Patents

Literature

247results about How to "No clumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

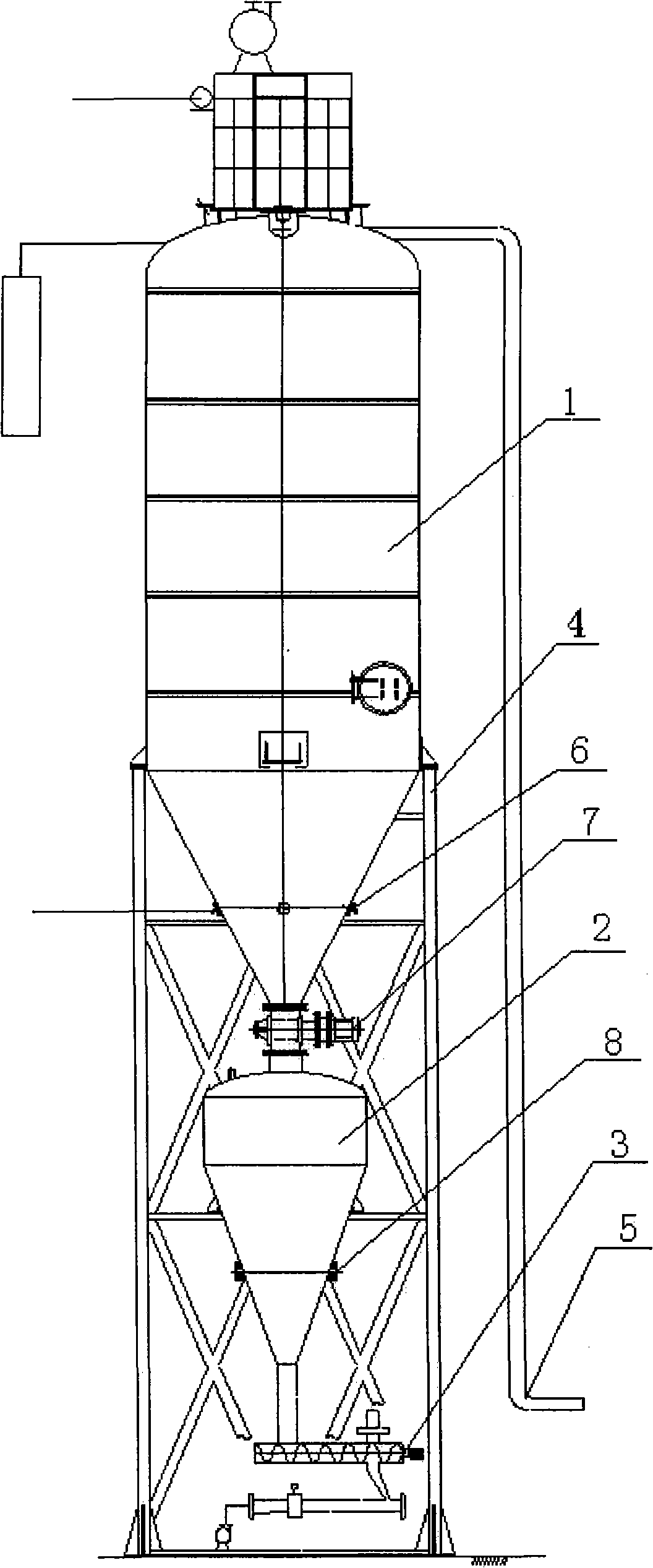

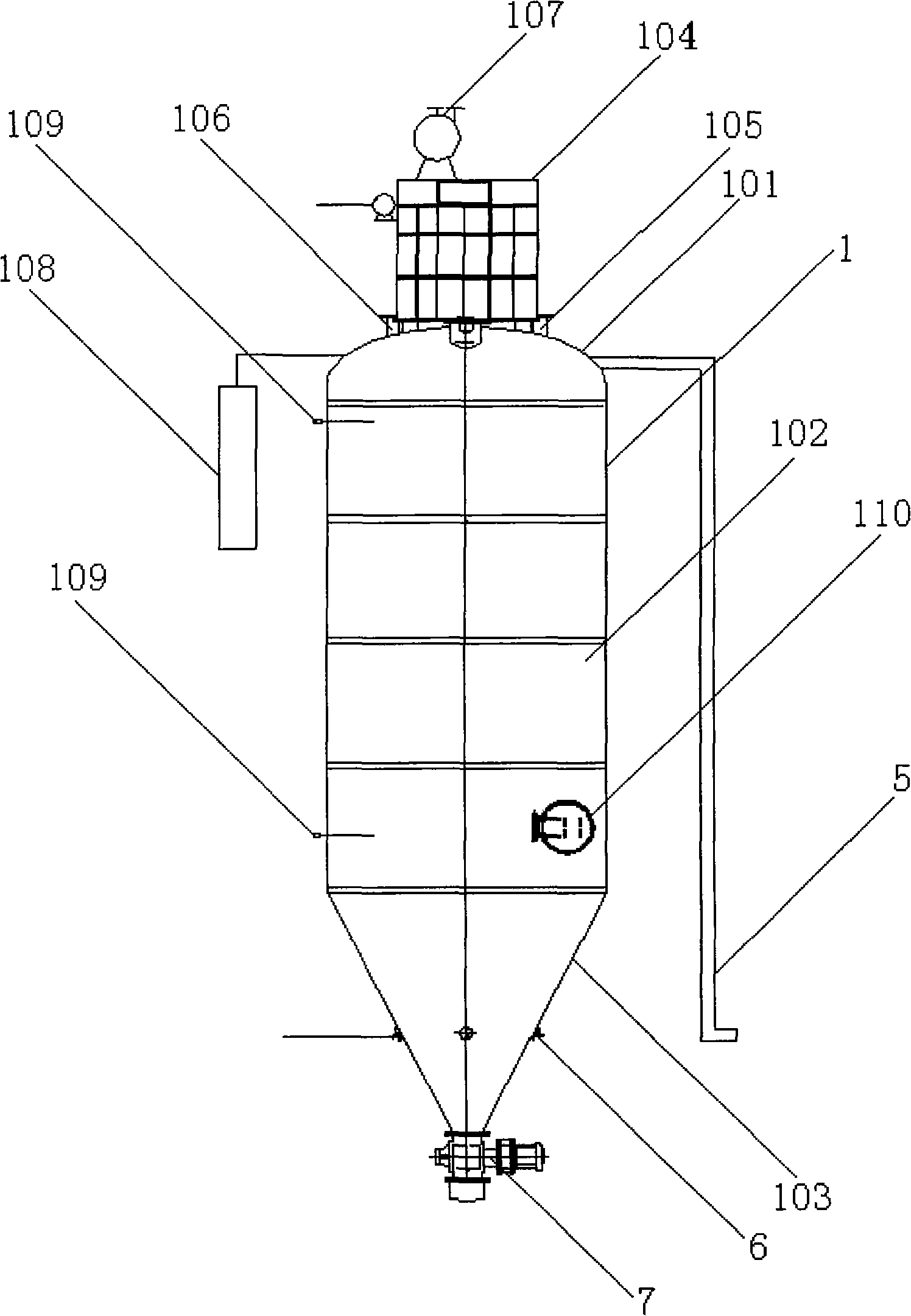

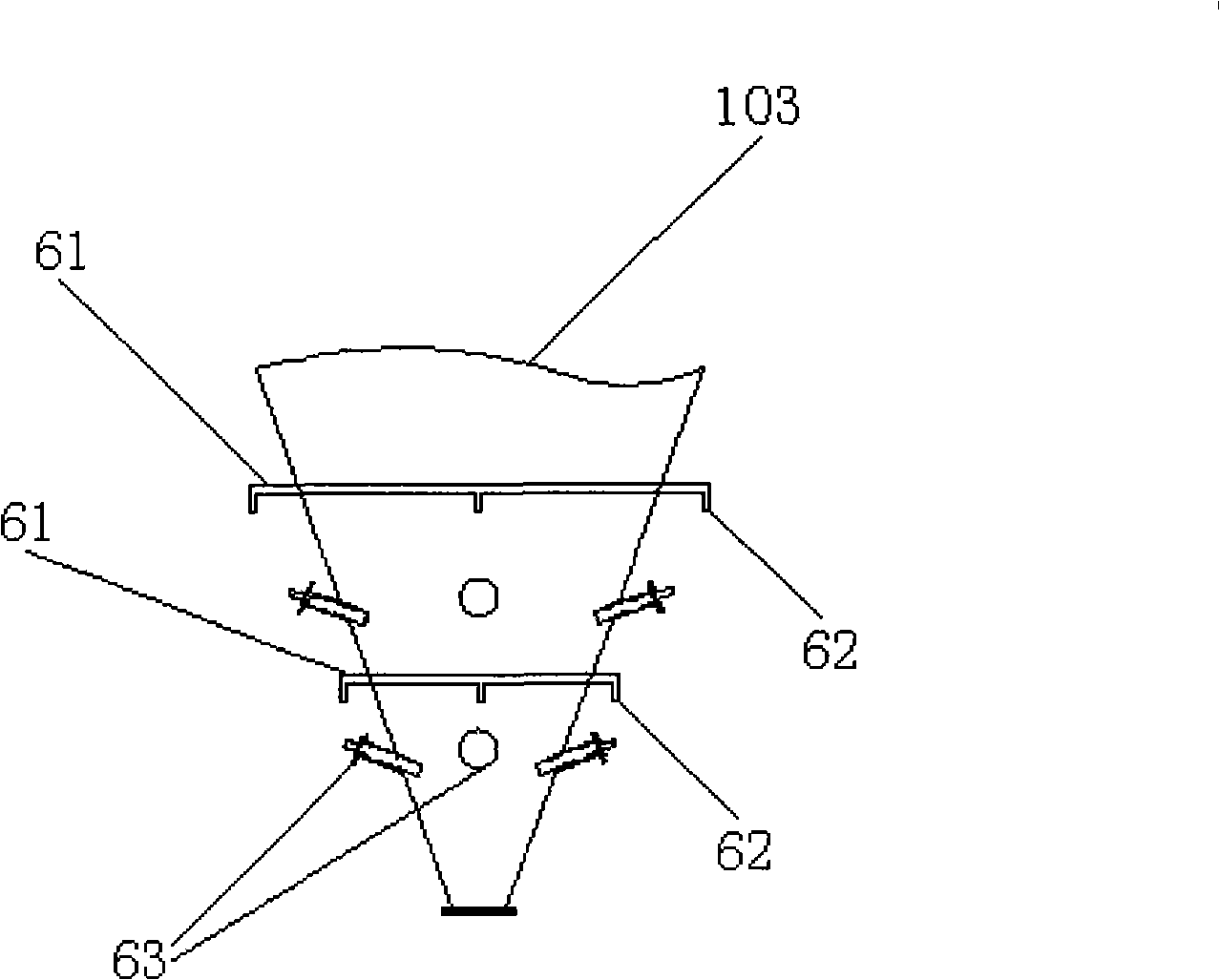

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Preparation method for highland barley dissolving powders

The invention provides a preparation method for highland barley dissolving powders and belongs to the field of food processing. Specifically, the highland barley is carefully chosen, cleaned, dried in a dryer and crushed in a pulverizer to prepare highland barley powders. After that, 60-70 weight parts of highland barley powders and 30-40 weight parts of rice flours are mixed up in a feed mixer and puffed in a twin screw extruder. The puffed highland barley is put into a fluidized bed to be dried, extruded by a tablet press, cooled and packaged. Due to the adoption of the above method, the defect in the prior art that the highland barley is not easy to process and mold due to the existence of amylopectin and the low content of gluten in the highland barley can be overcome. Highland barley dissolving powders prepared through the above method are brewed in boiled water to form a crisp and delicious highland barley paste. Therefore, not only the quality and the nutrient of the highland barley are maintained, but also the highland barley dissolving powders are convenient to take. The highland barley dissolving powders are suitable for the mass consumer. Meanwhile, the method is simple in process, high in mechanized level, suitable for large-scale industrial production and wide in popularization value.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

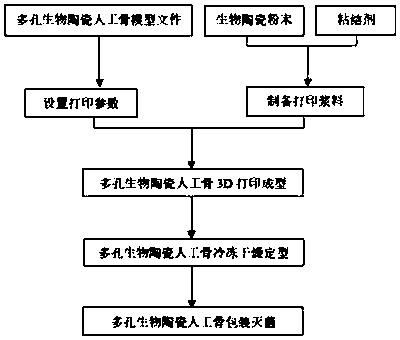

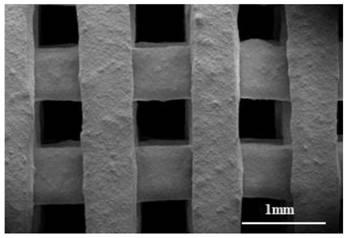

3D printing bionic porous biological ceramic artificial bone and preparation method thereof

ActiveCN111070376APrecise porosity controlGood molding propertiesAdditive manufacturing apparatusBone implantHuman bodyTissue fluid

The invention discloses a 3D printing bionic porous biological ceramic artificial bone and a preparation method thereof. A porous biological ceramic artificial bone model is designed through a TPMS and CSG combined method, slurry capable of being used for printing is prepared through biological ceramic powder and a binding agent, macropores and micropores are distributed in the porous biological ceramic artificial bone prepared through the combination with the 3D filament-free printing process, the pore diameter of the micropores is smaller than 100 micrometers, the pore diameter of the macropores is 200-800 micrometers, the total porosity is 20% to 80%, the communicating rate between the macropores is not lower than 99%, precise design of porosity, communication and homogeneity in the artificial bone is achieved, and meanwhile good pore communication is ensured. Adopted raw materials have good biocompatibility, entry passageways of cells and tissue fluid are provided by the macropores, the micropores can better adsorb tissue fluid nearby for cell growth, the cell growth speed and the new bone generation speed can be increased by combining the micropores with the marcropores, and application of the porous biological ceramic artificial bone in human body large bone defect repair clinic treatment is facilitated.

Owner:西安点云生物科技有限公司

Novel modified emulsifying olefin concrete curing agent

The invention relates to a novel modified emulsified paraffin concrete curing agent. Aiming at overcoming the defects that the existing concrete curing agent cannot reach the industrial standard on building material in terms of the water retention property and is unfavorable for environmental protection, the price is high and the decoration at later stage is also affected, the following technical proposal is provided: the curing agent is mixed with the following materials and water: 10-20% of vinyl acetate-ethene high molecular polymer emulsion, 0-5% of silicone resin modified acrylic polymer emulsion, 50-75% of paraffin emulsion, 0.1-0.5% of colloidal dispersing agent of the emulsified paraffin for stabilizing the emulsion state and 0.05-0.02% of special defoamer for emulsion. The invention has the beneficial effects that: the chemical curing method which is adopted for retaining water is an innovation for the traditional curing method; compared with the prior art, the method is labor-saving, time-saving and water-saving and is convenient to operate, can improve the film formation ability and the sealing ability of the emulsified paraffin emulsion, and can improve the bonding and absorbing capacity of the emulsified paraffin emulsion on the concrete surface, which leads the effective water retention rate of the coating film to reach more than 90%.

Owner:LIAONING BUILDING SCI RES INST

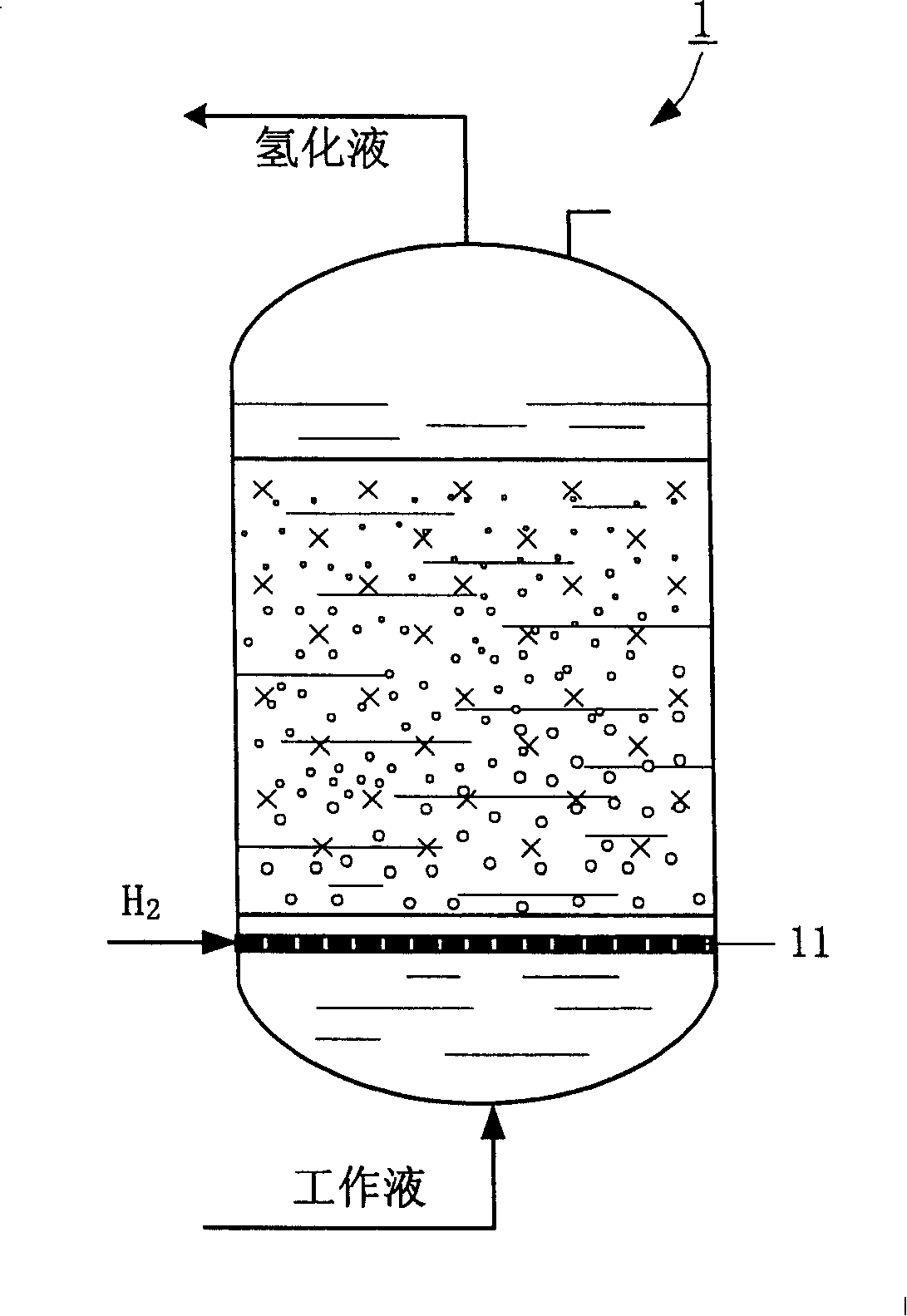

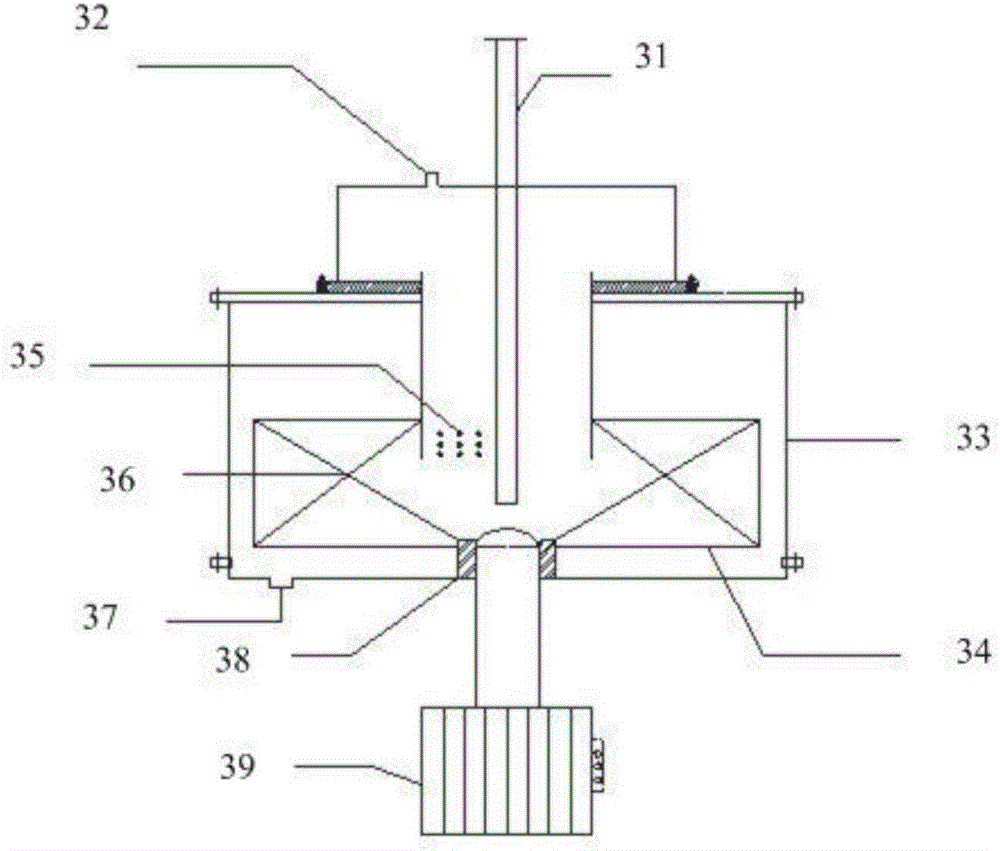

Method for producing hydrogen peroxide by anthraquinone process

InactiveCN101229915AIncrease production capacityEvenly distributedPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesWorking fluidHydrogenation reaction

The invention provides a process for producing hydrogen peroxide by using an anthraquinone method. The process includes the following steps: hydrogen is added in the anthraquinone to generate anthrahydroquinone which is oxidized to generate the anthraquinone and the hydrogen peroxide. The reaction in which the hydrogen is added in the anthraquinone to generate anthrahydroquinone means that working fluid with the anthraquinone and the hydrogen are led in a fixed bed reactor which is filled with catalyst with the hydrogen so that hydrogenation is generated between the working fluid with the anthraquinone and the hydrogen to generate the anthrahydroquinone under the effect of the catalyst; the obtained hydrogenated working fluid with the anthrahydroquinone is conducted out of an oxidation device, wherein, when the working fluid with the anthrahydroquinone and the hydrogen are conducted in the fixed bed reactor, the working fluid is continuous phase, in which the hydrogen is distributed in the form of bubbles; when the working fluid with the anthrahydroquinone and the hydrogen are conducted in the fixed bed reactor, a feeding inlet is made not higher than a discharging outlet where the hydrogenated liquid is discharged out of the fixed bed reactor. By using the method, utilization efficiency of the catalyst as well as the production capability of the reactor is promoted and bed resistance is reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

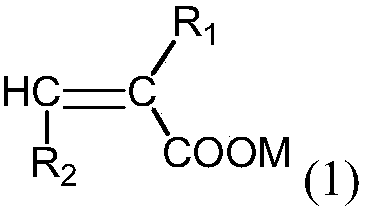

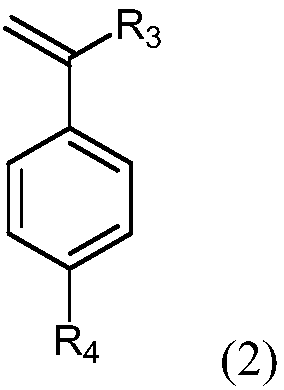

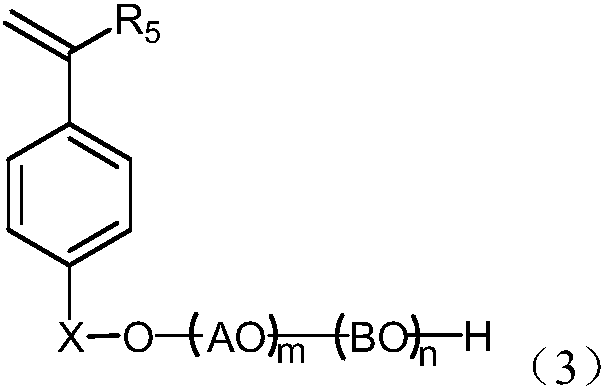

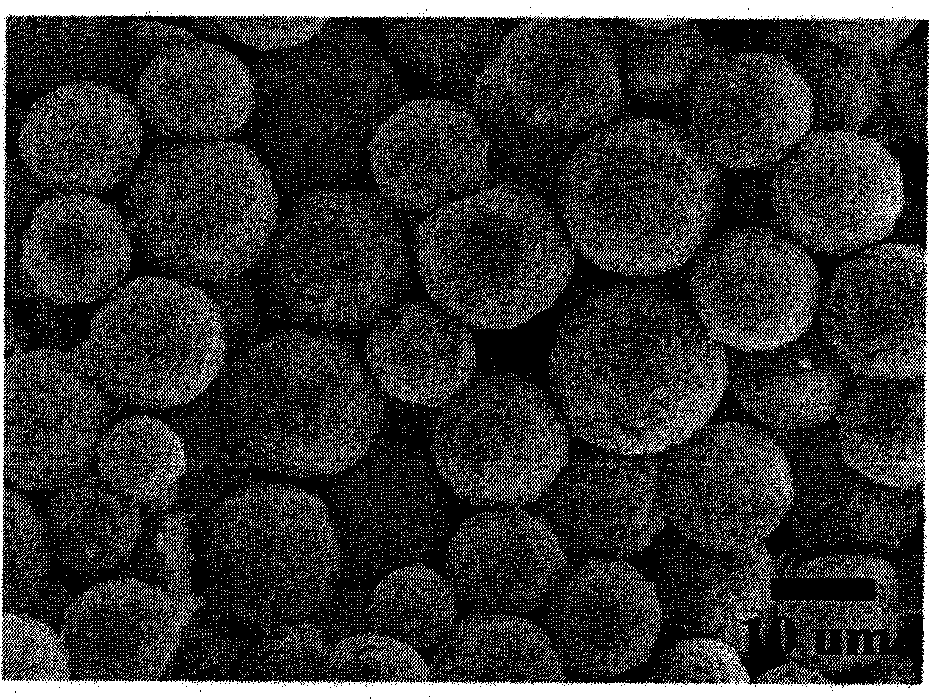

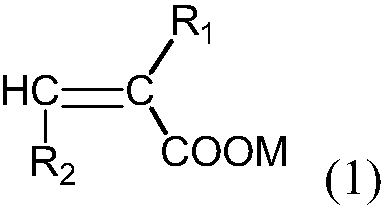

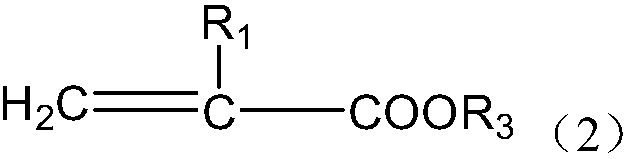

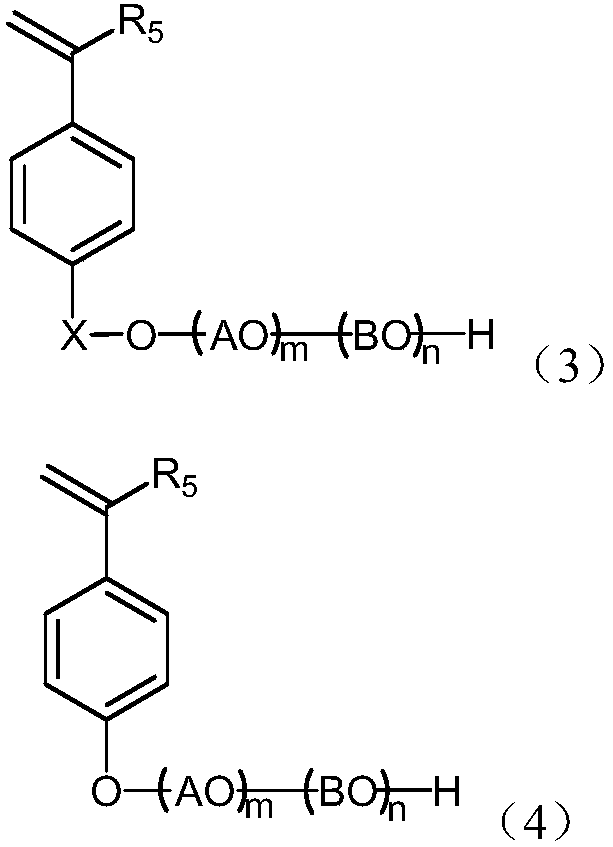

Preparation method and application of powdery polycarboxylic acid water-reducing agent

The invention discloses a preparation method and application of a powdery polycarboxylic acid water-reducing agent. The preparation method comprises the following steps: preparing from a carboxylic acid monomer a, a benzene ring-containing small monomer b and a benzene ring-containing polyether monomer c in an aqueous medium through free radical copolymerization to obtain polycarboxylic acid water-reducing agent mother liquor; and directly forming the polycarboxylic acid water-reducing agent mother liquor into fog drops through a centrifugal atomizer for a sprayer without adding an isolation agent, controlling the average particle size of powder to be 50-150 [mu]m, drying into powder after the fog drops enter a drying room, leading a material to a discharge port through an induced draft fan, and packaging and discharging by adopting a bagged packaging machine to obtain the powdery polycarboxylic acid water-reducing agent. The preparation method disclosed by the invention has the benefits that not only is the effective content of polymers in the powder improved, but also the production technical process is reduced, and the production cost is reduced; and the prepared powdery polycarboxylic acid water-reducing agent is optimal in fluidity, incapable of caking, high in storage stability, low in long-distance transportation cost, excellent in water-reducing property and suitable for various dry mortar.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Concrete with large doped quantity of mixed steel fibers and preparing method

The invention relates to a method for preparing concrete with a large doped quantity of mixed steel fibers. The concrete comprises a binding material, water, mixed steel fibers and a water reducing agent, wherein the binding material is prepared from cement and fly ash, and the mixed steel fibers contain more than two steel fibers in different sizes. The steel fiber concrete with high strength and the functions of crack resistance and the like can be produced, the volume doped quantity of the steel fibers can reach 6% and more, the problem that agglomeration easily occurs when the doped quantity of the steel fibers in the concrete is large is solved, and the compressive strength of the concrete can be improved by 50% above. The mixing ratio is reasonably designed, efficient and feasible. The method is particularly suitable for steel fiber concrete with strict strength and impact-resistant requirements.

Owner:HEFEI UNIV OF TECH

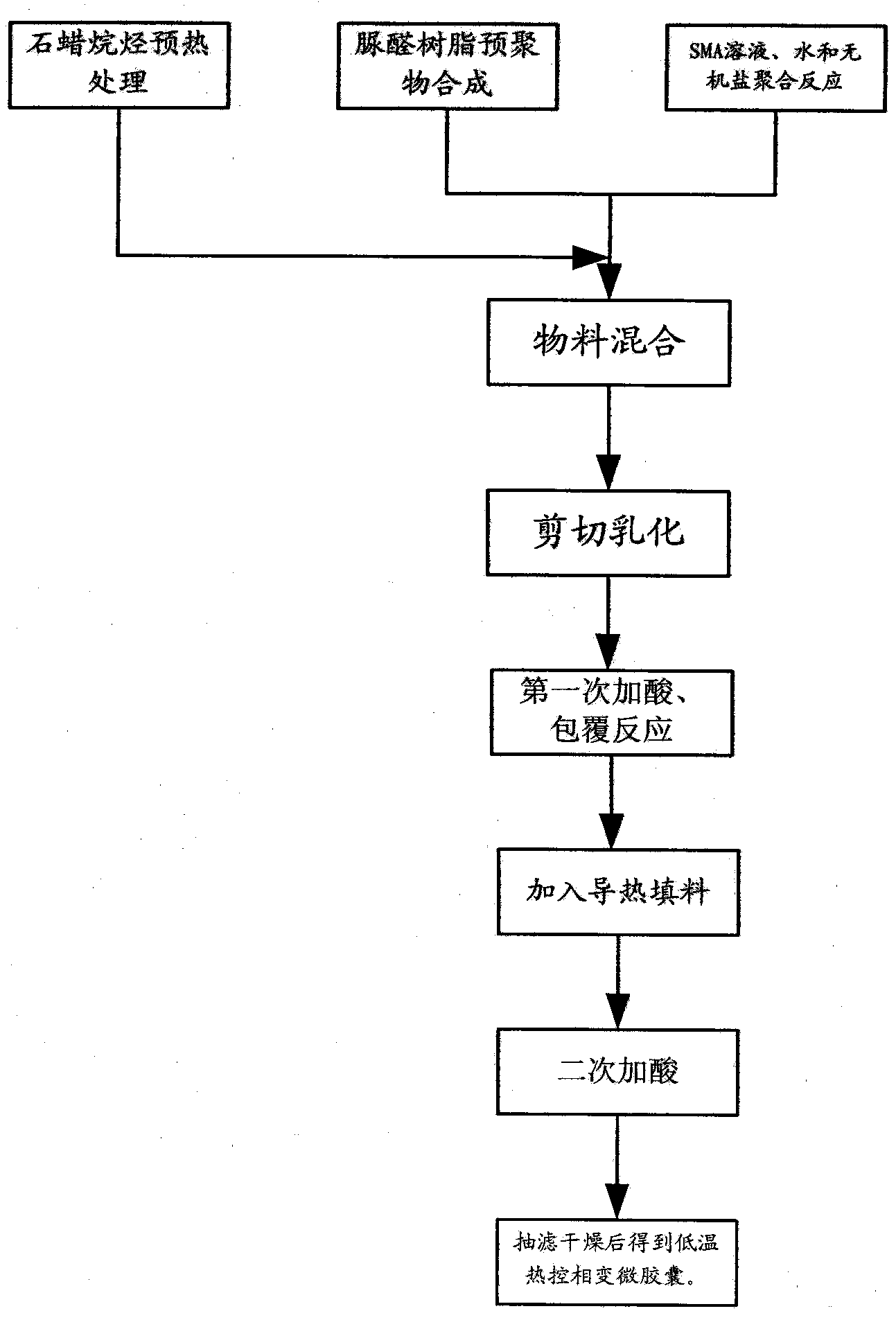

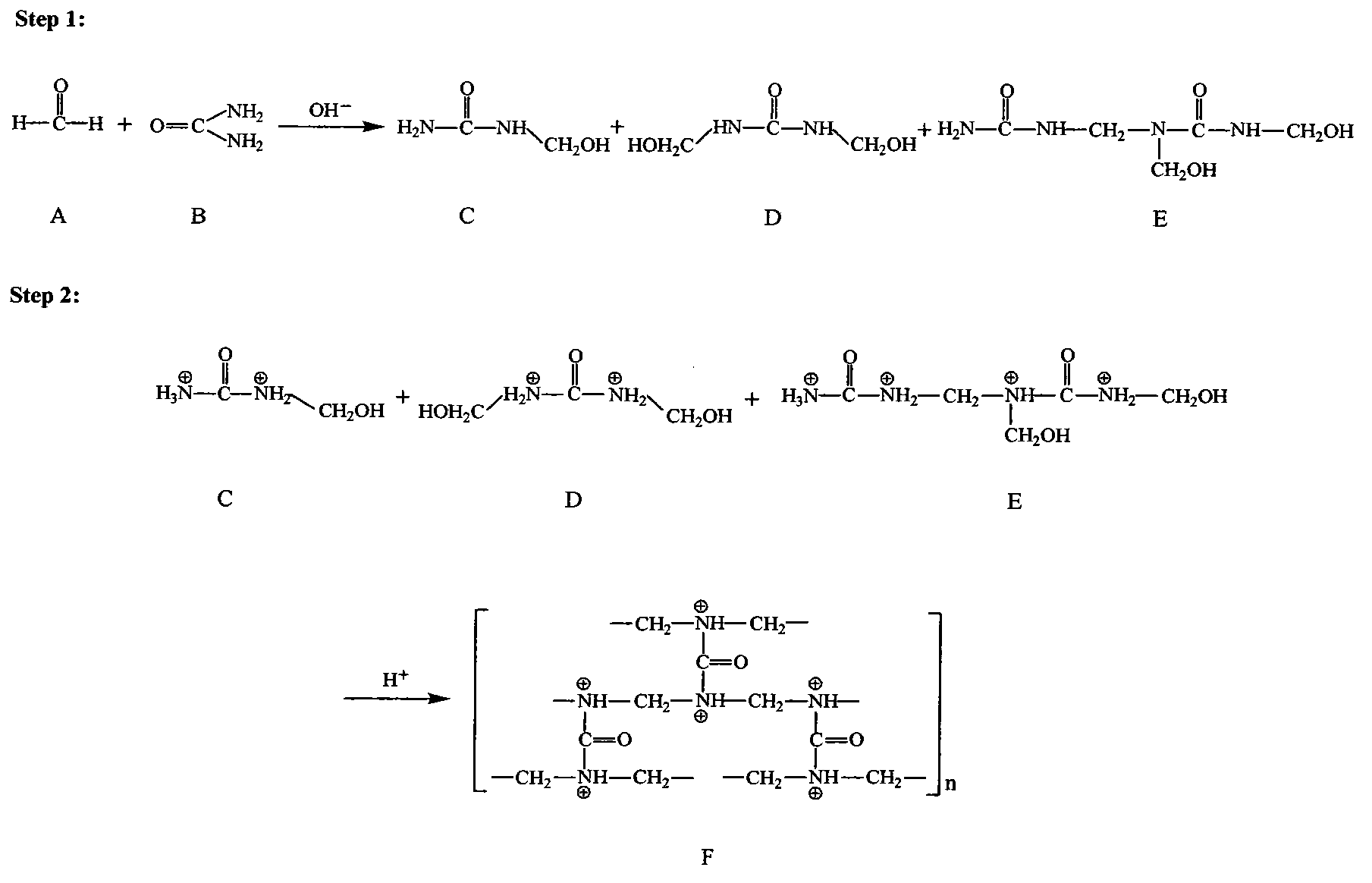

Low-temperature thermal control phase change microcapsule and preparation method thereof

ActiveCN104357019AImprove thermal conductivityEvenly dispersedHeat-exchange elementsMicroballoon preparationAlkanePermeation

The invention provides a low-temperature thermal control phase change microcapsule and a preparation method thereof. The low-temperature thermal control phase change microcapsule takes paraffin alkane as a core material and urea resin as a shell, and further comprises a heat conduction filler, the heat conduction filler is added in the process of coating the paraffin alkane by the urea resin, and the amount of the added heat conduction filler is 5%-30% that of the paraffin alkane. The low-temperature thermal control phase change microcapsule prepared by the invention is solid-solid phase change, the problems of fusion flowing and permeation migration are avoided, the range of phase change temperature is wide, the latent heat is large, the condensate depression is small, the phase change process is stable, the phase change is reversible, the material further has a higher heat conduction property, and as a relatively ideal thermal control phase change material, the low-temperature thermal control phase change microcapsule can be widely used in the fields of thermal protection, like aerospace, precise instruments, and electron devices.

Owner:海鹰空天材料研究院(苏州)有限责任公司

Method for producing vanadium nitride

InactiveCN101172585ANo clumpingHardening will not occurNitrogen-metal/silicon/boron binary compoundsVanadium compoundsHydrogenVanadium nitride

The invention provides a preparation method of vanadium nitride. Vanadium compound with the valence state of above quadrivalence or the mixture of the compound and organic carbon or inorganic carbon are formed through briquetting with adhesive agent, vanadium is pre-reduced into a lower valence state with the hydrogen with reducing property at 700 DEG C, then the temperature is gradually increased to 1100 to 1900 DEG C, therefore, the vanadium nitride product is gotten through reduction and nitridation. The block-shaped product is formed by contracting the material and no further agglomeration and adhesive bonding phenomenon occurs among blocks. The invention has the advantage that the melting and agglomeration phenomenon of the high valence vanadium compound near by the melting point is avoided.

Owner:冯良荣

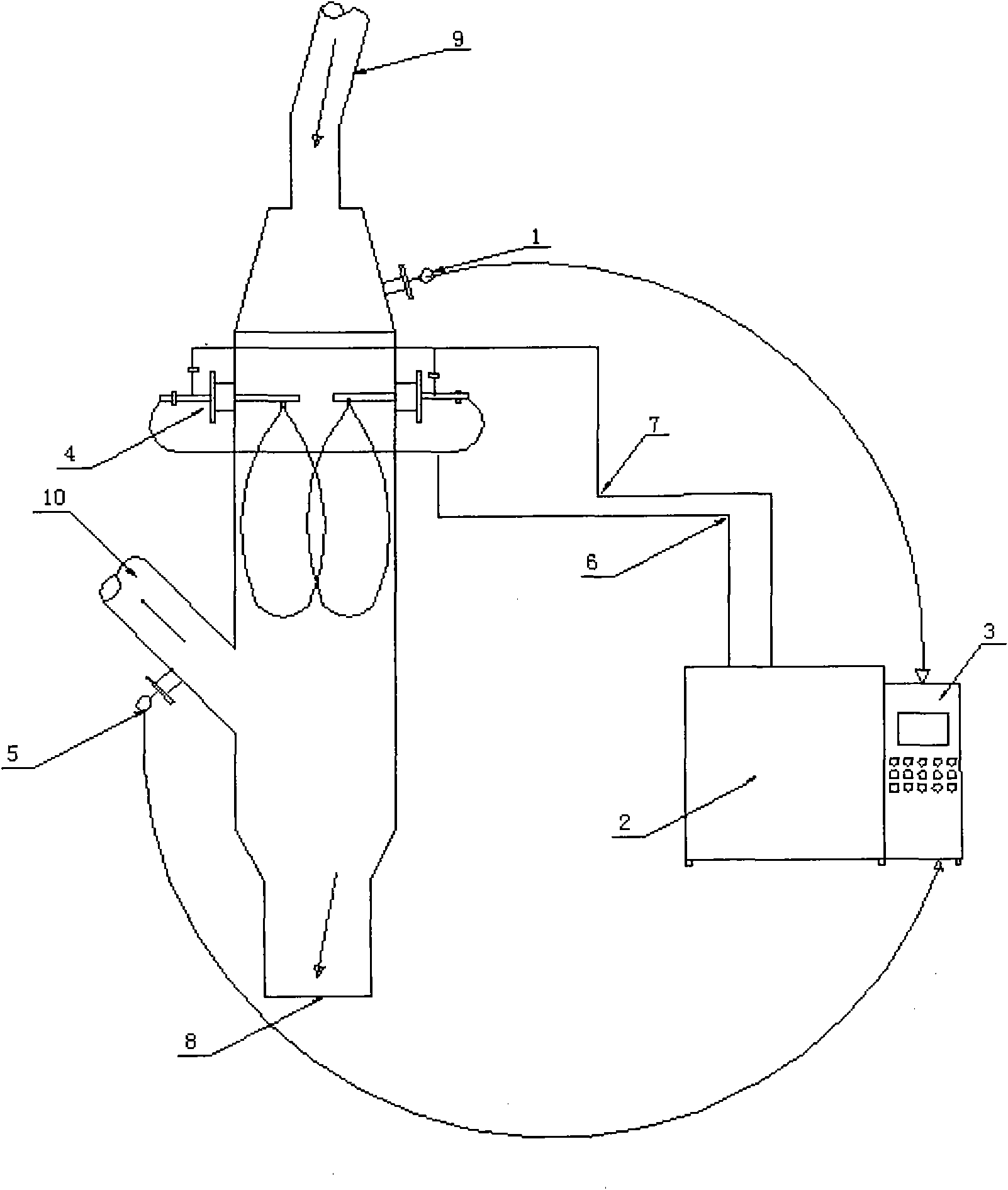

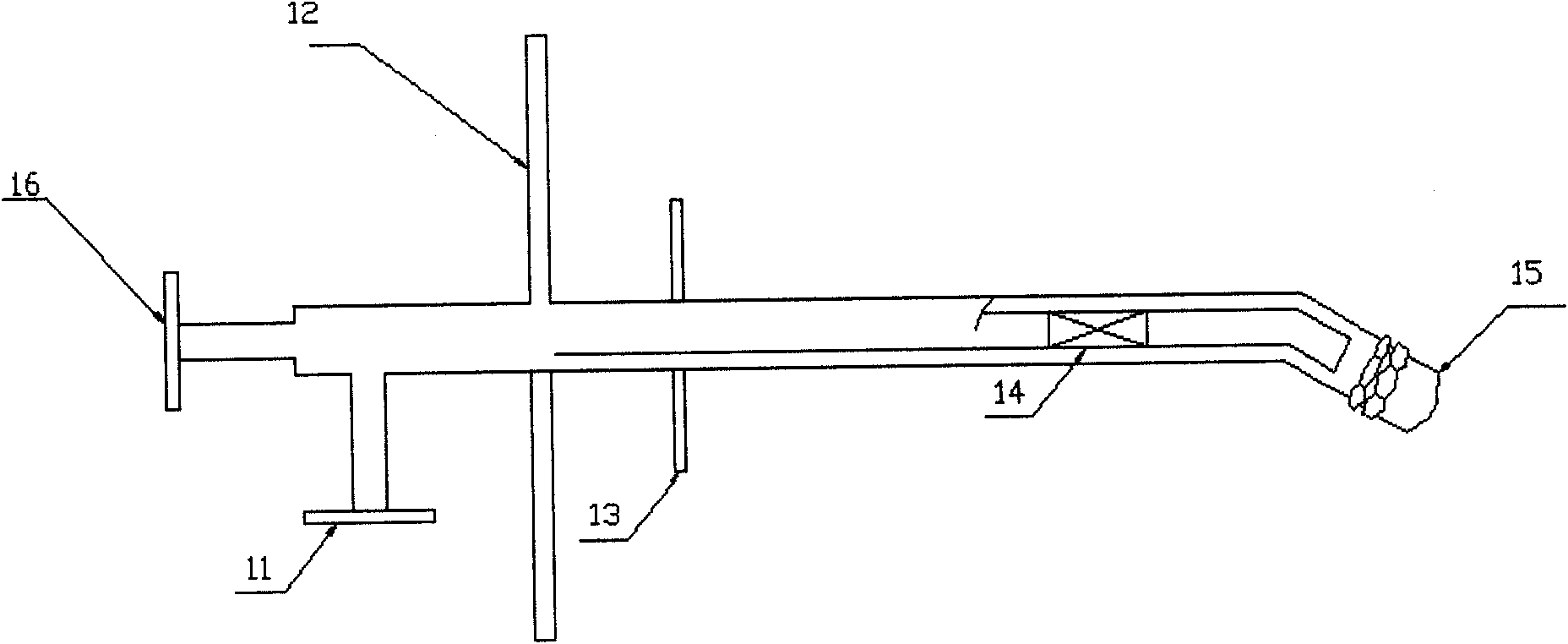

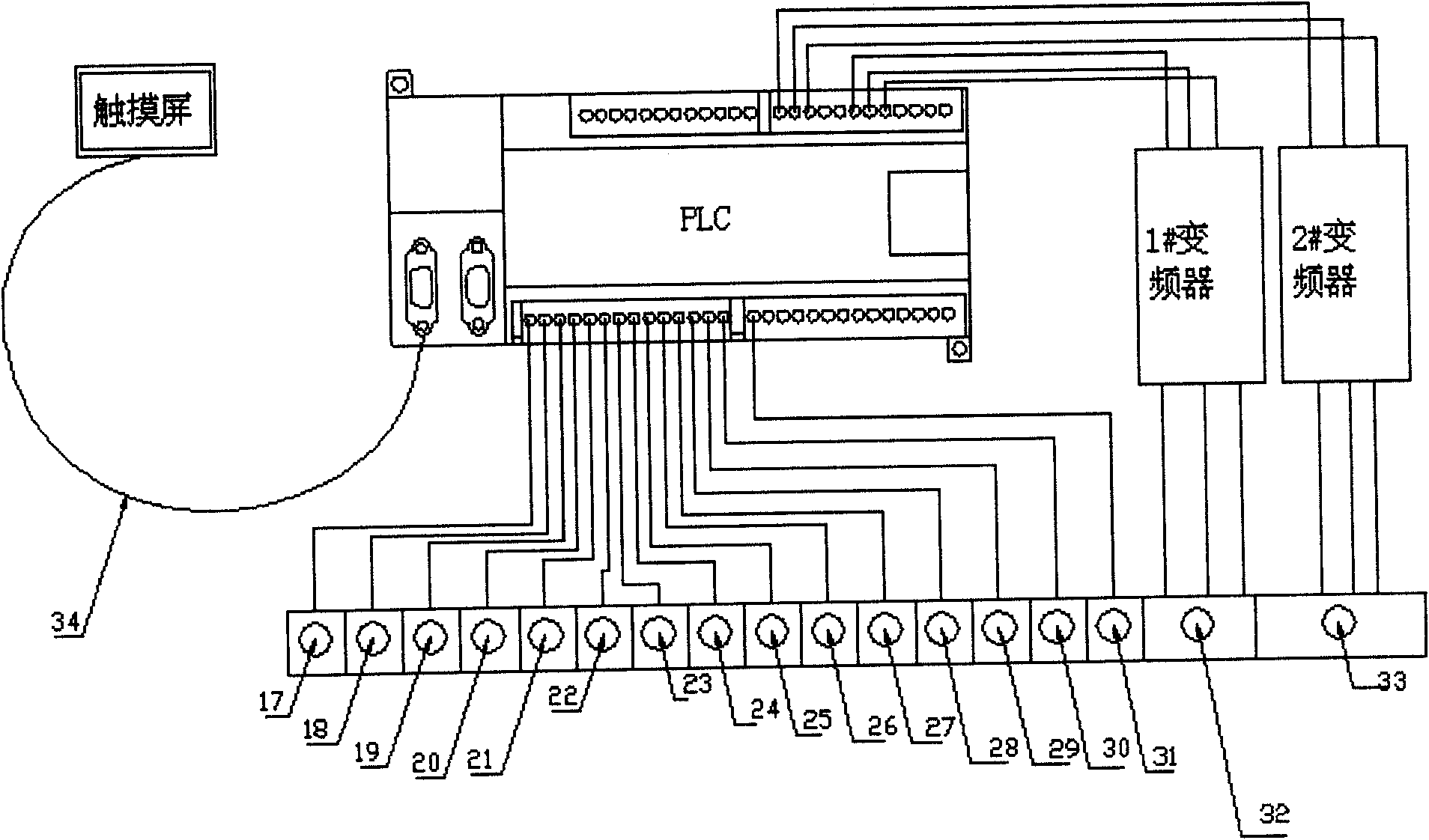

Quenching and tempering device for cooling high-temperature fume

InactiveCN101596389AEmission reductionReduce energy consumptionAuxillary pretreatmentEfficient regulation technologiesFrequency changerAir pump

The invention discloses a quenching and tempering device for cooling high-temperature fume, comprising a two-fluid electrical appliance controller, a water path and an air path arranged between a high-temperature fume inlet and a high-temperature fume outlet. The device of the invention is characterized in that a low pressure pump is arranged in the air path, a low pressure air path is combined into a water pipeline before a spray gun, two transducers are arranged to adjust the pressure and flow of a water pump and an air pump, the nozzle bore diameter is phi 6-7mm, and the spray particle diameter is smaller than 300 micrometers; a temperature sensor is respectively arranged at a wetting tower inlet and the fume outlet, and the outlet temperature is controller to 130-150 DEG C; an operation program is controlled to calculate the temperature difference of the fume inlet temperature and the fume outlet temperature, tower volume and spray fall height; two transducers are used for controlling the water pump and the air pump to automatically adjust operation power when low air pressure is 0.4-0.6MPa, and air flow quantity and water flow quantity are 5-25T / H. the particle diameter of sprayed water spray is small and even, which can better realize precise control to temperature and reduces atomization particle residence time and wet bottom danger. The dust removal device designed by the invention increases fume density and volume, lowers speed and improves dust removal function. In particular, the spray granularity is small, which can obviously control temperature and humidity, lower discharge Dioxin and furan mixed in dust and reduce environment protection cost.

Owner:SHENYANG XINCHENG TECH

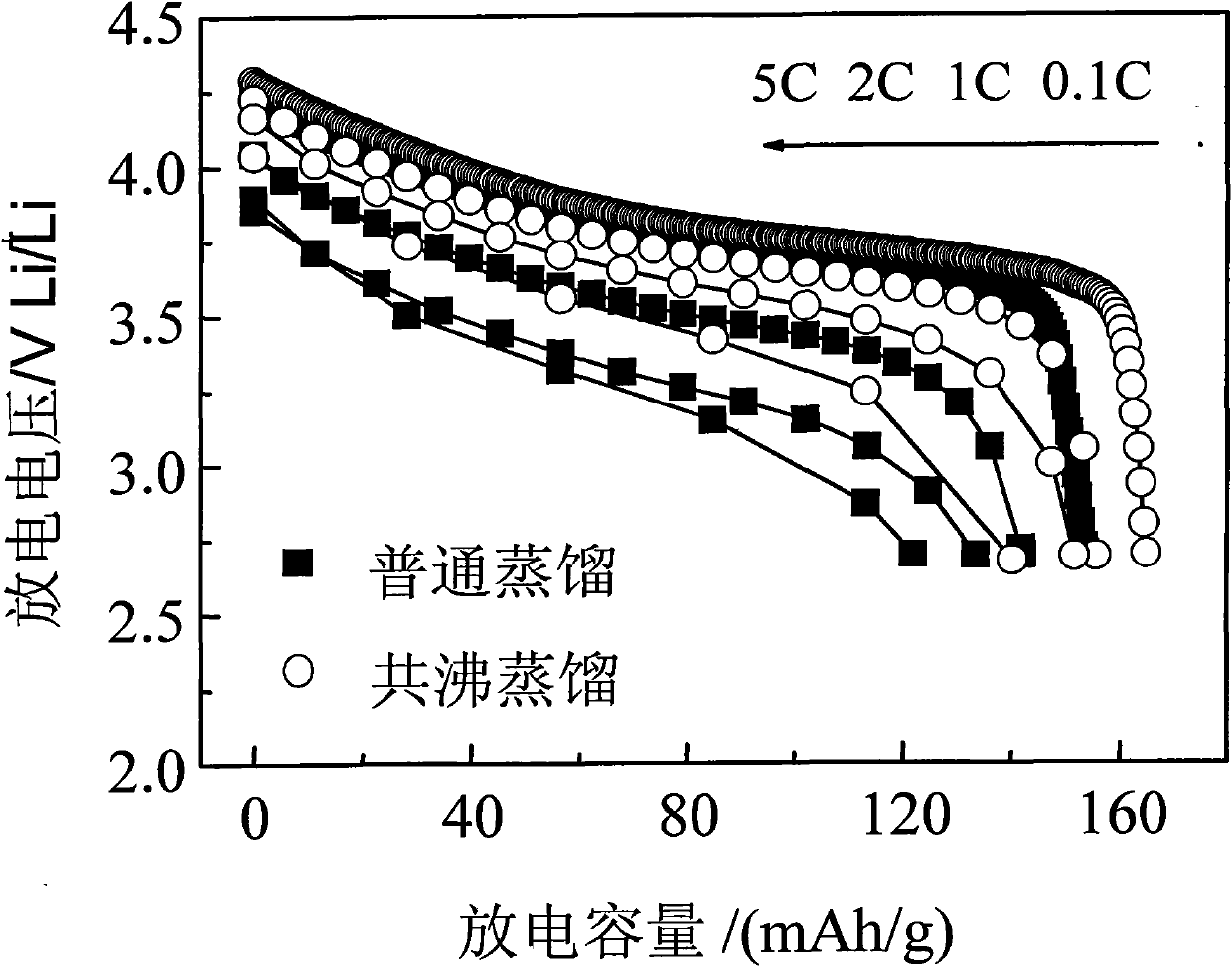

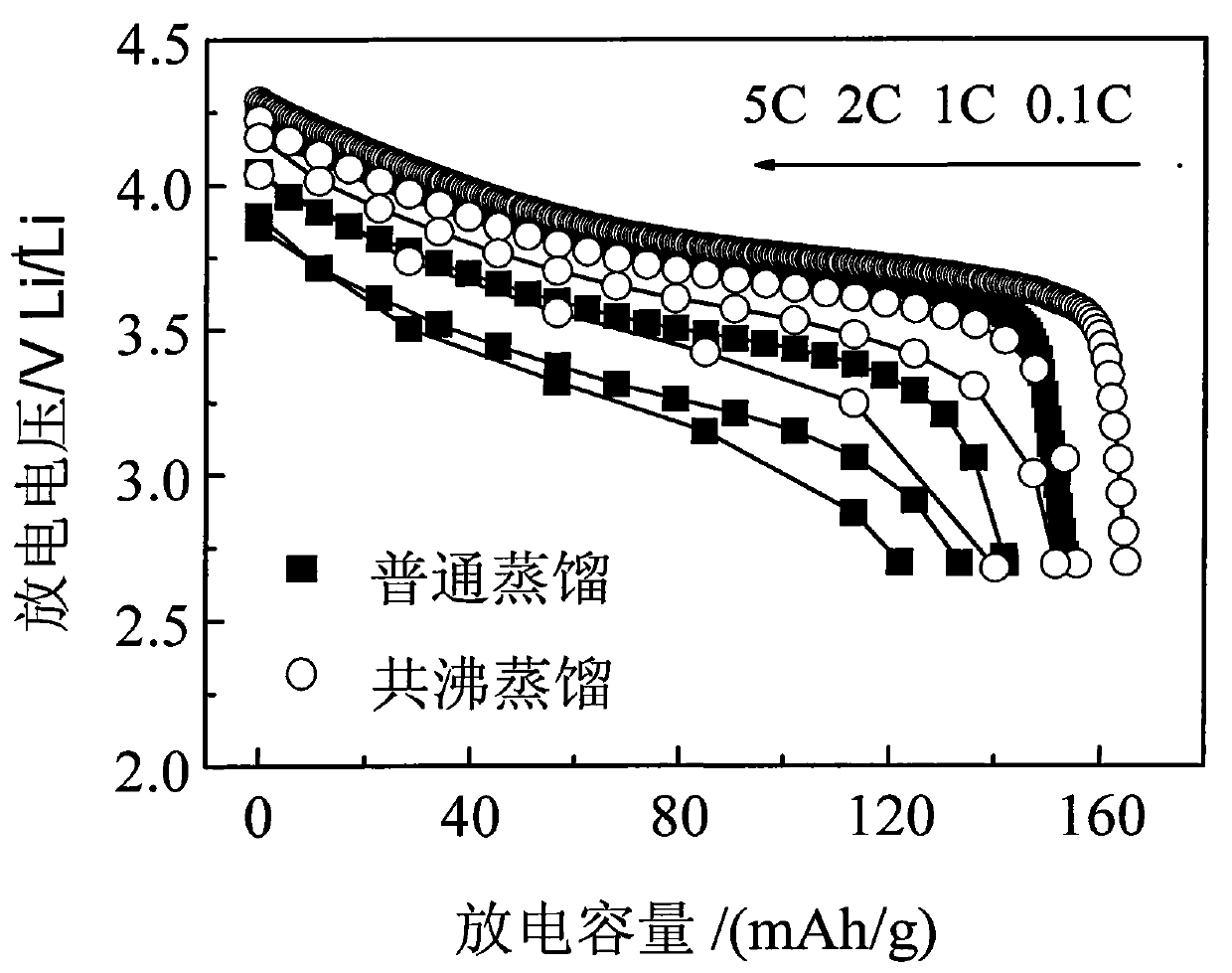

Method for preparing multielement cathode materials for lithium ion batteries

The invention relates to a method for preparing multielement cathode materials for lithium ion batteries and belongs to the field of secondary lithium ion batteries. The invention prepares various high-performance multielement cathode materials for the lithium ion batteries by using the method of drying a precursor by an azeotropic distillation method. The raw materials comprise lithium source compounds, nickel-cobalt-manganese source compounds, doped-metal source compounds and organic solvents which can form an azeotropic system with water. The invention improves the traditional coprecipitation method. The invention removes the moisture in the coprecipitation precursor by using the azeotropic distillation method, and replaces the precursor surface water with organic matters to obtain the high-dispersibility precursor which is uniformly mixed; and the precursor is sintered to form the product. Compared with the product prepared by the traditional method, the product of the invention has the advantages of small grains, uniform grain size distribution, high sphericity and large specific area, thereby promoting the diffusion of lithium ions and greatly enhancing the specific capacity and the heavy-current charging and discharging capability of the materials.

Owner:HUBEI HONGRUN HIGH-TECH NEW MATERIALS CO LTD

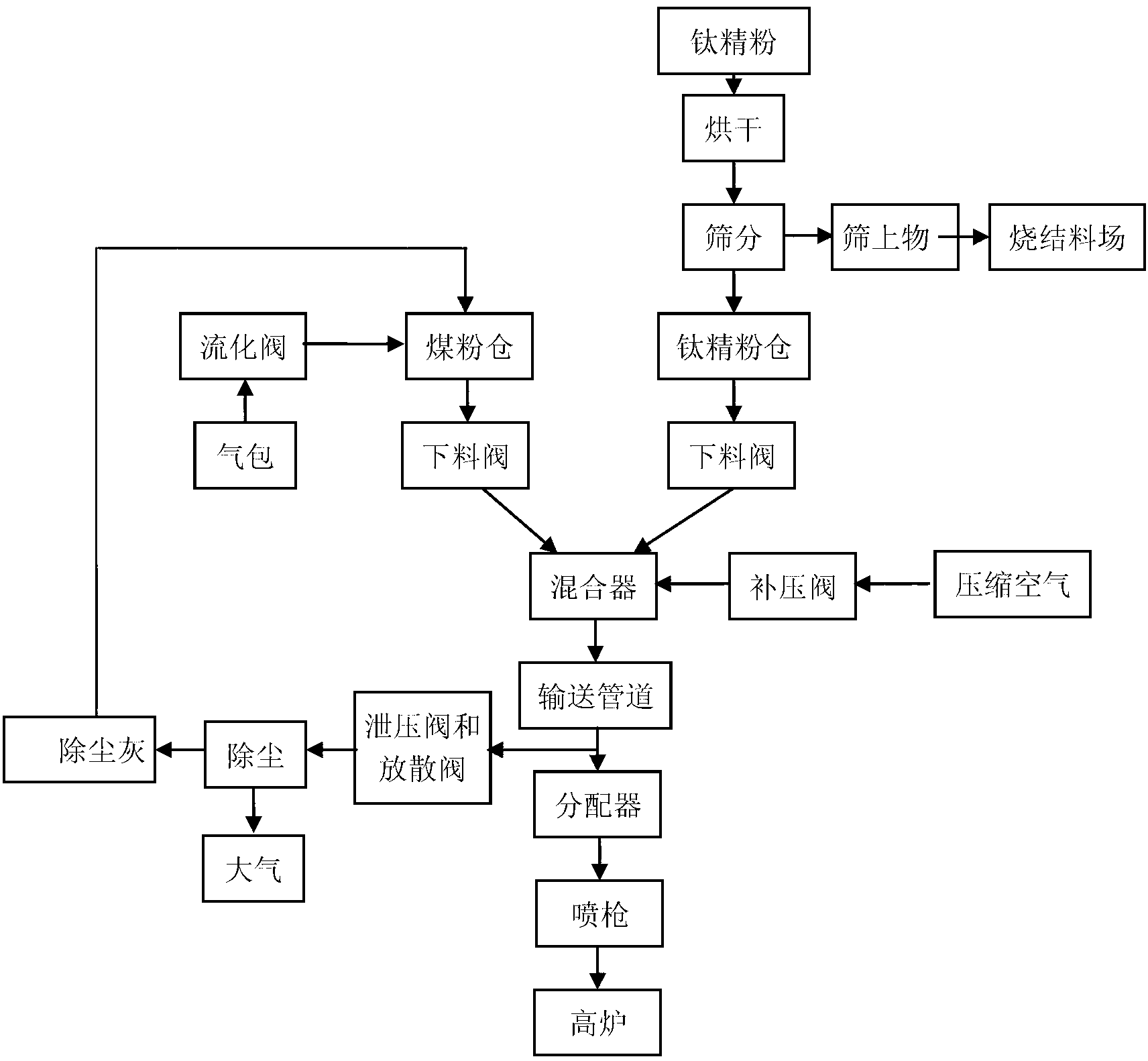

Method for feeding titanium fine powder serviced as furnace protecting agent of blast furnace into furnace through injection system

The invention relates to a method for feeding titanium fine powder serviced as a furnace protecting agent of a blast furnace into a furnace through an injection system. Titanium-containing fine powder is used as a raw material. The method comprises the following steps of: drying and screening the titanium-containing fine powder; delivering overtails to a sintering material yard for sintering; mixing throughs with coal dust, and delivering the mixture to a coal dust injection system through a delivery pipe and a distributor; injecting the mixture into the blast furnace through a spray gun; mixing the coal dust or the uniform mixture in gas in the delivering process, and discharging the coal dust or the uniform mixture through a pressure relief valve and a discharging valve; dedusting the discharged gas; diffusing the processed gas; and returning the removed dust to a coal dust bunker for recycling so as to save raw materials and prevent waste. According to the method, the technical problem of component segregation of the mixed powder caused by different densities and blockage at discharge ports are solved. The method is reasonable in design, advanced in process and low in cost and has a good furnace protecting effect.

Owner:LAIWU IRON & STEEL GRP

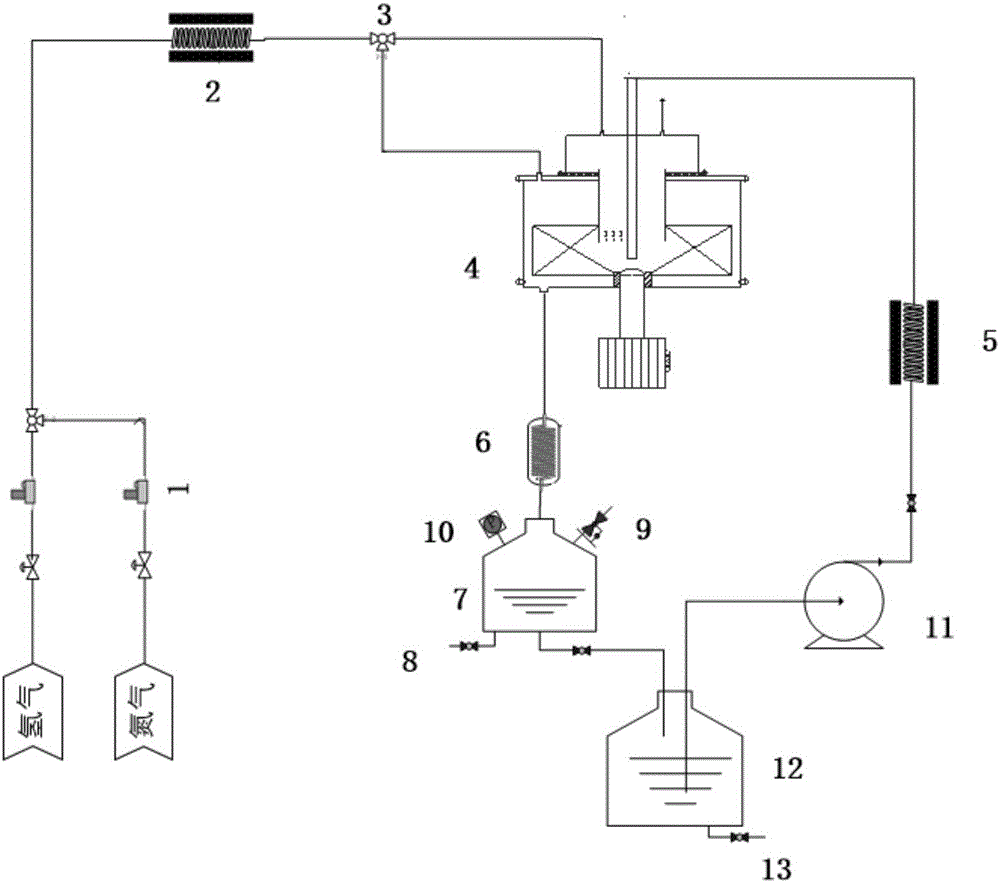

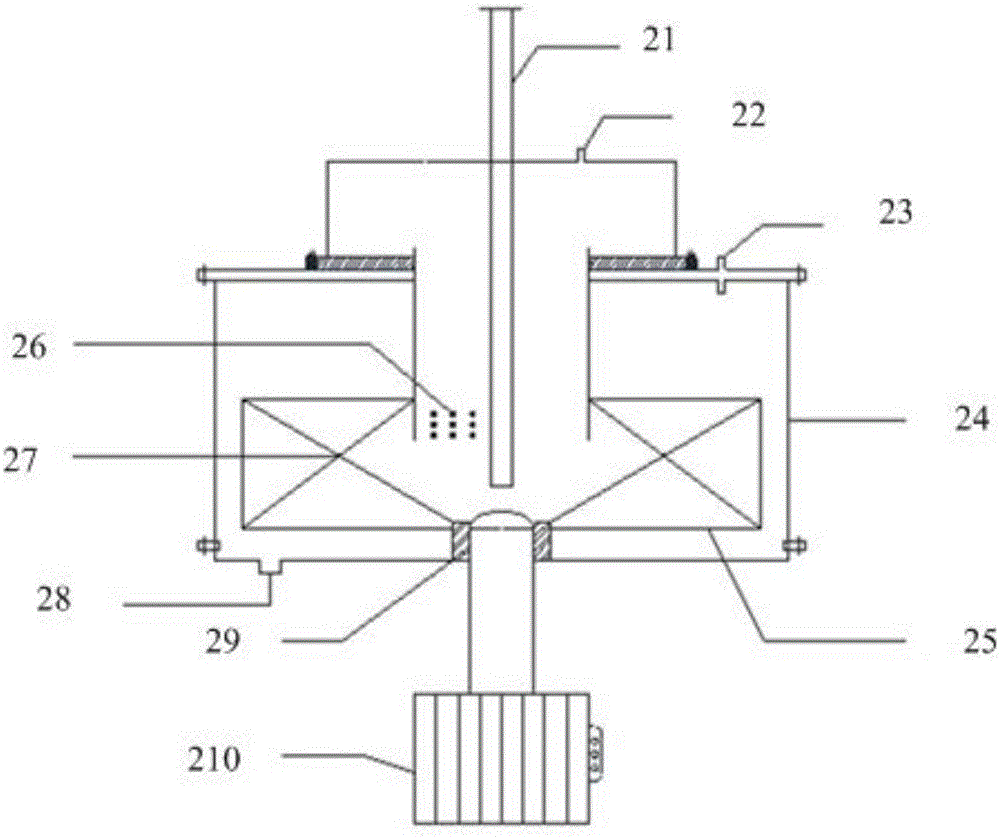

System and method for preparing hydrogen peroxide through anthraquinone method under supergravity condition

ActiveCN106430108AFast updateIncrease production capacityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesNuclear engineeringHydrogen peroxide

The invention provides a system and method for preparing hydrogen peroxide through an anthraquinone method under the supergravity condition. The system comprises a supergravity rotating packed bed, a gas conveying device, a liquid conveying device, a first preheating device and a second preheating device. The supergravity rotating packed bed comprises a shell, a reactor and a rotating device. The reactor is located in the shell, the wall of the reactor is filled with a catalyst, through holes are formed in the wall of the reactor, and the reactor is communicated with the shell through the through holes. The rotating device is connected with the reactor and used for driving the reactor to rotate. The system and method for preparing hydrogen peroxide through the anthraquinone method have the advantages of being short in reaction time, high in hydrogenation efficiency and mass transfer efficiency, easy to operate, small in equipment size, low in investment and the like when used for preparing hydrogen peroxide.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for producing modified polyvinyl chloride and nitrile butadiene rubber composite cable material

InactiveCN101265350AExtend the mixing timeReduce investmentRubber insulatorsPlastic/resin/waxes insulatorsChemistryCalcium carbonate

The invention provides an improved production method for a polyvinyl chloride and chemigum compound cable material, which simplifies the production process, reduces the production cost and ensures the product quality. In the method, polyvinyl chloride, dicapryl phthalate, a stabilizer, a toner, calcium carbonate and chemigum are used as raw materials. The method comprises the following production steps: (1) premixing the polyvinyl chloride, the stabilizer, the toner, and the calcium carbonate in a homogenizer until the mixed temperature reaches 70 DEG C to 80 DEG C; (2) mixing the mixture at slow speed of revolution after the mixed temperature reaches 70 DEG C to 80 DEG C, and adding a liquid plasticizer (DOP); (3) mixing the mixture at slow speed of revolution so that DOP is completely absorbed when the temperature reaches 110 DEG C; (4) adding powdered chemigum, and mixing the mixture for 1 to 2 minutes at slow speed of revolution; and (5) discharging.

Owner:WUXI DONGTIAN CABLE

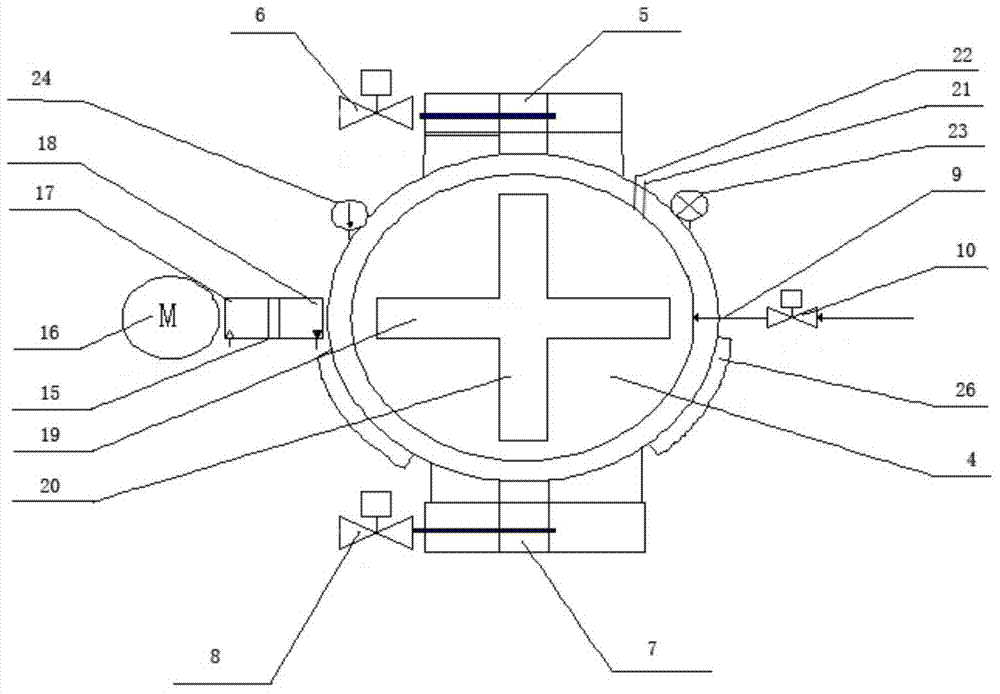

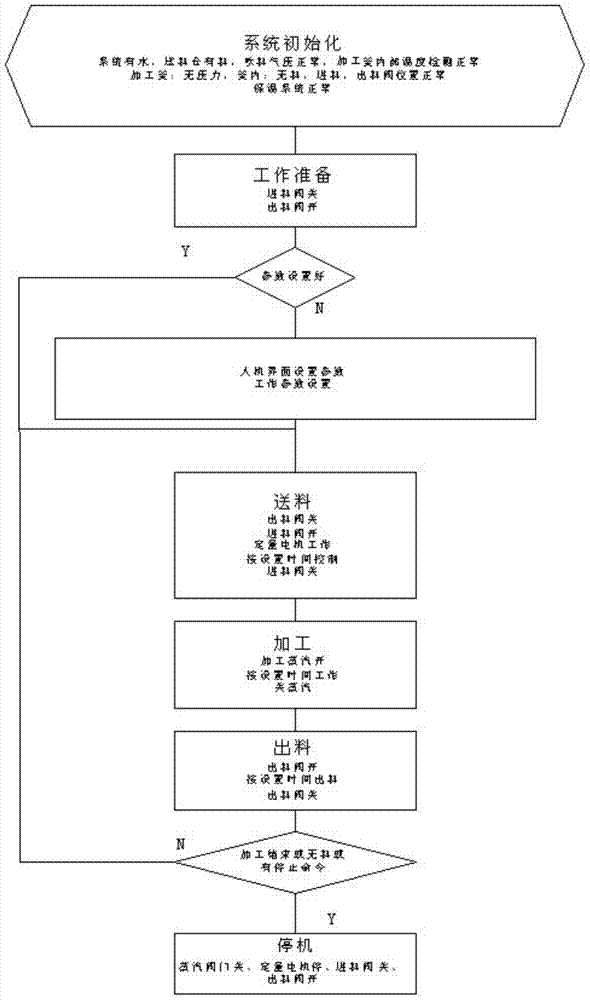

Superheated steam sterilization equipment and superheated steam sterilization method

ActiveCN103609660ANo clumpingReduce processing stepsFruits/vegetable preservation by heatingHeatEngineeringSuperheated steam

The invention discloses superheated steam sterilization equipment which comprises a sterilization container in which a material to be sterilized can be contained and a steam generation device for supplying steam to the sterilization container, wherein the steam generation device is a superheated steam generator (1); the superheated steam generator (1) comprises a steam generator (2) capable of generating saturated steam and a steam heater (3) for heating the saturated steam into superheated steam; the superheated steam can be used for directly heating and sterilizing the material in the sterilization container. The invention also discloses a superheated steam sterilization method which comprises the steps of (1) processing preparation; (2) material feeding of a processing kettle; (3) sterilization by the superheated steam; (4) material discharging; and (5) repeating of the steps from (2) to (4). The superheated steam sterilization equipment and the superheated steam sterilization method can be used for quickly and efficiently sterilizing powdered particles of food, the steps are reduced, and the cost is saved.

Owner:顶能科技有限公司

High-gloss antiscratch polypropylene masterbatch and preparation method and use thereof

The invention discloses high-gloss antiscratch polypropylene masterbatch and a preparation method and use thereof. The high-gloss antiscratch polypropylene masterbatch consists of polypropylene homopolymer, silicone powder, nucleating agent and antioxygen. The high-gloss antiscratch polypropylene masterbatch disclosed by the invention and polypropylene can be directly mixed and injected, the obtained products have high gloss and can be used without agglomeration, the components of the products are dispersed uniformly, the antiscratch performance of the products is stable, and the antiscratch performance of the high-gloss antiscratch polypropylene masterbatch is much higher than that of polypropylene; meanwhile, the mechanical properties of products prepared by mixing and injection of the masterbatch and polypropylene are improved. Therefore, the high-gloss antiscratch polypropylene masterbatch has promotion and use values.

Owner:GUANGDONG WAYLAM ENG PLASTICS

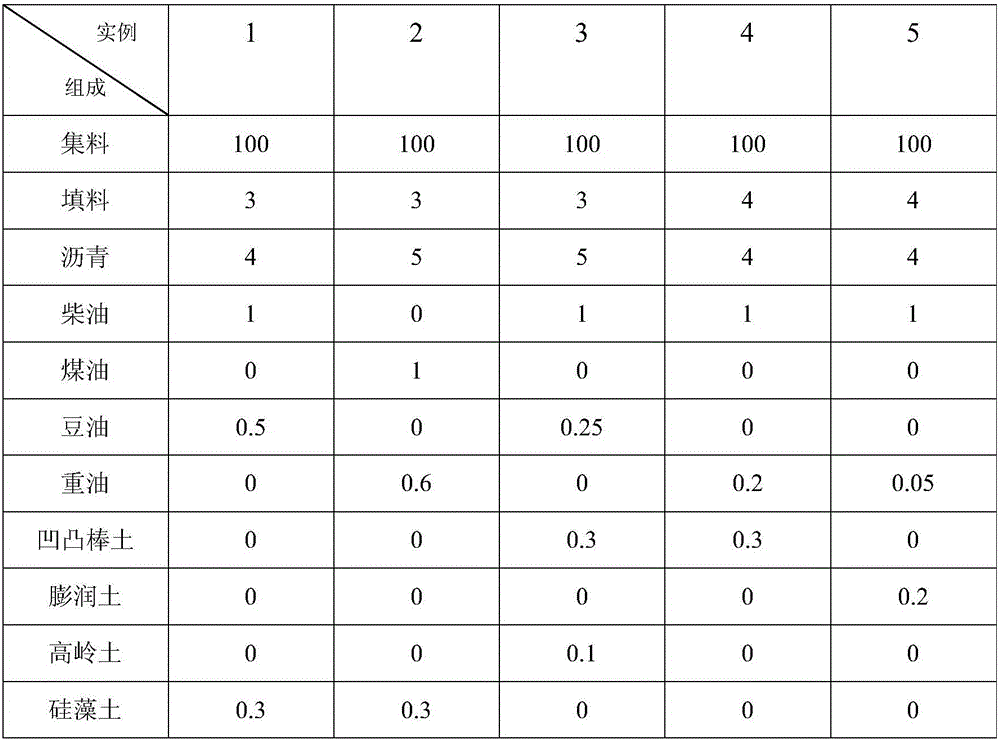

Cold patch asphalt mixture prepared from clay minerals and preparation method of cold patch asphalt mixture

The invention provides a cold patch asphalt mixture prepared from clay minerals and a preparation method of the cold patch asphalt mixture.According to the cold patch asphalt mixture prepared from the clay minerals, the clay minerals are selected as a modifier of cold patch asphalt, and the cold patch asphalt is prepared from aggregate, filler, diluent and the clay minerals; the mixing quantity of the clay minerals in the cold patch asphalt is 3%-9% the mass of the asphalt, and the clay minerals include attapulgite, bentonite, kaolin, kieselguhr and the like.The prepared cold patch asphalt mixture is simple in process and low in cost.Laboratory experiments and practical pavement construction show that the cold patch asphalt mixture has good pavement performance such as forming strength, water stability and high temperature stability.

Owner:SOUTHEAST UNIV

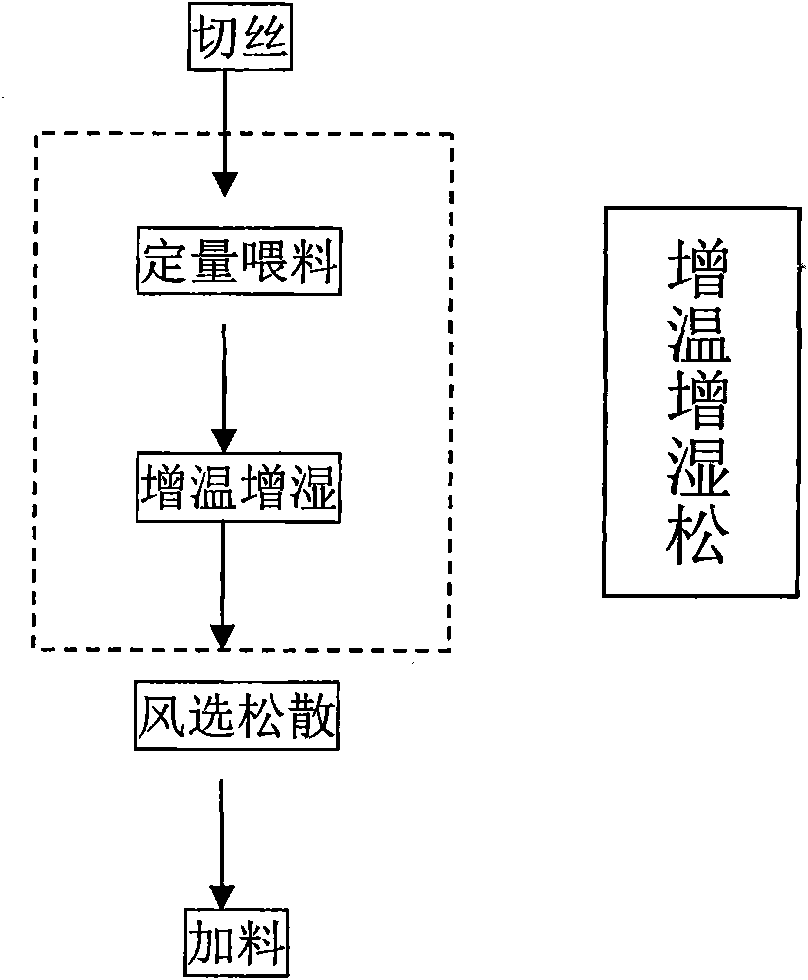

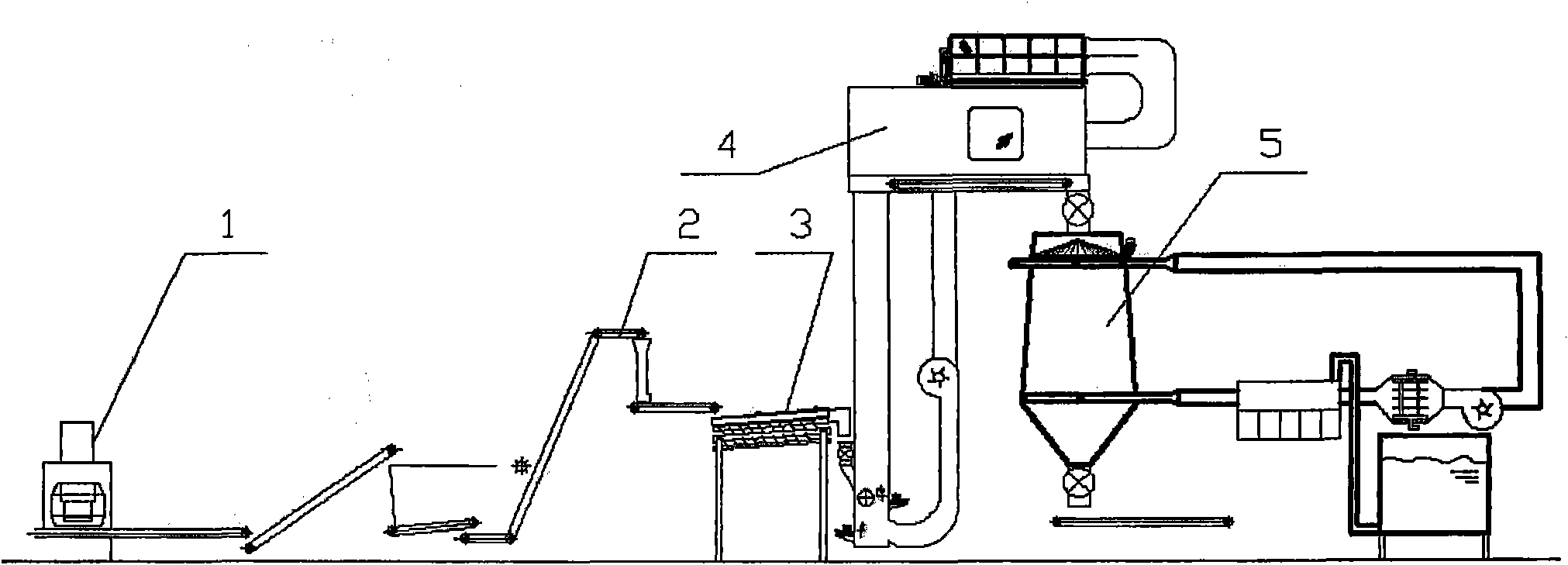

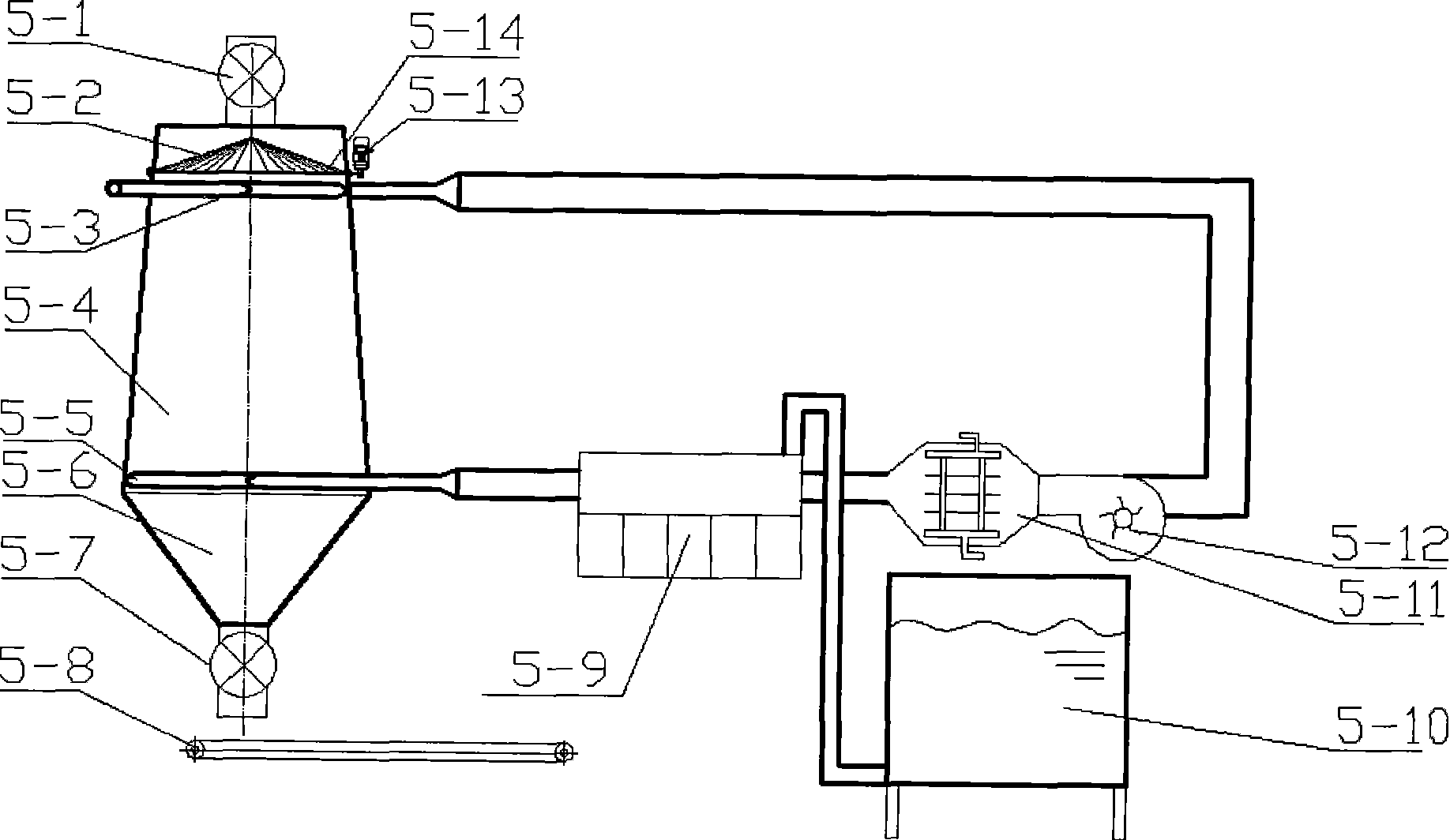

Leaf thread material feeding process and equipment

ActiveCN101773279AReduce sticking and drawingLoosely fullTobacco preparationTobacco treatmentVulcanizationMaterial scattering

The invention relates to a leaf thread material feeding process and equipment, which belong to the technical field of tobacco processing. The invention is characterized in that the leaf thread feeding process sequentially comprises the working procedures of thread cutting, temperature increasing and humidifying loosening, air separation loosening and material feeding. The equipment applicable to the process comprises a thread cutting machine, a quantitative material feeding machine, a vibration vulcanization bed, an air separation loosening device and a vertical material feeding machine which are sequentially ranged, wherein each equipment is connected through material conveying mechanisms, the vertical material feeding machine comprises a material feeding cavity, a material inlet airlock and a material outlet airlock are respectively arranged on the top and the bottom of the material feeding cavity, a material scattering mechanism is fixed on the upper part of the material feeding cavity, a material liquid atomizing system is communicated with the material feeding cavity through an air inlet pipe and a air return pipe of a hot air circulation system, and a sealed cyclic feeding system is formed. The process and the equipment can solve the problems of large thread cutting pulverization products of low-water-content tobacco flakes and material feeding aggregation of tobacco threads, the material liquid atomizing effect is good, the material liquid absorption velocity by the tobacco threads is high, the material feeding uniformity and the effectiveness are improved, in addition, the material storing time after the material feeding is shortened, and the production efficiency is high.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

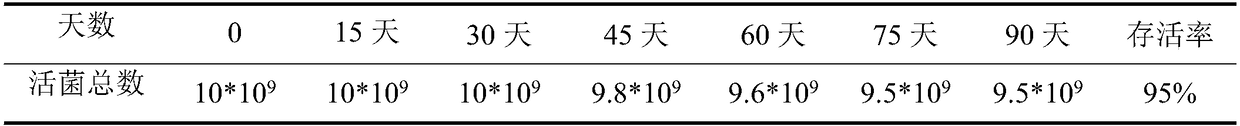

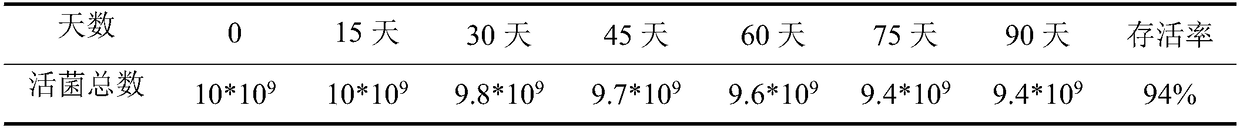

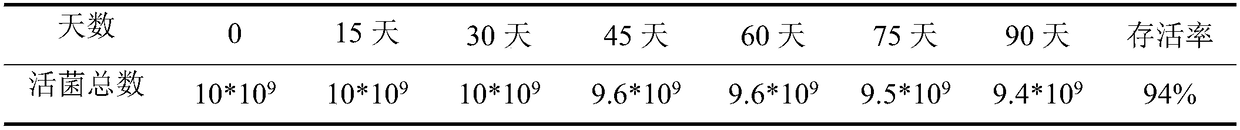

Probiotic soft capsules suitable for babies and preparation method of probiotic soft capsules

InactiveCN108113003AImprove stabilityEvenly dispersedFood ingredient as antioxidantLactobacillusForeign matterProbiotic

The invention discloses probiotic soft capsules suitable for babies and a preparation method of the probiotic soft capsules, and discloses the probiotic soft capsules suitable for babies. The contentsof the probiotic soft capsules comprise the following components of 5-15 parts of probiotics, 0.5-2 parts of silicon dioxide, 5-10 parts of oligosaccarides, and 40-70 parts of substrate oil. Along with the increment of the particle size of probiotic powder, the settling volume ratio is gradually increased, so that the oil-liquid stability is gradually improved; when the particle size of the probiotic powder is 100 meshes or above, the settling volume ratio is 0.9 or above, and the probiotic soft capsules are uniformly dispersed in oil; and after the probiotic soft capsules are uniformly stirred, floating oil and conglomeration are avoided. The probiotic powder is good in stability in oil dispersion liquid, and after being stored for half a year, the probiotic soft capsules are free from the phenomena of floating oil, sticking to walls, and foreign matters.

Owner:ZHEJIANG CONBA HEALTH PROD

Preparation method and application of powdery polycarboxylate slump retaining agent

The invention discloses a preparation method and application of a powdery polycarboxylate slump retaining agent. The preparation method comprises the following steps: performing free radical polymerization reaction on a carboxylate monomer a, a small monomer b capable of releasing adsorption groups, and a polyether monomer c containing a benzene ring in a water-based medium, so as to obtain a polycarboxylate slump retaining agent mother solution; performing atomization on the polycarboxylate slump retaining agent mother solution through a pressure atomizer, adding a release agent in a spray tower during atomization, then drying the polycarboxylate slump retaining agent mother solution into a powder polycarboxylate slump retaining agent, controlling the average grain diameter of powder, leading a material to a material outlet through an induced draft fan, and packaging through a bagging packaging machine and discharging, so as to obtain the powdery polycarboxylate slump retaining agent.The preparation method not only solves the problem that a polycarboxylate slump retaining agent is difficult to become powder, but also solves the problem the polycarboxylate slump retaining agent adheres to a wall and is agglomerated during atomization; the formed powder is high in flowability, not agglomerated, high in storage stability, low in long distance transportation cost, excellent in slump retaining performance, and applicable to special mortar, such as self-leveling mortar, grouting materials, grouting agents, waterproof mortar and external wall insulation mortar.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Boron-steel-containing mold flux dedicated for continuous casting

The invention discloses boron-steel-containing mold flux dedicated for continuous casting, comprising the following chemical ingredients by mass: 34-40% of CaO, 23-27% of SiO2, 2-4% of Al2O3, 6-8% of F, 1-2% of MgO, 2-4% of MnO, 7-9% of Na2O, 5-8% of C and 0.1-1.5% of Li2O. Experiments on site prove that boron-steel-containing 15MnVB and S400B are cast in a slab casting machine with specification of 200*900-1200mm <2> in a steel mill under the condition that the stable casting speed is 1.60m / min, the flux consumption is 0.38Kg / steel T; and no caking occurs in the process of melting the mold flux, no flux strip exists at molten steel meniscus, the thickness of a melt cinder layer on a molten steel surface is 10-15mm, the stable and even heat flux around a crystallizer is observed by a heat flow curve to be stable and uniform, and the frictional force of the crystallizer is stable. Therefore, the experiments show that heat transmission and lubrication performances of the mold flux are good.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

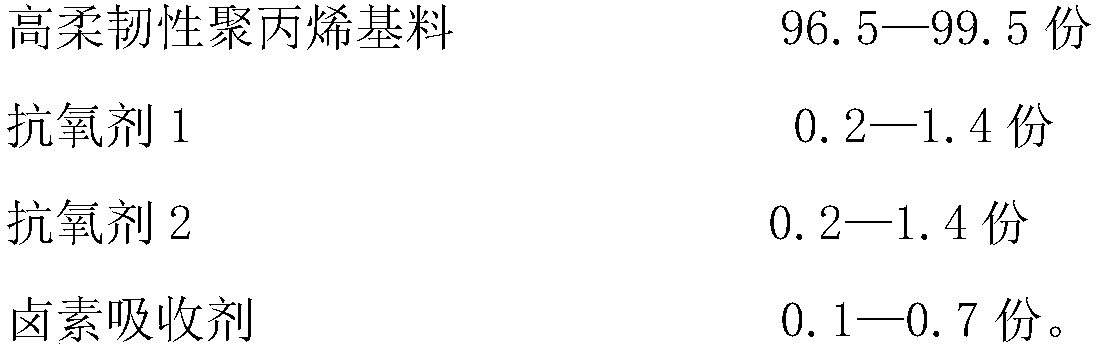

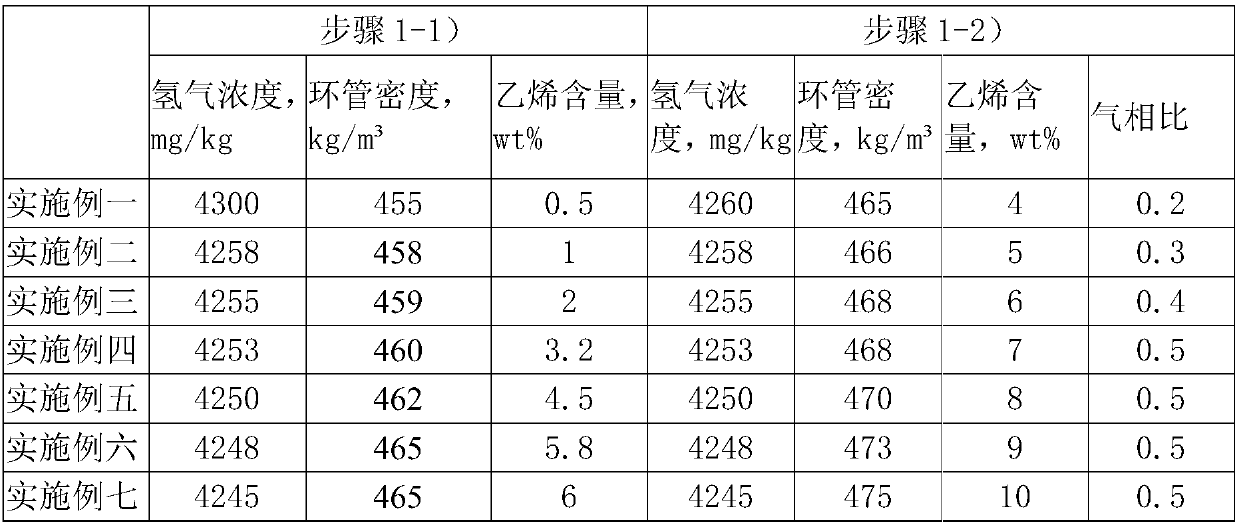

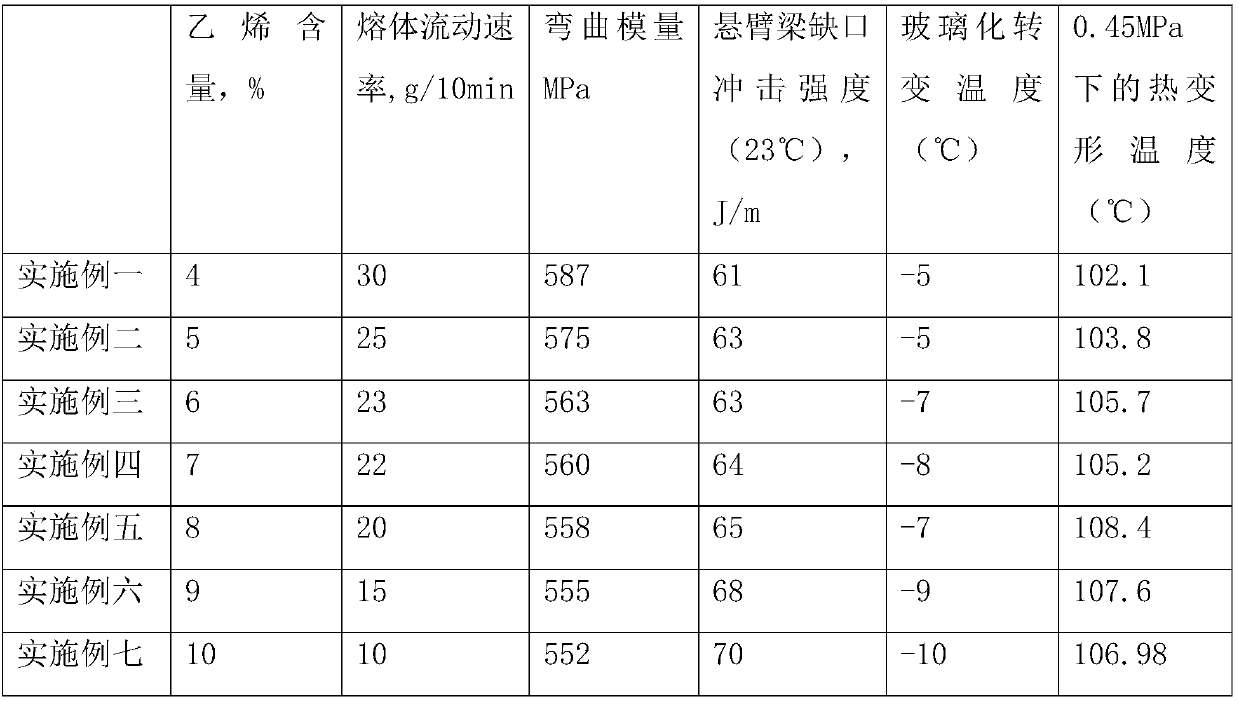

High-toughness polypropylene resin and production method thereof

The invention discloses high-toughness polypropylene resin and a production method thereof. The high-toughness polypropylene resin is mainly prepared from high-toughness polypropylene base materials,antioxidants 1, antioxidants 2 and halogen absorbing agents, and the base materials are produced by a two-step compounding method in a Spheripol process. A production method of the base materials particularly includes the steps: taking propylene and hydrogen as raw materials in a first loop reactor, adding a catalyst, an electron donor and a promoter, controlling the concentration of the hydrogento be 4245-4300mg / kg, controlling loop density to be 460kg / m<3>, controlling ethylene content to be 0.5-6wt%, and producing polypropylene random copolymers; performing gas-phase copolymerization reaction on propylene homopolymers and ethylene monomers in the polypropylene random copolymers acquired in the first step in a second loop reactor, controlling the concentration of the hydrogen to be 4245-4260mg / kg, controlling loop density to be 460kg / m<3>, controlling loop density to be 470kg / m<3>, controlling ethylene content to be 4-10wt%, controlling gas phase ratio to be 0.2-0.5, preparing polypropylene powder, and namely, preparing the base materials. The bending modulus is 600MPa or more, the impact strength of a cantilever beam gap is 60J / m (23 DEG C) or more, haze is smaller than 10, andthe polypropylene resin is provided with good-transparency soft impact-resistant polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-impact polypropylene with high ethylene content and high fluidity and preparation method thereof

The invention discloses an anti-impact polypropylene with high ethylene content and high fluidity. The polypropylene is a polypropylene alloy consisting of noblen and ethylene-propylene copolymer, wherein the weight percentage of ethylene is 10 to 30 percent; the polypropylene has a controllable cross-linked structure, and the weight percentage of gel in the anti-impact polypropylene is 0 to 30 percent. A preparation method of the polypropylene comprises the following steps of (1) propylene homopolymerization, i.e., in a reaction vessel, taking propylene as a monomer, taking hydrogen as a molecular weight modifier, and polymerizing under the action of a supported Ziegler-Natta catalytic system or a supported metallocene catalytic system; and (2) ethylene-propylene gas phase copolymerization, i.e., after propylene homopolymerization is finished, removing propylene and hydrogen in the reaction vessel, inletting ethylene-propylene mixed gas and the molecular weight modifier, i.e., the hydrogen into the reaction vessel, and adding inorganic powder II and a cross-linking agent to perform ethylene-propylene gas phase copolymerization to obtain the polymerisate granular alloy.

Owner:ZHEJIANG UNIV

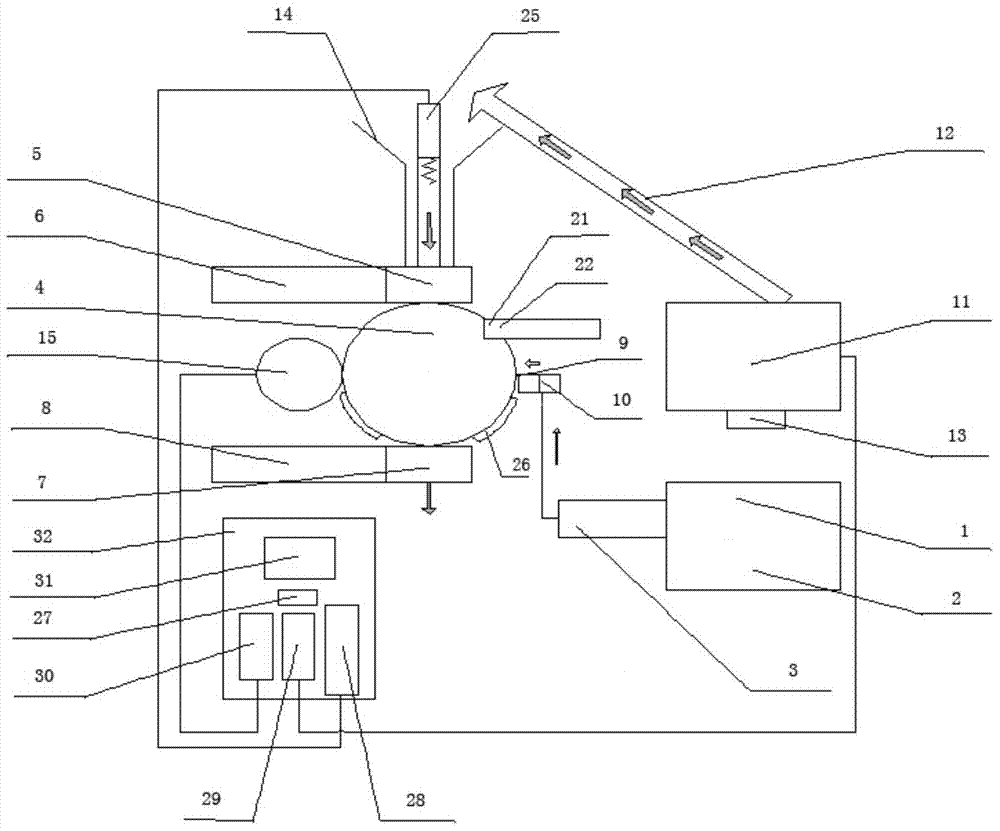

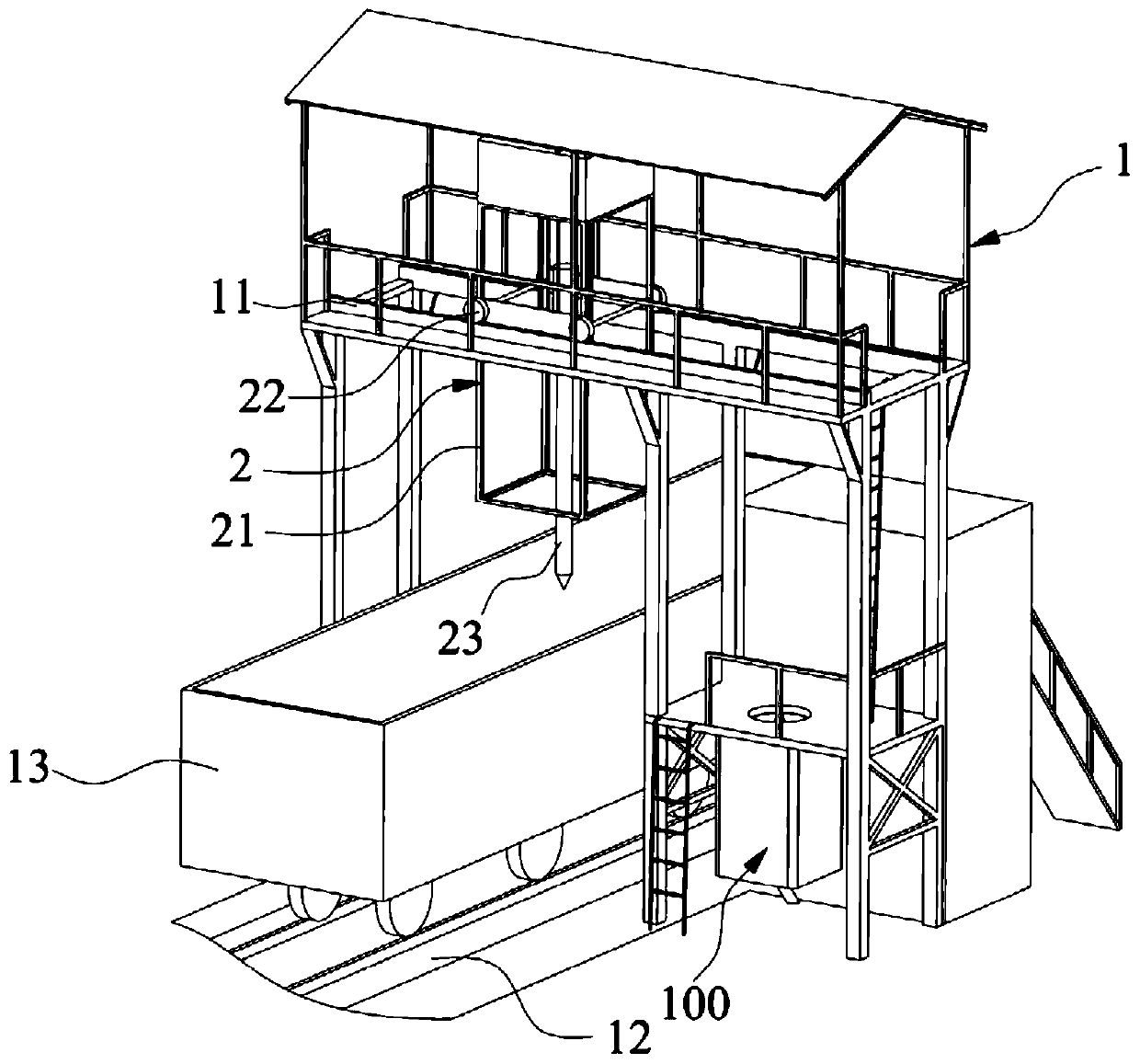

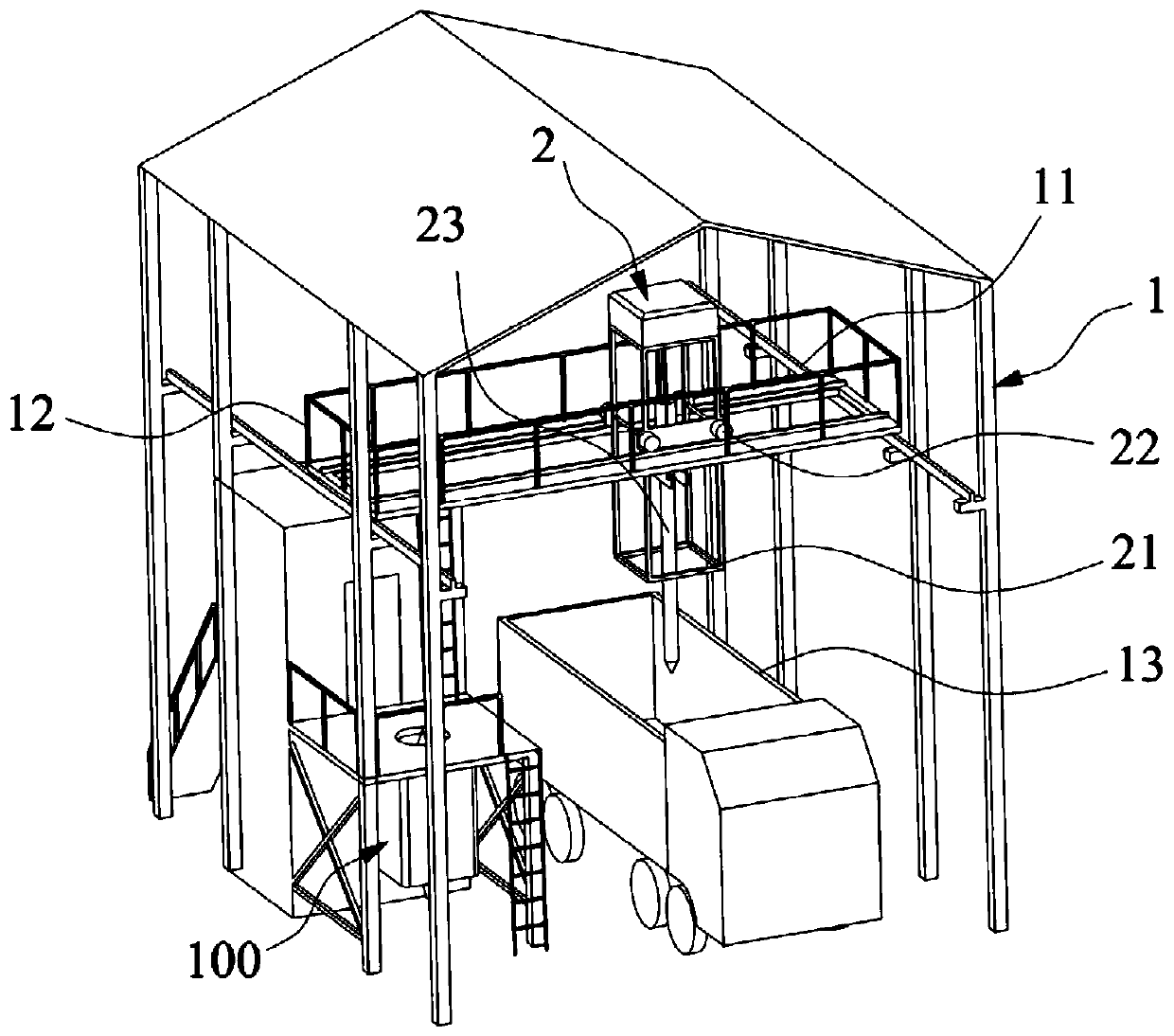

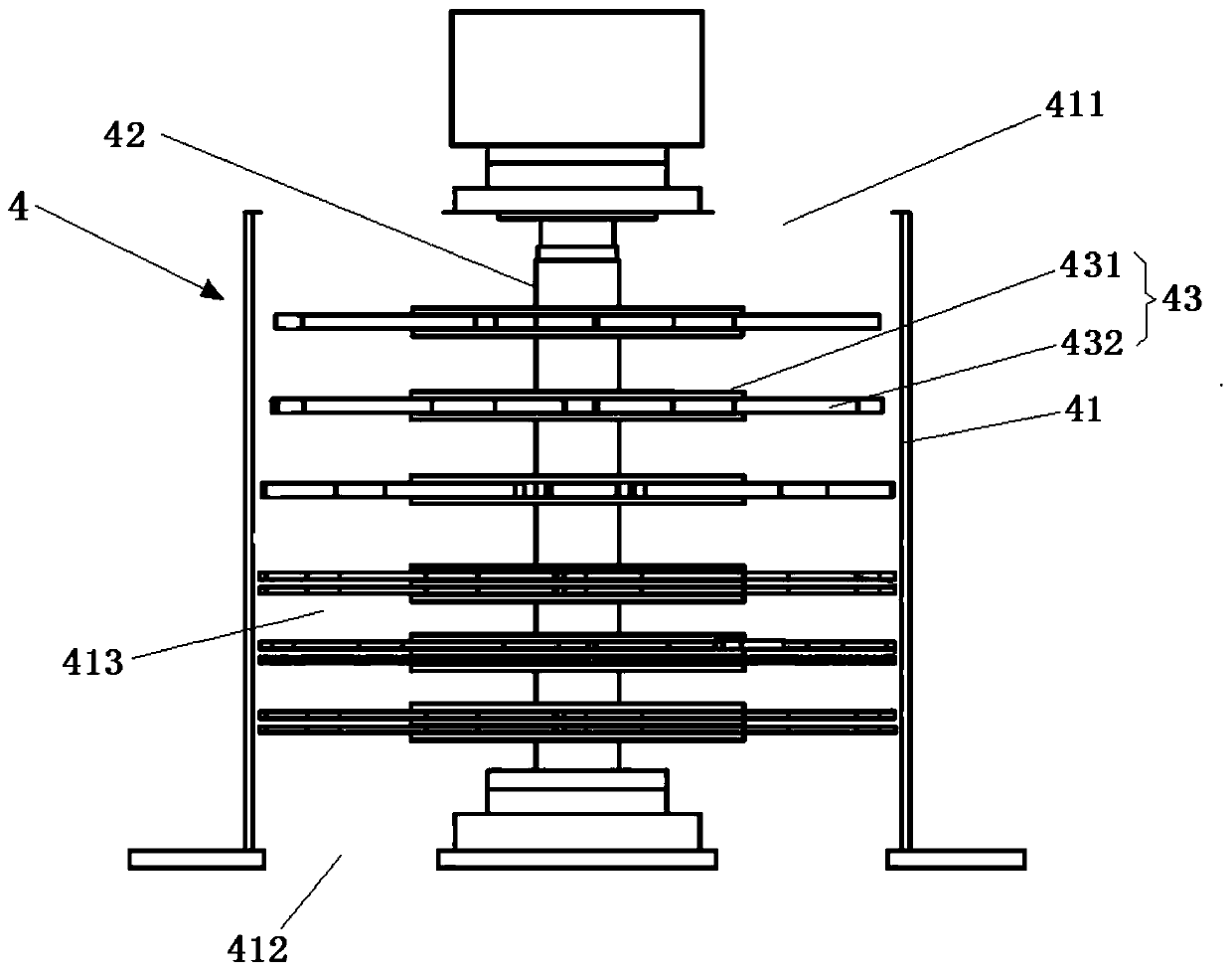

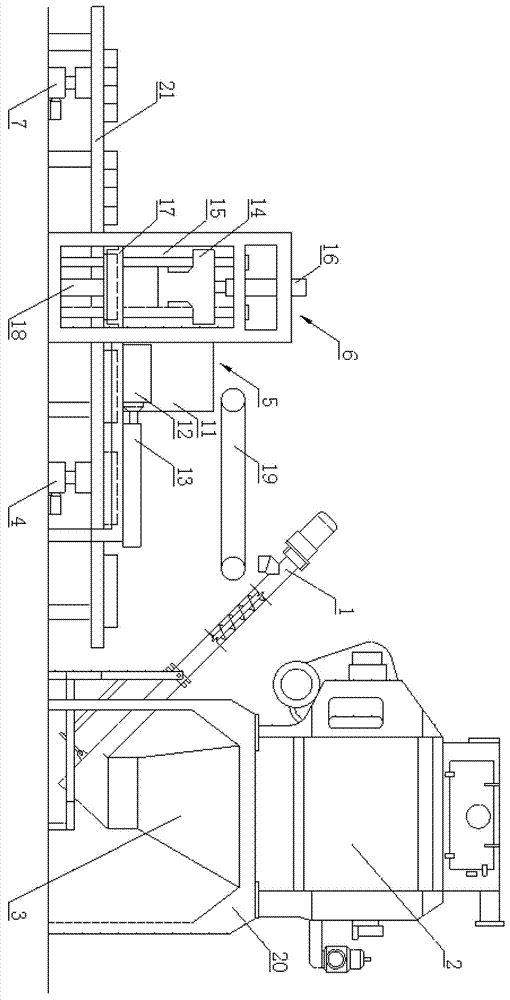

Beltless full-automatic mechanical sampling system for trains

PendingCN109946113AImprove operational efficiencyReduce moisture lossWithdrawing sample devicesPreparing sample for investigationProcess engineeringCrusher

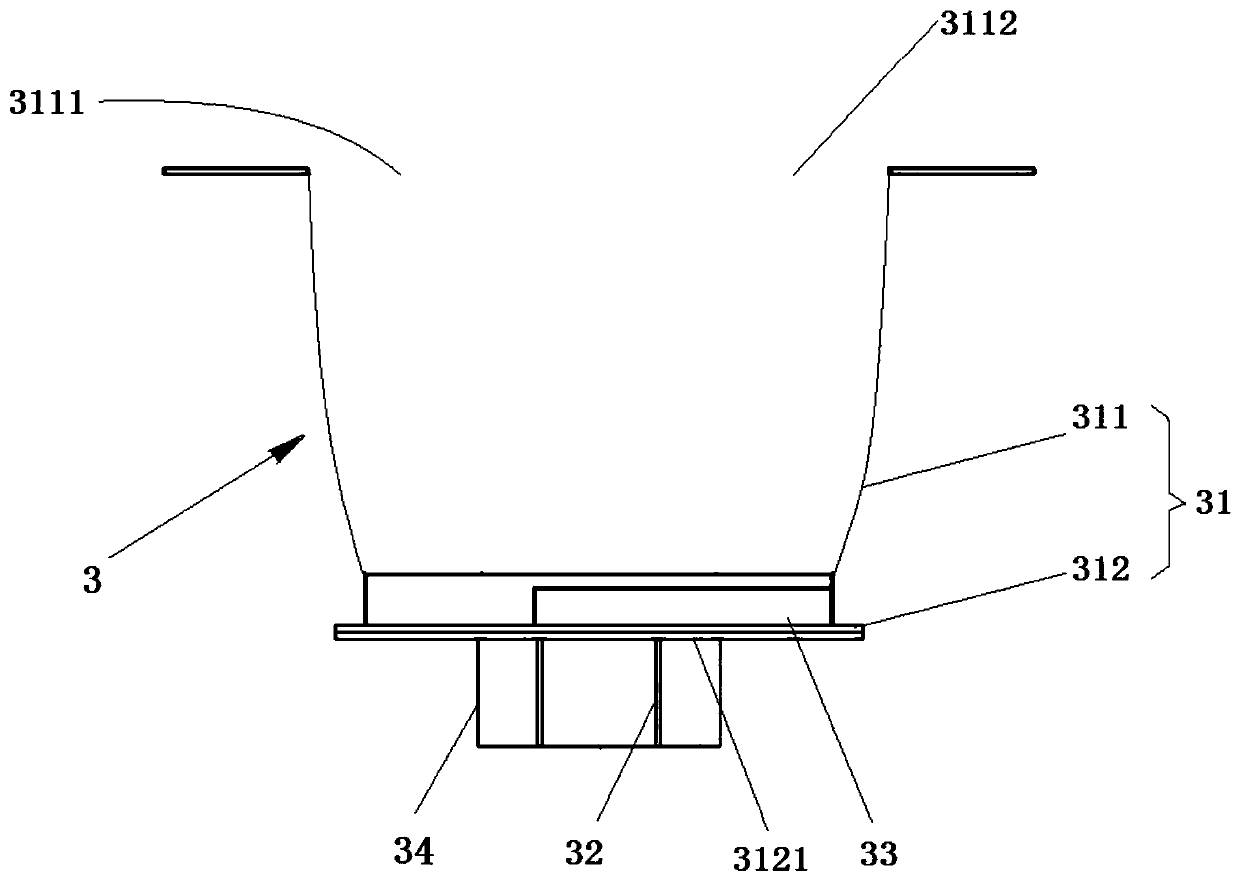

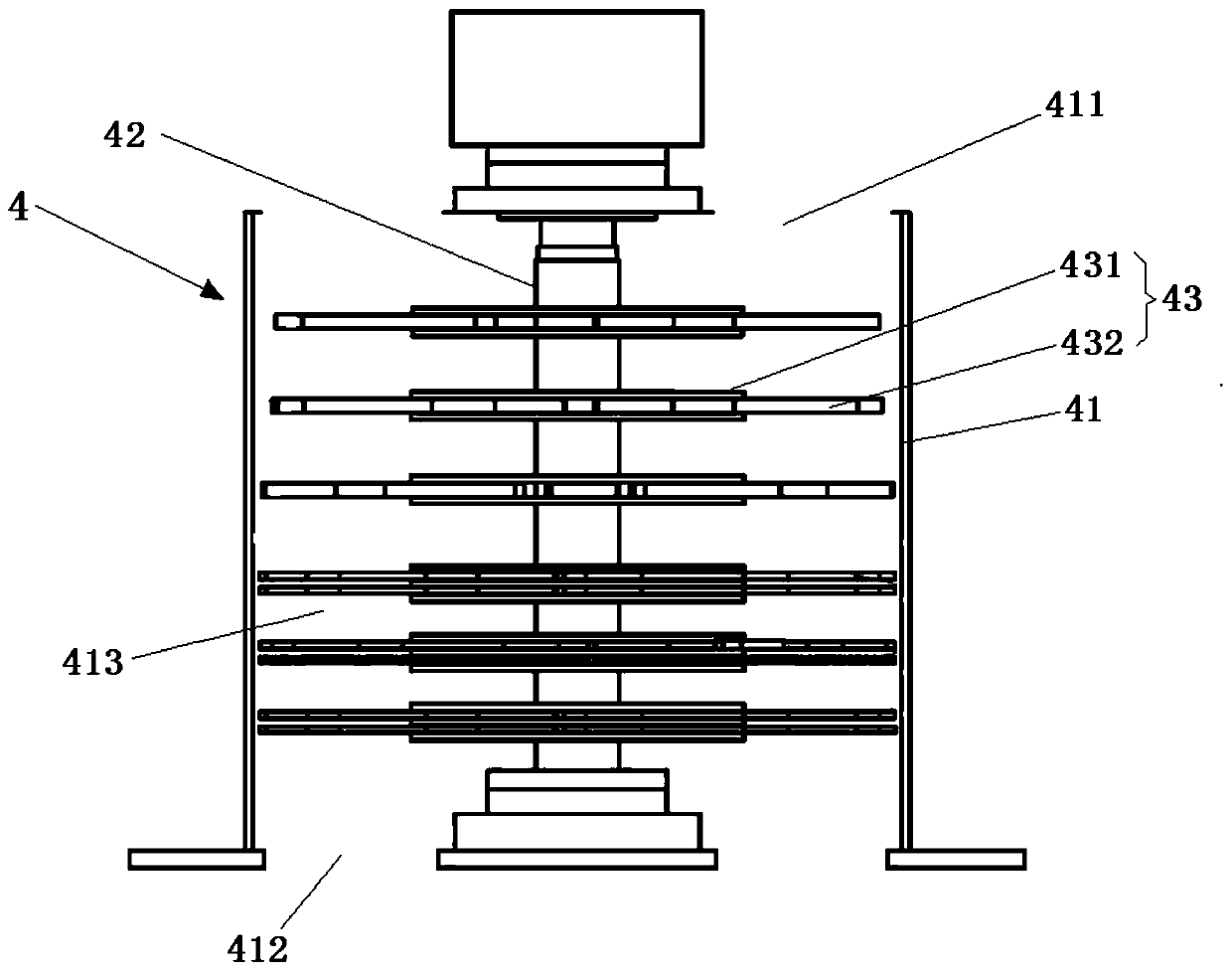

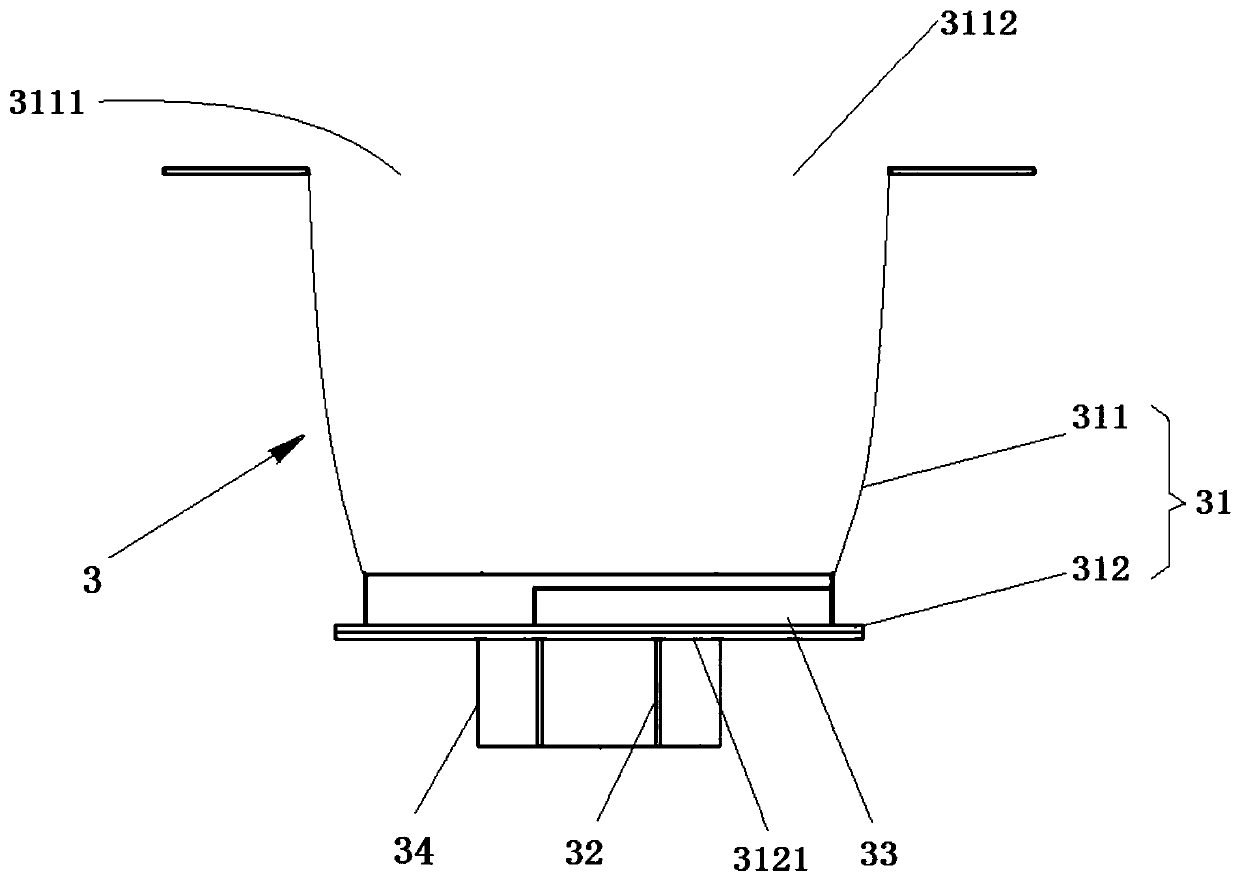

The invention particularly discloses a beltless full-automatic mechanical sampling system for trains. The system comprises an operation platform, a sampling mechanism and an integrated sample preparation unit. The operation platform is located above train rails; the full-sealed integrated sample preparation unit comprises a feeder, a crusher, a fixed mass division machine and a sample retaining barrel which are sequentially arranged from top to bottom; the sampling mechanism is used for collecting materials from train carriages and conveying the materials to the feeder, the feeder sends the materials to the crusher uniformly and continuously, the crusher crushes and conveys the materials to the fixed mass division machine, the fixed mass division machine divides the materials into samplesand waste, the samples are retained in the sample retaining barrel, and the waste is conveyed to carriages through a waste return unit. The waste return unit can replace manpower to treat the waste regularly, so that the operation efficiency is improved.

Owner:INFINITY INTELLIGENCE & INFORMATION (SUZHOU) TECH CO LTD

Beltless automobile fully-automatic mechanized sampling system

PendingCN109959526AImprove operational efficiencyDelay moisture lossWithdrawing sample devicesPreparing sample for investigationDischarge returnProcess engineering

The invention specifically discloses a beltless automobile fully-automatic mechanized sampling system, which comprises a working platform, a first frame, a first horizontal driving mechanism, a sampling mechanism and an integrated sample preparation unit, wherein a channel is arranged under the working platform; the sample preparation unit comprises a feeder, a crusher, a constant mass reduction machine and a sample holding barrel which are arranged in order from top to bottom; the sampling mechanism is used for collecting materials from a carriage and conveying the materials to the feeder; the silo of the feeder is internally provided with a rotatable feeding part to feed the materials to the crusher uniformly and continuously; the crusher crushes the materials and transports the materials to the constant mass reduction machine; and the constant mass reduction machine divides the materials into samples and discarded materials, the samples are kept in the sample holding barrel, and thediscarded materials are transported to a discarded material storage place through a discarded material discharge return unit. Manual timing processing of the discarded materials can be replaced through the discarded material discharge return unit, and the operation efficiency is improved.

Owner:INFINITY INTELLIGENCE & INFORMATION (SUZHOU) TECH CO LTD

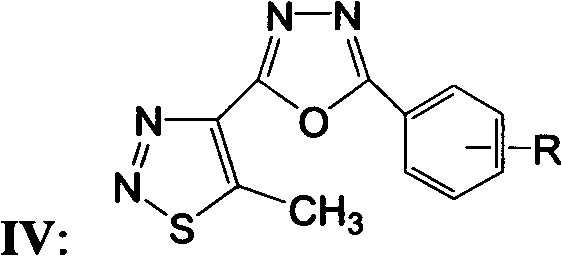

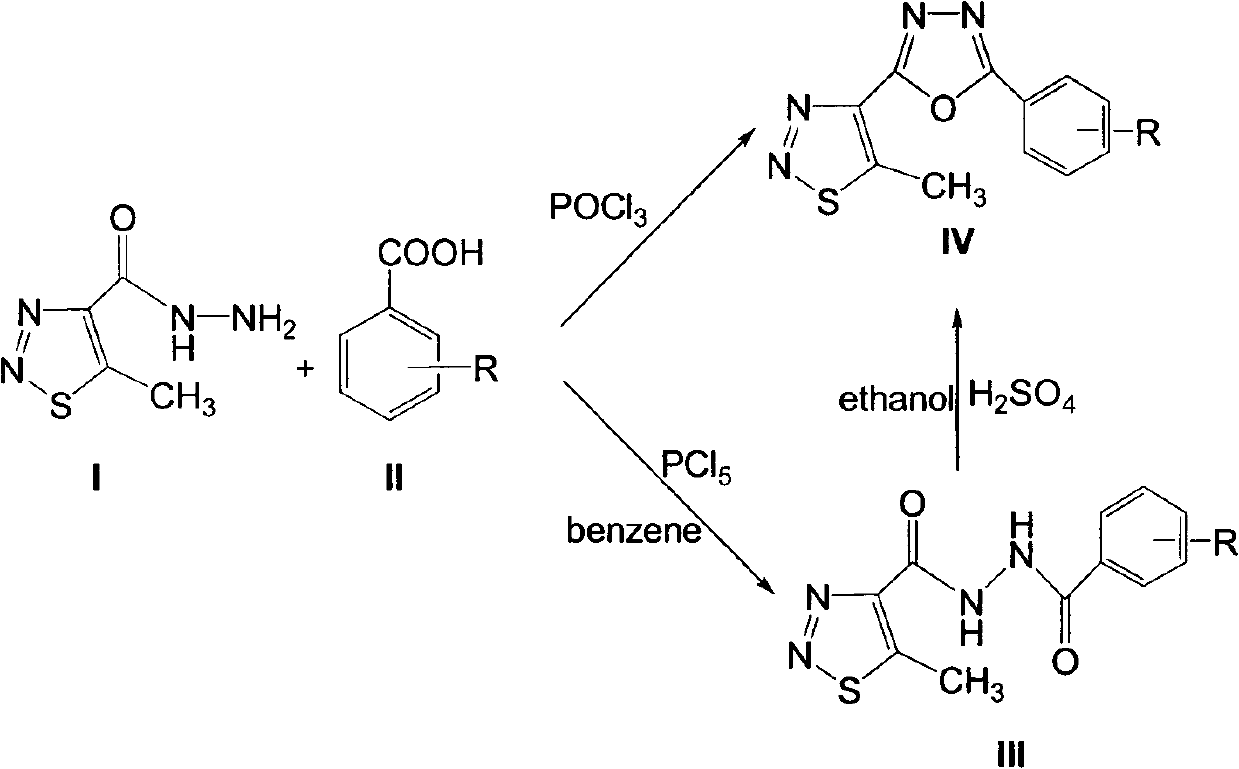

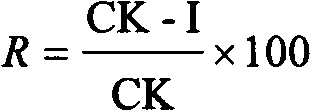

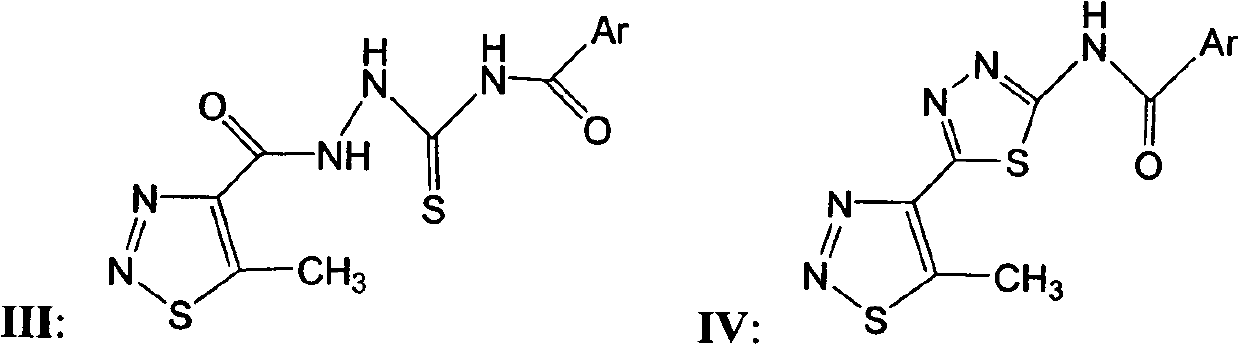

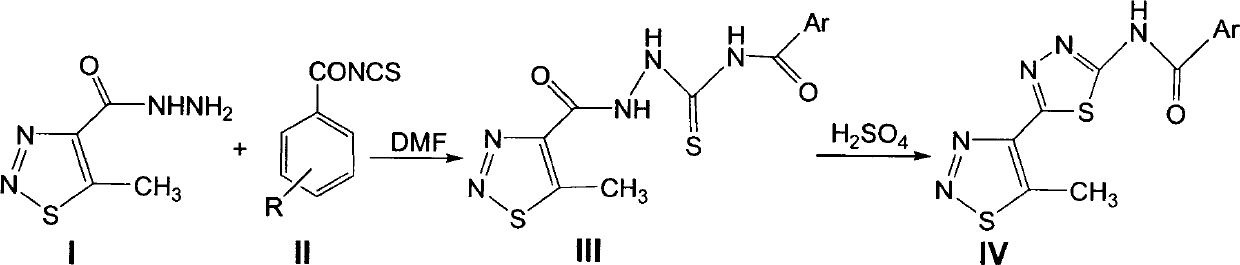

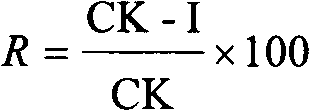

5-methyl-1,2,3-thiadiazole-1,3,4-oxadiazole derivatives, and preparation method and application thereof

InactiveCN102816158AExpand or reduce volumeExpand or shrink in sizeBiocidePlant growth regulatorsAdjuvantStructural formula

The invention provides 5-methyl-1,2,3-thiadiazole-1,3,4-oxadiazole derivatives, and a preparation method and application thereof. The invention relates to heterocyclic compounds containing 1,2,3-thiadiazole and having chemical structural formula IV. The invention discloses the structural general formula, and a synthetic method of the compounds and the application of the compounds for being used as bactericide, plant anti-viral agent and plant activator. The derivatives can be applied for preparing the bactericide, plant anti-viral agent and plant activator in combination with agriculturally acceptable adjuvant or synergist, and the invention also discloses application of the compounds in combination with commercial insecticide, bactericide, plant anti-viral agent and plant activator for treating and controlling diseases, pests and viruses in agriculture, forestry, and gardening industries, and the preparation method.

Owner:JIANGXI JIAYIN PHOTOELECTRIC MATERIAL

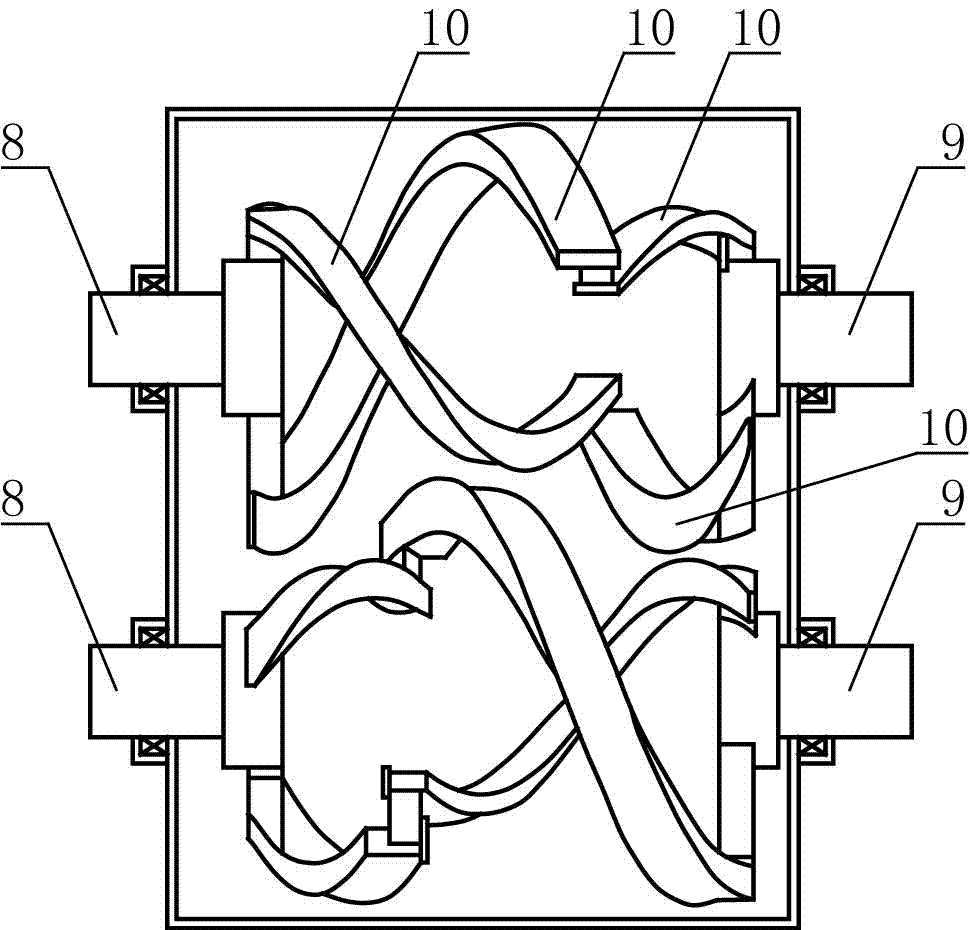

Continuous brick building block forming system

InactiveCN102825647ADouble the mixing efficiencyReduce energy consumptionCeramic shaping apparatusManufacturing technologyBrick

The invention relates to the technical field of manufacturing of brick block forming equipment, in particular to a continuous brick building block forming system which has the advantages of compact structure, short forming period, uniform distribution, good compaction effect of a product and reliability in operation. The continuous brick building block forming system comprises a stirring device, a spiral elevator (1) and a brick making building block device which are arranged in sequence, wherein the stirring device consists of a stirring machine (2) and a concrete storage hopper (3); the brick making building block device consists of an automatic plate feeder (4), an automatic distributor (5), a building block forming machine (6) and an automatic brick discharger (7); the concrete storage hopper (3) is hermetically arranged below the stirring machine (2); a discharge port of the concrete storage hopper (3) is hermetically connected with a feed end of the spiral elevator (1); the automatic distributor (5) is arranged below a discharge end of the spiral elevator (1); the automatic plate feeder (4) is connected below the automatic distributor (5), and the building block forming machine (6) is arranged on one side of the automatic plate feeder (4); and the automatic brick discharger (7) is arranged on the other side of the building block forming machine (6).

Owner:马倩

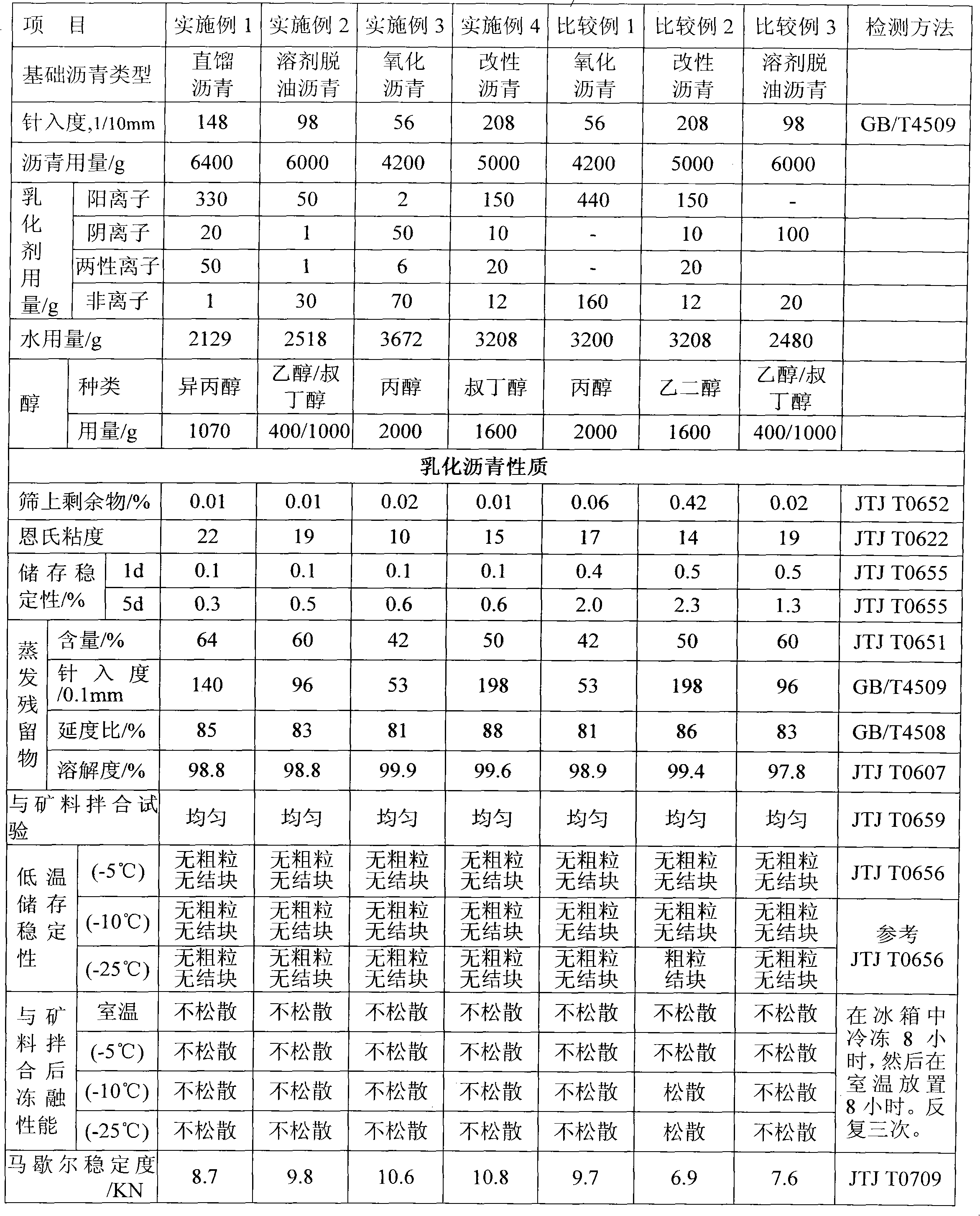

Frost resistant emulsified bitumen prepared from composite emulsifier, and preparation method thereof

ActiveCN102234435AReduce the amount requiredGood emulsifying effectWorking-up pitch/asphalt/bitumenBuilding insulationsFreeze thawingPropanol

The invention discloses frost resistant emulsified bitumen which is prepared from a composite emulsifier, and a preparation method thereof. The emulsified bitumen comprises bitumen, a cationic emulsifier, an anionic emulsifier, an amphoteric emulsifier, a nonionic emulsifier, an alcohol and water. The alcohol comprises one or more selected from ethanol, propanol, isopropanol and tert butyl alcohol. With the present invention, a combination of the composite emulsifier and the low molecular weight fatty alcohol is adopted for the emulsified bitumen while diluents such as diesel oil or kerosene and the like are not added, such that time of water evaporation is shortened, a hardening rate of mixture is increased, frost resistance is improved (the emulsified bitumen cannot be frozen at a temperature of -5 to -25 DEG C), original excellent properties such as bonding performance of the bitumen and the like are maintained, and shrinkage and cracking of the mixture due to a low temperature in winner or surface loosening of the mixture due to freeze thawing is avoided. The frost resistant emulsified frost resistant can be used for road curing and road maintenance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant coating fabric high in moisture-penetrability

The invention discloses a flame-retardant coating fabric high in moisture-penetrability. The flame-retardant coating fabric high in moisture-penetrability comprises a first base coating and a second base coating, wherein the first base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of a bridging agent, 1.6-2 parts of an accelerant, 1.4-1.6 parts of a washable agent and 9-11 parts of phosphate ester flame-retardant oil. The second base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of the bridging agent, 1.6-2 parts of the accelerant, 1.4-1.6 parts of the washable agent and 9-11 parts of phosphate ester flame-retardant oil. The flame-retardant coating fabric high in moisture-penetrability is small in smoke generation quantity, free of molten drop, high in flame-retardant effect and highly washable; the flame-retardant substance has a small possibility of hydrolyzing.

Owner:KUNSHAN HUAYANG NEW MATERIAL

5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives and their preparation method and use

InactiveCN102816135AHigh bactericidal activityImprove representationBiocidePlant growth regulatorsInsect pestStructural formula

The invention provides 5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives and their preparation method and use. The 5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives are 1,2,3-thiadiazole-containing heterocyclic compounds. Intermediates of the 5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives and the 5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives respectively have a general structural formula III and a general structural formula IV. The invention discloses the general structural formula and the preparation method of the 5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives, and also discloses a use of the 5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives as bactericides, plant virus resistance agents and plant activators. After being mixing with agriculture acceptable assistants or synergists, the 5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives can be used for preparation of bactericides, plant virus resistance agents and plant activators. The invention also discloses a use of the 5-methyl-1,2,3-thiadiazole-containing 1,3,4-thiadiazole derivatives combined with commercial insecticides, bactericides, plant virus resistance agents and plant activators in prevention and treatment on agricultural, forest and gardening diseases, insect pests and viral diseases, and also discloses a preparation method thereof.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com