Trigger switch with power failure restart protection function

A protection function and trigger technology, which is applied to the power device and electrical components inside the switch, can solve the problems of easy danger, non-conformity, and easy wear, and achieve the effect of low cost, compact structure, and easy maintenance and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

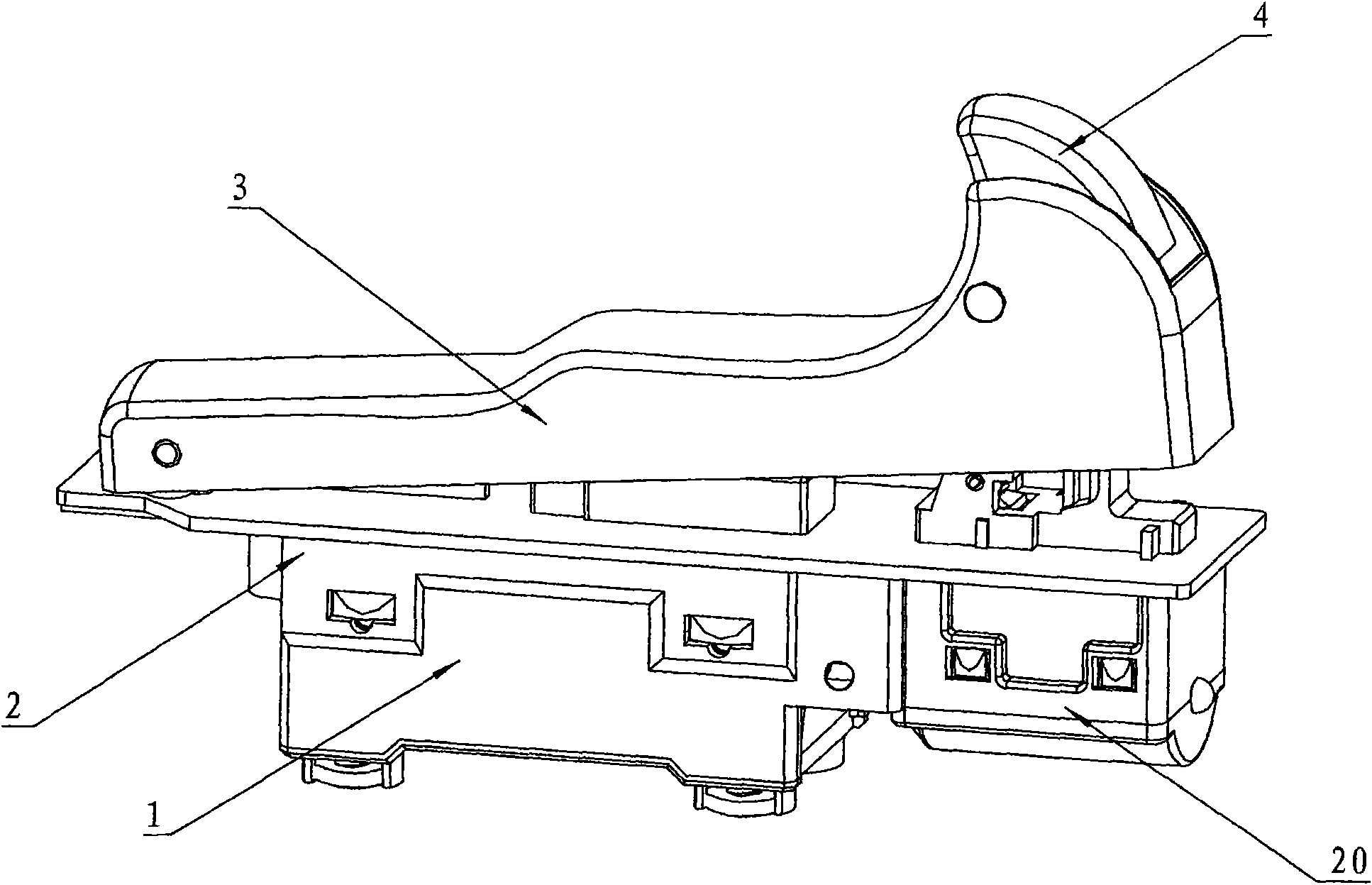

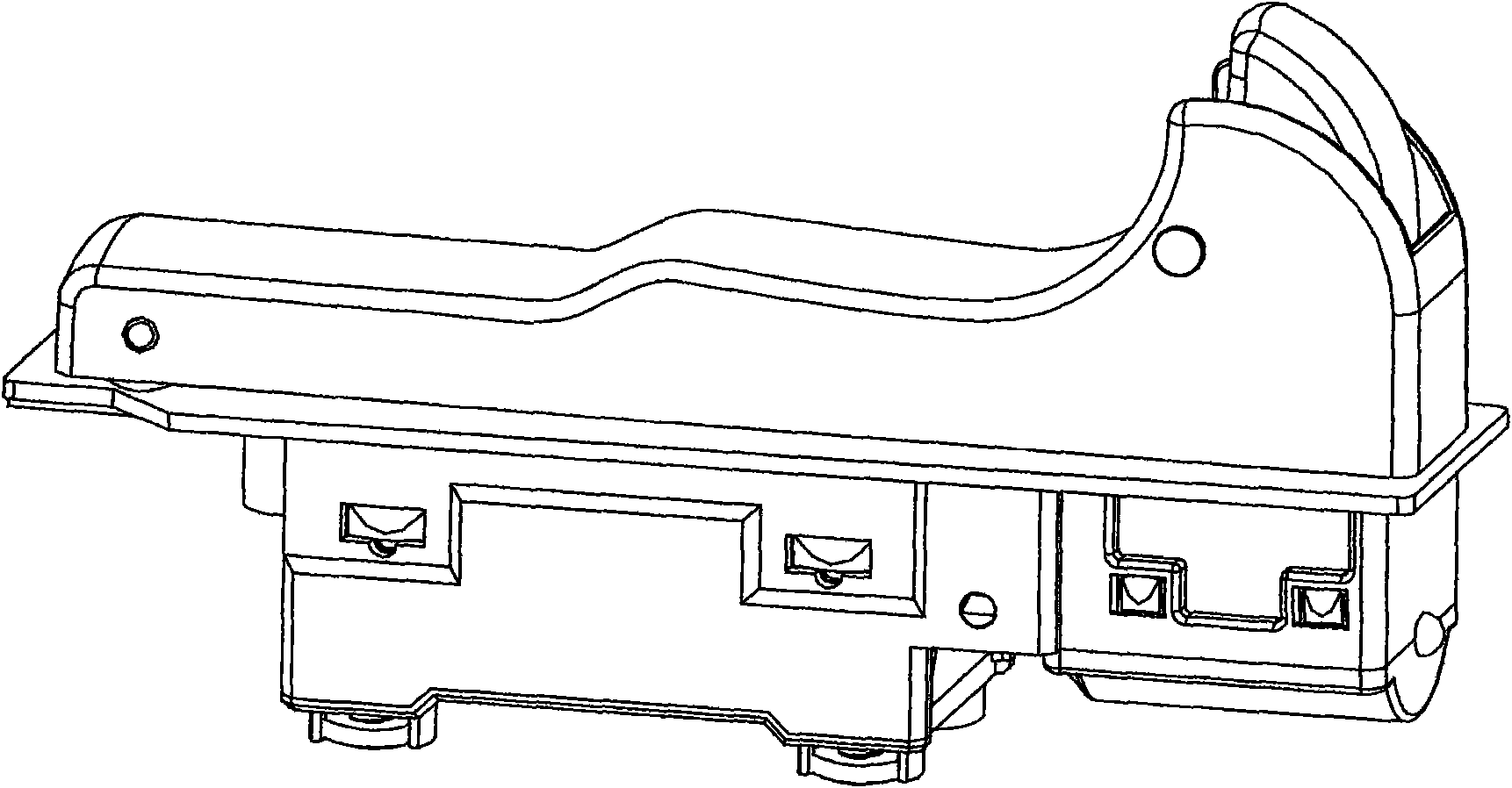

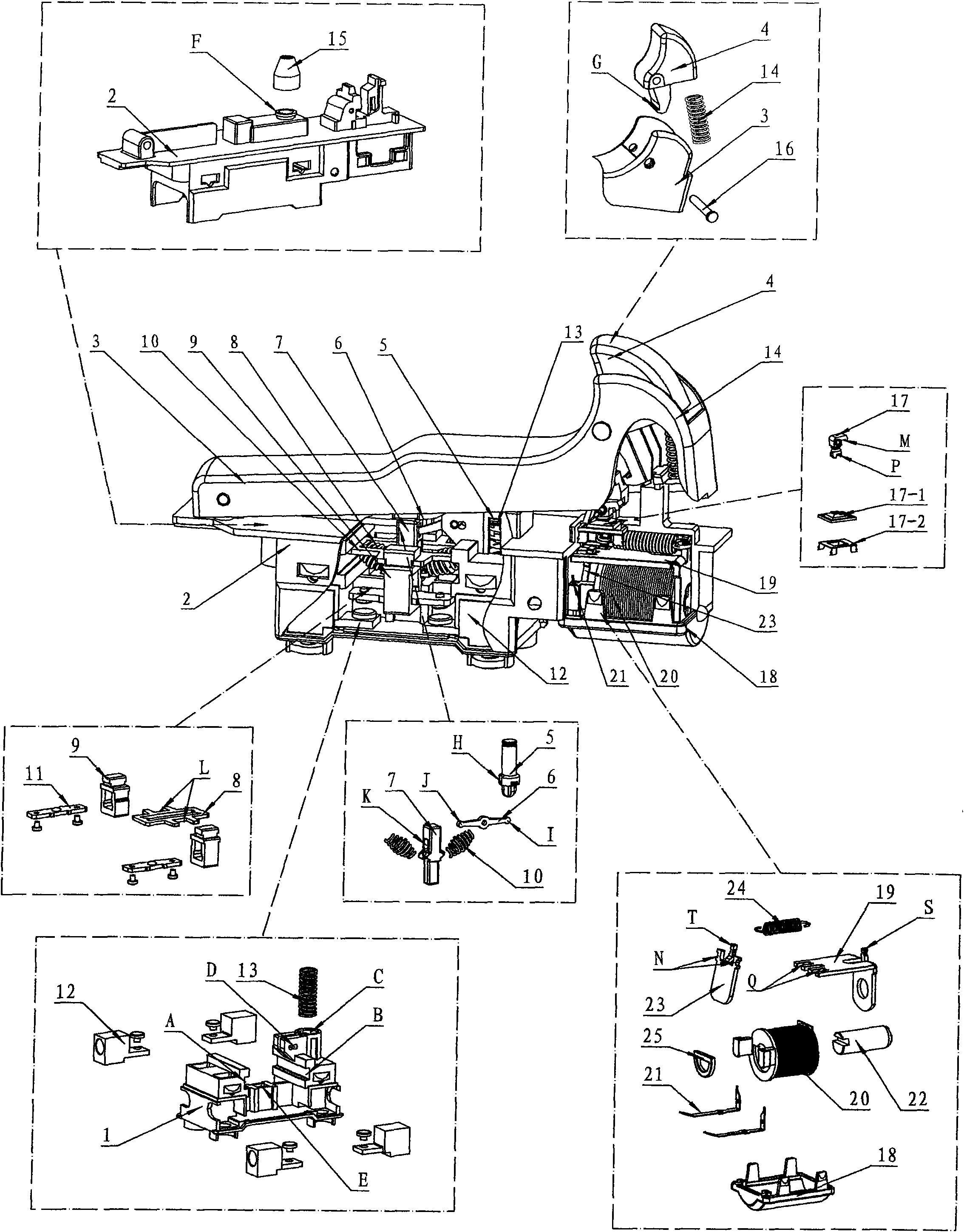

[0018] by Figure 1A , Figure 1B with figure 2 Shown, a trigger switch with power-off restart protection function is mainly composed of base body 1, housing 2, trigger 3, lock button 4, yoke 19, coil 20, iron core 22 and armature 23, among which: base The body 1, the housing 2, the trigger 3 and the lock button 4 and related structural elements constitute the mechanical structural part of the switch. The yoke 19, the coil 20, the iron core 22 and the armature 23 and related electromagnetic elements constitute the electromagnetic structural part of the switch. The trigger 3 makes the movable contact 11 and the terminal 12 produce closing and opening actions through the mechanical part and the electromagnetic structure part of the trigger switch.

[0019] The circular hole C of the base body 1 and the circular hole F of the housing 2 are sleeved with a push shaft 5 and a push shaft spring 13. The push shaft 5 can slide up and down to drive the pry bar 6 to be fixed on the base bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com