Patents

Literature

120 results about "Closed lock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

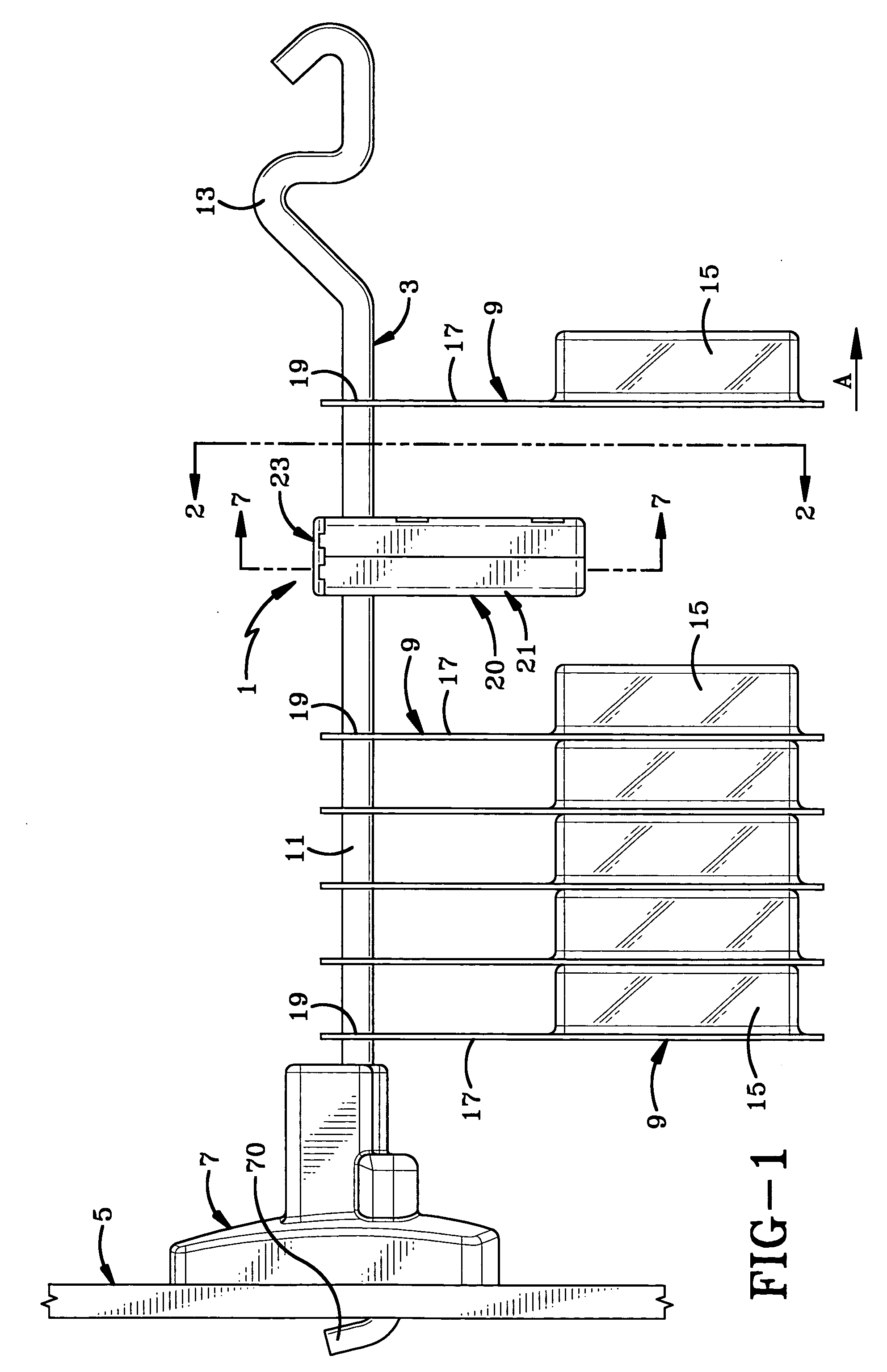

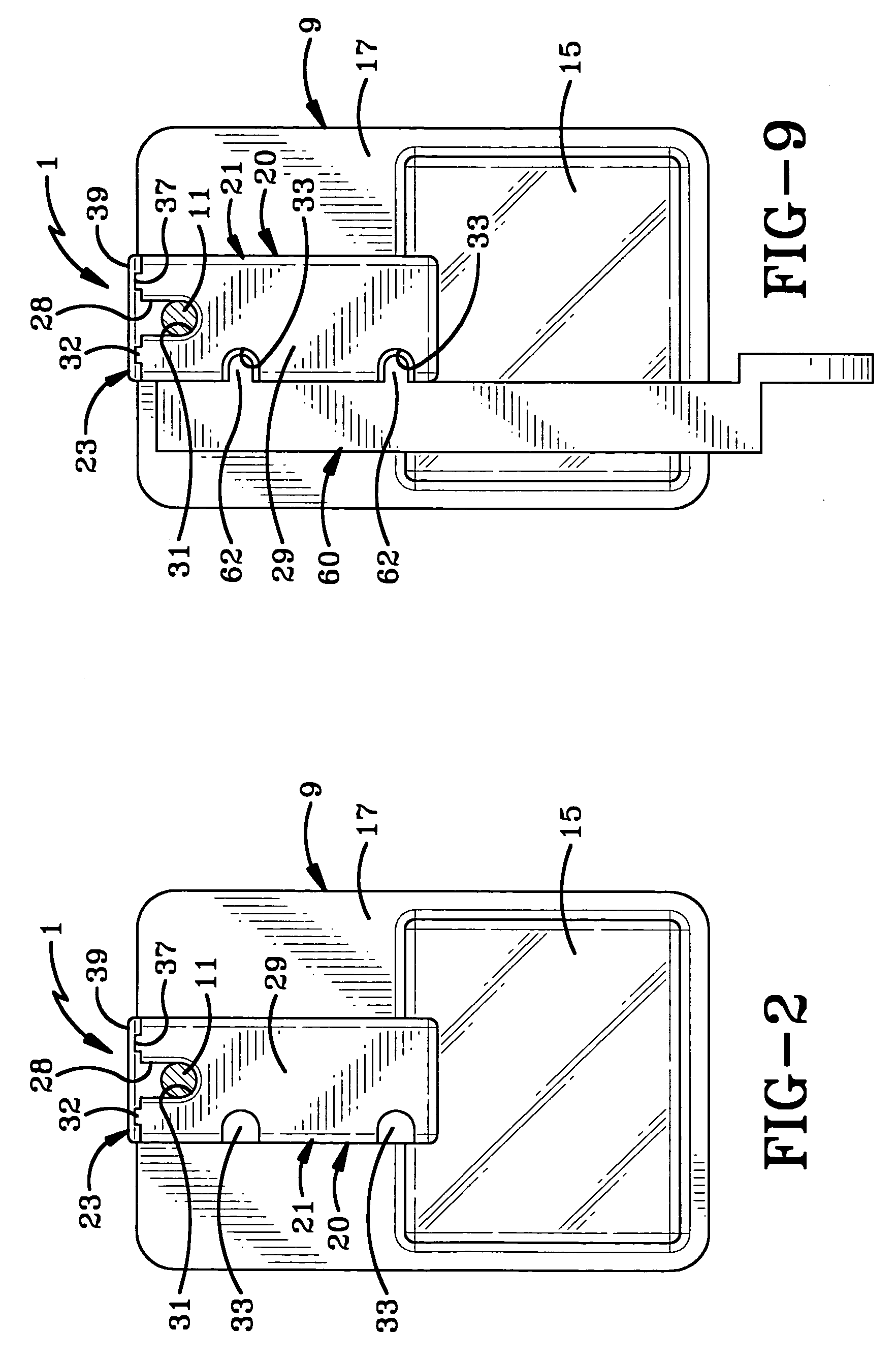

Display rod lock mechanism

InactiveUS20060157431A1Quick removalHighly effectiveLocks for portable objectsShow shelvesLocking mechanismEngineering

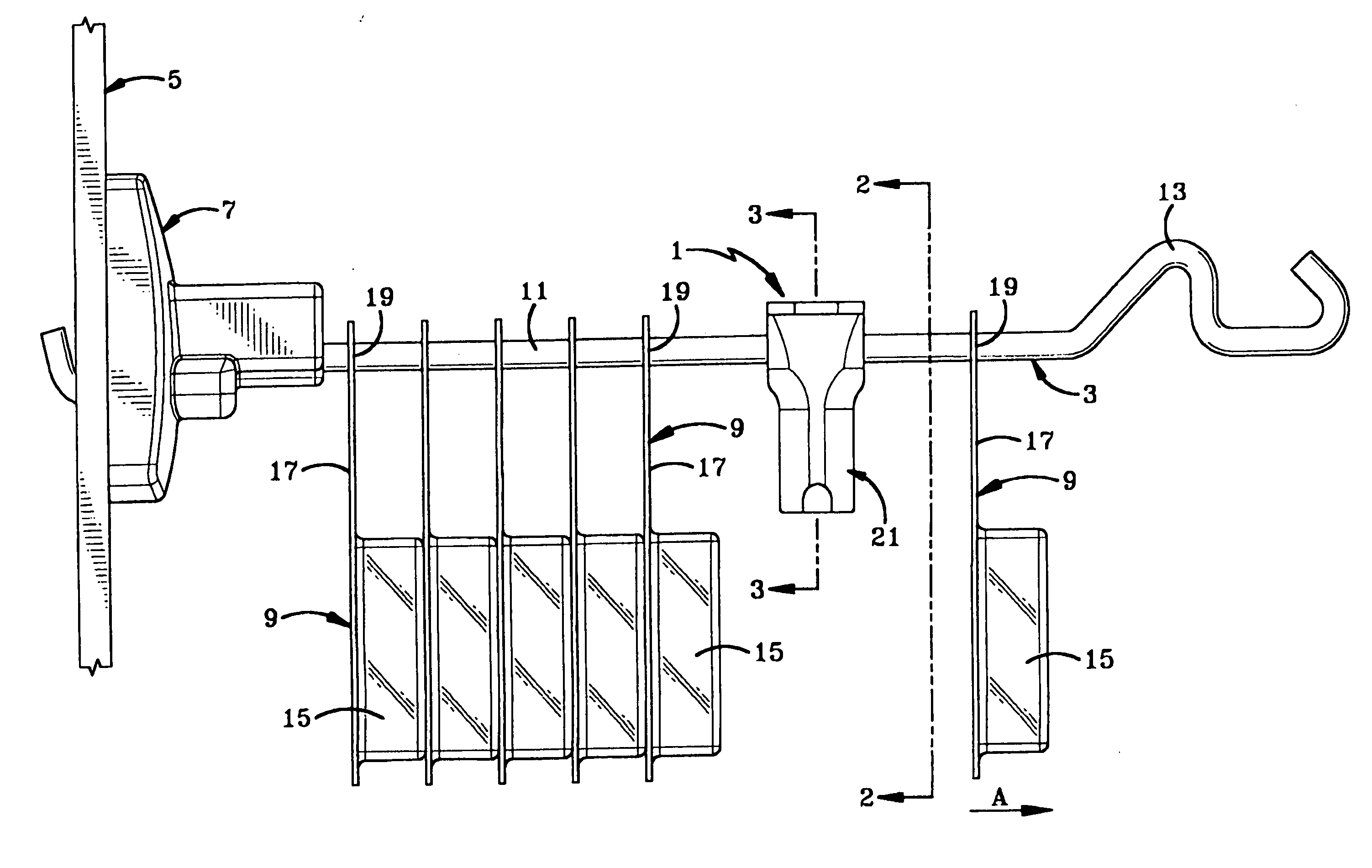

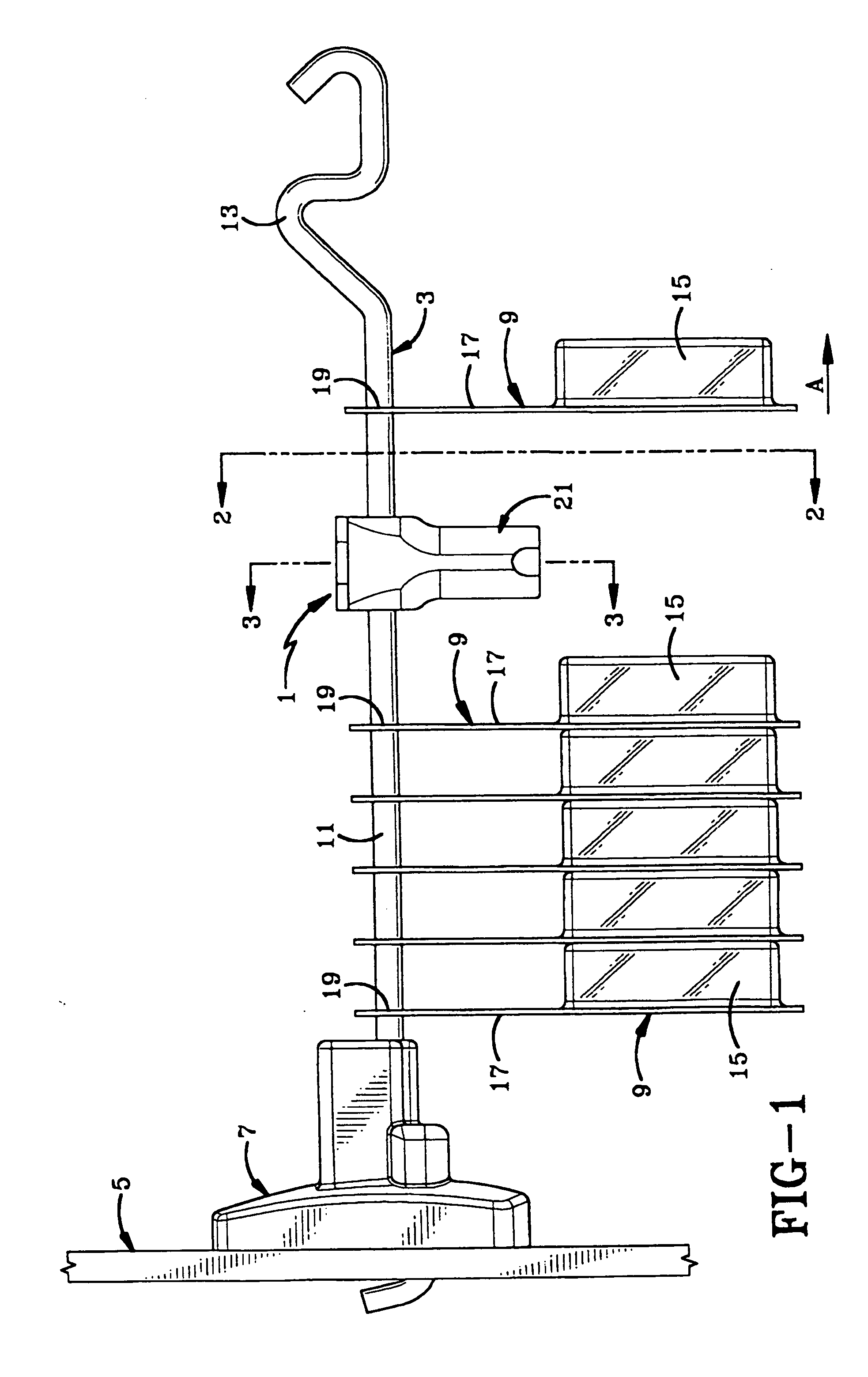

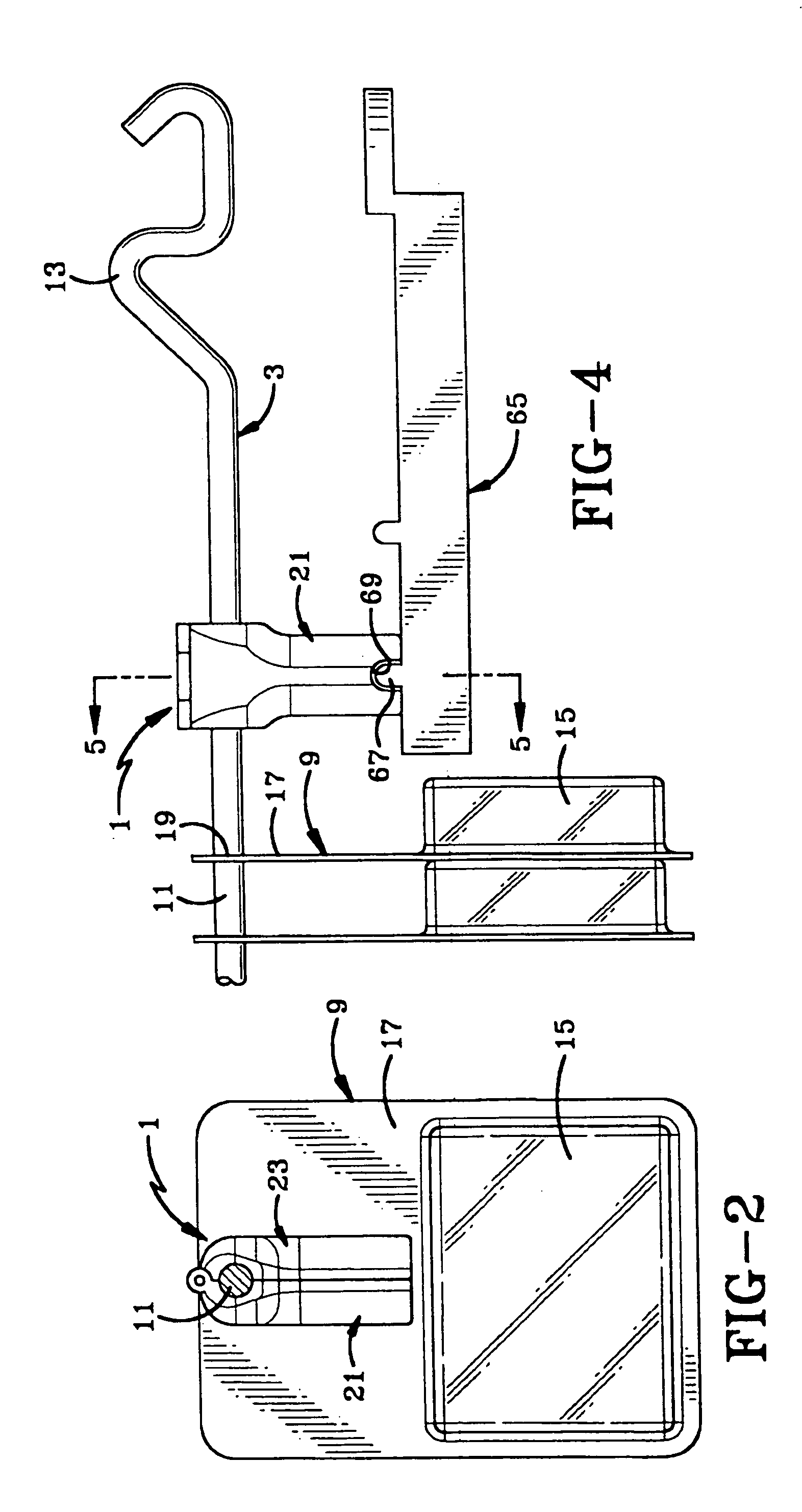

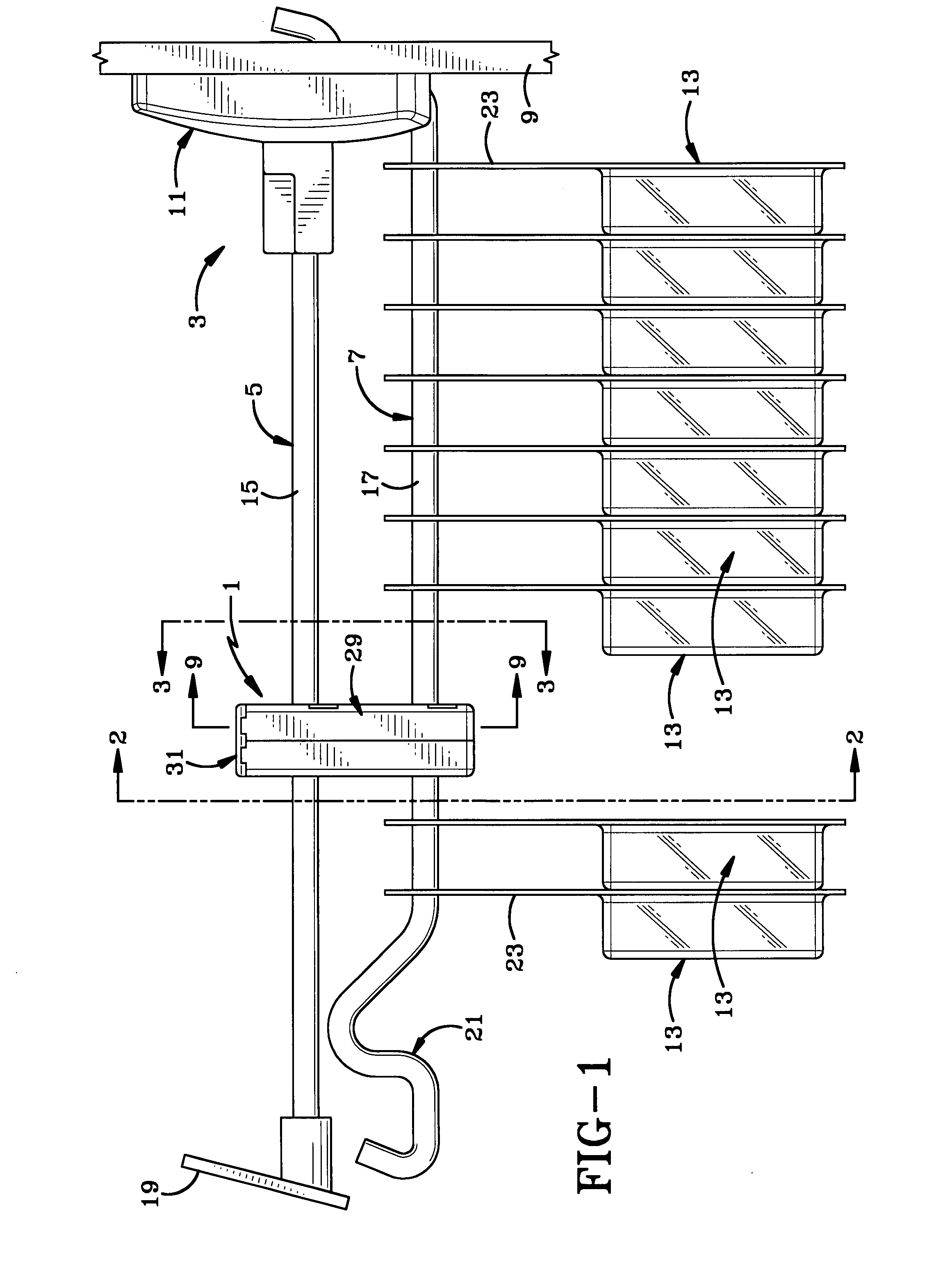

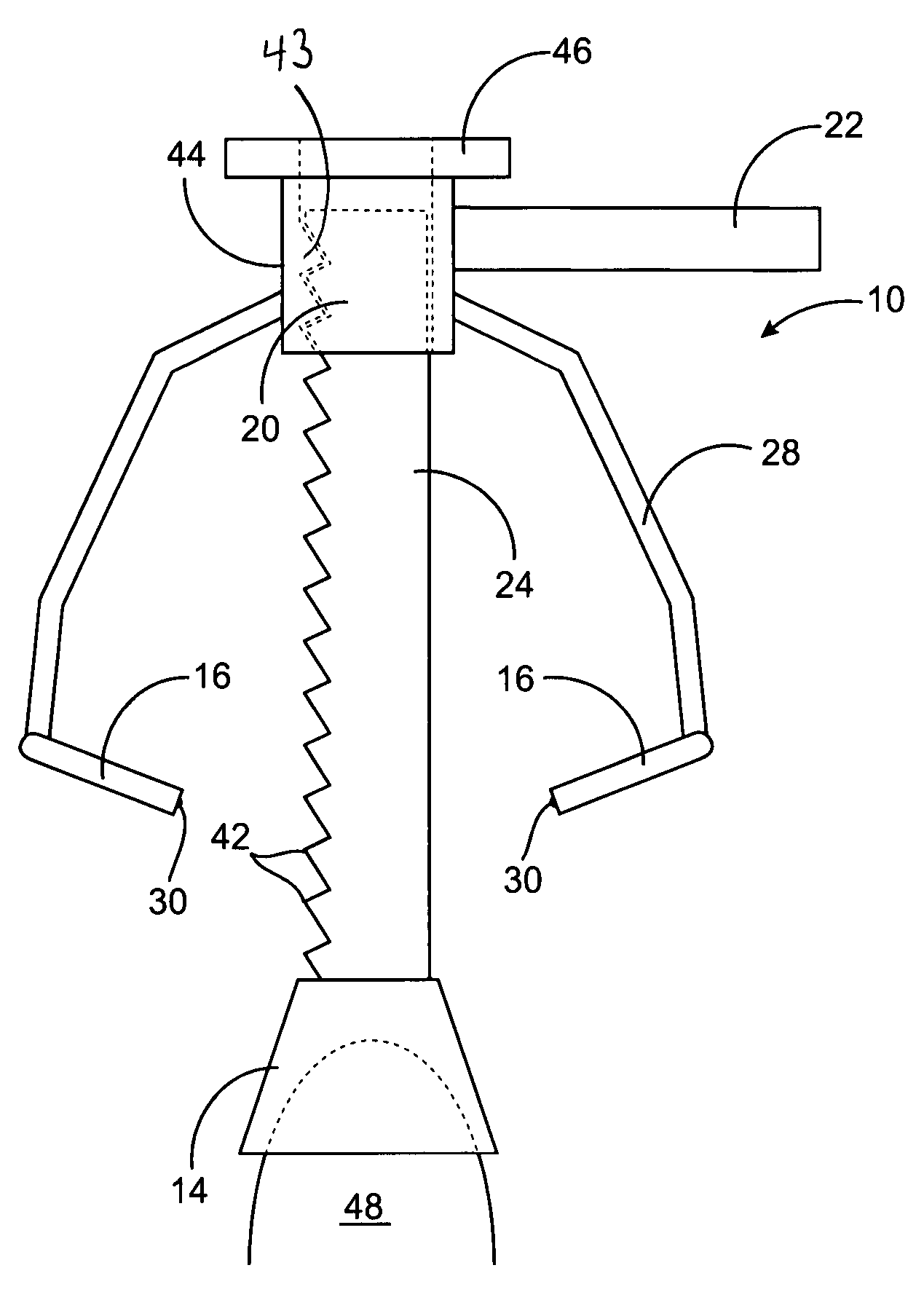

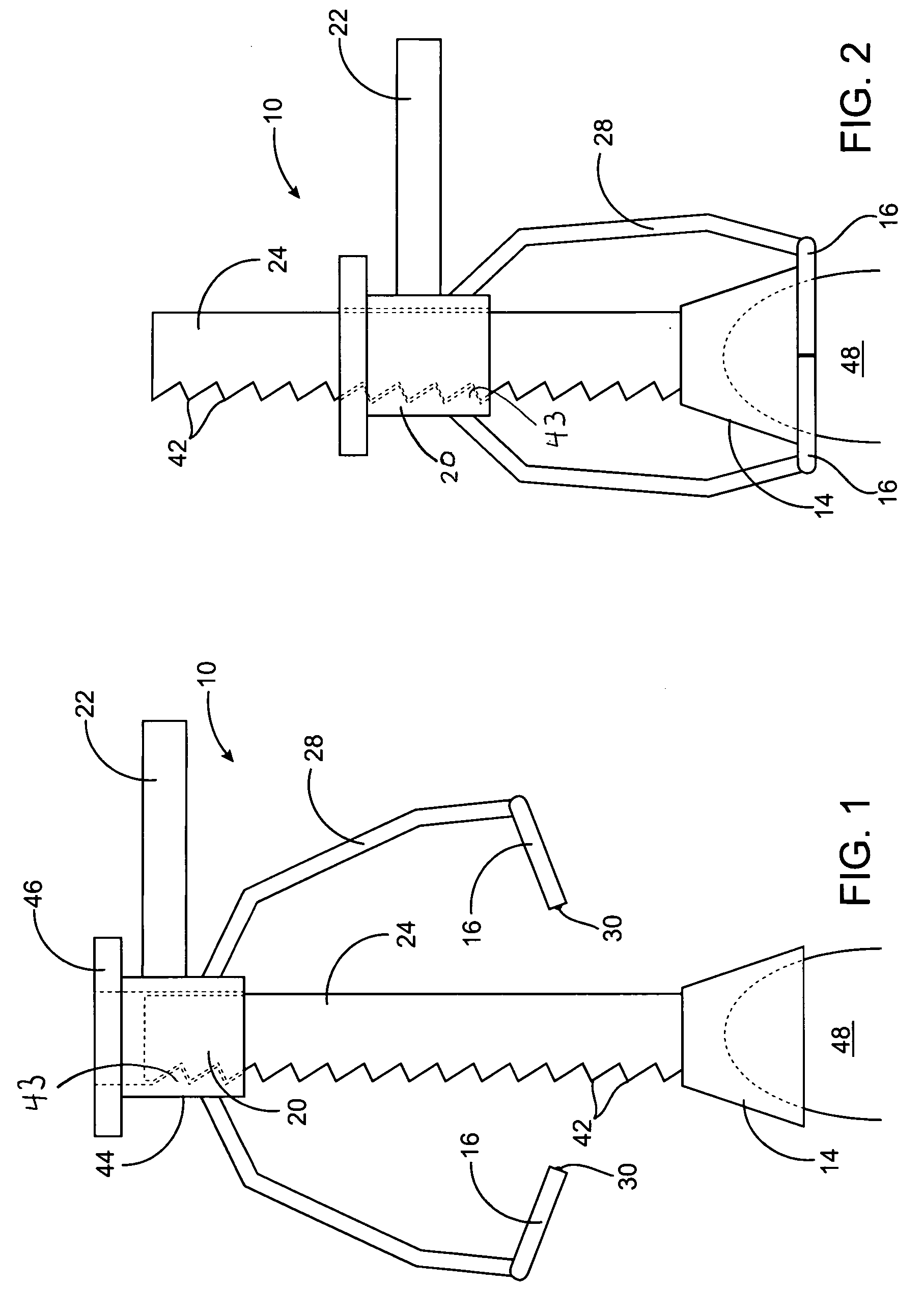

A lock mechanism is mounted on a merchandise display rod to prevent the removal of some items of merchandise from the rod. A pair of members are pivotally joined at one end and move between locked and unlocked positions. Each of the members is formed with a partial slot which align with each other when in the locked position to extend about the rod. A magnetically attractable plunger is mounted within one of the members and engages a recess formed in the other member to secure the members in a closed locked position on the rod. A magnetic key moves the plunger to an unlocked position to enable the members to pivot apart to an unlocked open position. The distal end of the rod is bent at an angle sufficient to prevent sliding removal of the lock mechanism from the rod when the members are in the locked position yet enable removal of merchandise items forward of the lock mechanism from the rod.

Owner:INVUE SECURITY PROD INC

Lock mechanism for display rod

InactiveUS7392673B2Quick removalSimple and compactClothing locksLocks for portable objectsLocking mechanismEngineering

Owner:INVUE SECURITY PROD INC

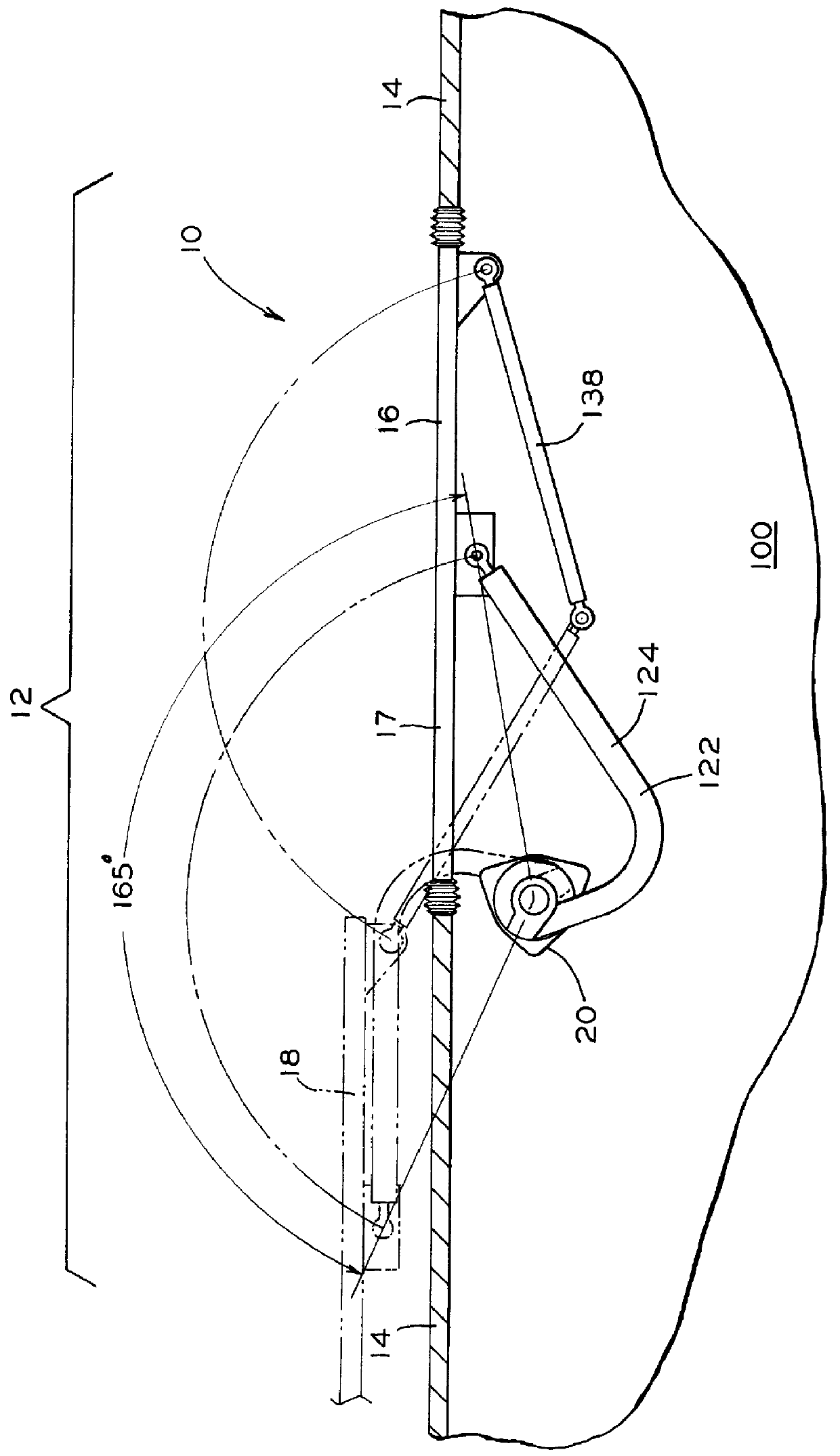

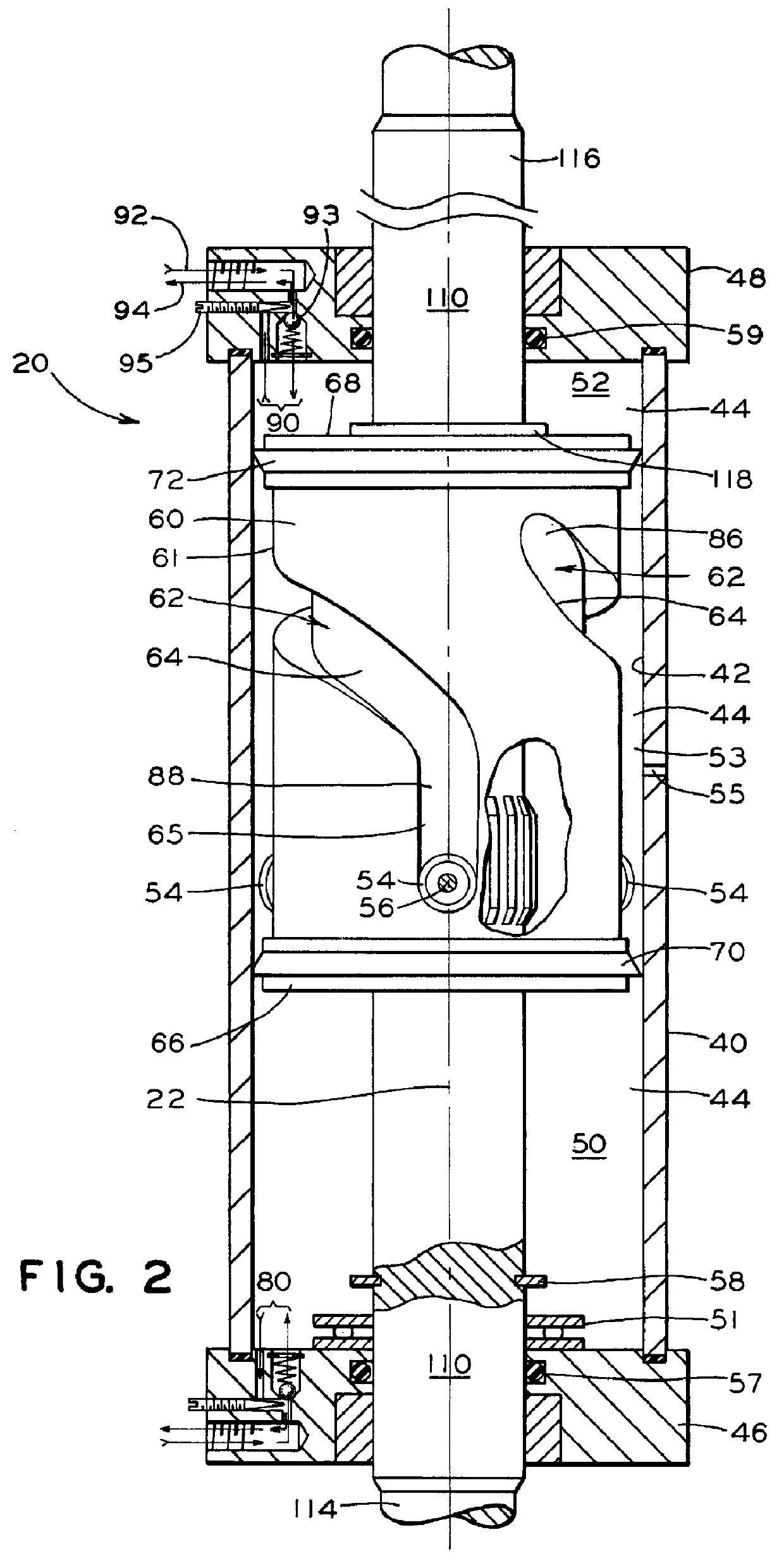

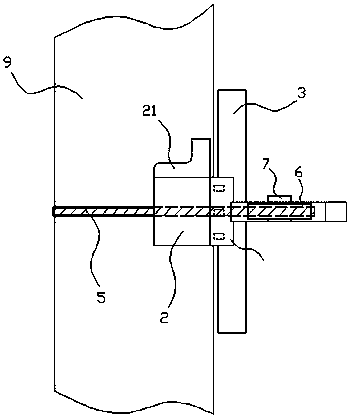

Transit vehicle door system

InactiveUS6141908APositive supportLarge spreadVehicle arrangementsMan-operated mechanismLinear motionActuator

The invention provides a door system for a transit vehicle. It has an actuator which provides a rotary motion about an axis of the actuator for moving the door panel between an open position uncovering the aperture and a closed unlocked position covering the aperture. The actuator also provides a linear motion along the axis of the actuator for moving the door panel between the closed unlocked position and a closed locked position. The rotary motion followed by the axial motion is provided by a cylinder having a piston moved by fluid pressure. The piston includes a guide track in its exterior which engages rollers in the cylinder. The guide track has one portion curving around the piston and one portion parallel to the axis. The curving part provides the rotary motion and the straight part provides the axial motion. When the rotary motion is completed the piston encounters a stop on a shaft which supports the door. The actuator then moves the door axially to engage locks.

Owner:WESTINGHOUSE AIR BRAKE CO

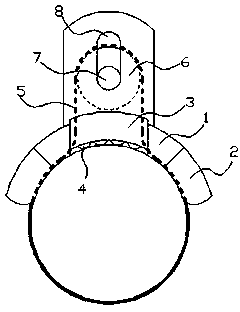

Clamp for performing circumcisions on newborns and a method of using the same

A circumcision device is a unitary combination comprised of a body, a conical bell over which the foreskin is disposed and into which the glans is inserted, a clamping ring, and a shaft coupled to the body and to one the bell is connected. The device is made from an injection-molded plastic so that there is no need for hinges due to the resiliency of plastic. The clamping ring is split and moves between an open and closed locked position. The bell is drawn up into the locked ring to clamp the foreskin. A handle is coupled to the device to position it. A handle is coupled to the shaft for moving the shaft relative to the body. A flange is connected to a collar on the shaft to drive the clamp down onto the bell with a push of the thumb. A plurality of skin clips is coupled to one of either the body or shaft and fixed relative to the bell for temporarily holding the foreskin in place against the bell.

Owner:DUEL BARRY P

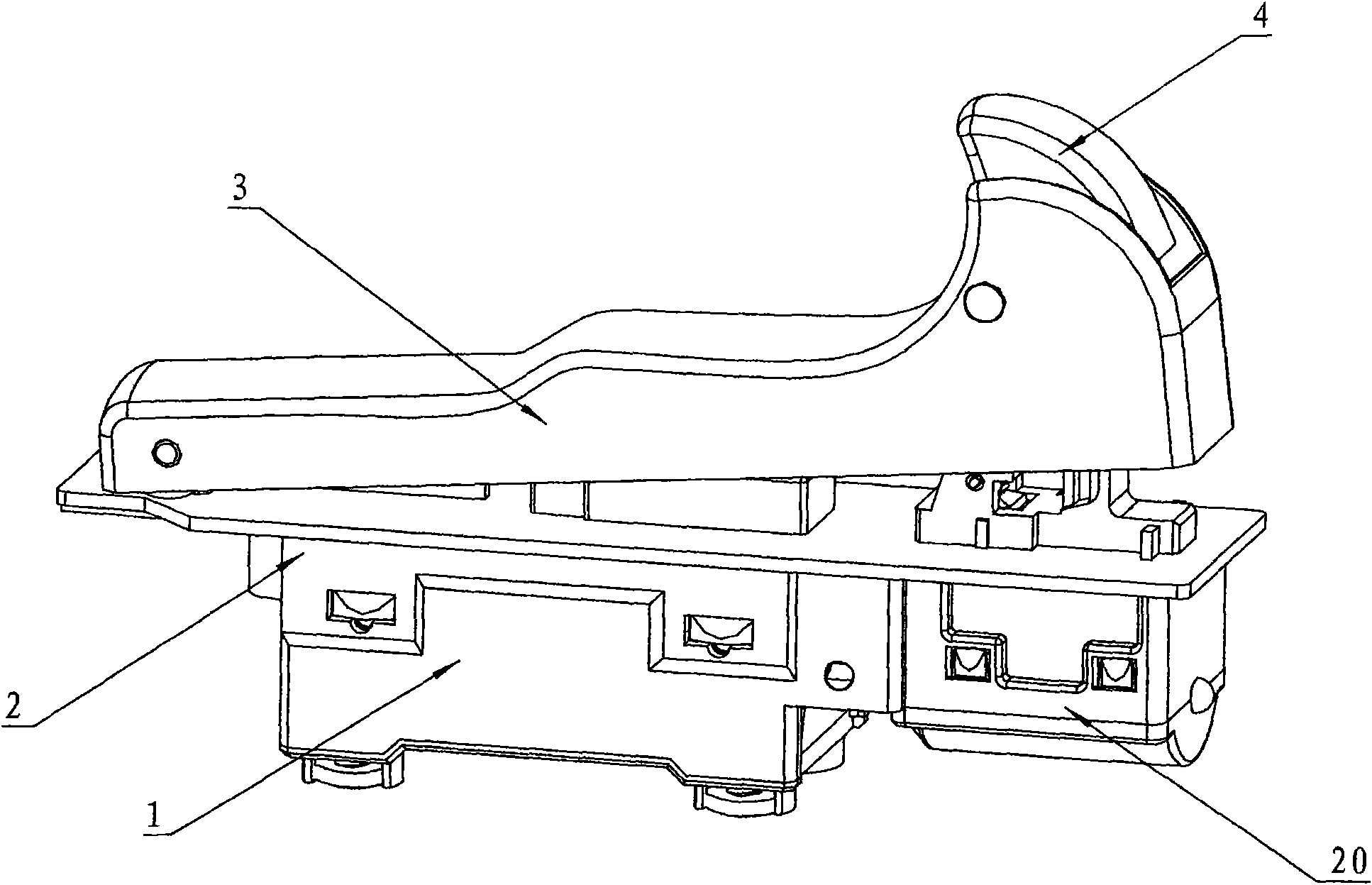

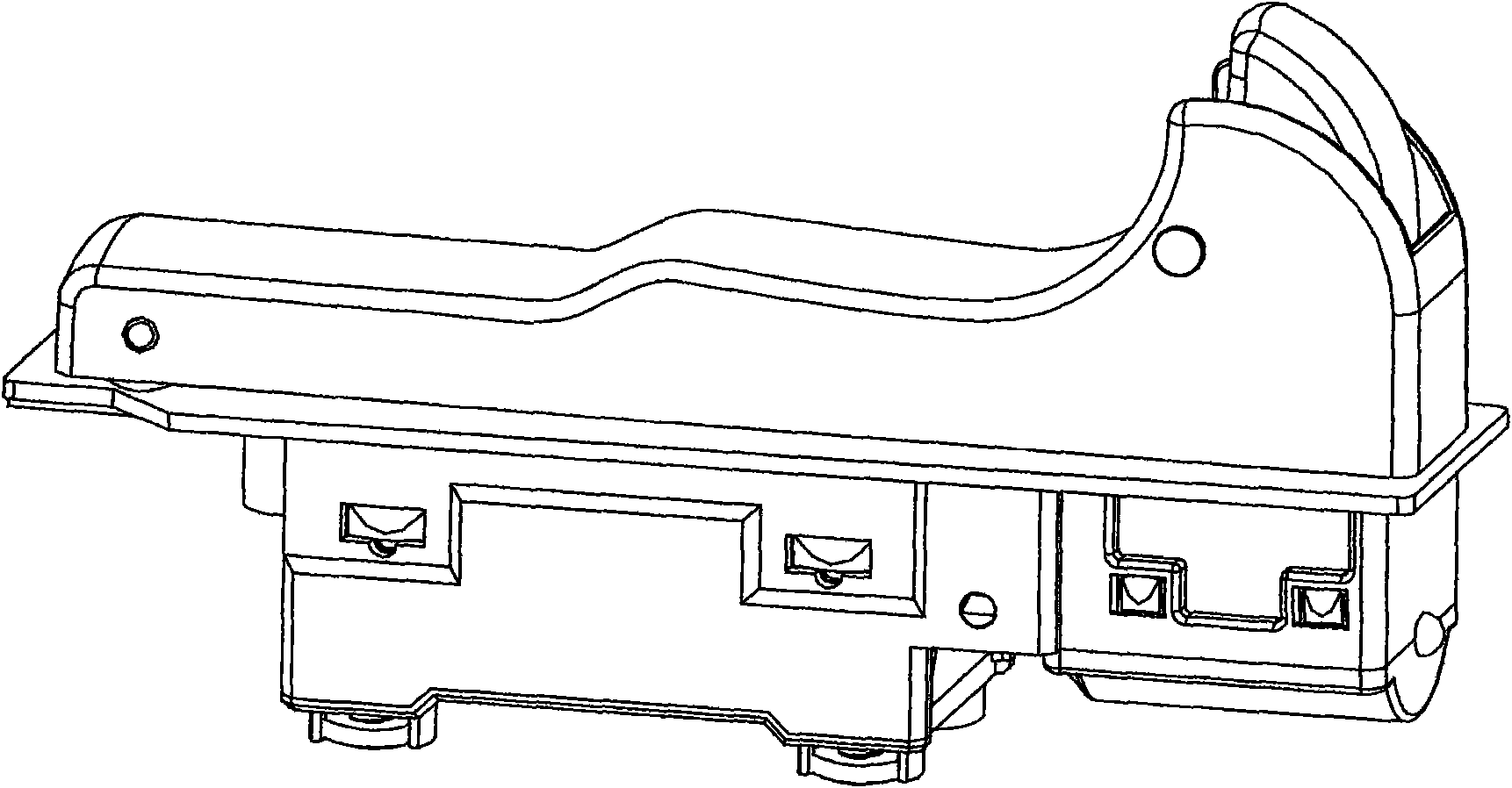

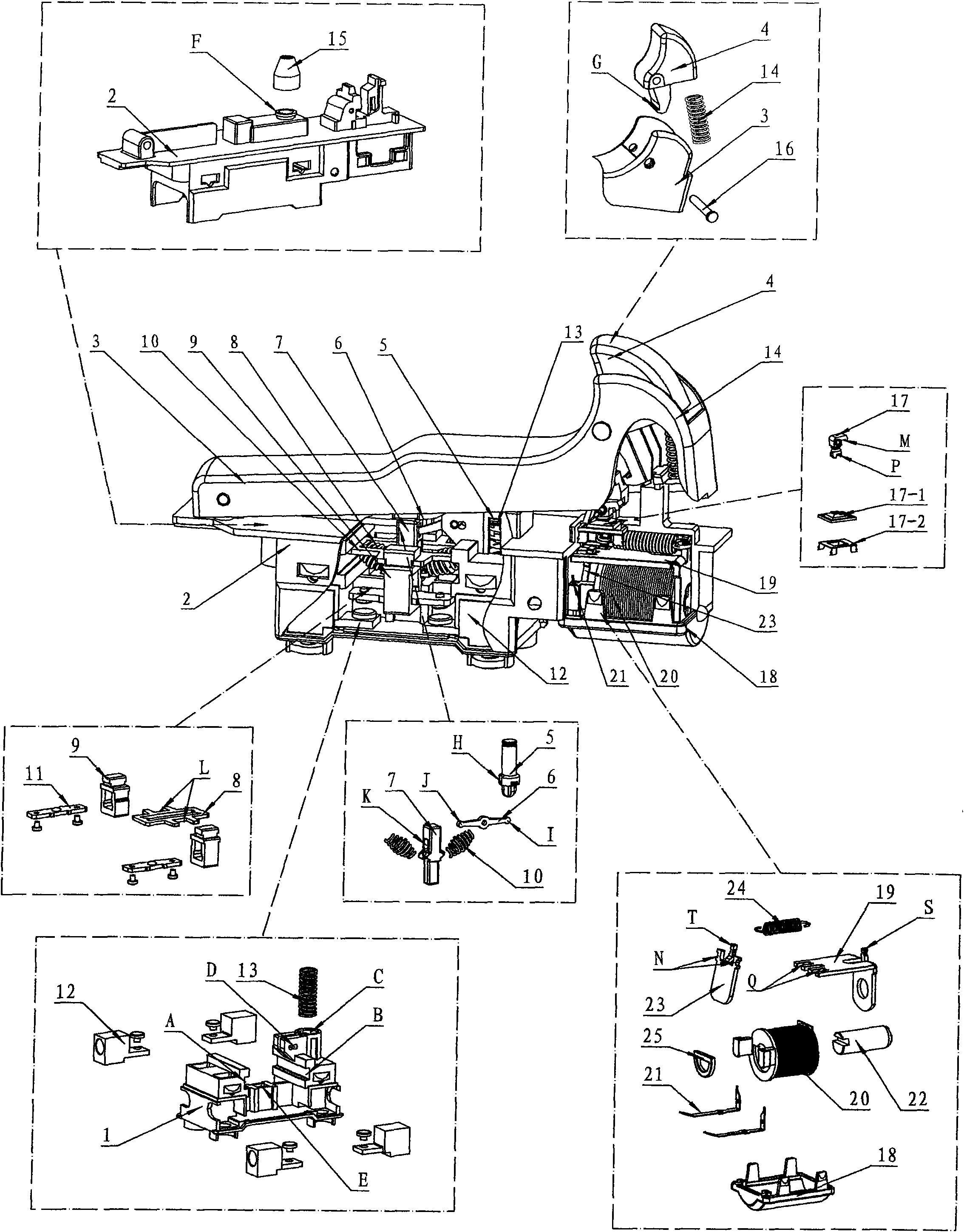

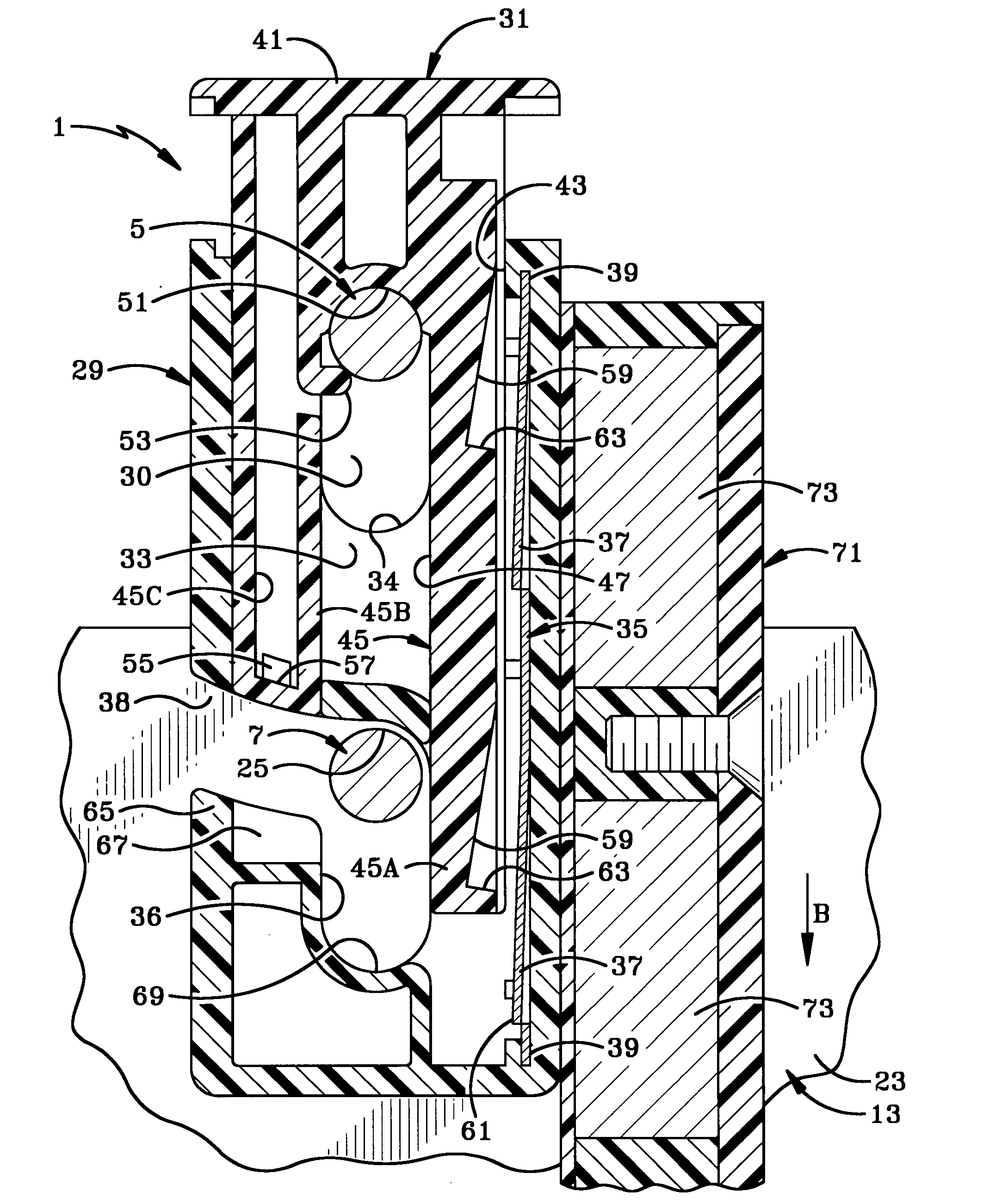

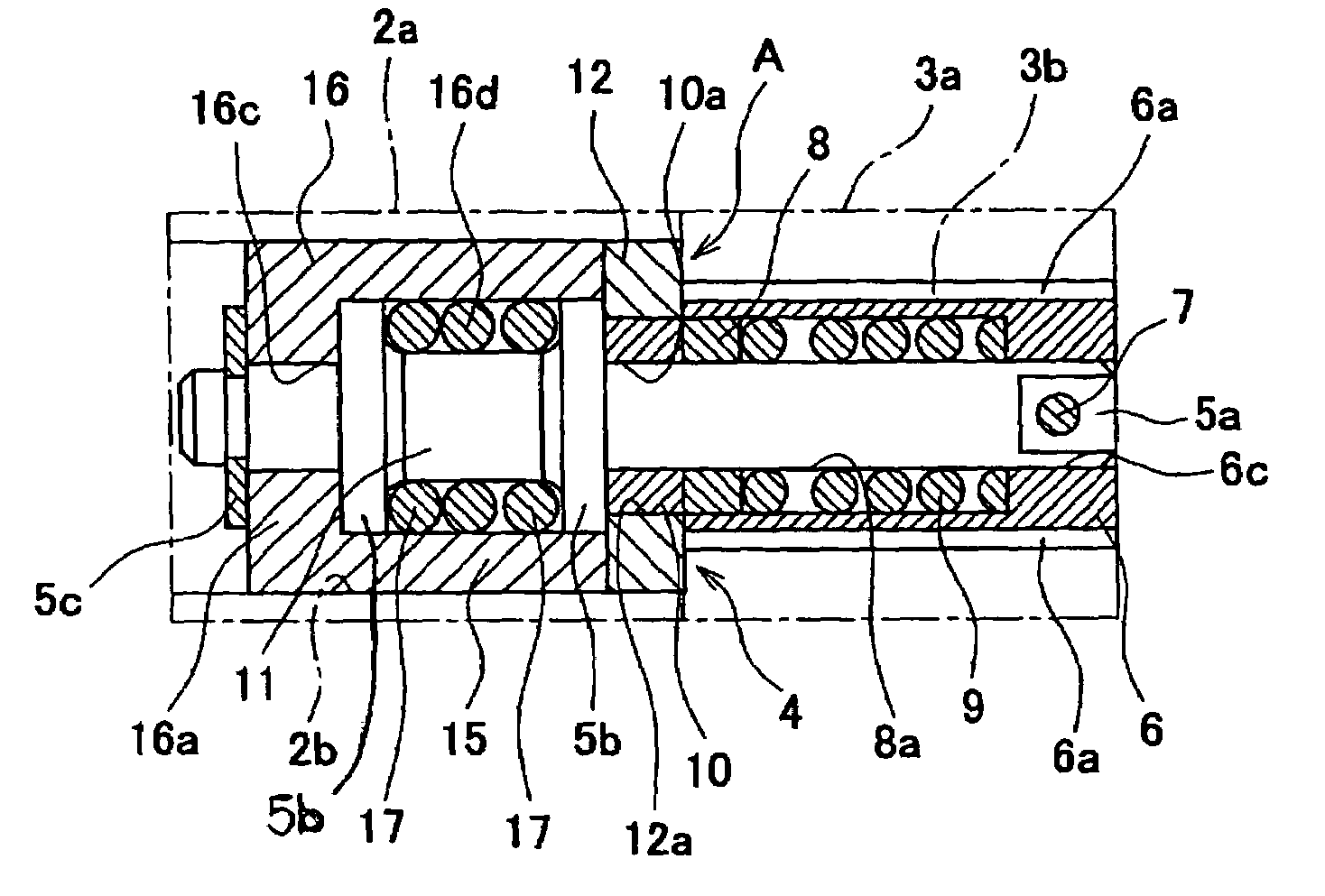

Trigger switch with power failure restart protection function

InactiveCN101882523ARealize the function of power failure restart protectionCompact structureSwitch power arrangementsEngineeringPower tool

The invention discloses a trigger switch with a power failure restart protection function, which mainly comprises a base body (1), a shell (2), a trigger (3), a lock knob (4), a magnetic yoke (19), a coil (20), a magnetic core (22) and an armature (23), wherein the base body (1), the shell (2), the trigger (3), the lock knob (4) and related structural elements form a mechanical structure part of the switch, and the magnetic yoke (19), the coil (20), the magnetic core (22), the armature (23) and relates electromagnetic elements form the electromagnetic structural part of the switch. The trigger switch formed by the mechanical structural part and the electromagnetic structural part can realize closed locking after the switch is switched on and the off functions of the switch when power failure occurs suddenly, and if the switch is expected to be switched on again, the trigger is required to be pressed again to realize the power failure restart protection function of the switch. The invention has compact structure and low manufacture cost, is suitable for large and middle sized angular finishing grinders, polishing machines, waxing machines and other electric tools, and accords with the national safety standard.

Owner:ZHEJIANG JIABEN ELECTRONICS CO LTD

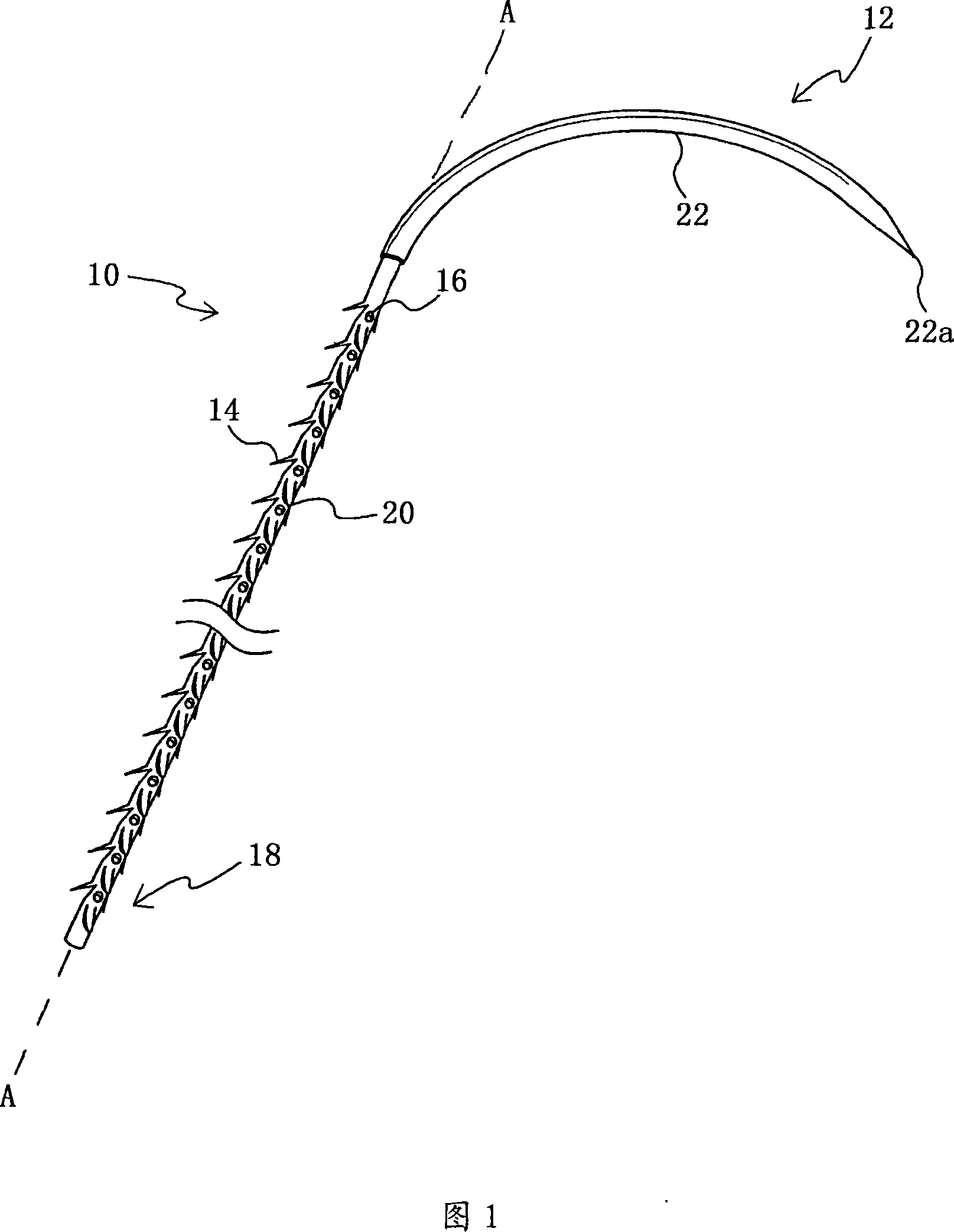

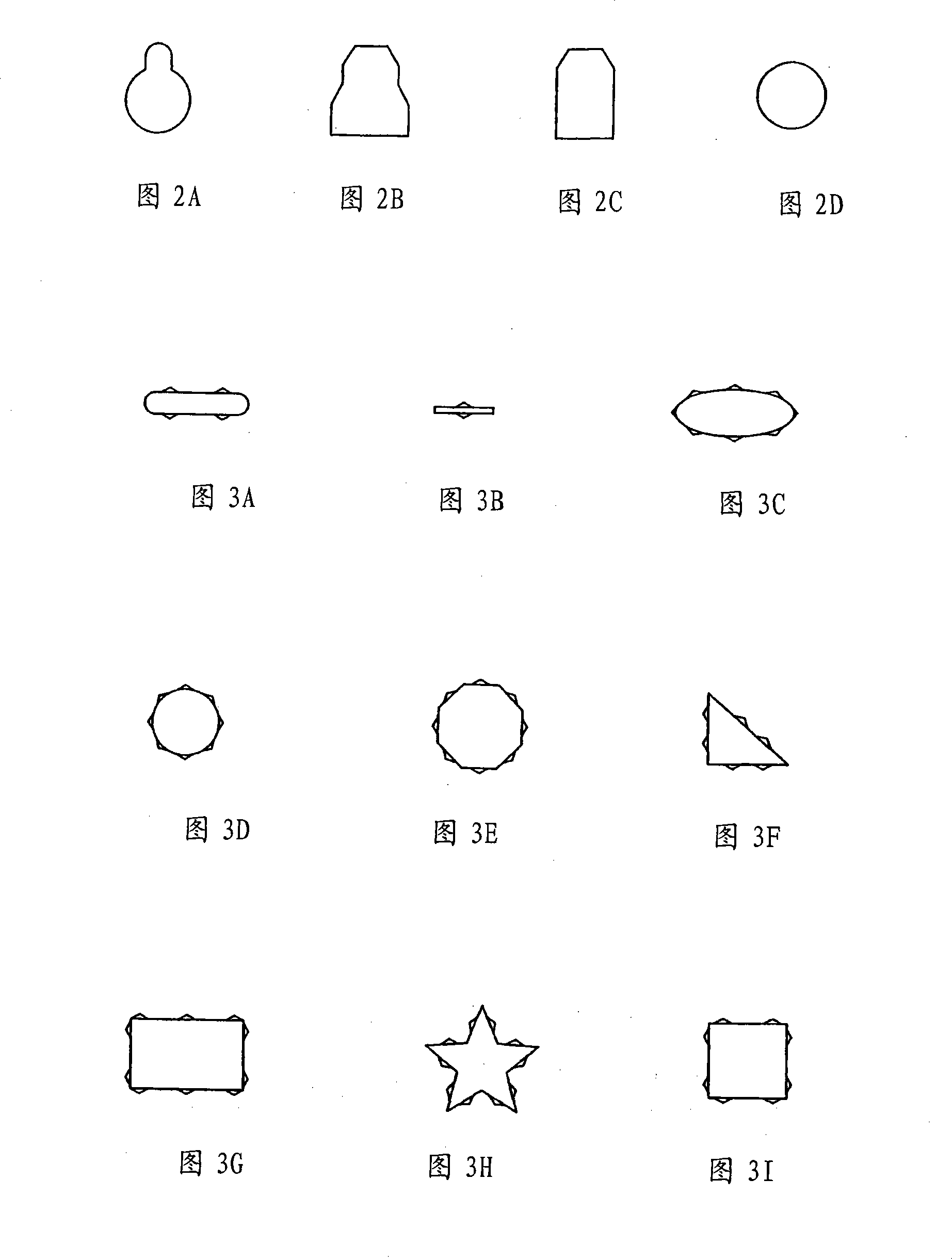

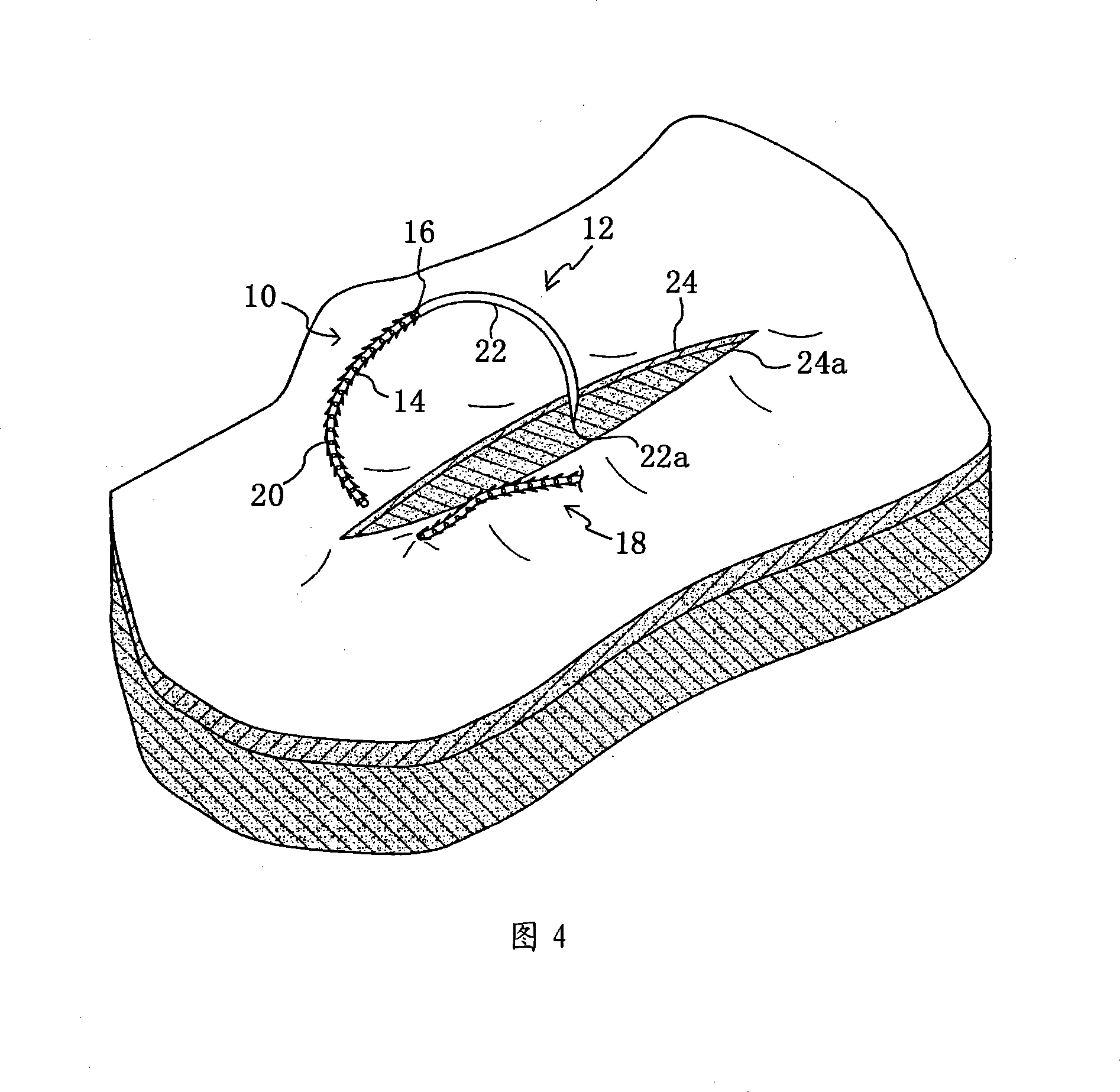

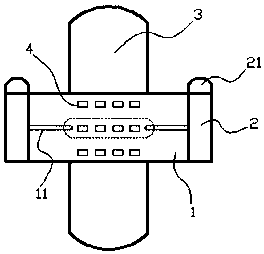

Knotless wound closure device

A knotless wound closure device includes an elongated flexible body having a proximal end and a distal end, the elongated flexible body having a plurality of apertures therethrough along its length, and defining a longitudinal axis with a plurality of Shaft extended surface features. The proximal end is shaped and sized to pass through body tissue and then selectively passed through at least one of a plurality of through holes so that at least one of the surface features also passes through the through hole to form a locking closure loops to ensure body tissue is securely held within.

Owner:TYCO HEALTHCARE GRP LP

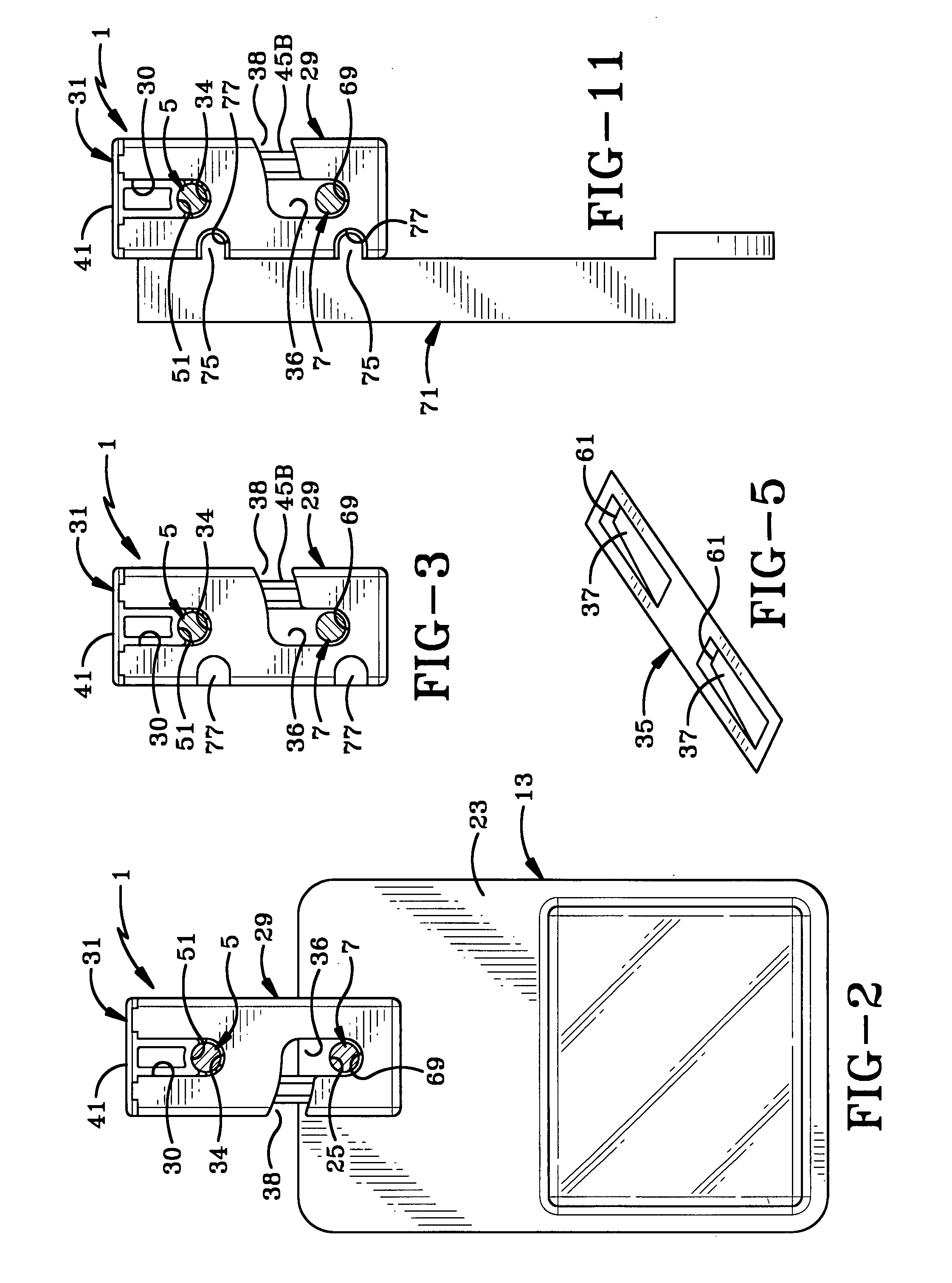

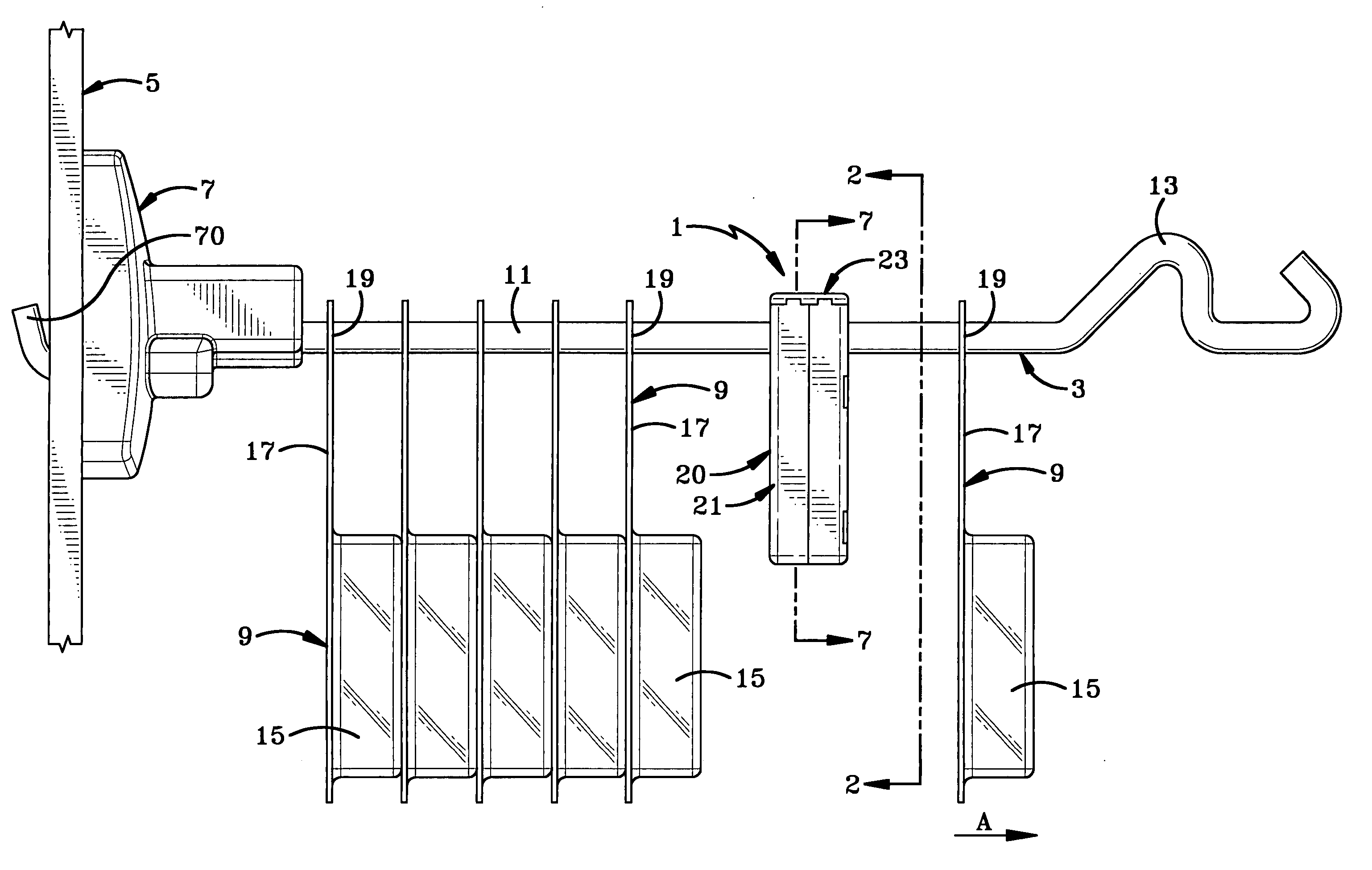

Lock mechanism for display rod

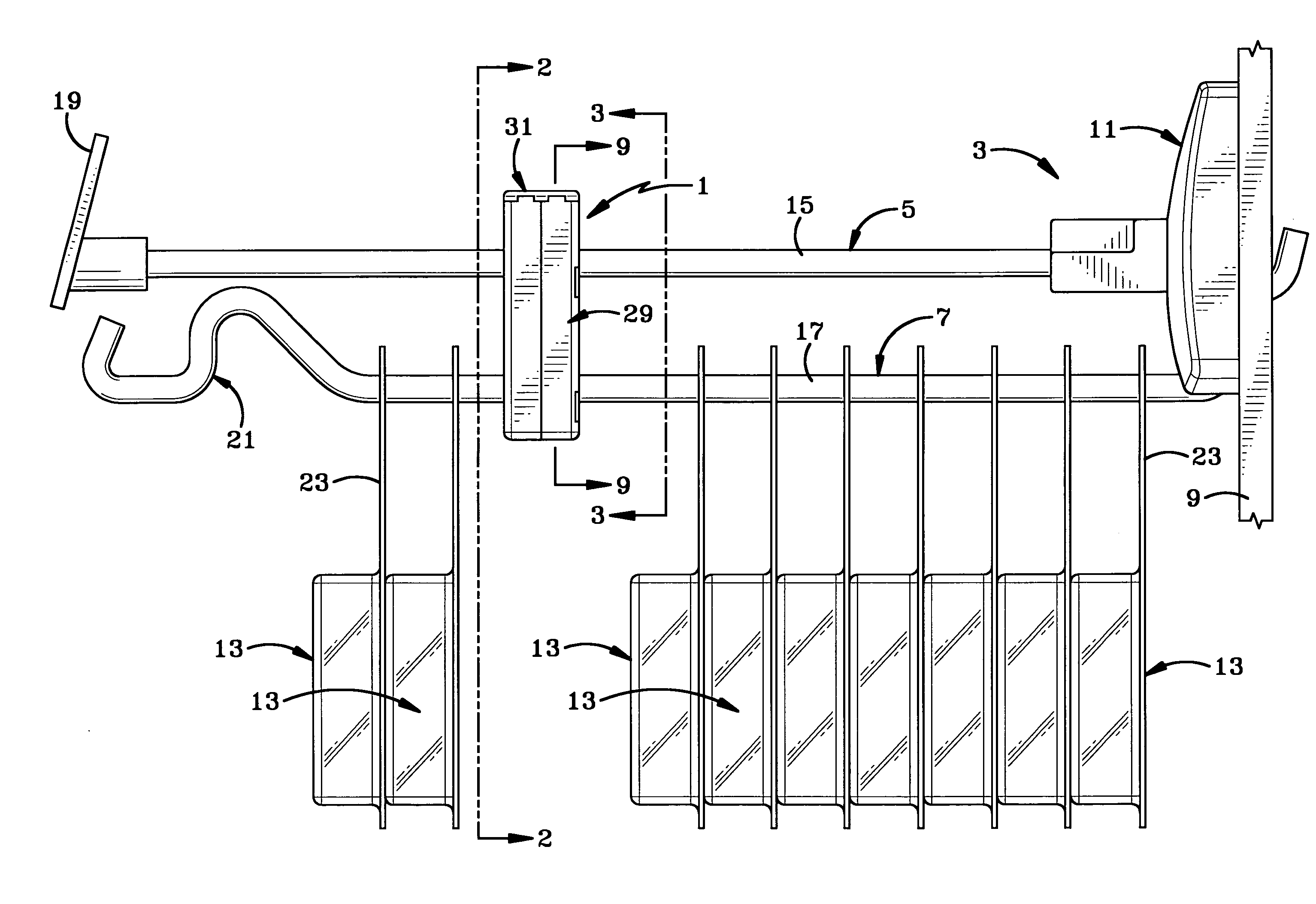

InactiveUS20070289344A1Highly effectiveEasy to removeClothing locksLocks for portable objectsLocking mechanismEngineering

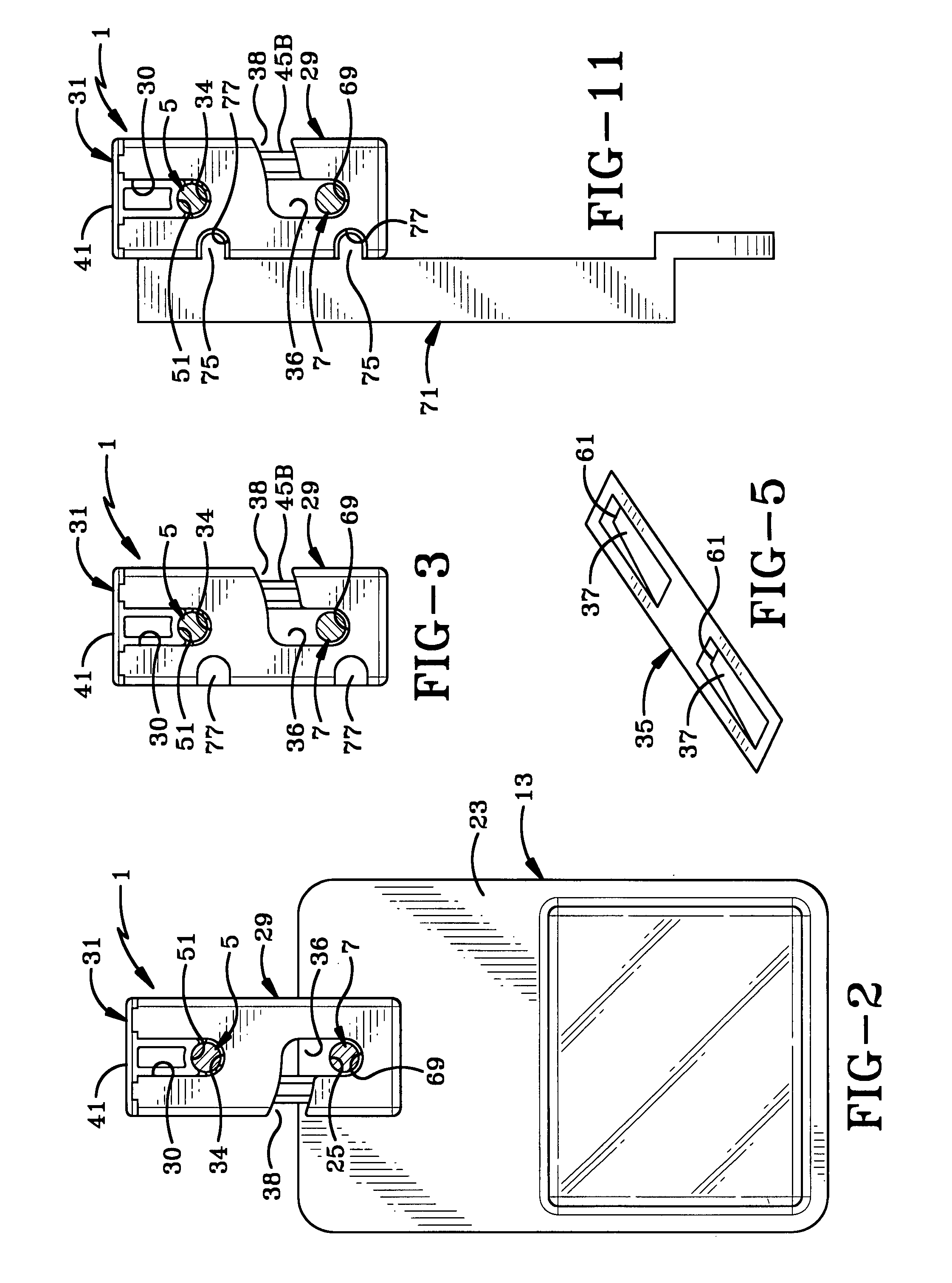

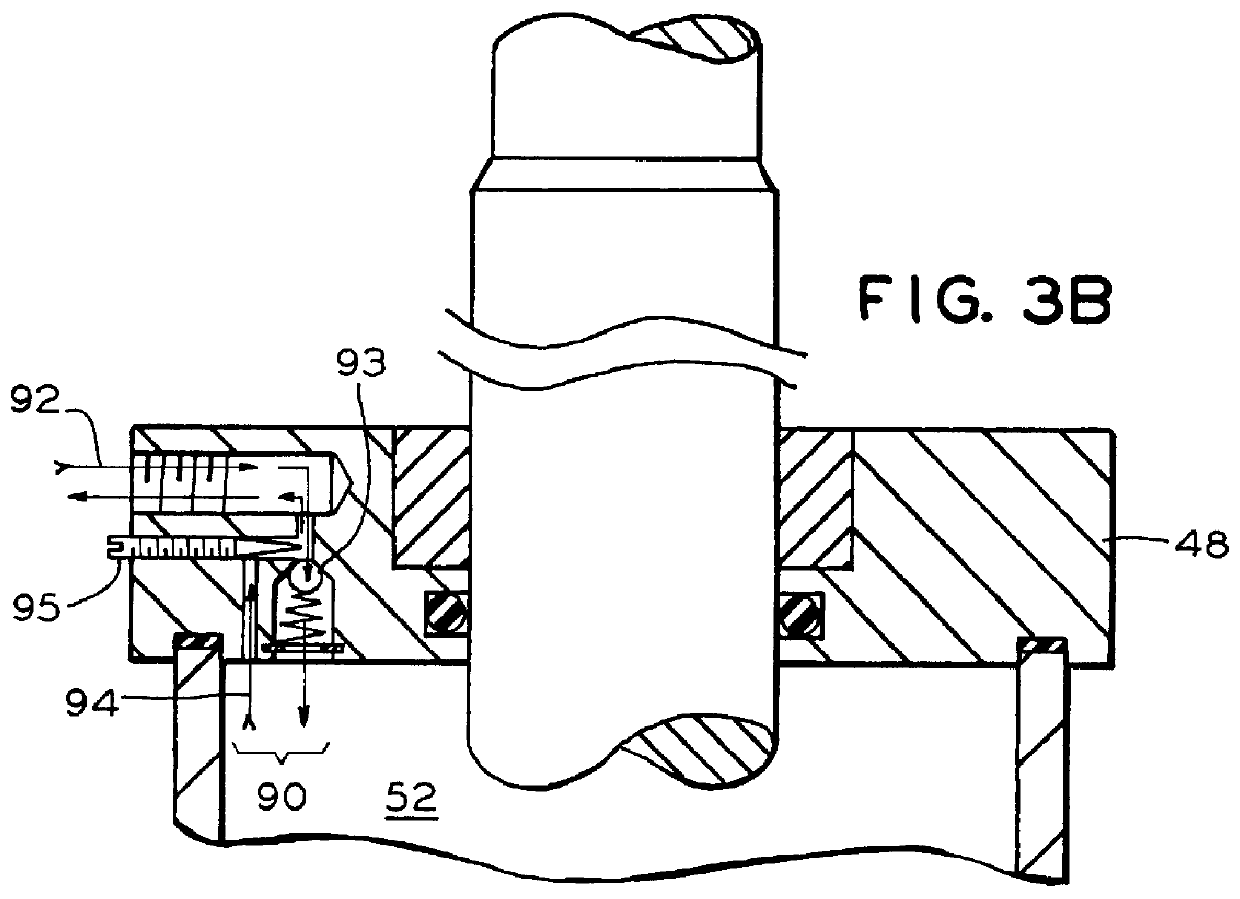

A lock mechanism is mounted on a pair of vertically spaced merchandise display rods to prevent removal of items of merchandise supported on the lower rod. The lock mechanism includes a housing having a internal lock chamber and a pair of upper and lower slots, each receiving one of the rods therethrough. The lower slot has a side opening enabling the lower rod to pass out of the housing when the housing is pivotally moved on the upper rod to an unlocked open position. A bayonet is slidably moveable in the chamber of the housing and has an elongated slot through which both of the rods extend. A locking device has a magnetically attractable locking tine which locks the housing and bayonet in a closed locked position on the pair of rods. A magnetic key moves the tine to an unlocked position enabling the housing and bayonet to move to an unlocked open position exposing the side opening of the housing lower slot for removing the housing out of engagement with the lower rod.

Owner:INVUE SECURITY PROD INC

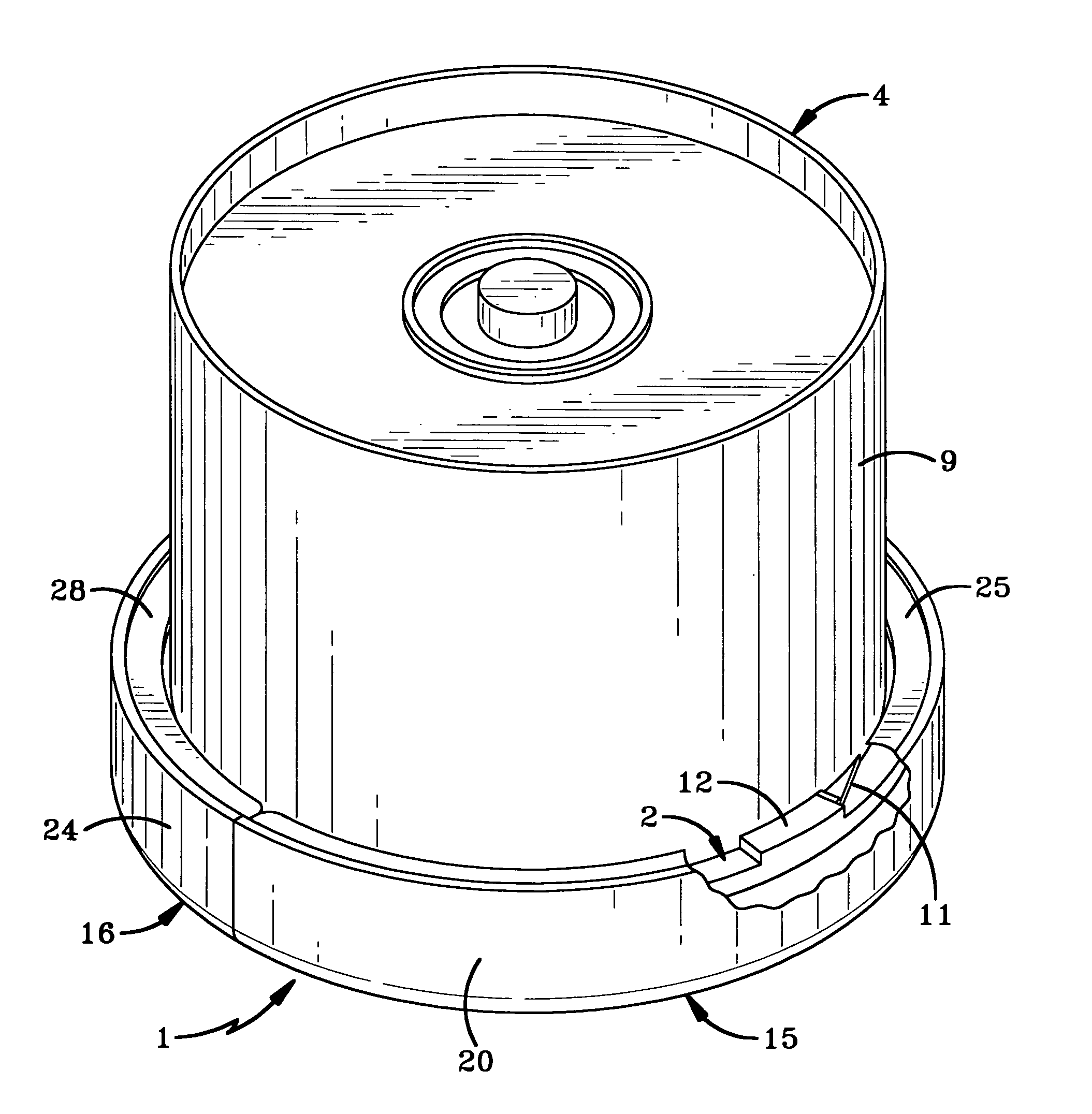

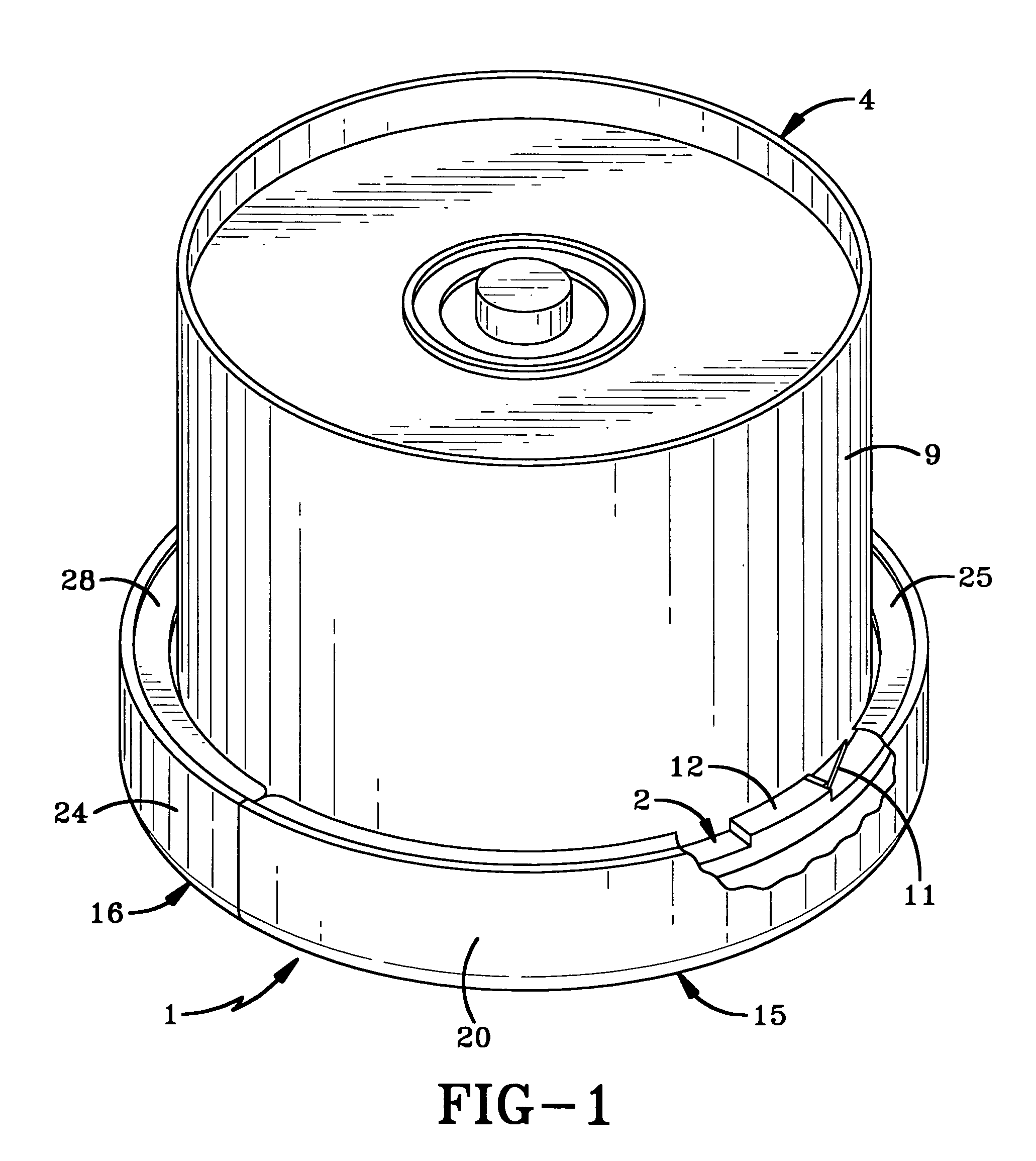

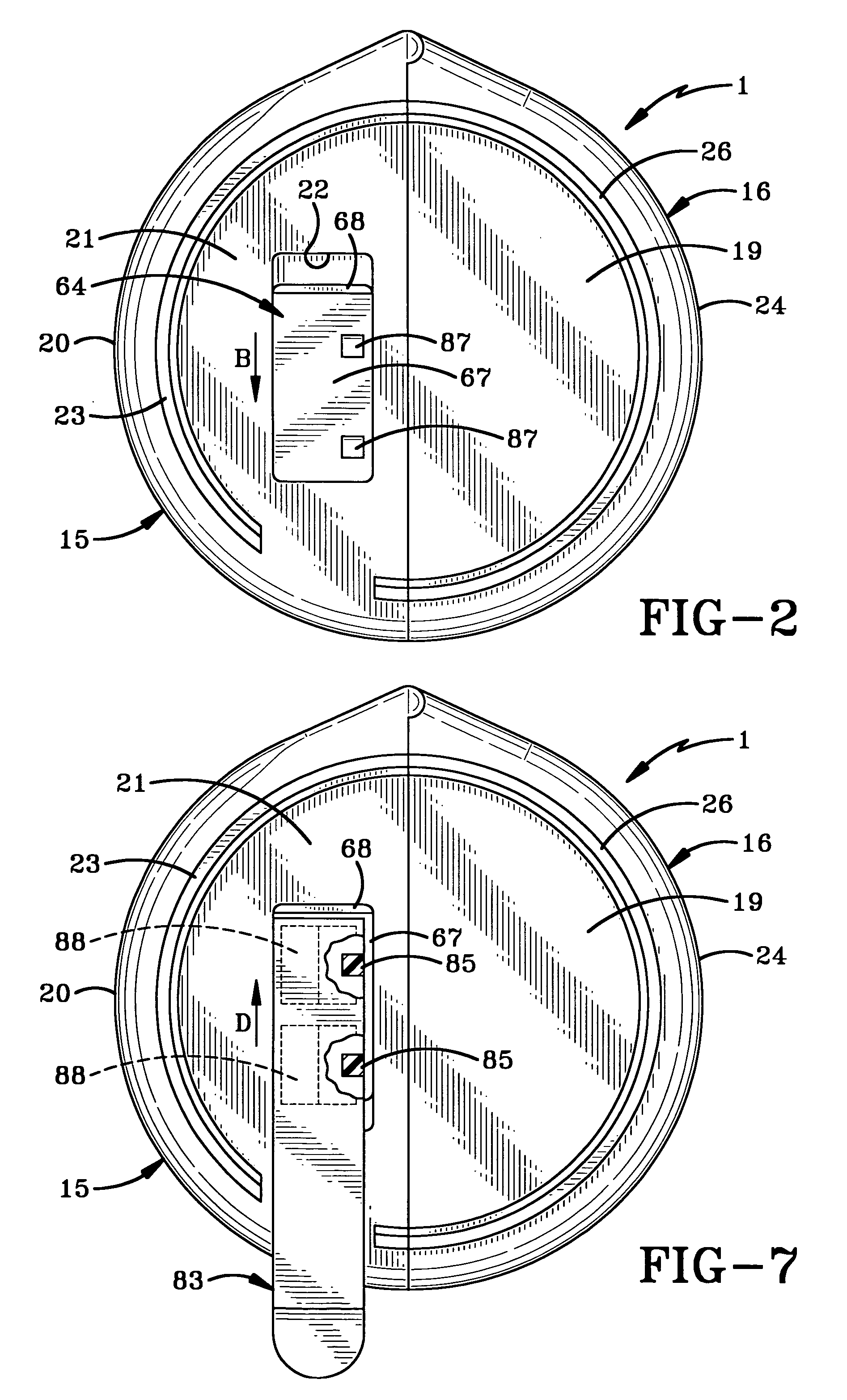

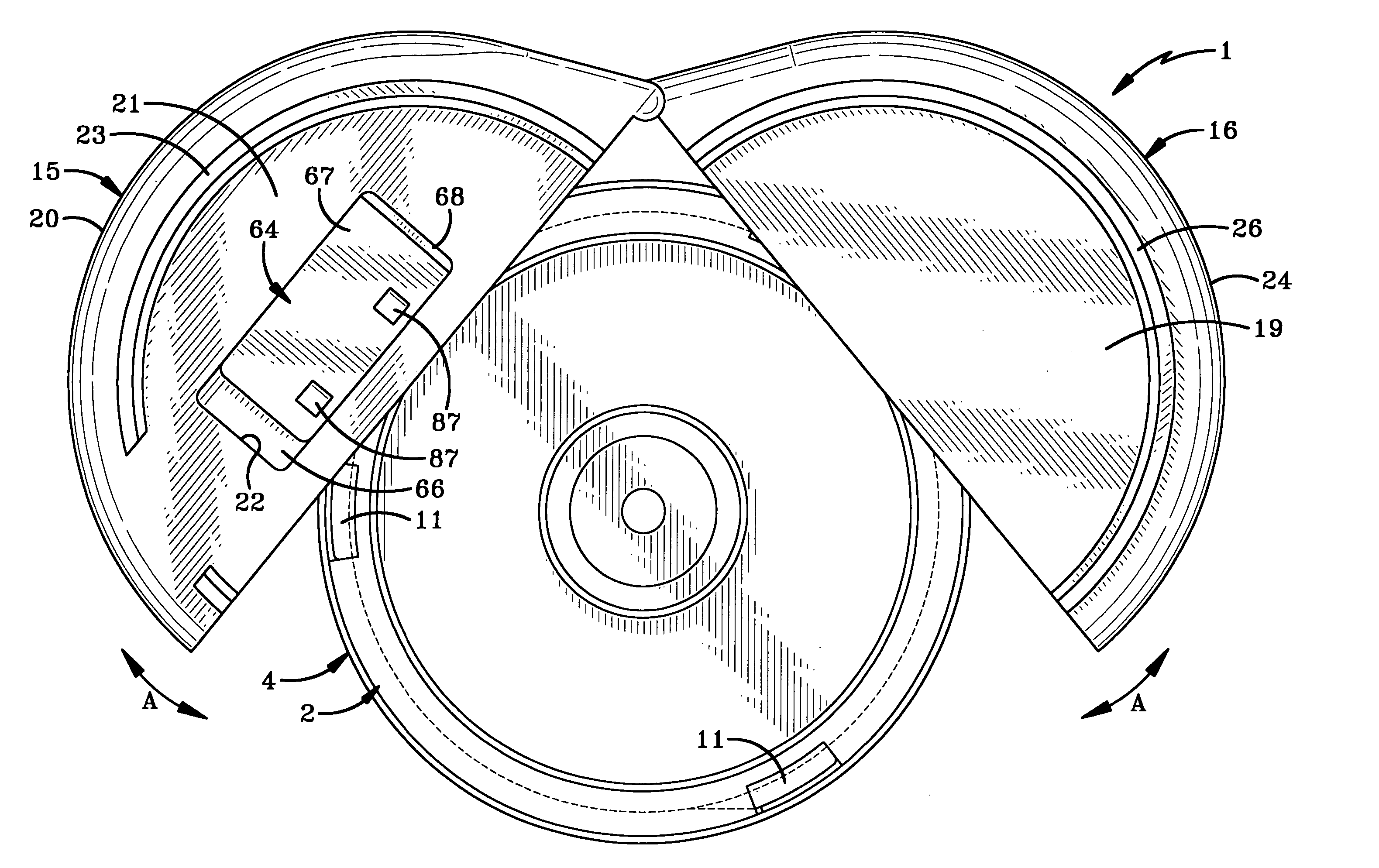

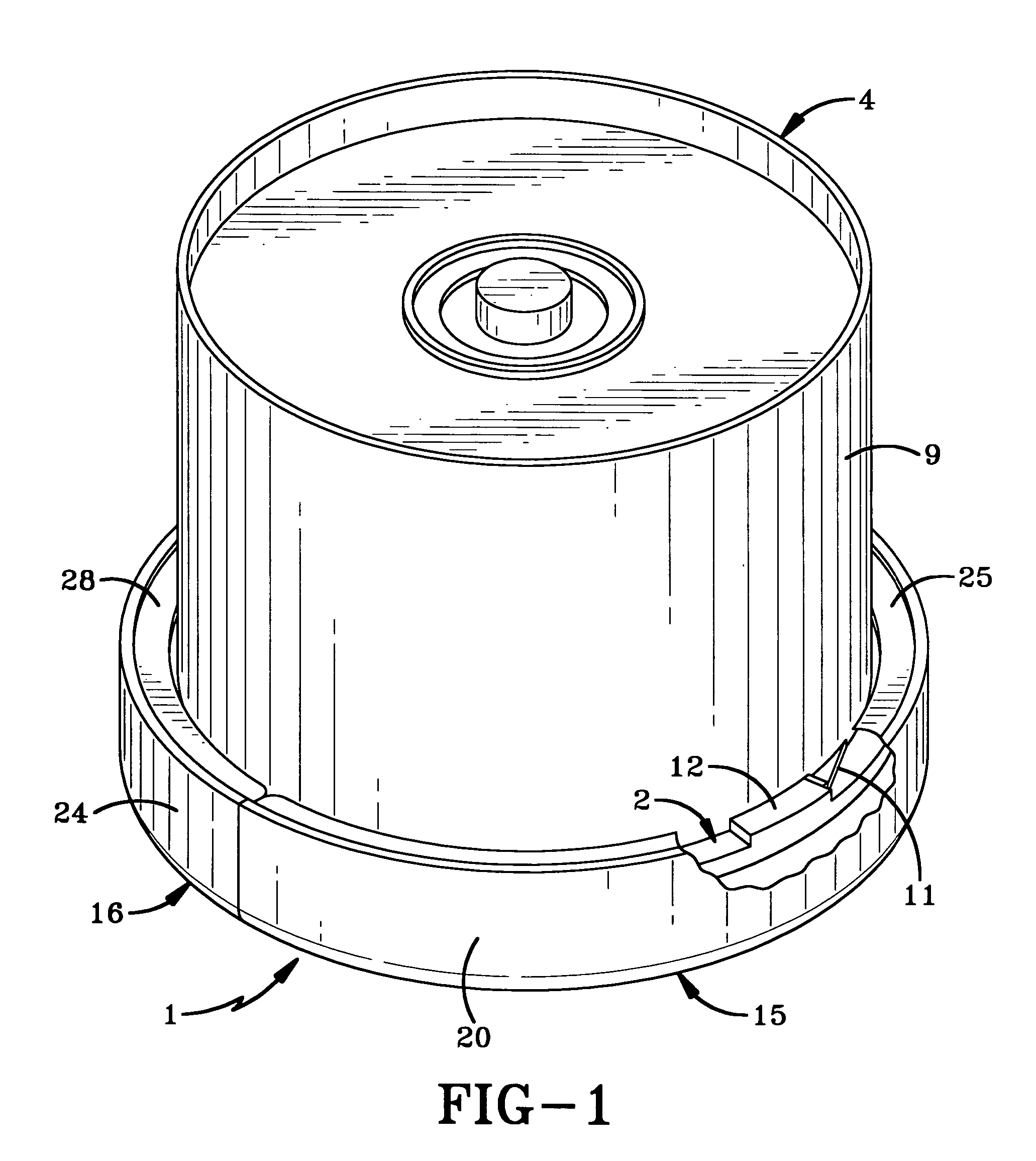

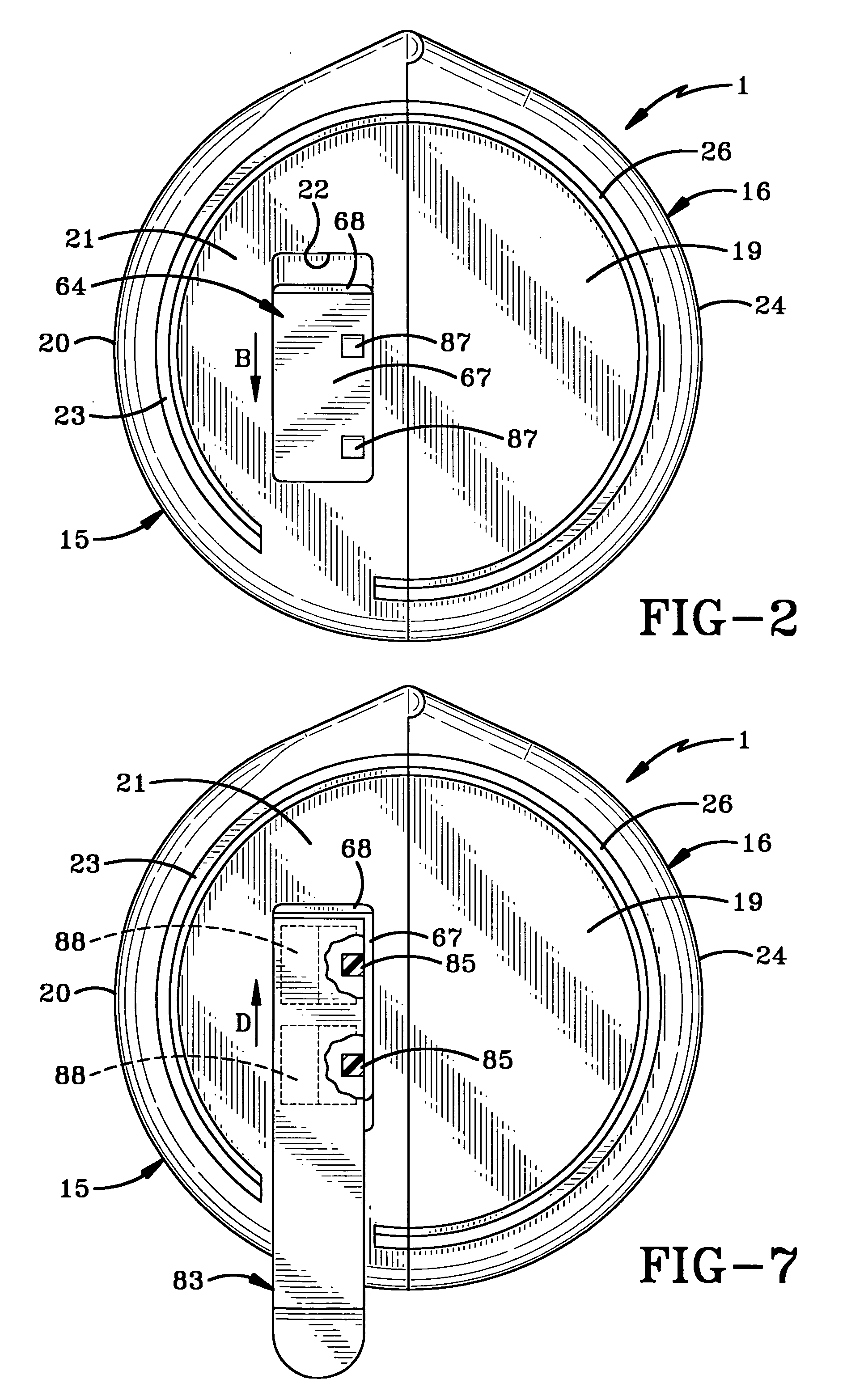

Security collar for media discs

InactiveUS7167096B2Easy to placeEasy to removeLocks for portable objectsRecord information storageLocking mechanismDisplay device

A security collar for placement around the base of a display package to prevent removal of a cover from the base to protect merchandise contained therein. An EAS security tag is contained in the collar. A magnetically actuated lock mechanism is formed on the collar to lock the collar in a closed locked position on the display package. The collar includes a pair of semi-circular housing members pivotally joined at one end and swingable between open and closed positions. The collar is formed with spaced projections which trap the base and portions of the cover therebetween to secure the collar about the base and cover. Each of the housing members each locking teeth which mutually engage each other to secure the housing members in locked position.

Owner:CHECKPOINT SYST INC

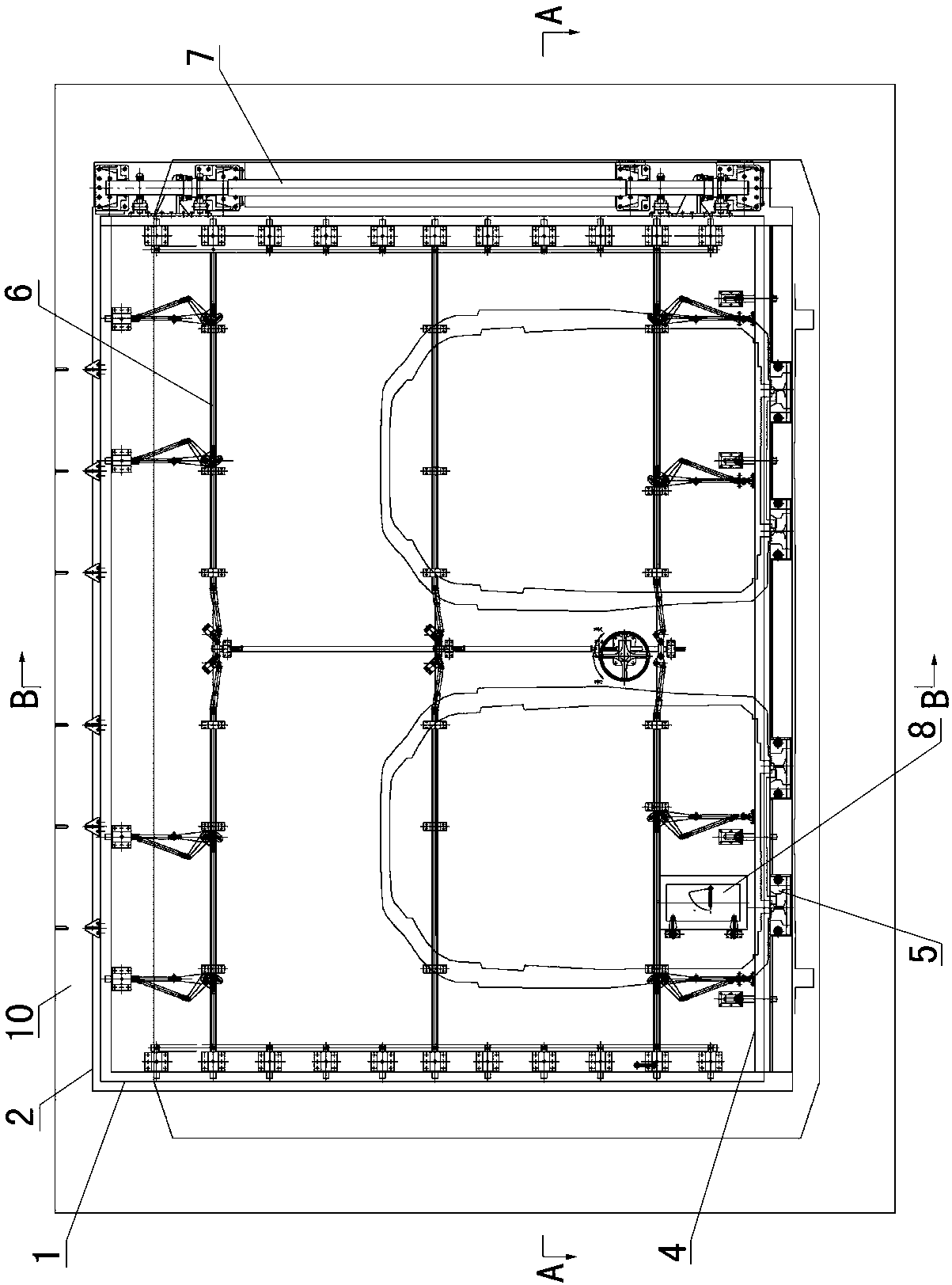

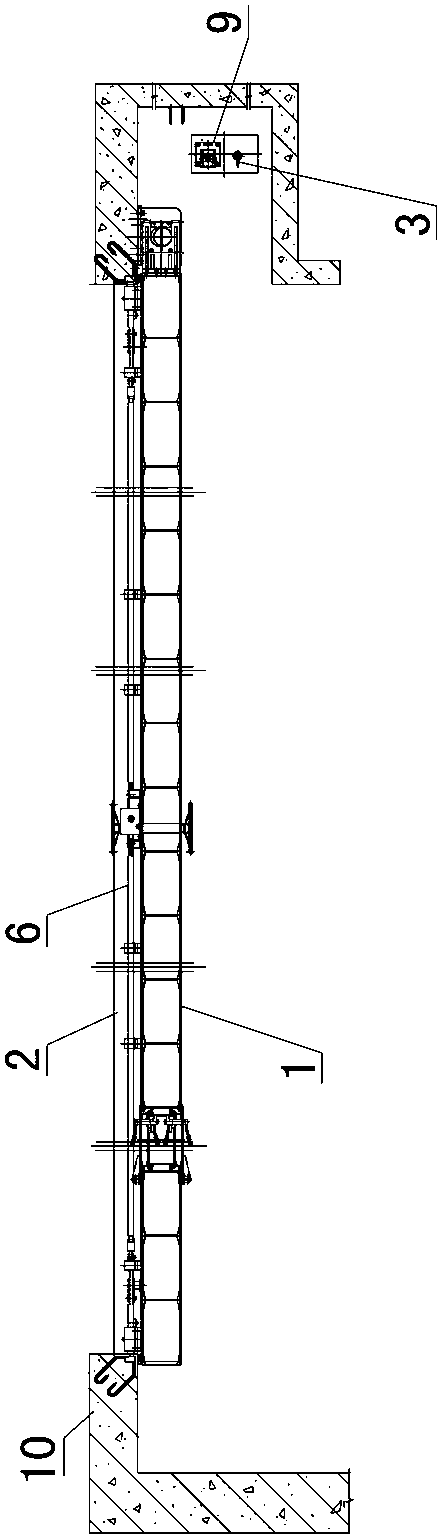

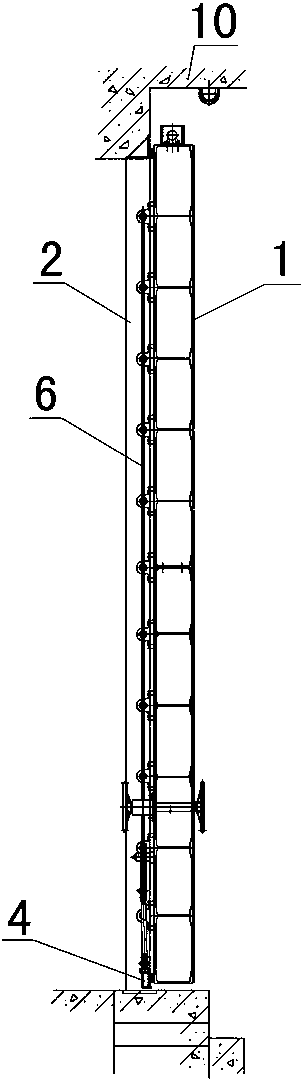

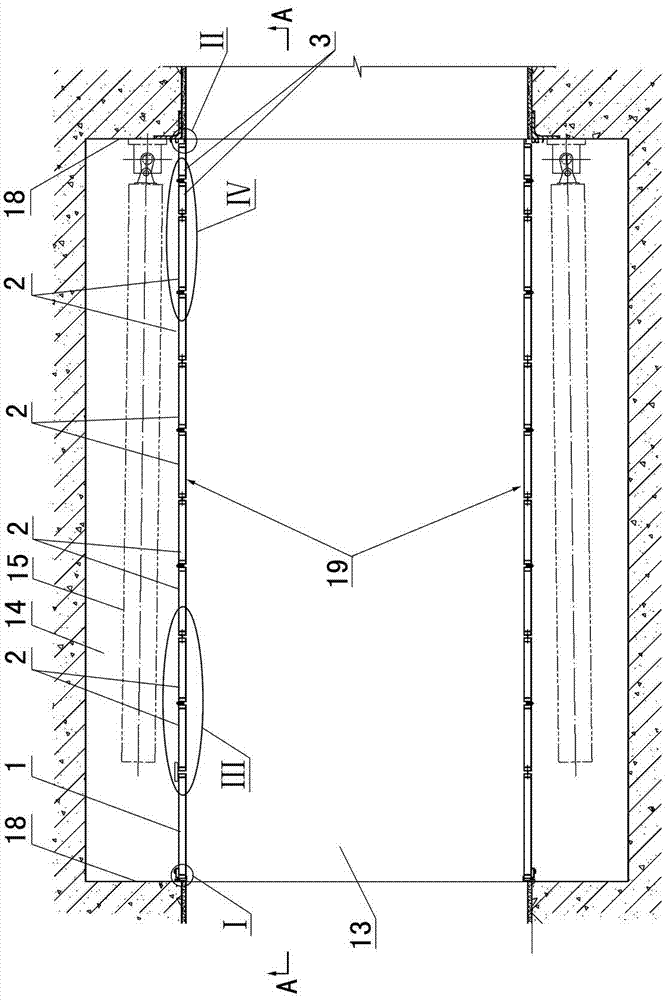

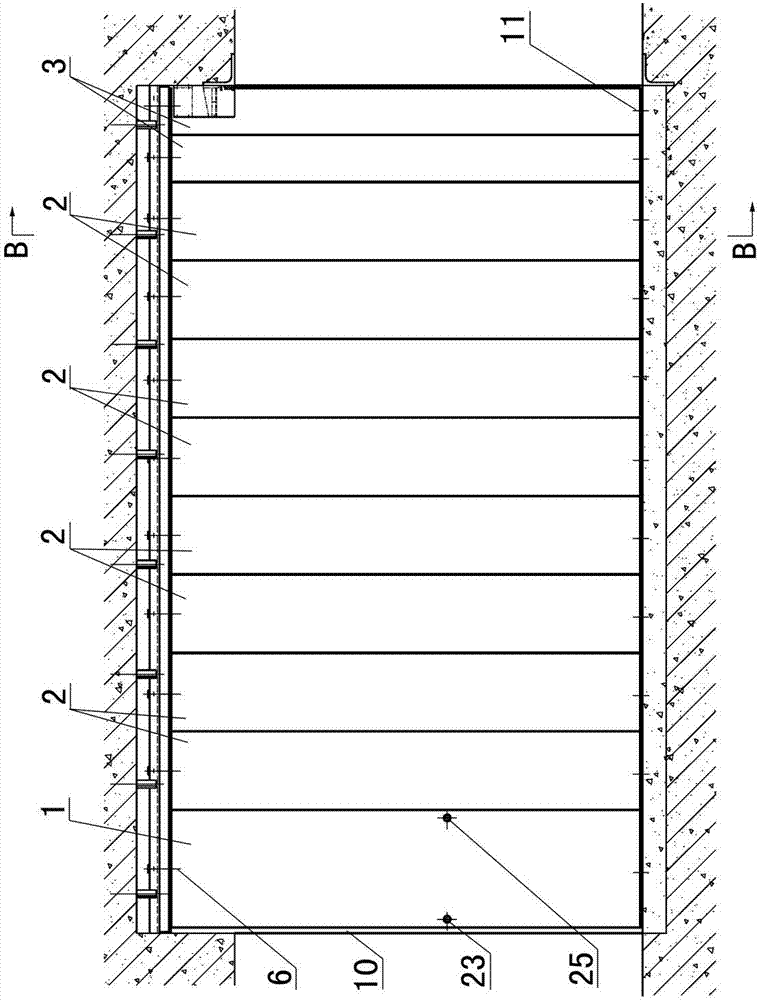

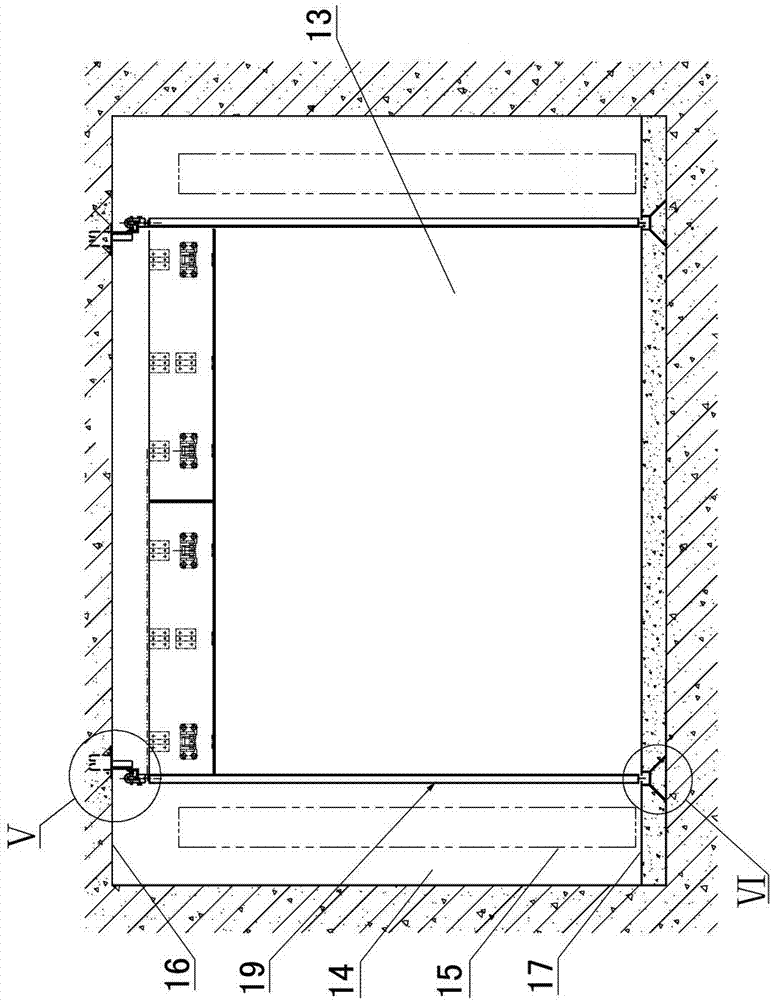

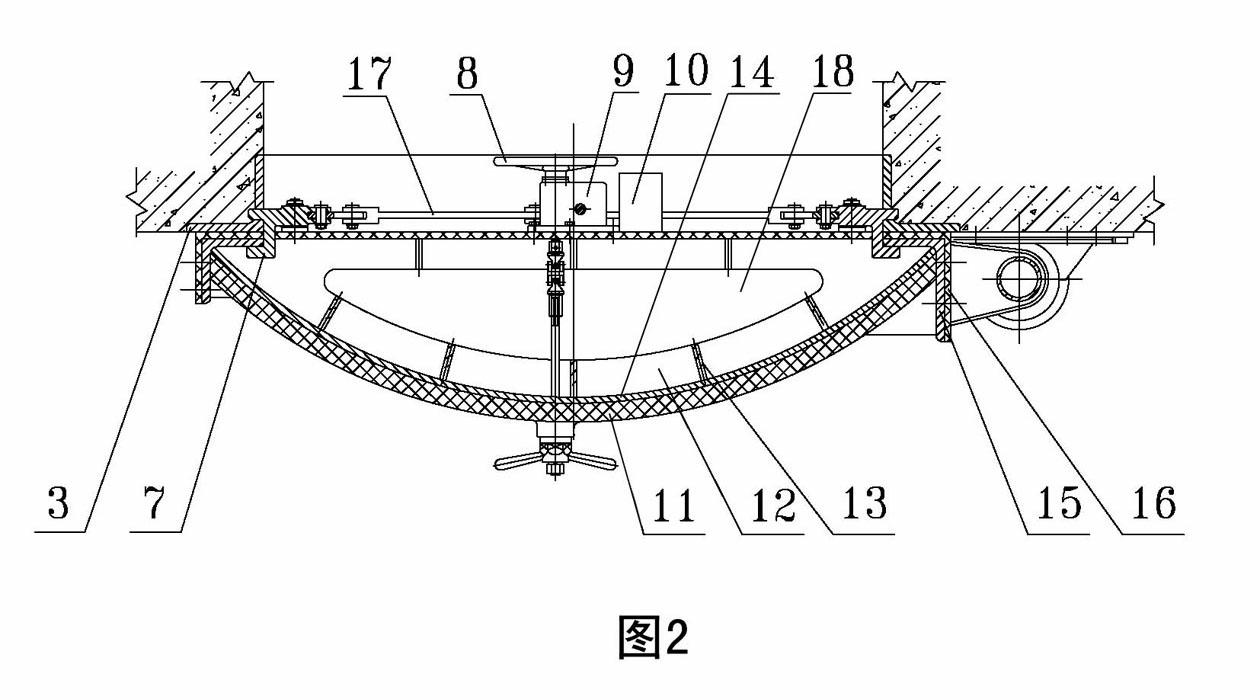

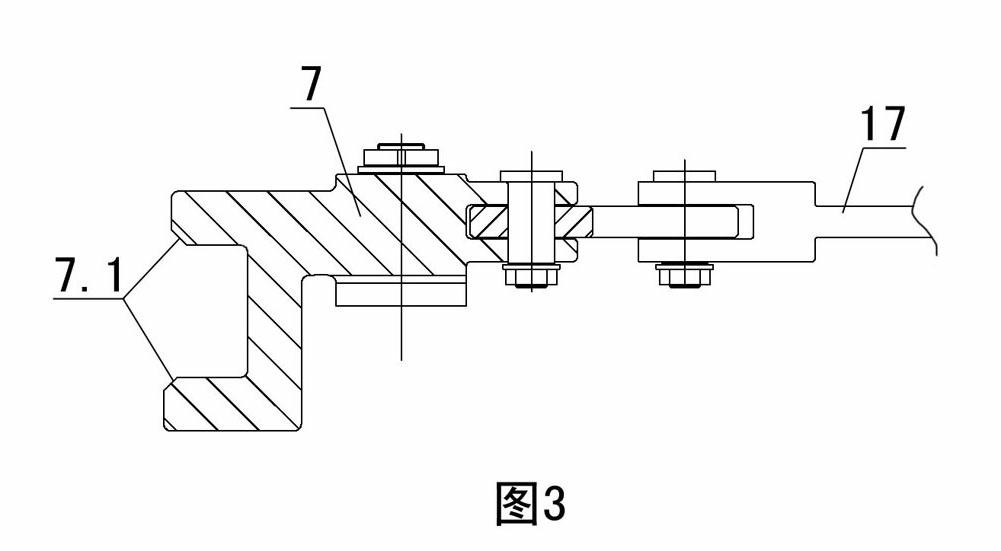

Oversized single-leaf protection airtight separation door for single-tunnel double-line section of metro

ActiveCN103266837AEnsure safe use in wartimeLow costBuilding locksSealing arrangementsEngineeringMechanical engineering

Provided is an oversized single-leaf protection airtight separation door for a single-tunnel double-line section of a metro. A door leaf is of a single-leaf structure and is arranged in the single-tunnel double-line section or a double-line tunnel of the metro. A closed lock comprises a vertical output shaft, a transverse connection rod, a locking head connection plate, locking heads on two sides, a top locking head lifting mechanism, a top locking head, a sealing beam lifting mechanism, a hand-operating mechanism and a locking head seat. The vertical output shaft is connected with the transverse connection rod through a linkage mechanism. The linkage mechanism comprises a connection piece, a rotating arm and a crank handle connection rod. The top locking head lifting mechanism comprises a J-shaped rocker and a locking head connection rod. The sealing beam lifting mechanism comprises a reversed-J-shaped rocker and a sealing beam connection rod. The protection airtight separation door is applicable to separation of sections of air-defense construction of urban underground rail transit with one tunnel provided with two lines, ensures wartime use safety of single-tunnel double-line sections or double-line tunnel sections with small line distance, and has the advantage of being simple in manufacture and low in manufacture cost.

Owner:SHANGHAI ZHONGXING PROTECTION TECH CO LTD

Display rod security device

InactiveUS20070062890A1Quick removalHighly effectiveShow shelvesShow hangersLocking mechanismEngineering

Owner:INVUE SECURITY PROD INC

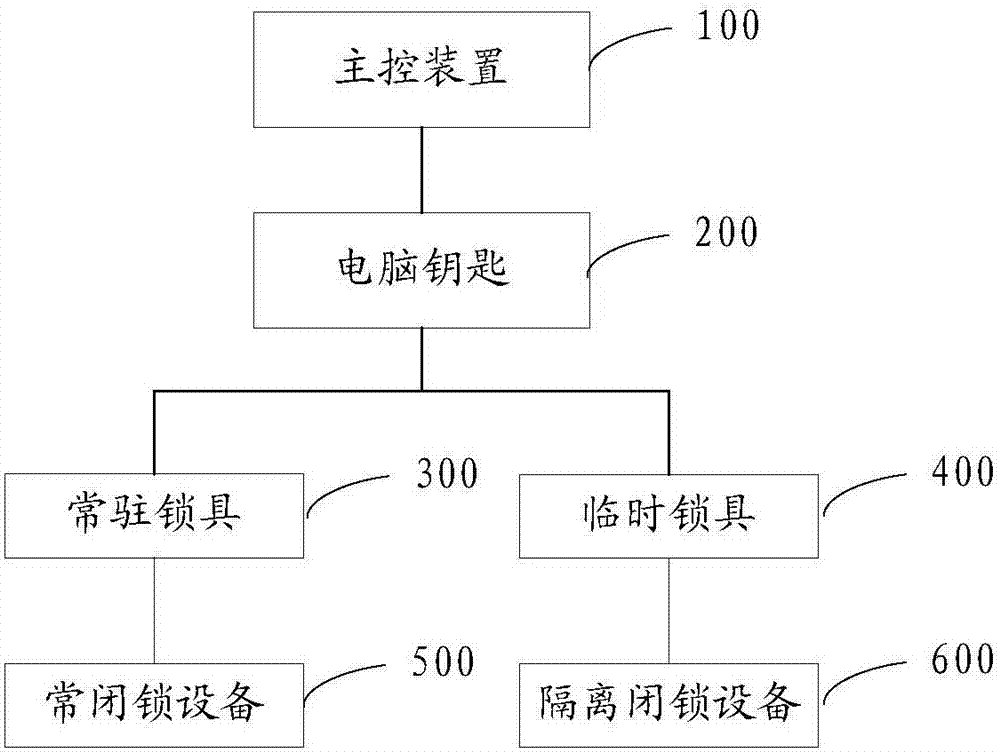

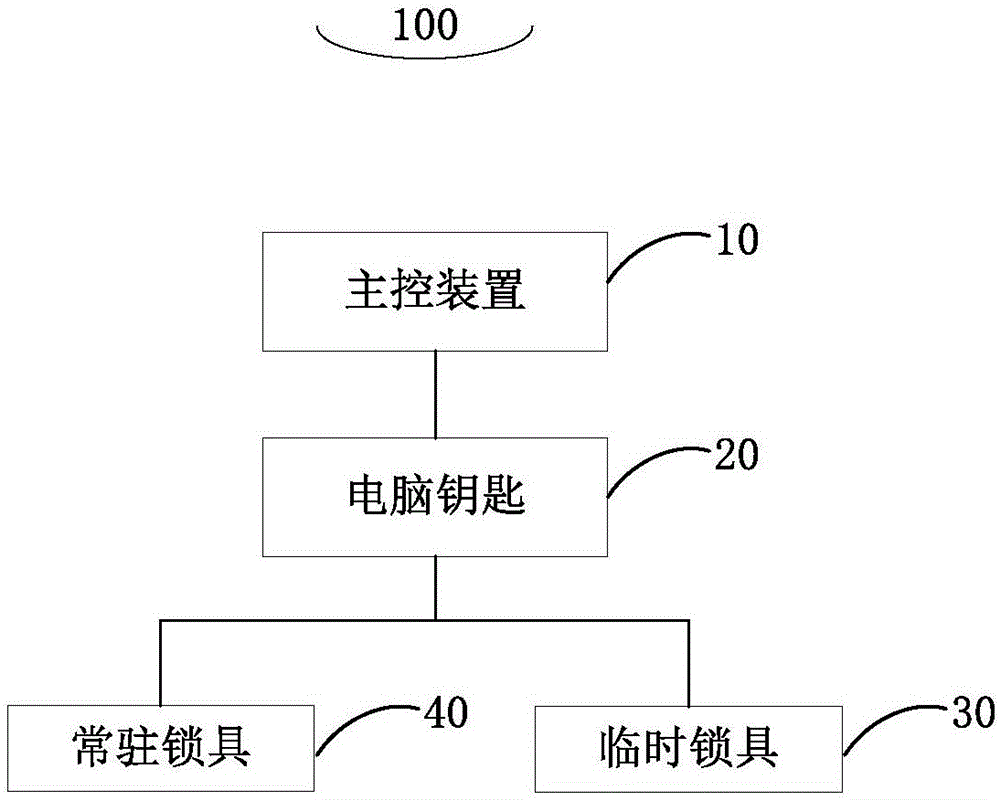

Management and control system and method for operation safety

PendingCN107346109AOperational securityEasy to operateProgramme control in sequence/logic controllersControl systemControl engineering

The invention provides a management and control system and a management and control method for operation safety. The management and control system comprises a main control device, a computer key, a resident lock and a temporary lock, wherein the main control device is used for receiving setting information, and generating an operation order of the resident lock and / or the temporary lock according to the setting information; the computer key is in communication connection with the main control device, and is used for controlling the resident lock and / or the temporary lock to execute a corresponding operation according to the received operation order; the resident lock is connected with the computer key, first encoding information is set in the resident lock, the resident lock is installed on normally-closed lock equipment, and the computer key realizes management and control of the normally-closed lock equipment through controlling the resident lock; and the temporary lock is connected with the computer key, second encoding information is set in the temporary lock, and the computer key realizes management and control of isolated blocking equipment through controlling the temporary lock. According to the management and control system and the management and control method, the management and control of the normally-closed lock equipment and / or the isolated blocking equipment can be realized by using one computer key, thus the operation of the equipment is smoother and the working efficiency is improved on the premise of ensuring safety.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

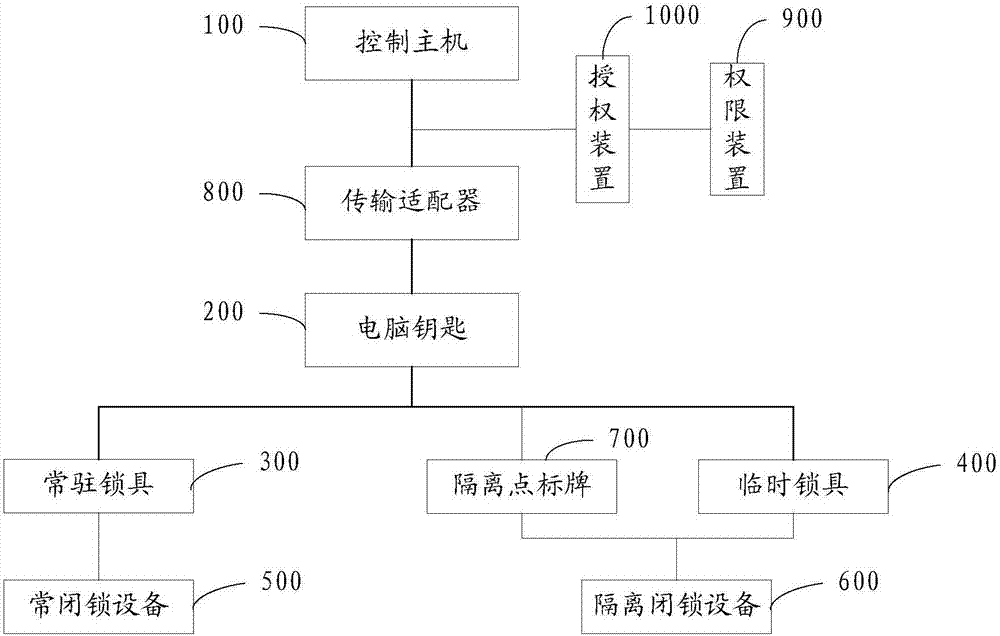

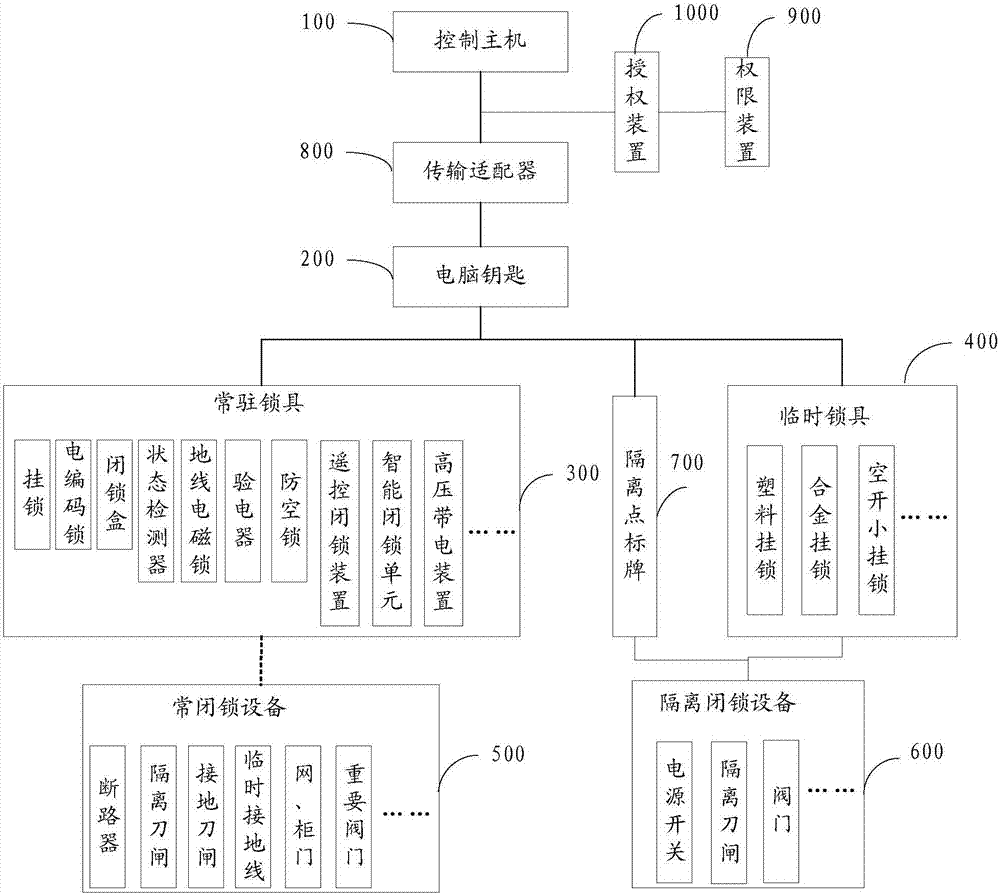

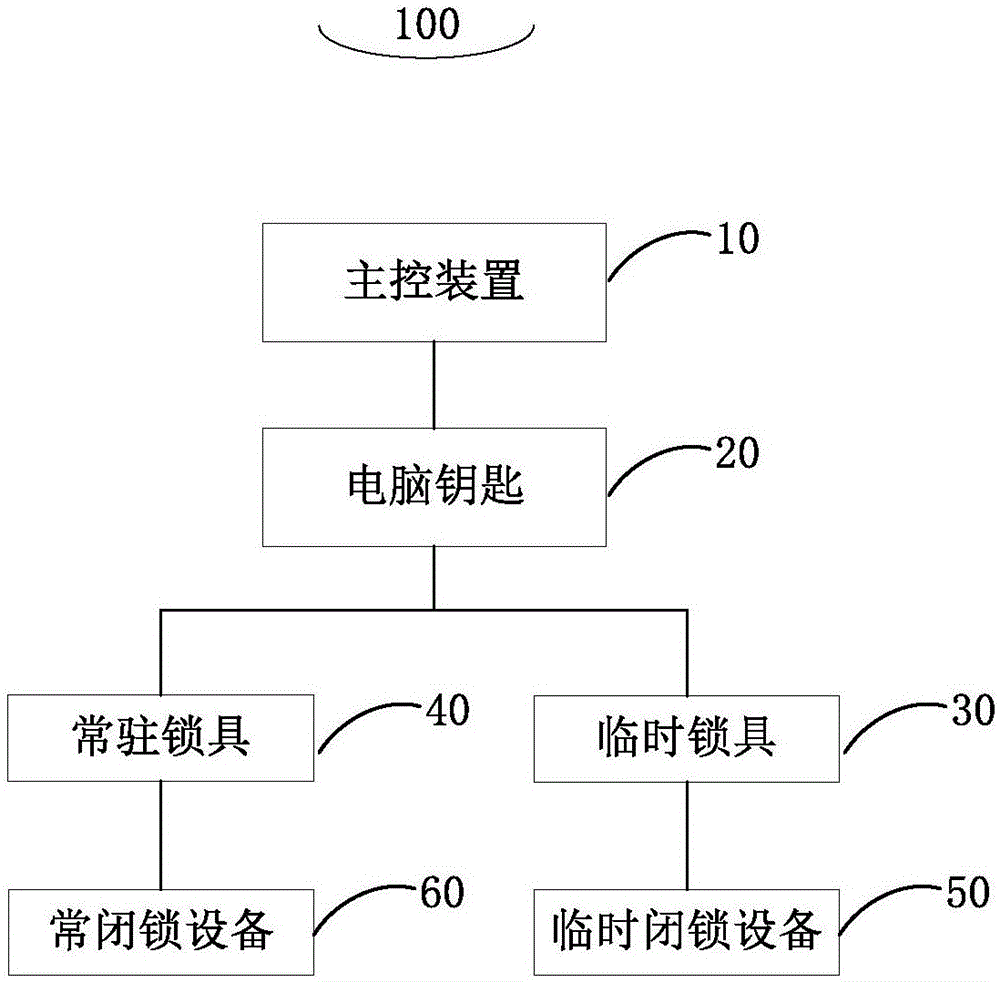

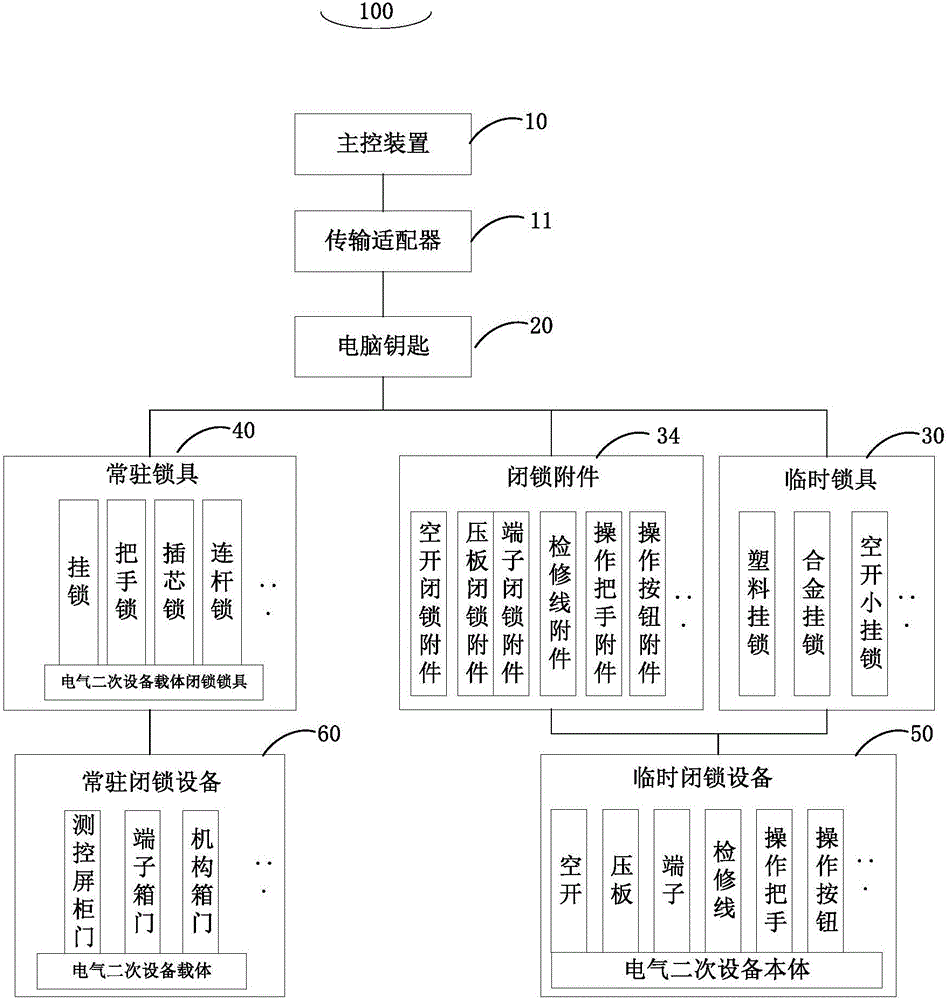

Management control system and method for preventing error operations of electrical secondary equipment

PendingCN106710051AAvoid misuseSwitching operation safetyIndividual entry/exit registersElectrical devicesEmbedded system

The invention provides a management control system for preventing error operations of electrical secondary equipment. The system comprises a master control device, a computer key, a resident lock and a temporary lock, wherein the master control device is used for receiving set information and generating an operation order according to the set information; the computer key is in communication connection with the master control device and is used for receiving the operation order transmitted by the master control device; the resident lock and the temporary lock are in communication connection with the computer key; the resident lock is mounted on normally closed lock equipment needing to be subjected to resident locking; the computer key controls the resident lock to execute operations according to the operation order; the temporary lock is mounted on temporary locking equipment needing to be subjected to temporary locking; and the computer key controls the temporary lock to execute operations according to the operation order. According to the resident lock and the temporary lock, hierarchical management control of the electrical equipment is realized, the condition that accidents are caused by error operations of the electrical equipment is effectively avoided, and the safety in the plant-station production operation process is improved.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

Express package intelligent lock with remote monitoring and protecting alarming function

InactiveCN105781254AMonitor location in real timeReal-time monitoring statusAlarm locksBurglar alarm by disturbance/breaking stretched cords/wiresLocking mechanismControl switch

An express package intelligent lock with a remote monitoring and protecting alarming function comprises a package bag, a mechanical locking mechanism and an electronic control device; the mechanical locking mechanism comprises a lock body and a lock beam; the lock beam is directly buckled to the lock body so that a closed lock can be formed; a plurality of tightening openings are formed in a bag opening of the package bag; the lock beam penetrates the tightening openings one by one so that the bag opening of the package bag can be tightened; an electronic control switch lock mechanism is assembled in the lock body; the intelligent lock is controlled to be opened and closed through an electromagnetic coil; and the electronic control device is connected with the lock body and can detect and control the locking mechanism and send relevant state and position information. The express package intelligent lock with the remote monitoring and protecting alarming function has the beneficial effects that the structure is reasonable and novel, revolution is brought to the whole express industry, the intelligent degree and safety of express delivery are improved, use is convenient, and popularization is facilitated.

Owner:陆勃屹

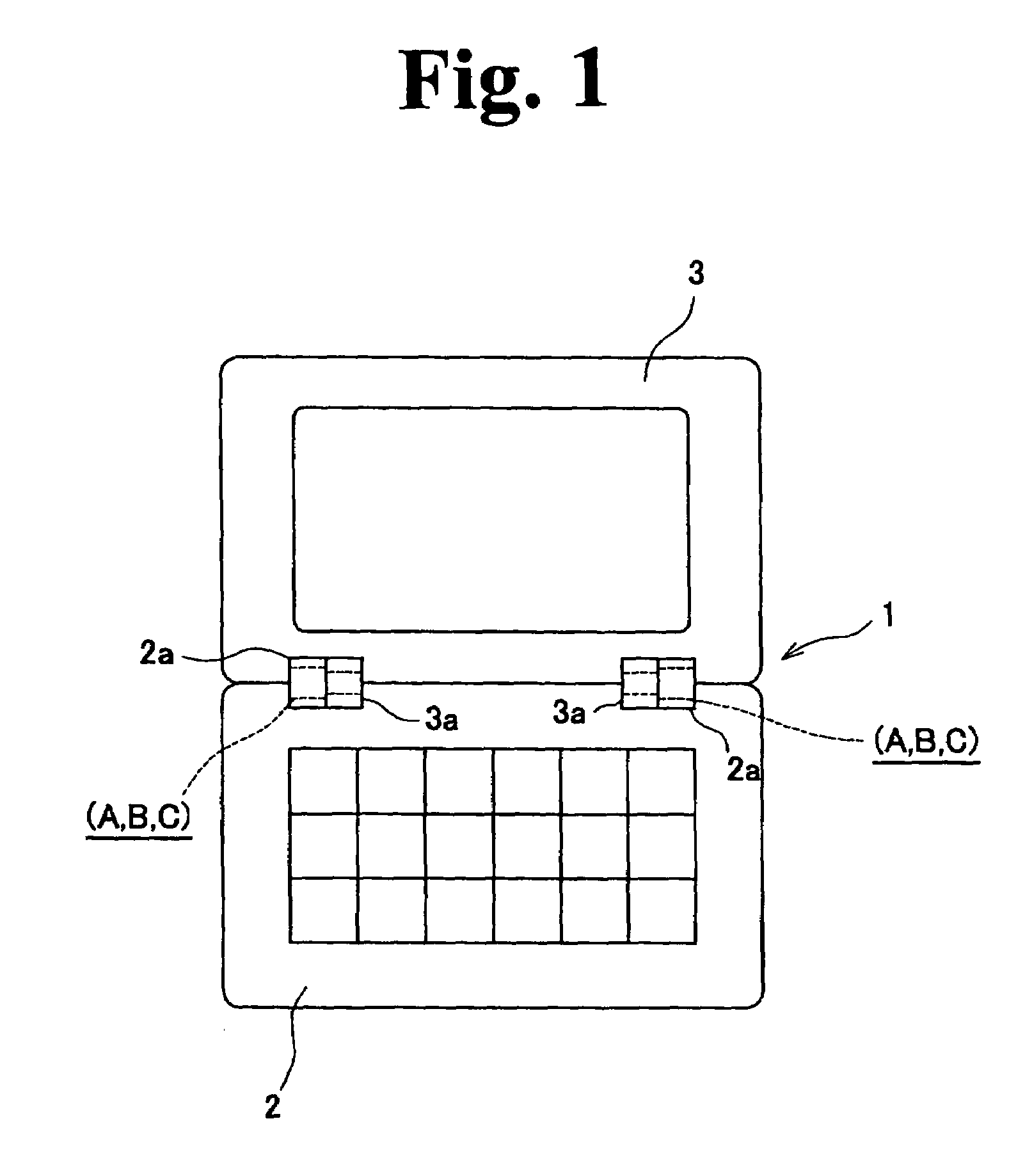

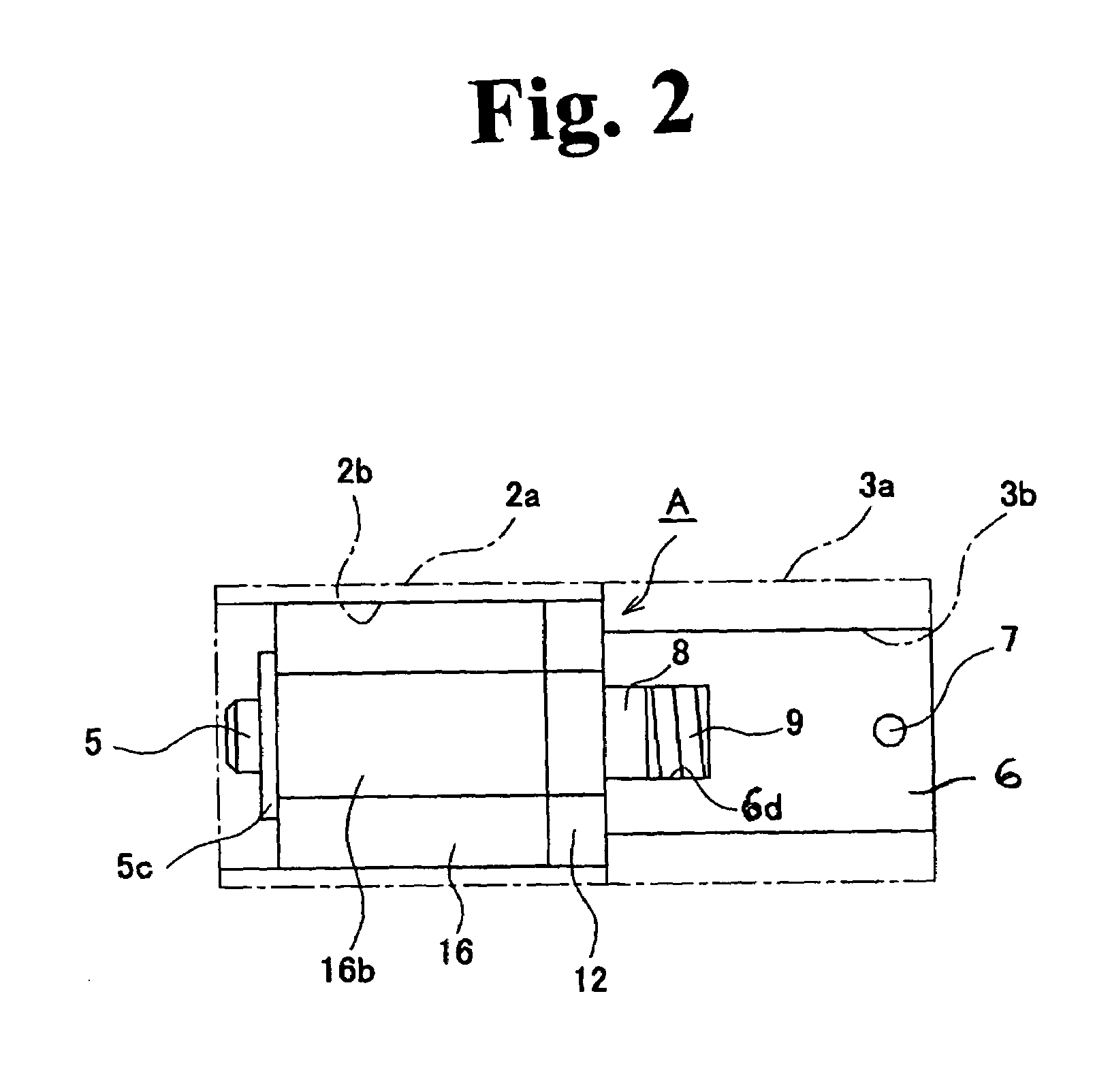

Hinge device

A hinge device of a portable intelligence terminal, which connects a first member having a keyboard and a second member composed of a comparatively massive display device in an openable and closable manner as well as possible includes a cam mechanism and a friction mechanism coaxially on a shaft. The cam mechanism is structured with a fixing cam provided by allowing a shaft to insert through axially at each central portion into a cam case having a rotation arresting means fixed on the shaft, a slider cam provided slidably in a manner to confront to the fixing cam, being restrained its rotation by the cam case, and an elastic means to press the slider cam toward the fixing cam side, and the friction mechanism is structured with a friction ring attached to the shaft and fitted into the friction case with pressure having a rotation arresting means attached to the shaft in a manner to be rotatable, so that both of automatic closed lock function from a predetermined closed angle between the first and second members and a free stop function when opening and closing operation of the first and second members can be realized together without strain.

Owner:KATOH ELECTRIC MACHINERY

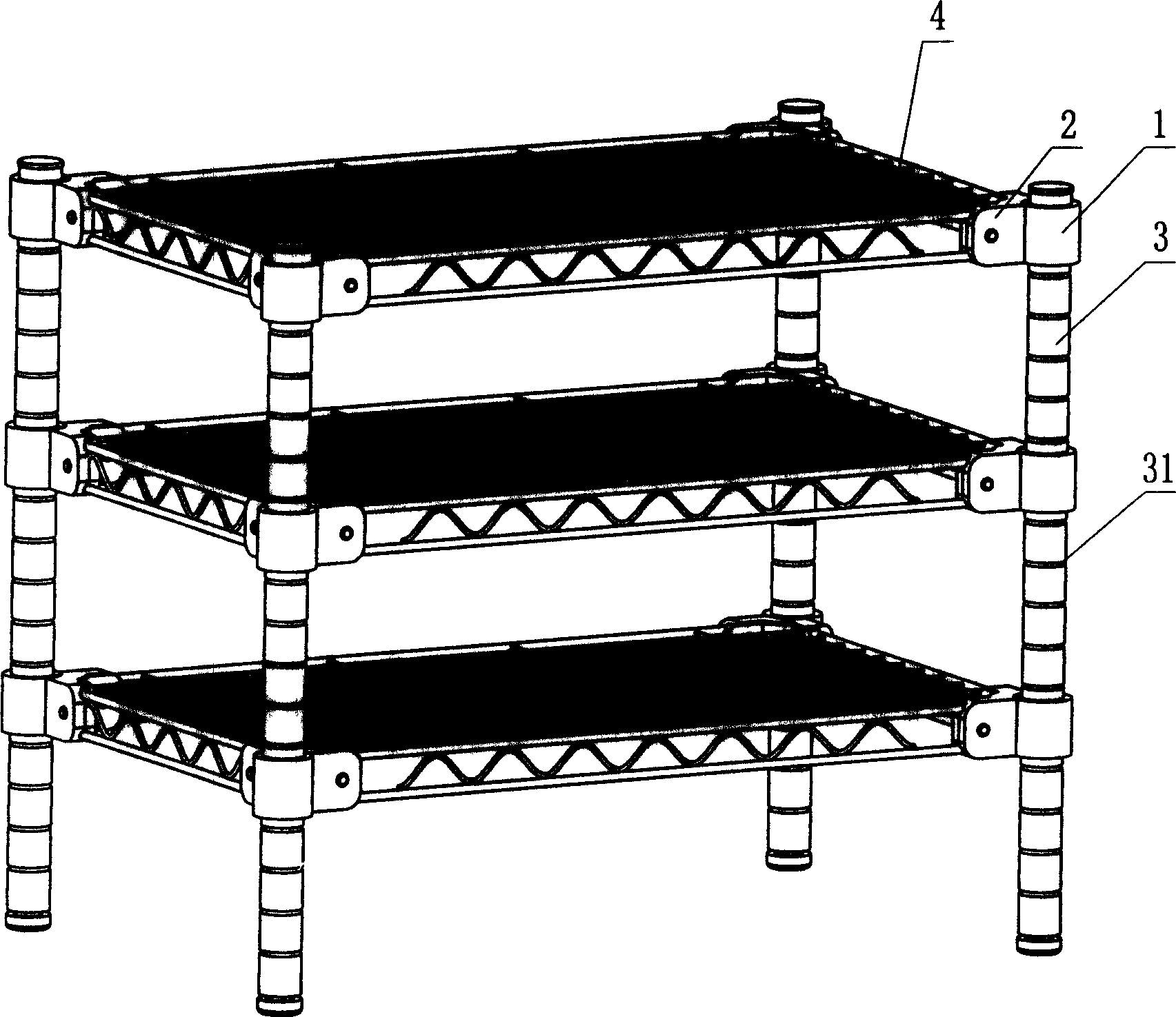

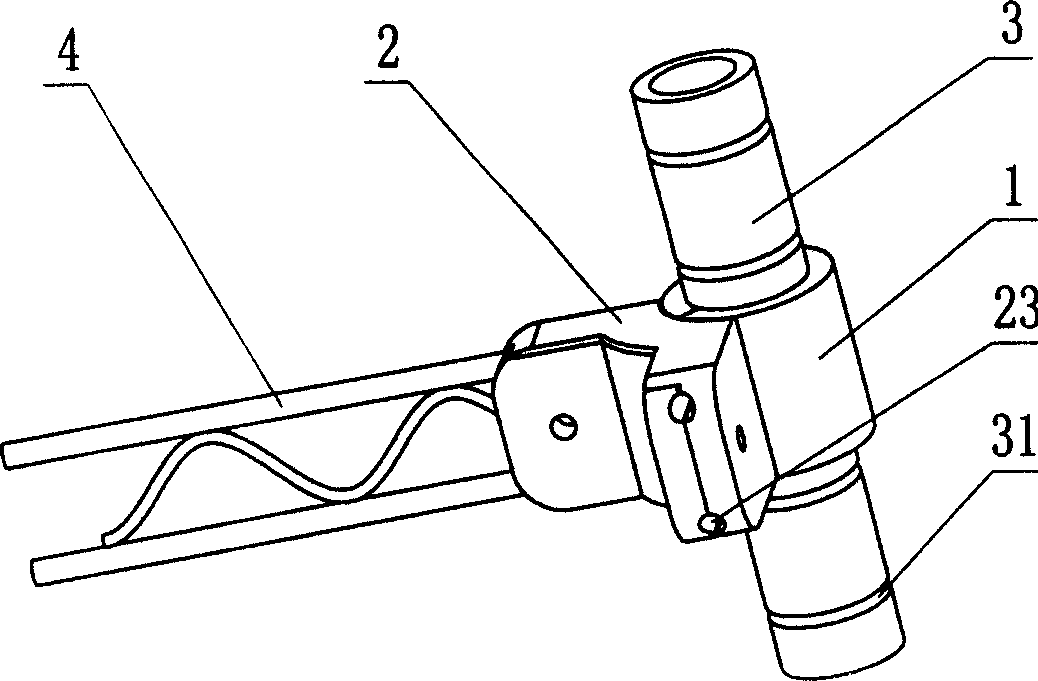

Goods rack connector

The device including slides the set and sleeve chuck, states the slippery wrap to be equipped with with the outrigger skids the coordinate cavity, its characteristic is states slides between a set of outflow boundary and the cavity opens has as soon as links up open slot, an above sleeve chuck end and the thing frame body are connected, another end establishes Yu Huatao in the outflow boundary, in sleeve chuck with slides between the set to be equipped with after sleeve chuck the card enters slides a set of outflow boundary to be able to slide a set of institute to suppose open slot to in closed locking organization. The invention because uses above tightens the organization, when assembly, the slippery wrap may facilitate the localization to the outrigger free position, then enters through sleeve chuck the card its locking, also because sleeve chuck an itself end is loaded with the installment position which matches with the thing frame body or sleeve chuck itself is the thing frame body nose, therefore causes an entire thing connection to change extremely simply, but acts according to the different frame body specification design the coupling, may adapt the many kinds of specifications different to set at a thing connection, greatly expanded the coupling applicable scope, provides a kind of new component for a thing production.

Owner:李向明

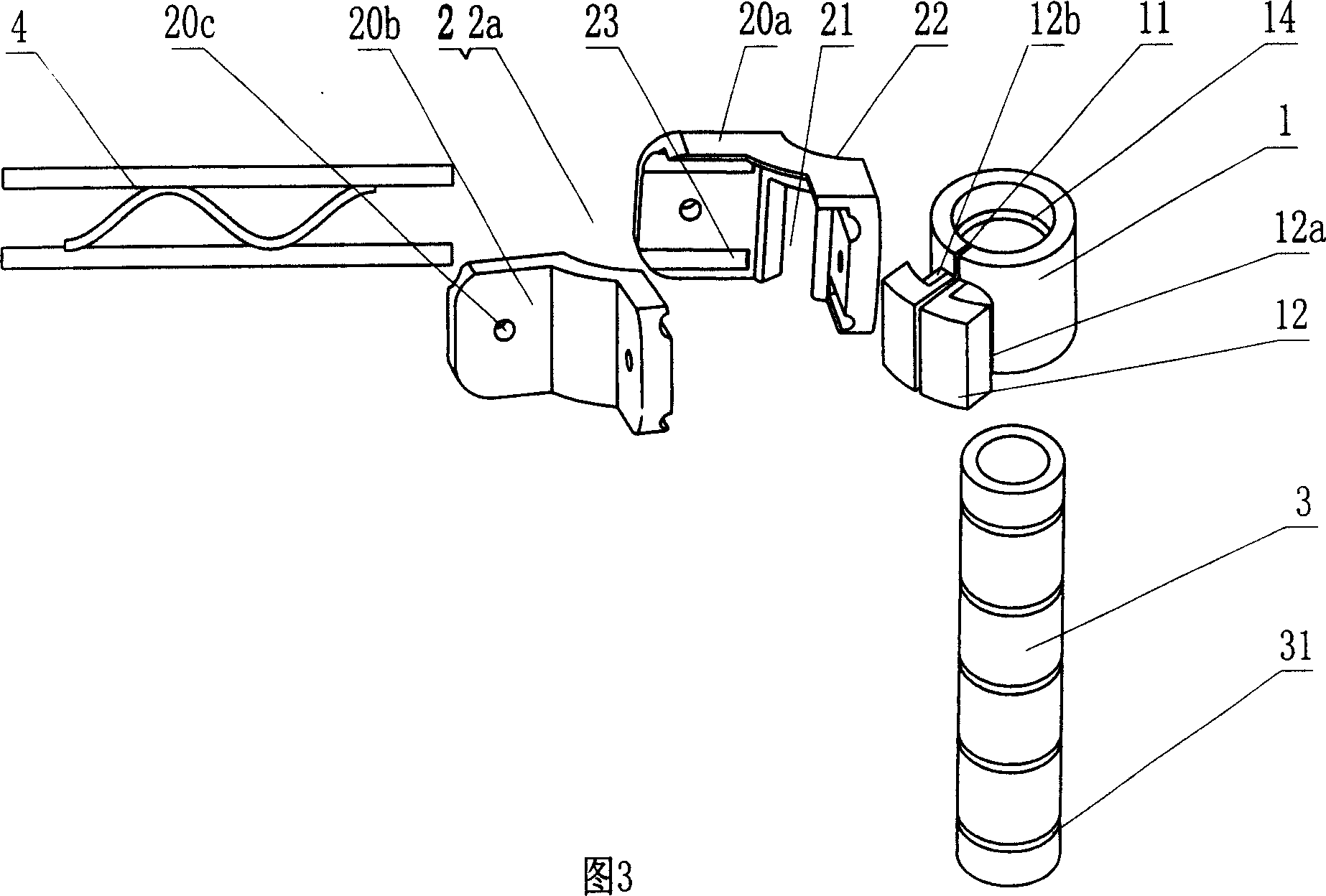

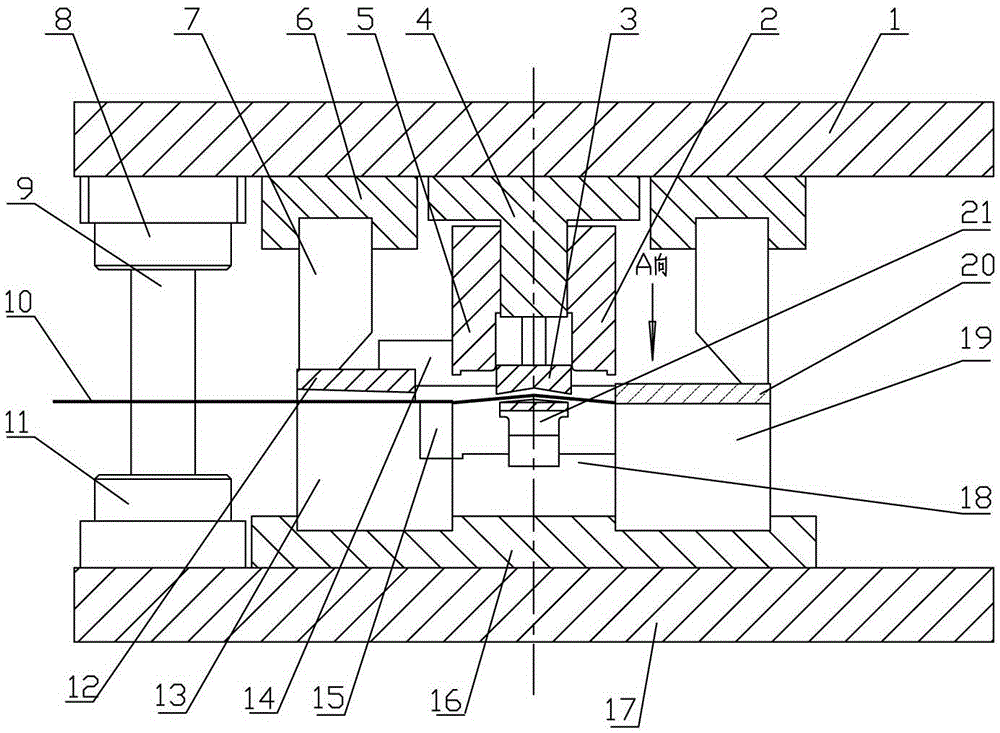

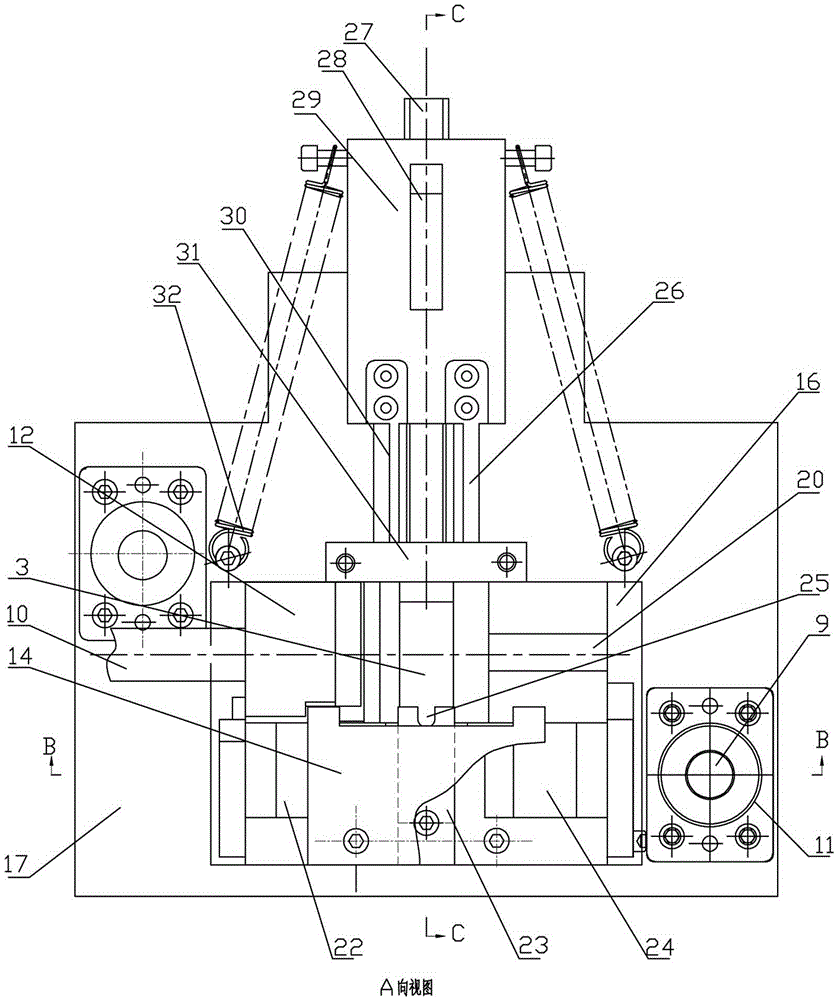

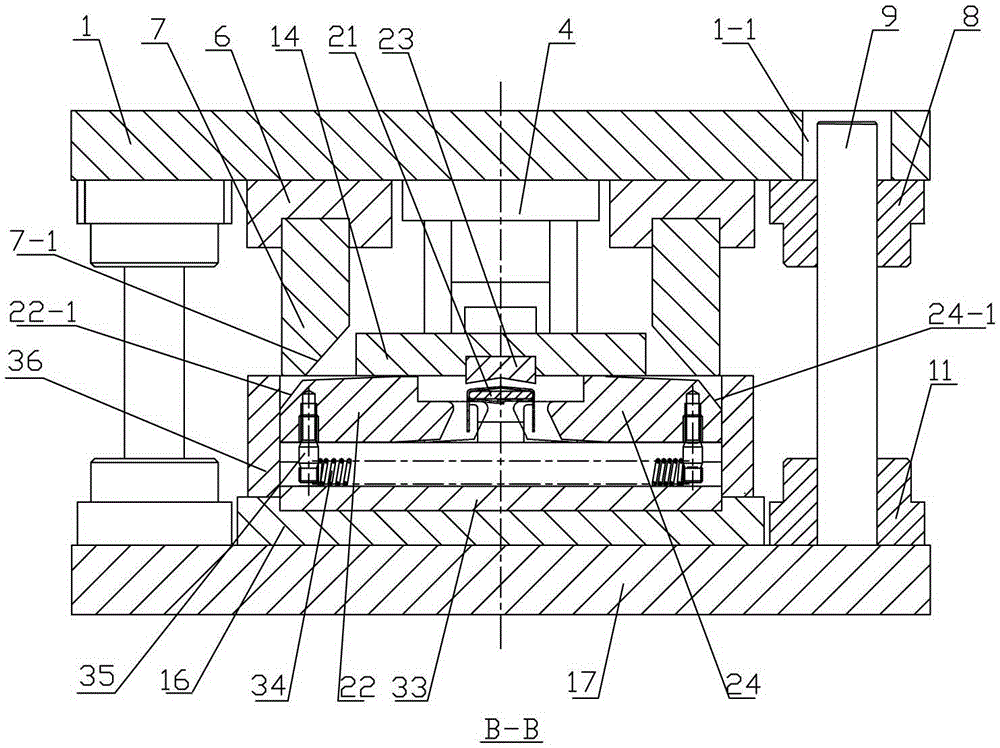

Processing mould for steel strip closed lock catches for packaging

ActiveCN105234288AReduce the amount of investmentImprove productivityShaping toolsProduction ratePunching

The invention belongs to the technical field of processing of steel strip lock catches for packaging and particularly relates to a processing mould for steel strip closed lock catches for packaging. The processing mould comprises an upper mould assembly, a lower mould assembly, a pushing device and two upper mould lifting guide pillar devices, wherein the upper mould assembly is composed of an upper mould plate, a cutter seat, two extrusion block seats, a cover plate seat, a cutter forming compound mould, a profiling upper cover I, two extrusion blocks and a profiling upper cover II; the lower mould assembly comprises a lower mould plate, a base plate, a left cavity block, a right cavity block, a forming lower mould seat, a forming lower mould, a left folding forming pushing block, a right folding forming pushing block, a pushing block reset device, a material feeding press plate and a positioning baffle; and the pushing device is composed of a roller seat, a roller, an inclined vertical plate, a sliding groove block, a left pushing cutter, a right pushing cutter, a straight track, a limiting block and two extension springs. By adopting the processing mould provided by the invention, the continuous production processes of feeding, punching, profiling, forming, taking out and the like of the steel strip lock catches for packaging can be completed by one punching machine, so that the equipment investment is reduced greatly and the production rate is increased.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

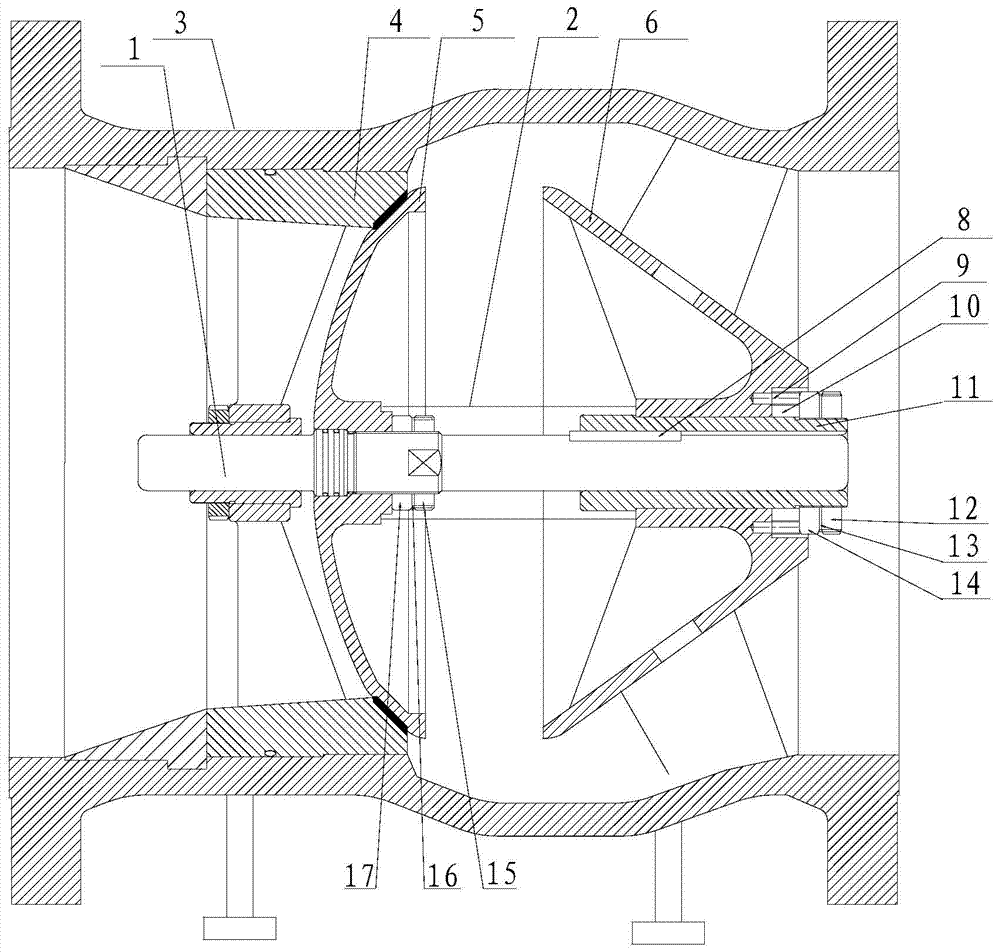

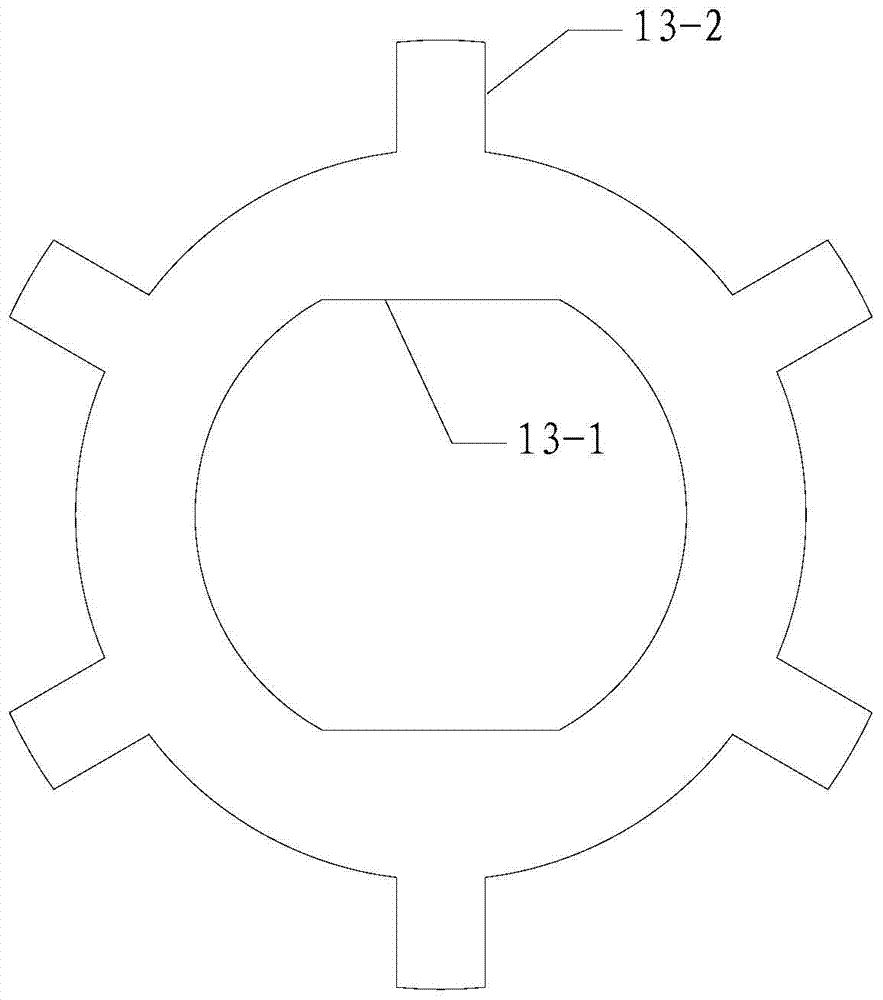

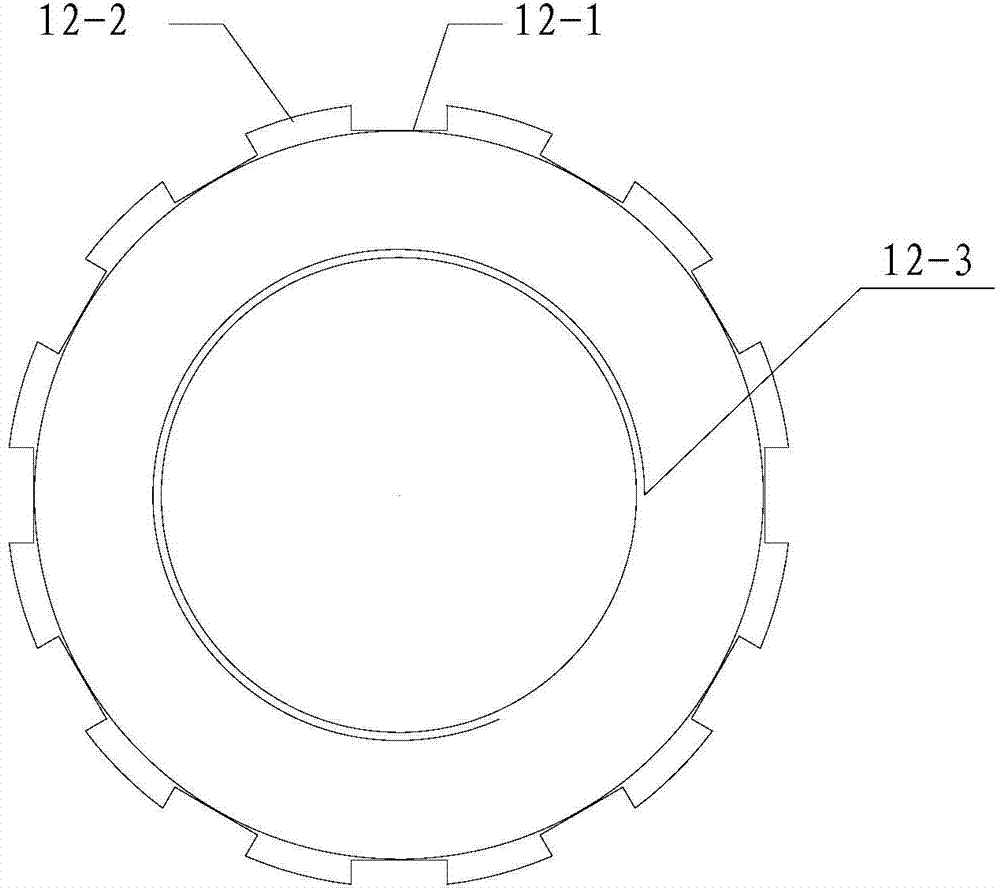

Axial-flow type check valve

ActiveCN104847932AInhibit sheddingAchieve absolute lockingCheck valvesLift valveEngineeringCheck valve

The invention discloses a valve structure, and particularly relates to an axial-flow type check valve. The axial-flow type check valve comprises a valve body, a valve rod, a valve seat, a valve clack, a valve sleeve, a bush, anti-falling locking nuts, thrust washers, closed locking nuts and a spring device. The anti-falling locking nuts comprise the first anti-falling locking nut and the second anti-falling locking nut. The thrust washers comprise the first thrust washer and the second thrust washer. The closed locking nuts comprise the first closed locking nut and the second closed locking nut. The axial-flow type check valve can achieve the effects that all the components of a valve element are prevented from falling and rotating and are resistant to vibrating and detachable, and the problems that the valve element of the axial-flow type check valve is prone to falling off and rotating, hard to maintain and the like are solved. Meanwhile, the use performance of valves of this kind is improved, and the service life of the valve is prolonged.

Owner:自贡新地佩尔阀门有限公司 +1

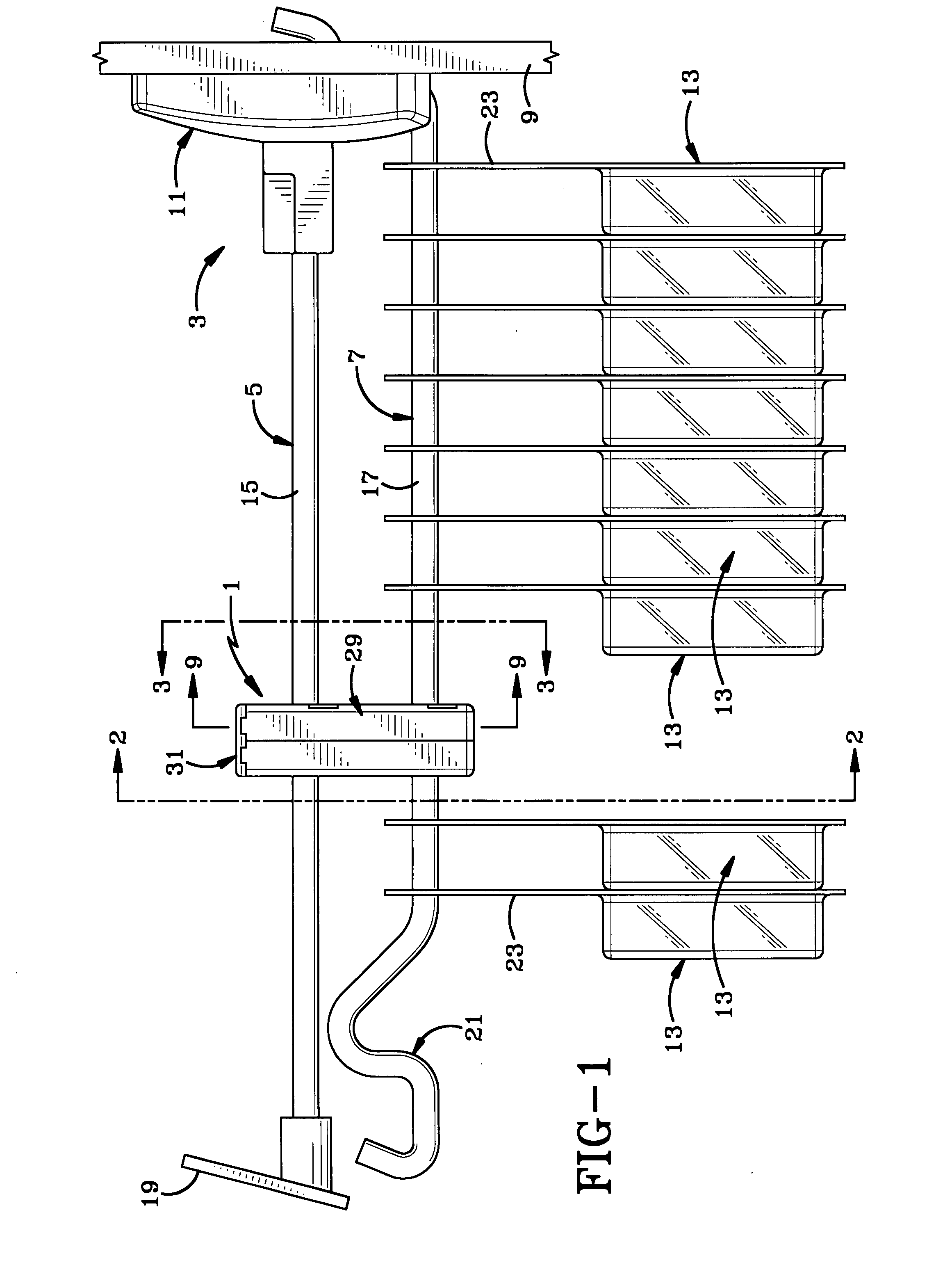

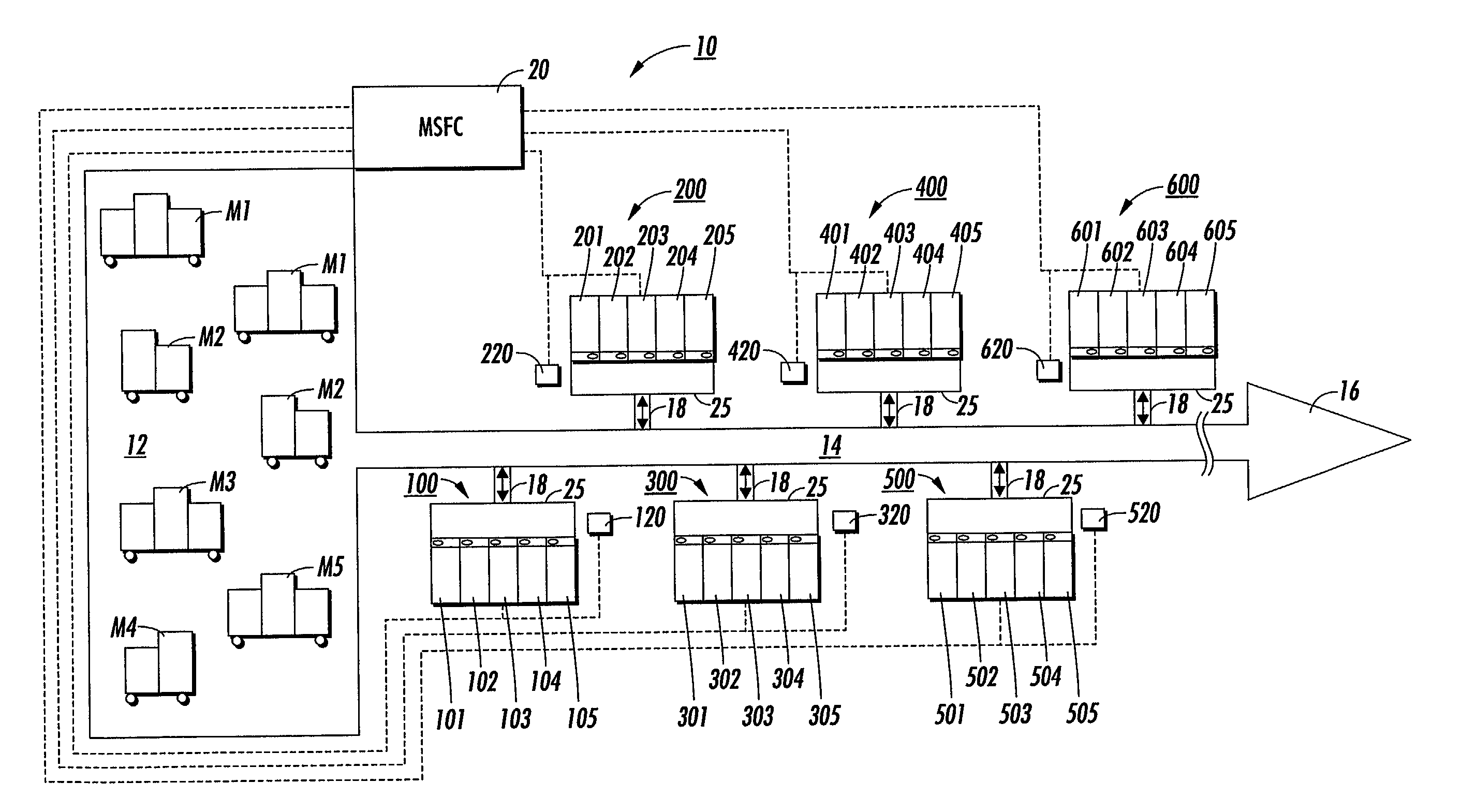

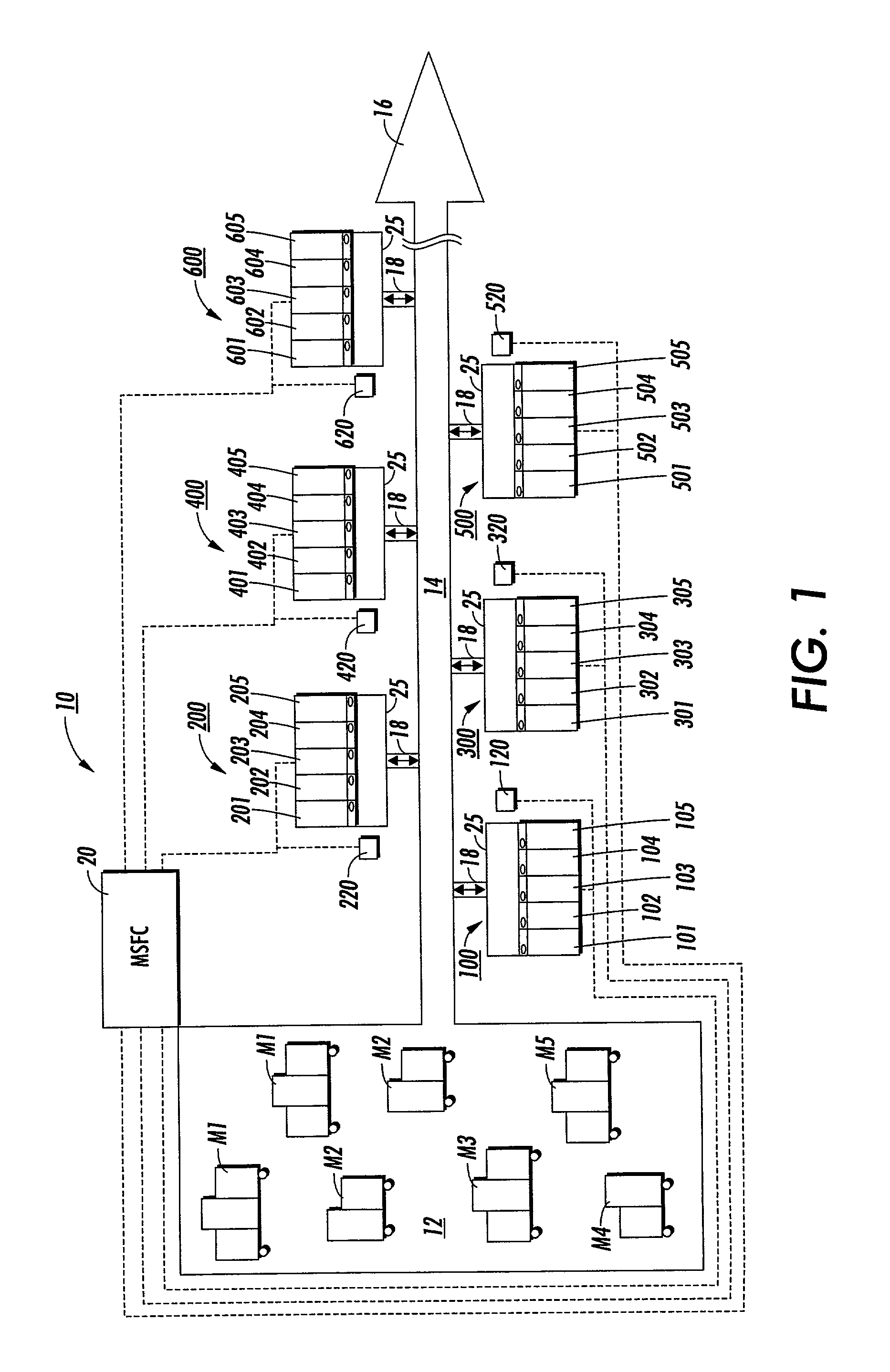

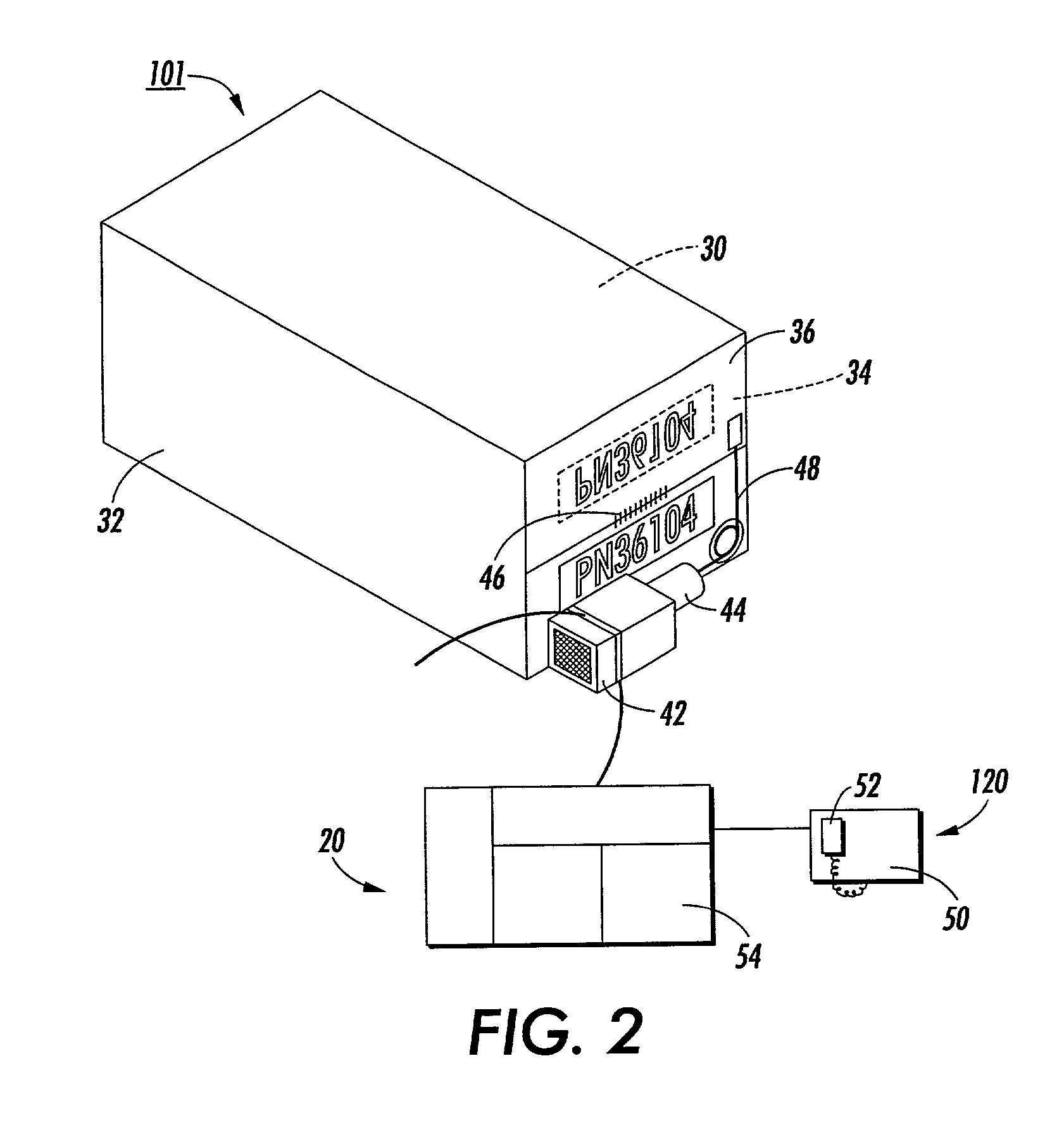

Machine models assembly including bin access control

InactiveUS20020087226A1Fast and accurate assemblyEffectively preventing inadvertent operator assembly errorAssembly machinesTotal factory controlEngineeringWorkstation

A machine models assembly workstation is provided for selectively assembling a variety of different machine parts to different machine models having different model identification numbers. The workstation includes a machine model assembly area for holding each different machine model during parts assembly; a machine travel path to, and from, the machine model assembly area; and a plurality of bins located at the machine model assembly area for holding the different machine parts to be selectively assembled to the different models. Each bin of the plurality of bins has walls defining a parts holding chamber, and an access opening into the chamber. A shutter is attached to the walls over the access opening, and has an unlocked open position and a closed locked position. The machine models assembly workstation also includes a bin access control device, responsive to an input machine model identification number, for selectively closing and locking a first set of the plurality of bins, and for automatically selecting, unlocking and opening a second set of the plurality of bins, such that the second set of the plurality of bins holds only approved machine parts for assembly into a machine having the input machine model identification number, thereby enabling fast and accurate assembly while effectively preventing inadvertent operator assembly errors.

Owner:XEROX CORP

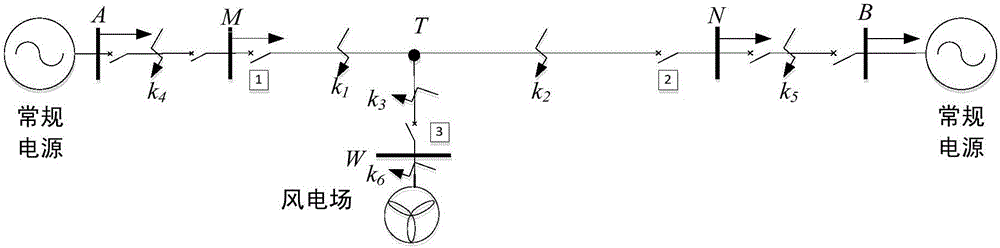

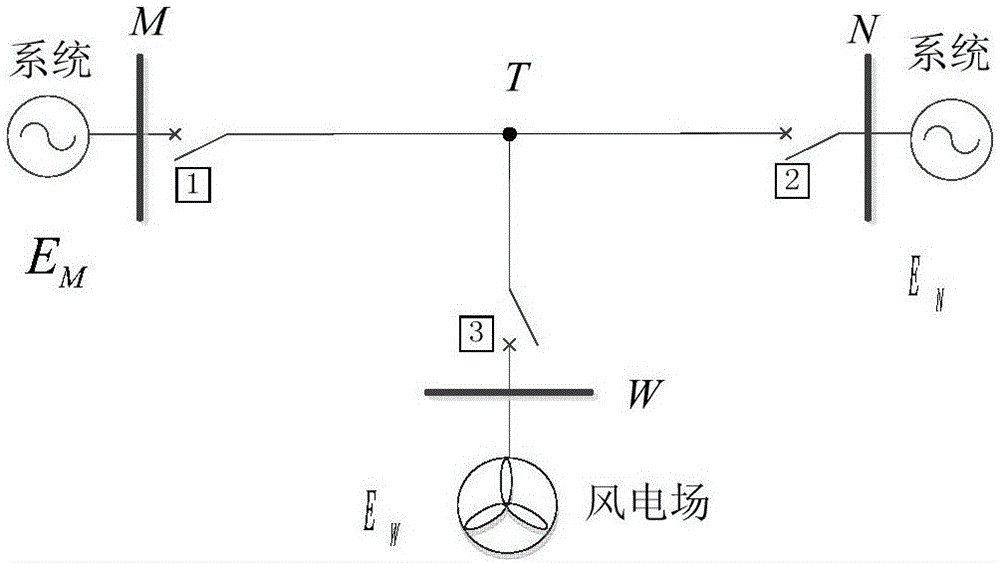

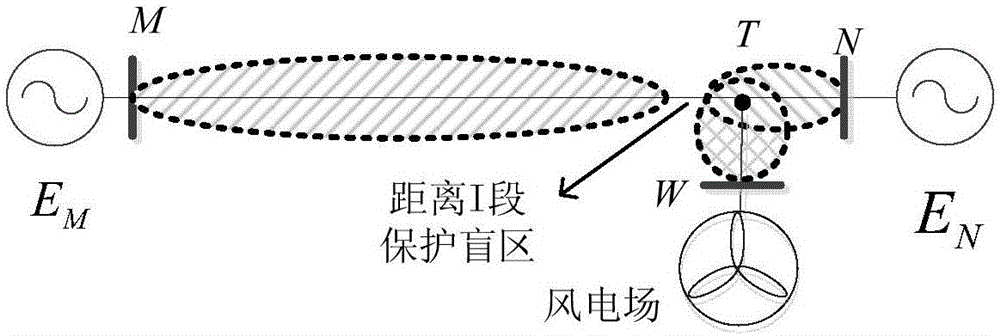

Wind power T-type connection line ground fault setting method

InactiveCN106405335AReduce configuration costsAvoid erectionFault location by conductor typesElectricityGround failure

The present invention relates to a wind power T-type connection line ground fault setting method. The method comprises the following steps: 1) extracting the zero-sequence voltage and the zero-sequence current at the wind power T-type connection line protection installation position, and solving the simulation impedance and the signaling threshold value of a sender according to system parameters; 2) calculating the power direction of each side, and determining the fault direction; and 3) if the faults are the positive direction faults, determining whether blocking signals are received or not, and if the blocking signals are received, determining that faults are the external faults of the T-type connection line, and protecting the closed lock; and if the closed locking signals are not received, determining that the faults are the internal faults of the T-type connection line, and immediately performing the tripping operation. The wind power T-type connection line ground fault setting method can effectively avoid the influence of the T-type connection line topology and the wind power fault features on the T-type connection line protection configuration and considers the economy so as to ensure the selectivity, the sensitivity and the reliability of the T-type connection line protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

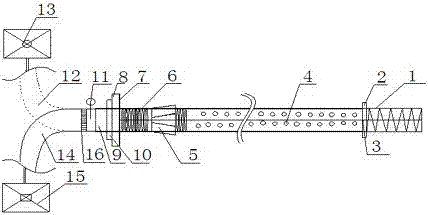

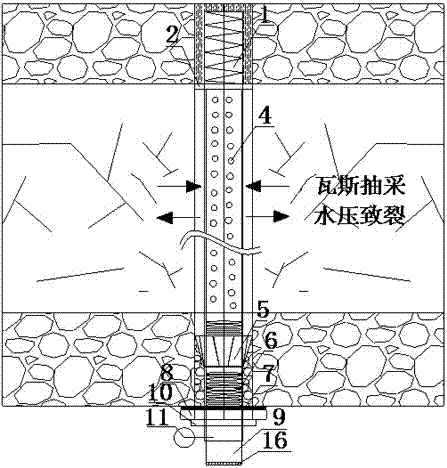

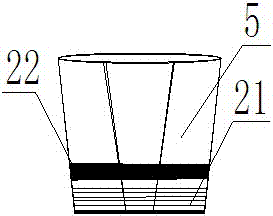

Anchor rod system used for gas extraction and hydraulic fracturing and extraction method

PendingCN107355253AEfficient extractionReduced Drainage BoreholesSurveyMining devicesHydraulic fracturingEngineering

The invention discloses an anchor rod system used for gas extraction and hydraulic fracturing and an extraction method. The anchor rod system comprises a hollow anchor rod, a retaining ring, a closed locking device, a gas extraction pressure pipe, a hydraulic fracturing system, a gas extraction system and the like. The hollow anchor rod comprises an anchoring section and a tensioning section. The anchoring section is a solid body, the retaining ring is arranged outside the anchor section, the diameter of the retaining ring is smaller than that of a drilled hole of the anchor rod, and the retaining ring serves as a connector of the anchoring section solid body and the hollow gas extraction part of the tensioning section. The tensioning section is connected with the closed locking device through an outer thread. The gas extraction pressure pipe is connected in the hollow anchor rod, the diameter of the gas extraction pressure pipe is slightly smaller than that of the hollow anchor rod, and threads are arranged on the upper end and the lower end of the gas extraction pressure pipe to be connected with the hollow anchor rod in a threaded mode. A gas content monitoring instrument is arranged on the lower section of the gas extraction pressure pipe. The gas extraction pressure pipe is connected with a gas extraction pipe of the gas extraction system through a system connecting thread. Gas can be efficiently extracted in an extraction roadway, the hole sealing rate is high, gas extraction intelligence is achieved, and the dangers such as local concentrated gas burst can be effectively pre-warned and predicted.

Owner:HUNAN UNIV OF SCI & TECH

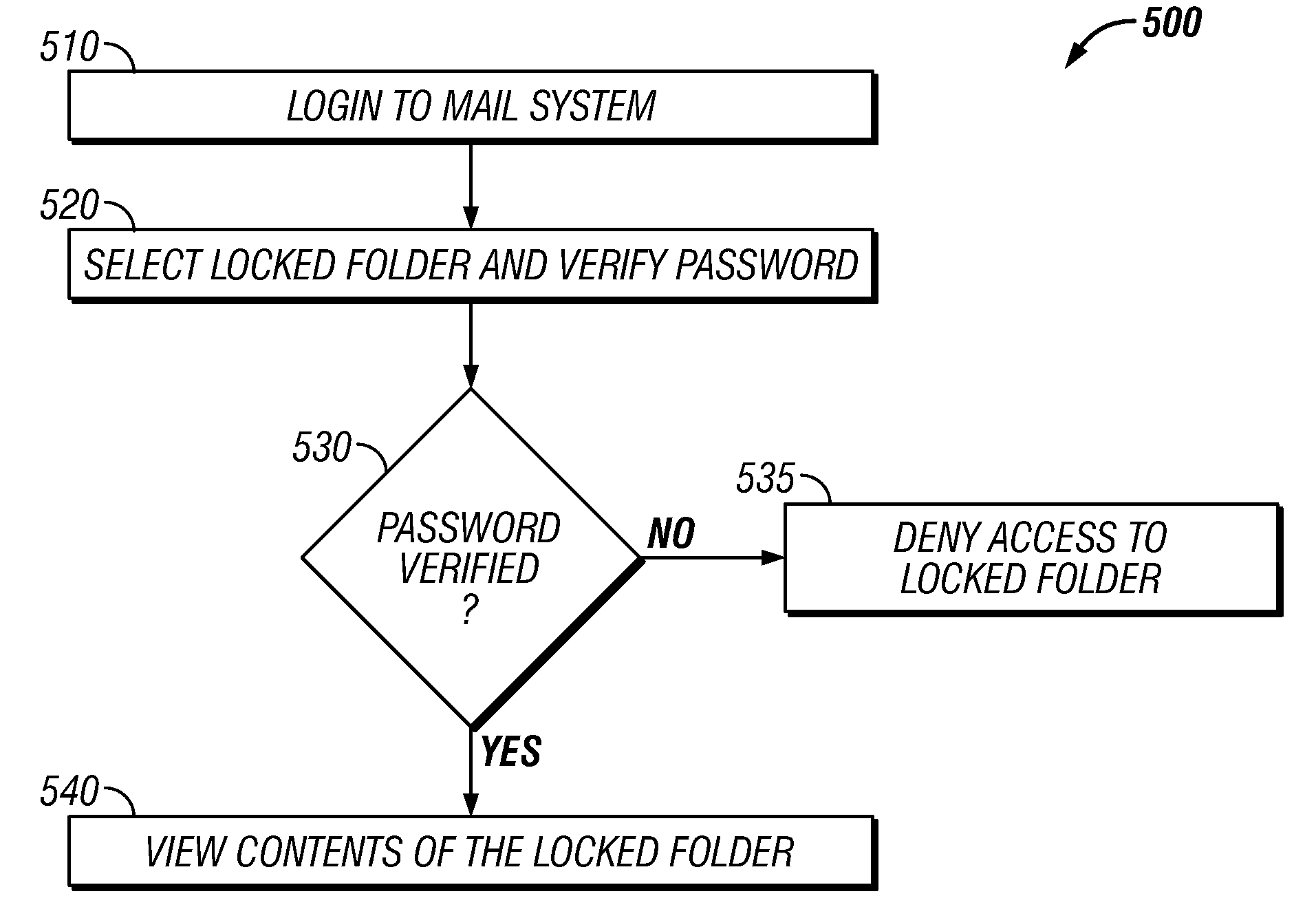

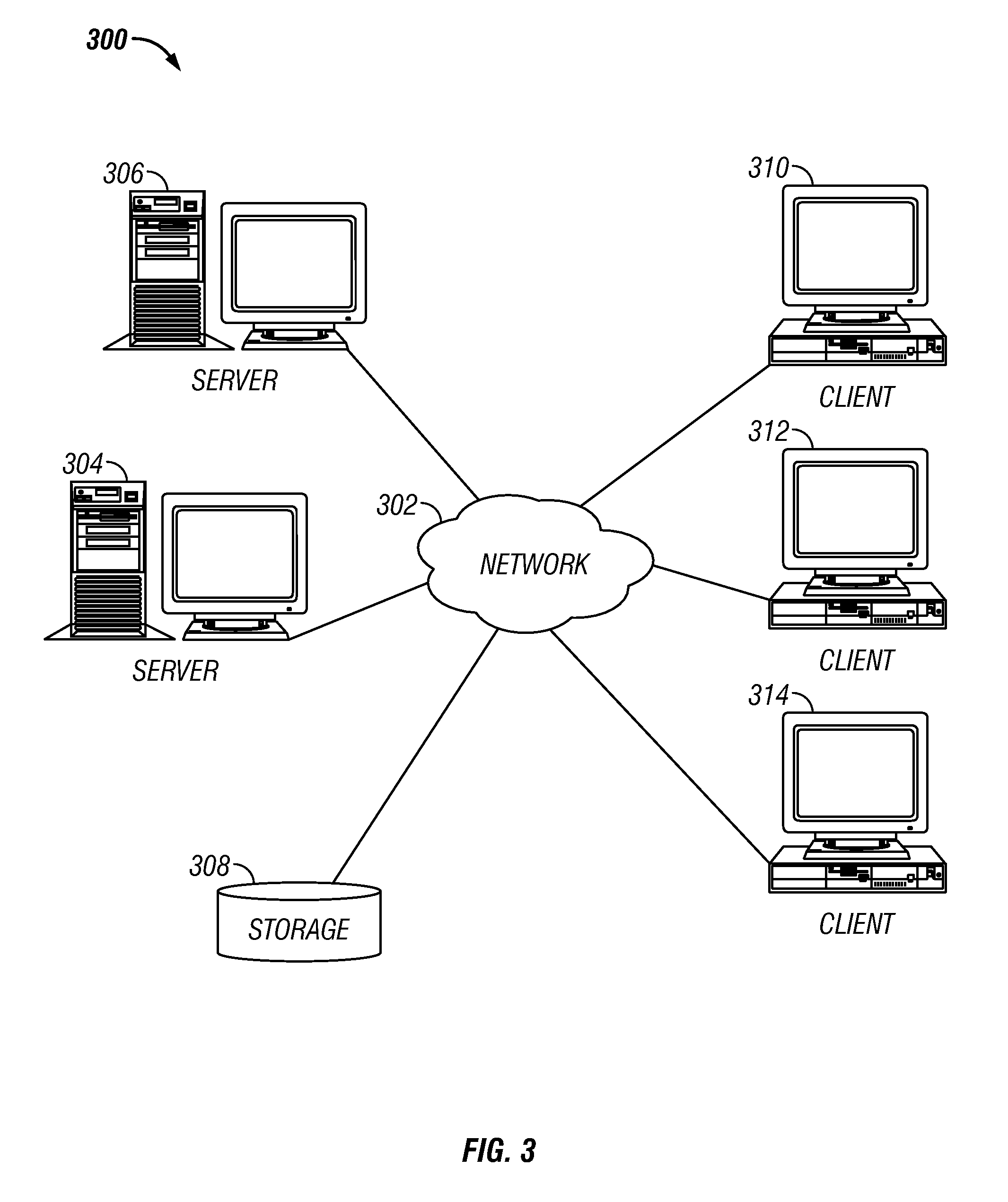

Method and system for securing electronic mail

InactiveUS20090282248A1Robust solutionUser identity/authority verificationComputer security arrangementsPasswordComputer science

A system and method for securing electronic mail by providing secure access to e-mail folders. A number of folders can be created in order to classify electronic mail content. Folders can be encrypted and locked utilizing a password. A “closed lock” symbol can be displayed by the side of a folder when the folder is locked and an “open lock” symbol can be displayed when the folder is opened, thereby providing a visual indication of the status of the folder. The folders can also be automatically locked after a period of time, which can be defined by a user or the e-mail system. The electronic mail content in the locked folders cannot be displayed when a user elects to display the contents of all folders, thereby providing an additional level of security. Similarly, restricted access can also be provided to a user or a group of users to access the locked folder(s).

Owner:IBM CORP

Security collar for media discs

InactiveUS20060152371A1Easy to placeEasy to removeLocks for portable objectsRecord information storageLocking mechanismEngineering

A security collar for placement around the base of a display package to prevent removal of a cover from the base to protect merchandise contained therein. An EAS security tag is contained in the collar. A magnetically actuated lock mechanism is formed on the collar to lock the collar in a closed locked position on the display package. The collar includes a pair of semi-circular housing members pivotally joined at one end and swingable between open and closed positions. The collar is formed with spaced projections which trap the base and portions of the cover therebetween to secure the collar about the base and cover. Each of the housing members each locking teeth which mutually engage each other to secure the housing members in locked position.

Owner:CHECKPOINT SYST INC

Improved power repair feet crawler

The invention relates to an improved power repair feet crawler. The improved power repair feet crawler comprises a main crawling machine; the side surface of the main crawling machine, facing an electric pole, is an arc-shaped crawling surface; universal rotating wheels are arranged at equal intervals on the crawling surface and electrically connected to a controller; a cable chute is formed in the crawling surface; a crawling cable is mounted in the cable chute, and threads are formed in the surface of the crawling cable; closed lock buckles are mounted at two ends of the crawling cable; the crawling cable is manufactured from non-stretching and bendable wearable materials; the crawling cable engages with a driving wheel; the driving wheel rotatably sleeves an adjusting shaft parallel to the electric pole; the adjusting shaft can horizontally move in an adjusting groove at the back of the main crawling machine in the radial direction of the electric pole. The feet crawler has a small size, and is convenient to carry, applicable to the electric poles of various sizes, safe and reliable, and simple to operate.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO +1

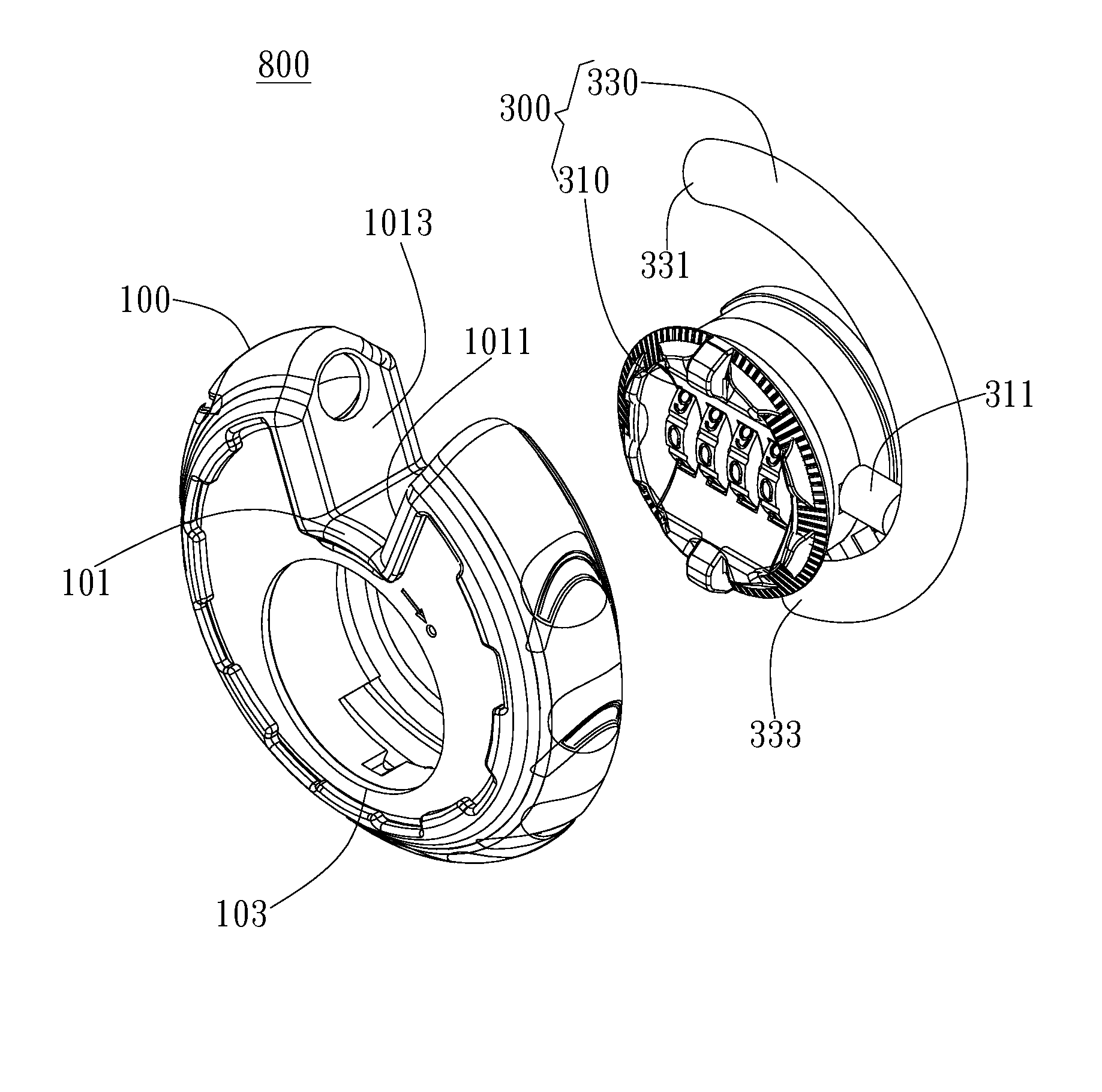

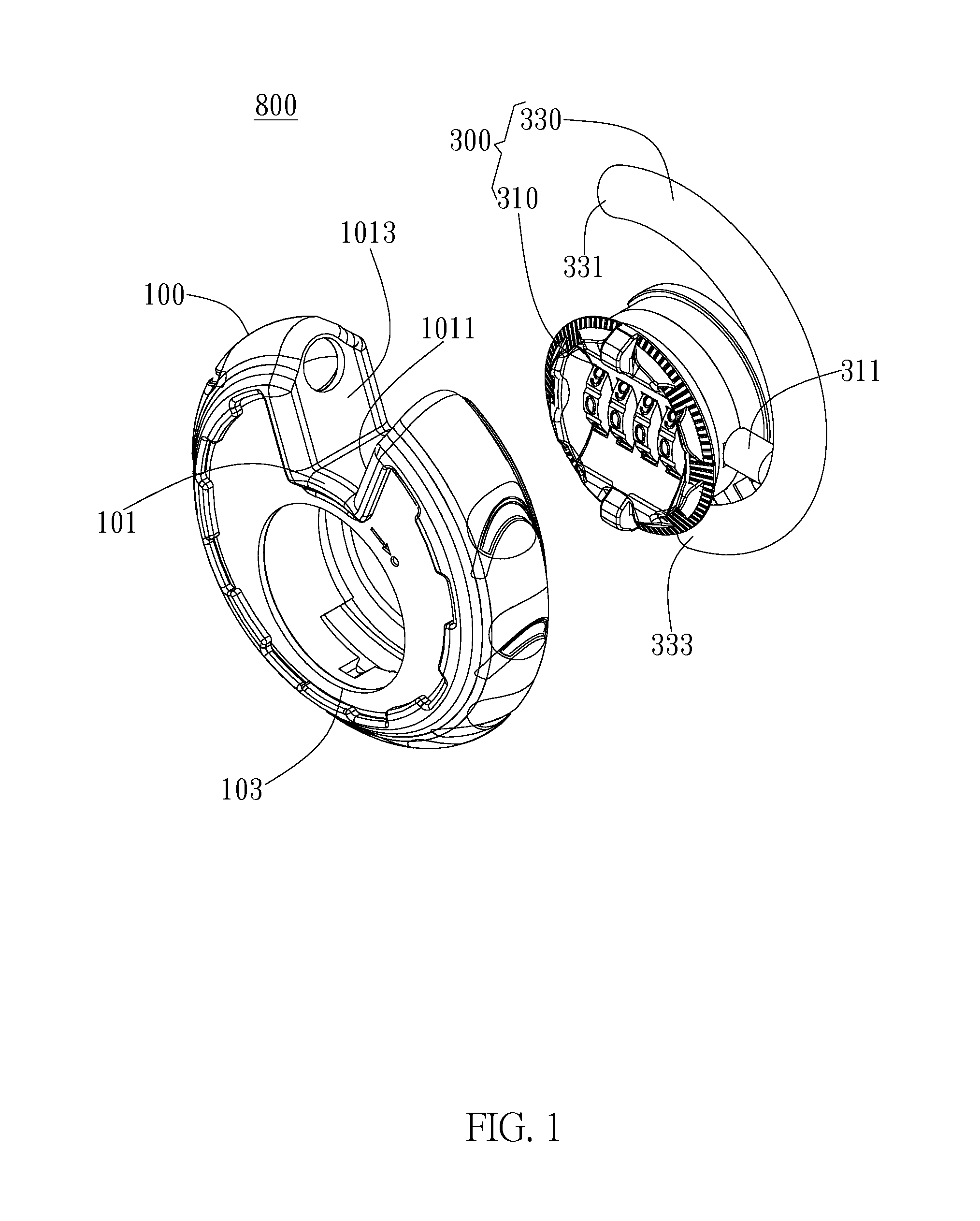

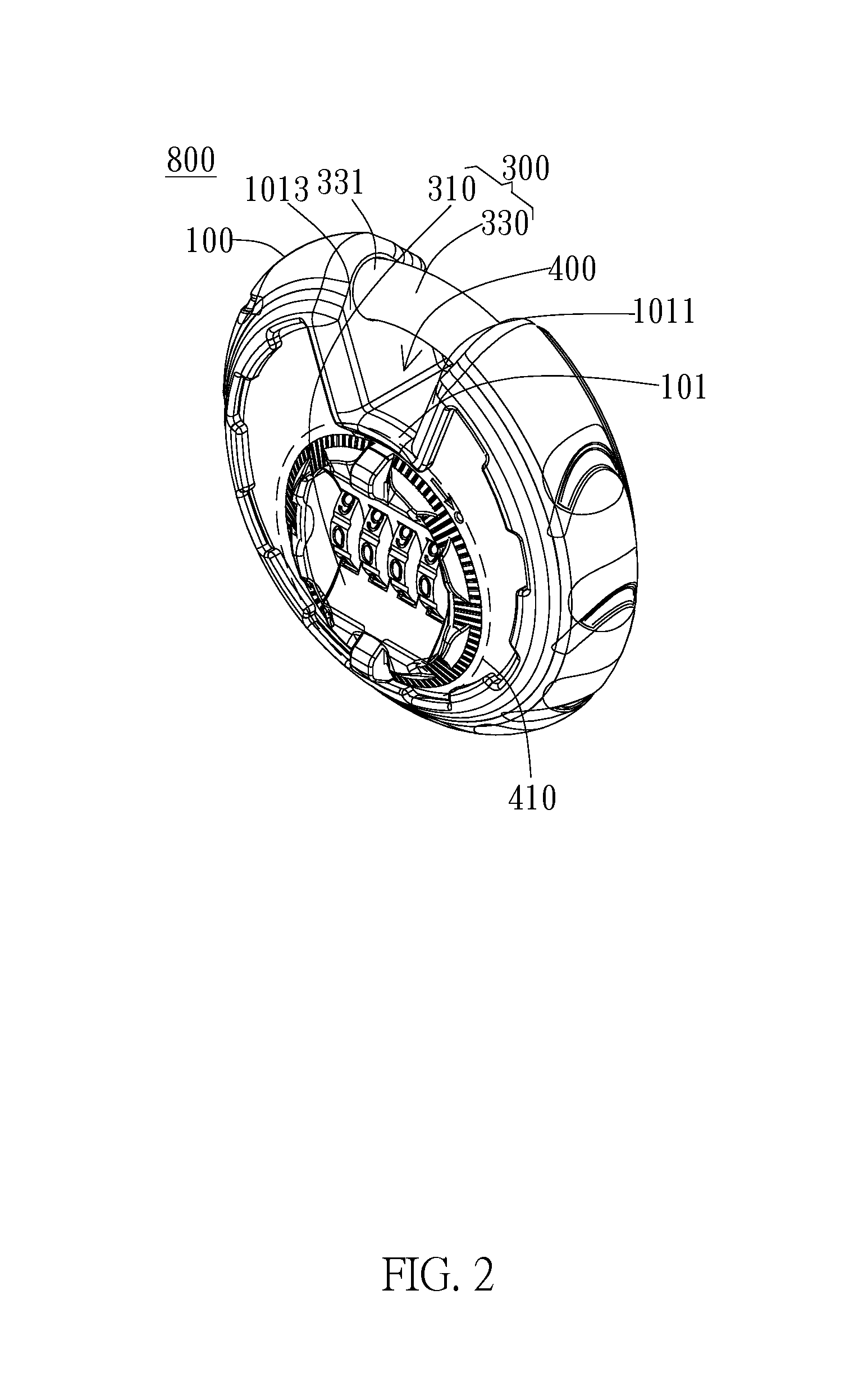

Turntable lock

Owner:SINOX LOCKKUNSHANCO LTD

Folding type disguising door of protective section of subway entrance and subway exit

ActiveCN103089122AQuick closeMeet the decorative performance requirementsWar-like protectionEngineeringMechanical engineering

A folding type disguising door of a protective section of a subway entrance and a subway exit comprises door leaves. The door leaves are arranged on doorways of protective door concealing chambers at the left side and the right side of a personnel gallery. The door leaves are composed of a free door leaf, at least one middle door leaf and a side door leaf. A mortise lock is arranged at one side of each free door leaf. A door frame is arranged on a side wall, near each free door leaf, of the protective door concealing chamber and a spring bolt hole matched with the mortise lock is formed in the door frame. The other side of each free door leaf is provided with a closed lock matched with the middle door leaf in use. A guide rail is arranged on a ceiling above each door leaf and a guide rail groove is formed in the ground below each door leaf. The disguising door has functions of decoration and disguising so that a function of a disguising protective door is achieved and rapid closing of the protective door is not influenced.

Owner:4TH DESIGN & RES INST OF ENGINEER CENT STAFF PLA

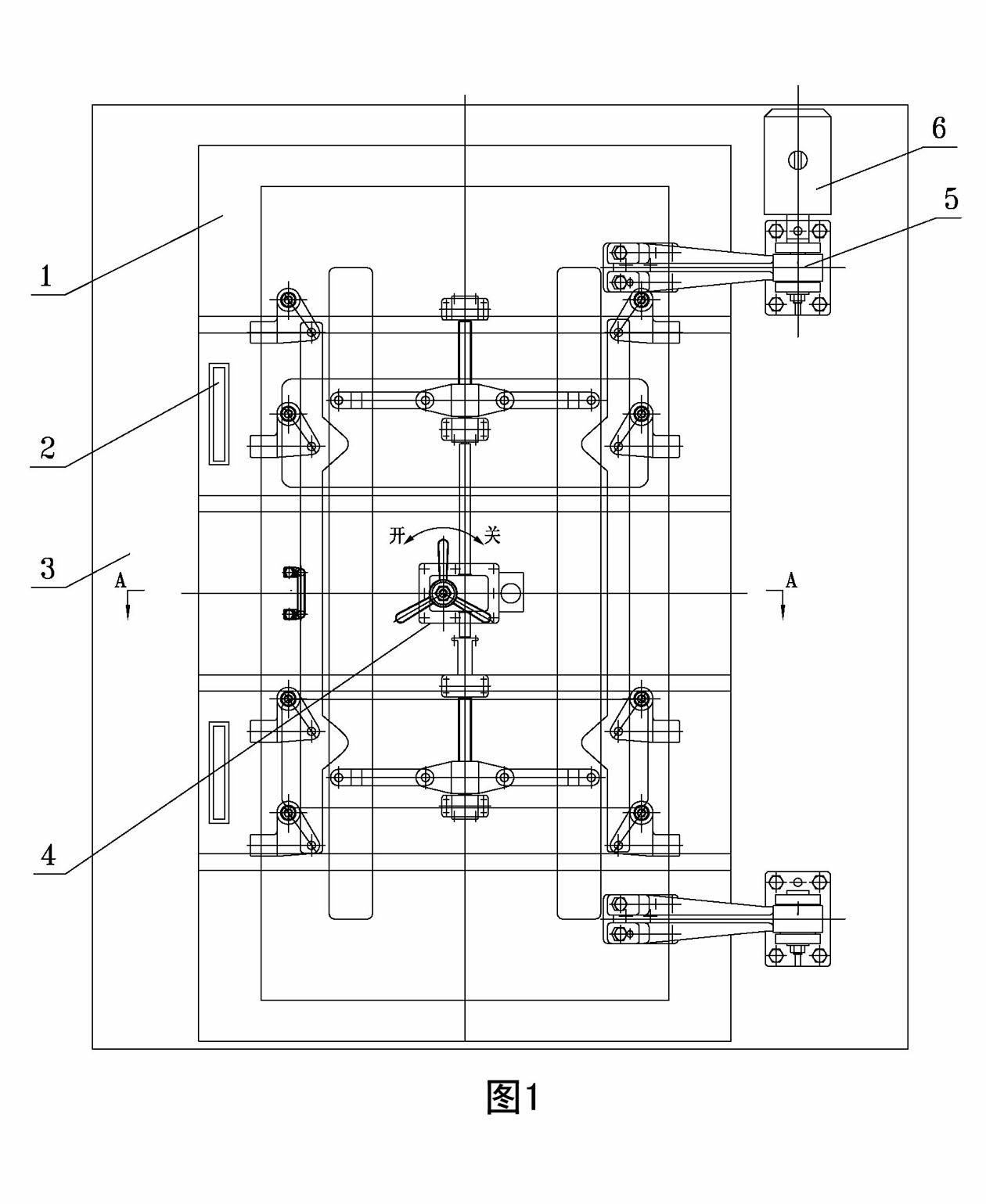

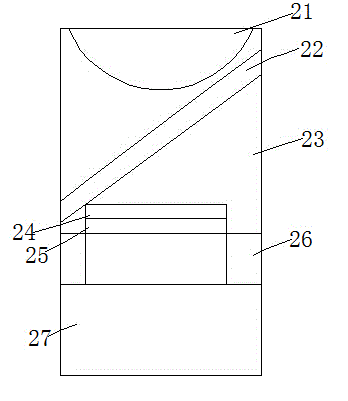

Light high-strength automatically controlled protective door

ActiveCN102206984ASmall footprintEasy to operateNon-mechanical controlsHandle fastenersClosed lockEngineering

The invention discloses a light high-strength automatically controlled protective door, comprising a door leaf, a door frame, a closed lock, a hinged leaf and a door leaf driving device. The door leaf comprises a door leaf arch plate, a rib plate, a reinforced grate, an inner arch plate, an arch corner and a pulling plate, wherein the door leaf arch plate and the pulling plate are made of light composite materials; the rib plate, the reinforced grate, the inner arch plate and the arch corner are made of steel or aluminium alloy; the inner arch plate is tightly appressed to the back of the door leaf arch plate; the rib plate and the reinforced grate are fixedly connected with the back of the inner arch plate; the arch corner is fixedly connected with left and right side edges of the door leaf arch plate and the inner arch plate; the pulling plate is fixedly connected with the backs of the rib plate and the reinforced grate; and left and right sides of the pulling plate are wrapped on the outer side surface of the arch corner. By means of the protective door, the technical problems that the traditional electric control protective door has a heavy door body, is difficult to convey, install and debug and has a complex driving mechanism and low reliability can be solved. The protective door has the advantages of high resistance, light and convenient door leaf, small occupation space of a driving system, convenience for installing and debugging, simple and rational integral structure, and convenience for operation and maintenance.

Owner:4TH DESIGN & RES INST OF ENGINEER CENT STAFF PLA

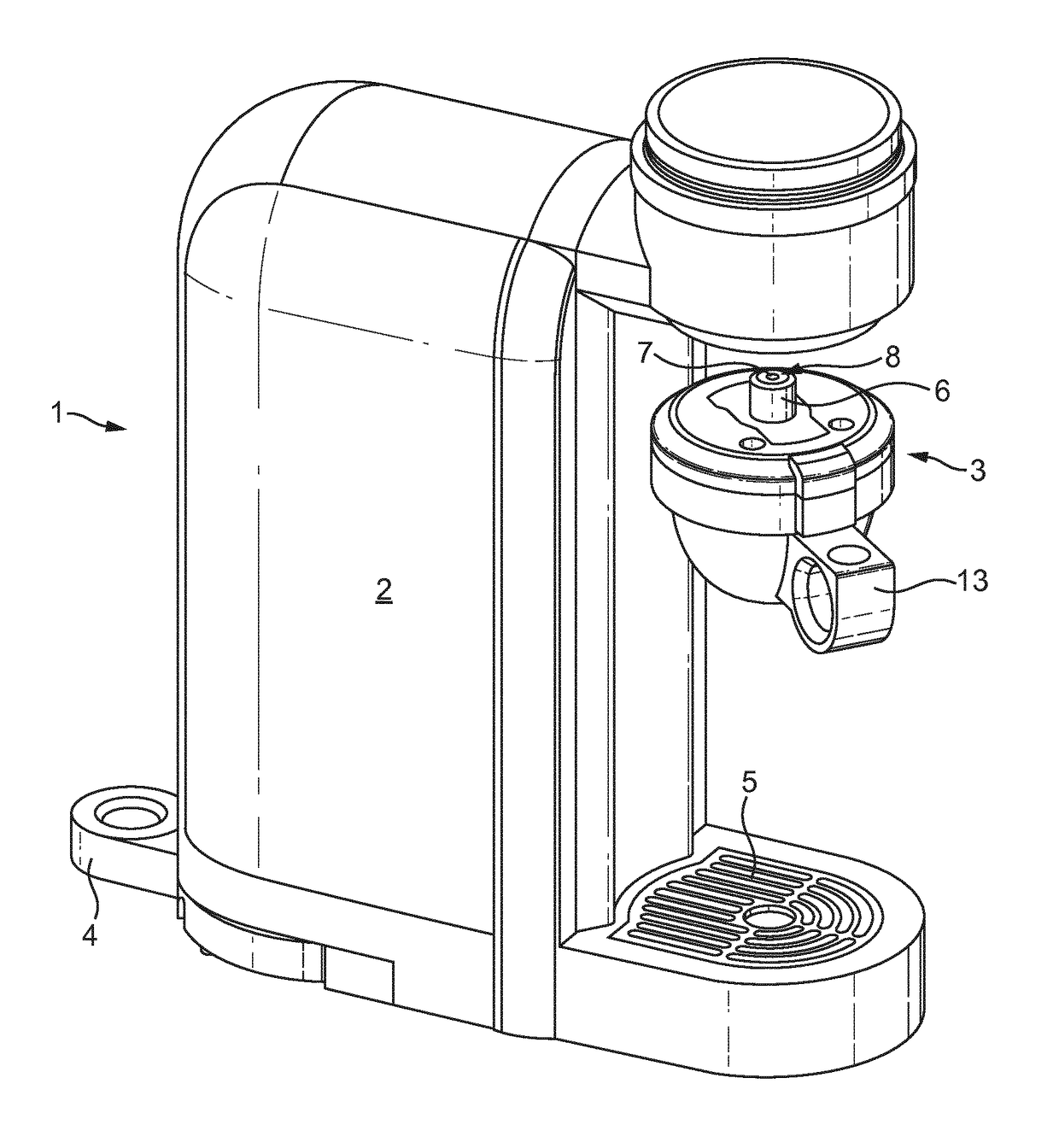

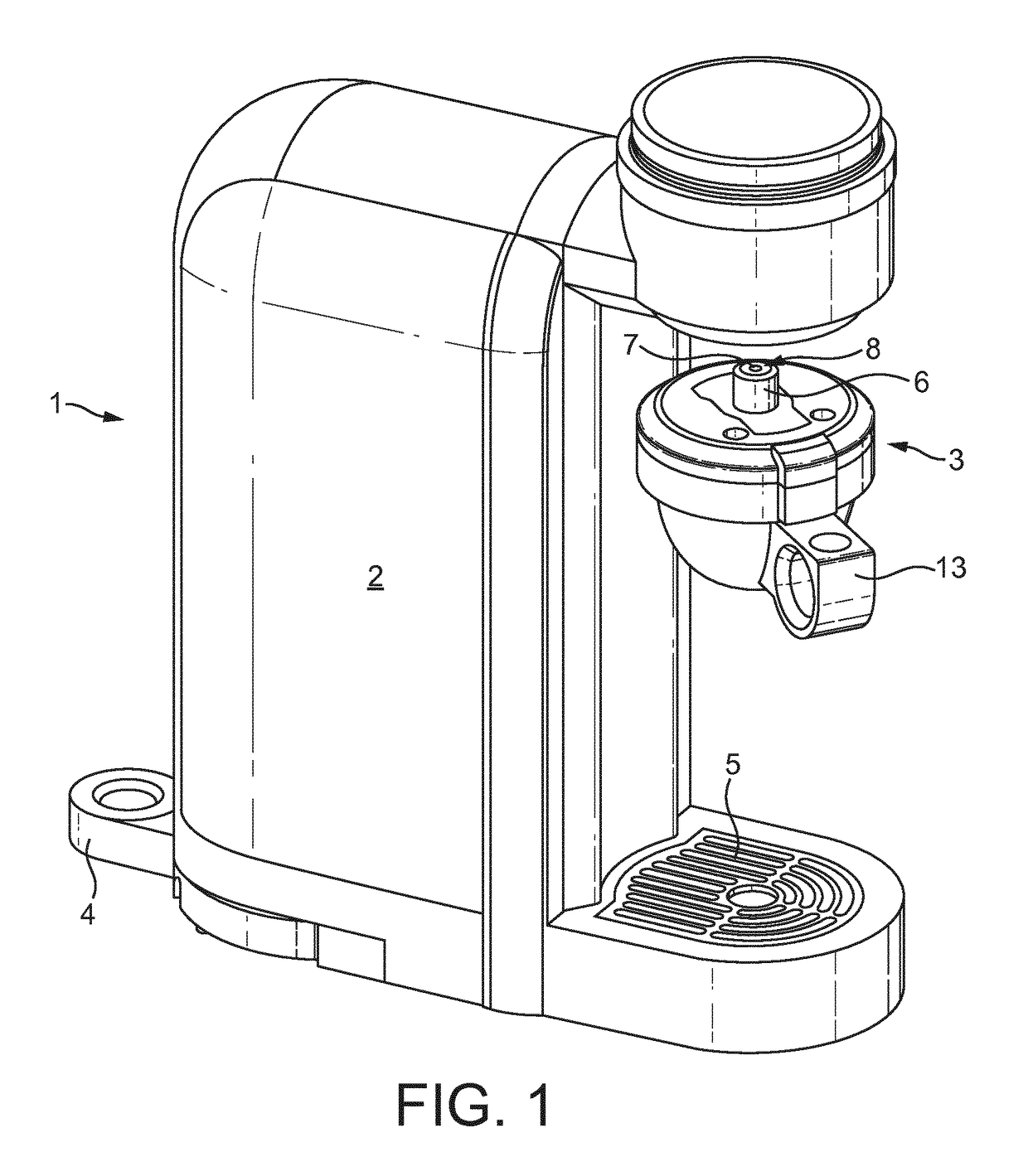

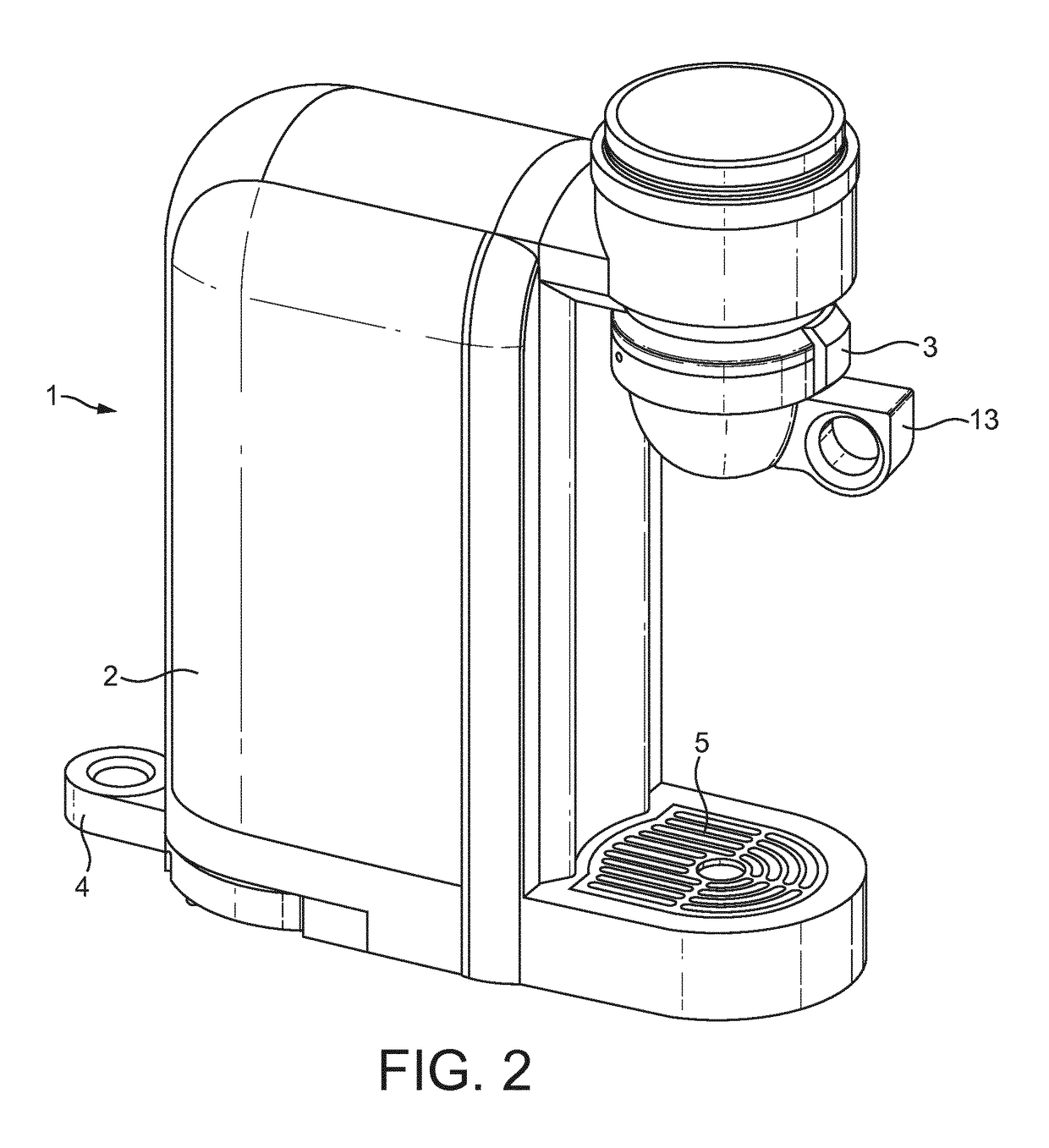

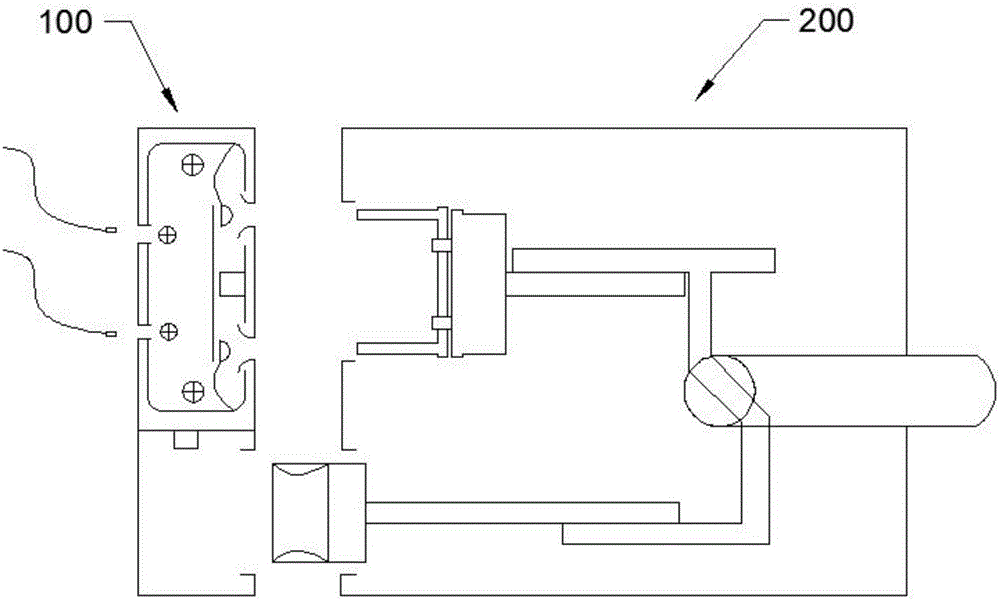

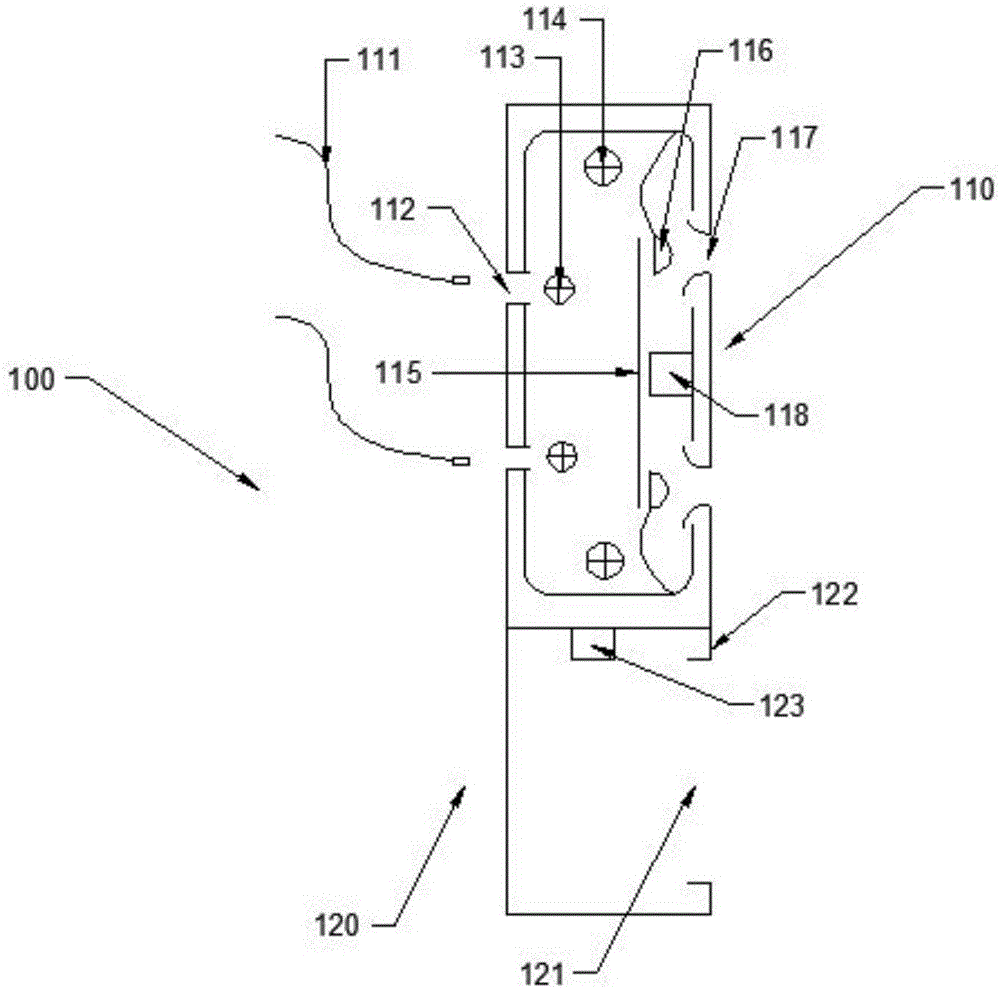

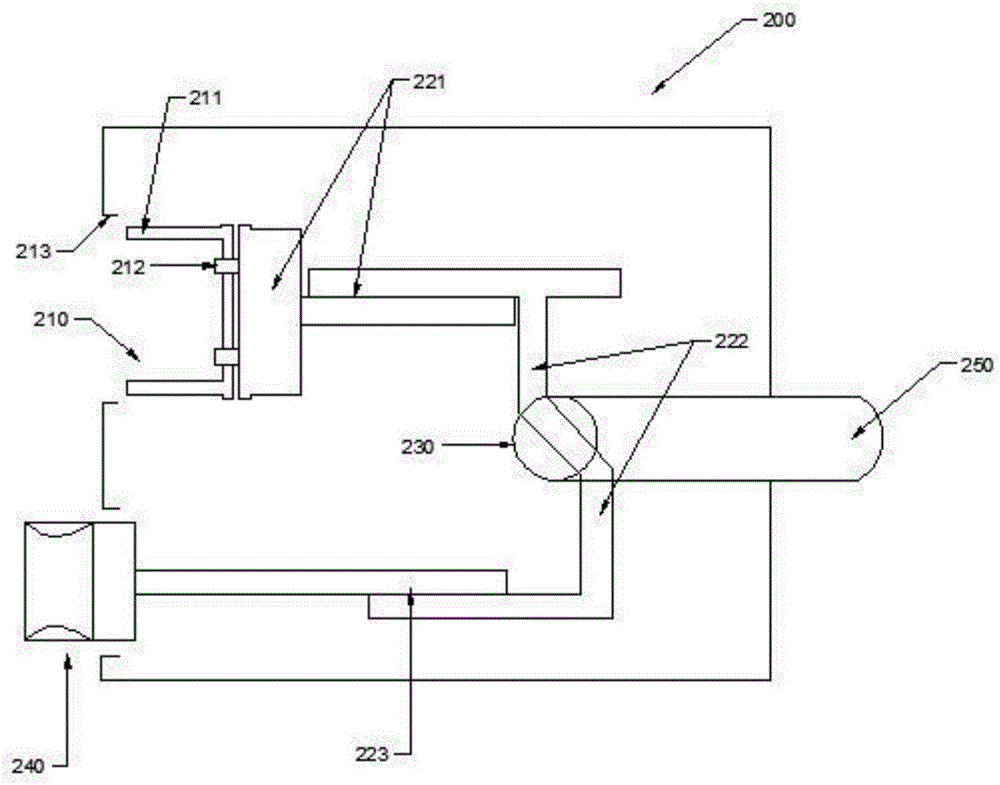

A brewing unit for a food preparation machine

ActiveUS20170127872A1Safely and reliably washSafely and reliably and cleanBeverage vesselsAdditive ingredientEngineering

The invention concerns a brewing unit (3) having a cavity for enclosing a food ingredient contained in a package (C), comprising first (14) and second (15) cavity parts, and fluid injection means (13), characterized in that said first and second cavity parts (14, 15) are hinged in a pivotal arrangement between open and closed positions and in that, when said cavity parts are pivoted in a closed position, the fluid injection means (13) and / or the first cavity part (14) are movable in translation relative to the second cavity part (15), between:—a closed unlocked position that allows relative pivotal movement between cavity parts, and—a closed locked position wherein said cavity parts are translated in contact with each other to close said brewing cavity, and wherein said injection means (13) protrude inside the brewing cavity to pierce a wall of the portion package.

Owner:SOC DES PROD NESTLE SA

Safely opened and closed lock

ActiveCN106285222AEnsure safetyAvoid stickingNon-mechanical controlsLock casingsClosed lockElectrical and Electronics engineering

The invention discloses a safely opened and closed lock which comprises a buckle box and a lock body, wherein the buckle box is positioned on the left side of the lock body. Under the condition that a safety door is closed, after the safety door is closed to an appropriate position, a lock tongue is inserted into a lock tongue hole, meanwhile a bolt is popped out under the action of a connecting rod, and is then inserted into a touch inserting hole, and a touch point can be pressed to an insulating base; under the condition that the safety door is opened, a handle is rotated downwards on the inner side of the safety door, the touch connecting rod and the lock tongue are driven by a middle connecting rod to move rightwards, and the bolt and the lock tongue are driven by the connecting rod to move rightwards, so that the opening state of the lock can be achieved, a well shaft safety door can be relatively rapidly and conveniently opened, the safety door can be closed under the conditions that the touch contacts the touch point, a first sensor works and a second sensor works, and the system security can be ensured; by adopting the safely opened and closed lock, the touch can be prevented from being adhered to the touch point, the situation that an elevator is powered on when the safety is closed but is not tightly locked can be avoided, and thus death and injury accidents such as shearing and falling can be avoided.

Owner:何京川

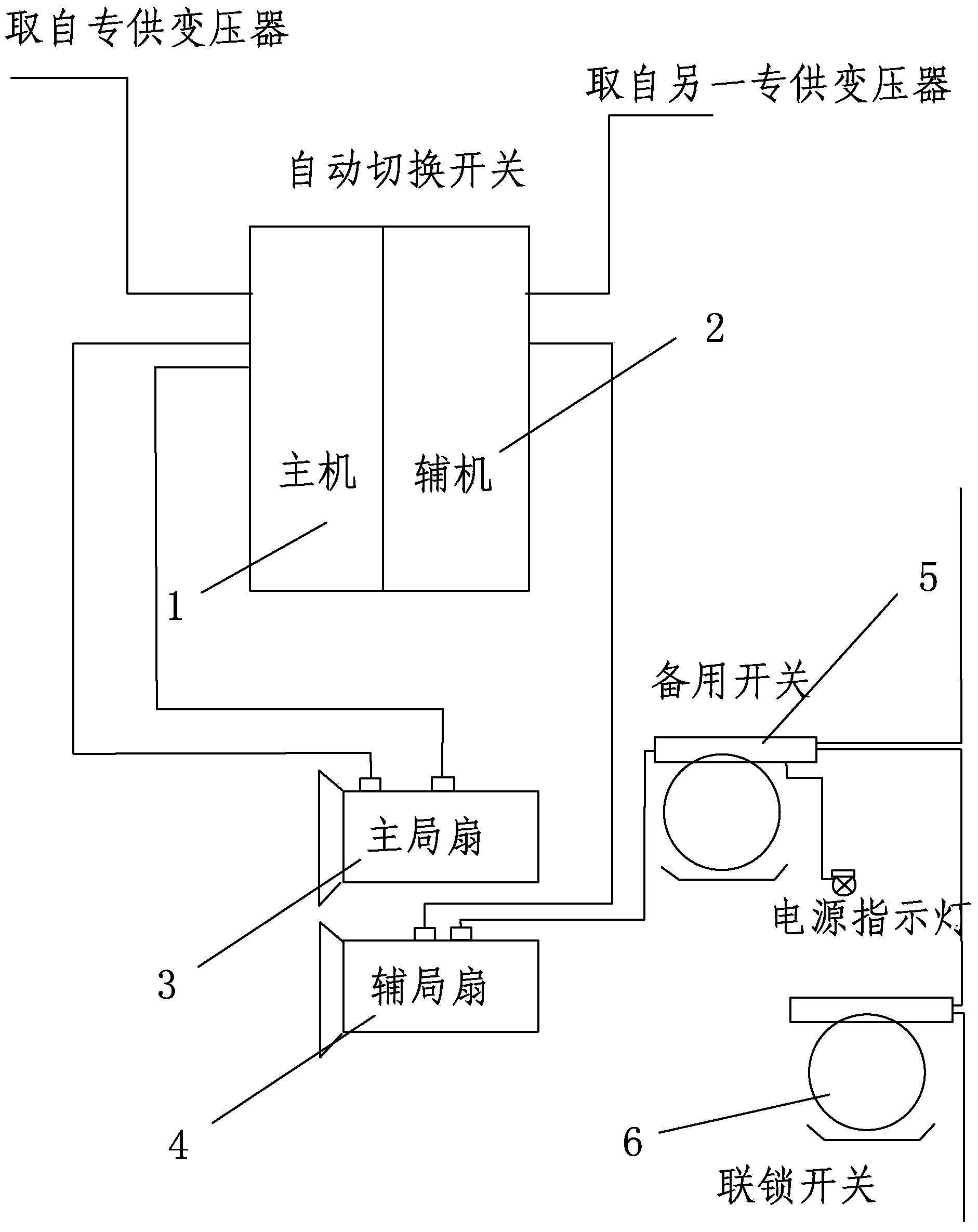

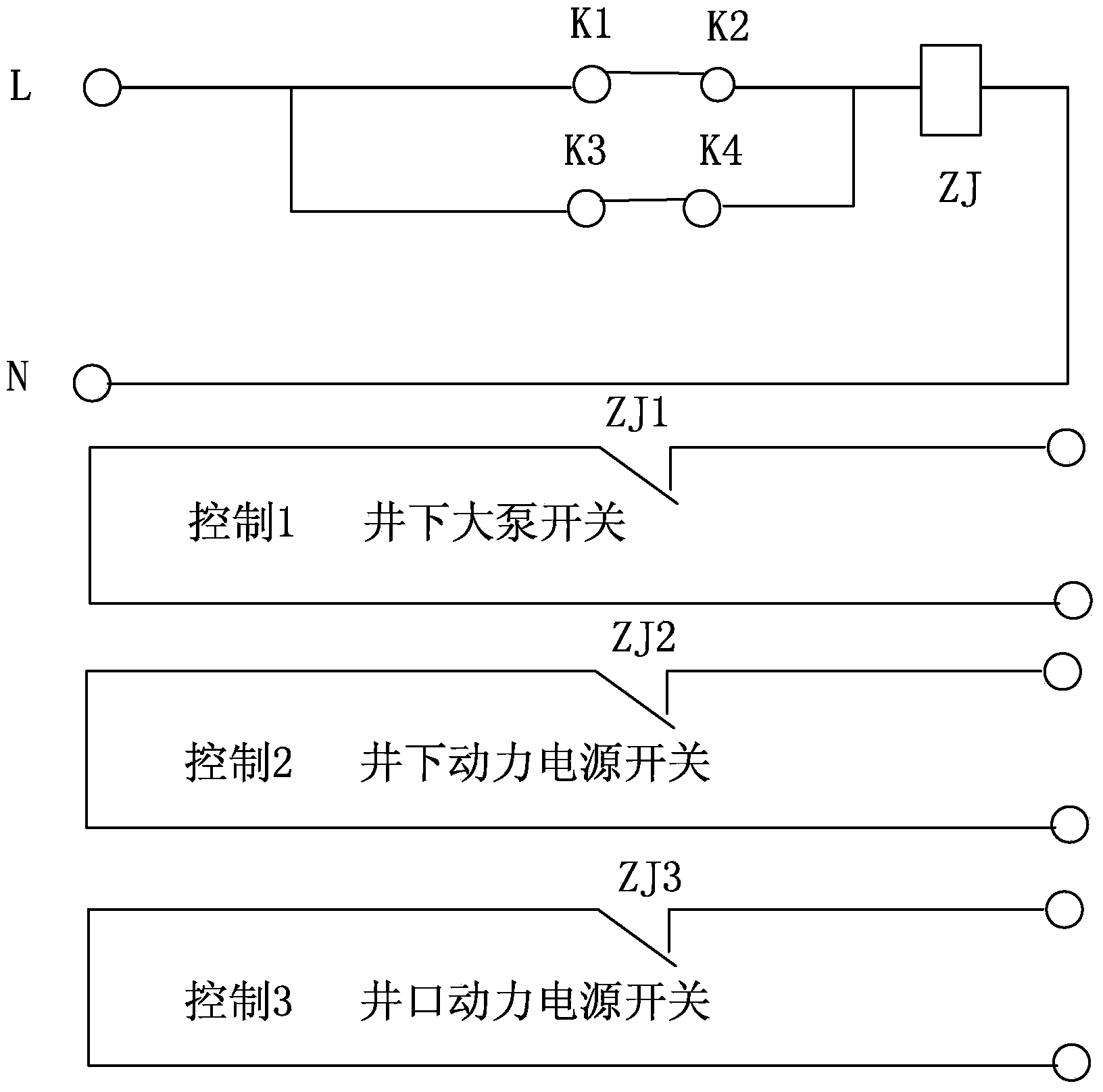

Underground local ventilator power supply system

ActiveCN103711520AGuaranteed air supplyGuaranteed to workMining devicesPower network operation systems integrationUnderground tunnelEngineering

The invention discloses an underground local ventilator power supply system. One power special supply circuit is additionally added for supplying power for fans and controlled by a spare fan switch on a basis of a power supply system with two fans, two power supplies, three special power supply lines and two closed locks so as to ensure the power special supply circuit supplies power normally when a fan special supply circuit has failure, so that unplanned wind stopping is avoided. Through the underground local ventilator power supply system, safety of power supply for a local ventilator on a coal mine underground tunneling working surface is improved; the situation of unplanned wind stopping on a tunneling head caused due to reasons of circuit failures, manual error operation and the like can be reduced and avoided; and potential safety hazard brought for production due to increase of gas of the tunneling head caused due to the unplanned wind stopping can be eliminated.

Owner:CHINA COAL XINJI ENERGY CO LTD

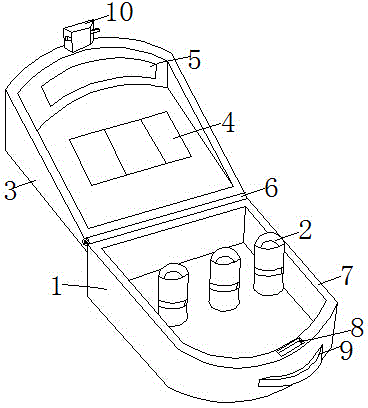

Portable biological chip detection device

InactiveCN104865262ASimple structureEasy to useMaterial analysis by optical meansLaser lightEngineering

The invention discloses a portable biological chip detection device which comprises a box body, detection units, and a box cover, wherein the detection units are arranged in the box body; the back surface of the box body is connected with the box cover through a back shaft; light-transmitting mirrors are arranged at the top of the box cover; a laser light source inlet is formed in the front surface of the box cover. The portable biological chip detection device adopts a box-type structure, so that the carrying is convenient; vibration springs are arranged on the left and right sides of a closed lock, so that the box body is simple and convenient to open and close, the situation that the box body is opened due to mistaken switch touching is avoided, and the safety of articles in the box body is guaranteed; the detection units adopt a laser counterpoint detection mode, so that the detection precision is improved, and the detection complexity is lowered; moreover, the light-transmitting mirrors are arranged at the top of the box body, so that synchronous observation can be conveniently performed. Therefore, the portable biological chip detection device is suitable for popularization and utilization.

Owner:黄浩

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com