Patents

Literature

105results about How to "Guaranteed workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-yield-ratio, high-strong toughness cast martensite stainless steel and production method thereof

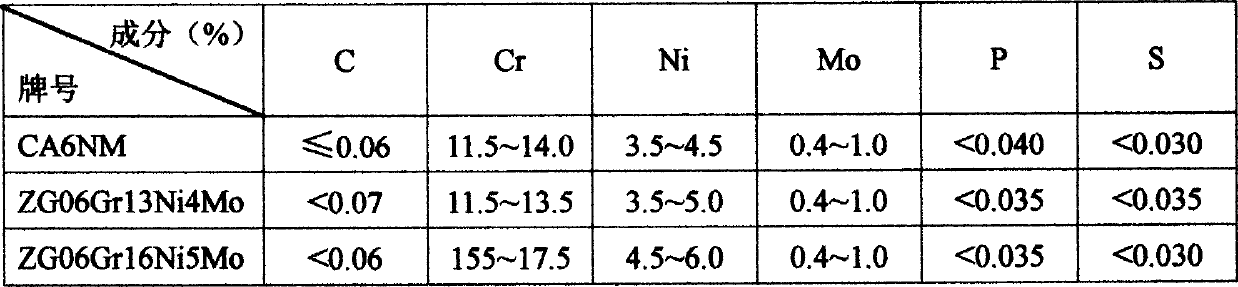

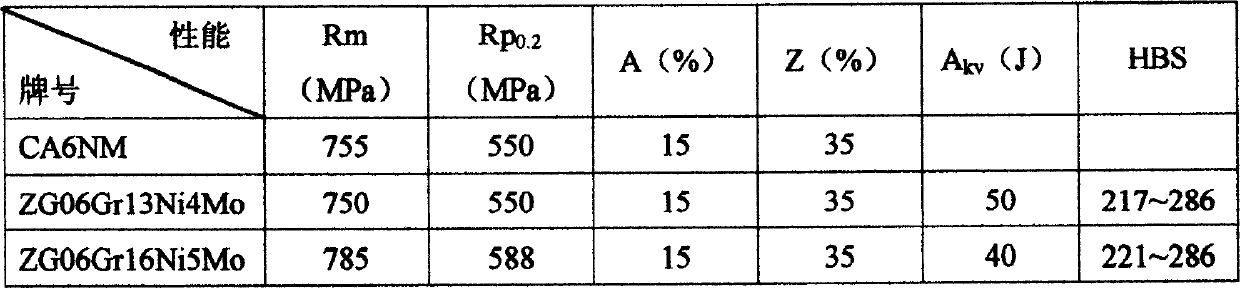

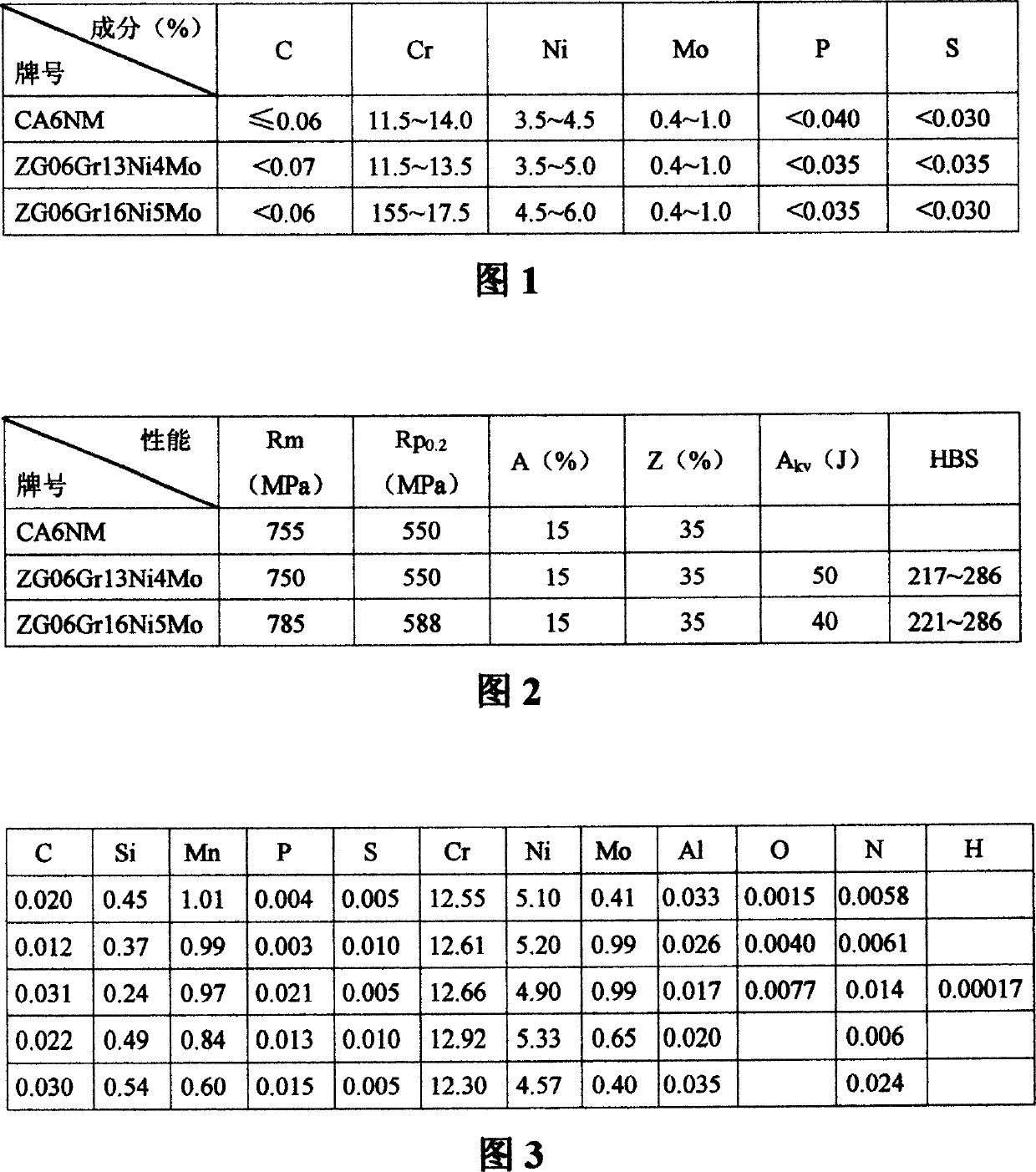

The invention is martensitic stain less steel with high yield ratio and high ductility, the character is that it contains: C is not more than 0.06%, Cr 11-16.5%, Ni 3.50-6.0%, Mn is not more than 2%, Mo 0.5-2%, Si is less than 1%, the residue are Fe and a little impurity. The impurity includes Al, [O], [N], [H], S, P, the content of then are Al <0.15%, [O]<0.01%, [N]<0.03%, [H] is not more than 0.0005%, S is not more than 0.020%, P is not more than 0.025%. The invention can enhances the synthesis performance index (high density, high rigidity, high ductility and yield ratio, excellent welding processing property, and fatigue preventing property under water) greatly, it can ensure that the stress of large wheel is smaller than 1 / 3 of material yield ratio, the stress of large welding wheel is smaller than 1 / 2 of material yield density. It maintains the higher etching preventing property and sand grinding resisting property.

Owner:SHENYANG RES INST OF FOUNDRY

Spherical high-frequency vector sensor vibration velocity channel and sound pressure channel integral processing method

InactiveCN101100096ASatisfy large depth requirementsMeeting the requirements of the hydroacoustic fieldVibration measurement in fluidHydrophoneEngineering

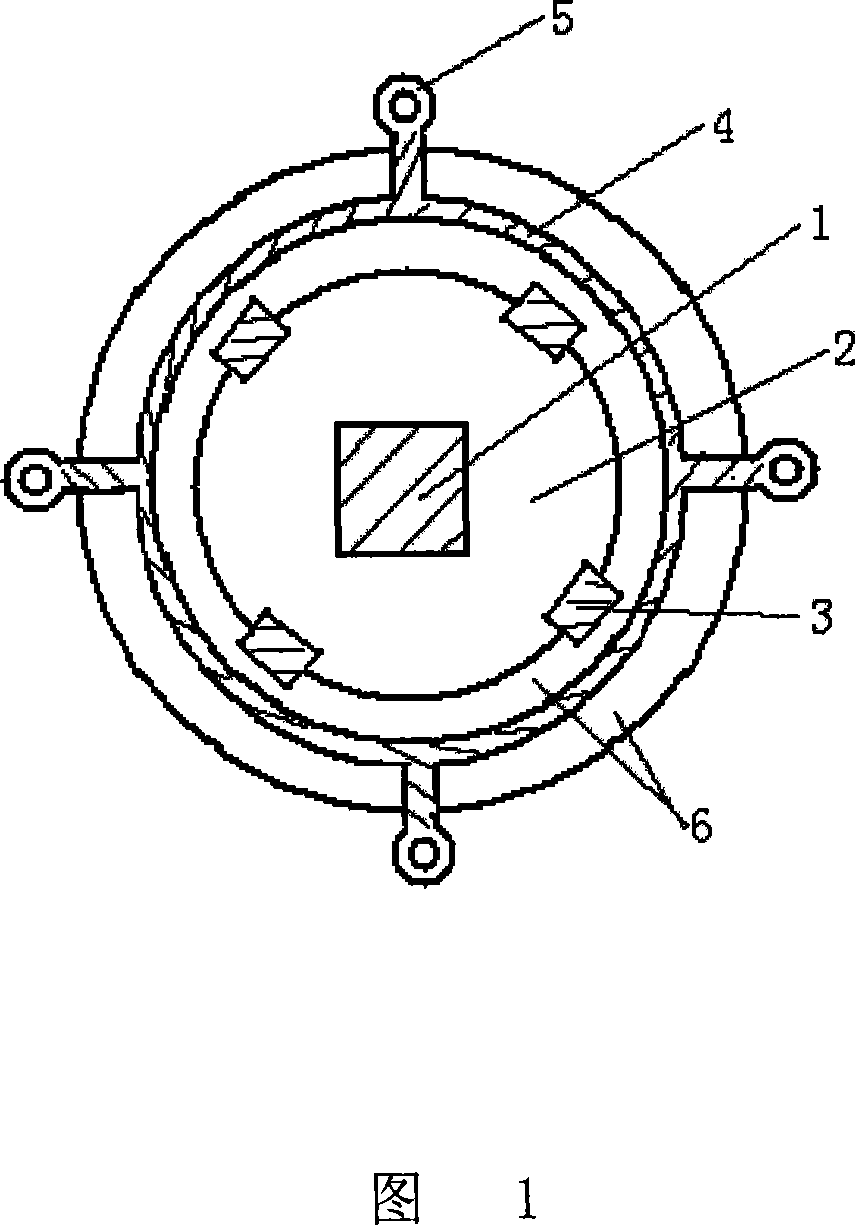

The present invention is process of machining spherical HF vector sensor with integrated vibration velocity channel and sound pressure channel. The process includes: setting one 3D vibration velocity sensor in the center of one sphere made of low density composite material, embedding eight sound pressure hydrophones homogeneously on the surface of the sphere, mounting one ring with four suspension loops outside the sphere in certain distance, and coating the sphere with sound penetrating material while exposing four suspension loops. The spherical HF vector sensor is applied in great depth hydroacoustic measurement.

Owner:HARBIN ENG UNIV

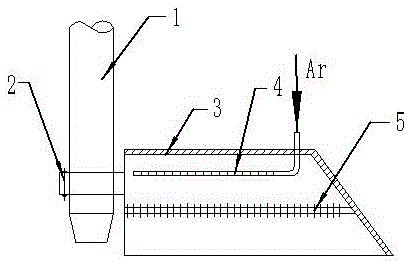

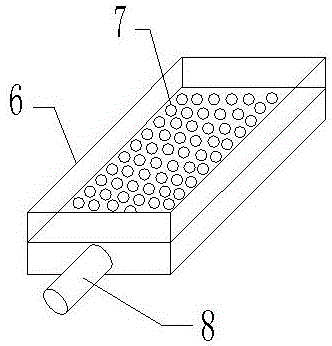

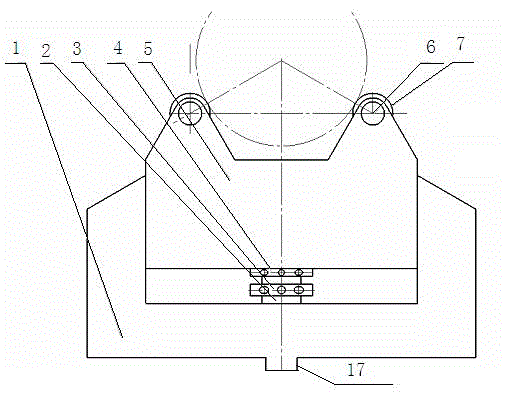

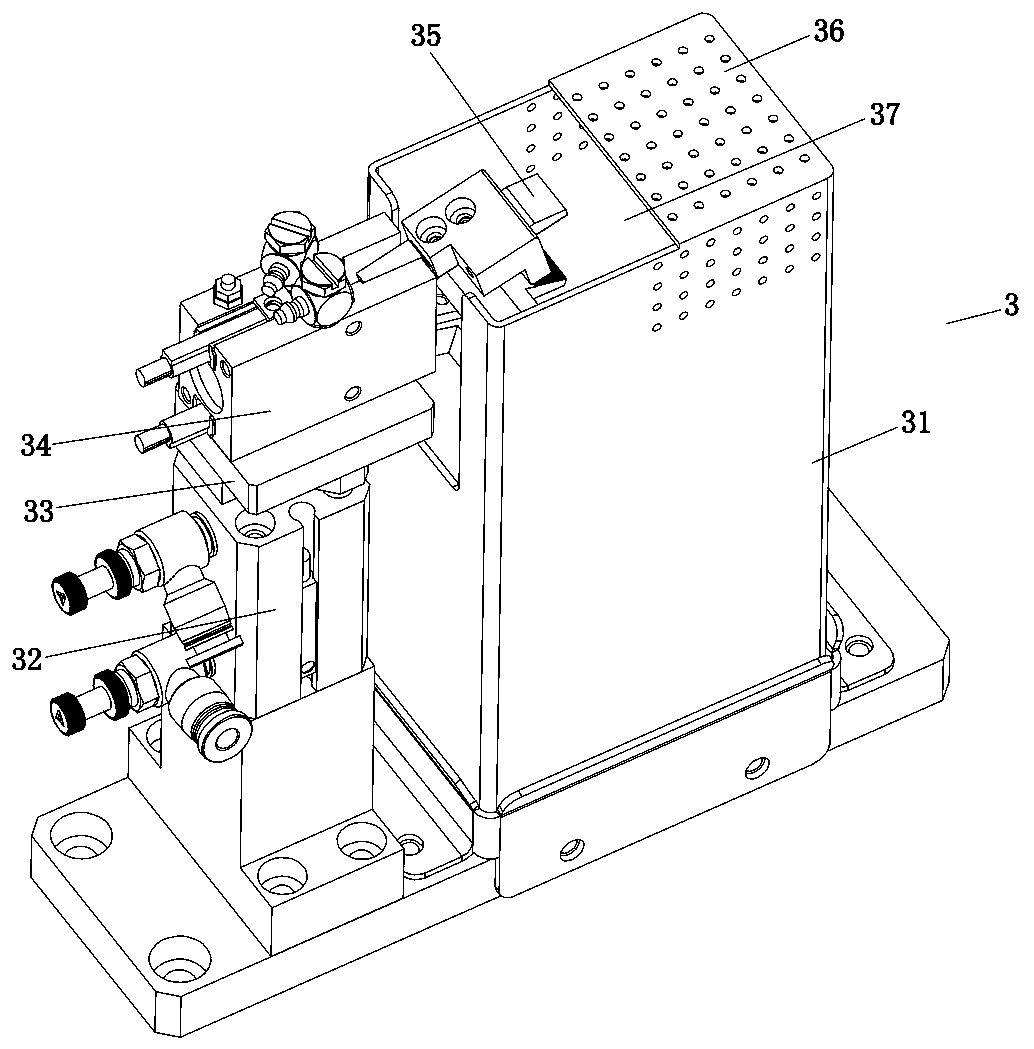

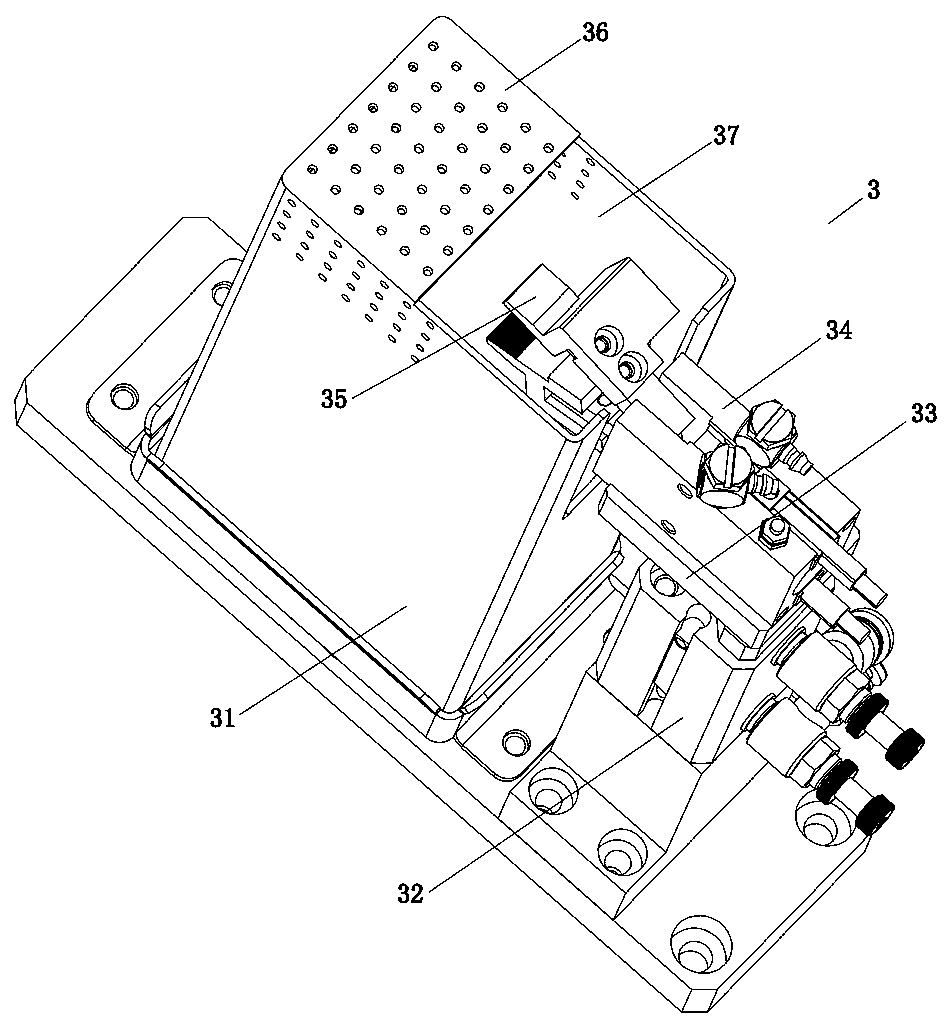

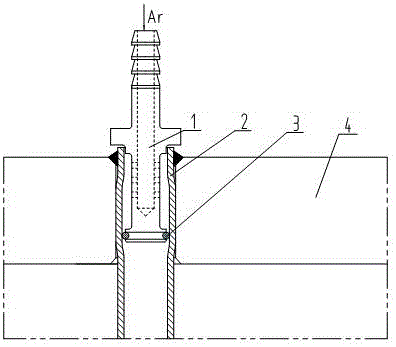

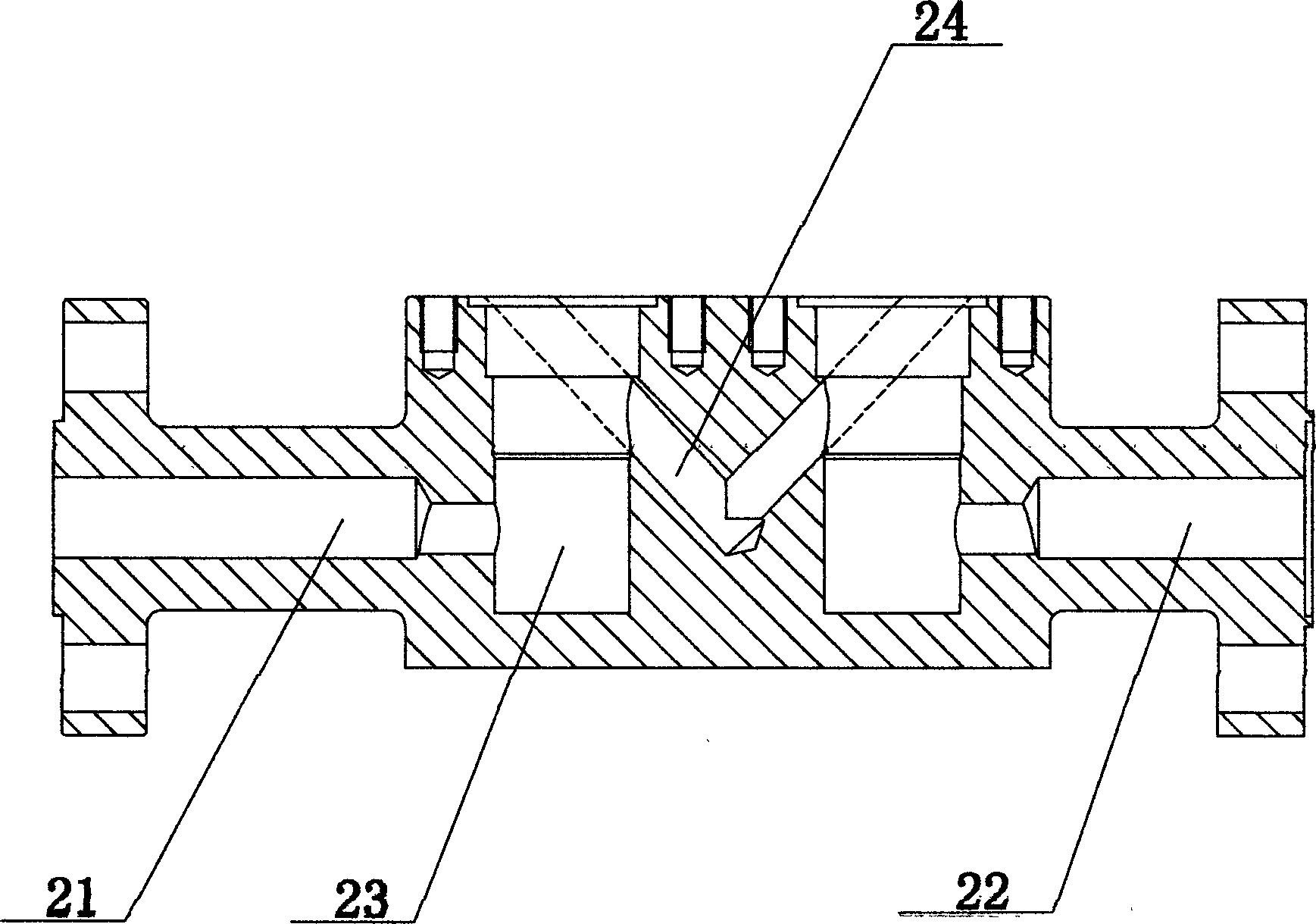

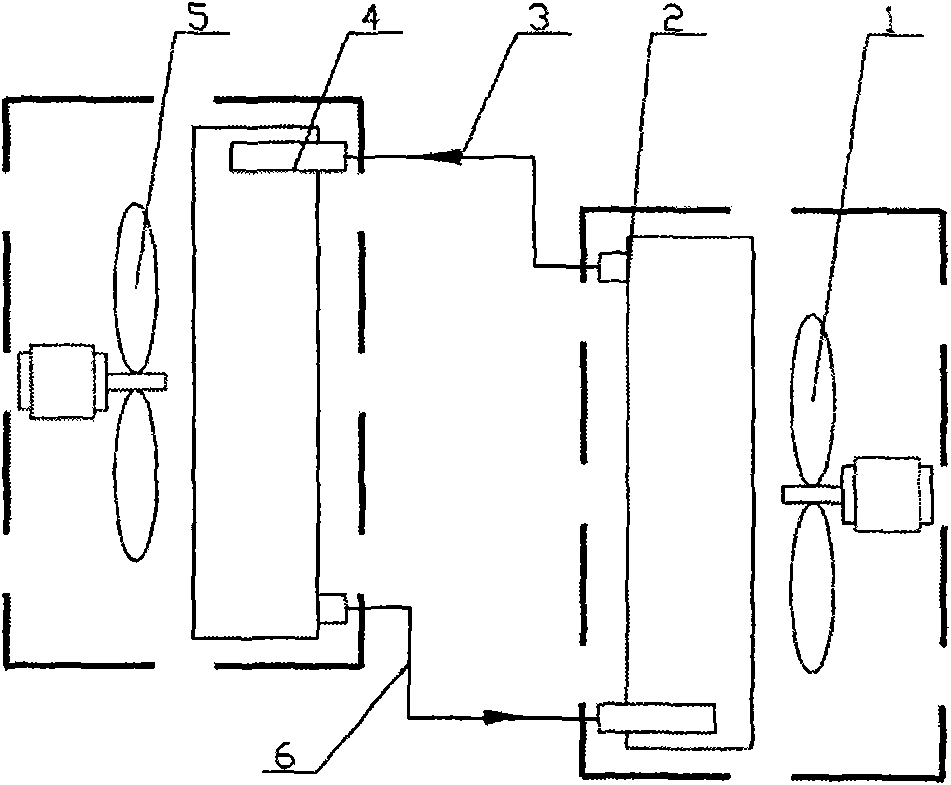

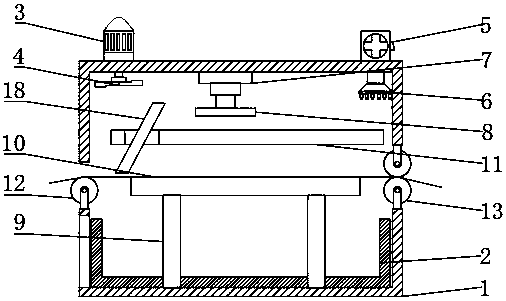

Argon shielding device for titanium material welding and usage method of device

InactiveCN105127559ASpeed up the flowGuaranteed workmanshipShielding gas supply/evacuation devicesWelding/soldering/cutting articlesSmall holeHose clamp

The invention discloses an argon shielding device for titanium material welding, belongs to the field of welding in the machinery industry, and solves technical problems of hydrogen absorption, oxygen absorption and the like of weld joint molten pools during titanium material welding. The device comprises two parts, namely, an upper gas shielding cover and a lower gas shielding tank, wherein the upper gas shielding cover structure comprises a welding torch 1, a hose clamp 2, a tail drag cover 3, a vent pipe 4 and a porous plate 5; the argon arc welding torch can be tightly clamped by the hose clamp 2, the tail drag cover 3 is connected with the hose clamp, and a plurality of small holes are formed in the bottom of the vent pipe 4; the lower gas shielding tank structure comprises a grooved steel plate 6, a porous plate 7 and a gas inlet pipe 8. A usage method of the device comprises steps as follows: a piece of weldment is placed between the upper gas shielding cover and the lower gas shielding tank, argon is fed from upper and lower sides respectively, the argon arc welding torch is fixed according to an operation procedure, the distance between the welding torch and the workpiece is adjusted, and welding is performed after air in the shielding tank is replaced. With the adoption of the device and the method, argon flows stably, the welding joint surface shielding effect is very good, the structure is simple, the cost is low, the manufacturing cost is greatly saved, and production efficiency and quality are improved.

Owner:LANZHOU LS HEAVY EQUIP

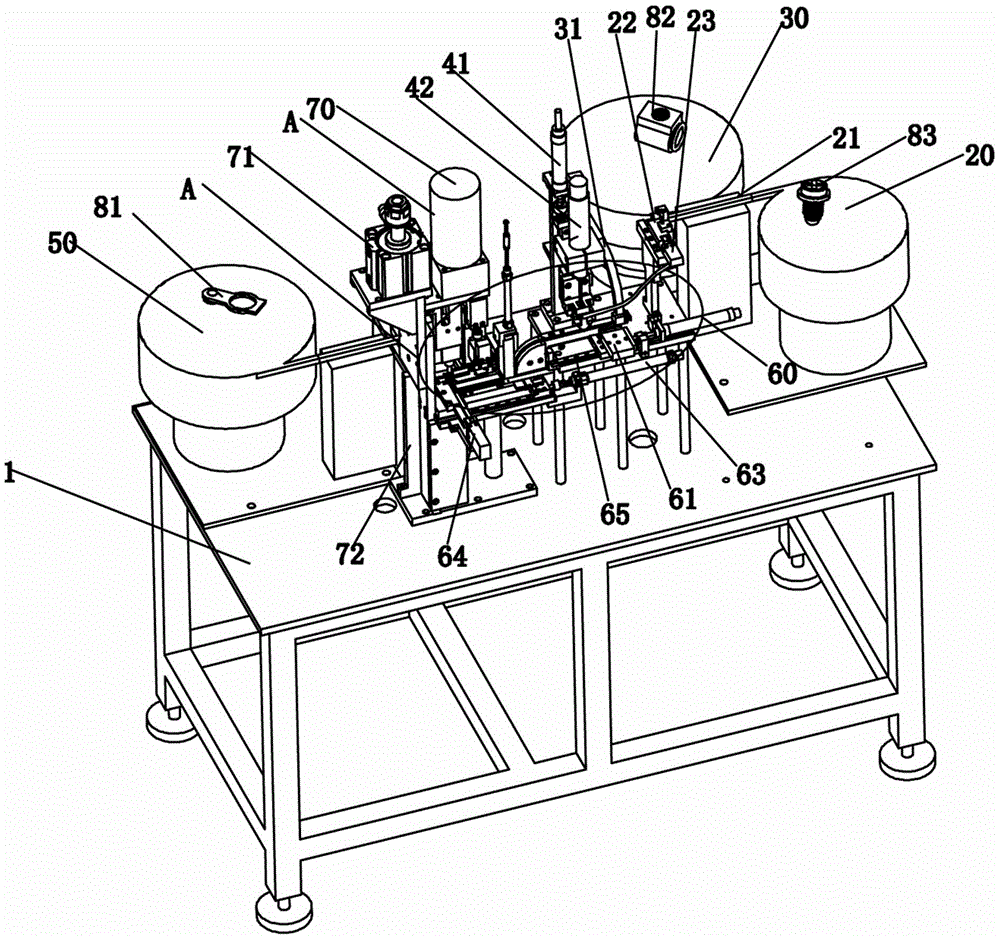

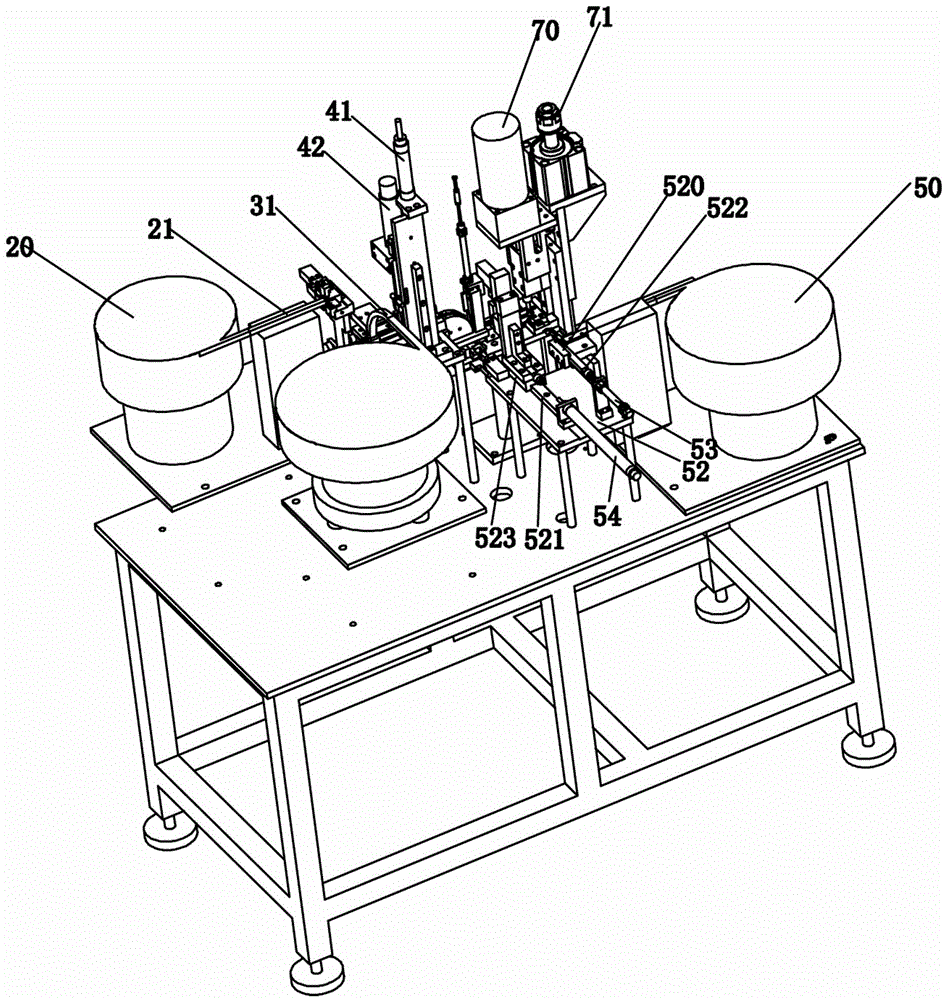

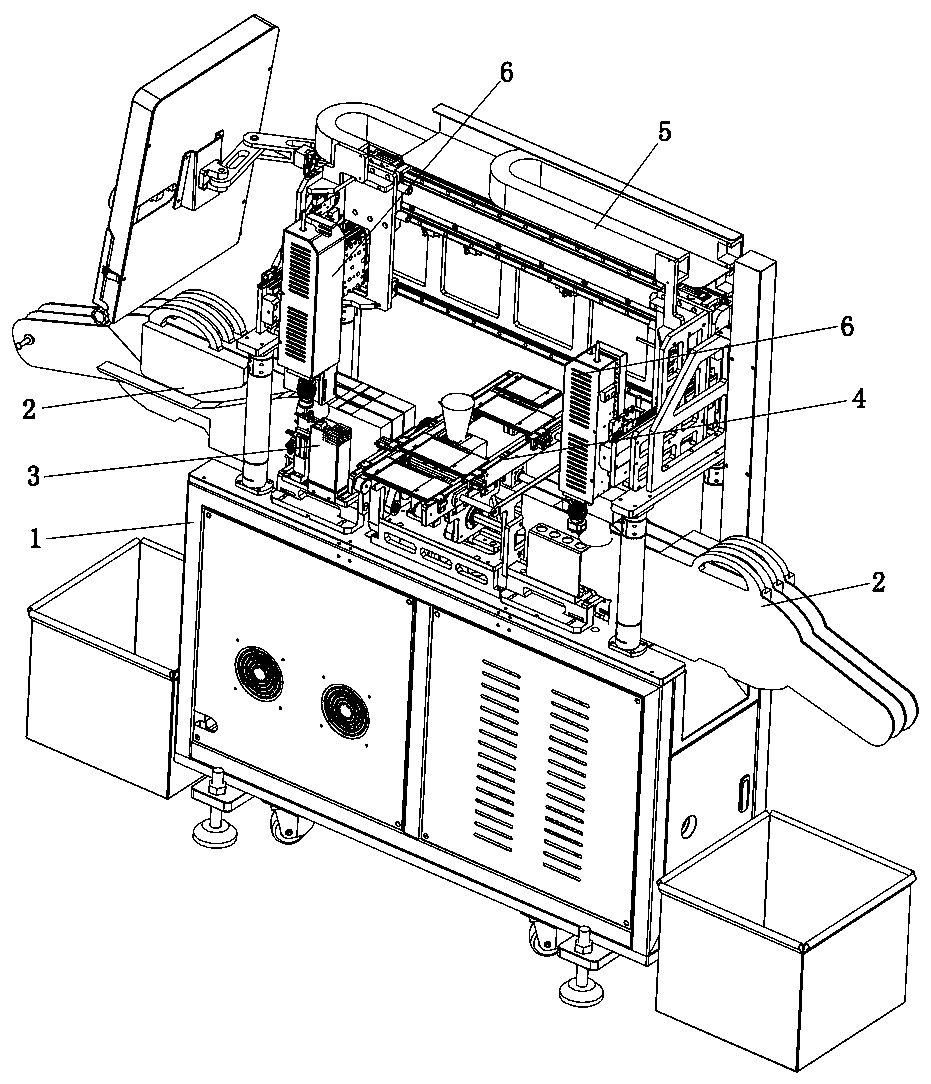

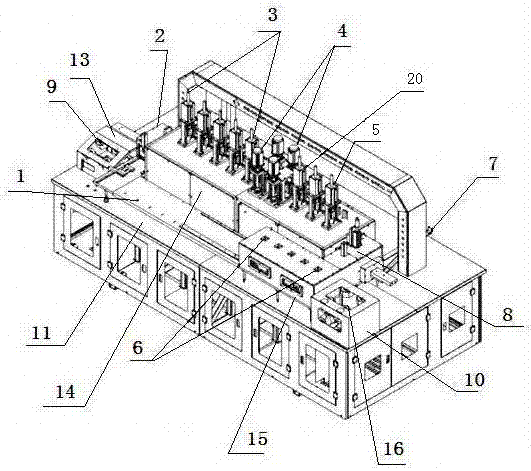

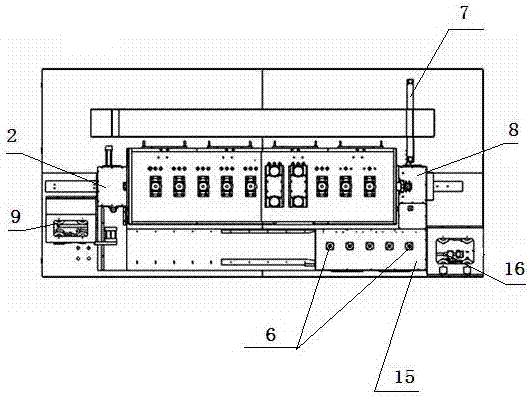

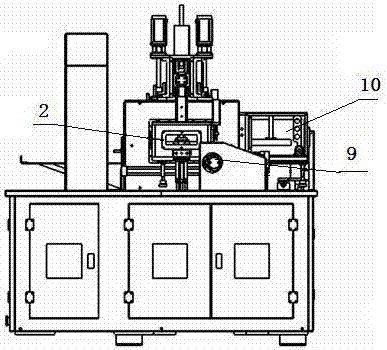

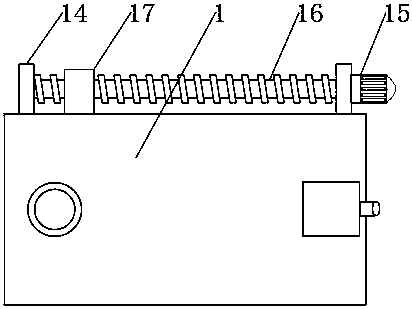

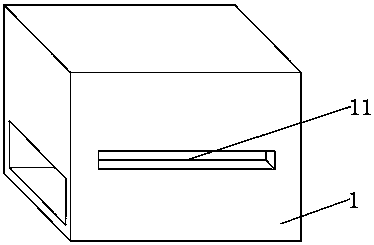

Full-automatic screw locking and sheet riveting feeding machine used for wiring terminal of switch socket

ActiveCN105563084ARealize automatic feedingNo manual operationMetal working apparatusMetal sheetMetal

The invention relates to a full-automatic screw locking and sheet riveting feeding machine used for a wiring terminal of a switch socket. According to the full-automatic screw locking and sheet riveting feeding machine disclosed by the invention, a screw, a metal column and a metal sheet are separately conveyed to a screw turning mechanism through a screw feeding mechanism, a metal column feeding mechanism, a metal sheet feeding mechanism and a material conveying mechanism, and the metal column is screwed up with the screw, and then, the metal column screwed up with the screw is conveyed to a sheet riveting mechanism through the material conveying mechanism for sheet riveting, therefore automatic operation of automatic feeding, automatic screw turning, automatic sheet riveting and the like is realized, so the full-automatic screw locking and sheet riveting feeding machine disclosed by the invention is capable of realizing full-automatic operation from feeding to screw locking to sheet riveting to discharge in a whole process of feeding, screw locking and sheet riveting without manual operation, therefore manual labor is greatly saved, production cost is reduced, and production efficiency is greatly increased.

Owner:FOSHAN SHUNDE MEIZHIMEI APPLIANCE MFG CO LTD

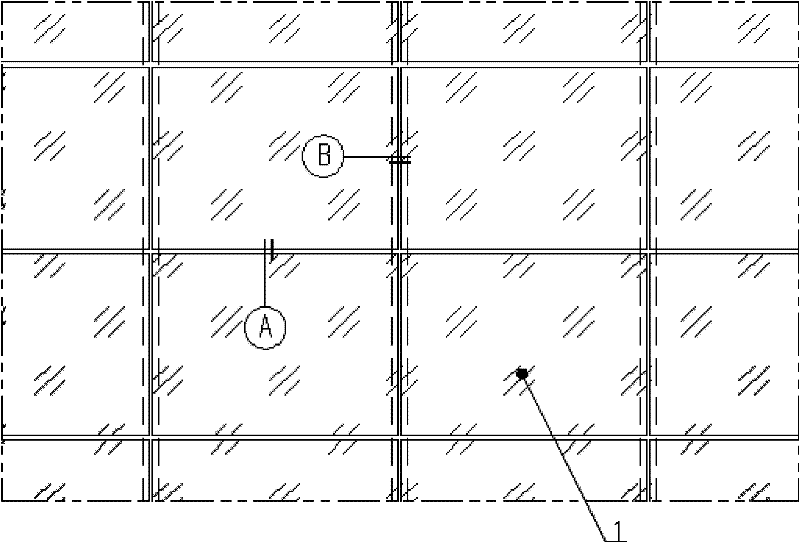

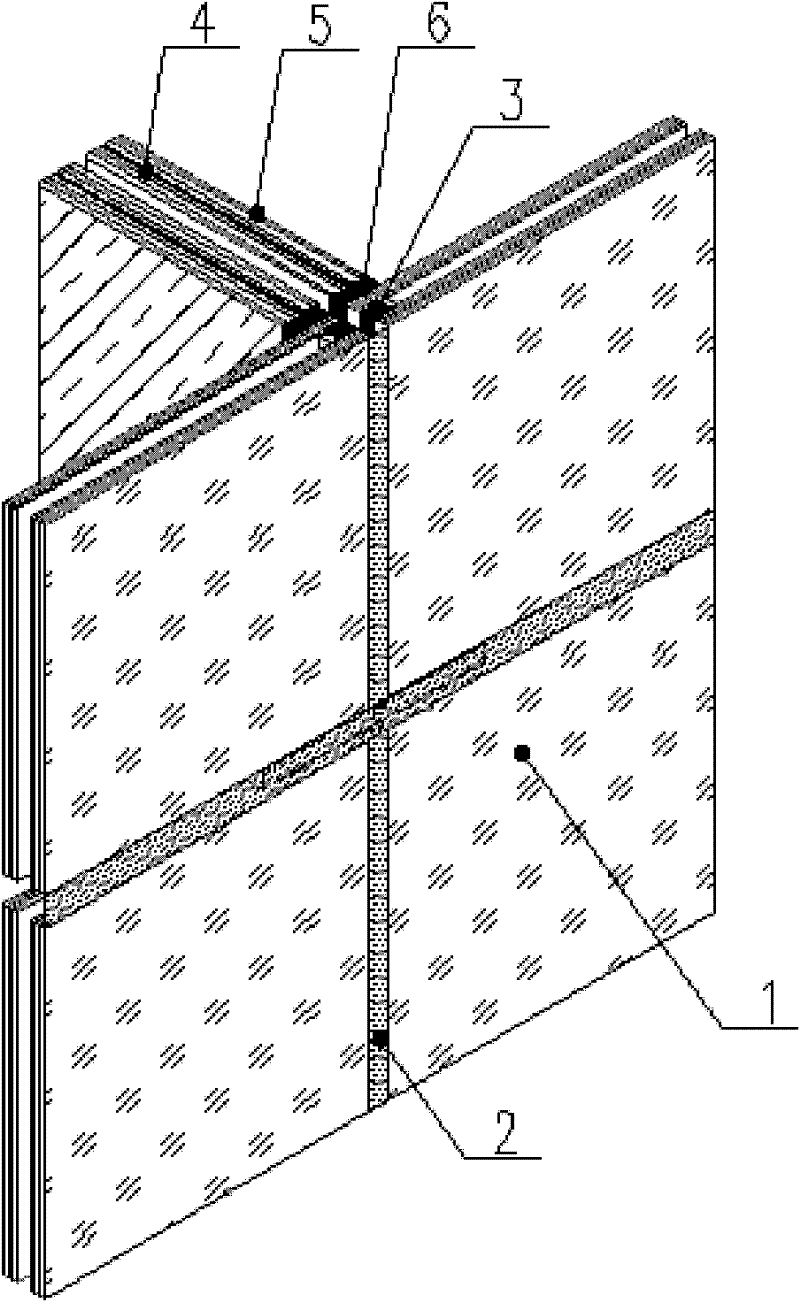

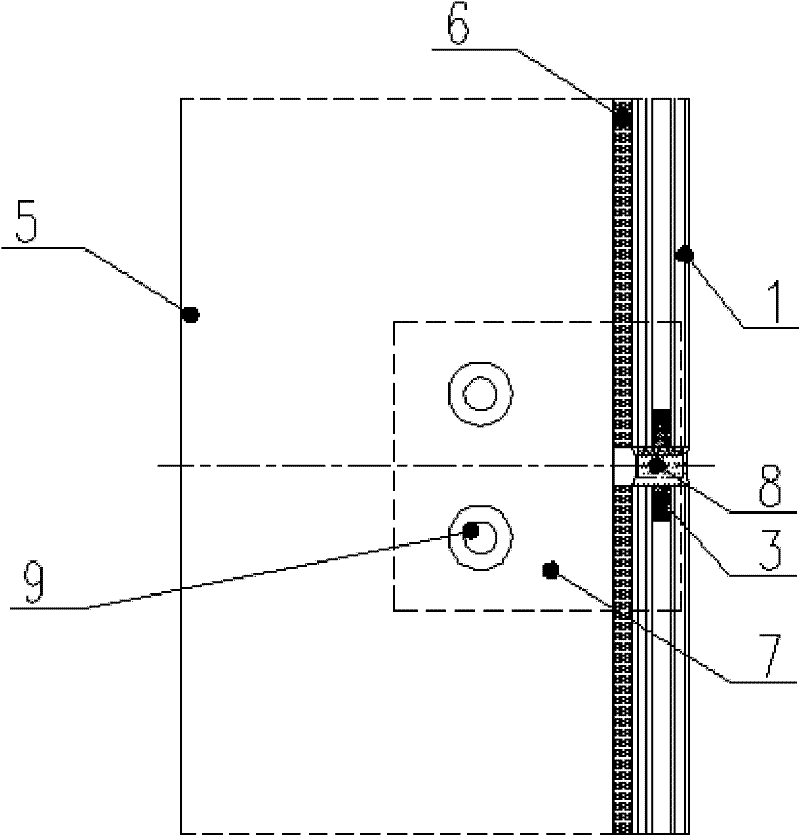

Glass curtain wall

A glass curtain wall comprises a glass panel and a fixing support frame, wherein the fixing support frame is manufactured by two pieces of rib plates which are bonded into a whole body in the middle of two pieces of glass by PVB (Polyvinyl Butyral) glue; a vertical supporting plate is arranged between the two pieces of rib plates; the vertical supporting plate and the two pieces of rib plates arebonded into a whole body by compatibility shearing resistant glue and are fastened by a group of bolts; a groove is arranged at a place of the front side part of the vertical supporting plate which corresponds to a transverse joint of the glass panel; a transverse supporting plate which is vertically jointed with the vertical supporting plate is inlaid in the groove; front side parts of the transverse supporting plate and the vertical supporting plate are respectively arranged in a transverse joint and a vertical joint of the glass panel; the glass panel and the two rib plates are bonded intoa whole body by structural glue; and sealing gum is filled in gaps at the periphery of the glass panel. The glass curtain wall has the advantages of large wind pressure resistance, good overall permeability and visual effect.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

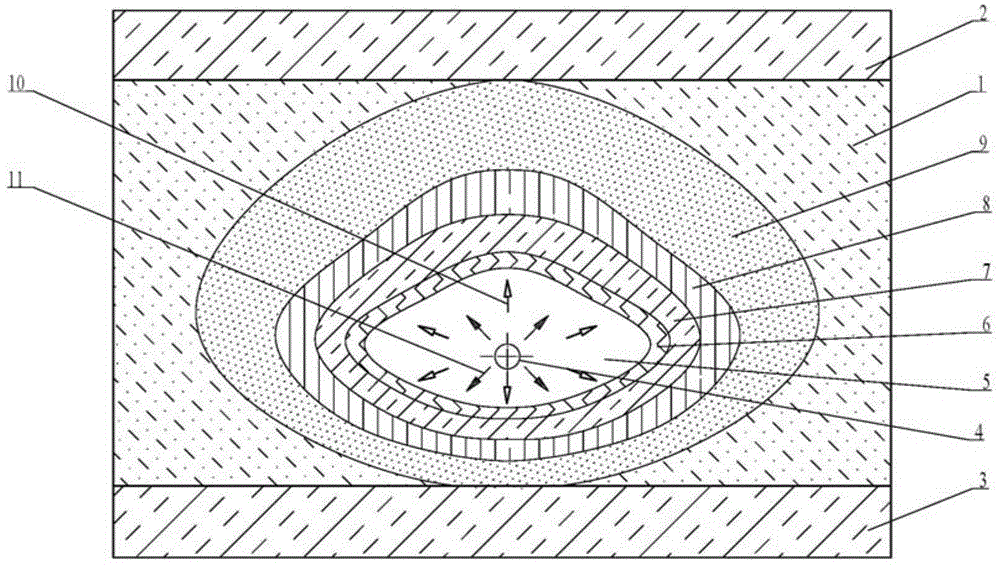

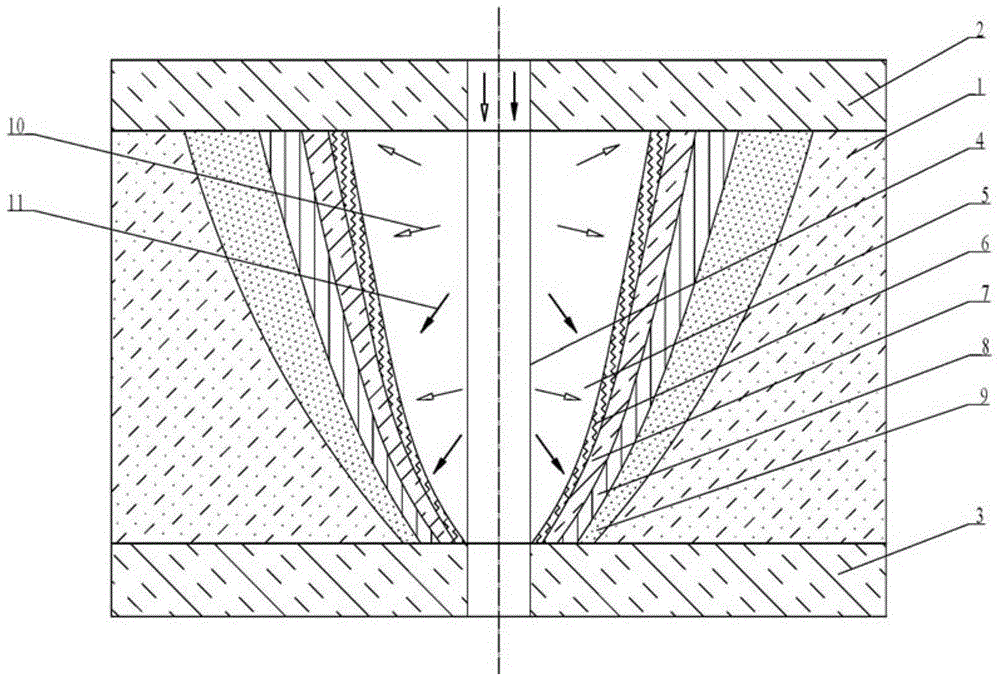

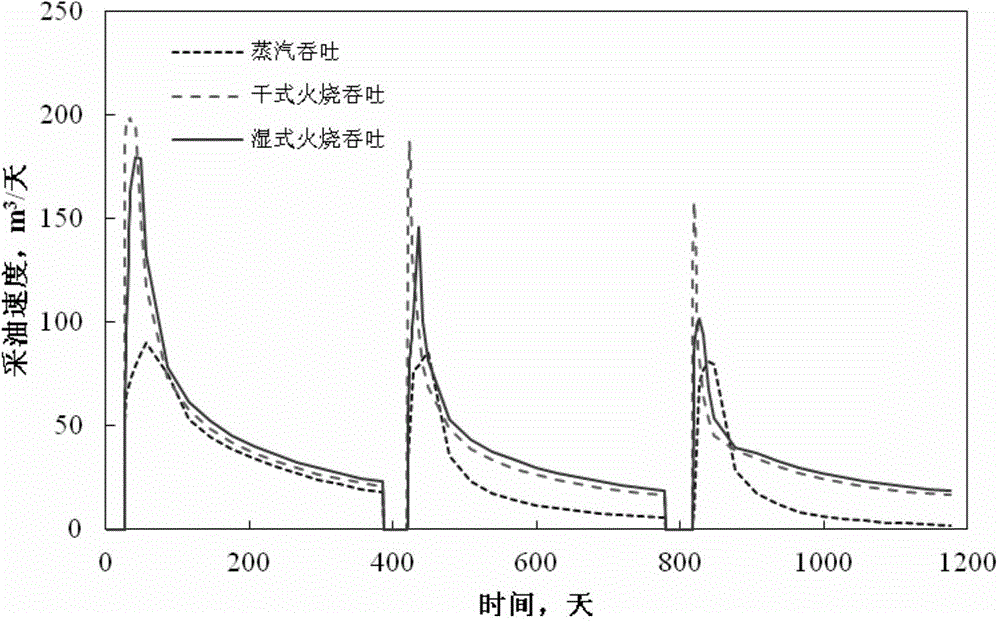

Wet type combustion huff-puff oil extraction method

The invention provides a wet type combustion huff-puff oil extraction method, comprising the steps of: 1, flushing an oil well, then injecting an oxidizing agent into an oil deposit, igniting to burn coke-like components generated by the oxidization and splitting decomposition of crude oil in the oil deposit to heat an oil layer; 2, while the oxidizing agent is completed injected or is injecting, injecting water to reduce the high temperature of a near wellbore formation, and extracting oil after soaking the well for 3-10 days; 3, after extracting oil for 100-700 days, performing a next round of processes of injecting the oxidizing agent, igniting, injecting water, soaking and extracting oil. According to the method provided by the invention, the water is injected into the oil deposit after the oxidizing agent is injected, and water flow flows through a combusted area and carries heat to the deep part of the oil deposit, so that the heating range of the oil deposit is enlarged, and the peripheral temperature of the oil well is prevented from being too high. According to the wet type combustion huff-puff oil extraction method, formation water and the injected water are vaporized to generate steam, heat, smoke and steam generated by combustion are comprehensively utilized to recover in a combined manner, the output and the recovery efficiency of the crude oil are improved, and the recovery efficiency is up to more than 70%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

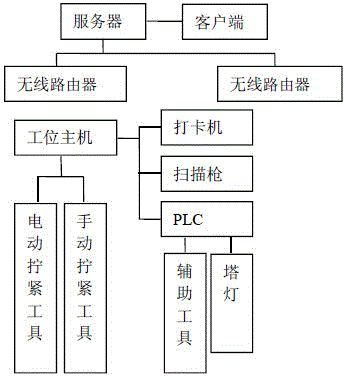

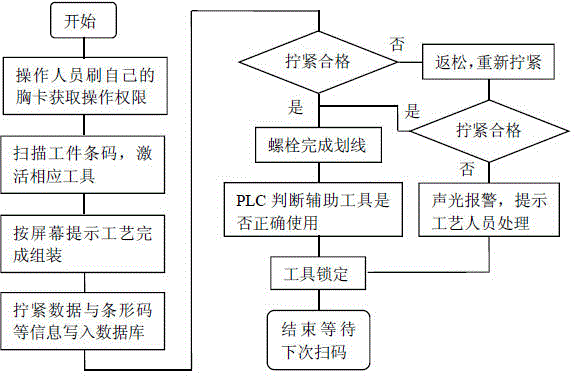

Quantized assembly and overhaul control system for locomotive

ActiveCN104950793AGuaranteed assembly qualityGuaranteed workmanshipProgramme control in sequence/logic controllersControl systemProgrammable logic controller

The invention provides a quantized assembly and overhaul control system for a locomotive. The system comprises a client, a server and an operating terminal, wherein the server is a database server; the operating terminal comprises multiple workstations; the client is connected with the server through a network; the workstations are in data interaction with the server through wireless nodes; each workstation comprises a workstation host, a card punch, a scanning gun, a PLC (programmable logic controller), an electric tightening tool, a manual tightening tool, a tower lamp and auxiliary tools, the card punch, the scanning gun and the PLC are connected with the workstation host through data lines respectively, data transmission interfaces of the electric tightening tool and the manual tightening tool are connected with the workstation host respectively, the tower lamp is connected with a PLC control port through a data line, and sensors are arranged at storage places of the auxiliary tools and connected with the PLC control port. The quantized assembly and overhaul control system for the locomotive can guarantee the tightening process and the tightening precision, effectively prevents wrong assembly, realizes whole tracing of the production process, and guarantees the assembly quality of the locomotive and a high-speed bullet train.

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

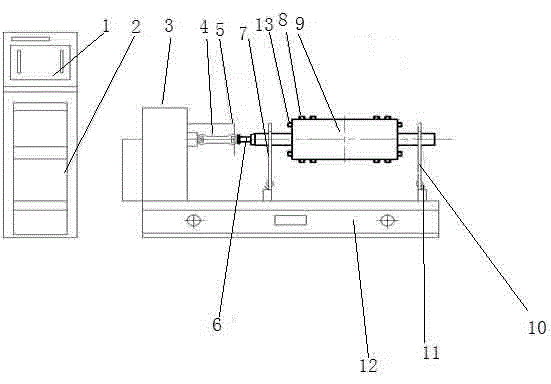

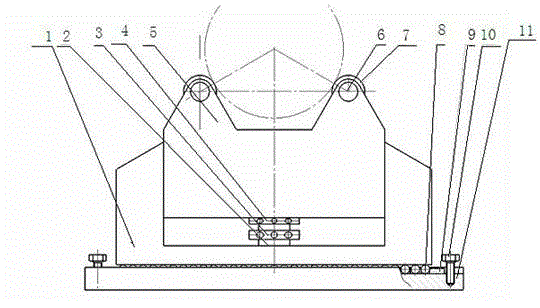

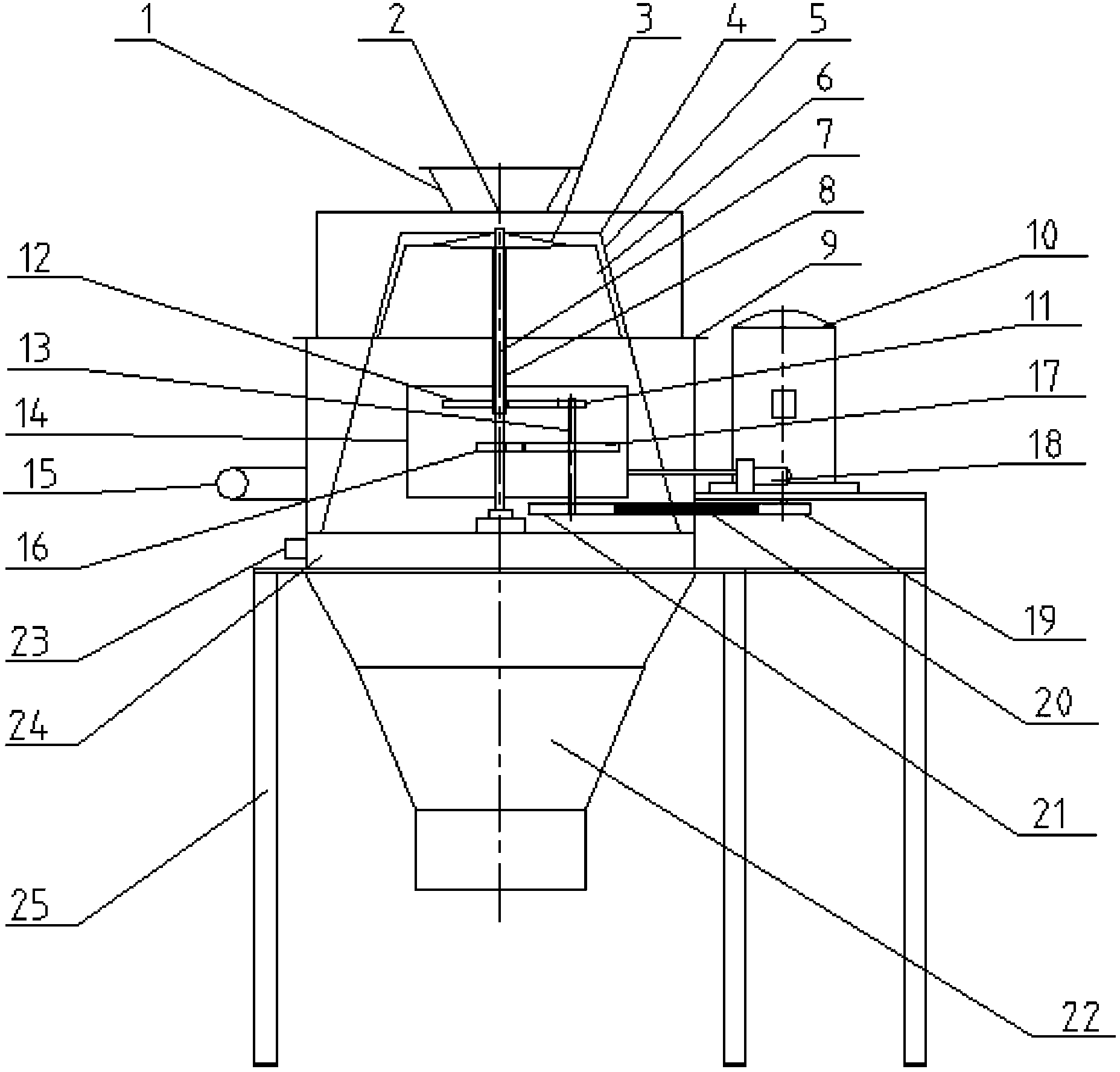

Hard bearing dynamic balancing machine precision detection and verifying unit and precision calibration process

ActiveCN104458127AGuaranteed workmanshipQuality assuranceStatic/dynamic balance measurementBalancing machineDynamic balance

The invention belongs to the technical field of machinery manufacturing and provides a hard bearing dynamic balancing machine precision detection and verifying unit and a precision calibration process. The precision detection and verifying unit comprises a connection flange shaft (6) and a detection verifying and calibration mandrel (9). The connection flange shaft (6) is connected between a universal coupling (4) and the detection verifying and calibration mandrel (9). The detection verifying and calibration mandrel (9) comprises a balance weight mandrel body (9.4), a front bearing shaft journal (9.3) and a rear bearing shaft journal (9.9), wherein the front bearing shaft journal (9.3) and the rear bearing shaft journal (9.9) are symmetrically arranged on the front end face and the rear end face of the balance weight mandrel body (9.4). The outer diameter face of the balance weight mandrel body (9.4) is provided with two sets of axial plus and minus balance weights (8). The front end face and the rear end face of the balance weight mandrel body (9.4) are provided with radial plus and minus balance weights (13). By means of the hard bearing dynamic balancing machine precision detection and verifying unit and the precision calibration process, the build as well as repair process implementation and product quality of crankshafts are guaranteed, and a technology and quality guarantee is provided for reliable operation of an internal combustion engine and the whole device.

Owner:CRRC LUOYANG CO LTD

Cold-resistant, soft and down-proof coating adhesive for textile and preparation method

The invention relates to a preparation method of cold-resistant, soft and down-proof coating adhesive for textile. The preparation method is characterized by comprising the steps of stirring 80-90 parts by weight of polyurethane binder and 0.3-0.5 parts by weight of defoaming agent for 10-30min at room temperature, adding 1.5-2.0 parts by weight of associated polyurethane rheological assistant, stirring for 30-45min, adding 5-10 parts by weight of hand feeling agent, stirring for 20-30min, and filtering and discharging to obtain the product. The adhesive is applicable to pure cotton, dacron and chinlon shell fabrics.

Owner:LIAONING FIXED STAR FINE CHEM

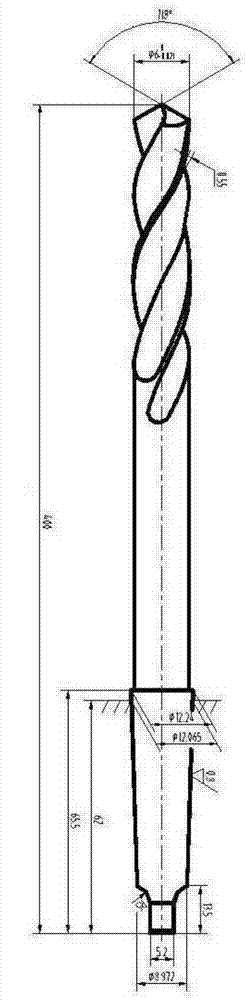

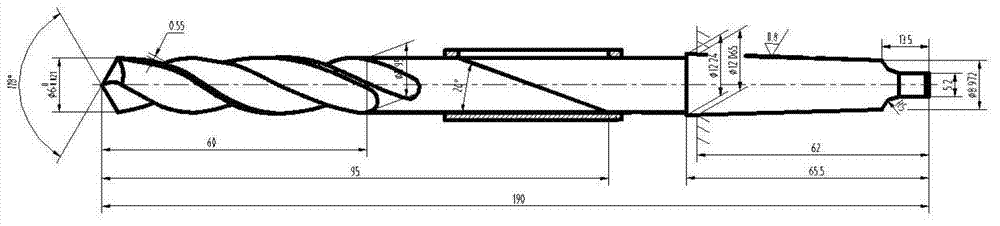

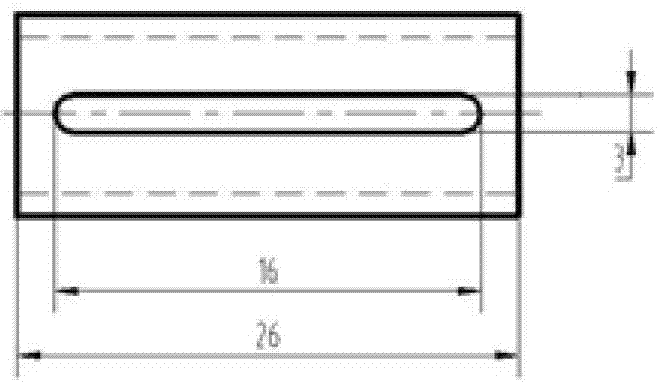

Method for machining extension drill

The invention discloses a method for machining an extension drill, belongs to the field of machining, and aims to solve the problem that the drill coaxiality cannot be met in the conventional process scheme. The method comprises the following steps: welding a straight shank twist bit together with a tool bar by adopting a welding sleeve, and turning the welding sleeve for welding an auxiliary component; grinding the blade excircle and taper shank of the extension drill; grinding a 118-degree taper lead angle and a back angle on a cutter grinding machine. According to the method, the standard straight shank twist bit is welded together with the tool bar, so that the milling stress and deformation of a drill groove are reduced; cutting parameters are optimized, so that the machining efficiency is increased to the maximum extent on the premise of ensuring the machining accuracy; a welding process scheme and the welding parameters are optimized, so that the extension drill has sufficient drill strength and qualified coaxiality and meets the use requirements.

Owner:HARBIN TURBINE

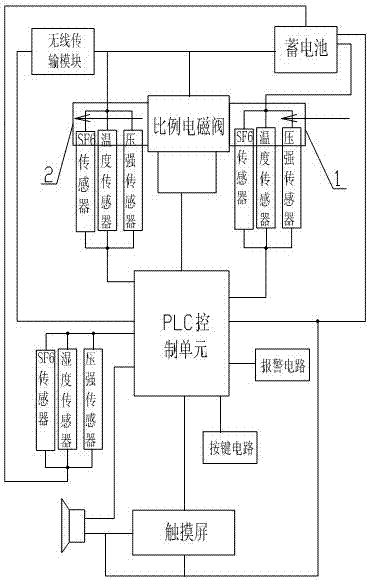

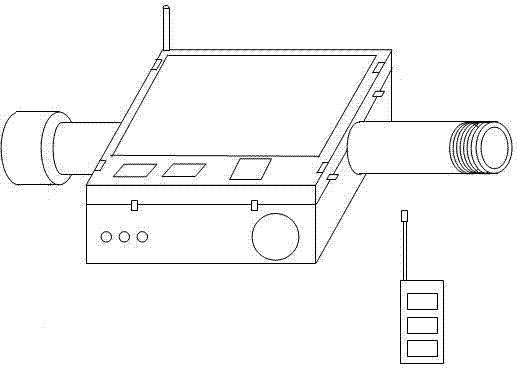

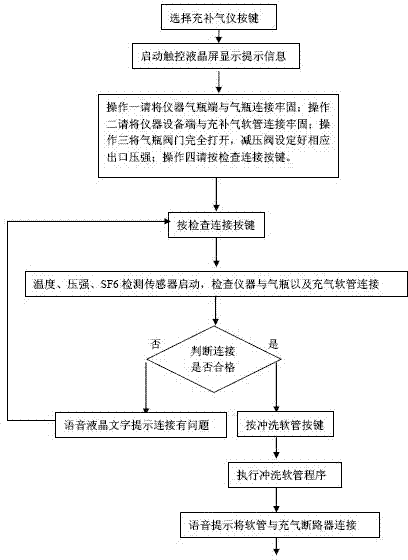

SF6 gas electronic control inflator

InactiveCN103090183AEnsure safetyGuaranteed safe operationContainer filling methodsContainer discharging methodsClamp connectionWireless transmission

The invention discloses an SF6 gas electronic control inflator, and relates to the technical field of gas measurement devices or inflating devices. The inflator comprises a housing, the housing comprises an upper end cover and a lower end cover, the upper end cover is in clamp connection with the lower end cover, and the contact position of the upper end cover and the lower end cover is provided with a waterproof sealing rubber strip. The inflator also comprises a PLC control unit, a tough screen, a proportional solenoid valve, a wireless transmission module, a power supply, temperature sensors, a humidity sensor, pressure sensors, SF6 sensors, an alarm circuit, a button circuit and a remote controller. The inflator has the characteristics of high inflating precision, safe and reliable use, and high work efficiency.

Owner:STATE GRID CORP OF CHINA +2

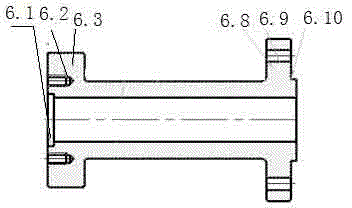

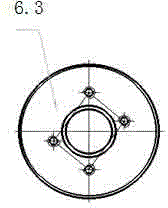

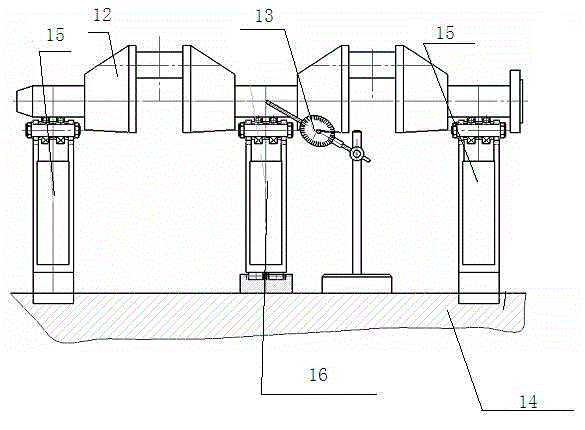

Bent axle coaxiality detecting device and detecting technology of high-power multi-cylinder internal combustion engine

ActiveCN103604356AGuaranteed workmanshipQuality assuranceMechanical measuring arrangementsStructural engineeringInternal combustion engine

The invention belongs to the technical field of manufacturing, repairing and detecting internal combustion engines, and provides a bent axle coaxiality detecting device and detecting technology of a high-power multi-cylinder internal combustion engine. The bent axle coaxiality detecting device of the high-power multi-cylinder internal combustion engine comprises three detecting supports, a dial indicator (13) and a detecting platform (14). Each detecting support comprises a supporting base (1), a supporting body (5) and a lead screw nut mechanism. The detecting support at the main shaft neck part of the free end of a bent axle and the detecting support at the main shaft neck part of the output end of the bent axle are fixed detecting supports. The detecting support at the main shaft neck part in the middle of the bent axle is a movable detecting support, sliding mechanisms are arranged below the supporting bases (1), a measuring contact of the dial indicator (13) is perpendicular to the detecting platform (14), and the coaxiality of each main shaft neck is detected. The building technology implementation and product quality of the bent axle are guaranteed, and technology and quality assurance is provided for reliable operation of the internal combustion engine and the whole device.

Owner:CRRC LUOYANG CO LTD

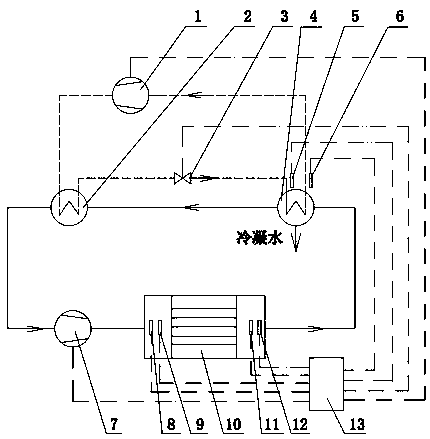

Control method of closed variable frequency heat pump drying equipment

ActiveCN111365977AReduce energy consumptionAchieve high efficiency and energy savingMechanical apparatusHeat pumpsThermodynamicsEngineering

The invention relates to a control method of closed variable frequency heat pump drying equipment. The control method comprises the following steps: a relation I of equivalent air inlet temperature T0' of a drying bin along with deviation change of actual air inlet humidity phi 1 and set air inlet humidity phi 0 is built; a controller adjusts the frequency of a variable frequency compressor through comparing the actual air inlet temperature T1 with the equivalent air inlet temperature T0'; the controller adjusts the openness of a throttling valve according to the optimal operation demands of aheat pump system and through comparing the actual air inlet humidity phi 1 with the set air inlet humidity phi 0; and the controller adjusts the frequency of a variable frequency fan through comparing the actual humidity change value delta phi of medium air entering and exiting from the drying bin with the set air humidity difference value delta phi' and comparing the actual temperature change value delta T with the set air temperature difference value delta T'. The control method has the following advantage: the drying equipment realizes the operation energy conservation under the conditionof satisfying drying process parameters.

Owner:SHUNDE POLYTECHNIC

Double-arm independent cooperation automatic assembling device and assembling process thereof

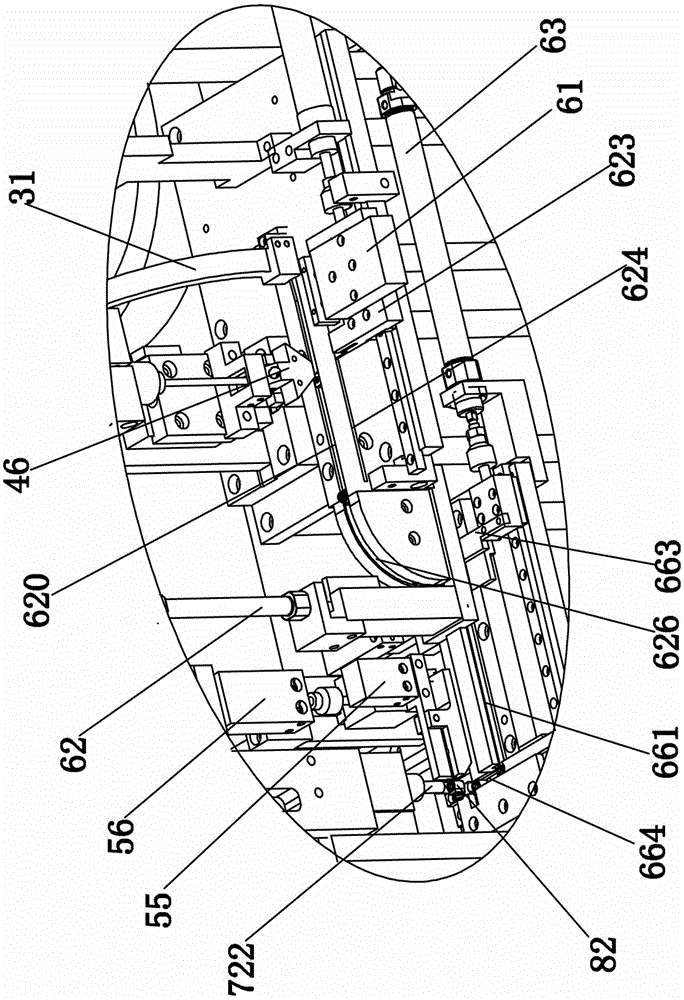

ActiveCN108908346AIncrease speedLow assembly defect rateProgramme-controlled manipulatorEngineeringLinear motor

The invention discloses a double-arm independent cooperation automatic assembling device and the assembling process thereof. The assembling device comprises flying-up feeding mechanisms, a product conveying mechanism, a bearing mechanism, and assembling manipulators. The number of the flying-up feeding mechanisms is two. The product conveying mechanism is arranged between the two flying-up feedingmechanisms in a longitudinal direction; the bearing mechanism is arranged above the product conveying mechanism in a transverse direction in a straddling mode; and the number of the assembling manipulators is at least two. The materials led out by the two flying-up feeding mechanisms are adsorbed or clamped by the two assembling manipulators separately and independently, and then are assembled toa product at a working position. The assembling device is provided with double-feeding and double-manipulator structures, driven by a linear motor, so that material feeding types and material takingrate are improved to a maximum extent. The manipulators have the functions of adsorption, clamping, rotation and pressure detection at the same time, is suitable for carrying and assembling materialsin different types and sizes, and a defective product rate is low. Synchronous linkage of adsorption and clamping is achieved through a single power structure, the synchronism is effectively guaranteed while the structure is simplified.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

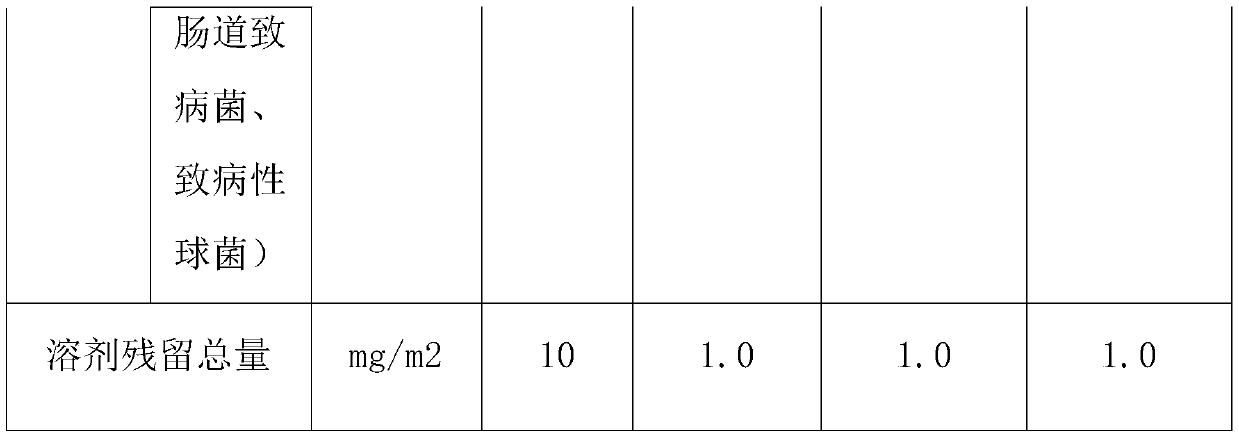

Functional lining body paper for cigarettes and preparation method of functional lining body paper

InactiveCN110565433ALow water vapor transmission rateLow water absorptionFlexible coversDefoamers additionFiberWater vapor

The invention provides functional lining body paper for cigarettes and a preparation method of the functional lining body paper. The body paper is of a double-layer structure, one layer is a lining paper body paper base layer, and the other layer is a functional coating. The preparation method comprises the following steps: performing pulping treatment on a fiber raw material; adding a wet strength agent, a sizing agent, a defoaming agent, a retention aid and a reinforcing agent into the pulp after the pulping treatment is finished, performing uniform mixing, and applying the pulp to a mesh for treatment; performing squeezing dehydration treatment on the pulp subjected to treatment by the mesh to obtain the body paper base layer; coating the surface of the body paper base layer by a functional coating; and sequentially drying, coiling and slitting the coated body paper base layer to obtain the body paper. According to the invention, the surface of the body paper base layer of the lining paper for cigarettes is coated by the functional coating, so that the lining paper for cigarettes has high-barrier, moisture-preserving and moisture-preserving functions, and compared with conventional printing lining paper and pre-coated lining paper, the body paper of the lining paper for cigarettes has a lower water vapor transmission rate and a water absorption rate and higher wet strength.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

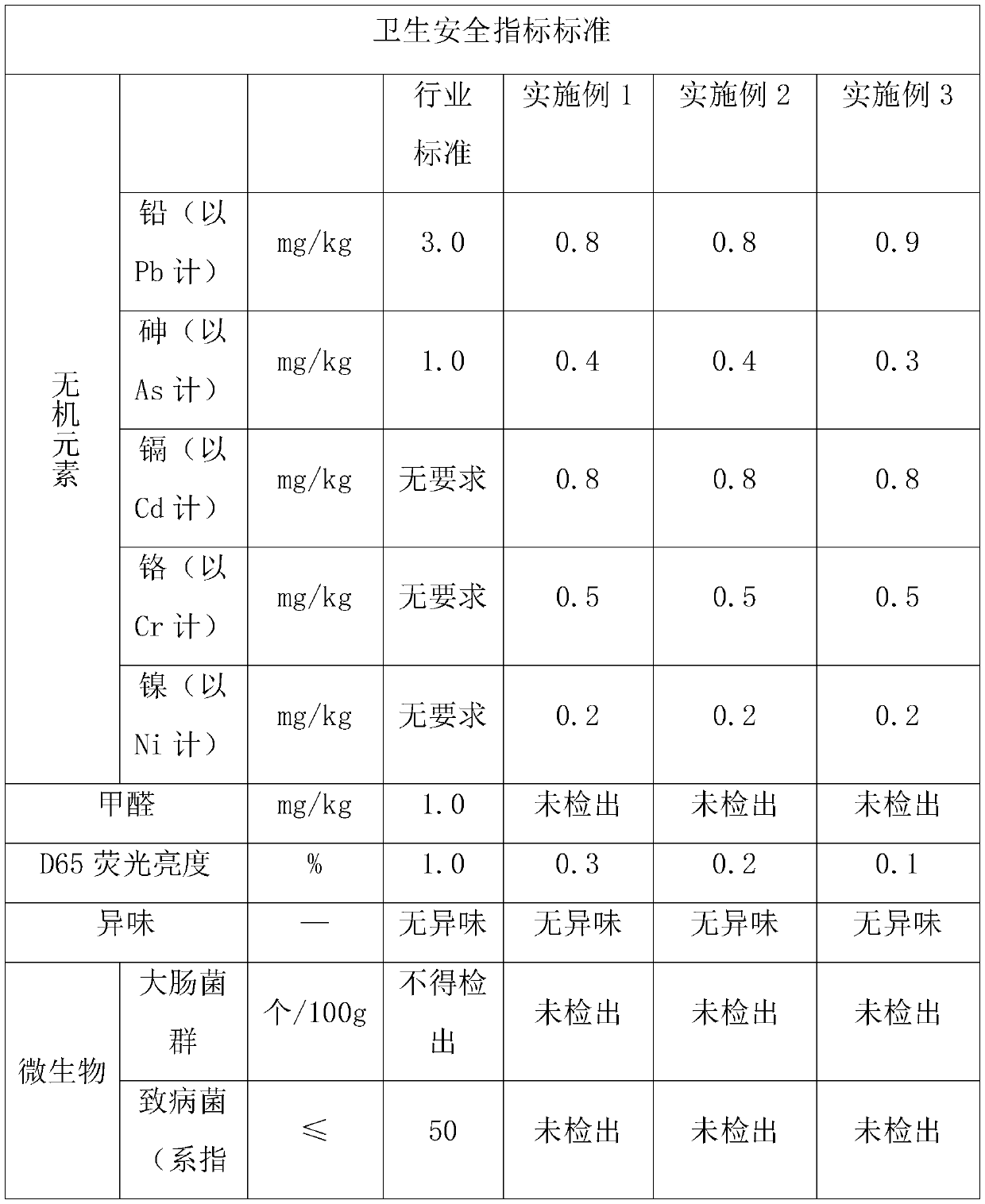

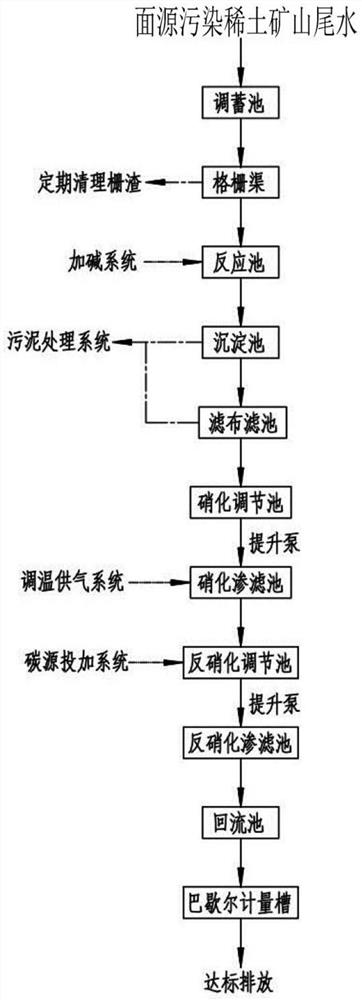

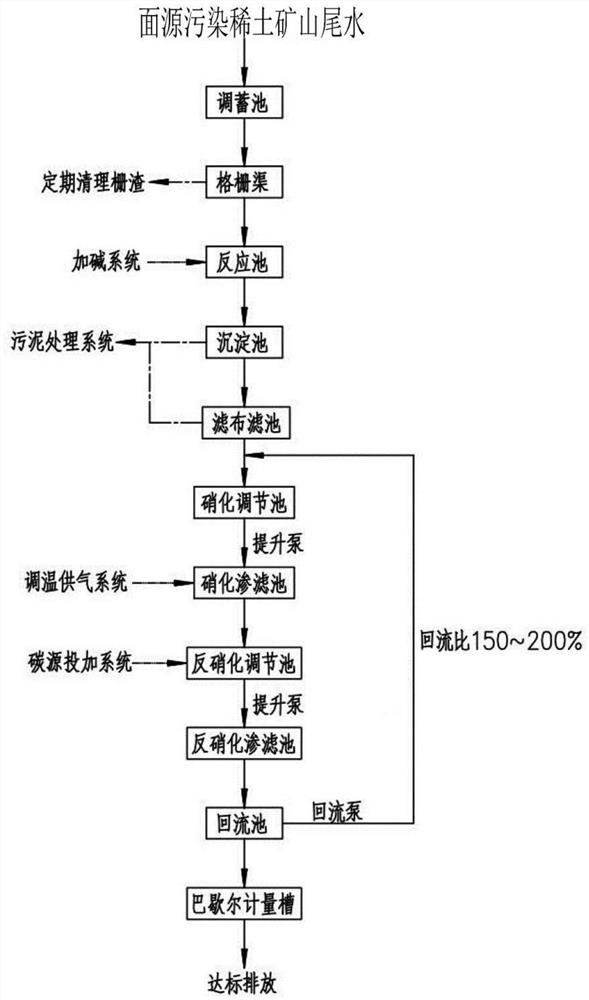

Rare earth mine tail water surface source pollution efficient percolation treatment system and process

InactiveCN112390461AWell-designed unitAdaptableWaste water treatment from quariesWater contaminantsDrainage basinPollution

The invention discloses a rare earth mine tail water surface source pollution efficient percolation treatment system and process, and aims to solve the problem that an existing nitrification and denitrification treatment process has higher requirements on operating temperature, carbon source demand, oxygen supply and the like, and greatly restricts the treatment of rare earth tail water. The system comprises a drainage basin regulation and storage unit, a pretreatment unit, a percolation biochemical treatment unit, a reflux unit and an auxiliary unit, According to the process, when the environment is in a normal water season, in a rich water period and in a dry water and low temperature period, the operation modes are respectively processed according to conditions. According to the systemand the process thereof, through perfect unit design, the stable operation of the surface source polluted rare earth mine tail water treatment system and process can be ensured under various conditions, particularly, the stable operation of nitrification and denitrification infiltration tanks in a core infiltration biochemical treatment unit of the system is ensured, and the maintenance labor intensity is further reduced.

Owner:江西挺进环保科技股份有限公司

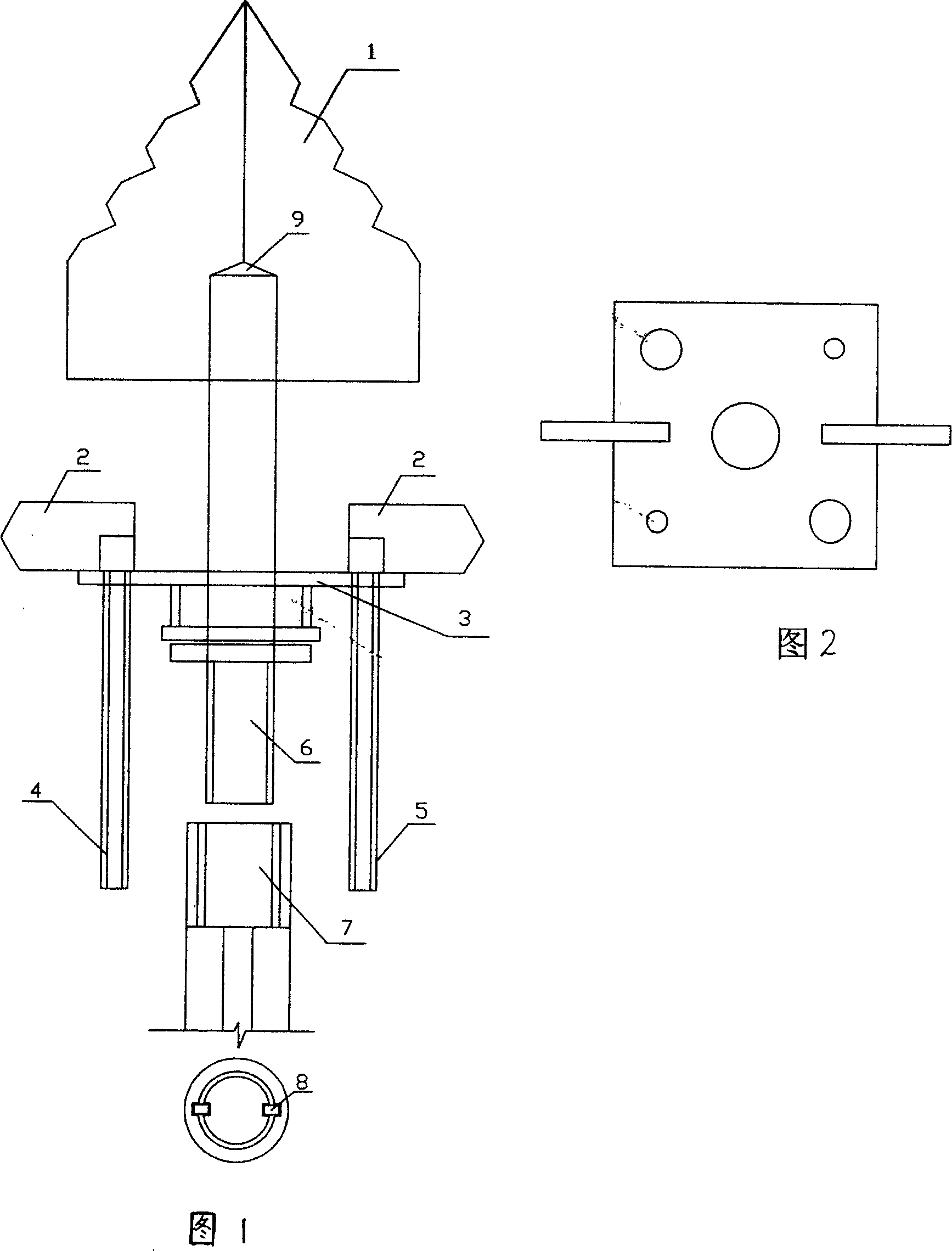

Soil body anchor rod construction process and anchor rod member thereof

InactiveCN101096849AGuarantee the construction qualityGuaranteed workmanshipExcavationsBulkheads/pilesHigh pressureCement mortar

The invention discloses a working craft of solid body anchor bar, which comprises the following steps: A, drilling with anchor bar machine; feeding water through self high pressure of drilling rod; reaching to high pressure on the drilling place for water flow; forming cutting for soil layer; B, setting the drill as zigzag type; connecting the drill and prestressed hank anchor solid end with common bearing or pressure bearing; supplementing a slip casting pipe; drilling into designing depth as the drill; C, taking up the drilling rod; leaving the prestressed hank anchor solid end, slip casting pipe and drill at the bottom of the drilling hole; proceeding slip casting or cement paste or cement sand paste through the casting pipe; reaching the designing demand; forming the inherent stress anchor rod. This method can increase efficiency and decrease cost, which can be used to breast, continuous wall under floor and so on working craft.

Owner:于艳芳

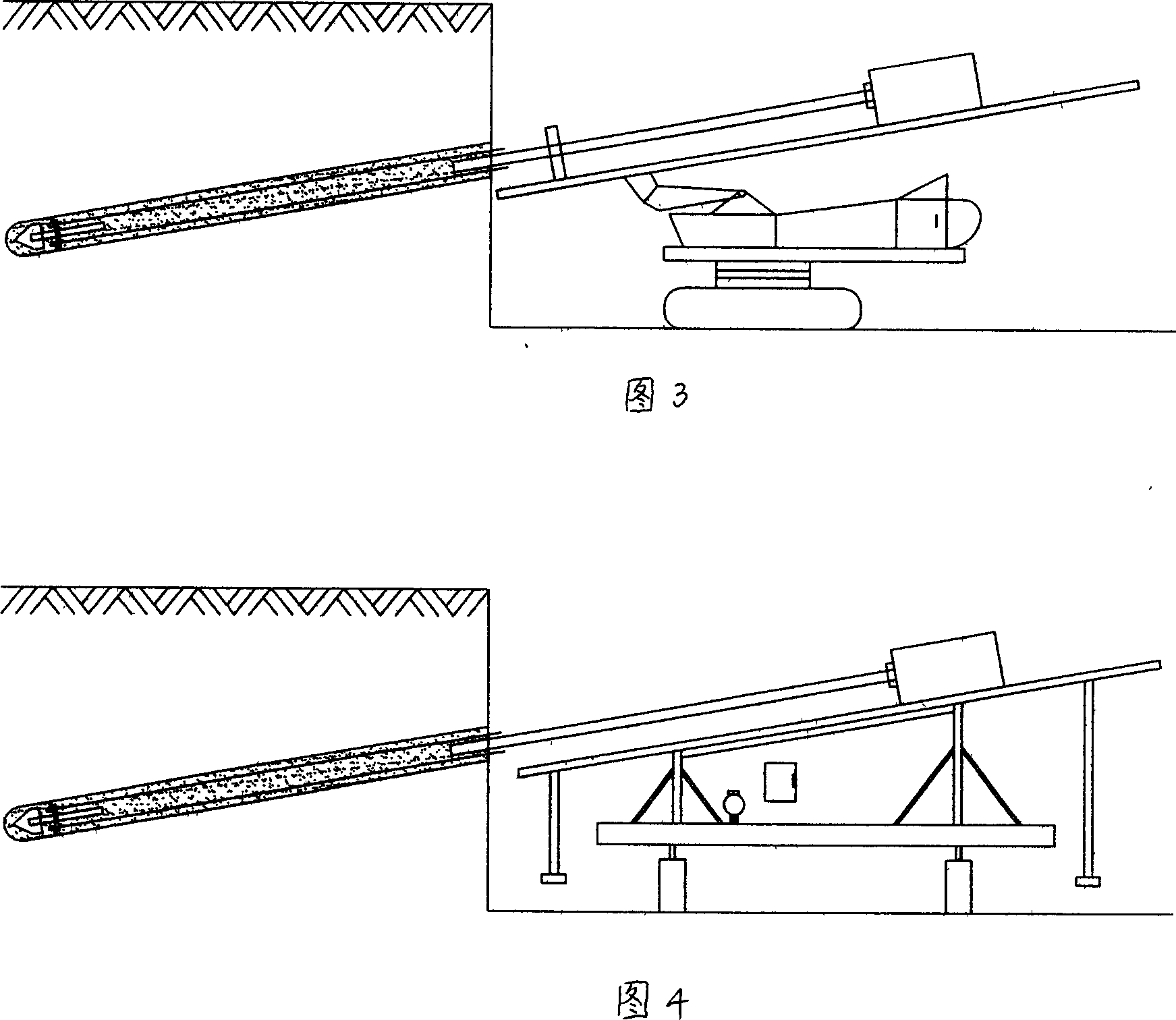

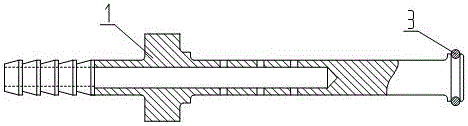

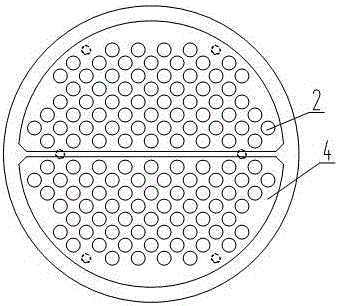

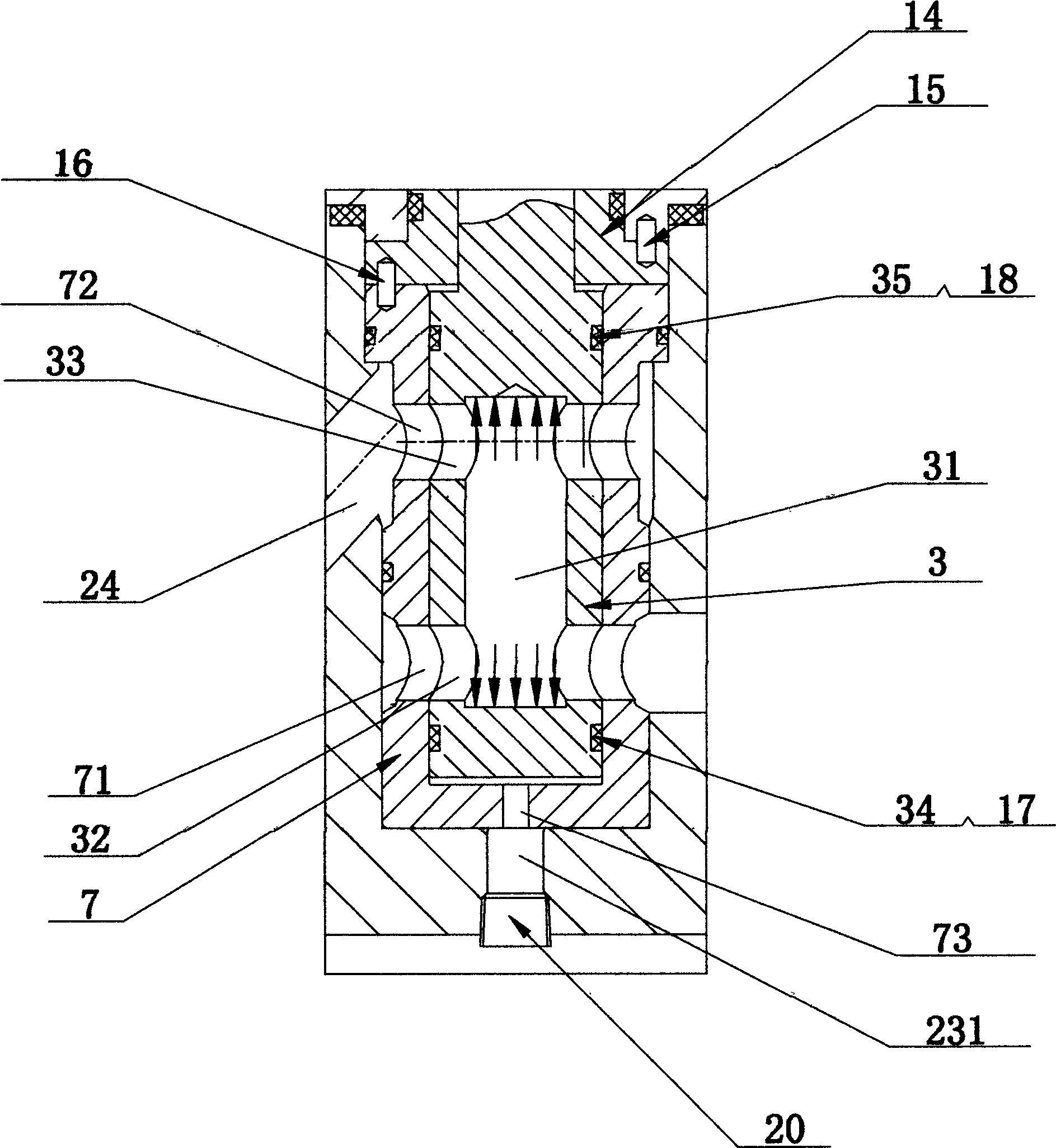

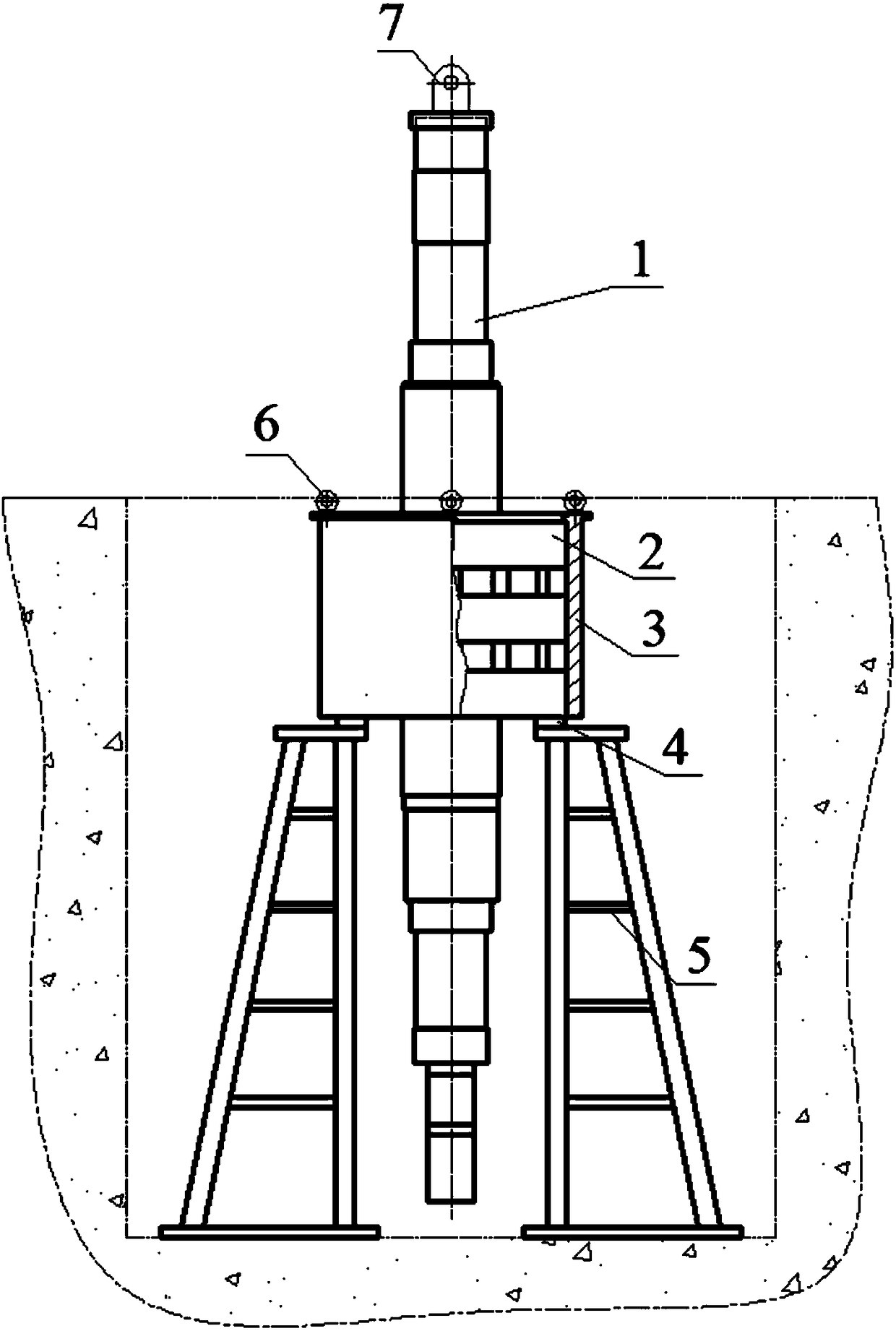

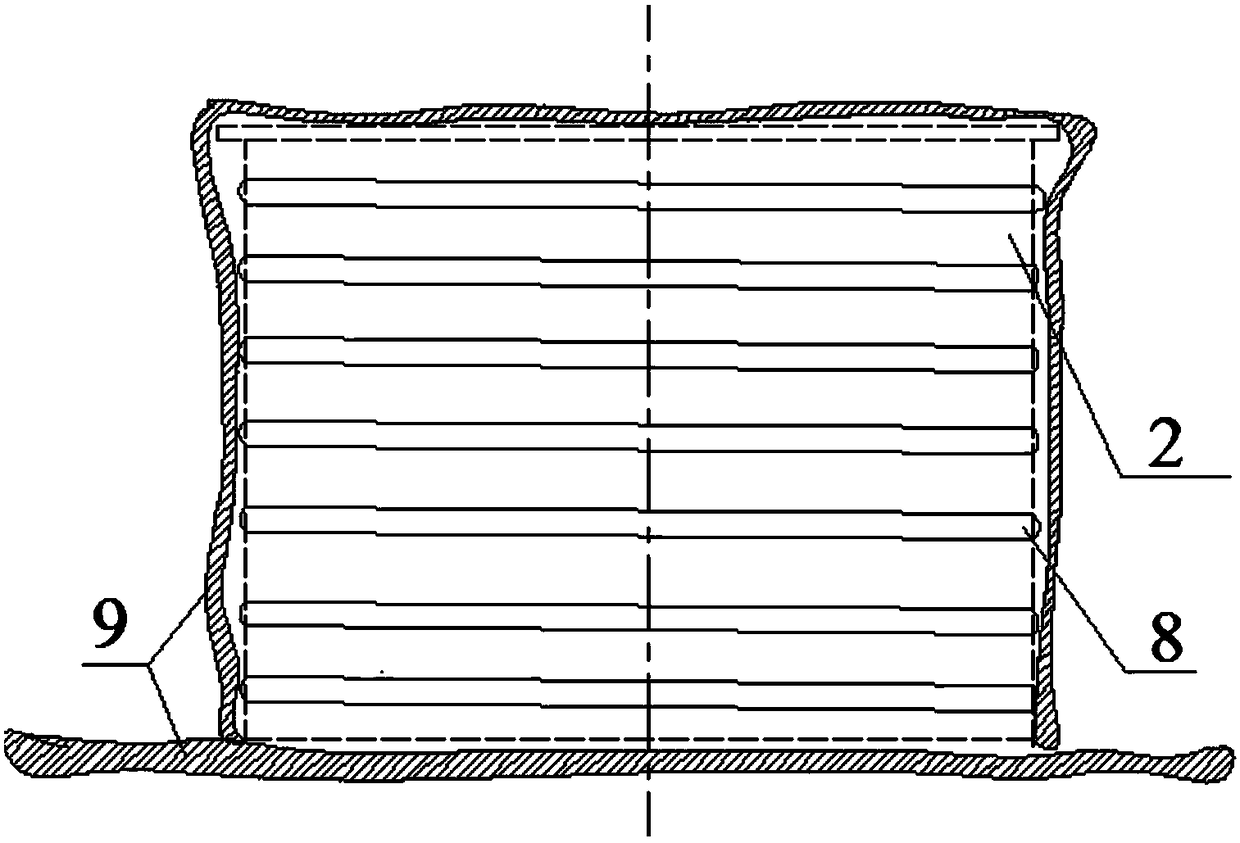

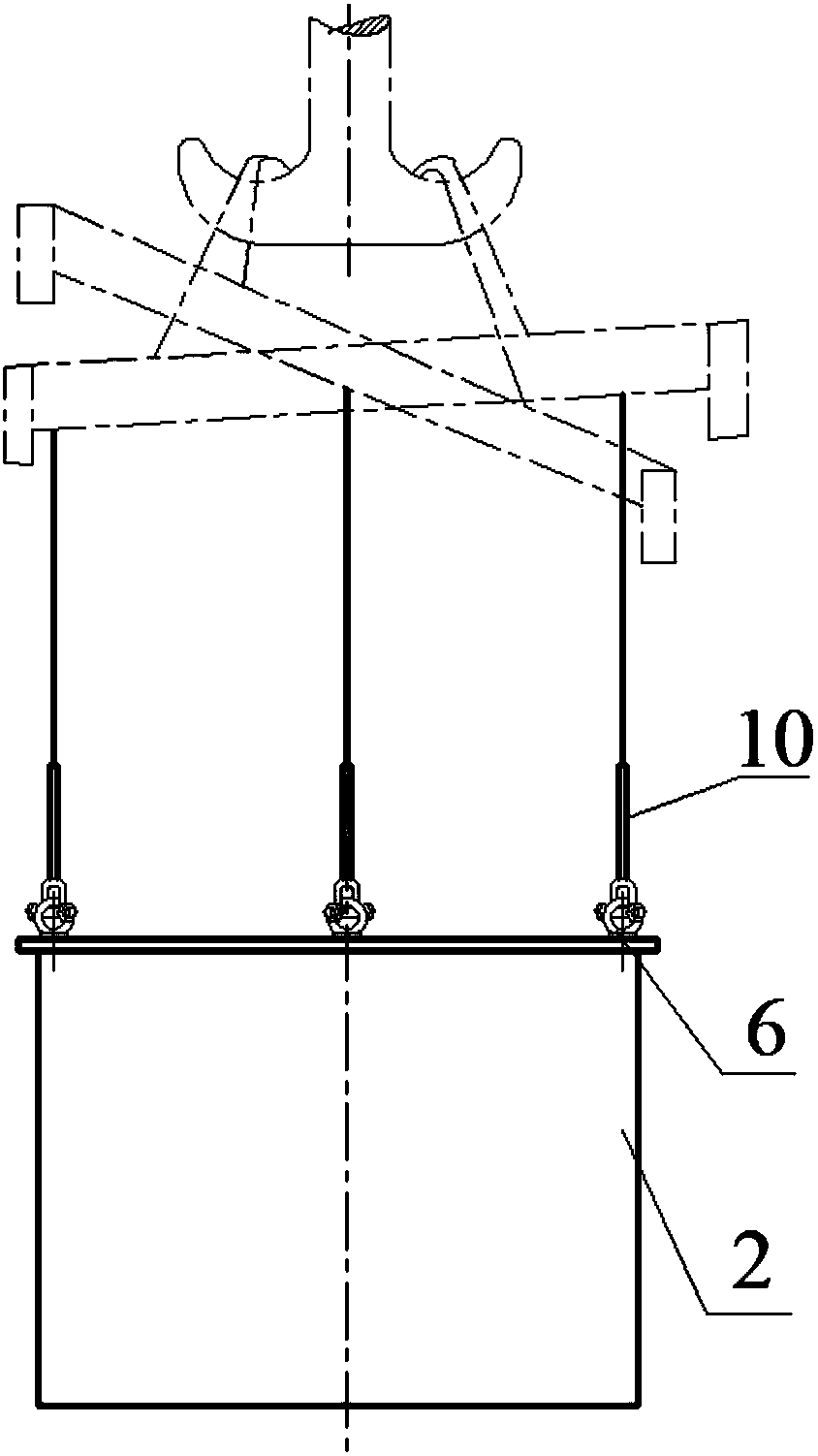

Titanium heat exchange tube welded argon shield device and using method thereof

InactiveCN105935832AArgon gas flow is smooth and sufficientGuaranteed process performance and mechanical propertiesShielding gas supply/evacuation devicesHeat exchange apparatusArgon flowTitanium

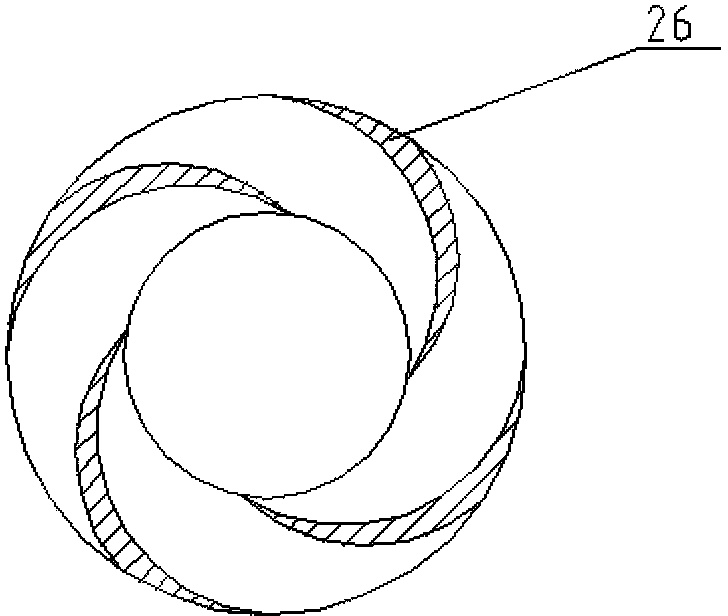

The invention discloses a titanium heat exchange tube welded argon shield device, and belongs to the field of welding machining in mechanical industry. The problem of titanium welding is solved. The device structurally comprises a main body device 1 and an O-shaped rubber sealing ring 3. The main body device 1 is in a pipe shape. One end of the main body device is provided with an air inlet pipe, and the other end of the main body device is closed. The position, close to the air inlet pipe, of the main body device 1 is provided with a large boss and a small boss. The pipe side face is provided with evenly-distributed small holes. The closed end is provided with an annular groove where the O-shaped rubber sealing ring 3 is placed. A using method of the titanium heat exchange tube welded argon shield device comprises the steps that the shield device is placed into a heat exchange pipe 2 to be welded, and the connector part of the air inlet pipe is left outside the heat exchange pipe; the O-shaped rubber sealing ring 3 is tightly attached to the inner wall of the heat exchange pipe 2 to play a sealing role; air inside the heat exchange pipe 2 is cleaned and replaced by argon for a period of time before welding; during welding, argon flows out of the evenly-distributed small holes and flows in the gap between two pipes; after welding, argon is reserved in the pipe for a period of time after a welding gun is turned off, and then the shield device is retreated. The titanium heat exchange tube welded argon shield device is simple in structure and low in cost and ensures production quality.

Owner:LANZHOU LS HEAVY EQUIP

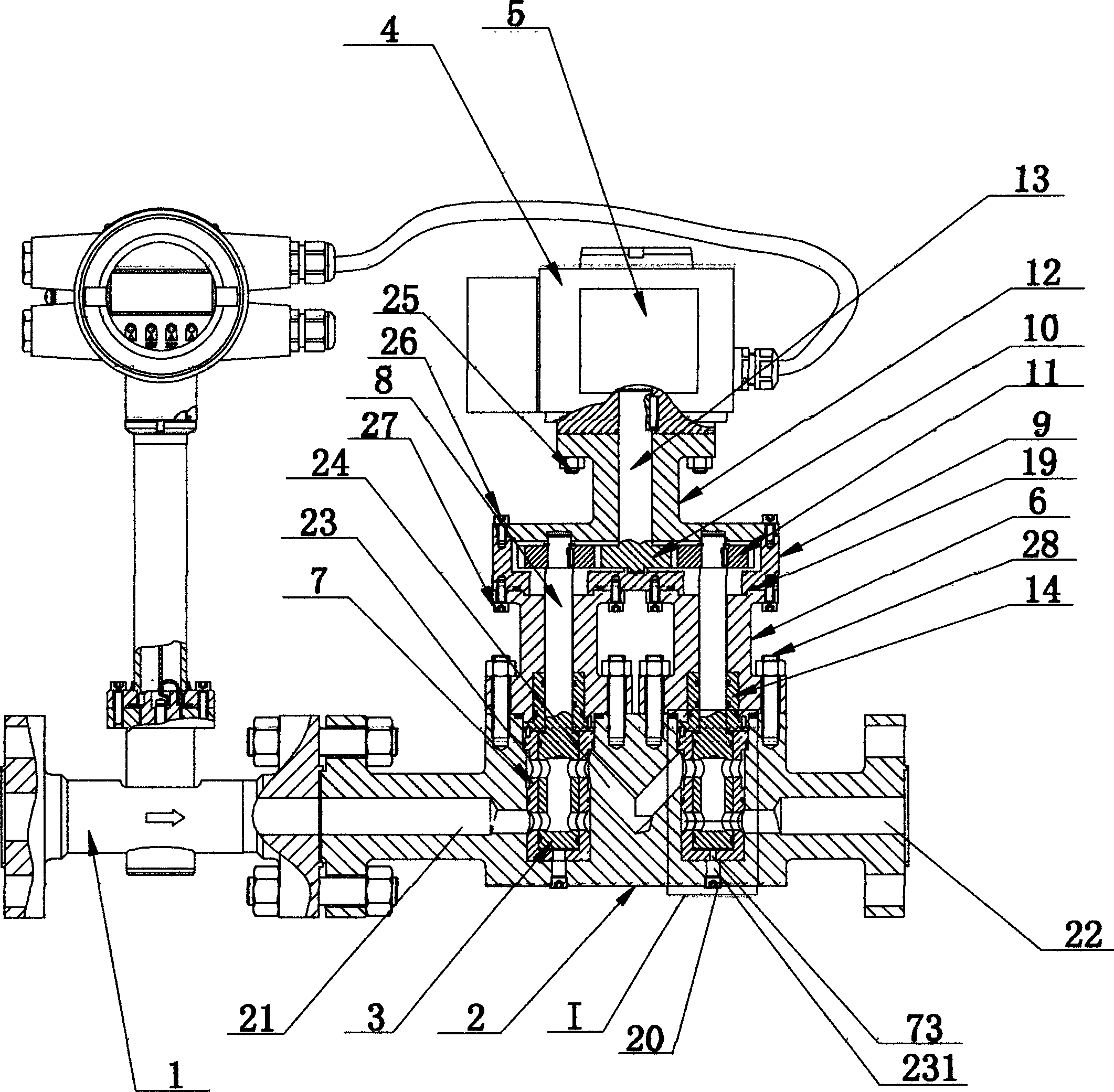

Ultra-high pressure flow controller

ActiveCN104265963AFirmly connectedEasy to connect and fixOperating means/releasing devices for valvesEqualizing valvesUltra high pressureInternal cavity

The invention discloses an ultra-high pressure flow controller comprising a flowmeter, a valve body, valve cores, an electric actuating mechanism, a digital regulator and a bonnet. A fluid passageway is formed between two inner chambers in the valve body. The longitudinal section of the fluid passageway is in the V shape. A valve rod is arranged at the upper end of each valve core in the integral manner. A gear box is arranged at the upper end of the bonnet and internally provided with a drive gear. Two lateral ends of the drive gear are provided with driven gears meshed with the drive gear. Central lines of the driven gears and those of the valve rods below the driven gears coincide. The upper ends of the valve rods are connected with the driven gears upon the same to form linkage. A frame is detachably arranged at the upper end of the gear box. The electric actuating mechanism is connected with the upper end of the frame. A connecting shaft is arranged between the electric actuating mechanism and the drive gear. The lower end of the connecting shaft is fixedly connected with the drive gear, and the upper end of the connecting shaft is connected with the electric actuating mechanism. The connecting shaft is driven by the electric actuating mechanism to rotate. The ultra-high pressure flow controller is reasonable in structural design, excellent in performance, long in service life and high in safety.

Owner:ZHEJIANG AOXIN INSTR

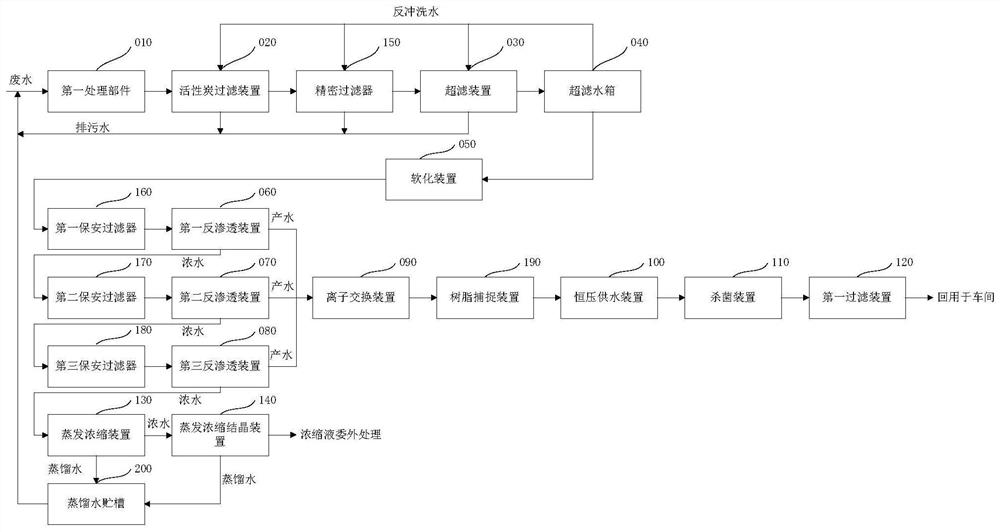

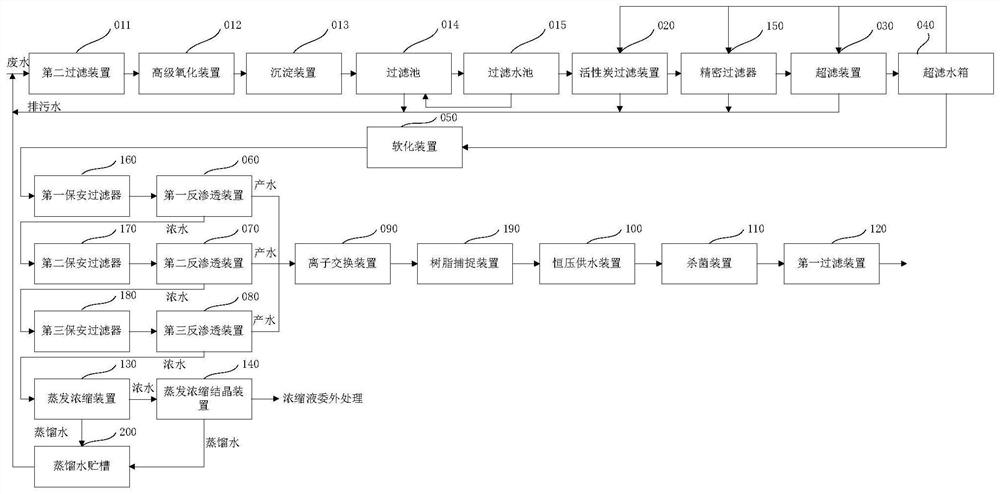

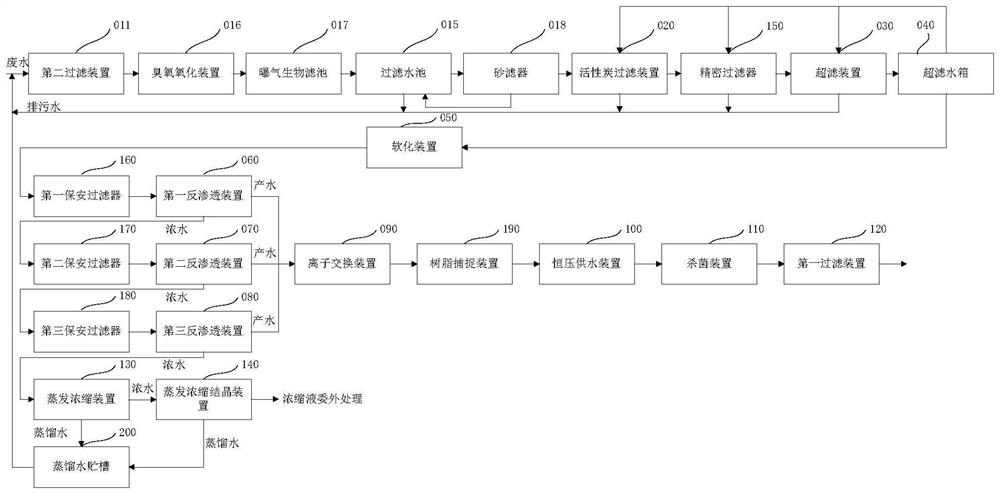

Treatment and reuse system and method for up-to-standard discharged painting wastewater

PendingCN111943457AMeet water quality requirementsGuaranteed uptimeWater/sewage treatment by irradiationSpecific water treatment objectivesWater useProduction line

The invention provides a treatment and reuse system and and method for up-to-standard discharged painting wastewater. A first treatment part, an activated carbon filtering device or a resin adsorptionCODcr device, an ultrafiltration device, an ultrafiltered water tank, a softening device and a first reverse osmosis device in the treatment and reuse system for the up-to-standard discharged painting wastewater are in fluid communication in sequence; an ion exchange device, a constant-pressure water supply device, a sterilization device and a filtering device are in fluid communication in sequence; penetrating fluid outlets of the first reverse osmosis device, a second reverse osmosis device and a third reverse osmosis device separately communicate with the ion exchange device; and a residual seepage liquid outlet of the first reverse osmosis device communicates with the second reverse osmosis device, and a residual seepage liquid outlet of the second reverse osmosis device communicateswith the third reverse osmosis device. According to the invention, the wastewater which is discharged after reaching the standard is deeply treated and is reused in a paint workshop as dilution waterfor a vehicle body surface treating agent in the paint workshop and pure water for a painting production line, so the wastewater can be recycled and prevented from polluting the environment.

Owner:SHANGHAI YIKE GREEN ENG

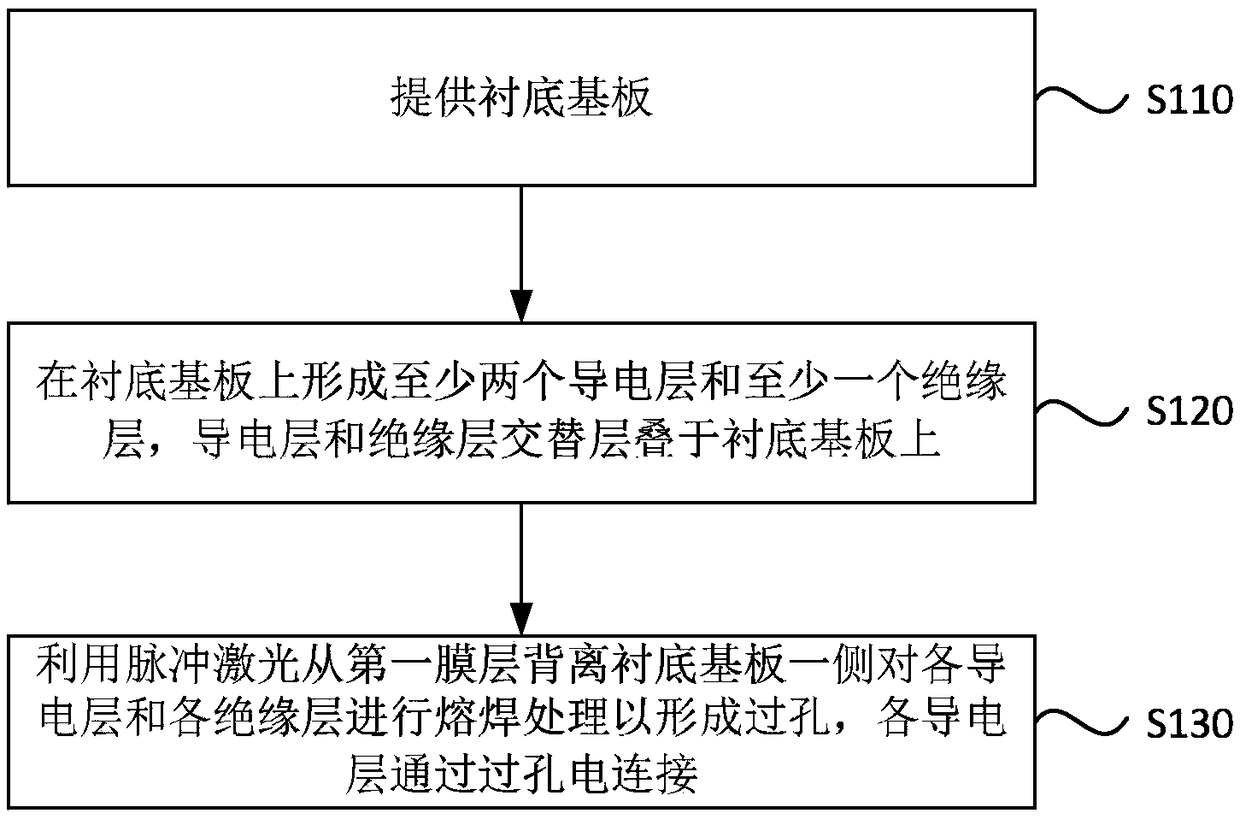

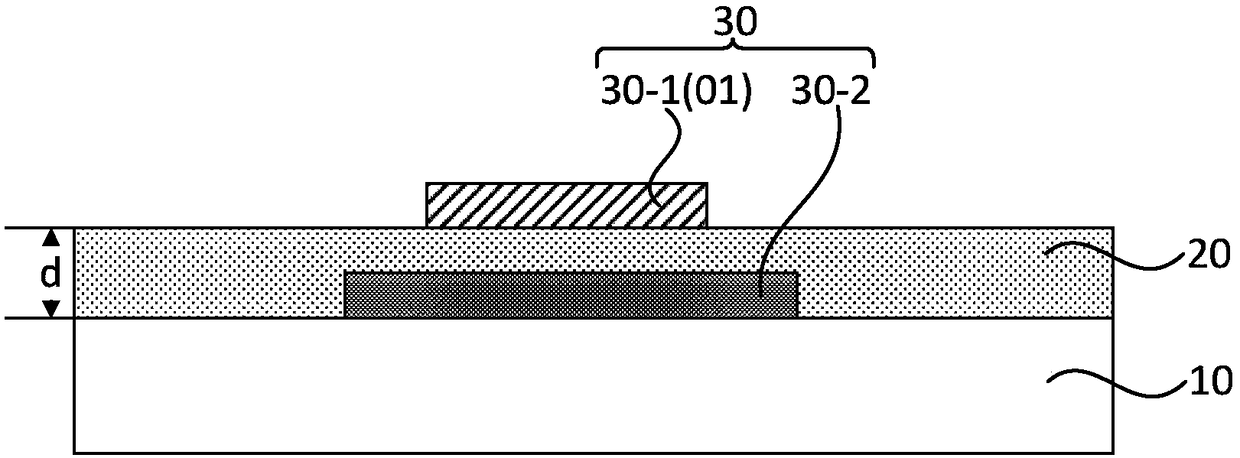

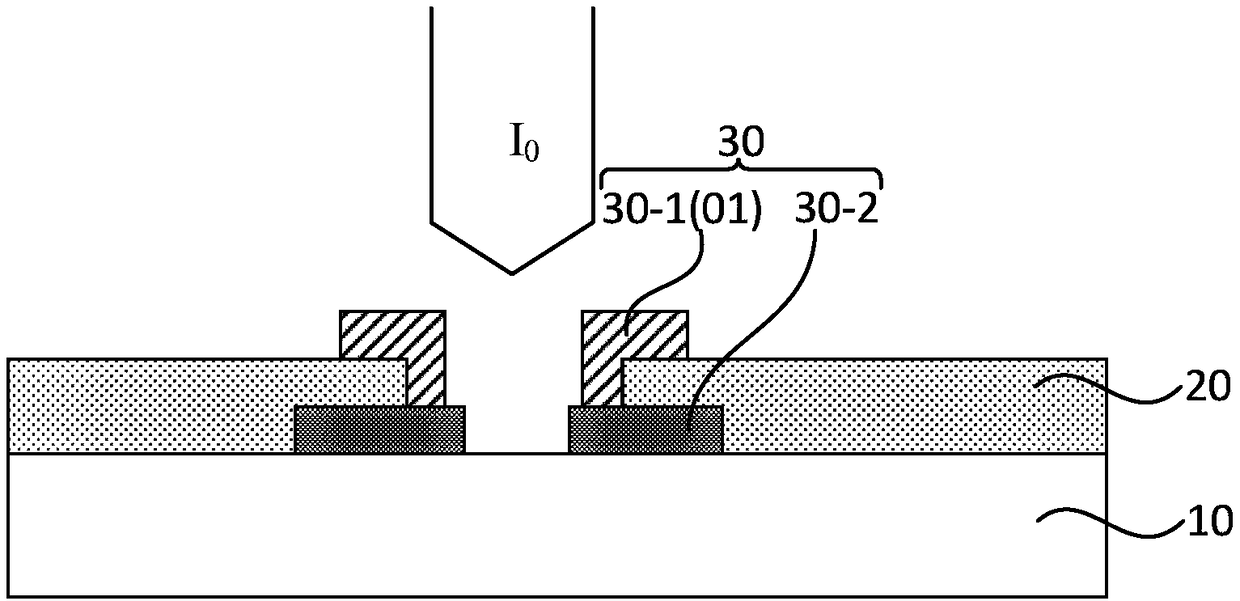

A through-hole manufacturing method, an array substrate manufacturing method and an array substrate

ActiveCN109216266AGuaranteed workmanshipGuaranteed costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLaser

The embodiment of the invention discloses a through-hole manufacturing method, an array substrate manufacturing method and an array substrate. The through-hole manufacturing method comprises the following steps of: providing a substrate substrate; At least two conductive layer and at least one insulating lay are formed on that substrate, and the conductive layer and the insulating layer are alternately laminate on the substrate; Wherein a film layer having a maximum distance between the at least two conductive layers and the at least one insulating layer and the substrate is a first film layer, A laser pulse is applied to each of that conductive lay and each of the insulating layers from the side of the substrate facing away from the first film lay to form holes, and each of the conductivelayers is electrically connected through the holes. The manufacturing method of the through hole provided by the invention can realize the purpose of simplifying the manufacturing process of the holes and reducing the manufacturing cost when electrically connecting a plurality of conductive layers.

Owner:SOUTH CHINA UNIV OF TECH

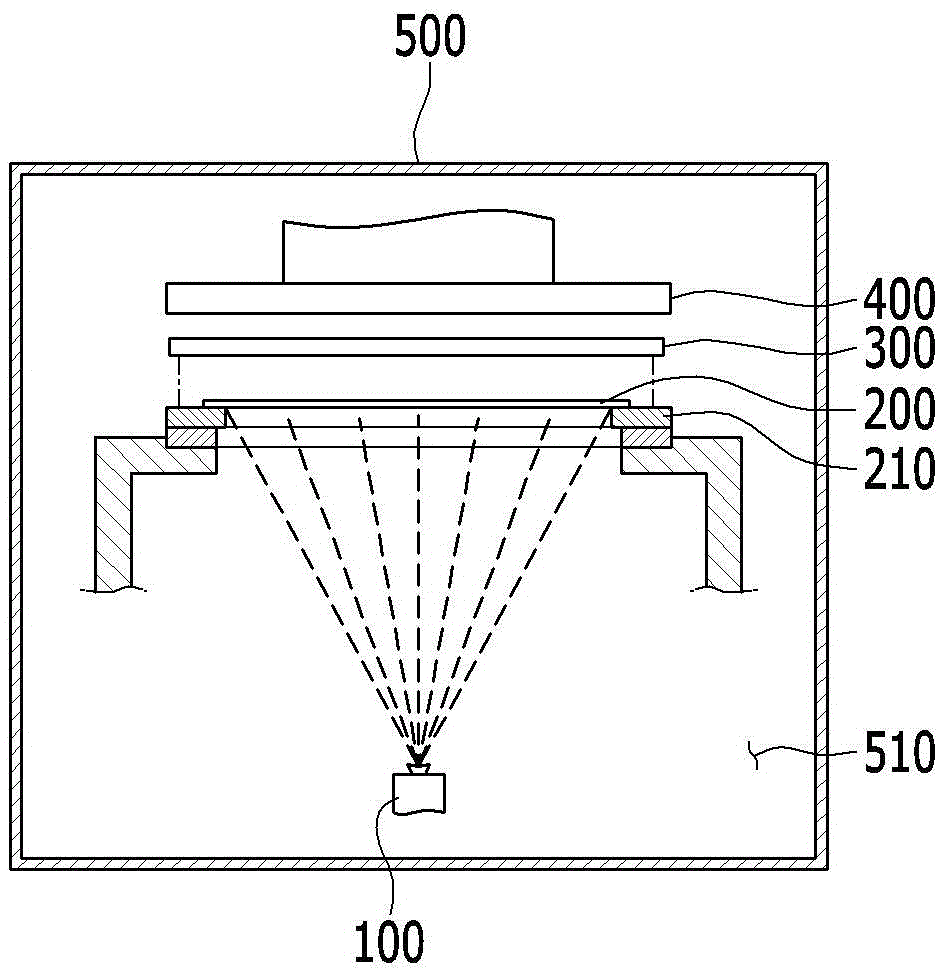

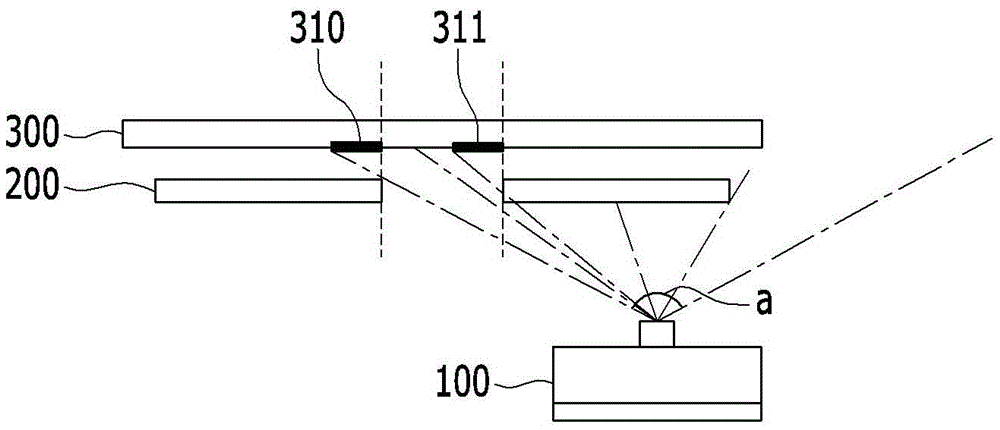

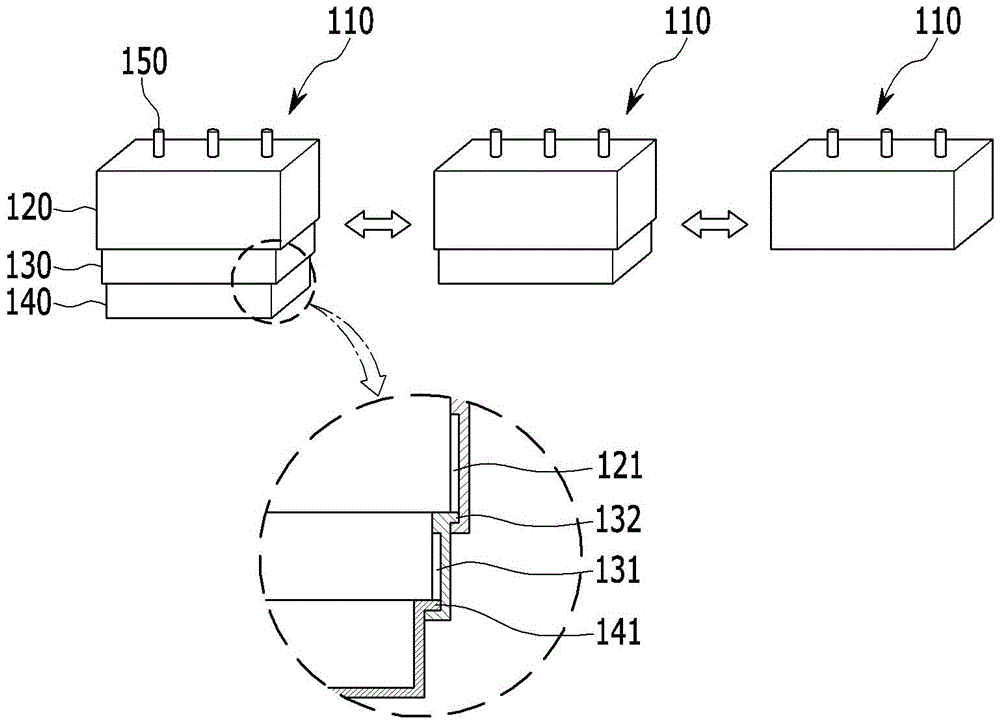

Precipitation source having volume changeable type crucible

InactiveCN105821380AFor fast and precise controlNarrow deposition angleVacuum evaporation coatingSputtering coatingThermal energyCrucible

Disclosed is a precipitation source having a volume changeable type crucible. The precipitation source comprises: a crucible containing an organic precipitate and having an overlaying structure, a heater heating the crucible and the organic precipitate, and at least one ejection nozzle arranged at one side of the crucible, wherein the overlaying structure is used for changing the internal volume. Through the construction, the provided precipitation source having a volume changeable type crucible has the following advantages that through change of the volume of the crucible containing the organic precipitate, volume control and thermal energy control are applied at the same time to fast accurately control the internal and external pressure differences of the crucible, and a relatively narrow precipitation angle is kept to reduce shadows. Furthermore, through the provided precipitation source, the process can be kept performing even if few organic precipitate is left at the final stage of precipitation.

Owner:SAMSUNG DISPLAY CO LTD

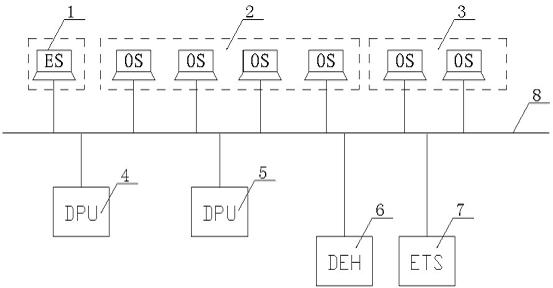

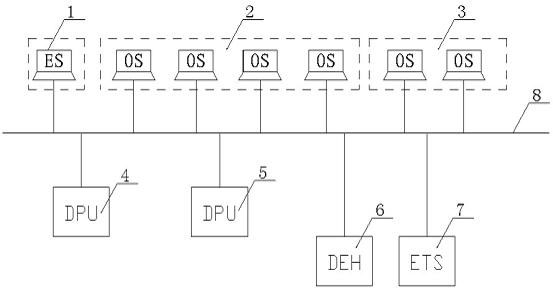

Integrated control system of cement clinker, waste heat power generation and steam turbine safety protection

InactiveCN102591294AAssurance process strategy and production managementSmooth runningTotal factory controlProgramme total factory controlProcess engineeringData sharing

The invention provides an integrated control system of cement clinker, waste heat power generation and steam turbine safety protection, in particular a plant control system that integrates cement clinker DCS, waste heat power generation DCS and steam turbine safety protection DEH and ETS. The invention is characterized in that the integrated control operating system with a same database, a same data industrial Ethernet, same DCS / PLC software, same software compatible DCS / PLC hardware and a same human-computer interface realizes local operation and overall monitoring of the whole plant through data sharing and network sharing so that production and equipment operate safely and efficiently so as to reduce the fixed number of workers and the labor intensity.

Owner:娄卡奔新能源科技发展(上海)有限公司

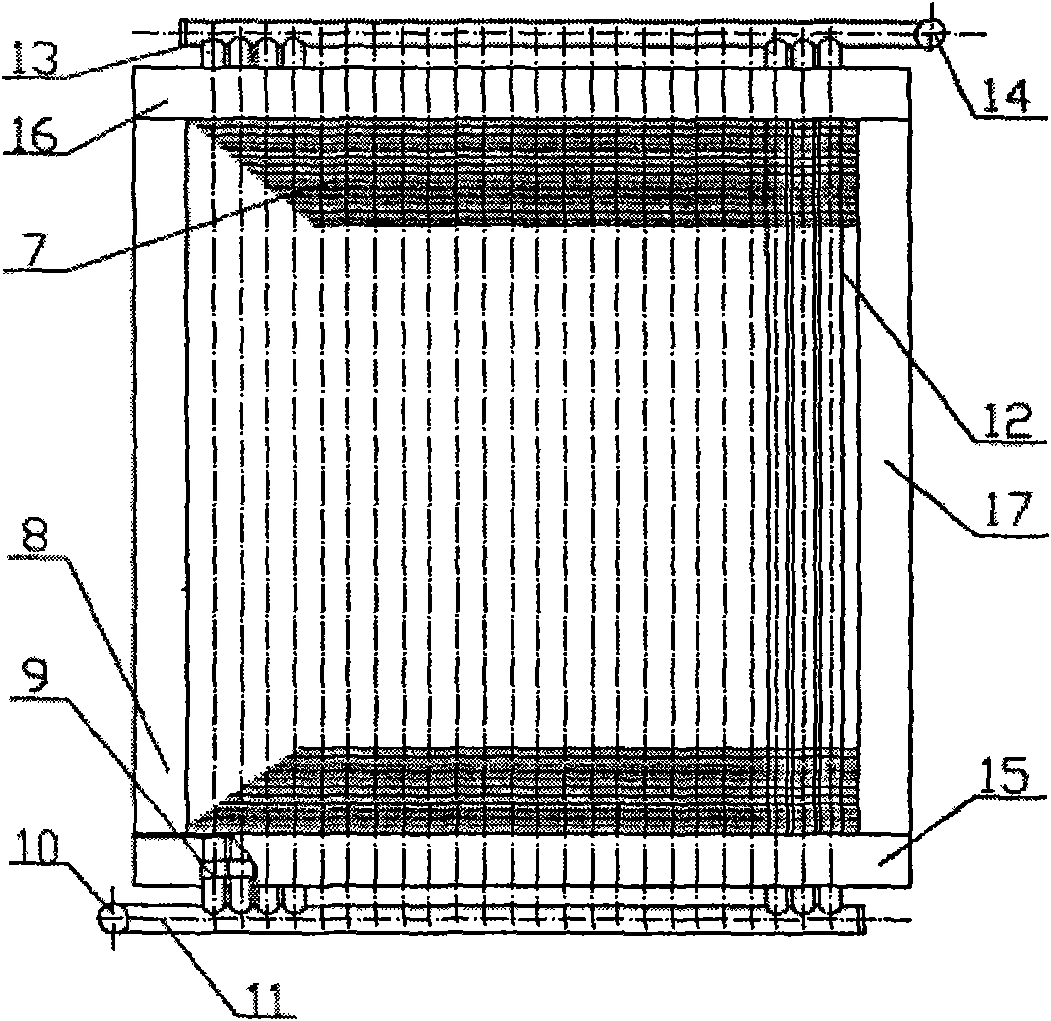

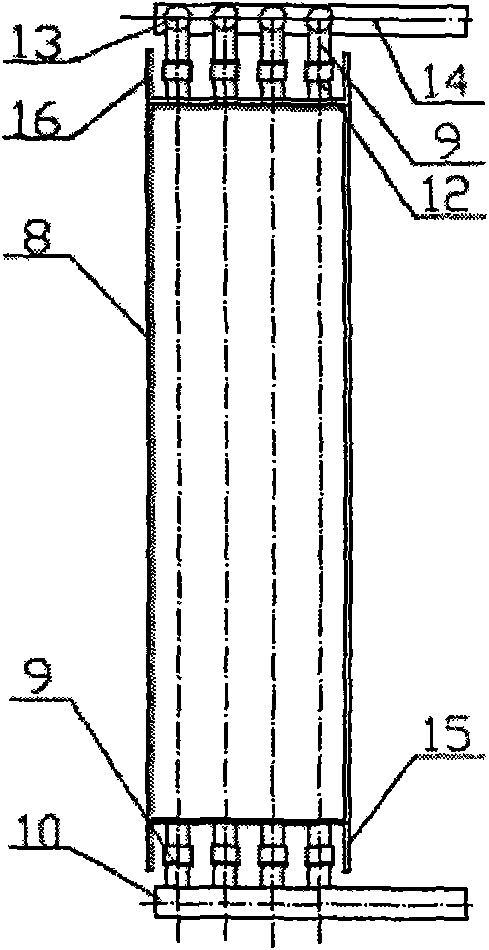

Separate combination type air heat regenerator

ActiveCN101644477AImprove heat transfer efficiencyImprove energy savingEnergy recovery in ventilation and heatingIndirect heat exchangersCold airTemperature difference

The invention relates to a separate combination type air heat regenerator, solving the recycling problem of air heat (cryogenic) energy in an air conditioner system. The invention comprises a hot sideheat exchanger, a cold side heat exchanger, a hot side fan and a cold side fan; the heat exchangers comprise more than one row of heat exchanging pipes, each row comprises more than ten heat exchanging pipes; the upper extending-outwards end of each heat exchanging pipe on each row is respectively communicated with an air converging pipe through a connecting pipe, and one end of four air converging pipes is an air inlet end or an air outlet end; the lower extending-outwards end of each heat exchanging pipe on each row is respectively communicated with a liquid converging pipe through a connecting pipe, and one end of four liquid converging pipes is a liquid outlet end or a liquid inlet end. The invention is a high effective air heat exchanger, as long as the temperature difference of coldair flow and hot air flow exceeds 3 DEG C the energy can be recycled, and with the increase of the temperature difference of cold air flow and hot air flow the energy saving effect grows more obvious. The invention can be widely applied in conditions such as air cooling, air heating, air backheating and the like in refrigeration air conditioner laboratories.

Owner:HEFEI GENERAL ENVIRONMENT CONTROL TECH

Machine and method for forming free curved surfaces of silicate glass

InactiveCN107129133AImprove insulation effectReduce power consumptionGlass reforming apparatusGlass productionSilicate glassMolding machine

The invention discloses a machine and a method for forming free curved surfaces of silicate glass, and is applicable to machines and methods for forming free curved surfaces of silicate glass. The machine comprises a tank (11). An upper plane of the tank is fixed to a worktable (1), a furnace chamber (14) and a cooling chamber (15) are mounted above the worktable, the cooling chamber is mounted at the front end of the furnace chamber, a feed chamber (2) and a discharge chamber (8) are arranged on two sides of the furnace chamber, a push mechanism B (10) is mounted on the right side of the cooling chamber, the left side of the worktable is connected with a push mechanism A (13) by bolts, preheating devices (3), forming devices (4), a setting device (20) and a slow cooling device (5) are arranged in the furnace chamber, and cooling devices (6) are arranged in the cooling chamber. The machine and the method have the advantage that the problems of explosion and deformation phenomena of glass, decrease of the yield of products and deterioration of the quality of the products due to the fact that existing hot bending machines for the glass with curved surfaces directly enter annealing stations after the glass is formed, molds are excessively high in cooling speeds and the glass is excessively high in temperature difference can be solved.

Owner:HARBIN XINLI PHOTOELECTRIC TECH

Centrifugal dewatering drying device and drying method for tobacco leaves

InactiveCN104041931ARealize dehydration and dryingContinuous dischargeTobacco preparationPulp and paper industryMoisture

The invention discloses a centrifugal dewatering drying device for tobacco leaves, which comprises a machine base, wherein a sieve basket is arranged in a cavity formed by the machine base and an upper cover; a material distributing cone is fixedly arranged at the top of the sieve basket; a feeding cover is arranged above the material distributing cone; the sieve basket is fixedly connected with a central shaft through the material distributing cone; a spiral scraper arranged in the sieve basket is fixedly connected with a rotor shaft; a sieve basket driven gear is fixedly arranged on the central shaft; a scraper driven gear is fixedly arranged on the rotor shaft; a motor is used for driving a middle shaft to rotate through a belt driving pair; the middle shaft is used for respectively driving the sieve basket and the spiral scraper to rotate. According to the invention, the tobacco leaves are dried through centrifugal dewatering, so that the large dewatering problem of the tobacco leaves is solved, the moisture content of the tobacco leaves is reduced from 130% to about 50%; the feeding and discharging can be continuously performed; the tobacco leaves after dewatering are loosened and are not caked, so that the technical requirement of subsequent process and re-drying of the tobacco leaves is met. The invention also discloses a centrifugal dewatering drying method for tobacco leaves.

Owner:CHINA TOBACCO MACHINERY TECH CENT +3

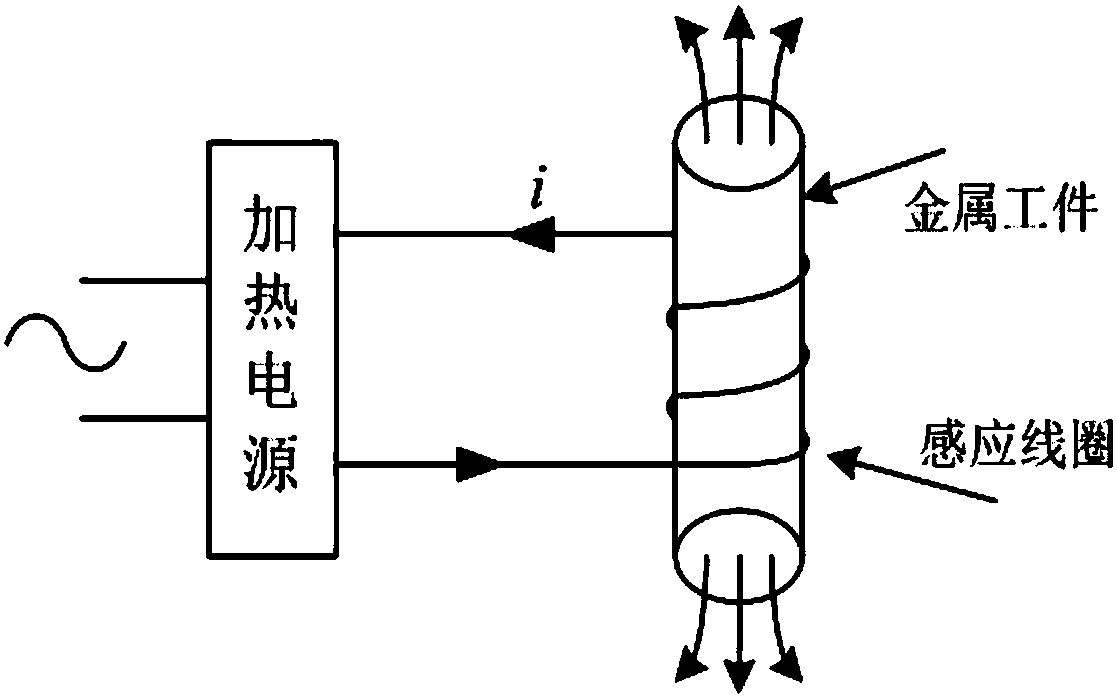

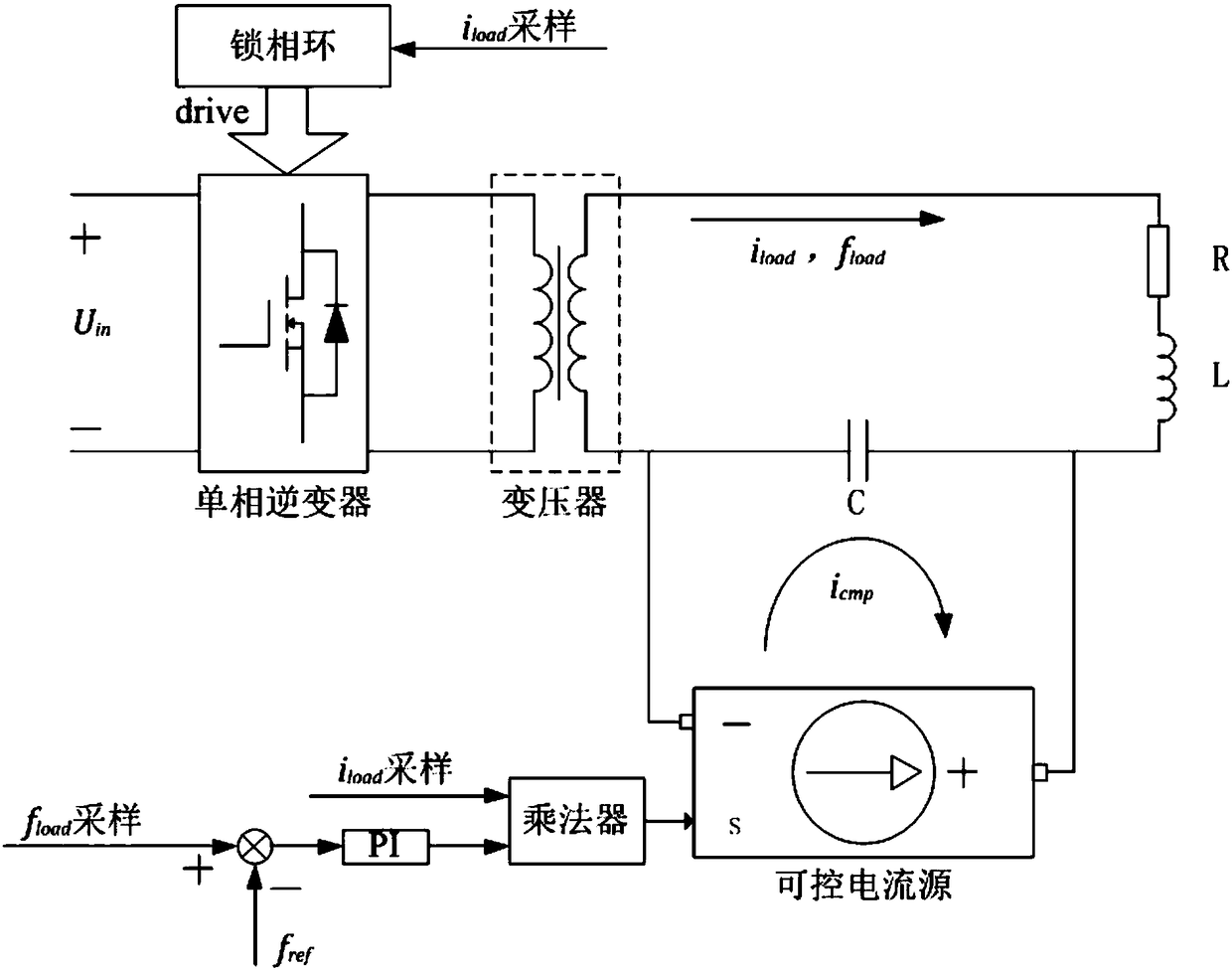

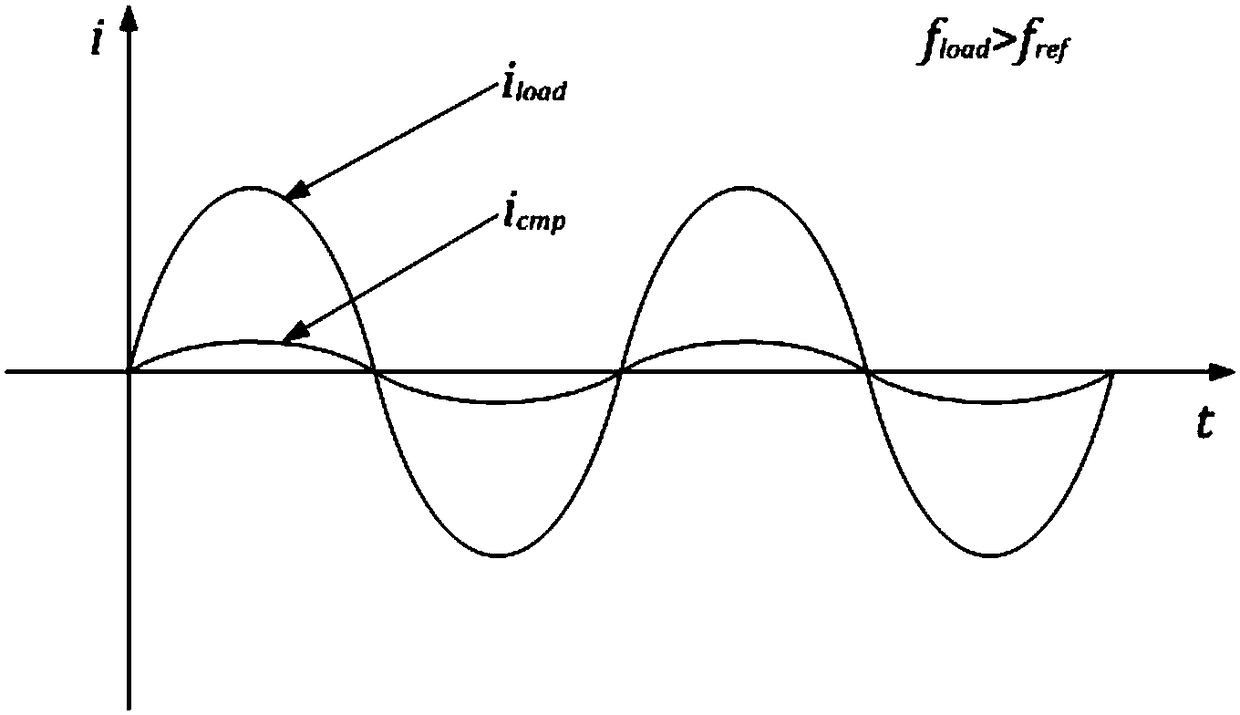

Series-type induction heating power resonant frequency adjustable method based on current compensation

ActiveCN108064095ADynamic control of resonant frequencyResonant frequency controlInduction current sourcesInduction heating controlCapacitanceCapacitor

The invention provides a series-type induction heating power resonant frequency adjustable method based on current compensation. The method comprises the following steps: (1), enabling a controllablepower source to output a compensation current; (2), enabling the controllable current source to output a compensation current which has the same phase as or reverse phase to a sampling current when the resonant frequency is higher or lower than a given resonant frequency; (3), injecting the compensation current at two ends of a capacitor C, and adjusting the size of the resonant frequency of an induction heating system; (4), enabling an RLC resonant circuit to work at the resonant frequency; (5), outputting a new resonant frequency value, and repeatedly carrying out the steps (1)-(5) till theend. The method can achieve the controllable heating depth, improves the heating efficiency, and improves the induction heating technology level.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Vertical hot sleeving process method for flange end-free long and thin main shaft

InactiveCN108406226AGuaranteed workmanshipLower the lifting heightMetal working apparatusLoad-engaging elementsFlangeThin walled

The invention discloses a vertical hot sleeving process method for a flange end-free long and thin main shaft. By means of the process method, the requirement for the fastening amount obtained after the flange end-free long and thin main shaft and a thin-walled part are subjected to hot sleeving can be met, and the hot sleeving efficiency and the assembling quality are improved. The fixing mannerof the main shaft without a flange end after erecting is fundamentally innovated, pit installation stations of a workshop are utilized, the situation that too much space is occupied due to the fact that a climbing scaffold is erected is avoided, the problem that the height exceeds limitation when a component is hoisted during hot sleeving is also avoided, the hot sleeving preparation and assemblyperiod is shortened, the hot sleeving safety is improved, the installation stations and tools can also be utilized for a long time, and the installation cost is greatly reduced.

Owner:HARBIN ELECTRIC MASCH CO LTD

Waste collection device facilitating processing of sueded cloth

InactiveCN110592860AGuaranteed workmanshipImprove collection efficiencyMechanical cleaningPressure cleaningLap jointWaste collection

The invention relates to the technical field of sueded cloth, and discloses a waste collection device facilitating processing of sueded cloth. The device comprises an external box body, a cloth discharging wheel and cloth feeding wheels; the inner bottom wall of the external box body is in lap joint with a collection box, a first motor is fixedly connected to the top surface of the external box body, the output end of the first motor penetrates through the external box body and is fixedly connected with a fan, and a water pump is fixedly connected to the top surface of the external box body. The waste collection device facilitating processing of the sueded cloth can collect waste fluff during sueding processing through the cooperation of a thread shaft, a slide sleeve, a collection plate,an atomizing nozzle and the water pump, so that the problems are solved that during sueding processing, a large number of fluff can be generated and are easily scattered in air due to lightweight, andif workers breathe in the fluffs during breathing, the bodies of the workers are injured.

Owner:吴江市高迪纺织品有限公司

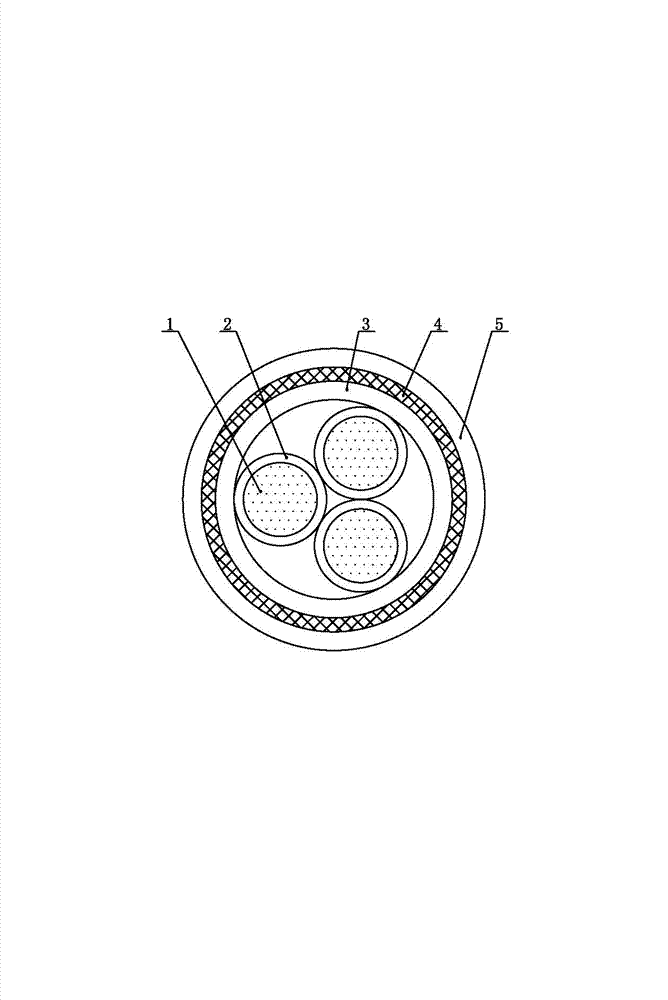

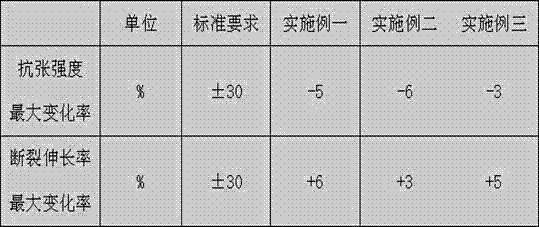

Whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and manufacturing method thereof

InactiveCN102969064AExcellent light aging performanceGood physical and mechanical propertiesPower cablesCable/conductor manufactureCopper conductorInsulation layer

The invention relates to a whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; a plurality of insulation wire cores are stranded to the right to form a cable core; and then an inner lining layer is extruded, a copper alloy wire weaving armor layer is coated, and an outer sheath is extruded successively. The insulation layer is prepared from the following raw material components: 12 parts of Keltan5508, 8 parts of Keltan21, 0.4-0.6 parts of TAIC, 0.5-0.8 parts of DCP (Dicumyl Peroxide), 0.3 -0.6 part of Ager MB, 0.1-0.2 parts of anti-aging agent 2246, 0.8-1.2 parts of oxidation zinc, 0.1-0.3 parts of stearic acid; 1-1.5 parts of a rutile-type titanium dioxide, 10-12 parts of lightweight calcium carbonate, 10-12 parts of ultrafine talcum powder, 2-3 parts of 38# cylinder oil, 2-3 parts of vapor-phase-method hydrated silica, 0.05-0.1 parts of ultraviolet absorbent UV-326, and 0.1-0.3 parts of coupling agent A-174. The insulation layer of the cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com