Calcium oxide-based desulfurizer for steelmaking and preparation method thereof

A calcium oxide and desulfurization agent technology, applied in chemical instruments and methods, chemical/physical processes, mixers with rotating stirring devices, etc., can solve the problems of lower production costs, unstable performance, poor desulfurization effect, etc., and achieve reduction Production cost, good grinding effect, and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

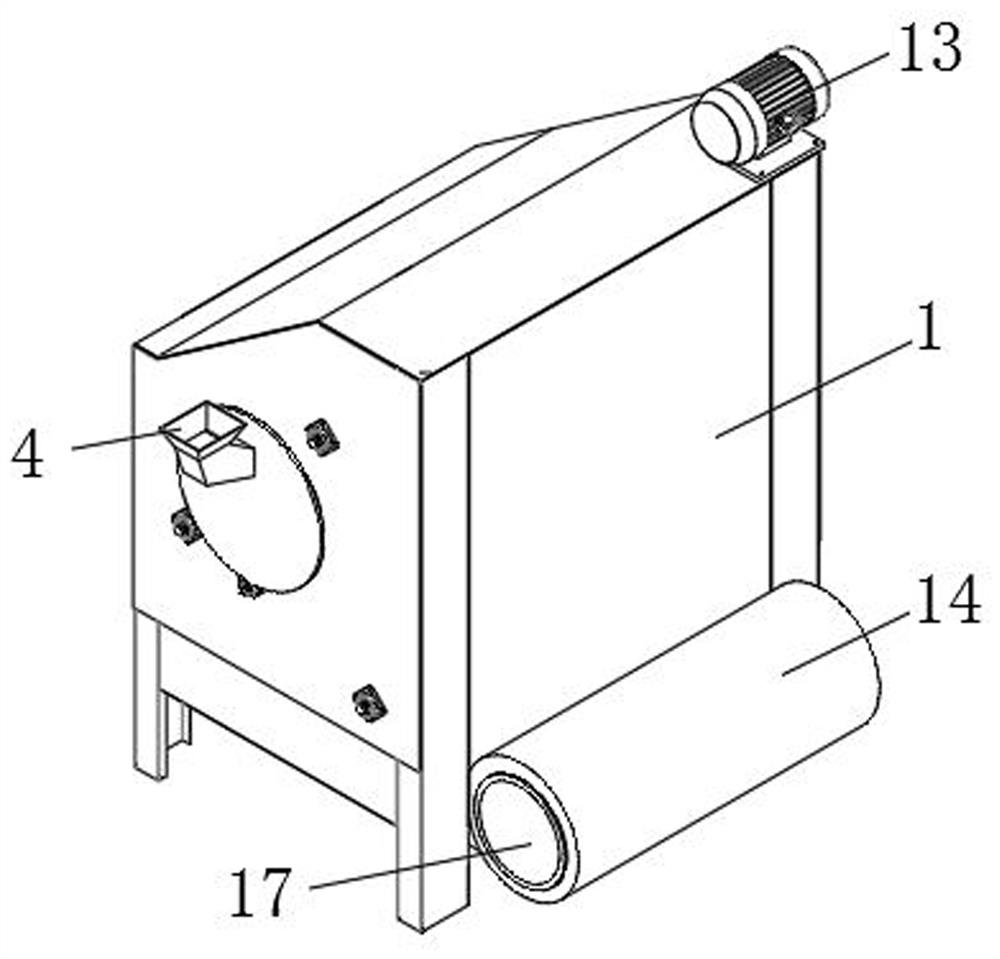

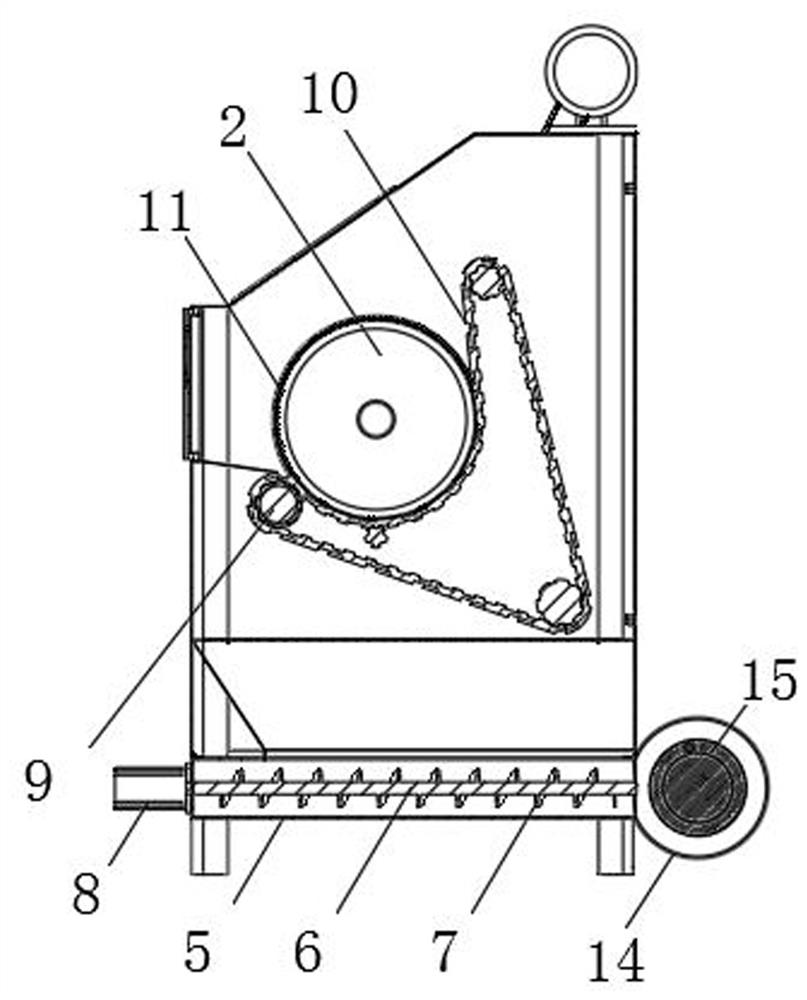

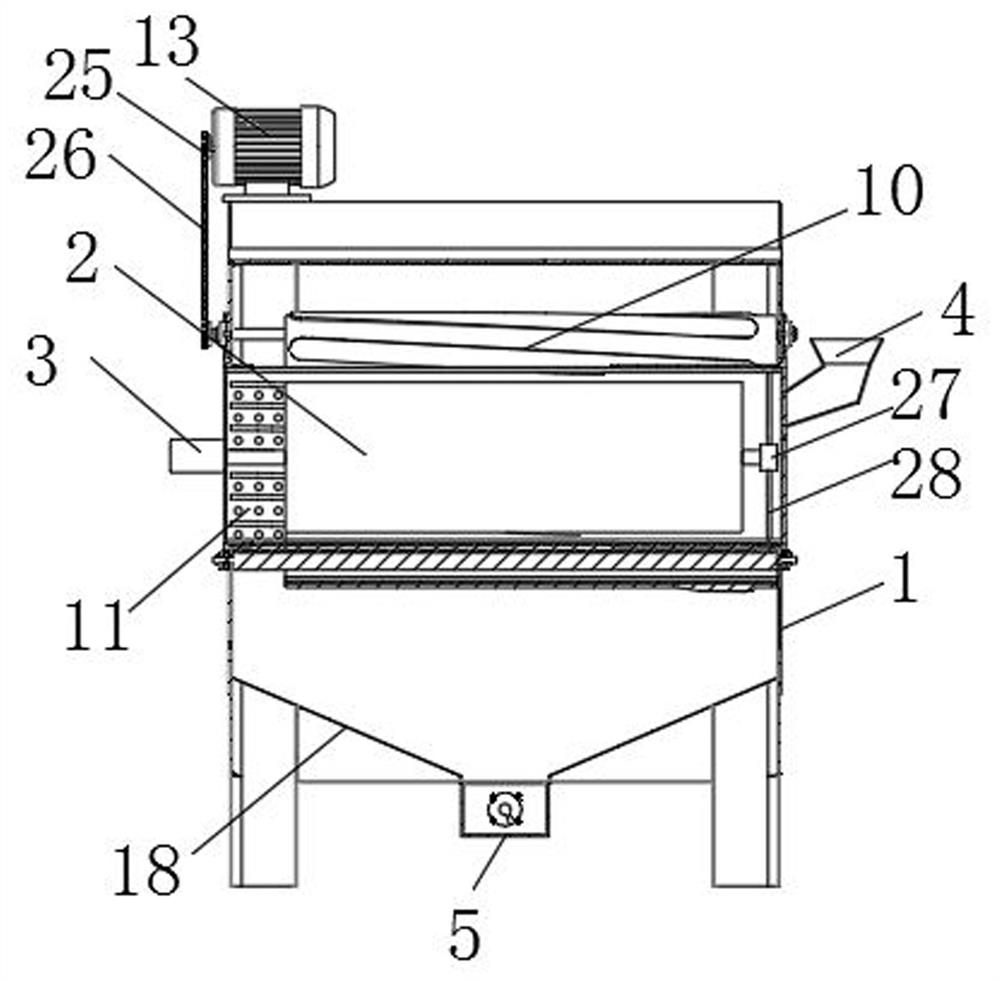

[0037] Such as Figure 1-6 Shown, a kind of calcium oxide-based desulfurizer for steelmaking, the desulfurizer is prepared by the raw materials of the following parts by weight:

[0038] Calcium oxide 30 parts, aluminum ash 15 parts, iron slag 14 parts, calcium difluoride 8 parts, barium carbonate 6 parts, attapulgite 5 parts, boric anhydride 4 parts, flame retardant silicone grease 3 parts.

[0039] A method for preparing a desulfurizer for steelmaking based on calcium oxide, the method specifically includes the following steps:

[0040] Step 1. Add calcium oxide, calcium difluoride, barium carbonate, attapulgite, boric anhydride and flame-retardant silicone grease into the mixer, and stir at a speed of 400r / min for 15 minutes to obtain a mixture 1;

[0041] Step 2. Soak the aluminum ash in hot water above 85°C for 0.5 days, rinse with clean water, and let it dry for later use;

[0042] Step 3, adding iron slag to a sodium hydroxide solution with a mass concentration of not...

Embodiment 2

[0046] Such as Figure 1-6 Shown, a kind of calcium oxide-based desulfurizer for steelmaking, the desulfurizer is prepared by the raw materials of the following parts by weight:

[0047] 35 parts of calcium oxide, 20 parts of aluminum ash, 18 parts of iron slag, 9 parts of calcium difluoride, 8 parts of barium carbonate, 7 parts of attapulgite, 6 parts of boric anhydride, and 7 parts of flame-retardant silicone grease.

[0048] A method for preparing a desulfurizer for steelmaking based on calcium oxide, the method specifically includes the following steps:

[0049] Step 1. Add calcium oxide, calcium difluoride, barium carbonate, attapulgite, boric anhydride and flame-retardant silicone grease into the mixer, and stir at a speed of 600r / min for 20 minutes to obtain Mixture 1;

[0050] Step 2. Soak the aluminum ash in hot water above 85°C for 1.5 days, rinse with clean water, and dry it for later use;

[0051] Step 3, adding iron slag to a sodium hydroxide solution with a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com