High basicity tundish cover agent and its production method

A technology of covering agent and tundish, which is applied in the field of metallurgy, can solve the problems of fast melting speed of covering agent and slow melting speed of covering agent, and achieve rapid and uniform slagging ability, obvious environmental protection effect, and small temperature fluctuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

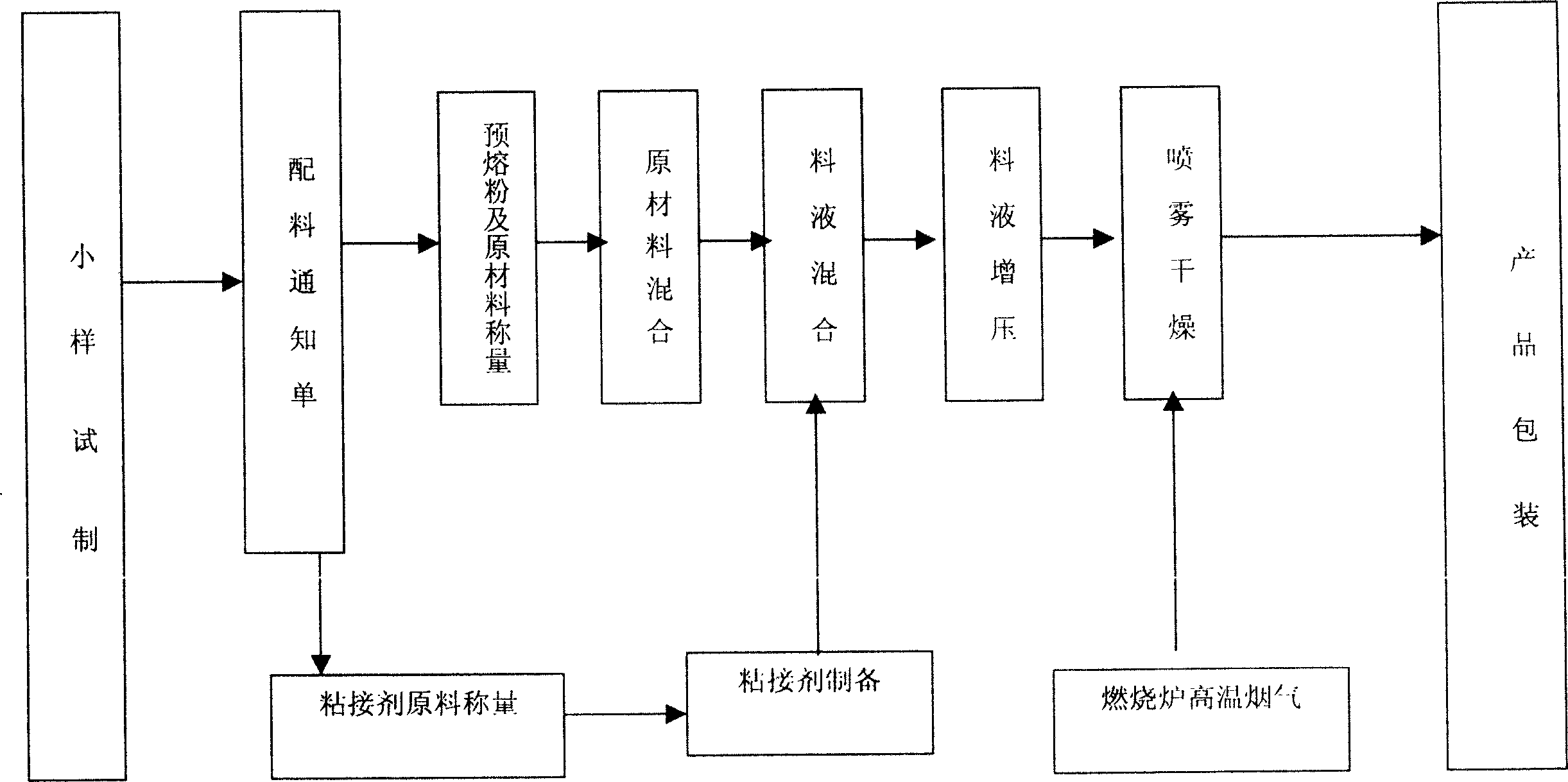

Method used

Image

Examples

Embodiment Construction

[0020] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

[0021] Reality

apply

example

Covering agent composition (weight percent %)

Bulk specific gravity

(g / cm 3 )

CaO

SiO 2

Al 2 o 3

MgO

CaF 2

B 2 o 3

Na 2 o

burning

Additives

one

50.28

6.29

30.39

2.56

3.51

1.50

1.50

1.47

2.5 (yellow dextrin)

0.82

two

30.88

4.12

38.62

7.62

3.60

1.50

1.50

9.16

3.0 (801 glue)

1.058

three

54.17

10.83

27.21

2.11

1.0

1.15

0.53

2.0 (yellow dextrin)+

1.0 (801 glue)

0.87

Four

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com