Centrifugal dewatering drying device and drying method for tobacco leaves

A technology of centrifugal dehydration and drying device, which is applied in the field of centrifugal dehydration and drying of tobacco leaves and centrifugal dehydration and drying device of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

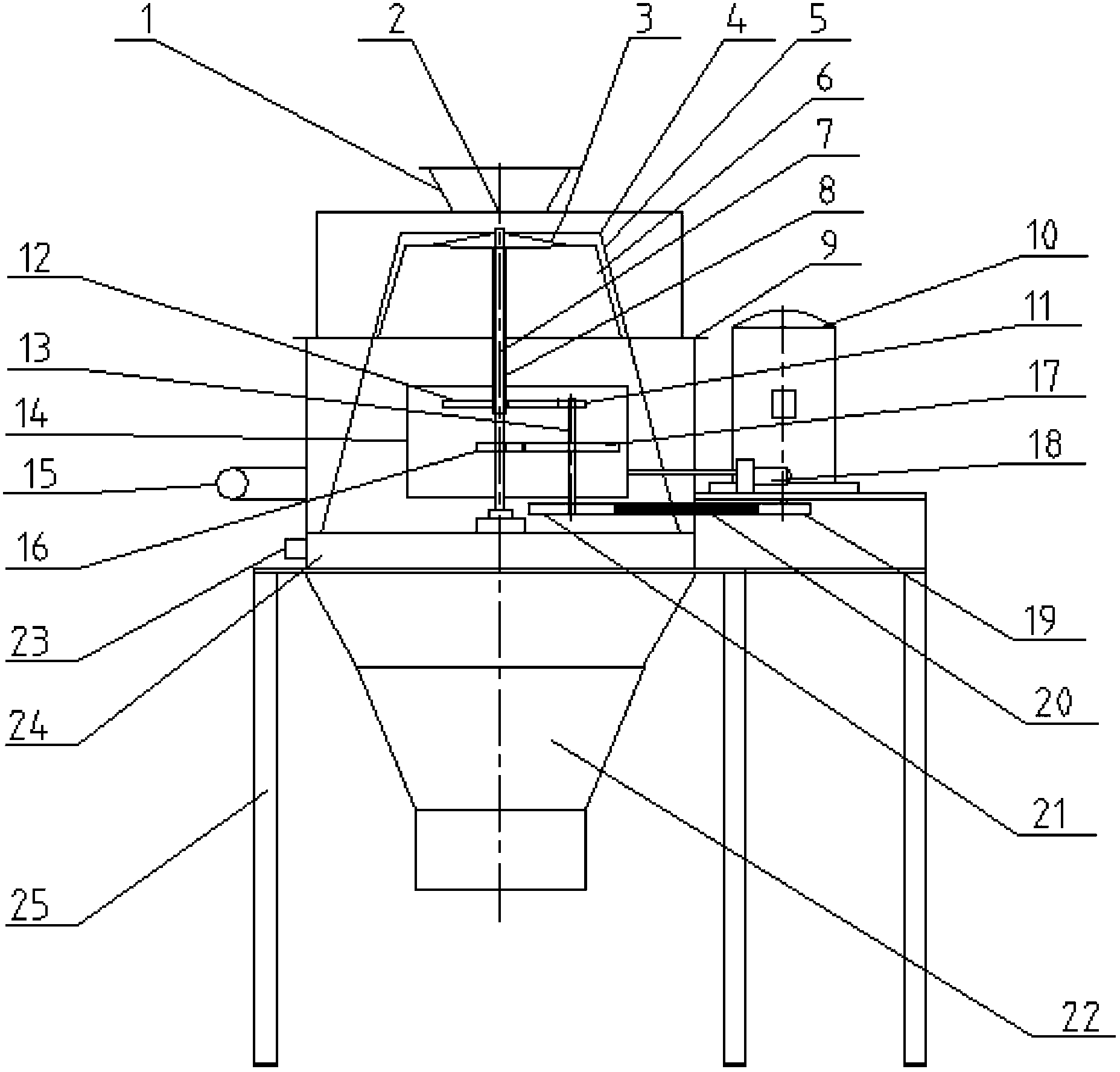

[0039] Such as figure 1 As shown, the centrifugal dehydration and drying device for tobacco leaves of the present invention includes a machine base 9, the top of which is fixedly connected to the upper cover 2, and the sieve basket 4 is arranged in the cavity formed by the machine base 9 and the upper cover 2; A feeding cover 1 with a large top and a small bottom is fixedly arranged, and the feeding cover 1 is used for feeding materials; the machine base 9 is fixedly arranged on the frame 25;

[0040] The sieve basket 4 is surrounded by the sieve 5 into a tapered shape with a small upper part and a larger lower part;

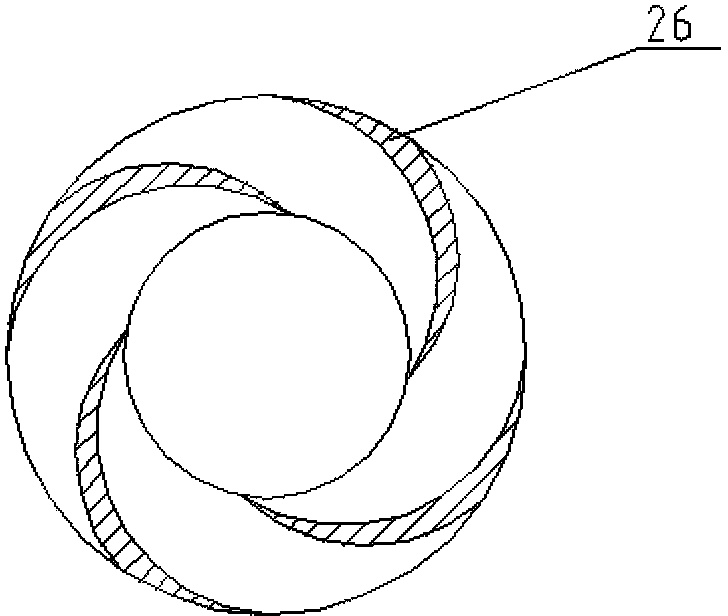

[0041] The top of the sieve basket 4 is fixed with a distributing cone 3, and the feeding cover 1 is arranged above the distributing cone 3; the sieve basket 4 is fixedly connected with the central shaft 7 through the distributing cone 3; the spiral scraper 6 arranged inside the sieve basket 4 and the rotor The shaft 8 is fixedly connected; the rotor shaft 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com