Motor train unit pantograph working mode test device

A technology of working mode and test device, applied in the field of working mode test device of EMU pantograph, can solve the problems such as easy loss of force and sudden drop, increase in size of test device, high cost of insulator, etc., so as to reduce test expenses. , saving test time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

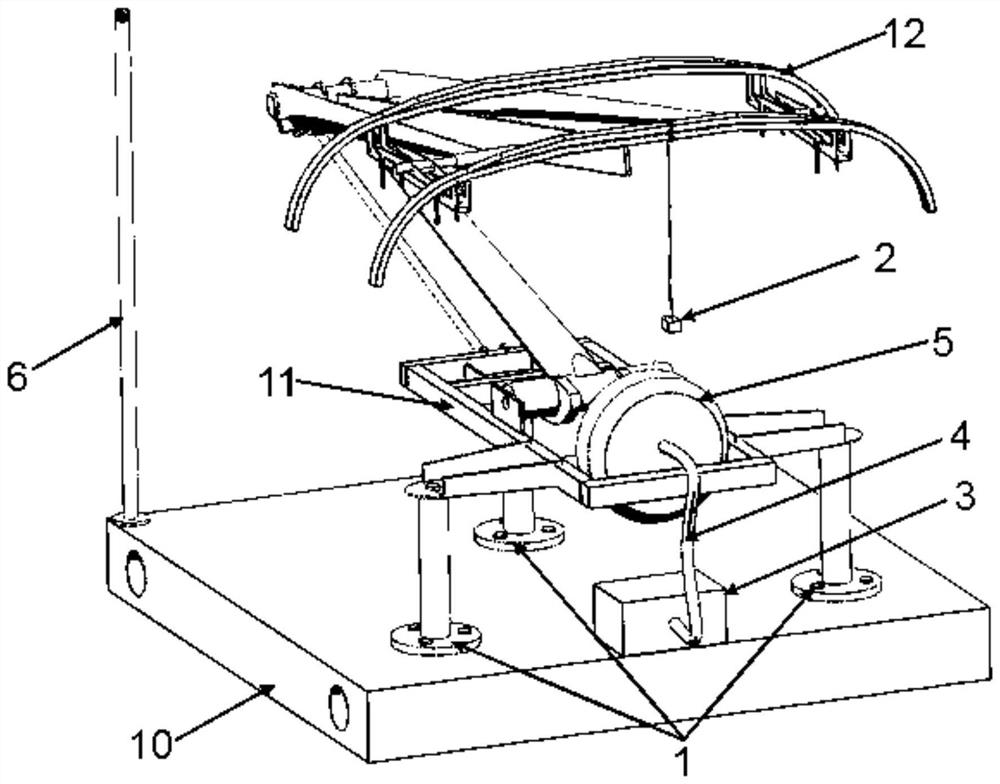

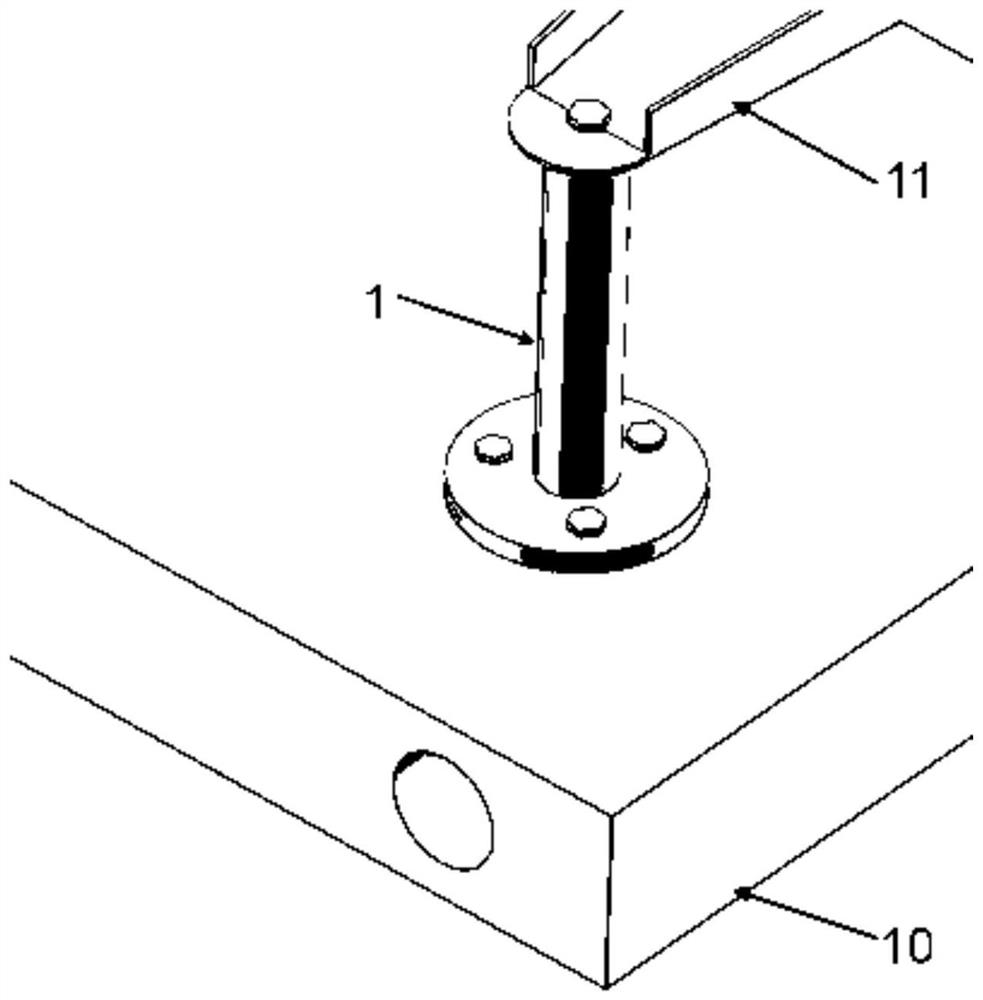

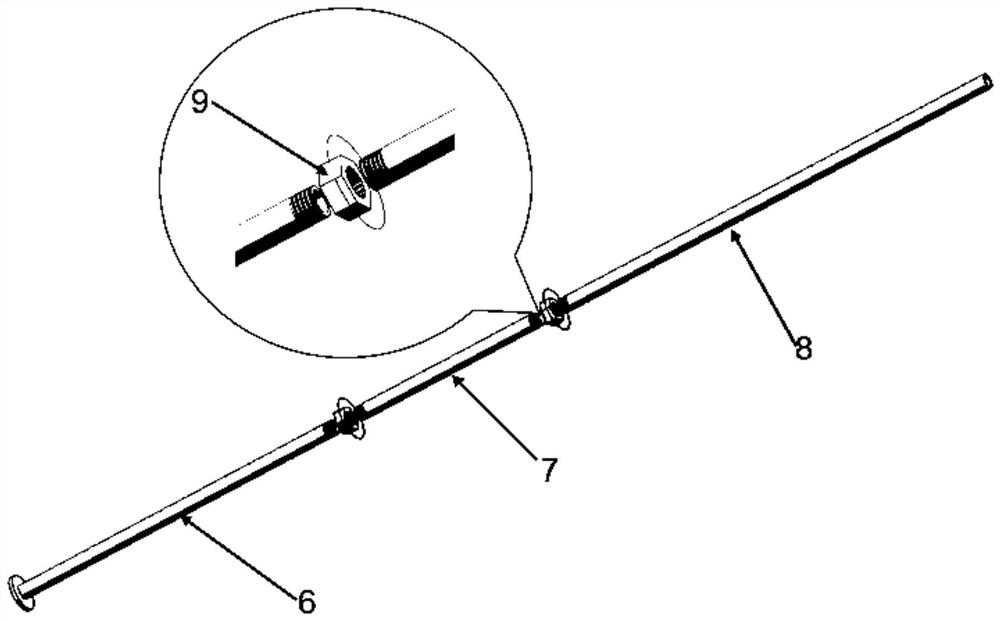

[0039] Such as Figure 1-5 As shown, the present invention provides a pantograph operating mode test device for EMUs, including: pantograph and experimental device, characterized in that the experimental device includes: supporting structure, driving structure, measuring structure and weight structure, the support structure includes a support base 10 and a support column 1, the support column 1 is set on the support base, the pantograph is set on the support column 1, and the support column 1 includes to support Column I, supporting column II and supporting column III, the supporting column I, the supporting column II and the supporting column III are arranged in a triangle, the supporting column I, the supporting column II and the supporting column Column III is connected to the pantograph base 11 through bolts, the structures of the supporting column I, the supporting column II and the supporting column III are the same, and the supporting column I is a circular tube structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com