Patents

Literature

475results about How to "Avoid secondary oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

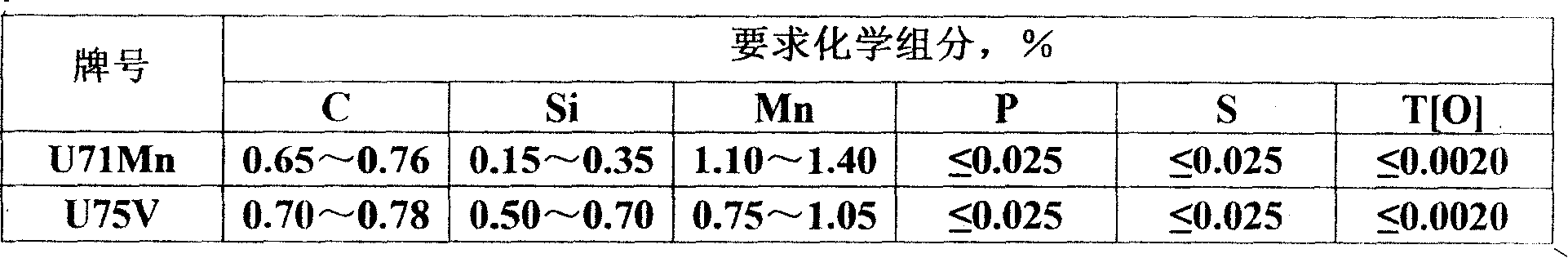

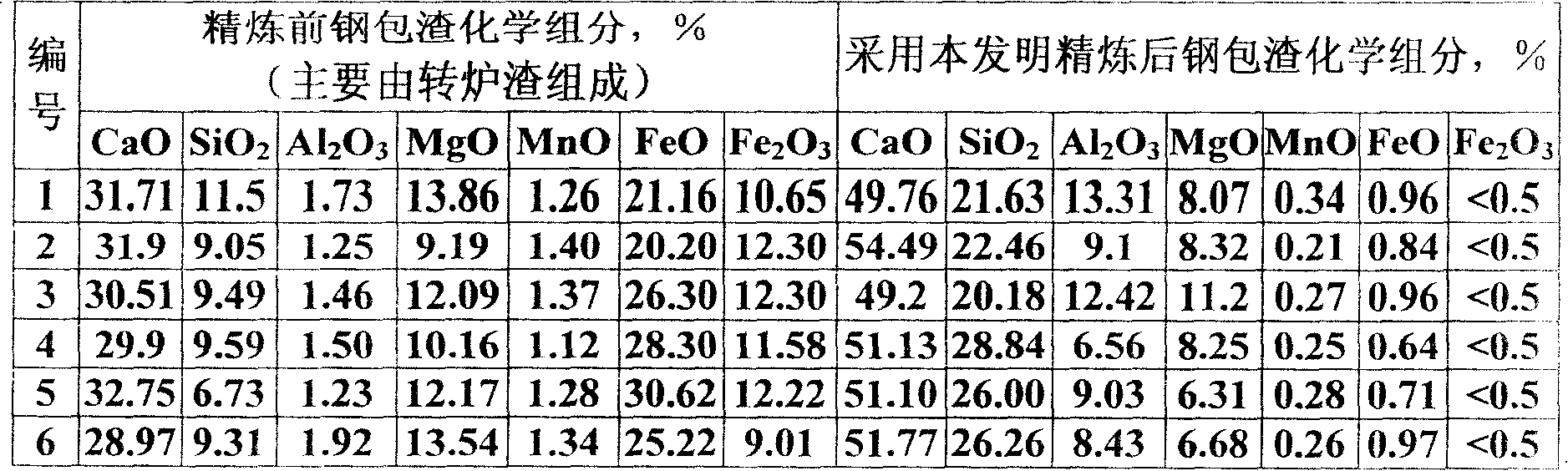

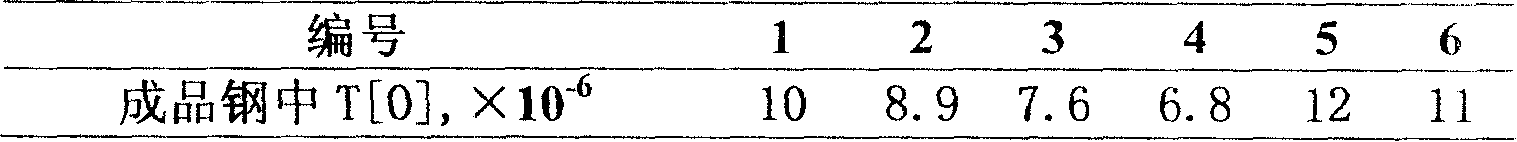

Multifunctional composite refining agent for steel-smelting

The invention provides a multi-functional refining agent which can effectively control inclusion in steel. The refining agent consists of CaO, CaC2, SiC, Na2CO3, C, CaF2 and BaCaSi alloy, wherein the weight percentage of the refining agent is: 30-60 percent of the CaO: 5-15 percent of the CaC2: 5-15 percent of the SiC: 5-15 percent of the Na2CO3: 5-15 percent of the CaCO3: 5-15 percent of the CaF2: 2-10 percent of the BaCaSi: 2-10 percent of the C; the melting point is less than or equal to 1400 DEG C. The refining agent has the functions of wiping off the inclusion in the steel, expanding foam for submerged arc and removing sulfur. After being matched with the complex refining agent, the T(O) in finished steel is declined to the range of 5 multiplied by 10<-6> to 15 multiplied by 10<-6>, and the evaluation grade of the inclusion of B, C and D class is less than 1.0 grade with good sulfur removal effect as well.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Method for increasing flaw detection yield of continuous casting sheet head billet and tail billet

ActiveCN103586433AImprove internal qualityImprove the qualified rate of flaw detectionMetallurgyContinuous casting

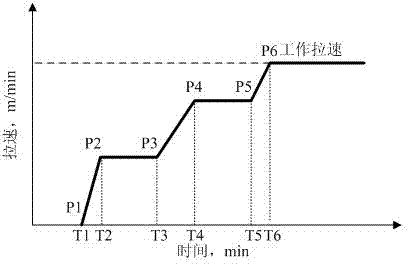

The invention discloses a method for increasing the flaw detection yield of a continuous casting sheet head billet and a tail billet. The flaw detection yield of the head billet and the tail billet is increased by improving internal quality of casting billets in the casting process and after the casting stopping process and optimizing technological operation. According to the method, through technological optimization and control under the unstable state condition, the internal quality of the head billet and the internal quality of the tail billet are improved, and then the flaw detection yield of steel sheets is increased. The method is suitable for the field of sheet billet continuous casting, and has significant economical value and practical significance in improving the quality of the casting billets under the continuous casting billet unstable state condition, and especially in improving the quality of variety steel and the material yield.

Owner:NANJING IRON & STEEL CO LTD

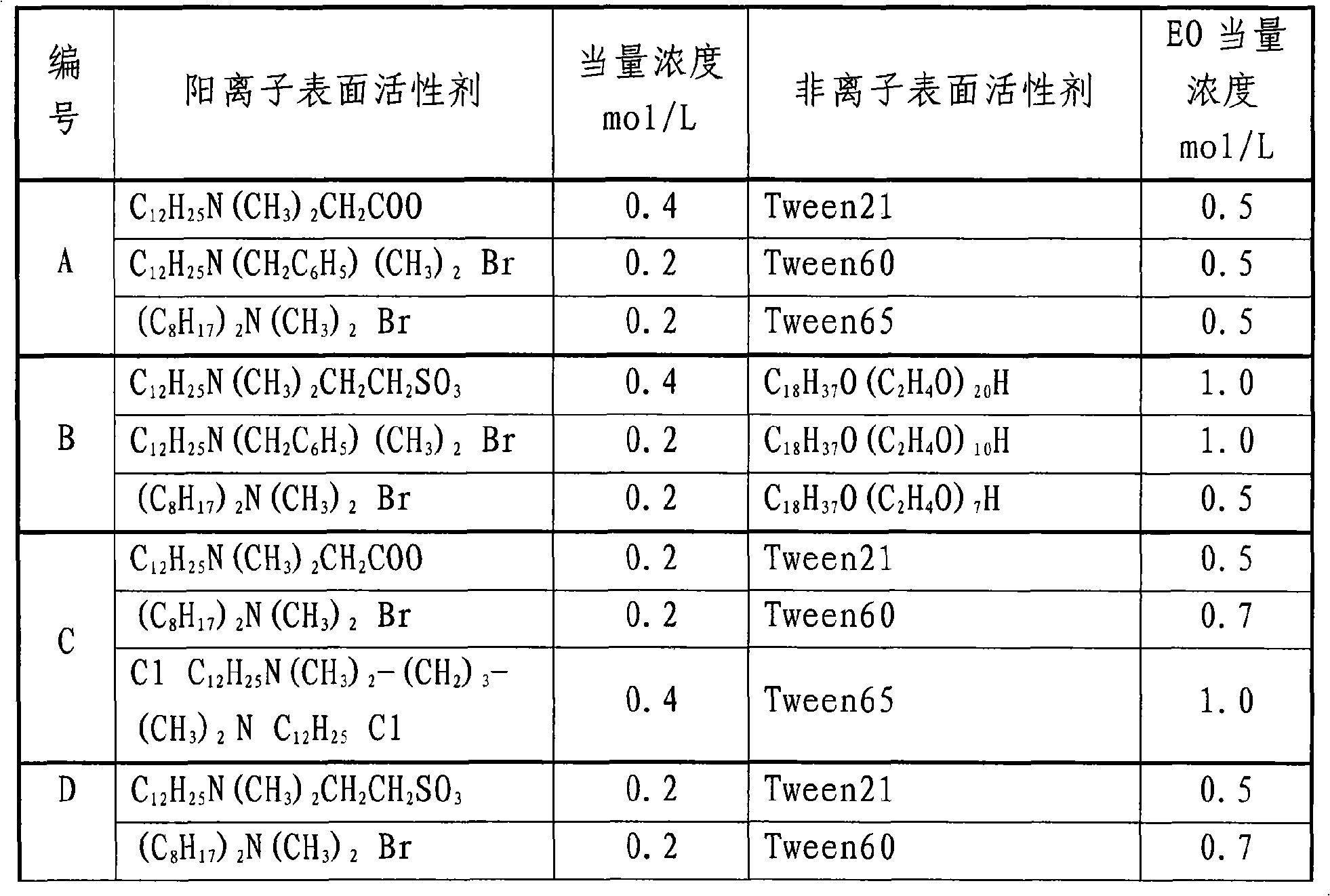

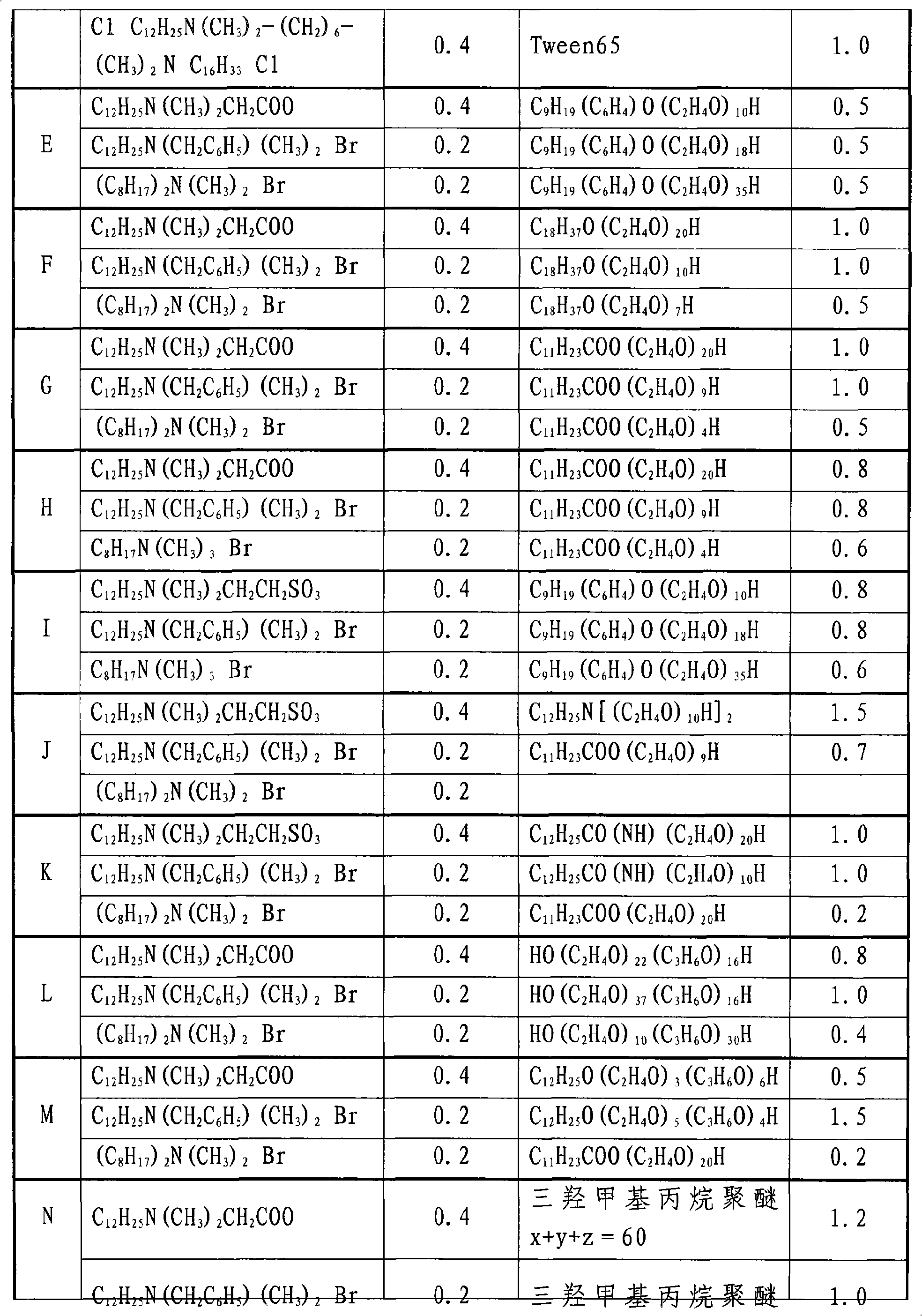

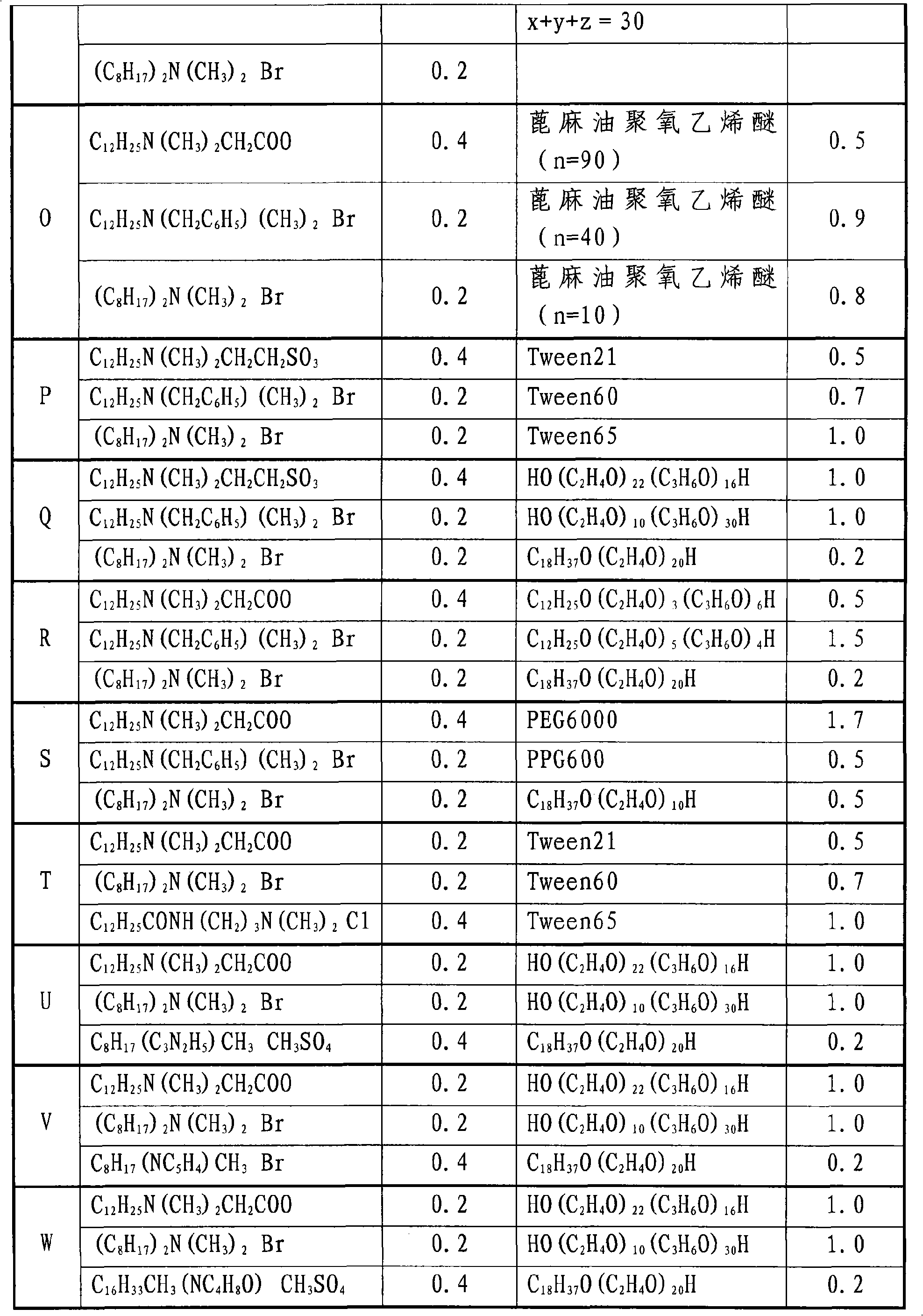

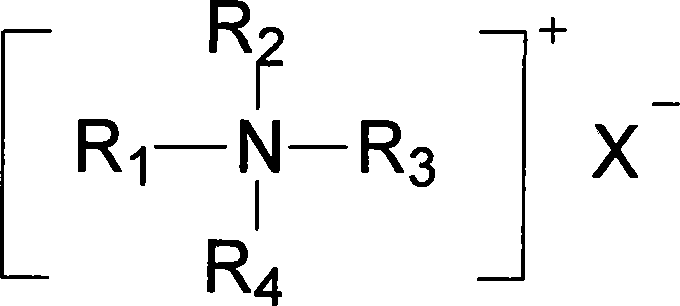

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

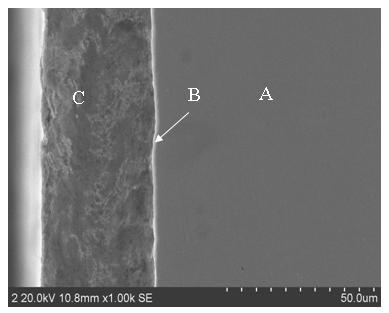

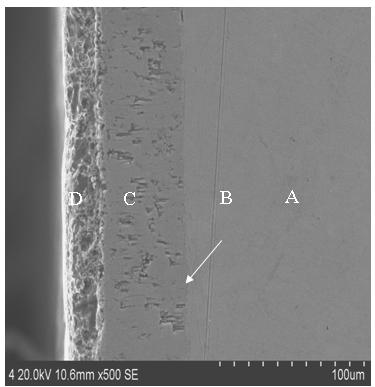

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Direct forming manufacturing method of metal-based multilayer/gradient composite board and process unit of direct forming manufacturing method

ActiveCN105643215AHigh bonding strengthEliminate surface stressRoll force/gap control deviceMetal rolling arrangementsHigh energyBound property

The invention discloses a direct forming manufacturing method of a metal-based multilayer / gradient composite board and a process unit of the direct forming manufacturing method. Scale, corrosion materials and other impurities on the joint surface of a base board are removed through chemical cleaning, the cleaned surface is subjected to gradient power electromagnetic induction heating or laser bombardment surface treatment, all phases near the joint surface are fully dissolved, a solid solution is enhanced, toughness and corrosion resistance are improved, the surface stress of the board is eliminated, and surface laser treatment is conducted to improve the binding property of a composite layer; raw materials of the composite layer are added and injected through powder laying, a high-energy heat source is adopted for irradiation or induction heating to melt powder, metallurgical bonding is formed between the composite layer and a base, and control over the final shape of a cold / hot-rolled board is conducted. The obtained multilayer / gradient composite board is compact in surface structure, bonding between the composite layer and the base and between layers is good, and the interlayer bonding performance of the composite board is remarkably improved. The process is high in flexibility, and the production period of the metal-based composite board can be greatly shortened after the process is combined with an existing continuous casting technology.

Owner:SHANGHAI UNIV

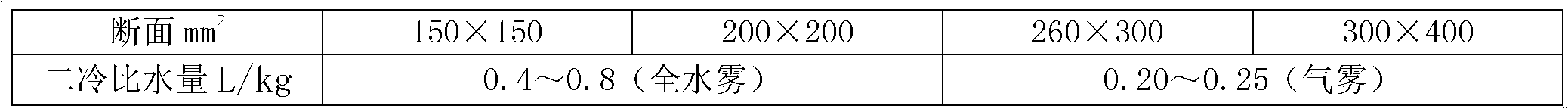

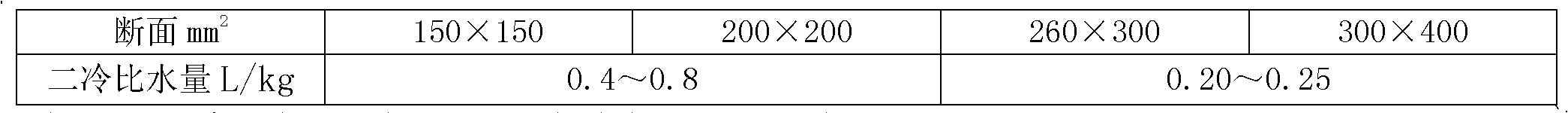

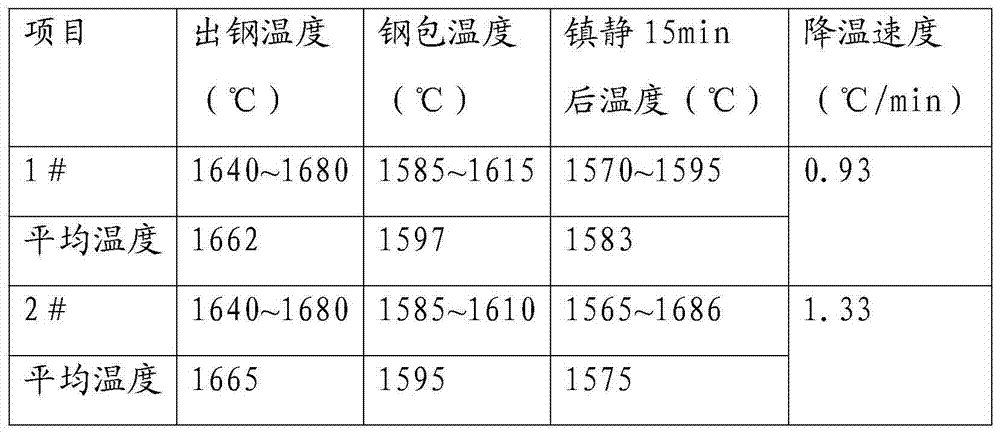

Continuous casting production process for improving quality of free cutting steel casting blank

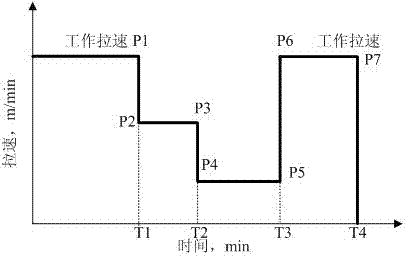

ActiveCN102303108AAvoid secondary oxidationPrevent a series of defects such as subcutaneous air bubblesSlagTemperature difference

The invention discloses a continuous casting production process for improving quality of a free cutting steel casting blank. The quality defects of lead segregation, slag inclusion, subsurface bubbles, surface pinholes, skull patch, scab, hollowness, cracks and the like of the free cutting steel casting blank are overcome by optimizing and controlling the parameters of superheat degree and stretching speed of the continuous casting process, taper of a crystallizer, cooling water inlet and outlet temperature difference of the crystallizer, amplitude of the crystallizer and the like; and the quality of the free cutting steel continuous casting blank is improved.

Owner:SHOUGANG GUIYANG SPECIAL STEEL

Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

InactiveCN101948990AEasy to dryImprove protectionHot-dipping/immersion processesElectrolysisEthylic acid

The invention relates to electrolytic plating assistant for hot dip galvanizing of a steel wire. Electrolytic plating assistant comprises the following components: 30-220 g / L of zinc chloride, 0-150 g / L of potassium chloride, 0-150 g / L of sodium chloride, 2-90 g / L of ammonium chloride, 0-100 g / L of boric acid, 0-70 g / L of acetic acid, 1-25 g / L of sodium fluoride, 2-50 g / L of cerium chloride, 0-50 g / L of potassium fluozirconate, 0-50 g / L of methanol, 0.5-20 g / L of hydrogen peroxide and the balance of water. The electrolytic plating assisting method comprises the following steps: washing with alkali, removing oil, washing with water, washing with acid to remove rust, washing with water, activating with weak acid, electrolyzing to assist plating, drying, and purifying the electrolytic plating assistant. The method can reduce the generation of AlCl3, prevent skip plating and reduce the generation of smoke dust. The electrolytic plating assistant has the characteristic of relatively high melting point, and thus, can increase the drying temperature and shorten the drying time. The dried plating assistant has the characteristics of low brittleness, high compatibility with electrogalvanizing, and low tendency to shedding.

Owner:NORTHEASTERN UNIV

Additive for heat zinc coating auxiliary agent

InactiveCN101126142AHigh activityIncrease profitHot-dipping/immersion processesSlagSurface-active agents

The invention provides an additive used in hot-dip galvanizing assistant plating agent, belonging to the technical field of metal material plating. The invention is used for solving the problem of assistant plating efficiency. The technical proposal of the invention is that the additive is a de-ionized water solution; the water solution contains cation surface active agent and organic solvent of the long chain alkyl; the content of the long chain alkyl cation surface active agent is 100 to 800 gram per liter; the organic solvent can be ethanol, isopropyl alcohol, acetone or one of nickel and N-dimethyl formamide, with adding content of 30 to 160 gram per liter. The invention has the advantages that the assistant plating agent is made and the made element have a plating face with excellent wettability and compatibility, which can increase the activity and the utilization rate, improve the assistant plating efficiency, prevent plated element from escaping, prevent the plated element which is assistant plated from being secondarily oxidized in air, reduce zinc slag, prevent the zinc liquid from splashing and increase the surface quality of the made element. Furthermore, the invention can be directly added into the assistant agent, and then is evenly mixed, with the character of easy operation. The invention is not limited by the temperature of the assistant plating agent so that the invention can be used under room temperature.

Owner:陈冬

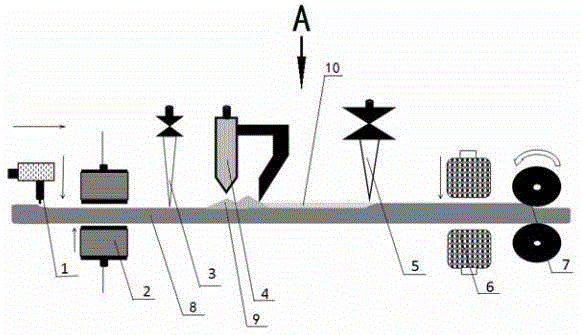

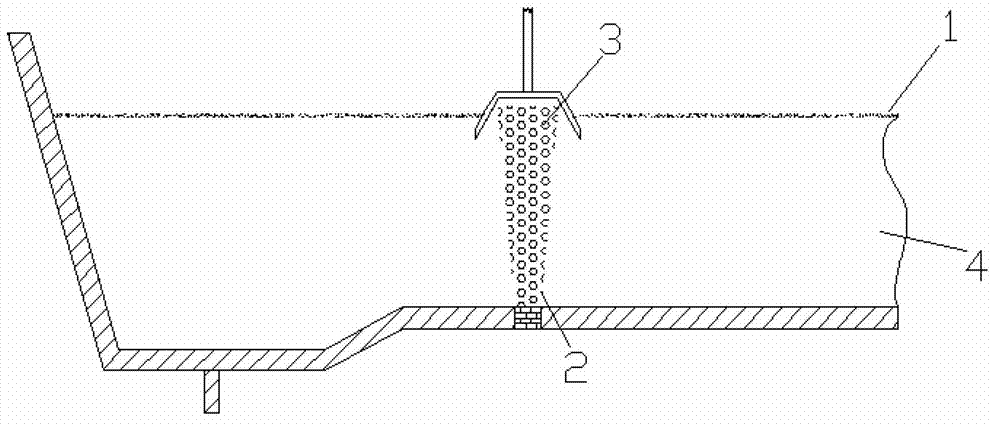

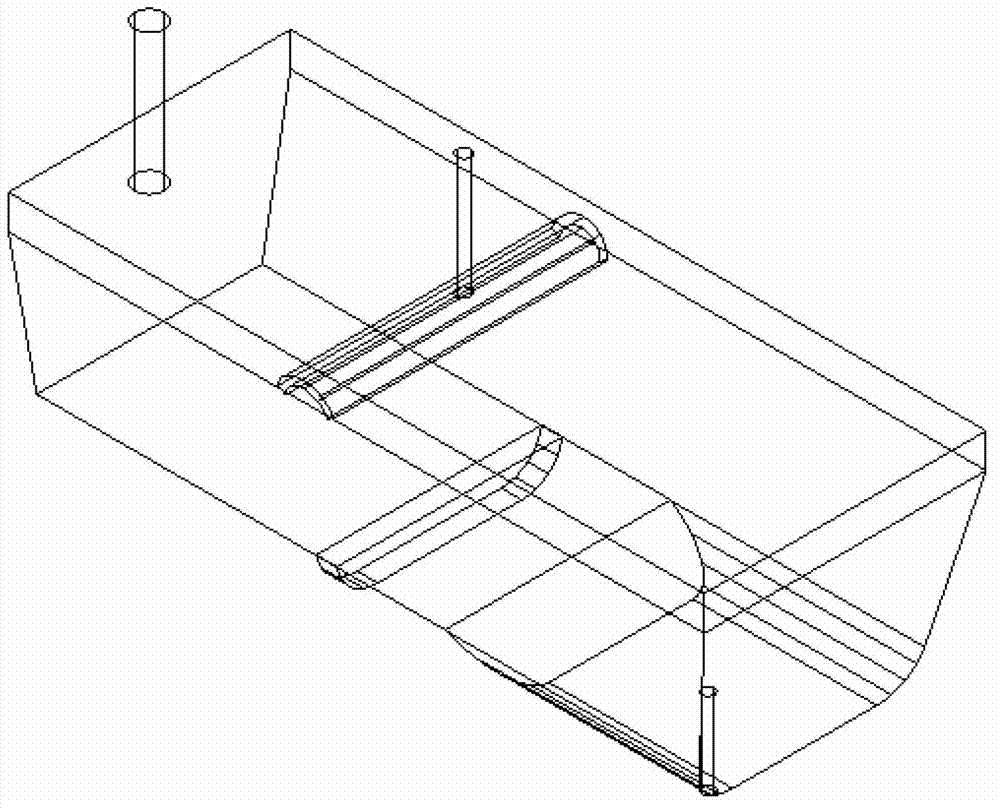

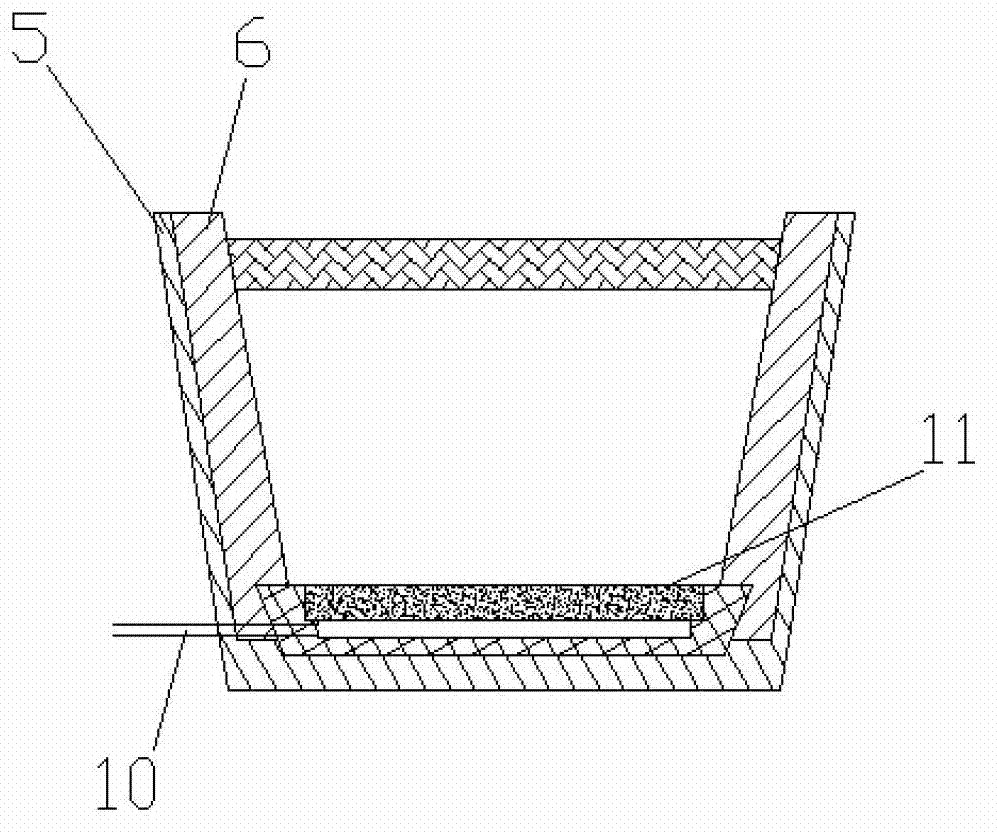

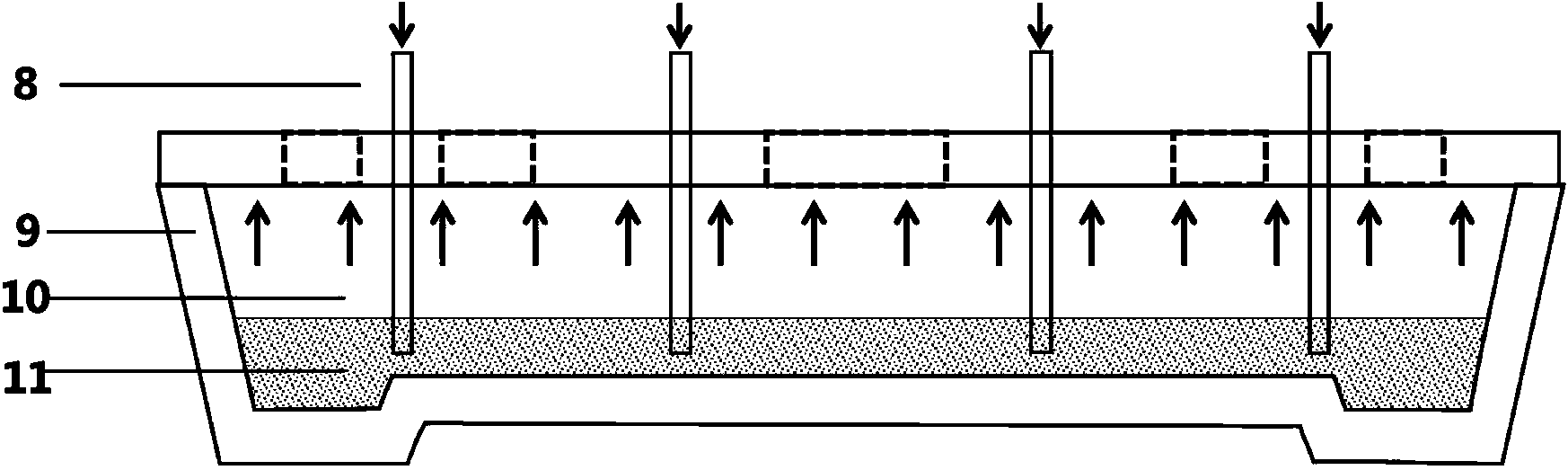

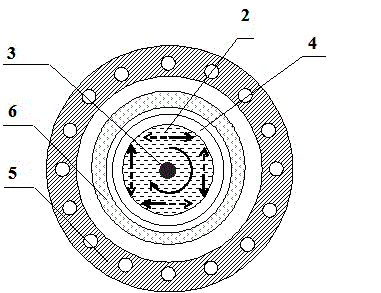

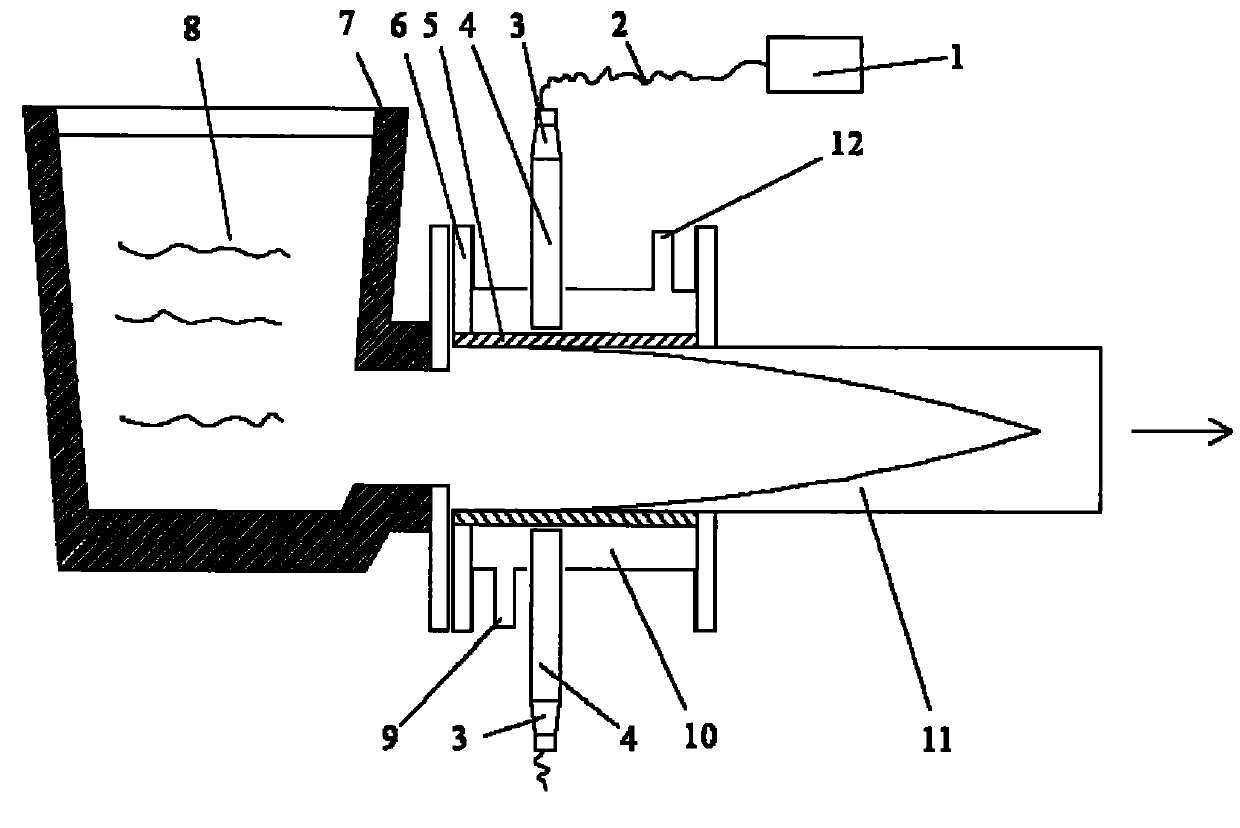

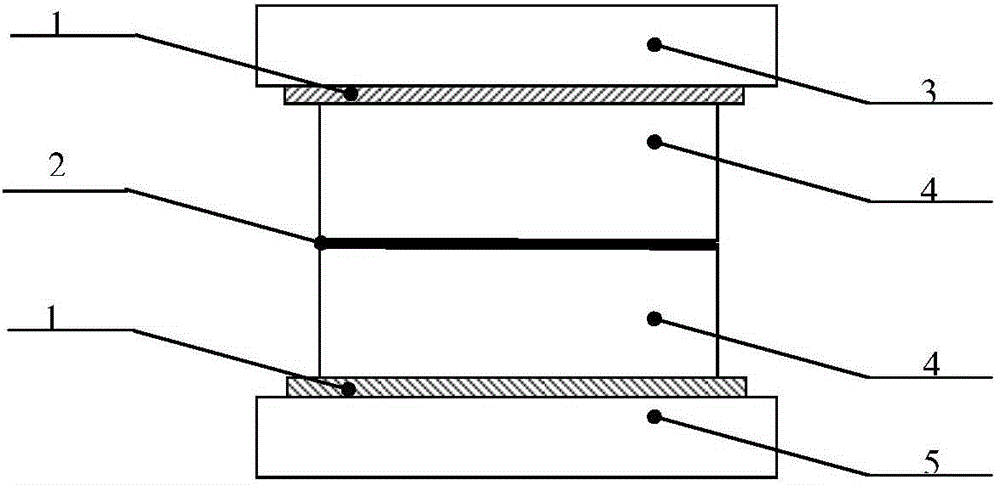

Blowing and refining device and method used for removing tundish molten steel inclusion

The invention discloses a blowing and refining device and method used for removing the tundish molten steel inclusion. The blowing and refining device is characterized by comprising a tundish 1, a blowing device 2 and a dipping cover 3, wherein the tundish comprises a permanent layer and a working layer arranged on the inner surface of the permanent layer; the bottom of the permanent layer is provided with the blowing device; the blowing device comprises an air brick and a ventilating pipe; the air brick comprises a dense layer and a ventilating layer; the middle of the ventilating layer is provided with an air chamber; and the dipping cover is a refractory material cover supported by a steel plate, is connected with an automatic lifting system and is arranged above the blowing device. According to the blowing and refining device, an air curtain retaining wall with a big air flow can be introduced in to form continuous and tight bubble columns, the average residence time of molten steel in the tundish is obviously prolonged, the molten steel flowing behavior is obviously improved, the molten steel can be stirred by a great quantity of tiny bubbles, inclusions with a smaller size can be adsorbed, and meanwhile, steel slag rolling and mixing and the secondary oxidation of the molten steel due to big blowing amount can be avoided.

Owner:UNIV OF SCI & TECH BEIJING

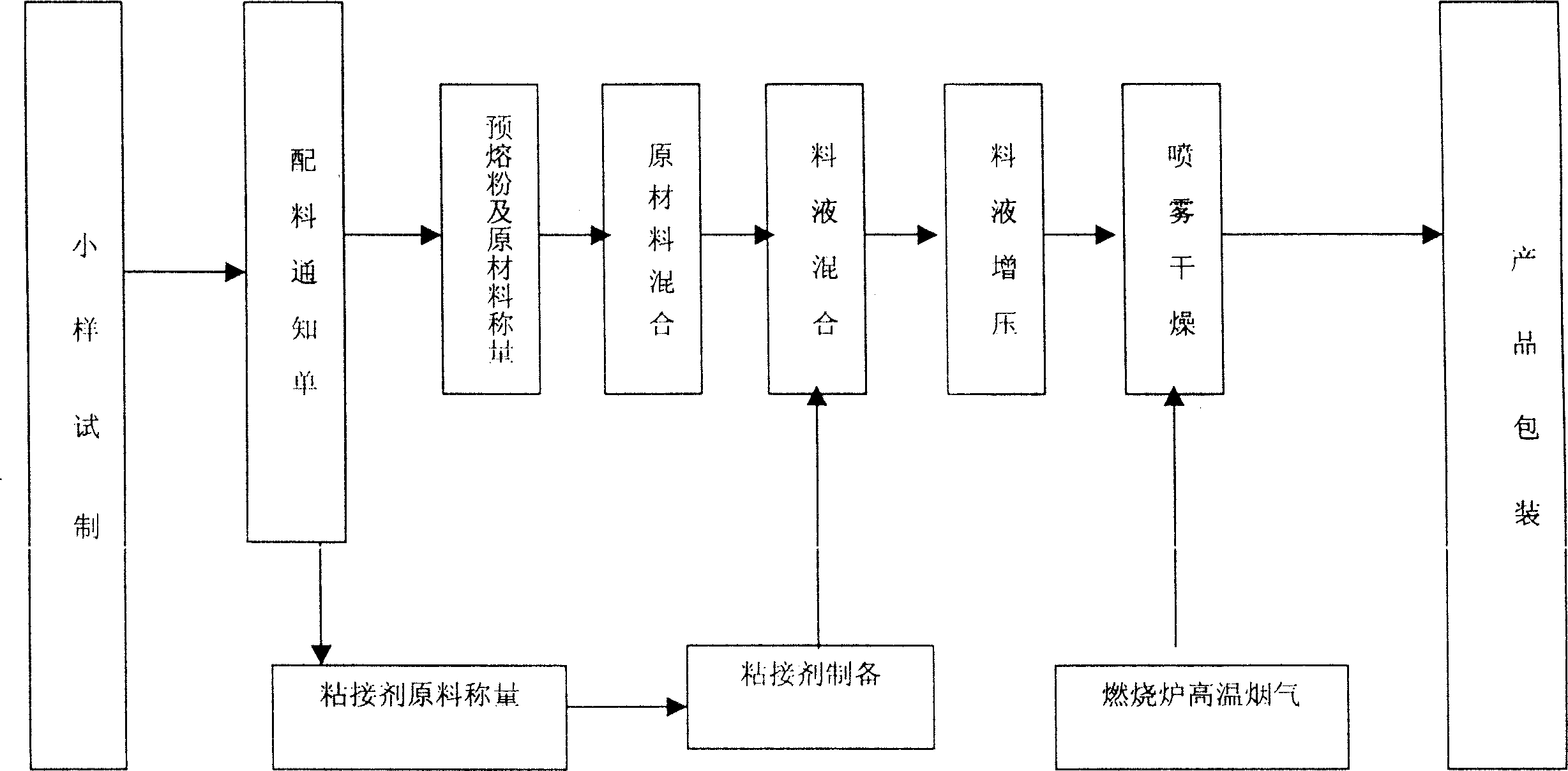

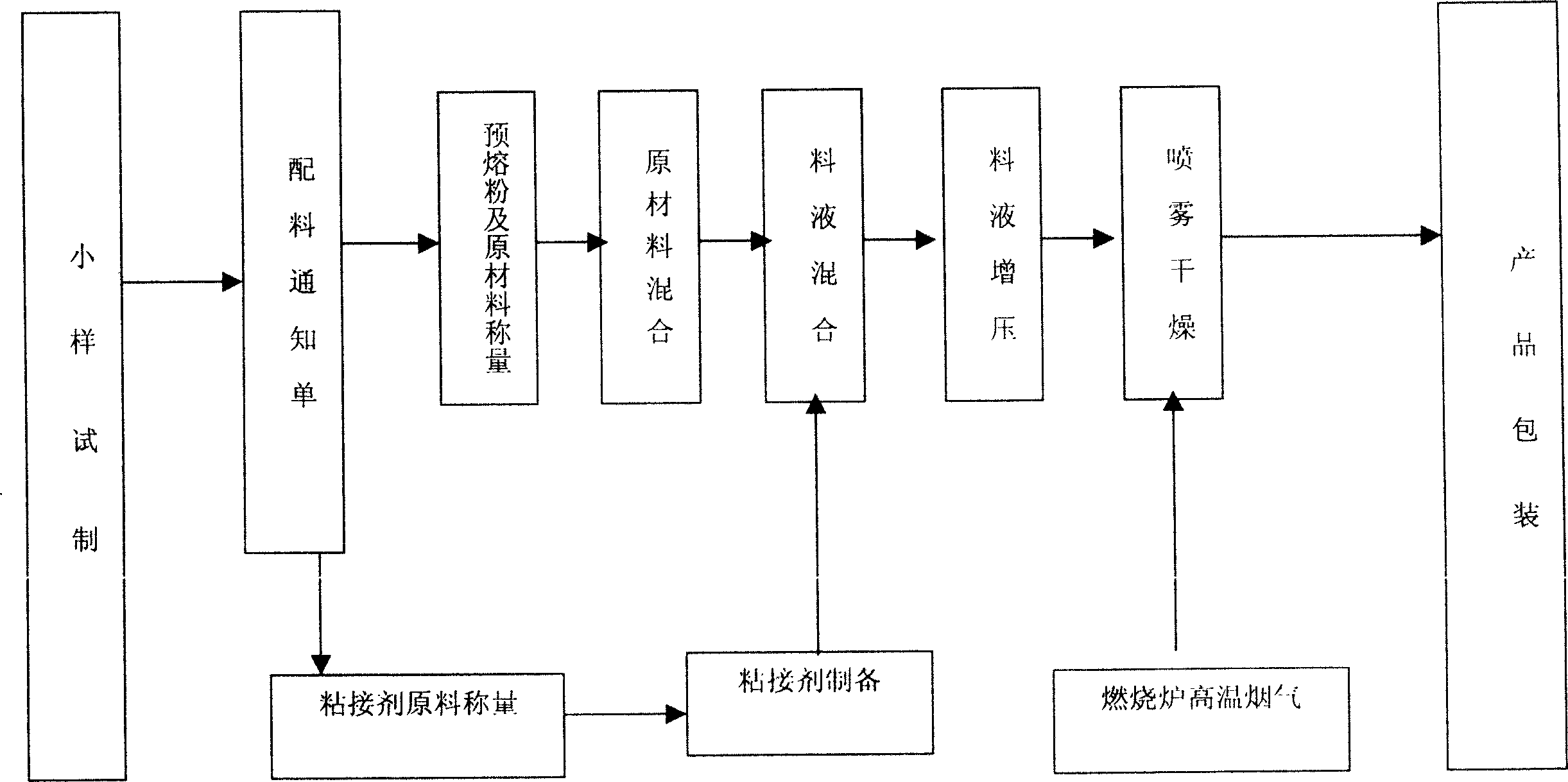

High basicity tundish cover agent and its production method

InactiveCN1970196ARapid and uniform slag forming abilityPrevent resulfurizationGranulation by liquid drop formationTundishAluminium

A high PH value ball type hollow coating agent comprises burnt lime, silica dioxide, and alumind, with the former two taking 30%-60% of the total weight and their rate 8:12, alunind taking 20%-50% of the total weight, with pre smelt, high PH value, carbon free material and spraying grain making process, enjoying fine heat preserving capacity, retaining three layer structure, without crustization, with improved capability in avoiding secondary oxidization of steel liquid and impurities adhesion.

Owner:上海盛宝冶金科技有限公司

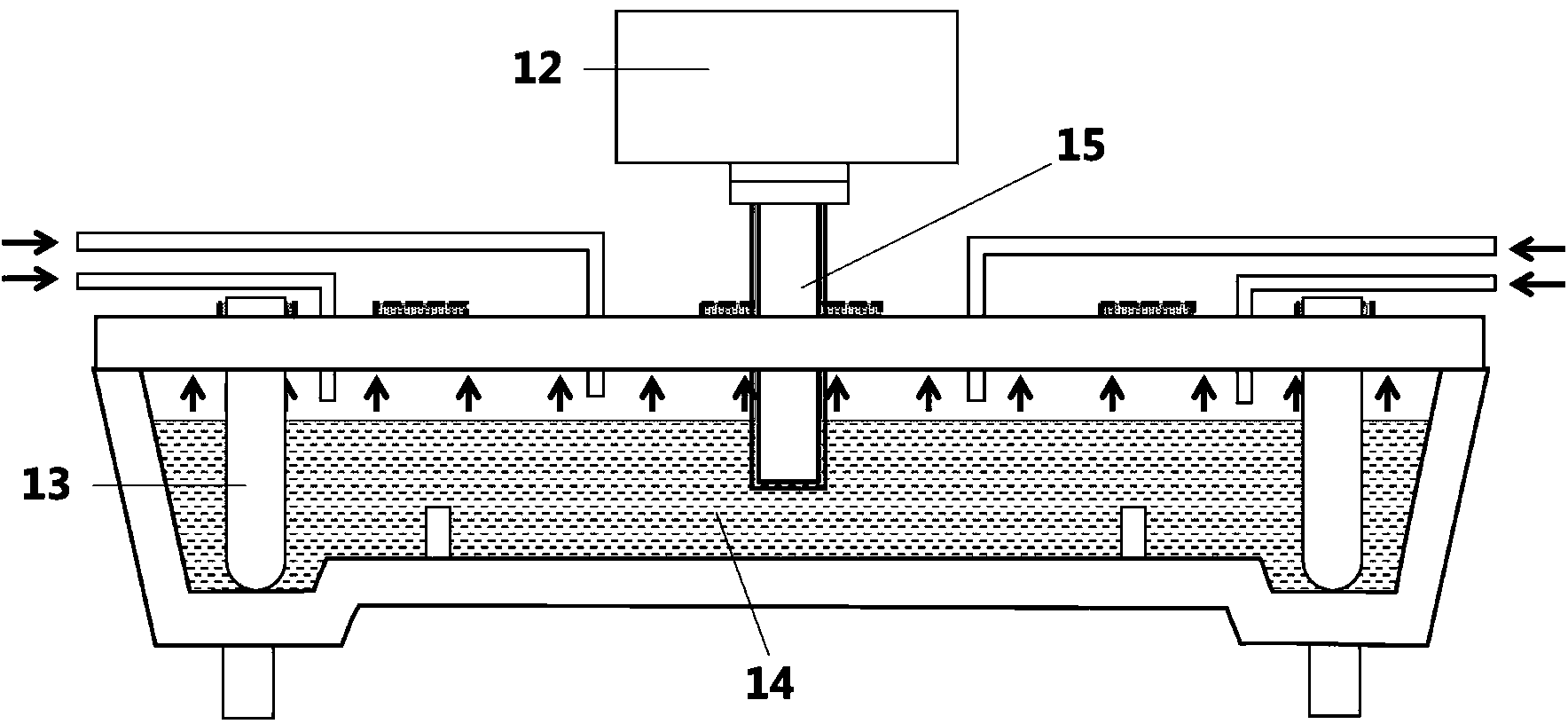

Device and method for eradicating secondary oxidation of tundish during continuous casting

ActiveCN103949628AAvoid secondary oxidationReduced responseMelt-holding vesselsProduct gasMetallurgical industry

The invention provides a device and a method for eradicating secondary oxidation of a tundish during continuous casting, and relates to the field of metallurgical industry. The device rapidly replaces gas in the tundish before casting, prevents secondary oxidation of the tundish during casting, and ensures that the tundish is completely protected during casting; a tundish sealing cover is adopted to seal the tundish, anaerobic atmosphere manufacture is performed to the tundish through an occlusion system before casting and argon blowing protection is performed during casting, so that the reaction between molten steel in the tundish and air can be effectively reduced. The device has a simple and compact structure, is safe and reliable, and can greatly improve the head blank quality and reduce flaws of casting blanks; the method is relatively simple to operate, the cost is relative low, and the method can be widely applied to the full sealing protection casting of tundishes adopted in domestic enterprises.

Owner:UNIV OF SCI & TECH BEIJING

Continuous Casting Process of Steel for High Titanium Alloy Welding Rod

ActiveCN102266925AAvoid secondary oxidationGuaranteed stabilityMelt-holding vesselsTundishElectromagnetic stirring

The invention relates to a continuous casting process of the metallurgy field and discloses a continuous casting process of steel for high titanium alloy welding rods. Full protection pouring is used during continuous casting, and long nozzle argon sealing protection pouring is used from a steel ladle to an intermediate ladle. The whole built-in submersed nozzle protection pouring is used from the intermediate ladle to a crystallizer. A covering agent is used by molten steel in the intermediate ladle. The electromagnetic stirring is used in the process of continuous casting and pouring. Full automation liquid level detection is carried out on the liquid level of the crystallizer. The continuous casting pulling speed is controlled automatically according to the degree of superheat of the intermediate ladle. The degree of superheat of the intermediate ladle in a first continuous casting and pouring furnace is controlled at 30-40 degrees centigrade. The pouring pulling speed is controlled in a range of 1.8-2.4 m / min. The protection slag is composed of the following components measured in percentage by weight: 0.80 + / - 0.15% of R, 35.0 + / - 3.5% of SiO2, 28.0 + / - 3.5% of CaO, less thanor equal to 5.0% of Al2O3, less than or equal to 4.0% of Fe2O3, less than or equal to 5.0% of MgO, 4.5 + / - 1.5% of F<->, 5.0 + / - 2.0% of K2O + Na2O and 12.0 + / - 2.5% of solid C. According to the continuous casting process, the molten steel is prevented from second oxidization in the process of pouring effectively; the stability of titanium in the molten steel is ensured; protection slag is prevented from denaturing; and the quality of the surface of a casting blank is enhanced.

Owner:NANJING IRON & STEEL CO LTD

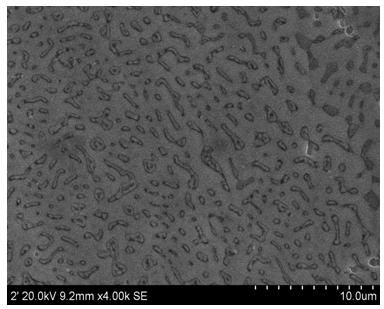

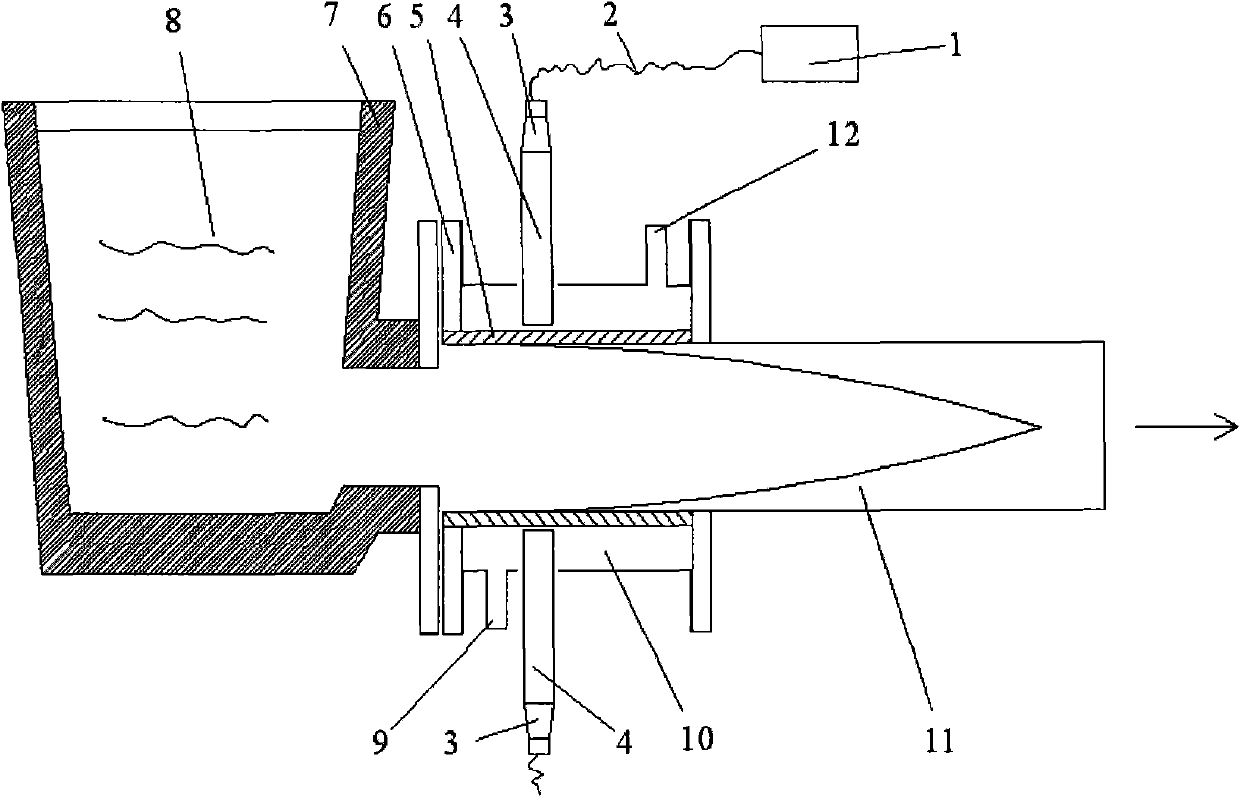

Method for controlling metal solidification phase texture in combined mode through external rotating magnetic field and current and fusion casting device of method

The invention discloses a method for controlling metal solidification phase texture in a combined mode through an external rotating magnetic field and current and a fusion casting device of the method. In a metal solidification process, firstly, the rotating magnetic field is exerted on a metal melt area on the front edge of a metal melt solidification interface, and meanwhile the current is exerted on metal melt nearby a solid-liquid interface area of a whole continuously cast bloom through an external power supply. Under the combined action of the rotating magnetic field and the current, electromagnetic combined stirring is conducted on metal liquid nearby the metal melt solidification interface, so that collision, friction and scour occur among primary grains of the metal melt and between the primary grains and the metal melt, fragmentation of the primary grains can be caused, and therefore the solidification texture of the continuously cast bloom is refined. The method is used for preparing high-quality metal materials.

Owner:SHANGHAI UNIV

Thermal-insulation cover agent and preparation method thereof

The invention provides a thermal-insulation cover agent. The thermal-insulation cover agent is characterized in that the thermal-insulation cover agent is composed of, by mass, 25%-45% of silicon oxide, 18%-35% of aluminum oxide, 13%-28% of calcium oxide, 2%-15% of ferric oxide, 2%-5% of carbon, 2%-5% of magnesium oxide, 1.2%-4% of expanding agents, 2.6%-5% of heat generating agents, and the balance is aluminum. The invention further provides a preparation method of the thermal-insulation cover agent. The preparation method includes the following steps of ingredient weighing, mother liquor preparation, pulping, pelleting, drying and screening. The thermal-insulation cover agent has the advantages of being good in spreadability and thermal insulation performance, and capable of reducing molten steel temperature drop speed, avoiding secondary oxidation from happening on the surface of molten steel and greatly reducing pollution to operation environment.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

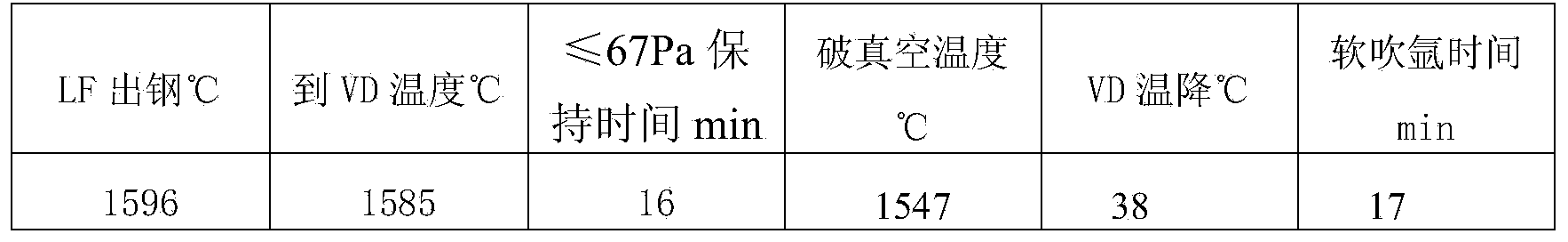

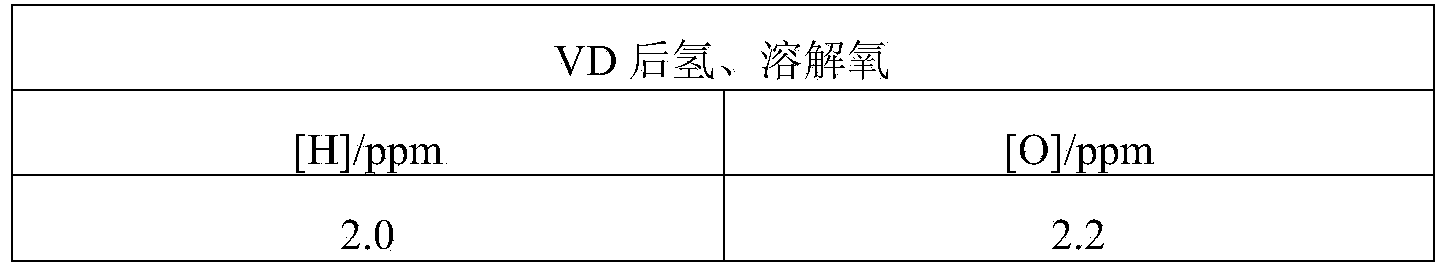

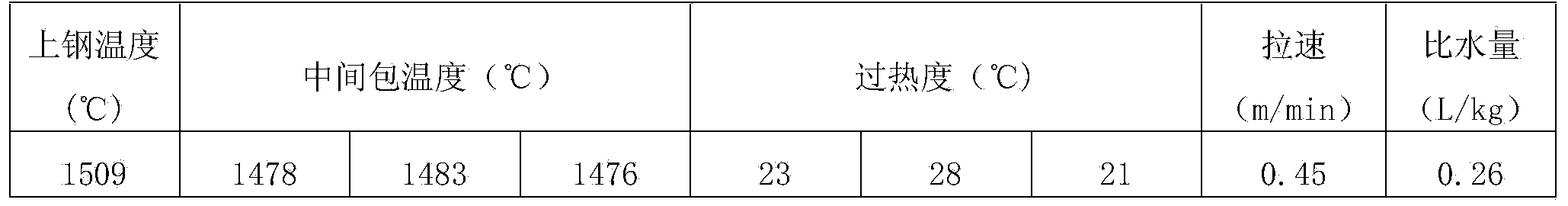

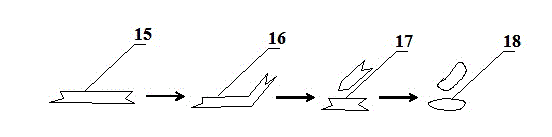

Bearing steel GCr15 production technology capable of preventing plugging of continuous casting water gap

ActiveCN103103443AAvoid secondary oxidationImprove cleanlinessManufacturing convertersAlkalinitySlag

The invention relates to a bearing steel GCr15 production technology capable of preventing the plugging of a continuous casting water gap. The technology route comprises the steps of a top and bottom combined blow converter, an LF refining furnace, VD vacuum degassing and six-strand billet continuous casting of a Comcast six machine in sequence, the top and bottom combined blow converter conducts dephosphorization by adopting a double-slag method, the high catch carbon [C] at finishing point is more than or equal to 0.25%, final slag alkalinity before tapping is over 3.5, Als content in the molten steel in refining of the LF refining furnace is controlled to be over 0.05%, and Als / Alt is more than 95%; and argon blowing protection is conducted in the whole process of the continuous casting procedures, and low-pulling rate weak-cooling technology is adopted. Under the conditions of the technology, the cleanness of the molten steel can be improved, the non-metallic inclusion can be reduced, the plugging phenomenon of the continuous casting water gap can be prevented, the quality of the continuous casting blank can be improved, and the cost of the casting blank can be lowered, thereby finally improving the product quality.

Owner:TIANJIN IRON & STEEL GRP

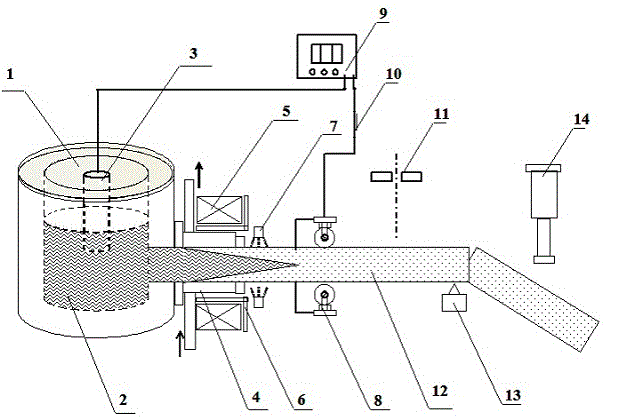

Preparation process for high-strength high-conductivity micro copper wire

The invention discloses a preparation process for a high-strength high-conductivity micro copper wire. The preparation process comprises the following steps: S1, adding electrolytic copper into a smelting furnace, preserving heat and melting the electrolytic copper completely to obtain molten copper, introducing an inert gas, adding a composite refining agent, standing and slagging; S2, detecting that the molten copper comprises the following components in percentage by weight: 0.45 to 0.55 percent of Ti, 0.25 to 0.35 percent of Zr, 0.07 to 0.09 percent of Te, 0.07 to 0.09 percent of La, 0.03 to 0.05 percent of Y, 0.15 to 0.25 percent of Sn, less than or equal to 0.05 percent of Mg, and the balance of Cu; S3, enabling a crystallizer of a continuous casting machine to extend into the molten copper, and drawing upwards through a drawing roller mechanism to form an oxygen-free copper rod; S4, extruding the oxygen-free copper rod continuously and drawing repeatedly to obtain the high-strength high-conductivity micro copper wire. According to the copper wire which is prepared by the preparation process, the electric conductivity reaches over 95 percent IACS, and moreover, the tensile strength is also over 480 MPa.

Owner:安徽晋源铜业有限公司

Smelting method for vulcanization easy cutting plastic mold steel

The invention provides a smelting method for plastic die steel which is added with sulphur and easily cut; the materials after being smelted by an electric furnace is fed into a refining process; the content of the sulphur in the molten steel is controlled less than 0.005 percent during the refining process; the weight percentage of the steel slag in the molten steel is adjusted between 0.8 and 1.2 percent through slagging off; then the molten steel is fed into a vacuum furnace; an aluminum wire is fed into the molten steel; the weight of the fed aluminum wire is 0.08 to 0.10 percent of the weight of the molten steel; then the steel slag is added; the weight percentage of the steel slag in the molten steel is adjusted between 1.5 to 2 percent; then the molten steel is maintained for 15 to 30 minutes under the pressure of 60 to 70Pa; then the vacuum is released; a sulfurous iron wires are fed in and a calcium silicon block is added to finish smelting. In the invention, the occluded foreignsubstance in the molten steel can be mostly removed; the purify of the molten steel is improved to a large extent; the molten steel smelt after the invention can obtain the plastic die steel which is added with sulphur and easily cut through casting; the inspection grade of the die steel accords with requirments through detection; each property is further improved.

Owner:WUYANG IRON & STEEL

Cap agent with light alkaline particle steel coating

InactiveCN1778493AAvoid secondary oxidationSecondary oxidation will notProcess efficiency improvementChemical reactionRefractory

A light-weight alkaline particle used as the covering agent of steel ladle contains siO2 (18-26 Wt%), CaO (26-34), MgO (6-12), Al2O3 (5-8), Fe2O3 (0.5-2.0), and stabilized C (18-26). Its advantages are low specific bulk weight, high insulating performance, and high effect to prevent oxidization of molten steel and decrease the corrosion to refractory of ladle.

Owner:上海宝谊保温材料有限公司

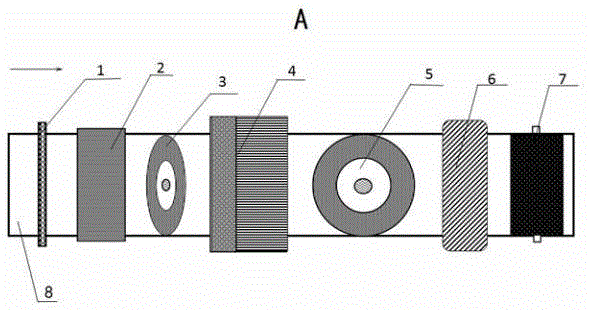

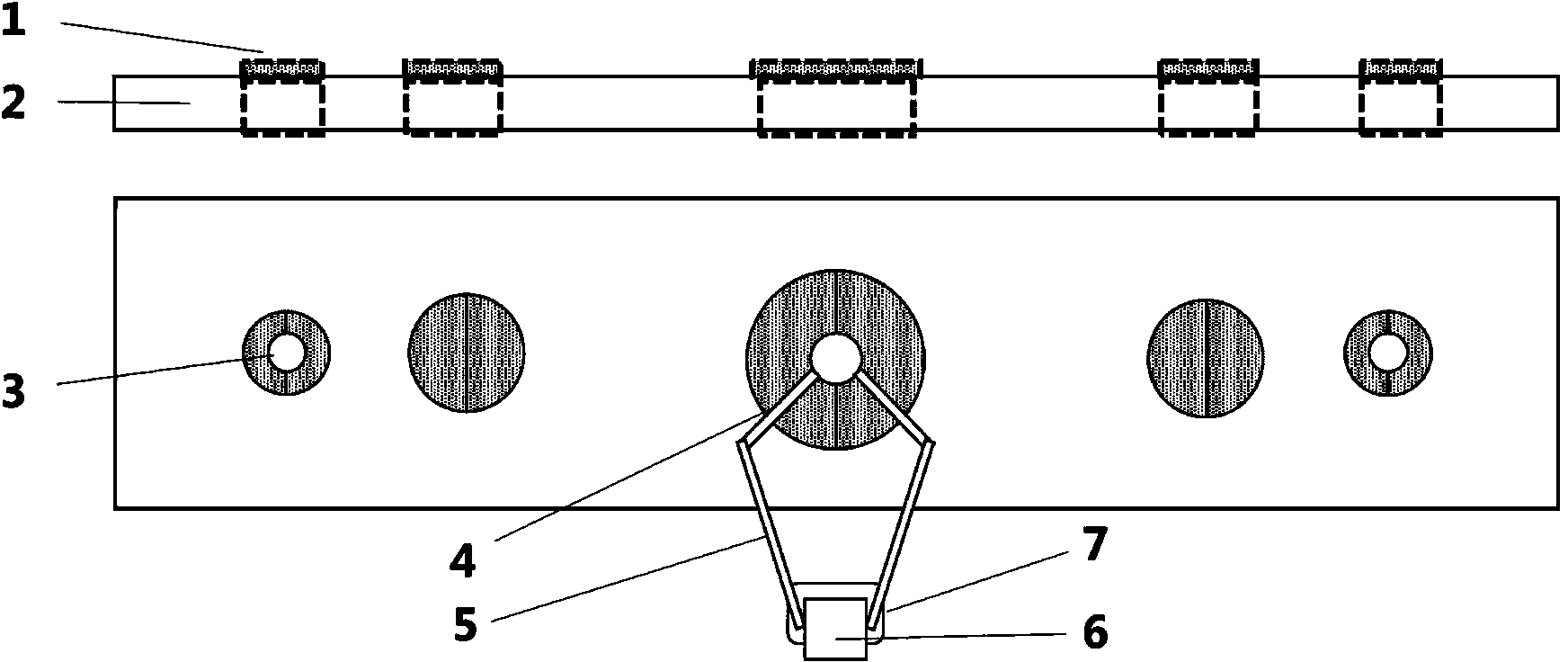

Continuous casting crystallizer device using ultrasonic vibration

InactiveCN101905295AEliminate stickingEliminate surface defectsUltrasonic vibrationUltrasonic guided wave

The invention provides a continuous casting crystallizer device using ultrasonic vibration, which belongs to the technical field of metallurgical casting. The device of the invention comprises a trough, a crystallizer, a crystallizer copper plate, ultrasonic guide rods, an energy converter and an ultrasonic power supply, wherein the crystallizer is directly connected with the trough; the ultrasonic guide rod is arranged on each reverse side of the crystallizer copper plate and connected with the energy converter; the energy converter is connected with the ultrasonic power supply; the ultrasonic guide rod passes through a cooling water tank and is vertically connected with the crystallizer copper plate; and the length of the ultrasonic guide rod is an integral multiple of the wavelength or half-wavelength of the used ultrasonic. The vibration mode of the ultrasonic vibration crystallizer provided by the invention breaks through the traditional mechanical vibration limit, and the continuous casting crystallizer device using the ultrasonic vibration is favorable for promoting the production of deflect-less continuous casting blanks without surface defects such as vibration marks and improving the quality of the casting blanks and steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

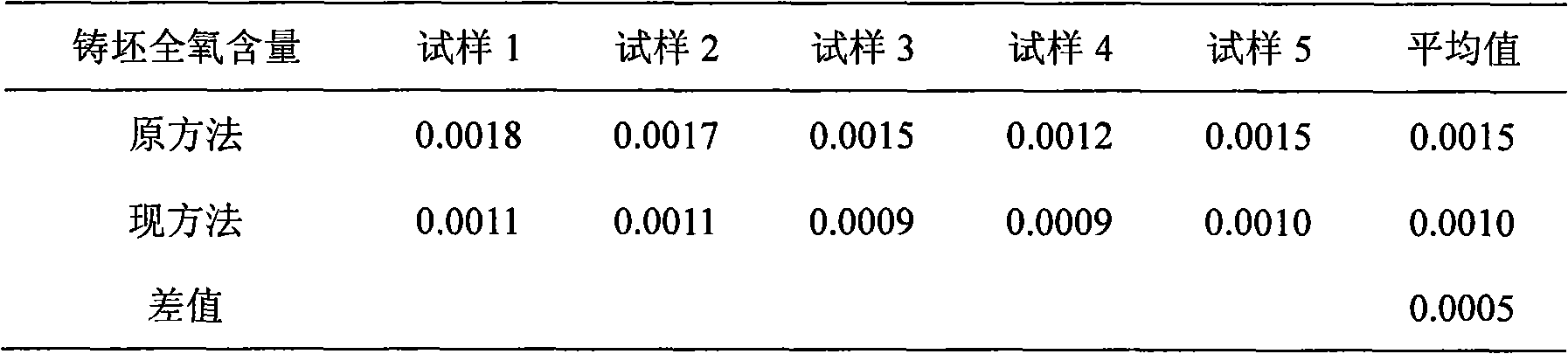

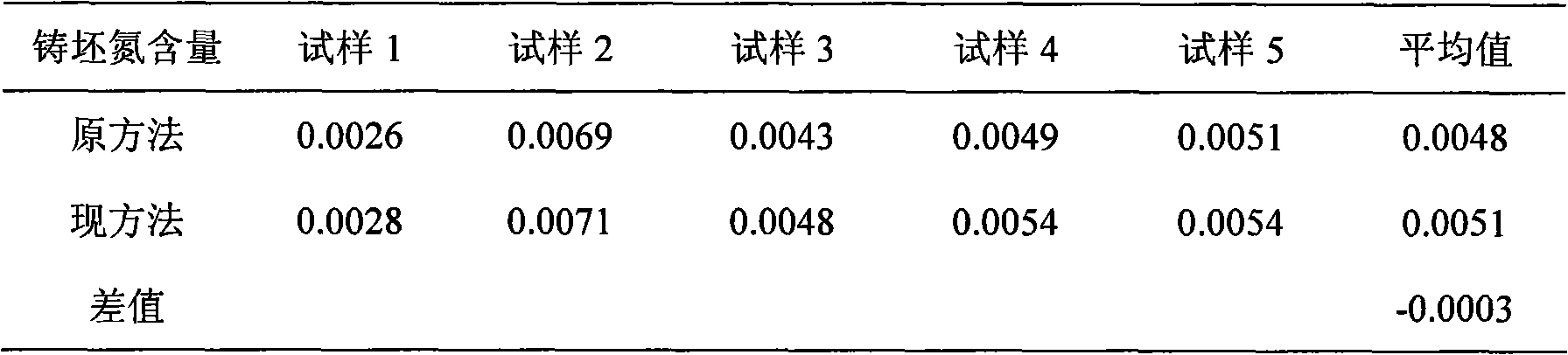

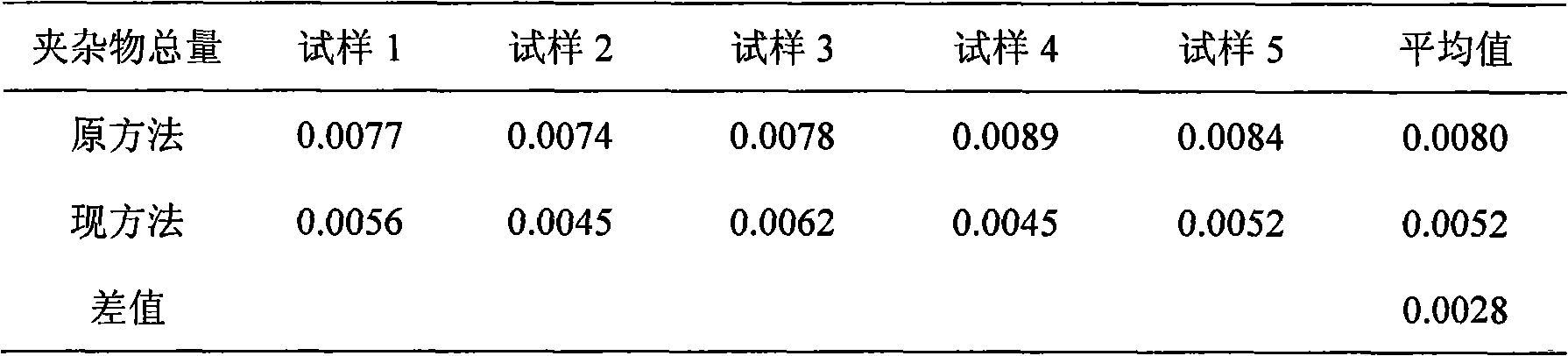

Method for reducing inclusion content of casting blank

The invention discloses a method for reducing inclusion content of a casting blank. The production processes comprise steel making, refining, continuous casting, heating in a heating furnace and continuous rolling. The method is characterized in that: during continuous casting, before molten steel is injected into a tundish, an inert gas is blown into the tundish by using a breather pipe above the tundish; after the interior of the tundish is basically covered by the inert gas, a long nozzle at the bottom of a molten steel tank is opened so that the molten steel enters the tundish; after the molten steel in the tundish reaches 1 / 4 of the height of the tundish, a covering agent is added into the tundish; and after the covering agent is melted and the molten steel is fully covered, the blowing of the inert gas is stopped. The tundish is covered by the inert gas blown into the tundish before casting, and then the molten steel at the initial casting stage is prevented from directly contacting the atmosphere so that air suction and secondary oxidation of the molten steel are avoided and the purpose of reducing the inclusion in the casting blank is fulfilled.

Owner:ANGANG STEEL CO LTD

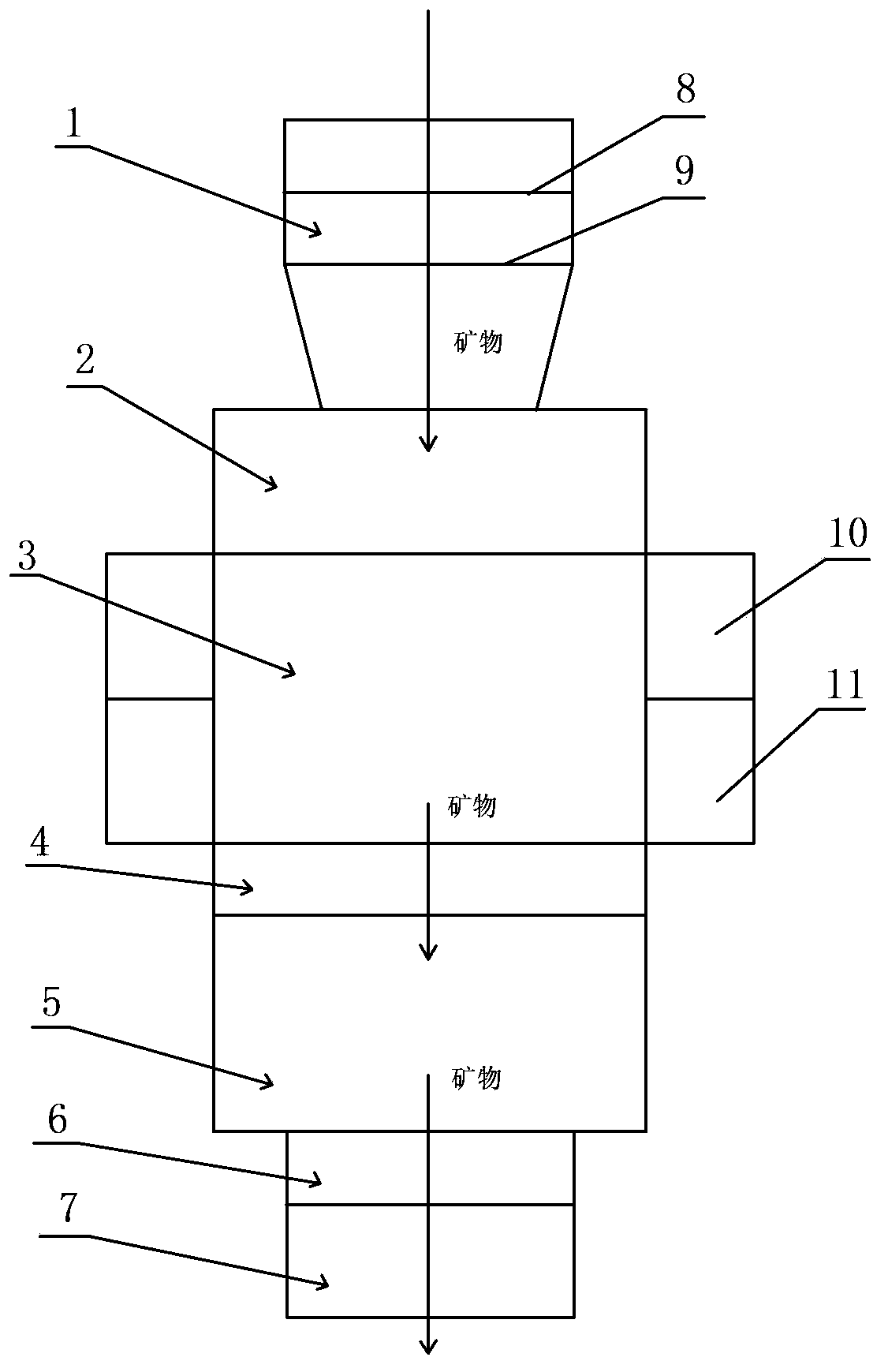

Mineral roasting reduction device and application method thereof

The invention discloses a mineral roasting reduction device. The device comprises a feeding zone, a drying preheating zone, a roasting oxidation reaction zone, a pressure-regulating zone, a reduction reaction zone, a discharging zone and a water-sealing cooling zone, which are arranged from the top down and communicated with one another, wherein the feeding zone is provided with an automatic sealing device; the drying preheating zone is provided with a directional pressurizing device for vacuum-pumping; the roasting oxidation reaction zone is provided with an incendiary agent adding device; the pressure-regulating zone is provided with a plurality of pressure-regulating air doors; the reduction reaction zone is provided with a reducing agent adding device. The mineral roasting reduction device is provided with the directional pressurizing device, so that negative pressure can be generated in the inner part of the device; molecular flows of both an incendiary agent and an reducing agent are in uplink, while mineral is in downlink, so that a convection current movement is formed to ensure conversion affinity of the solid phase and the gas phase; in the device, the mineral sequentially is subjected to drying, preheating, heating, resolving, reducing, water quenching, cooling and discharging from the top down, and all processes are performed in an air-free state thoroughly to complete roasting reaction.

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

Continuous casting tundish hollow particle carbon-free covering agent and preparation method thereof

The invention relates to a continuous casting tundish hollow particle carbon-free covering agent, belonging to the iron and steel smelting field. The carbon-free covering agent comprises the followingcomponents by weight percent: 25-35% of SiO2, 8-20% of Al2O3, less than 1.5% of Fe2O3, 25-35% of CaO, 8-16% of MgO and less than 0.5% of H2O, wherein 0.15-1.0mm of particles account for 90-100% and the bulk specific weight is 0.6-0.9g / cm<3>. The continuous casting tundish hollow particle carbon-free covering agent has good spreadability, when added the covering agent can be molten fast and can cover the whole surface of molten steel, thus avoiding the secondary oxidation of molten steel; the covering agent has function of absorbing inclusion, can purify molten steel and increase the casting blank quality; the covering agent has good thermal insulation property, thus significantly reducing the temperature loss of molten steel; the slag of the covering agent can not incrust and stick to thestopper rod; and the content of carbon in molten steel is not increased.

Owner:SHANDONG IRON & STEEL CO LTD

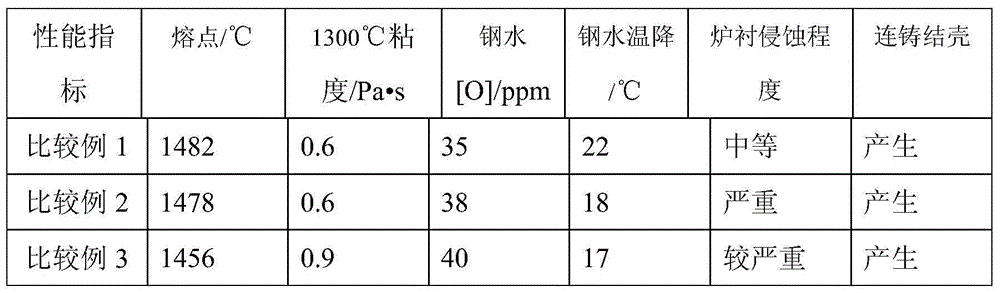

Tundish covering agent and application thereof

The invention relates to a tundish covering agent and application thereof and belongs to the technical field of tundishes in the continuous casting process. The tundish covering agent is mainly prepared from, by percentage content, 35-45% of CaO, 8-15% of SiO2, 25-30% of Al2O3, 5-15% of MgO, 5-12% of (Na2O+Li2O), 1-5% of B2O3 and 0.5-1% of TiO2. The tundish covering agent has the advantages that the melting point is low and is 1250-1350 DEG C, the viscosity is high and is 0.8-1.2 Pa*s at the temperature of 1300 DEG C, and the basicity is high and is 3-6. The tundish covering agent is applicable to the continuous casting production process, for producing the tundishes, of titanium-added steel. When the tundish covering agent is applied to the continuous casting production process of the titanium-added steel, produced TiO2, produced TiN and other produced inclusion can be effectively dissolved. The inclusion is prevented from entering a crystallizer, the cleanness degree of molten steel is improved, and therefore the quality of cast blanks is improved.

Owner:CENT SOUTH UNIV

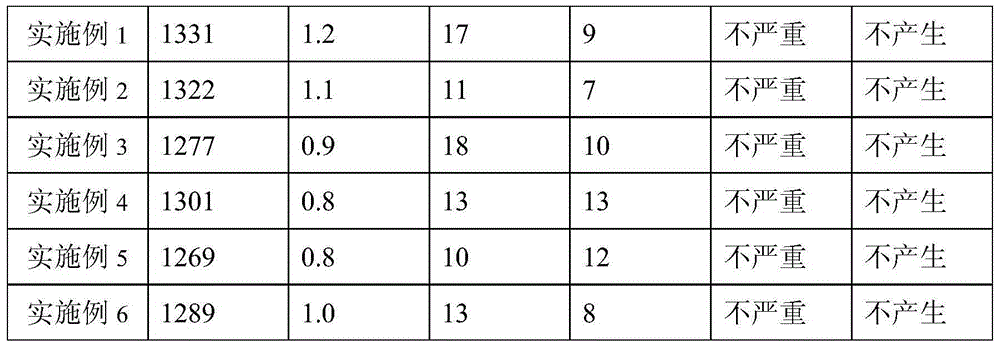

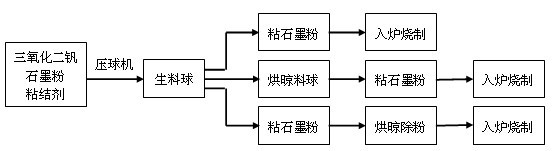

Method for anti-adhesion nitrogen increase in the process of producing vanadium nitride

ActiveCN102140587APrevents sinter sticking problemsHigh nitrogen contentPretreatment methodVanadium nitride

The invention relates to a method for anti-adhesion nitrogen increase in the process of producing vanadium nitride, and belongs to the technical field of vanadium nitride alloy production. The technical scheme comprises the following steps of: pretreating raw pellets before the vanadium nitride raw pellets enters a furnace to be fired, and putting the raw pellets into graphite powder, wherein a pretreatment method of sticking and coating the graphite powder on the surface is adopted, and the graphite powder is taken as an anti-adhesion material; and putting the raw pallets uniformly stuck with the graphite powder into a reaction furnace for firing. By the method, the problem of adhesion among products in the process of producing vanadium nitride can be effectively solved, the appearance quality of the products and the finished product ratio are improved, the surface area of nitriding reaction can be increased by 1 / 8 to 1 / 2 when the vanadium nitride pellets are fired, and the graphite powder on the surfaces of the pellets can consume partial residual oxygen and protect vanadium carbide / vanadium nitride in the pellets so as to prevent the vanadium carbide / vanadium nitride from being oxidized, improve the nitrogen content in the products and improve the grade and yield of the products. The method is suitable for all vanadium nitride production modes, particularly production of vanadium nitride by the most mature horizontal pusher kiln method at present.

Owner:HEBEI IRON AND STEEL

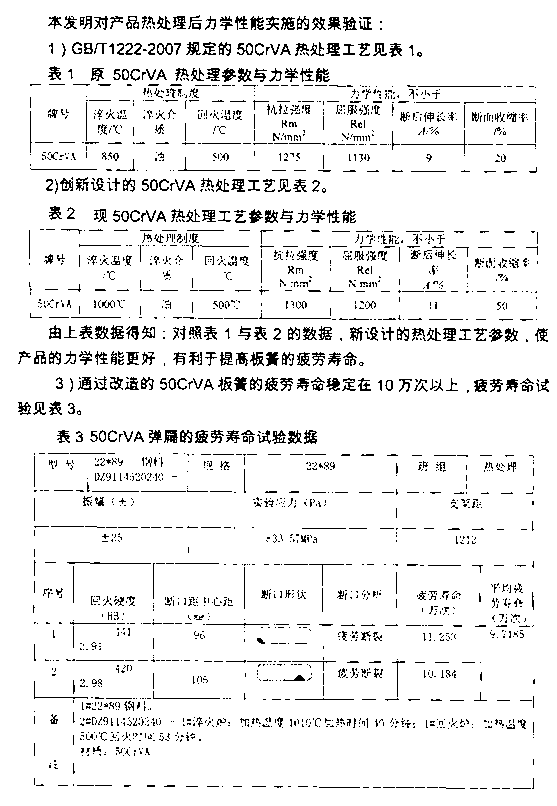

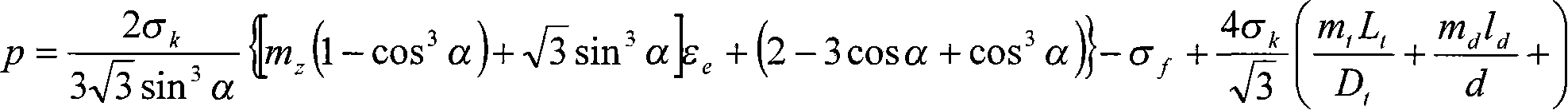

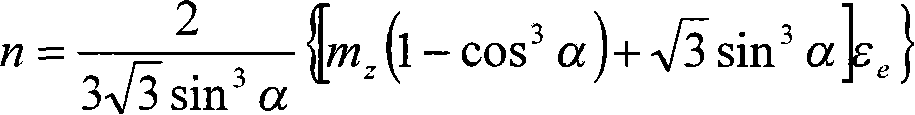

Technique for prolonging fatigue life of 50CrVA plate spring

ActiveCN103014533AGood deoxidation effectAvoid formingFurnace typesHeat treatment furnacesChemical compositionSlag

The invention provides a technique for prolonging the fatigue life of a 50CrVA plate spring. The technique includes the optimal design for the following chemical components of a 50CrVA flat spring steel: 0.49 to 0.53% of C, 0.20 to 0.30% of Si, 0.65 to 0.75% of Mn, 0.90 to 1.05% of Cr, 0.11 to 0.15% of V, 0.006 to 0.009% of Al, 0.018 to 0.020% of P, 0.016 to 0.020% of S, not greater than 0.25% of Ni, and not greater than 0.25% of Cu. The method for controlling and denaturating treatment on nonmetallic inclusion in steel comprises the following steps: (1) sealing a connector between a long nozzle of a large steel ladle and an intermediate submersed nozzle through an argon seal ring; controlling the amount of slag in tapping to 0 to 5kg / t; controlling the weight of the molten steel of the steel ladle to be not less than 7t; and controlling the molten steel level of a crystallizer to fluctuate within the scope of + / -2mm; and (2) carrying out denaturating treatment on inclusion; and adding SiCa wires at 2.1m / t through a wire feeder under a white slag condition, wherein the molten steel is at temperature of 1550 to 1580 DEG C; the parameters in heat treatment of the plate spring include quenching temperature of 1000 DEG C, tempering temperature of 500 DEG C, tensile strength of not less than 1300N / mm<2>, yield strength of not less than 1200N / mm<2>, percentage elongation after fracture of not less than 11%, and percentage reduction of area of not less than 50%.

Owner:XINJIANG BAYI IRON & STEEL

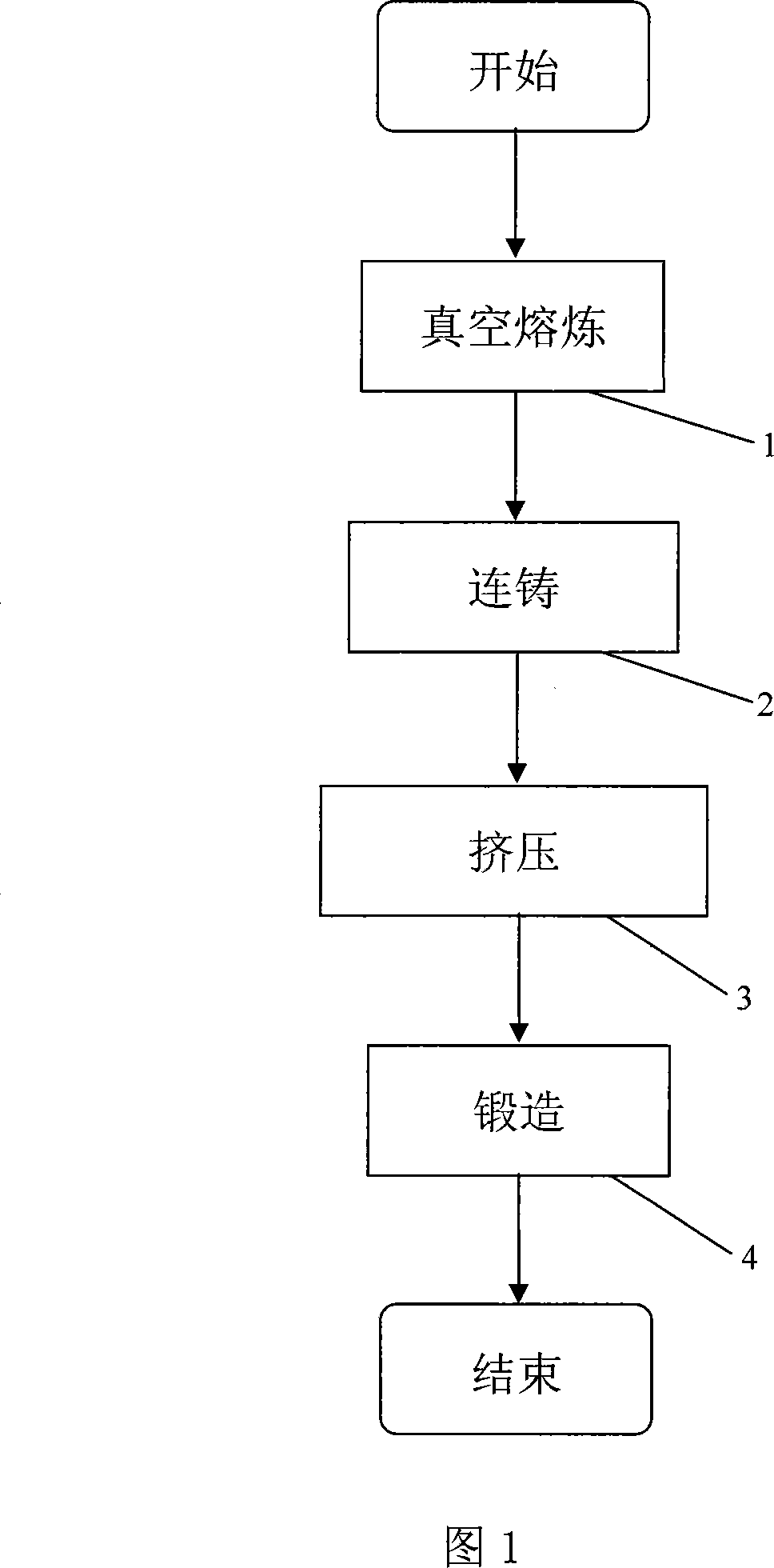

Technique for processing high-strength high-tractility magnesium alloy member

InactiveCN101121980AAvoid secondary oxidationGuarantee casting safetyExtrusion control devicesSteering controlElectromagnetic pump

The invention discloses a technology of processing a magnesium alloy with high intensity and flexibility, which subsequently includes vacuum melting, continuous casting, extrusion, forging and such procedures. The invention reasonably matches the solution body composition and the metamorphism liquid during casting process, and the grains are refined through the chilling action of a crystallizer at first; the magnesium alloy liquid is transmitted by an electromagnetic pump so as to prevent secondary oxidation and ensure safety in casting of the magnesium alloy; and then further refining the grains through electromagnetic mixing power, large ratio extrusion and heat treatment secondary crystallization, which effectively ensures tiny enough isometric crystals can be obtained from the alloy microstructure. The magnesium alloy elements of the automotive steering control arms, support elements of motorcycles and bicycles, can be obtained for the first time by the improvement, which are fully filled, good in surface quality, fine and even in grain size, reasonable in streamline distribution and without disordered streamline, vortexing and draining phenomena. The invention combines a plurality of technological processes into a production cycle, which reduces the turnover links, saves energy and reduces cost.

Owner:王仁辉

Production technology of copper-clad steel wire in soft state

ActiveCN102254629AAvoid crackingGuaranteed elongationCommunication cablesManufacturing extensible conductors/cablesElectricityElectrolysis

The invention relates to a production technology of a copper-clad steel wire in a soft state. The production technology successively comprises the following steps: drawing; tempering under high temperature; carrying out electro-deposition pretreatment; carrying out acid electrolysis; washing; carrying out pretreatment of electro-deposition; washing; carrying out electrodeposition thick treatment; washing; carrying out anti-oxidation processing; drying; drawing; washing; carrying out anti-oxidation processing; tempering under high temperature; polishing; carrying out anti-oxidation processing; and spooling to obtain a finished product. An advantage of the production technology of the copper-clad steel wire in the soft state is that an elongation rate of the produced copper-clad steel wire is greater than or equal to 8%, wherein the elongation rate, which is compared with an elongation rate of a copper-clad steel wire produced by a traditional tempering technology, can be enhanced by at least more than one time..

Owner:ZHEJIANG PUJIANG BAICHUAN IND

Aluminum alloy constant-strength diffusion connecting method

InactiveCN104084691AAvoid secondary oxidationActive connectionWelding/soldering/cutting articlesNon-electric welding apparatusAluminium alloyMechanical property

The invention discloses an aluminum alloy constant-strength diffusion connecting method which is used for solving the technical problem that in an existing diffusion connecting method, the mechanical property of an aluminum alloy connecting joint is poor. According to the technical scheme, passivation is carried out on a hexanethiol organic liquid membrane to remove an oxidation membrane of an aluminum alloy to-be-welded surface, the aluminum alloy to-be-welded surface is adopted, a single-layer self-assembling molecular membrane is formed on the aluminum alloy to-be-welded surface through bonding of Al-S bonds, secondary oxidation on an aluminum alloy to-be-welded piece in the stove charging and vacuumizing process is avoided, when the temperature in a stove rises to 154 DEG C, hexanethiol is escaped out of the aluminum alloy to-be-welded surface to be volatilized to enable Al atoms on the aluminum alloy to-be-welded surface to be in contact, and aluminum alloy effective connection when the diffusion welding temperature is achieved is accordingly achieved. By means of the aluminum alloy constant-strength diffusion connecting method, the mechanical property of the aluminum alloy connecting joint can be improved. Tests show that the aluminum alloy connecting joint obtained with the method achieves 85%-100% of after-welded base materials, and the extension rate of the aluminum alloy connecting joint achieves 10%-21%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High basicity tundish cover agent and its production method

InactiveCN1970197AImproved ability to float inclusionsImprove insulation effectGranulation by liquid drop formationAlkalinityBall type

A high PH value ball type hollow coating agent comprises burnt lime, silica dioxide, and alumind, with the former two taking 35%-65% of the total weight and their rate 5:8, alunind taking 18%-45% of the total weight, with pre smelt, high PH value, carbon free material and spraying grain making process, enjoying fine heat preserving capacity, retaining three layer structure, without crustization, with improved capability in avoiding secondary oxidization of steel liquid and impurities adhesion.

Owner:上海盛宝冶金科技有限公司

Method for increasing nitrogen in refining furnace

The invention provides a method for increasing nitrogen in a refining furnace. The steps of the method is characterized by: (1) blowing in nitrogen with the pressure of not less than 0.5MPa and with the bottom blowing total flow of not less than 500L / min after the completeness of VOD refining furnace reduction or after the completeness of dehydrogenation in VD refining furnace; and (2) calculating the time of nitrogen increasing: a. figuring out the increased nitrogen required by liquid steel: delta N=[N]-[N][before]; wherein, delta N is the increased nitrogen required by liquid steel (%), [N] is the target nitrogen content which the liquid steel needs to achieve after the completeness of each steel ball processing (%), [N][before] is nitrogen content in liquid steel before increasing nitrogen (%); and b. figuring out the time to increase nitrogen: in the nitrogen increasing process, the temperatrue drop of liquid steel is calculated by rendering that y equals to 1.2 DEG C / min-2.0 DEG C / min; the formula is as follows: delta N=1.25*Q*t*10<-188 / (T-yt+273)-1.25+0.51gP-1gf>; wherein, Q is the bottom blow total flow (L / min), t is the time to increase nitrogen (min), T is the temperature of liquid steel before increasing nitrogen (DEG C), P is vacuum degree in the furnace (10<5>Pa), and y is the temperature drop of liquid steel in the process of increasing nitrogen (DEG C / min). The method for increasing nitrogen in the refining furnace has low cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com