Conical superfine grinding grading machine

A technology of ultra-fine pulverization and classifier, which is applied in grain processing and other directions to achieve the effect of reasonable structure, expanding pulverizing area and reducing powder flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

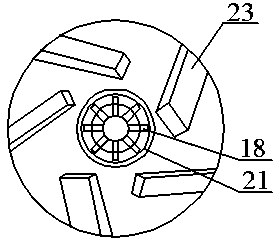

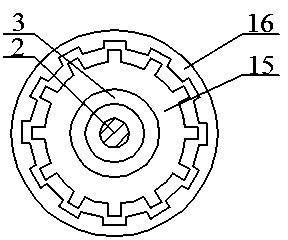

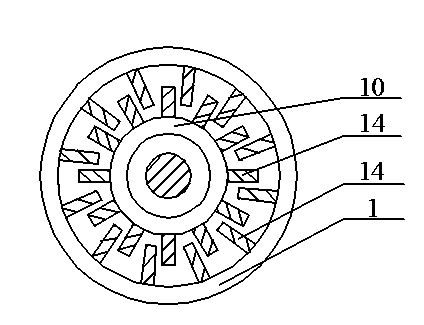

[0011] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a cone 1, the cone 1 is conical with a wide top and a narrow bottom. It is characterized in that: the grading shaft 2 passes through the bottom of the cone 1 and is placed in the cone 1, and one end of the sleeve shaft 3 passes through the bearing 4 is installed on the grading shaft 2 inside the cone 1, and is compressed with a compression nut 5. The other end of the sleeve shaft 3 is installed on the protruding end of the grading shaft 2 through the bearing 4, and the opposite ends of the bearings 4 on the sleeve shaft 3 A washer 6 is pressed on one side, a top ring 7 is pressed on the other side of the bearing 4, the shaft pulley 8 is set on the extension end of the sleeve shaft 3, the grading pulley 9 is set on the end of the grading shaft 2 extension, the crushing disc 10 is fixed on the sleeve shaft 3 at the inner lower end of the cone tube 1 through the sleeve 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com