Aluminum alloy constant-strength diffusion connecting method

A diffusion connection and aluminum alloy technology, which is applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of poor mechanical properties of aluminum alloy connection joints, achieve the effect of preventing secondary oxidation, improving strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

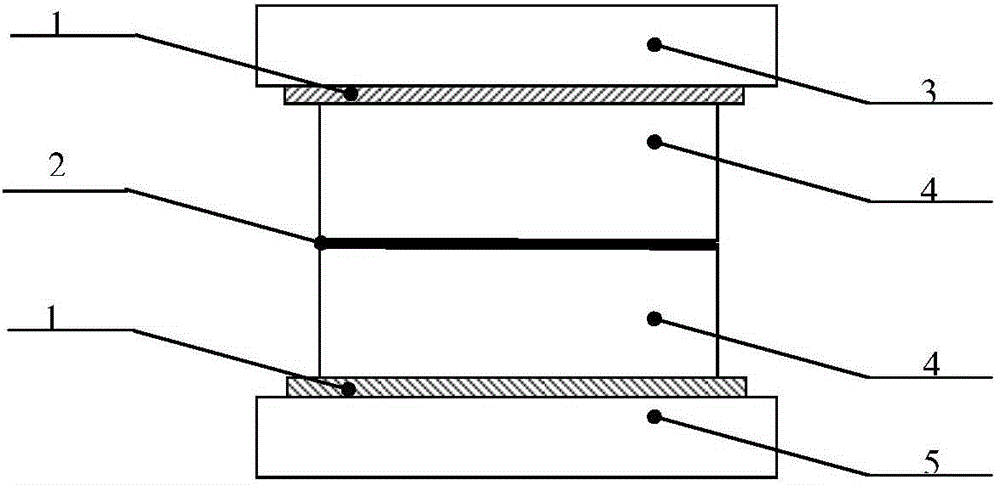

[0015] Example 1: Vacuum diffusion welding of aluminum alloy 6063 and aluminum alloy 6063.

[0016] Select two pieces of size A rod-shaped aluminum alloy 6063 (Al-Mg-Si series) is used as a welding piece. First, sand the surface of aluminum alloy 4 to be welded to 2000 # , Then polish to make the surface roughness Ra value of aluminum alloy 4 to be welded 0.02μm; then put the aluminum alloy 4 to be welded surface in 15% NaOH solution for 60s, then rinse with water, and then aluminum alloy 4 to be welded The surface is cleaned in 30% HNO3 solution for 30 seconds, and finally the aluminum alloy 4 to be welded parts are placed in alcohol, ultrasonically cleaned for 60 seconds, and then dried with cold air, and a layer of hexyl mercaptan is immediately uniformly coated on the aluminum alloy 4 to be welded surface (CH 3 -(CH 2 )-CH 2 -SH) Organic liquid film 2. Two pieces of aluminum alloy 4 with hexamethylene mercaptan organic liquid film 2 to be welded are brought into contact wit...

Embodiment 2

[0018] Example 2: Vacuum diffusion welding of aluminum alloy 5056 and aluminum alloy 5056.

[0019] Select two pieces of size The rod-shaped aluminum alloy 5056 (Al-Mg series) is used as the weldment. First, sand the surface of aluminum alloy 4 to be welded to 2000 # , Then polish to make the surface roughness Ra value of aluminum alloy 4 to be welded 0.03μm; then put the surface of aluminum alloy 4 to be welded in 15% NaOH solution for 90s, then rinse with water, and then aluminum alloy 4 to be welded The surface is cleaned in 30% HNO3 solution for 50s, and finally the aluminum alloy 4 parts to be welded are placed in alcohol, ultrasonically cleaned for 30 seconds, and then dried with cold air, and a layer of hexyl mercaptan is immediately uniformly coated on the aluminum alloy 4 to be welded surface (CH 3 -(CH 2 )-CH 2 -SH) Organic liquid film 2. Two pieces of aluminum alloy 4 with hexamethylene mercaptan organic liquid film 2 to be welded are brought into contact with each o...

Embodiment 3

[0021] Example 3: Vacuum diffusion welding of aluminum alloy 2024 and aluminum alloy 2024.

[0022] Select two pieces of size A rod-shaped aluminum alloy 2024 (Al-Cu series) is used as the workpiece to be welded. First, sand the surface of aluminum alloy 4 to be welded to 2000 # , And then polished to make the surface roughness Ra value of aluminum alloy 4 to be welded 0.05μm; then the surface of aluminum alloy 4 to be welded is cleaned in 15% NaOH solution for 75s, then rinsed with water, and aluminum alloy 4 is to be welded The surface is cleaned in 30% HNO3 solution for 60 seconds, and finally the aluminum alloy 4 to be welded parts are placed in alcohol, ultrasonically cleaned for 50 seconds, and then dried with cold air, and a layer of hexyl mercaptan is immediately uniformly coated on the aluminum alloy 4 to be welded surface (CH 3 -(CH 2 )-CH 2 -SH) Organic liquid film 2. Two pieces of aluminum alloy 4 with hexamethylene mercaptan organic liquid film 2 to be welded are b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com