Patents

Literature

31results about How to "Prevent resulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

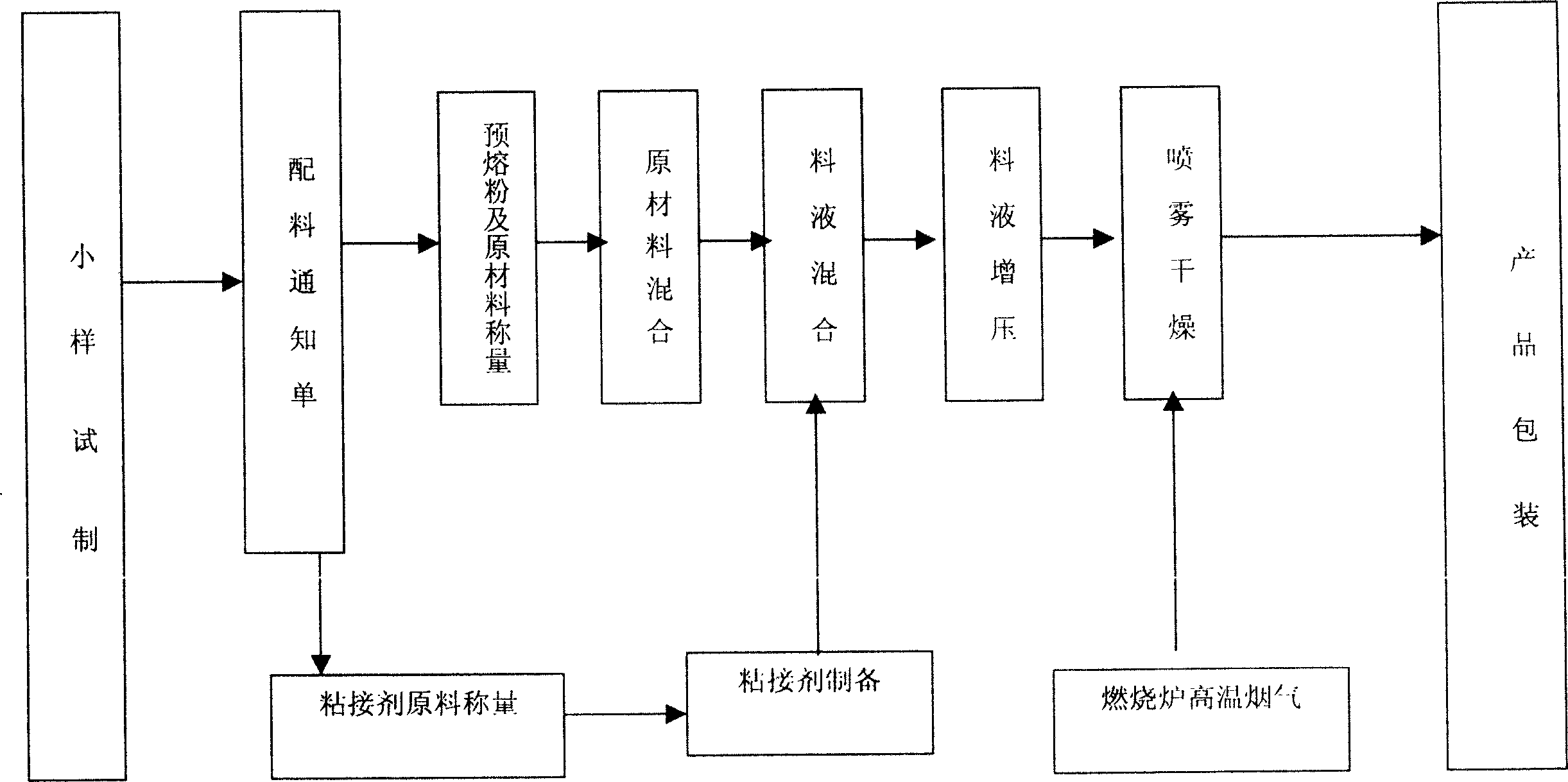

High basicity tundish cover agent and its production method

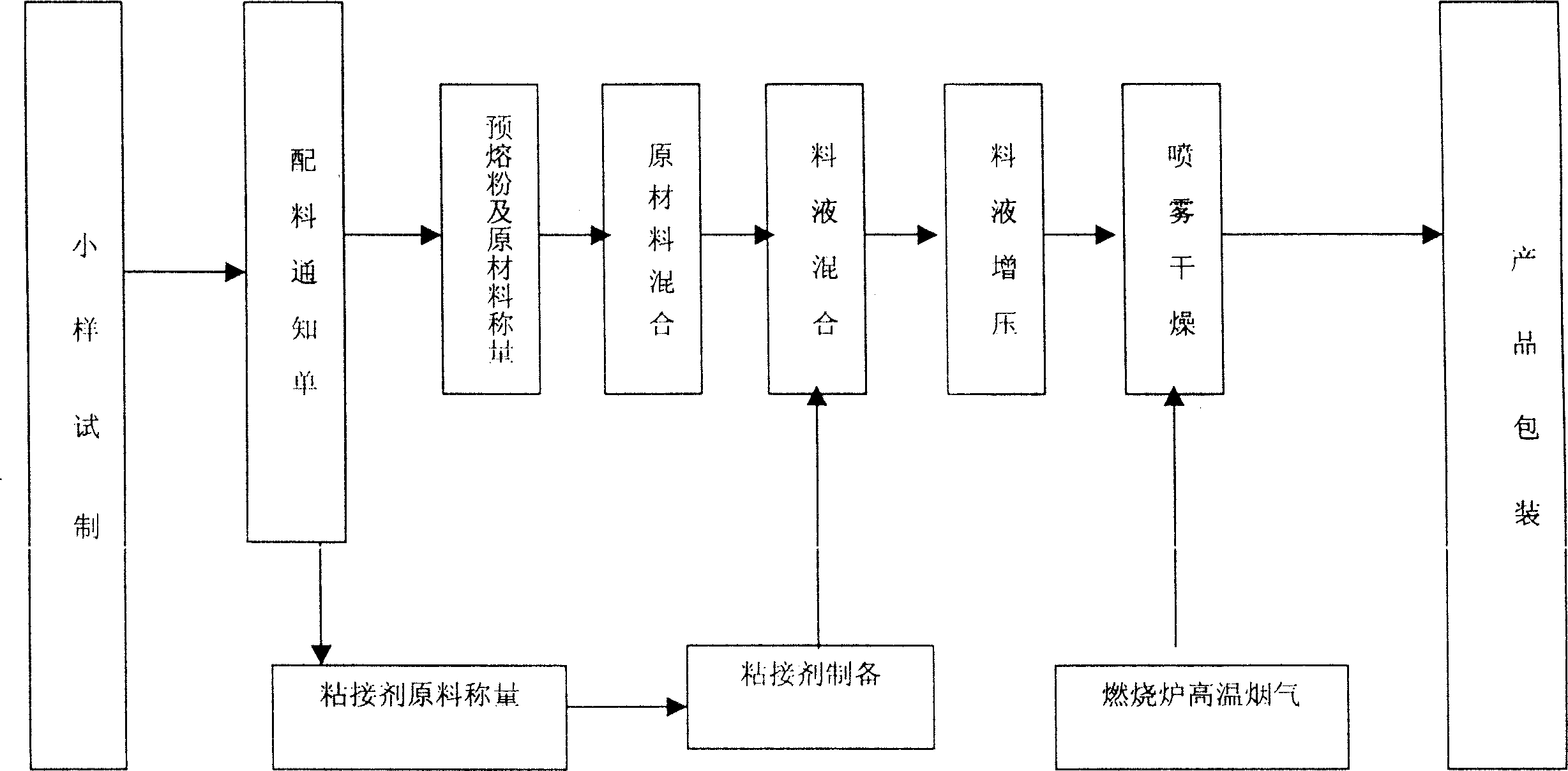

InactiveCN1970196ARapid and uniform slag forming abilityPrevent resulfurizationGranulation by liquid drop formationTundishAluminium

A high PH value ball type hollow coating agent comprises burnt lime, silica dioxide, and alumind, with the former two taking 30%-60% of the total weight and their rate 8:12, alunind taking 20%-50% of the total weight, with pre smelt, high PH value, carbon free material and spraying grain making process, enjoying fine heat preserving capacity, retaining three layer structure, without crustization, with improved capability in avoiding secondary oxidization of steel liquid and impurities adhesion.

Owner:上海盛宝冶金科技有限公司

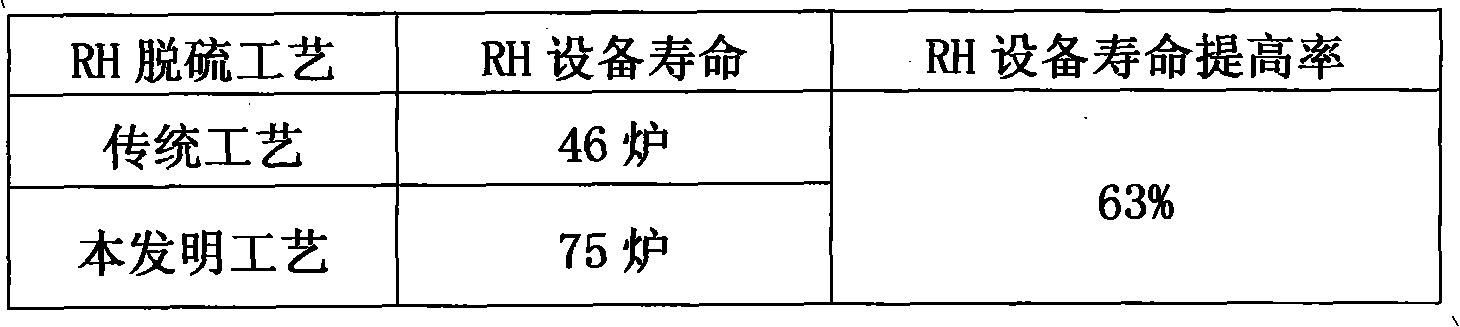

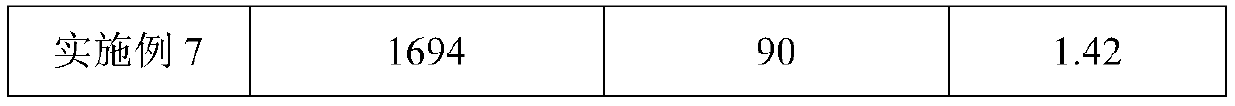

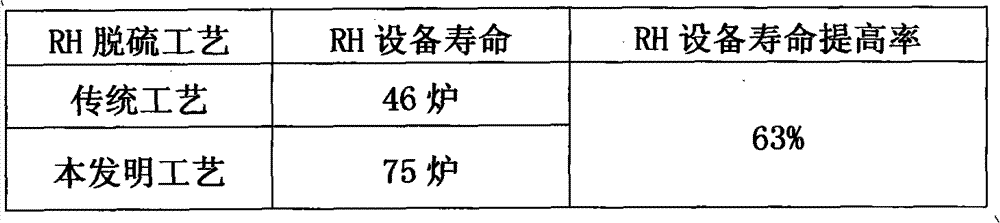

RH refining desulphurization process of non-oriented electrical steel

InactiveCN102010934AGood desulfurization effectMeet the requirements of deep desulfurizationAlkalinityElectrical steel

The invention discloses an RH refining desulphurization process of non-oriented electrical steel, belonging to the technical field of steel making. The process comprises the following steps: setting the lift gas flowrate to 1200 NL / min after the entering of the RH, and enhancing the lift gas flowrate to 1600 NL / min 3 minutes later; blowing oxygen to perform the forced decarburization when the vacuum degree is reduced to 2.0 mba, and when the oxygen blowing is finished and the vacuum degree is lower than 2.0 mba, performing the natural decarburization for 20 minutes; adding the aluminum for deoxidation when the vacuum decarburization is finished; and performing the silicon alloying by using the low carbon ferrosilicon, and adding the desulfurizing agent into the vacuum chamber in two timesthrough the RH alloy bin. The circulation time of the test furnace batch is from 10 minutes to 15 minutes. The process provided by the invention has the advantages that the RH device needs no reconstruction, and the operation is simple. The average RH desulphurization degree is 36.7%, and the desulphurization effect is better. The contents of the FeO and the MnO of the ladle slag have significantinfluence on the desulphurization effect, and the enhancing of the alkalinity of the ladle slag can increase the RH desulphurization efficiency as well as reduce the corrosion of the RH device.

Owner:KUNMING UNIV OF SCI & TECH

Casting process of nodular cast iron planet carrier

The invention relates to a casting process of a nodular cast iron planet carrier, which comprises the following procedures of modeling, iron melt melting, spheroidizing, modifying, casting and stress relieving and annealing. The design of a casting system adopts a step casting method which takes consideration of both bottom casting and top casting to improve the finished product rate of castings, and also adopts technical schemes of placing chill iron at the position of thick walls, adding Sn element in the iron melt, optimizing, spheroidizing, modifying, casting and the like, so that the produced planet carrier not only meets the high demands on property, but also achieves great improvement in production cost and efficiency.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

High basicity tundish cover agent and its production method

InactiveCN1970197AImproved ability to float inclusionsImprove insulation effectGranulation by liquid drop formationAlkalinityBall type

A high PH value ball type hollow coating agent comprises burnt lime, silica dioxide, and alumind, with the former two taking 35%-65% of the total weight and their rate 5:8, alunind taking 18%-45% of the total weight, with pre smelt, high PH value, carbon free material and spraying grain making process, enjoying fine heat preserving capacity, retaining three layer structure, without crustization, with improved capability in avoiding secondary oxidization of steel liquid and impurities adhesion.

Owner:上海盛宝冶金科技有限公司

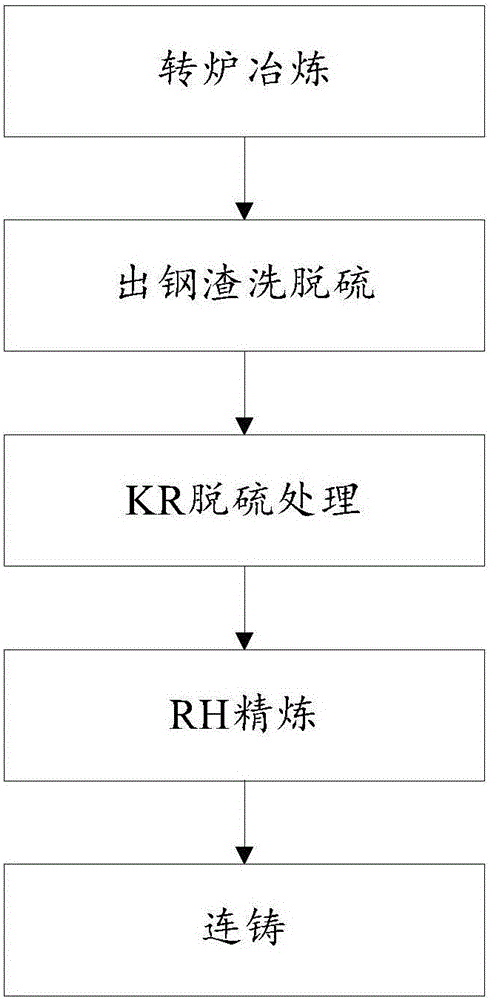

Smelting method for low-sulfur steel

ActiveCN105803148AAvoid mass transferMitigate mass transferManufacturing convertersSlagContinuous casting

The invention relates to the technical field of metallurgy, in particular to a smelting method for low-sulfur steel. The smelting method includes the processes of converter smelting, steel slag discharging and washing desulfuration, KR desulfuration treatment, RH refining and continuous casting. By means of the smelting method for the low-sulfur steel in the embodiment, the technical problems that in the prior art, production processes for low-sulfur steel are complex, and the production cost is high are solved, the technical processes for the low-sulfur steel are simplified, the quality of the low-sulfur steel is improved, and the production cost of the low-sulfur steel is reduced.

Owner:SHOUGANG CORPORATION

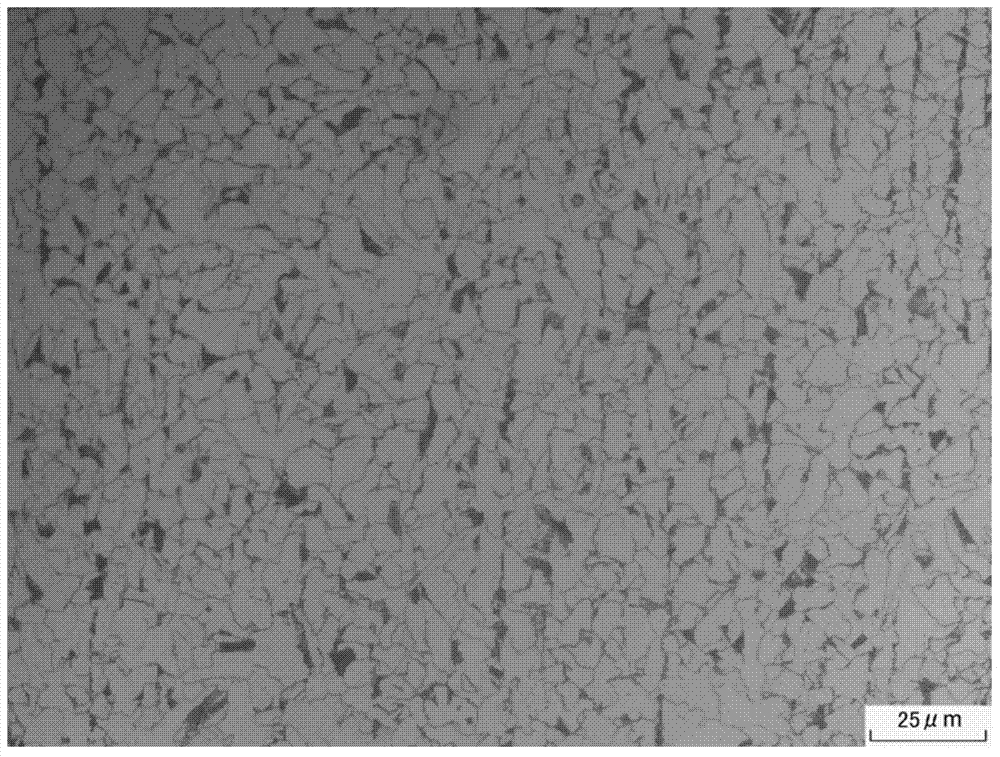

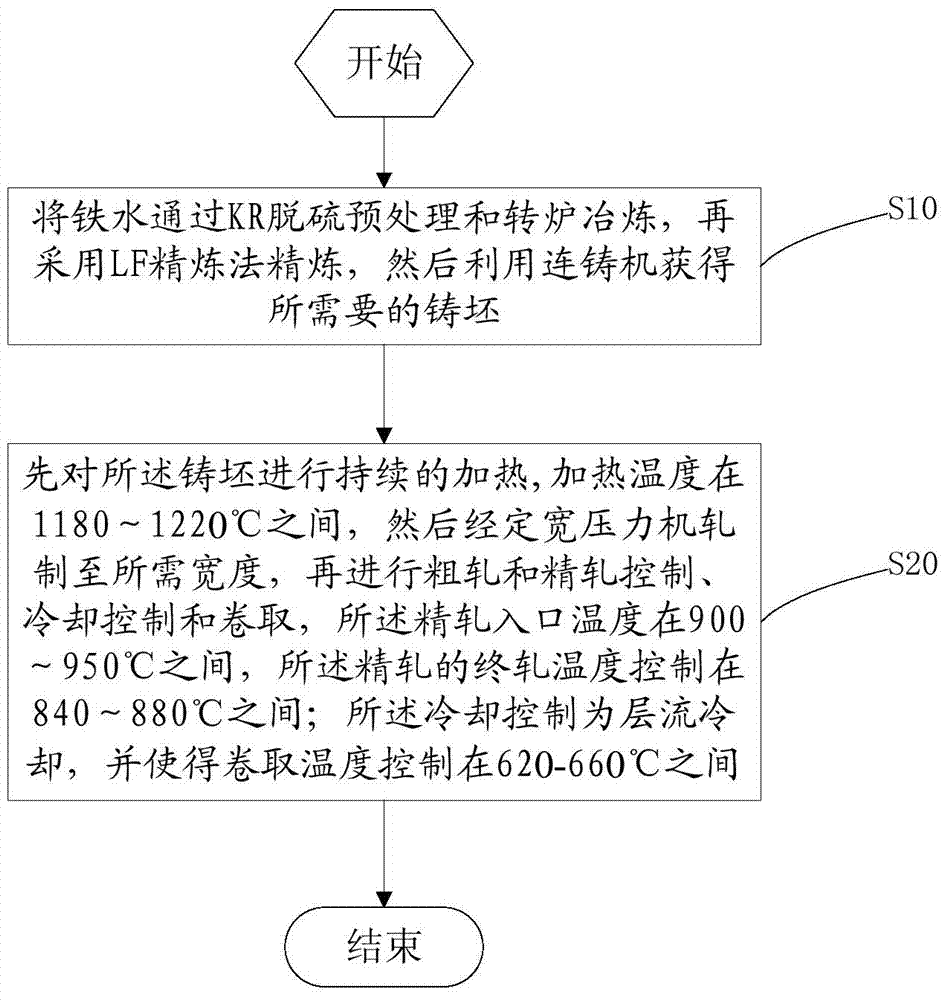

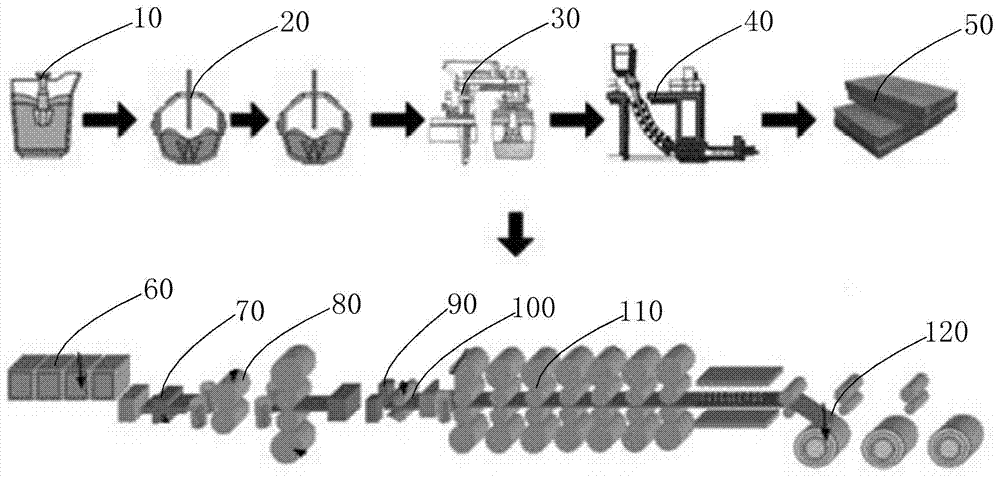

Steel for heavy-truck super-thick steel-made spokes and manufacturing method of steel

The invention relates to the technical field of steel rolling, and relates to steel for heavy-truck super-thick steel-made spokes and a manufacturing method of steel. The steel comprises the following trace elements in percent by mass: carbon, 0.07~0.12%; silicon, 0.05-0.15%; manganese, 0.7-1.1%; niobium, 0.01-0.03%; titanium, 0.01-0.03%; phosphor, <=0.015%; sulfur, <=0.005%; aluminium, 0.02-0.05%; and nitrogen, <=0.006%. The manufacturing method comprises: performing KR desulphurization and LF-method processing to obtain casting blanks, performing rough rolling and finish rolling, and performing laminar flow cooling and reeling to obtain the needed steel. By utilizing smelting to obtain the casting blanks with the above trace-element mass percentages and employing the technologies of low-temperature heating, low-temperature rolling and high-temperature reeling, the demands of heavy-truck spokes on easy spinning property, surface quality and performance stability are satisfied, and the collapsing crushing rate of heavy-truck wheels is substantially reduced.

Owner:SHOUGANG CORPORATION

High basicity tundish cover agent and its production method

InactiveCN1970198AImproved ability to float inclusionsImprove insulation effectGranulation by liquid drop formationAlkalinityBall type

A high PH value ball type hollow coating agent comprises burnt lime, silica dioxide, and alumind, with the former two taking 40%-70% of the total weight and their rate 2.8:5, alunind taking 15%-40% of the total weight, with pre smelt, high PH value, carbon free material and spraying grain making process, enjoying fine heat preserving capacity, retaining three layer structure, without crustization, with improved capability in avoiding secondary oxidization of steel liquid and impurities adhesion.

Owner:上海盛宝冶金科技有限公司

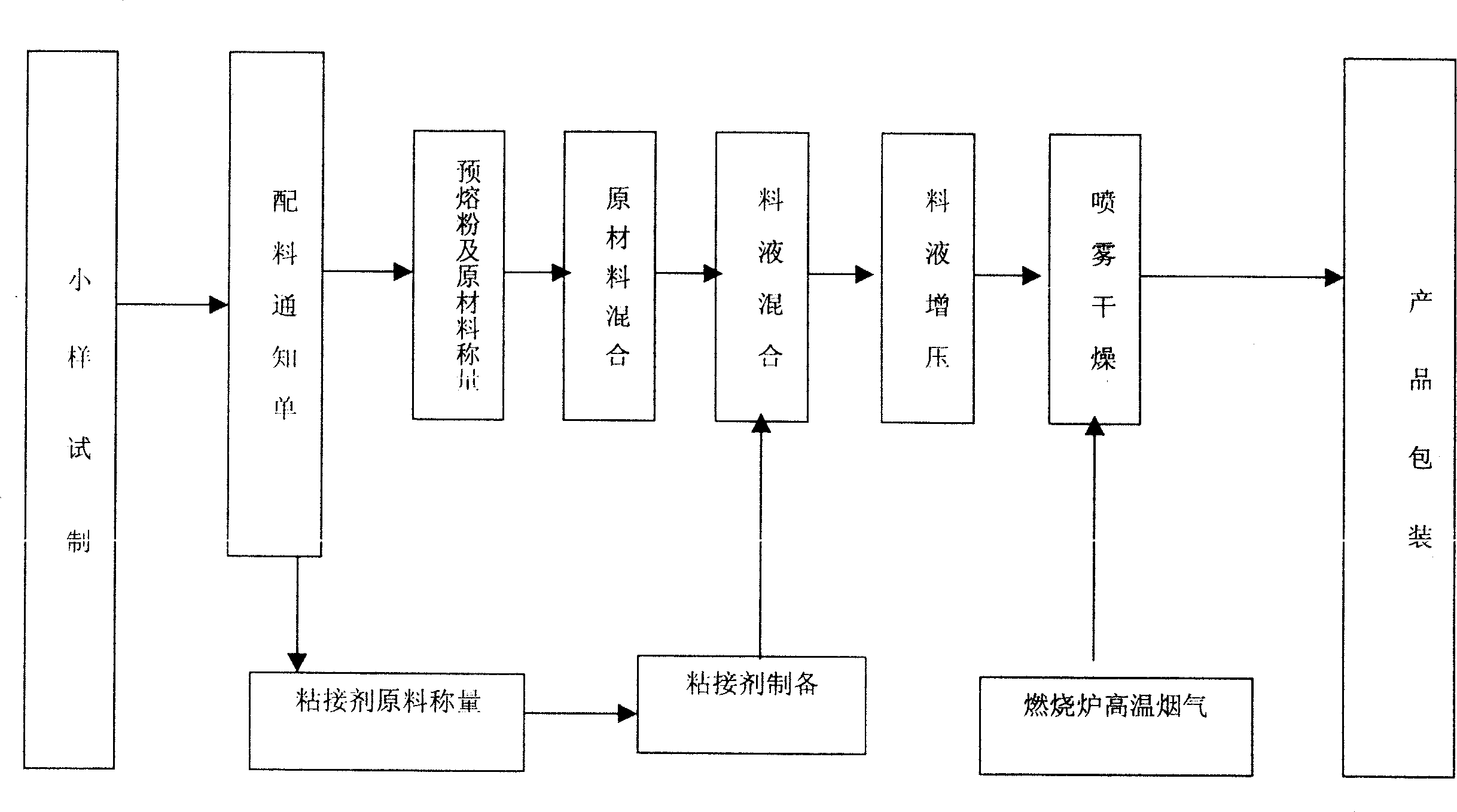

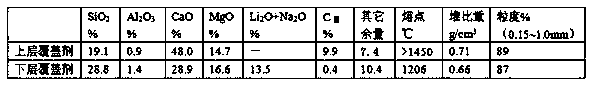

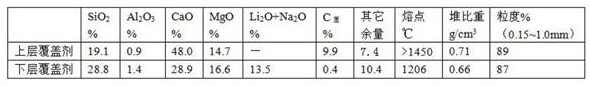

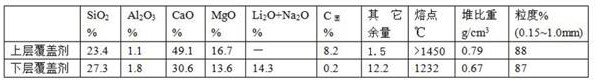

Double-layer tundish covering agent for ultrathin belt

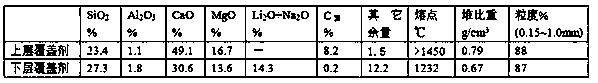

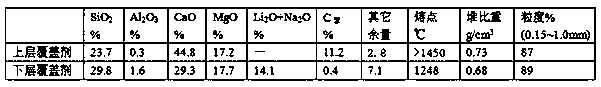

ActiveCN109454210AReduce the speed of heat transfer to the outsideHeap specific gravitySpray GranulationMolten steel

The invention discloses a double-layer tundish covering agent for an ultrathin belt, and relates to the technical field of metallurgy. The upper covering agent and the lower covering agent are hollowgranular products which are subjected to spray granulation. The upper covering agent comprises the following chemical components of, in percentage by weight, 45%-55 wt% of CaO, 18.0-24.0 wt% of SiO2,14.0-18.0 wt% of MgO, less than or equal to 1.9 wt% of Al2O3, 7.5-11.5 wt% of C-solid and the balance inevitable impurities, and the melting point of the upper covering agent is greater than 1450 DEGC. The lower covering agent comprises the following chemical components of, in percentage by weight, 25.0-31.0 wt% of CaO, 27.0-37.0 wt% of SiO2, 13.0-18.0 wt% of MgO, less than or equal to 1.9 wt% ofAl2O3, 13.0-17.0 wt% of (Li2O + Na2O), less than or equal to 0.5 wt% of C-solid and the inevitable balance impurities, and the melting point of the lower covering agent is 1150-1250 DEG C. The product has the advantages that the specific gravity is light, the upper layer is carbon-containing and the lower layer is extremely few in carbon-containing, carbon-increasing is prevented and heat preservation is achieved, the content of Al2O3 in the upper layer and the lower layer is low, the impurities are fully absorbed, the melting point of the upper layer is high, the insulation of the air is isolated, the melting point of the lower layer is low, and rapid melting can be achieved so as to prevent the carbon-containing upper layer from being in contact with the molten steel to increase the carbon.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

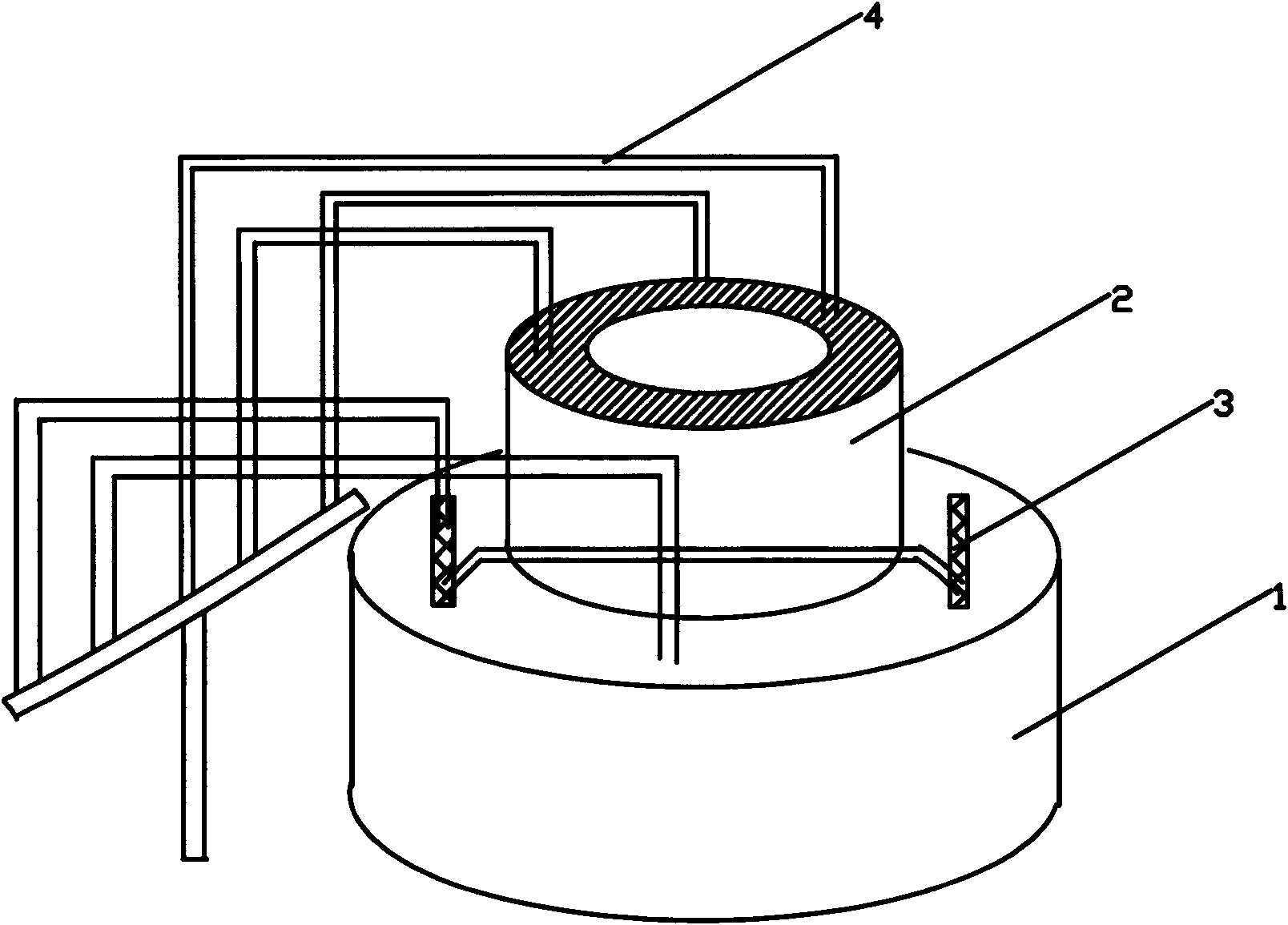

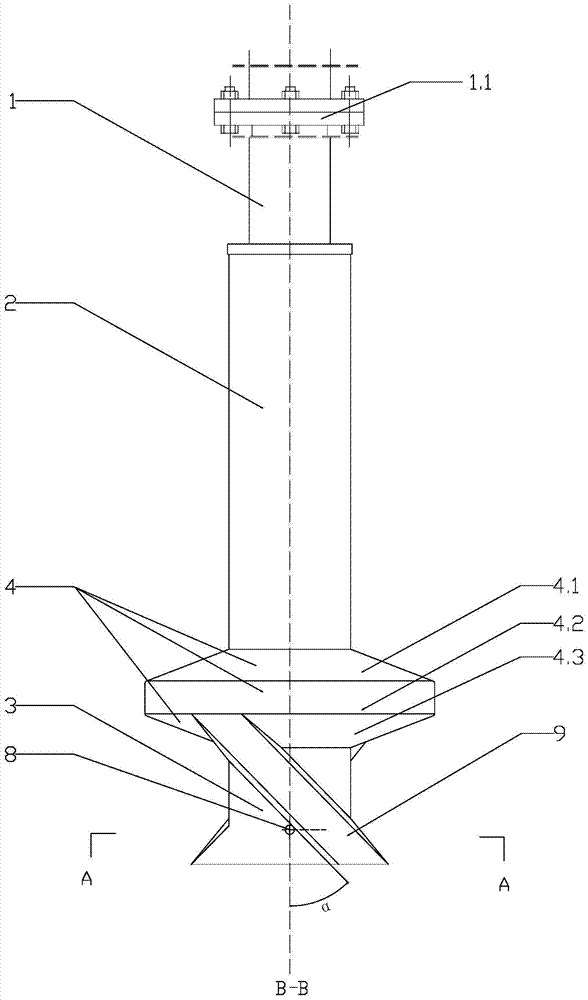

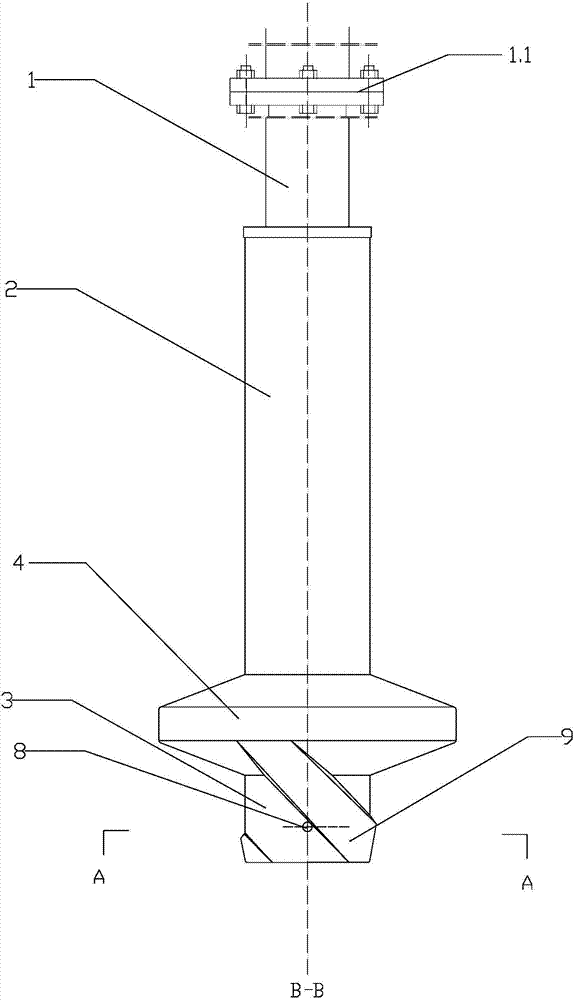

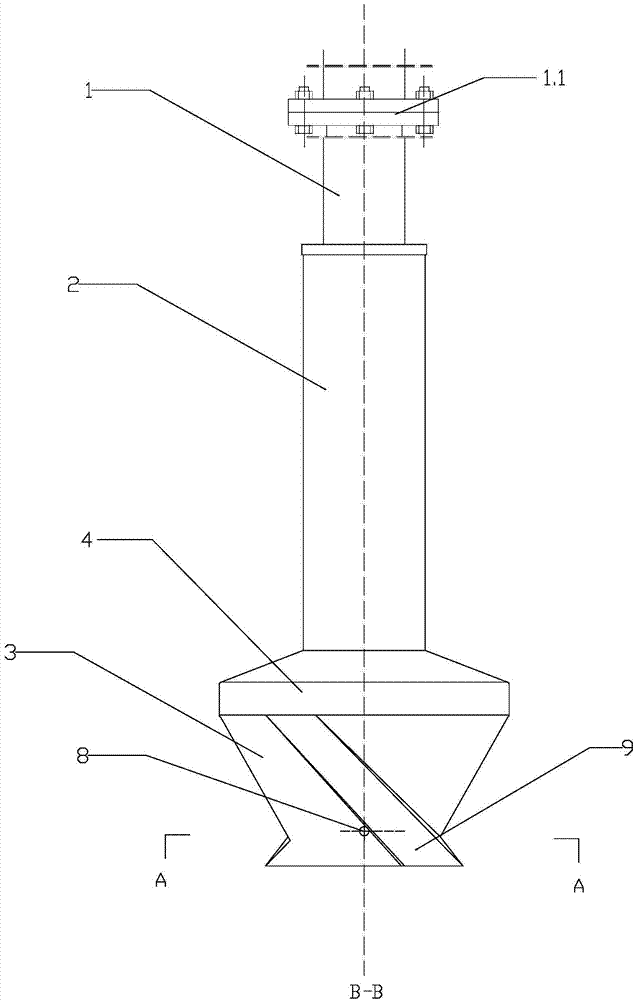

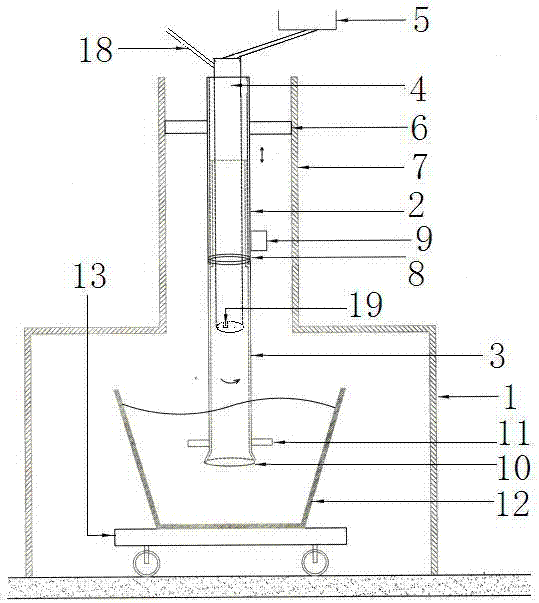

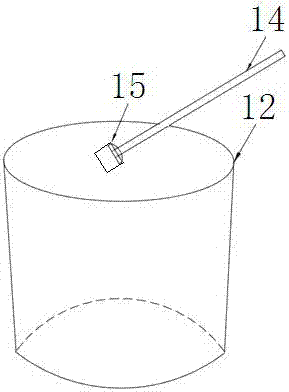

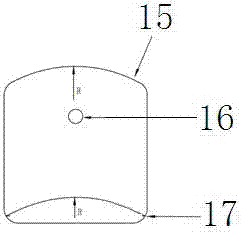

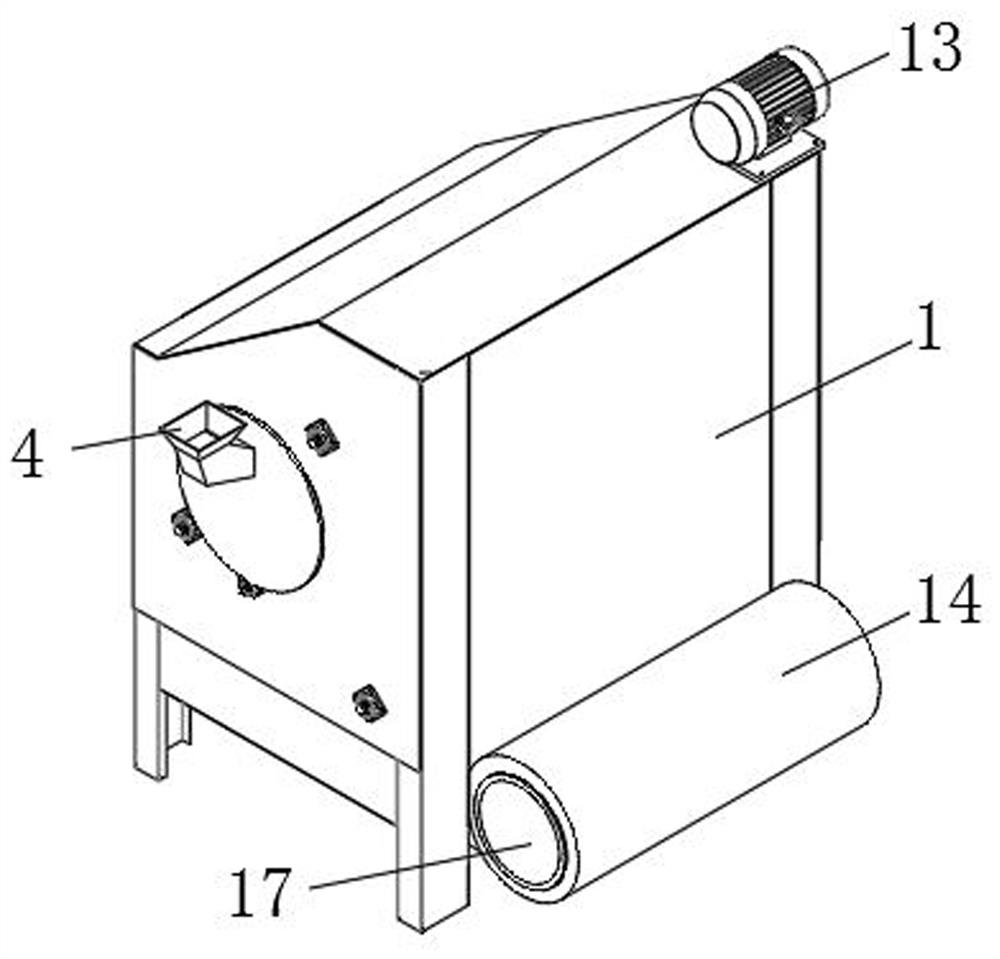

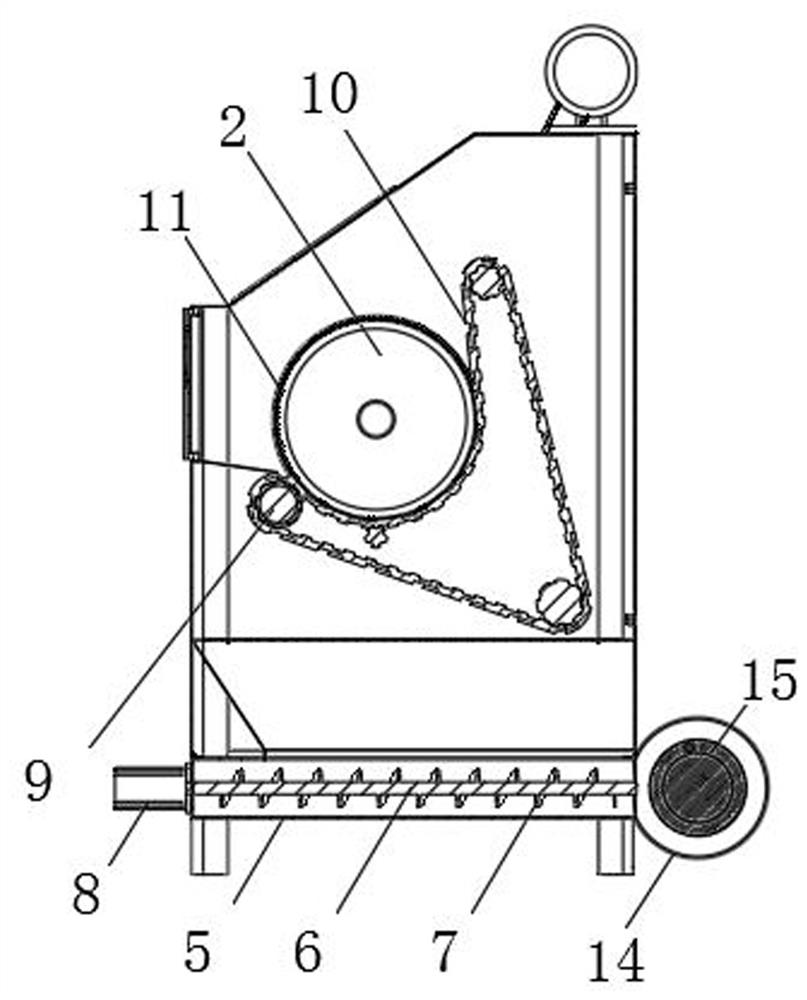

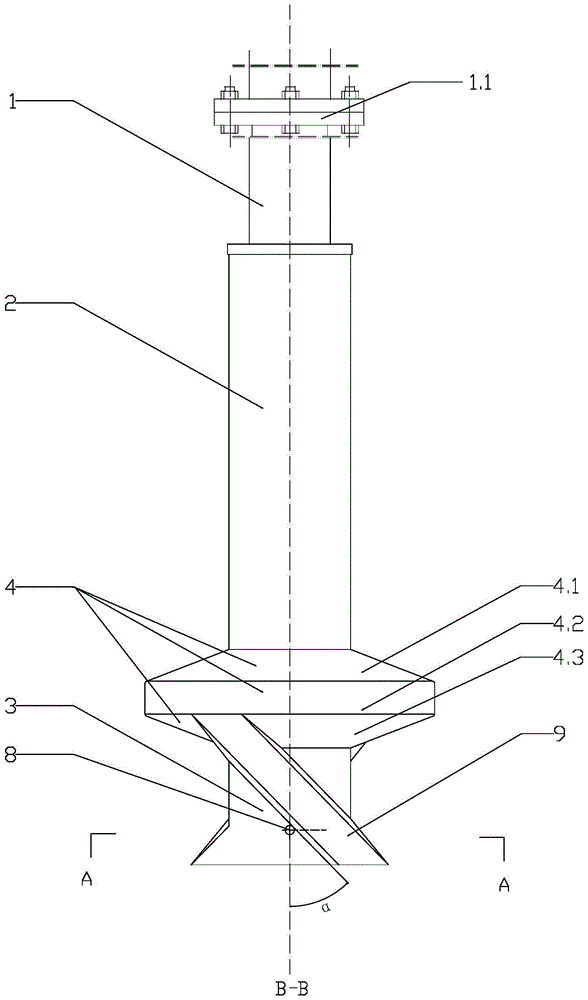

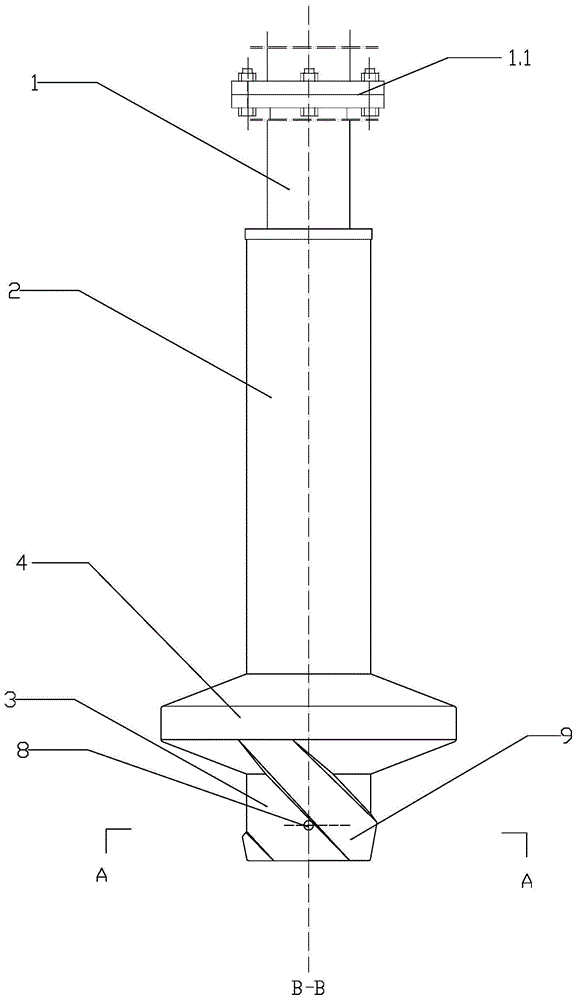

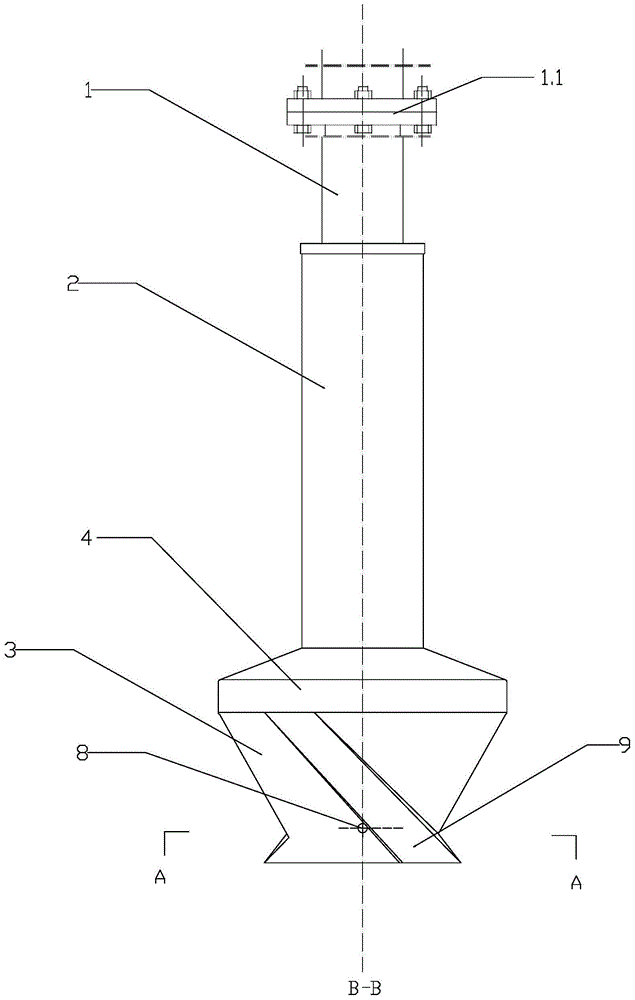

High-performance spray gun for molten iron injection pretreatment

The invention discloses a high-performance spray gun for molten iron injection pretreatment. The high-performance spray gun comprises a connection segment, a gun body segment and an injection segment, which are sequentially communicated, wherein a swirling diffuser is arranged between the gun body segment and the injection segment and comprises an upper cone, a cylinder and a lower reversed cone, which are sequentially communicated; 2-4 nozzles are uniformly formed between a main pipe of the spray gun and a seal head in the circumferential direction of the spray gun and positioned in the side wall of the injection segment; swirling pieces obliquely arranged on the outer wall from the top end of the lower reversed cone to the bottom end surface of the injection segment and positioned above the nozzles. By strengthening three key kinetic parameters of molten iron injection pretreatment, the spray gun significantly improves the kinetic conditions of molten iron injection pretreatment and achieves the comprehensive purposes of improving the sulfur removal efficiency of injection pretreatment and the utilization rate of desulfurizer reaction, shortening the injection time and increasing the production capacity of desulfurization equipment.

Owner:武汉钢铁有限公司

Method for preventing sulphur from flowing back into liquid steel tank after steel tapping

InactiveCN108950142AGuarantee product qualityPrevent resulfurizationMolten metal pouring equipmentsProcess efficiency improvementSlagLiquid steel

Owner:ANGANG STEEL CO LTD

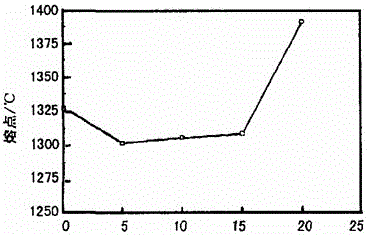

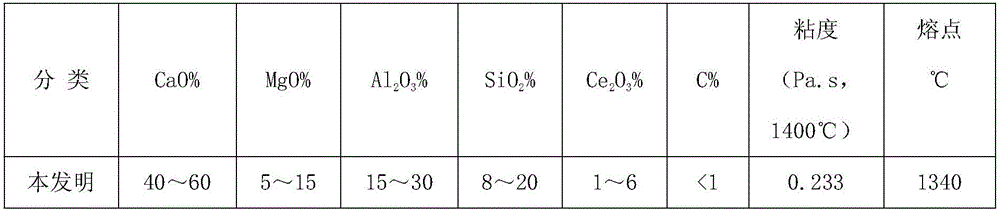

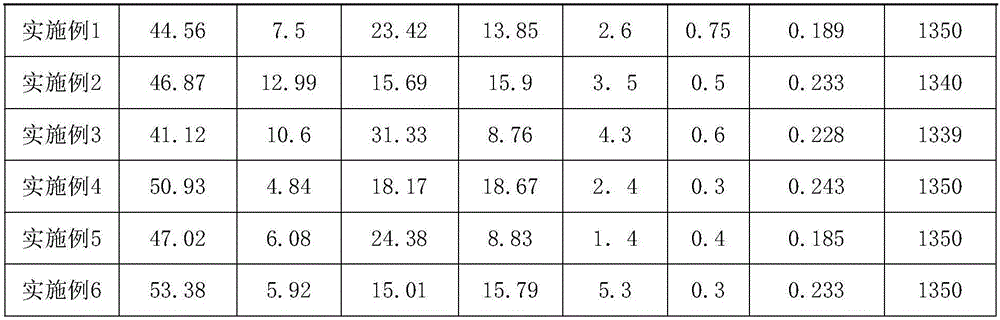

Tundish covering agent for ultra-low carbon steel

ActiveCN104226947BStrong ability to absorb inclusionsImprove insulation effectAlkalinityMolten steel

The invention relates to a tundish covering agent for ultra-low carbon steel, belonging to the technical field of steelmaking and continuous casting. The invention mainly solves the technical problem that the high-alkalinity tundish covering agent in the prior art has poor thermal insulation performance and is difficult to meet the continuous casting of ultra-low carbon molten steel. The technical solution adopted in the present invention is: a tundish covering agent for ultra-low carbon steel, the weight percentage of which is composed of: CaO 40-60%, MgO 5-15%, Al 2 o 3 15~30%, SiO 2 8~20%, Ce 2 o 3 1~6%, C<1%, and the rest are unavoidable impurities. The invention is mainly used for heat insulation and heat preservation of molten steel in a tundish when a slab caster casts ultra-low carbon molten steel, and for absorbing inclusions in molten steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Slag conglomeration agent for hot metal pretreatment of magnesium injection and deep desulphurization and use method thereof

The invention relates to a slag conglomeration agent applied to hot metal pretreatment magnesium injection deep desulphurization and an application method thereof, which pertain to the technical field of hot metal pretreatment in the steelmaking process. The slag conglomeration agent is sealed and packaged at 3kg to 7kg after magnesium injection or scattered on the slag surface evenly in the formof particulate. The addition amount is 0.5 kg / t to 1.0kg / t iron which contains the following components by the weight percentages: MgO: 32 percent to 40 percent, SiO2: 0.4 percent to 1.1 percent, S: 0.010 percent to 0.025 percent, water: 0 percent to 0.5 percent, and the rest is CaO and inevitable impurities. The weight percentages of various slagging constituents in the slag conglomeration agentare as follows: light-burned dolomite: 85 percent to 100 percent, and quick lime: 0 percent to 15 percent. The slag conglomeration agent has the advantages that: the slag conglomeration agent can be added immediately after magnesium injection to cause slag to form into blocks which are easy to remove, and resulfurization is prevented by adding acid slag conglomeration agent that is generally adopted.

Owner:SHOUGANG CORPORATION

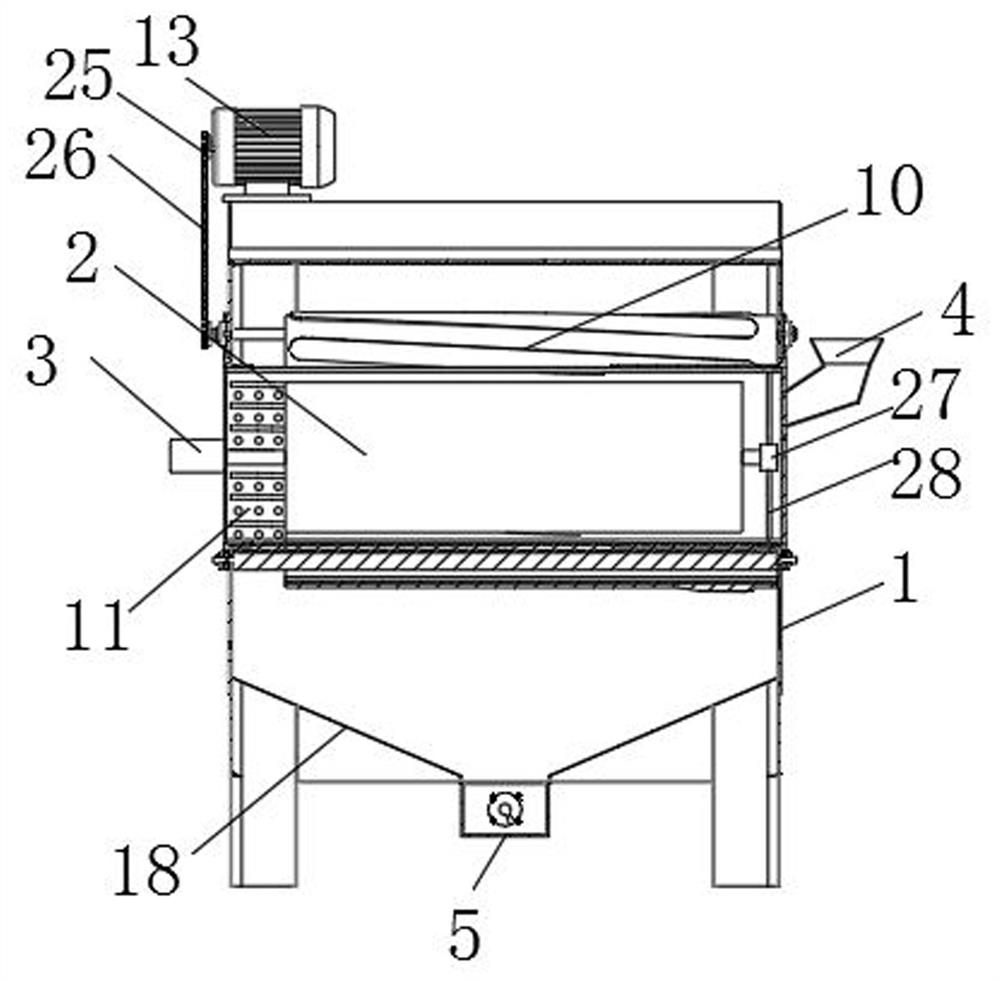

HG hot metal desulfurization device and desulfurization method thereof, and desulfurizer and slag remover

The invention discloses a HG hot metal desulfurization device and desulfurization method thereof, and a desulfurizer and a slag remover. A nozzle of the desulfurizer is formed in a support, the nozzle of the desulfurizer is fixed inside a sleeve, the sleeve is movably connected to the support in up and down direction, the lower part of the sleeve is rotationally connected with a stirred tube, one end of the nozzle of communicates with desulfurizer a stock bin of the desulfurizer, the other end of the nozzle of the desulfurizer communicates with the lower nozzle of the stirred tube, a nitrogen gas tube is in connection with the nozzle of the desulfurizer, the outlet direction of the nitrogen gas tube points to the lower nozzle of the stirred tube, a stirred tube is located at outside of the tube wall under the position of the lower part of the nozzle and fixed with a stirred rod , and the stirred tube is connected to a rotating motor fixed on the outside wall of the sleeve in a transmission mode. According to the structure of the HG hot metal desulfurization device, not only the dynamic property conditions of desulfurization is strengthened, but also a deep, complete, and full mixing of the desulfurizer with the hot mental can be made and desulfurization by reaction, thus utilization ratio of desulfurizer is improved, waste of desulfurizer is avoided, and in addition, nodulation of the stirring device is prevented.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Cast steel riser covering agent as well as preparation and using method thereof

The invention belongs to the field of metallurgy, and relates to a cast steel riser covering agent as well as a preparation and using method thereof. The cast steel riser covering agent comprises thefollowing components of, with the total mass units being 100 parts, 15-40 parts of aluminum electrolysis waste cathode carbon block, 10-35 parts of dolomite, 10-25 parts of vermiculite, and 20-40 parts of aluminum electrolysis waste silicon carbide-silicon nitride bricks. During preparing, firstly, crushing and grinding the dried raw materials, wherein the particle size is not more than 2 mm; weighing the raw materials according to the composition quality of the raw materials, uniformly stirring, and drying to obtain the cast steel riser covering agent. During using, a steel ladle is added into the cast steel riser covering agent to form a slag layer, so that the thickness of the slag layer is 6-8 cm, the liquid surface of the steel ladle does not leak red, and the slag layer is not crusted. By using the cast steel riser covering agent, the heat loss at the top of the riser can be solved, the solidification speed of molten steel in the riser can be prolonged, the feeding capacity of the molten steel in the riser is improved, the process yield of the casting is guaranteed, the height of the riser is reduced, the molten steel is saved, and finally the cost is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Desulfurizing agent for pipeline steel smelting

InactiveCN103789504APlay the role of desulfurizationPlay the role of flame retardantOxalateOXALIC ACID DIHYDRATE

The invention discloses a desulfurizing agent for pipeline steel smelting. The desulfurizing agent is composed of the following components in parts by weight: 70-80 parts of rare earth and passivated magnesium composite material, 10-12 parts of calcium fluoride, 5-8 parts of barium carbonate and 15-18 parts of attapulgite, wherein the rare earth and passivated magnesium composite material comprises 60-70 parts of Mg, 3-5 parts of CeO and 15-25 parts of MgO. The preparation method of the rare earth and passivated magnesium composite material comprises the steps of firstly, carrying out dry mixing on Mg, CeO and MgO to prepare a mixed material; then, heating the mixed material, and controlling the temperature at 60-70 DEG C; next, mixing oxalic acid, magnesium chloride and water to prepare a passivation solution; then, pouring the passivation solution into the mixed material, stirring until the material is dry, and naturally cooling to prepare the rare earth and passivated magnesium composite material, wherein the weight ratio of the passivant, namely oxalic acid to magnesium chloride is 1: (3-4), the concentration of the passivation solution is 40-50g / L, and the weight ratio of the passivation solution to the mixed material subjected to dry mixing is 1: (20-25).

Owner:WUXI CHENGBO SCI & TECH DEV

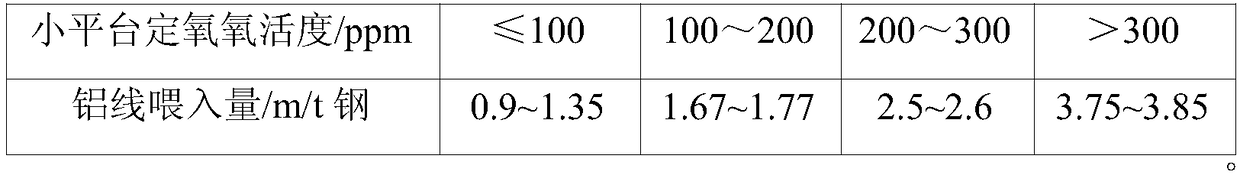

Semi-steel steelmaking converter post-furnace desulfurization method

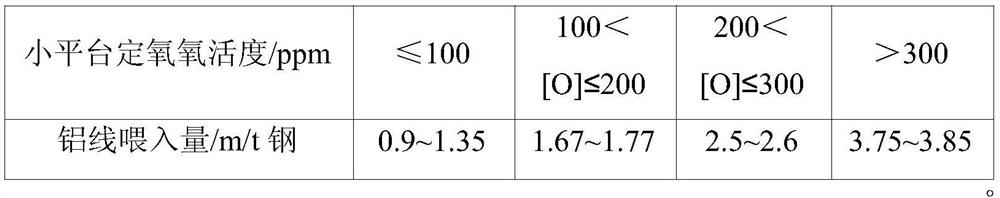

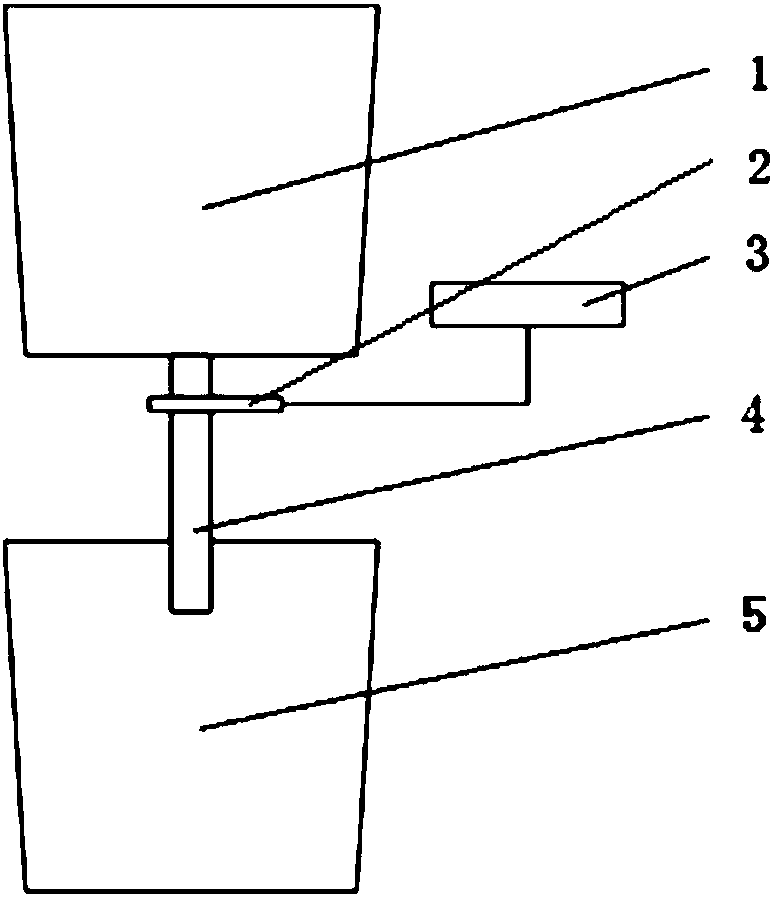

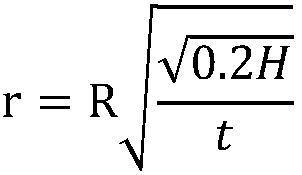

The invention discloses a semi-steel steelmaking converter post-furnace desulfurization method and belongs to the technical field of metallurgy. Aiming at the technical problem of resulfurization caused by high oxygen activity in present converter steelmaking, the invention provides the semi-steel steelmaking converter post-furnace desulfurization method which comprises the steps that calcium carbide is added to a steel ladle in the converter steel output process, argon is blown to the steel ladle in the whole process, then oxygen fixation is performed on a little platform, and aluminum wiresare fed in after oxygen fixation, so that converter post-furnace desulfurization is realized. By means of the semi-steel steelmaking converter post-furnace desulfurization method, post-furnace resulfurization can be avoided, post-furnace desulfurization can be further realized, the desulfurization rate reaches 40% or above, and control of the sulfur content in molten steel is facilitated.

Owner:SICHUAN PAN YAN TECH

RH refining desulphurization process of non-oriented electrical steel

The invention discloses an RH refining desulphurization process of non-oriented electrical steel, belonging to the technical field of steel making. The process comprises the following steps: setting the lift gas flowrate to 1200 NL / min after the entering of the RH, and enhancing the lift gas flowrate to 1600 NL / min 3 minutes later; blowing oxygen to perform the forced decarburization when the vacuum degree is reduced to 2.0 mba, and when the oxygen blowing is finished and the vacuum degree is lower than 2.0 mba, performing the natural decarburization for 20 minutes; adding the aluminum for deoxidation when the vacuum decarburization is finished; and performing the silicon alloying by using the low carbon ferrosilicon, and adding the desulfurizing agent into the vacuum chamber in two timesthrough the RH alloy bin. The circulation time of the test furnace batch is from 10 minutes to 15 minutes. The process provided by the invention has the advantages that the RH device needs no reconstruction, and the operation is simple. The average RH desulphurization degree is 36.7%, and the desulphurization effect is better. The contents of the FeO and the MnO of the ladle slag have significantinfluence on the desulphurization effect, and the enhancing of the alkalinity of the ladle slag can increase the RH desulphurization efficiency as well as reduce the corrosion of the RH device.

Owner:KUNMING UNIV OF SCI & TECH

Calcium oxide-based desulfurizer for steelmaking and preparation method thereof

ActiveCN112080610BImprove performanceImprove desulfurization effectRotary stirring mixersTransportation and packagingSteelmakingSilicone grease

Owner:浙江振鑫新材料科技有限公司

Low-carbon ultralow-sulfur pure iron smelting method

PendingCN114350879APrevent resulfurizationSmelting to achieveManufacturing convertersProcess efficiency improvementSlagDecarburization

The invention relates to a low-carbon ultralow-sulfur pure iron smelting method. The process route comprises the steps of molten iron pretreatment, converter double-slag smelting, RH decarburization, LF dephosphorization, molten steel slagging-off, LF desulfurization and continuous casting. The method specifically comprises the following steps: 1) molten iron pretreatment desulfurization: the S content of molten iron before pretreatment is less than or equal to 0.040%; s is required to be less than or equal to 0.002% after molten iron pretreatment desulfurization; (2) converter double-slag smelting is carried out to control resulfurization, specifically, special pure iron waste steel is added into a converter, oxygen blowing is started, a slagging material is added after oxygen blowing is carried out for 40-50 s, oxygen blowing is carried out for 4-5 min, the oxygen accumulation amount of oxygen blowing is 3500-4500 standard cubic meters, and a gun is lifted to discharge slag; 3) LF desulfurization: after molten steel slagging-off is finished and argon blowing is confirmed to be normal, carrying out oxygen determination operation; the top slag is strongly modified and desulfurized, and it is guaranteed that the outbound S is controlled to be 10 ppm or below; atomized aluminum powder is used in the middle and later periods of LF desulfurization, so that it is guaranteed that outbound Alt is not higher than 0.010%; and 4) controlling the resulfurization by a casting machine. According to the invention, after RH decarburization, LF desulfurization is carried out, and then the desulfurization is directly carried out on a machine, so that the resulfurization in the RH treatment process is avoided, and the ultralow sulfur control that the sulfur content of a finished product is less than or equal to 0.001% is ensured.

Owner:ANGANG STEEL CO LTD

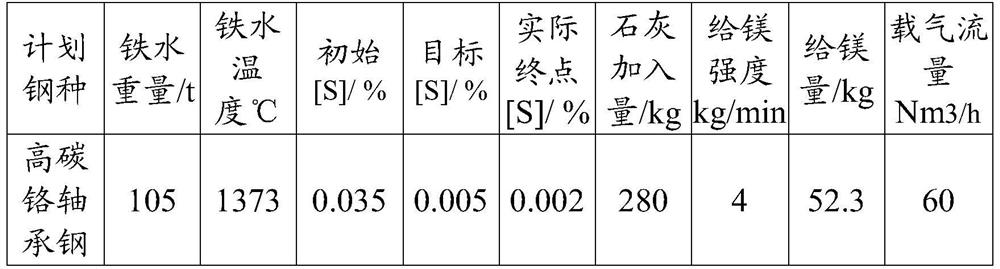

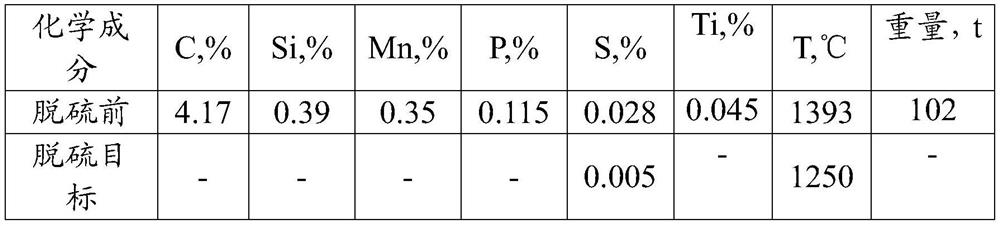

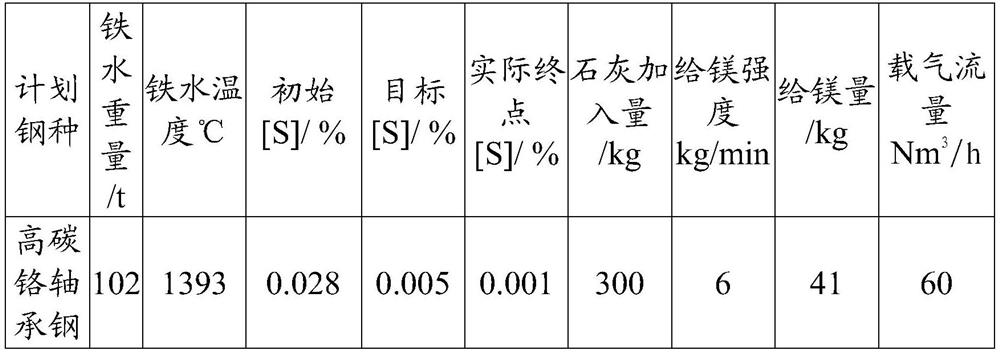

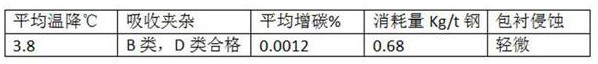

Method for improving desulfurization effect of single-blown granular magnesium

The invention provides a method for improving the desulfurization effect of single-blown granular magnesium. The method includes the specific process that molten iron is fed into a station, slagging off is performed before desulfurization, lime is added to the surface of the molten iron, granular magnesium is blown, and slagging off is performed after desulfurization. According to the method, thelime is added to an iron ladle before granular magnesium is blown, CaO in the lime is promoted to be subjected to molten iron desulfurization under the stirring effect generated by granular magnesiumgasification pressure which is not balanced under the static pressure of the molten iron in the single-blown granular magnesium desulfurization process, the S content in the desulfurized molten iron is higher than 0.002%, and the desulfurization effect is improved.

Owner:QINGDAO SPECIAL STEEL CO LTD

Converter furnace steel-making desulfurizing agent and preparation method thereof

The invention discloses a converter furnace steel-making desulfurizing agent and a preparation method thereof. The converter furnace steel-making desulfurizing agent is mainly obtained by evenly mixing the following composition raw materials in parts by weight: calcium oxide, calcium fluoride, barium carbonate, silica, carborundum, attapulgite, boron anhydrous and flame retardant silicone grease.The preparation method is used for the converter furnace steel-making desulfurizing agent which is the desulfurizing agent free from aluminum and can be used for improving the physical, mechanical and technical performances of steel. According to the converter furnace steel-making desulfurizing agent, gas is removed, nonmetal inclusions are changed, and the quality and mechanical performance of furnace steel making can be improved.

Owner:芜湖县天海耐火炉料有限公司

A double-layer tundish covering agent for ultra-thin tape

ActiveCN109454210BReduce the speed of heat transfer to the outsideHeap specific gravitySpray GranulationBi layer

The invention discloses a double-layer tundish covering agent for an ultrathin belt, and relates to the technical field of metallurgy. The upper covering agent and the lower covering agent are hollowgranular products which are subjected to spray granulation. The upper covering agent comprises the following chemical components of, in percentage by weight, 45%-55 wt% of CaO, 18.0-24.0 wt% of SiO2,14.0-18.0 wt% of MgO, less than or equal to 1.9 wt% of Al2O3, 7.5-11.5 wt% of C-solid and the balance inevitable impurities, and the melting point of the upper covering agent is greater than 1450 DEGC. The lower covering agent comprises the following chemical components of, in percentage by weight, 25.0-31.0 wt% of CaO, 27.0-37.0 wt% of SiO2, 13.0-18.0 wt% of MgO, less than or equal to 1.9 wt% ofAl2O3, 13.0-17.0 wt% of (Li2O + Na2O), less than or equal to 0.5 wt% of C-solid and the inevitable balance impurities, and the melting point of the lower covering agent is 1150-1250 DEG C. The product has the advantages that the specific gravity is light, the upper layer is carbon-containing and the lower layer is extremely few in carbon-containing, carbon-increasing is prevented and heat preservation is achieved, the content of Al2O3 in the upper layer and the lower layer is low, the impurities are fully absorbed, the melting point of the upper layer is high, the insulation of the air is isolated, the melting point of the lower layer is low, and rapid melting can be achieved so as to prevent the carbon-containing upper layer from being in contact with the molten steel to increase the carbon.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

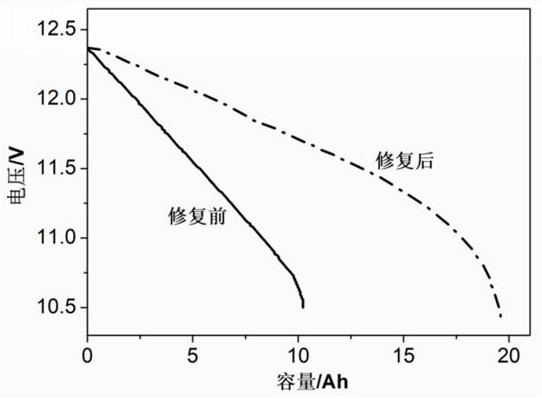

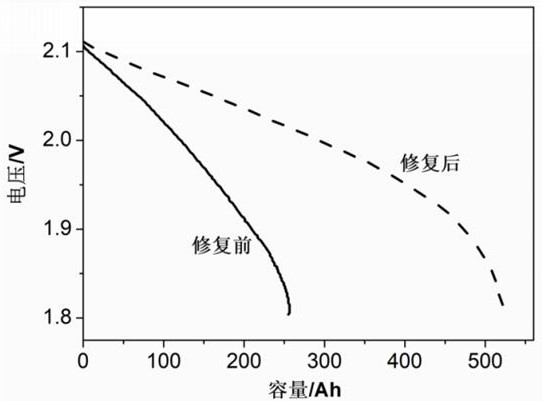

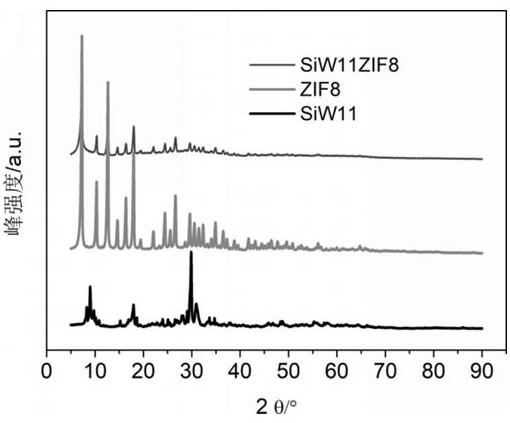

Preparation method and application of an activated compatibilizer for repairing failed lead-acid batteries

ActiveCN112054253BShorten repair timeAdd lessLead-acid accumulatorsElectrolyte/reactants regenerationAluminium sulfateSulfate zinc

The invention provides a preparation method of an activated compatibilizer for repairing a failed lead-acid storage battery. The composition of the activated compatibilizer includes: a nanometer activator SiW 11 @ZIF‑8, PEG2000, Ammonium Acetate, Zinc Sulfate, Magnesium Sulfate, Sodium Sulfate, Aluminum Sulfate, Potassium Sulfate, Ammonium Sulfate, Sorbitol, Tetramethylammonium Chloride. Using the activated solubilizing agent of the invention to repair the lead-acid storage battery that has failed due to the vulcanization of the negative electrode plate has high capacity repair degree, short repair time, low cost and long discharge time after repair.

Owner:UNIV OF JINAN

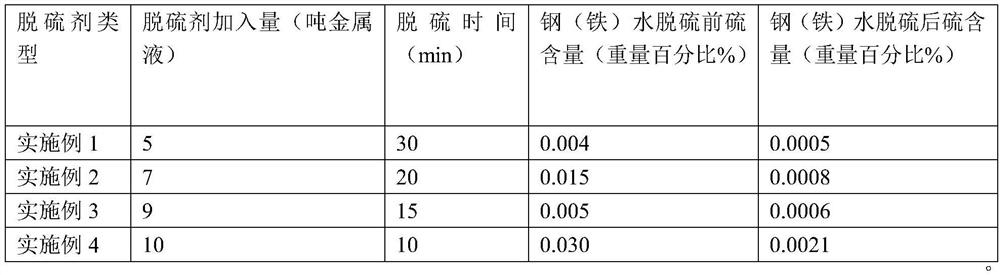

Efficient desulfurizer and preparation and use methods thereof

ActiveCN112981044AStrong desulfurization abilityImprove desulfurization effectPhysical chemistryMaterials science

The invention discloses an efficient desulfurizer and preparation and use methods thereof. The desulfurizer is prepared from the following raw materials in percentage by weight: 20-30% of Mg3N2, 40-55% of CaO, 1-4% of a binder and the balance iron. Aiming at the defects of the existing magnesium-based desulfurizer, the invention provides the efficient desulfurizer which is prepared from magnesium nitride as a raw material and a reaction promoter, so that the problem of low utilization rate of pure magnesium is solved, and the desulfurization efficiency is remarkably improved. Therefore, the desulfurizer has the advantages of convenience in use, high utilization rate, high desulfurization efficiency and the like.

Owner:ANGANG STEEL CO LTD

Post-furnace desulfurization method of semi-steel steelmaking converter

The invention discloses a semi-steel steelmaking converter post-furnace desulfurization method and belongs to the technical field of metallurgy. Aiming at the technical problem of resulfurization caused by high oxygen activity in present converter steelmaking, the invention provides the semi-steel steelmaking converter post-furnace desulfurization method which comprises the steps that calcium carbide is added to a steel ladle in the converter steel output process, argon is blown to the steel ladle in the whole process, then oxygen fixation is performed on a little platform, and aluminum wiresare fed in after oxygen fixation, so that converter post-furnace desulfurization is realized. By means of the semi-steel steelmaking converter post-furnace desulfurization method, post-furnace resulfurization can be avoided, post-furnace desulfurization can be further realized, the desulfurization rate reaches 40% or above, and control of the sulfur content in molten steel is facilitated.

Owner:SICHUAN PAN YAN TECH

Sulfur fixing agent without slag accretion agent for magnesium spraying and deep desulphurizing for molten iron , and desulphurization process thereof

Disclosed is a slag conglomeration agent-free sulfur-fixing agent for magnesium-spraying deep desulfurization in the hot metal pretreatment as well as a desulfurization process thereof, belonging to the technique field of hot metal pretreatment in the steelmaking process. The materials of the sulfur-fixing agent include quicklime, light-burned dolomite and fluorite; and are present in weight percentage: quicklime: 57 to 80 percent, light-burned dolomite: 15 to 35 percent, and fluorite: 0 to 8 percent; and chemical constituents of the sulfur-fixing agent comprise, in weight percentage: CaO: 55to 80 percent, MgO: 5 to 25 percent, SiO2: 0 to 9 percent, CaF2: 0 to 8 percent, Al2O3: 0 to 3 percent, MnO: 0 to 2 percent, K2O: <0.30 percent, Na2O: <0.01 percent, S: <0.025 percent, and P2O5: <0.1percent. The materials are added before hot metal charging or in the hot metal charging process of the hot metal pretreatment. Slag of the sulfur-fixing agent added with molten iron for magnesium-spraying pretreatment has strong capacities of sulfur adsorption and fixation, and has rather high viscosity and melting point, is easy in accumulation and agglomeration, the direct slag skimming can be implemented without adding slag conglomeration agent, meanwhile, the resulfurization caused by adding generally adopted acid slag conglomeration agent can be prevented.

Owner:SHOUGANG CORPORATION

A method for removing slag from molten iron

ActiveCN106914610BStable automation controlGuaranteed separation effectCasting cleaning apparatusAutomatic controlSlag

The invention discloses a molten iron slag-removal method, and belongs to the field of molten iron desulfurization pretreatment. The molten iron slag-removal method comprises the following steps of: hoisting a roasted hot metal ladle with a slide plate mechanism to a molten iron carrying position through an overhead crane with a weighing device, recording weight of an empty idle, carrying molten iron, and performing temperature measuring and sampling after tapping is completed; then, performing desulfuration according to a normal procedure, and performing temperature measuring and sampling after desulfuration is completed; hoisting the hot metal ladle subjected to desulfuration, and recording weight of the full ladle, thereby obtaining total weight of the molten iron and iron slag; moving a long nozzle to a position above a common hot metal ladle, opening a slide plate, naturally injecting the molten iron into the common hot metal ladle from the long nozzle to perform ladle pouring operation, displaying through a scale of the overhead crane, respectively closing the slide plate once when residual molten iron is 10 ton and 5 ton, and starting a slag-unloading monitoring and control system when the molten iron is reduced to be 10 ton. The molten iron slag-removal method has the advantages of being simple, stable and controllable, getting rid of limitation that technical level of people is depended, and realizing automatic control on stable control. The molten iron slag-removal method guarantees an iron slag separation effect, can realize 100% slag-free control, and prevents reflux to the greatest extent.

Owner:SHOUGANG CORPORATION

High-performance lances for hot metal injection pretreatment

The invention discloses a high-performance spray gun for molten iron injection pretreatment. The high-performance spray gun comprises a connection segment, a gun body segment and an injection segment, which are sequentially communicated, wherein a swirling diffuser is arranged between the gun body segment and the injection segment and comprises an upper cone, a cylinder and a lower reversed cone, which are sequentially communicated; 2-4 nozzles are uniformly formed between a main pipe of the spray gun and a seal head in the circumferential direction of the spray gun and positioned in the side wall of the injection segment; swirling pieces obliquely arranged on the outer wall from the top end of the lower reversed cone to the bottom end surface of the injection segment and positioned above the nozzles. By strengthening three key kinetic parameters of molten iron injection pretreatment, the spray gun significantly improves the kinetic conditions of molten iron injection pretreatment and achieves the comprehensive purposes of improving the sulfur removal efficiency of injection pretreatment and the utilization rate of desulfurizer reaction, shortening the injection time and increasing the production capacity of desulfurization equipment.

Owner:武汉钢铁有限公司

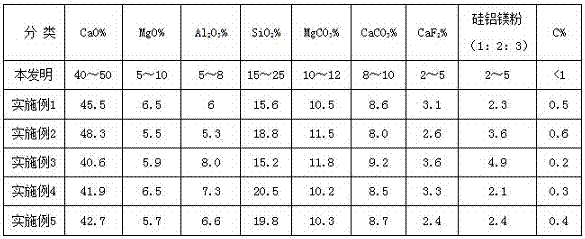

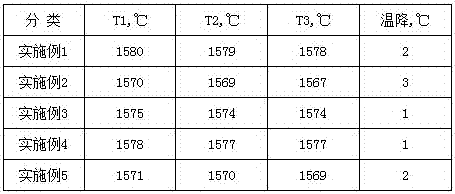

Tundish covering agent for non-oriented silicon steel

ActiveCN105312523BImprove adsorption capacityImprove insulation effectChemical compositionThermal insulation

The invention relates to a tundish covering agent for non-oriented silicon steel, which mainly solves the technical problems that the existing tundish covering agent has high content of impurity elements and poor thermal insulation performance, and is difficult to meet the continuous casting of non-oriented silicon steel. The technical scheme adopted in the present invention is: a tundish covering agent for non-oriented silicon steel, the weight percent of its chemical composition is CaO 40-50%, SiO2 15-25%, Al2O3 5-8%, MgO 5-10%, MgCO3 10~12%, CaCO3 8~10%, CaF2 2~5%, C <1%, Ti<0.06%, P <0.01%, S <0.01%, silicon aluminum magnesium powder 2~5%, silicon aluminum magnesium The mass ratio of silicon, aluminum and magnesium in the powder is 1:2:3, and the rest are unavoidable impurities. The covering agent of the invention has good thermal insulation performance, can effectively absorb inclusions, prevent molten steel from increasing carbon, and is mainly used in the production of non-oriented silicon steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A kind of casting steel riser covering agent and its preparation and use

The invention belongs to the field of metallurgy, and relates to a cast steel riser covering agent and its preparation and use method. The cast steel riser covering agent includes 15 to 40 parts of aluminum electrolysis waste cathode carbon blocks in 100 parts by mass, 10-35 parts of dolomite, 10-25 parts of vermiculite, 20-40 parts of waste silicon carbide-silicon nitride bricks for aluminum electrolysis; during preparation, the dried raw materials are first crushed and ground, and the particle size is not greater than 2mm; Then weigh each raw material according to the composition quality of the raw materials, then stir evenly, and dry to obtain the casting steel riser covering agent. When in use, the cast steel riser covering agent is added to the ladle to form a slag layer, and finally the thickness of the slag layer is 6-8 cm, the liquid surface of the ladle does not leak red, and the slag layer does not crust. By using the casting steel riser covering agent of the present invention, the heat loss at the top of the riser can be solved, and the solidification speed of the molten steel in the riser can be extended, thereby improving the feeding capacity of the molten steel in the riser, ensuring the process yield of castings, and reducing the risk of leakage. The height of the mouth can save molten steel and ultimately reduce the cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com