Plastic track mechanical capable of changing curvature radius in assembling process and transmitting electric power

A technology for power transmission and curvature radius, which is applied in the track field, can solve problems such as track installation, inconvenient transportation, increased construction workload and construction cost, and curvature radius that cannot be changed, so as to facilitate construction, facilitate construction and installation, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

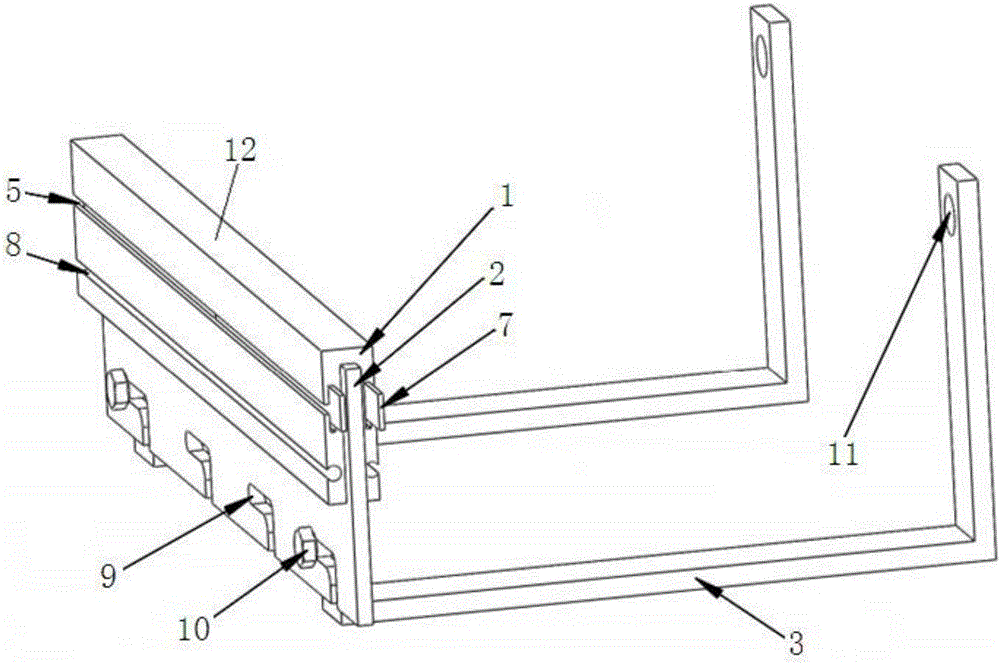

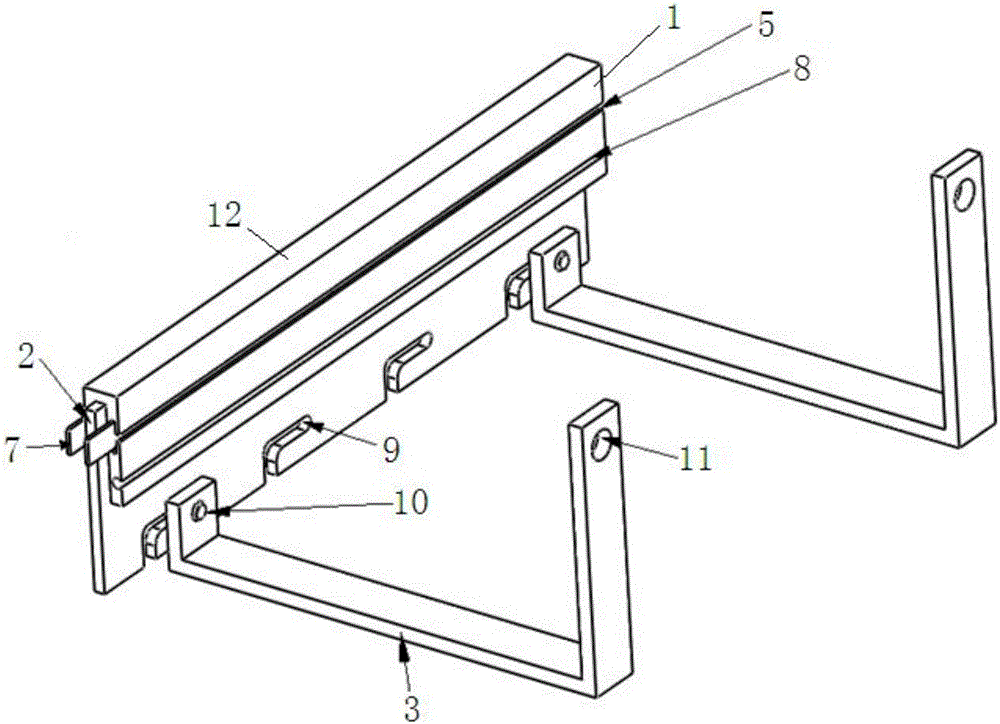

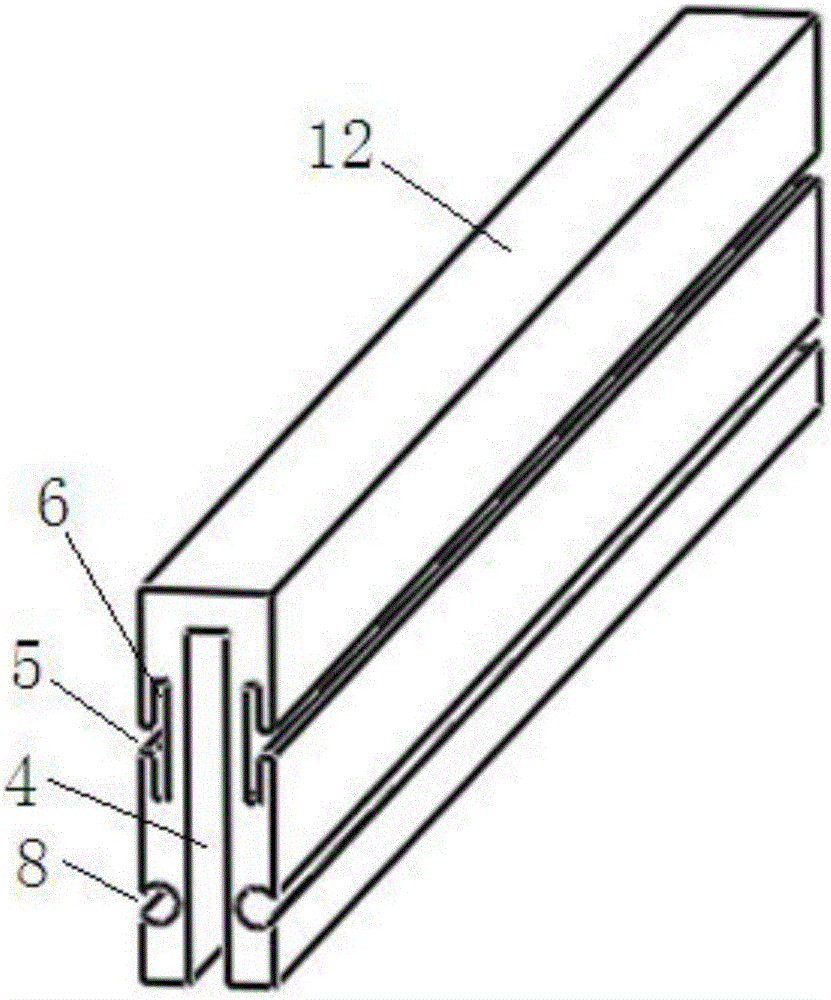

[0030] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0031] As shown in the drawings, the present invention includes: a plastic track 1, a metal support frame 2 and a fixed pendant 3, the plastic track 1 is made of plastic, the bottom surface of the plastic track 1 is provided with a supporting metal slot 4, and the upper part of the metal support frame 2 is inserted In the support metal slot 4, the lower part of the metal support frame 2 is detachably connected to the fixed pendant 3, the side of the plastic track 1 is provided with a power-taking slot 5, and the plastic track 1 is provided with a copper slot 6, and the copper slot 6 is set On the inner side of the power-taking tank 5 and connected with the power-taking tank 5, a conductive copper piece 7 is inserted in the copper piece slot 6, and the supporting metal slot 4, the power-taking tank 5, and the copper piece slot 6 are all along the plastic track 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com