Additive for heat zinc coating auxiliary agent

A technology of additives and fluxing agents, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of difficult post-treatment of plating fluxes, cumbersome operation, unsatisfactory effect, etc., and achieve improved fluxing effect, improved surface quality, good interfacial wetting and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

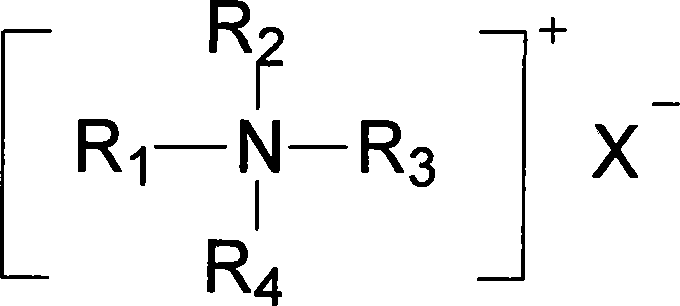

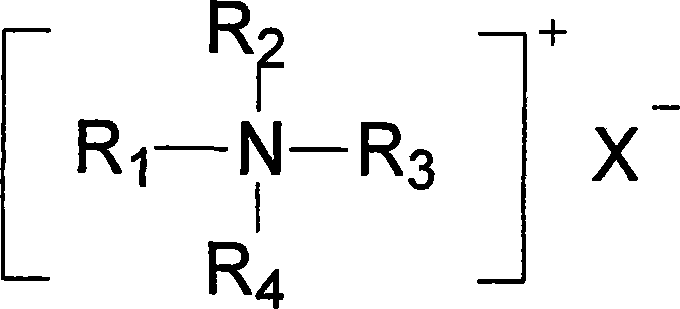

[0021] Take 500g of dodecyltrimethylammonium bromide, 100g of isopropanol, and 350g of deionized water in a reaction vessel with a heating device, heat and stir at 50°C for two hours, cool down to room temperature and use deionized water Set the volume to 1 liter and stir evenly to obtain this additive.

[0022] Add 5ml of this additive to 500ml of flux consisting of 30% ammonium chloride + 40% zinc chloride, stir evenly, dip a clean glass piece (40mm*60mm) in the above uniform mixture and take it out . There will be a very uniform attachment on the glass sheet without water droplets. After drying with a hair dryer, an extremely uniform snowflake-like salt adhesion layer will be seen, and the glass dipped in the mixed solution without this additive Sheets cannot form a uniform liquid film.

[0023] The present invention once carried out experiment in hot-dip galvanizing factory spot. Take 8 kg of the additive of the present invention and add it to 600 kg of fluxing agent co...

Embodiment 2

[0025] Take 100g of dodecyldimethylethylammonium bromide, 30g of isopropanol, 120g of fatty alcohol polyoxyethylene (9) ether, and 280g of deionized water and place them in a reaction vessel with a heating device. Stir under heat preservation for 2 hours, lower to room temperature and dilute to 1 liter with deionized water, and stir evenly to make an additive.

[0026] According to field experiments of hot-dip galvanizing, the surface quality of the galvanized layer formed by adding the present invention is good, and there are no missing plating and zinc explosion phenomena.

Embodiment 3

[0028] Take 800g of cetyltrimethylammonium bromide, 160g of isopropanol, 80g of alkylphenol polyoxyethylene (10) ether, and 400g of deionized water and place them in a reaction vessel with a heating device. Insulate and stir for two hours, lower to room temperature and dilute to 1 liter with deionized water, and stir evenly to make additives.

[0029] Field experiments on hot-dip galvanizing show that the surface quality of the galvanized layer formed by adding the present invention is good, there is no phenomenon of missing plating and galvanizing, and the surface of the galvanized layer is uniform and beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com