Patents

Literature

31results about How to "Fast desulfurization reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Limestone-plaster wet method flue gas desulfurization composite synergistic agent

The invention relates to a limestone-plaster wet method flue gas desulfurization composite synergistic agent, which comprises the following ingredients in percentage by mass: 40 percent to 50 percent of organic acid synergistic agents, 25 percent to 35 percent of organic salt synergistic agents, 15 percent to 20 percent of efficient activating agents, 5 to 10 percent of oxidation catalysts and 1 percent of tracers. The half dissolving time of limestone is shortened by more than 40 percent, and the dissolving speed of the limestone is greatly accelerated, so the activity of the limestone is greatly improved. Under the work condition of the designed surfur content, the circulation intensity of serous fluid can be reduced by one third to one half, the liquid-gas ratio of a system is reduced, the system resistance is reduced, the energy consumption of a desulphurization system is obviously reduced, the utilization rate of limestone and oxidation air is improved, and the scale formation and blockage effects on back-stage equipment are reduced. Under the condition that the coal-fired sulfur exceeds the design value, the utilization rate of the oxidation air can be improved by 50 percent to 60 percent, on the basis without transforming the original oxidative system, the oxidation effect that when the fired-coal surfur content exceeds 20 to 30 percent can be met, and the requirements of the desulfurization efficiency and the clean flue gas SO2 discharge concentration are met.

Owner:XIAN THERMAL POWER RES INST CO LTD

Novel knotted reactor (KR) desulfurization stirring method

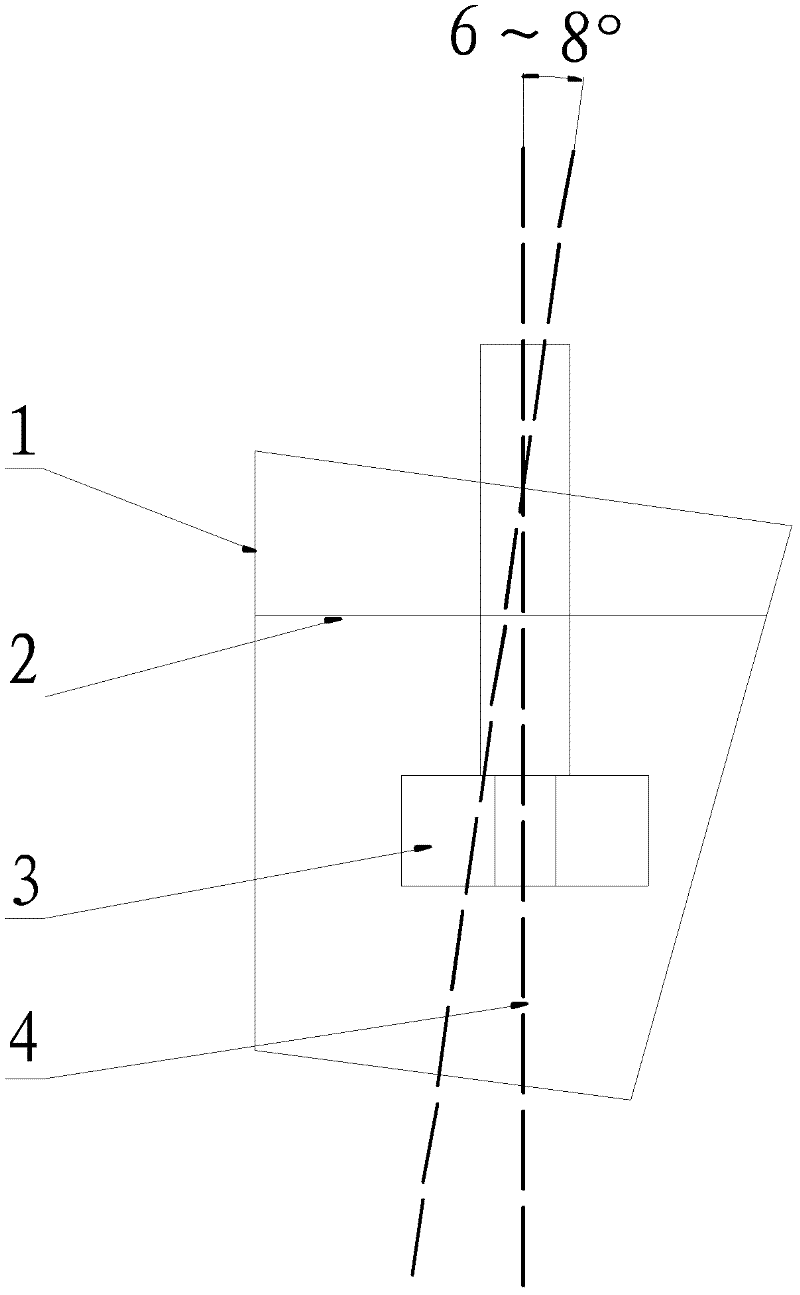

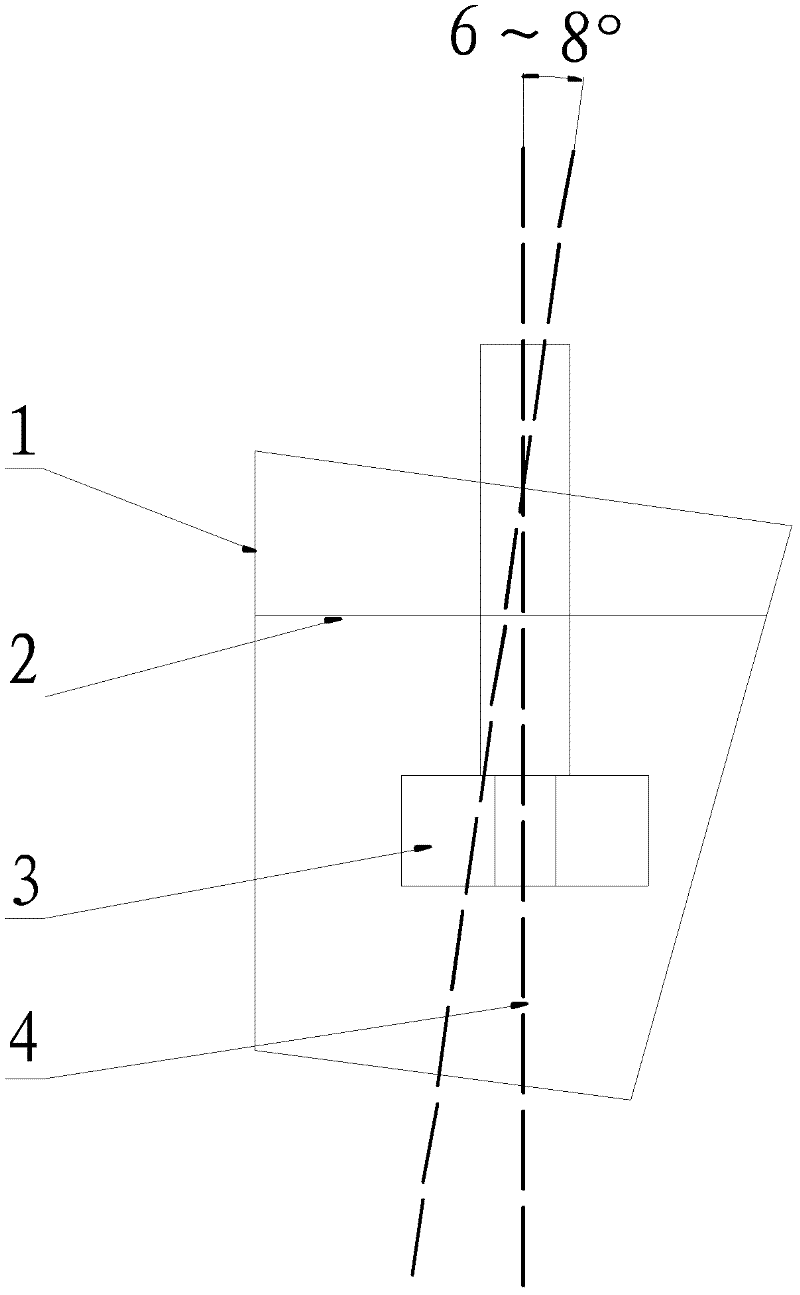

The invention relates to a desulfurization method outside a molten iron furnace in front of a converter, in particular to a molten iron mechanical stirring desulfurization method of molten iron desulfurization pretreatment in a molten iron tank. According to the method, stirring blades of a stirrer arranged above the molten iron tank are soaked into the molten iron for a certain depth, and through the rotary stirring of the stirrer, desulfurization agents on the molten iron surface are involved into the molten iron for mixed desulfurization. The method is characterized in that the molten iron tank deviates from the vertical position for 6 to 8 degrees. Compared with an ordinary KR method, the method has the advantages that the contact region between the desulfurization agents and the molten iron is expanded, the desulfurization reaction speed is accelerated, the utilization rate of the desulfurization agents is improved, and the production cost is effectively reduced.

Owner:LAIWU IRON & STEEL GRP

Efficient composite desulfurizer

The invention discloses a high-efficiency compound desulfurizing agent, relating to the ladle desulphurization accessory field. In the existing ladle desulphurization, the uniserial desulfurizing agent is uniformly adopted, with narrower function, and non-agreeable desulphurization effect. Aiming at the condition that small and medium-sized steel mills do not have liquid iron pretreatment systems or desulphurization stations, and do not have powder spraying desulphurization devices, the desulfurizing agent of the invention adopts ingredient with multi-components, namely, the compound desulfurizing agent consisting of limestone, calcined soda, fluorite, calcium carbide, magnesium powder and caustic-calcined magnesite, with the weight proportion of 40 to 50, 10 to 20, 5 to 15, 10 to 20, 4 to 6 and 5 to 15 sequentially. The desulfurizing agent has the following advantages that: 1. the integral desulphurization capability is strong, and the sulfur content can be reduced to 20ppm; 2. sulfur substance can be contained, and resulfurization phenomenon can not be generated; 3. the desulfurizing agent can be directly poured, and equipment and investment are not needed to be increased; and 4. the desulphurization speed is high.

Owner:西峡县福盈冶金材料有限公司

Preparation of composite reclaiming agent and uses thereof

InactiveCN101249374AHighly water soluble baseSave resourcesDispersed particle separationLiquid wasteSulfur

The invention discloses a method for preparing composite desulfurizer and the application thereof. According to the method, various kinds of alkali waste liquid and waste solid are mixed and processed, or various kinds of alkali waste liquid and waste solid are mixed with limestone / slaked lime to get the desulfurizer. Based on substituting the composite desulfurizer from waste solid and waste liquid for limestone flour and quicklime fully or partially, the invention makes use of alkaline waste resources to reduce pollution, save limestone resource and reduce the cost of desulphurization; in addition, the composite desulfurizer reacts more quickly than limestone or quicklime does in desulphurization reaction with high efficiency as the composite desulfurizer is treated with alkaline liquor and is provided with alkali which is highly soluble in water. The desulphurization product is fertilizer with microelements such as calcium, magnesium, zinc, iron, boron, silicon, sulfur and so on, and can be widely applied on farms. The invention makes use of alkaline waste for preparing the composite desulfurizer with the byproduct of trace fertilizer, and becomes an important technical way in energy industry developmental cycle economy.

Owner:廖宗文 +1

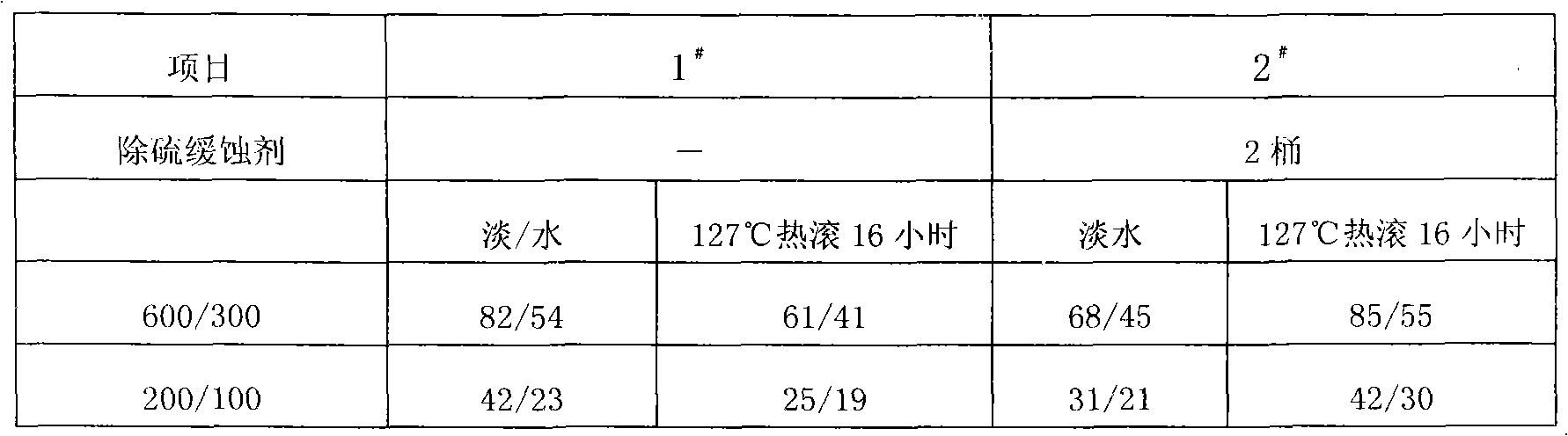

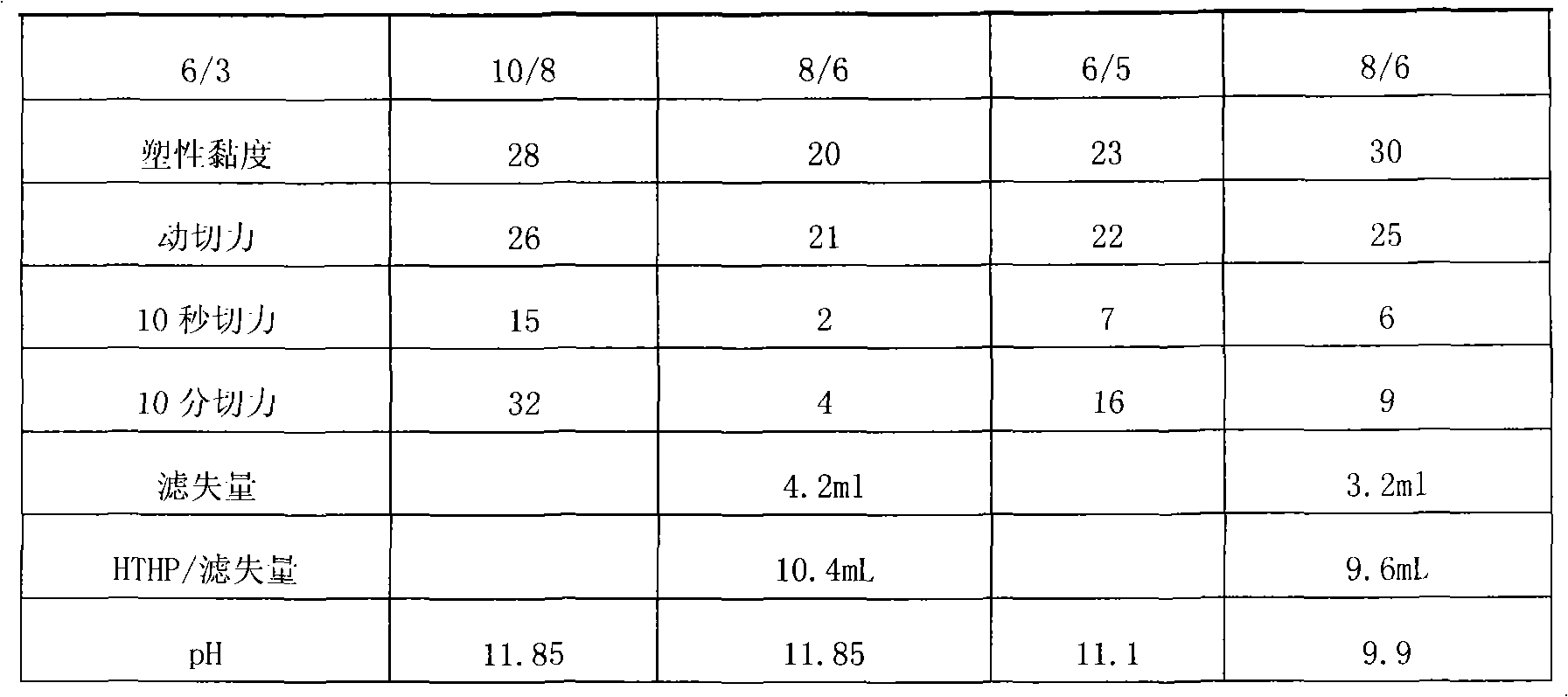

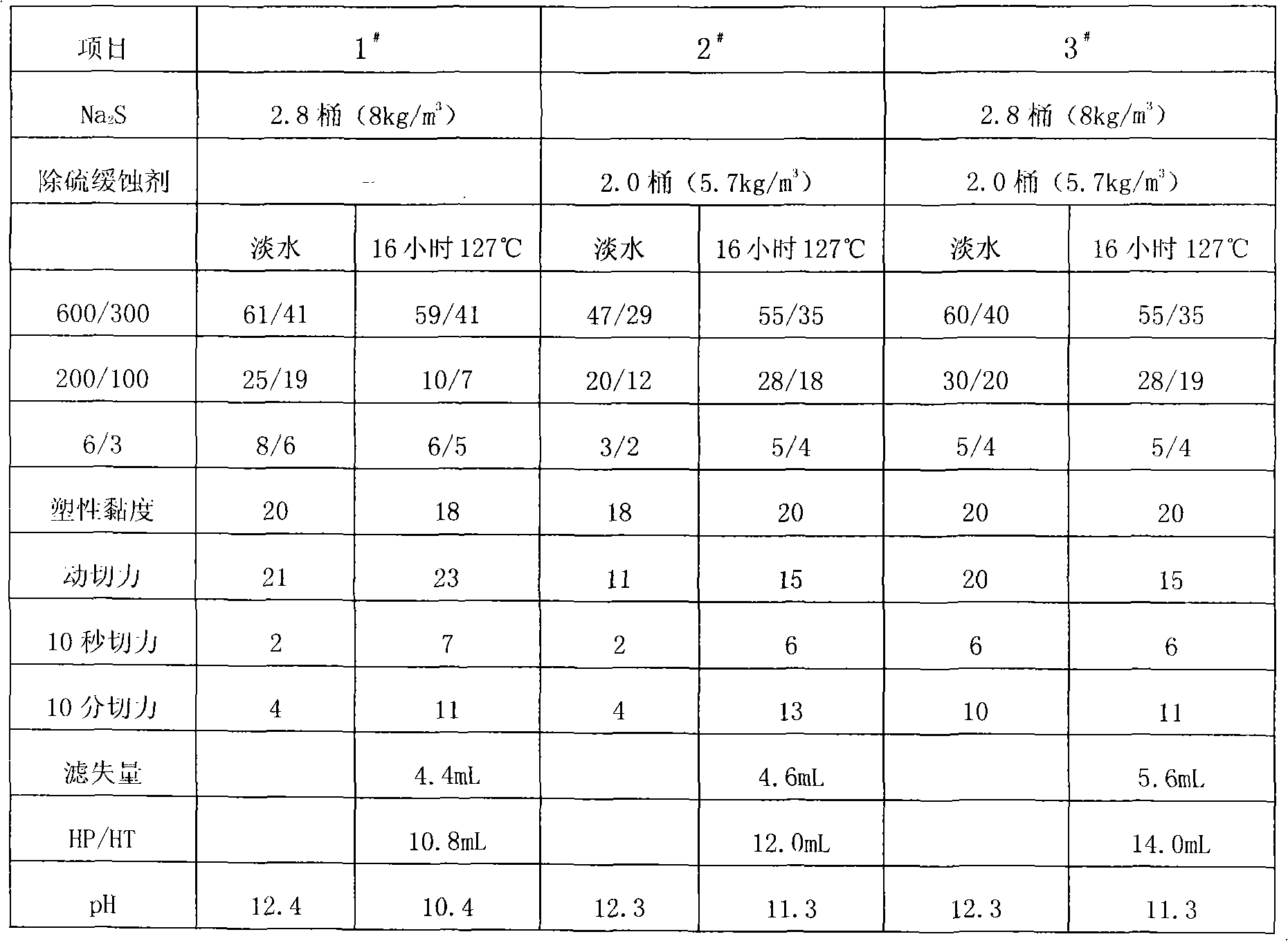

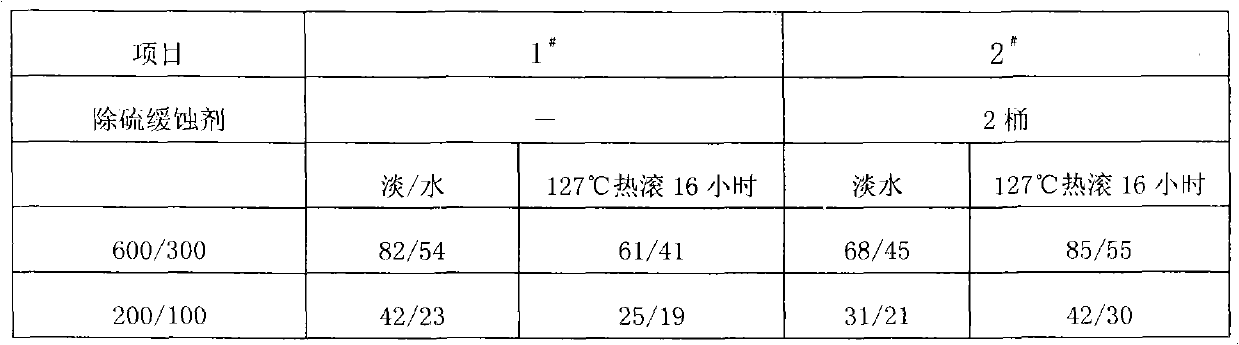

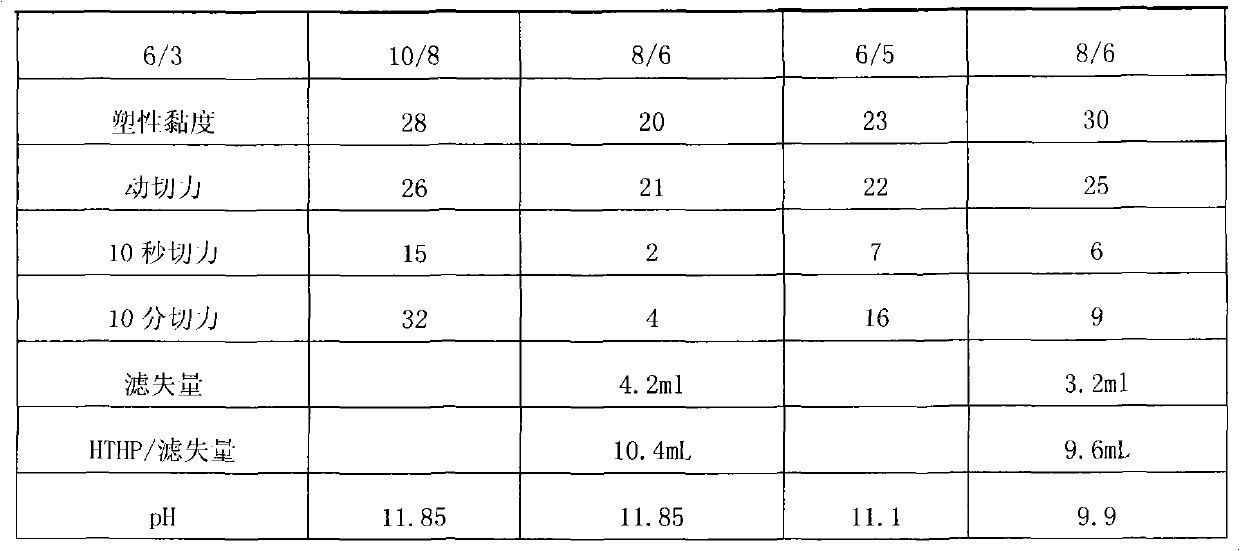

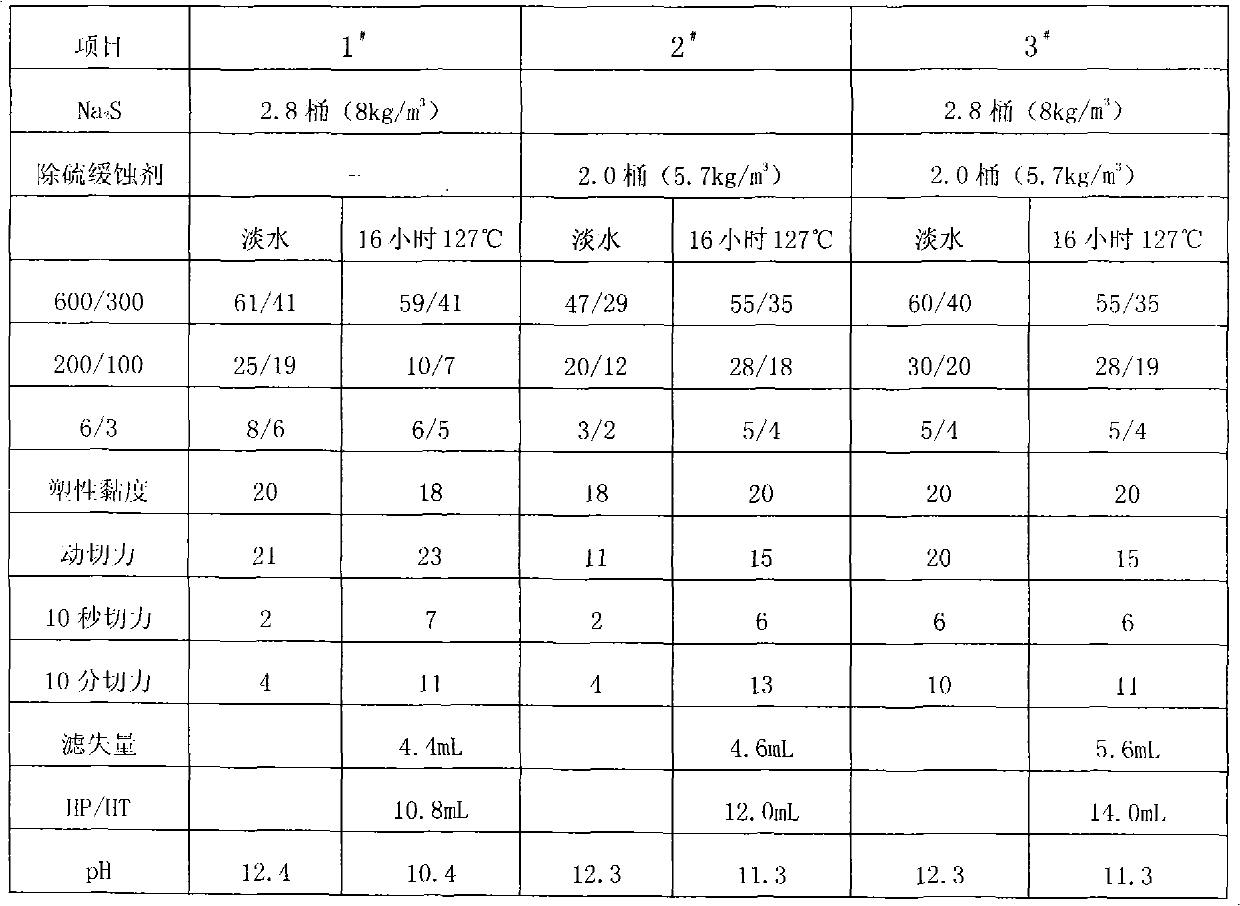

Sulphur removal corrosion inhibitor and preparation method thereof

ActiveCN101955766ALittle impact on performanceNo pollution in the processDrilling compositionBorehole/well accessoriesGluconic acidStearic acid

The invention relates to a sulphur removal corrosion inhibitor, which is prepared from the following components in percentage by weight: 26% of calcium gluconate, 18% of ferrous sulfate, 10% of basic zinc carbonate, 9% of stearic amide and the balance of water. The sulphur removal corrosion inhibitor is insensitive to the pH value, has no effect on the rheological behavior of drilling fluid and simultaneously has good compatibility with other finishing agents in the drilling fluid. Ferrous ions in the sulphur removal corrosion inhibitor are easy to absorb by organic matters, a complex compound of the ferrous ions and organic acid is environment-friendly, and the discharge of drilling cuttings and the drilling fluid containing iron ion filtrate cannot cause environmental problems.

Owner:SICHUAN ZHENGRONG IND +1

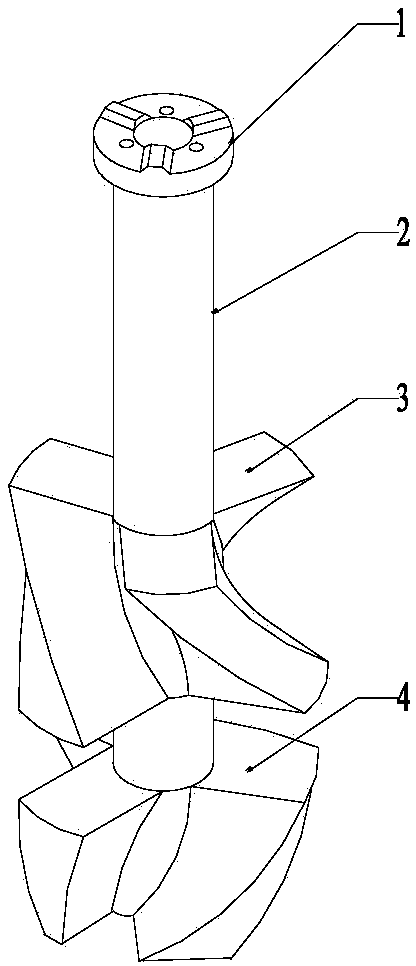

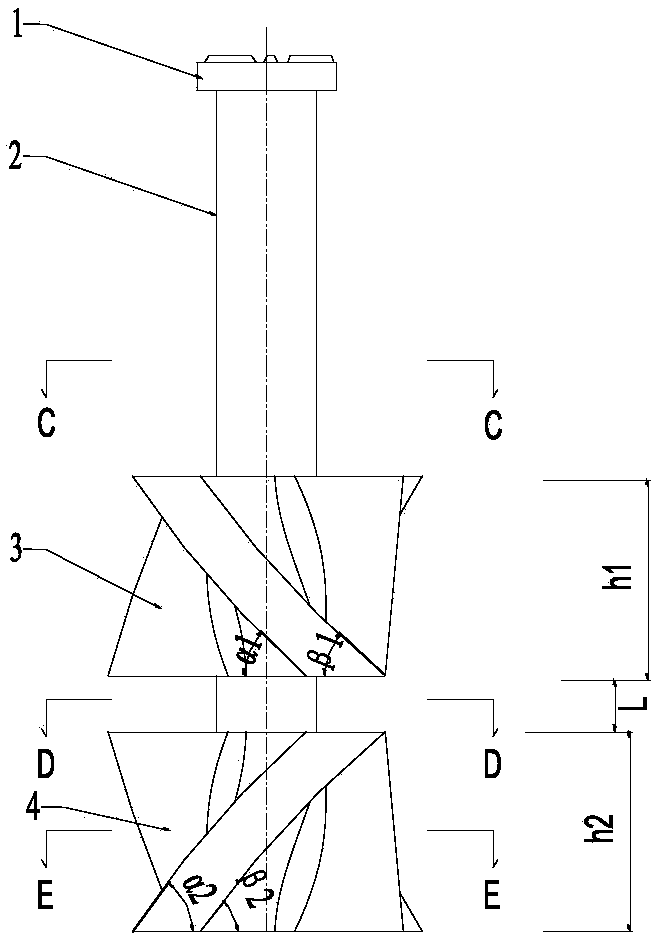

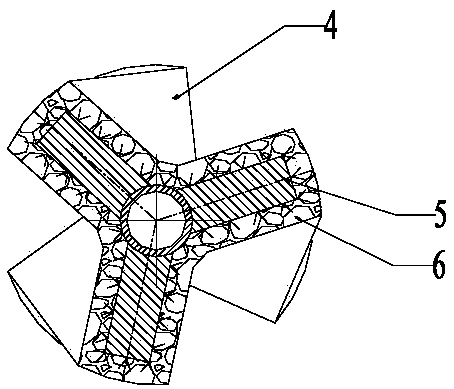

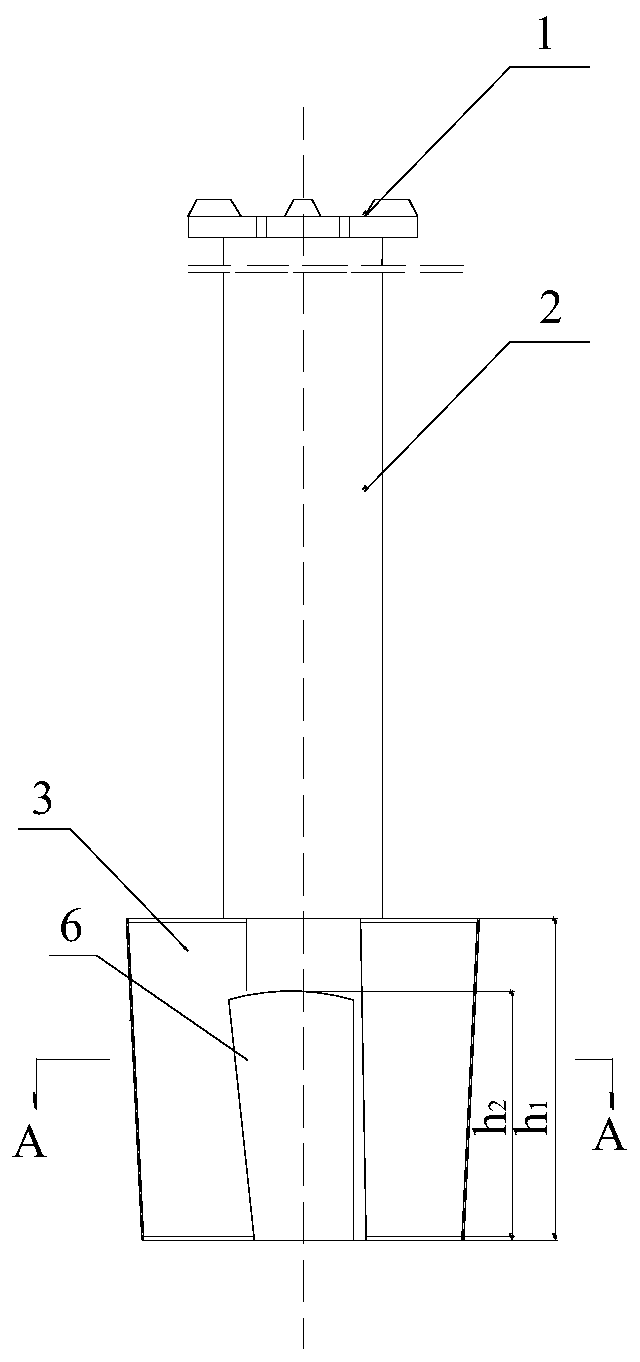

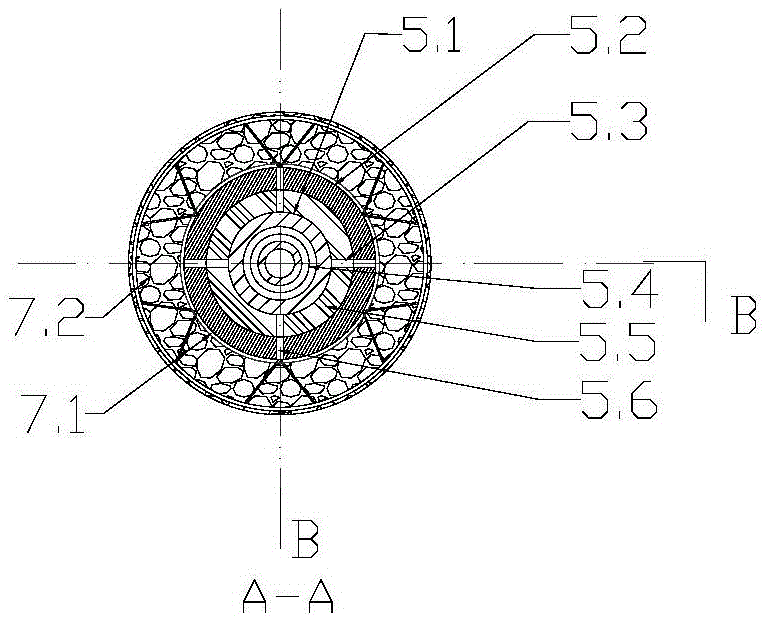

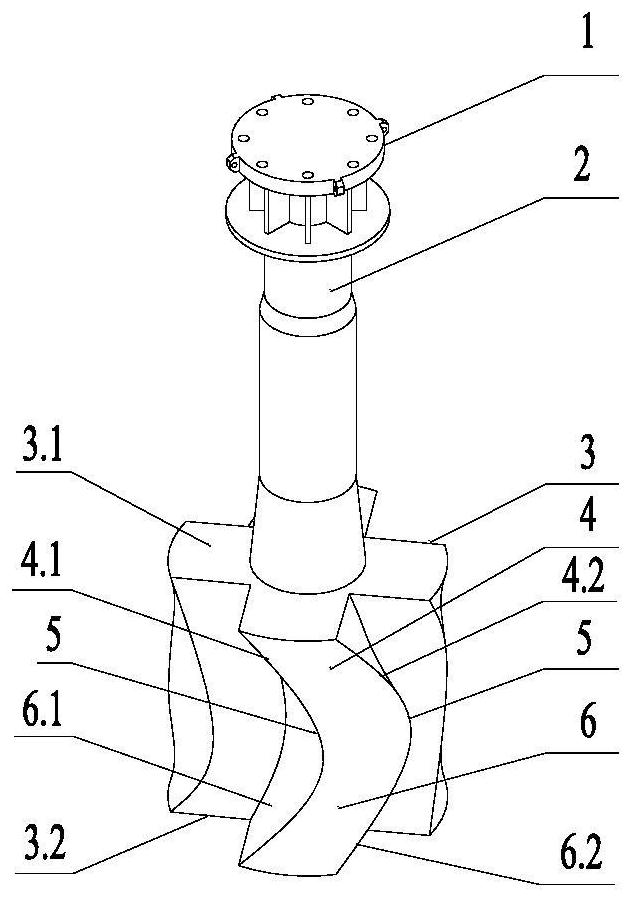

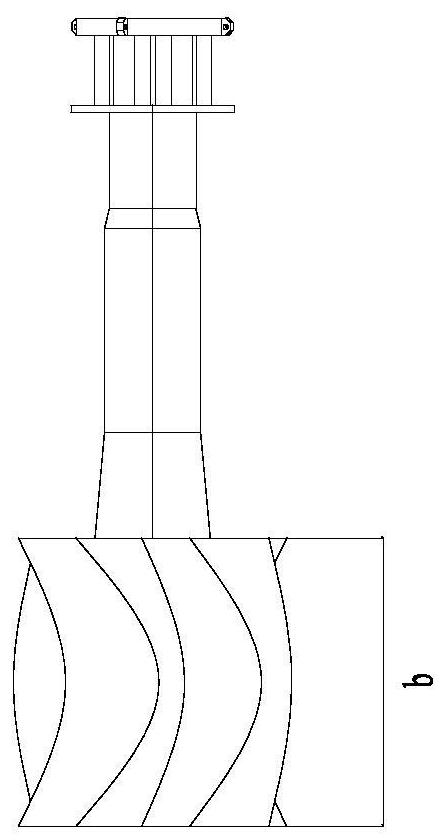

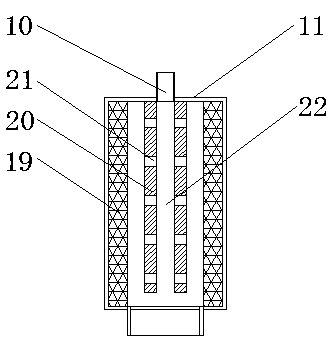

Molten iron full-domain stirring and desulfurization stirrer and using method thereof

The invention discloses a molten iron full-domain stirring and desulfurization stirrer. The stirrer comprises a stirring shaft, a stirrer connecting flange, upper-layer stirring blades and lower-layerstirring blades, each upper-layer stirring blade and each lower-layer stirring blade each comprises a stirring blade core and a stirring blade core fire-resistant pouring material lining, each upper-layer stirring blade is a left-rotated spiral blade rotating in the same direction as the stirring direction, each lower-layer stirring blade is a right-rotated spiral blade rotating in the directionopposite to the stirring direction, and the lower-layer stirring blades and the upper-layer stirring blades are arranged at the same circumferential angle in the circumferential direction of the stirring shaft or are arranged in a front-back equal-angle staggered angle mode. Through the double-layer stirring blade structure arranged up and down, the arrangement distance of the stirring blades in the length direction of the stirring shaft is greatly increased, the stirring depth and the effective stirring area of the stirrer on the molten iron in a molten iron ladle are expanded, stirring of the molten iron at the bottom of the molten iron ladle and stirring, mixing and mass transfer of the full-domain molten iron are remarkably enhanced, and the dynamic conditions of the full-domain molteniron stirring and desulfurization reaction are greatly improved.

Owner:武汉钢铁有限公司

Desulfurizing agent for non-oriented silicon steel

The non-oriented silicon steel desulfurizer consists of CaO 45-58 wt%, Al2O3 8-23 wt%, CaF2 15-30 wt%, SiO2 3-8 wt%, Mg 2-6 wt%, C not more than 0.015 wt%. Before it is applied in desulfurizing molten steel, the silicon steel desulfurizer is surface deactivated via adding organic solvent in 0.3-1.0 wt%. The desulfurizer containing metal Mg has excellent deoxidation function and excellent molten steel desulfurizing effect. The desulfurizer with one hydrophobic protecting layer formed through the deactivation treatment has high damp-proofing effect and high desulfurizing reaction performance.

Owner:BAOSHAN IRON & STEEL CO LTD

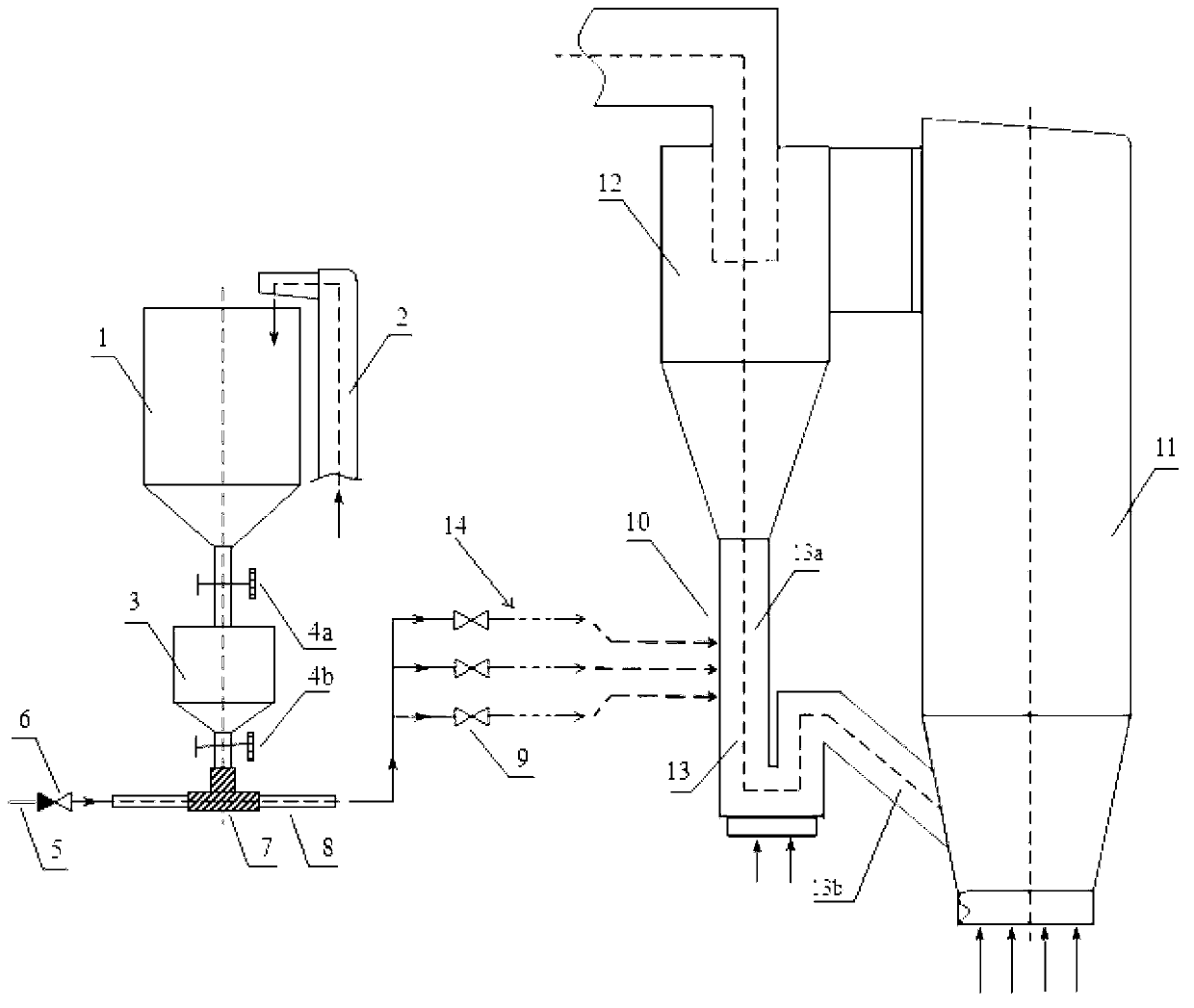

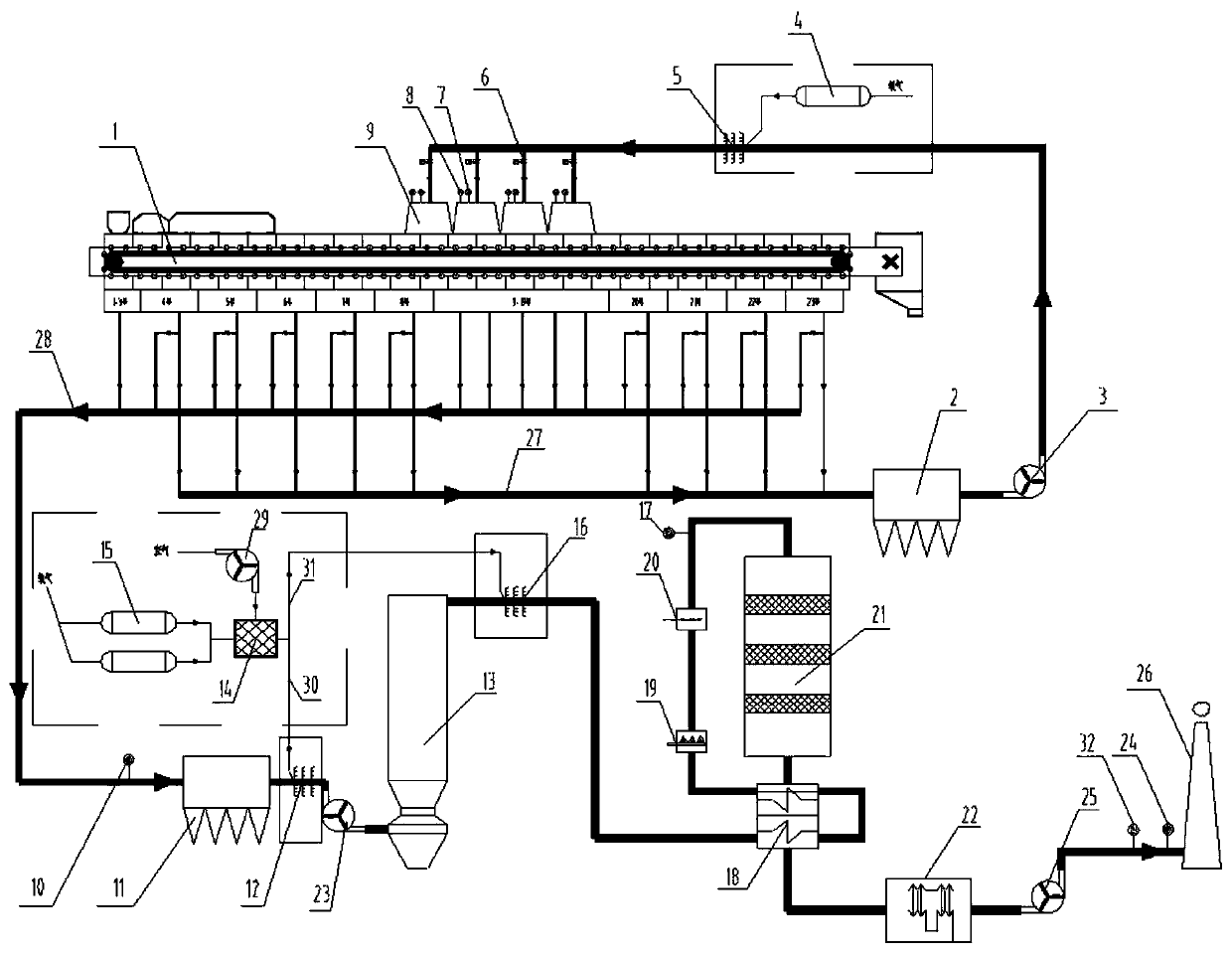

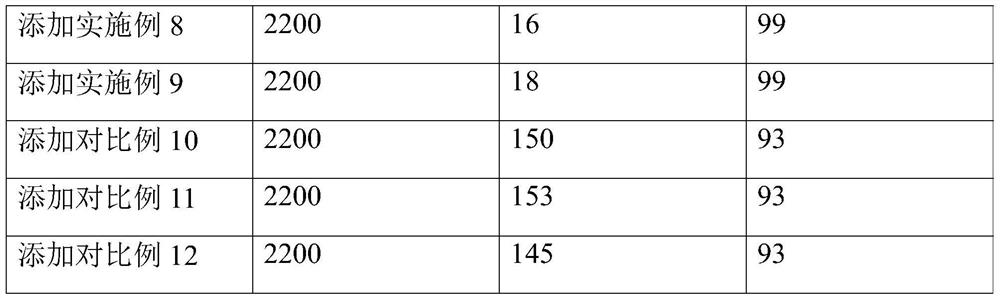

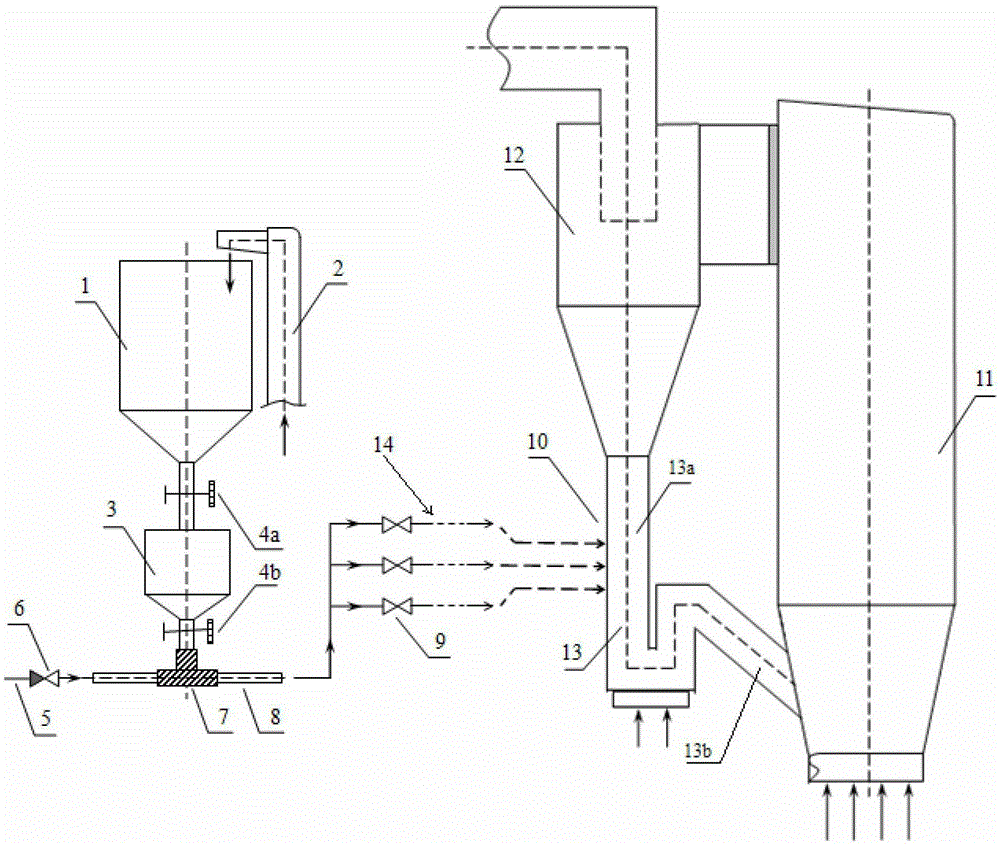

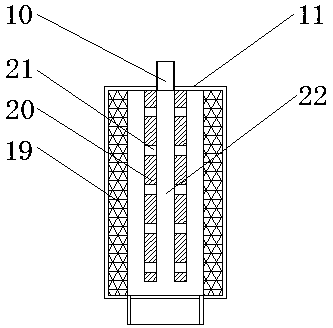

Desulfurization system of circulating fluidized bed boiler

ActiveCN103272475AFast desulfurization reactionImprove desulfurization efficiencyDispersed particle separationFluidized bedHearth

The invention discloses a desulfurization system of a circulating fluidized bed boiler. The desulfurization system comprises a cyclone separator (12), wherein the upper part of the cyclone separator (12) is connected with the upper part of a hearth (11) of the boiler; the lower part of the cyclone separator (12) is connected with the lower part of the hearth (11) through a material returning pipe (13); the material returning pipe (13) is provided with a desulfurization agent inlet (10); and the desulfurization agent inlet (10) is formed in a negative-pressure position of the material returning pipe (13). The desulfurization agent in the desulfurization system can be easily sprayed into the boiler, the desulfurization efficiency is high and the energy consumption is low.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for finely removing hydrogen sulfide from natural gas at normal temperature

InactiveCN102115685AFast desulfurization reactionHigh sulfur capacityGaseous fuelsActivated carbonCatalytic oxidation

The invention discloses a method for finely removing hydrogen sulfide from natural gas at a normal temperature. The method adopts the following technical scheme: the natural gas enters a fine desulfurizing tower loaded with activated-carbon fine desulfurizing agent after the processes of drying and gas-water separation, so that H2S in the gas is removed under the effect of the desulfurizing agent; the fine desulfurizing agent is filled in a two-layer or multi-layer manner; the total height-to-diameter ratio of a bed layer is 1.5 to 4.0, the temperature is between normal temperature and 150 DEG C, and the pressure is between normal pressure and 2.5MPa; and through the measurement of a sulfur meter, when the contents of H2S in the natural gas reach 5mg / Nm3 after desulfurization through the desulfurizing tower, the desulfurizing process is completed. The desulfurizing agent uses particles or formed activated carbon as carriers of an activated component (i.e. CuO), and the contents of CuOin the desulfurizing agent are 2Wt% to 9Wt%; and the radial crushing strength is larger than or equal to 60N / cm, the bulk density is 0.5kg / I to 0.7kg / I, the specific surface is larger than 140m2 / g, and the specific pore volume is 0.4ml / g to 0.8ml / g. Copper-loaded activated carbon is adopted as the desulfurizing agent for desulfurization, so that the special surface structure of the activated-carbon material is utilized for H2S purification through adsorption and catalytic oxidation.

Owner:克拉玛依金叶化工有限责任公司

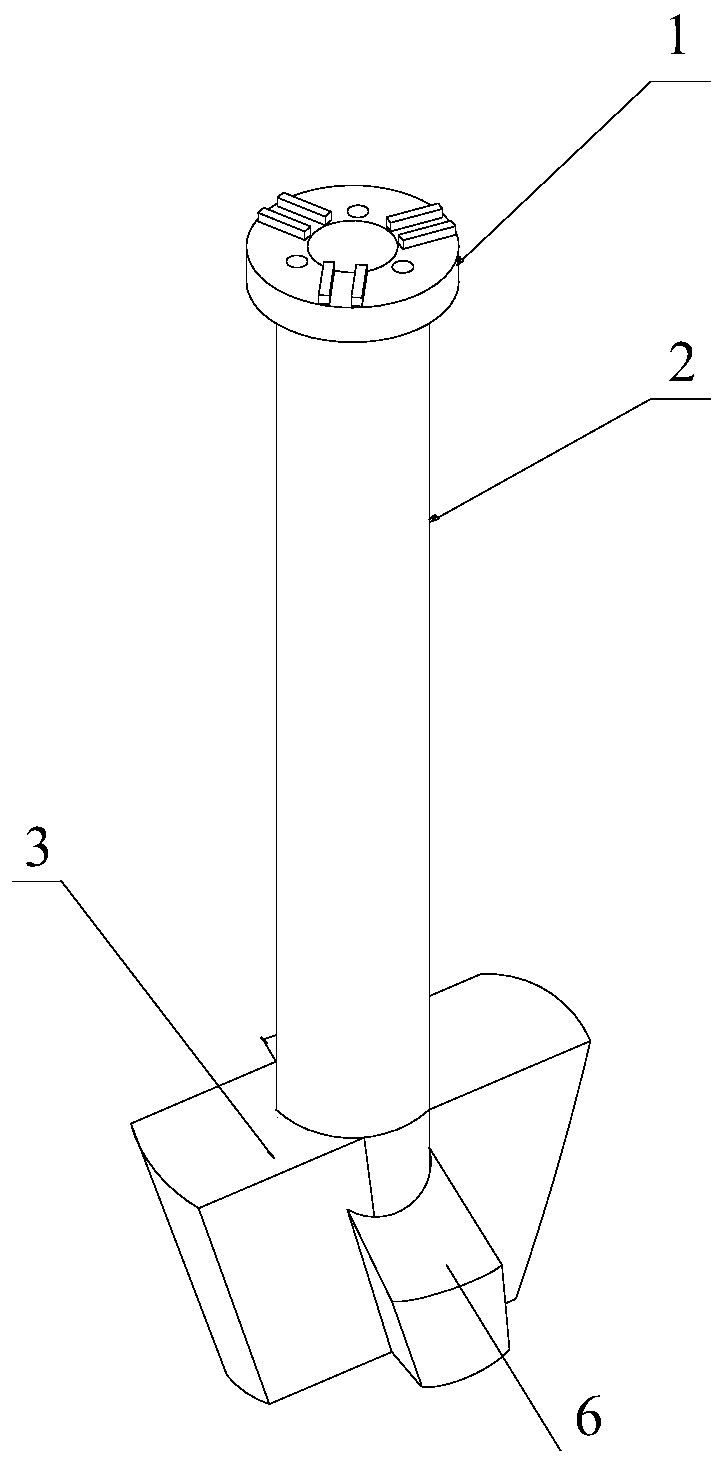

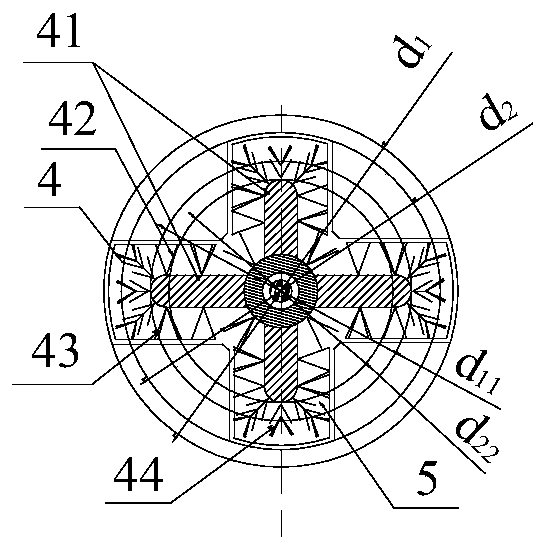

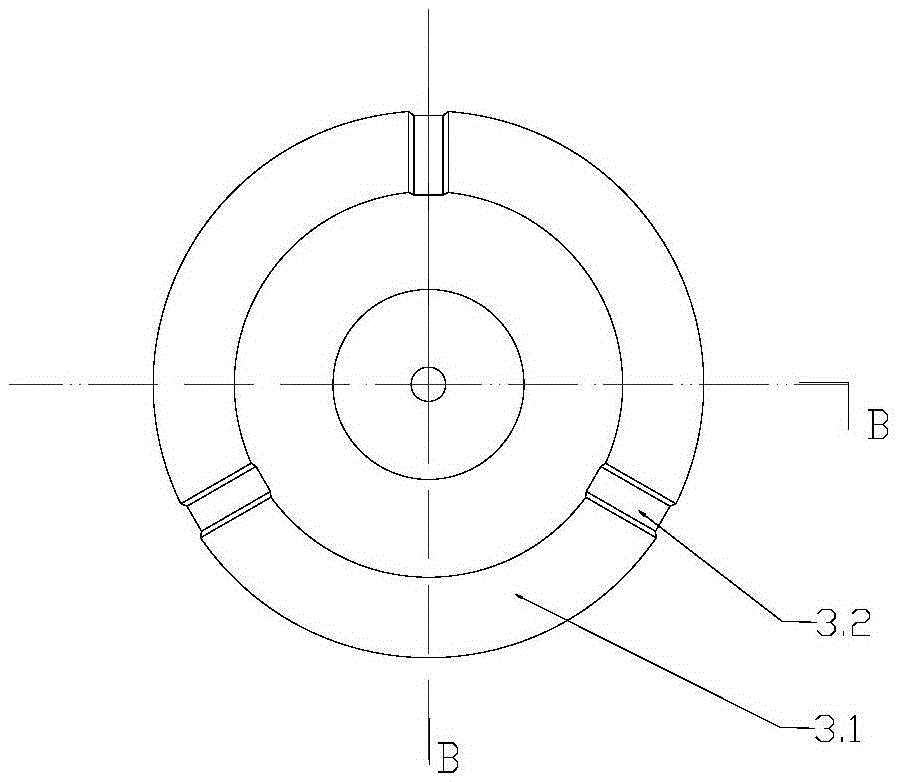

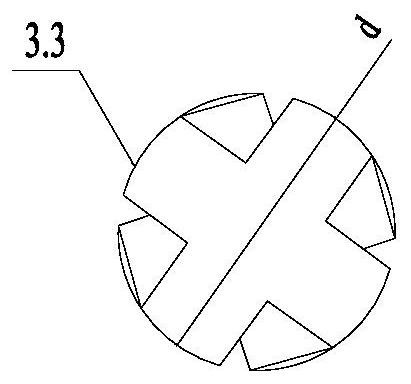

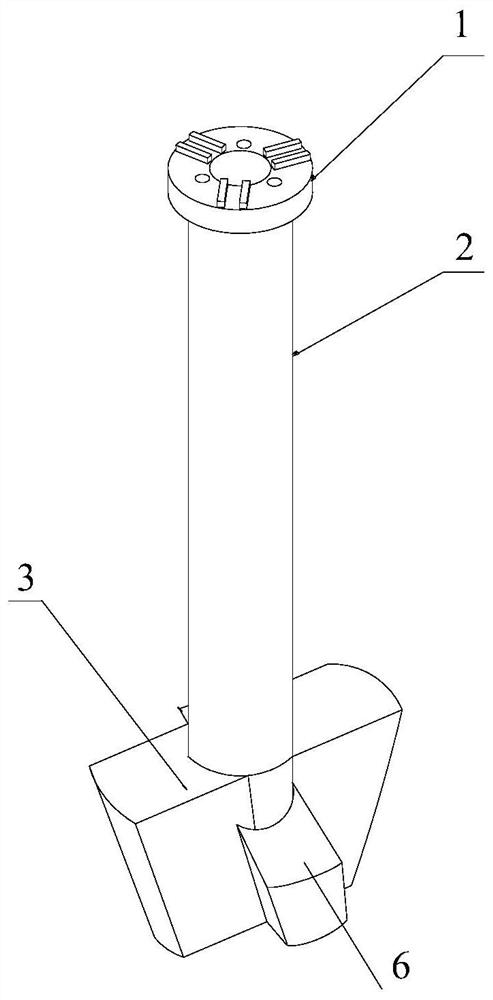

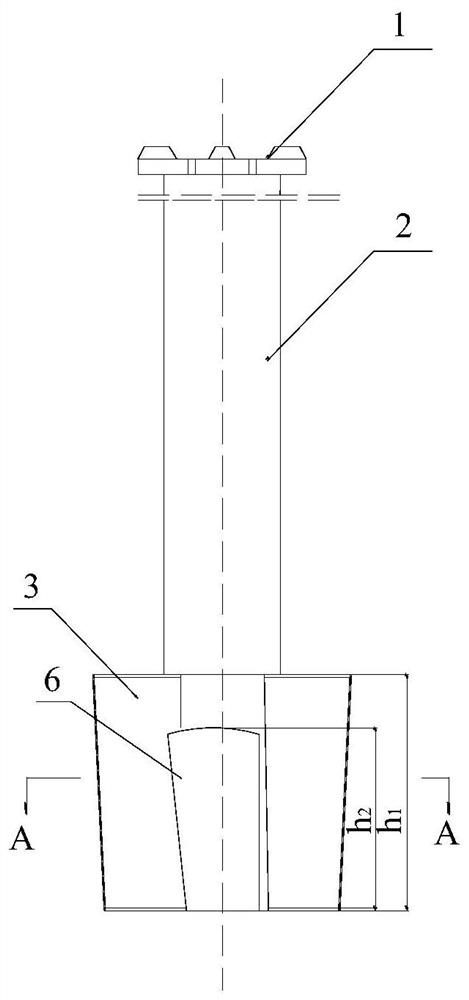

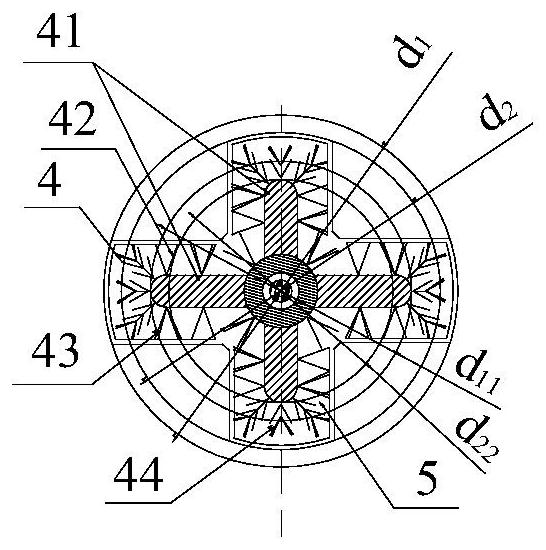

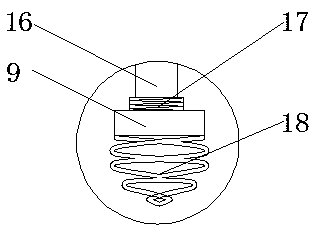

Self-excitation oscillating pulse stirring desulfurization stirrer for iron melt

ActiveCN109758955AExtended service lifeOptimizationShaking/oscillating/vibrating mixersReaction rateEngineering

The invention discloses a self-excitation oscillating pulse stirring desulfurization stirrer for iron melt. The stirrer comprises a stirring shaft, a stirrer connecting flange arranged at the top endof the stirring shaft and stirring vanes, wherein the stirring shaft comprises a stirring shaft core and a stirring shaft core refractory castable lining; the stirring vanes comprise big stirring vanes and small stirring vanes which are equal in quantity, all the big stirring vanes and all the small stirring vanes are welded to the outer periphery of the stirring shaft around the circumferential direction of the stirring shaft in an alternating and uniform manner, and bottom faces of the big stirring vanes and bottom faces of the small stirring vanes are all parallel and level to the bottom face of the stirring shaft. By adopting big-small stirring vane structural design and optimizing structural parameters, the comprehensive effects of increasing a desulfurization reaction rate, increasing desulfurization efficiency, shortening stirring time, prolonging the service life of the stirrer and the like are achieved, and finally, the expected aims of improving KR stirring desulfurization dynamic conditions and desulfurization technology economic indicators of the iron melt are achieved.

Owner:武汉钢铁有限公司

Method for preparing steelmaking flux from refining waste slag under thermal state

InactiveCN104046710AReduce processing stepsLow costManufacturing convertersRecycling and recovery technologiesAlkalinitySteelmaking

The invention relates to a method for preparing a steelmaking flux from refining waste slag under a thermal state. The method comprises the following step: a, desulfurizing refining waste slag: introducing oxygen into a melting furnace, controlling the temperature of the melting furnace to be 1300-1500 DEG C, wherein the partial pressure of introduced oxygen is 1-2atm and the reaction time is 30 minutes-60 minutes, removing sulfur in the refining waste slag in a gaseous manner; b, preparing the steelmaking flux: preparing a premelting refining slag agent from high-Al low-Si type refining waste slag; preparing a premelting converter slag-forming flux from high-Al refining waste slag, or preparing a premelting converter slag-former from high-alkalinity low-Al refining waste slag. According to the invention, the full advantage of the sensible heat of the molten refining slag is taken, the treatment process of the refining waste slag is shortened, the energy conservation is achieved, sulfur in the refining waste slag is removed in a SO2 gaseous manner and the desulfurization efficiency reaches 97%, the steelmaking flux obtained by the invention is not easily chalked, the briquetting is not needed and the steelmaking flux can be directly used after the steelmaking flux is crushed.

Owner:中钢集团武汉安全环保研究院有限公司

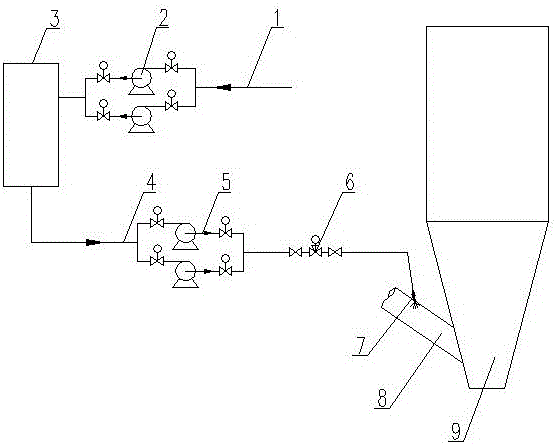

Desulfurization and denitration system and method combining sintering flue gas circulation with ozone pre-oxidation

The invention provides a desulfurization and denitration system and method combining sintering flue gas circulation with ozone pre-oxidation. The system includes an ozone preparation device, a desulfurization reaction device, a denitration reaction device and a sintering flue gas circulation device; ozone is used for primary ozone pre-oxidation treatment of flue gas before a desulfurization reaction in a main flue of a sintering machine and secondary ozone pre-oxidation treatment of flue gas before a denitration reaction; the desulfurization reaction device is used for desulfurization treatment and primary denitration treatment of the flue gas; the denitration reaction device is used for secondary denitration treatment of the flue gas; and the sintering flue gas circulation device can supply oxygen to the high-temperature flue gas for recycling the flue gas. The desulfurization and denitration method includes the steps of sintering flue gas circulation, desulfurization and denitrationreactions after ozone pre-oxidation treatment, and discharge of flue gas. The system and method provided by the invention can improve the flue gas circulation rate to 30% or more, improve the denitration reaction rate, and reduce the use amount of a catalyst and prolong the service life, so that the NOx emission reaches or exceeds ultra-low emission of flue gas.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

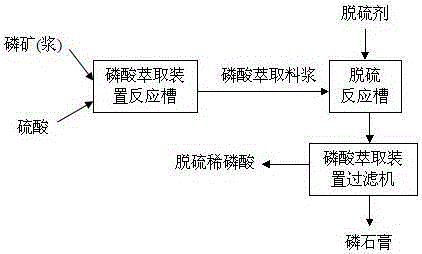

A method for reducing sulfate radical content in dihydrate dilute phosphoric acid

ActiveCN103754850BShort reaction timeImprove responsePhosphorus compoundsO-Phosphoric AcidSulfate radicals

The invention discloses a method for reducing the content of sulfate radicals in dihydric dilute phosphoric acid, which is characterized in that a desulfurizer is added to wet-process phosphoric acid extraction slurry, mixed and stirred, and mixed and reacted at 60-80°C for 5-30 minutes. Then the mixed slurry is sent to the filter of the phosphoric acid extraction device for filtration, and the diluted phosphoric acid with a sulfate mass percentage content of less than 1.2% is obtained by filtration; The mass ratio of sulfate radicals in the medium is 0.35-0.50:1. The present invention solves the problem of high sulfate content in the dilute phosphoric acid of the dihydrate method, and is beneficial to the use of the dihydrate method phosphoric acid in the production of high-nutrient ammonium phosphate fertilizer, feed grade phosphate, industrial grade ammonium phosphate and phosphoric acid purification products. Simple, short desulfurization reaction time, good desulfurization effect and low desulfurization cost.

Owner:WENGFU (GRP) CO LTD

Molten iron lime-based KR efficient desulfurizer and preparation method thereof

PendingCN114875194AReduce dust escape rateImprove utilization rate of desulfurizationProcess efficiency improvementCalcium aluminatesCarbon alloy

The invention relates to a molten iron lime-based KR efficient desulfurizer and a preparation method thereof. The desulfurizer comprises the following components in percentage by mass: 70-85% of lime particles and 15-30% of an additive, the lime particles comprise active lime particles and passivated lime particles; the additive comprises, by mass, 37%-63% of sintered calcium aluminate, 6%-13% of used magnesia carbon brick particles, 15%-30% of industrial sodium carbonate, 6%-13% of fluorite and 10%-20% of silicon-aluminum-calcium-carbon alloy. The desulfurizer prepared by the invention has the advantages of high desulfurization efficiency, large sulfur capacity, strong deliquescence resistance, small environmental pollution, simple preparation, low cost and the like.

Owner:武汉钢铁有限公司

Desulfurizing agent for pipeline steel smelting

InactiveCN103789504APlay the role of desulfurizationPlay the role of flame retardantOxalateOXALIC ACID DIHYDRATE

The invention discloses a desulfurizing agent for pipeline steel smelting. The desulfurizing agent is composed of the following components in parts by weight: 70-80 parts of rare earth and passivated magnesium composite material, 10-12 parts of calcium fluoride, 5-8 parts of barium carbonate and 15-18 parts of attapulgite, wherein the rare earth and passivated magnesium composite material comprises 60-70 parts of Mg, 3-5 parts of CeO and 15-25 parts of MgO. The preparation method of the rare earth and passivated magnesium composite material comprises the steps of firstly, carrying out dry mixing on Mg, CeO and MgO to prepare a mixed material; then, heating the mixed material, and controlling the temperature at 60-70 DEG C; next, mixing oxalic acid, magnesium chloride and water to prepare a passivation solution; then, pouring the passivation solution into the mixed material, stirring until the material is dry, and naturally cooling to prepare the rare earth and passivated magnesium composite material, wherein the weight ratio of the passivant, namely oxalic acid to magnesium chloride is 1: (3-4), the concentration of the passivation solution is 40-50g / L, and the weight ratio of the passivation solution to the mixed material subjected to dry mixing is 1: (20-25).

Owner:WUXI CHENGBO SCI & TECH DEV

Sulphur removal corrosion inhibitor and preparation method thereof

ActiveCN101955766BFast desulfurization reactionGuaranteed SolubilityDrilling compositionBorehole/well accessoriesGluconic acidStearic acid

The invention relates to a sulphur removal corrosion inhibitor, which is prepared from the following components in percentage by weight: 26% of calcium gluconate, 18% of ferrous sulfate, 10% of basic zinc carbonate, 9% of stearic amide and the balance of water. The sulphur removal corrosion inhibitor is insensitive to the pH value, has no effect on the rheological behavior of drilling fluid and simultaneously has good compatibility with other finishing agents in the drilling fluid. Ferrous ions in the sulphur removal corrosion inhibitor are easy to absorb by organic matters, a complex compound of the ferrous ions and organic acid is environment-friendly, and the discharge of drilling cuttings and the drilling fluid containing iron ion filtrate cannot cause environmental problems.

Owner:SICHUAN ZHENGRONG IND +1

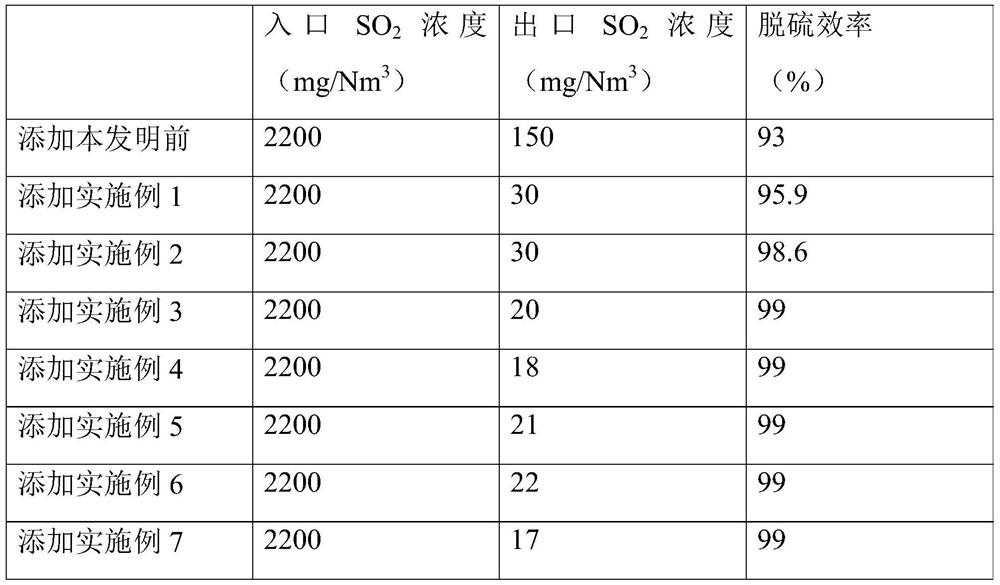

Desulfurization synergistic additive

ActiveCN114307600AImprove solubilityImprove gas-liquid mass transfer efficiencyCombination devicesOther chemical processesSodium acetateGlutaric acid

The invention discloses a desulfurization synergistic additive which comprises the following components in parts by weight: 20-35 parts of sodium formate, 15-30 parts of glutaric acid, 10-20 parts of succinic acid, 5-15 parts of sodium acetate, 15-25 parts of adipic acid, 0-20 parts of sodium polycarboxylate, 0-15 parts of 1-hydroxyethylidene-1, 1-diphosphonic acid and 0-5 parts of amorphous iron oxyhydroxide, and the powder of the components is uniformly mixed at normal temperature and normal pressure in a dry state. According to the desulfurization synergistic additive, the solubility of limestone in a liquid phase is improved, the solubility of the limestone is enhanced, the SO2 gas-liquid mass transfer efficiency in the desulfurization reaction process is effectively improved, SO2 absorption is enhanced, the desulfurization reaction speed of the limestone is effectively improved, and the treatment capacity and desulfurization efficiency of a desulfurization system are effectively improved; the cost performance is more prominent, and the long-time safe and stable operation of the desulfurization system is enhanced.

Owner:北京中德华信能源科技有限公司

Hot metal global impact mixing long life agitator

ActiveCN113073175BReduce areaExtended service lifeStirring devicesProcess efficiency improvementEngineeringAgitator

The invention discloses a long-life stirrer for full-area impact mixing of molten iron, comprising a stirrer connecting flange, a stirring shaft and a stirring blade; the stirring blade is a single-layer special-shaped structure stirring blade, and the top surface and the bottom surface of each stirring blade are planes and outer surfaces It is a circular arc surface, the upper anti-iron surface and the upper back iron surface are positive helical surfaces, the lower anti-iron surface and the lower back iron surface are reverse helical surfaces; the forward helical surface of the upper anti-iron surface and the lower anti-iron surface The junction of the reverse helical surface is an arc-shaped transition surface, and the junction of the forward helicoid of the upper back iron surface and the reverse helicoid of the lower back iron surface is an arc-shaped transition surface. Through the structural design of special-shaped stirring blades and the optimization of structural parameters, the erosion wear area and erosion process of the molten iron in the agitator are significantly reduced, the service life of the agitator is greatly extended, the size of the upper and lower circulation flow areas of the agitation is enlarged, and the velocity of the upper and lower circulation flow is increased. And kinetic energy, to ensure the reliability and stability of the radial discharge jet impingement flow field of the stirring up and down circulation flow.

Owner:武汉钢铁有限公司

Composite desulfurizer

The invention discloses a high-efficiency compound desulfurizing agent, relating to the ladle desulphurization accessory field. In the existing ladle desulphurization, the uniserial desulfurizing agent is uniformly adopted, with narrower function, and non-agreeable desulphurization effect. Aiming at the condition that small and medium-sized steel mills do not have liquid iron pretreatment systemsor desulphurization stations, and do not have powder spraying desulphurization devices, the desulfurizing agent of the invention adopts ingredient with multi-components, namely, the compound desulfurizing agent consisting of limestone, calcined soda, fluorite, calcium carbide, magnesium powder and caustic-calcined magnesite, with the weight proportion of 40 to 50, 10 to 20, 5 to 15, 10 to 20, 4 to6 and 5 to 15 sequentially. The desulfurizing agent has the following advantages that: 1. the integral desulphurization capability is strong, and the sulfur content can be reduced to 20ppm; 2. sulfursubstance can be contained, and resulfurization phenomenon can not be generated; 3. the desulfurizing agent can be directly poured, and equipment and investment are not needed to be increased; and 4.the desulphurization speed is high.

Owner:西峡县福盈冶金材料有限公司

Self-excited oscillating pulse stirring desulfurization agitator for molten iron

ActiveCN109758955BExtended service lifeFast desulfurization reactionShaking/oscillating/vibrating mixersThermodynamicsPhysical chemistry

Owner:武汉钢铁有限公司

Calcium oxide-based desulfurizer for steelmaking and preparation method thereof

ActiveCN112080610BImprove performanceImprove desulfurization effectRotary stirring mixersTransportation and packagingSteelmakingSilicone grease

Owner:浙江振鑫新材料科技有限公司

Converter furnace steel-making desulfurizing agent and preparation method thereof

The invention discloses a converter furnace steel-making desulfurizing agent and a preparation method thereof. The converter furnace steel-making desulfurizing agent is mainly obtained by evenly mixing the following composition raw materials in parts by weight: calcium oxide, calcium fluoride, barium carbonate, silica, carborundum, attapulgite, boron anhydrous and flame retardant silicone grease.The preparation method is used for the converter furnace steel-making desulfurizing agent which is the desulfurizing agent free from aluminum and can be used for improving the physical, mechanical and technical performances of steel. According to the converter furnace steel-making desulfurizing agent, gas is removed, nonmetal inclusions are changed, and the quality and mechanical performance of furnace steel making can be improved.

Owner:芜湖县天海耐火炉料有限公司

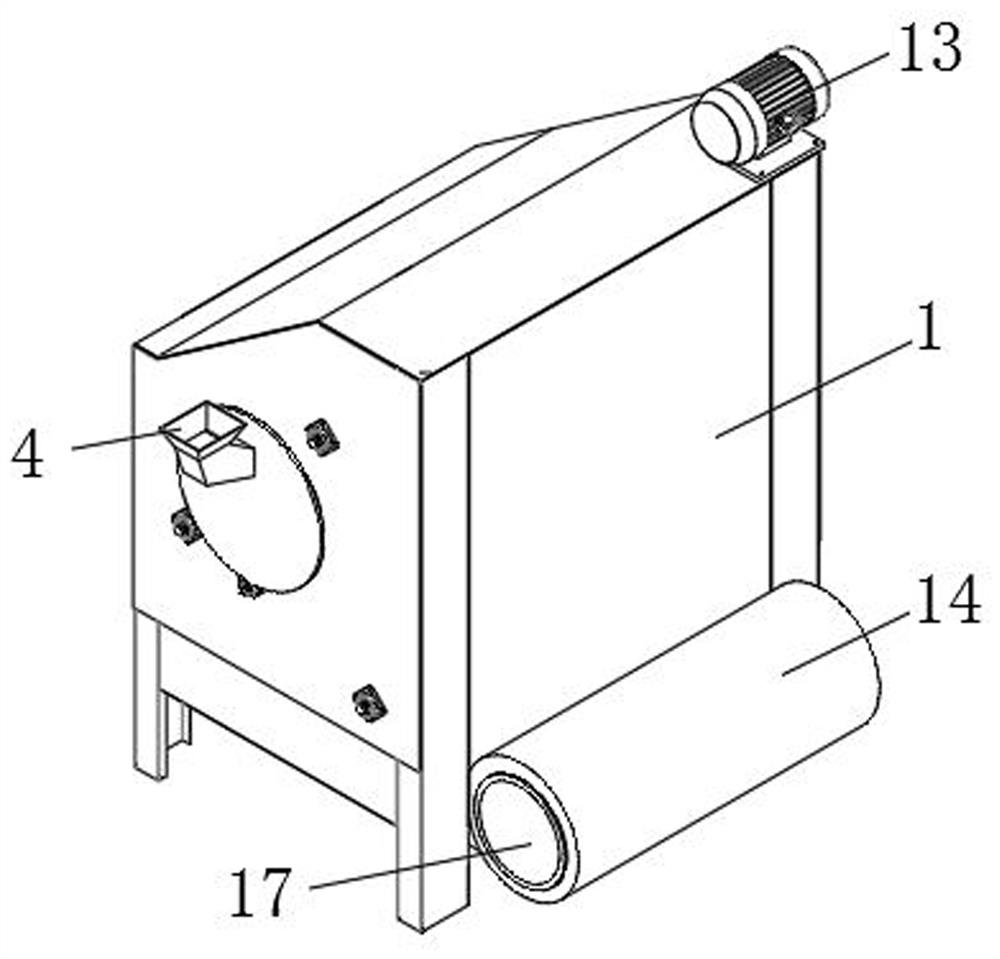

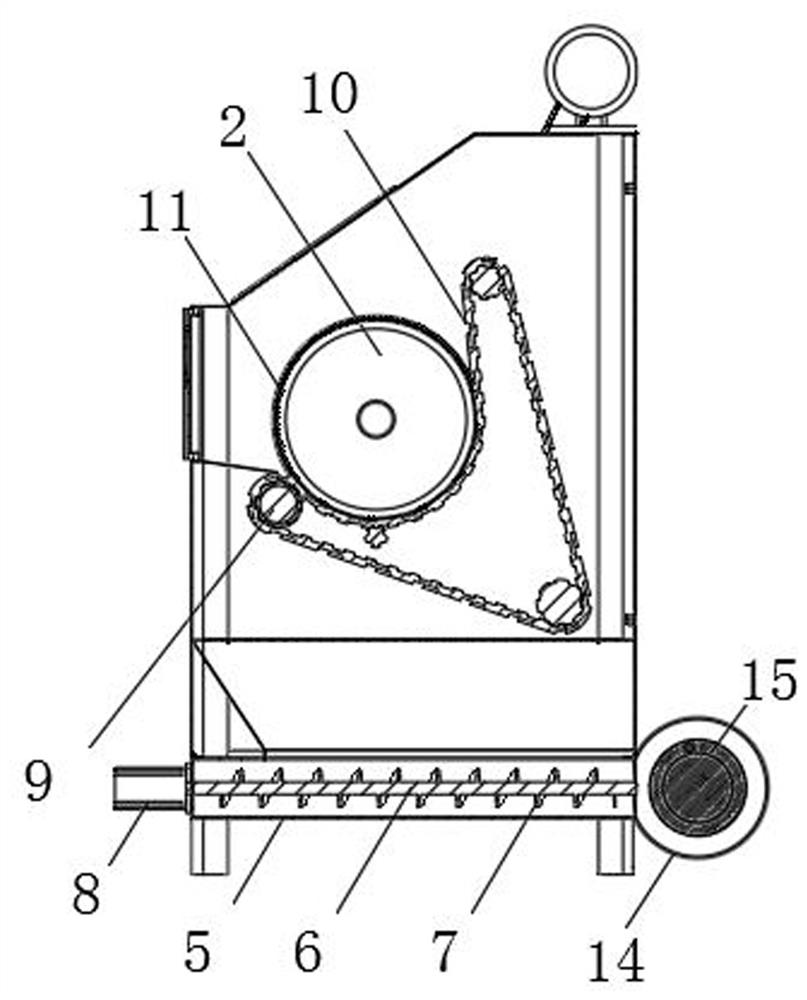

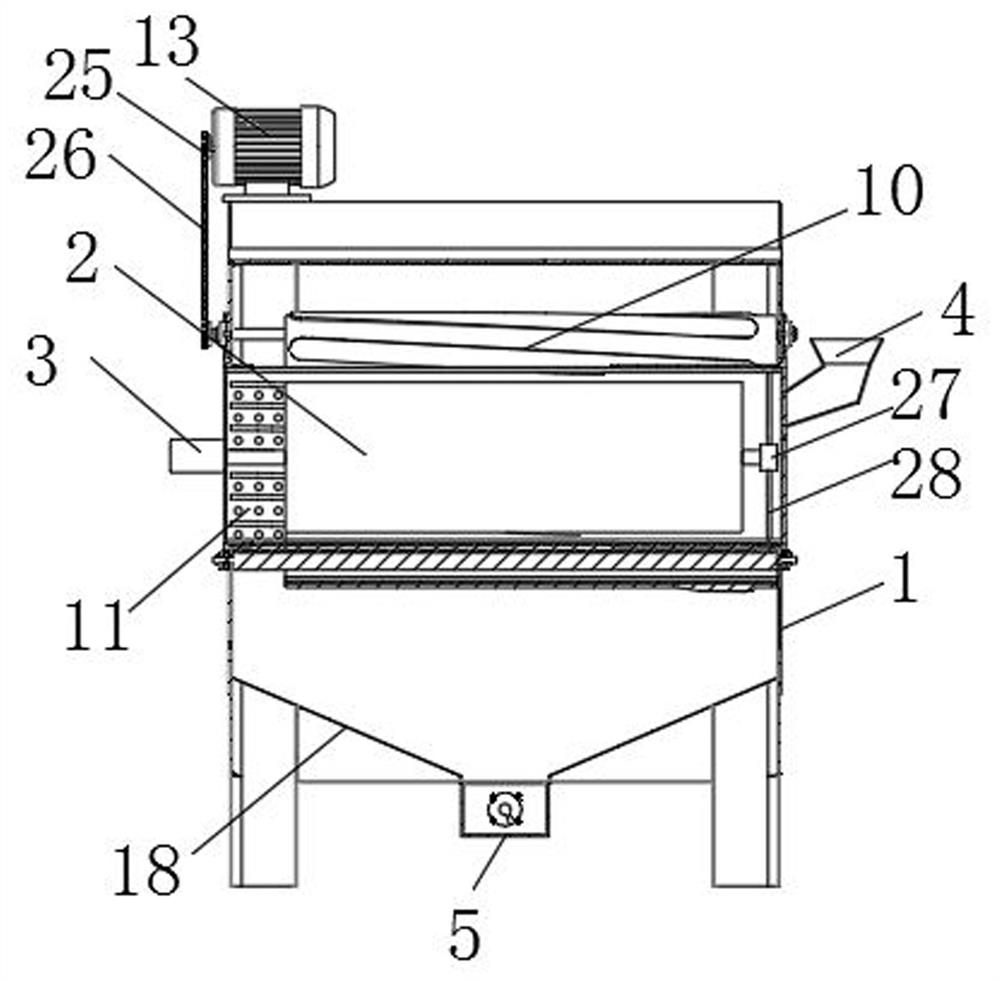

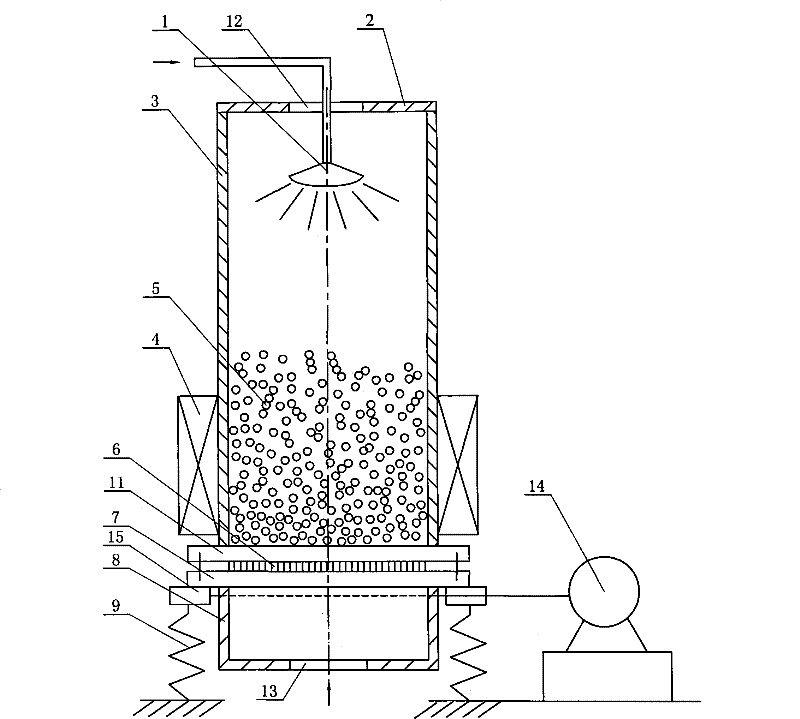

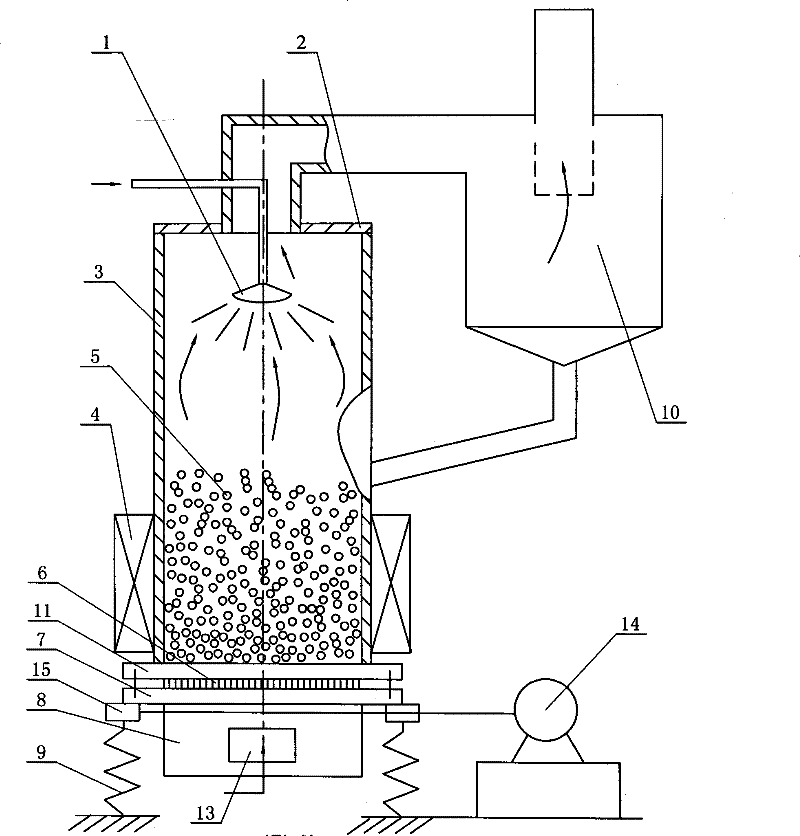

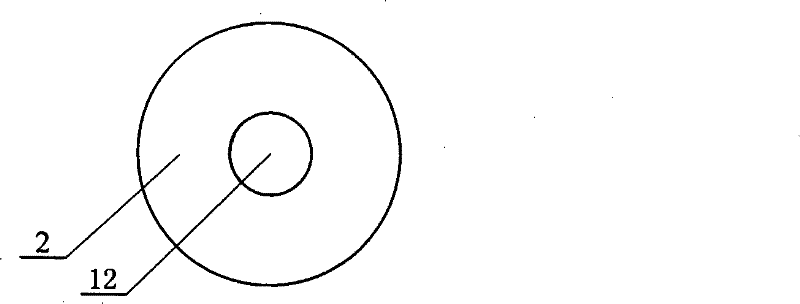

Vibration-magnetic coupling fluidized bed flue gas desulfurization reactor

InactiveCN101259374BIncrease exerciseIncrease collisionDispersed particle separationFlue gasFluidized bed

The utility model relates to a vibration-magnetic coupling fluidized bed flue gas desulfurization reactor, which relates to a fluidized bed flue gas desulfurization reactor. For the magnetic fluidized bed flue gas desulfurization device, the desulfurization reaction speed is slow, the time is short, and the efficiency is low. The annular upper cover (2) is fixedly connected to the upper end surface of the cylinder (3), the central hole of the annular upper cover (2) is the flue gas outlet (12), and the upper and lower fixed frame plates are fixed on the simplified body (3) and the bellows (8), the cylinder body (3) is equipped with a magnetic bed material (5), the air distribution plate (6) is fixed between the upper and lower fixed frame plates, and the atomizing nozzle (1) is hoisted on the cylinder body (3 ), the cylinder body (3) is covered with a magnetic helical coil (4), and the two ends of three to four exciting springs (9) are respectively fixed with the base (15) and the ground, and the base (15) is fixed with the lower The frame plate (7) is fixedly connected, and three to four bases (15) are all connected with the excitation motor (14). The invention has the advantages of fast desulfurization reaction speed, long time and high efficiency, and the inner wall of the reactor is not easily scaled.

Owner:HARBIN INST OF TECH

Chromium-free normal-temperature efficient purifying adsorbent for removing H2S or SO2 and preparing method thereof

InactiveCN100341617CFast desulfurization reactionHigh conversion rate of desulfurizationOther chemical processesDispersed particle separationChromium freeSorbent

The invention is desulfurizing sorbent which is made up by immersing at least two kinds of transition metal and alkali metals compound and polyacrylic ester on coal active char (the weight are 3-30%, 1-40%, 0.2-10% of char weight respectively). The manufacturing method is: the water-soluble transition metal, kalium compound and polyacrylic ester are marinated on the char carrier respectively or jointly, and they are dried and actived in air at 80-160 deg.C. The reaction speed of the sorbent is fast, it can purifies H2S, SO2 to ppb grade, the rate can reach 50000 h-1. It has no chromium, no dust on the surface and it is smooth. It can be used in semiconductor industry, special life supporting system closed room, and medical and health, cultural relic protection and environment protection fields.

Owner:NO 63971 TROOPS PLA

High yield desulfuration boiler

ActiveCN108592066AFast desulfurization reactionSpeed up circulationEmission preventionSpray nozzleEngineering

The invention discloses a high yield desulfuration boiler which comprises a boiler body, a flue and a processing chamber. An absorbent groove is formed above the left portion of the boiler body, an air blower is installed on the left side of the absorbent groove, a heat preservation layer is arranged on the outer side of the boiler body, the flue is fixed above the boiler body, a ventilator is installed at the right lower corner of the flue, the processing chamber is arranged at the tail end of the right side of the flue, a water tank is fixed above the processing chamber, a booster pump is installed on the left side of the lower portion of the interior of the water tank, a water pipe is arranged below the booster pump, a connector is installed below the water pipe, a spraying nozzle is fixed below the connector, a jetting opening is formed below the spraying nozzle, and a water inlet is formed in the lower right portion of the water tank. The high yield desulfuration boiler is provided with the absorbent groove, the absorbent groove is filled with limestone flour which can be dissolved into calcium oxide and carbon dioxide after heated, and the calcium oxide and sulfur dioxide influe gas react to generate calcium sulfite for desulfuration processing on the interior of the boiler body.

Owner:SHANXI JINNAN IRON & STEEL GRP CO LTD

Desulfurizing agent for non-oriented silicon steel

Owner:BAOSHAN IRON & STEEL CO LTD

Desulfurization System of Circulating Fluidized Bed Boiler

ActiveCN103272475BFast desulfurization reactionImprove desulfurization efficiencyDispersed particle separationFluidized bedEngineering

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

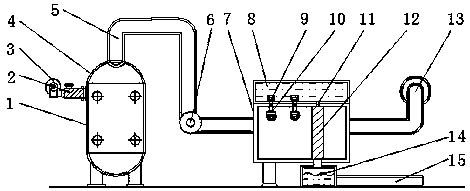

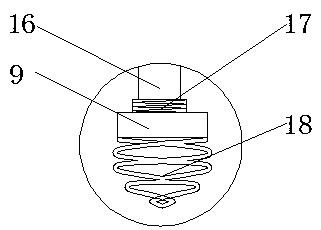

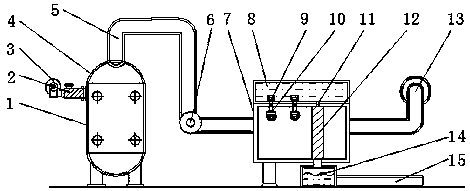

Device for improving desulfurization efficiency of circulating fluidized bed boiler and method for improving desulfurization efficiency

InactiveCN106224944AFast calcinationIncrease profitFluidized bed combustionEmission preventionFlue gasFluidized bed

The invention relates to a device for improving desulfurization efficiency of a circulating fluidized bed boiler and a method for improving desulfurization efficiency. At present, an in-furnace desulfurization technology of the fluidized bed boiler adopts the method that lime stone is directly added from a material return valve, the interior of the lime stone cannot be in full contact with flue gas, the desulfurization reaction speed is relatively low, and improvement of the in-furnace desulfurization efficiency is limited. The device comprises a water feeding pipeline (1), wherein an inlet of the water feeding pipeline is connected with water feeding pumps (2); the water feeding pumps are connected with an inlet of a water storage tank (3) through the water feeding pipeline; an outlet of the water storage tank is connected with one ends of booster water pumps (5) through a water supply pipeline (4); the other ends of the booster water pumps are connected with flow adjusting valves (6); the flow adjusting valves are connected with a humidifying water spray gun (7) through the water supply pipeline; the humidifying water spray gun is mounted inside a material return leg (8); and the material return leg is mounted at the lower part of the fluidized bed boiler (9). The device is used for improving desulfurization efficiency of the circulating fluidized bed boiler.

Owner:HARBIN BOILER

A high-yield desulfurization boiler

ActiveCN108592066BFast desulfurization reactionSpeed up circulationEmission preventionEngineeringCalcium sulfite

The invention discloses a high yield desulfuration boiler which comprises a boiler body, a flue and a processing chamber. An absorbent groove is formed above the left portion of the boiler body, an air blower is installed on the left side of the absorbent groove, a heat preservation layer is arranged on the outer side of the boiler body, the flue is fixed above the boiler body, a ventilator is installed at the right lower corner of the flue, the processing chamber is arranged at the tail end of the right side of the flue, a water tank is fixed above the processing chamber, a booster pump is installed on the left side of the lower portion of the interior of the water tank, a water pipe is arranged below the booster pump, a connector is installed below the water pipe, a spraying nozzle is fixed below the connector, a jetting opening is formed below the spraying nozzle, and a water inlet is formed in the lower right portion of the water tank. The high yield desulfuration boiler is provided with the absorbent groove, the absorbent groove is filled with limestone flour which can be dissolved into calcium oxide and carbon dioxide after heated, and the calcium oxide and sulfur dioxide influe gas react to generate calcium sulfite for desulfuration processing on the interior of the boiler body.

Owner:SHANXI JINNAN IRON & STEEL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com