Patents

Literature

52results about How to "Avoid erection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

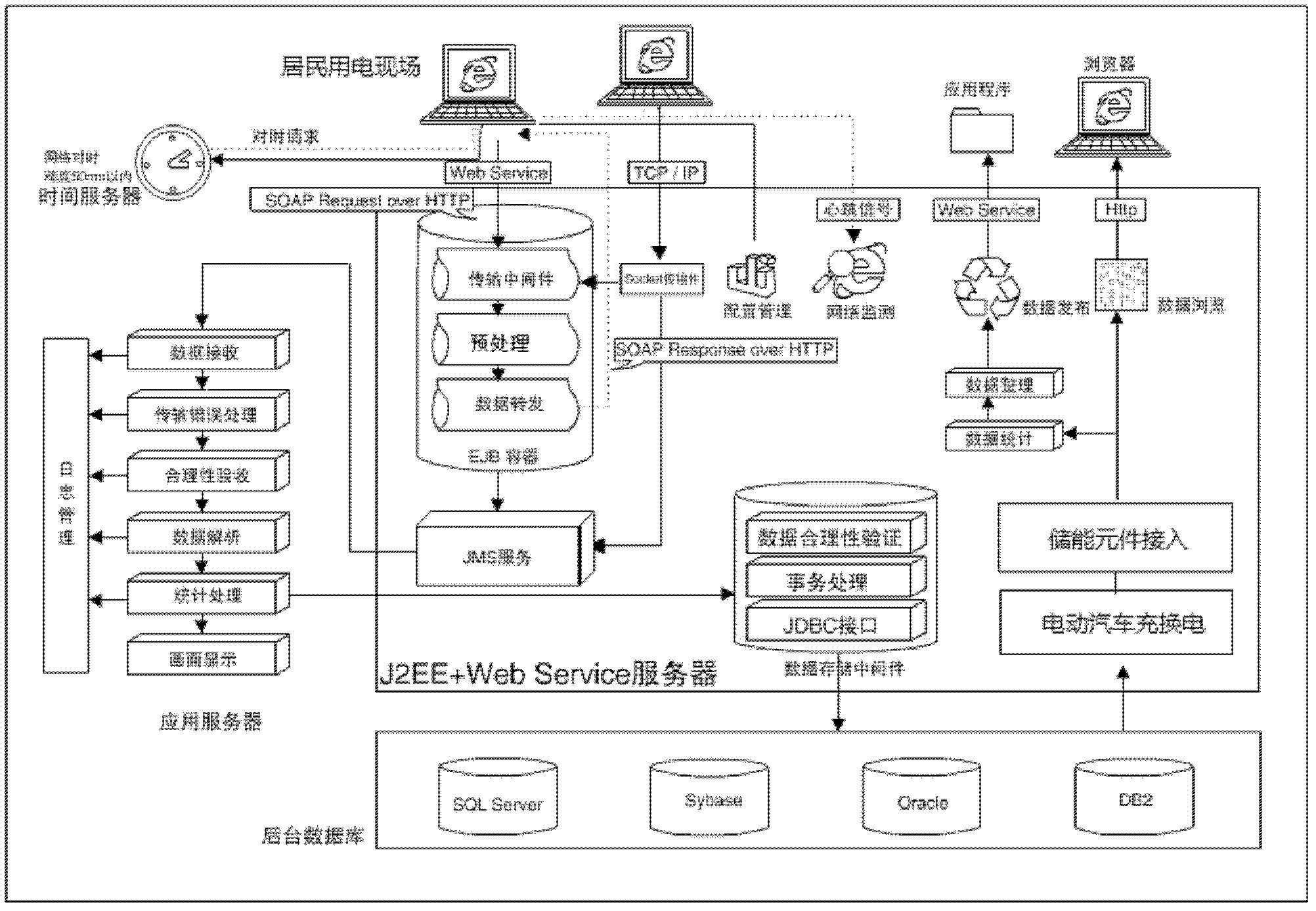

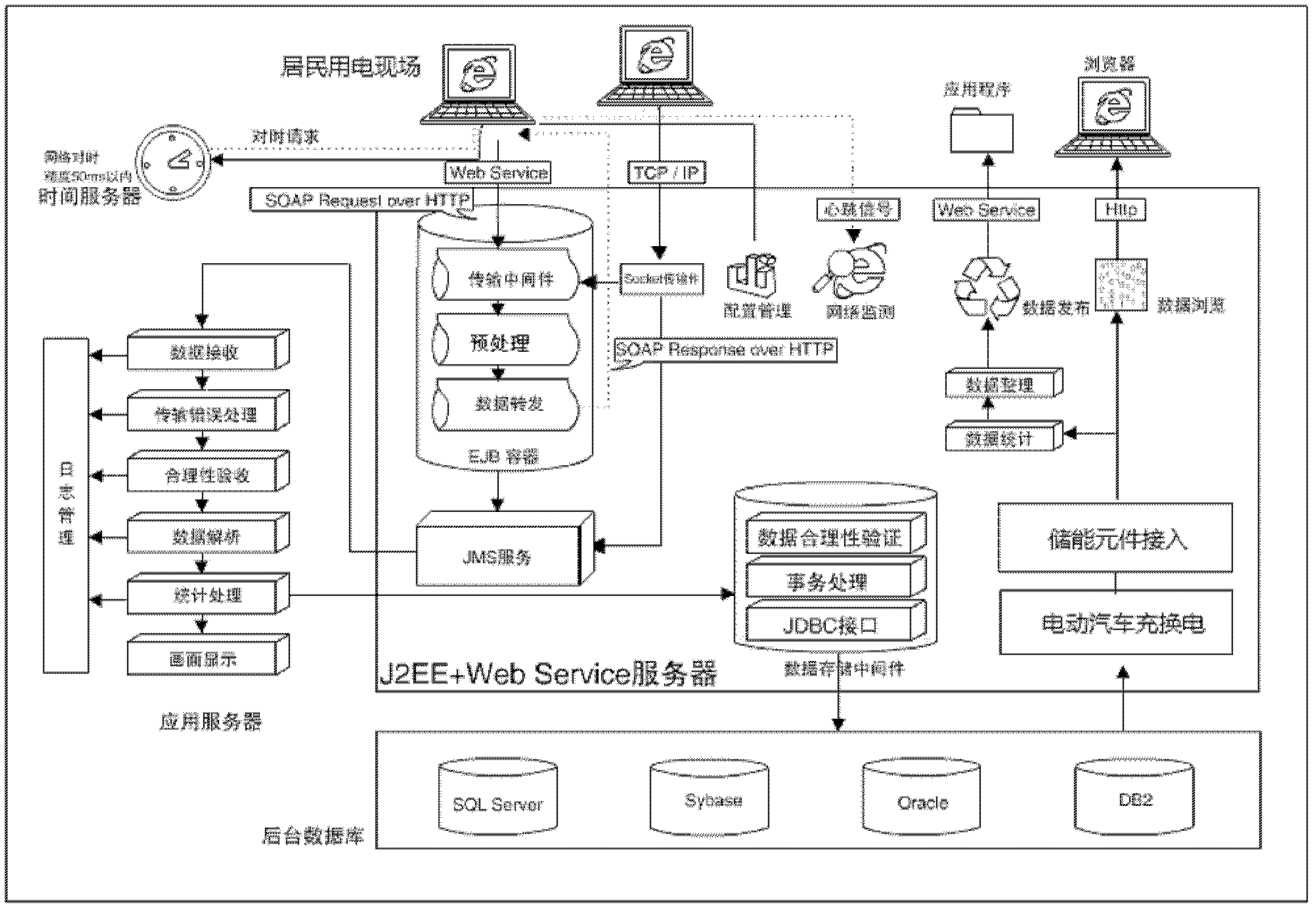

Intelligent resident electricity utilization management method and management system

InactiveCN102509162AReduce the impactQuick calculationData processing applicationsElectric vehicle charging technologyElectricityManagement efficiency

The invention discloses an intelligent resident electricity utilization management method and a management system. The management system comprises an intelligent electric energy meter, a collector, a concentrator, a host station server, a short message platform, an energy storage element, and an electric vehicle electricity charging and conversion management module. The management method comprises the steps of intelligent acquisition for the resident electricity consumption condition, ordered electricity utilization management realization, on-line energy charge calculation, line loss analysis for power distribution grid which directly powers resident users, management in energy storage element access and charge-discharge, and management in conversion and charging of the electric vehicle. Through the management system and the management method, the advantages of intelligent electricity utilization management, improved management efficiency, and reduced management cost are achieved.

Owner:SHENZHEN CLOU ELECTRONICS

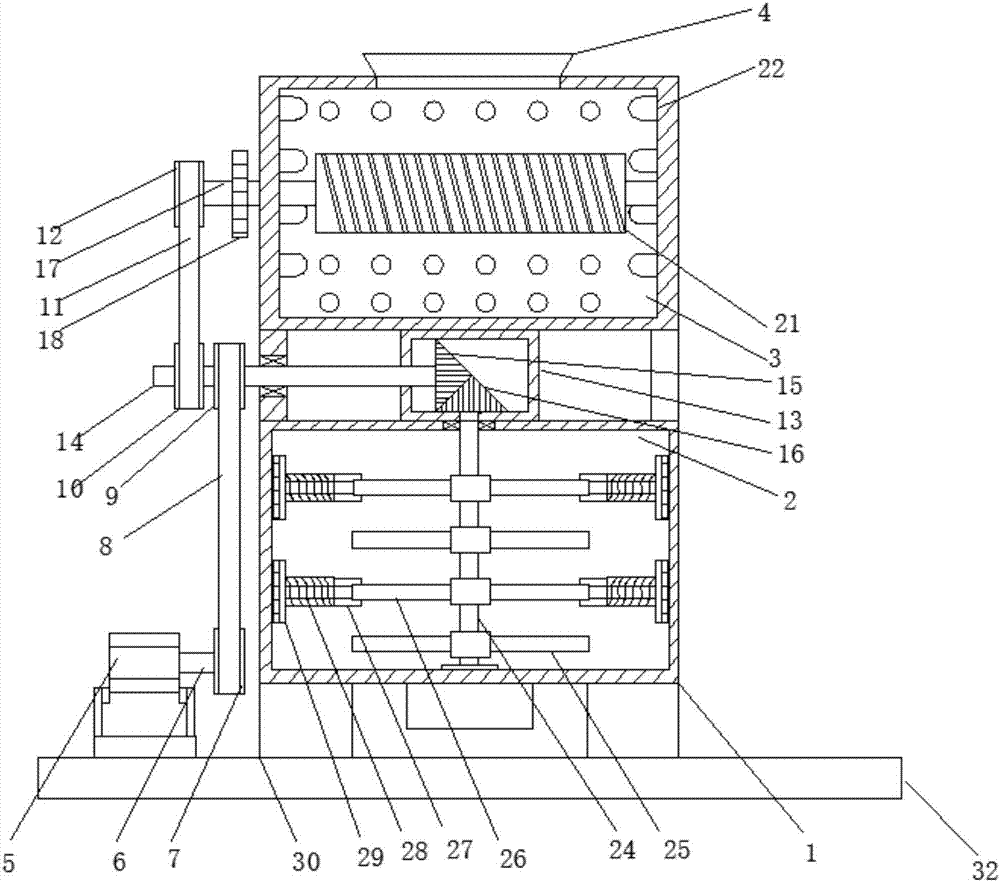

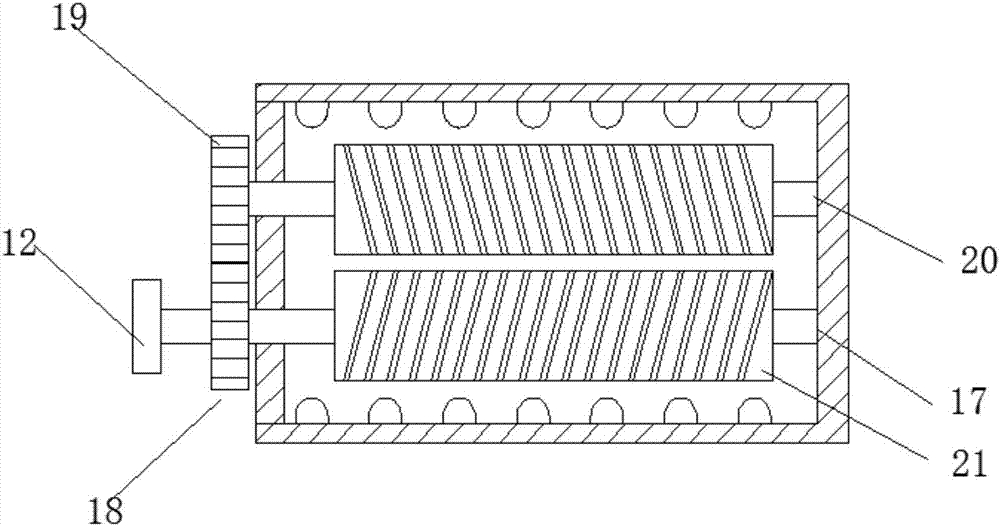

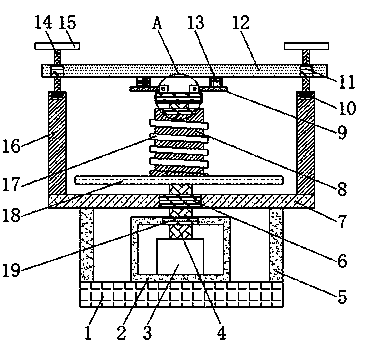

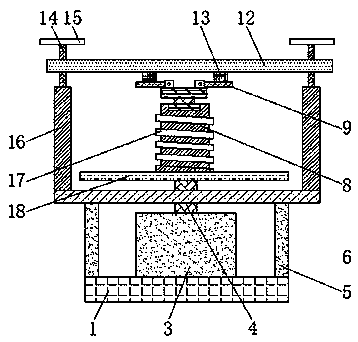

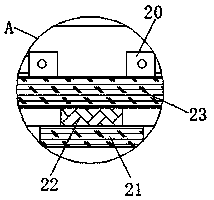

Crushing and stirring device for building cement

InactiveCN107297819AAvoid erectionImprove qualityMixing operation control apparatusPretreatment controlDrive wheelDrive shaft

The invention discloses a crushing and stirring device for building cement, which comprises a frame and a base. The frame includes a stirring box and a crushing box. The right end of the rotating shaft is equipped with a driving wheel, the middle position of the frame is horizontally provided with a first transmission shaft, the left end of the first transmission shaft is equipped with a primary driven wheel and a secondary driven wheel, and the driving wheel and the primary driven wheel They are connected by the first belt, the second transmission shaft and the third transmission shaft are horizontally arranged in the crushing box, the second transmission shaft and the third transmission shaft are horizontally parallel, and the left end of the second transmission shaft is installed with The third-stage driven wheel, the second-stage driven wheel and the third-stage driven wheel are connected through the second belt; the beneficial effect of the present invention is: the transmission structure of the belt and the gear is utilized, the working motor is reduced, and the operation safety is improved , fully milled and crushed to improve the quality of the material.

Owner:黄瀚

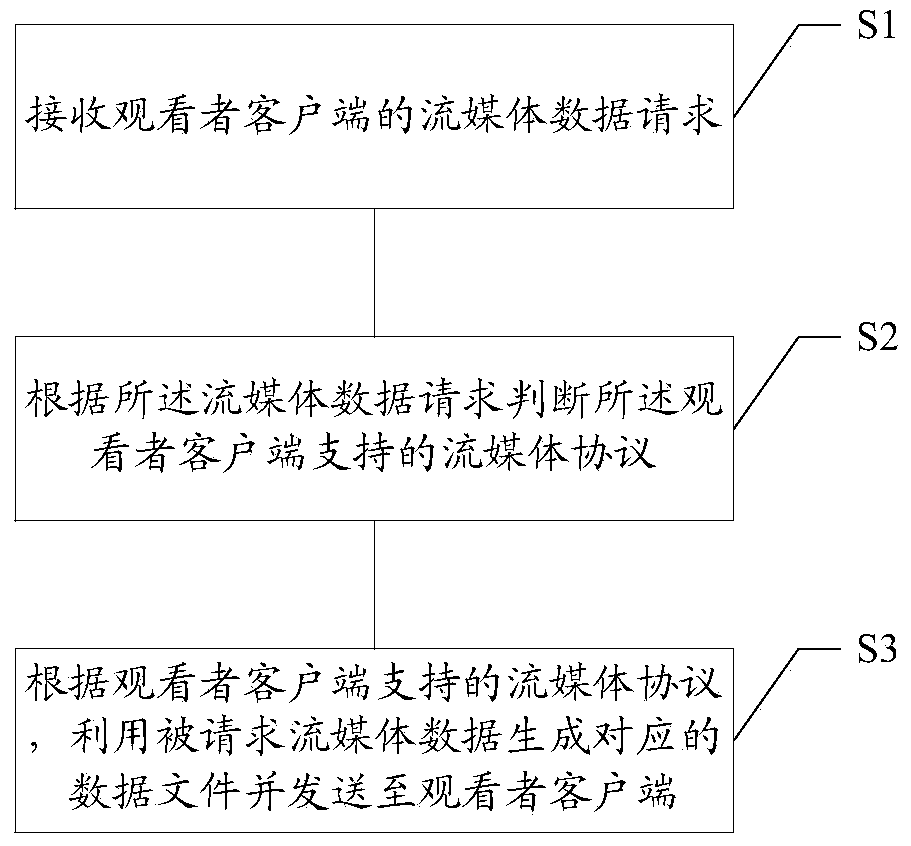

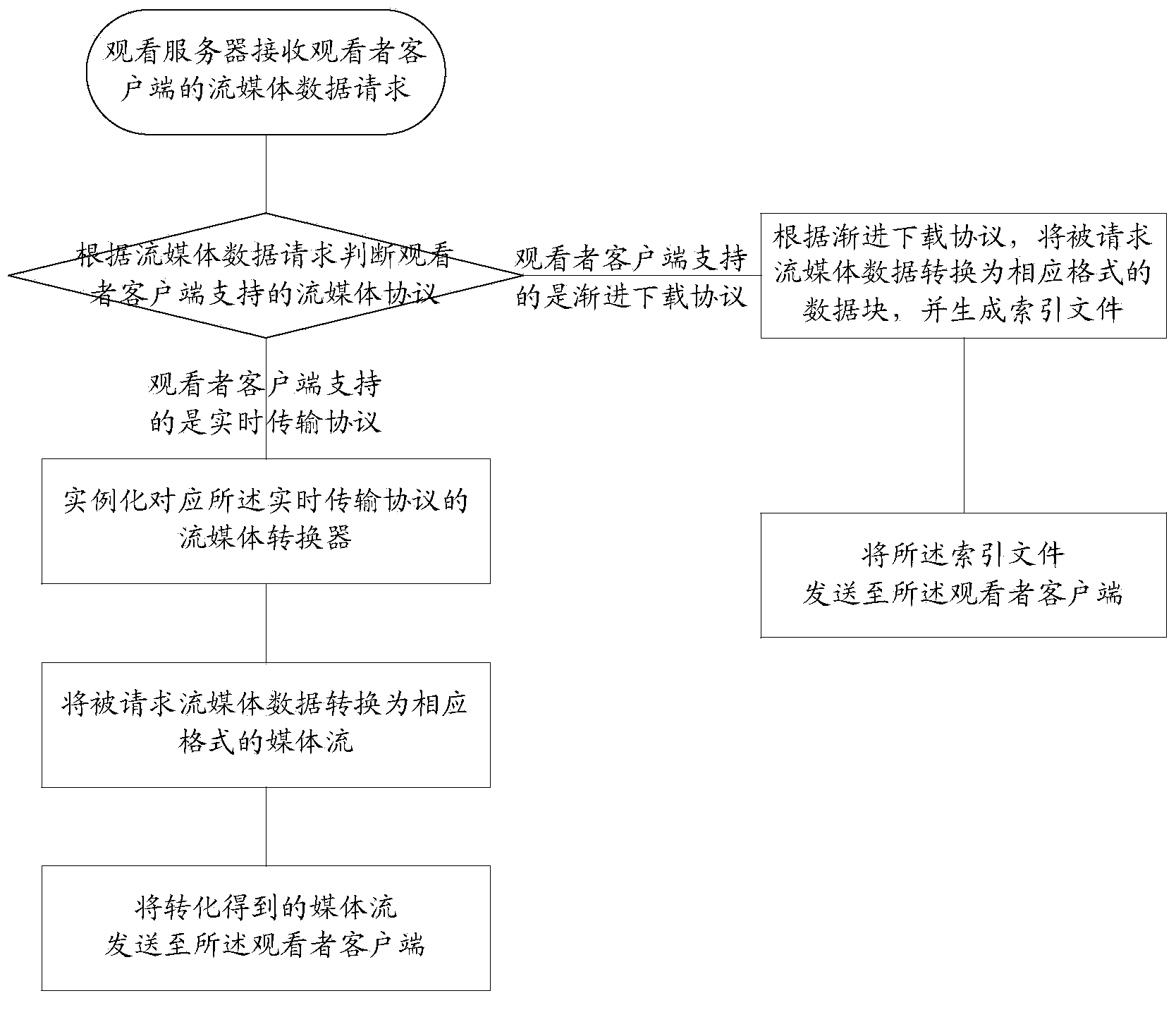

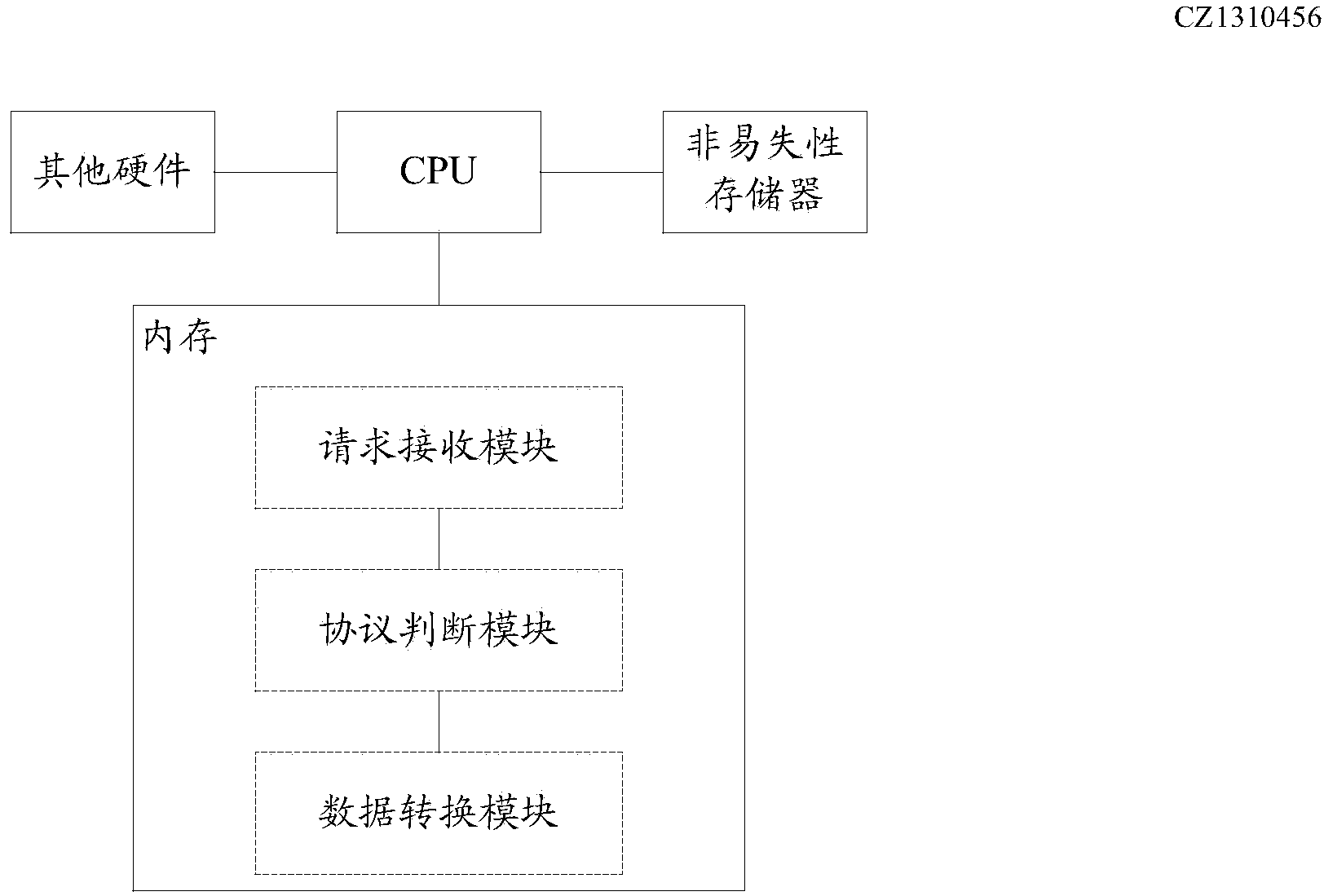

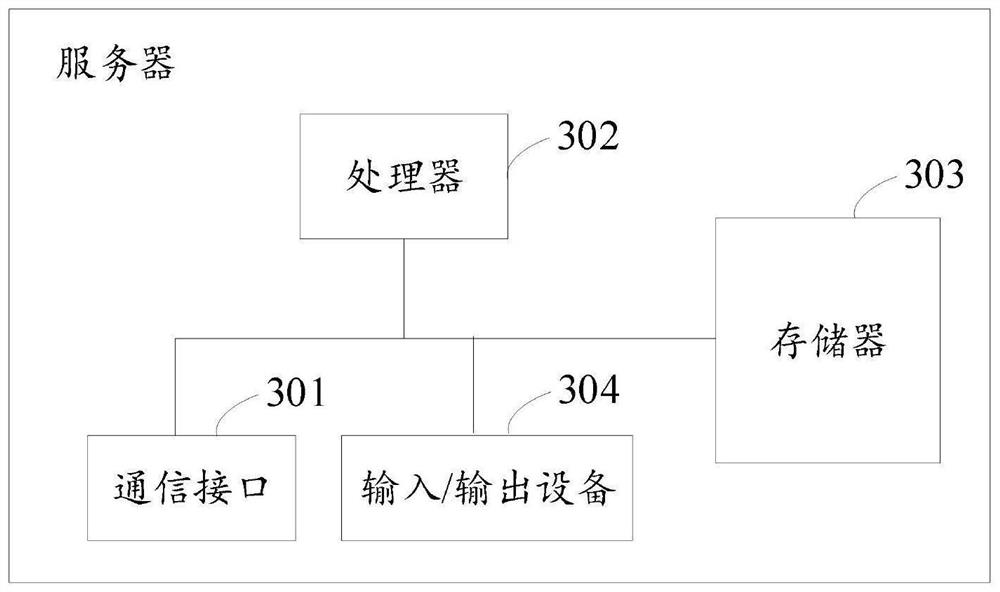

CDN system, watching server and streaming media data transmission method

InactiveCN103826139AReduce operating costsReduce release cost and release timeSelective content distributionProtocol for Web Description ResourcesData transmission

The invention provides a CDN system, a watching server and a streaming media data transmission method. The streaming media data transmission method is applied to the watching server and includes the steps of firstly, receiving a streaming media data request of a watcher client side; secondly, judging a streaming media protocol supported by the watcher client side according to the streaming media data request; thirdly, generating a corresponding data file through requested streaming media data according to the streaming media protocol supported by the watcher client side and sending the data file to the watcher client side. Through the method, on one hand, an additional CDN system is prevented from being erected, and running cost is reduced; on the other hand, an issuer only needs to issue the data file corresponding to the simplex streaming media protocol to the CDN system, issuing cost is reduced, and issuing time is shortened.

Owner:北京花房科技有限公司

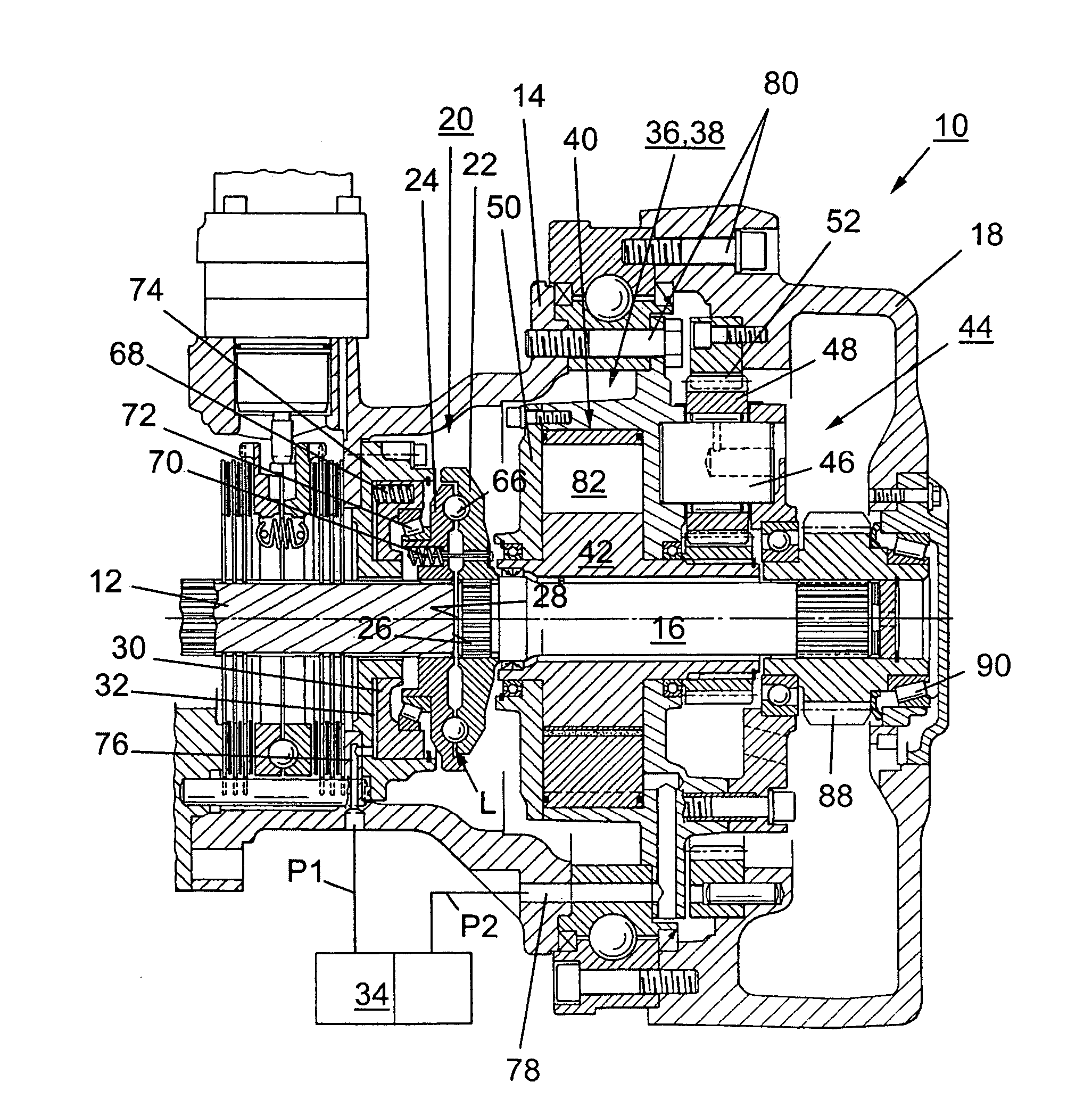

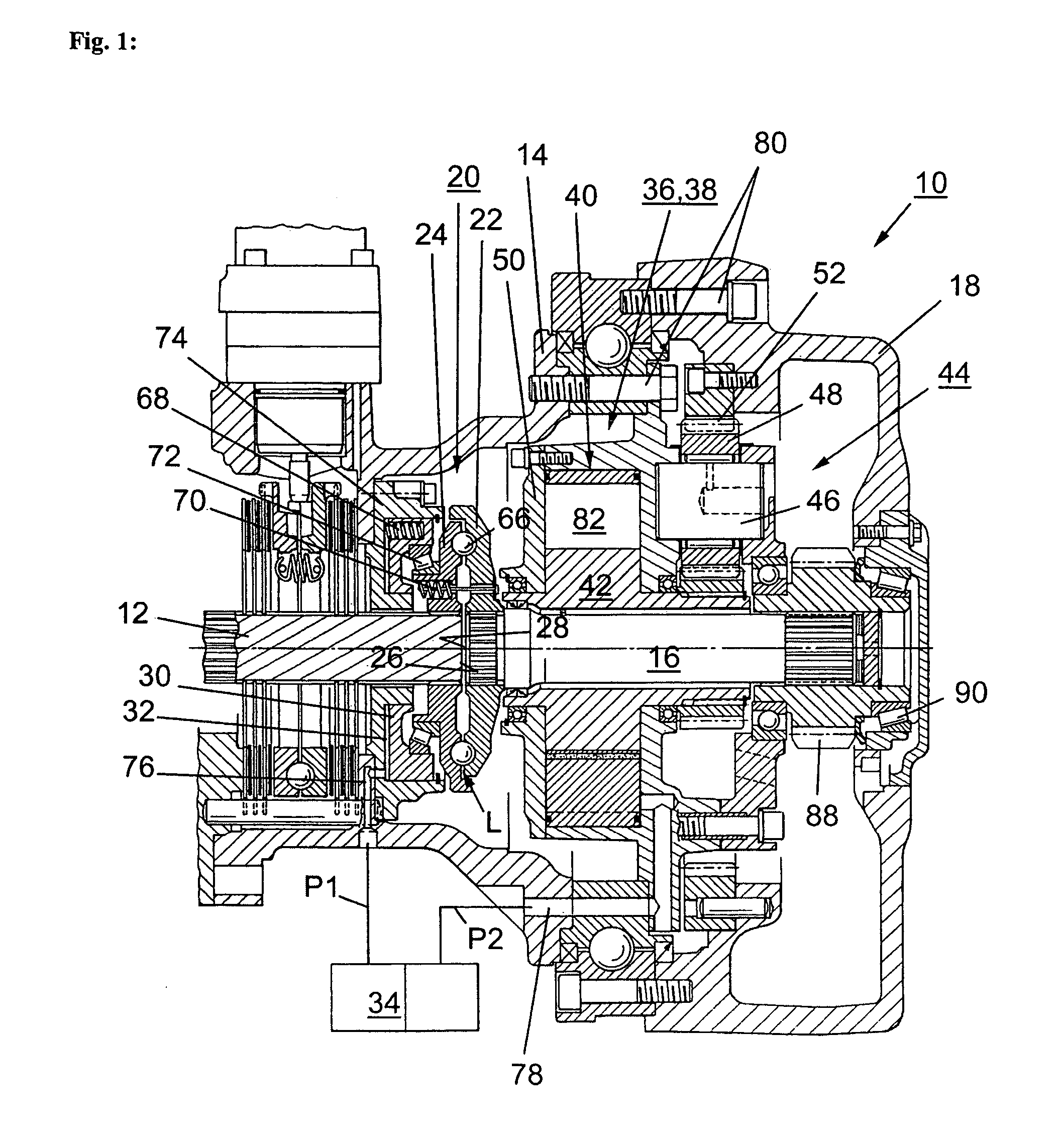

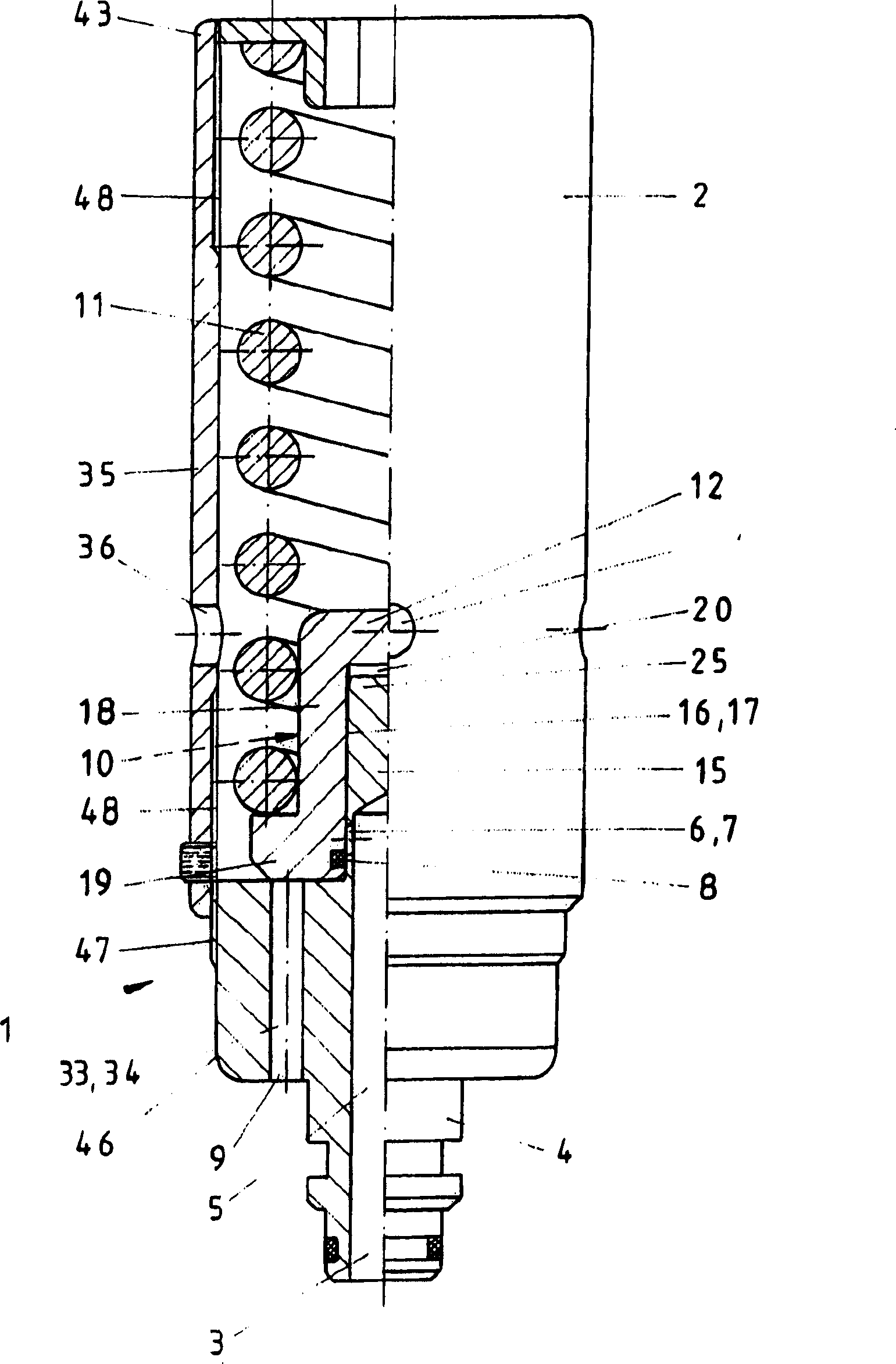

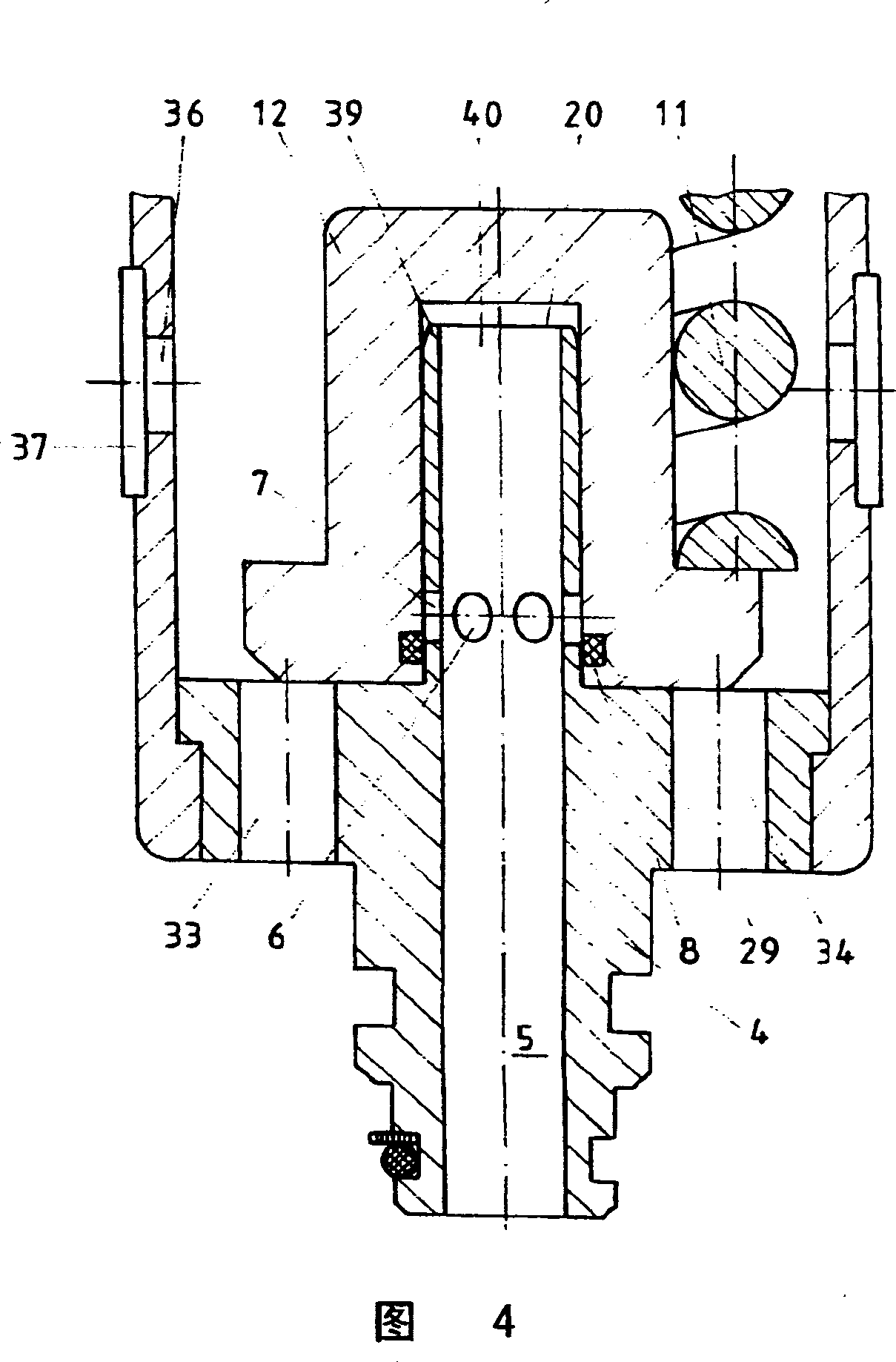

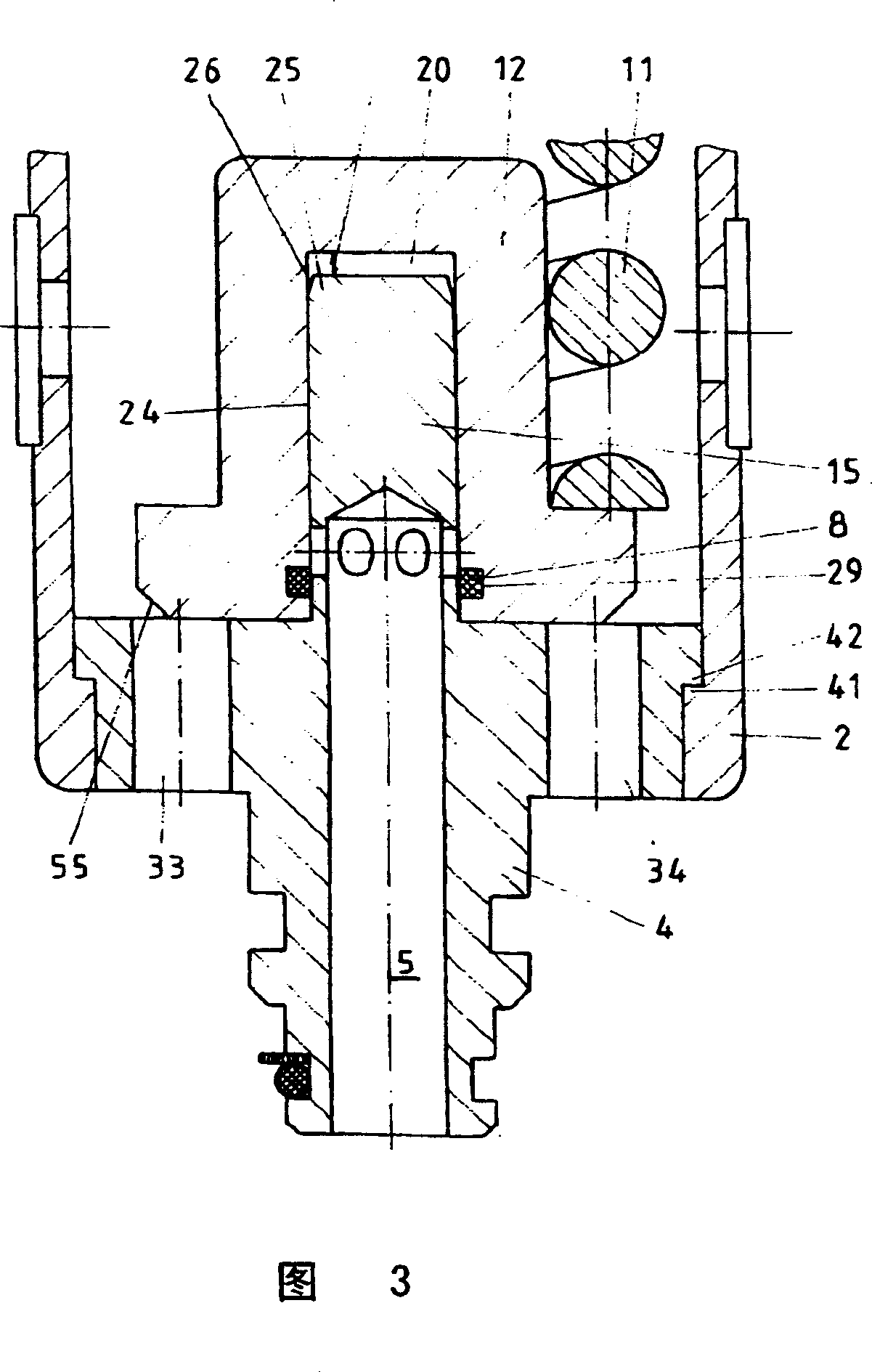

Device and method for continuous regulation of the erection of a tandem axle

InactiveUS7258182B2Avoid erectionContinuous transmissionGearing controlVehiclesVehicle frameSystem pressure

The present invention relates to a device for continuously regulating the erection of a tandem axle of a vehicle or a self-moving working machine having a vehicle frame and at least one drive axle, wherein a tandem drive axle with a movable tandem axle housing is respectively disposed at the ends of the drive axle, and the torque introduced by the drive axle is mechanically distributed to the wheels disposed in the tandem axle housing through the drive tandem axle. Therein, the drive axle is coaxially connected to the drive tandem axle through a ball ramp device, wherein the ball ramp device is comprised of a first ball ramp disk connected to an end of the drive tandem axle opposing an end of the drive axle, and a second ball ramp disk disposed in an axially displaceable manner at the end of the drive tandem axle, and the distance L between the second ball ramp disk and the first ball ramp disk is increased by a torque of the drive tandem axle counteracting the drive torque, wherein the second ball ramp disk is operatively connected to a piston, and a pressure with a value of P1 is produced in a volume by the axial movement of the second ball ramp disk, wherein P1 is passed to a control valve, and the control valve controls the level of a system pressure P3 or P4 depending on P1, and a resulting pressure with the value of P2 serves for controlling a compensating device for achieving a compensating torque counteracting the erection effect. The invention further relates to a method for continuously regulating the erection of a tandem axle of a vehicle or a self-moving working machine.

Owner:NAF NEUNKIRCHENER ACHSENFABRIK

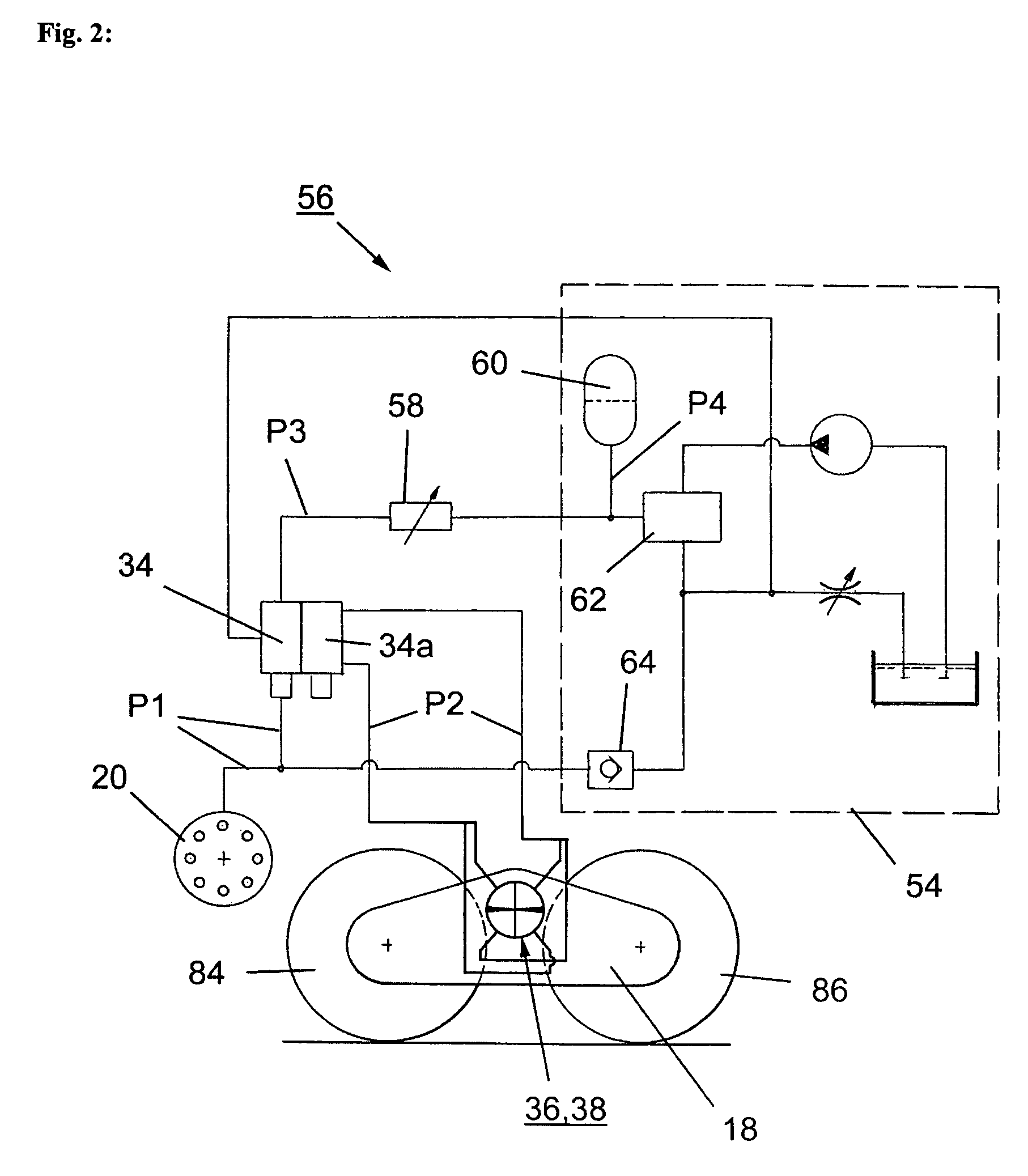

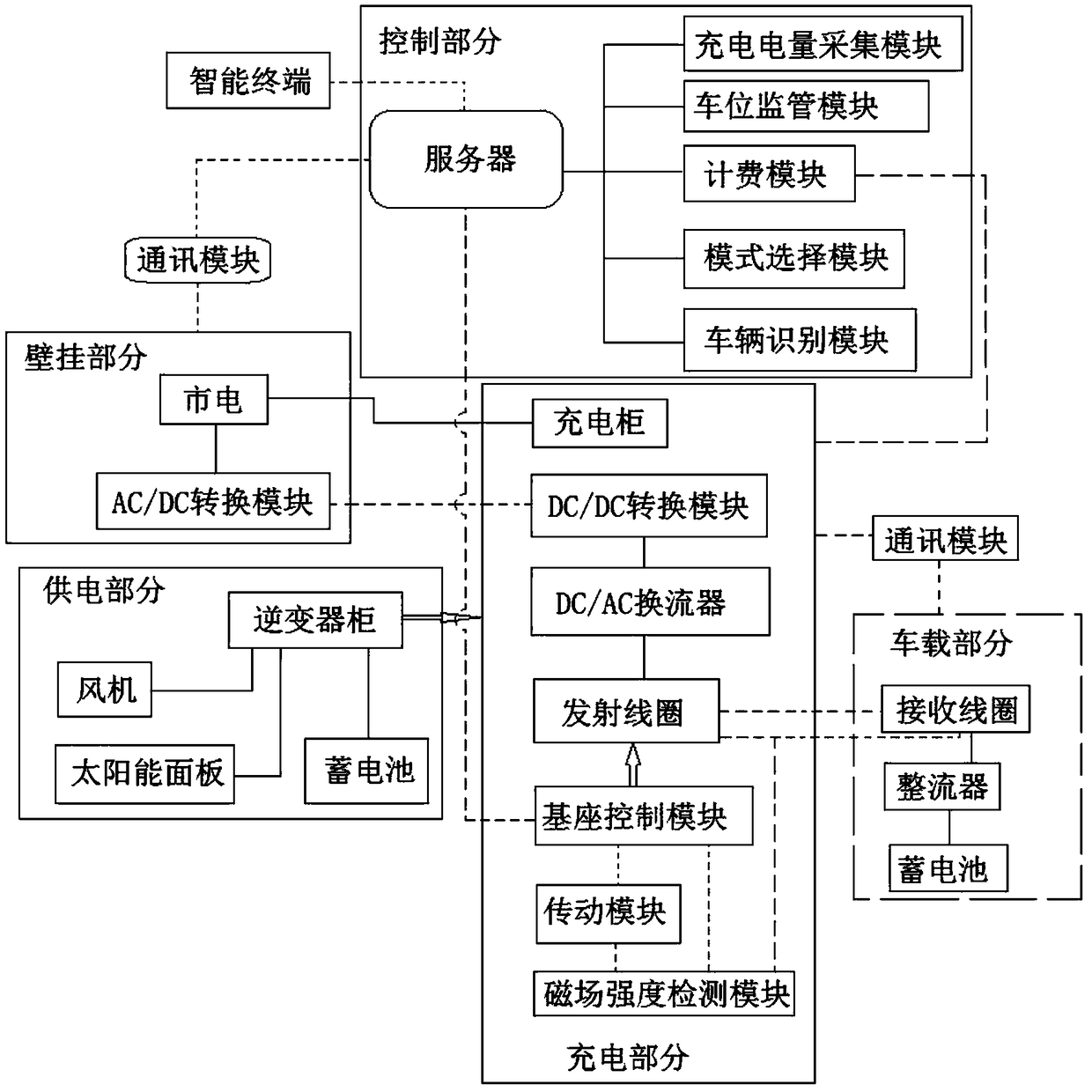

Intelligent stereo garage control system for new energy vehicle charging

InactiveCN108775170AIncrease profitAvoid erectionMobile unit charging stationsElectric powerNew energyControl system

The invention discloses an intelligent stereo garage control system for new energy vehicle charging and relates to the technical field of intelligent garages. The system comprises a wall-mounted part,a power supply part, a charging part, a control part, an intelligent terminal and a vehicle-mounted part. A server is in control connection with a base control module through a WiFi wireless communication module, the base control module performs drive control on movement of a transmission coil base. A transmission coil is mounted in a vehicle carrying board of a garage, the position of the transmission coil is adjusted through a drive module, each parking space is equipped with a charging cabinet, and wired and wireless charging of vehicles can be realized; the charging quantity and use information of parking spaces are checked remotely through an intelligent terminal, the comprehensive utilization rate of power generation equipment can be increased, energy saving and emission reduction effects can be realized, electric vehicles can be charged while the parking difficulty is solved, the cost is lower than that for independent construction of a charging pile, the wireless charging manner is more convenient, charging equipment is prevented from being erected in the open-air environment, the safety performance is high, and the floor area is saved.

Owner:合肥市春华起重机械有限公司

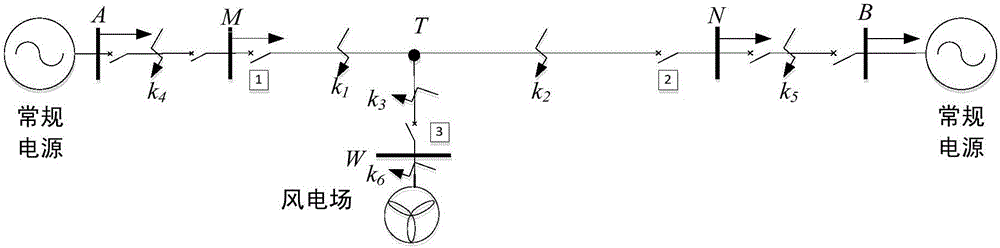

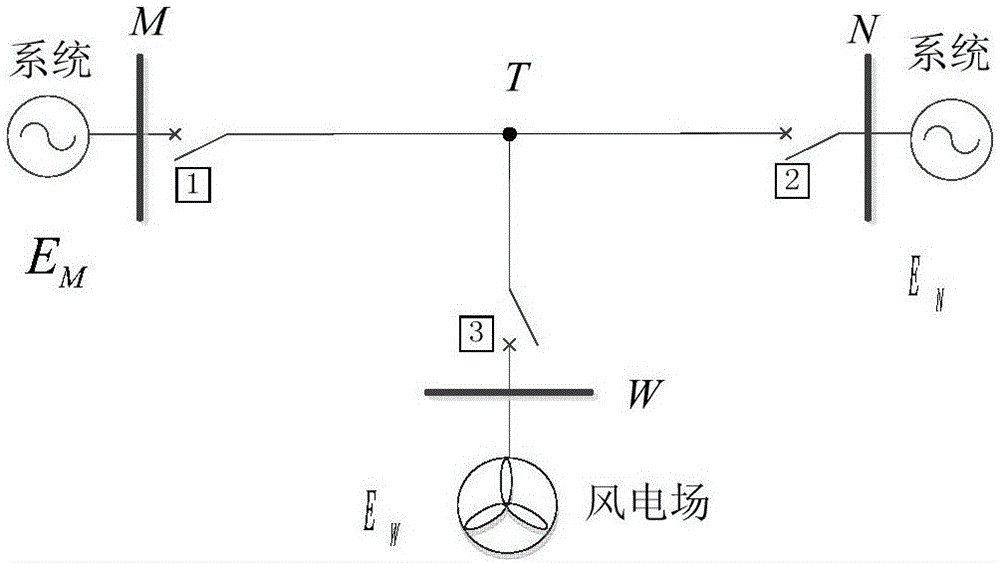

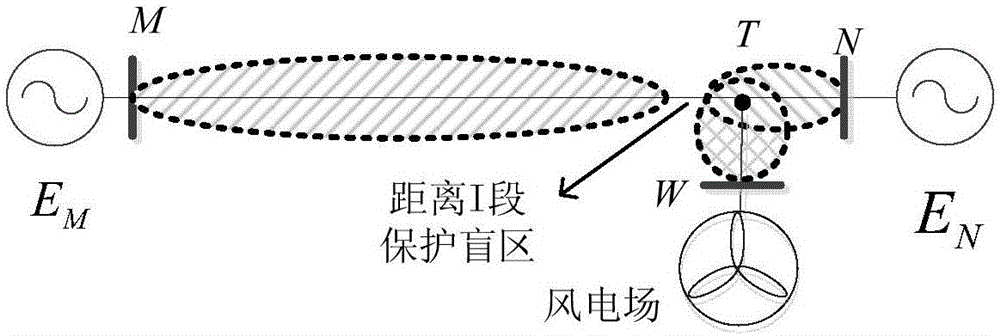

Wind power T-type connection line ground fault setting method

InactiveCN106405335AReduce configuration costsAvoid erectionFault location by conductor typesElectricityGround failure

The present invention relates to a wind power T-type connection line ground fault setting method. The method comprises the following steps: 1) extracting the zero-sequence voltage and the zero-sequence current at the wind power T-type connection line protection installation position, and solving the simulation impedance and the signaling threshold value of a sender according to system parameters; 2) calculating the power direction of each side, and determining the fault direction; and 3) if the faults are the positive direction faults, determining whether blocking signals are received or not, and if the blocking signals are received, determining that faults are the external faults of the T-type connection line, and protecting the closed lock; and if the closed locking signals are not received, determining that the faults are the internal faults of the T-type connection line, and immediately performing the tripping operation. The wind power T-type connection line ground fault setting method can effectively avoid the influence of the T-type connection line topology and the wind power fault features on the T-type connection line protection configuration and considers the economy so as to ensure the selectivity, the sensitivity and the reliability of the T-type connection line protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

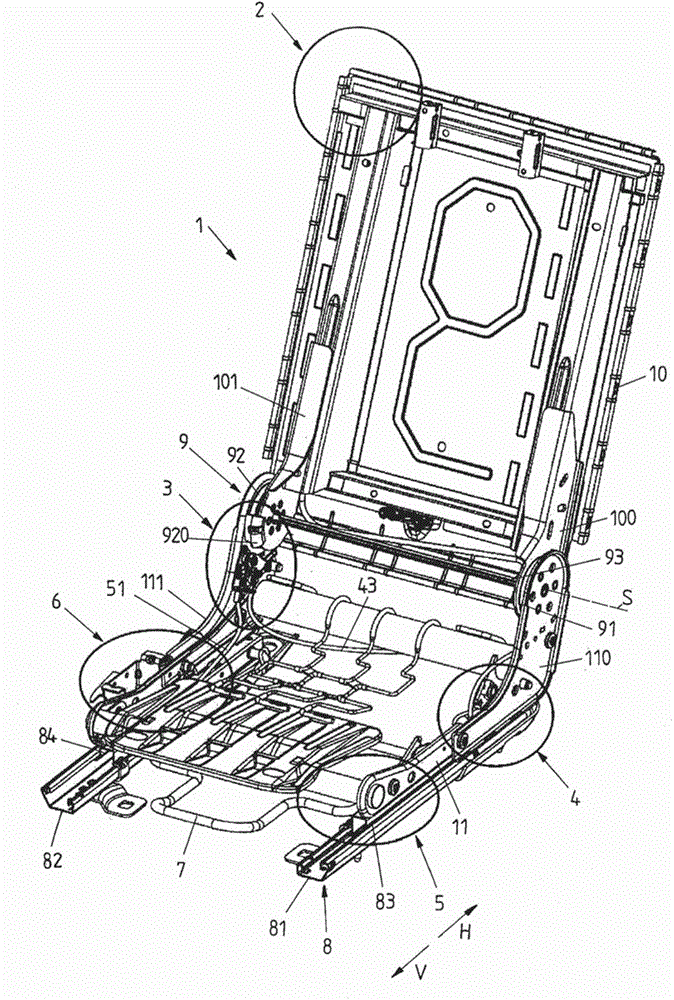

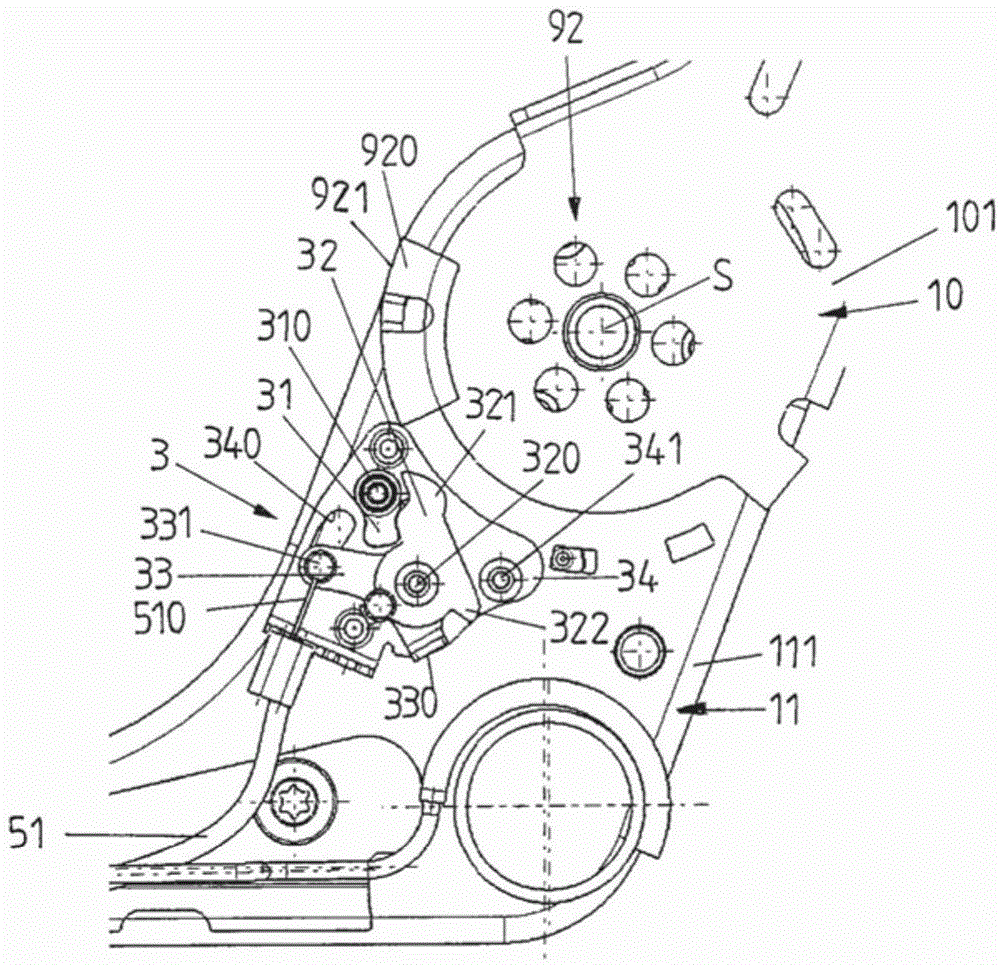

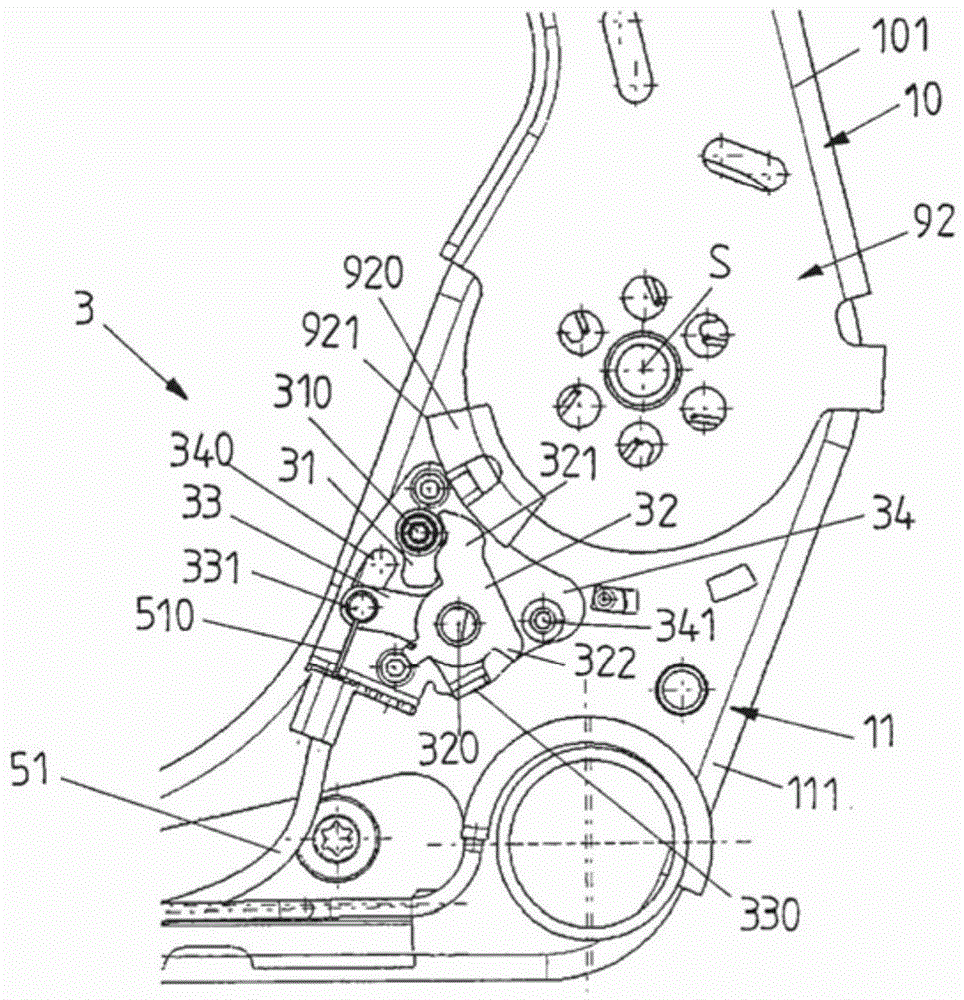

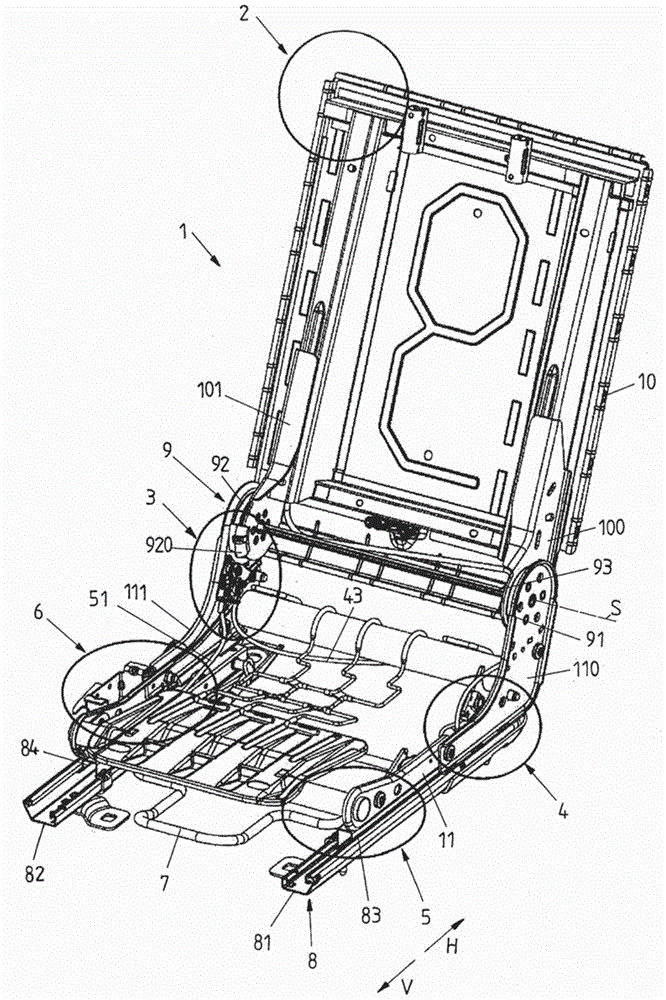

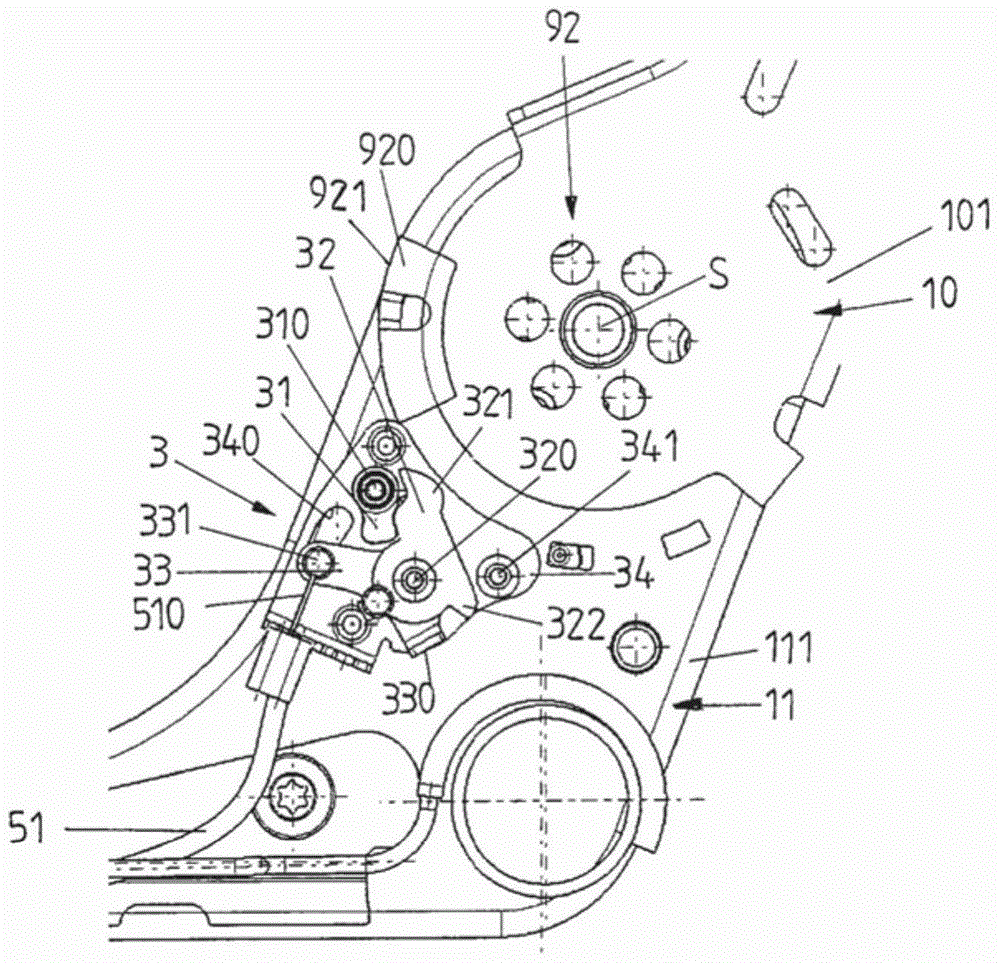

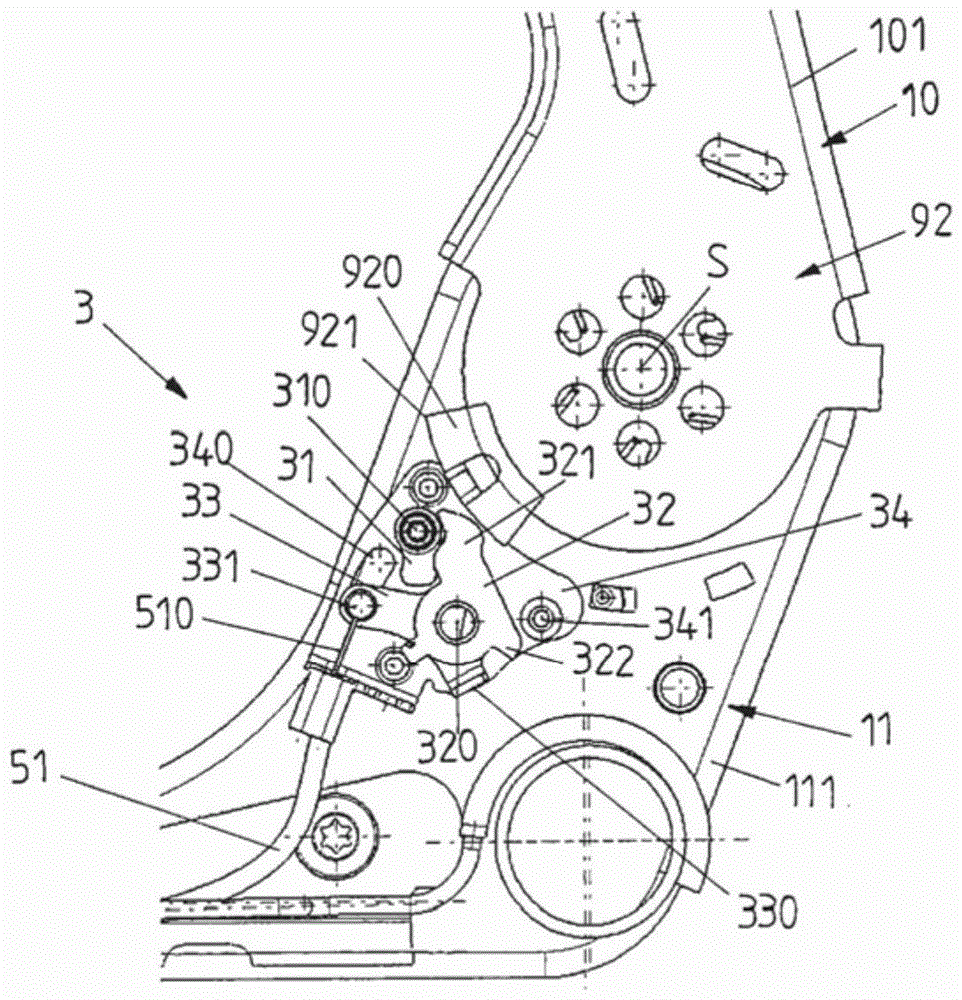

Vehicle seat

A vehicle seat comprises a seat part, a backrest part and a least one fitting which connects the backrest part with the seat part pivotally about a pivot axis and in a locked condition is formed to hold the backrest part in position to the seat part, and in an unlocked condition is formed to permit pivoting of the backrest part relative to the seat part. For actuating the at least one fitting, a first actuating element and a second actuating element different from the first actuating element are provided. Via a coupling element, the second actuating element is coupled with a fitting lever, wherein by shifting the second actuating element the fitting lever is movable for actuating the at least one fitting. The coupling element and the fitting lever are coupled with each other via a first connecting means and a second connecting means.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

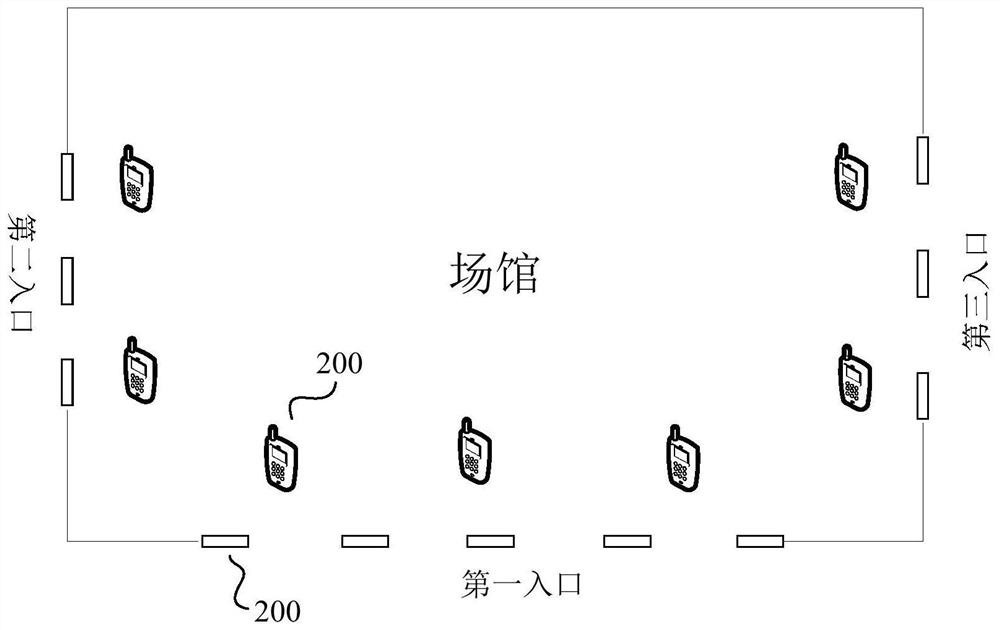

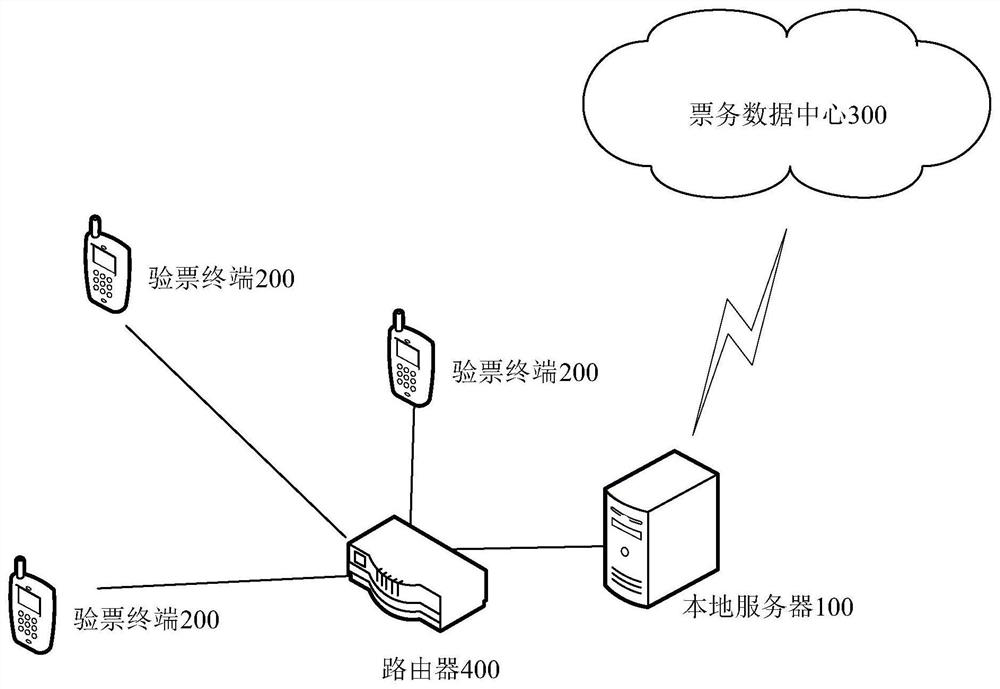

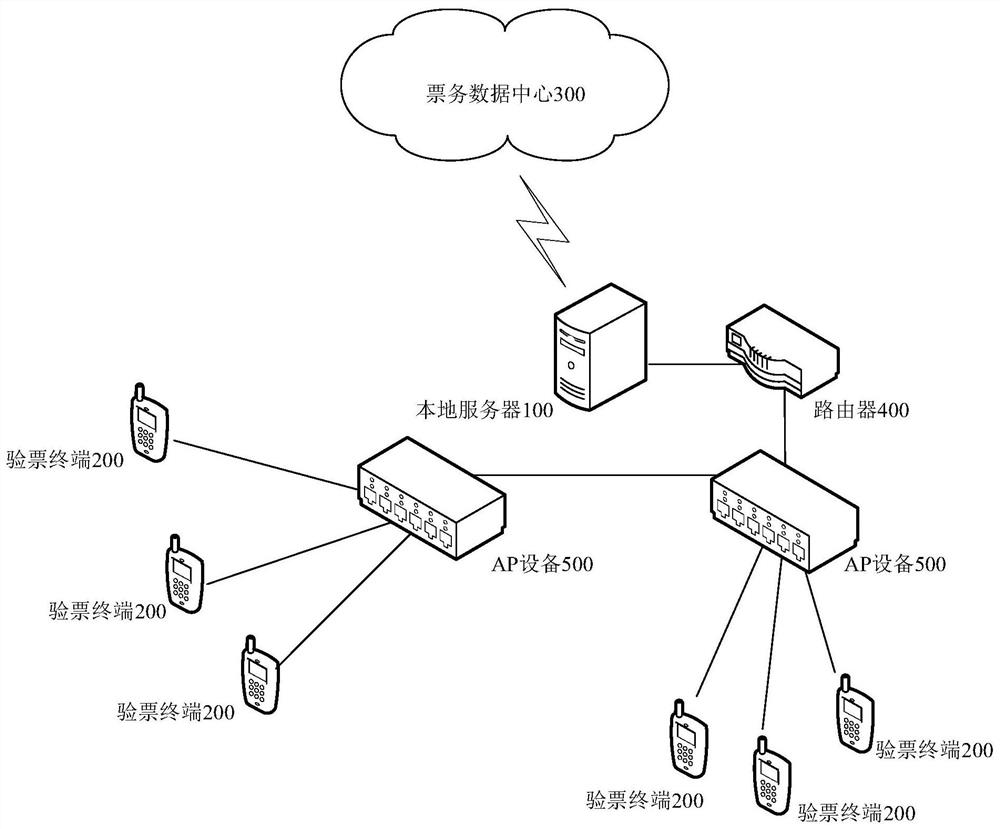

On-site ticket checking system

ActiveCN111726376AReduce complexity and costReduce complexityTicket-issuing apparatusTransmissionEngineeringTicket

The invention discloses an on-site ticket checking system which comprises a local server and a plurality of ticket checking terminals. Each ticket checking terminal and the local server are configuredas nodes in the peer-to-peer network, and each node is connected with at least one other node; the local server is set to be connected with the ticket data center through a wide area network; each node propagates respective ticket data in a peer-to-peer network, the ticket data comprising: first ticket data acquired by a local server from a ticket data center; each ticket checking terminal checksthe ticket checking data obtained by the experience ticket according to the respective first ticket data to generate second ticket data.

Owner:ALIBABA GRP HLDG LTD

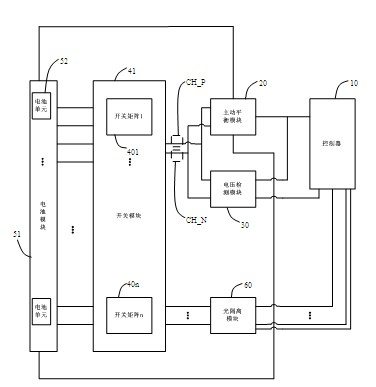

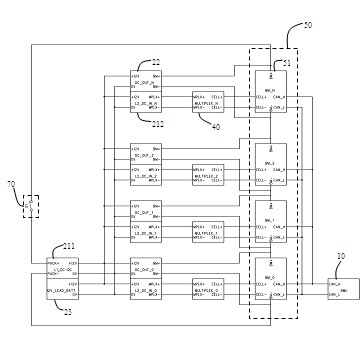

Battery management system

InactiveCN102427259AAvoid erectionReduce complexityCircuit monitoring/indicationCharge equalisation circuitEngineeringBattery management systems

The invention relates to a battery management system. The battery management system comprises a plurality of battery units which are mutually connected in series, a voltage detection module, an active balance module, a controller and signal buses, wherein the controller is electrically connected with the voltage detection module and the active balance module; and the signal buses are optionally electrically connected with the anode and the cathode of one of the plurality of battery units. The controller can be used for controlling the voltage detection module and the active balance module to detect the voltage of the battery units or charge the battery units through the same signal buses, so that the erection of excessive lines is prevented, and the complexity and production cost of a line framework are lowered.

Owner:SUZHOU GOLDEN CROWN NEW ENERGY +1

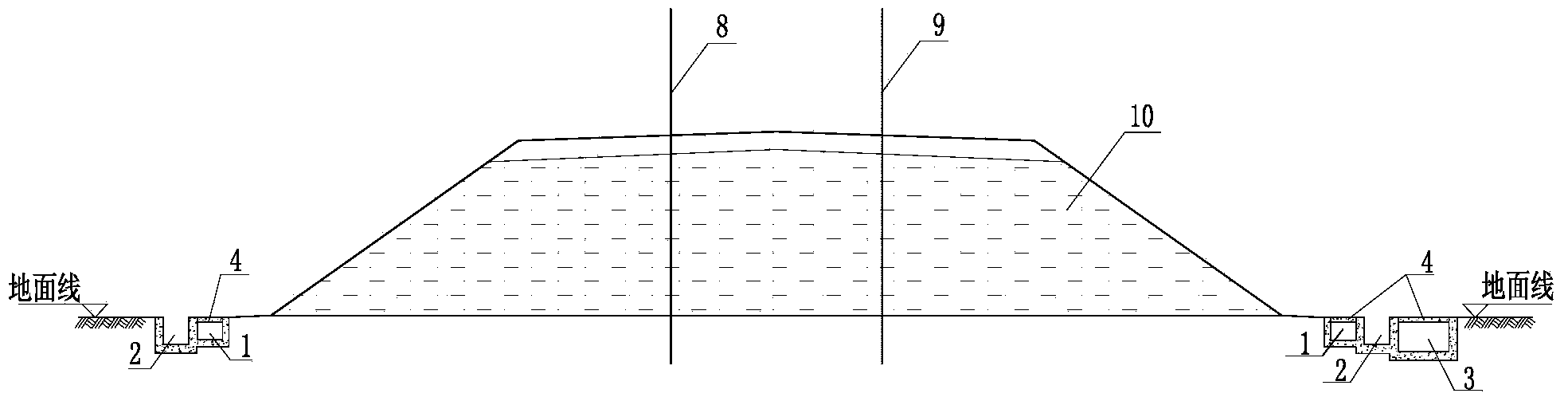

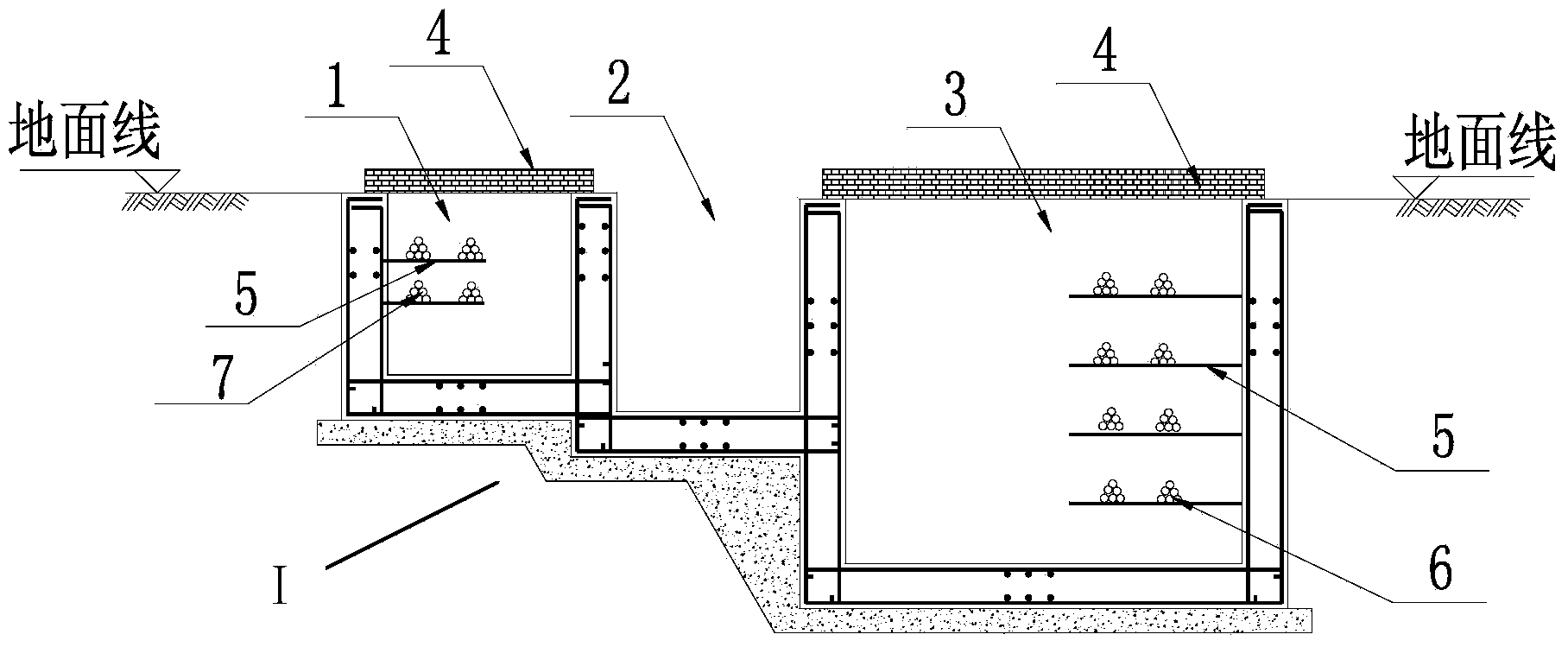

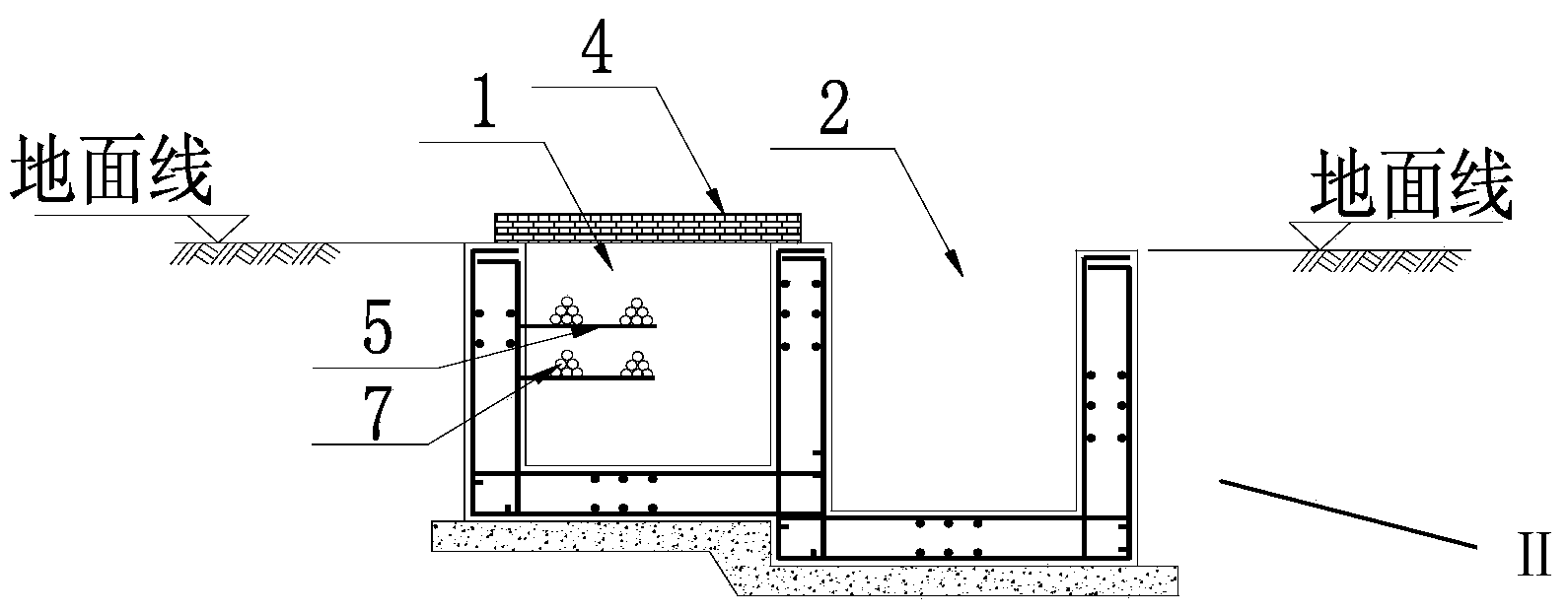

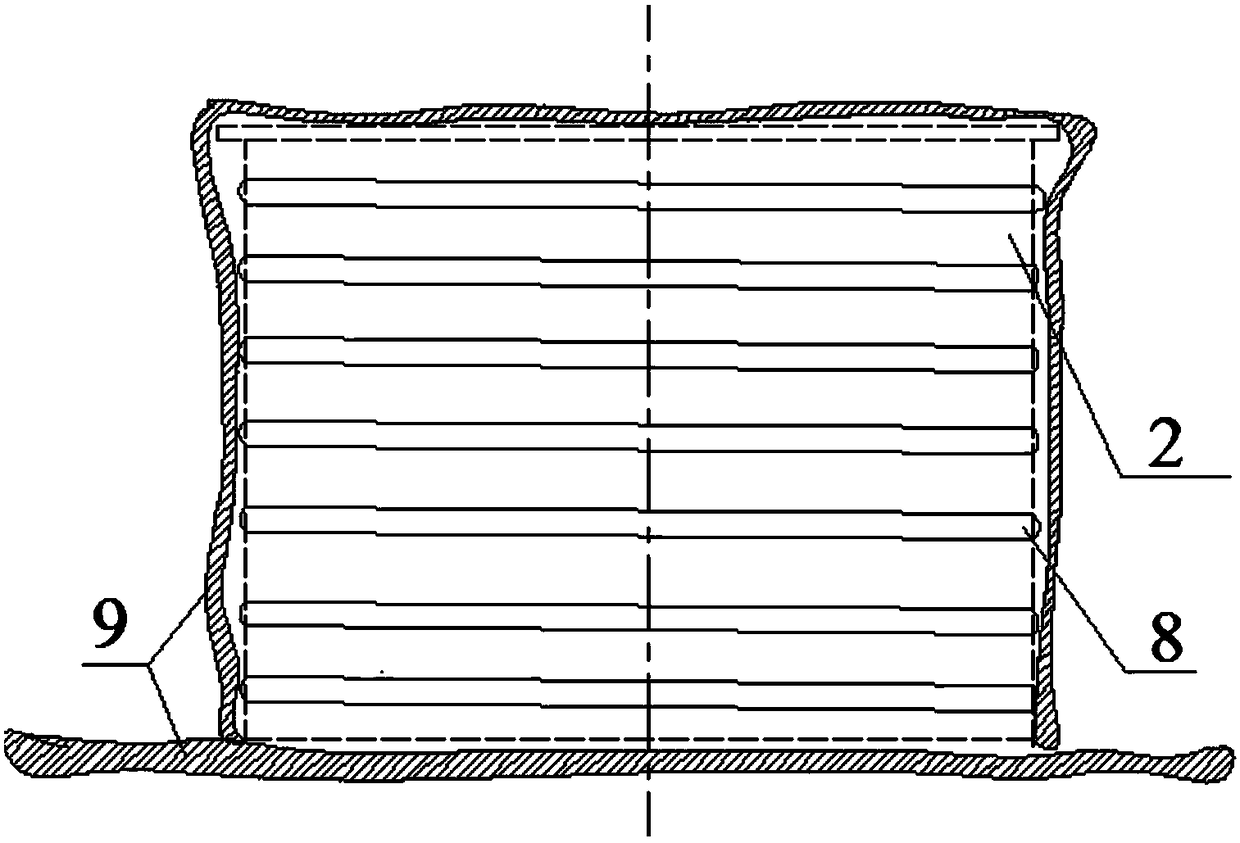

Integrated pipe trench structure applied to interregional ground line roadbed of urban rail transit project

ActiveCN103469816AThe design is easy to obtainFlexible size adjustmentArtificial islandsUnderwater structuresWeak currentGrounding line

The invention provides an integrated pipe trench structure applied to an interregional ground line roadbed of an urban rail transit project. The integrated pipe trench structure comprises a heavy-current pipe trench, weak-current pipe trenches and drainage trenches and is distributed at the two sides of a ground line roadbed of the urban rail transit project, wherein integrated pipe trenches at the two sides are laid parallel to the line roadbed, the cross-sectional structure of the integrated pipe trench I at one side comprises one weak-current pipe trench, one drainage trench and the heavy-current pipe trench, the cross-sectional structure of the integrated pipe trench II at the other side comprises one weak-current pipe trench and one drainage trench, and cover plates are respectively arranged at the tops of the heavy-current pipe trenches and the tops of the weak-current pipe trenches. The integrated pipe trench structure has the effects that the layout is compact, the arrangement is reasonable, the mutual interference is avoided, the width of the roadbed is reduced, and the floor occupation of the project is reduced; the movable cover plates are arranged, the opening is facilitated so as to inspect and repair cables, and the cables can be excellently protected from wind and sun; the pipe trenches are provided with longitudinal slopes with the gradient not lower than 0.02%, so that water accumulated in the trenches can be removed in time.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

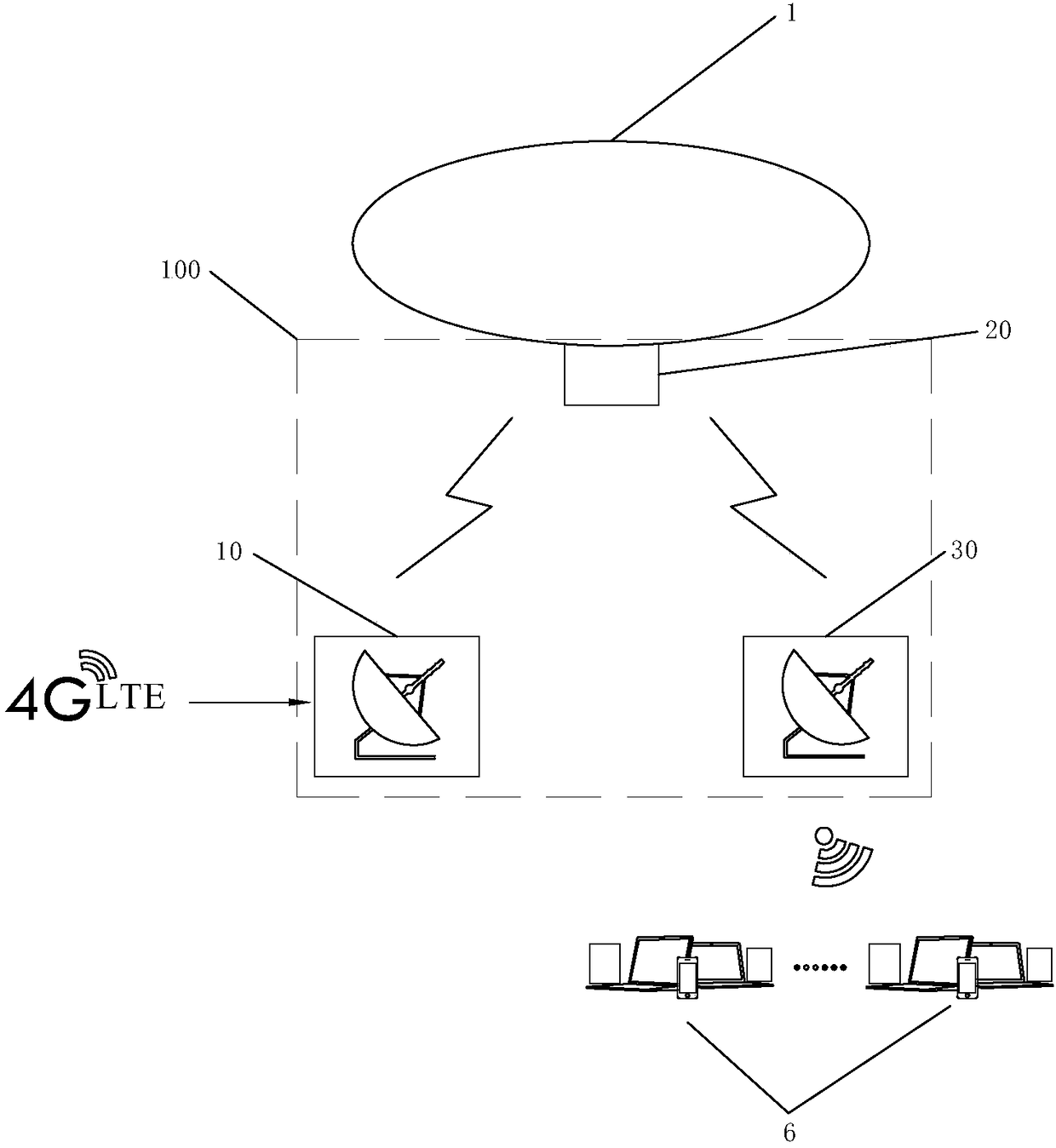

Network signal coverage system based on stratospheric airship

InactiveCN108111218AImprove network signal coverageLarge coverage areaRadio transmissionTerminal equipmentEngineering

The invention discloses a network signal coverage system based on a stratospheric airship. The stratospheric airship is arranged on a stratospheric layer; the network signal coverage system comprisesa transmitting device, a relay device and a receiving device; the transmitting device receives a network signal; the transmitting device transmits a wireless signal to the stratospheric airship according to the network signal; the relay device is arranged on the stratospheric airship; the relay device receives the wireless signal; the relay device transmits a relay signal according to the wirelesssignal; the receiving device is arranged in a coverage range of the relay signal; the receiving device is towards the relay device and receives the relay signal; the receiving device shares a hotspotsignal to surroundings according to the relay signal; any terminal device within a coverage range of the hotspot signal receives the hotspot signal; the terminal device is in communication connectionwith the receiving device by virtue of the hotspot signal; and the terminal device is accessed to the network signal by virtue of the hotspot signal. According to the network signal coverage system provided by the invention, the action distance is far, the signal coverage range is wide, the system position is set flexibly, the system cost is low, and the deployment and the maintenance are easy.

Owner:BEIJING UNIV OF AERONAUTICS & ASTRONAUTICS DONGGUAN

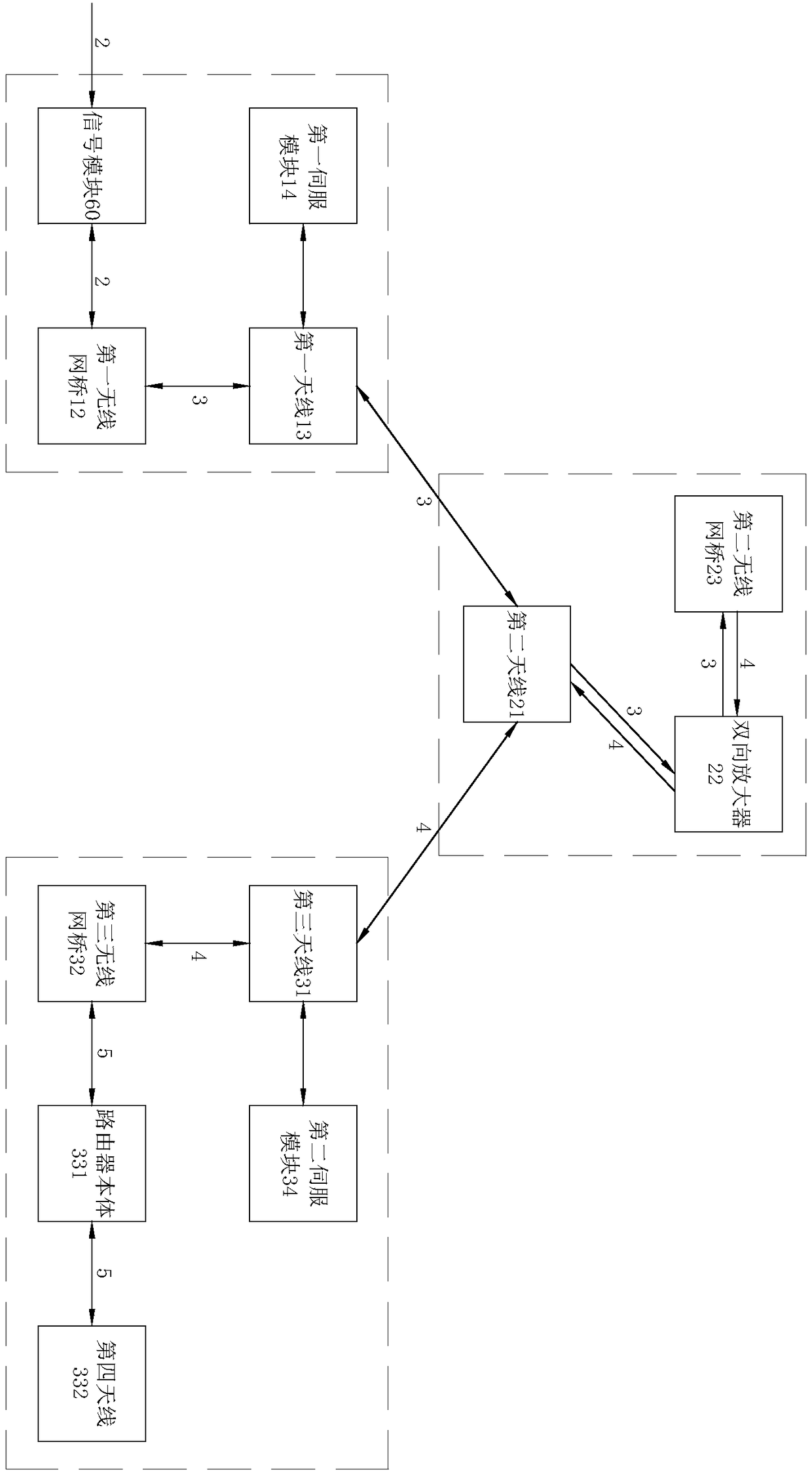

System for livestock fecal biological fermentation drip fertilization

InactiveCN106342463AIncrease profitAvoid erectionLiquid fertiliser regulation systemsPressurised distribution of liquid fertiliserLivestock manureFeces

The invention discloses a system for livestock fecal biological fermentation drip fertilization, including a distributed drip irrigation pipeline for dropper work,a drip irrigation water supply reservoir for suppying water to the distributed drip irrigation pipeline and providing a stable water pressure,a annular projecting support table is arranged inside of the wall of the drip irrigation water supply reservoir,the annular projecting support table divides the drip irrigation water supply reservoir into a water and fertilizer fluid storage section and a livestock manure dissolving section,the water and fertilizer fluid storage section is located above the annular projecting support table,the livestock manure dissolving section is located below the annular projecting support table,the distributed drip irrigation pipeline communicates with the water and fertilizer fluid storage section,a filters support sieve is arranged in the livestock manure dissolving section,the filter support sieve is disposed on annular projecting support table,a filter nonwoven fabric is arranged inside of the filter support sieve.the invention can use the drip irrigation technique to fertilize the bio-organic fertilizer with the livestock manure as the matrix.

Owner:滁州朝昱农业科技有限公司

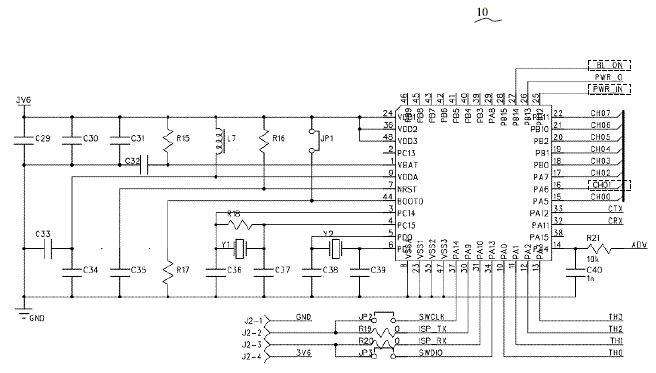

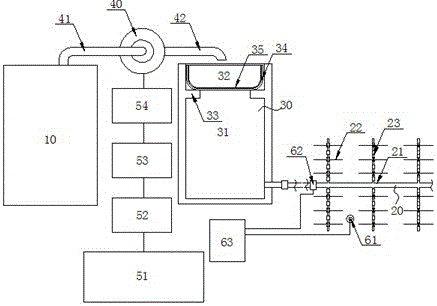

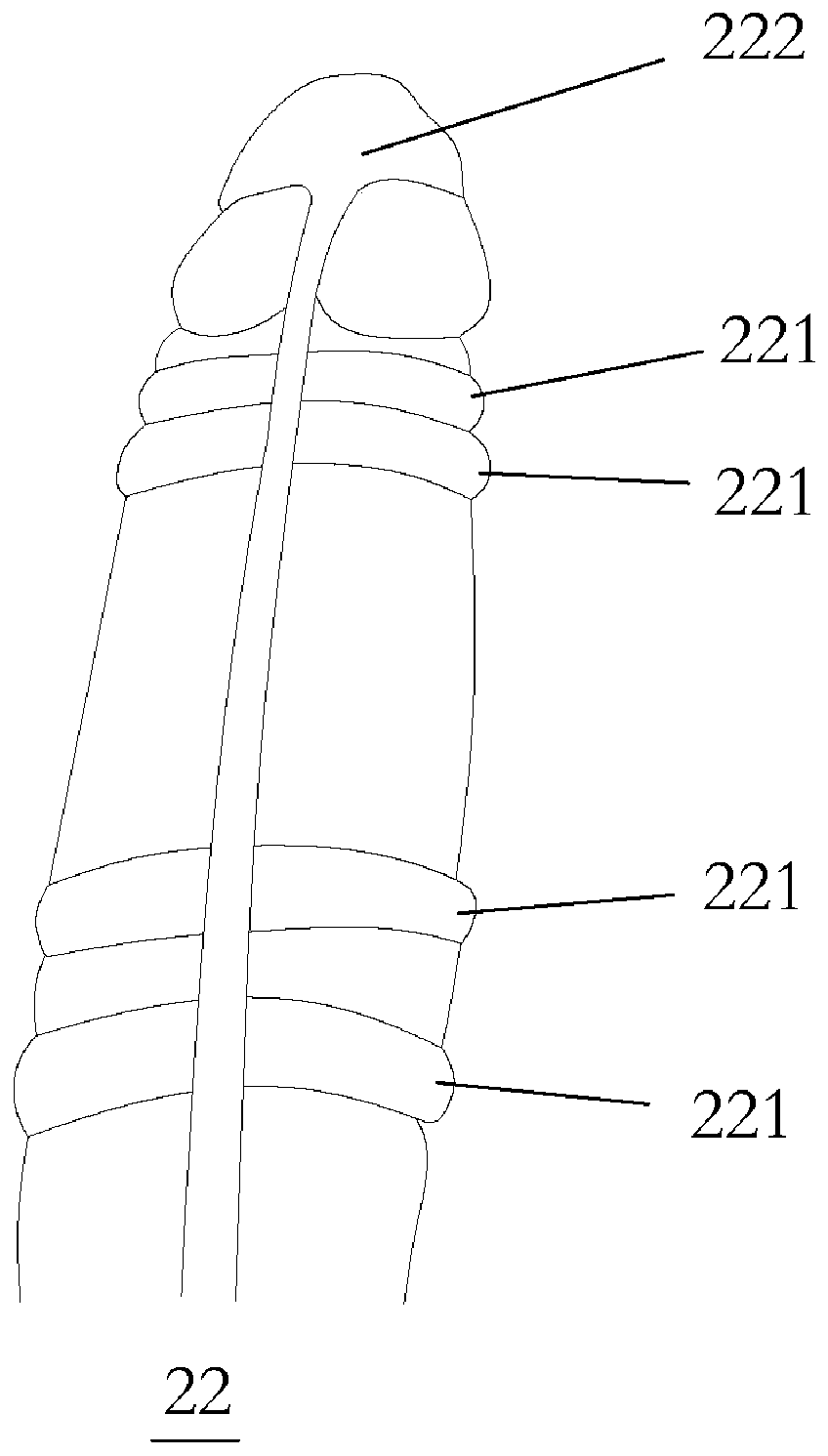

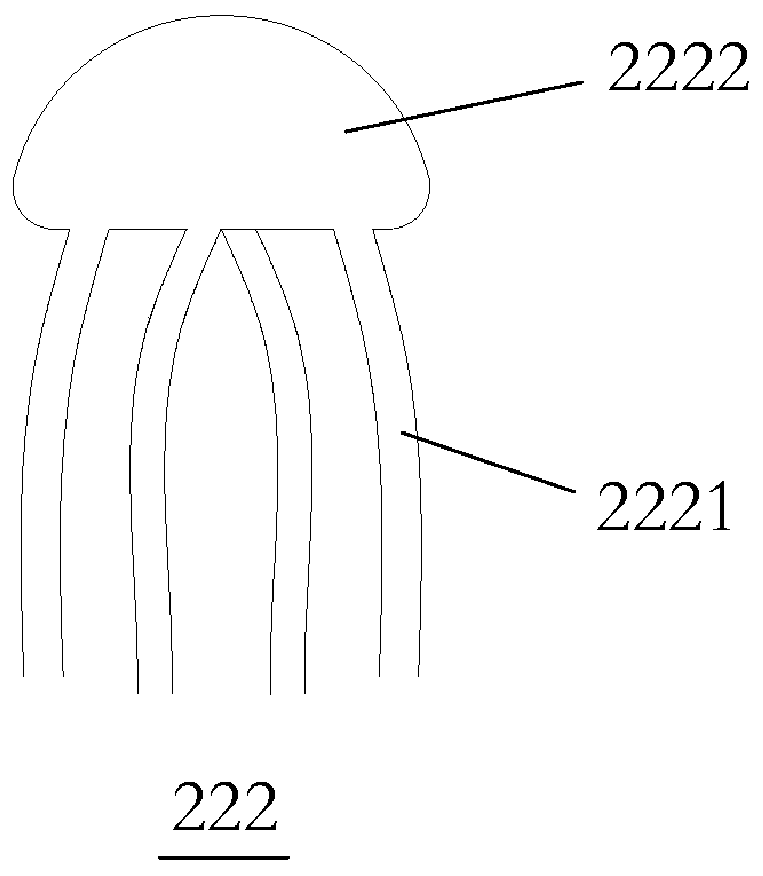

Penile erection multi-parameter evaluation system based on flexible sensor and evaluation method

PendingCN111543951AAccurate hardnessAvoid repeated stimulationDiagnostic signal processingSensorsPenisMedicine

The invention provides a penile erection multi-parameter evaluation system based on a flexible sensor and an evaluation method. The penile erection multi-parameter evaluation system comprises a circumference measuring device, a hardness measuring device and a data processing device. The circumference measuring device comprises a circumference change sensor which is a flexible tensile strain sensor; the hardness measuring device comprises a radial hardness sensor and an axial hardness sensor which are used for measuring the corresponding deformation of the penis along with the change of the hardness of the penis in an erection process, and the radial hardness sensor and the axial hardness sensor are both flexible stretchable pressure sensors; and the data processing device is used for receiving data acquired by the circumference change sensor and the radial hardness sensor and processing the data. On one hand, the radial pressure change of the penis can be measured, on the other hand, the axial pressure change of the penis can be measured, then the radial hardness and the axial hardness of the penis are determined, and meanwhile the peripheral diameter change of erection of the penis and the penis blood flow and temperature are recorded.

Owner:THE THIRD AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

Vertical hot sleeving process method for flange end-free long and thin main shaft

InactiveCN108406226AGuaranteed workmanshipLower the lifting heightMetal working apparatusLoad-engaging elementsFlangeThin walled

The invention discloses a vertical hot sleeving process method for a flange end-free long and thin main shaft. By means of the process method, the requirement for the fastening amount obtained after the flange end-free long and thin main shaft and a thin-walled part are subjected to hot sleeving can be met, and the hot sleeving efficiency and the assembling quality are improved. The fixing mannerof the main shaft without a flange end after erecting is fundamentally innovated, pit installation stations of a workshop are utilized, the situation that too much space is occupied due to the fact that a climbing scaffold is erected is avoided, the problem that the height exceeds limitation when a component is hoisted during hot sleeving is also avoided, the hot sleeving preparation and assemblyperiod is shortened, the hot sleeving safety is improved, the installation stations and tools can also be utilized for a long time, and the installation cost is greatly reduced.

Owner:HARBIN ELECTRIC MASCH CO LTD

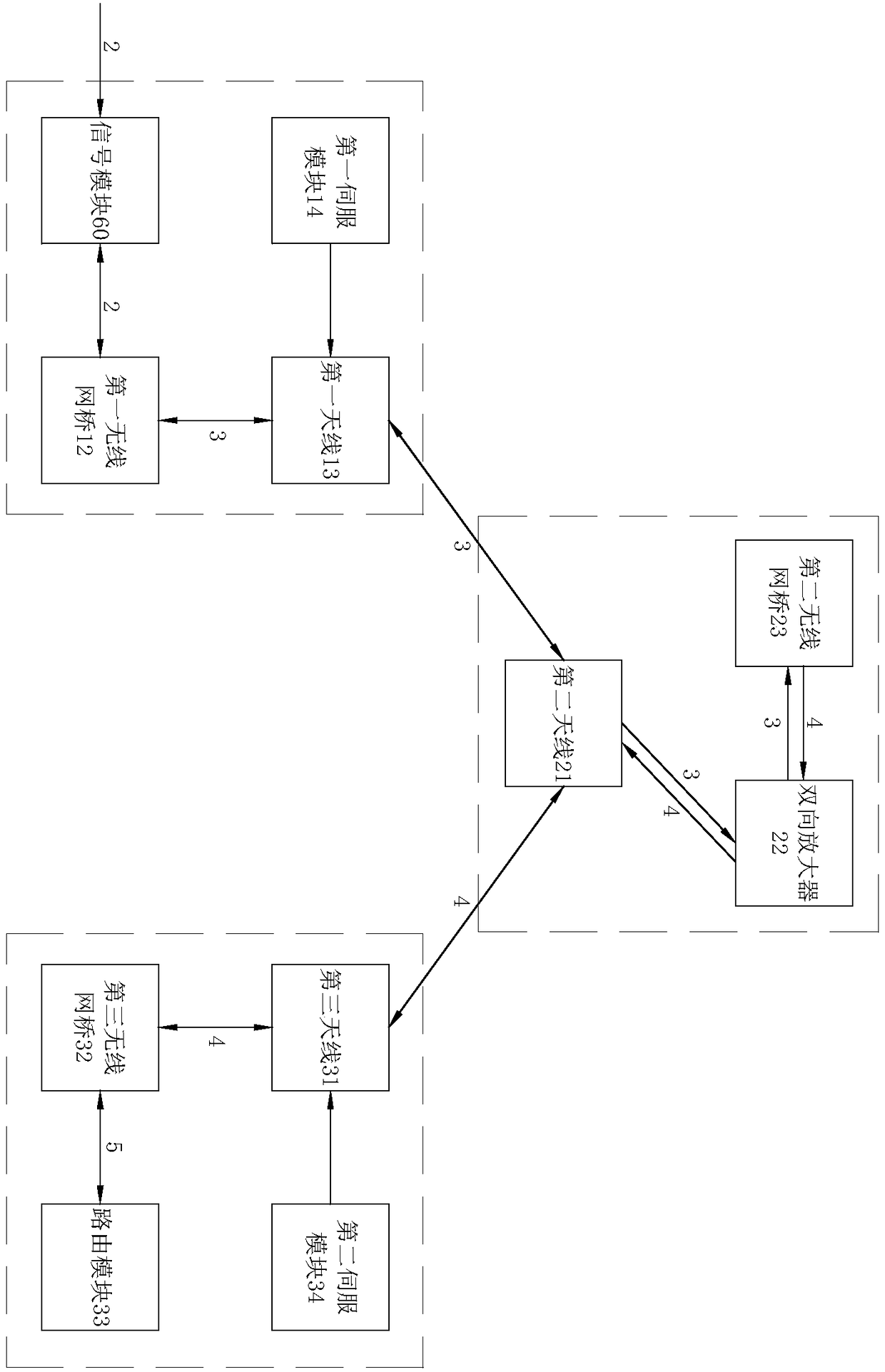

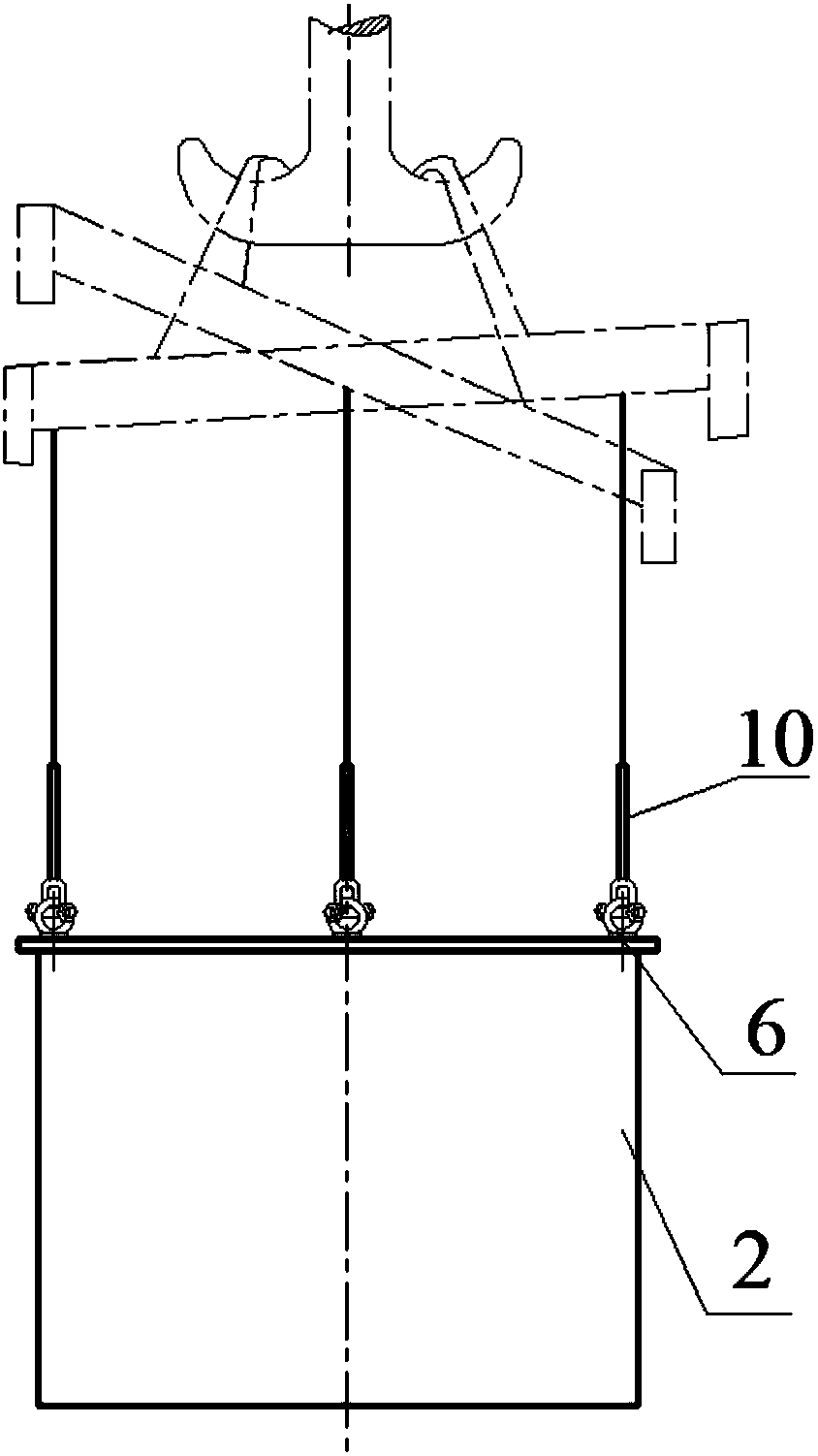

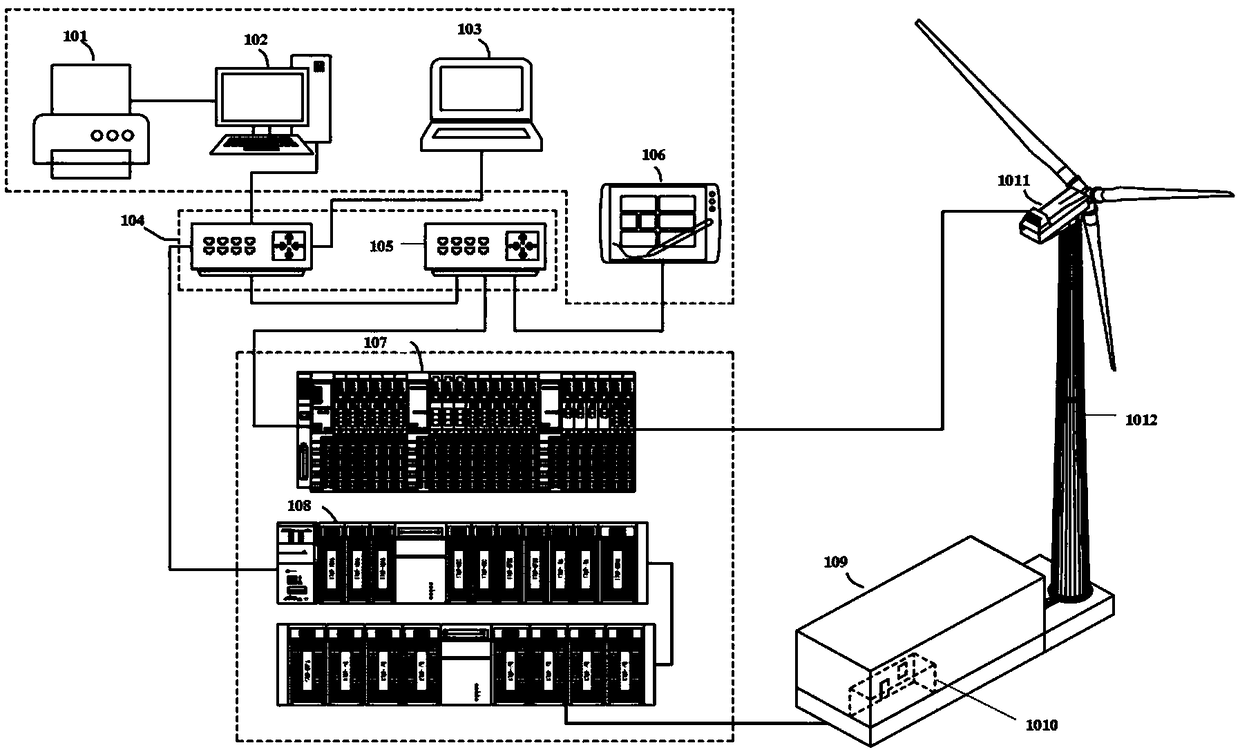

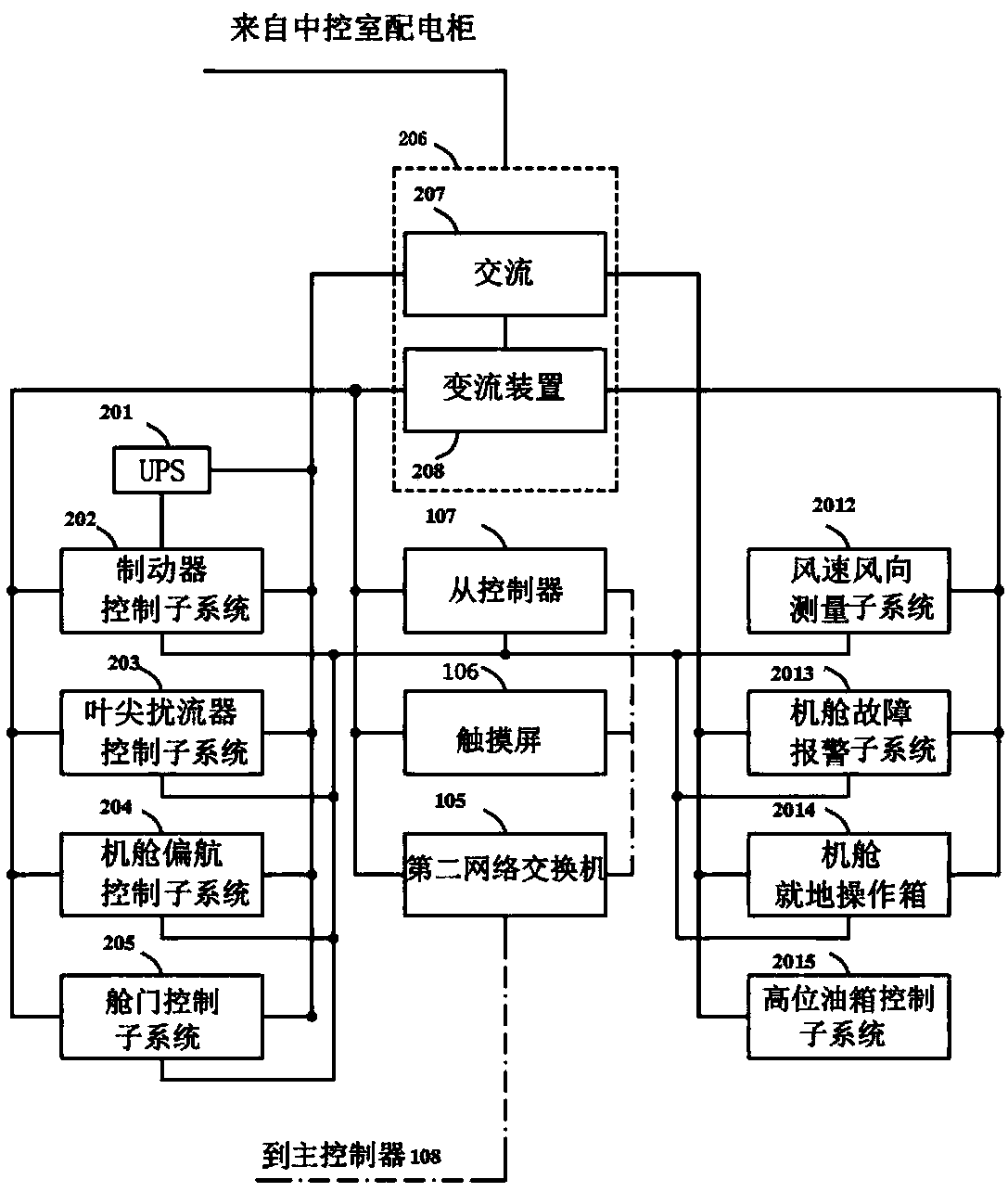

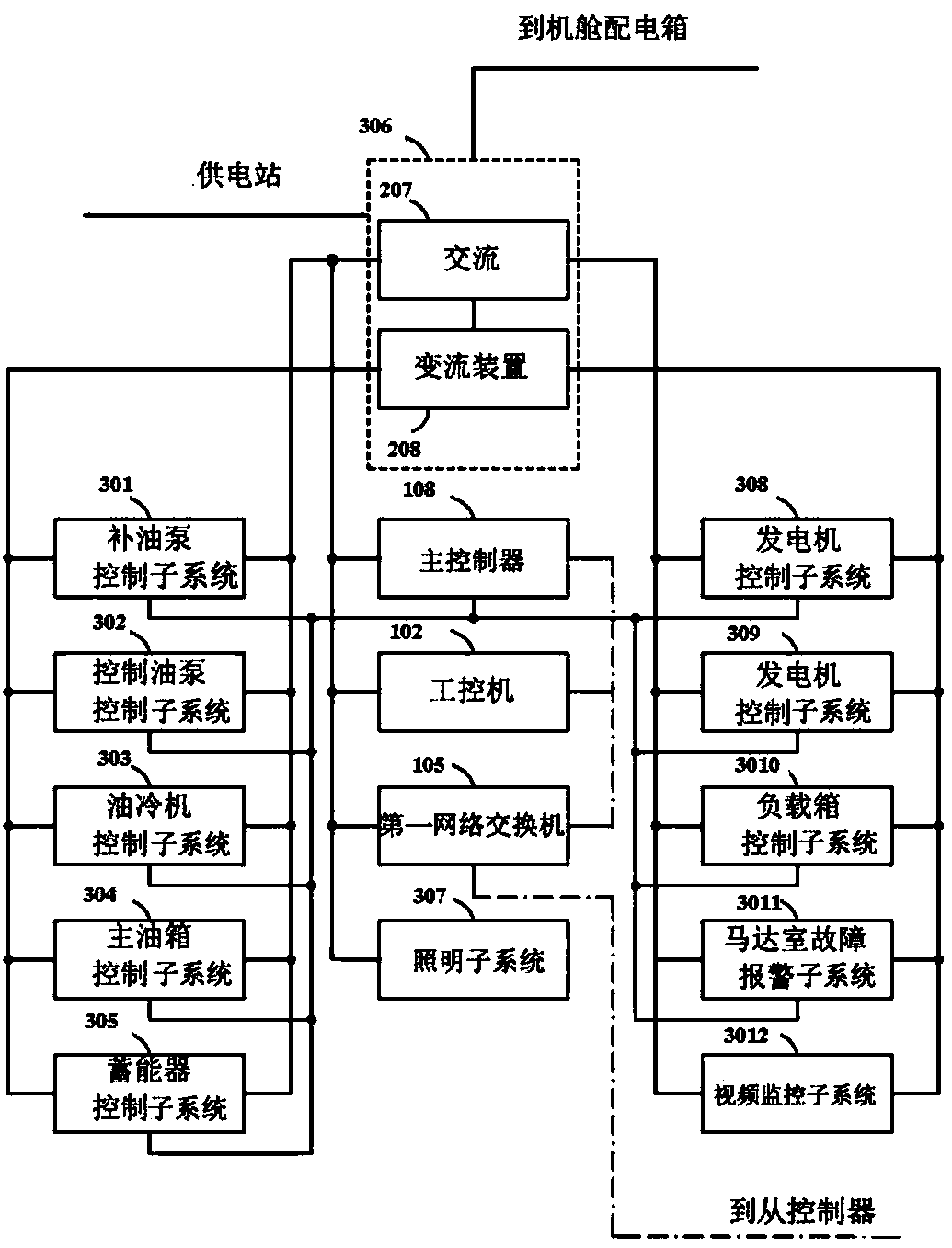

Control system for hydrostatic energy storage type hydraulic transmission type wind turbine generator system

ActiveCN108131249AAvoid erectionReduce in quantityWind motor controlEngine fuctionsControl systemControl room

The invention discloses a control system for a hydrostatic energy storage type hydraulic transmission type wind turbine generator system. The system comprises an industrial personal computer located in a central control room, a first network interchanger, a main controller, a touch screen located in a cabin, a second network interchanger, a subordinate controller and a cabin control subsystem, a motor room control subsystem is connected to the main controller, the main controller is connected to the industrial personal computer through the first network interchanger, and the cabin control subsystem is connected to the back of the subordinate controller and the touch screen and is connected with the first network interchanger through the second network interchanger; a principal-subordinatedistribution system of an industrial personal computer monitoring cabin control subsystem, a motor room control subsystem and a touch screen monitoring cabin control system is constituted, different controllers arranged in the main control room and the cabin are arranged to cooperate with each other synergistically, and the system not only timely and efficiently controls the cabin and a motor, butalso achieves communications and signal transfer between the two controllers.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

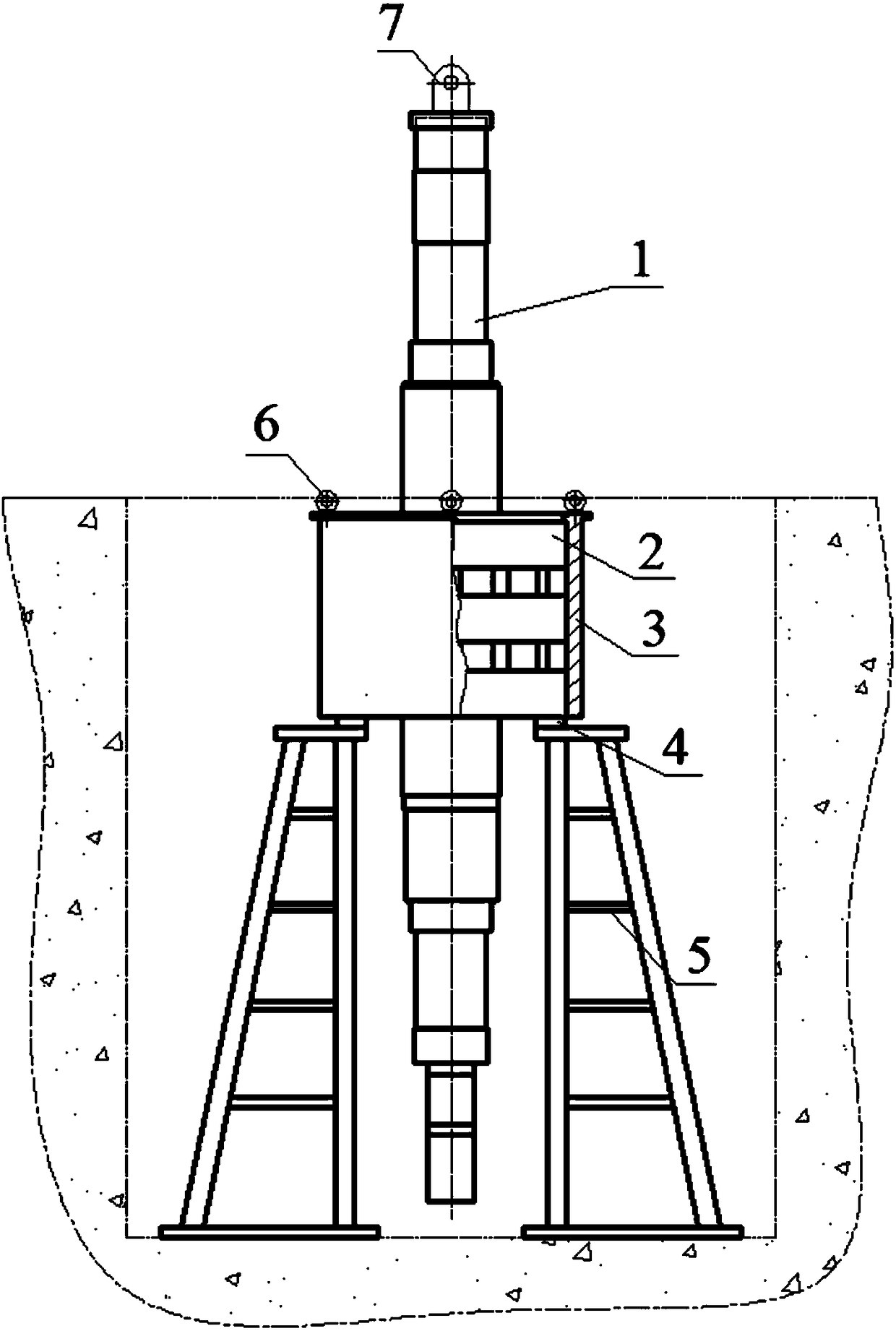

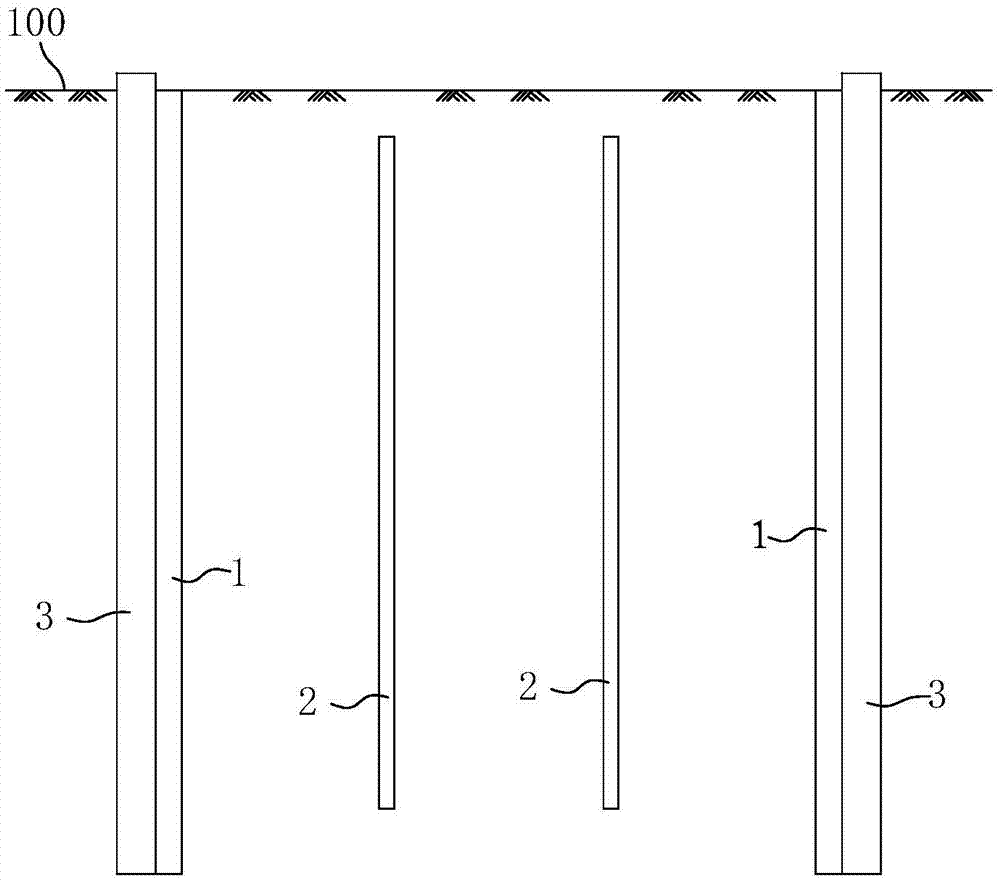

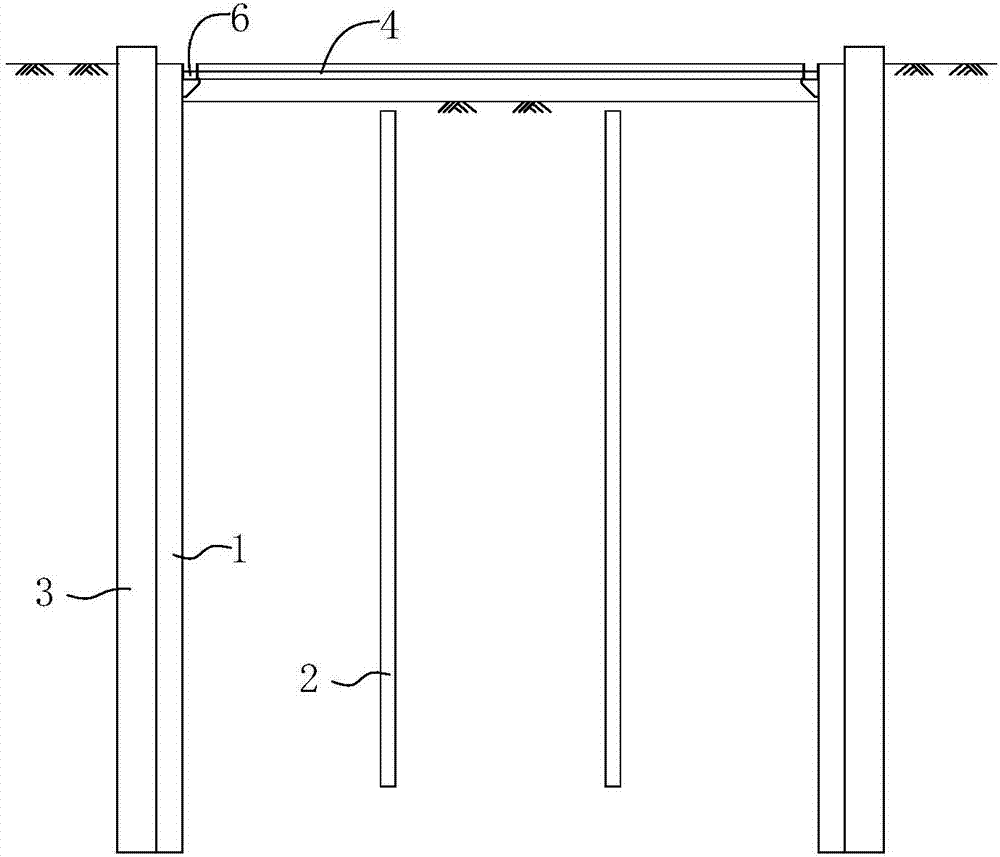

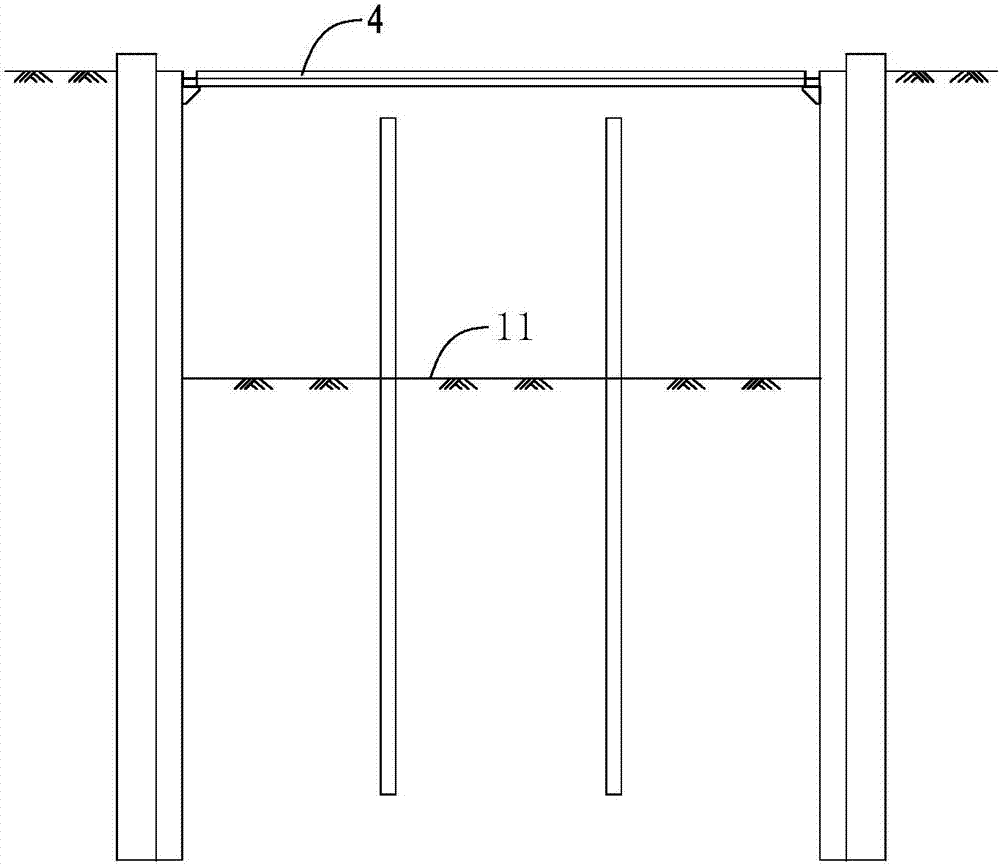

A construction method for an underground garage

ActiveCN107313454AImprove construction efficiencyReduce downtimeArtificial islandsUnderwater structuresBuilding construction

The invention provides a construction method for an underground garage. According to the method, an underground garage is at least divided into two construction sections from top to bottom. The method comprises the steps of: (1) performing construction of guard posts and stand columns and forming guard walls; (2) performing the construction of the first construction section: digging earth to finish the earth digging in the first construction section, stopping digging, building middle parking platforms of the underground garage, casting outer walls via pouring, and finishing a roof of the underground garage; (3) continuing earth digging and finishing the earth digging in the second construction section, building middle parking platforms and continuing pouring of outer walls, and connecting the outer walls of the two construction sections mutually; (4) repeating the step (3) and performing construction in each construction section until the pouring of the outer walls and the building of the middle parking platforms in all the construction sections are finished, wherein the guard walls and the outer walls form wall bodies of the underground garage together. The construction method can effectively increase the construction speed of an underground garage and improve the safety of an underground garage.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

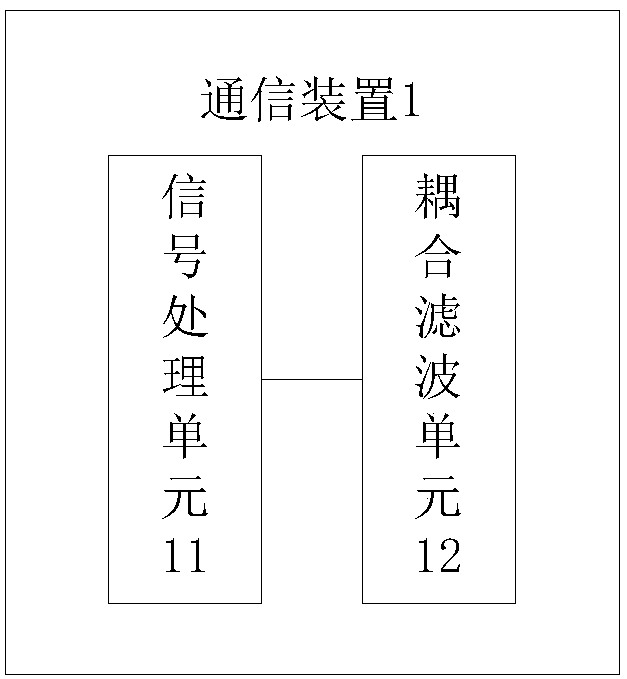

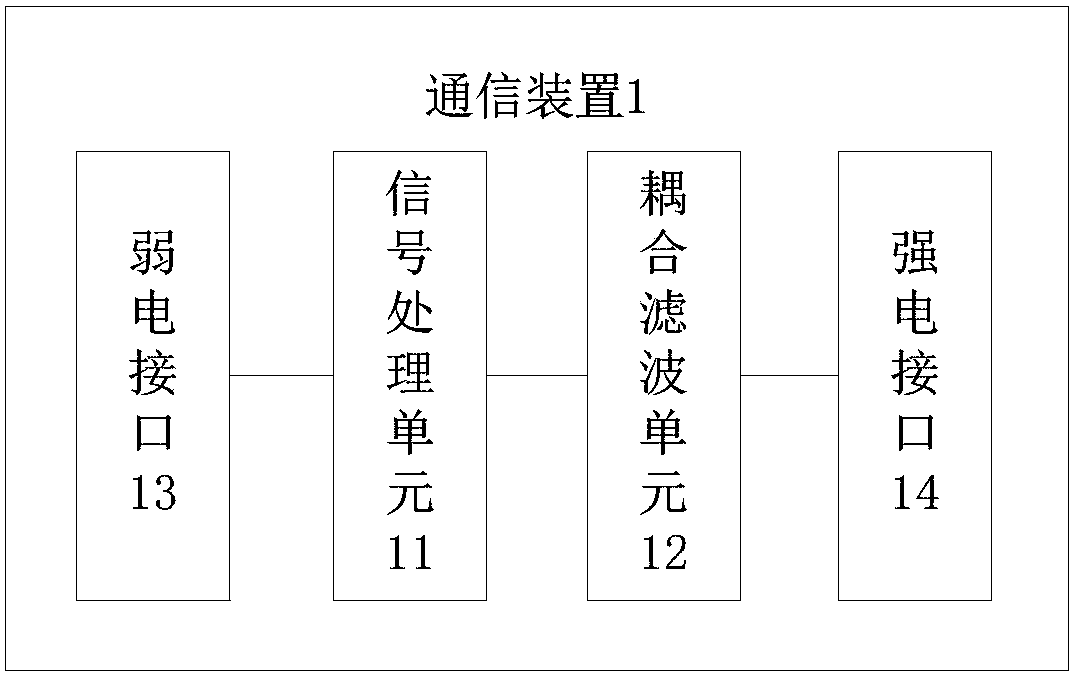

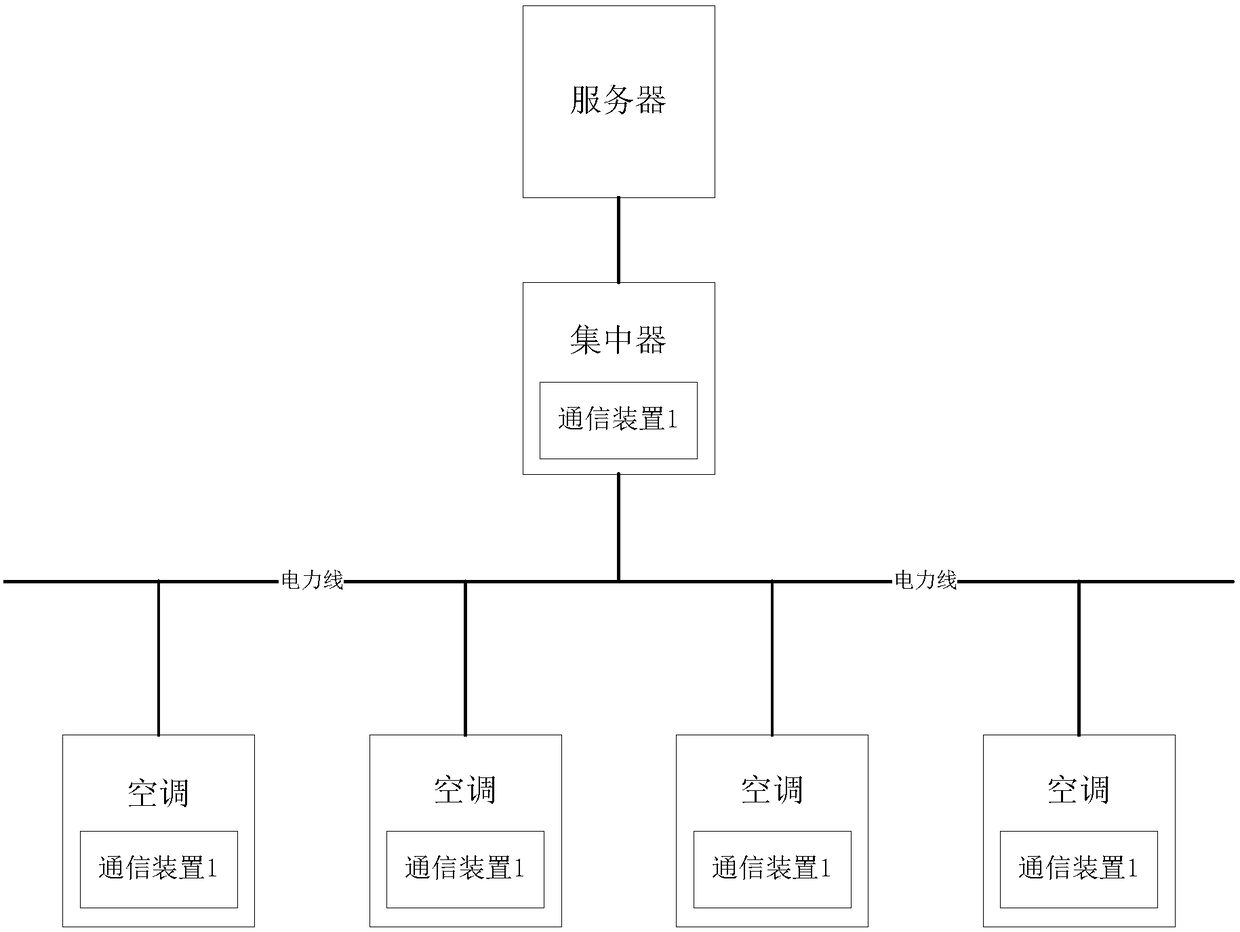

Communication device and method, storage medium and equipment

InactiveCN108242942AAvoid erectionRealize remote data communicationPower distribution line transmissionCarrier signalControl data

The present invention provides a communication device and method, a storage medium and equipment. The method comprises a signal processing unit used for modulating first data to be transmitted to obtain a first carrier signal and transmitting the first carrier signal to a coupling filtering unit, the coupling filtering unit used for receiving the first carrier signal sent by the signal processingunit and sending the received first carrier signal to a power communication line to send the first carrier signal to master equipment or slave equipment through the power communication line, wherein when a belonging device is the master equipment, the first data includes control data of the slave equipment, and / or, when the belonging device is the slave equipment, the first data includes running data of the slave equipment. According to the scheme provided by the invention, the networking communication of the equipment is achieved through a power line, and the issuance of collection and control instructions or policies is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

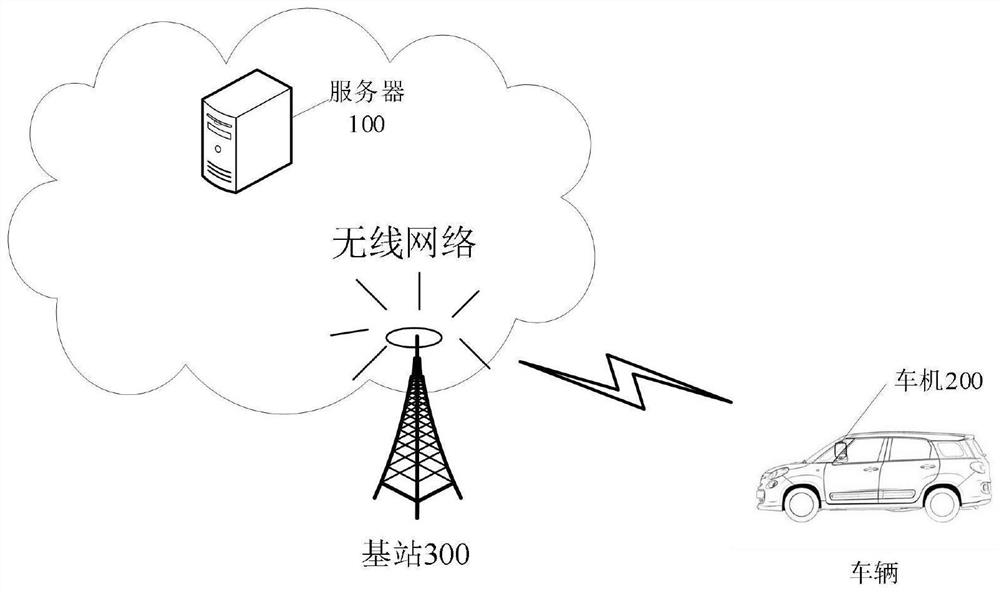

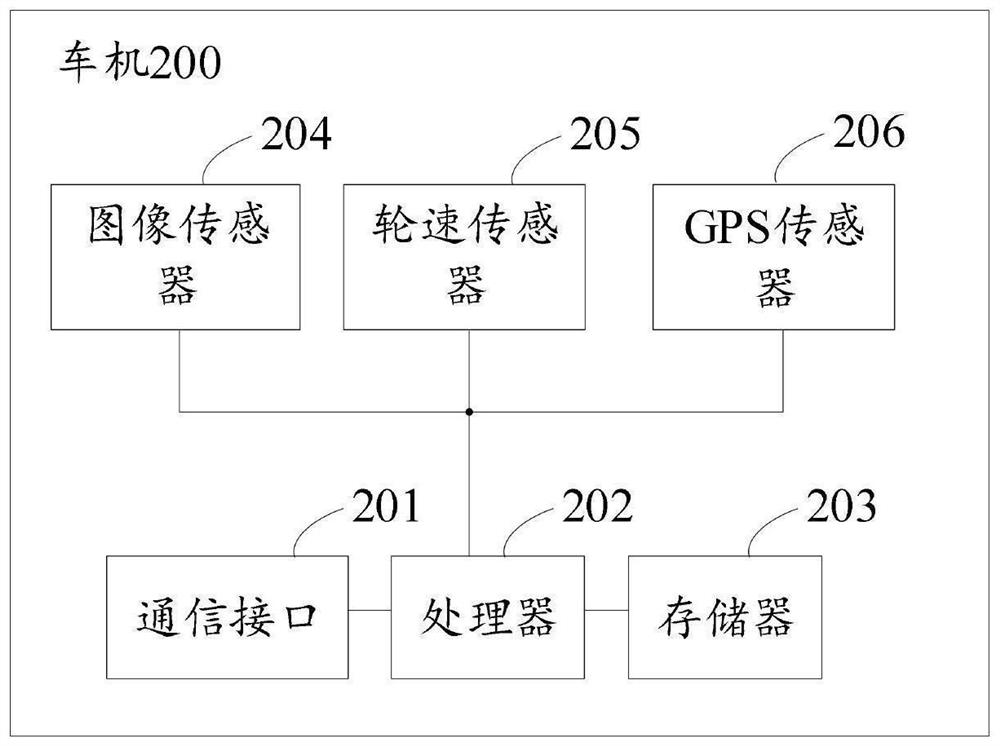

Point cloud map construction method, device and equipment

The invention discloses a point cloud map construction method, device and equipment, and the method comprises the steps: obtaining the feature point information of a plurality of frames of images, the first speed information of a vehicle, and the positioning information of the vehicle, and the feature point information comprises the feature points of each frame of image and the matching relation of the inter-frame feature points; the first speed information of the vehicle comprises a first linear speed and / or a first angular speed of the vehicle, and the first speed information is measured through a wheel speed sensor; determining first pose information of the vehicle according to the feature point information and the first speed information; determining second pose information of the vehicle according to the first pose information and the positioning information of the vehicle; and performing point cloud reconstruction by using the feature point information of the multi-frame image and the second pose information to obtain a point cloud map. According to the method, the linear speed and / or the angular speed of the vehicle are / is obtained through measurement of the wheel speed sensor, the speed information of the vehicle is measured instead of an IMU, noise introduced by IMU measurement is avoided, meanwhile, erection and arrangement of the IMU are avoided, and the production cost is saved.

Owner:BEIJING HORIZON ROBOTICS TECH RES & DEV CO LTD

Winding device for straight wire tube

InactiveCN109399350AAffect the winding workAvoid the misalignment of winding and detachment from the rotating columnFilament handlingEngineeringMechanical engineering

Owner:JIANGYIN YONGCHANG TRAFFIC MACHINERY PARTS

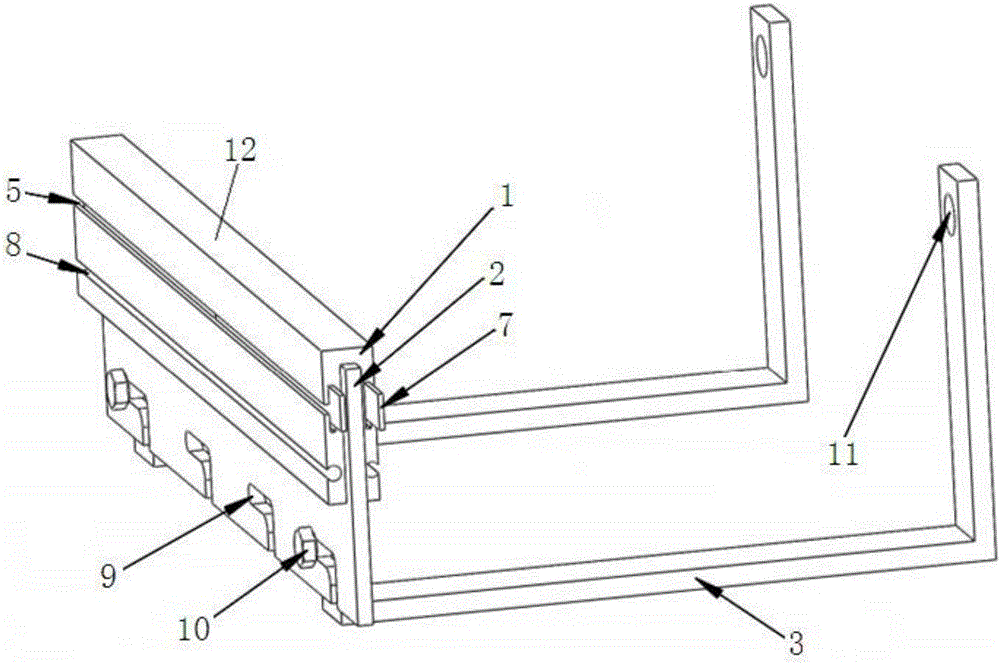

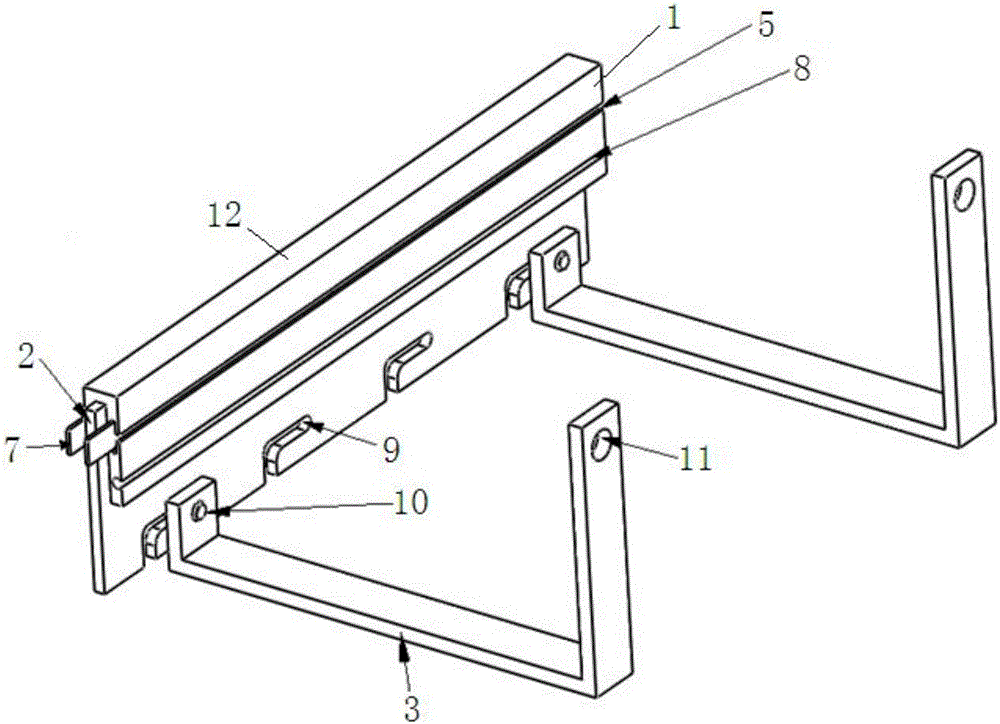

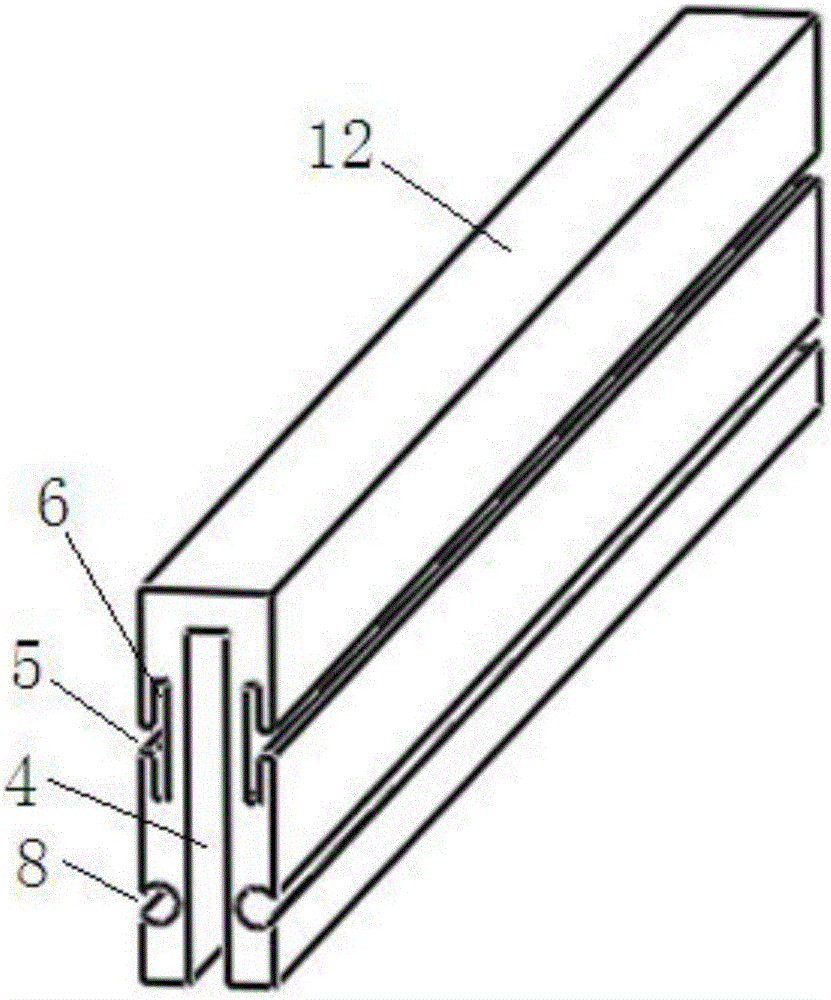

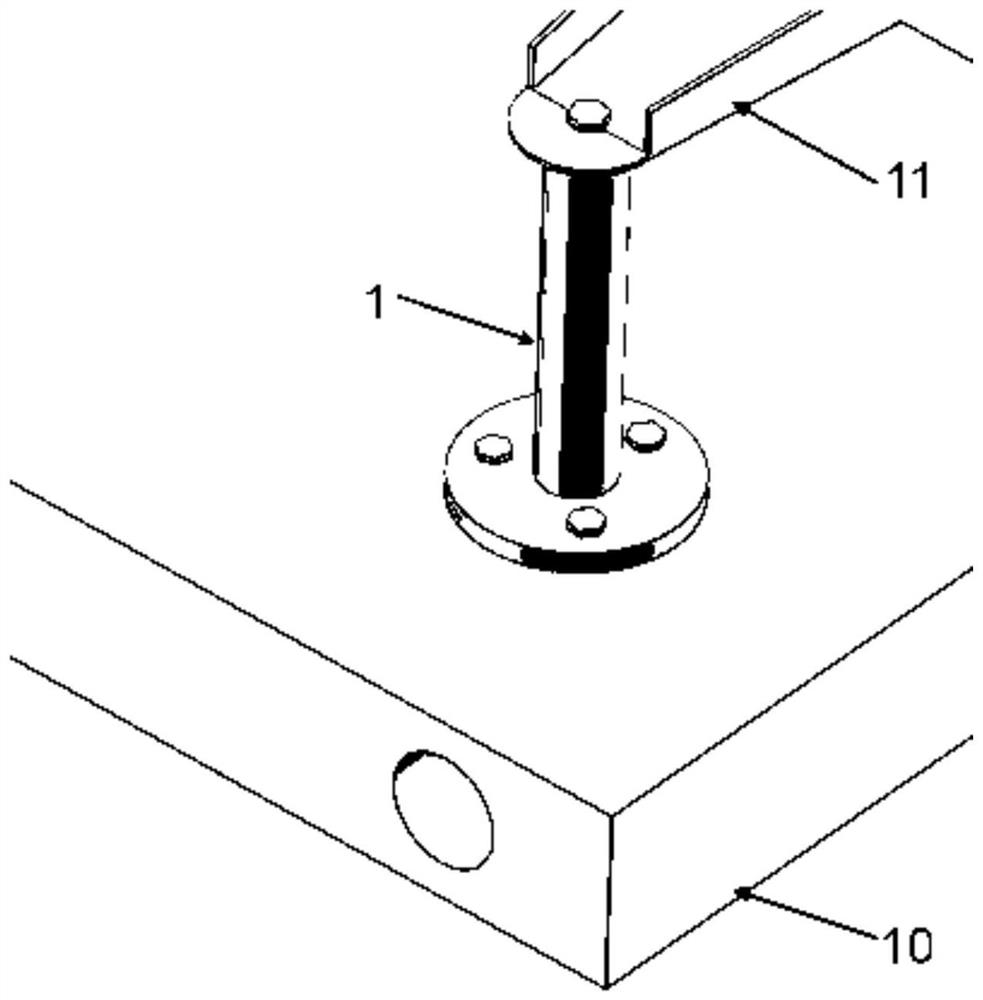

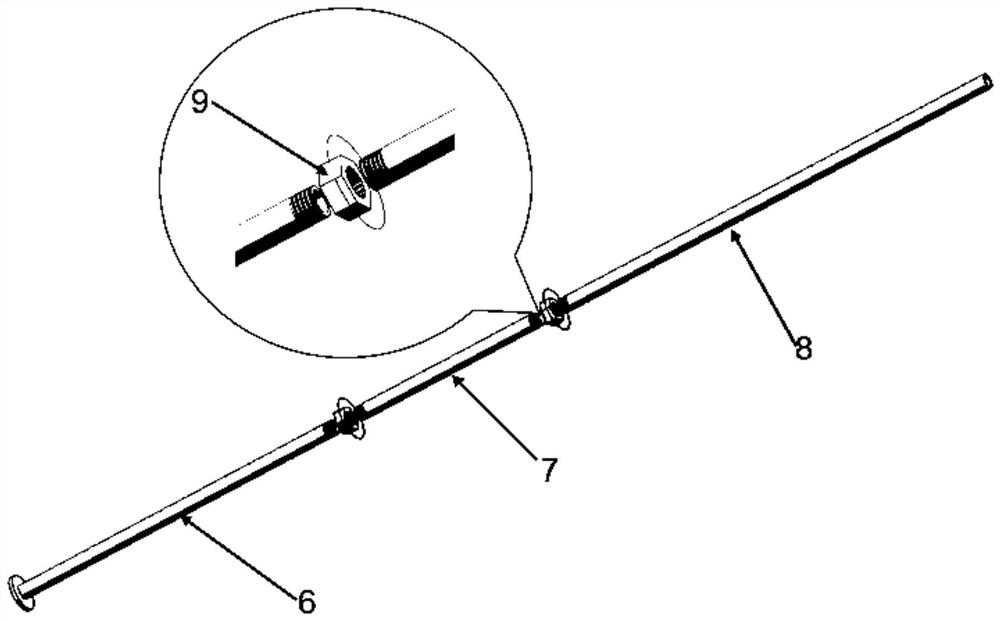

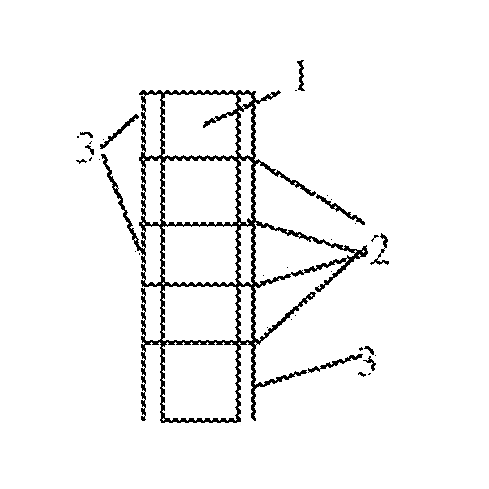

Plastic track mechanical capable of changing curvature radius in assembling process and transmitting electric power

InactiveCN105811194ANatural insulating propertiesReduce workloadCoupling parts mountingElectric power systemCopper

The invention relates to a plastic track mechanical capable of changing curvature radius in an assembling process and transmitting electric power. The plastic track mechanism comprises a plastic track (1), a metal supporting framework (2) and a fixed hanging piece (3), wherein the plastic track (1) is made of plastic; a supporting metal slot (4) is formed in the bottom of the plastic track (1); the upper part of the metal supporting framework (2) is inserted into the supporting metal slot (4); the lower part of the metal supporting framework (2) is detachably connected with the fixed hanging piece (3); power-taking grooves (5) are formed in the side faces of the plastic track (1); copper piece slots (6) are formed in the plastic track (1); the copper piece slots (6) are formed in the inner sides of the corresponding power-taking grooves (5); conductive copper sheets (7) are inserted in the corresponding copper piece slots (6); and the supporting metal slot (4), the power-taking grooves (5) and the copper piece slots (6) are all extended along the length direction of the plastic track (1). The plastic track mechanical is capable of changing the curvature radius of the bending part on the assembling site according to installation requirements so as to well solve the existing problems.

Owner:忻琦

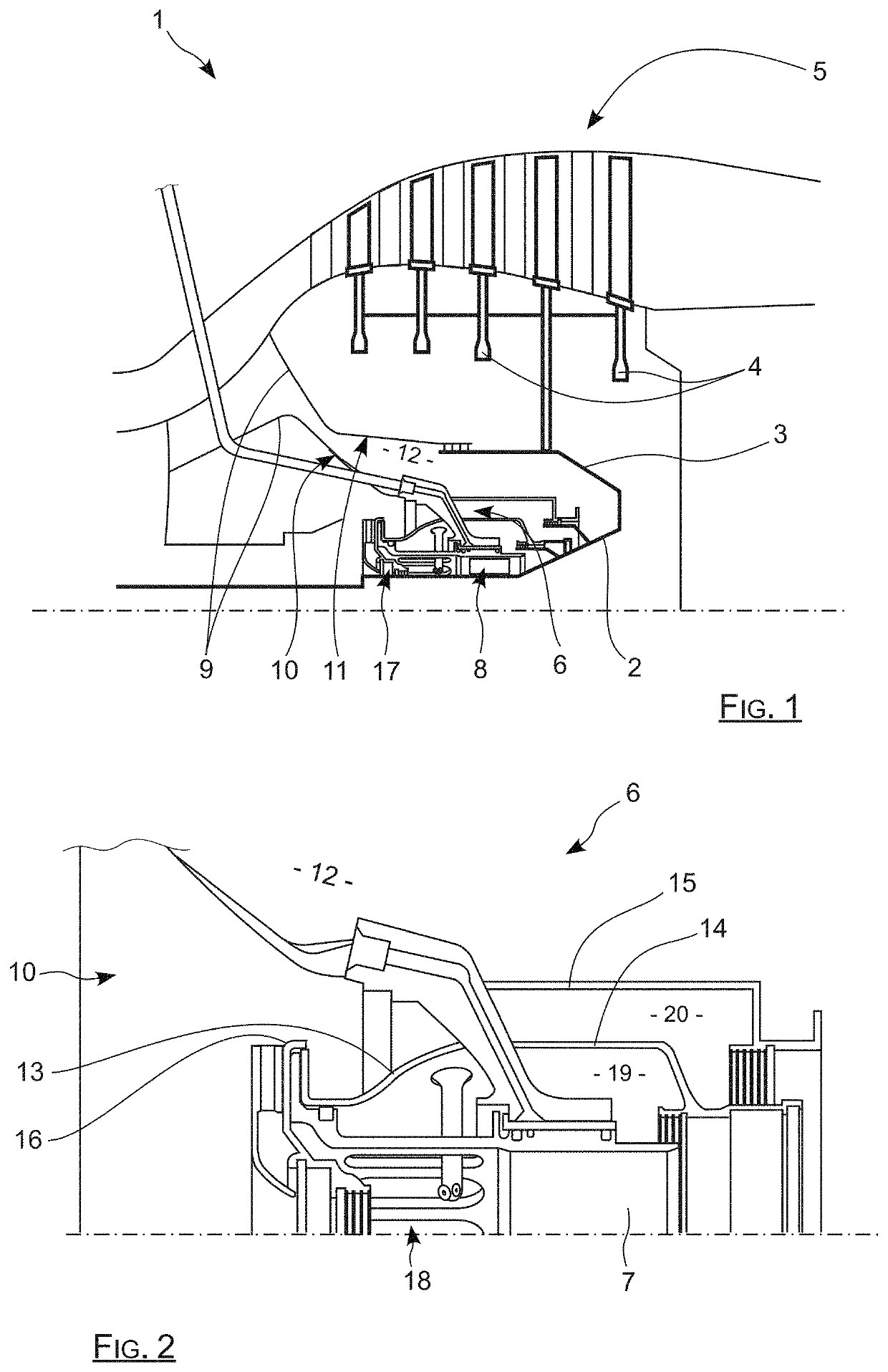

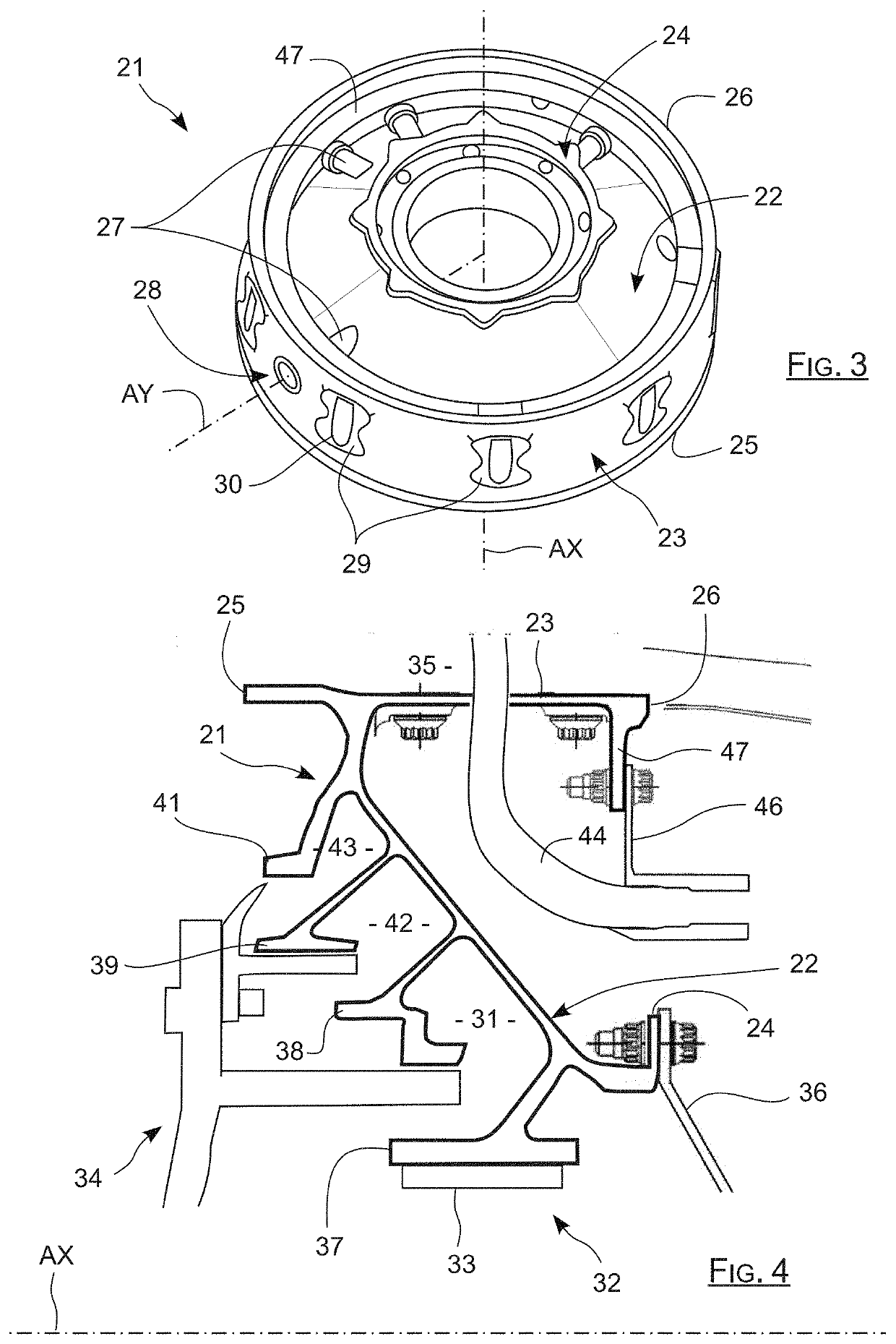

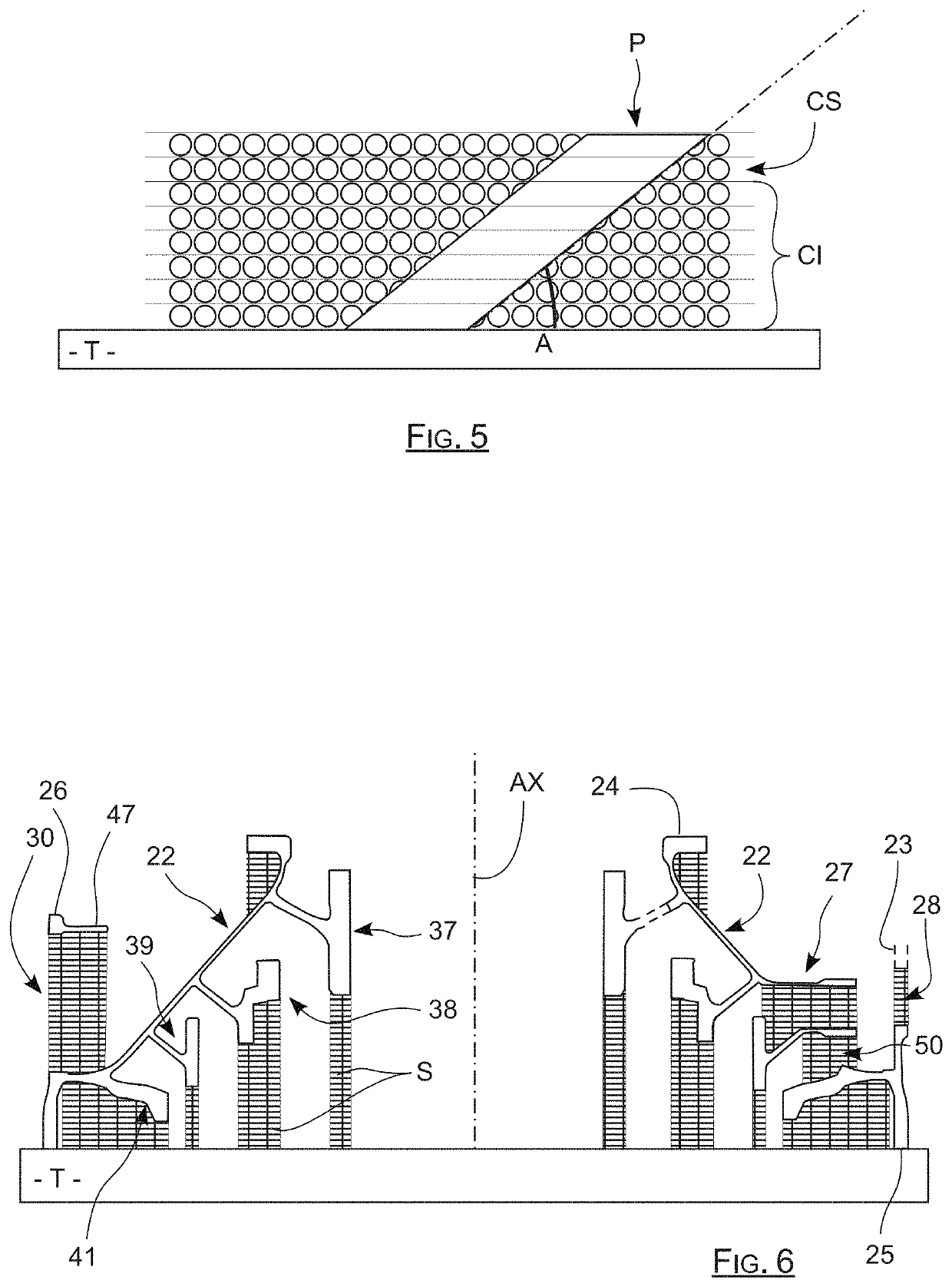

Optimisation of supports for the additive manufacturing of a component

PendingUS20210008624A1Lower the volumeAvoid erectionTurbinesAdditive manufacturing apparatusMechanical engineeringAdditive layer manufacturing

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

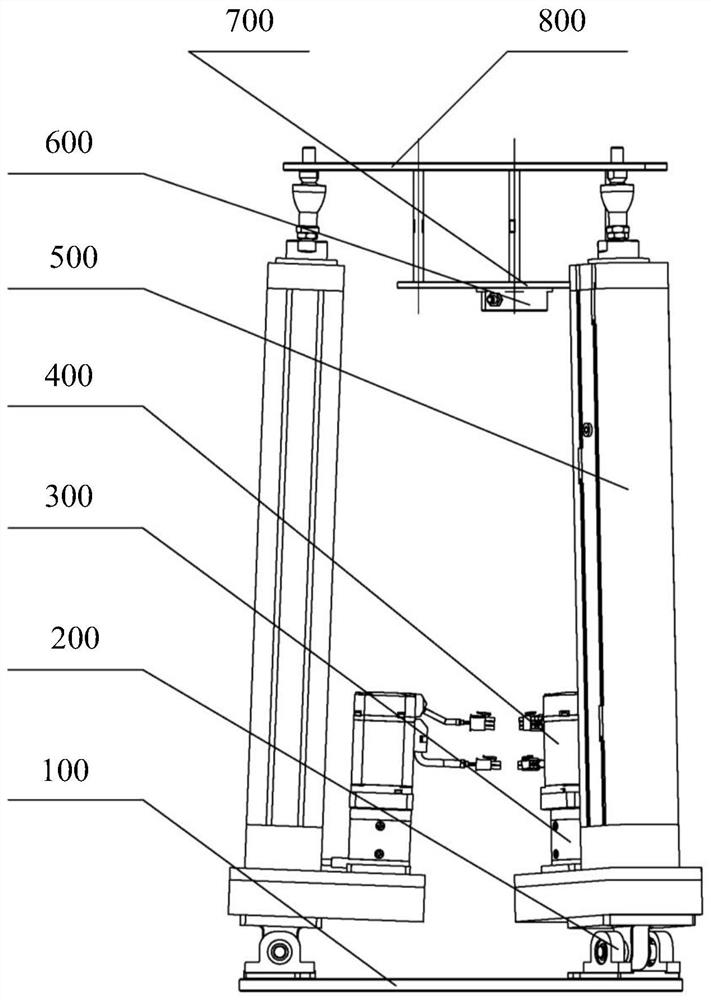

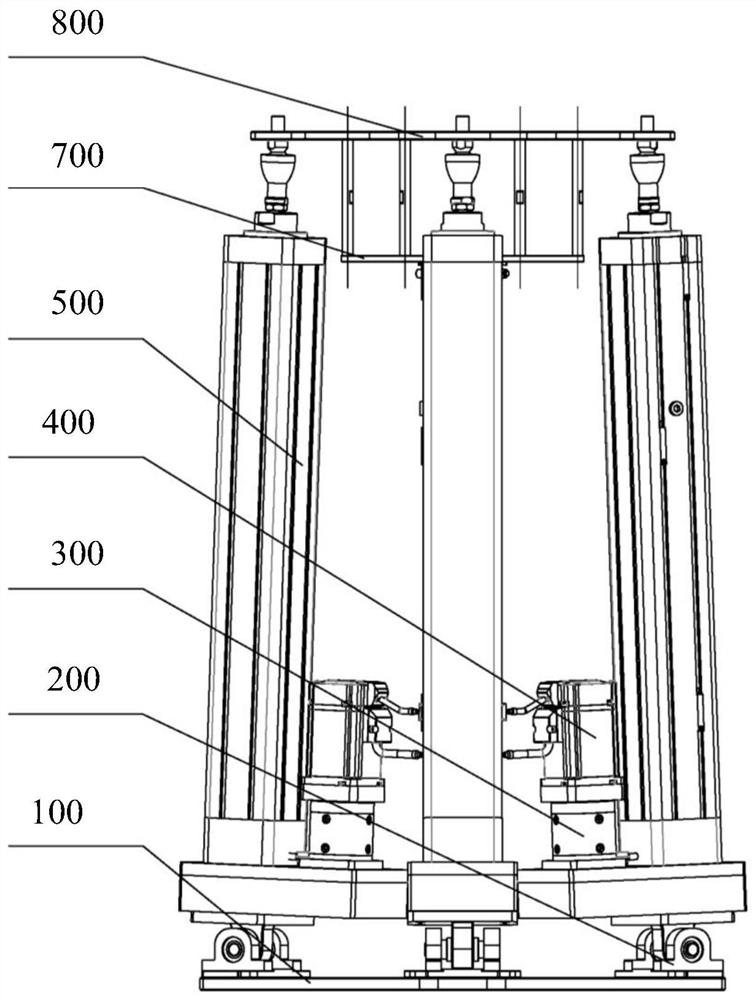

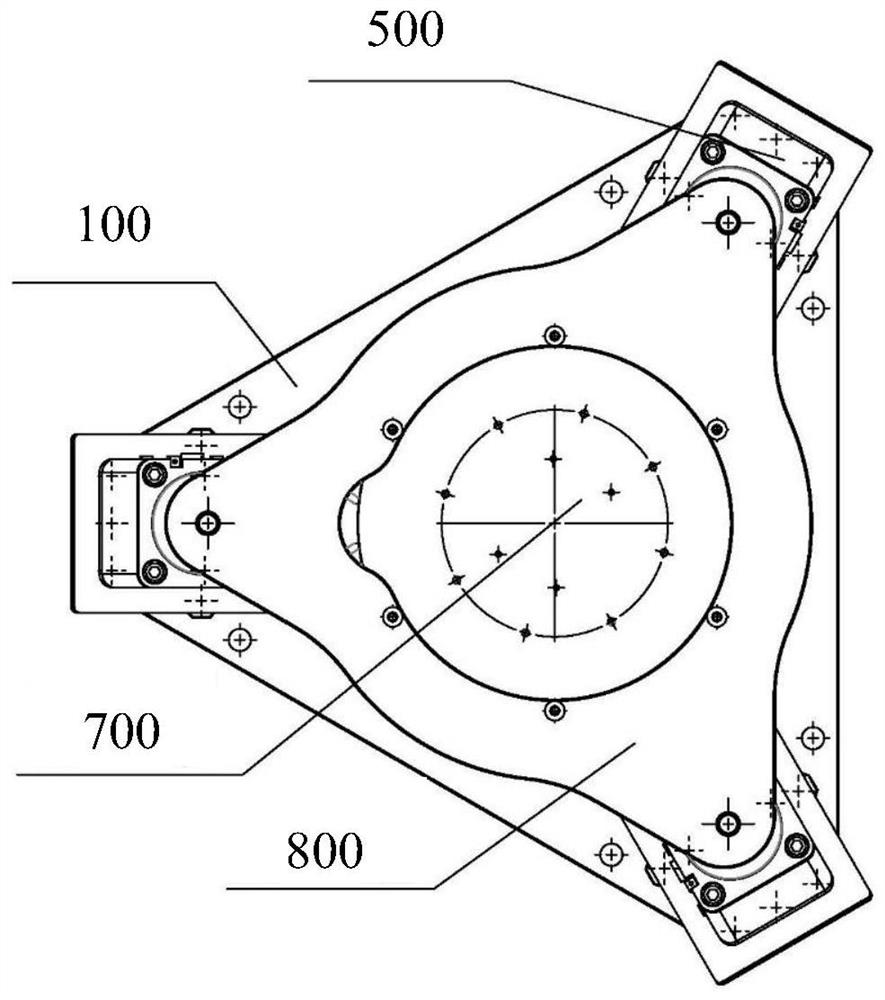

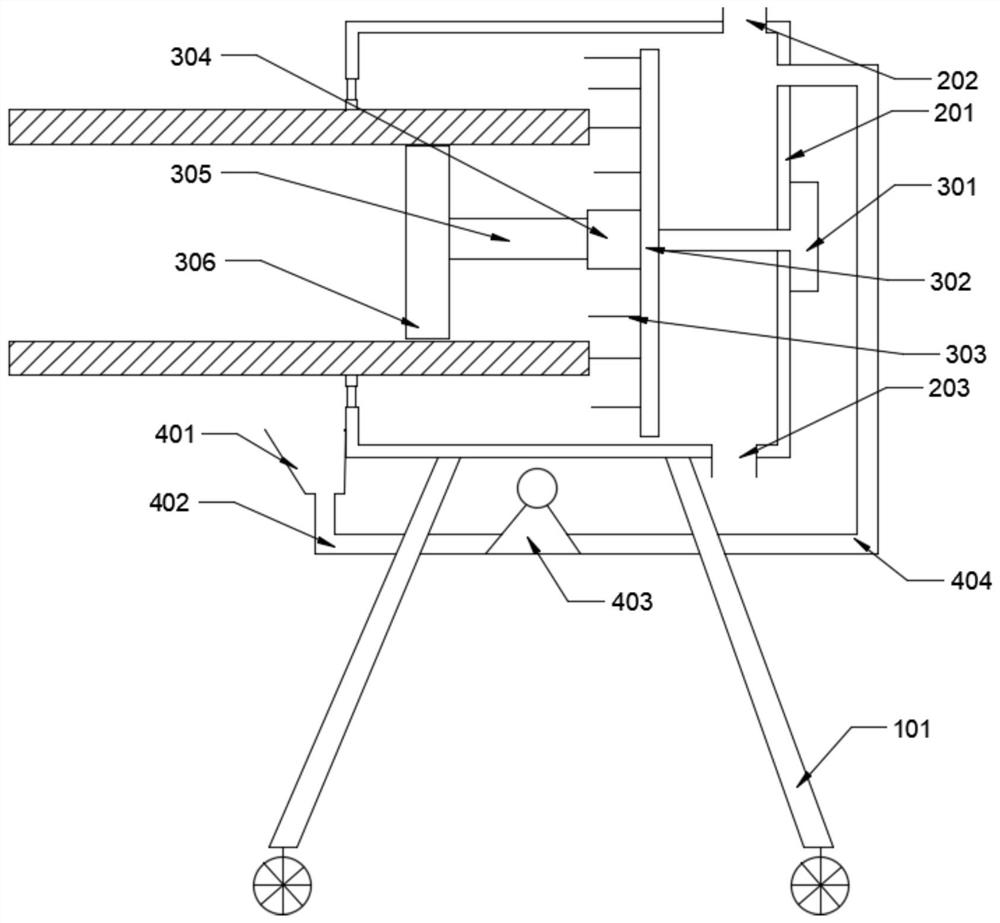

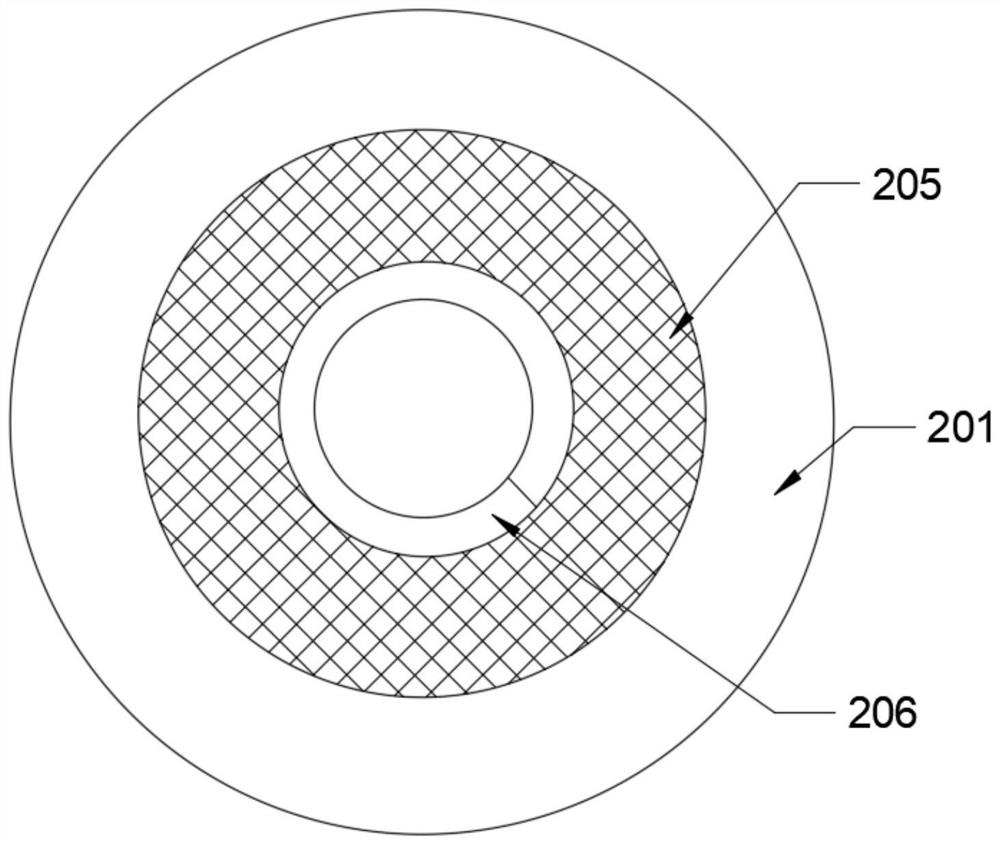

Automatic lifting and leveling device and using method

PendingCN113154213AFast levelingImprove efficiencySurveying instrumentsStands/trestlesStructural engineeringTotal station

The invention provides an automatic lifting and leveling device and a using method. The automatic lifting and leveling device comprises a supporting platform, an upper mounting plate, a lower mounting plate, three electric push rods and three servo motors. The supporting platform is used for supporting and fixing a total station; the upper mounting plate is fixedly connected with the supporting platform; the lower mounting plate is used for being fixedly connected with a carrier; the lower ends of the three electric push rods are all hinged to the lower mounting plate, the upper ends of the three electric push rods are all connected with the upper mounting plate in a ball head mode, and a three-point supporting structure is formed between the upper mounting plate and the lower mounting plate and used for lifting and leveling the upper mounting plate; and the three servo motors are connected with the three electric push rods correspondingly and provide power for the three electric push rods. The automatic lifting and leveling device can meet the functions of automatic leveling and lifting during measurement of the total station, and improves the measurement efficiency.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +2

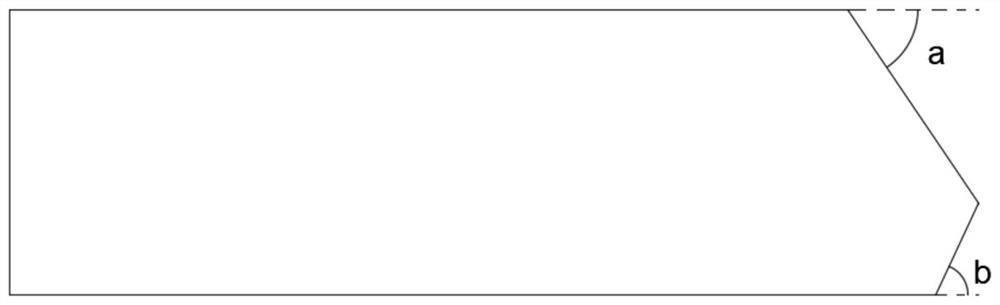

Welding method of tp347 high pressure thick wall stainless steel pipe

ActiveCN111299883BImprove welding qualityImprove construction efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSS - Stainless steelPipe

The invention discloses a welding method for TP347 high-pressure thick-walled stainless steel pipes, which includes the following steps: Step 1, pipe bevel processing: two pipes to be welded are processed by a bevel machine, and the bevels are double V-shaped; Step 2. Cleaning the groove of the pipeline: firstly, the groove is polished and cleaned, and then the nozzle of the pipeline with the groove is placed in a sodium hydroxide solution with a mass fraction of 5% for 2 hours using a soaking device. Including: bracket, cleaning tank, outer sealing component, cleaning component, inner sealing component; step 3, pipe pairing: pair the two pipes to be welded, and pair the two V-shaped grooves on the outside to form the outer pairing slope and fix the outer pair of grooves by spot welding, and the two V-shaped groove pairs on the inner side form the inner pair of grooves; Step 4, pipe welding. The invention processes the bevel by means of a beveling machine, which can effectively improve the welding quality, reduce labor input and improve construction efficiency.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

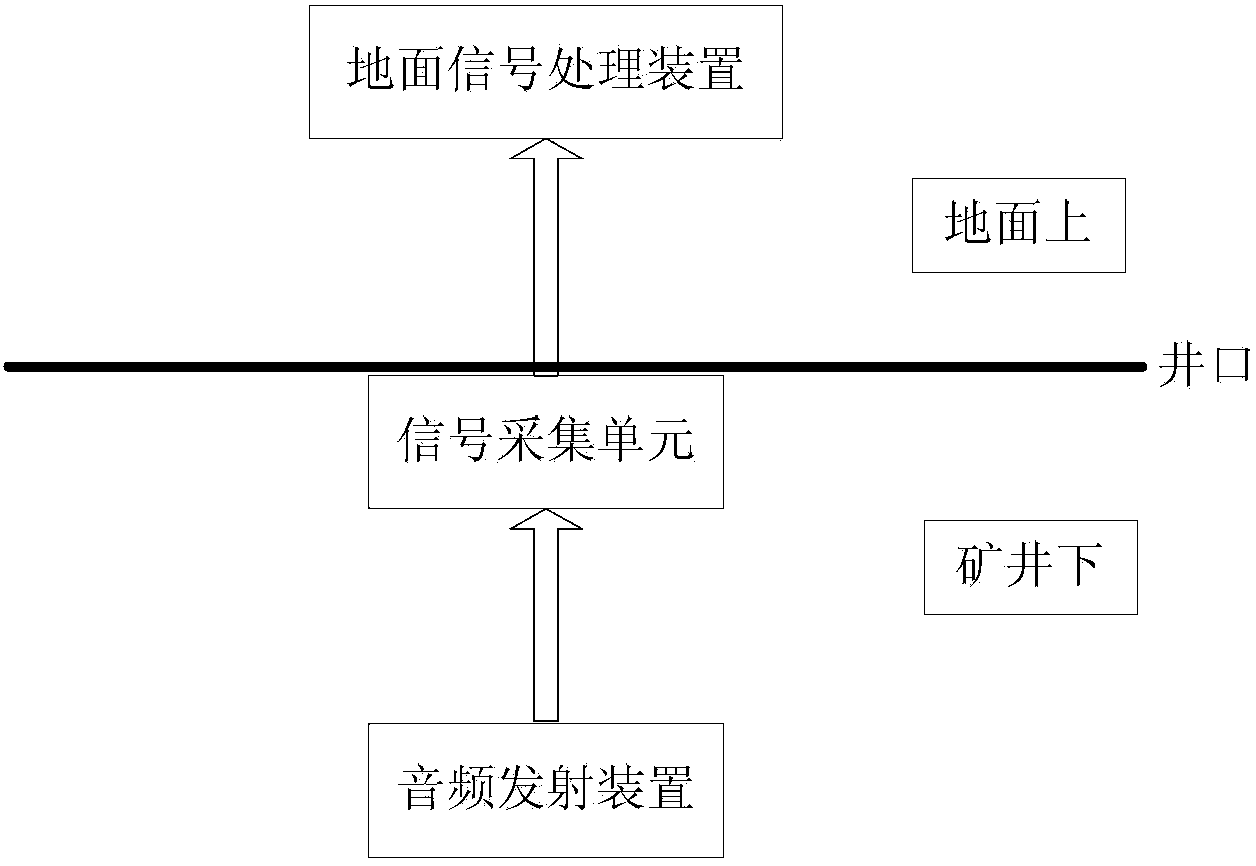

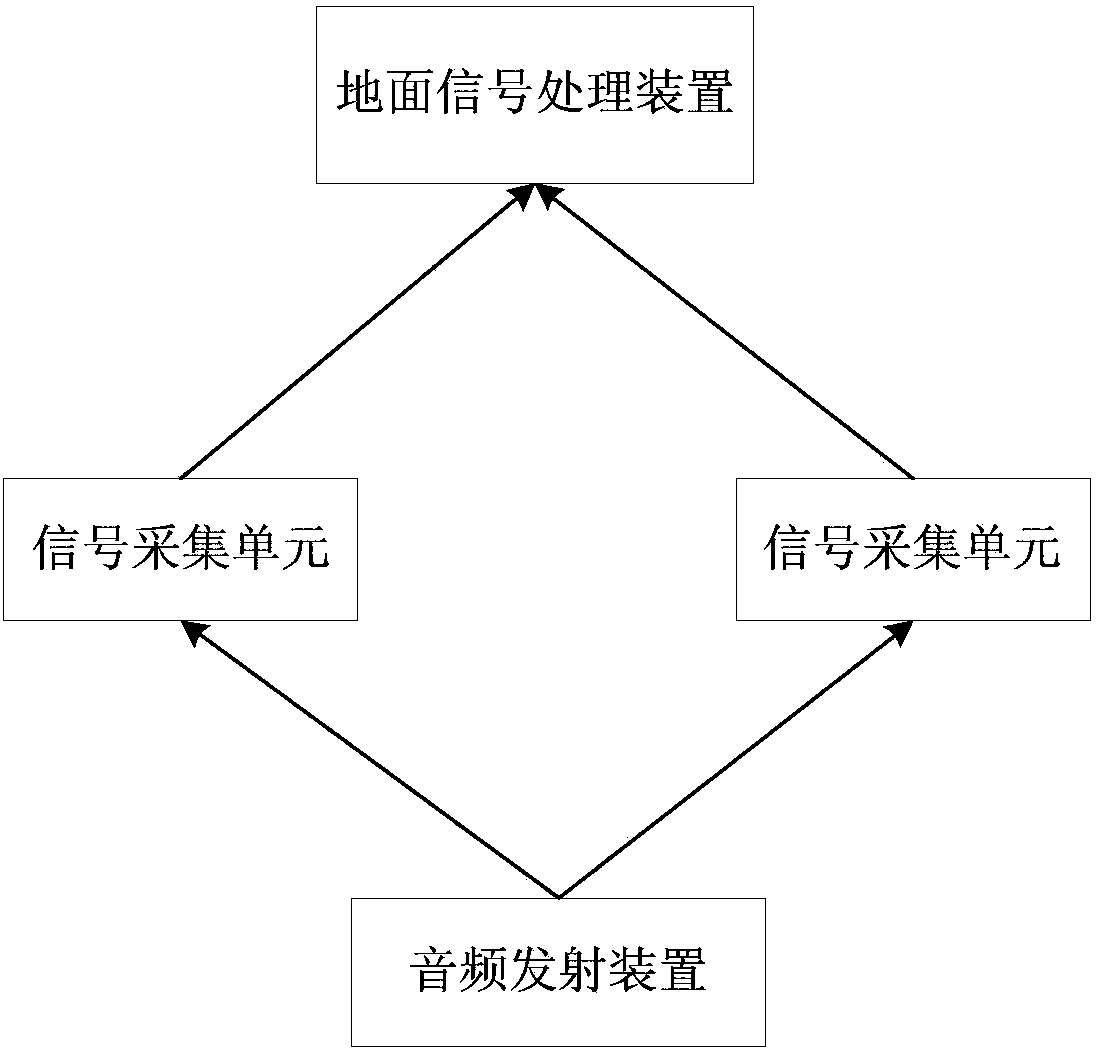

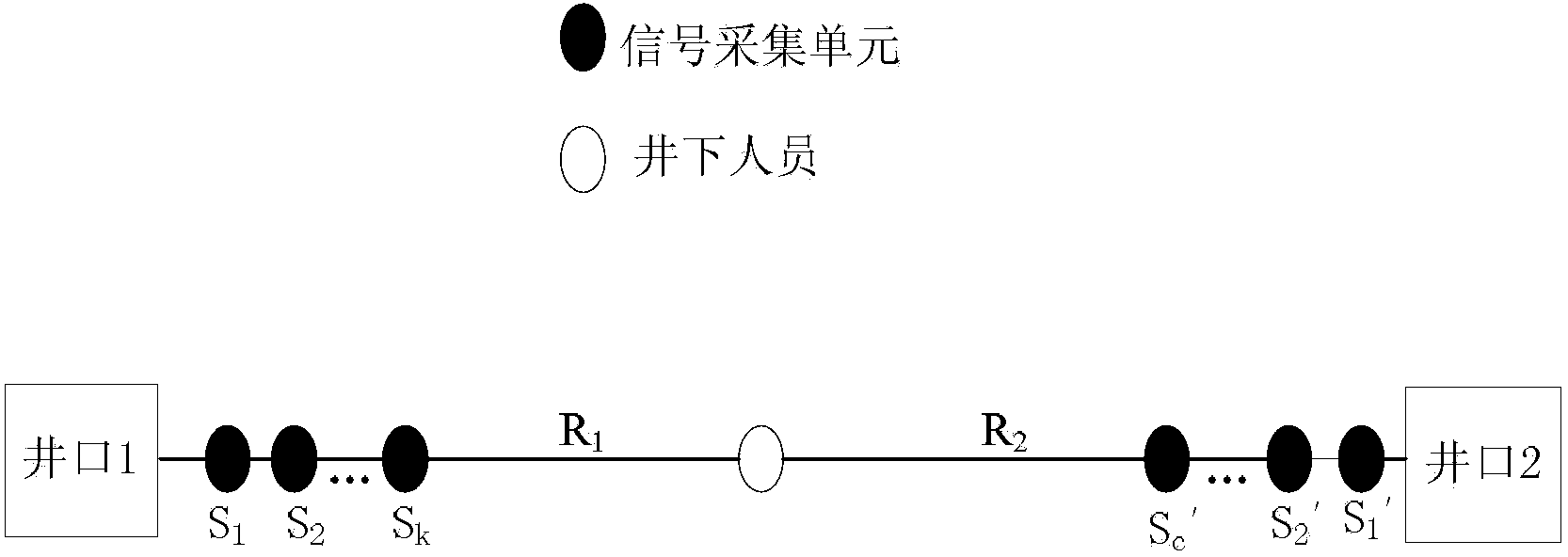

Down-hole remote locating method and system based on beam forming

ActiveCN102981149BImprove signal-to-noise ratioAvoid erectionSpeech analysisPosition fixationFrequency spectrumEngineering

The invention discloses a down-hole remote locating method and a system based on the beam forming. The down-hole remote locating method the beam forming includes transmitting sound signals; collecting sound signals; processing sound signals by a processing unit, wherein the sound signal processing specifically comprises beam forming stacking; spectral analysis and characteristic signal extraction; determining time differences of characteristic signals arriving at a signal collection unit; and calculating a located position according to the arrival time differences. According to the locating method, used sound signals utilize roadway metal structures as communication media, the penetrating capability is high, the propagation distance is far, and erecting of base stations is avoided. A beam forming technology is used for processing the sound signals, so that the signal to noise ratio of the sound signals is enhanced. According to the down-hole remote locating method and the system based on the beam forming, the locating accuracy is high, the reliability is high, and the cost is low.

Owner:RUN TECH CO LTD

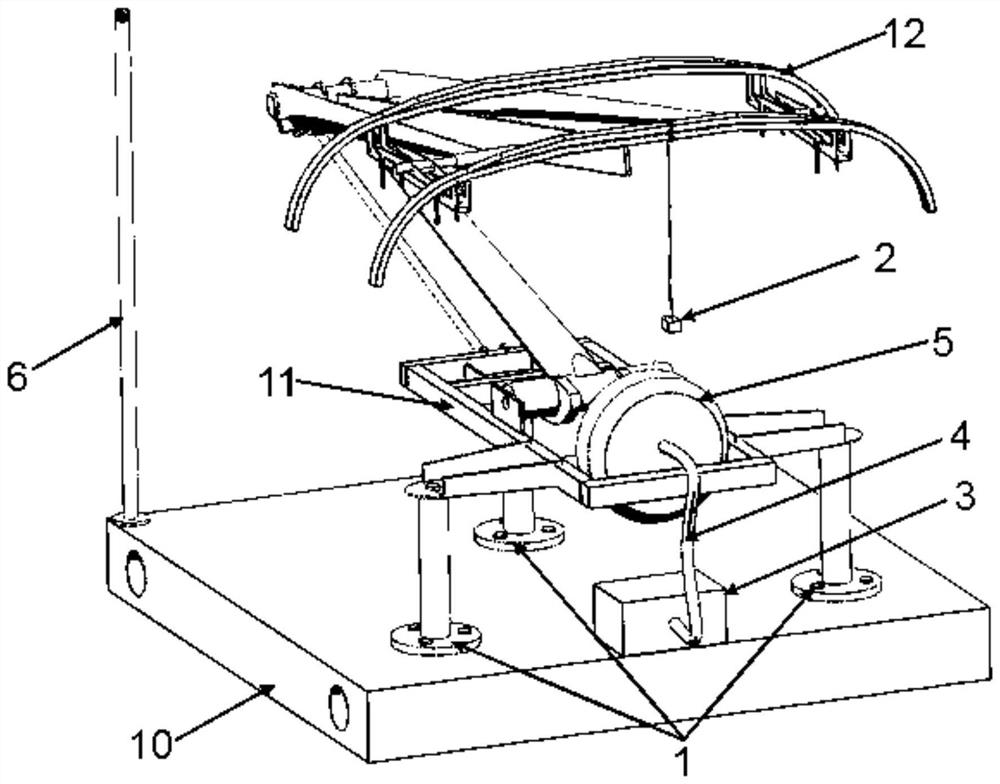

Motor train unit pantograph working mode test device

PendingCN112484947ALow costAvoid erectionVibration testingShock testingControl engineeringStructural engineering

The invention provides a motor train unit pantograph working mode test device which comprises a pantograph and an experiment device, the experiment device comprises a supporting structure, a driving structure, a measuring structure and a weight structure, the supporting structure comprises a supporting base and a supporting column, the supporting column is arranged on the supporting base, and thepantograph is arranged on the supporting column; the driving structure is an air bag structure, and the air bag structure is arranged in front of a pantograph truss of the pantograph; the measuring structure is a measuring pipe, and the measuring pipe is arranged on the supporting base; and the weight structure is a weight, and the weight is arranged at the pantograph head of the pantograph. The pantograph is erected to drive the pantograph through the air bag, and therefore on the premise that experiment requirements are met, the size is smaller, precision is higher, and experiment steps aresimpler and more labor-saving.

Owner:DALIAN JIAOTONG UNIVERSITY

Pressure limiting valve with direct hydraulic damper

InactiveCN1673592BBest short pathSimple structureEqualizing valvesSafety valvesEngineeringHydraulic fluid

The invention relates to a pressure relief valve which involves direct hydraulic damping and protects hydraulic brace system from rock surges and other suddenly occurring overload. The pressure relief valve comprises a valve housing with a connection, wherein an input and an output sides of the valve housing are separated from one another by means of a closing part, which can be displaced against the force of a valve spring and comprises a seal, and are connected to one another when an overload situation occurs to drain the hydraulic fluid, wherein the closing part is formed by a piston, which is linked to the connection, and a valve spring retainer, which comprises said piston, is arranged displaceably thereon and accordingly has a cylindrical design, the seal is arranged in a groove, which is incorporated in a contact surface of the valve spring retainer at a distance from a base of the valve spring retainer, which guarantees a sufficiently large sealing surface beneath radial bores on the piston.

Owner:沃尔夫冈·福斯

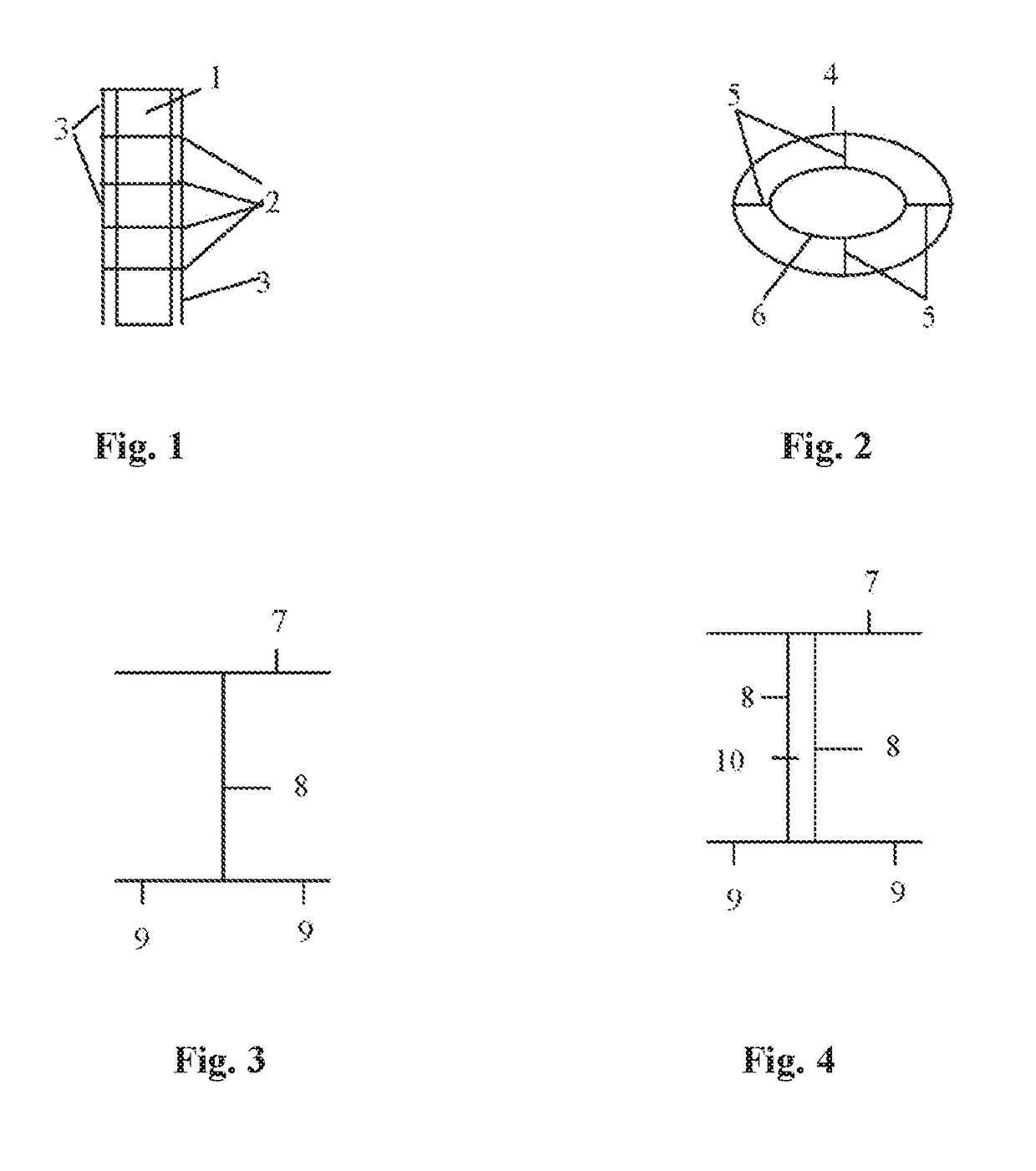

Skeleton clothing

InactiveUS20180310647A1Avoid erectionAvoid embarrassmentGarment special featuresConvertible garmentEngineering

A skeleton clothing, comprising: an adjustable skeleton (2), a cloth (3) and a filler that match each other and the materials of which may be selected as required. The adjustable skeleton (2) realizes a small void between the body and the clothing. The present invention is beneficial for heat dissipation, and has a masking and beautifying effect, and a dynamic aesthetic feeling. There can be a variety of skeleton clothing, for example, skeleton raincoat, skeleton thermal clothing, skeleton fire-proof clothing, skeleton bullet-proof clothing, skeleton diving clothing, skeleton space clothing, skeleton flying clothing, skeleton anti-radiation clothing, and skeleton motorcycle clothing.

Owner:TONG JIANLUN

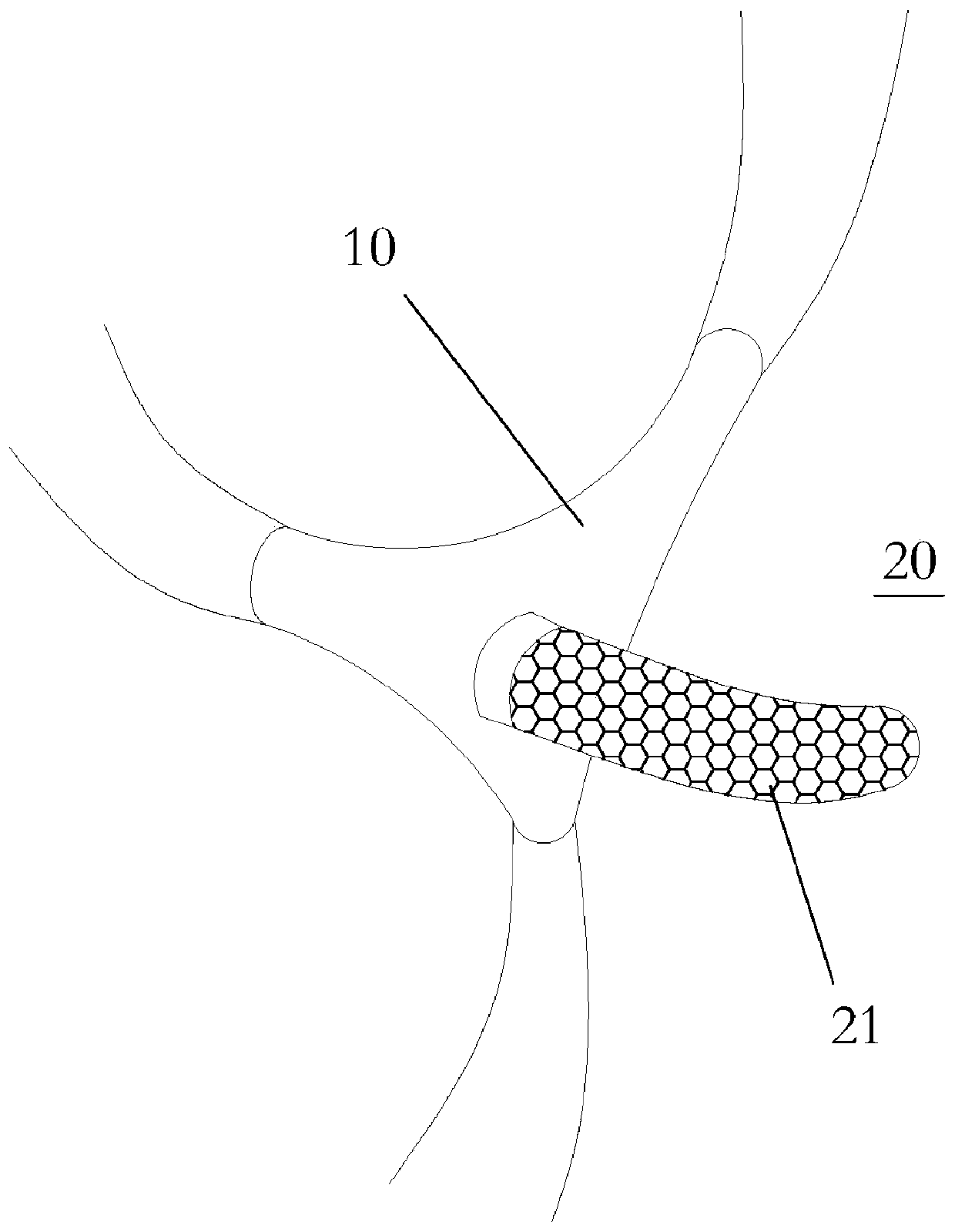

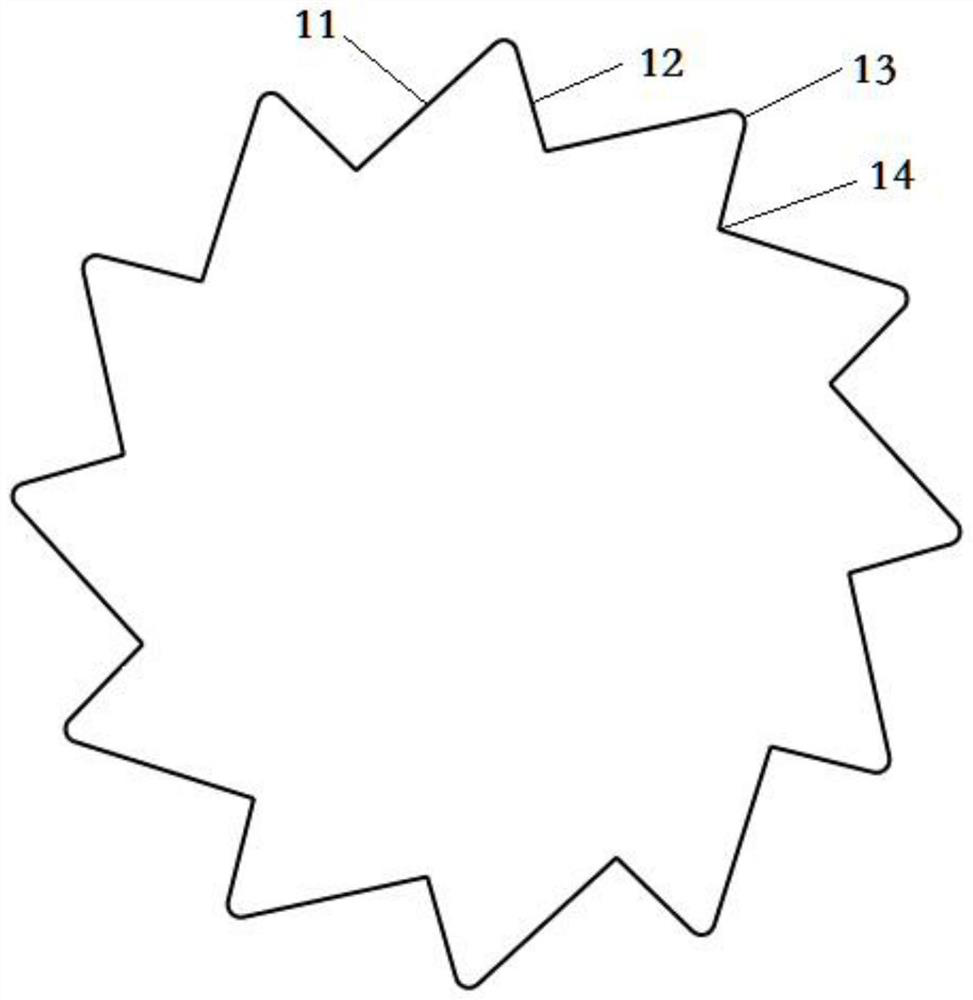

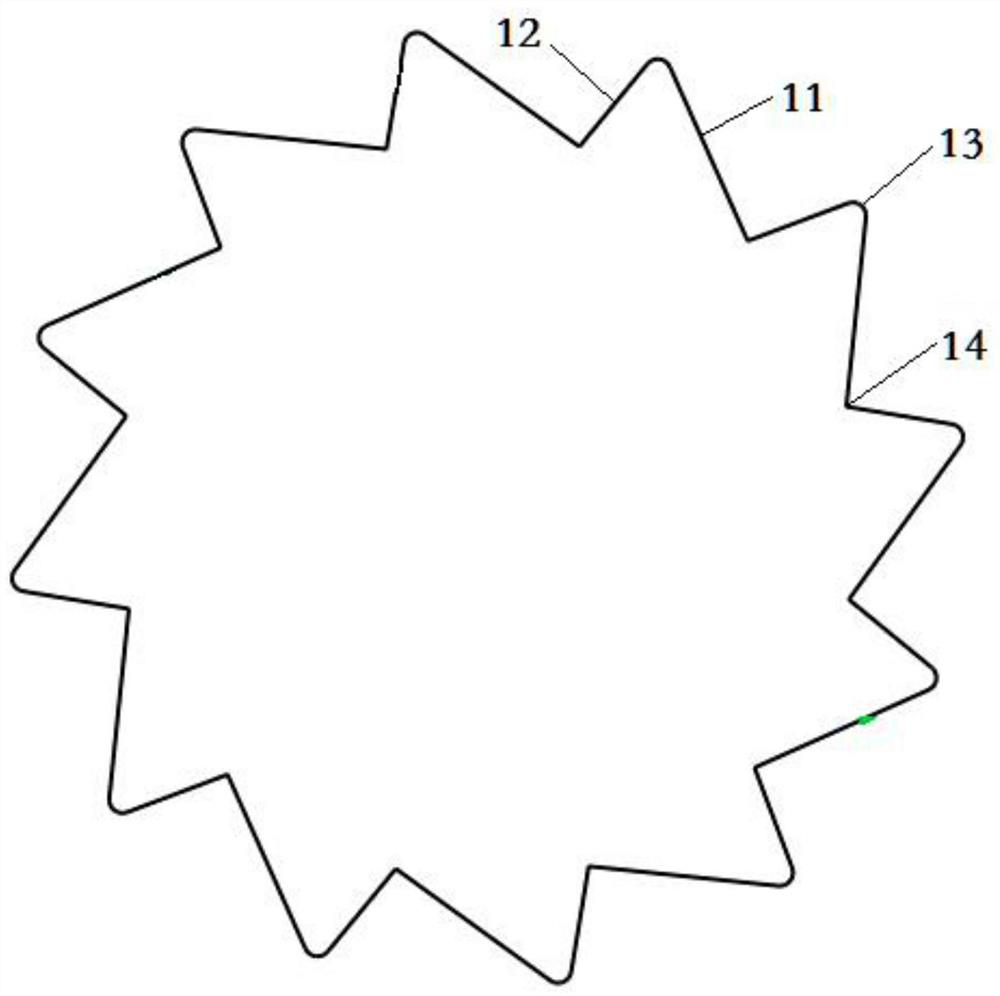

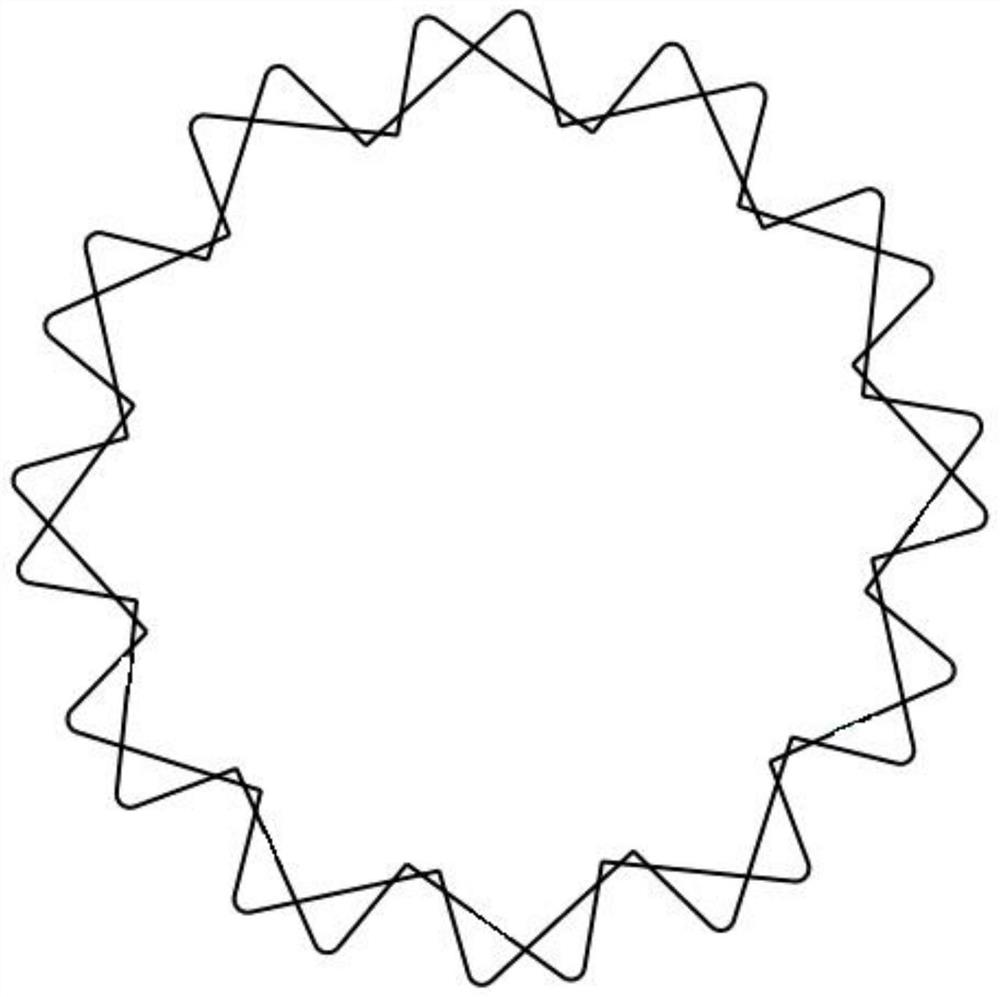

New truss-type human body pipeline support

ActiveCN109925104BSufficient radial support strengthIncrease contact areaStentsAdditive manufacturing apparatusHuman bodyLesion site

The invention discloses a novel truss type human body pipeline stent which comprises at least one layer of telescopic structures. Each telescopic structure comprises a first frame, a second frame, a third frame, a first connecting rod and a second connecting rod, wherein the first frame comprises at least three assemblies, the assemblies comprise long rods and short rods, the circumferential arrays of at least three assemblies form the first frame, the first frame and the third frame are identical and completely opposite to each other, and the second frame is obtained by overturning the firstframe and rotating the first frame. The centers of the arrays of the second frame and the third frame are collinear, the convex points of the first frame, the second frame and the third frame are connected through a first connecting rod, and the concave points of the first frame, the second frame and the third frame are connected through a second connecting rod. According to the novel truss type human body pipeline stent, the axial length of the stent can be extended in the expansion process, so that the lesion part is completely covered, and the sufficient actual contact area between the stent and a human body pipeline is ensured.

Owner:HARBIN INST OF TECH

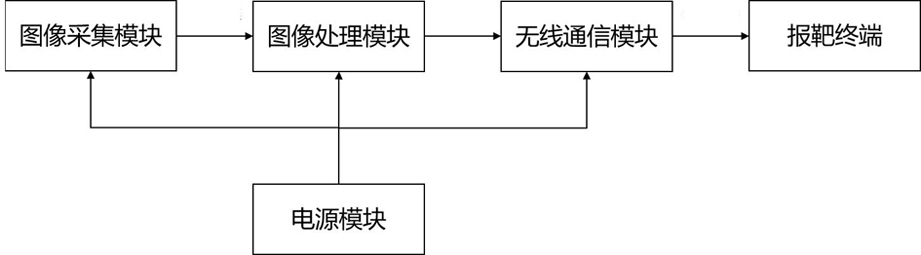

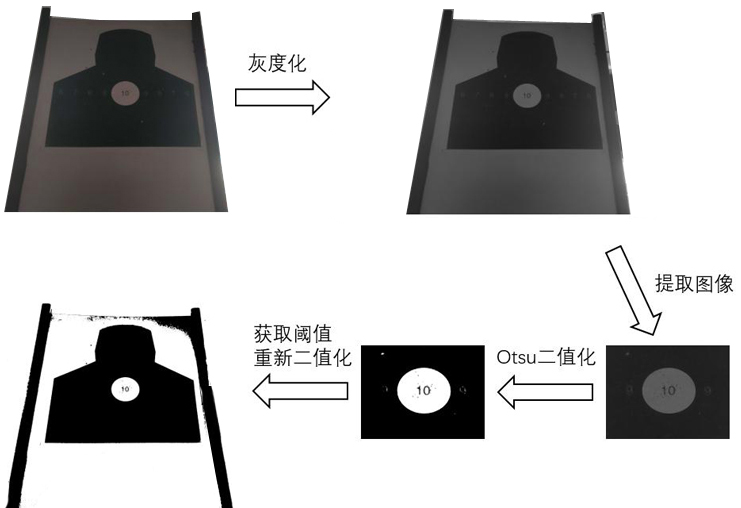

Video-based live ammunition and laser dual-mode target scoring system and target scoring method

ActiveCN113983871AImprove securityImprove efficiencyTraining adaptationHigh level techniquesImaging processingEngineering

The invention discloses a video-based live ammunition and laser dual-mode target scoring system and a target scoring method. The target scoring system is of a box type structure and comprises an image acquisition module, an image processing module, a wireless communication module and a power supply module before a target plate is arranged; the image acquisition module is connected with the image processing module, the image processing module is connected with a target scoring terminal through the wireless communication module, and the power supply port of the power supply module is respectively connected with the power supply ends of the image acquisition module, the image processing module and the wireless communication module. The target scoring method sequentially comprises the following steps of image acquisition, image processing and transmission of an image processing result to the target scoring terminal. The system has the characteristics of portability, simple deployment, high precision and the like. According to the method, the problems of danger and low efficiency of manual target scoring are solved, and the military training efficiency of troops is improved. The system is suitable for any live ammunition or laser shooting training field.

Owner:河北砺兵科技有限责任公司

car seat

The invention relates to a vehicle seat comprising a seat part, a backrest part and at least one recliner which pivotably connects the backrest part to the seat part about a pivot axis and is designed to position the backrest part in a locked state. The backrest part remains in position relative to the seat part and in the unlocked position allows the backrest part to pivot relative to the seat part. A first actuating element and a second actuating element different from the first actuating element are provided for actuating the at least one recliner. The second operating element is coupled with the recliner rod by the coupling element, and the recliner rod is moved by adjusting the second operating element to operate at least one recliner. The coupling element and the recliner lever are coupled to each other via a first and a second connecting device, preventing operation of the at least one recliner by the second operating element when the at least one recliner is operated by the first operating element, the first connecting device There is a first sliding slot and a first engaging element engaged therein, and the second connecting device has a second sliding slot and a second engaging element engaged therein.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com