Feed crushing and grinding equipment for animal husbandry

A technology for animal husbandry and feed, which is applied in the field of feed crushing and grinding equipment for animal husbandry, which can solve problems such as insufficient crushing, and achieve the effects of improving crushing efficiency, avoiding mesh blockage, and sufficient crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

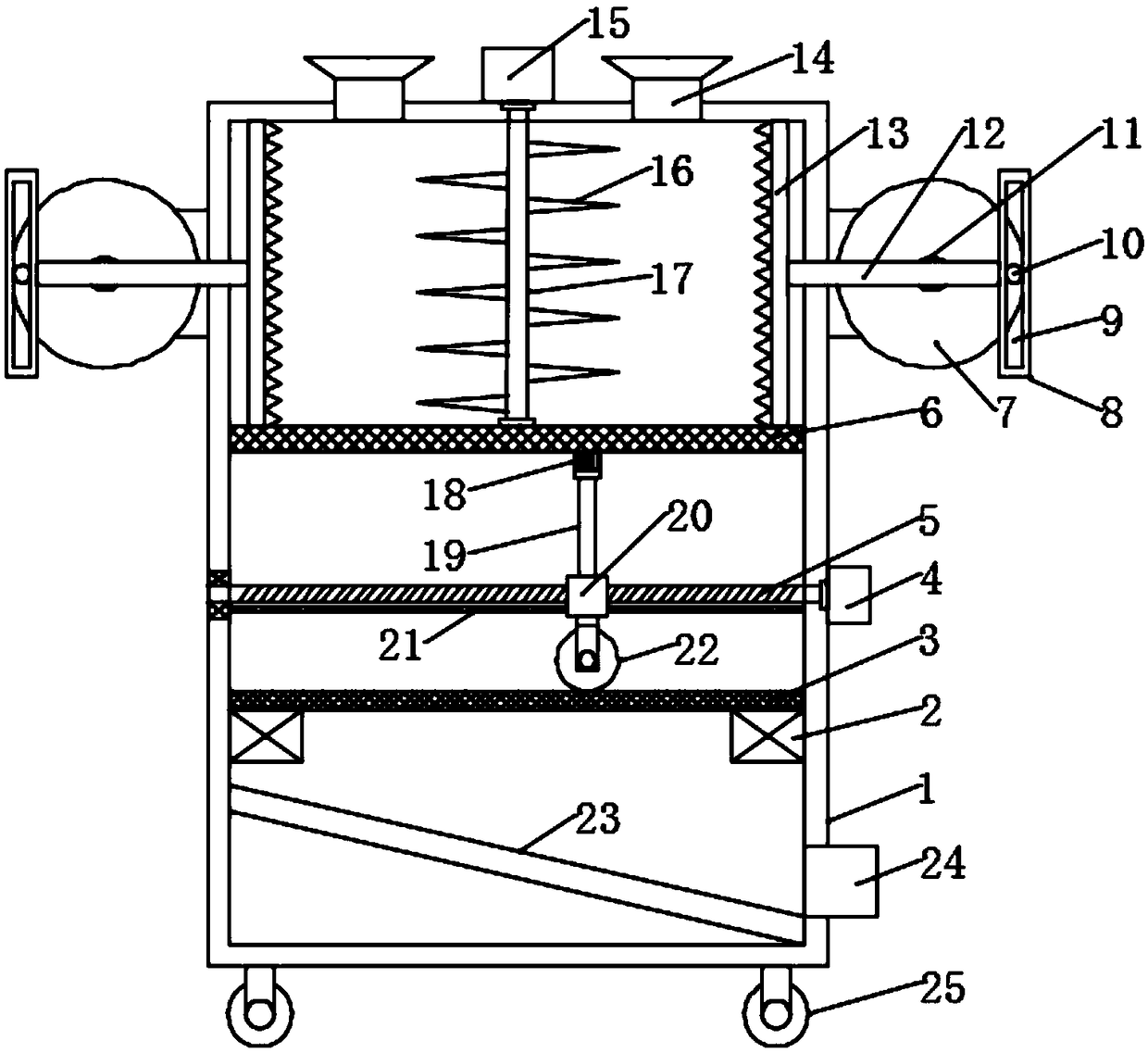

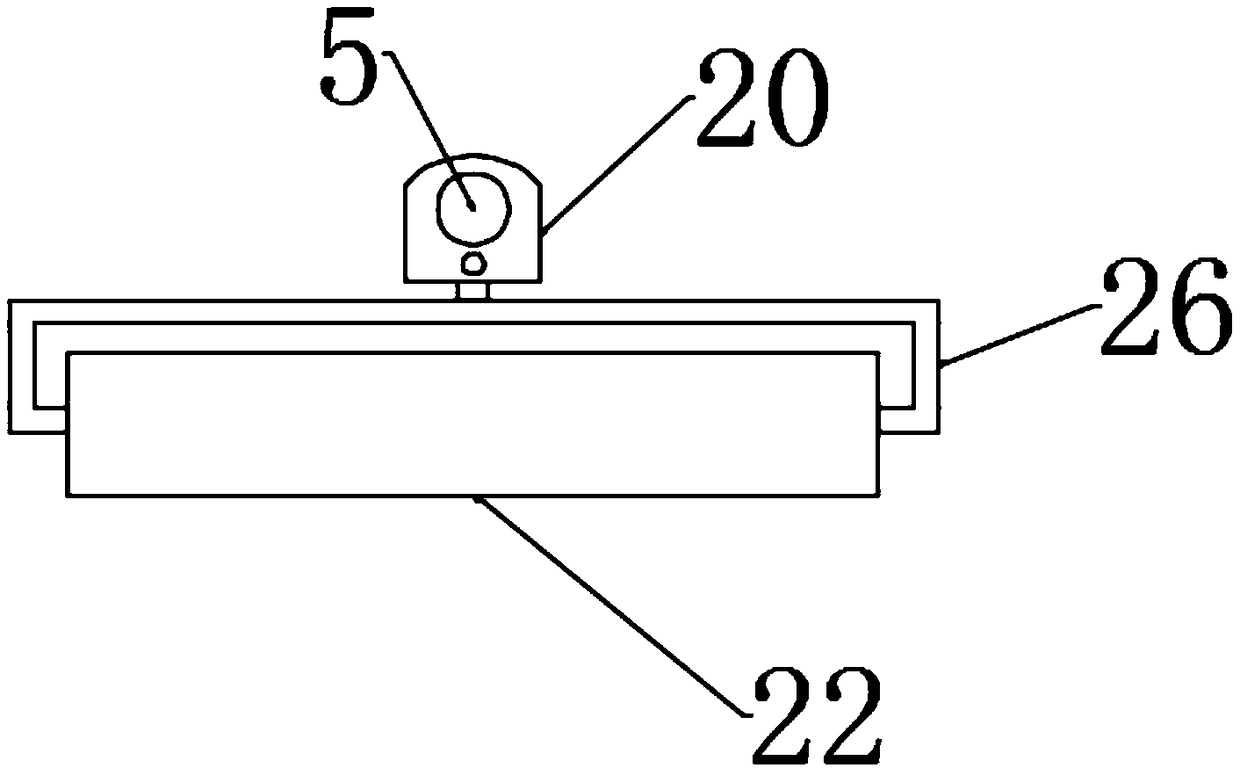

[0022] see Figure 1~2 , in the embodiment of the present invention, a feed crushing and grinding equipment for animal husbandry includes a box body 1, a first motor 15, a rotating shaft 17, a crushing blade 16, a first screen 6, a grinding roller 22 and a second screen 3, Rollers 25 are installed on the four corners of the bottom of the box body 1. The rollers 25 are self-locking rollers. A box door is installed on the front side wall of the box body 1 through hinges and buckles. A feed hopper 14 is provided, a discharge port 24 is provided on one side of the bottom of the box body 1, and a first screen 6 and a second screen 3 are installed at intervals from top to bottom in the inner cavity of the box body 1. The mesh is larger than the mesh of the second screen 3, and a sliding plate 23 is installed obliquely below the second screen 3 in the box body 1. The bottom of the sliding plate 23 extends to the discharge port 24, and the second screen 3 The vibration exciter 2 is i...

Embodiment 2

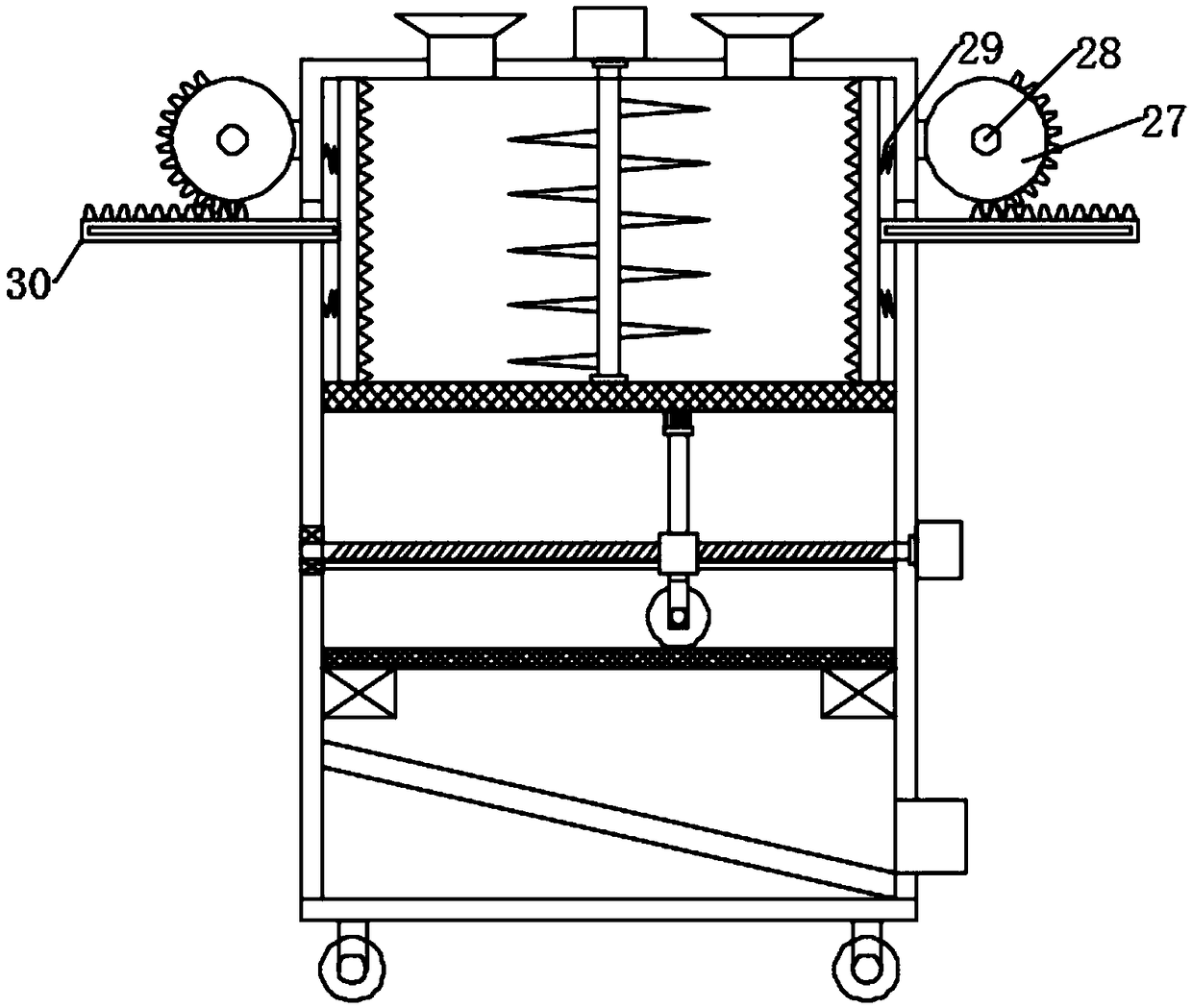

[0024] see image 3, The difference between this embodiment and Embodiment 1 is that the first driving mechanism is replaced by a second driving mechanism, and the second driving mechanism includes a third motor 28, an incomplete gear 27, a rack 30 and an extension spring 29. The third motor 28 is installed on the side wall of the box body 1 through a mounting plate, an incomplete gear 28 is installed at the end of the output shaft of the third motor 28, and a rack 30 is provided under the incomplete gear 28, and the incomplete gear 28 meshes with the rack 30, the other end of the rack 30 runs through the side wall of the box body 1 and is welded and fixed with the crushing plate 13, the side wall of the box body 1 is provided with a through hole for the movement of the rack 30, the front and rear sides of the rack 30 are The integral type is provided with long strip-shaped protrusions, and the through-hole wall of the side wall of the box body 1 is provided with a chute to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com