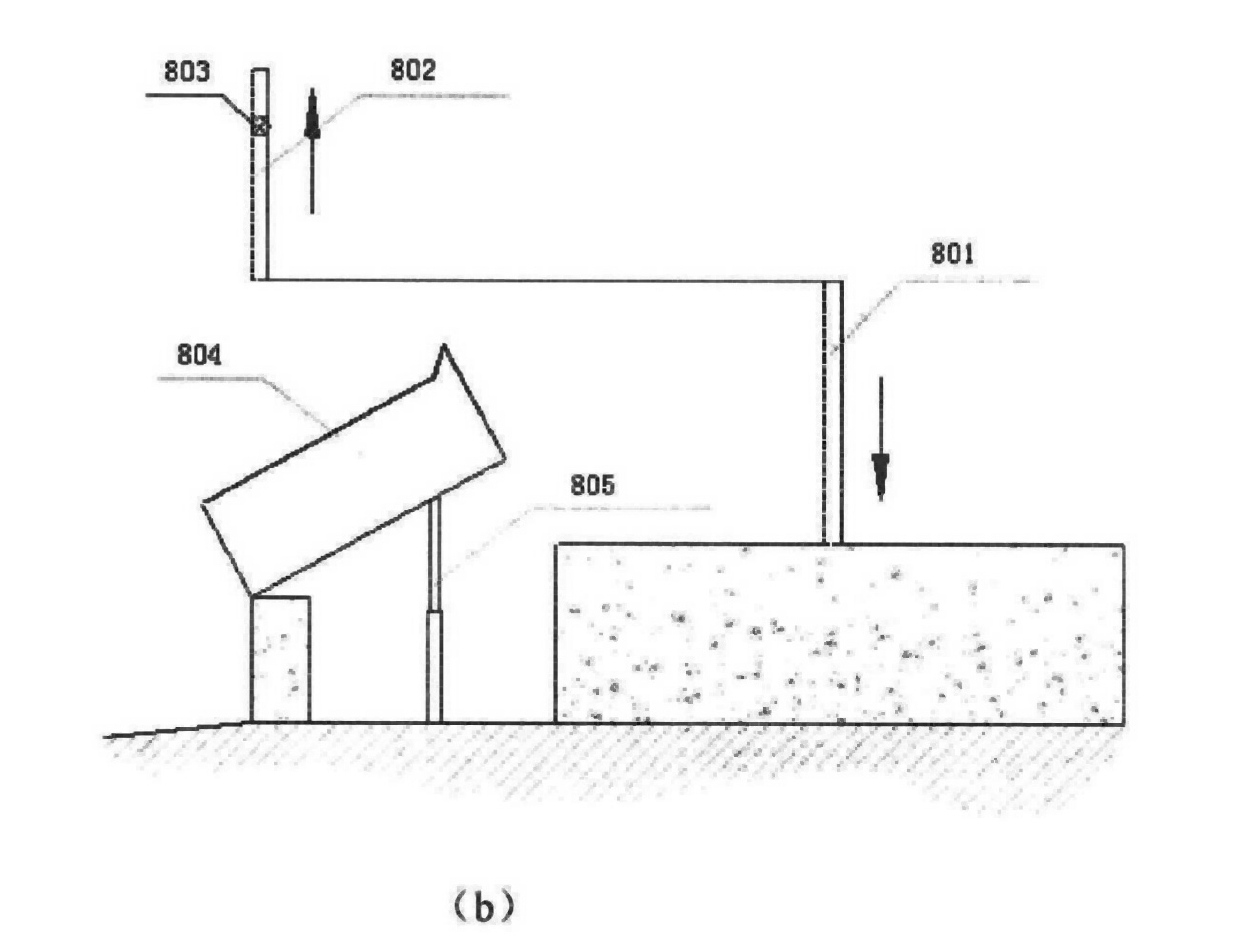

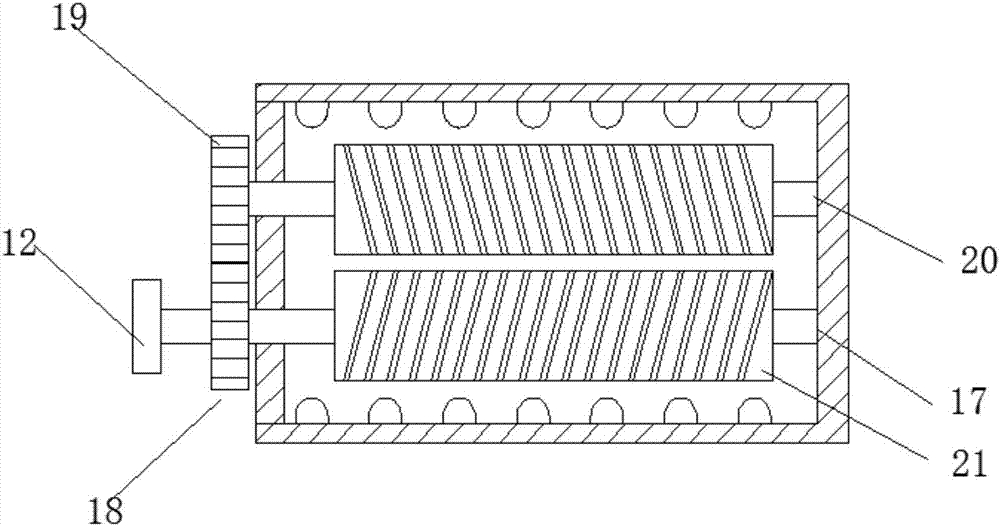

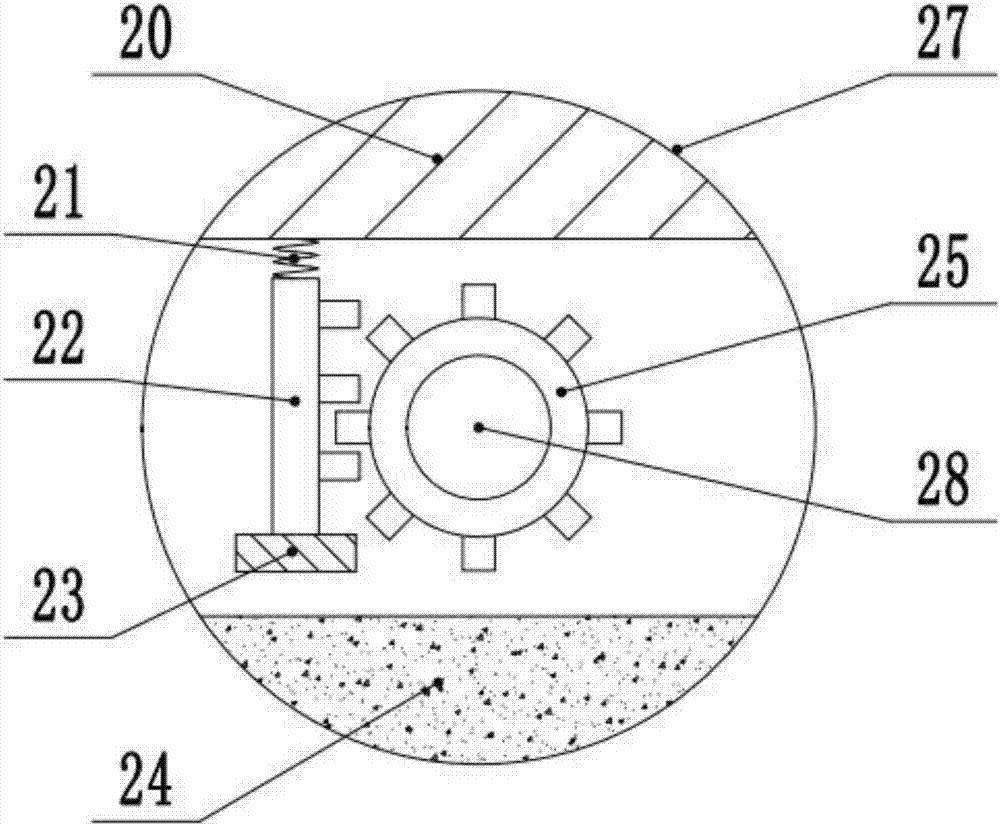

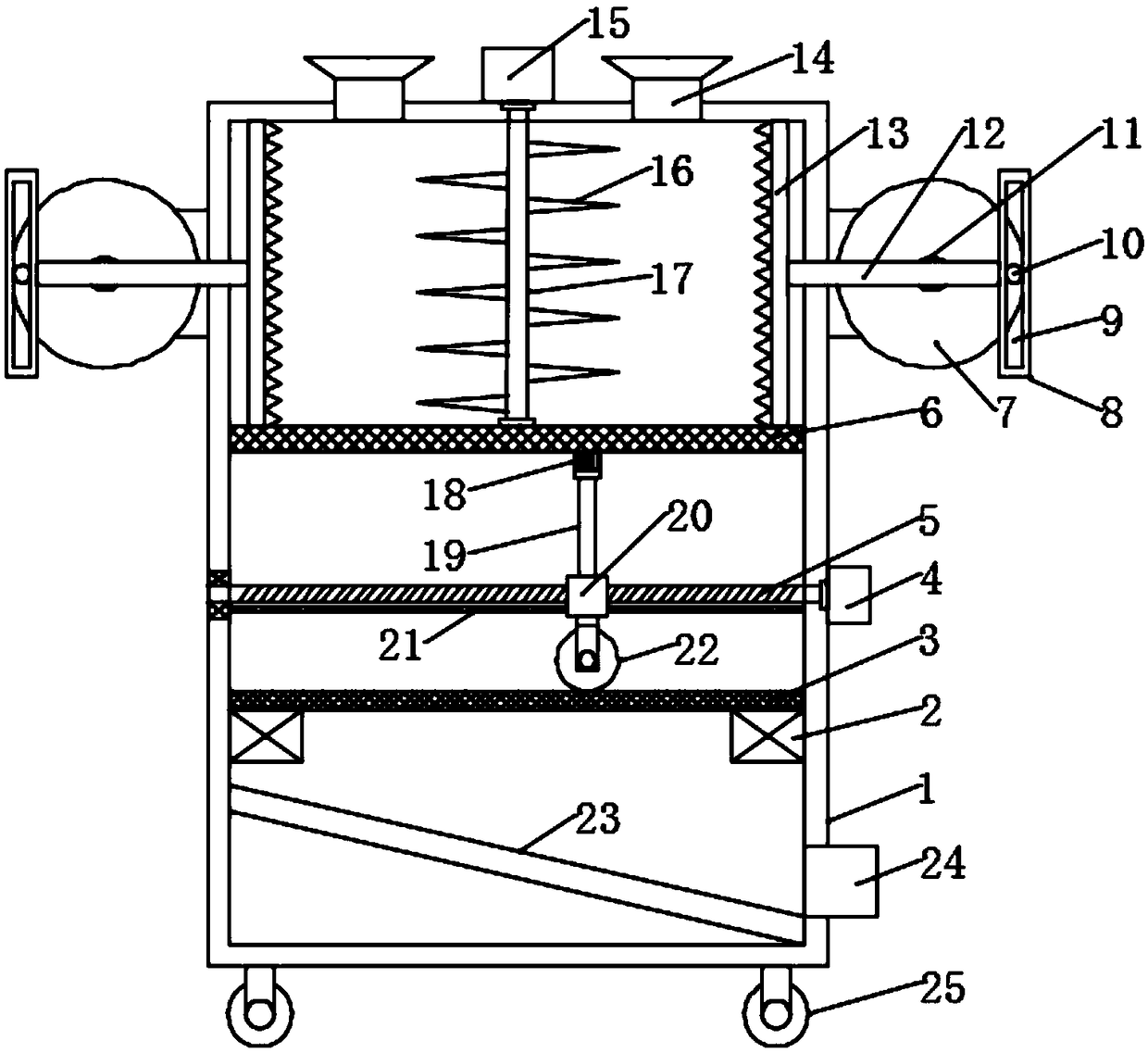

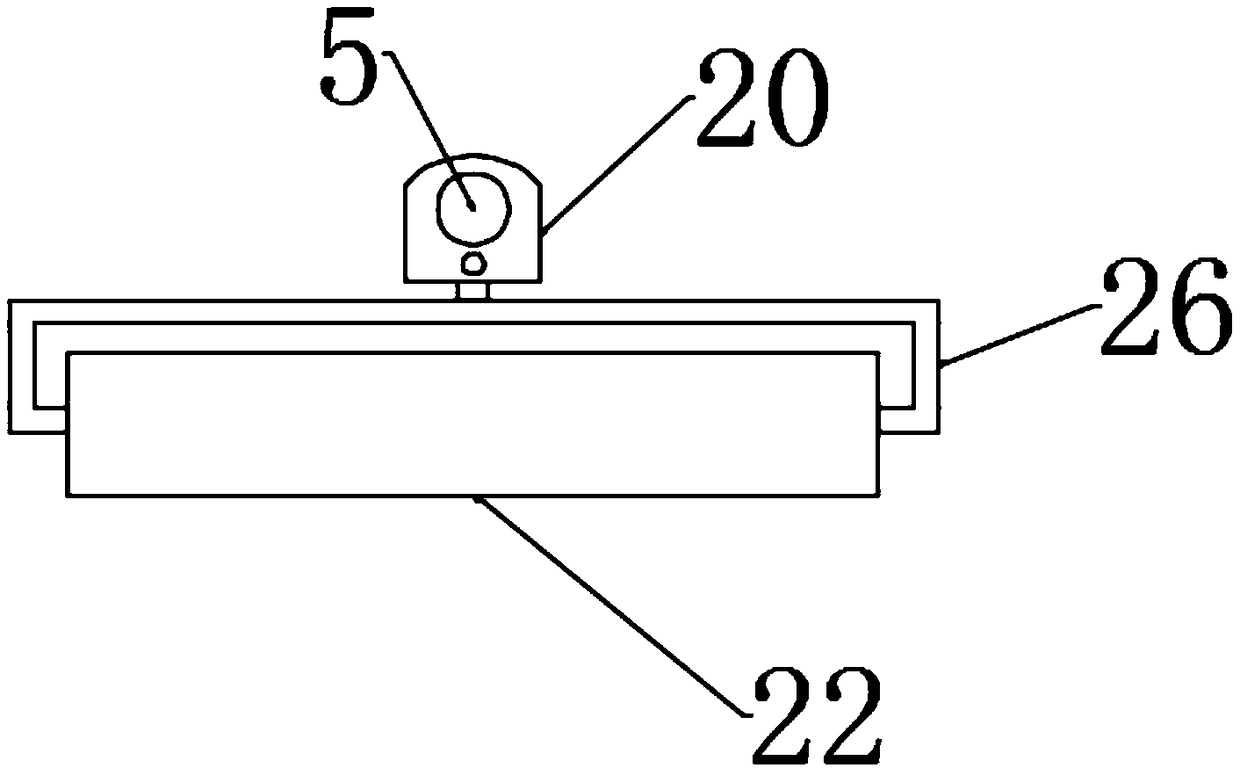

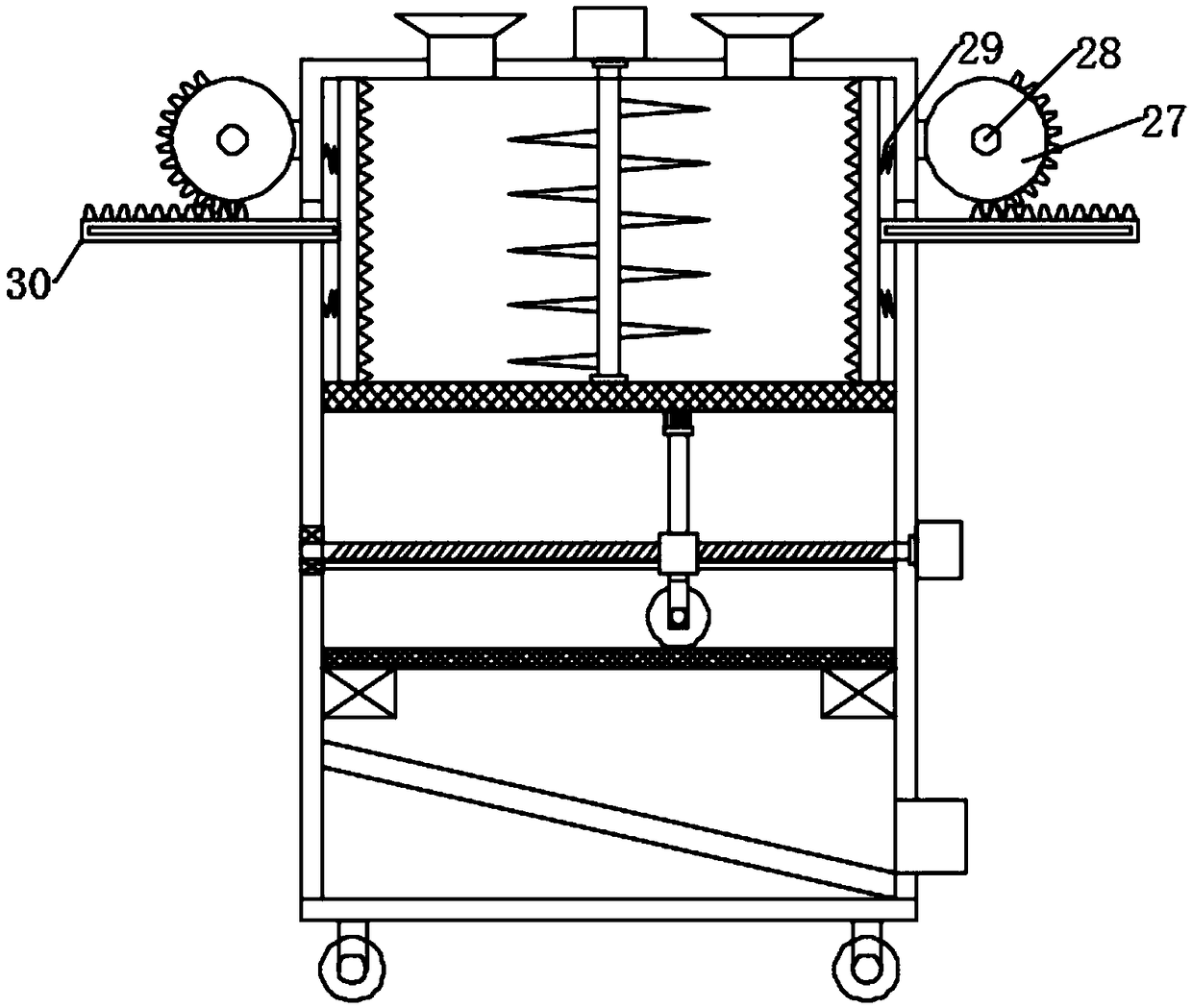

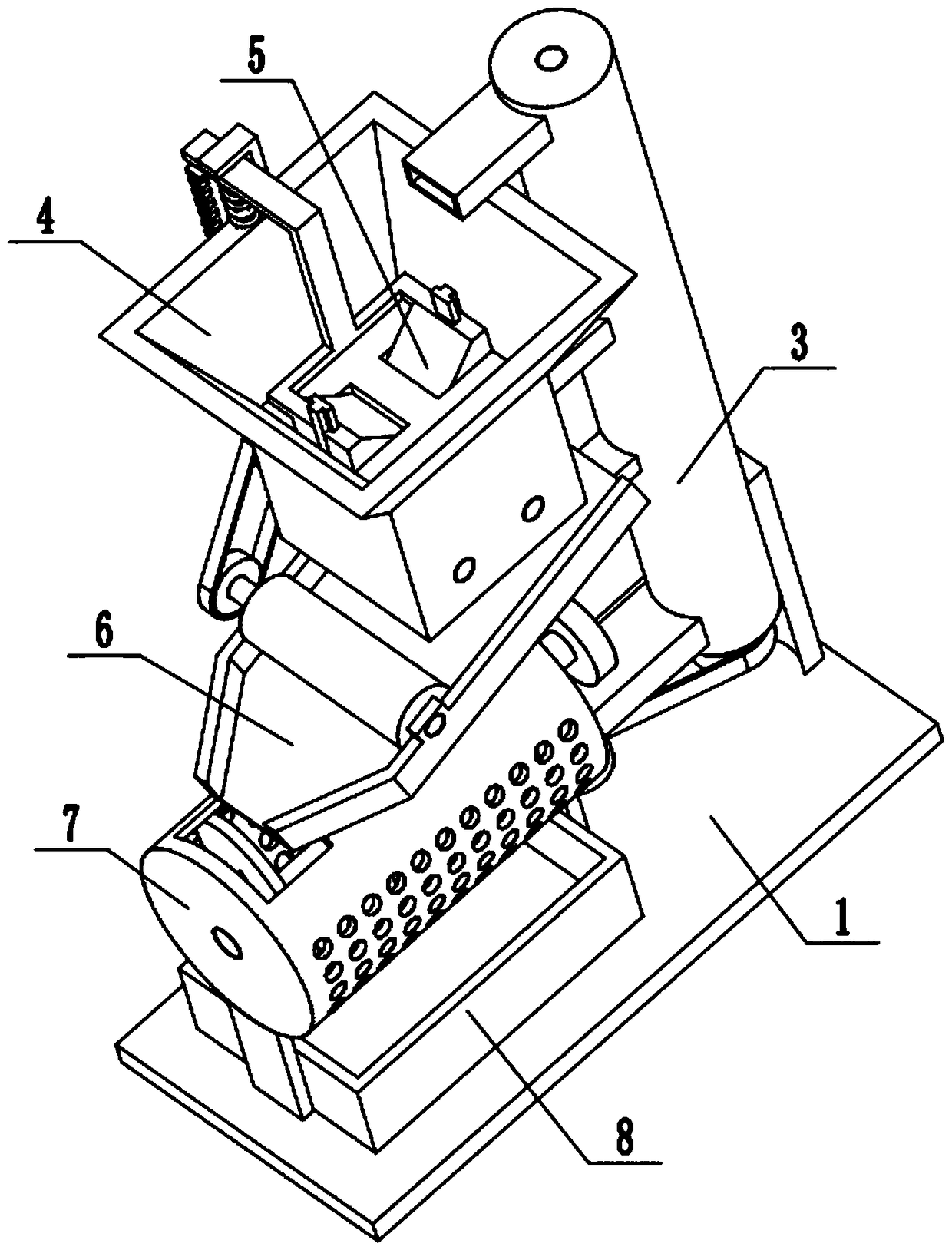

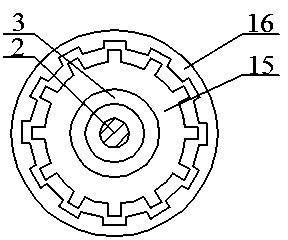

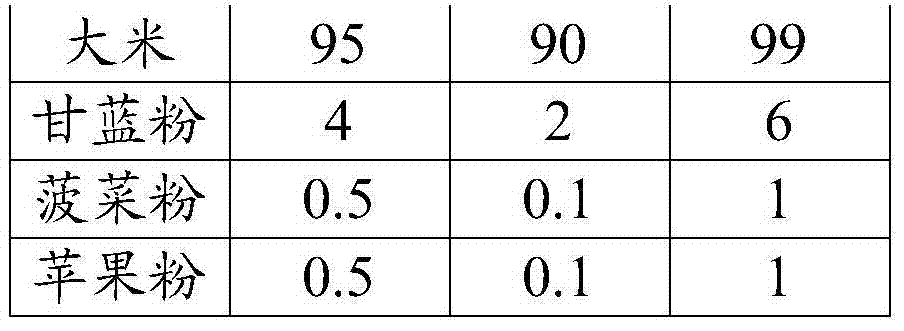

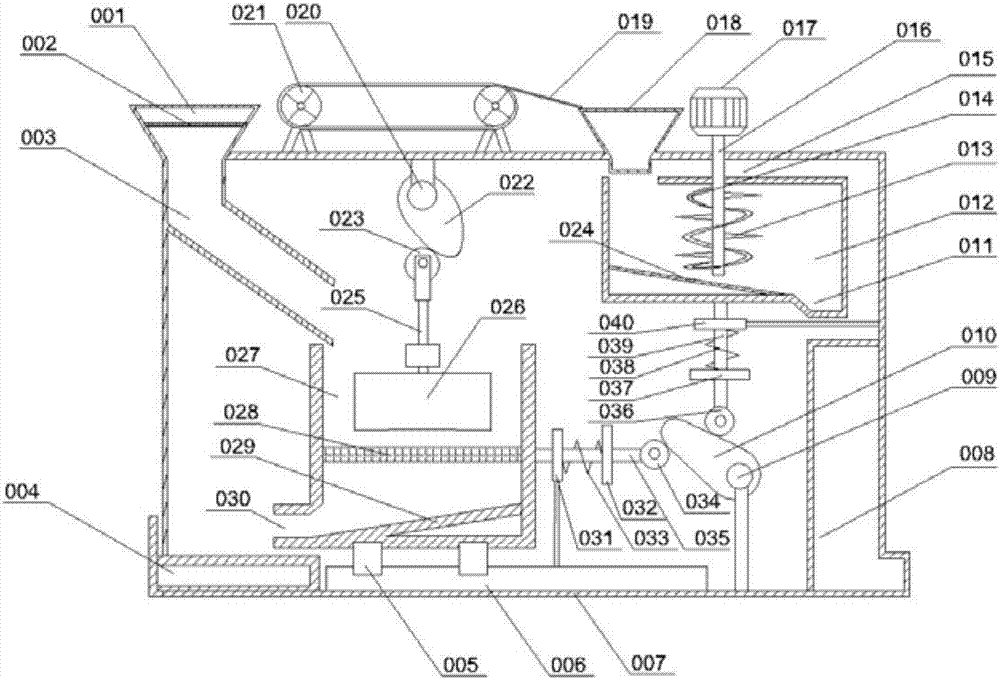

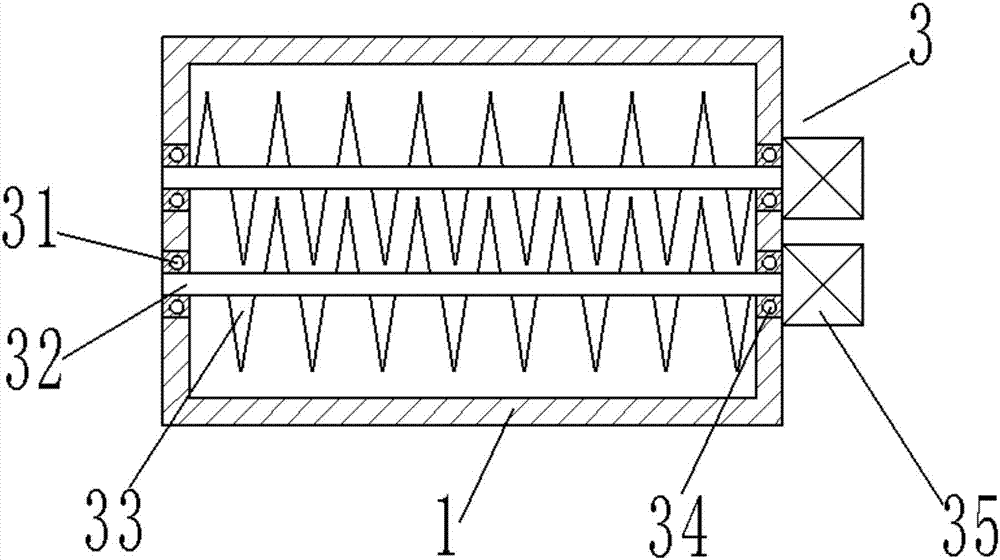

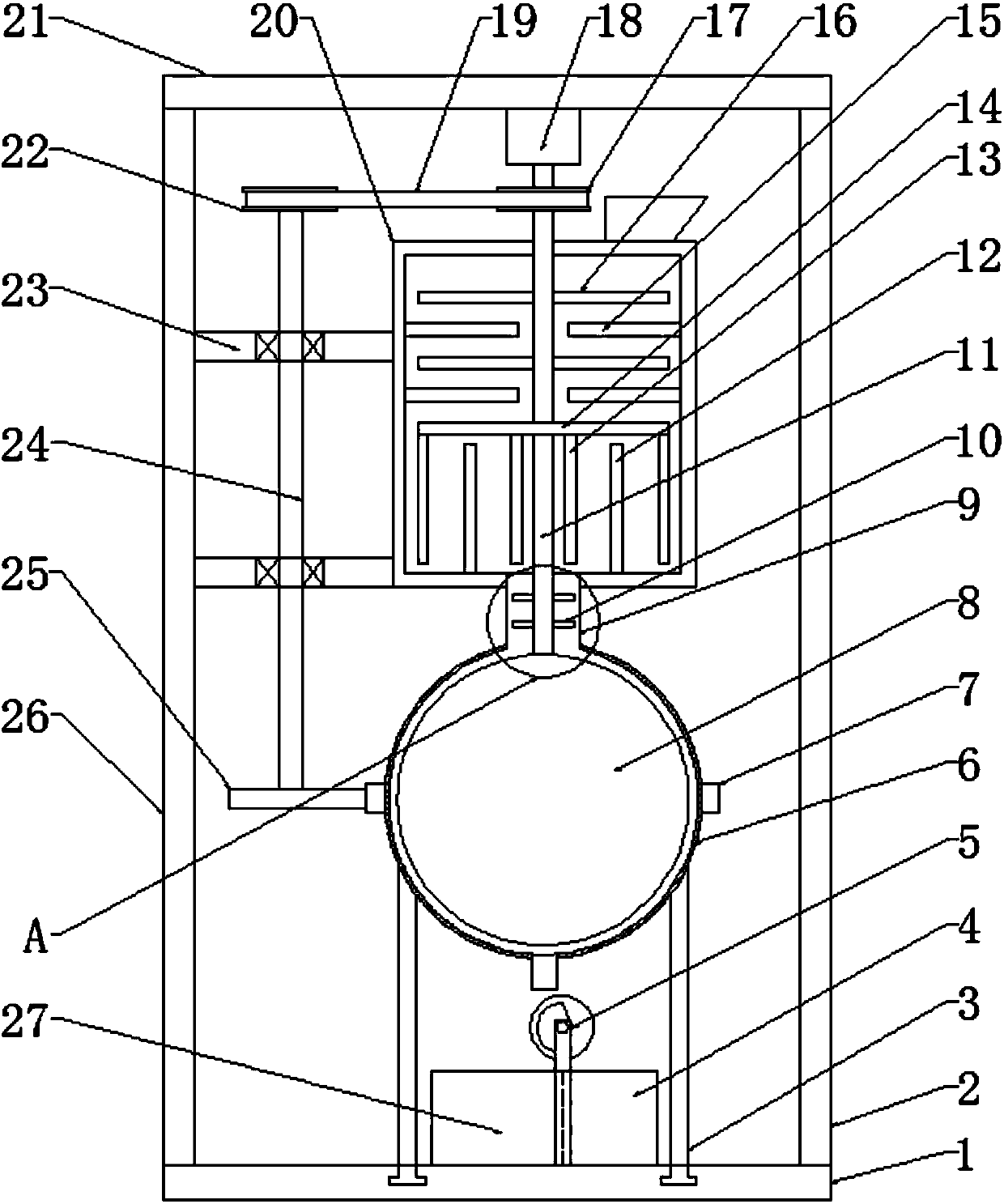

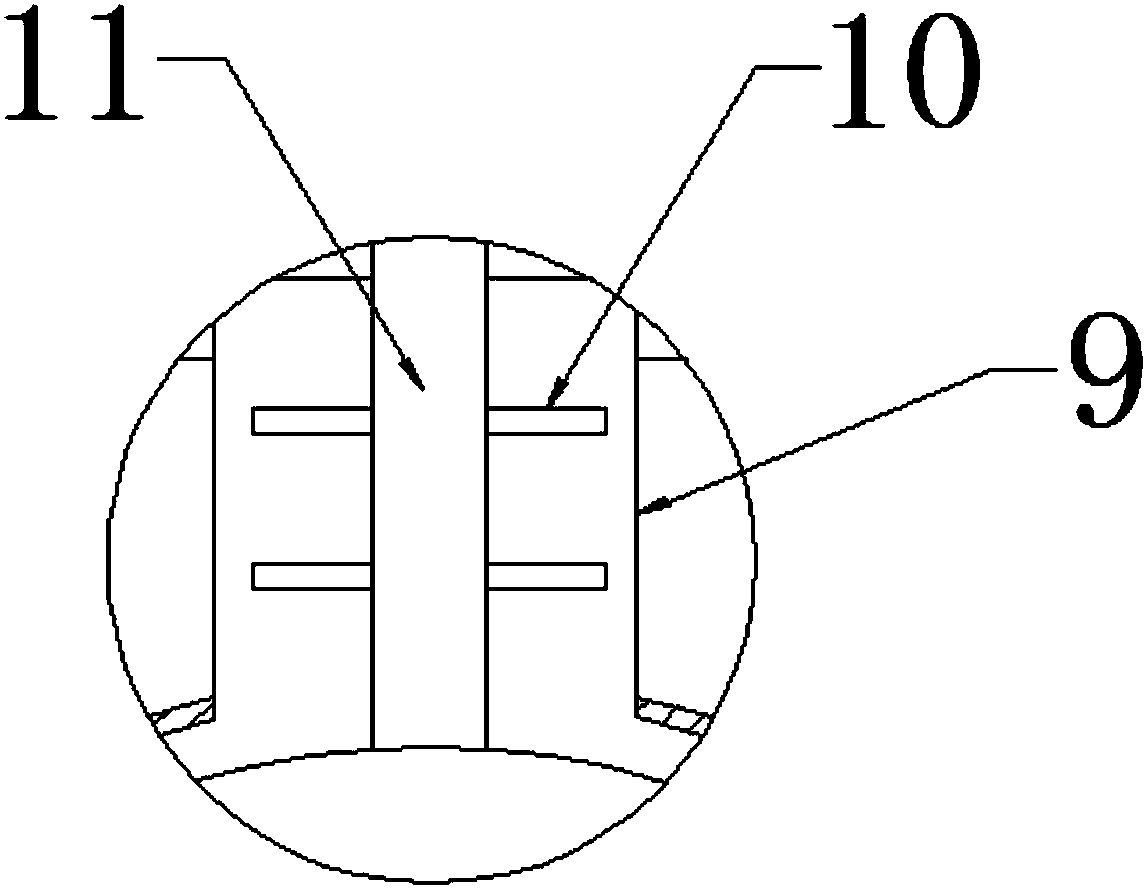

Self-circulation Chinese herbal medicine crushing and grinding integration device

InactiveCN107790244ACrushed fullyImprove crushing effectGrain treatmentsReciprocating motionElectric machinery

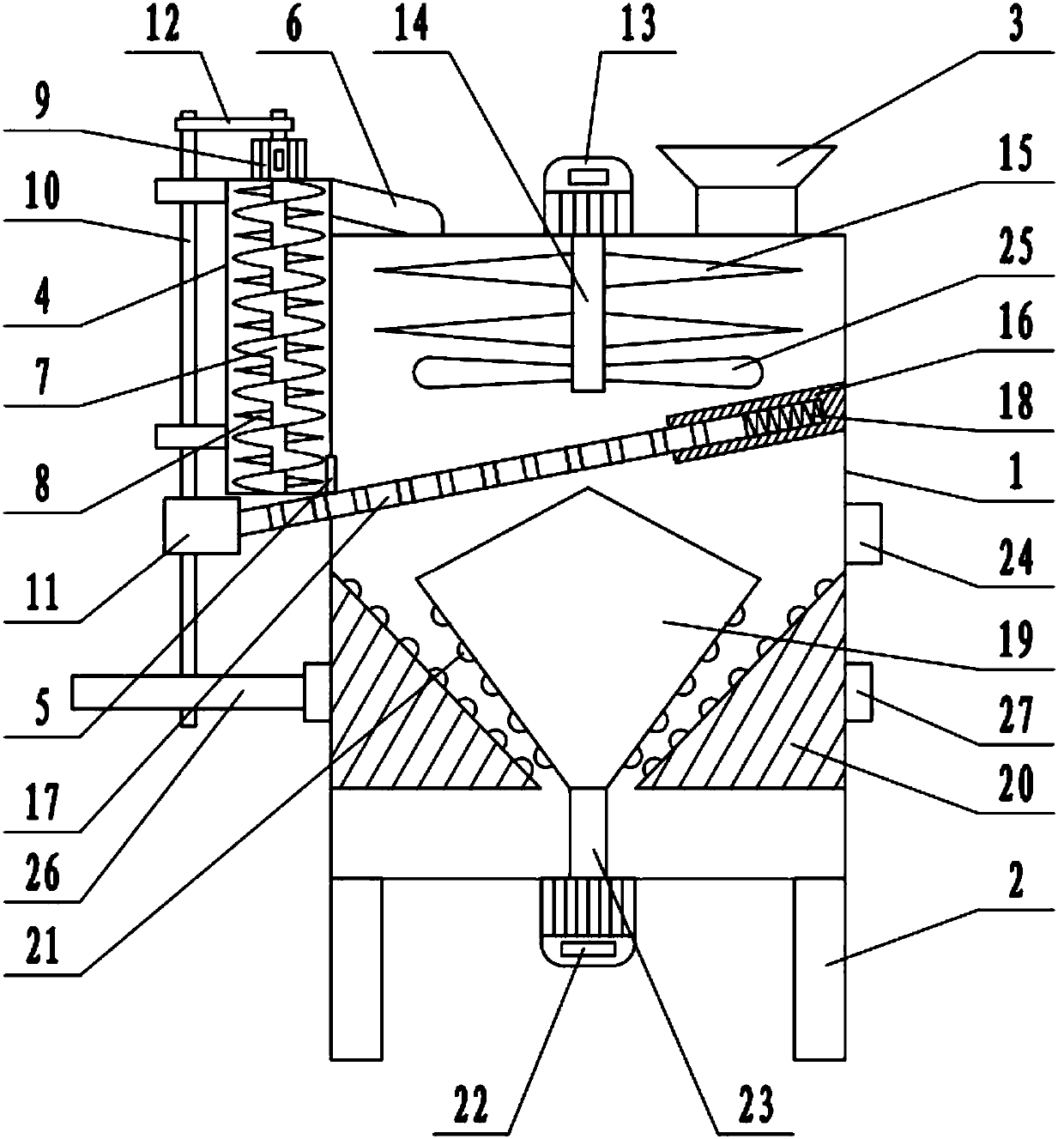

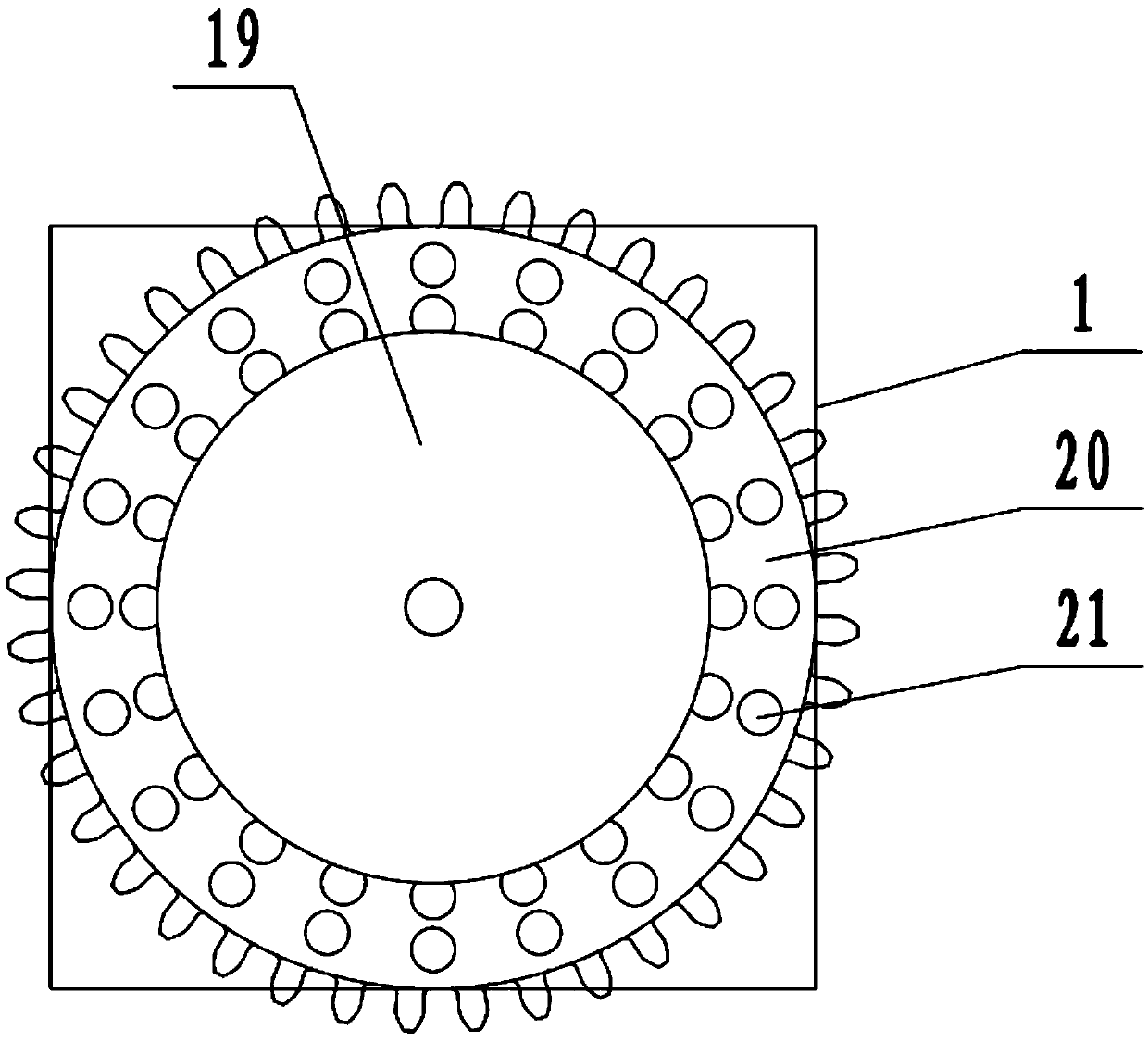

The invention discloses a self-circulation Chinese herbal medicine crushing and grinding integration device. The self-circulation Chinese herbal medicine crushing and grinding integration device comprises a shell, support legs, a feed port, a crushing motor, a crushing shaft, a crushing blade, a conical grinding hammer and a grinding motor; the left side wall of the shell is fixedly connected witha circulating cylinder; a screw rod is arranged in the circulating cylinder; the upper surface of the circulating cylinder is fixedly connected with a double-shaft motor; the upper surface of the shell is fixedly connected with the crushing motor; a shaft extension end of the crushing motor is fixedly connected with the crushing shaft; a screen plate is arranged below the crushing shaft; a grinding table is arranged below the screen plate; the conical grinding hammer is arranged in the grinding table; traditional Chinese medicines are crushed by using the crushing blade, and are stirred by using stirring blades during crushing, so that the traditional Chinese medicines are crushed more sufficiently; the crushed traditional Chinese medicines fall onto the screen plate, and the screen plateperforms a left-right reciprocating motion to improve the efficiency of the traditional Chinese medicine passing through the screen plate; and the conical grinding hammer and the grinding table are matched to crush the traditional Chinese medicines, and are opposite in rotating direction to improve the grinding efficiency.

Owner:李欢欢

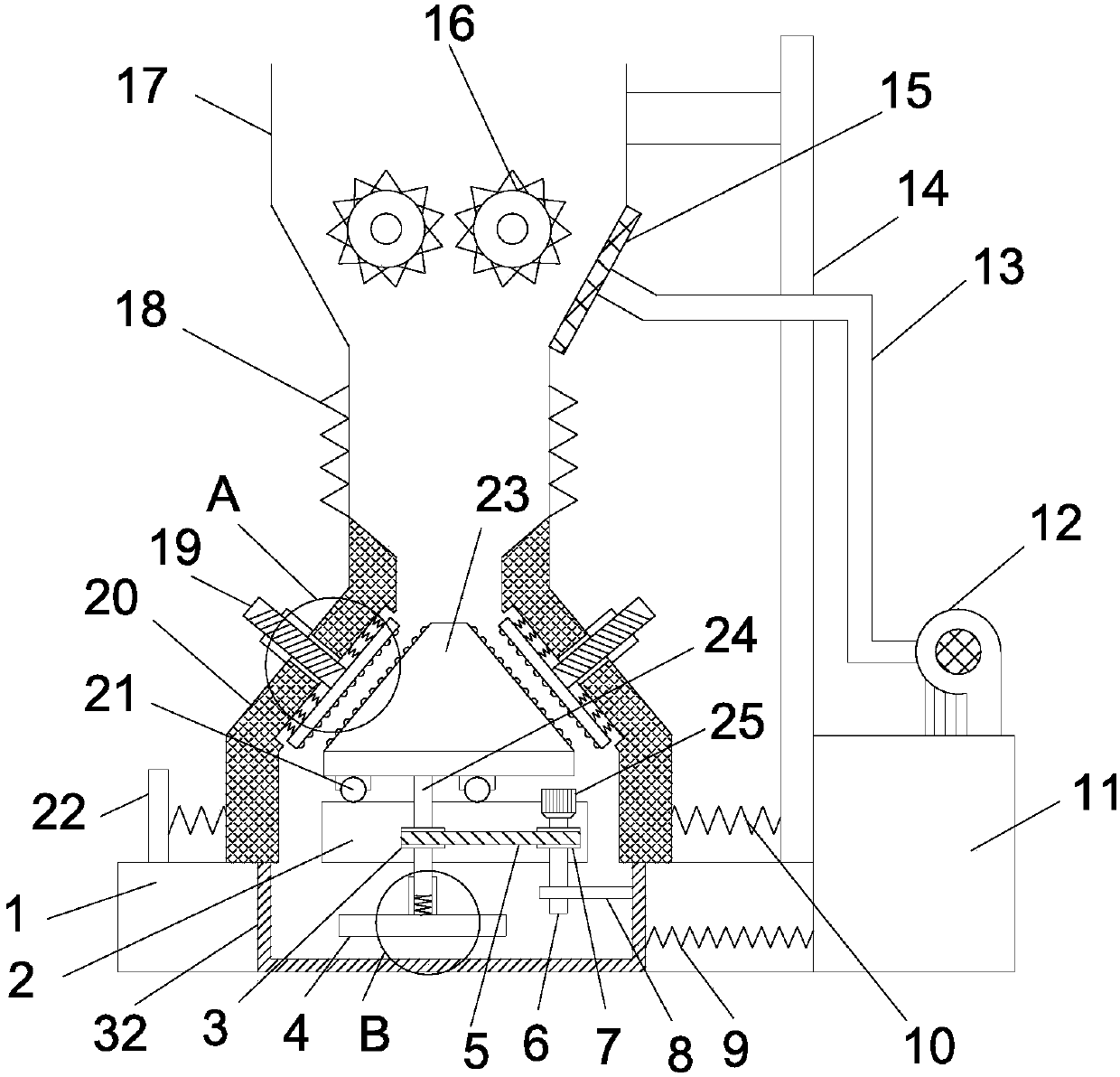

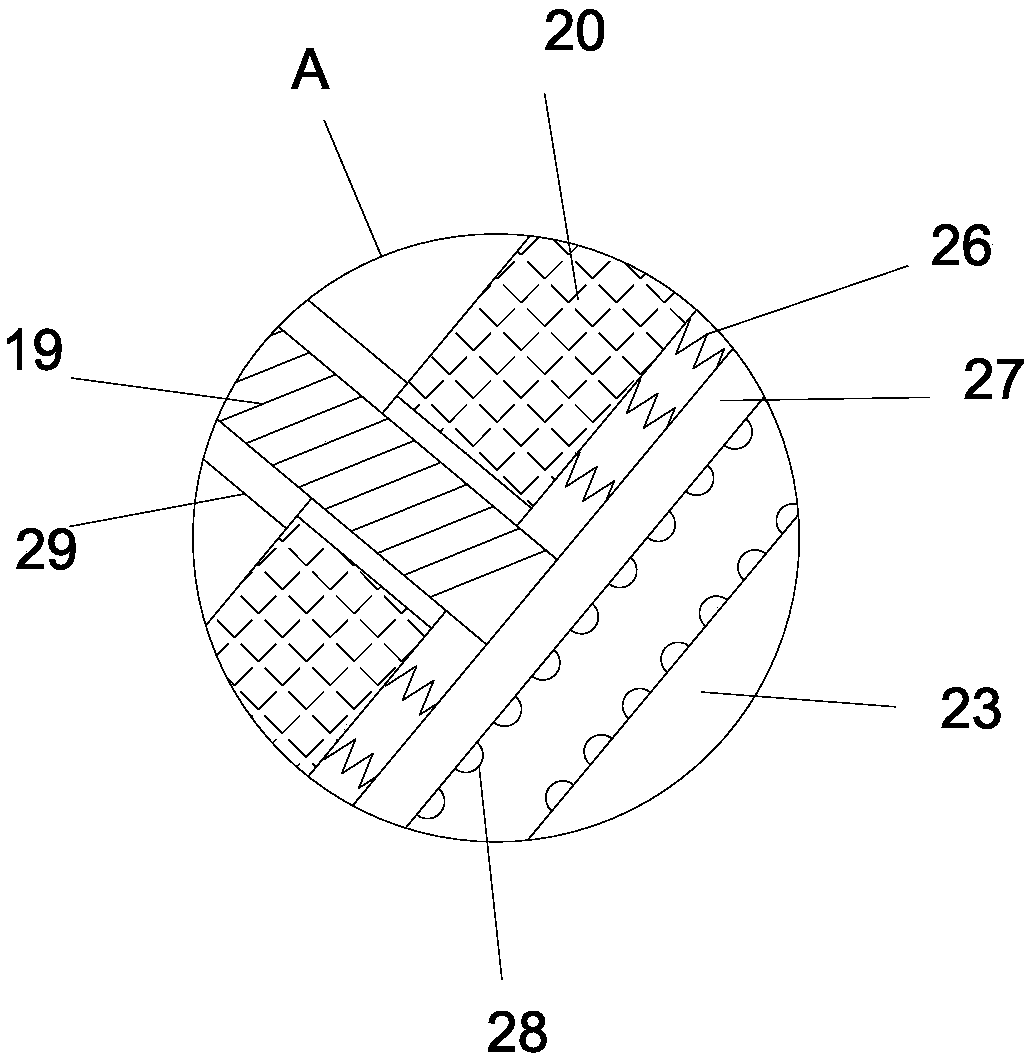

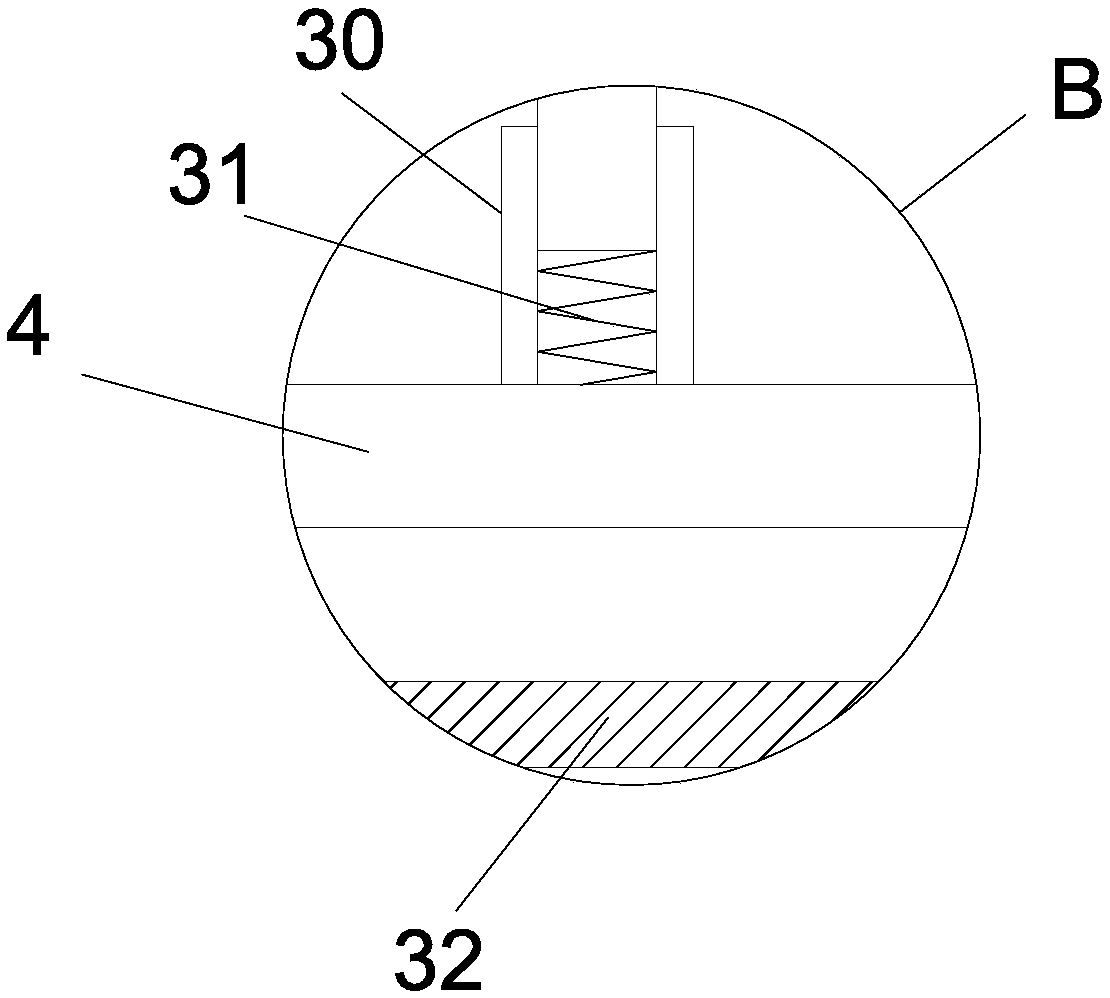

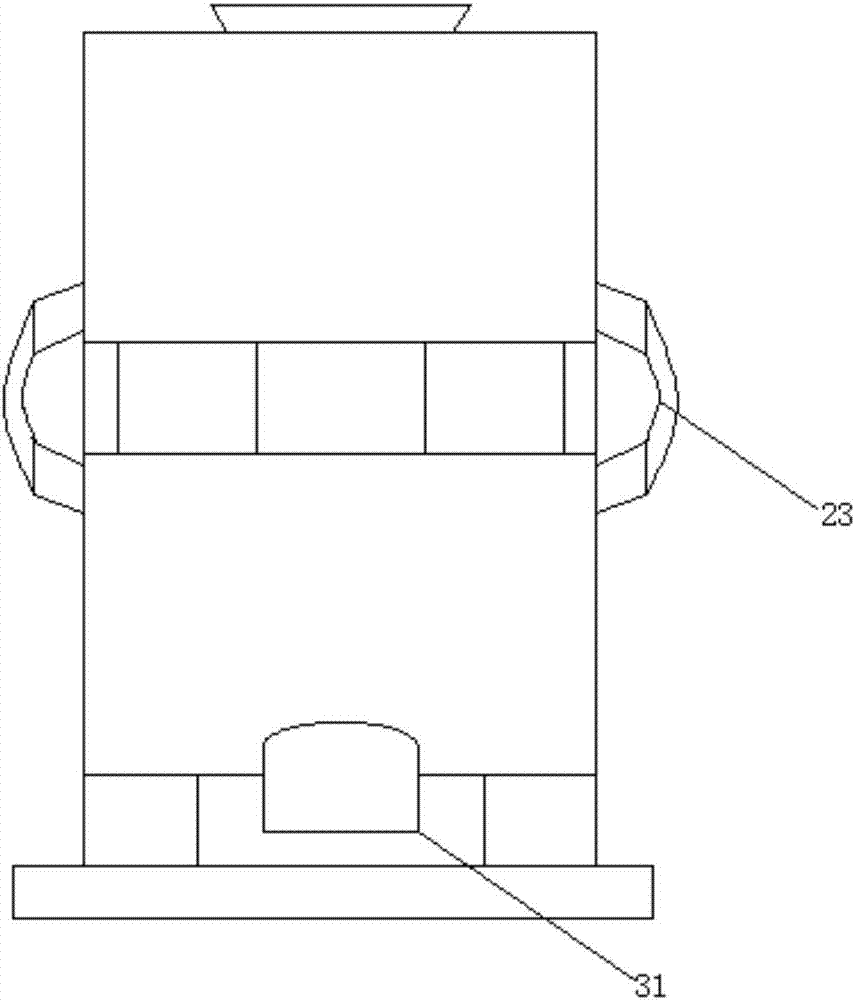

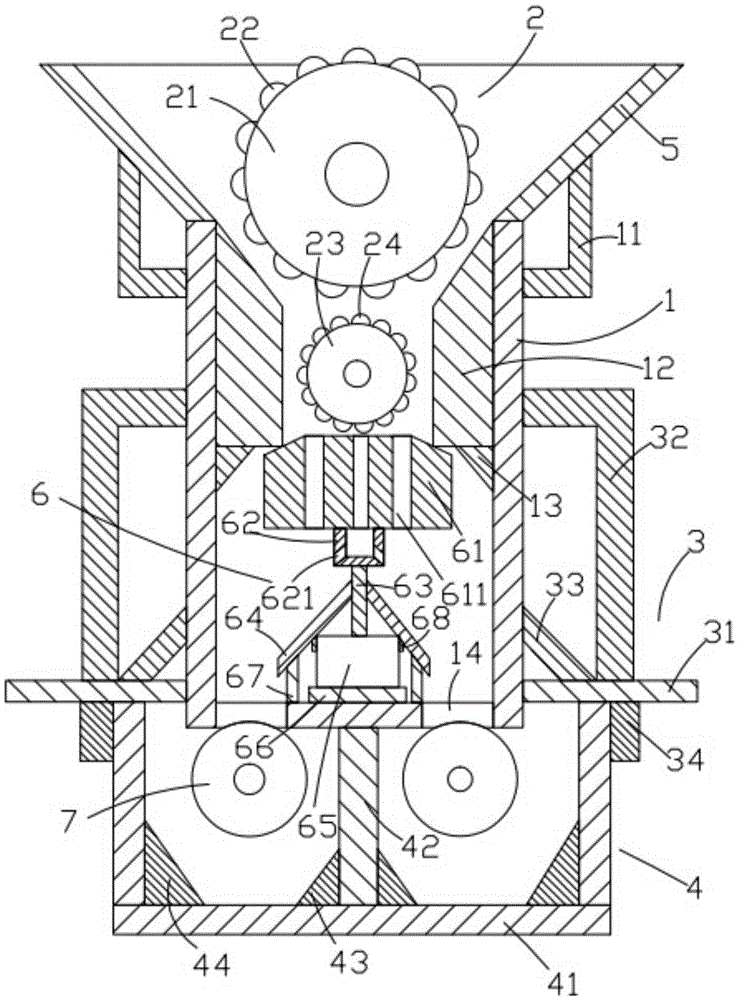

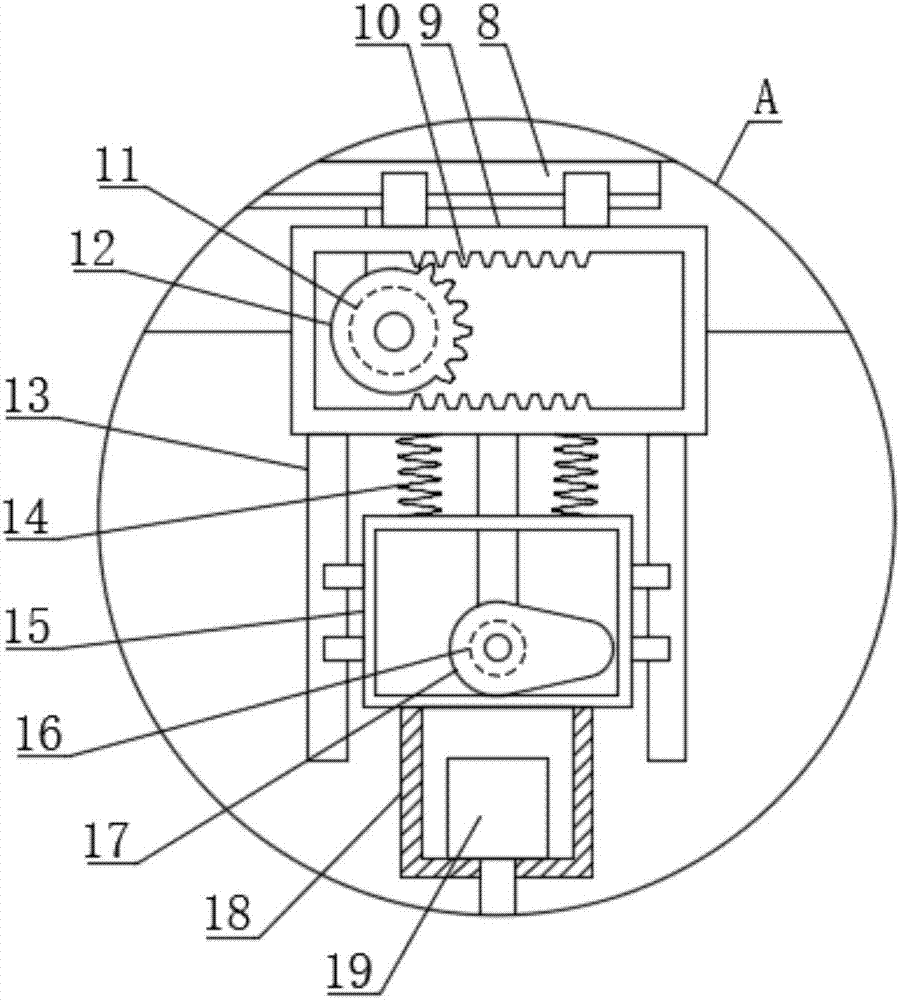

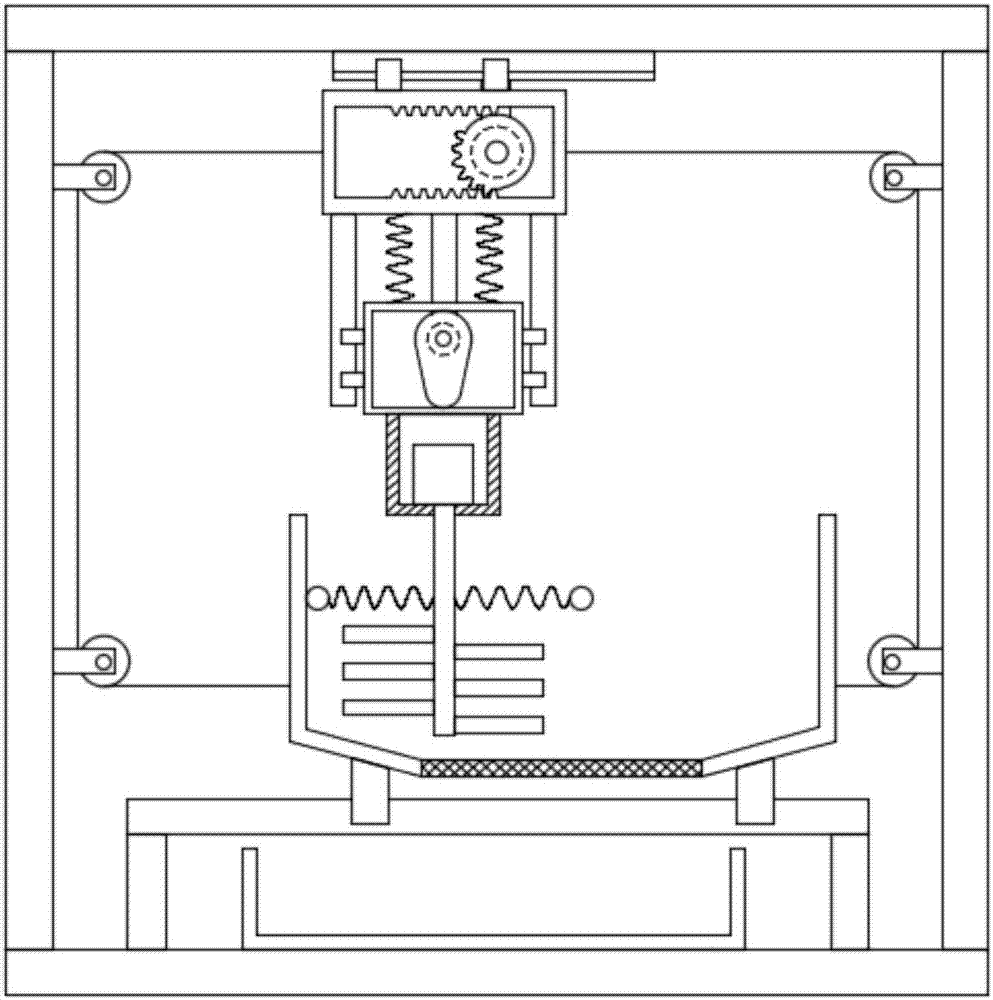

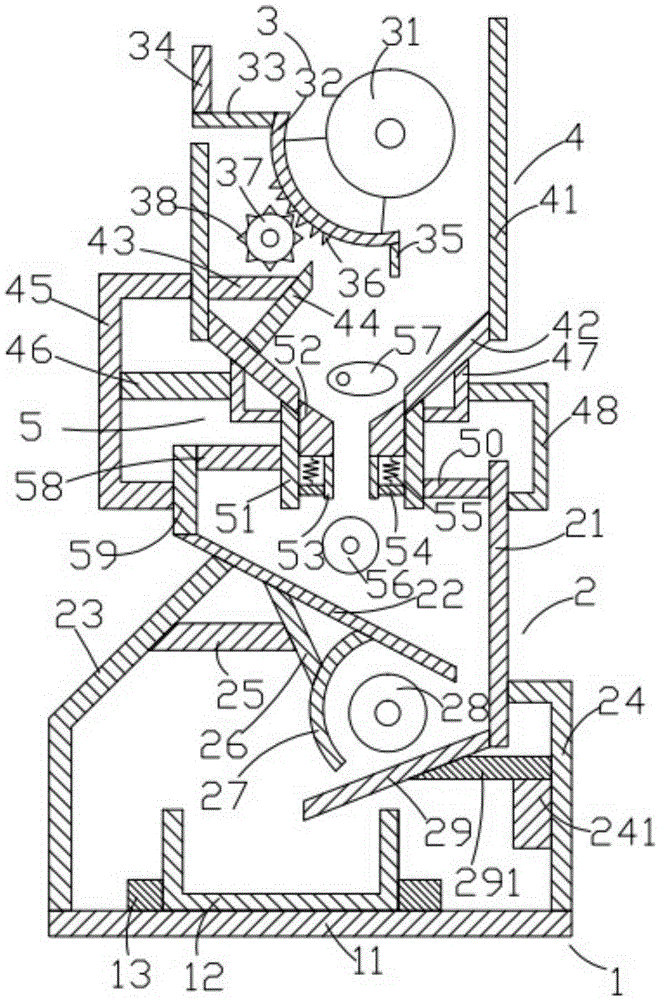

Medical waste rapid crushing device

InactiveCN107597361AIngenious structureEasy to operateUsing liquid separation agentMedical waste disposalCamReciprocating motion

The invention discloses a medical waste rapid crushing device. The medical waste rapid crushing device comprises a crushing chamber; a separation plate is arranged in the crushing chamber horizontallyand fixedly; a plurality of separation holes are formed in the separation plate; an oval cam abuts against the left side wall of a first push plate and the right side wall of a second push plate; a right pull rope is arranged on the right side wall of the first push plate; the right pull rope is wound on a first fixed pulley and a fourth fixed pulley sequentially from top to bottom; a reset spring is connected between a left pressing plate and the crushing chamber; a reset spring is connected between a right pressing plate and the crushing chamber; and a driven belt wheel is arranged on a rotating wheel coaxially and fixedly. The medical waste rapid crushing device is ingenious in structure; a rotating motor can do up-and-down reciprocating motion while driving a crushing roller to rotatably crush the medical waste, so that the medical waste is completely crushed; and the left pressing plate and the right pressing plate move towards each other in opposite directions and move towards opposite directions repeatedly, so that the medical waste is extruded and crushed, the medical waste is gathered, the crushing effect of the crushing roller on the medical waste is improved, and the crushing efficiency is improved.

Owner:鲍鹏升

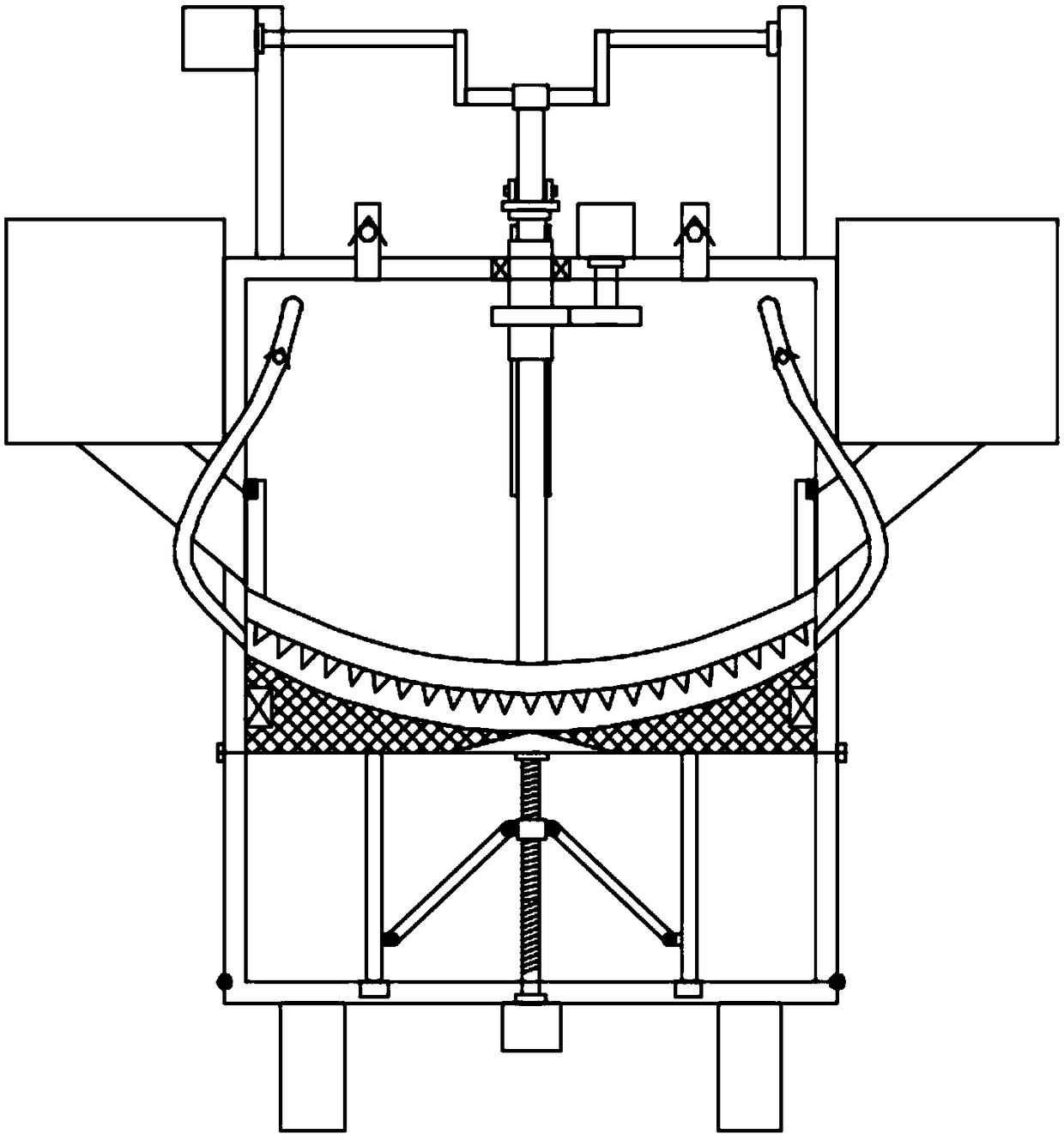

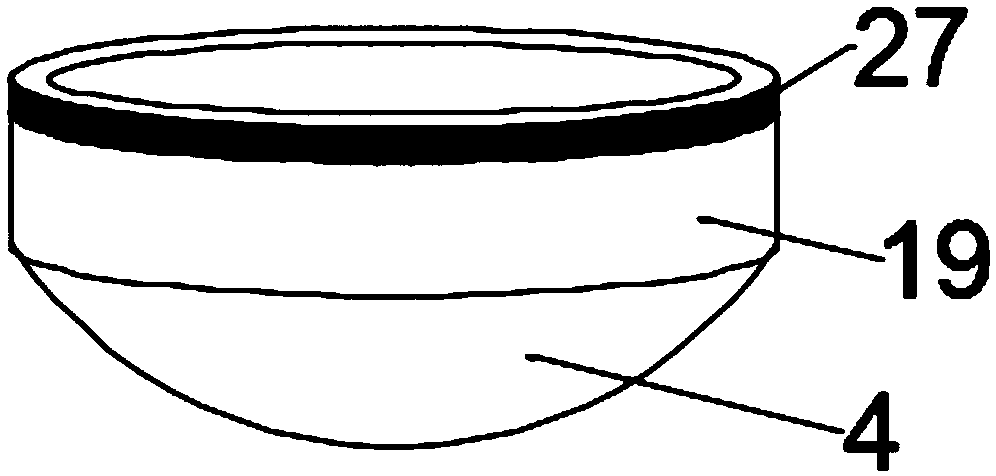

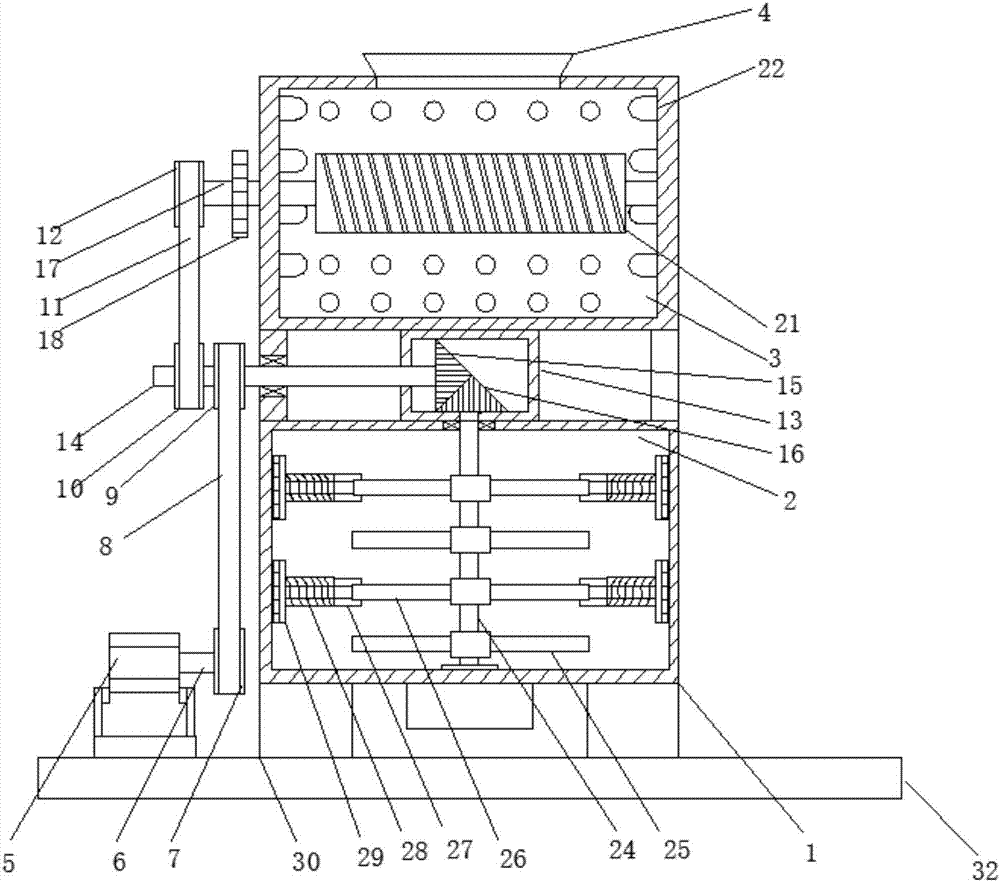

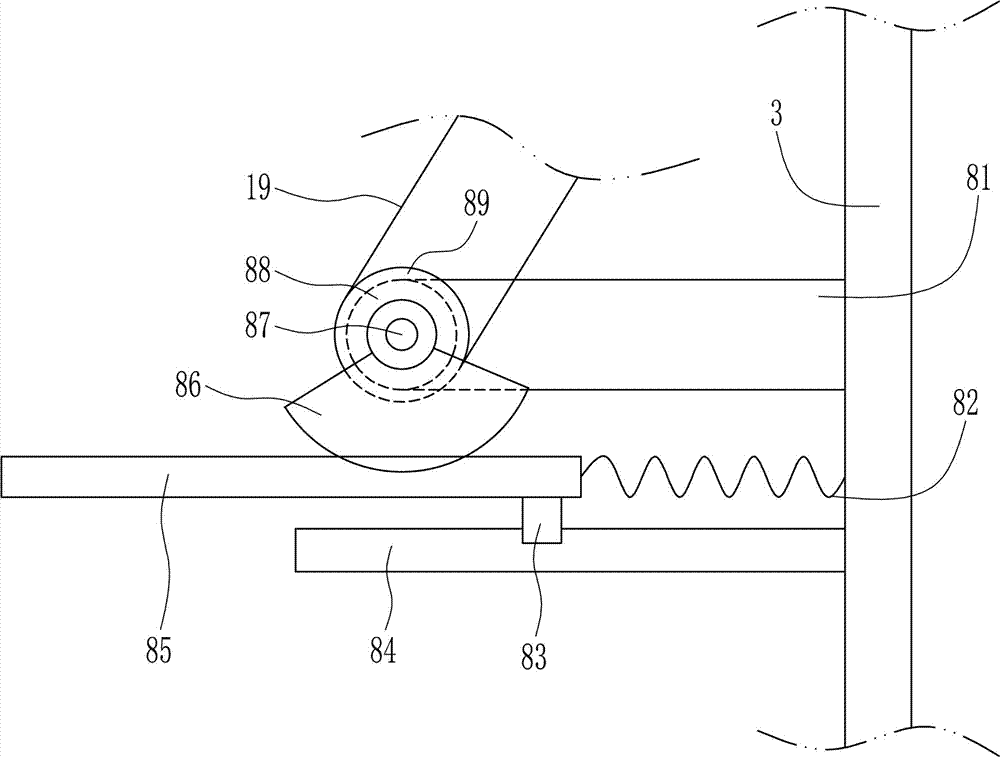

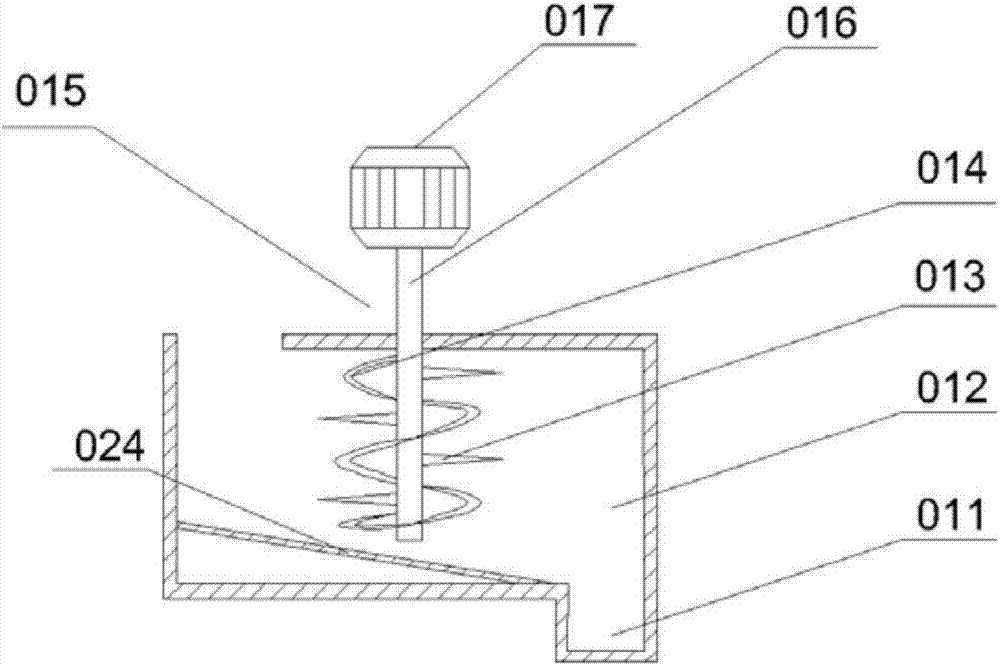

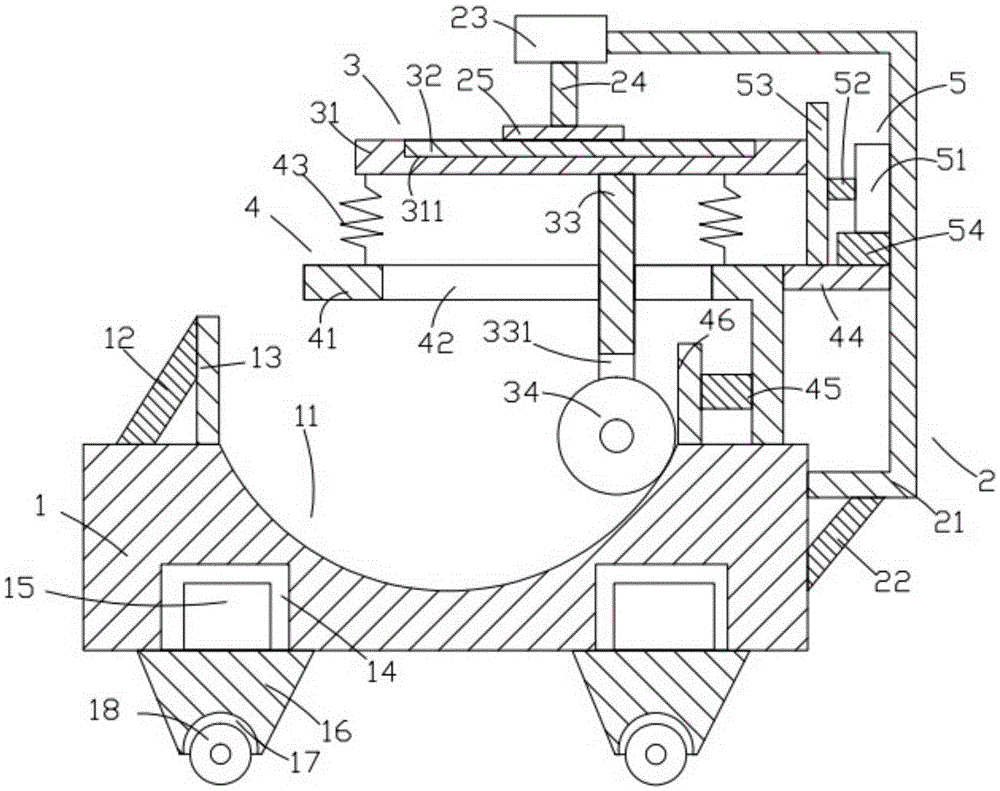

Eccentric rotary cone type stone crushing device for mineral processing

InactiveCN107552138AIngenious structureReasonable designDirt cleaningGrain treatmentsAbsorption effectEngineering

The invention discloses an eccentric rotary cone type stone crushing device for mineral processing, which comprises a bottom box with a hollow structure inside the bottom box, and a grinding basket is horizontally slidable inside the bottom box, and a grinding basket is connected with the inner wall on the right side of the bottom box. The first return spring, the driven shaft is rotated in the bearing table, the driven shaft is provided with a driven pulley, the driven shaft extends into the grinding basket, and the side wall of the conical cover plate is slidingly provided with thread positioning The inside of the grinding basket is connected to the flexible bellows through the channel formed by the bearing platform, the crushing cone and the conical cover plate; the design of the invention is reasonable, and the distance between the pressing plate and the crushing cone can be adjusted according to the specific ore size. The adjustment is stronger, the eccentrically set driven shaft drives the crushing cone to rotate, and the conical cover plate can move left and right under the action of the second return spring, which has a good buffering and shock absorption effect and prevents the ore from crushing the cone Stuck, greatly reducing the failure rate and improving work efficiency.

Owner:浙江燕思志网络科技有限公司

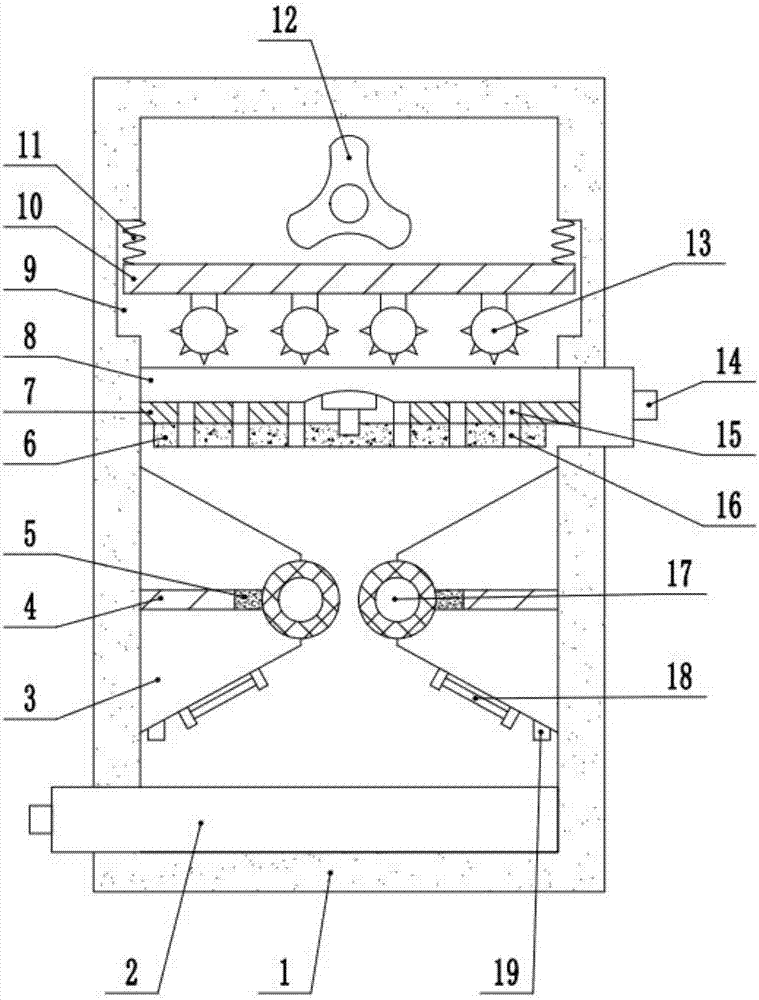

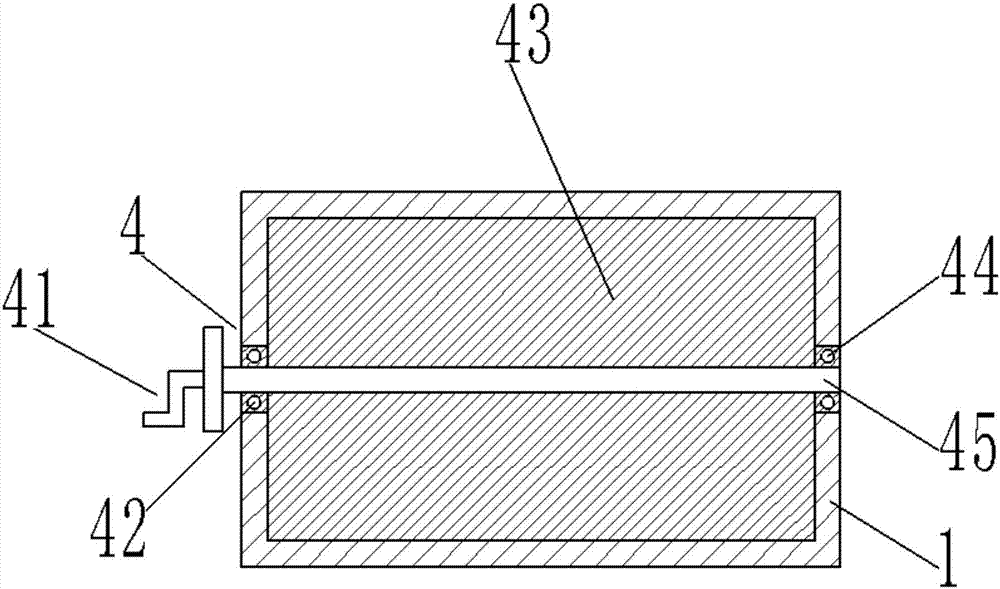

Crushing device for chemical industry production

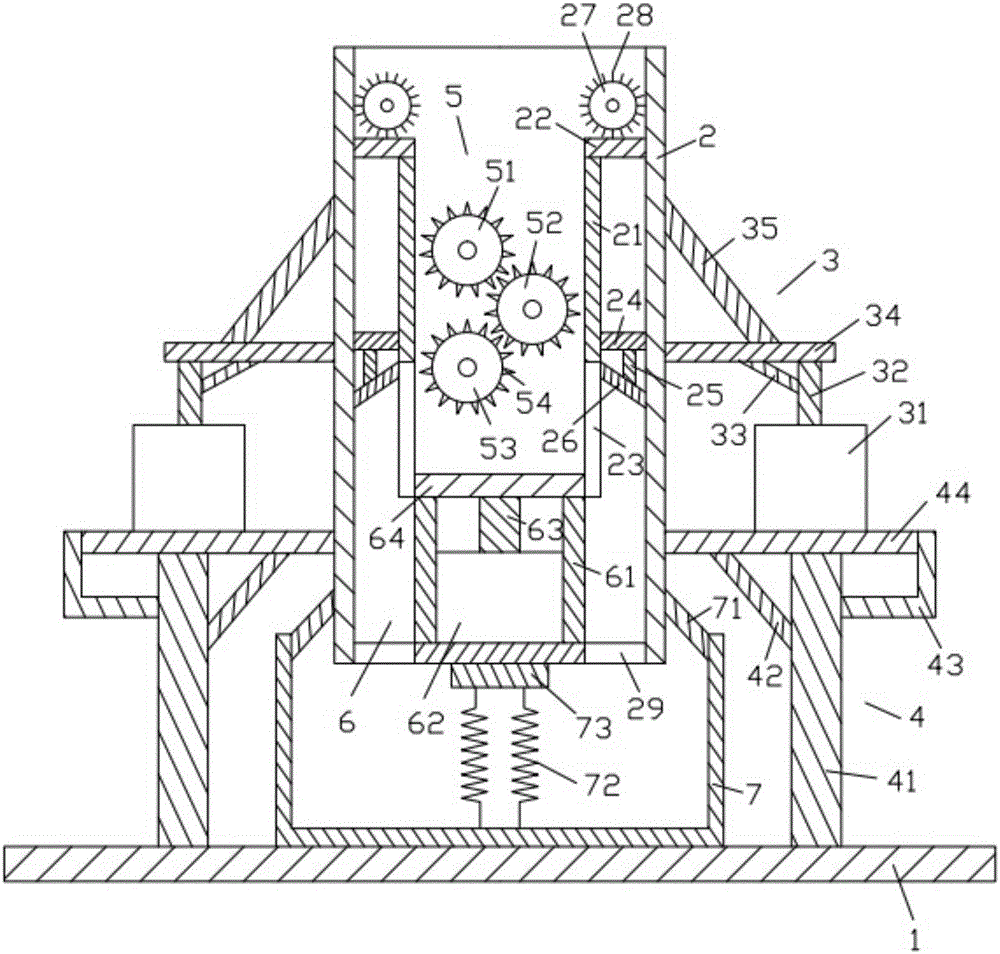

InactiveCN106733113AQuality assuranceImprove work efficiencyGrain treatmentsChemical industryHydraulic cylinder

The invention discloses a crushing device for chemical industry production. The crushing device for chemical industry production comprises a crushing machine body. The crushing machine body is divided into a crushing cavity and a smashing cavity in an upper-lower mode. The bottom end of the left side of the crushing cavity is connected with a feeding pipe, a feeding hopper is arranged on the upper side of the feeding pipe, and an iron removing rotary shaft is horizontally arranged in the center in the feeding hopper. Permanent magnet sheets are arranged on the outer wall of the iron removing rotary shaft in a vertically symmetrical mode. A telescopic column is vertically arranged in the center in the crushing cavity, the top end of the telescopic column stretches out of the crushing cavity and is connected with a hydraulic cylinder fixed on the outer wall of the upper side of the crushing machine body, and the bottom end of the telescopic column is connected with a crushing hammer arranged horizontally. The crushing device for chemical industry production can conduct iron removing on materials twice, thereby being good in iron removing effect and sufficient in iron removing; two crushing mechanisms arranged up and down are adopted for sufficiently crushing materials, gears are engaged to conduct crushing, and thus the crushing effect is good, and crushing is sufficient; and besides, effective shock absorption can be achieved, and the service life of the machine body is prolonged.

Owner:GUANGXI UNIV

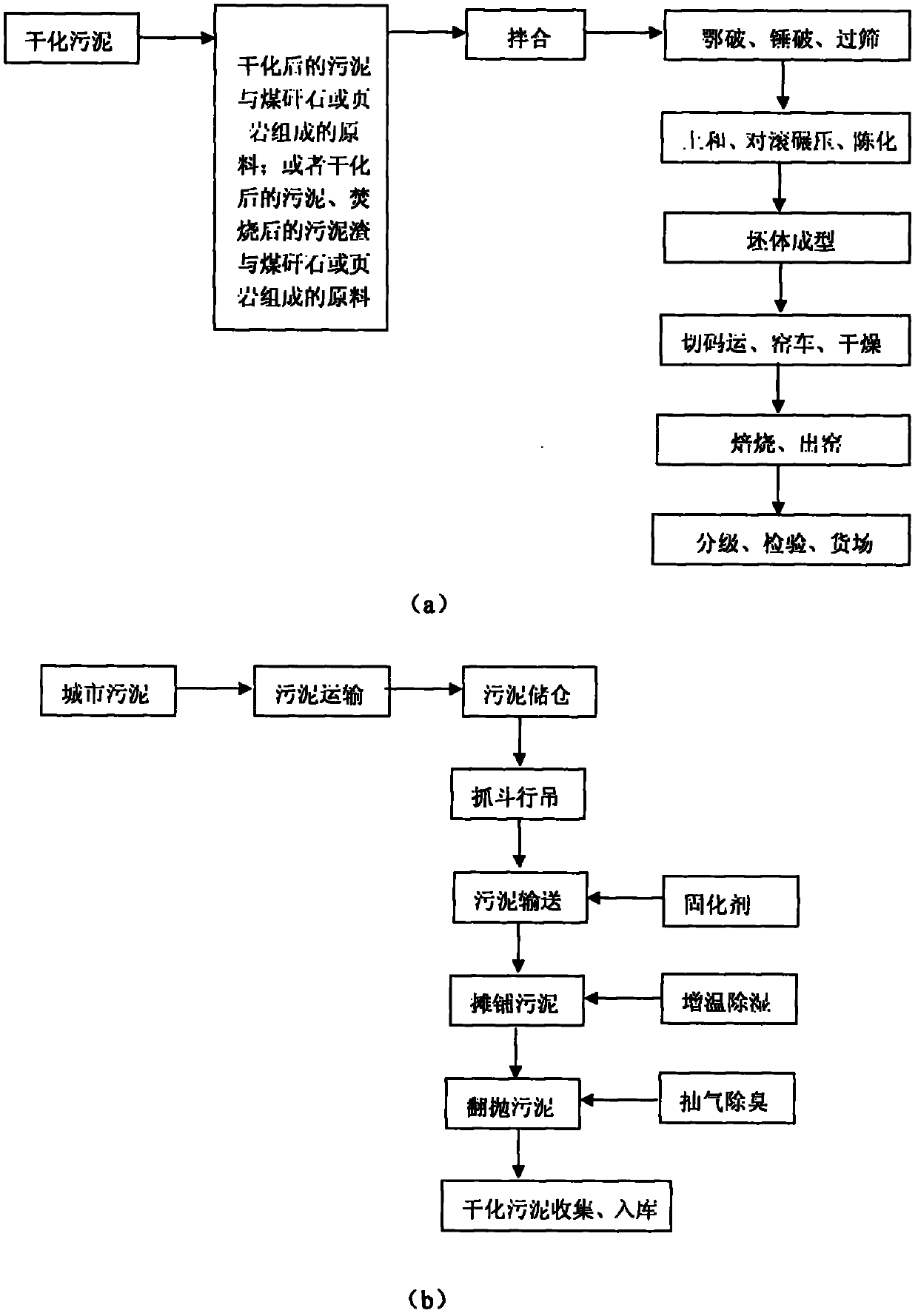

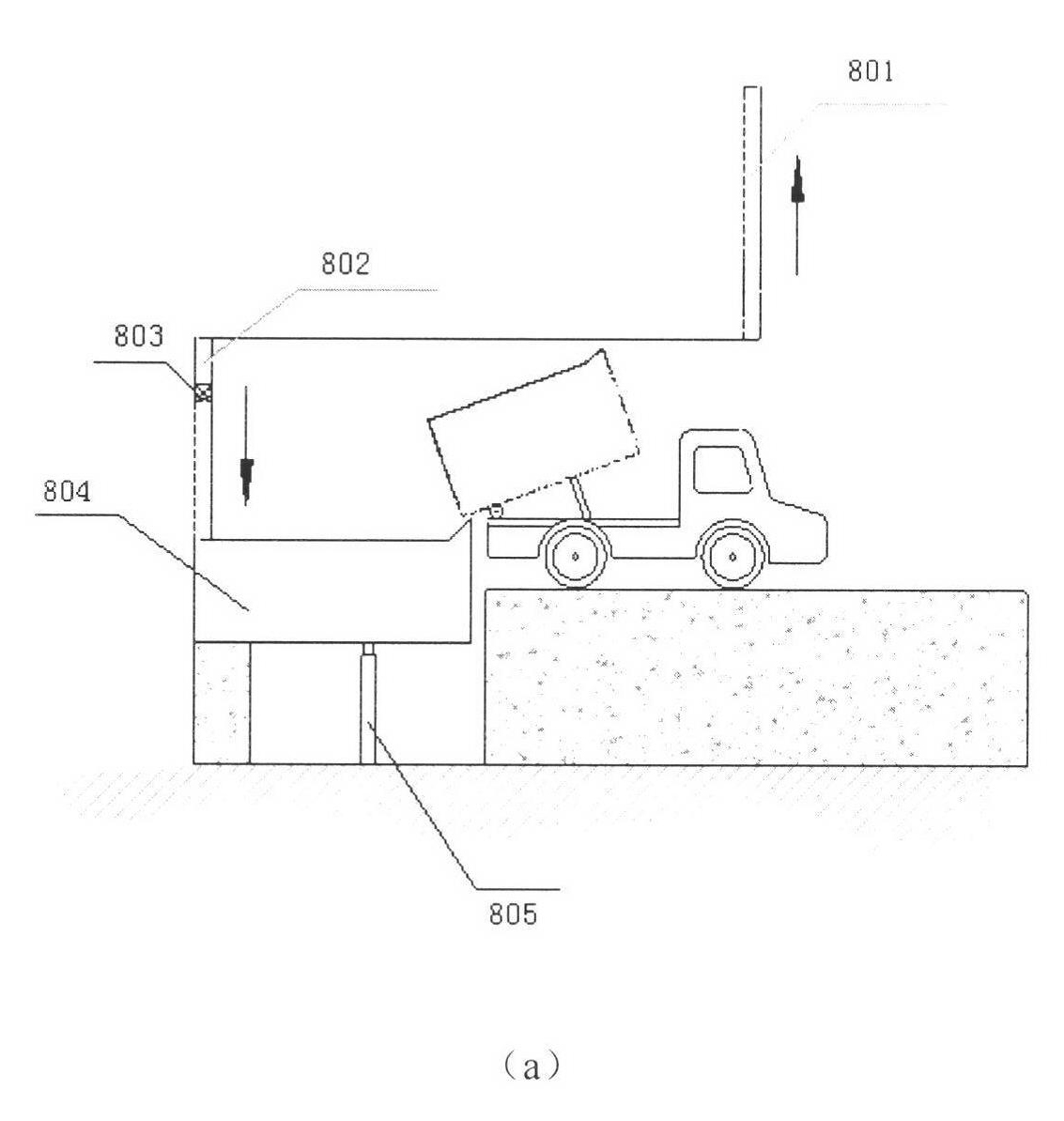

Method for brickmaking by comprehensive utilization of desiccated sludge

ActiveCN102381877AReduce moisture contentCrushed fullySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentBrickSolar drying

The invention discloses a method for brickmaking by comprehensive utilization of desiccated sludge; sludge is desiccated and is used as a raw material for brickmaking; the method comprises the following steps: firstly transporting municipal sludge with water content of 80-85% to a sludge warehouse for sealing storage, grabbing the sludge in the sludge warehouse by controlling a grab bucket traveling boom through a PLC system, transferring the sludge to a feed hopper of a sludge feeding device, adding a curing agent into the feed hopper, fully stirring, transporting the sludge to a desiccationchamber of a desiccation device, performing desiccation in the desiccation chamber by solar energy and waste heat of a tunnel furnace so as to obtain sludge which is used as a material for brickmaking. The invention performs desiccation by using brickkiln waste heat and solar energy; the physical heat at a brick-baking tail part of the tunnel furnace is made full use of, which increases self heat, and saves a lot of energy; sludge is added into various raw materials, and no clay is used; with respect to baked brick production by using municipal sludge with a high mixing amount, the highest mixing amount of municipal sludge is up to 50%.

Owner:南京鑫翔环保产业有限公司

Environment-friendly smashing and recovering device for waste electronic products

The invention discloses an environment-friendly smashing and recovering device for waste electronic products. The environment-friendly smashing and recovering device comprises a barrel, a screen, a crank, a second motor, a shaft bushing, a connection rod, a movable rod, a smashing plate, a ring-shaped baffle, a tank, a first motor, a threaded rod, a first sleeve, a connection rod, a pressing plate, an air outlet pipe, an air inlet pipe, a rotating sleeve, a third motor, a first gear and a second gear. Through arrangement of the second motor, the crank, the connection rod, the movable rod, thesmashing plate and the ring-shaped baffle, intermittent discharging is achieved, sufficient and uniform smashing is ensured, and the smashing efficiency is improved; through arrangement of the third motor, the first gear, the second gear and the rotating sleeve, rotating smashing is carried out, fertilizer can be ground, the smashing speed is further increased, and the smashing efficiency is improved; and through arrangement of the first motor, the threaded rod, the connection rod and the pressing plate, smashed electronic products are automatically compressed, then a door is opened, the compressed products are pushed out, and discharging and collection are facilitated.

Owner:童拓

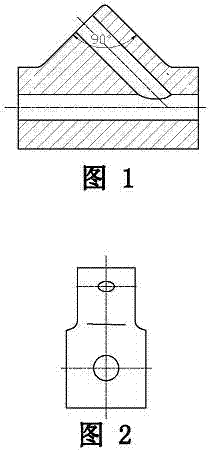

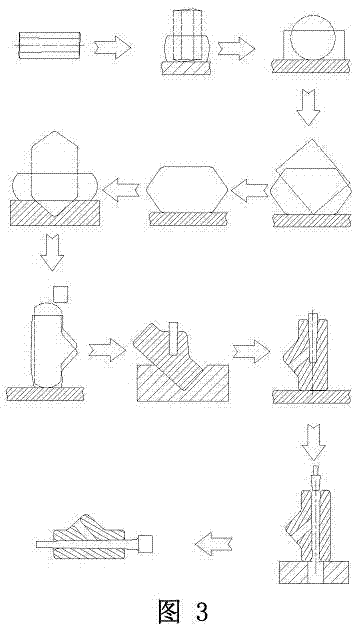

Forging forming technology for high-temperature steam pipeline of supercritical unit

The invention discloses a forging forming technology for a high-temperature steam pipeline of a supercritical unit. The forging forming technology comprises the steps that firstly, a heat-resisting steel ingot is selected and used; secondly, the steel ingot is heated up to 580 DEG C to 620 DEG C, and heat preservation is carried out for 3 hours; the steel ingot is heated up to 830 DEG C to 870 DEG C at a rate ranging from 55 DEG C / h to 60 DEG C / h; heat preservation is carried out for 4 hours; the steel ingot is heated up to 1130 DEG C to 1170 DEG C at a rate ranging from 78 DEG C / h to 82 DEG C / h; heat preservation is carried out for 4 hours; the steel ingot is heated up to 1210 DEG C to 1250 DEG C at a rate ranging from 78 DEG C / h to 82 DEG C / h; heat preservation is carried out for 2 hours; thirdly, the heated steel ingot is taken from a furnace, the head and the tail of the steel ingot are chopped off; fourthly, upsetting is carried out on a forging stock, and an upset piece is drawn out to form a square flat forging stock; fifthly, a tilted three-way forge piece is formed by the forging stock; sixthly, a branch pipe hole is punched; seventhly, main pipe holes are punched at the two ends of a main pipe body of the tilted three-way forge piece respectively; eighthly, heat treatment is carried out after forging. According to the forming technology, the production efficiency is high, internal organizations of the forge piece is even and dense, the forming technology is applicable to forging forming of tilted three-way forge pieces of supercritical units and ultra supercritical units with various specifications.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

Crushing and stirring device for building cement

InactiveCN107297819AAvoid erectionImprove qualityMixing operation control apparatusPretreatment controlDrive wheelDrive shaft

The invention discloses a crushing and stirring device for building cement, which comprises a frame and a base. The frame includes a stirring box and a crushing box. The right end of the rotating shaft is equipped with a driving wheel, the middle position of the frame is horizontally provided with a first transmission shaft, the left end of the first transmission shaft is equipped with a primary driven wheel and a secondary driven wheel, and the driving wheel and the primary driven wheel They are connected by the first belt, the second transmission shaft and the third transmission shaft are horizontally arranged in the crushing box, the second transmission shaft and the third transmission shaft are horizontally parallel, and the left end of the second transmission shaft is installed with The third-stage driven wheel, the second-stage driven wheel and the third-stage driven wheel are connected through the second belt; the beneficial effect of the present invention is: the transmission structure of the belt and the gear is utilized, the working motor is reduced, and the operation safety is improved , fully milled and crushed to improve the quality of the material.

Owner:黄瀚

Drawer type medical glass pulverizing device

The invention discloses a drawer-type medical glass crushing device, which comprises a body, a discharge drawer, a cleaning brush, a feed drawer, a cam and an ultraviolet lamp; a movable plate is arranged under the cam, and a number of crushing devices are uniformly arranged on the bottom of the movable plate. Hammer; the bottom of the feed drawer is provided with a base, and a turntable is installed on the lower side of the base; two bosses are symmetrically installed on the inner wall of the body, and two grinding rollers are also symmetrically arranged inside the body There are two ultraviolet lamps, and the two ultraviolet lamps are respectively installed on the lower side of the boss; the discharge drawer is slidably installed on the bottom of the body through a chute. The present invention is provided with a drawer-type feed port and a discharge port to facilitate the crushing of medical glass waste; it is also provided with a grinding roller and an ultraviolet lamp, which can grind the glass waste into powder and sterilize it, preventing the glass waste from polluting the environment and harming people. healthy.

Owner:金波

Construction garbage crushing device

Owner:刘汉佑

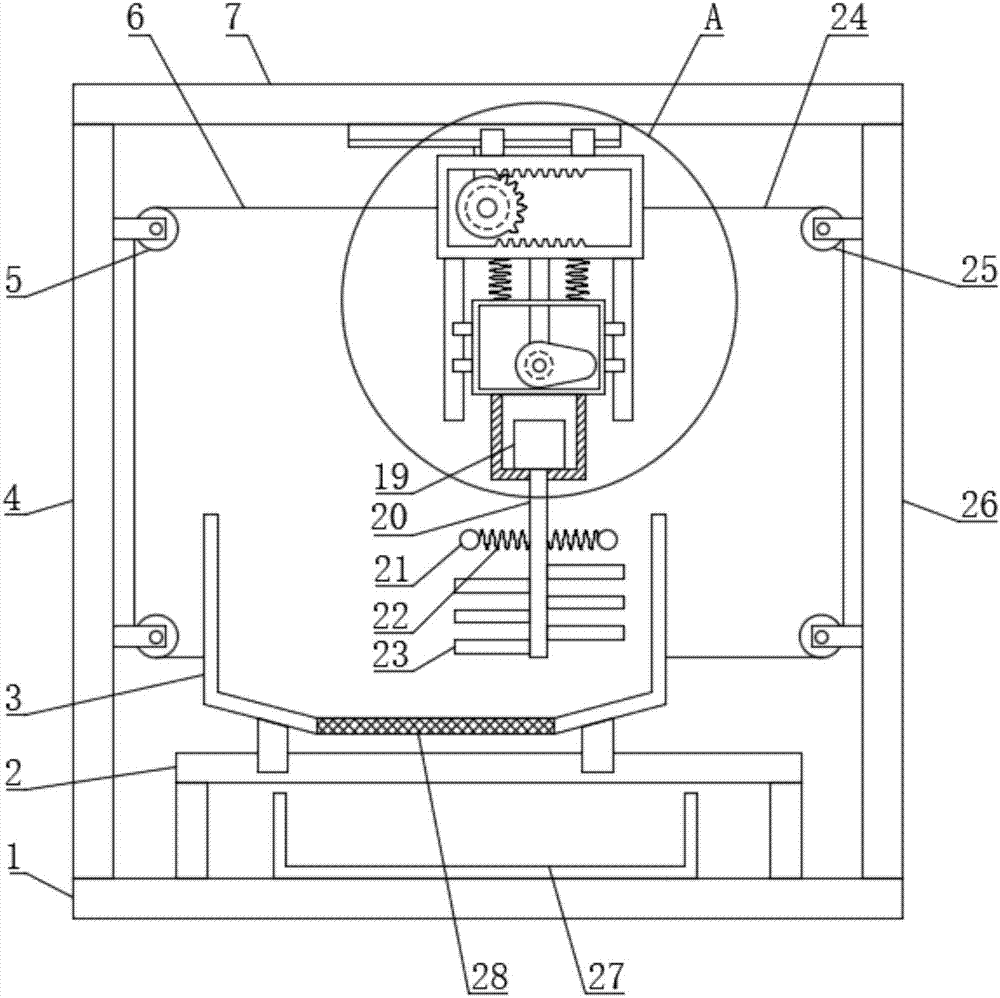

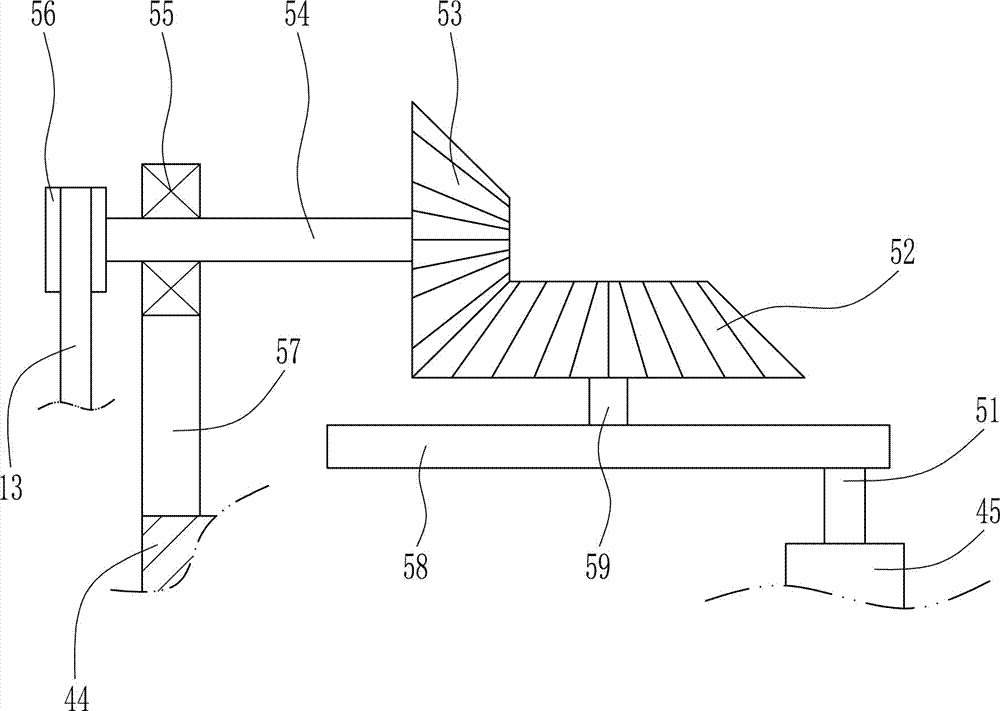

Efficient smashing and screening device for traditional Chinese medicinal materials

The invention discloses an efficient smashing and screening device for traditional Chinese medicinal materials. The efficient smashing and screening device for the traditional Chinese medicinal materials comprises a base. A first sliding rail is fixedly arranged on the base through a support. A smashing box is connected with the upper side of the first sliding rail in a sliding manner through a sliding block. The bottom of the smashing box is provided with a screening net. The left side and the right side of the top of the base are provided with a top plate through a left support plate and a right support plate. A second sliding rail is arranged at the bottom of the top plate. The lower side of the second sliding rail is connected with a moving frame through a sliding block. The bottom of the moving frame is provided with a left third sliding rail and a right third sliding rail. A lifting frame is connected between the left third sliding rail and the right third sliding rail through sliding blocks in a sliding manner. A motor seat is fixedly arranged at the bottom of the lifting frame. A first motor is arranged in the motor seat. A motor shaft of the bottom end of the first motor is connected with a rotating shaft. Smashing blades are installed on the rotating shaft. According to the efficient smashing and screening device for the traditional Chinese medicinal materials, the smashing blades move up and down and left and right in the smashing process, so that the smashing range is wider, and the smashing efficiency is higher; and the smashed medicinal materials are screened and filtered through the screening net, and therefore the quality of the medicinal materials is higher.

Owner:朱玥

Feed crushing and grinding equipment for animal husbandry

The invention discloses feed crushing and grinding equipment for animal husbandry, relates to the technical field of animal husbandry. The feed crushing and grinding equipment aims to solve the problem that an existing device is single in crushing mode. The feed crushing and grinding equipment comprises a box body, a first motor, a rotating shaft, crushing blades, a first screen, a grinding rollerand a second screen; an inner cavity of the box body is provided with the first screen and the second screen at intervals from top to bottom; crushing plates are arranged at the positions, located onthe two sides of the upper portion of the first screen, in the box body; first driving mechanism are arranged at the positions, located at the crushing plates, of the two outer walls of the box body;a movable block sleeves the outer side of a threaded rod; the grinding roller is arranged at the bottom of the movable block; and a brush strip is arranged at the top of the movable block. The feed crushing and grinding equipment has the advantages that the crushing plates and the driving mechanisms are arranged, so that a feed is pushed to the crushing blades, and therefore the crushing efficiency is improved, and crushing is more sufficient and uniform; and a forward and reverse rotation motor, the threaded rod, the movable block, the grinding roller and the brush strip are arranged, so that the feed on the second screen is further ground, meanwhile, meshes of the first screen are prevented from being blocked, and therefore the screening efficiency is improved.

Owner:吕桂英

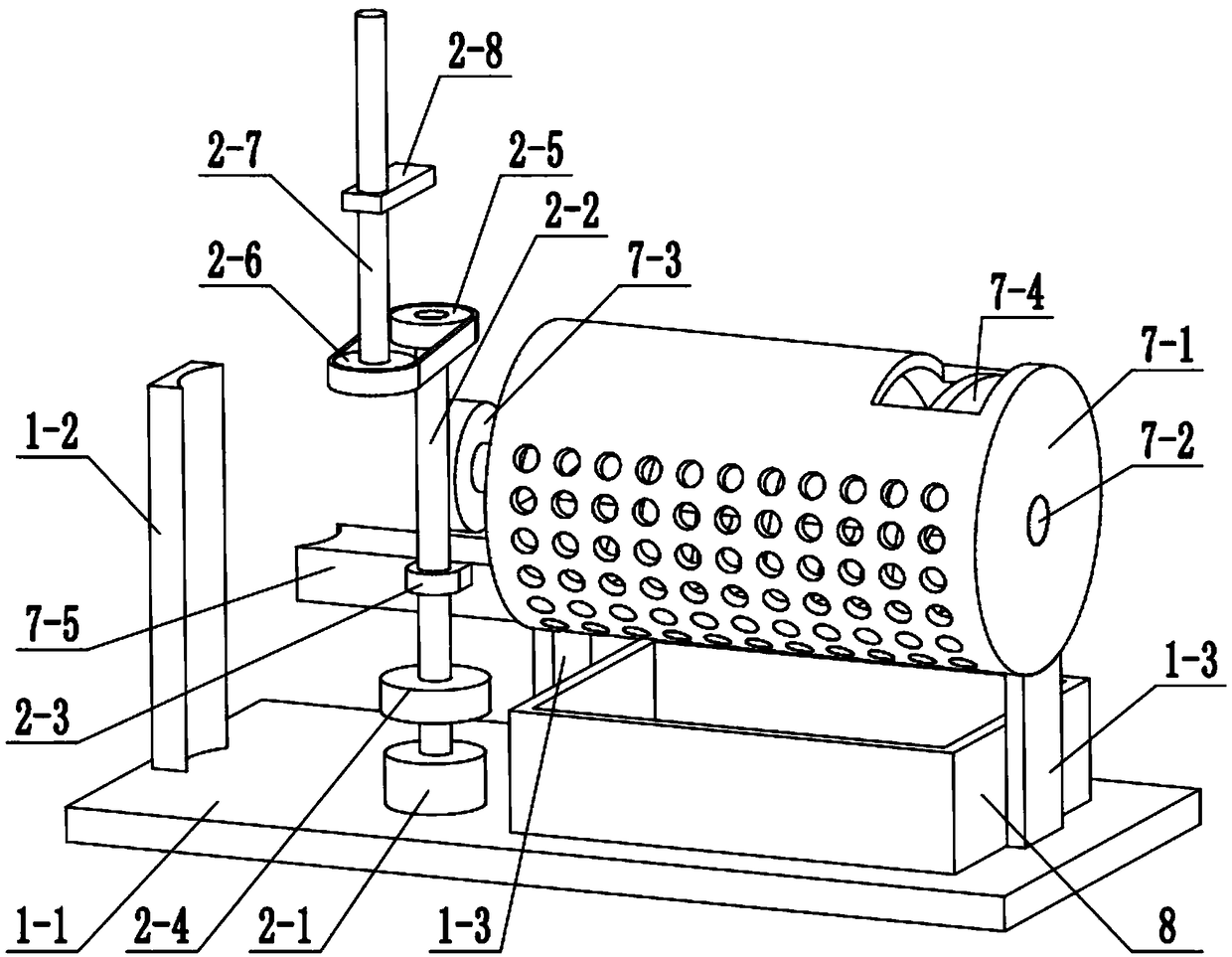

Fishbone separator and separating method thereof

The present invention is small fishbone separator and its separating method with high fish meat yield and high efficiency and suitable for use in restaurant. The fishbone separator includes a pestling unit and a separating unit connected via pipe and set inside the separator frame. The pestling unit includes pestling motor, pestling barrel with material inlet, and pestling shaft in the middle of the pestling barrel and with toothed rods. The separating unit includes separating motor and separating barrel with closely distributed separating holes. The present invention can separate fish meat from fishbone and fish skin effectively and suitable for food producing enterprise and restaurant.

Owner:关健

Preparation method for coarse grain rice noodles

ActiveCN103271292AConserve waterReduce manufacturing costFood preparationEnergy consumptionWater content

The invention discloses a preparation method for coarse grain rice noodles. The preparation method comprises the following steps of (1) mixing raw materials of rice and coarse grains according 55-75% by weight of the rice and 25-45% by weight of the coarse grains; (2) adding water to adjust water content in powder so as to make the powder accounts for 35-45% of a total weight of rice pulp, adding a quality improver with an amount of 0.3% of the total weight of the rice pulp, stirring and mixing uniformly to form powder base, performing early steam by passing through steam to make the gelatinization degree of the powder base reach 70-80%; (3) putting the powder base into a rice machine to extrude noodles, re-steaming for 8-12 minutes, cutting the re-steamed rice noodles into sections; and (4) sending the cut rice noodles into a drying oven, drying the rice noodles, controlling the water content within 11-13 wt%, and cooling the dried rice noodles to obtain the coarse grain rice noodles. The preparation method can increase preparation efficiency of the rice noodles and at the same time, reduces water consumption and energy consumption in the preparation process.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

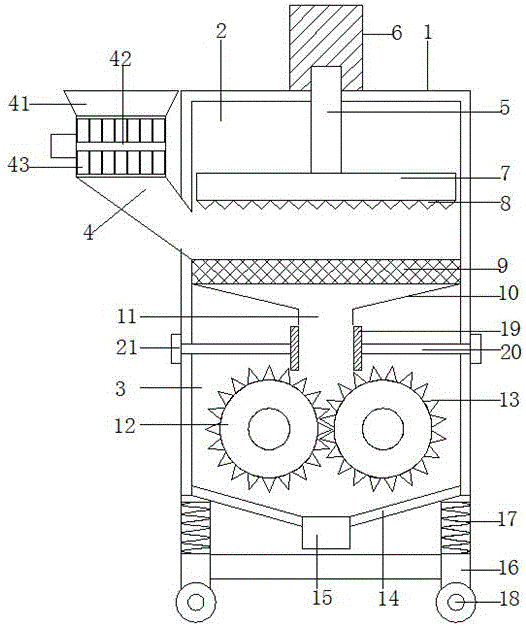

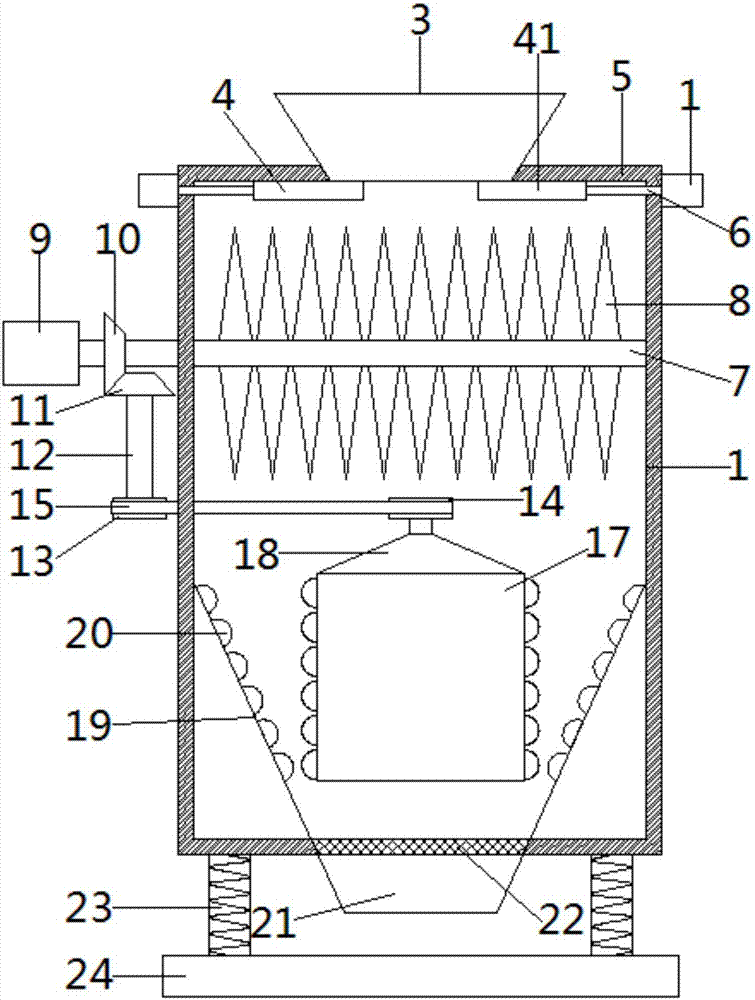

Damping smashing device for traditional Chinese medicine processing

InactiveCN107469969AAvoid corrosionExtended service lifeGrain treatmentsEngineeringEnergy consumption

The invention discloses a shock-absorbing crushing device for traditional Chinese medicine processing, which comprises a machine body, the outer wall of which is covered with a ceramic layer, a circular feeding port is opened on the upper side of the machine body, and a feeding hopper is connected to the feeding port , the bottom of the feed hopper matches the size of the feed port, and the left and right feed baffles are respectively arranged at the left and right ends of the lower side of the feed port, and the left feed baffle and the right feed The baffle is a semicircular baffle arranged symmetrically. This invention is a shock-absorbing crushing device for processing traditional Chinese medicine, which can control the feeding amount and feeding speed, and effectively improve work efficiency. Two crushing mechanisms are arranged inside the machine body. The material is fully crushed, and the two crushing mechanisms are driven by one motor, which effectively reduces energy consumption, greatly improves the crushing efficiency, and makes the medicinal materials crushed more fully. In addition, it can effectively reduce the vibration generated during the operation of the device and improve the operation of the device. stability.

Owner:单开禹

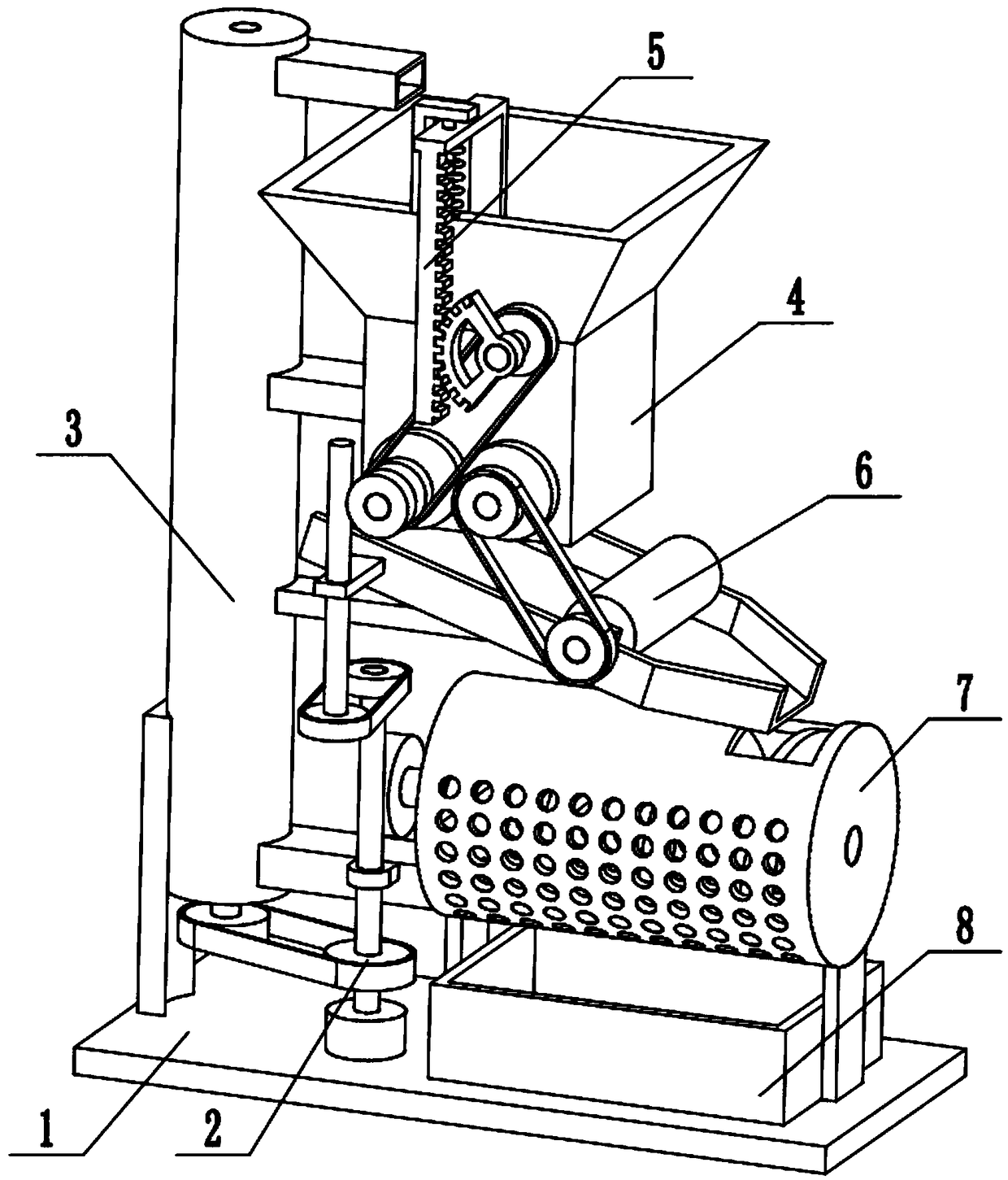

Biomass raw material processing device in field of new energy

The invention relates to the technical field of new energy, in particular to a biomass raw material processing device in the field of new energy. The biomass raw material processing device is characterized in that a power mechanism is fixedly connected to the middle end of a base, the power mechanism is in transmission connection with a circulating return assembly through a belt, the circulating return assembly is fixedly connected to the left end of the base, a crushing assembly is fixedly connected to the upper end of the circulating return assembly, the power mechanism is in meshed transmission connection with the crushing assembly, an intermittent feeding assembly is slidably connected in the crushing assembly, the intermittent feeding assembly is in meshed transmission connection withthe crushing assembly. According to the biomass raw material processing device, biomass raw materials can be sufficiently crushed, intermittent discharging can be achieved, so that the phenomenon ofblockage is prevented, meanwhile, the biomass raw materials can be continuously pushed to move downwards, so that the crushing efficiency is improved, morever, the crushed biomass raw materials can bescreened so that the biomass raw materials meeting requirements can be screened out, secondary reworking treatment does not need to be performed manually, and it is guaranteed that the crushed biomass raw materials can be fully combusted.

Owner:义乌飞思科技有限公司

Wastewater impurity precipitation machine for water utilization

InactiveCN107469458ACrushed fullyMix well and evenlyTreatment involving filtrationMultistage water/sewage treatmentWastewaterPulp and paper industry

The invention relates to a precipitation machine and particularly relates to a wastewater impurity precipitation machine for water utilization. The wastewater impurity precipitation machine has the beneficial effects that the adequate precipitation is realized, and the precipitation time is short. The wastewater impurity precipitation machine comprises a collection tank, a first mounting plate, a second mounting plate, a stirring mechanism, a linkage mechanism, a crushing mechanism, a first shaking mechanism, a second shaking mechanism and the like, wherein the second mounting plate is fixedly connected to the end part of the first mounting plate along the vertical direction; the first shaking mechanism, a first slide rail and the second shaking mechanism are sequentially fixedly connected to the side part of the second mounting plate along the height direction, and the first shaking mechanism is located above the first rail. The wastewater impurity precipitation machine has the beneficial effects that the adequate precipitation is realized, and the precipitation time is short.

Owner:高月江

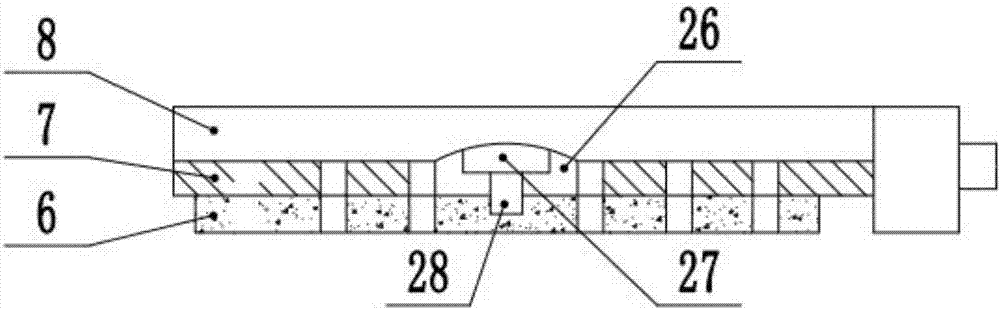

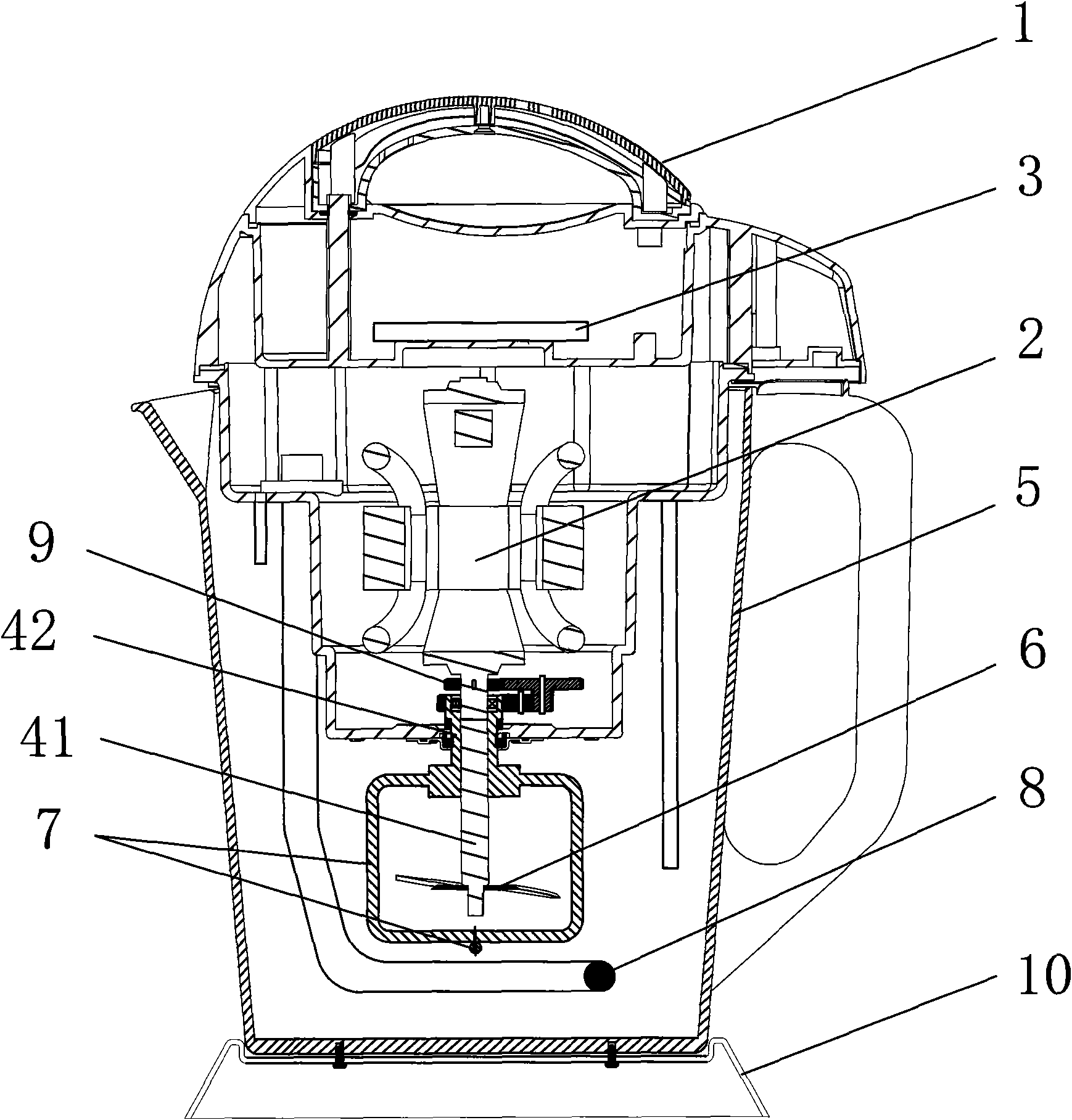

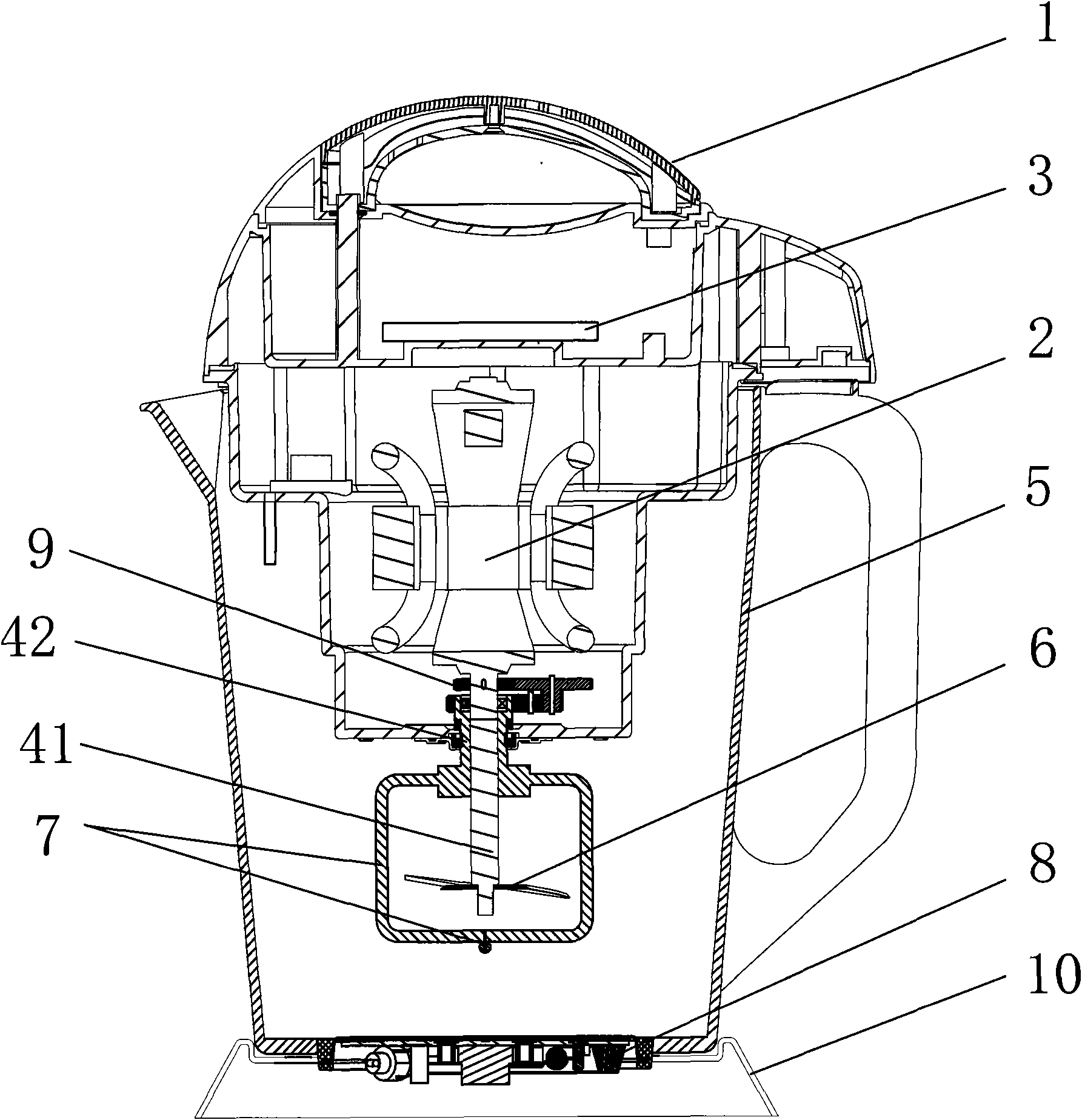

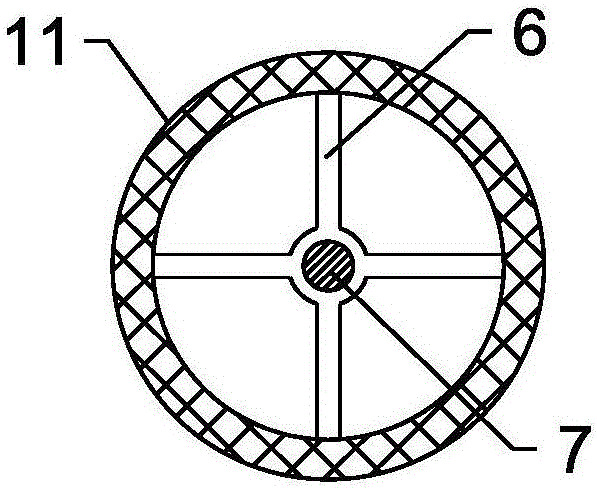

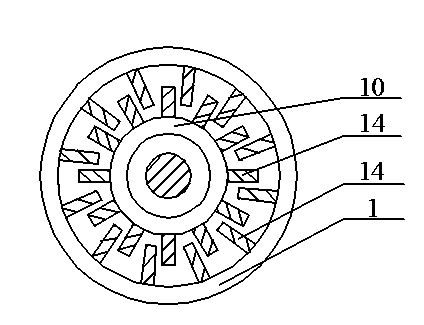

Soybean milk machine capable of completely smashing pulping materials

InactiveCN101647535AImprove beating efficiencyAvoid the problem of sticking the bottom of the tubeBeverage vesselsFood preparationEngineeringMotor shaft

The invention relates to a soybean milk machine capable of smashing pulping materials, comprising a pedestal, a nose, an electric motor arranged in the nose, a control device, a cup body and a heatingdevice. The soybean milk machine is characterized in that an inner shaft and an outer shaft extend from the downside of the nose to the interior of the cup body, one end of the inner shaft is connected with a smashing device, one end of the outer shaft is connected with a stirring frame, and the inner shaft and the outer shaft are connected with the electrical motor output shaft by a transmissiondevice. The invention adopts the electric motor to connect the outer and inner shafts, and the smashing device and the stirring frame are respectively fixed on the inner and outer shafts, when the soybean milk machine is in operation, the stirring frame and the smashing device synchronously operate in inverse direction, beans are smashed by collision with the smashing device under the rotating driving of the stirring frame and further smashed by collision with the stirring frame, thus not only pulping efficiency of the soybean milk machine is improved but also the problem of tube and bottom pasting is avoided. Besides, no flow disturbing rib or device is required to be arranged in the cup body of the soybean milk machine, so that the cleaning of the soybean milk machine is more convenientand simper.

Owner:MIDEA GRP CO LTD

Uniform stirring device for contaminated soil remediation

InactiveCN106363018ACrushed fullyEasy to crushRotary stirring mixersTransportation and packagingHelical bladeSoil remediation

The invention discloses a uniform stirring device for contaminated soil remediation. The uniform stirring device comprises a first box and a second box, wherein the second box is arranged at the left end of the first box, a second motor is arranged at the left end of the second box, a first motor is arranged at the right end of the first box, a rotary shaft connected with the second motor is arranged on the inner side of the second box, a rotary drum connected with the first motor is arranged on the inner side of the first box, a plurality of stirring blades are arranged uniformly on the outer side of the rotary drum, helical blades are arranged on the rotary shaft on the inner side of the second box, and a plurality of smashing cutters are arranged uniformly in a staggered manner on the rotary shaft on the inner side of the rotary drum. The uniform stirring device is compact and stable in structure, can be used for rapid and uniform stirring for contaminated soil remediation, and improves the contaminated soil remediation effect.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

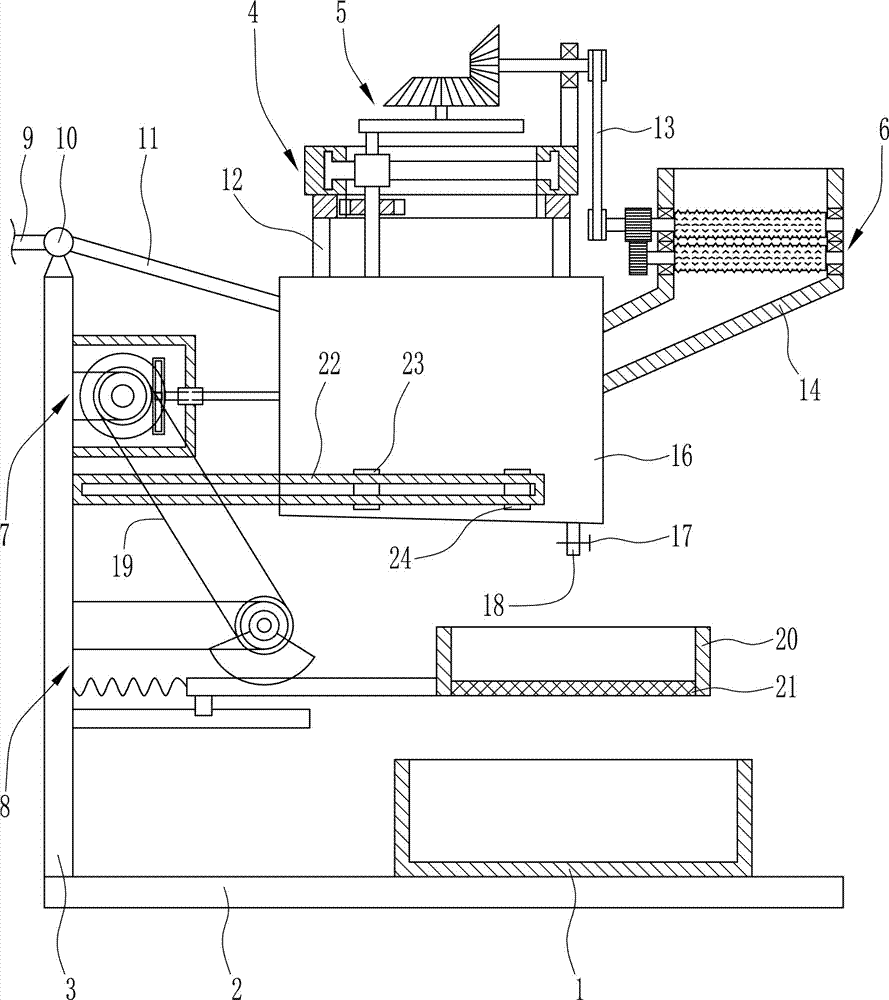

Food pulverizing device

A food pulverizing device comprises a bottom plate device, a first pulverizing device, a second pulverizing device, a frame device and a third pulverizing device, wherein the bottom plate device comprises a bottom plate, a material storage box and a first fixed block; the first pulverizing device comprises a first vertical plate, a first oblique plate, a first bracket, a second bracket, a first cross rod, a first oblique rod, a bend plate, a first roller and a second oblique plate; the second pulverizing device comprises a pulverizing frame, a moving block, a first positioning rod, a first fixed rod, a first spring, a second roller, a cam, a third cross rod, a first vertical rod and a fourth cross rod; the frame device comprises a frame body, a material collecting hopper, a fifth cross rod, a second oblique rod, a third bracket, a sixth cross rod, a fourth bracket, a fifth bracket and a sixth bracket; and the third pulverizing device comprises a third roller, a pulverizing plate, a connecting rod, a grip rod, a second positioning rod, first saw teeth, a fourth roller and second saw teeth. The food pulverizing device can thoroughly pulverize food during food processing and is great in pulverizing effect.

Owner:ZHONGSHAN ZHAISHI HEALTH PRESERVATION CO LTD

Pulverizer for producing ceramics and achieving convenient discharge function

InactiveCN104923358AAvoid cakingImprove work efficiencyGrain treatmentsDischarge efficiencyEngineering

The invention discloses a pulverizer for producing ceramics and achieving a convenient discharge function. The pulverizer comprises a pulverizer body, a stirring rotating shaft and pulverizing blades. The upper side of the pulverizer body is provided with a feeding hopper. The lower side in the feeding hopper is horizontally provided with the stirring rotating shaft. The outer wall of the stirring rotating shaft is vertically and symmetrically provided with the pulverizing blades. A first pulverizing mechanism is horizontally arranged on the upper side in the pulverizer body. A second pulverizing mechanism is horizontally arranged on the lower side of the first pulverizing mechanism. According to the pulverizer for producing the ceramics and achieving the convenient discharge function, a stirring mechanism in the feeding hopper can pre-pulverize, stir and scatter materials, and the follow-up pulverizing effect and efficiency are improved; the two pulverizing mechanisms arranged in a staggered mode are adopted to pulverize materials fully, the pulverized materials are screened, the materials of which the size does not meet the requirement are lifted into the pulverizer in a circulation mode through a lifting machine to be pulverized, the pulverizing effect is guaranteed, the pulverizing efficiency is improved, discharging is driven through a conveying belt, no manual operation is needed, the discharging efficiency is improved, and the pulverizer is convenient and fast to use.

Owner:苏晓玲

Conical superfine grinding grading machine

The invention provides a conical superfine grinding grading machine which can improve the grinding capacity, the grinding effect and the grinding efficiency, effectively produce a superfine powder product and increase the product yield. A cone is in a conical shape with large top and narrow bottom, a grading shaft penetrates through the bottom end of the cone to be arranged inside the cone, one end of a sleeve is installed onto the grading shaft in the cone through a bearing and held down by a compression nut, the other end of the sleeve is installed on the extending end of the grading shaft through a bearing, two opposite sides of bearings on two ends of the sleeve are respectively provided a washer in a pressing manner, the other side of each bearing is provided with an ejector ring in a pressing manner, a sleeve belt pulley is installed on the extending end of the sleeve in a sleeved manner, a grading belt pulley is arranged on the extending end part of the grading shaft in a sleeved manner, a crushing tray is fixed on the sleeve on the inner lower end of the cone through the cooperation of a bushing and a lower bearing and compressed onto the cone through a bottom gland, the crushing tray and the corresponding cone are respectively provided with grinding rod pins which are distributed in a staggering manner and provided with helical grooves, and a crushing barrel with conical teeth and a crushing ring with conical teeth, which is correspondently installed on the inner wall surface of the cone, are alternately arranged.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

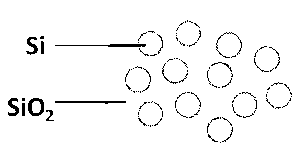

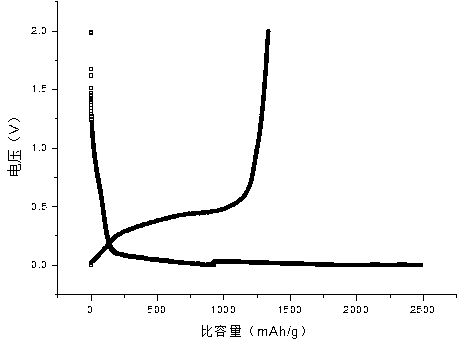

Lithium ion battery silicon-based negative material and preparation method thereof

InactiveCN103236517ASmall particle sizeAlleviate volume effectCell electrodesSilicon monoxideSilicon oxide

The invention relates to a lithium ion battery silicon-based negative material and a preparation method thereof, which belong to the technical field of lithium ion battery negative materials. The lithium ion battery silicon-based negative material is prepared from silicon monoxide; the macroscopic particle diameter of the negative material is 10-25 micrometers; according to a microstructure, the negative material is composed of nanometer silicon particles covered with silica; the internal silicon particle diameter of the negative material is 20-30 nanometers; and at 0.1C discharge rate, the first discharge capacity of the negative material reaches 2010-2640 mAh / g, and is 420-790 mAh / g after 50 cycles. The negative materials with the structure characteristic combines the dispersion and the reduction of silicon particles; and on one hand, the silicon particles can be dispersed by a pore channel structure of silica so as to provide a space for the expansion of silicon in charge and discharge processes, on the other hand, the particle diameter of silicon can be reduced, and therefore, a volume effect of silicon in the charge and discharge processes can be weakened.

Owner:中国东方电气集团有限公司

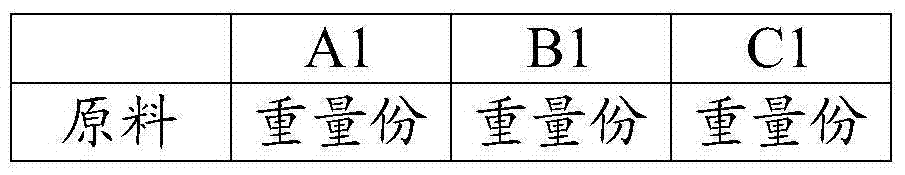

Food therapy and health care compound fruit and vegetable rice flour composition, preparation method and applications thereof

ActiveCN104256411AImprove stubborn diseasesImprove stubborn diseases such as mouth ulcersFood ingredient functionsFood preparationFlavorAdditive ingredient

The present invention discloses a compound fruit and vegetable rice flour composition with food therapy and health care efficacy, a preparation method and applications thereof. The compound fruit and vegetable rice flour composition comprises the following raw materials by weight: 85 to 99 parts of rice, 1 to 10 parts cabbage powder, and 0.1 to 5 parts of other vegetable powder and / or fruit powder. The compound fruit and vegetable rice flour composition in the present invention has homology of medicine and food, is natural and safe; is suitable for general people, can be compounded according to different people so as to process and produce compound fruit and vegetable rice flour with different food therapy and health care efficacy and suitable for different people; has balanced and comprehensive nutrition, reasonable nutrition structure, has good conditioning and preventing effects on mouth ulcer and effects of invigorating stomach and nourishing stomach, loosening bowel to relieve constipation, and enhancing immunity with validations; has pure and delicate taste, can well make up the disadvantages that the nutrients and the color of traditional rice flour are single, and meets the requirement of consumers for taste, flavor and nutrition.

Owner:高燕

Chinese herbal medicine sorting and crushing device

The invention discloses a sorting and crushing device for Chinese herbal medicine, which relates to the technical field of crushing devices for medical Chinese herbal medicine. The invention includes a crushing device shell, a feed port 1 and a feed port 2, and a pounding box is arranged in the middle of the crushing device shell. The upper part of the pounding box is provided with a pounding block, and the bottom of the pounding box is moved on the moving slide rail by setting a slider. A crushing box is arranged in the shell of the smashing device, and a crushing mechanism is set in the crushing box. A motor is arranged on the top wall of the crushing device shell. , motor one connects cam one, contact roller one, first connecting rod and pounding block sequentially from top to bottom, cam two is arranged on the bottom wall of the shell of the pulverizing device, and cam two connects contact roller two and the second one from left to right in sequence The second connecting rod and the side wall of the pounding box, and the right side of the second cam are sequentially connected from bottom to top to contact the third and third connecting rods and the bottom of the crushing box. The present invention adopts the method of first sieving and then classifying and crushing Chinese herbal medicines, and the smashing efficiency is high. The crushing effect is good, saving time and effort, and improving work efficiency.

Owner:弘毅天承知识产权股份有限公司

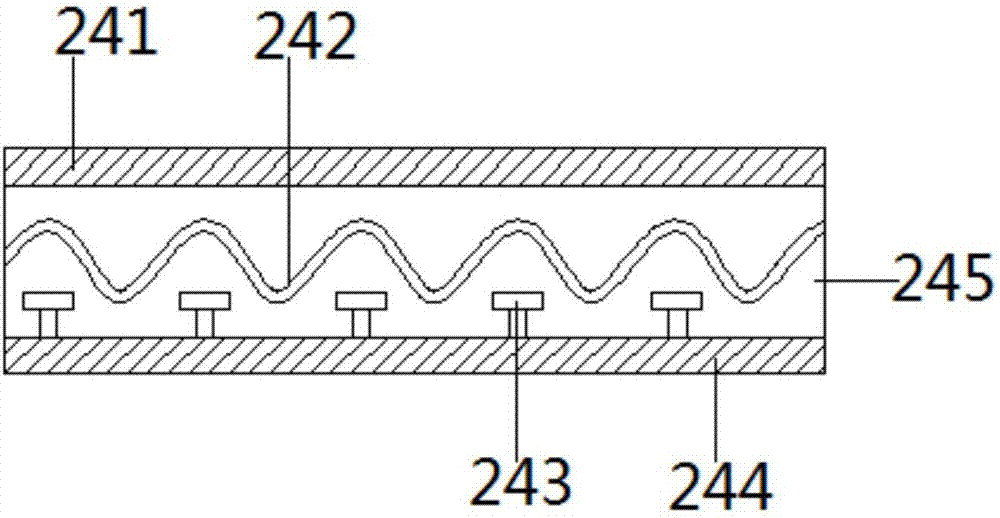

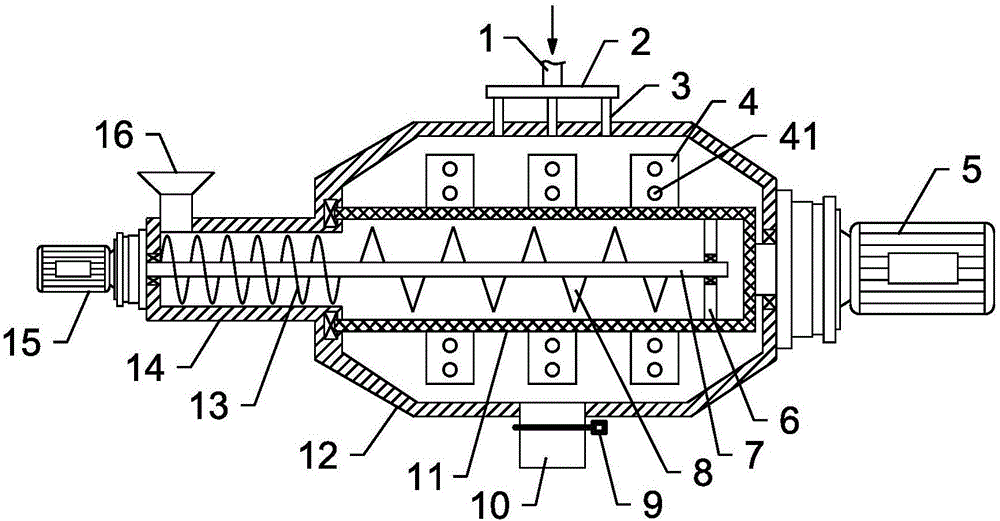

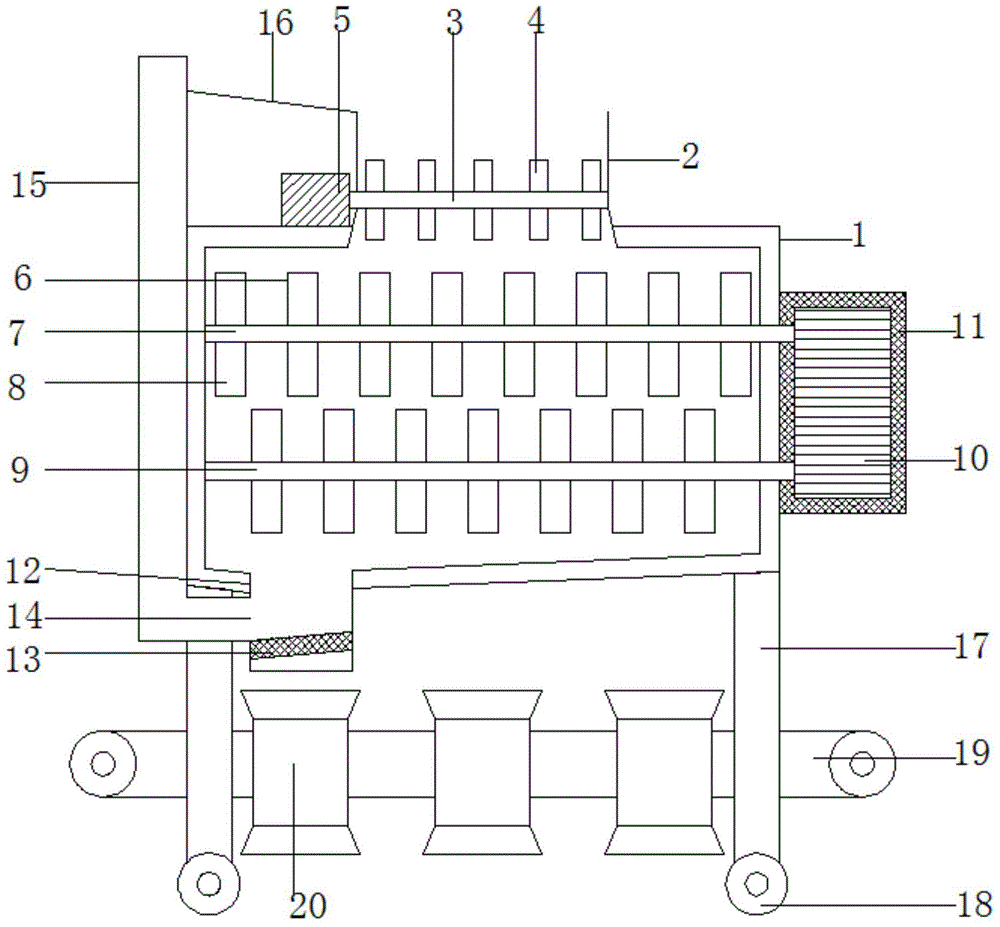

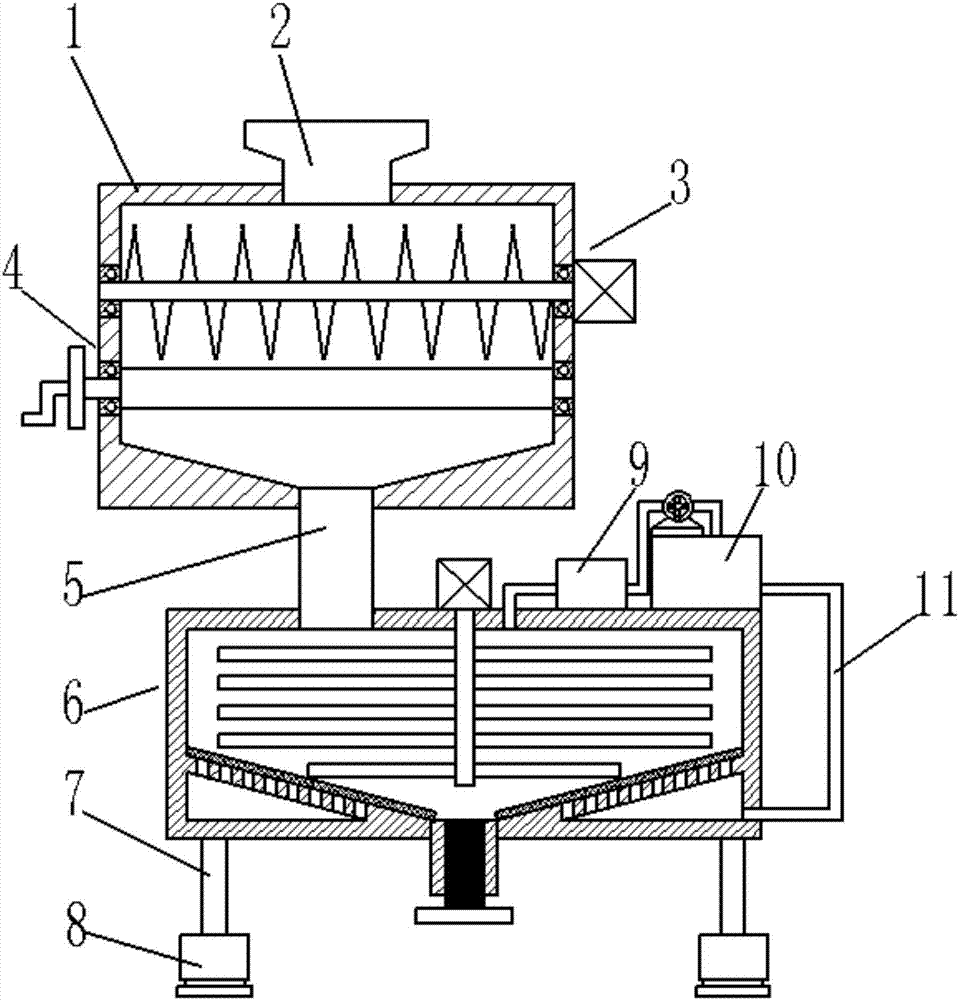

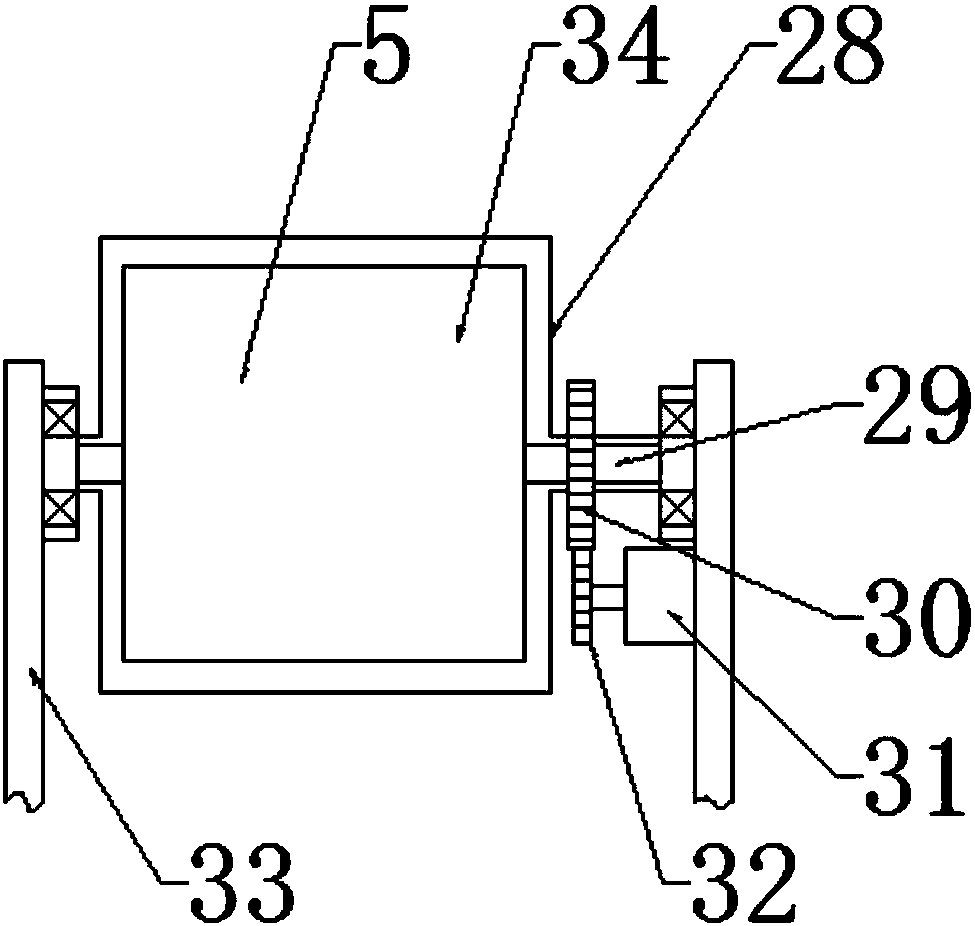

Straw grinding stirring drying device

InactiveCN107211666ACrushed fullyImprove crushing qualityDrying gas arrangementsCuttersPulp and paper industryComminution

The invention provides a novel straw crushing, stirring and drying device, which belongs to the technical field of mechanical equipment. It includes a crushing device (3), a stirring and drying device (6), a dehumidification device (9) and an air heating device (10); the crushing device (3) is fixed above the inside of the crushing box (1); the stirring and drying device (6) Welded on the four supporting columns (7); the dehumidification device (9) is fixedly installed on the right side of the upper end of the stirring drying box (61) in the stirring drying device (6); the air heating device ( 10) Fixedly installed on the right side of the upper end of the stirring drying box (61) in the stirring drying device (6), on the right side of the dehumidification device (9). The novel device of the invention has high crushing quality of straw, and after crushing, the straw is stirred and dried, and the air in the stirring drying box is extracted to carry out circulating hot air drying, thereby ensuring the drying efficiency of the straw, and the dried straw is convenient for storage.

Owner:合肥多智科技开发有限公司

Medicine material crushing device

A medicine material crushing device comprises a body, a support device, a crushing device body, a supporting device and a cylinder device. The body is provided with a first groove, a first inclined rod, a first vertical plate, a second groove, a counterweight block, a supporting block, a third groove and wheels. The support device comprises a first support, a first inclined rod, a first cylinder, a first pushing rod and a first pushing block. The crushing device body comprises a movable plate, a sliding block, a second pushing rod and a crushing wheel. The supporting device comprises a second support, a square hole, a spring, a first transverse rod, a second transverse rod and a vertical rod. The cylinder device comprises a second cylinder, a third pushing rod, a pushing plate and a cushion block. By means of the device, medicine materials can be fully crushed, crushing efficiency is improved, the automation degree is high, manual crushing is not needed, labor intensity of workers is relieved, and manual cost is reduced.

Owner:黄斌

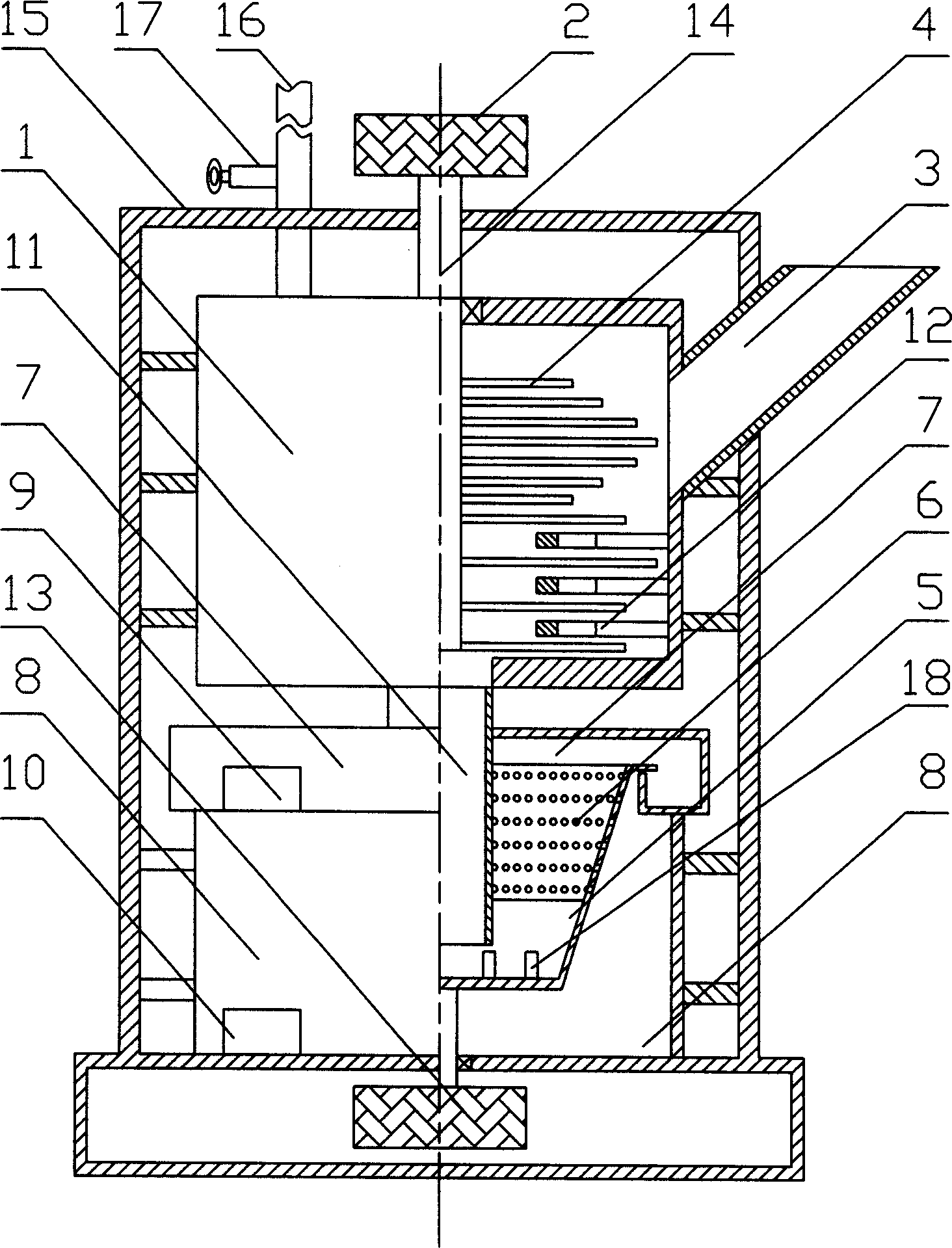

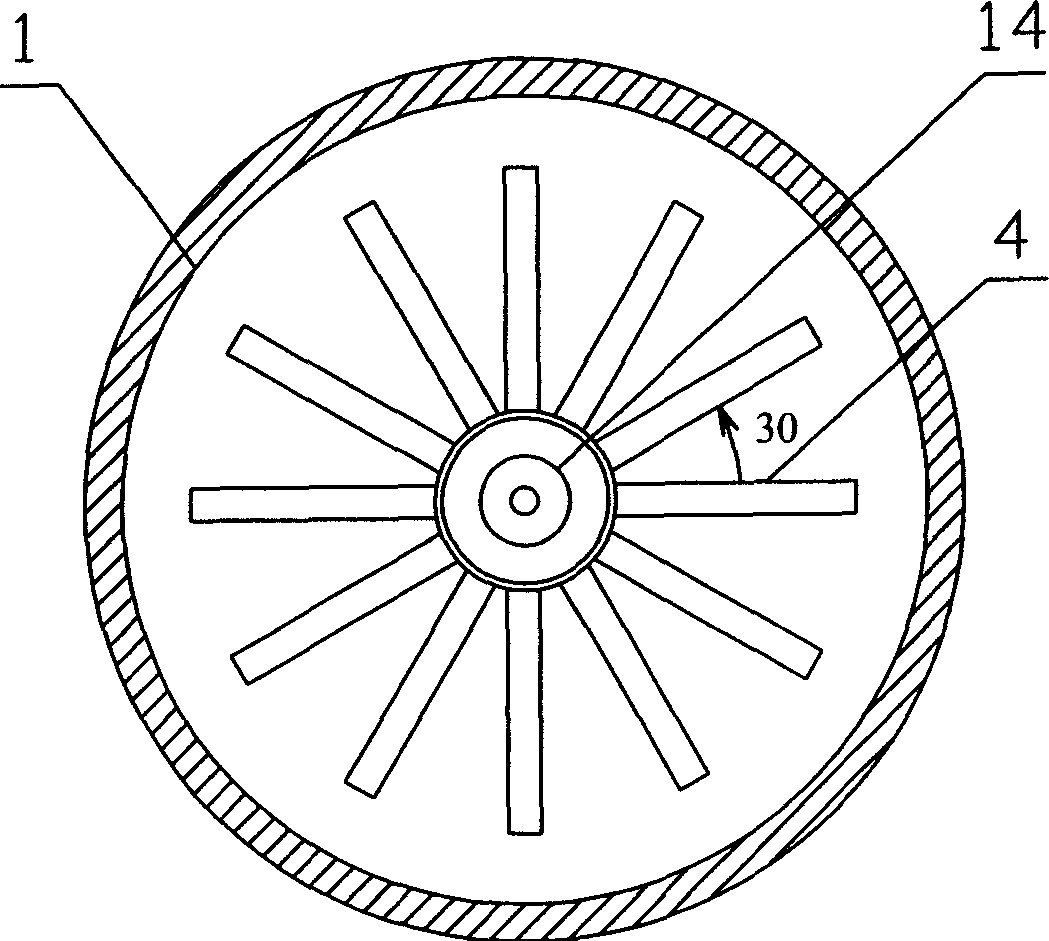

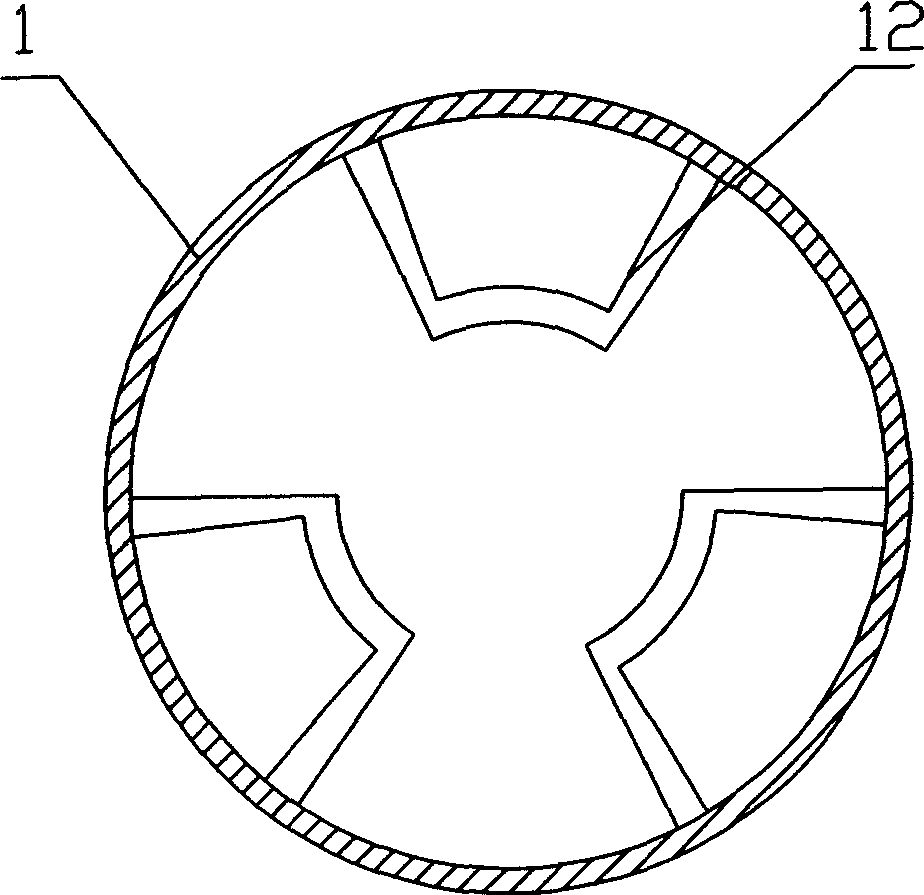

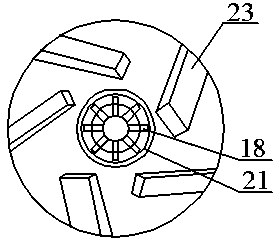

Crushing and grinding intenerated equipment for traditional Chinese medicines with iron removal function

InactiveCN107638924AAffect qualityImprove crushing efficiencyMagnetic separationGrain treatmentsDrive shaftGear wheel

The invention discloses crushing and grinding intenerated equipment for traditional Chinese medicines with an iron removal function. The crushing and grinding intenerated equipment for the traditionalChinese medicines with the iron removal function comprises a bottom plate, a crushing barrel, a grinding shell, a first motor, first crushing blades, second crushing blades, third crushing blades, fourth crushing blades, a grinding ball and an iron removal device, wherein the iron removal device comprises a sector electromagnet, a cylindrical shell and a second motor, the crushing and grinding intenerated equipment is provided with the first motor, a rotating shaft, the first crushing blades, the second crushing blades, the third crushing blades and the fourth crushing blades, two ways of horizontal crushing and vertical crushing are used simultaneously, so that the traditional Chinese medicines are crushed more fully, and the crushing effect is better, a first pulley, a second pulley, abelt, a transmission shaft, a first gear and a rack are arranged, and matched to make the rotating directions of the grinding shell and the grinding ball opposite, therefore, the grinding efficiency is improved, and the iron removal device is arranged, and comprises the sector electromagnet, the cylindrical shell and the second motor, so that iron chips can be removed and collected from Chinese medicinal materials to prevent the iron chips from affecting the quality of the medicinal materials.

Owner:广州林腾生物科技有限公司

Vibrating type wheat straw smashing machine

A vibrating type wheat straw smashing machine comprises a base, a collecting box, a frame, air cylinder devices, supporting devices, a smashing device and a motor device. First cross plates, first vertical plates, first filter plates, first connecting rods, first supporting rods, first inclined rods, first rolling wheels, bristles and through holes are arranged on the frame. The supporting devices comprise first supporting rods, second inclined rods, first supports and horizontal rods. The air cylinder devices comprise air cylinders, push rods, push plates, third inclined rods and fourth inclined rods. The smashing device comprises a first smashing wheel, a second smashing wheel, a third smashing wheel and smashing teeth. The motor device comprises first supporting columns, a motor, a rotary shaft and a rotary disc. The collecting box comprises second supporting rods, first springs and an abutting block. One end of each second supporting rod is fixedly connected with the inner surface of the collecting box, and the other ends of the second supporting rods are in sliding connection with the side face of the frame. Wheat straw can be fully smashed, smashing efficiency is high, and the effect is good; and meanwhile, repeated smashing can be carried out.

Owner:山东分秒智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com