Thermal-insulation cover agent and preparation method thereof

A technology of thermal insulation covering agent and covering agent, which is applied in the field of liquid casting and hydraulic casting, which can solve the problems of short chemical reaction time, exposure to air, heat loss of molten steel, etc., and achieve the goals of reducing heat conduction speed, improving thermal insulation effect, and prolonging reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

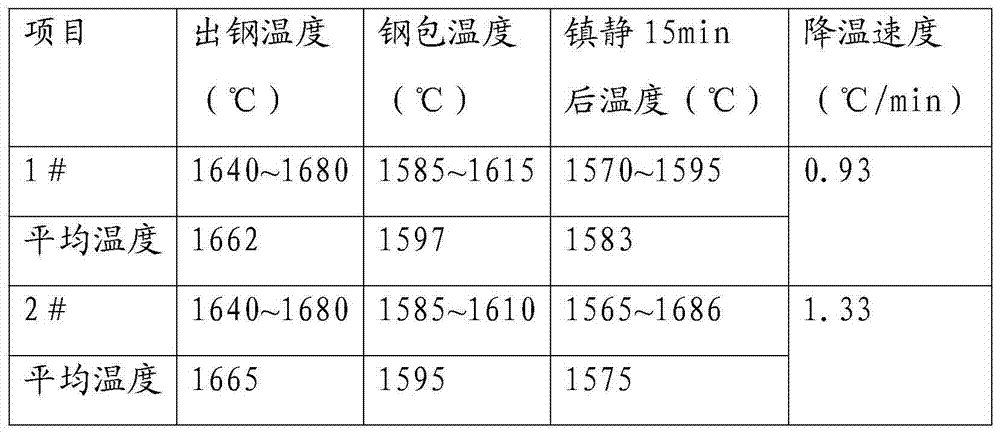

Image

Examples

Embodiment 1

[0037] The composition and mass percentage (%) of the covering agent is 28SiO 2 , 24Al 2 o 3 , 18CaO, 5Fe 2 o 3 , 2.5C, 3.5MgO, 3.0 expansion agent, 4 heating agent, and the balance is Al;

[0038] The melting point of the covering agent is 1350°C, and the melting speed is 73 seconds at 1320°C.

Embodiment 2

[0040]The composition and mass percentage (%) of the covering agent is 30SiO 2 , 26Al 2 o 3 , 20CaO, 8Fe 2 o 3 , 3.5C, 4MgO, 3.5 expansion agent, 4.5 heating agent, the balance is Al;

[0041] The covering agent has a melting point of 1310°C and a melting rate of 73 seconds at 1320°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com